Drainage blind pipe and assembly thereof

A technology for drainage blind pipes and components, which is applied in the direction of drainage, pipe components, pipes/pipe joints/fittings, etc. It can solve the problems that railway tunnel collection and drainage projects cannot be used, and steel materials are not corrosion-resistant, so as to achieve improved weather resistance, acid resistance and corrosion resistance. Strong corrosion resistance and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

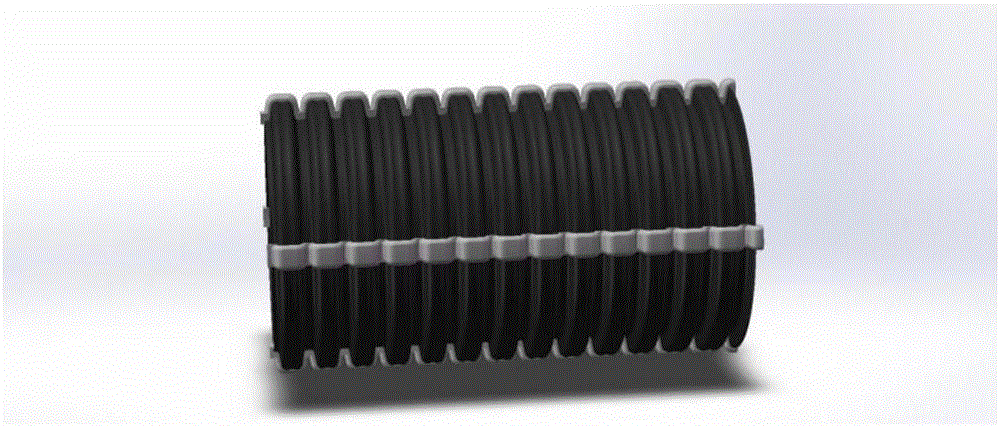

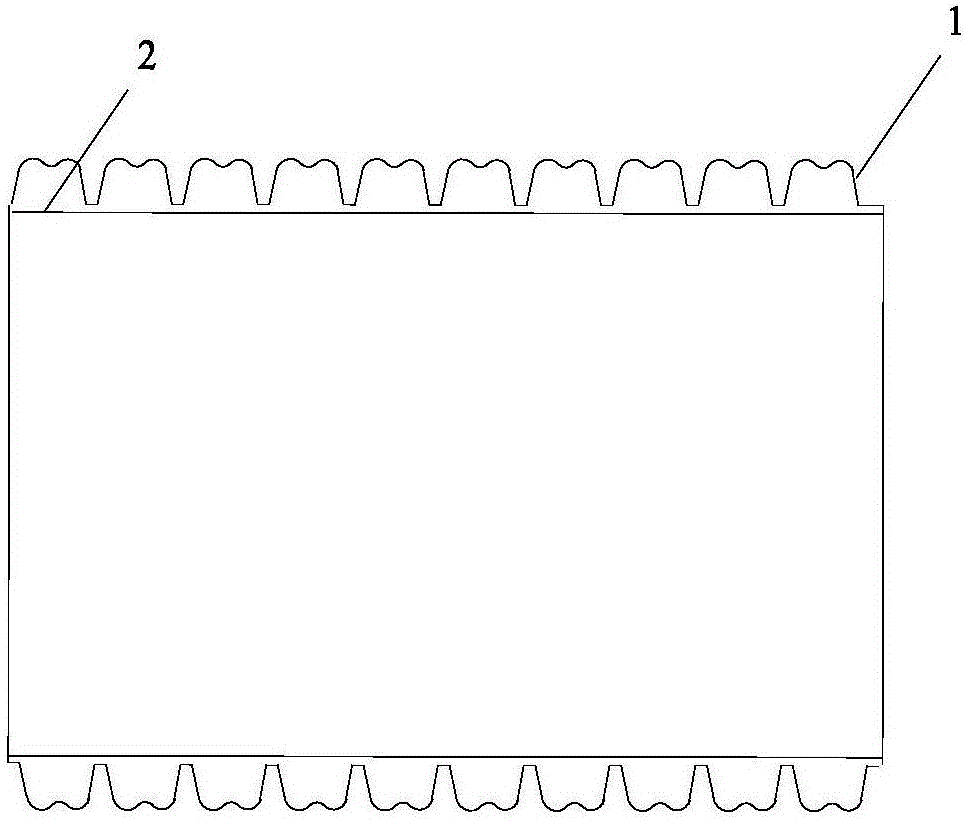

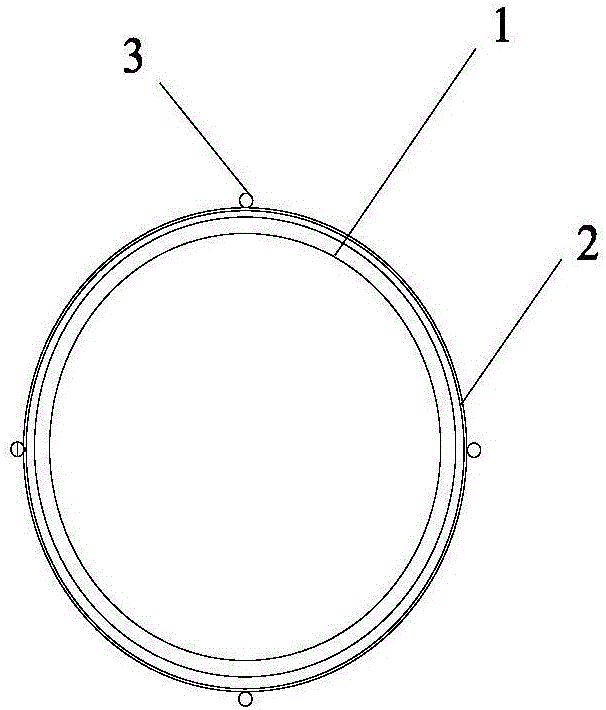

[0041] A drainage blind pipe is a multi-layer structure composed of an inside-out anti-crystallization coating 9, an inner wall drainage layer 2, an outer wall structure layer 1 and a filter layer, and the drainage blind pipes are connected by components.

[0042] The main resins of the outer wall structure layer are low-density polyethylene, high-density polyethylene, and EVA, and the ingredients and ratios are shown in Table 1; the main resin of the inner wall drainage layer is high-density polyethylene (HDPE), and the ingredients and ratios are shown in Table 1. Table 2 (all are parts by mass in the formula).

[0043]The mass ratio of reinforcing agent in the outer wall component is: high-density polyethylene 12, alkali-free glass fiber 20, superfine talc powder 25, ABS high rubber powder 10, paraffin wax 5, graphene oxide 10, silane coupling agent 0.8 , stearic acid 1, elastomer POE 10.

[0044] The outer wall structure layer and the inner wall drainage layer are molded f...

Embodiment 2

