Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Increase the placement density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

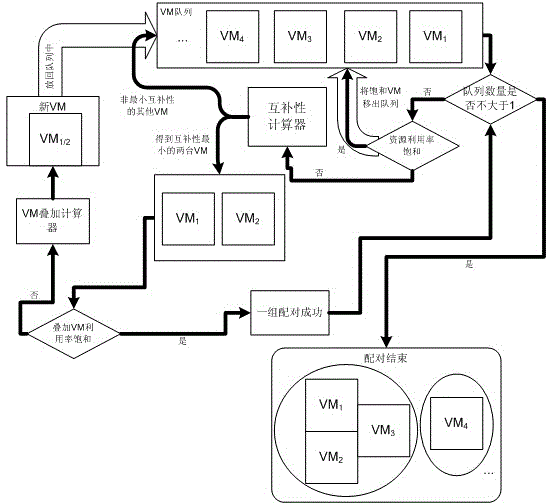

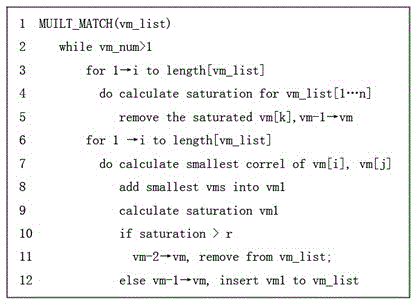

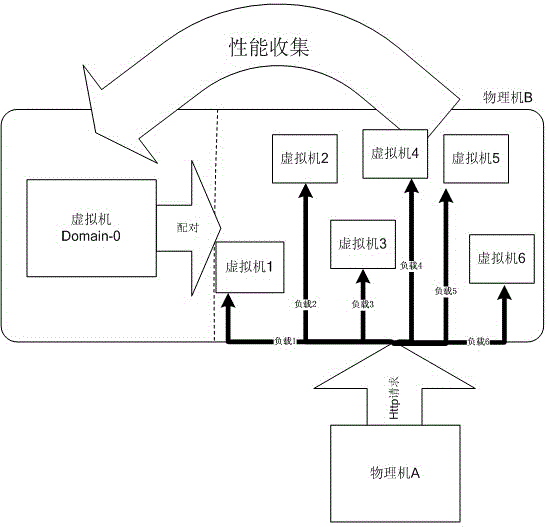

Method for placing load-related virtual machine

ActiveCN102541622AImprove resource utilizationNo reduction in service qualityResource allocationSoftware simulation/interpretation/emulationVirtualizationQuality of service

The invention relates to a method for placing a load-related virtual machine. In a currently common virtualized environment, in order to ensure performance, resources are often excessively allocated, leading to a low resource utilization level and resulting in increase of the cost and resource waste. By utilizing a multi-iteration complementary pairing method provided by the invention, the problems of a low resource utilization ratio as well as unreasonable pairing caused by random pairing or one-time pairing can be solved; and the iteration degree is controlled by setting a saturation of the resource utilization ratio, so that the performance of the system and the service quality of a user are controlled within an acceptable range. By a multi-iteration virtual machine method, by utilizing the time complementarity of the resources, the resource utilization ratio of the virtual machine can be improved in a relatively deep level on the premise of not reducing the service quality of the user.

Owner:HANGZHOU DIANZI UNIV

Aging testing method and device for power-supply device

InactiveCN1869728ARaise the severity levelLow calorific valuePower supply testingAging testEngineering

