Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Increase wattage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

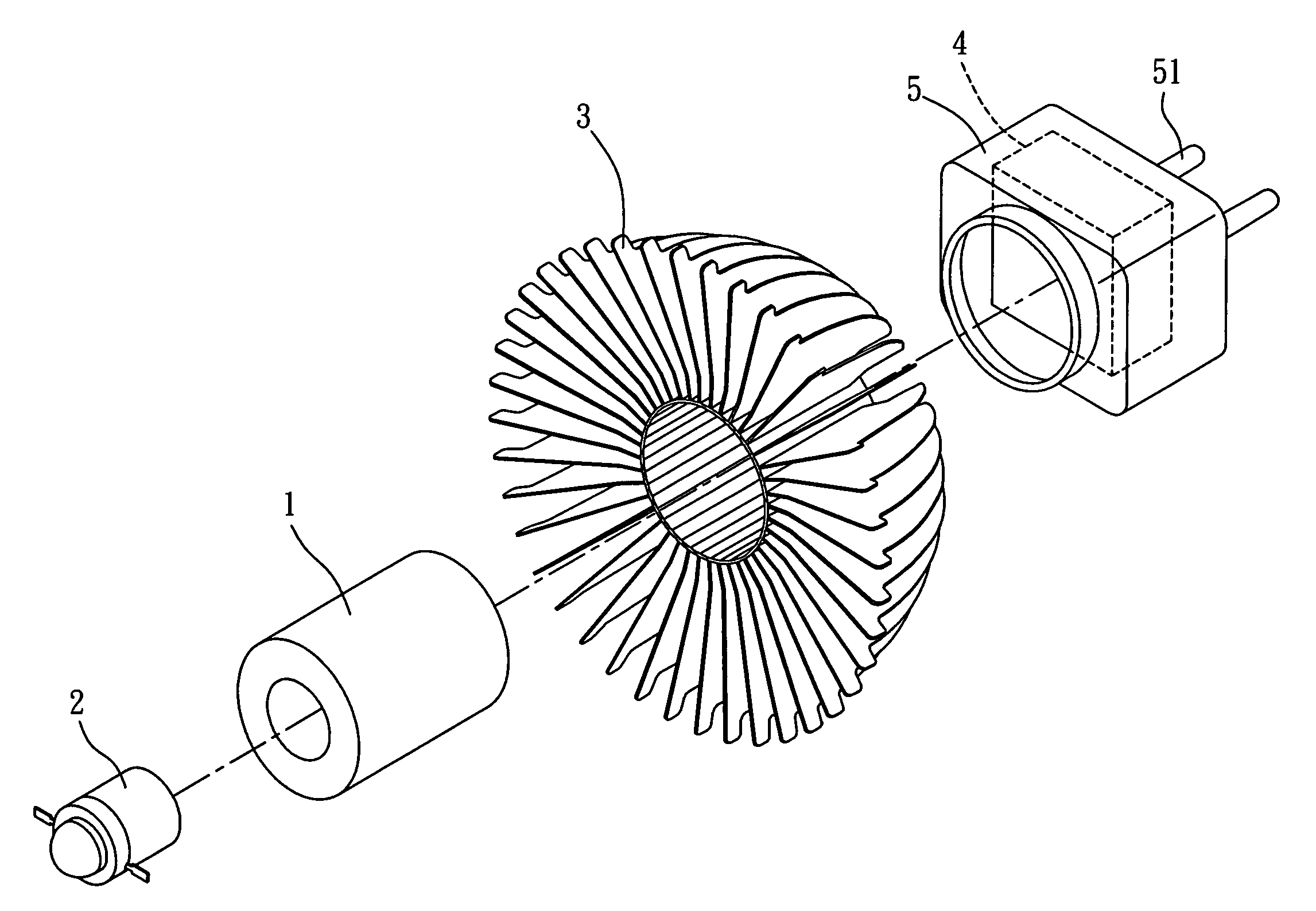

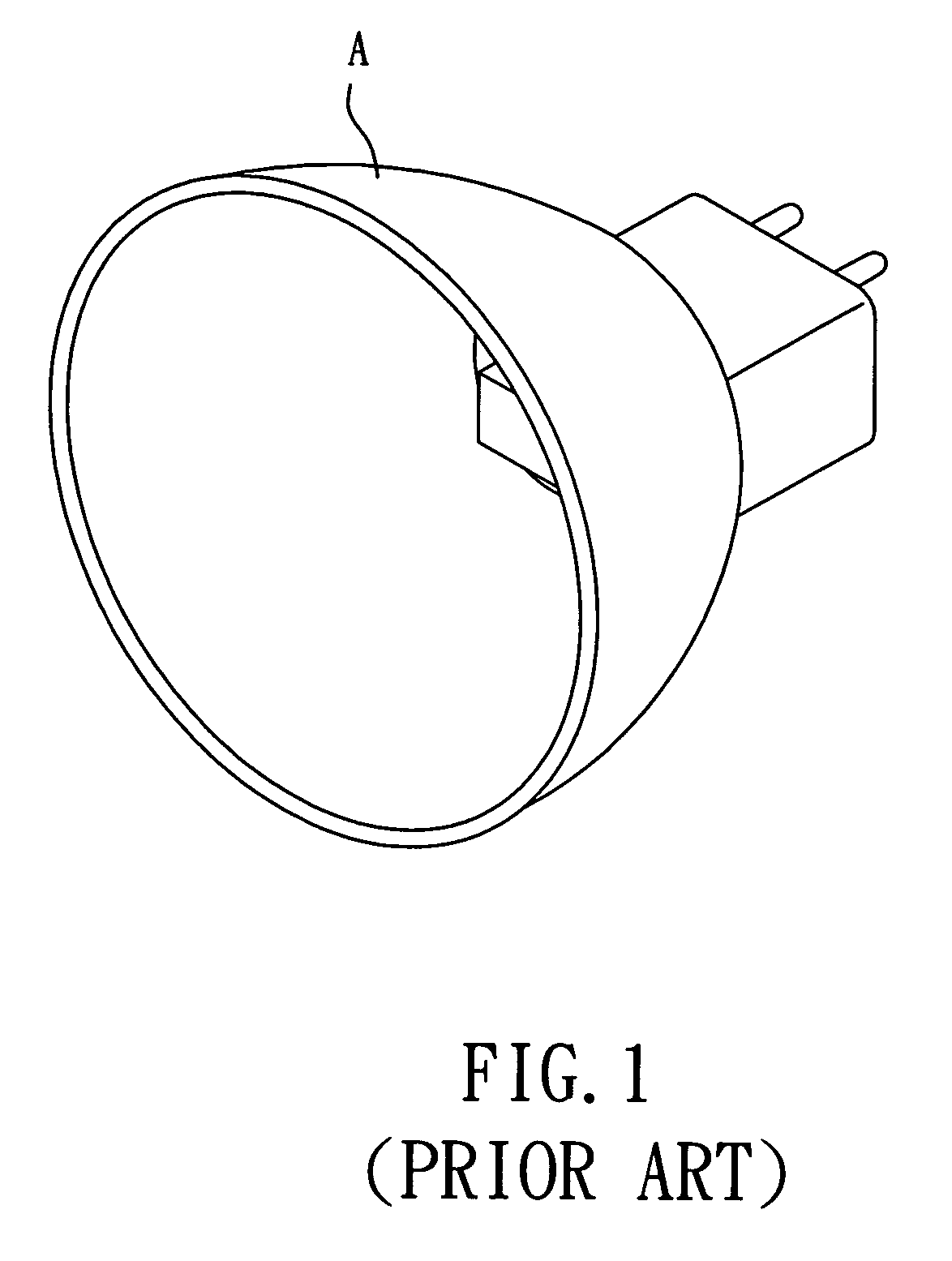

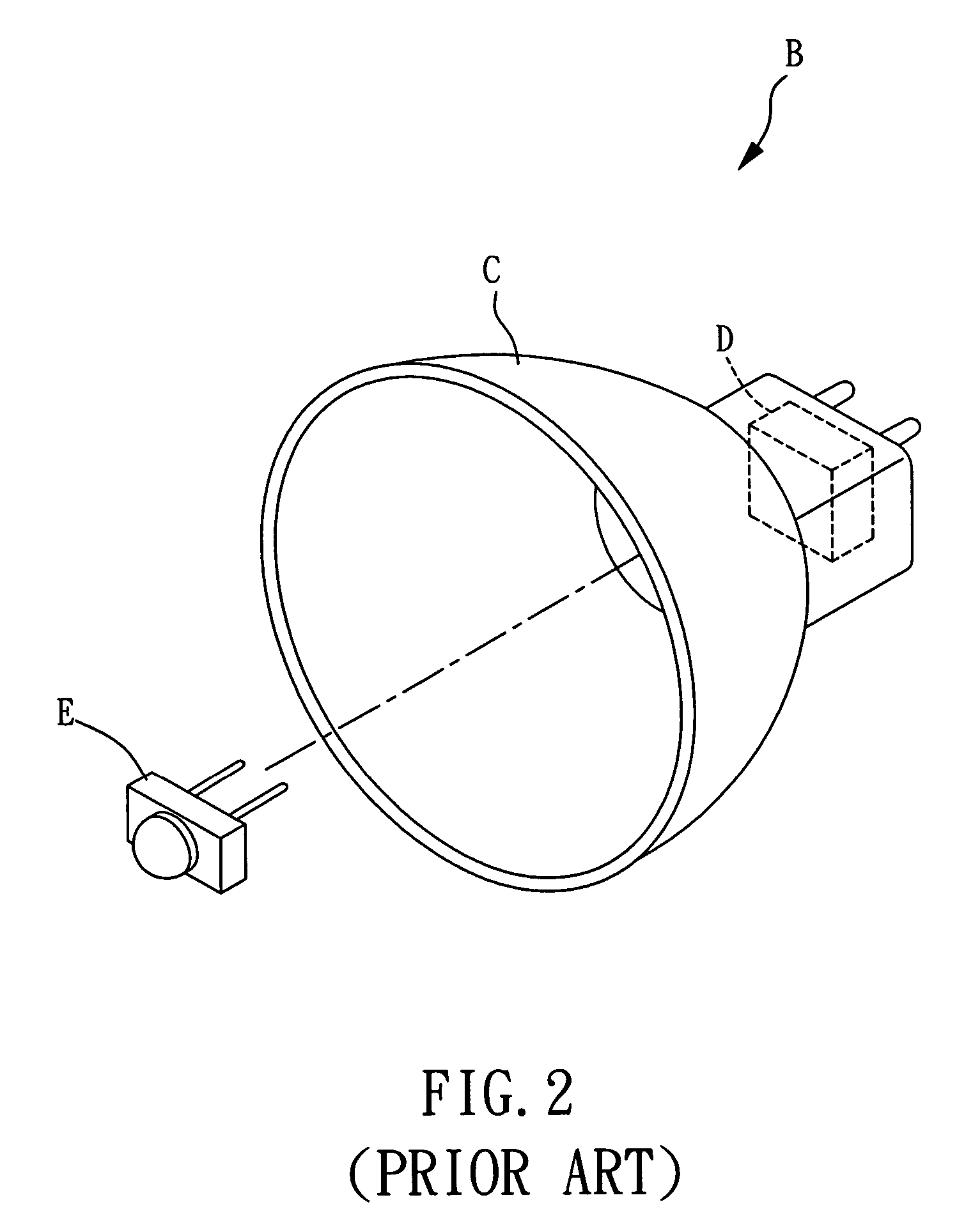

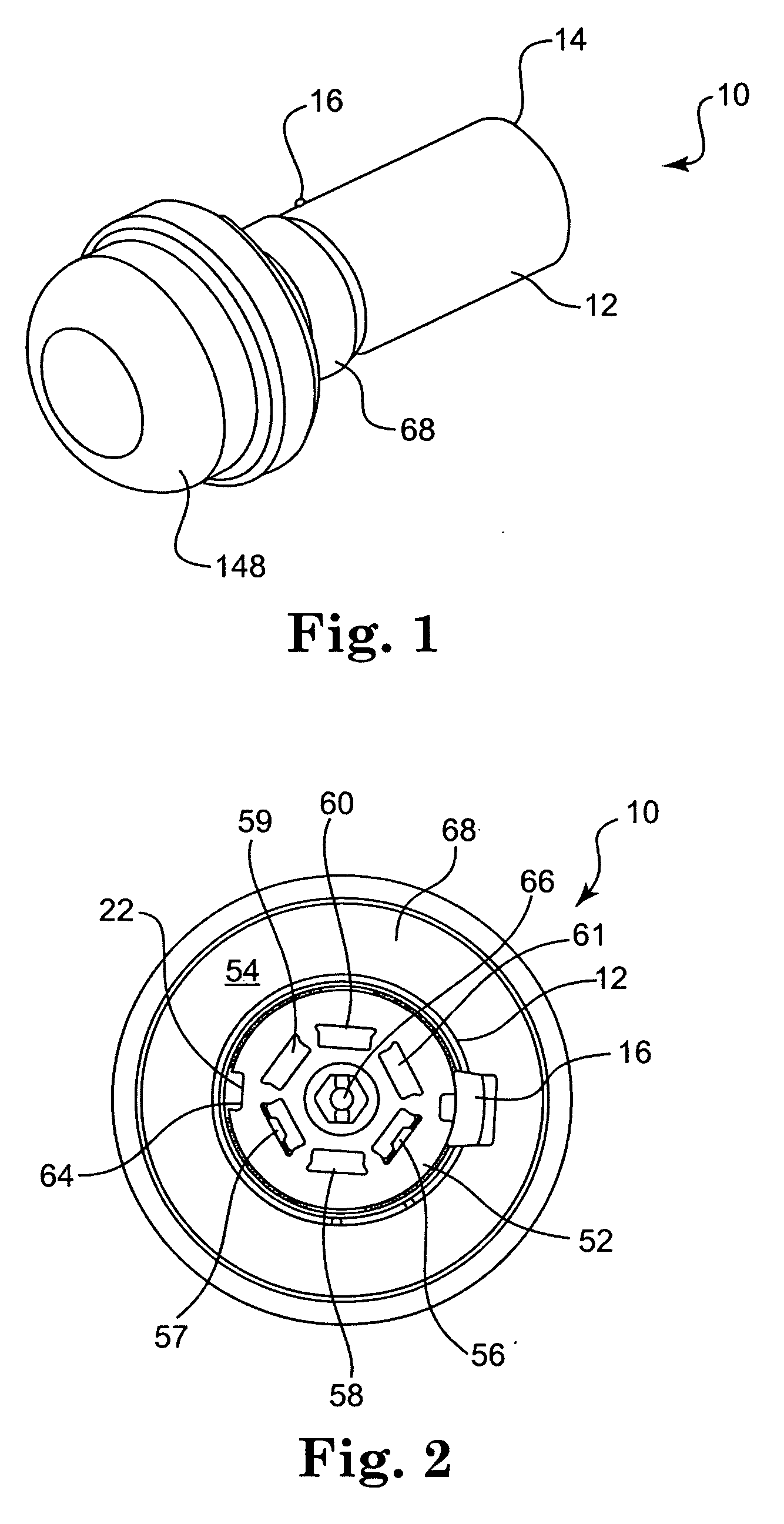

LED projector light module

InactiveUS7674015B2Improve cooling efficiencyIncrease heat transfer areaPoint-like light sourceVehicle interior lightingElectricityEngineering

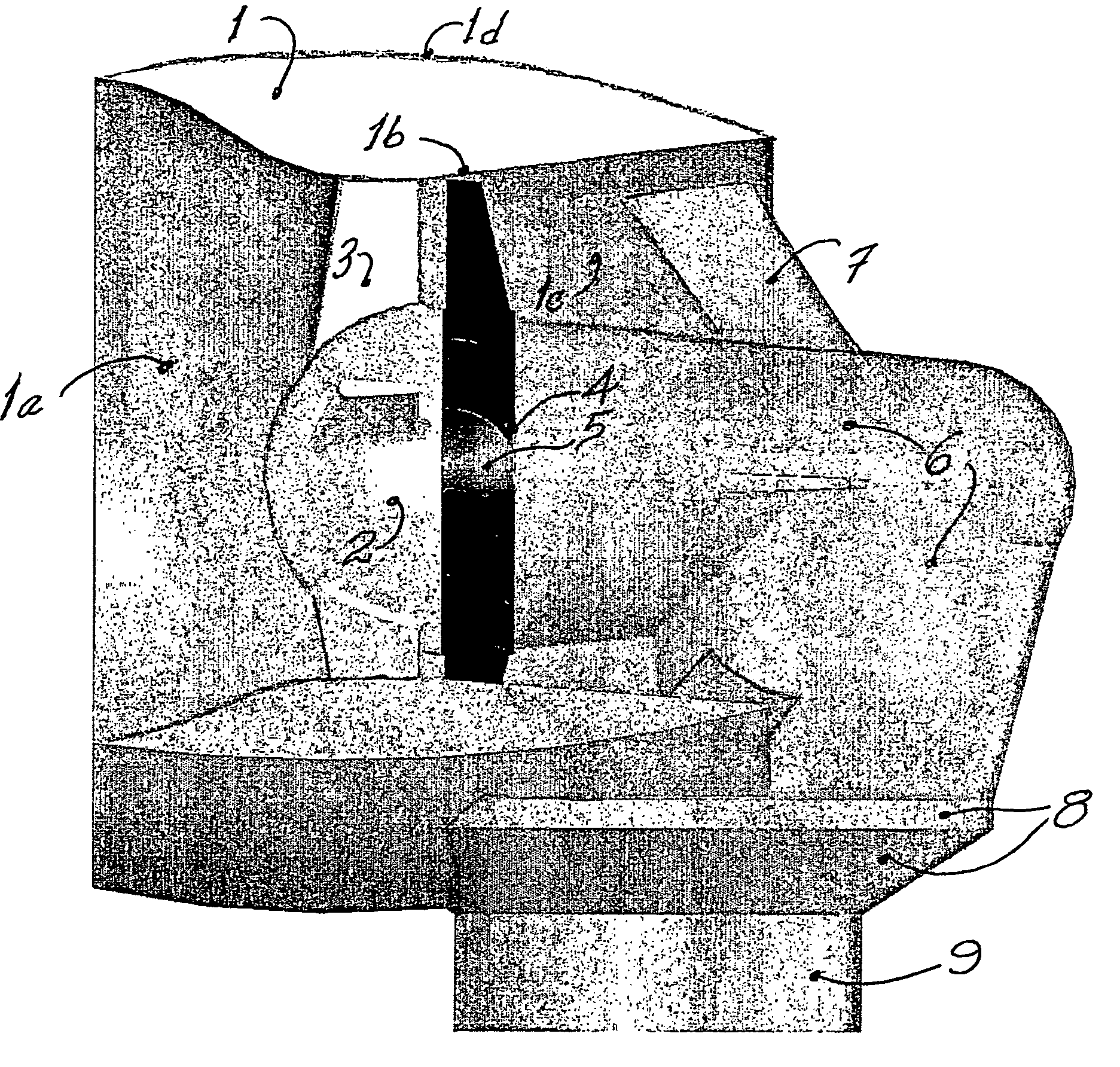

A LED projector light module comprising a main body, a LED unit, a heat-radiating unit, a voltage conversion unit and a base is disclosed. The main body is made of metallic material with good thermal conductivity (e.g. copper) and contains a space for accommodating the LED unit. The LED unit and the voltage conversion unit are electrically connected. The voltage conversion unit is configured inside the base. The base is connectable to the main body. The bottom surface of base is disposed with an electrically conductive pin that matches the projector socket. The electrically conductive pin is electrically connected to the voltage conversion unit at one end. The invention is characterized in which the heat-radiating unit is arranged at the outer rim of main body and the heat generated by the LED unit can be effectively transferred to the heat-radiating unit through the main body and then rapidly dissipate, which enhances the efficiency of heat dissipation, thereby allowing the use of higher wattage LED to enhance luminance.

Owner:FIN CORE

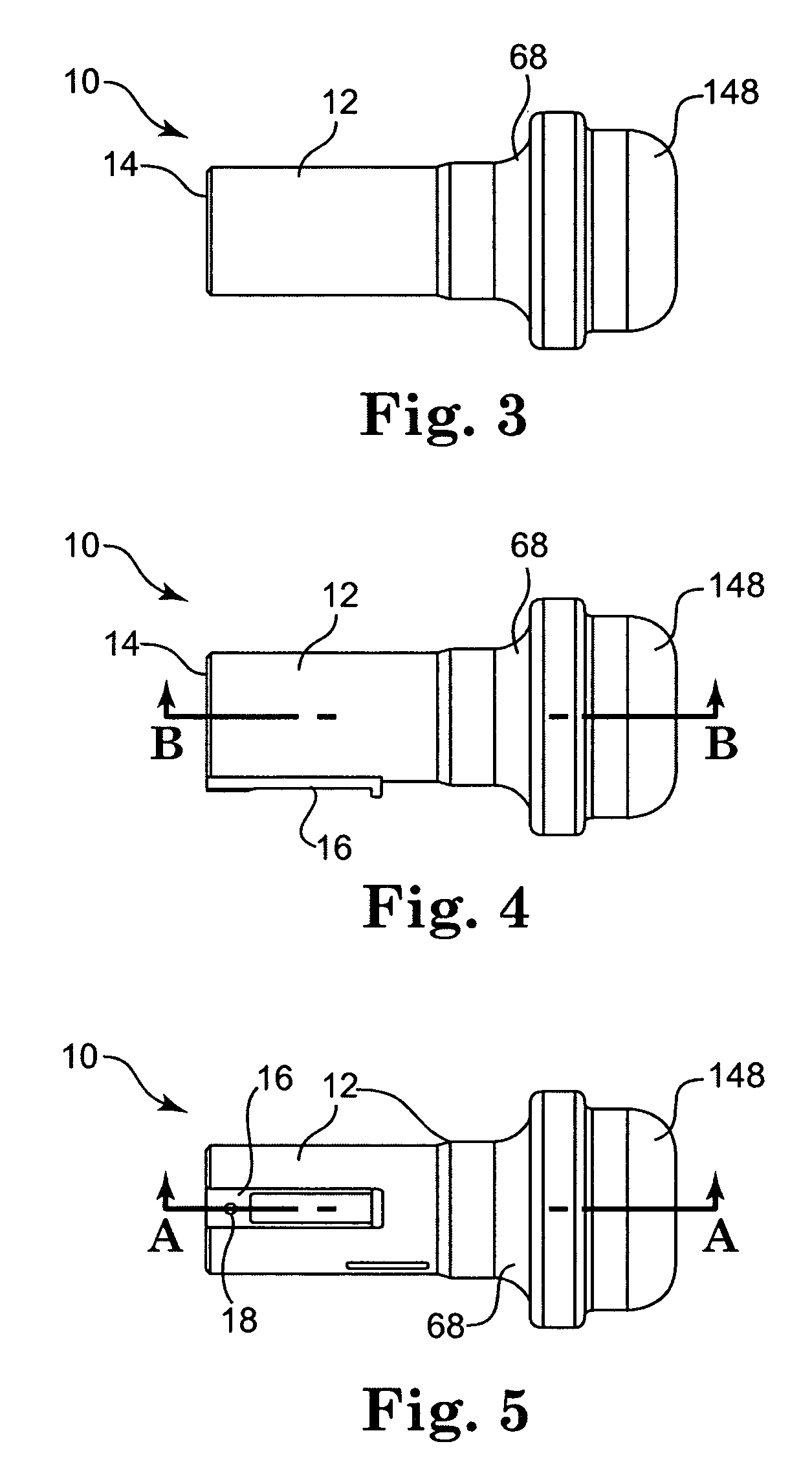

Removable, multi-purpose utility light for motor vehicles

InactiveUS20070019421A1Easy to mountEasy to removeLighting heating/cooling arrangementsOptical signallingHeat managementEffect light

Auxiliary lighting for motor vehicles. The lighting system of the invention may be configured so that it both mounts to and draws power from a socket on the vehicle. The lighting systems may use one or more heat management strategies to help dissipate heat generated during operation. A user may easily switch among two or more operational modes. In preferred modes, the user may select among available modes simply by relative rotational motion among housing components. Some aspects of the invention also use a combination of reflecting elements that provide a very favorable pattern of illumination. According to one such embodiment, a primary reflector includes a dichroic surface that reflects some light outward, but allows some light to pass. A secondary reflector is then used to capture and reflect the passing light outward as well.

Owner:MOTOTRIX

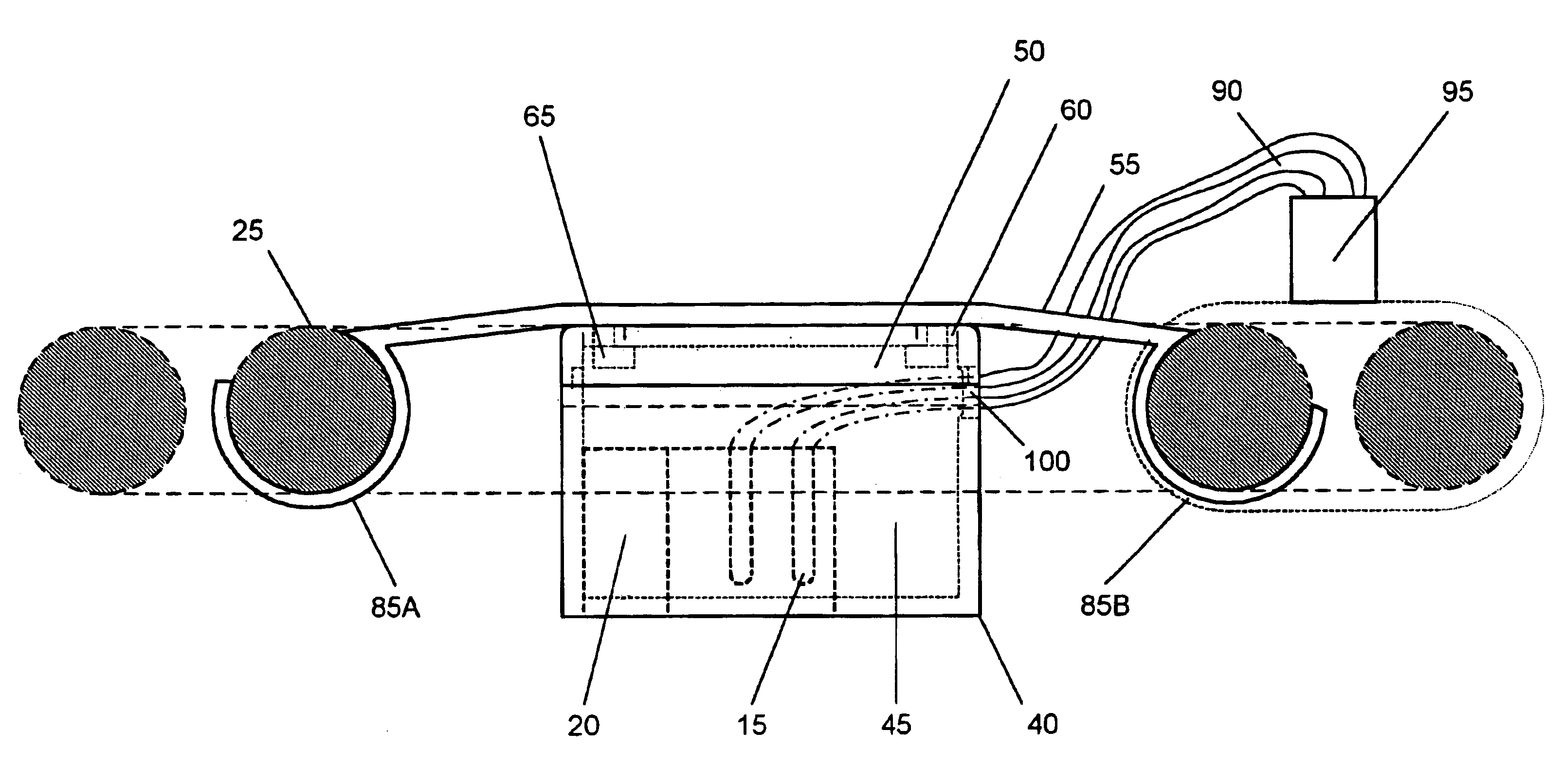

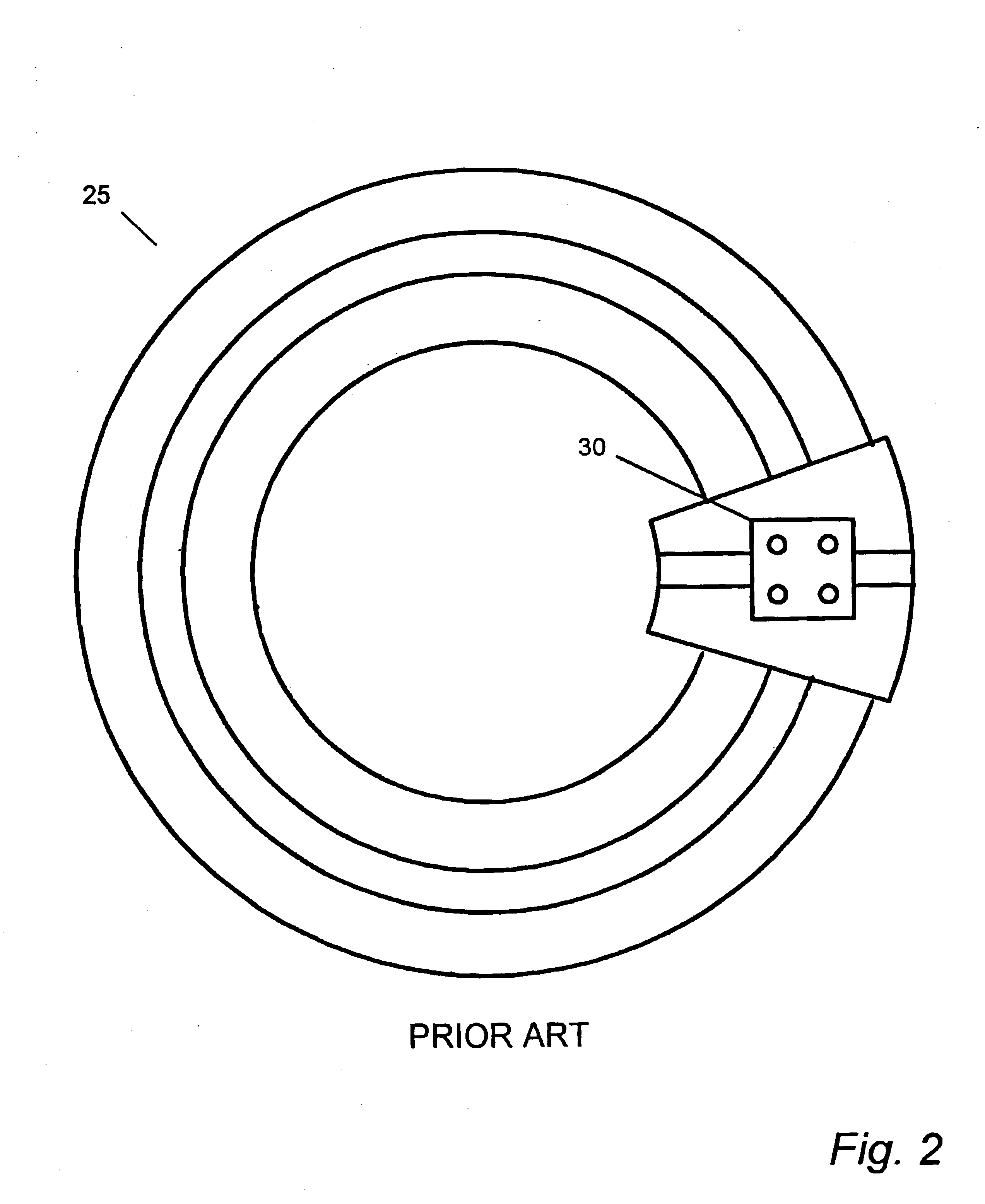

Retrofit fluorescent lamp adaptor

InactiveUS6869205B1Easy to installEliminate potentialCoupling device connectionsNon-electric lightingFluorescenceEffect light

A novel fluorescent lamp adaptor that safely converts an existing fluorescent lighting fixture that was designed to hold a “2D” 4-pin series fluorescent lamp to one that uses a “2C” series twin circular fluorescent lamp. The use of a type “2C” fluorescent lamp is advantageous because of its compactness, and greater efficiency, which is commensurate with a longer operational life.

