MUPO double-layer double-wave structure wall pipe

A wave structure and wall tube technology, applied in the field of MUPO double-layer double-wave structure wall tube, can solve the problems of low modulus and glass transition temperature, increase in cost, stiffness, strength, and decrease in thermal distortion temperature, and meet performance requirements. , the effect of improving the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

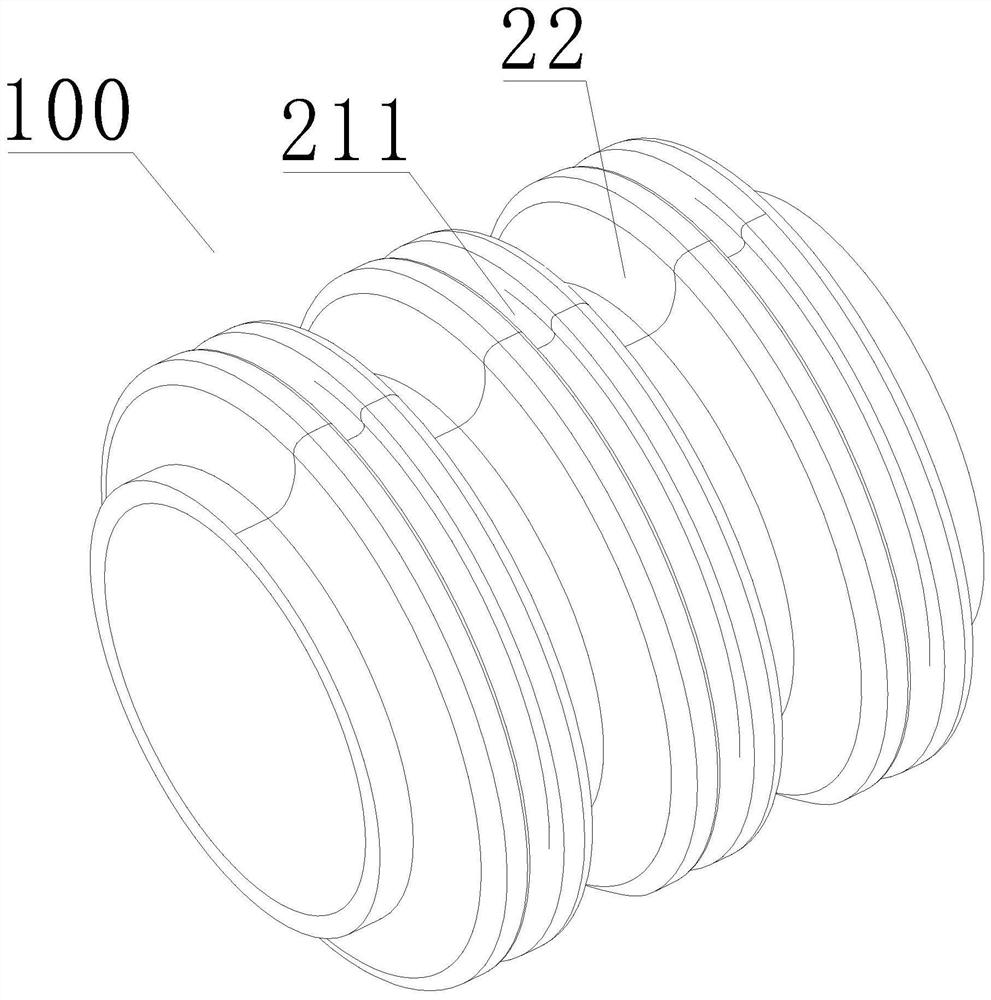

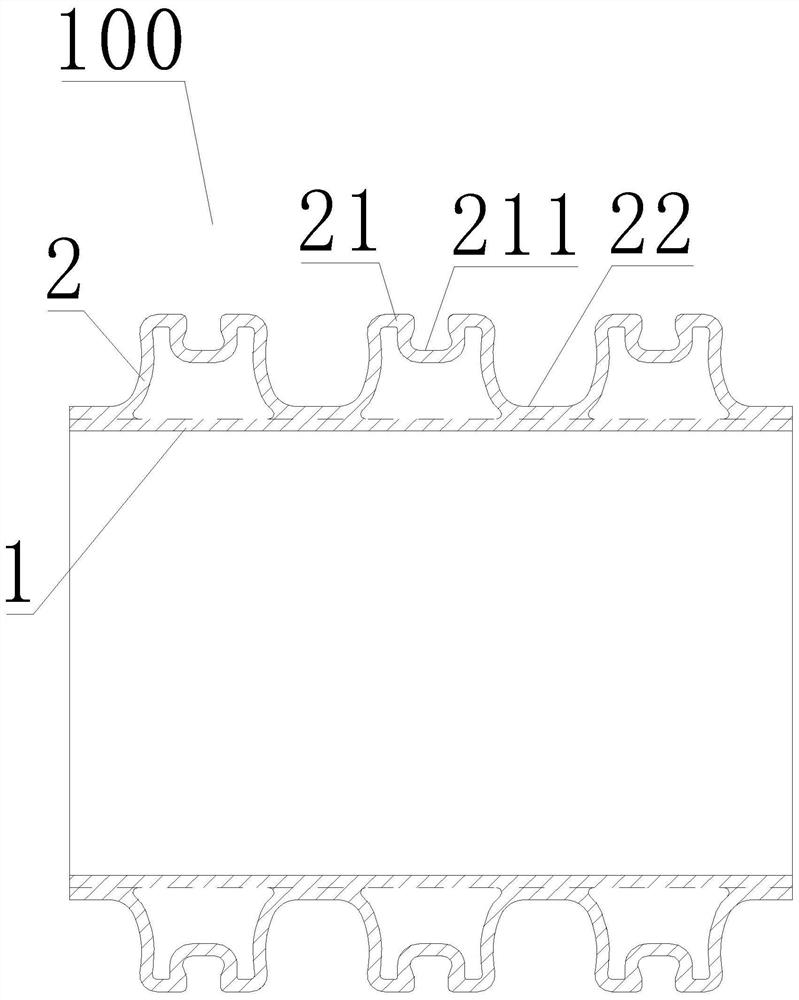

[0029] A kind of MUPO double-layer double-wave structure wall pipe, such as figure 1 As shown, the inner layer 1 and the outer layer 2 are formed by hot-melt compounding, and both the inner layer 1 and the outer layer 2 are made of nano-modified polyolefin materials;

[0030] The nano-modified polyolefin material comprises the following raw materials by weight: 60 parts of polyolefin, 5 parts of composite cold-resistant elastomer toughening agent, and 35 parts of inorganic nano-composite toughened reinforcing material;

