HDPE hollow wall composite reinforced winding pipe and its preparation method

A composite reinforced and wound pipe technology, which is applied to pipes, rigid pipes, mechanical equipment, etc., can solve the problems of easy deformation of pipes, pipe collapse, and poor ring flexibility, so as to avoid serious decrease in ring stiffness and improve ring stiffness and ring flexibility , The effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

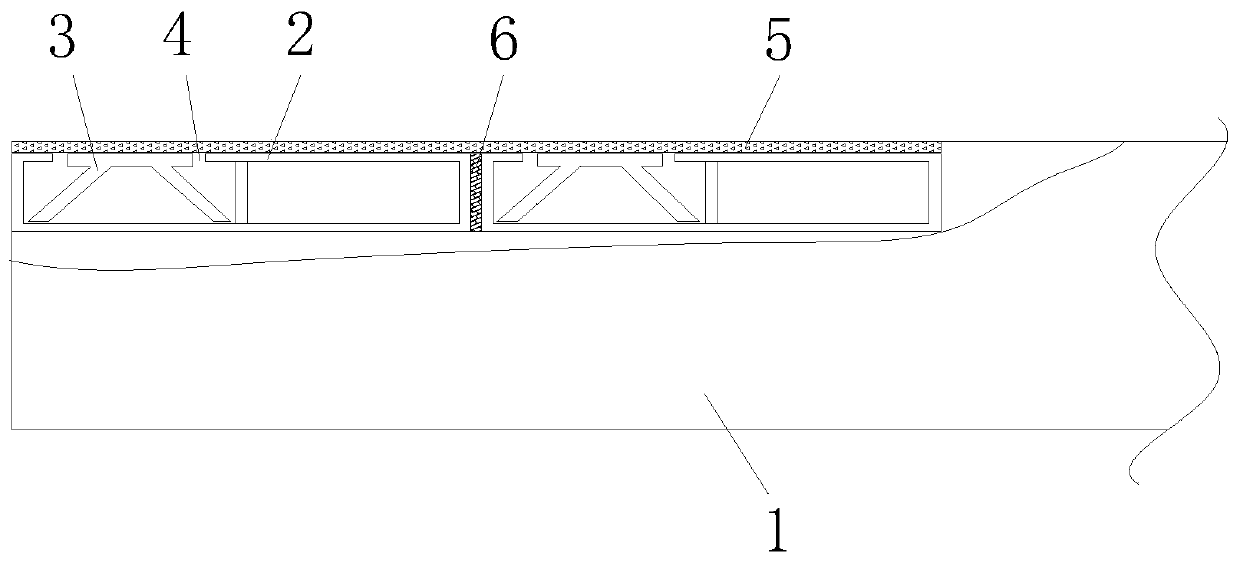

[0065] like figure 1 As shown, according to an embodiment of the HDPE hollow wall composite reinforced winding pipe 1 of the present invention, it includes a hollow pipe wall 2 and a reinforced skeleton 3, and the reinforced skeleton 3 is arranged in the hollow pipe wall 2; the hollow pipe The outer wall 21 of the wall 2 is provided with a through hole 22, the top 31 of the reinforced skeleton 3 is flush with the outer wall 21, and there is a gap 4 between the top 31 of the reinforced skeleton 3 and the outer walls 21 on both sides; the hollow tube The wall 2 is made of HDPE material, and the reinforcing skeleton 3 is made of PVC material; the outer surface of the hollow pipe wall 2 is thermally covered with a HDPE material layer 5; multiple hollow pipe walls are vertically connected by HDPE hot melt material 6 .