Owner:TECHNICAL COSUMER PROD INC

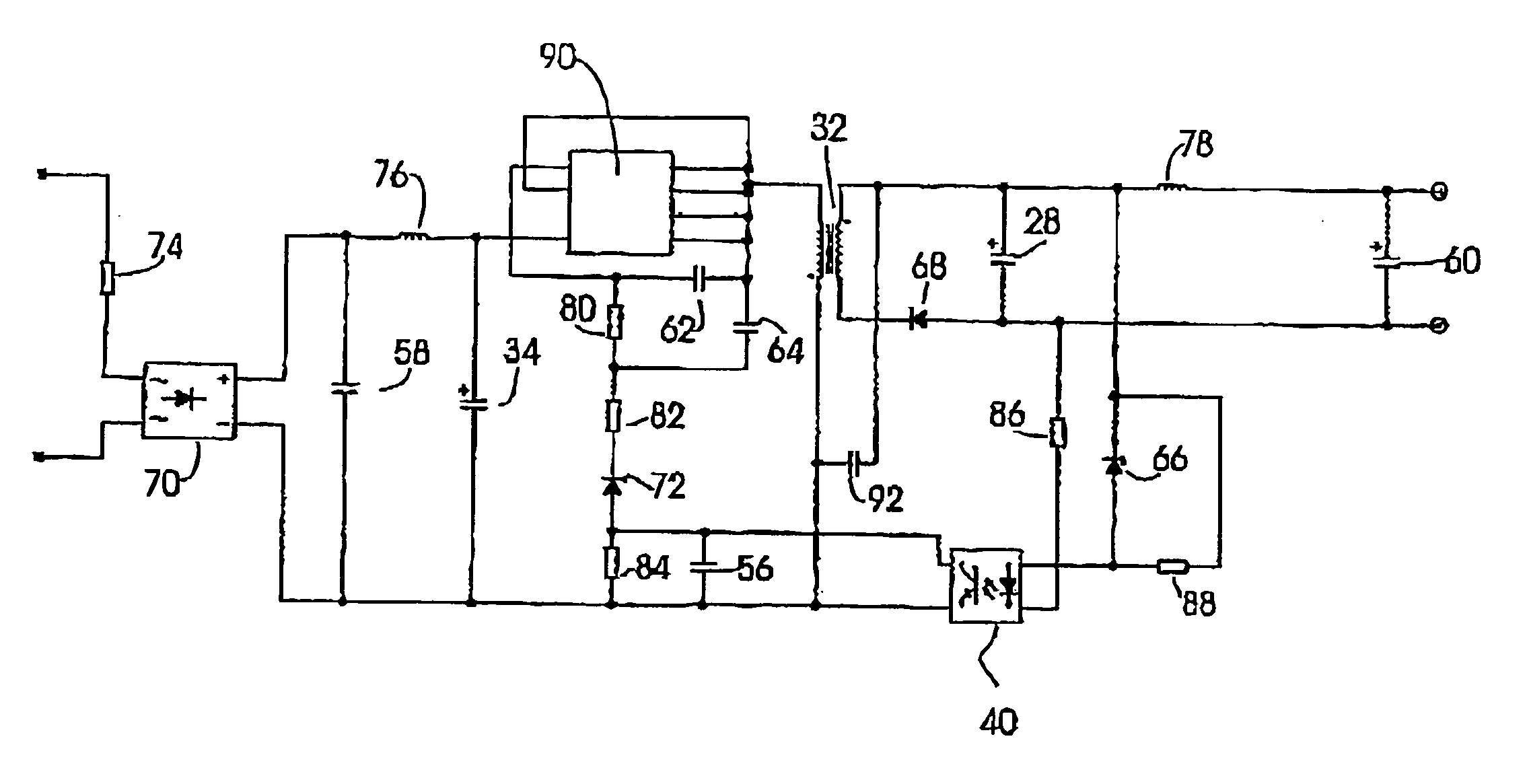

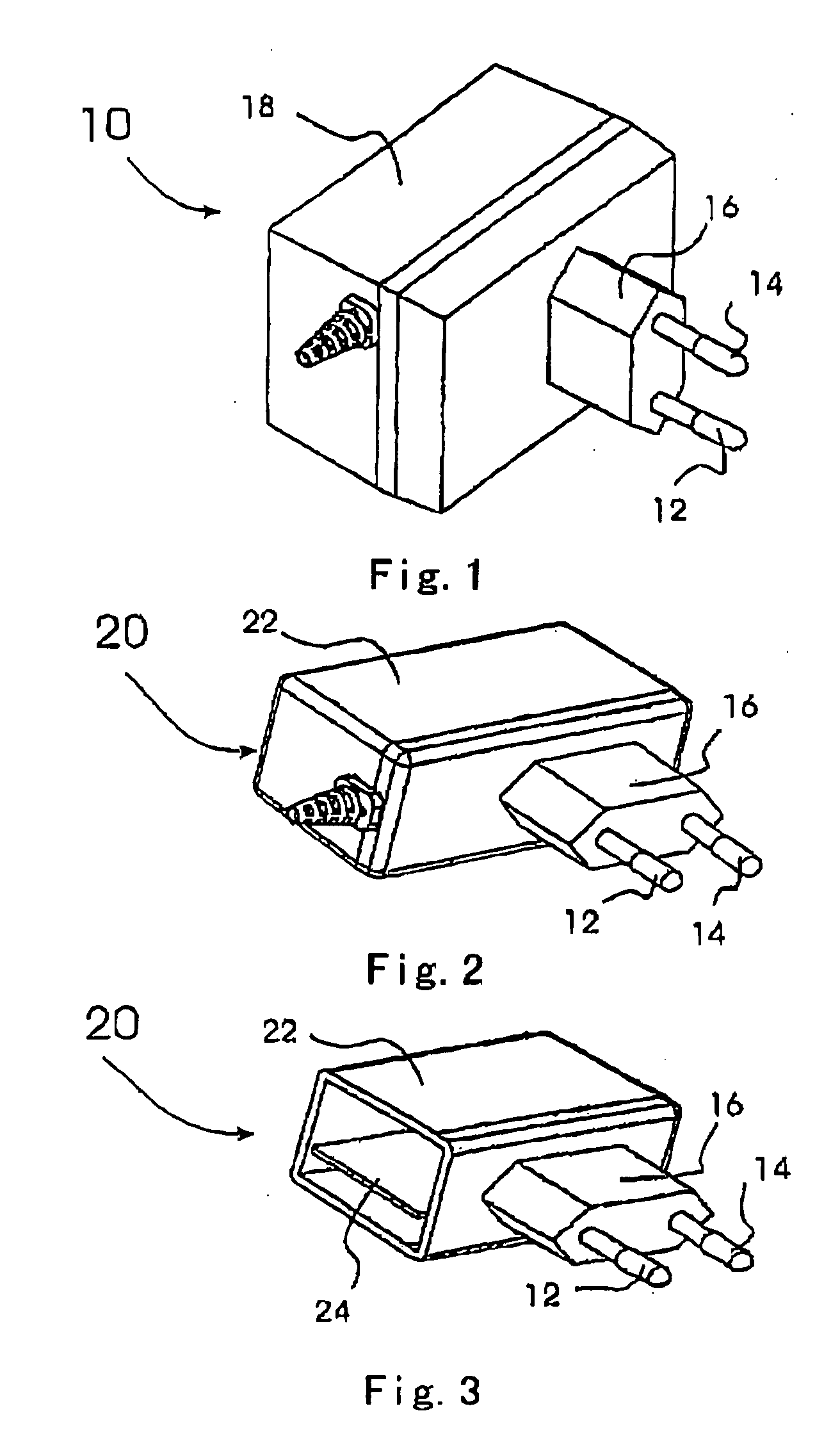

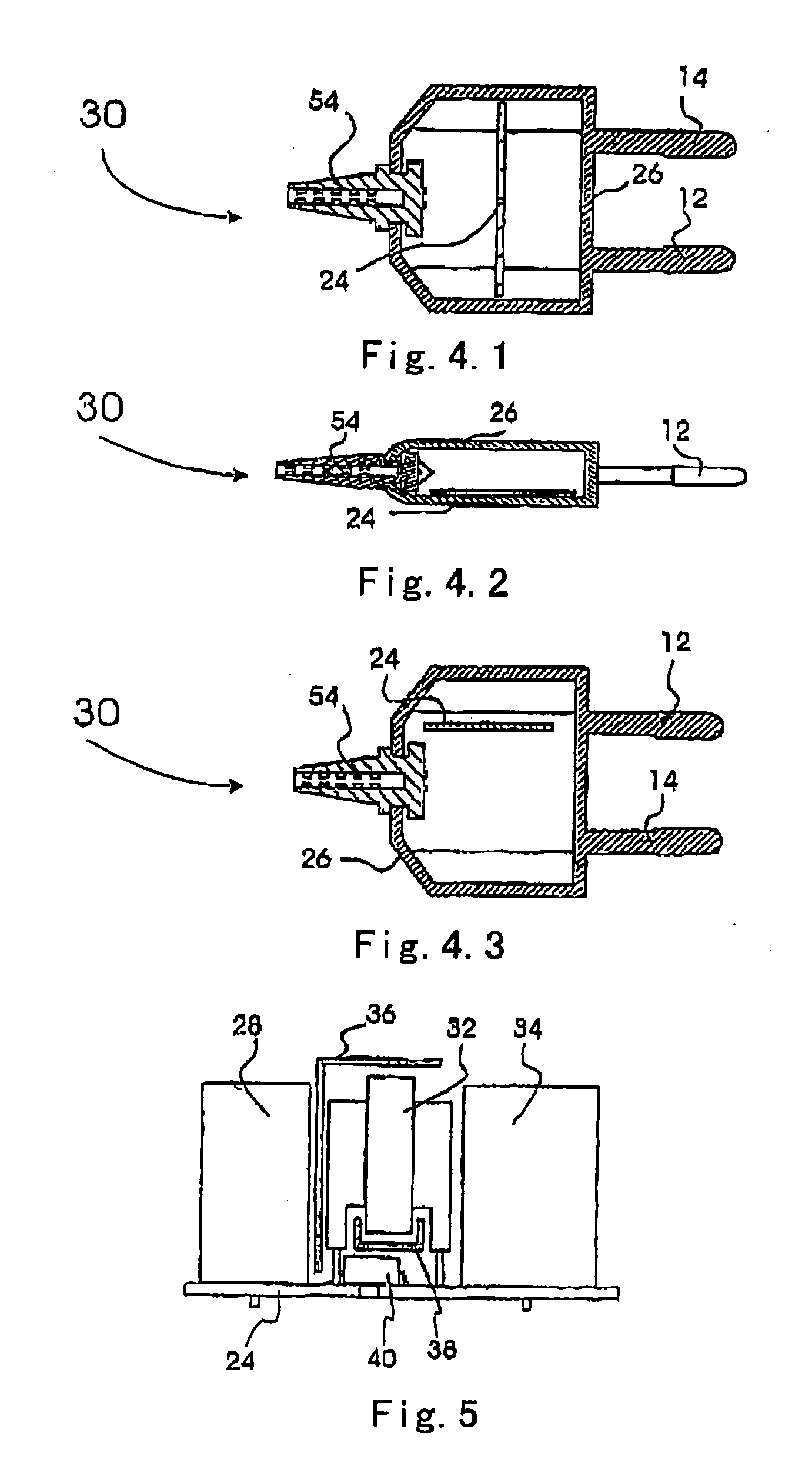

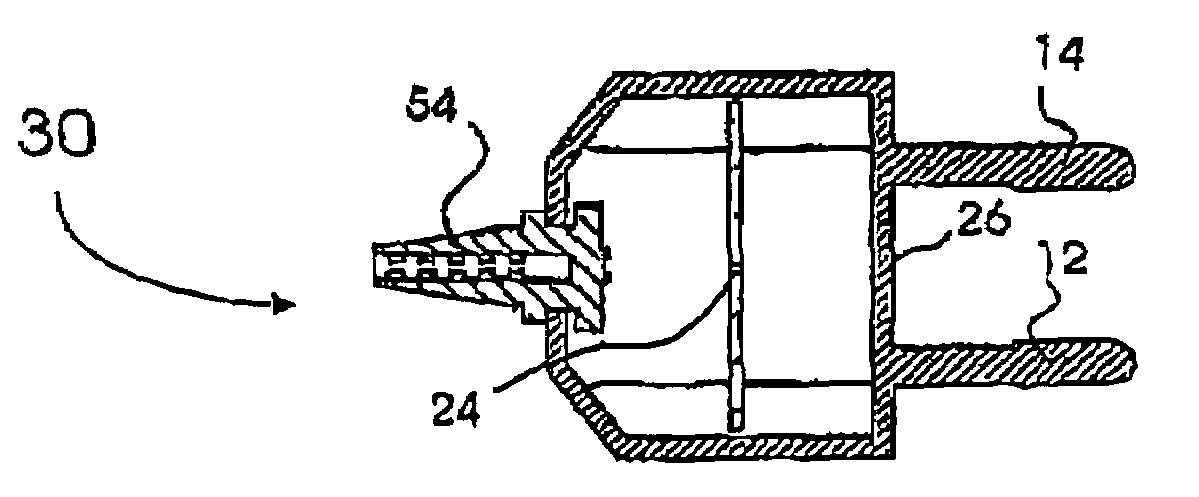

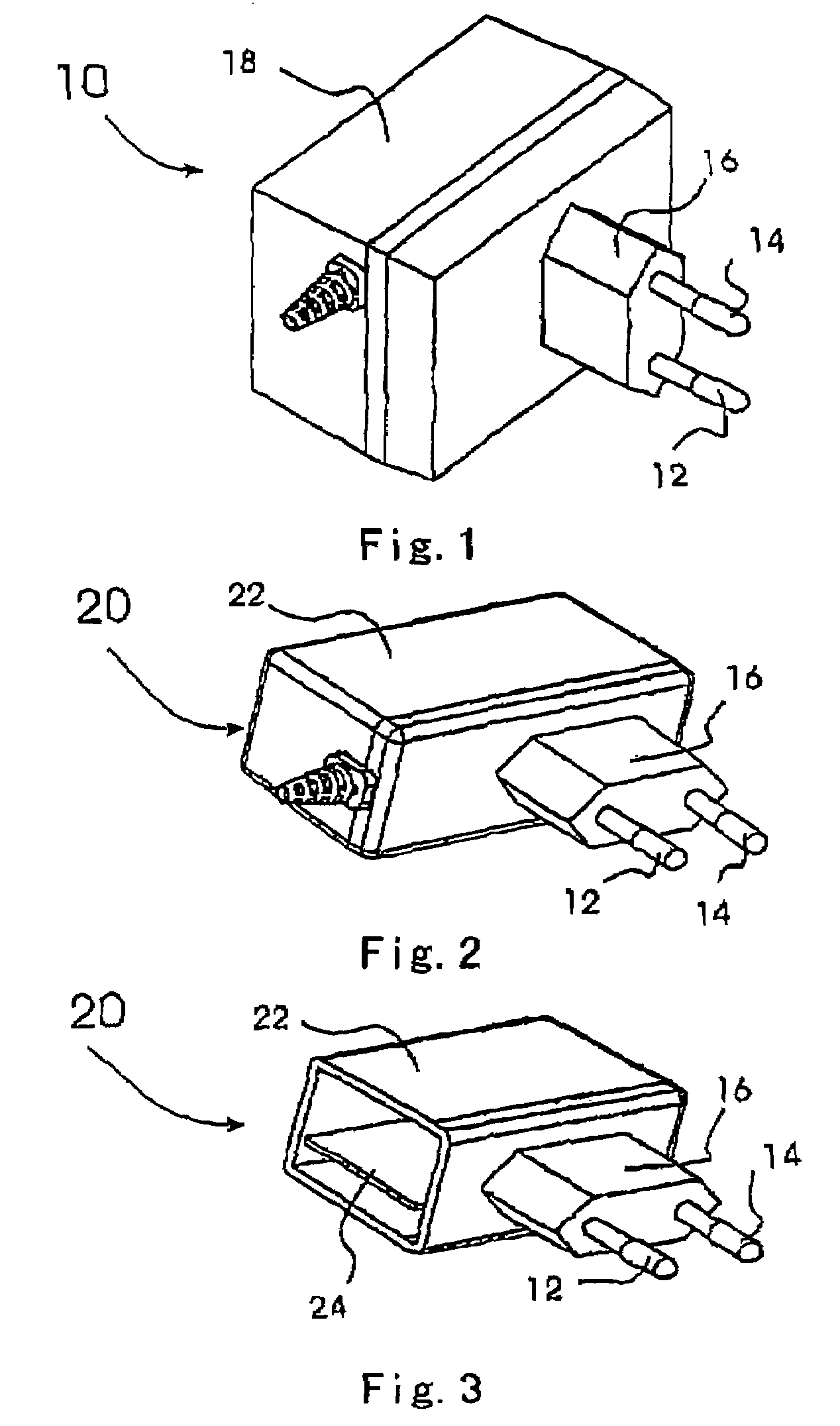

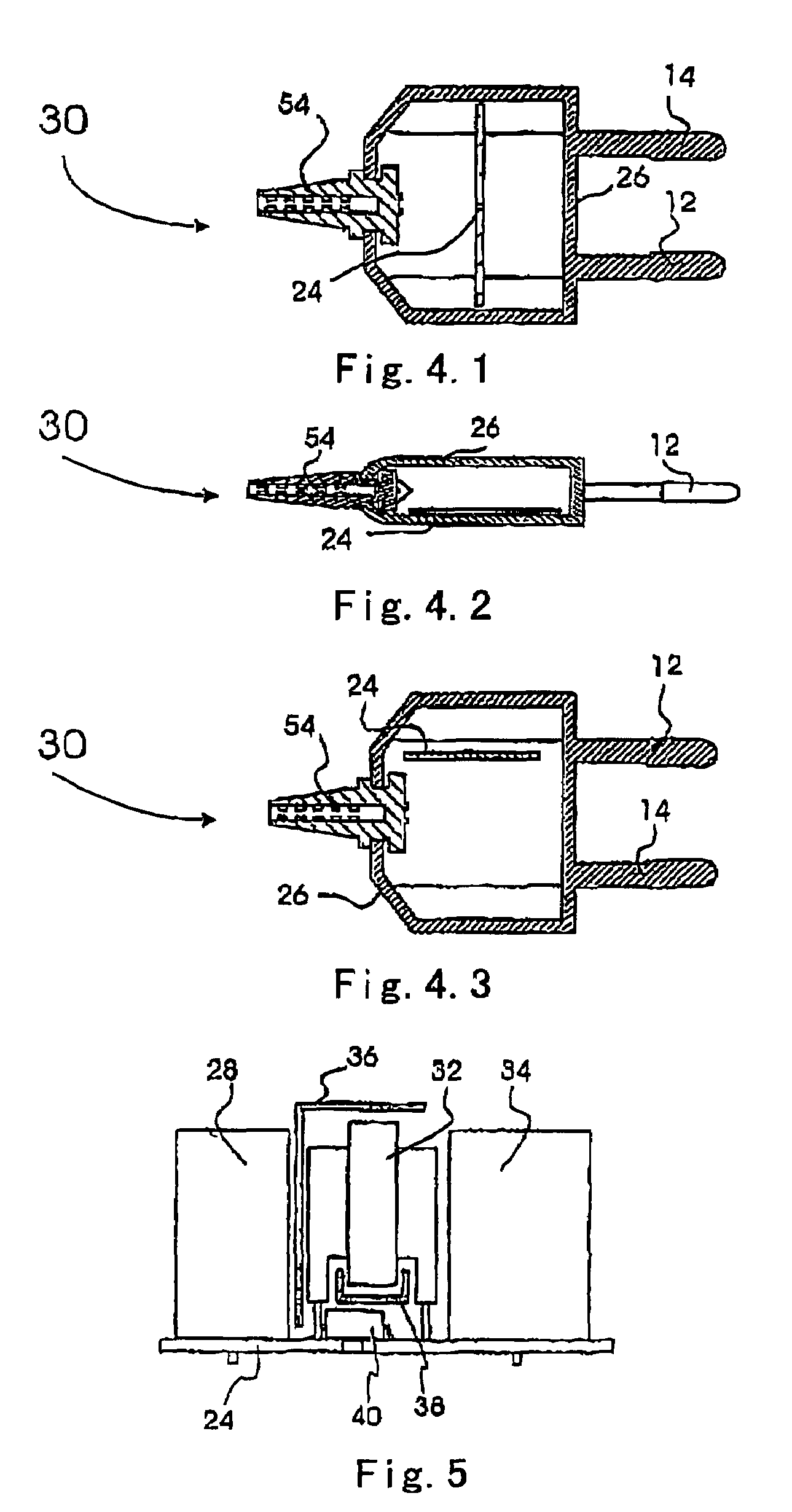

Power supply unit

InactiveUS20060044858A1Space saveSmall pcb surface areaTransformers/inductances coils/windings/connectionsAc-dc conversionPrinted circuit boardSwitched-mode power supply

A plug device with a built-in power supply of switch mode power supply type is disclosed. The plug device comprises a printed circuit board upon which a high-frequency transformer, a low-voltage capacitor and other components which make up a switch mode power supply are arranged. A first isolating barrier extends form the housing in between the high-frequency transformer and said low-voltage capacitor. A third isolating barrier (46) extends form the housing and into a first slot in the printed circuit board and a fourth isolating barrier extends from said housing and into a second slot in the printed circuit board. These slots are placed between the high-voltage and low-voltage connection terminals of the high-frequency transformer. A second isolating barrier extends from said housing and between the high-frequency transformer and the printed circuit board and beneath said high-frequency transformer.

Owner:TINYPLUG TECH SHENZHEN

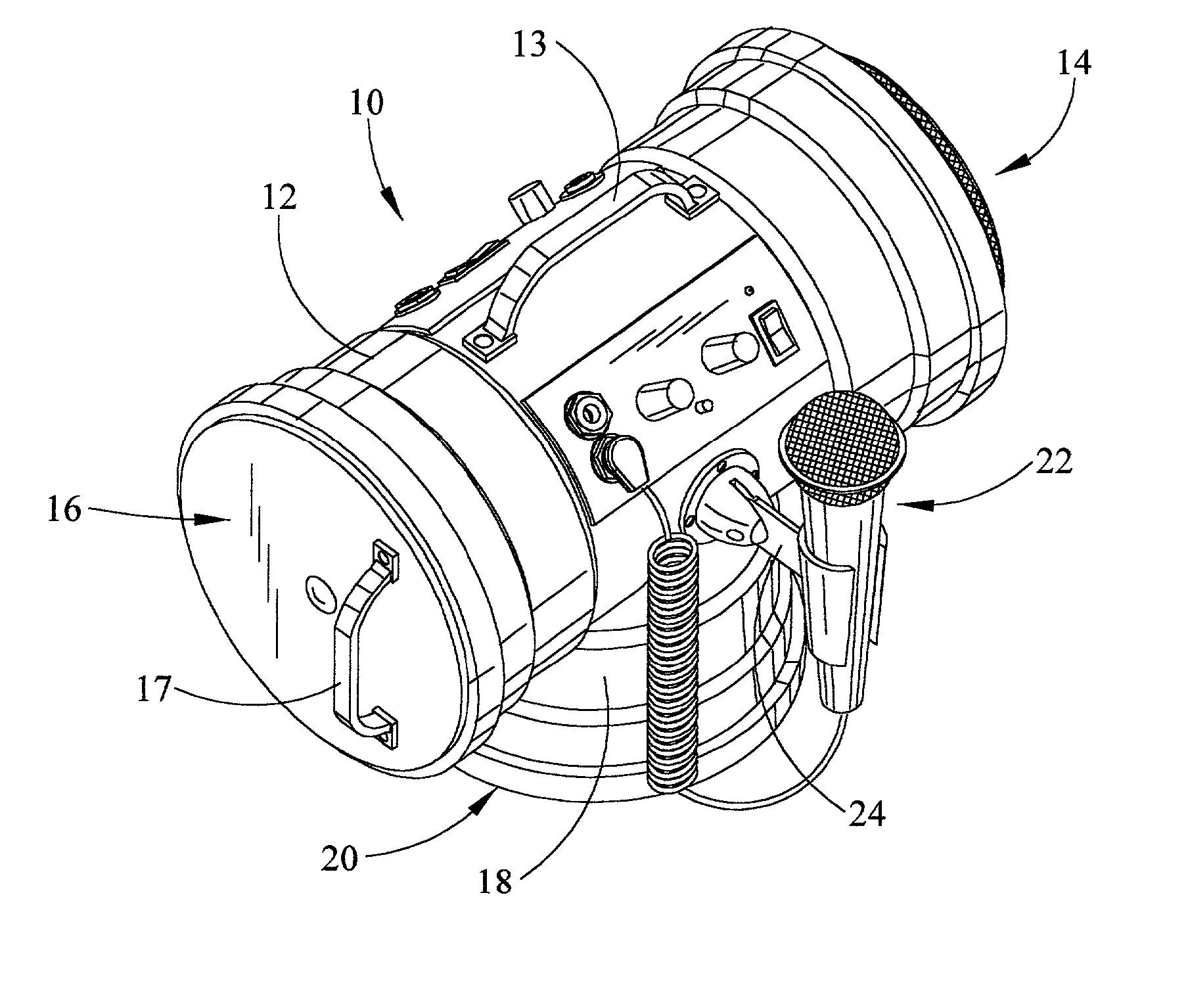

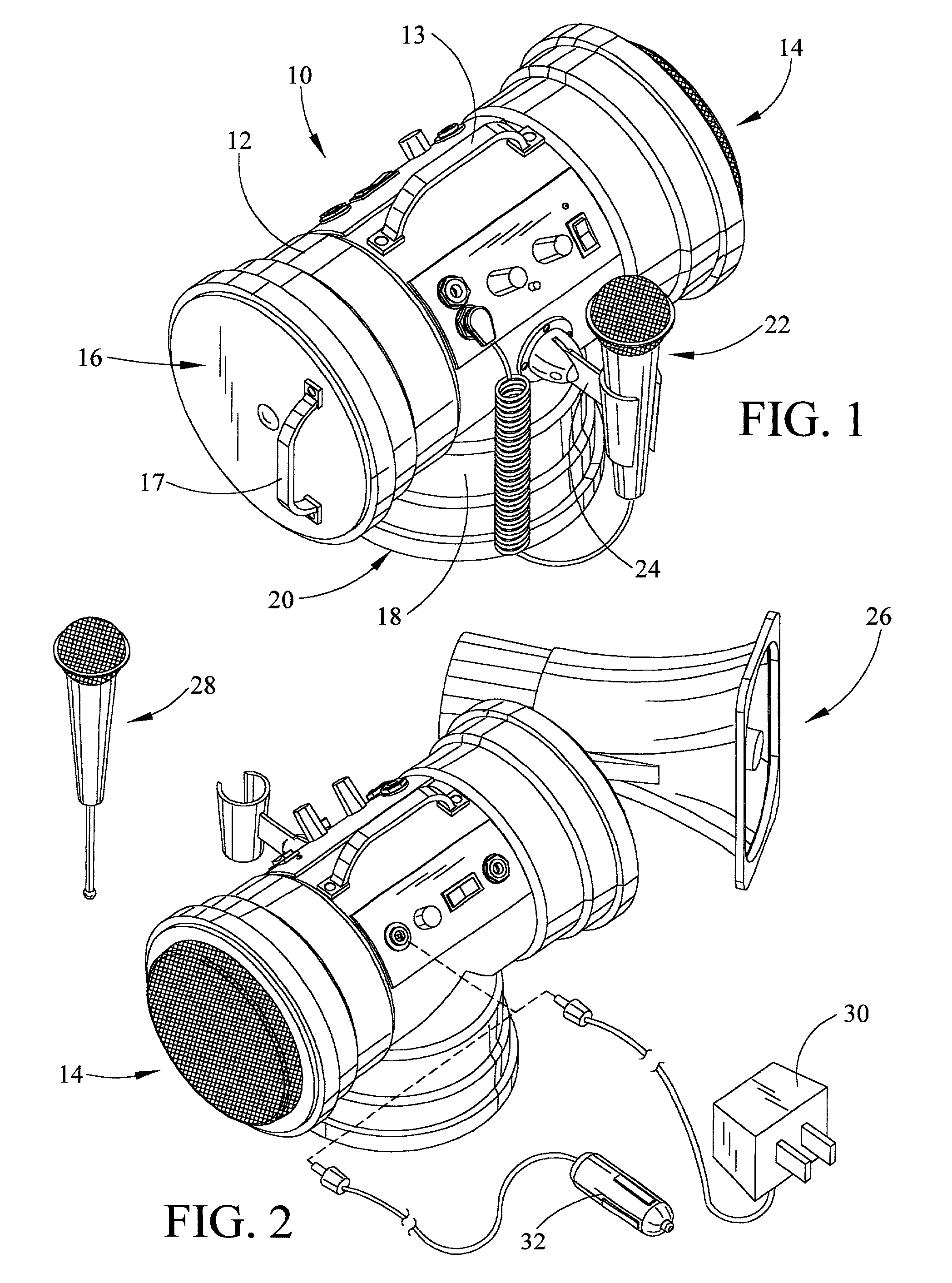

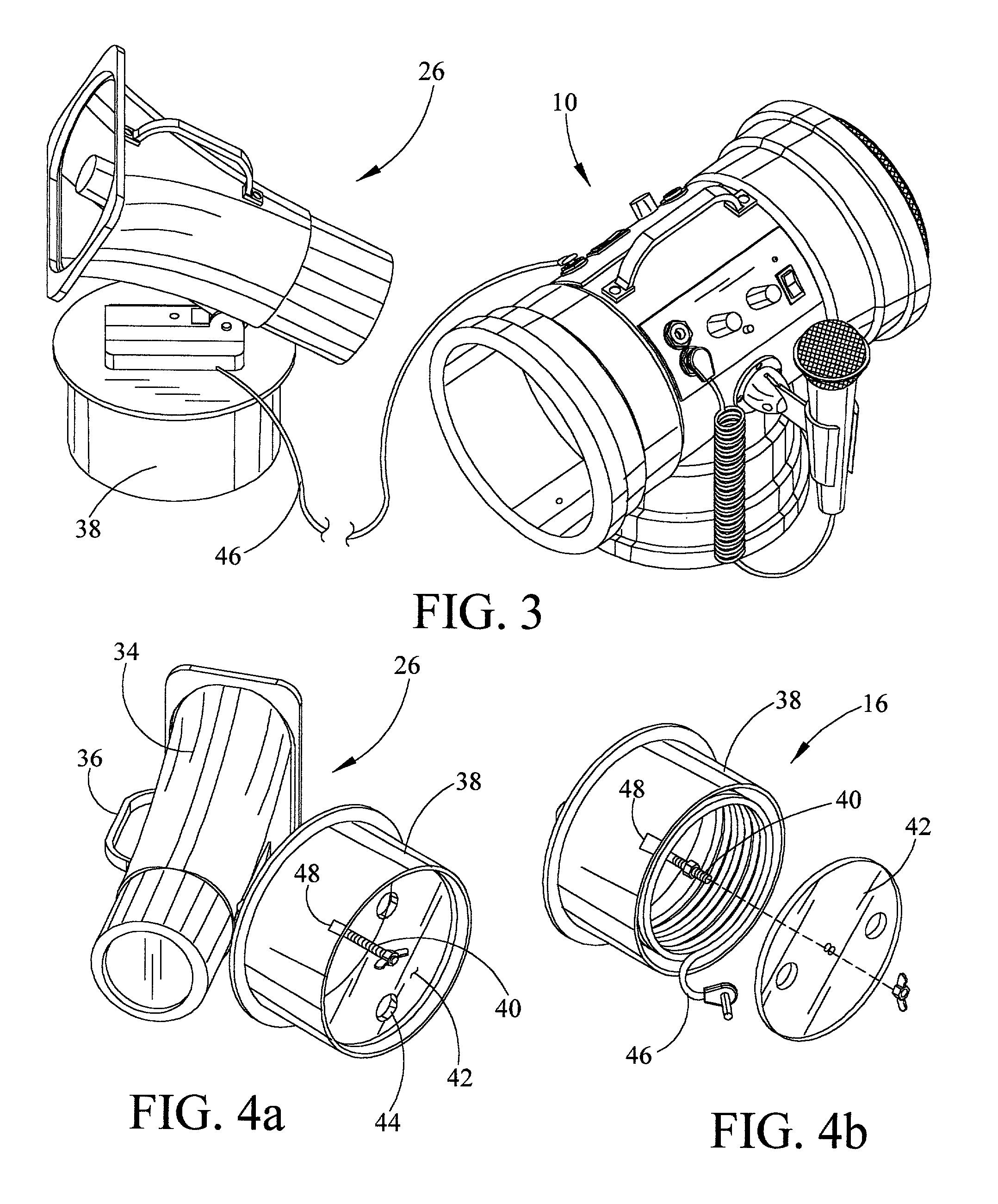

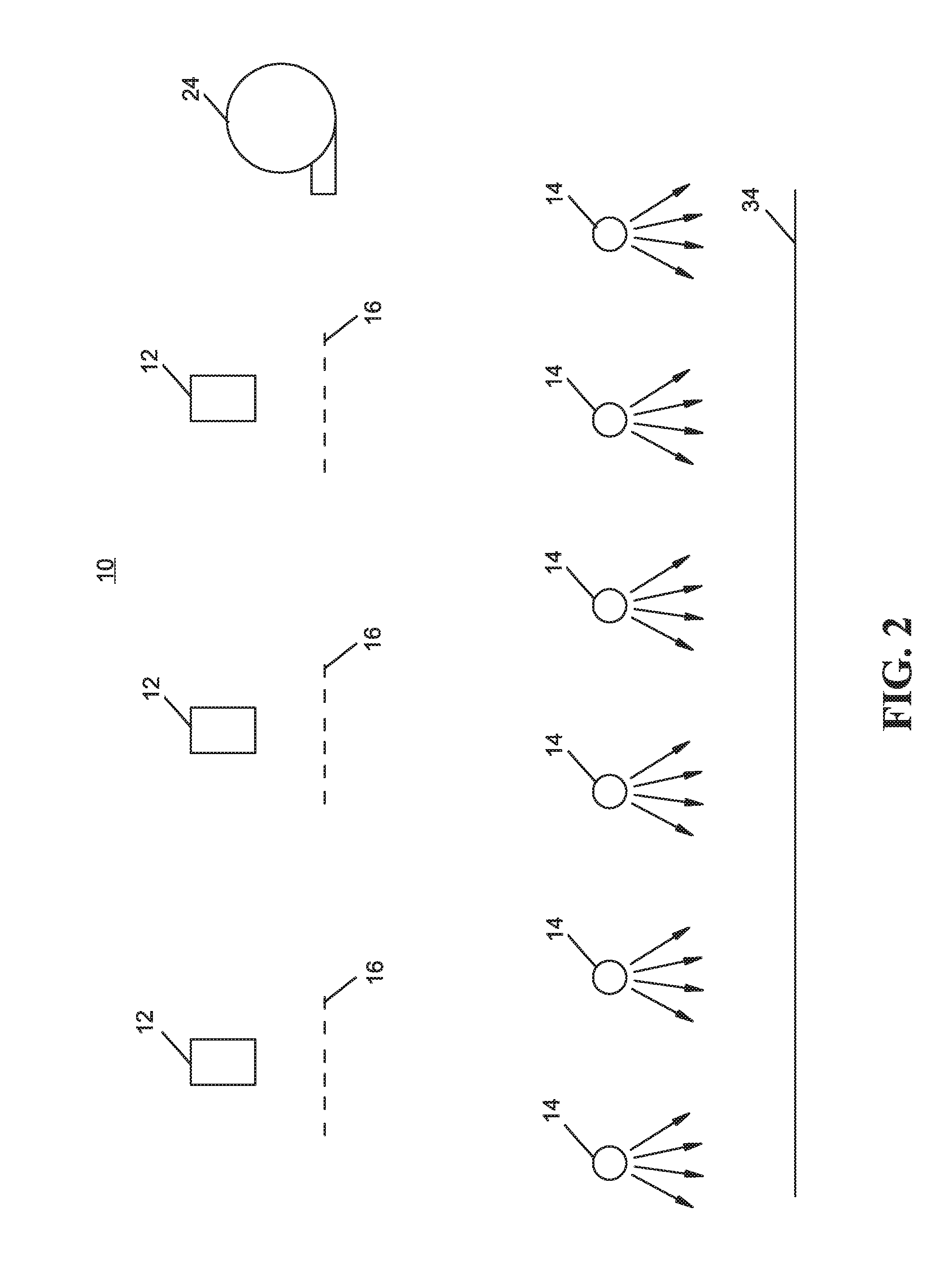

Method and apparatus for a portable public address system

InactiveUS20030063754A1Improve fidelityIncrease wattageElectric megaphonesPublic address systemWireless microphone

An improved light weight, portable public address system configured with high fidelity omni-directional and high wattage directional speakers for both indoor and outdoor use with a wide variety of sound inputs assembled in a self-contained, compact housing. Optional systems provide for the remote deployment of up to two speakers and the use of a remote wireless microphone. Improved options include a unique compact configuration that allows for modular construction of all components for plug and play operation and rapid field replacement; a weatherproof housing for operation in inclement weather, and a tape player to provide prerecorded programming.

