High-density polyethylene double-wall corrugated pipe

A high-density polyethylene, double-wall corrugated pipe technology, used in hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor pressure bearing performance, low ring stiffness, short service life, etc. The effect of light weight, good toughness and high ring stiffness

Inactive Publication Date: 2015-09-16

浙江中财管道科技股份有限公司

View PDF6 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to overcome the shortcomings of the above-mentioned prior art, and provide a high-density polyethylene double-wall corrugated pipe, which aims to solve the problems of low rigidity, poor pressure bearing performance and long service life of the double-wall corrugated pipe in the prior art. short technical question

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0032] Concrete preferred embodiment one of the present invention is as follows:

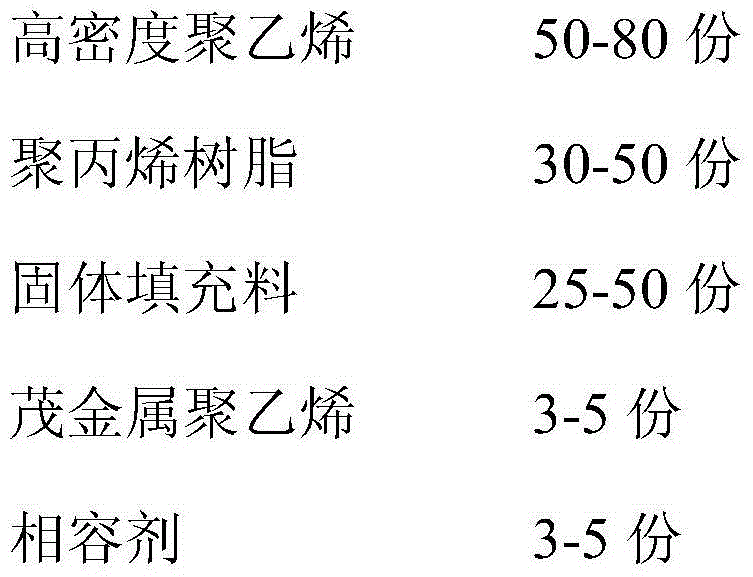

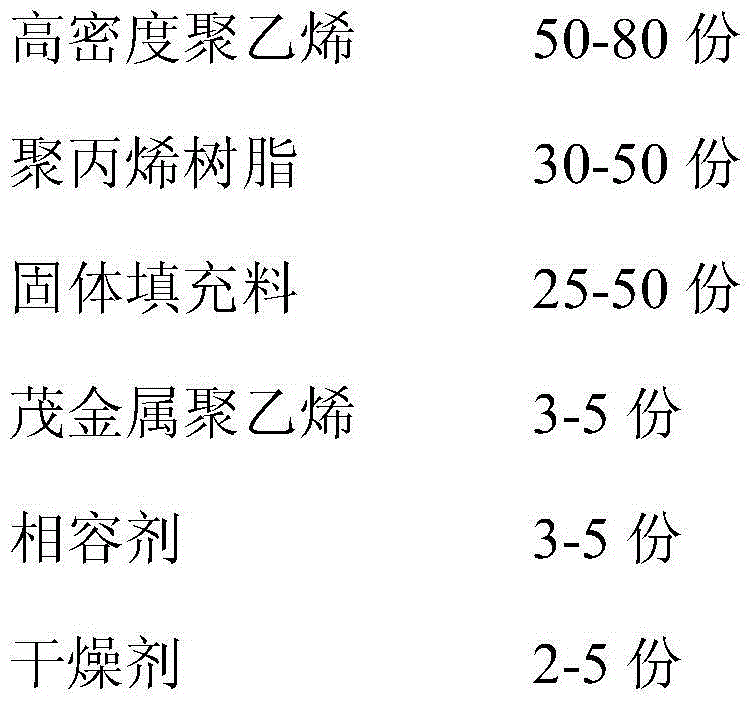

[0033] The composition material of the outer tube is:

[0034]

[0035] The composition material of the inner tube is:

[0036]

[0037]

Embodiment 2

[0038] Concrete preferred embodiment two of the present invention is as follows:

[0039]

[0040] The composition material of the inner tube is:

[0041]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to the field of engineering plastic processing manufacturing, and discloses a high-density polyethylene double-wall corrugated pipe, which comprises an outer pipe and an inner pipe, wherein the materials of the outer pipe comprise 50-80 parts of high-density polyethylene, 30-50 parts of a polypropylene resin, 25-50 parts of a solid filling material, 3-5 parts of metallocene polyethylene, 3-5 parts of a compatibilizing agent, and 2-5 parts of a drying agent, and the materials of the inner pipe comprise 50-80 parts of high-density polyethylene, 30-50 parts of a solid filling material, and 2-5 parts of a drying agent. According to the modified high-density polyethylene double-wall corrugated pipe of the present invention, the inner pipe and the outer pipe have characteristics of high melt strength, high rigidity and good impact resistance, such that the double-wall corrugated pipe has characteristics of high ring rigidity, good compression resistance, and light pipe weight; the metallocene polyethylene is added to the materials of the outer pipe, such that the ring flexibility of the outer pipe is increased, and the toughness is good; and the high-density polyethylene double-wall corrugated pipe can be widely used in non-pressure plastic underground drainage and sewage drain pipelines, and has good application prospects and market competitiveness in the fields of plastic pipelines.

Description

【Technical field】 [0001] The invention relates to the field of engineering plastics processing and manufacturing, in particular to a high-density polyethylene double-wall corrugated pipe. 【Background technique】 [0002] At present, HDPE double-wall corrugated pipes are mainly used in drainage and sewage, and their applications in the market are becoming more and more extensive. Due to the increase of enterprises producing plastic pipes, the market competition is becoming more and more fierce. Many manufacturers ignore the quality of products in order to compete in the market and reduce product prices. The ring stiffness of the product does not meet the standard requirements, resulting in accidents such as project rework and delays in the construction period, and a serious waste of social resources. Therefore, it has become a necessary trend to find out a double-wall corrugated pipe formula with low production cost and good quality. 【Content of invention】 [0003] The pur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/06C08L23/12C08L51/06C08K3/34C08K7/04F16L11/11F16L11/20

CPCC08L23/06C08K2201/003C08L2203/18C08L2205/035C08L2207/062F16L11/11F16L11/20C08L23/12C08K3/34C08L51/06

Inventor 陈建春陆亦飞刘江辉

Owner 浙江中财管道科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com