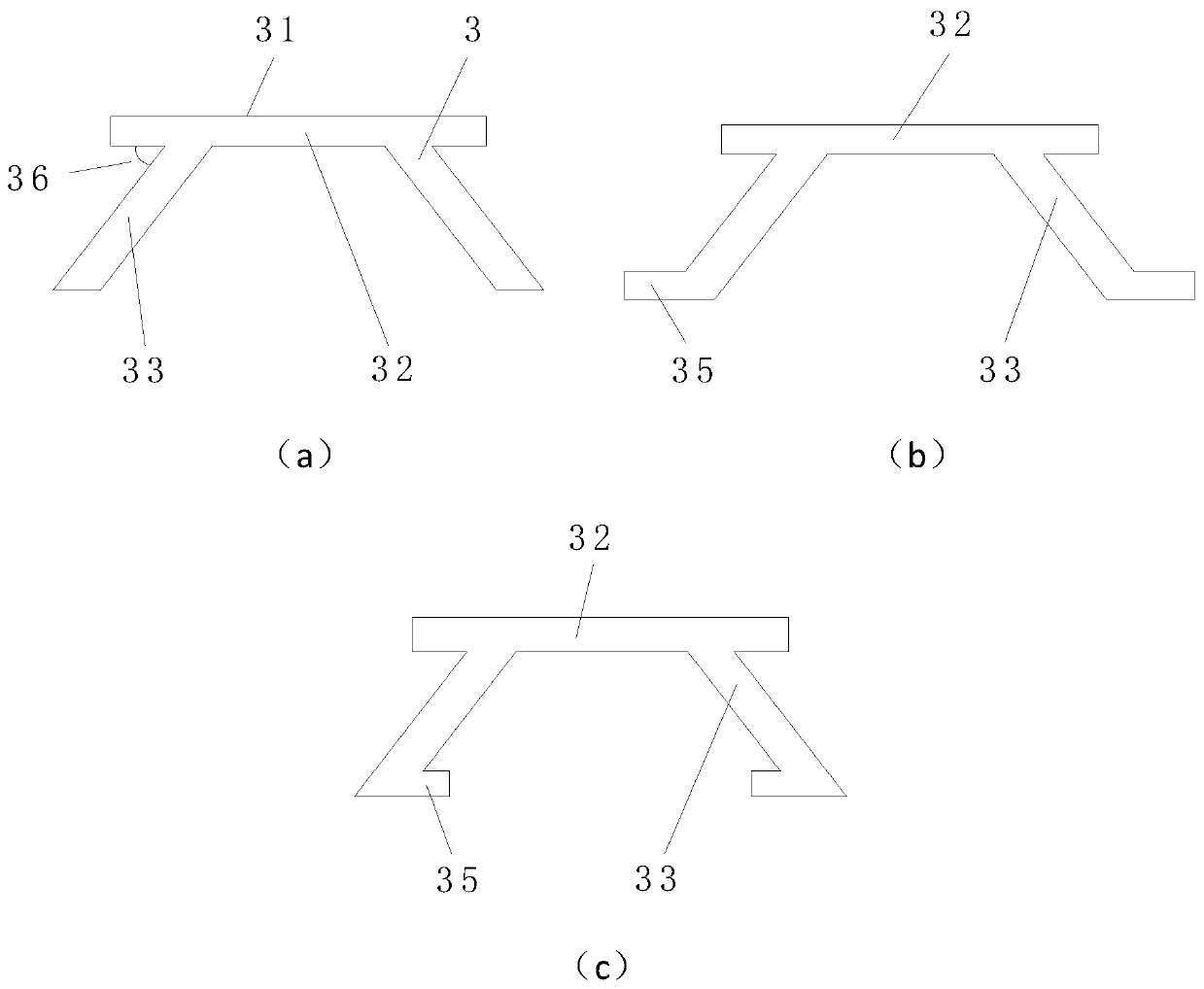

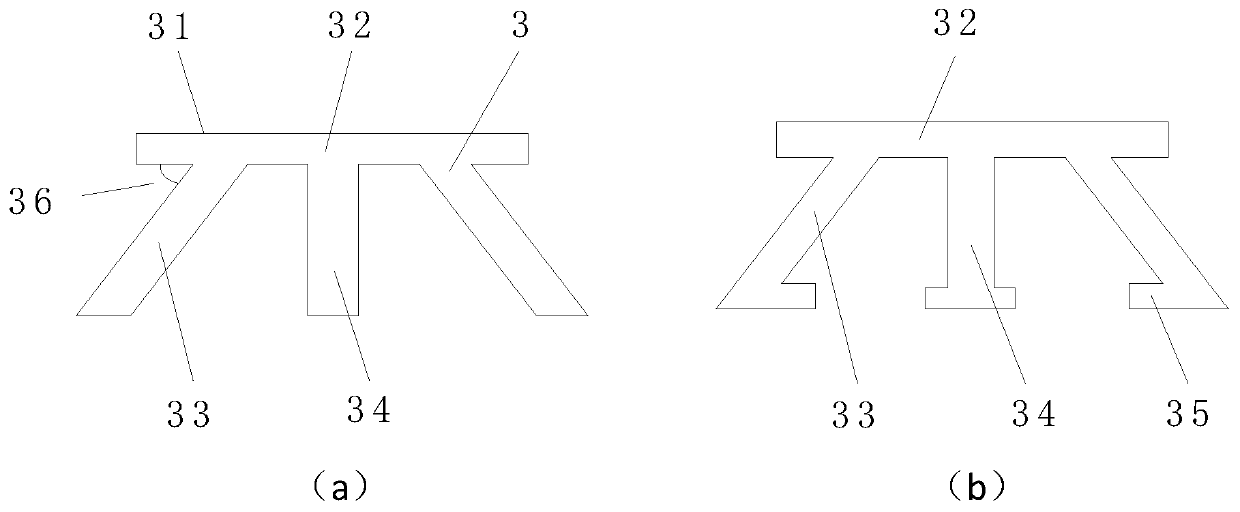

[0066] like Figure 2-5 As shown, the shape of the reinforced skeleton is varied. The reinforcing frame 3 includes a horizontal bracket 32 and an oblique bracke...

Embodiment 2

[0080] According to another embodiment of the HDPE hollow-wall composite reinforced winding pipe of the present invention, its structure, positional relationship between the components, beneficial effects, etc. are the same as those of Embodiment 1, the difference is:

[0081] The thickness of HDPE hollow pipe wall h=2mm;

[0082] The thickness of PVC skeleton H=4h=8mm;

[0083] The angle α between the horizontal support and the inclined support in the PVC skeleton is α=30°;

[0084] The gap C=0.8H=6.4mm between the horizontal support and the outer walls on both sides of the through hole in the hollow pipe wall;

[0085] The thickness of the heat-coated HDPE material layer on the outer surface of the HDPE hollow pipe wall is A, 2mm﹤A﹤8mm and A=2.5h=5mm.

Embodiment 3

[0087] According to another embodiment of the HDPE hollow-wall composite reinforced winding pipe of the present invention, its structure, positional relationship between the components, beneficial effects, etc. are the same as those of Embodiment 1, the difference is:

[0088] The thickness of HDPE hollow pipe wall h=1.7mm;

[0089] The thickness of PVC skeleton H=3.8h=6.46mm;

[0090] The angle α between the horizontal bracket and the inclined bracket in the PVC skeleton is α=40°;

[0091] The gap C=0.5H=3.23mm between the horizontal support and the outer walls on both sides of the through hole in the hollow pipe wall;

[0092] The thickness of the heat-coated HDPE material layer on the outer surface of the HDPE hollow pipe wall is A, 1.7mm﹤A﹤6.46mm and A=2.2h=3.74mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com