Owner:MEARS RAYMOND L

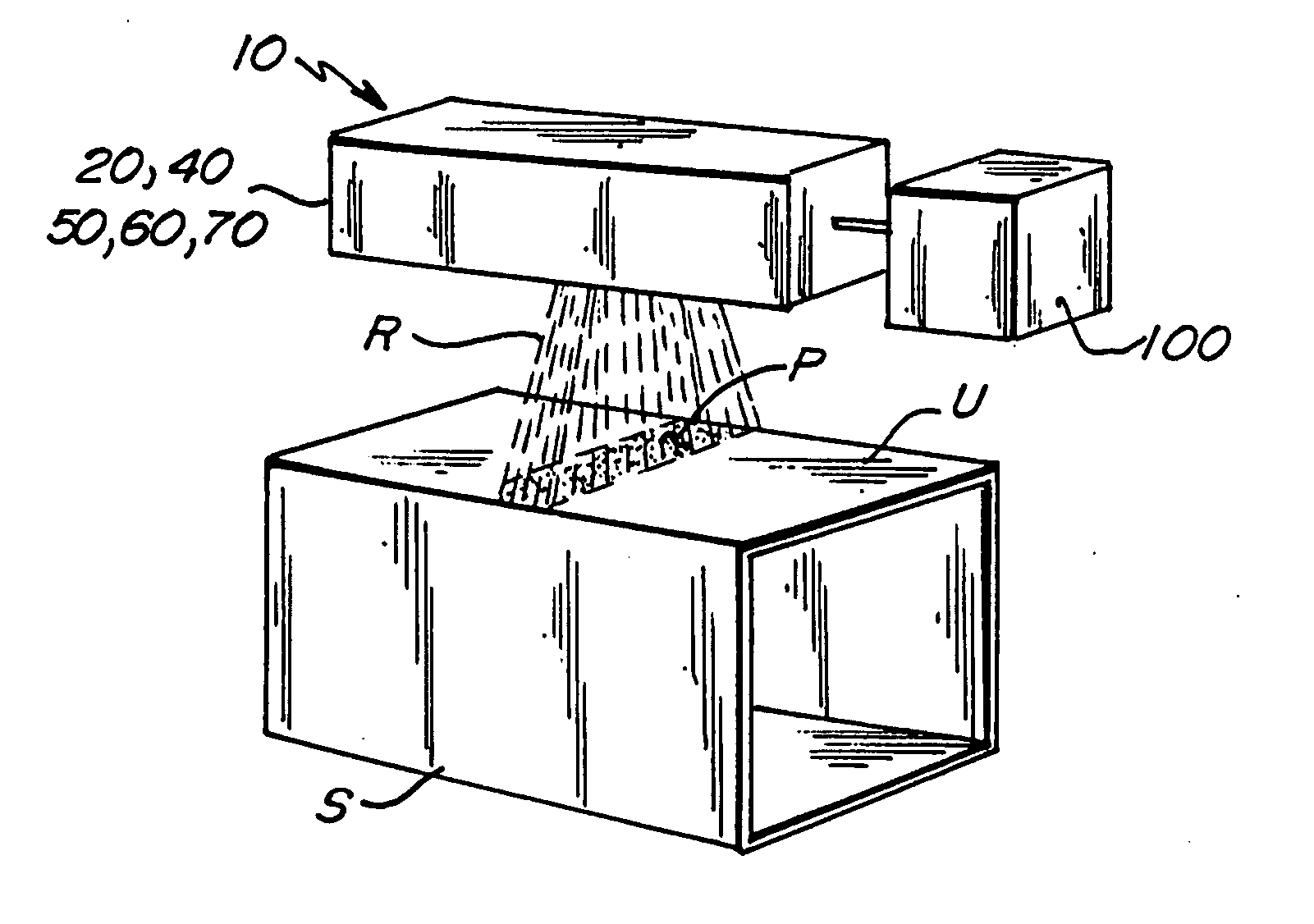

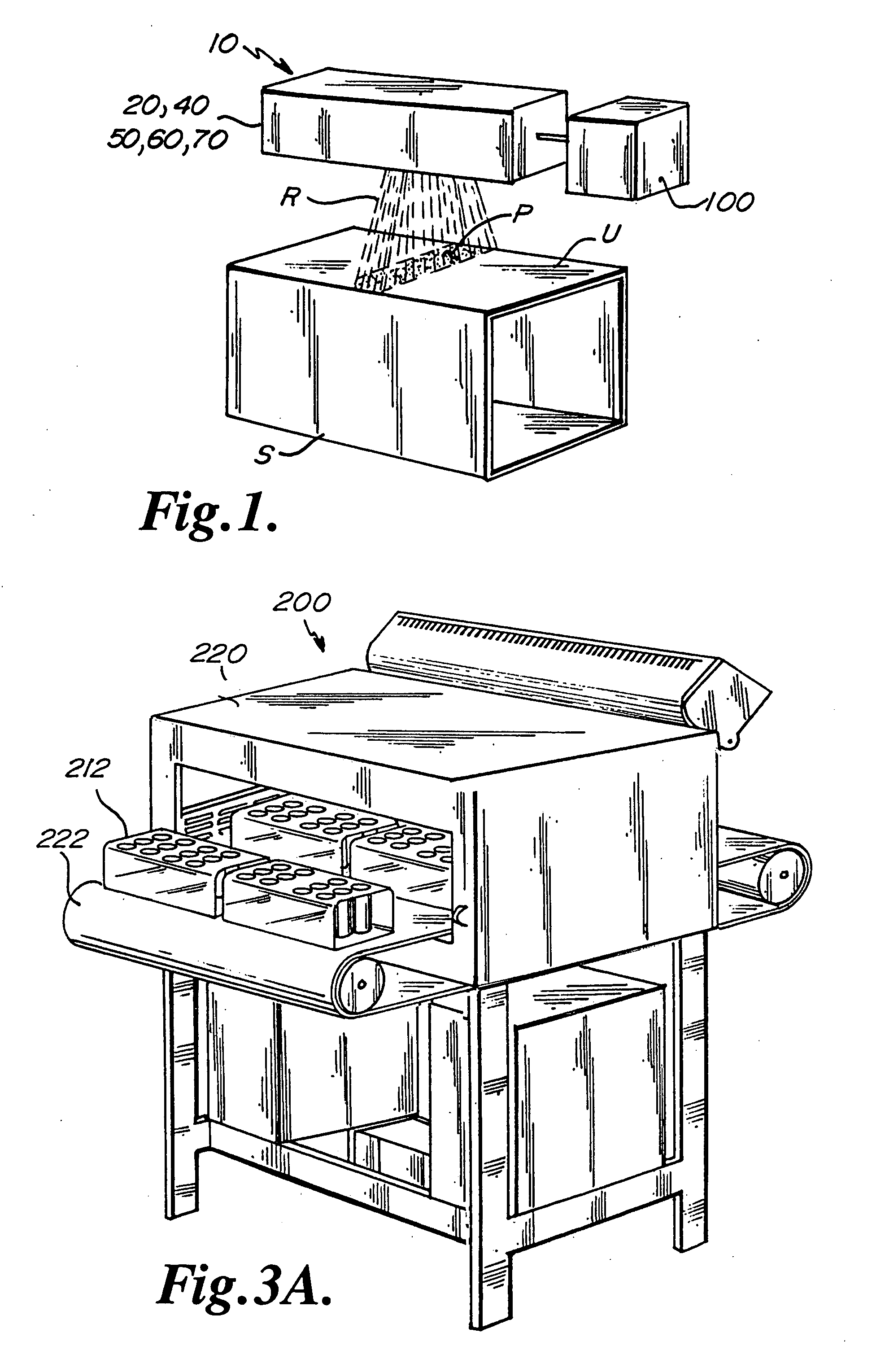

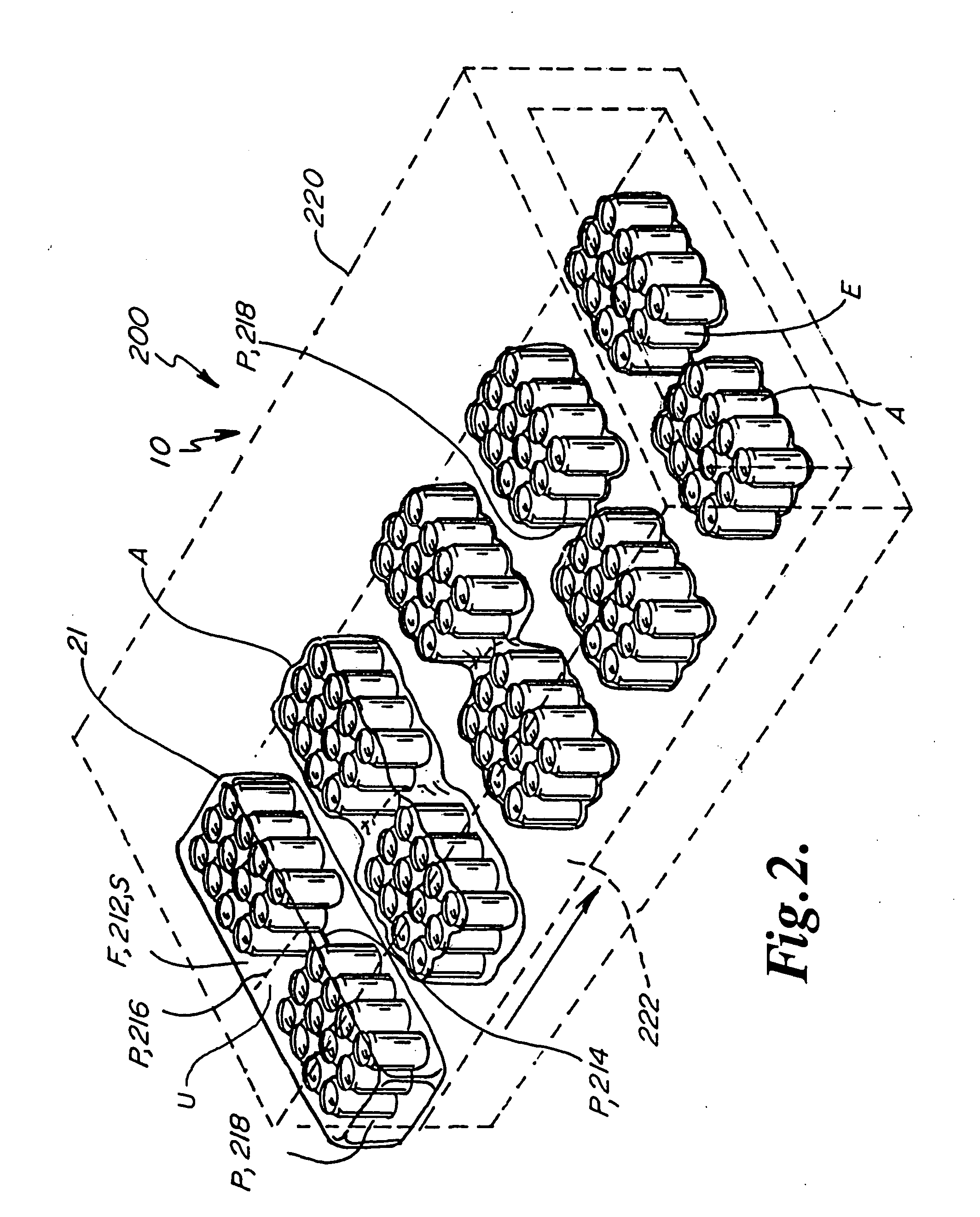

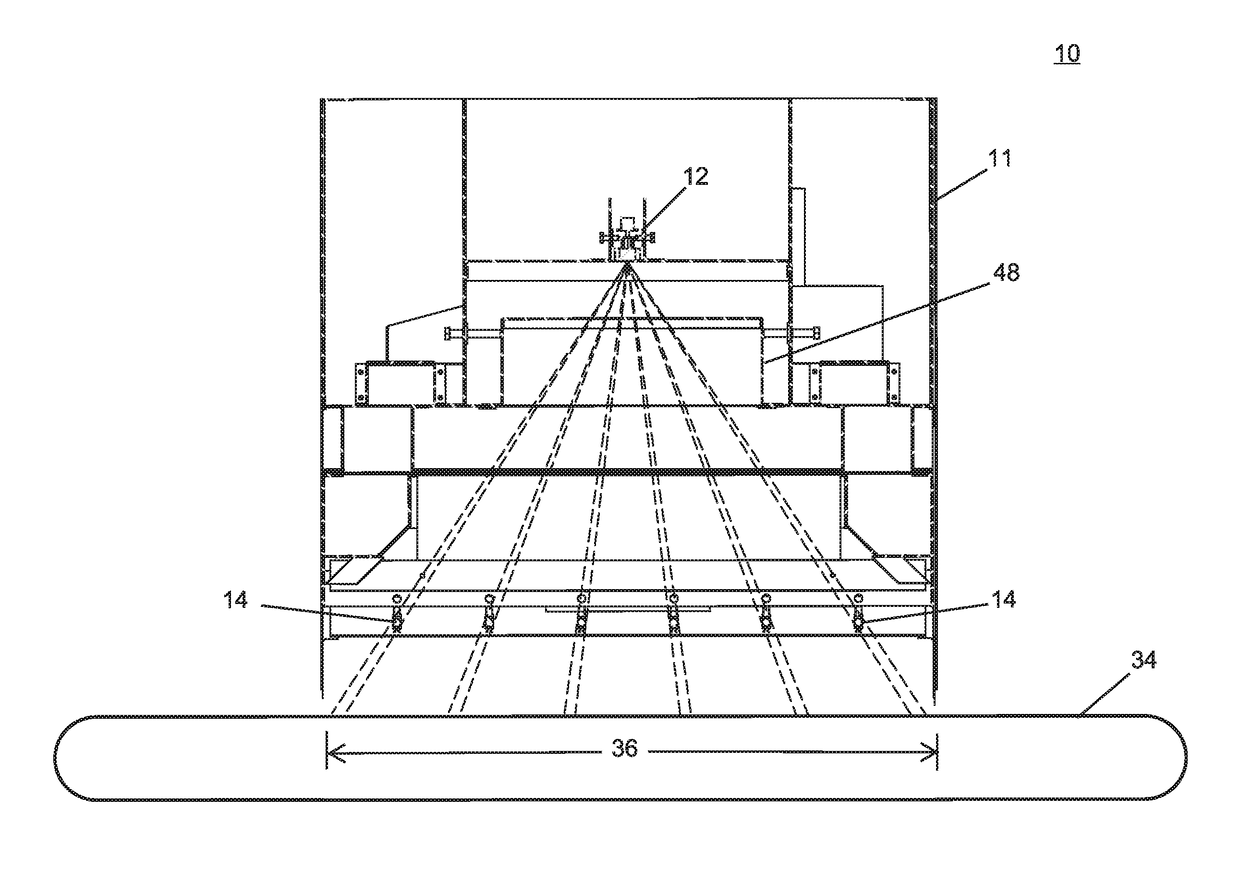

Apparatus and method for selective processing of materials with radiant energy

InactiveUS20050193690A1Increase speedReduce heating capacityWrappers shrinkageDomestic articlesControl systemDna testing

Apparatus for selective processing of a substrate using radiant energy. The substrate can consist of any target material having a portion to be processed using the radiant energy and a larger portion to be unprocessed. The apparatus consists of a source of radiant energy (preferably a quantum cascade laser) that has a customizable spectrum that can be configured to be specifically absorbed only by the portion to be processed, and a control system for targeting the radiant energy only at the portion to be processed. Specific examples of the use of the apparatus and method are in the technologies of heat-shrinking polyethylene film, fusing toner to paper in a laser printer, heating reaction vessels in DNA testing, and temperature profiling bottle pre-forms.

Owner:DOUGLAS MACHINE LIABILITY

Power supply unit

InactiveUS7259975B2Increase wattageSufficient supplyTransformers/inductances coils/windings/connectionsCoupling device detailsLow voltageTransformer

A plug device with a built-in power supply of switch mode power supply type is disclosed. The plug device comprises a printed circuit board upon which a high-frequency transformer, a low-voltage capacitor and other components which make up a switch mode power supply are arranged. A first isolating barrier extends form the housing in between the high-frequency transformer and said low-voltage capacitor. A third isolating barrier extends form the housing and into a first slot in the printed circuit board and a fourth isolating barrier extends from said housing and into a second slot in the printed circuit board. These slots are placed between the high-voltage and low-voltage connection terminals of the high-frequency transformer. A second isolating barrier extends from said housing and between the high-frequency transformer and the printed circuit board and beneath said high-frequency transformer.

Owner:TINYPLUG TECH SHENZHEN

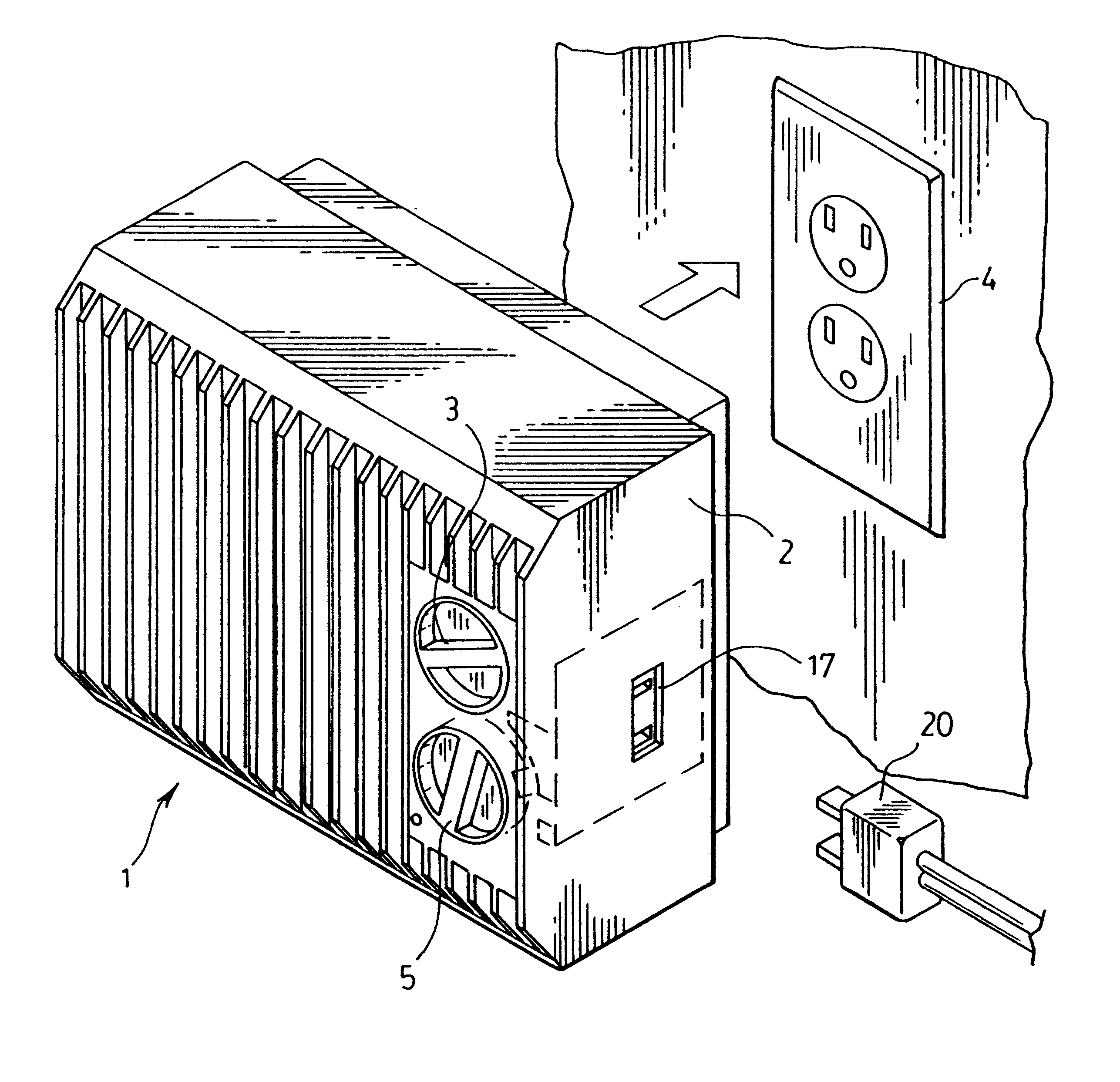

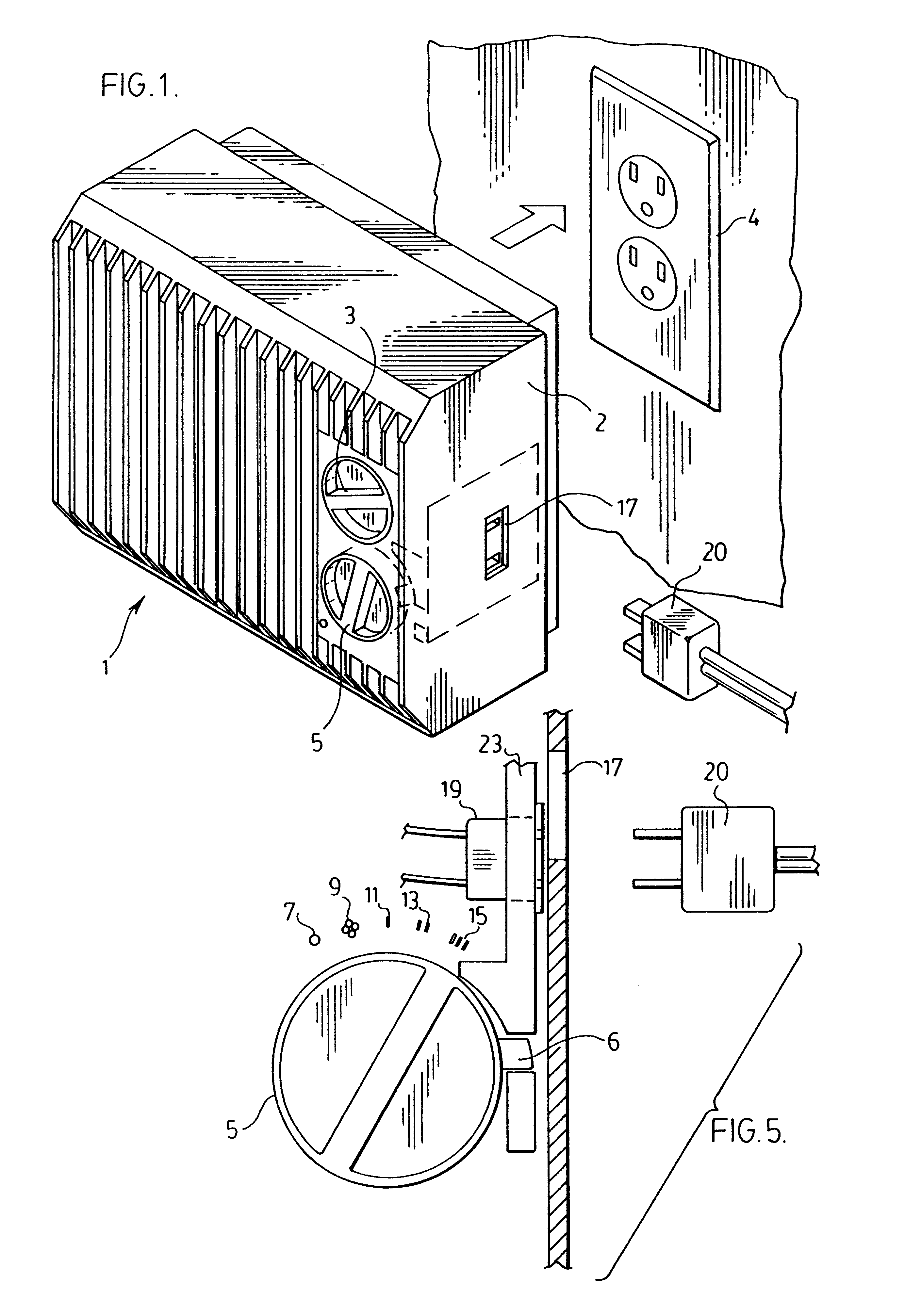

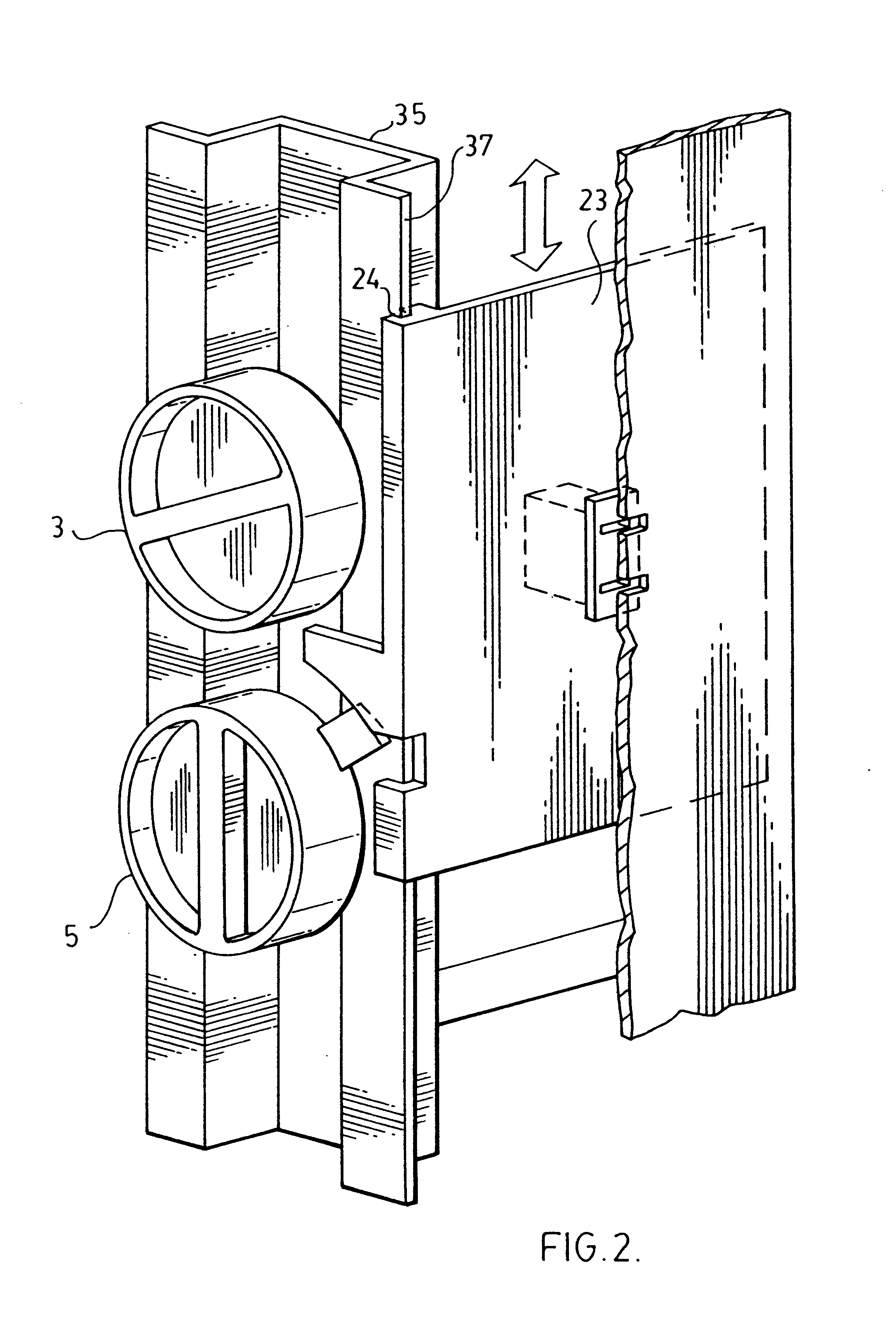

Wall mounted heater fan with electrical outlet

InactiveUS6280211B1Increase wattagePrevent overloading of the circuitElectric discharge tubesAir heatersElectricityEngineering

An electrical appliance has a plug receptor to receive the plug of another appliance such that both appliances can draw power from a single electrical outlet. The appliance of the present invention is operable at different wattages and has a switch which is movable to different switch settings to determine the wattage at which the appliance is operating. When the switch is set such that the appliance operates at a high wattage, the plug receptor is blocked from access to the plug of the other appliance to prevent over loading of the electrical outlet.

