PE double-wall corrugated pipe and machining equipment

A double-wall corrugated pipe and processing equipment technology, applied in the direction of mechanical equipment, pipes, hoses, etc., can solve problems such as performance differences and adverse effects, achieve improved appearance, high breaking strength and elongation at break, and improve ring flexibility performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

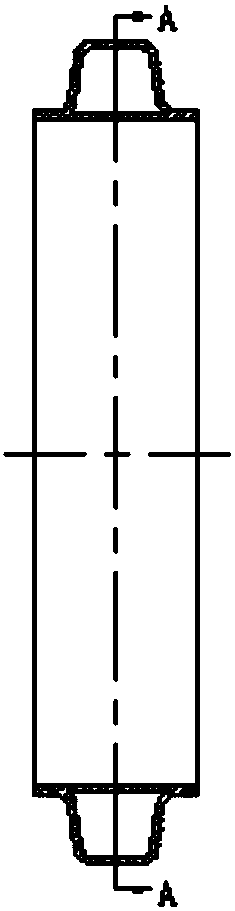

[0052] The pipe produced is DN / ID200mm specification, the flexible reinforcement layer is located on both sides of the pipe clamping seam, symmetrically distributed, the width of the flexible reinforcement layer is 5-6mm, and the thickness is 0.1-0.2mm. The material of the flexible reinforcement layer is according to Percentage by weight, the formula is as follows:

[0053] PE100 pipe material: 85%

[0054] EVA resin: 10%

[0055] Masterbatch: 5%

Embodiment 2

[0057] The pipe produced is DN / ID500mm specification, the flexible reinforcement layer is located on both sides of the pipe joint, symmetrically distributed, the width of the flexible reinforcement layer is 10-12mm, and the thickness is 0.4-0.5mm, and the material of the flexible reinforcement layer is according to Percentage by weight, the formula is as follows:

[0058] PE100 pipe material: 85%

[0059] EVA resin: 12%

[0060] Color Masterbatch: 3%

Embodiment 3

[0062] The pipe produced is DN / ID1200mm in size, the flexible reinforcement layer is located on both sides of the pipe joint, symmetrically distributed, the width of the flexible reinforcement layer is 20-25mm, and the thickness is 0.8-1.0mm, and the material of the flexible reinforcement layer is according to Percentage by weight, the formula is as follows:

[0063] PE100 pipe material: 80%

[0064] EVA resin: 15%

[0065] Masterbatch: 5%

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com