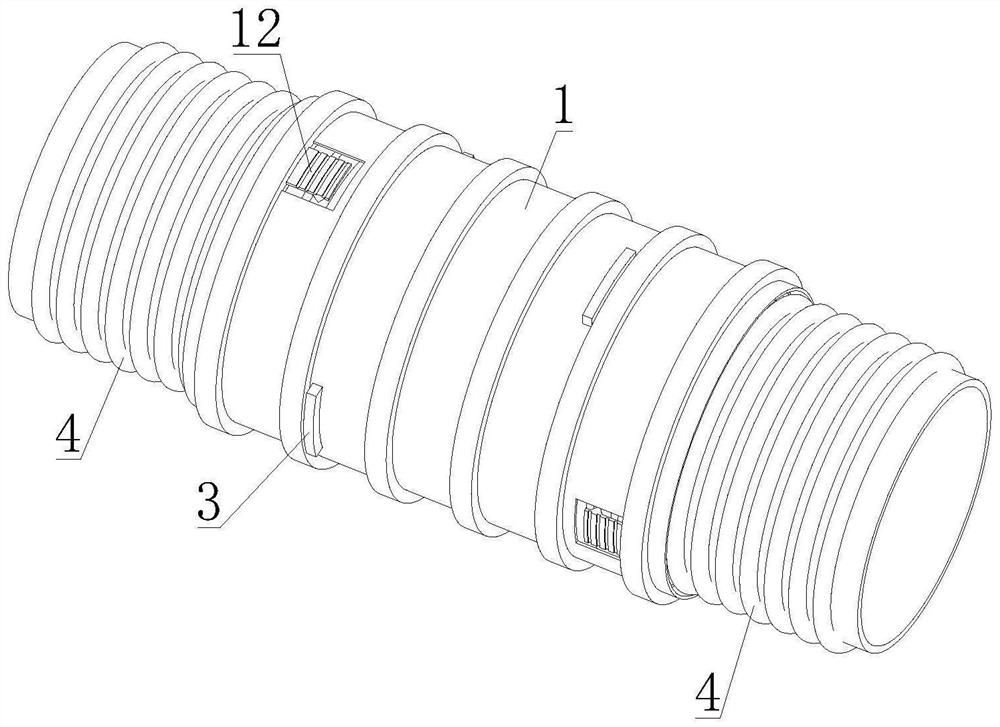

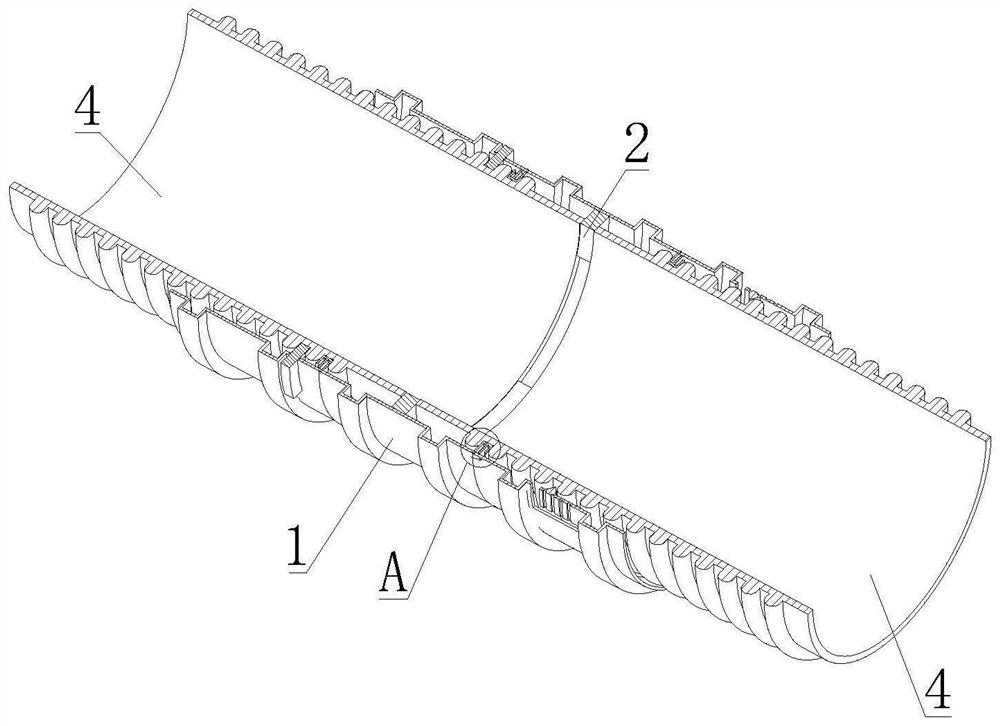

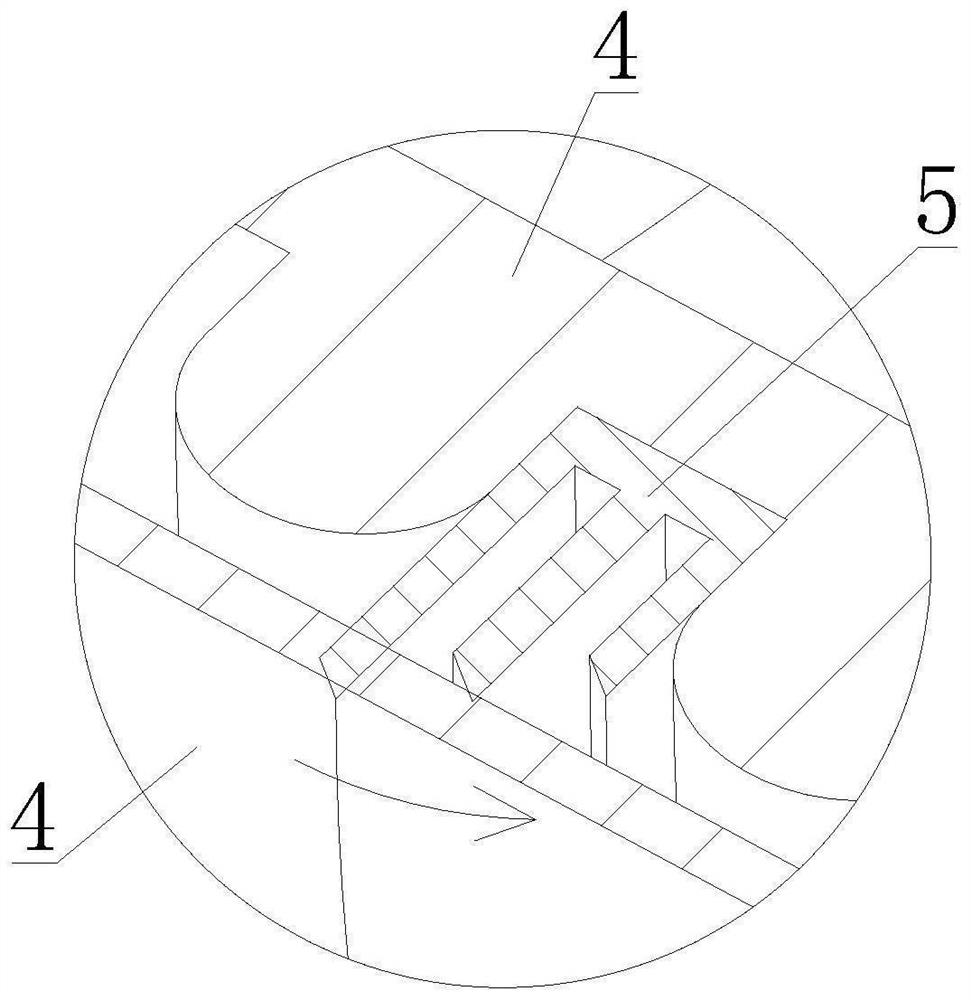

Ultrahigh molecular weight polyethylene reinforced modified polypropylene straight-wall pipe

A technology of ultra-high molecular weight and polyethylene, applied in the direction of pipes/pipe joints/fittings, pipes, hoses, etc., can solve the problems of low temperature brittleness, insufficient rigidity, low ring flexibility, etc., to meet special environmental performance requirements, high Effect of low temperature performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The formula of ultra-high molecular weight polyethylene reinforced modified polypropylene (PP-UHM) straight wall pipe composite material is as follows:

[0031] Prepare raw materials according to the following parts by weight: 25 parts of PPR, 25 parts of PPB, 8 parts of ultra-high molecular weight polyethylene, 8 parts of linear polyethylene LLDPE, 3 parts of compatible toughening agent, 0.3 parts of beta nucleating agent, 0.2 parts of melt grease conditioning Add the above materials into a high-speed mixer and mix for 5-10 minutes to prepare material A;