Owner:TATEISHI ART K

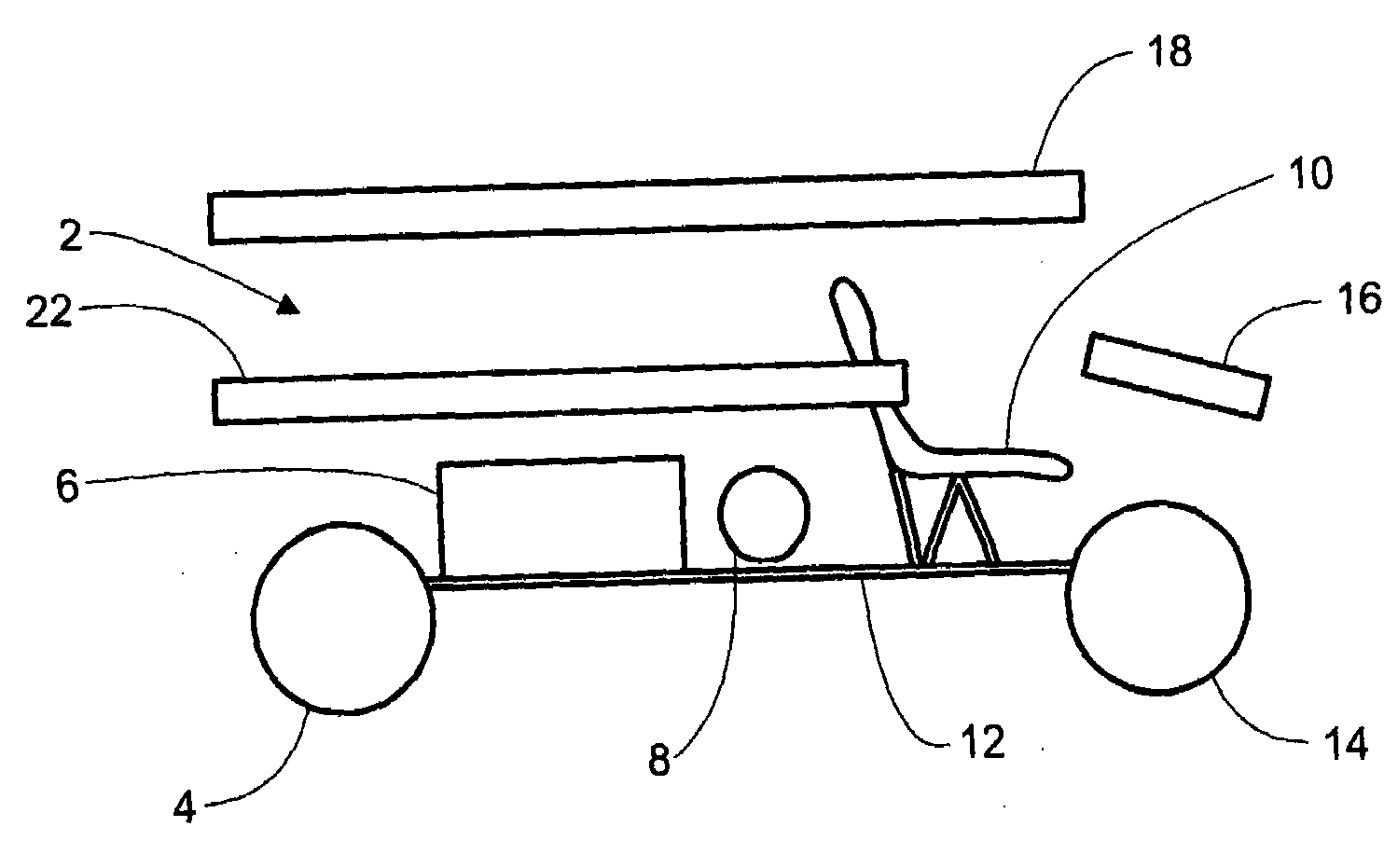

Very efficient and safe solar car

InactiveUS20090288890A1Maximizes solar outputImprove abilitiesAuxillary drivesElectric propulsion mountingEngineeringElectric power

A Solar Car that is safer and far more ecologically benign than any automobile on the road today. All of its solar panels would serve a secondary purpose besides providing power. As a thin vehicle whose chasis was no wider than forty five inches, it would need an electrical system less than ninety seven volts. Connected in series, the four or five solar panels contemplated in this patent would provide most of the power. To make sure that one could use their vehicle regularly, there would also be a supplemental plug in capacity.

Owner:FREEMAN BENJAMIN DAVID

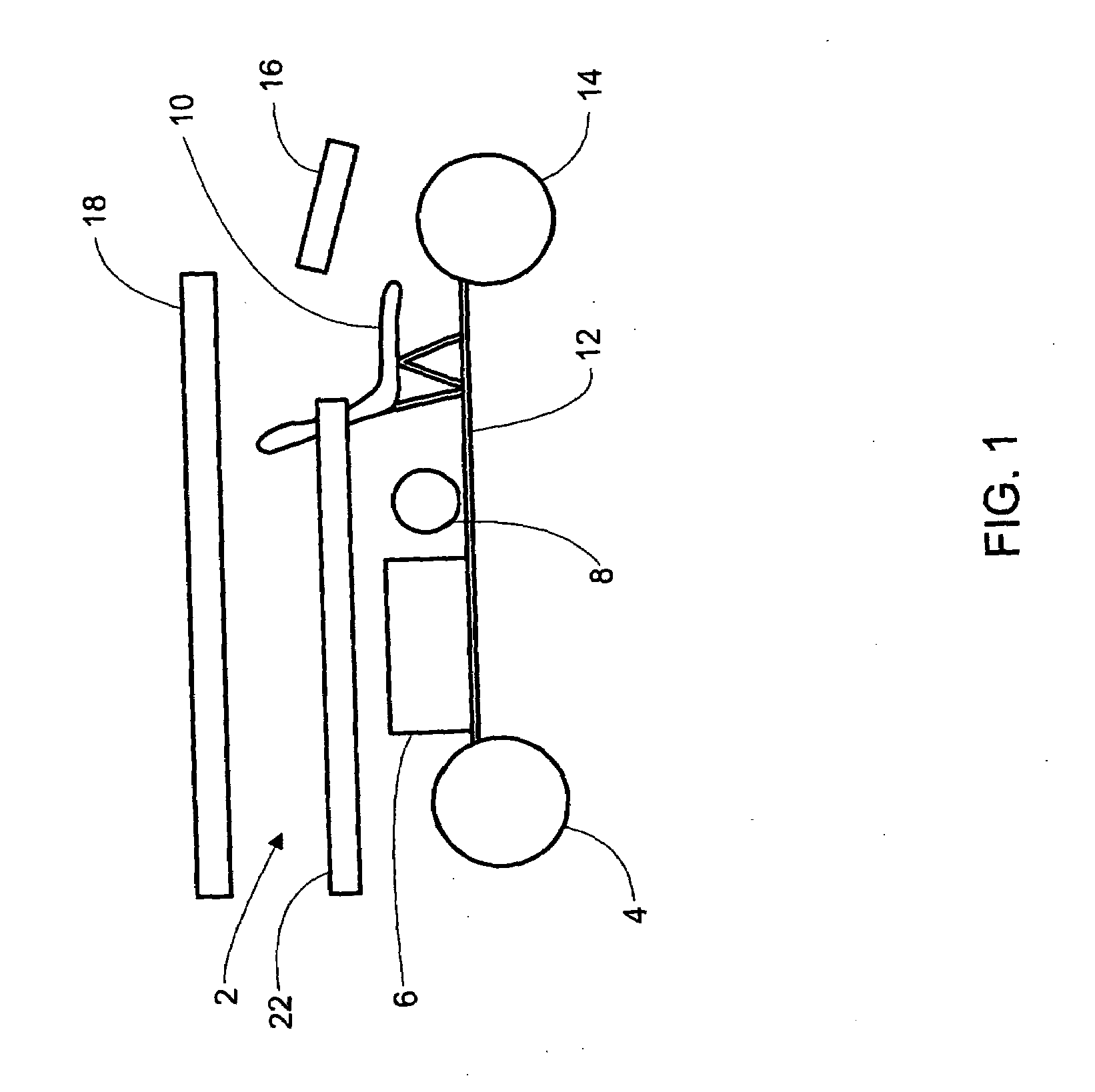

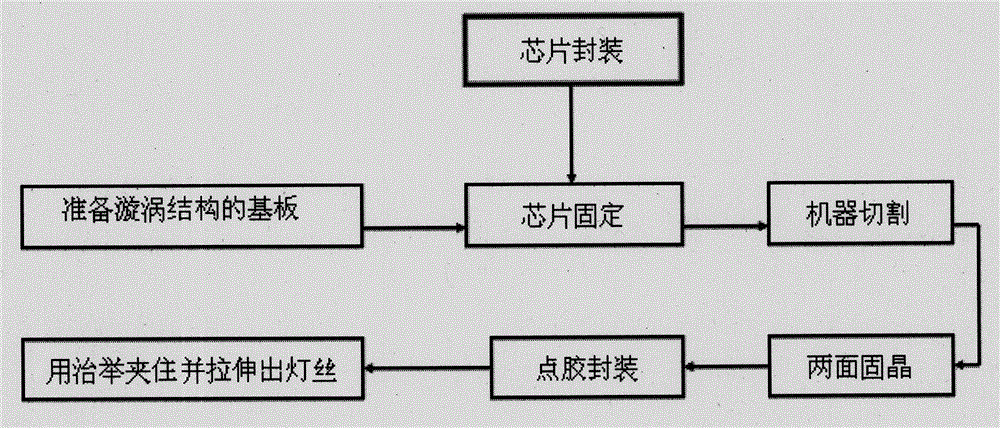

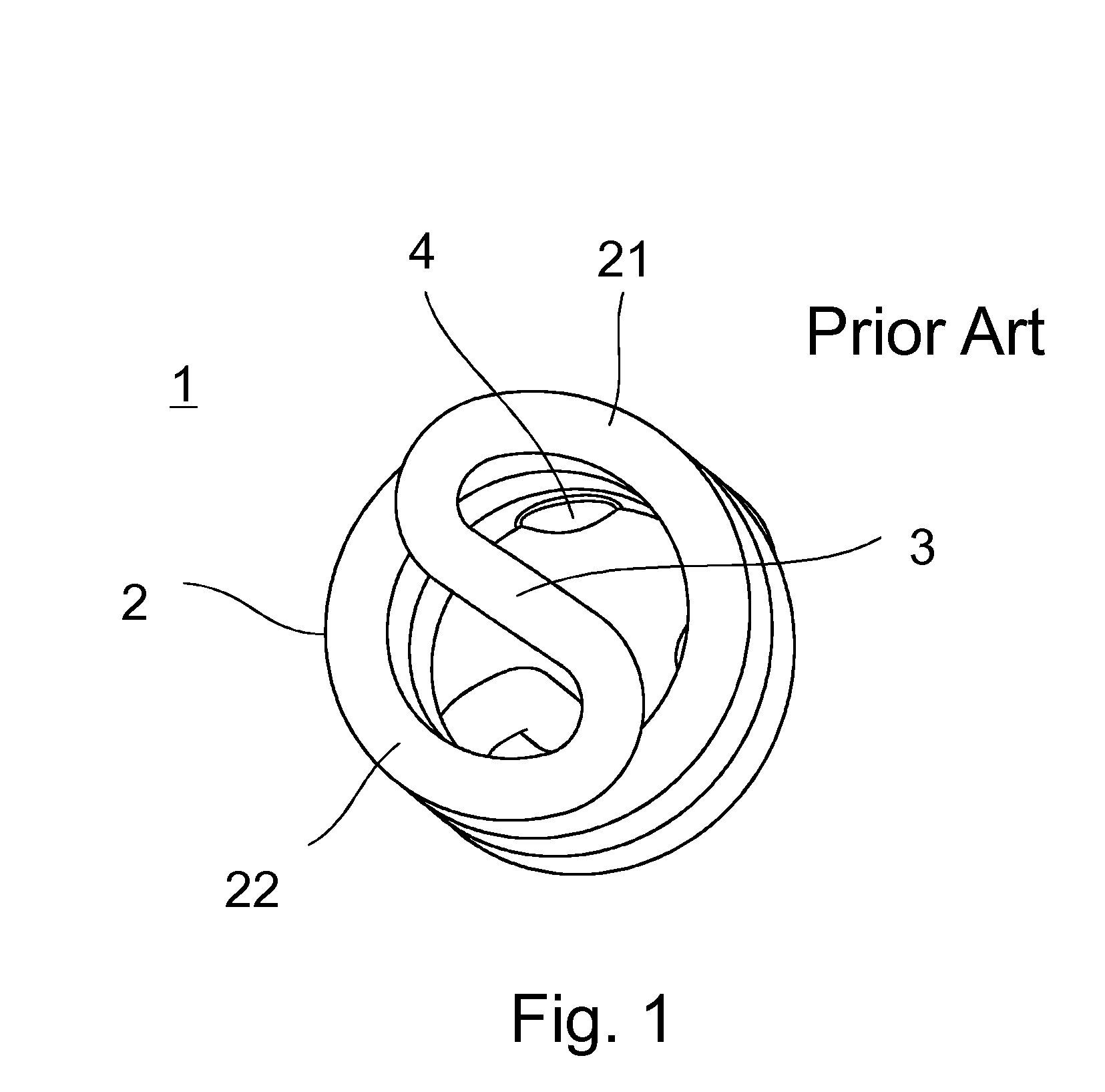

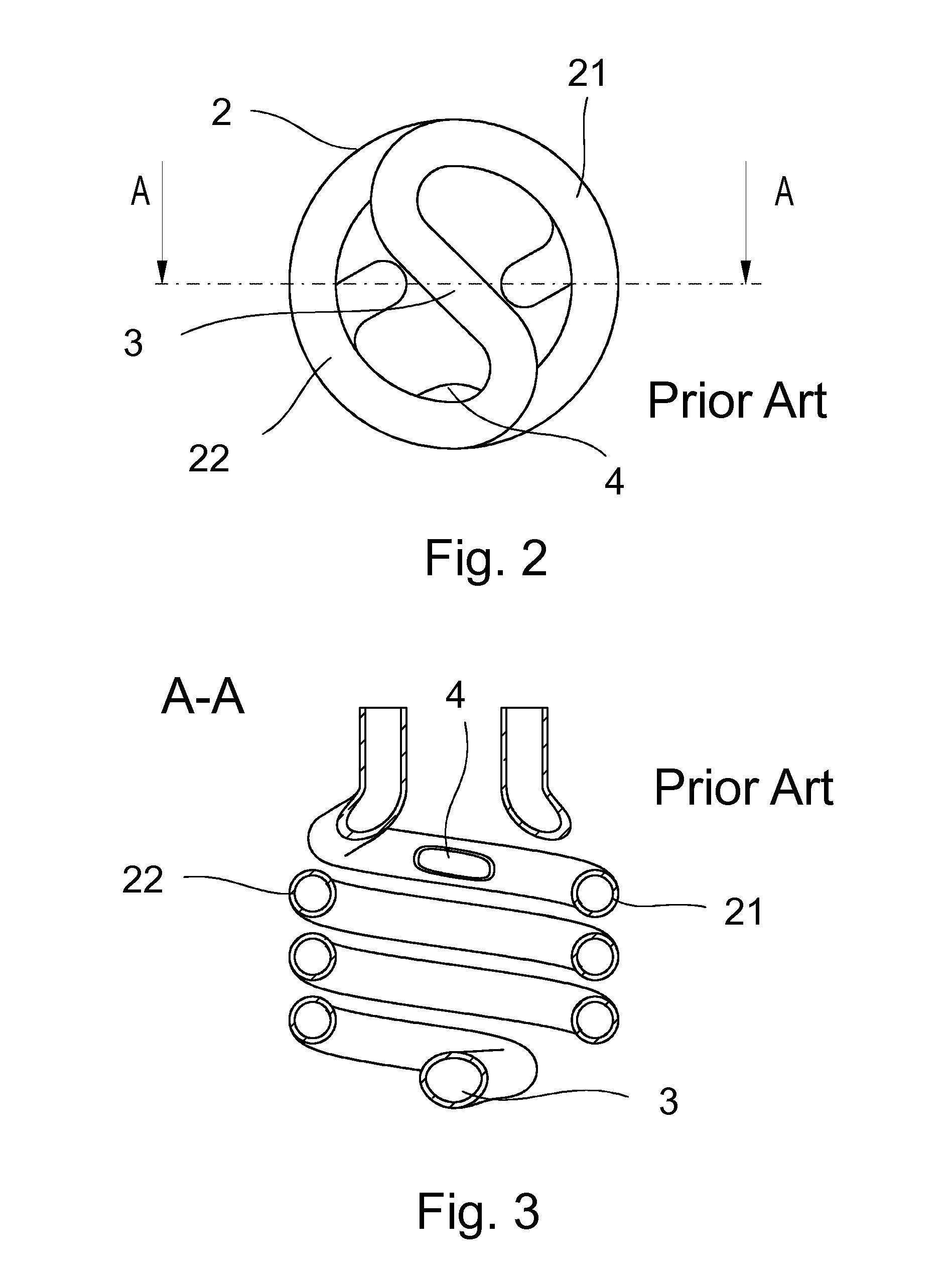

Manufacturing technology for bent LED filament and bulb with bent LED filament

InactiveCN105240703AIncrease wattageUniform brightnessPoint-like light sourceElectric circuit arrangementsManufacturing technologyEngineering

The invention discloses a manufacturing technology for a bent LED filament and a bulb with the bent LED filament. The manufacturing technology mainly includes the steps that a spiral circuit is mechanically carved on a flexible metal plate or a resin plate through a circuit carving machine, then crystallization is conducted on a front face and a back face, and crystallization is conducted on the upper side and the lower side of a flexible metal wire or a line-shaped resin wire; and secondly, a corresponding bent die is used for manufacturing the flexible metal wire or the line-shaped resin wire into a bent LED light-emitting bar. The invention further discloses a bulb with the bent LED filament. The bulb is internally connected with the bent LED light-emitting bar. The bent LED light-emitting bar can be conveniently produced, and all original lamp manufacturing devices can be used on the new technology at the same time. The manufactured LED bulb is higher in wattage and more even in brightness than a straight bar type LED filament, and the radiating effect of the LED bulb is good. The power output of the LED bulb in the same glass-bulb cavity can be improved, and the same effect can be achieved by the LED bulb like traditional 100w bulbs and 12w LED bulbs with the same color temperature (2400 k) as the traditional bulbs.

Owner:汤雄

Method and apparatus for a portable public address system

InactiveUS6947566B2Improve fidelityIncrease wattageElectric megaphonesPublic address systemWireless microphone

Owner:MEARS RAYMOND L

Wind powered turbine engine

InactiveUS20060291993A1High speedAvailable energyWind motor controlMachines/enginesWind powerWind force

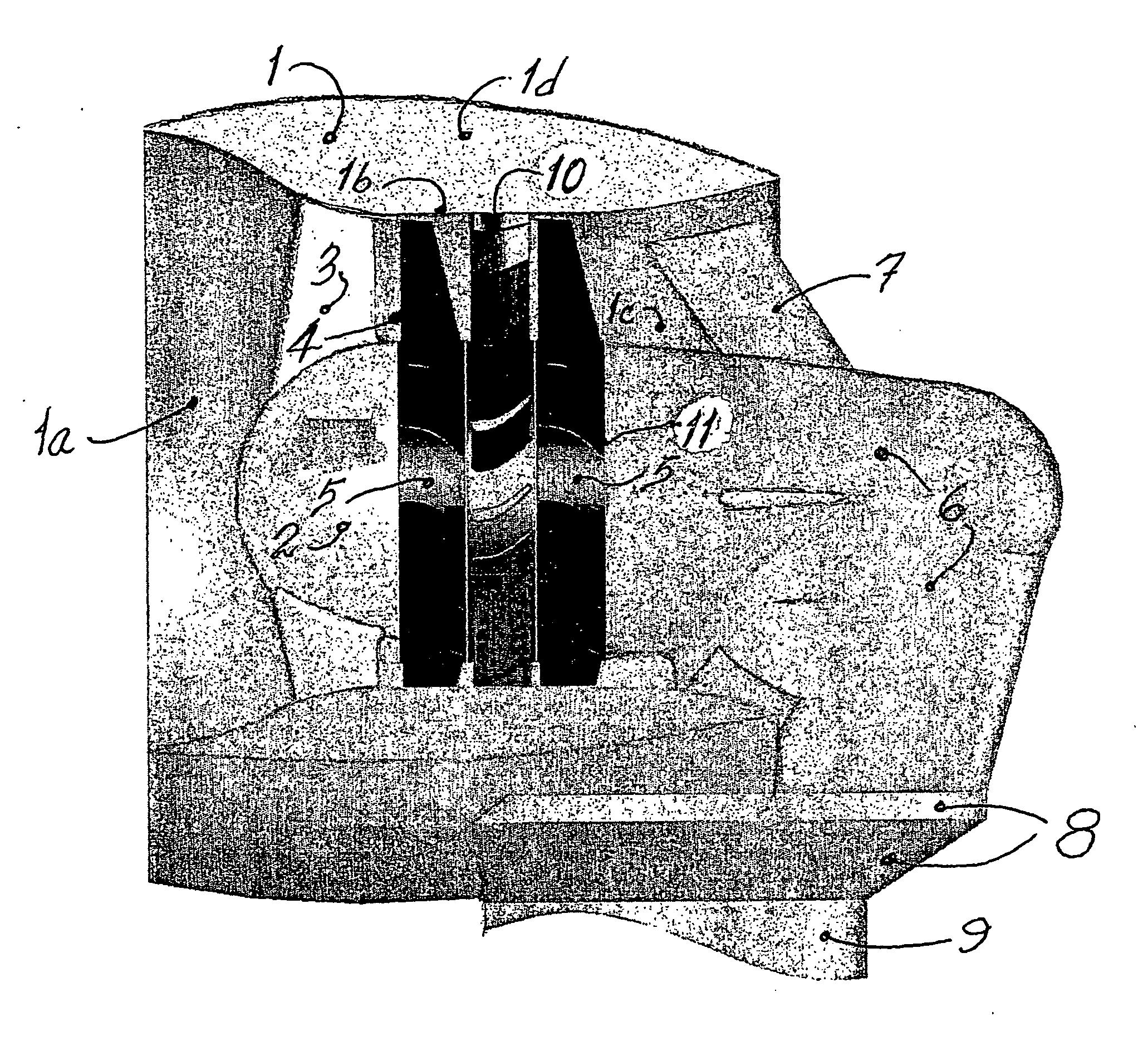

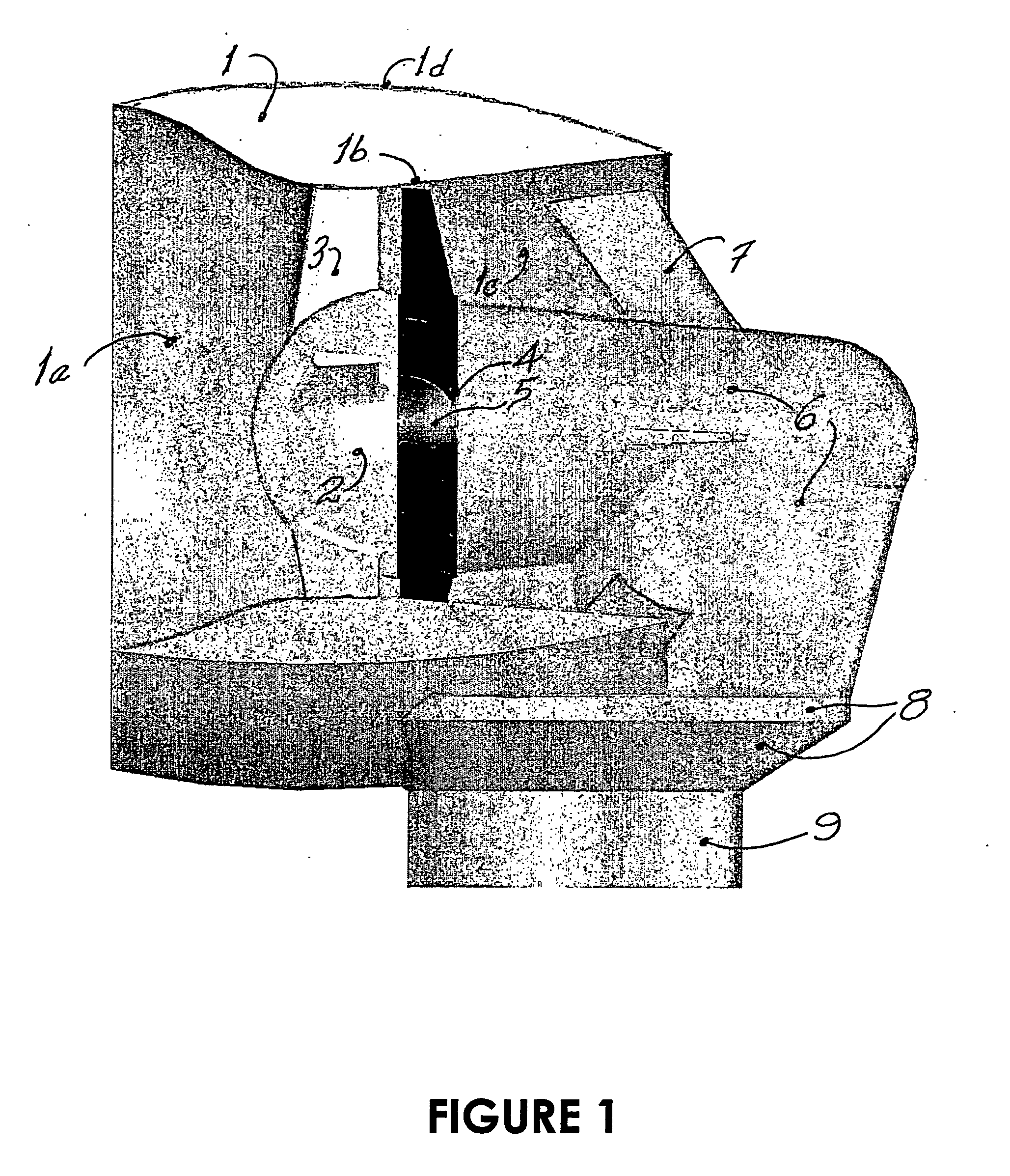

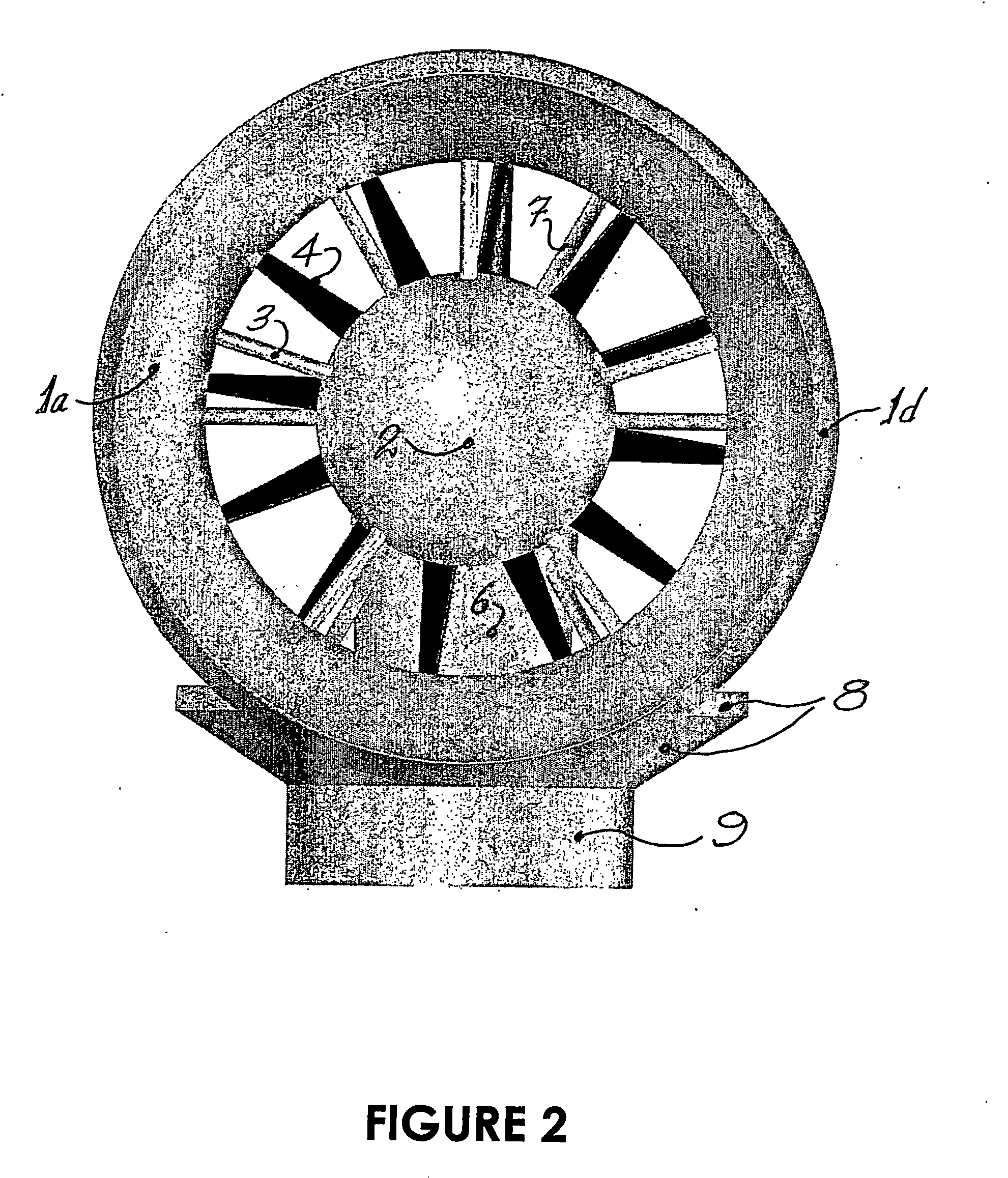

A wind turbine engine comprising rotor blades disposed within an outer casing and a half-spherical head located in front of the rotor blades and blocking the inner 50% of the radius of the rotor blades, the casing and head creating an acceleration chamber wherein incoming wind is speeded up and redirected around the head, and the accelerated wind then rotates the wind turbine rotor blades to generate power.

