Hollow-wall pipe and manufacturing method thereof

A manufacturing method and hollow technology, applied in the field of pipes, can solve the problems of large bending residual stress, poor flexibility of pipe rings, shortened service life of pipes, etc., and achieve excellent compressive strength, high compressive strength, and improved ring stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach ( 1

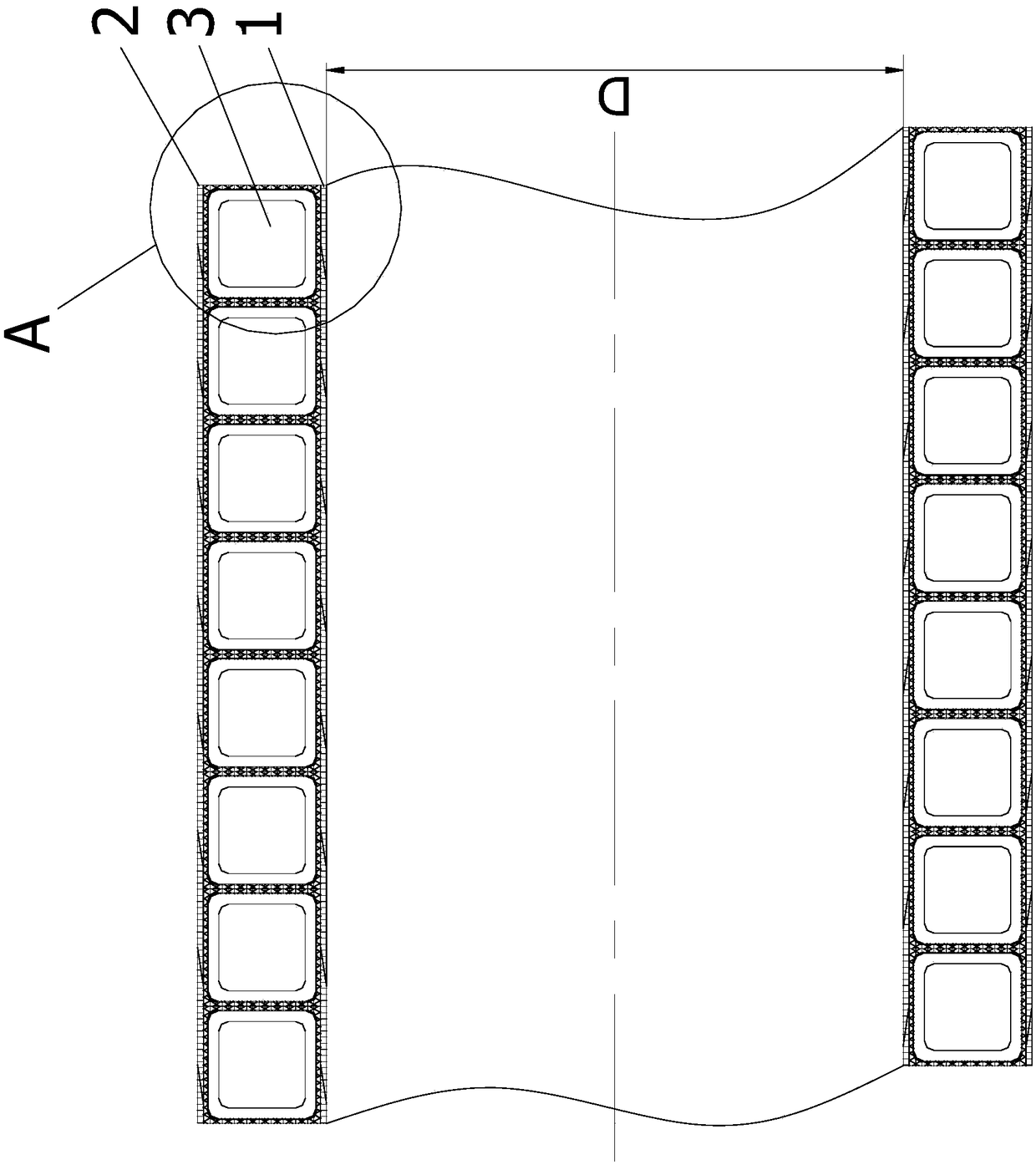

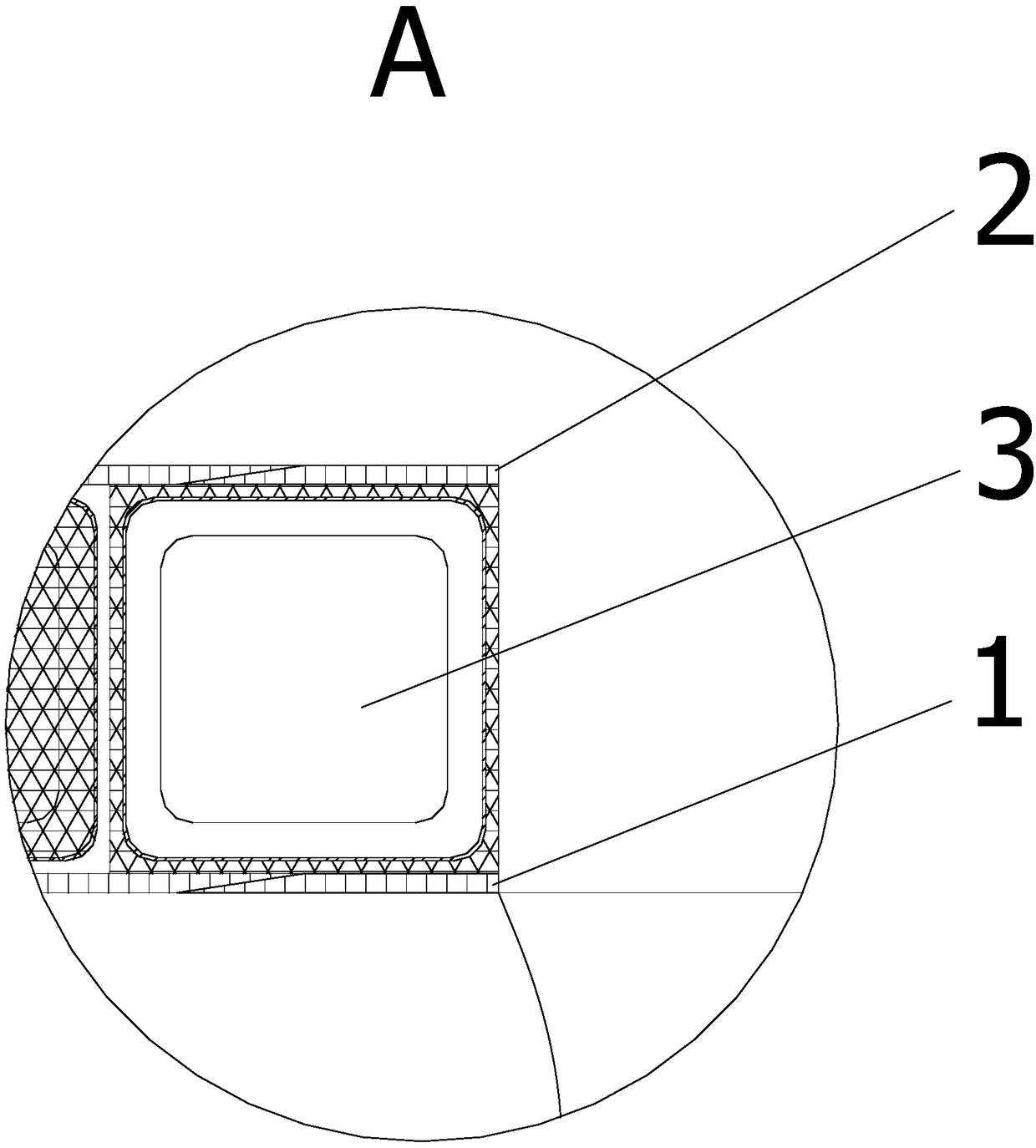

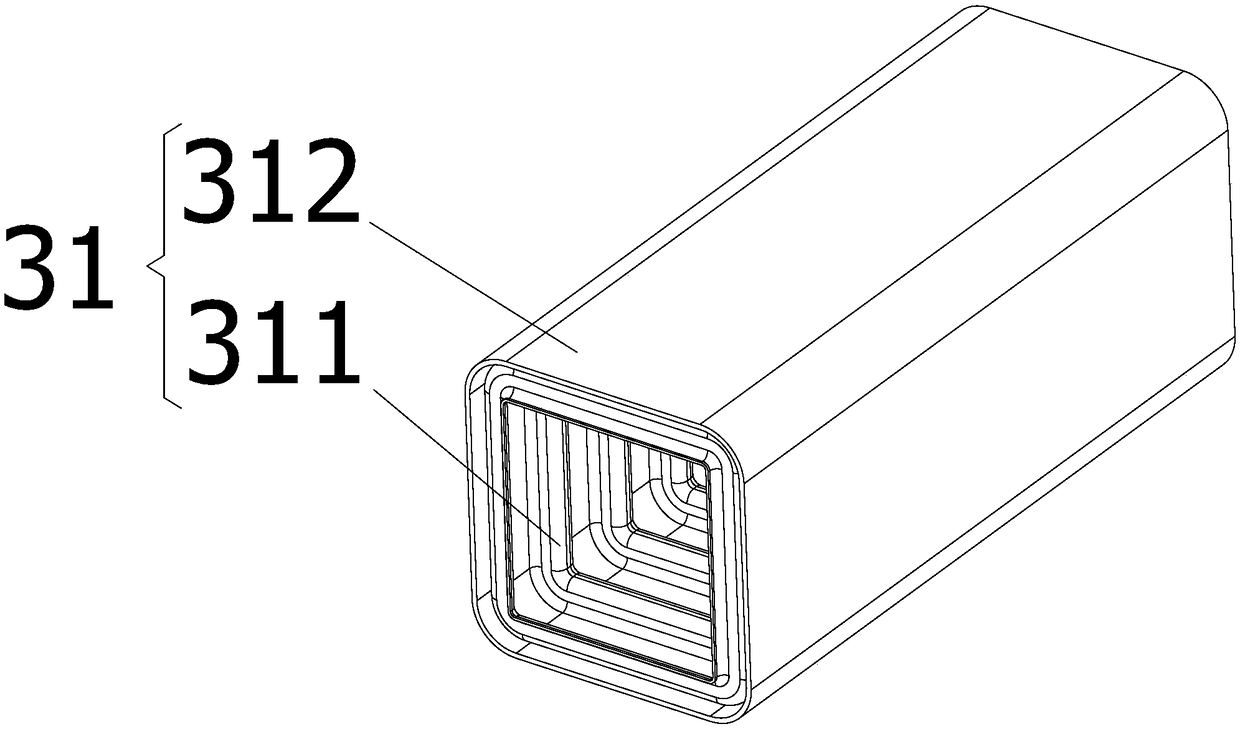

[0043] Such as Figure 1-6 Shown is a hollow-wall pipe provided by the present invention, which is characterized in that it includes an inner layer 1, an outer layer 2, and a hollow reinforced layer 3 arranged between the inner layer 1 and the outer layer 2, and the hollow reinforced layer 3 is composed of The linear profile 31 is