High-performance polyethylene double-wall corrugated pipe

A technology of double-wall bellows and polyethylene pipes, which is applied in the direction of rigid pipes, pipes, pipes/pipe joints/fittings, etc., which can solve the problems of short service life, low ring stiffness, low impact performance of ring flexibility, and affecting the overall stability of bellows and other problems to achieve the effect of eliminating internal stress and improving ring rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the specific embodiments and the description of the drawings.

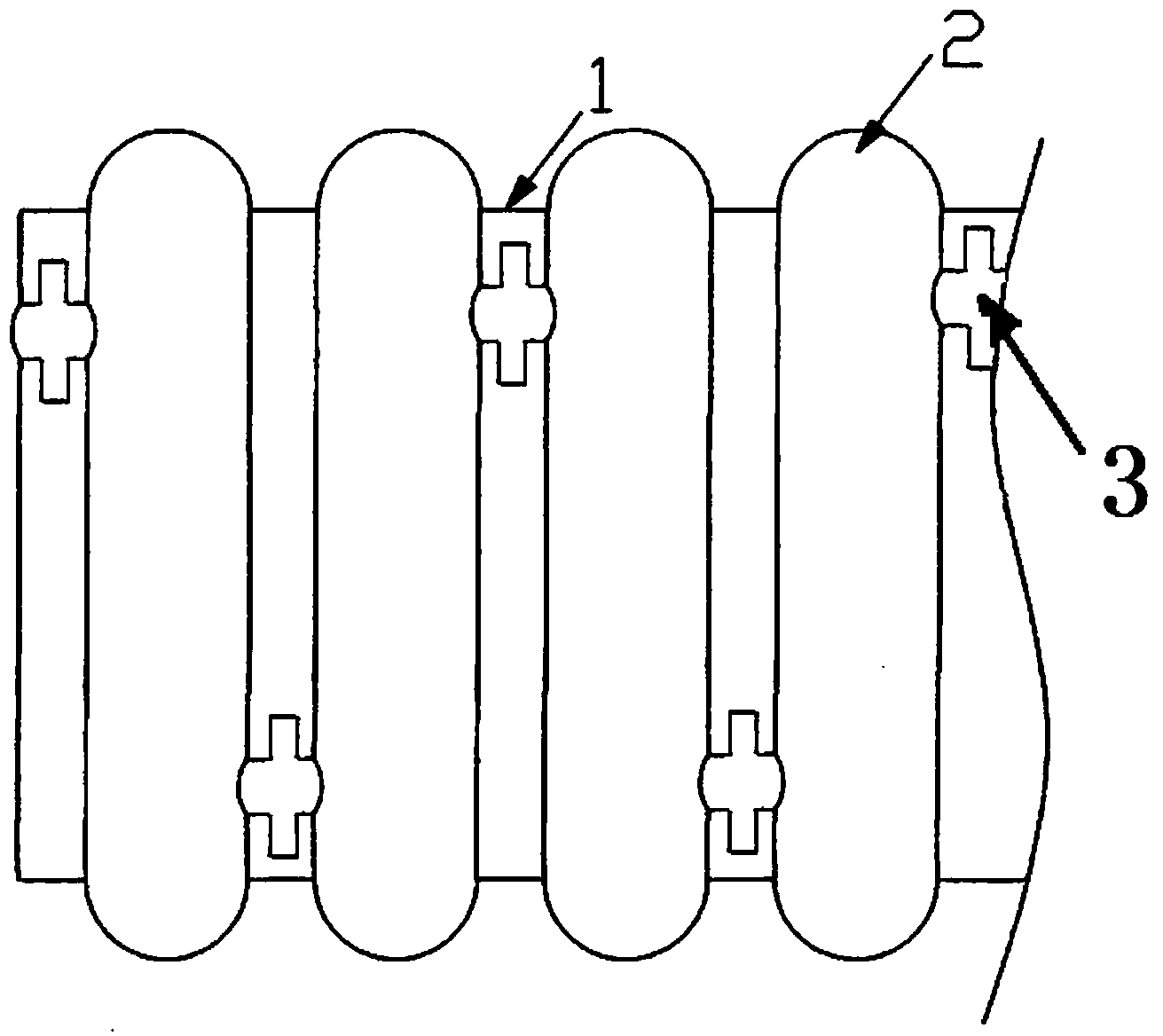

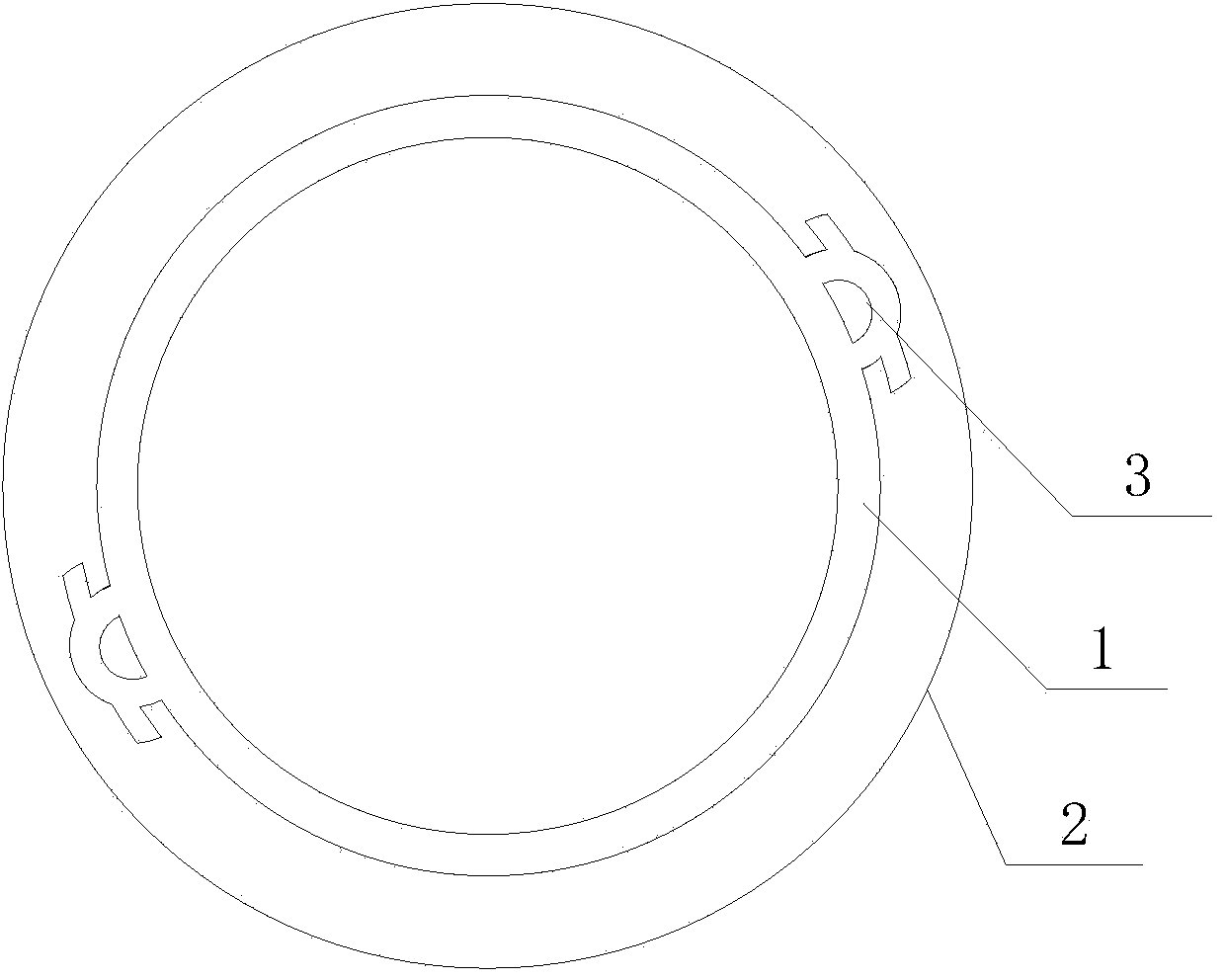

[0019] A high-performance polyethylene double-wall corrugated pipe. The high-performance polyethylene double-wall corrugated pipe comprises a smooth polyethylene pipe base (1) and a polyethylene corrugated pipe layer (2) attached to the outer surface of the pipe base (1) ), the corrugated tube layer (2) is provided with several symmetrical discontinuous reinforcement ribs (3) at the axial wave trough, and the reinforcement ribs (3) are periodically distributed at the wave trough of the corrugated tube layer (2). In the present invention, the reinforcement ribs (3) of the polyethylene double-wall corrugated pipe forming module are designed to be symmetrical but discontinuously distributed along the trough of the pipe axis, and a module is used as the distribution period. By improving the structural design of the reinforcing rib ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com