Composite mixture and preparation method thereof

A technology of composite materials and mixtures, applied in the direction of mechanical equipment, rigid pipes, pipes/pipe joints/pipe fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

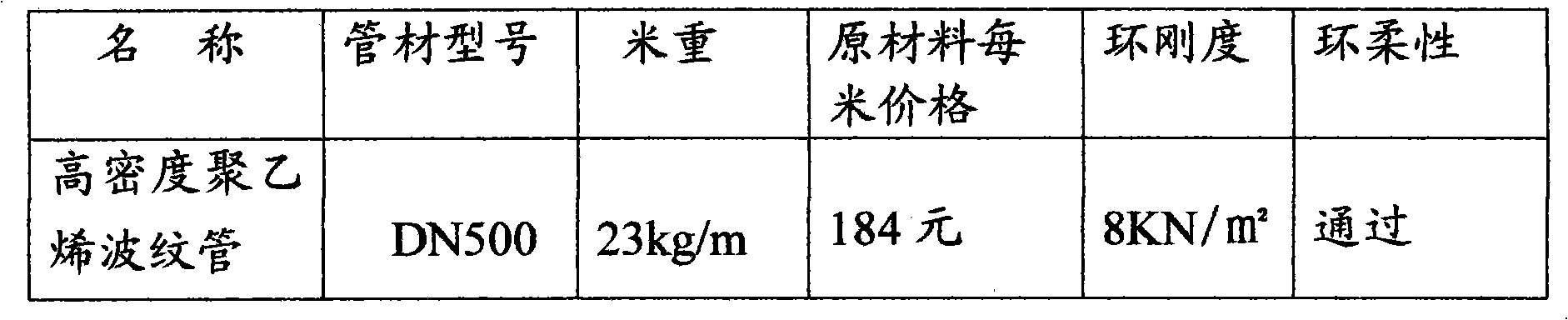

Image

Examples

Embodiment 1

[0061] After putting 120kg of polyethylene terephthalate (PET) printed single film into the machine pot of the chemical fiber high-speed granulator HR-450, during the stirring process, the high-speed rotating blade and the fixed The shearing action of the blade makes the polyethylene terephthalate (PET) printed single film quickly cut into pieces, and the chopped polyethylene terephthalate (PET) printed single film is placed on the chemical fiber Under the action of the centrifugal force of the rotary cutter disc of the type high-speed granulator, it flows along the wall surface of the pot body, and at the same time, the material is turned up and down by the pulping action, and moves from the surrounding to the center of the pot body. (PET) The friction between the fragments of the printed single film and the friction with the pot wall and the blade of the chemical fiber type high-speed granulator generates a lot of frictional heat, so that the polyethylene terephthalate (PET) ...

Embodiment 2

[0063] 200kg of high-density polyethylene (HDPE) blow-molding grade return material is manually cleaned by a water gun and put into the crusher. The material is quickly rotated by the three moving knives and two fixed knives of the crusher in the crusher, and the HDPE is blown The plastic-grade recycled material is cut into small pieces of different sizes, and then the broken material is filtered through the sieve under the crusher to obtain 200kg of particles of the same size.

Embodiment 3

[0065] 20kg polyethylene terephthalate (PET) granule 1 prepared by embodiment 1, 60kg high-density polyethylene (HDPE) blow molding grade return granule 1 prepared by embodiment 2, compatibilizer fusabond E MB100D / Elvaloy PTW (produced by U.S. DuPont) 5kg, impact modifier SEBS FG1924X (produced by Kraton company) 4kg, tackifier PR-4370 (produced by BASF company) 0.3kg are placed in high-speed mixer 300L and stirred, wherein the temperature of the pot machine Mixture 1 was prepared at 80°C, stirring speed 735r / min, and stirring time 10min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com