spirally wound between the inner layer 1 and the outer layer 2. The linear profile 31 includes a square single-wall corrugated tube 311 and a cladding layer 312 covering the outer periphery of the square single-wall corrugated tube 311. The four walls of the square single-wall corrugated pipe 311 have a corrugated structure in which crests 3111 and troughs 3112 are arranged alternately in the axial direction, and the positions of the crests 3111 and the troughs 3112 of the four walls of the square single-wall corrugated pipe 311 correspond to each other. , the joints of the four walls of the square single-wall corrugated pipe 311 adopt rounded corner...

specific Embodiment approach ( 2

[0047] A method for manufacturing a hollow-wall pipe, characterized in that the method comprises the following steps:

[0048] ① Melting the material for making the square single-wall corrugated pipe 311, and extruding it with an extruder to form the square single-wall corrugated pipe 311;

[0049] ② if Figure 7-8 As shown, the square single-wall corrugated pipe 311 prepared in step ① is introduced into the overmold 4, and the overmold 4 includes an outer mold 41 and an inner mold 42 arranged in the outer mold 41, and the outer mold 41 is along the A square through hole 1 is provided in the axial direction, and the outer peripheral wall of the inner mold 42 is square, and the inner mold 42 is provided with a square through hole 2 421 whose size matches the square single-wall corrugated pipe 1 along the axial direction. ,Such as Figure 8 As shown, one end of the inner mold 42 and one end of the outer mold 41 are fixedly connected by bolts. After fixing, the end of the pouri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com