Owner:ENVISION

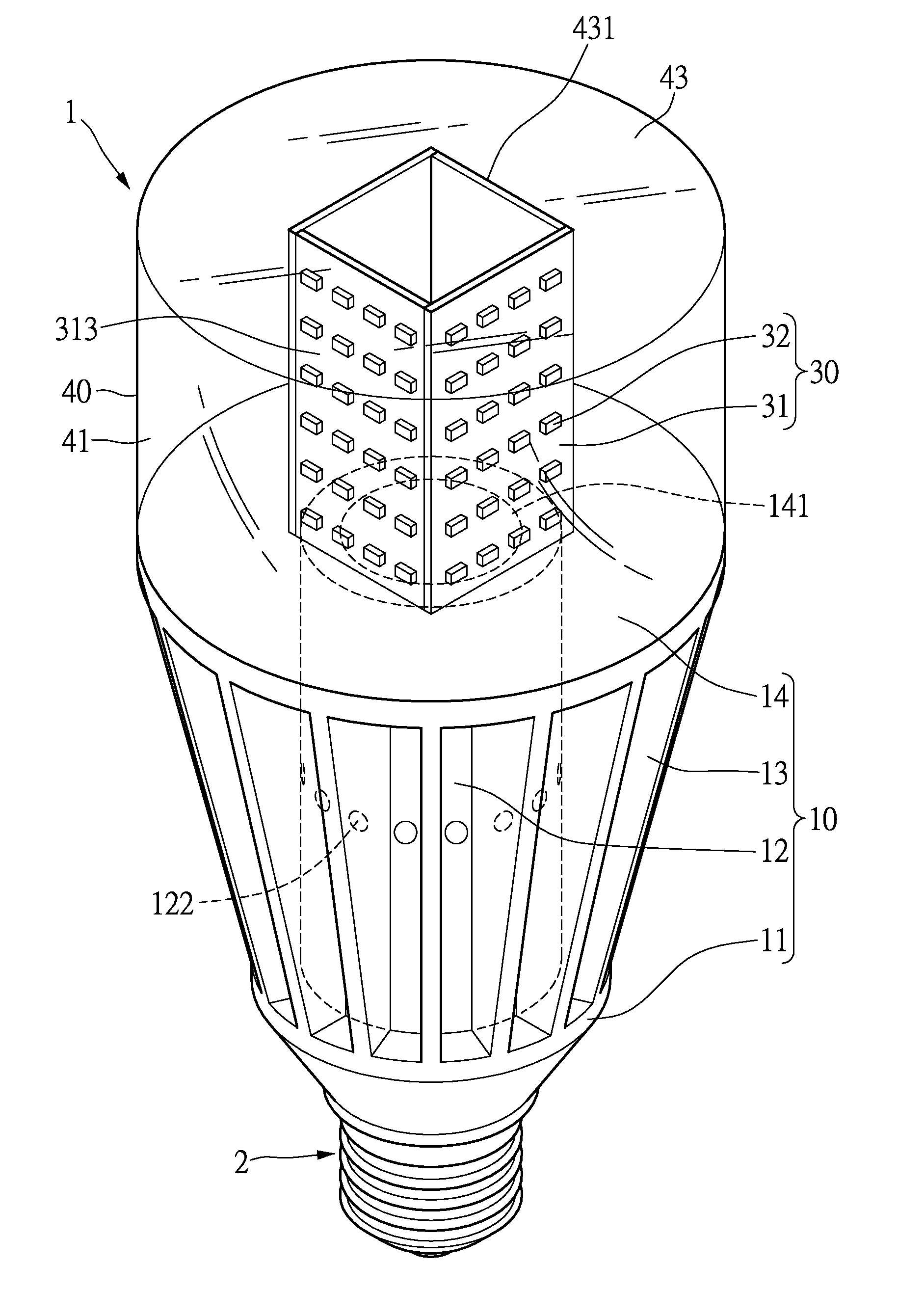

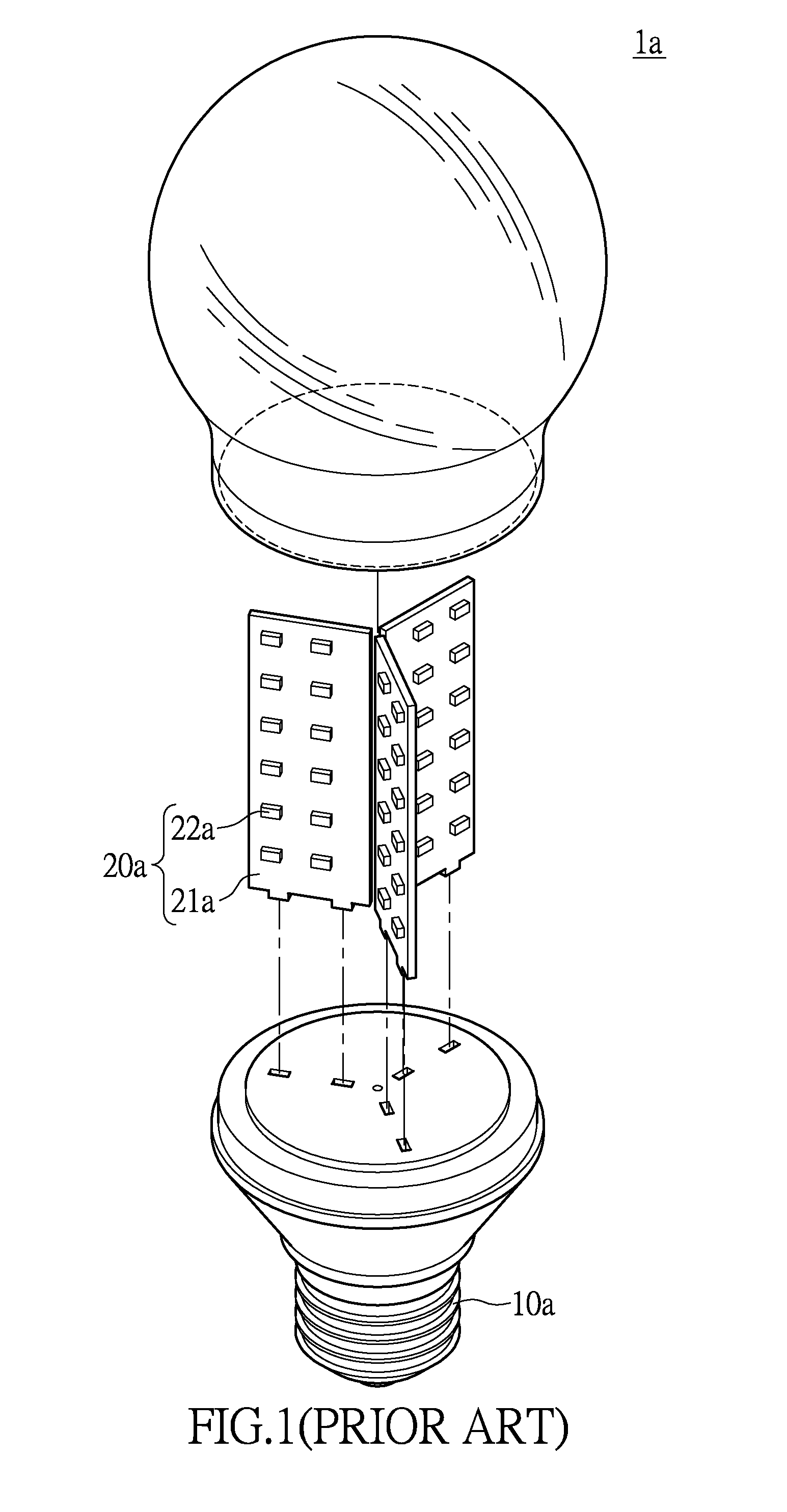

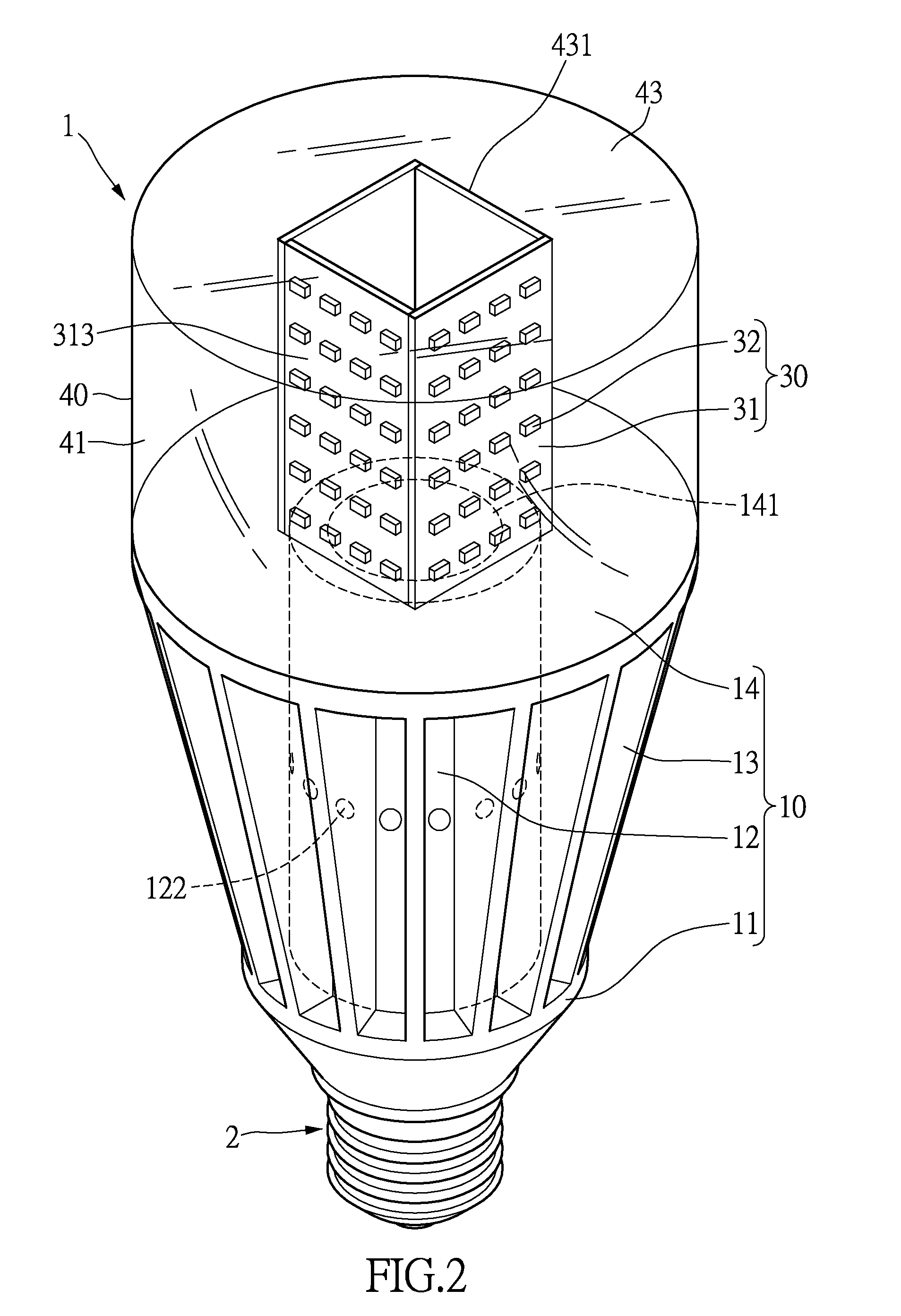

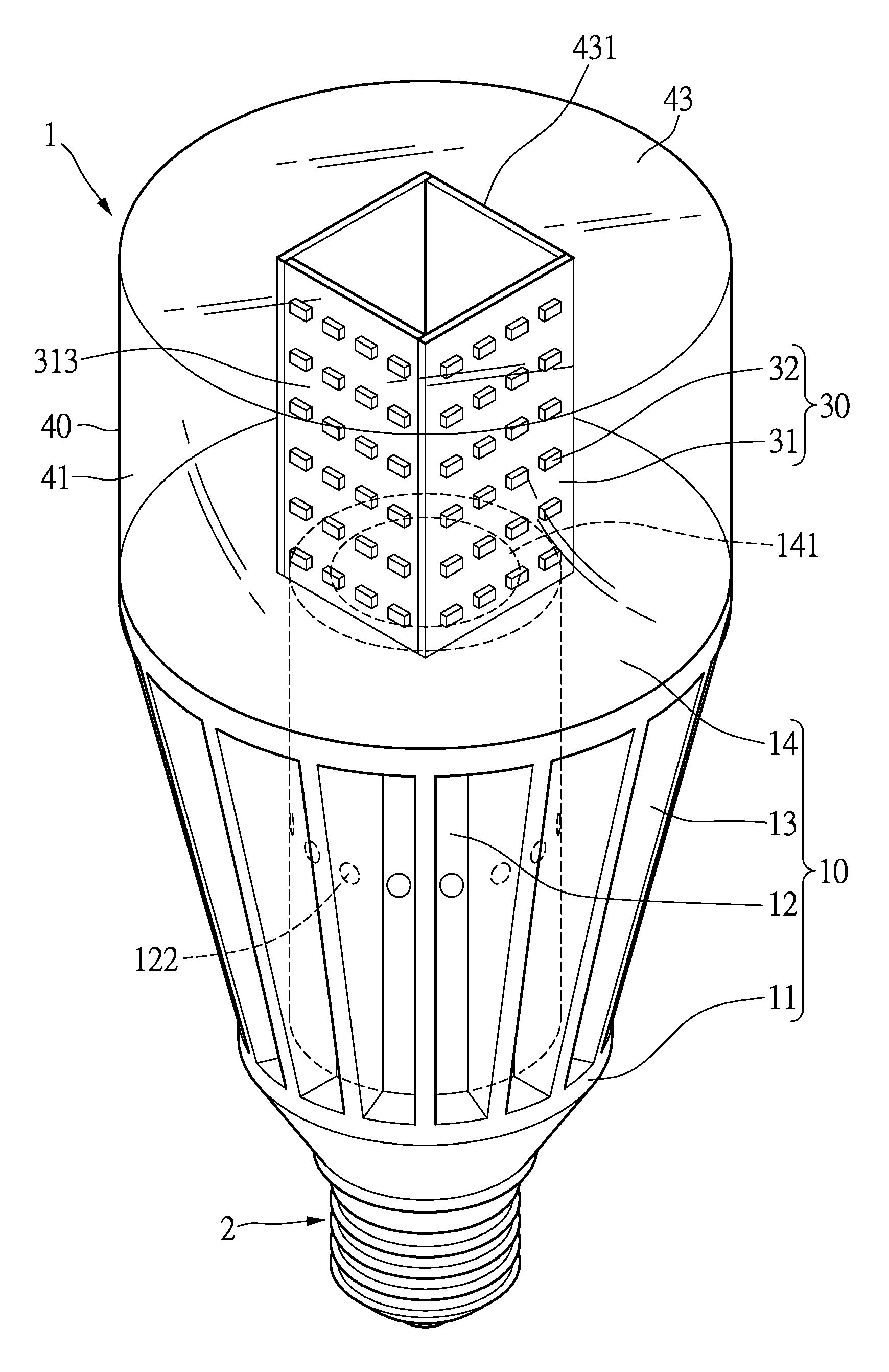

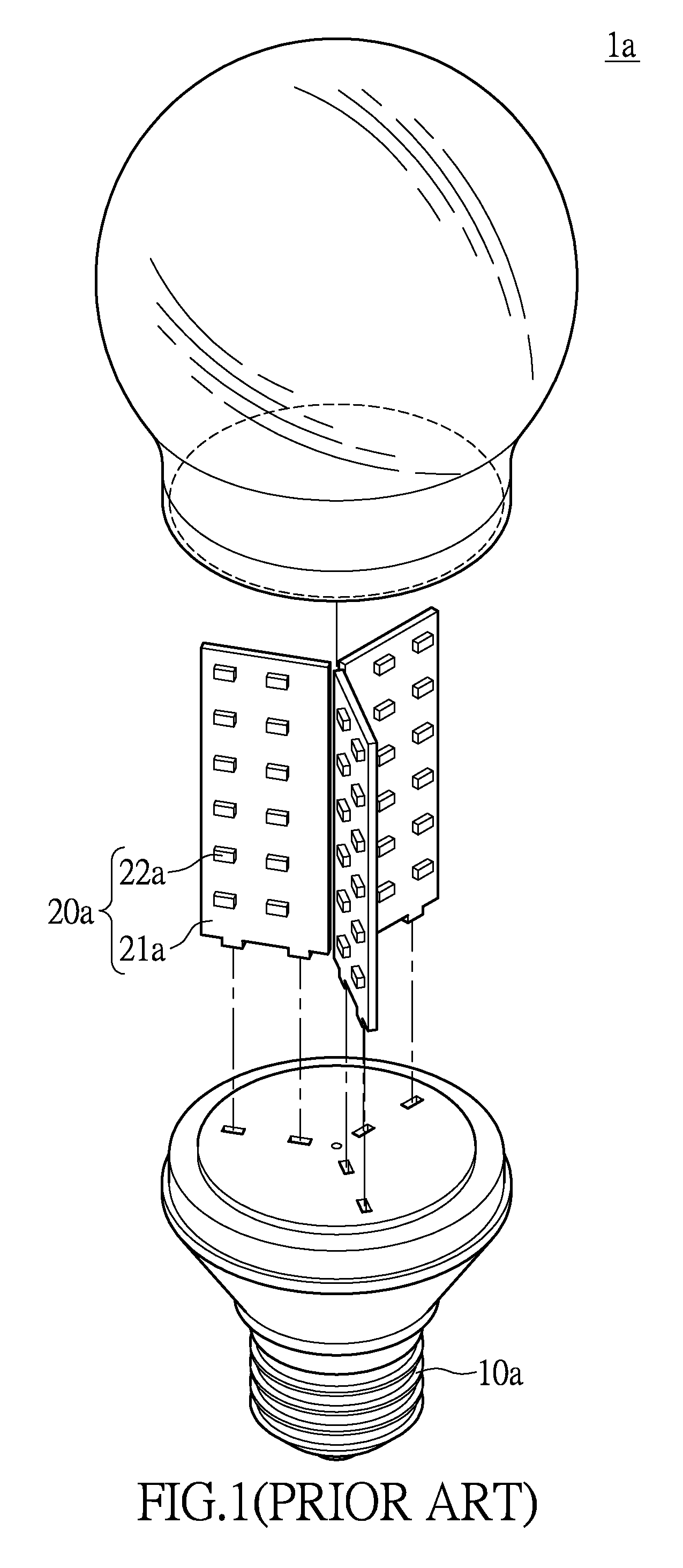

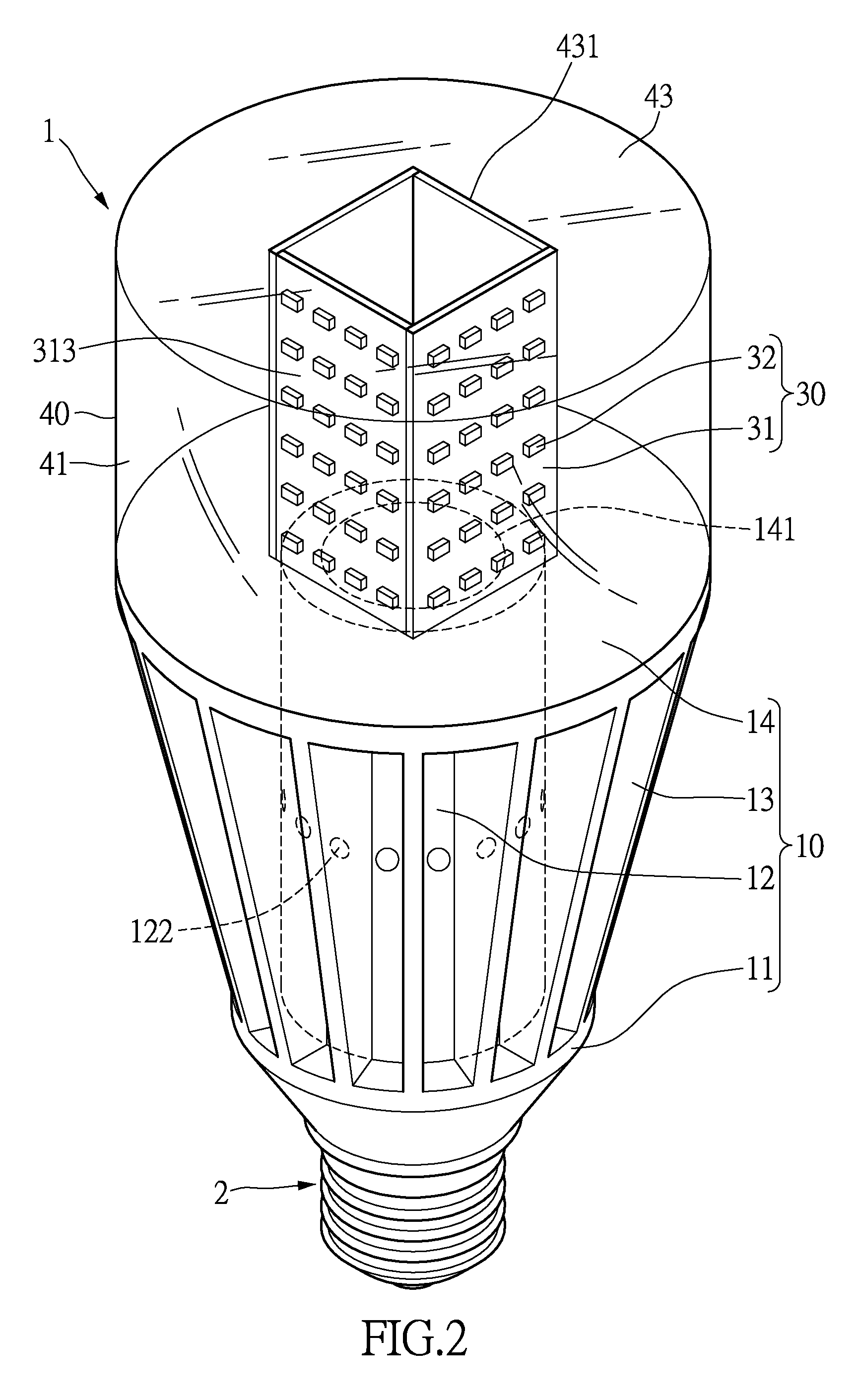

LED lighting device

ActiveUS20150077997A1Increase brightnessSolve low usagePoint-like light sourceLighting support devicesElectricityEffect light

Owner:HUANG TAI YIN

Fluid powered turbine engine

InactiveUS7845899B2Efficient use ofHarnessing much of the cross section of energyPump componentsWind motor controlWind forceAcceleration Unit

A wind turbine engine comprising rotor blades disposed within an outer casing and a half-spherical head located in front of the rotor blades and blocking the inner 50% of the radius of the rotor blades, the casing and head creating an acceleration chamber wherein incoming wind is speeded up and redirected around the head, and the accelerated wind then rotates the wind turbine rotor blades to generate power.

Owner:ENVISION

Linear electric motor controller and system for providing linear control

InactiveUS7265516B2Increase fuel economyReduce weight and sizeAC motor controlDC motor speed/torque controlDigital-to-analog converterLinear control

The invention relates to a method of, and system for, linear speed control for an electric motor, in which a digital to analog converter means is used for converting an 8-bit digital signal to an analog voltage for setting voltage across a motor, a digital state machine means is used for converting the duty cycle of an input signal for output to the digital to analog converter means, and a closed loop feedback loop means is used for monitoring and setting the voltage across the motor. An over-current sense circuit can be used for monitoring the current across the electric motor. An over / under voltage sense circuit can be used for monitoring voltage of the electric motor. The resulting 8-bit digital control signal is converted to an analog voltage for the electric motor. Such methods and systems find particular use in automotive applications.

Owner:2112376 ONTARIO

LED lighting device

ActiveUS9303824B2Increase brightnessFulfil requirementsPoint-like light sourceElectric circuit arrangementsEffect lightLight source

Owner:HUANG TAI YIN

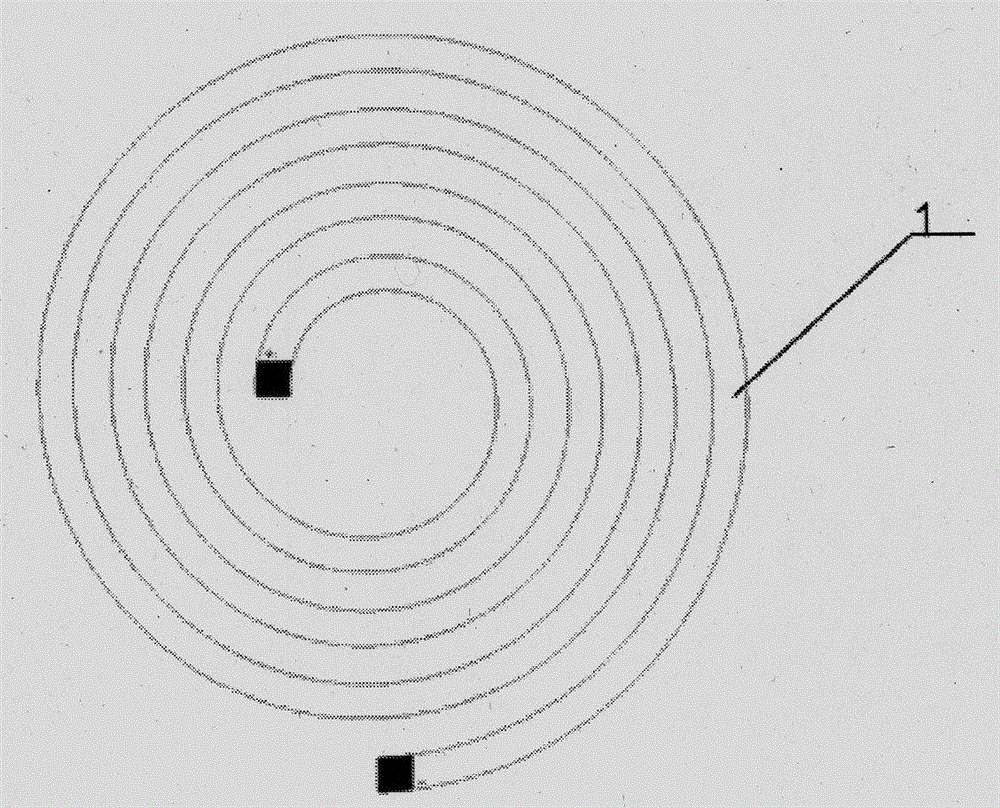

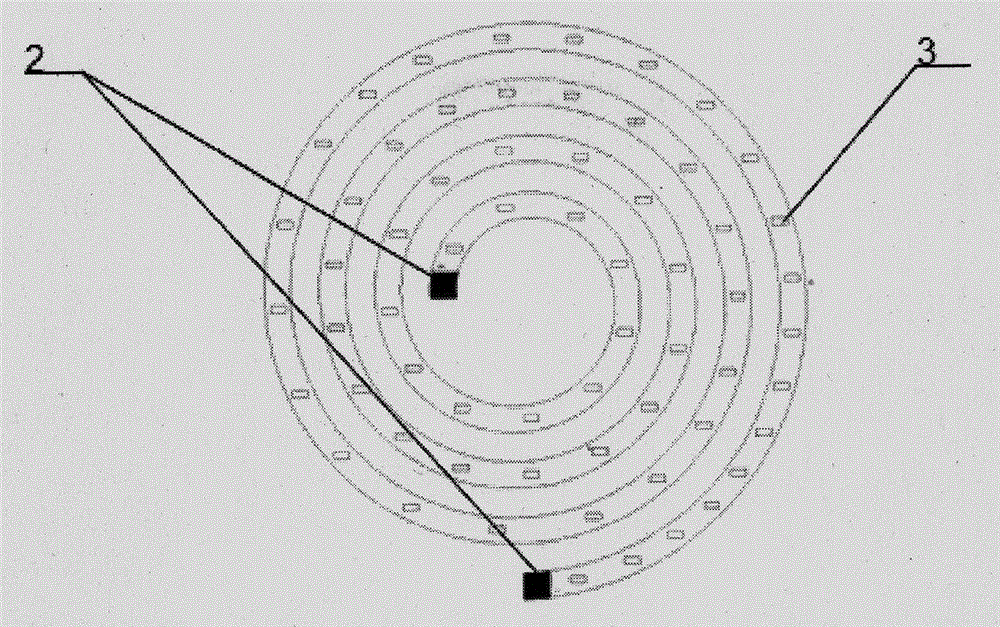

Preparation method of bent LED lamp filament and bulb provided with same

InactiveCN106678579AImprove thermal conductivityIncrease powerElectric circuit arrangementsSemiconductor devices for light sourcesEngineeringDie bonding

The invention discloses a technological preparation method of a bent LED lamp filament. The preparation method mainly comprises the following steps: etching a circuit on a metal substrate, using a machine to punch or cut a mosquito-repellent incense type vortex shaped structure, carrying out die bond, adhesive deposite and packaging on the lamp filament on the metal substrate, clamping two ends of the lamp filament with a fixture, and uniformly stretching the lamp filament outwards to manufacture the LED lamp filament. Based on the preparation method, the invention further discloses a bulb with the bent LED lamp filament. Compared with the lamp filament made of traditional ceramic, the lamp filament made of the metal or nonmetal substrate is higher in thermal conductivity and power; die bond is carried out on the front side and the reverse side of the metal or nonmetal substrate to enable luminescence of the front side and the reverse side of the LED lamp filament to be more uniform; the vortex shape enables luminescence of the lamp filament to be more three-dimensional and realizes low possibility of breakage of the lamp filament, and the yield of the bent LED lamp filament is higher; and the LED bulb prepared through the preparation technology disclosed by the invention is more uniform in luminescence, higher in wattage and longer in service life.

Owner:ZHEJIANG EMITTING OPTOELECTRONICS TECH

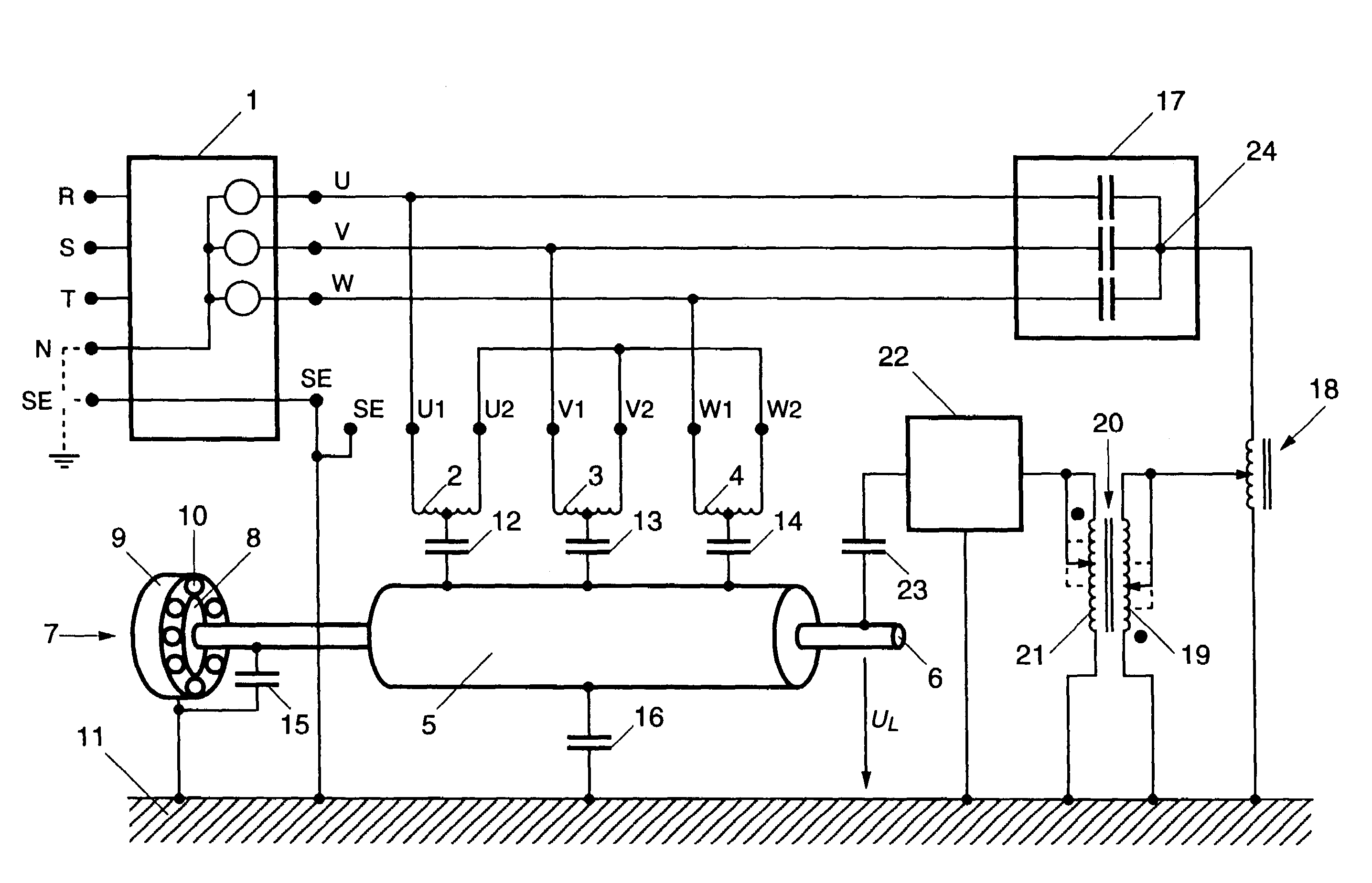

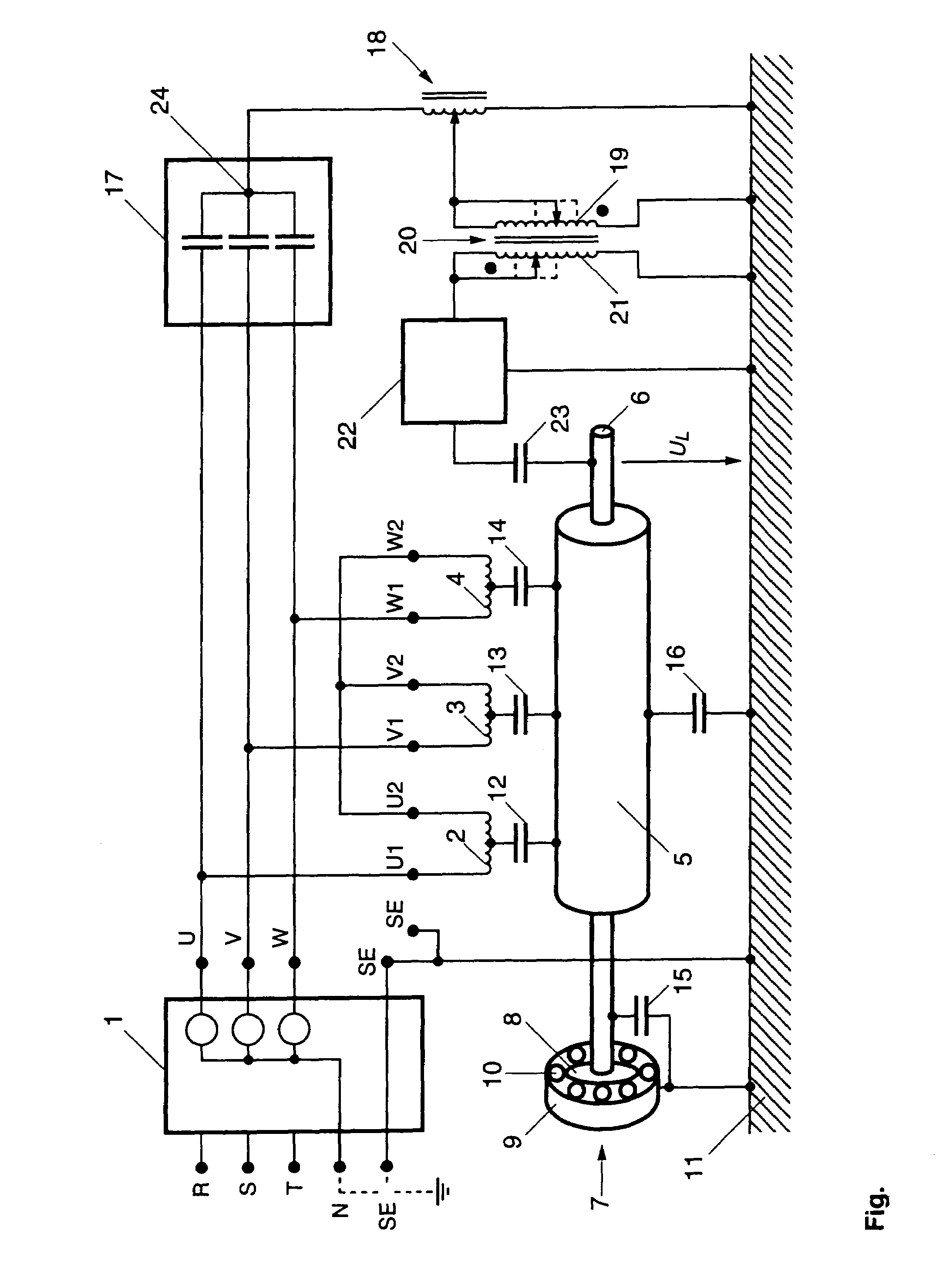

Device for protection of the bearing of an electrical machine against damaging passage of current

ActiveUS7446989B2Increase wattageIncrease the number ofAssociation with control/drive circuitsAssociation with grounding devicesCouplingElectric machine

A device for protecting the bearing of an electrical machine against the damaging passage of current, wherein the electrical machine comprises a stator and a rotor pivotally mounted relative to the stator by the bearing. The device is provided with a compensation circuit which produces a compensation current which compensates for a parasitic current formed during operation of the electrical machine by the bearing and a coupling element for directly or indirectly coupling the compensation current into the bearing.