[0031] The preparation method of nano-modified polyolefin material is as follows: polyolefin, composite cold-resistant elastomer toughening agent and inorganic nano-composite toughened reinforcing material are mixed, and then extruded and melted by a two-stage extrusion granulator to obtain nano-modified polyolefin. Permanent polyolefin material, barrel temperature: 160°C, 180°C, 180°C, 190°C, 190°C, die temperature: 190°C.

[0032] The polyolefin includes th...

Embodiment 2

[0043] A MUPO double-layer double-wave structure wall pipe. The difference between this embodiment and Embodiment 1 is that the nano-modified polyolefin material includes the following raw materials by weight: 70 parts of polyolefin, 10 parts of composite cold-resistant elastomer toughening agent parts, 20 parts of inorganic nanocomposite toughened reinforcing materials.

[0044] The composite cold-resistant elastomer toughening agent comprises the following ingredients by weight: 80 parts of ethylene octene copolymer, 20 parts of EVA, 6 parts of styrene, 3 parts of maleic anhydride, and 3 parts of dicumyl peroxide.

[0045] The inorganic nanocomposite toughening reinforcing material comprises the following ingredients by weight: 70 parts of nanoscale talcum powder, 30 parts of nanoscale active calcium carbonate, 3 parts of silane coupling agent, and 1.5 parts of aluminate coupling agent.