[0047] A drainage blind pipe is a multi-layer structure composed of an inside-out anti-crystallization coating 9, an inner wall drainage layer 2, an outer wall structure layer 1 and a filter layer, and the drainage blind pipes are connected by components. The main resins of the outer wall structure layer are low-density polyethylene, high-density polyethylene, and EVA, and the ingredients and ratios are shown in Table 1; the main resin of the inner wall drainage layer is high-density polyethylene (HDPE), and the ingredients and ratios are shown in Table 1. 2. The outer wall stiffener and the outer wall structural layer are made of the same material.

[0048] The mass ratio of the reinforcing agent in the outer wall component is: high-density polyethylene 15, alkali-free glass fiber 30, superfine talc powder 30, ABS high rubber powder 12, paraffin wax 6, graphene oxide 15, silane coupling agent 1.0, stearic acid 1.5, elastomer POE 15. The inner wall drainage layer 2 is coated...

Embodiment 3

[0056] Hole design:

[0057] Using the materials in Example 1, a double-wall corrugated pipe was made, and the diameter of the trough of the outer wall pipe was 80 mm. Every 10m long vertical drainage blind pipe is connected to a horizontal water pipe, and the inner diameter of the horizontal water pipe is 100mm, then: the drainage area of the horizontal water pipe S=πR 2 =3.1×52=78.5cm 2

[0058] The diameter of the longitudinal drainage pipe is 80mm, and the circumference of the trough of the pipe

[0059] L=2πR=2×3.14×4cm=25.12cm

[0060] The upper third of the hole can provide a perforation perimeter of 25.12cm / 3 = 8.37cm. The sum of the lengths of the perforations is less than this length; In the same situation, the required trough width X=S / L=78.5 / 25.12=3.125cm.

[0061] Assume that the width of both the trough and the crest is 5mm, and the hole is a long hole of 1cm×0.2cm, then the number of troughs on the drainage pipe with a unit length of 1m is 1m / 10mm=100,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com