[0032] Prepare the raw materials according to the following parts by weight: 20 parts of nanoscale talc, 10 parts of 1250 mesh talc, 3 parts of white carbon black, 0.6 parts of diffusion oil, 2 parts of silane coupling agent, 0.6 parts of light stabilizer, 0.6 parts of antioxidant 1010, 0.6 part of antioxidant 168, add the above materials into a high-speed mixer and mix for 5-10 minutes to prepare material B.

[003...

Embodiment 2

[0041] The ultra-high molecular weight polyethylene reinforced modified polypropylene (PP-UHM) straight-wall pipe composite material, the difference between this embodiment and the first embodiment is that in this embodiment:

[0042] Prepare the raw materials according to the following parts by weight: 30 parts of PPR, 30 parts of PPB, 10 parts of ultra-high molecular weight polyethylene, 10 parts of linear polyethylene LLDPE, 5 parts of compatible toughening agent, 0.5 parts of beta nucleating agent, 0.4 parts of melt grease conditioning Add the above materials into a high-speed mixer and mix for 5-10 minutes to prepare material A;

[0043] Prepare the raw materials in the following parts by weight: 15 parts of nano-scale talc, 5 parts of 1250 mesh talc, 1 part of white carbon black, 0.3 part of diffusion oil, 1 part of silane coupling agent, 0.3 part of light stabilizer, 0.3 part of antioxidant 1010, 0.3 parts of antioxidant 168, add the above materials into a high-speed mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com