Owner:AB SKF

Linear electric motor controller and system for providing linear control

InactiveUS20080024084A1Small and lighter in weightReduce weight and sizeAC motor controlVector control systemsLinear controlControl signal

The invention relates to a method of, and system for, linear speed control for an electric motor, in which a digital to analog converter means is used for converting an 8-bit digital signal to an analog voltage for setting voltage across a motor, a digital state machine means is used for converting the duty cycle of an input signal for output to the digital to analog converter means, and a closed loop feedback loop means is used for monitoring and setting the voltage across the motor. An over-current sense circuit can be used for monitoring the current across the electric motor. An over / under voltage sense circuit can be used for monitoring voltage of the electric motor. The resulting 8-bit digital control signal is converted to an analog voltage for the electric motor. Such methods and systems find particular use in automotive applications.

Owner:2112376 ONTARIO

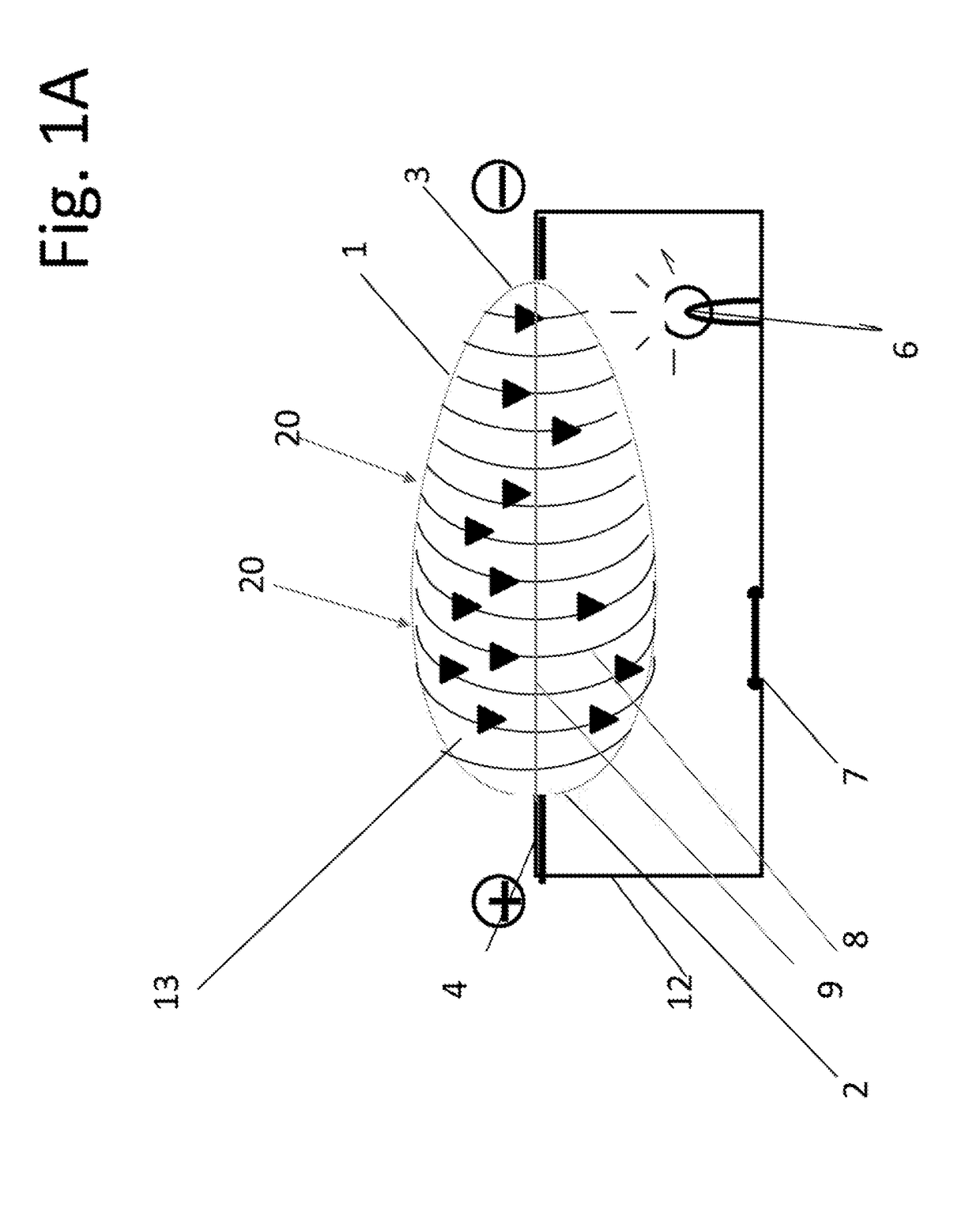

Perpetual magnetoelectric energy direct current power supply

InactiveUS20180337617A1Improve efficiencyIncrease wattageDynamo-electric machinesGenerators/motorsEngineeringMagnet

The system provides for the transformation of permanent magnetic energy into a continuous electric energy current flow within a circuit. This is accomplished by creating a very strong egg shaped planetary permanent magnet. The magnet contains a longitudinal channel through its center to allow for initial energization. The initial energization is accomplished by applying a very strong burst of electrical current from a direct current power source. The magnet embodying the present invention is an egg shaped object that shall be held in one place without any physical or visible rotation of the magnet itself. Instead, the egg shape of the magnet creates varying field strengths patterns for energy transfer and polarization due to the internal left hand rule principles of electric current. This arrangement will create a permanent or near permanent perpetuating magnetic field. This magnetic field maintains intrinsic, centripetal, magnetic forces that create a magnetic whirl-pool that rotates the magnetic field within the magnet without rotating the magnet itself. The system created by the present invention is capable of self-sufficiency, recharging itself through power flow in the system's circuit. Additionally, the power is supplemented with atmospheric energy seeking termination, or moving towards the magnet, due to the centripetal forces generated by the magnetic angular momentum depression inside the magnet.

Owner:GULLIVER KENNETH A

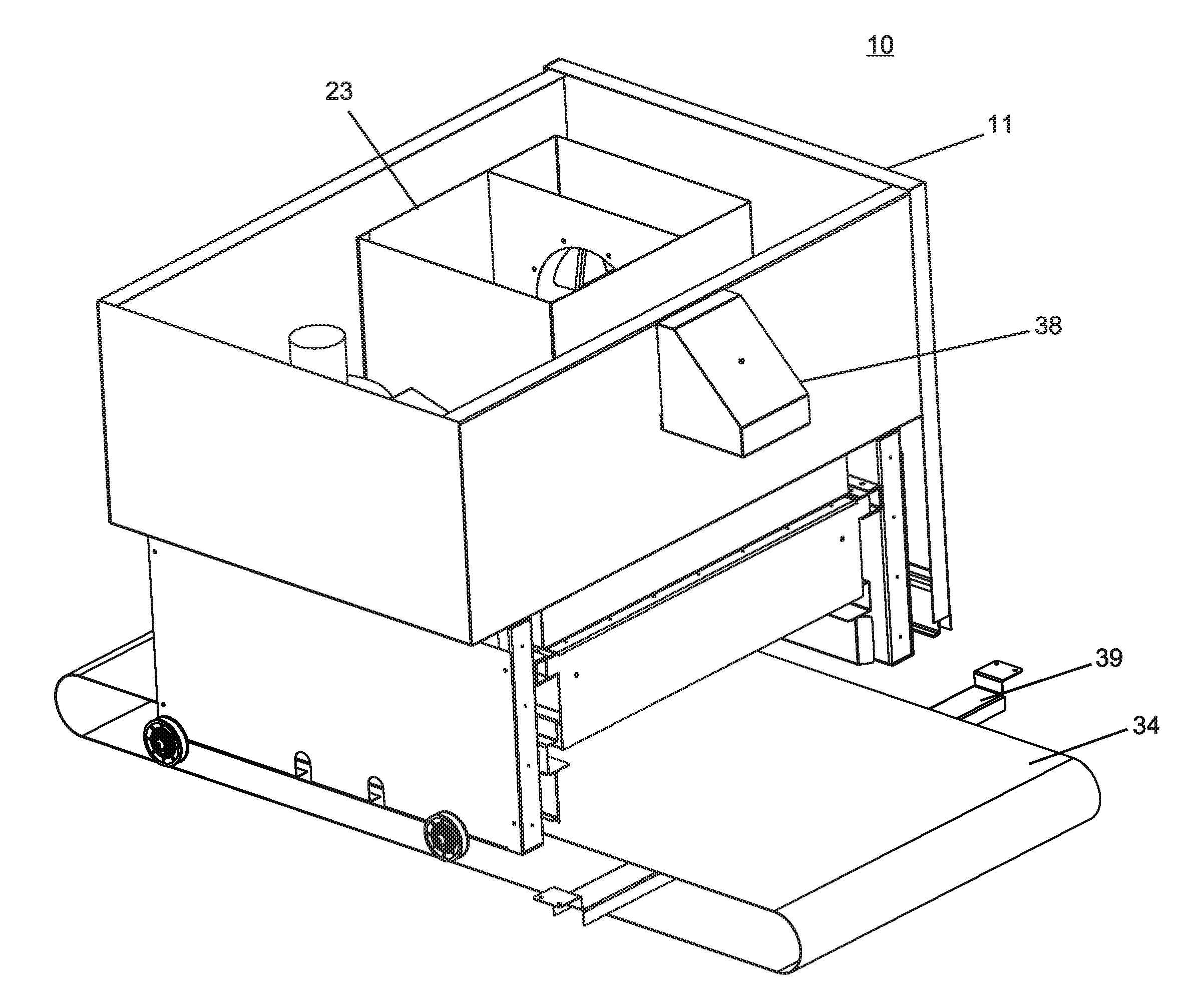

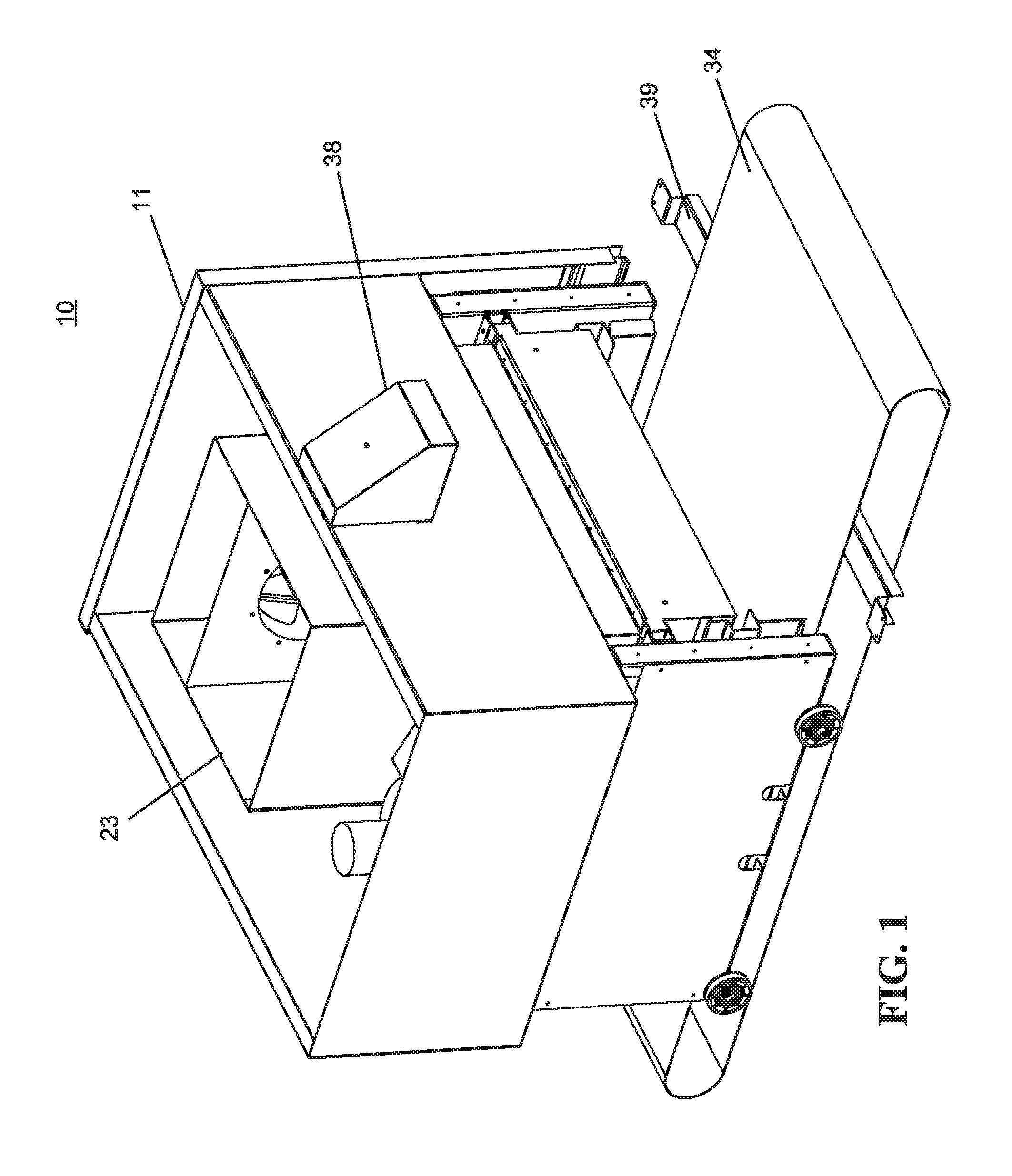

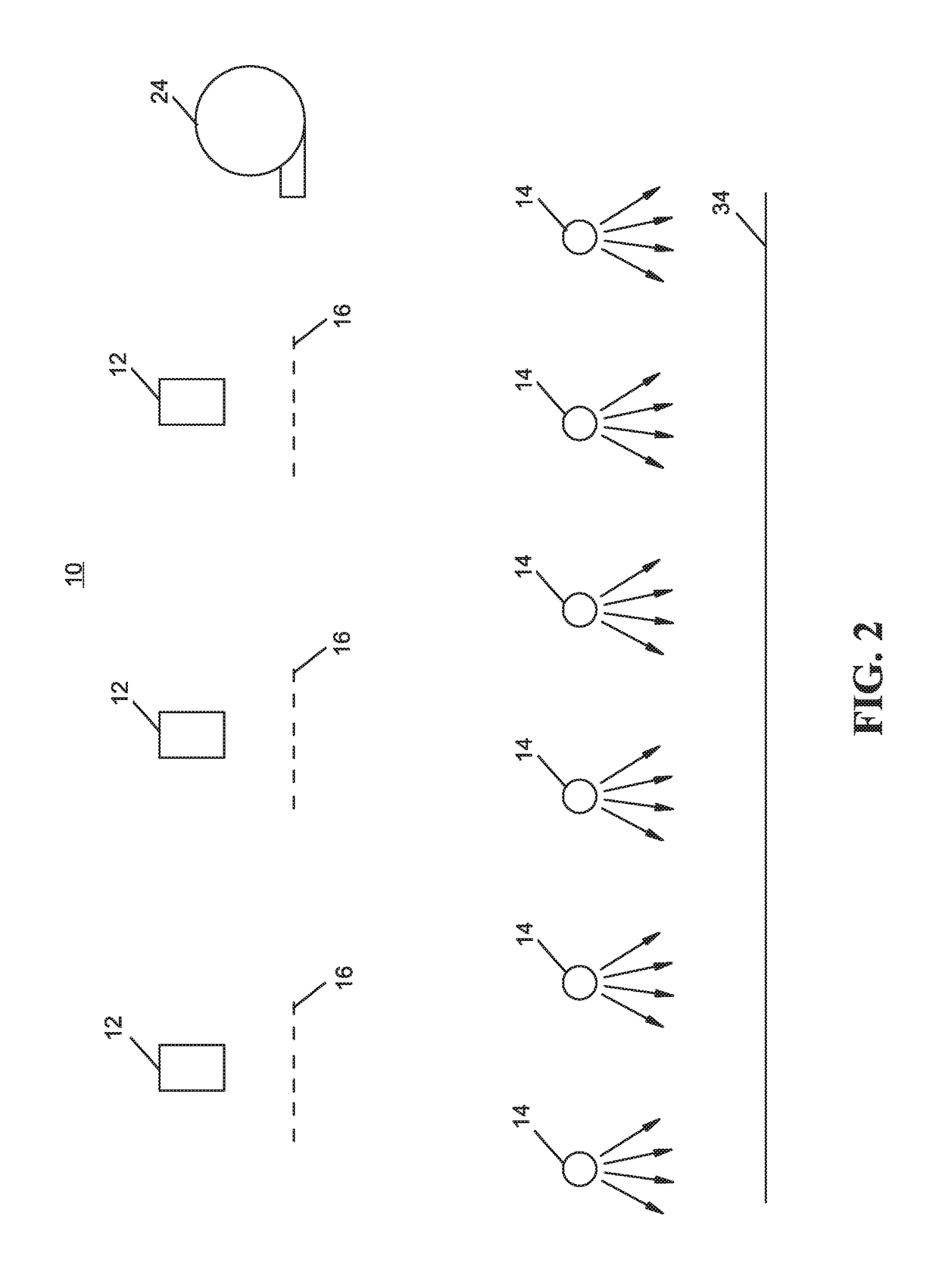

Ink curing apparatus and method

ActiveUS20170021655A1Increase temperatureReduce bleedingTypewritersDyeing processScreen printingPad printing

An ink curing apparatus for curing ink on an object and method includes at least one thermal imaging sensor that is configured to image thermal radiation of the object and at least one heating element that is configured to generate heat energy. A control responsive to the imaging sensor controls the heating element. The control controls the heating element as a function of the thermal radiation of the object to heat the object to a particular radiation level. The method may be used to cure ink on the object. The object may be made of a textile. The method may be used with at least one chosen from screen printing, digital printing, sublimation ink printing, discharge ink printing, and pad printing.

Owner:BROWN MFG GRP

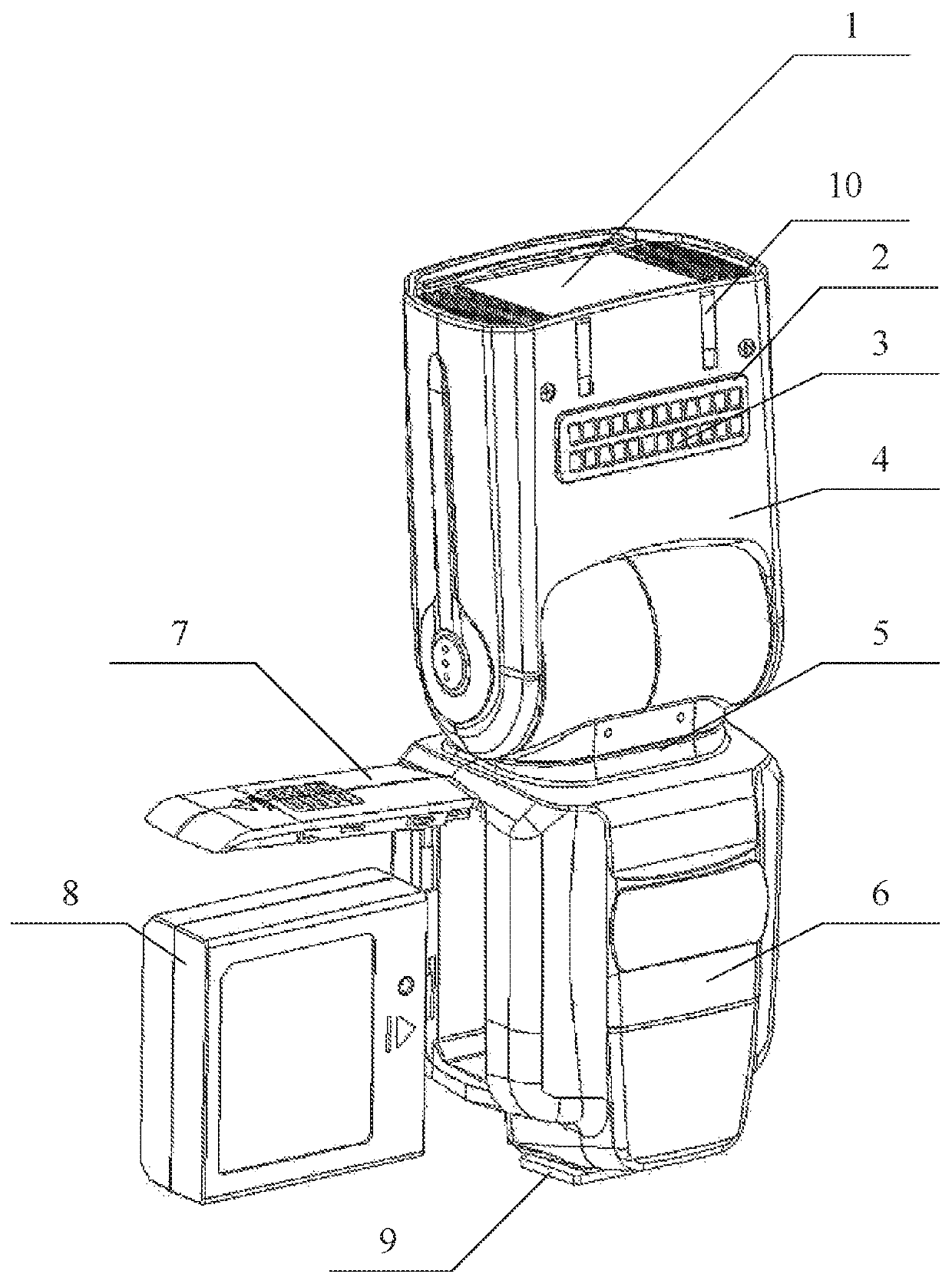

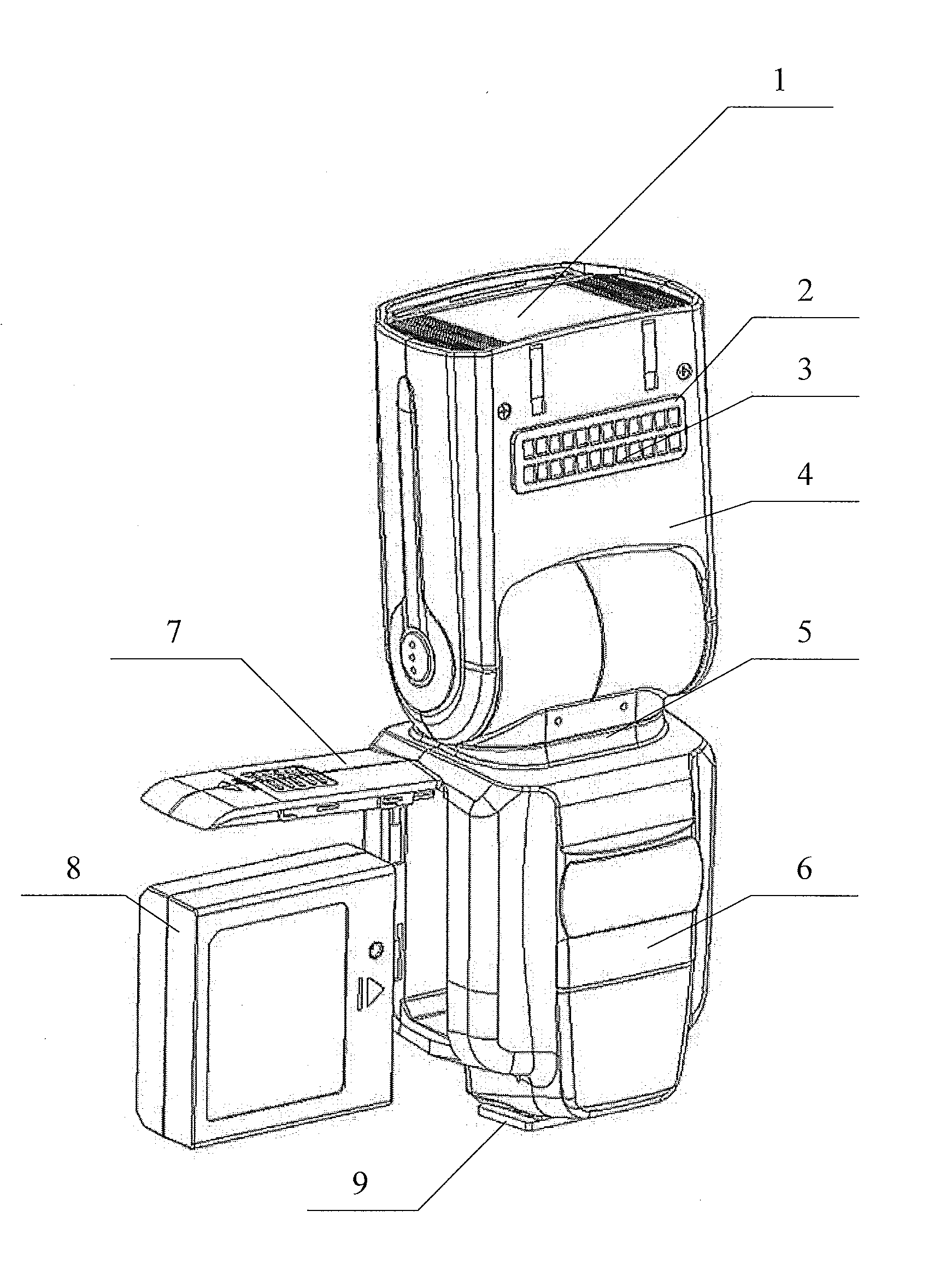

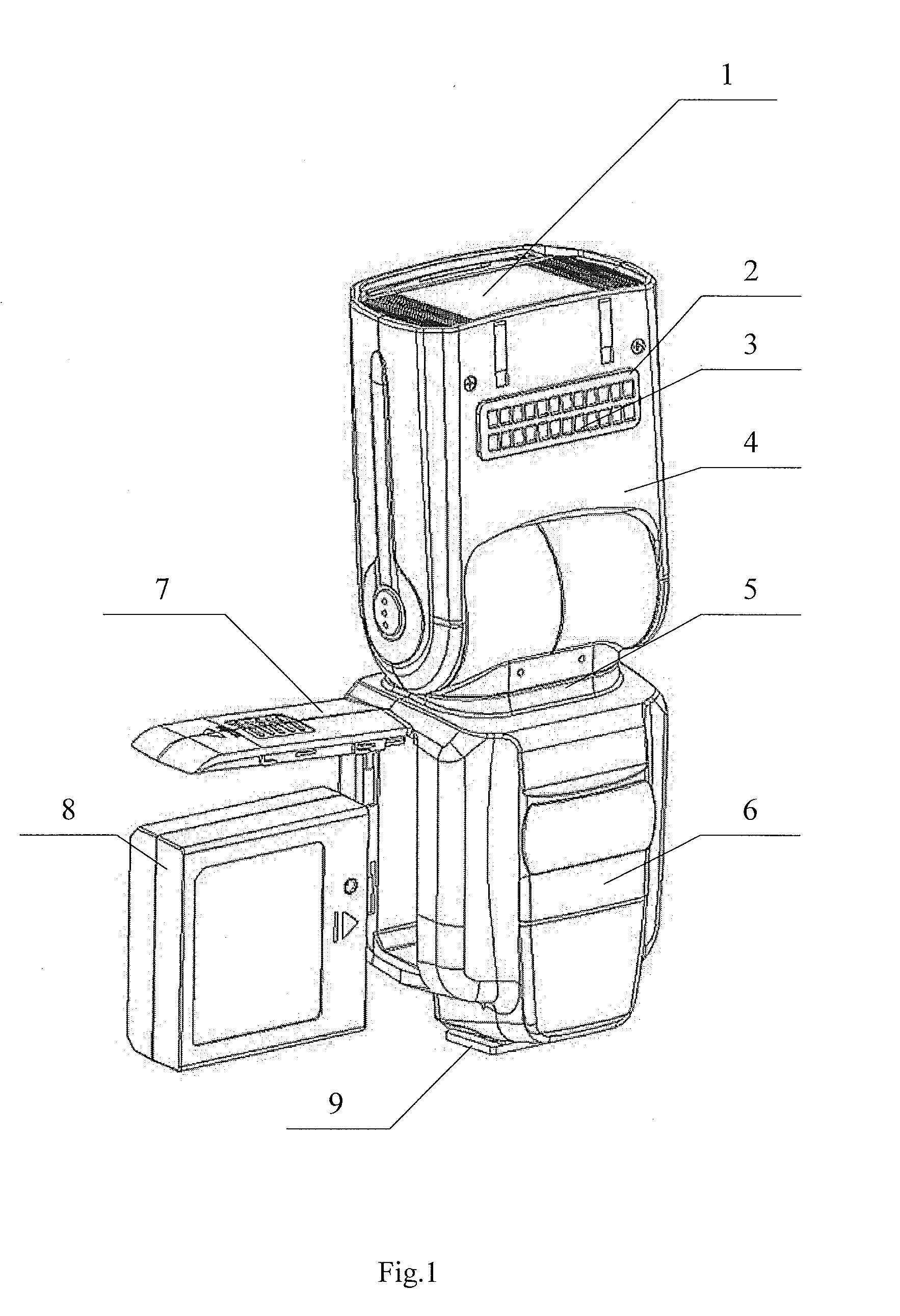

On-camera flashlight

ActiveUS10768509B2Effective guidanceIncrease wattageMechanical apparatusDomestic lightingEngineeringFlashlight

The present invention is an on-camera flashlight, comprising a lower light holder and a top light holder freely rotatably connected to the lower light holder. A flashlight light source is mounted on the top of the top light holder. The light emitting diode and the flashlight light source are mounted on the on-camera flashlight, combined for ease of use. Two functions-in-one lighting device saves space, avoids overloading the camera, and makes it portable. Because the two light sources are set in combination, the cooperation and sequence of the two light sources are easier to control. As the light emitting diode is mounted on the top light holder which may freely rotate with respect to the lower light holder, the light emitting diode may also freely rotate. It is also convenient to adjust the light direction. Above features all remarkably facilitate operation and versatility of the on-camera flashlight.