[0046] Table 2: The physical and mechanical properties of the MUPO double-layer double-...

Embodiment 3

[0049] Such as Figure 1-2 As shown, a MUPO double-layer double-wave structure wall pipe includes an inner layer 1 and an outer layer 2; both the inner layer 1 and the outer layer 2 are of a rotary structure, and the outer layer 2 is coaxially arranged on the inner layer 1 through hot-melt composite On the outer peripheral surface, the outer layer 2 is wave-shaped, and the outer layer 2 has a plurality of crests 21 and a plurality of troughs a22. Structure, high structural strength.

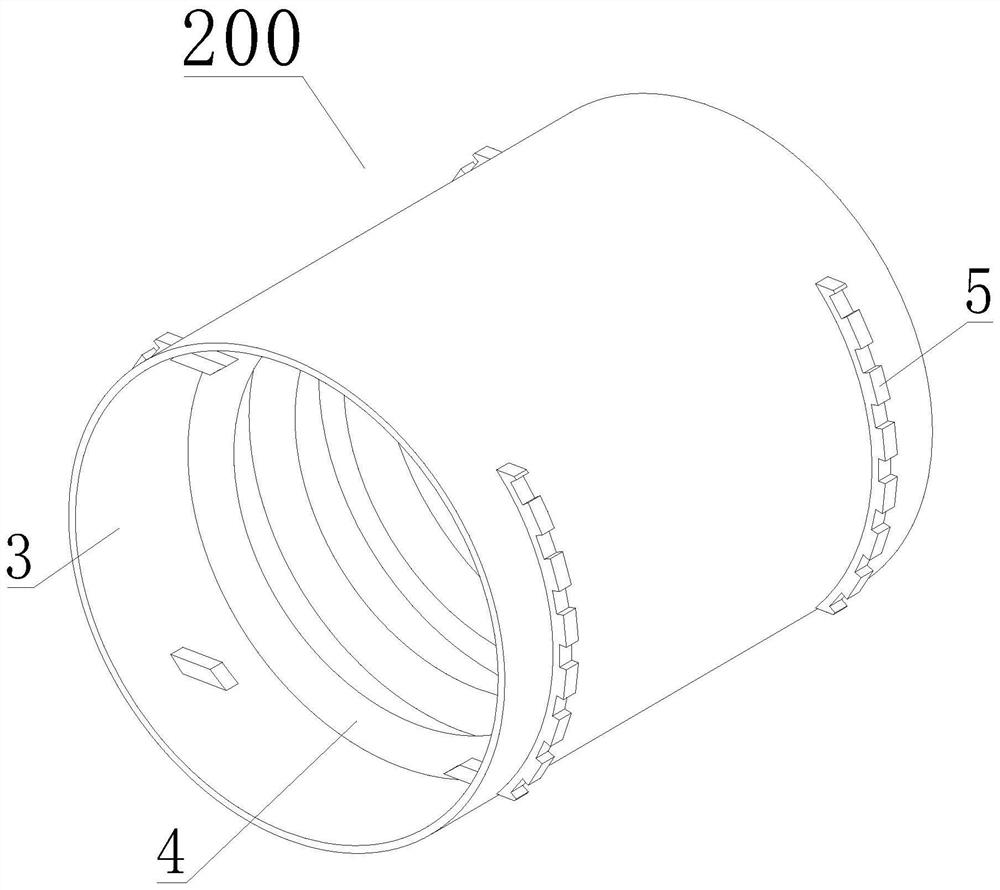

[0050] Two double-layer double-wave structure wall tubes 100 pass through such as Figure 3-6 The connecting piece 200 shown is connected. The connecting piece 200 includes an outer ring part 3, an undercut assembly and a buckle 5; Hole 302, two groups of undercut components are arranged symmetrically along the central axis direction of the outer ring part 3, and the undercut components include a plurality of ring-shaped undercut parts 4 coaxially arranged side by side along the central axis di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com