Owner:YUEQING ORIGINALITY PHOTOGRAHY EQUIP

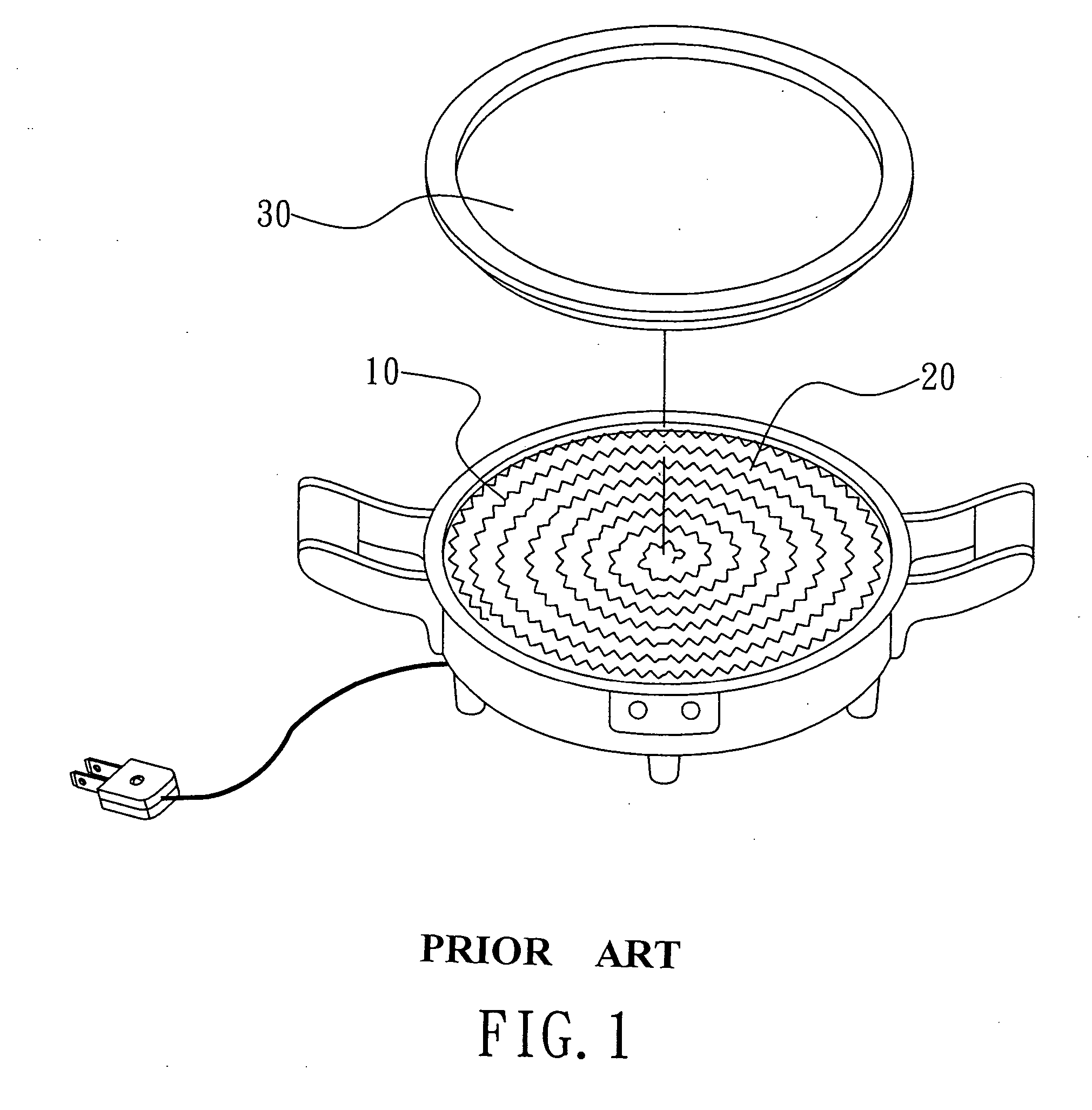

Self temperature control protection heater

InactiveUS20060076344A1Improve heating efficiencyIncrease wattageHeating element materialsTemperature controlElectricity

A heater with self-temperature control protection comprised of a thick film metalized substrate, a signal touch switch, a level detection circuit, a control circuit, a signal amplification circuit and a temperature setup circuit to deliver electricity from the signal touch control respectively to both inputs of the control circuit to output to the signal touch switch for providing instantaneous self-protection at a given temperature with greater energy, smaller area, and higher efficiency than that of the conventional heater.

Owner:MOBILETRON ELECTRONICS

Ink curing apparatus and method

ActiveUS10011136B2Increase wattageIncrease temperatureTypewritersDyeing processPad printingScreen printing

An ink curing apparatus for curing ink on an object and method includes at least one thermal imaging sensor that is configured to image thermal radiation of the object and at least one heating element that is configured to generate heat energy. A control responsive to the imaging sensor controls the heating element. The control controls the heating element as a function of the thermal radiation of the object to heat the object to a particular radiation level. The method may be used to cure ink on the object. The object may be made of a textile. The method may be used with at least one chosen from screen printing, digital printing, sublimation ink printing, discharge ink printing, and pad printing.

Owner:BROWN MFG GRP

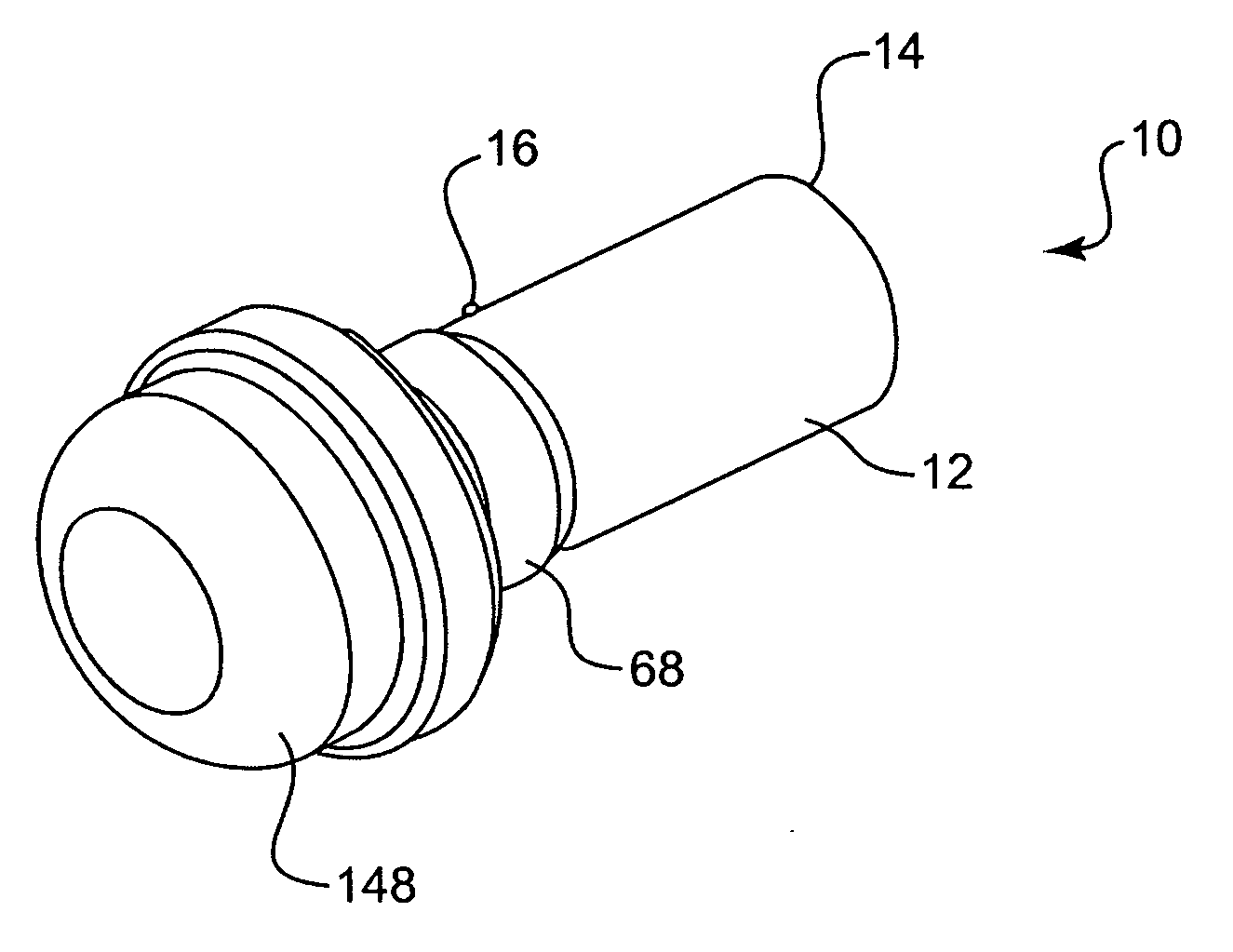

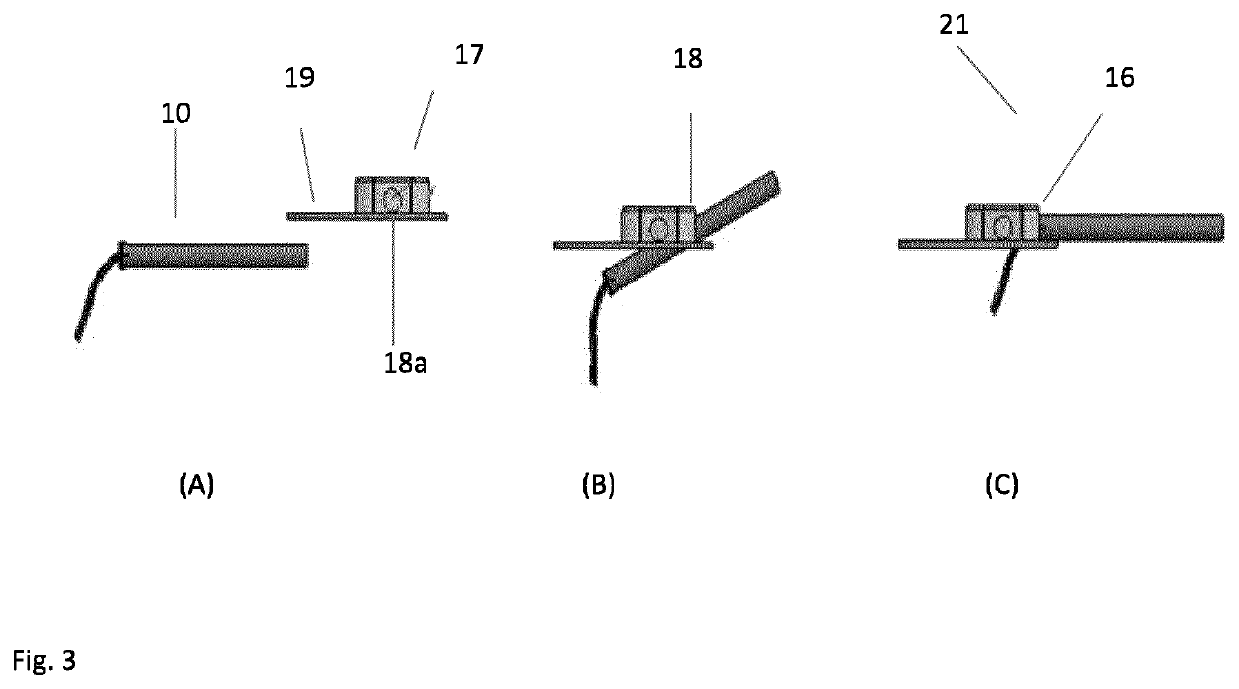

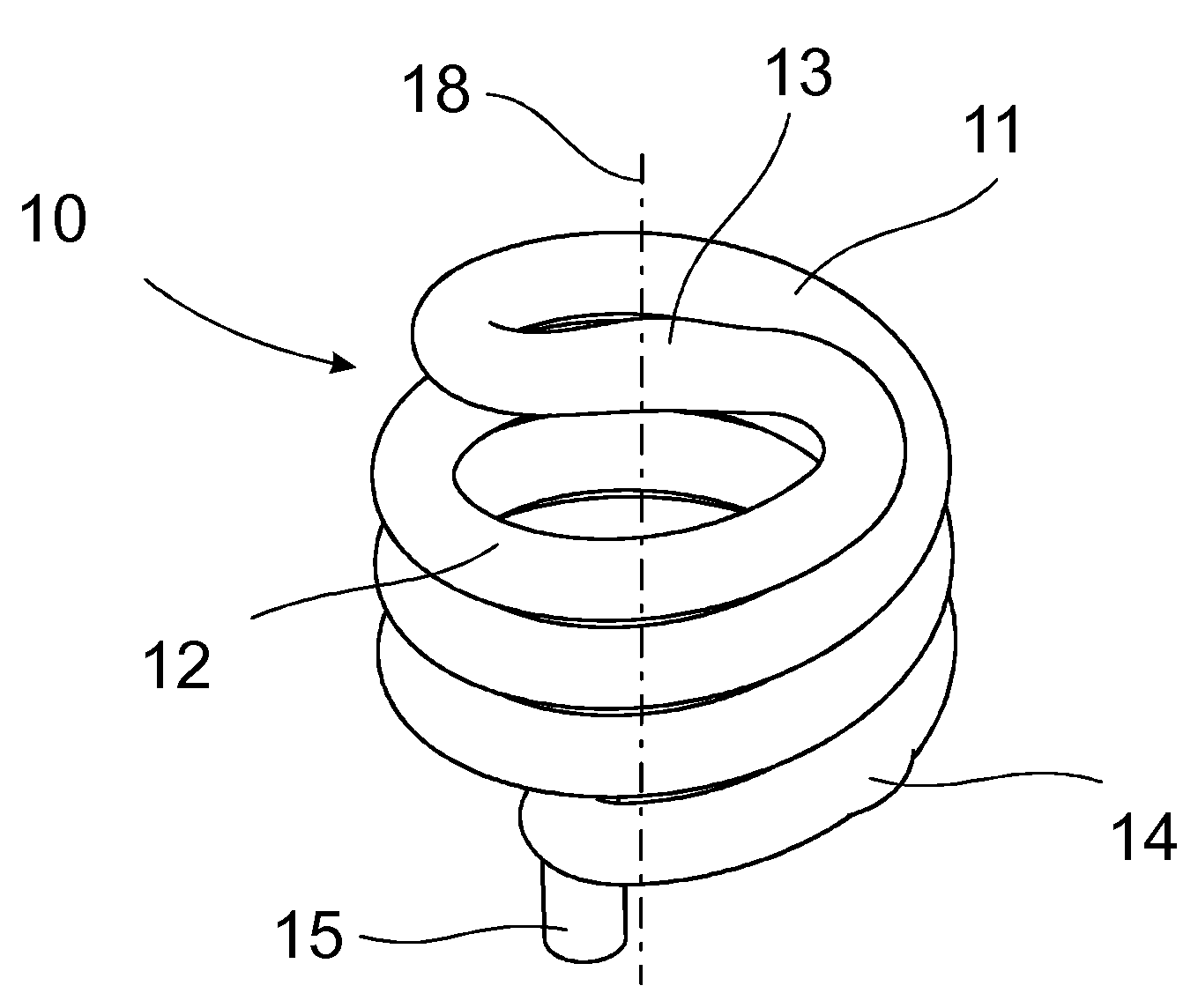

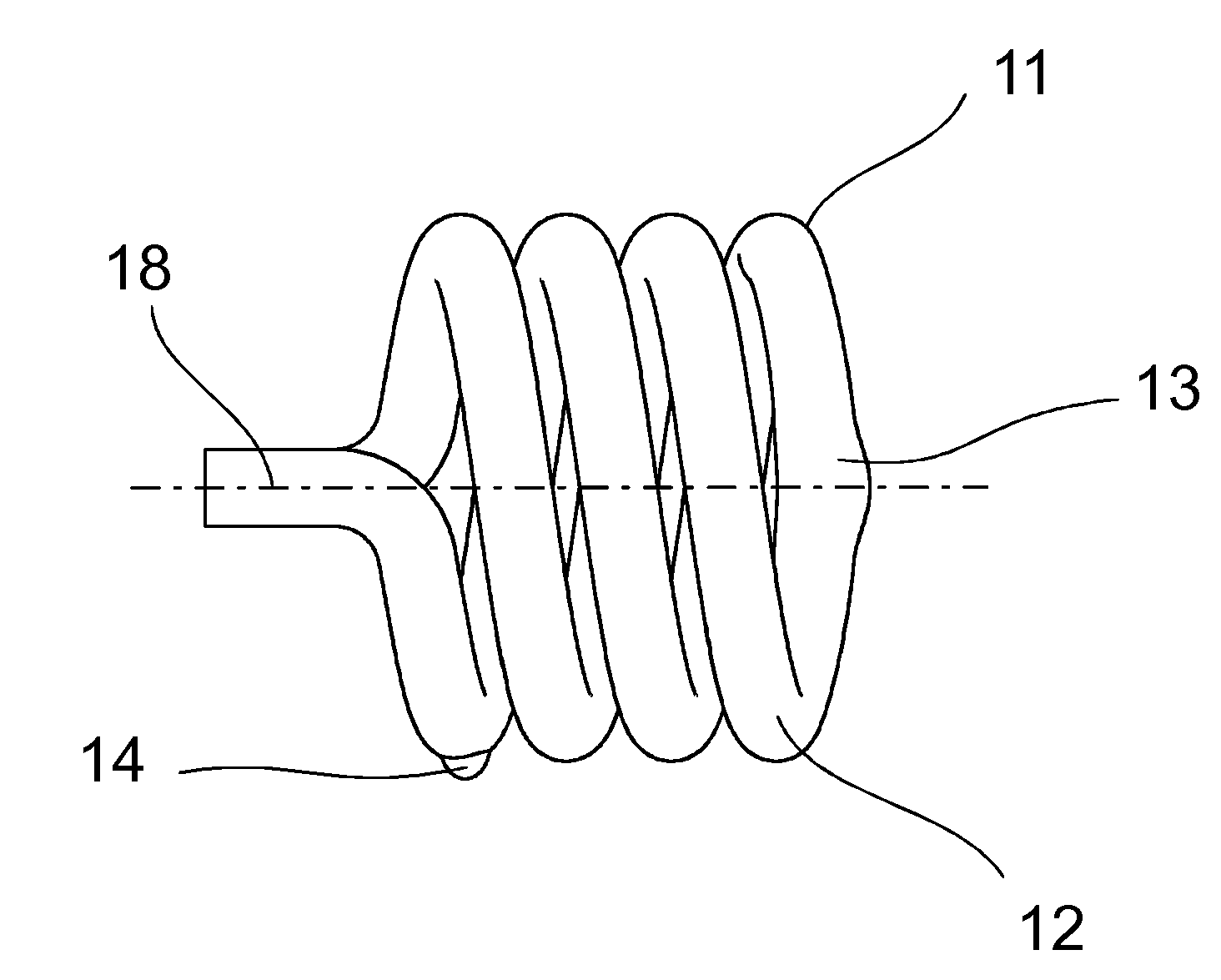

Luminaire driver and method of installation

ActiveUS20220196232A1Increase spaceIncrease powerElectrical apparatusElectric circuit arrangementsElectrical connectionStructural engineering

Drivers (10) for a luminaire (12) are disclosed. The driver (10) includes a housing (13) designed to be capable of being inserted at least partially through an opening (18) formed by removing a knockout tab (18a) in a junction box (17) and into a plenum space that is not part of the splice compartment of the junction box. A plurality of components (11) for driving the luminaire (12) are locatable within the housing (13). An electrical connection (14) is provided to electrically coupling the plurality of components (11) to the luminaire (12). A method of installation for the drivers (10) is also disclosed.

Owner:SIGNIFY HLDG BV

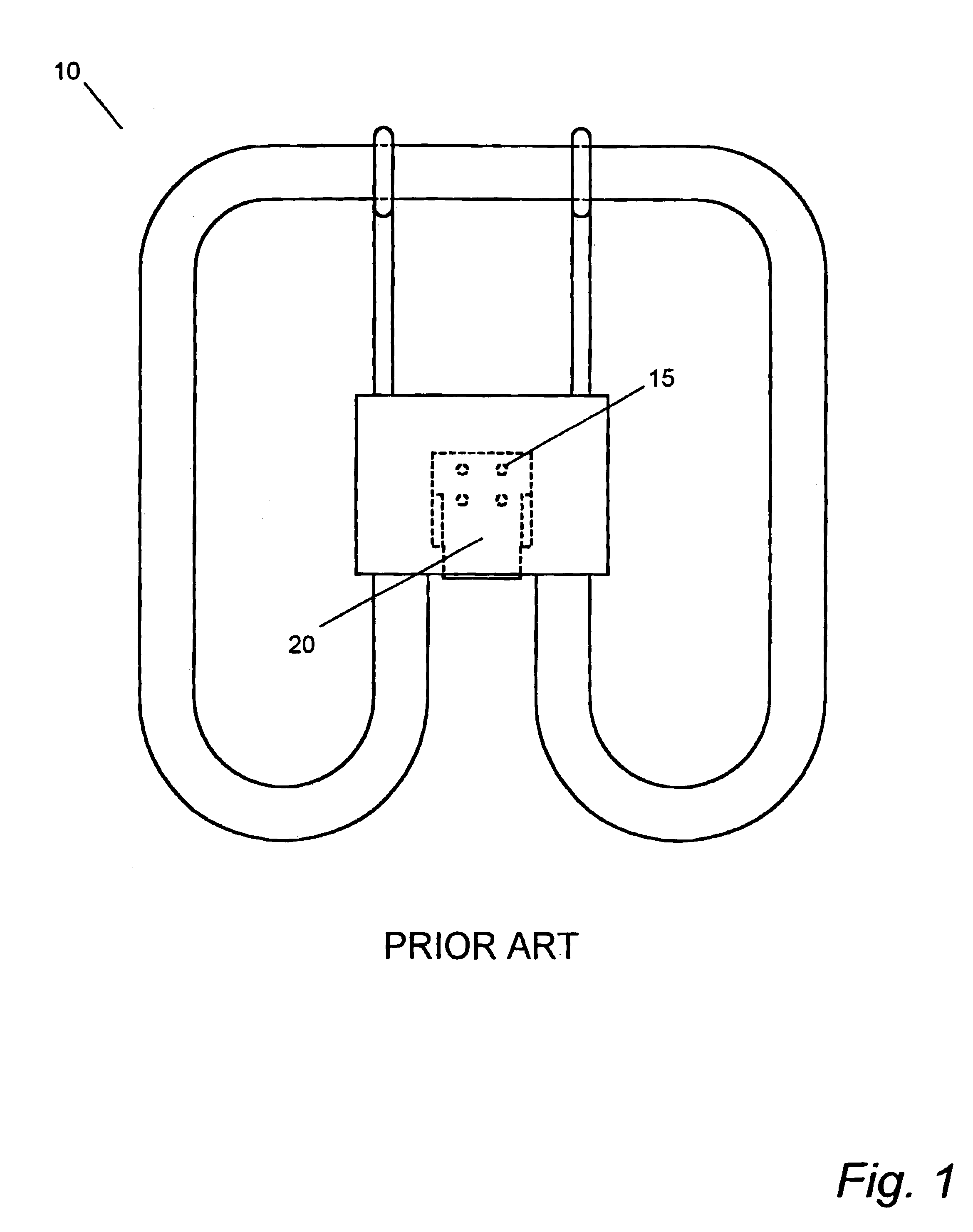

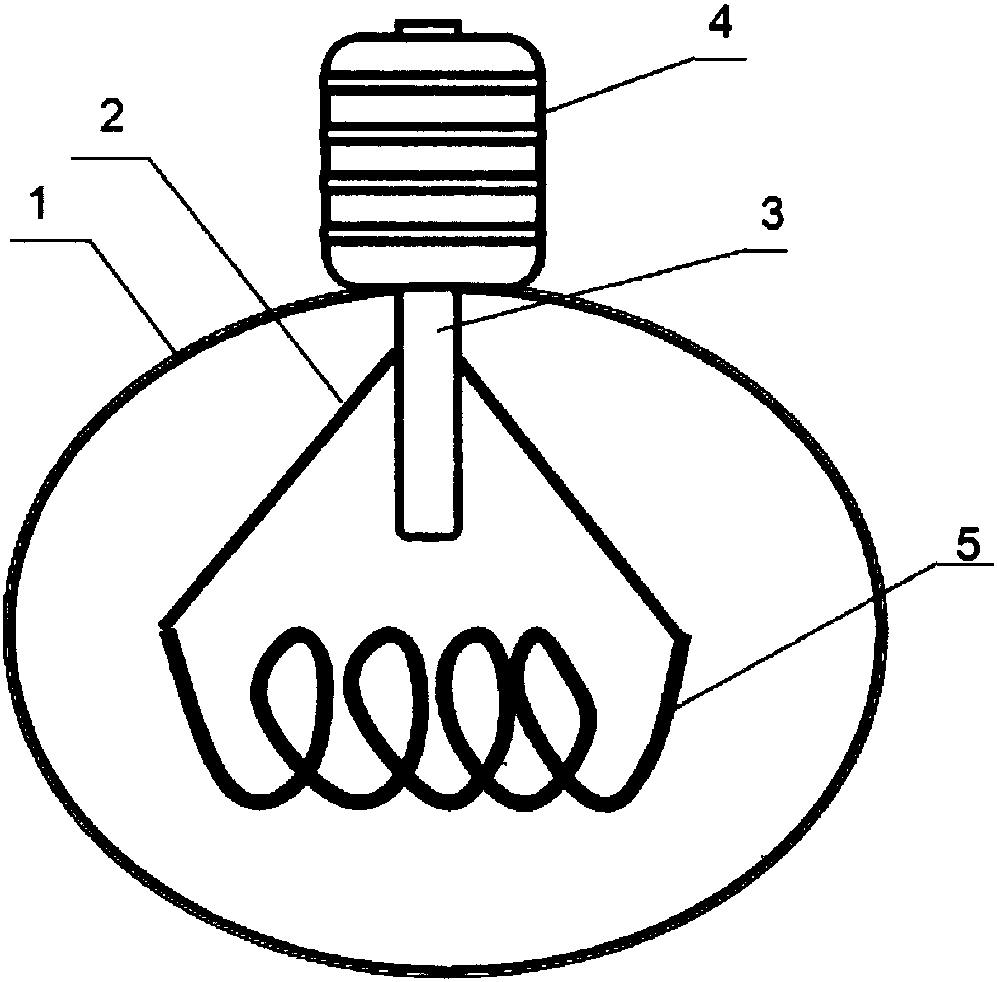

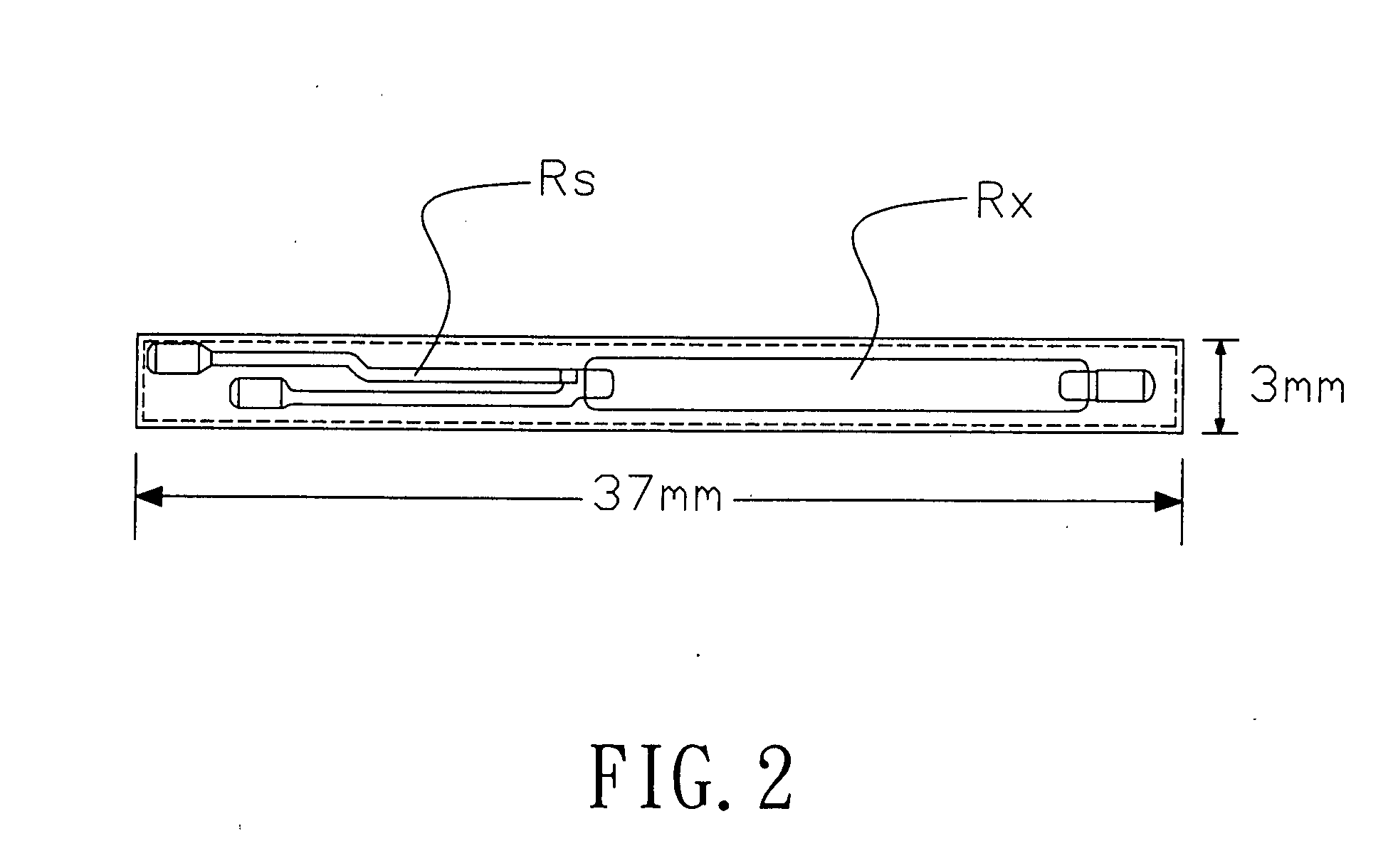

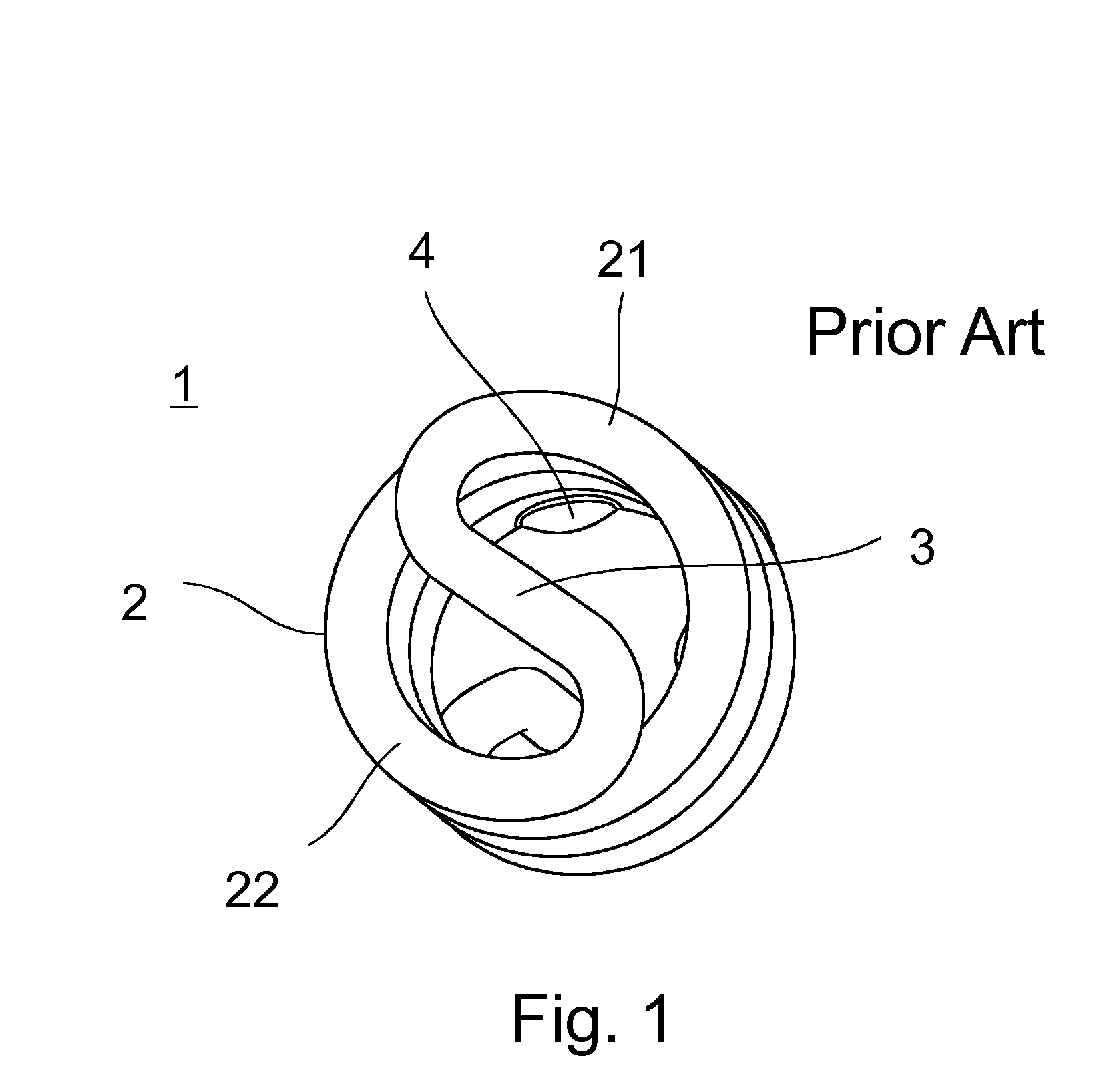

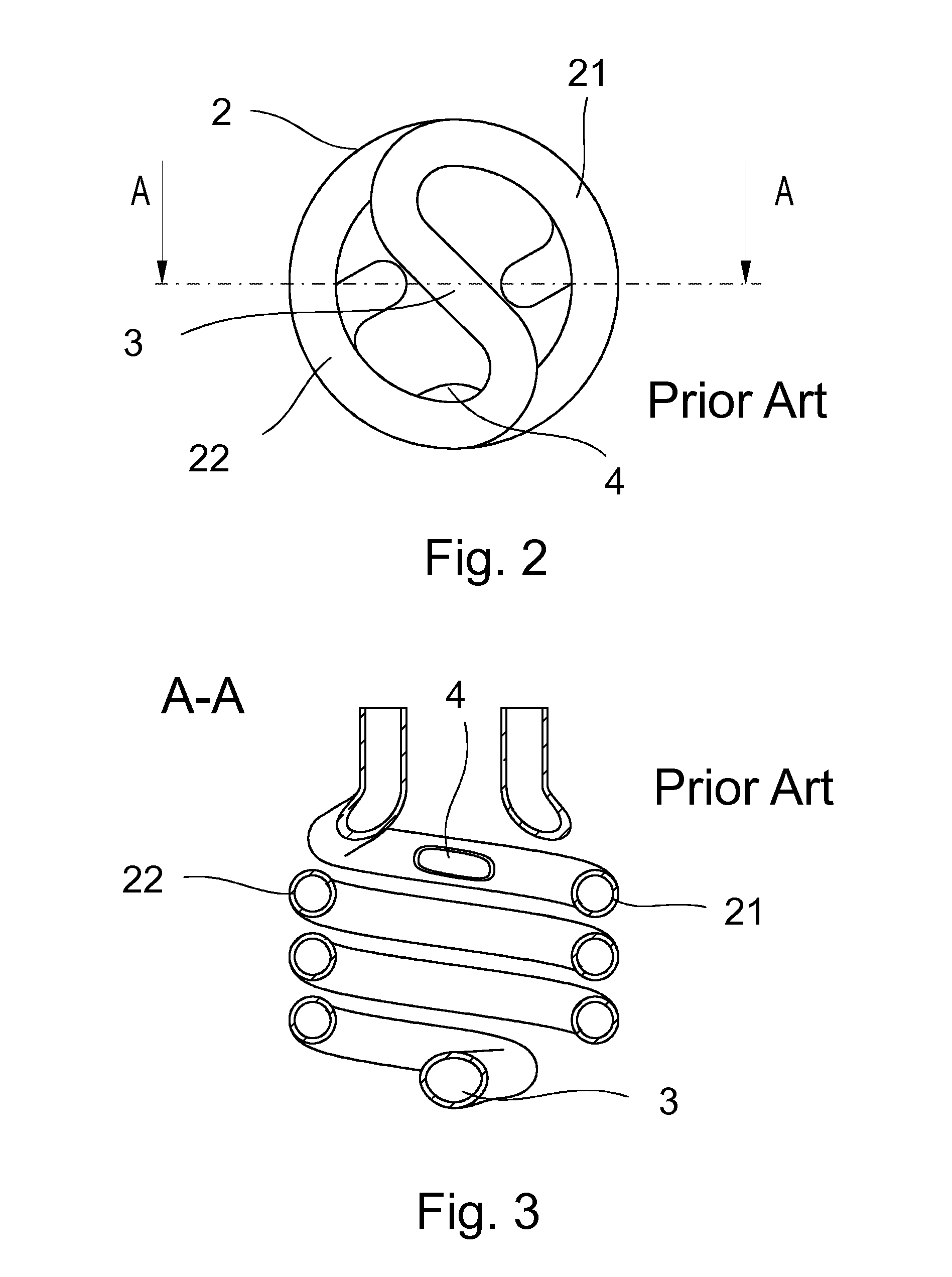

Discharge tube and lamp with improved luminance

InactiveUS20090243463A1Improve light outputWell formedDischarge tube luminescnet screensElectric discharge tubesPhosphorStraight tube

A discharge tube arrangement for a compact fluorescent lamp is provided. This discharge tube arrangement has a central axis and longitudinal end portions, and is formed of at least one discharge tube made of glass, encloses a discharge volume which is filled with a discharge gas and has a fluorescent phosphor coating disposed on an inner surface portion of the tube. The tube forms a continuous arc path and has electrodes disposed at each end of the arc path. The discharge tube arrangement comprises a first cold chamber in order to control and maintain a required mercury vapor pressure. The first cold chamber is located in a longitudinal end portion of the tube arrangement. The discharge tube arrangement is further provided with at least one second cold chamber, which is positioned between the longitudinal end portions of the discharge tube arrangement. The at least one second cold chamber is positioned on the wall of the tube, and has a cold chamber wall protruding substantially away from the central axis of the discharge tube arrangement. The discharge tube arrangement may have a coiled configuration with helical tube portions or a multifinger configuration with straight tube members.

Owner:GENERAL ELECTRIC CO

Discharge tube and lamp with cooling chambers and improved luminance

InactiveUS7759850B2Improve light outputWell formedDischarge tube luminescnet screensElectric discharge tubesStraight tubeCooling chamber

Owner:GENERAL ELECTRIC CO

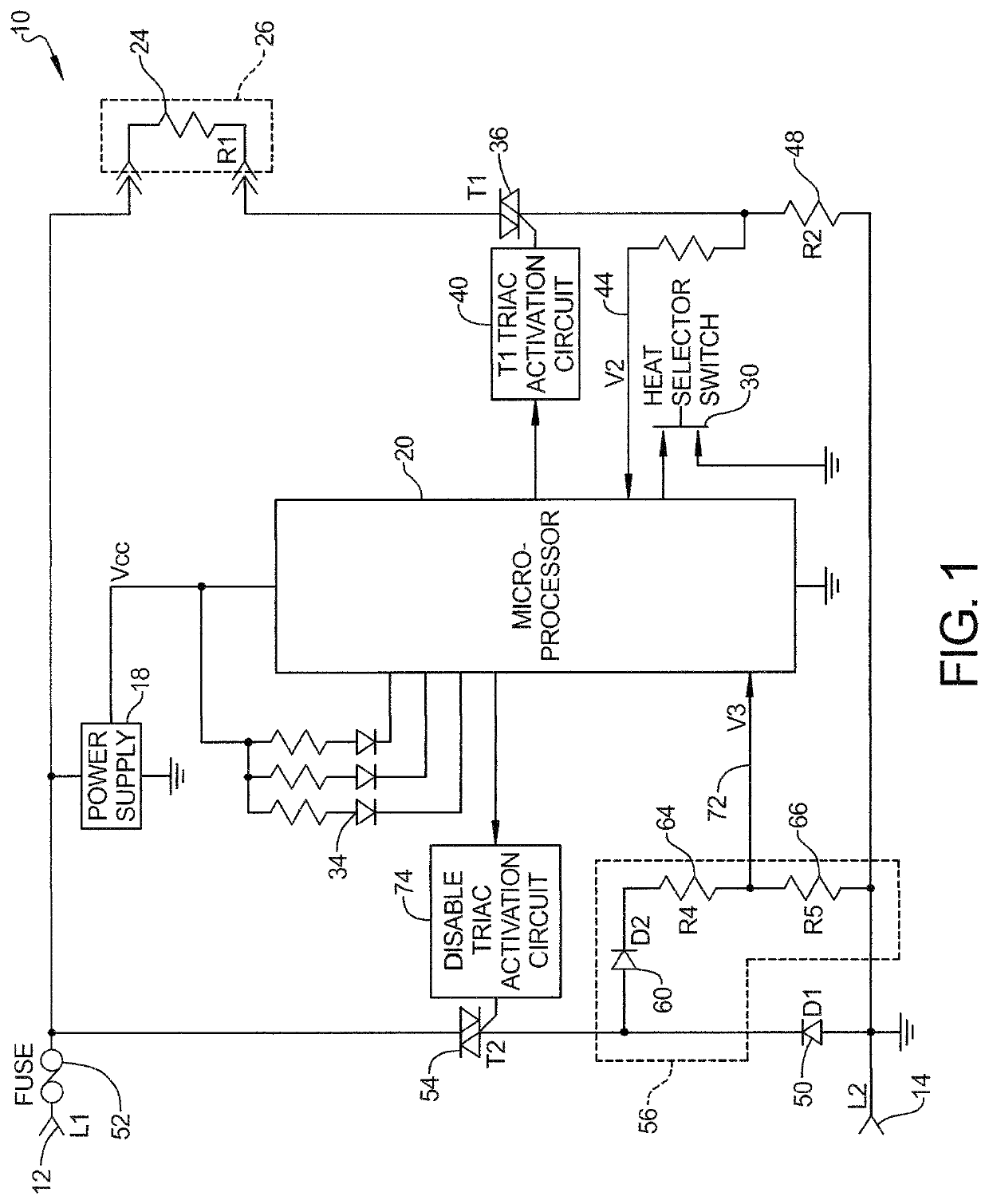

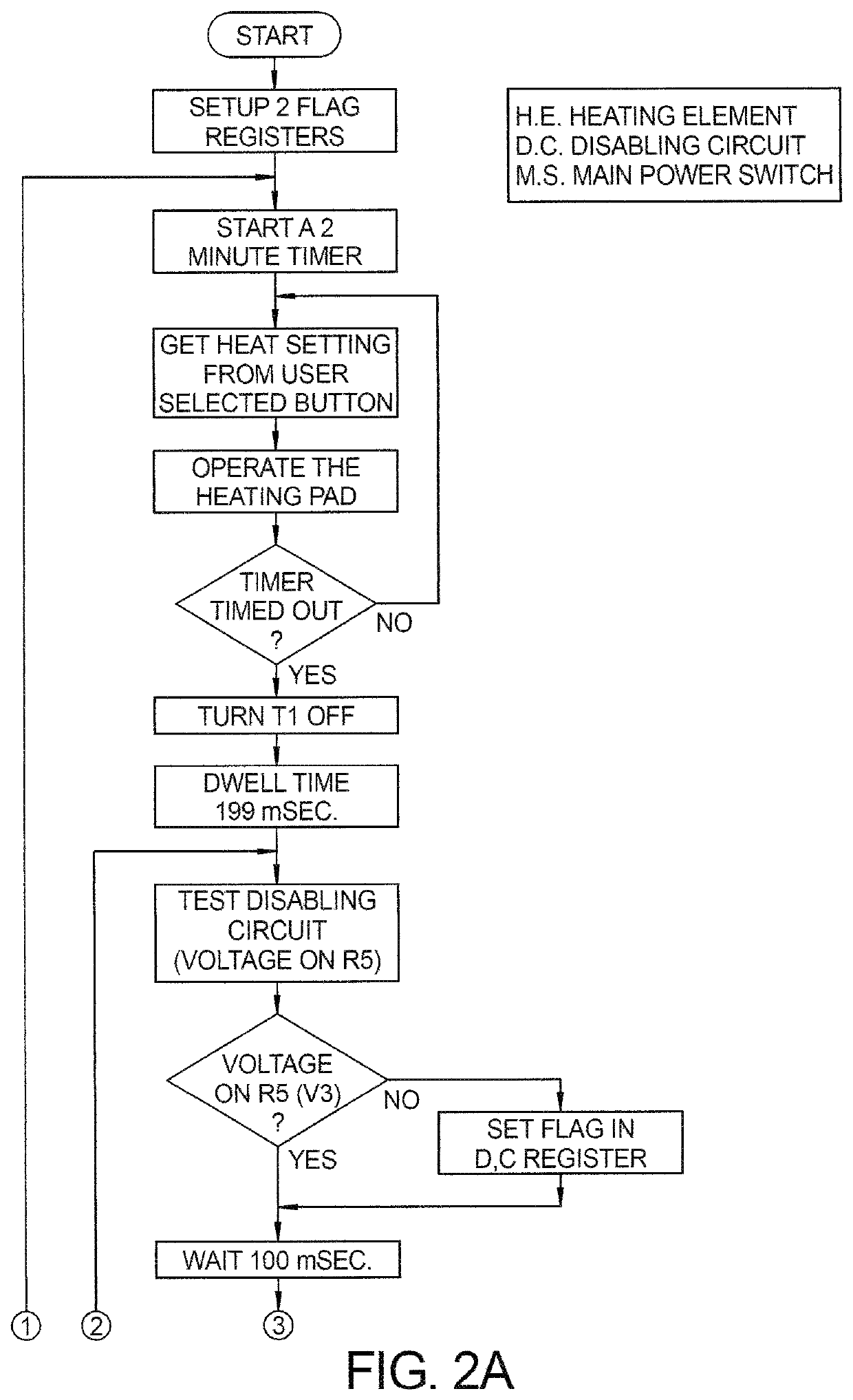

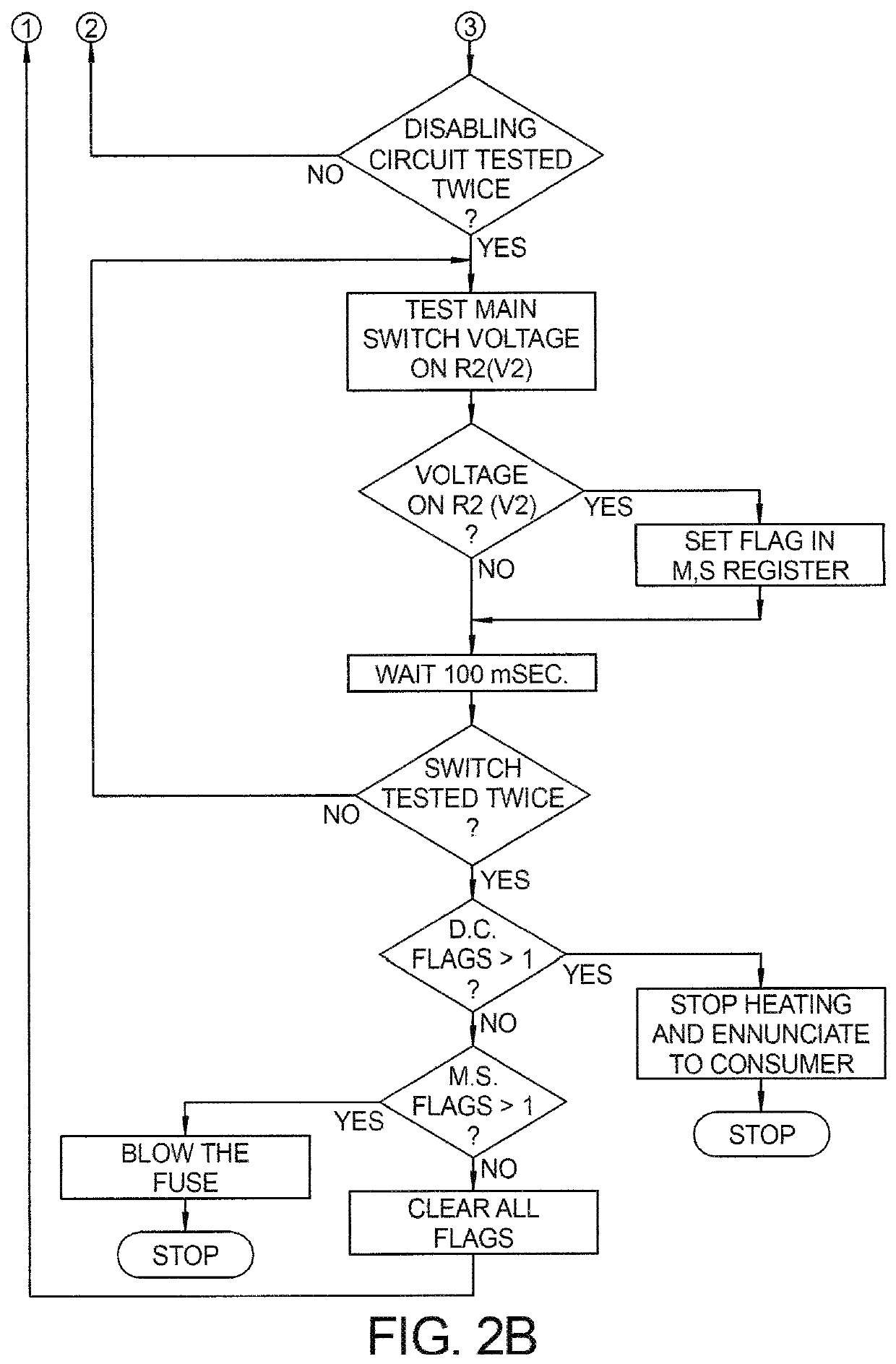

Safety circuits for electric heating element

ActiveUS11089655B1Avoid adjustmentIncrease wattageProgramme controlComputer controlPower switchingFuse (electrical)

A system controller such as a microprocessor receives voltage signals produced from a resistor identifying the functional or nonfunctional operating state of a power switch which controls the amount of power provided to a load in an electrical system. The resistor is also used to provide voltage signals representing the temperature of a heating element of the type used in heating pads and heating blankets. The functional or nonfunctional operating state of a safety switch in a safety circuit capable of blowing a fuse and cutting power to the load is periodically tested to ensure the safety of the electrical system.

Owner:FAN YU HEALTH TECH BUSINESS CO LTD

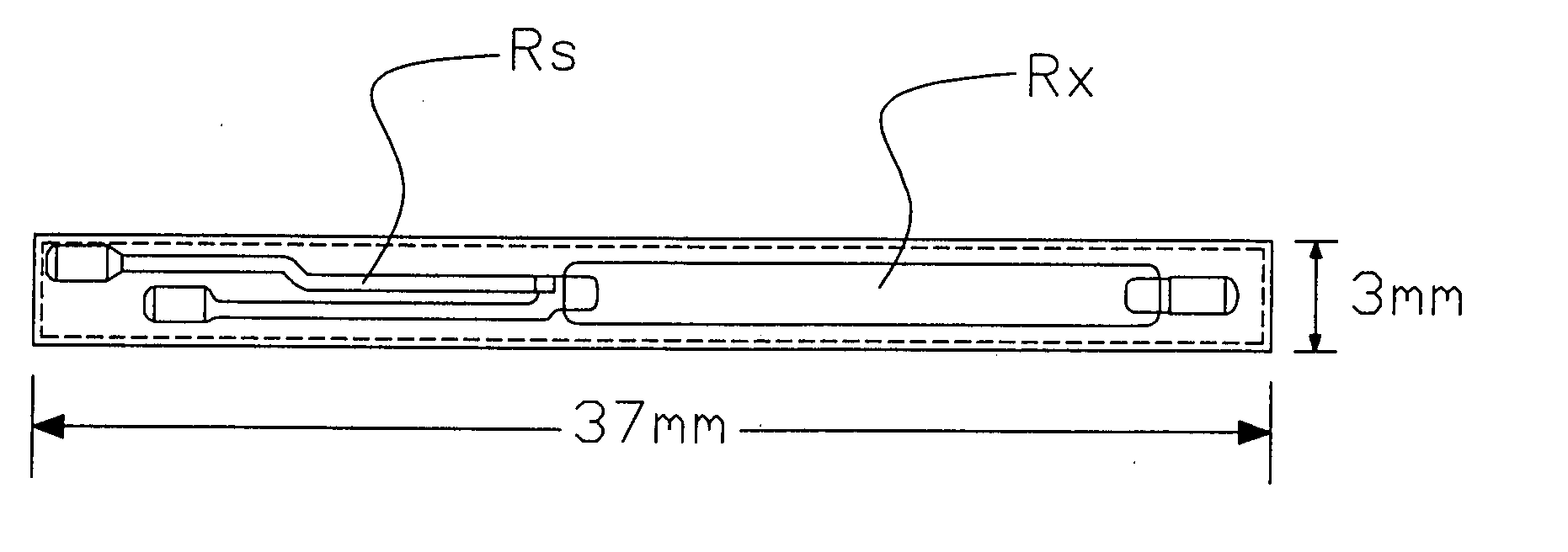

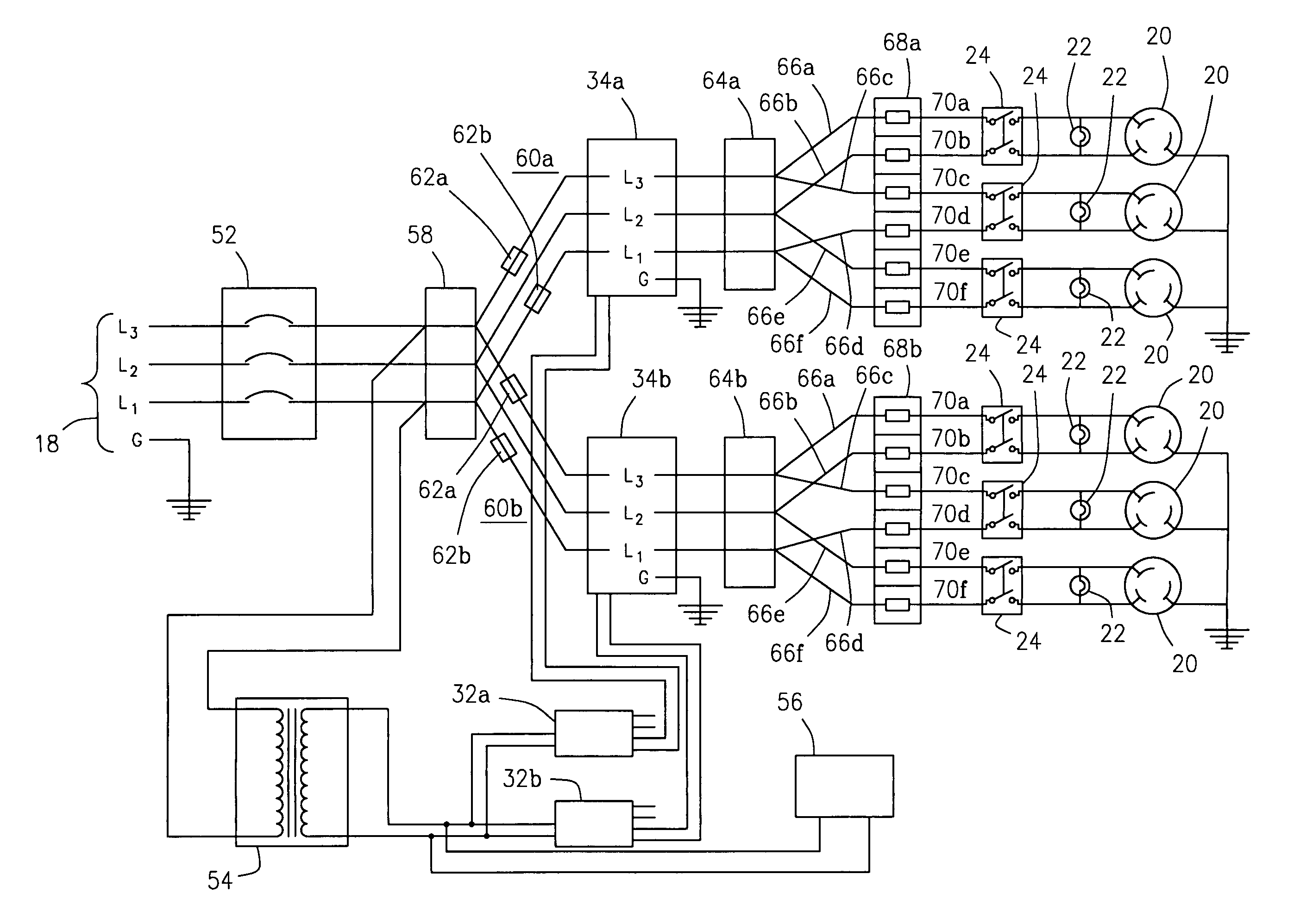

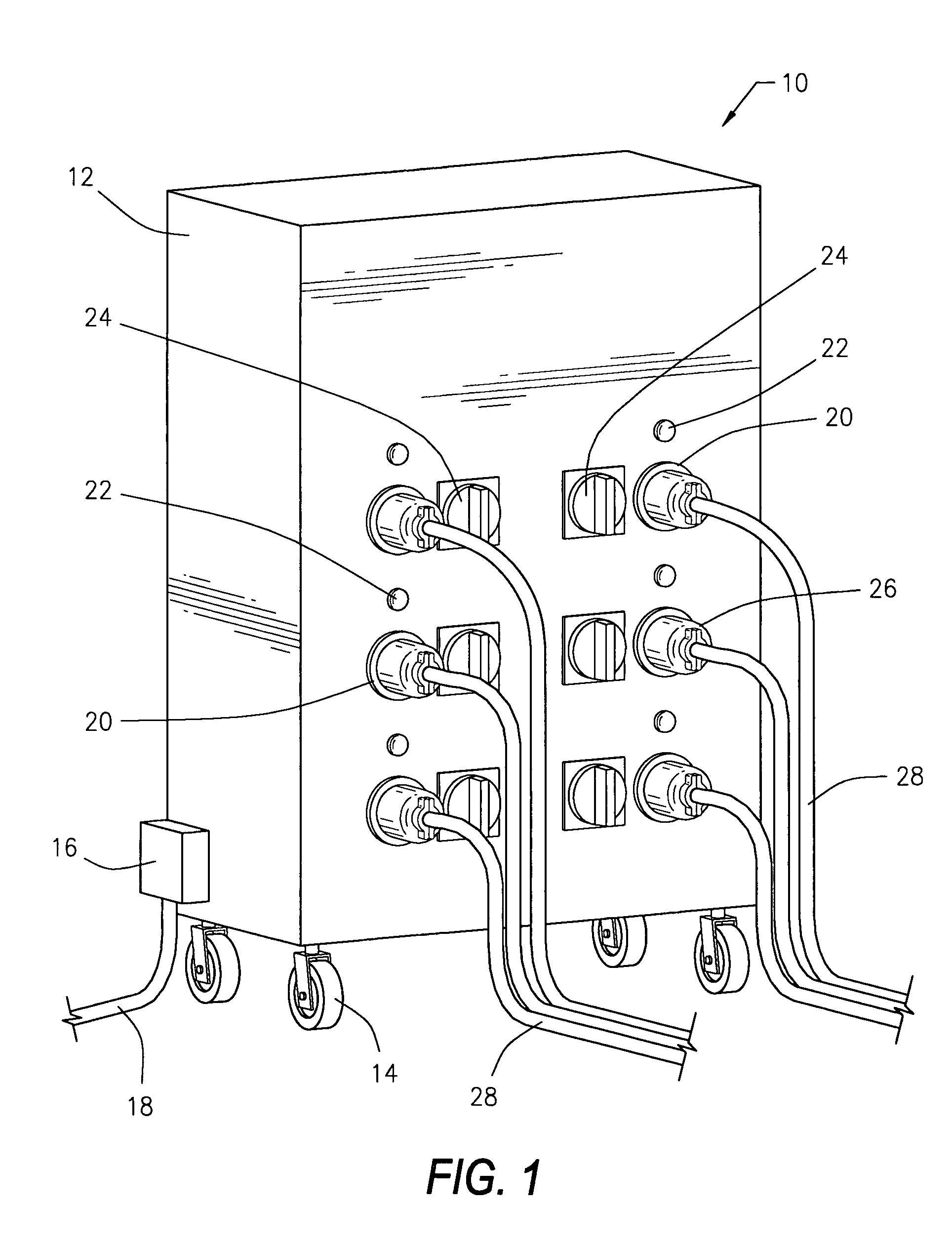

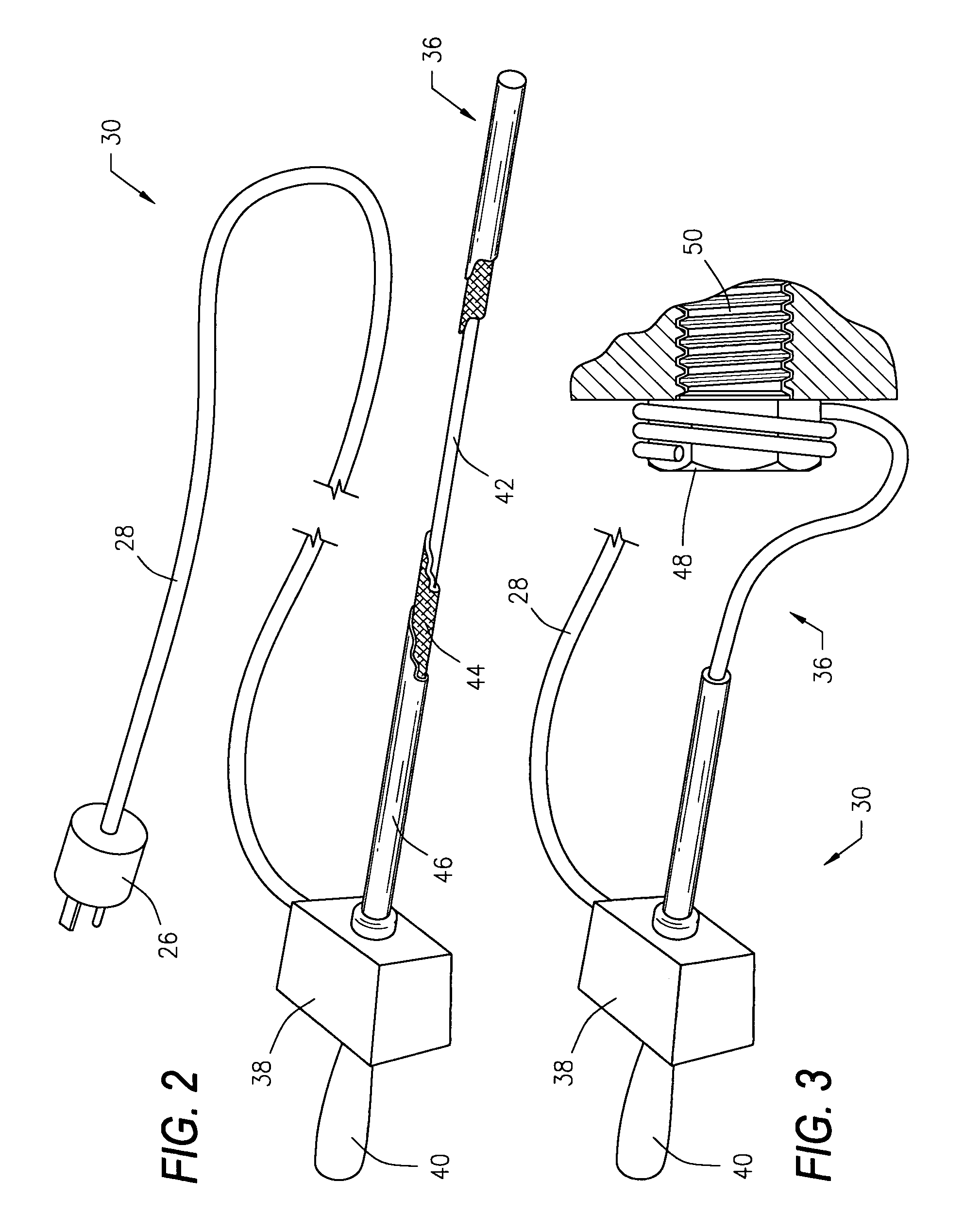

Compact, portable resistance heating device

ActiveUS9062704B2High voltageIncrease wattageDielectric heatingElectric discharge heatingElectricityElectrical resistance and conductance

A compact, portable resistance heating device that takes a source of alternating current electricity and through a series of connections and circuitry splits the alternating current electricity into a plurality of circuits. The compact, portable resistance heating device is capable of heating a plurality of cartridge heaters at one time, individually or a combination thereof. The compact, portable resistance heating device is controlled by at least one controller that controls three (3) power output receptacles. The controller is capable of producing 0-100% output power to each respective cartridge heater. Each cartridge heater may be individually controlled by an on / off switch, and an indicator light may be provided and illuminate when each cartridge heater is energized. The cartridge heaters of the compact, portable resistance heating device do not require close tolerances with an axial bore of a stud or threaded bolt and are further capable of being bent to suit the particular operation.

Owner:ANALYTIC STRESS RELIEVING INC

On-Camera Flashlight

ActiveUS20160202597A1Effective guidanceIncrease wattageMechanical apparatusDomestic lightingPhysicsLight source

The present invention is an on-camera flashlight, comprising a lower light holder and a top light holder freely rotatably connected to the lower light holder. A flashlight light source is mounted on the top of the top light holder. The light emitting diode and the flashlight light source are mounted on the on-camera flashlight, combined for ease of use. Two functions-in-one lighting device saves space, avoids overloading the camera, and makes it portable. Because the two light sources are set in combination, the cooperation and sequence of the two light sources are easier to control. As the light emitting diode is mounted on the top light holder which may freely rotate with respect to the lower light holder, the light emitting diode may also freely rotate. It is also convenient to adjust the light direction. Above features all remarkably facilitate operation and versatility of the on-camera flashlight.

Owner:YUEQING ORIGINALITY PHOTOGRAHY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com