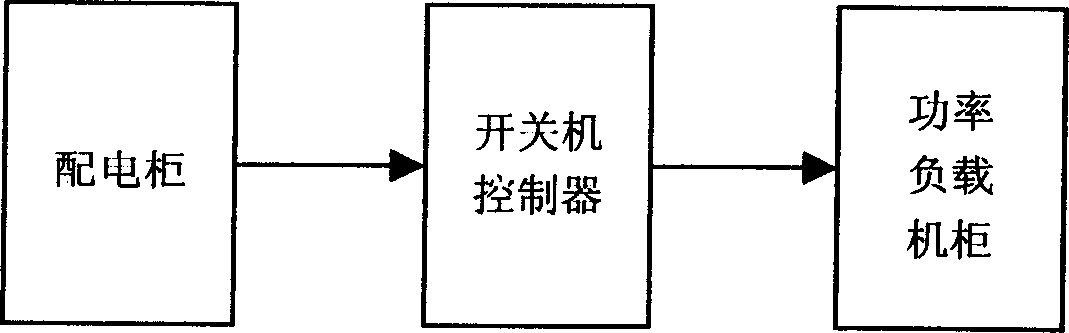

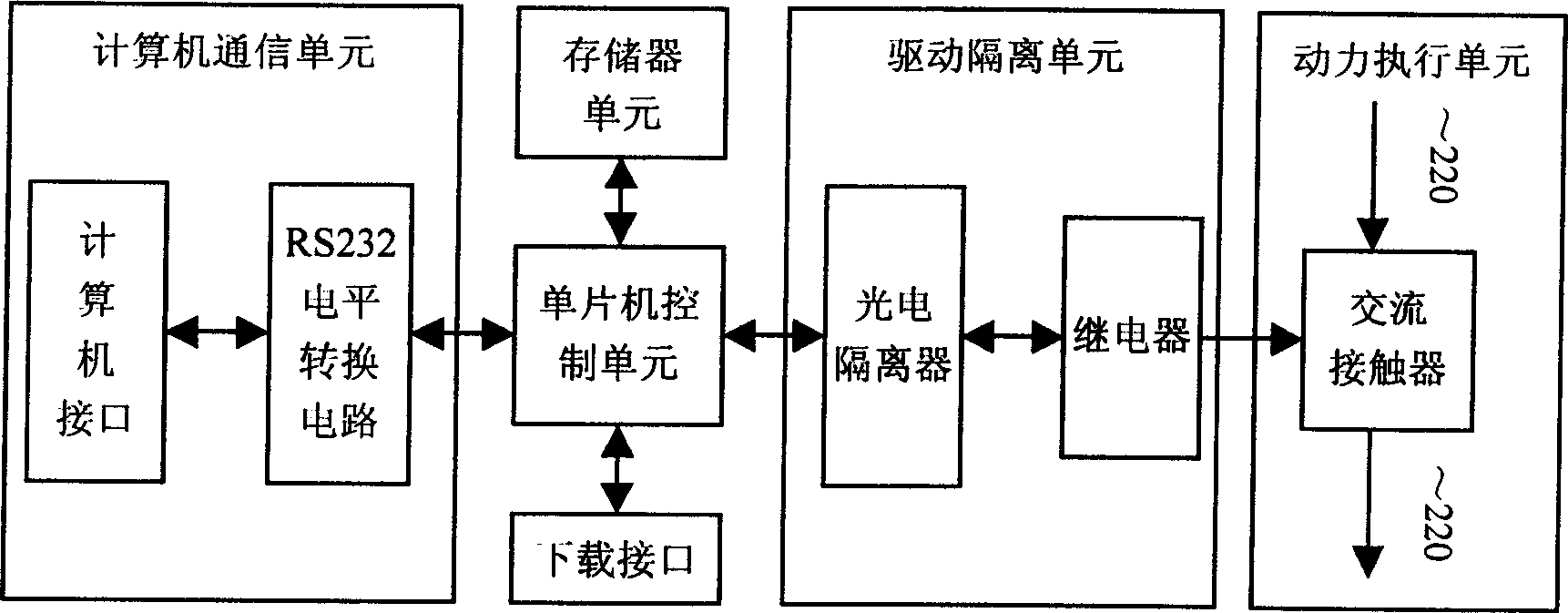

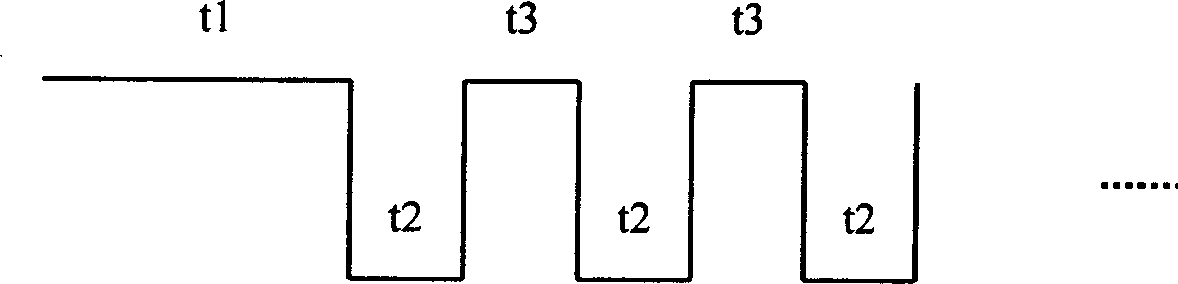

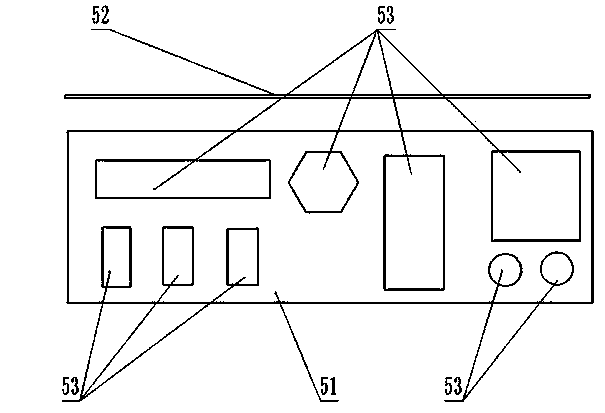

The invention relates to power supply technique, especially relating to power supply device ageing test, providing a power supply device ageing test method and device. And its technical solution: the method makes ON and OFF surge test on the power supply device in the ageing test course. And the ageing test device comprises distribution cabinet and power load cabinet, and switch controller, where the switch controller is connected with the power load cabinet to control the power supply of the power load cabinet. And it can detect abilities of components to resist ON surge current; and raise utilization ratio of the ageing test device and save production cost.

Owner:MAIPU COMM TECH CO LTD

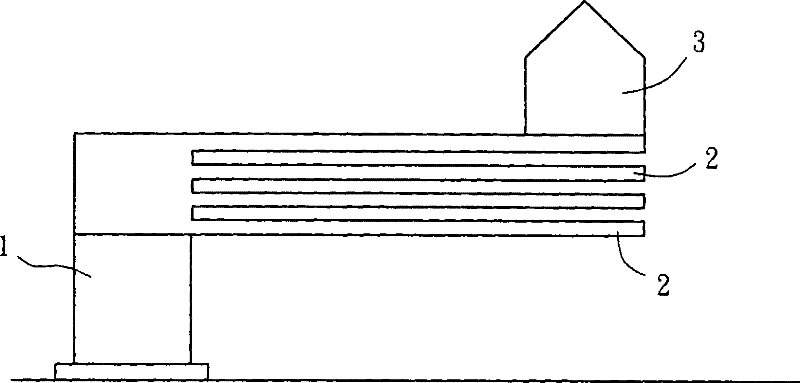

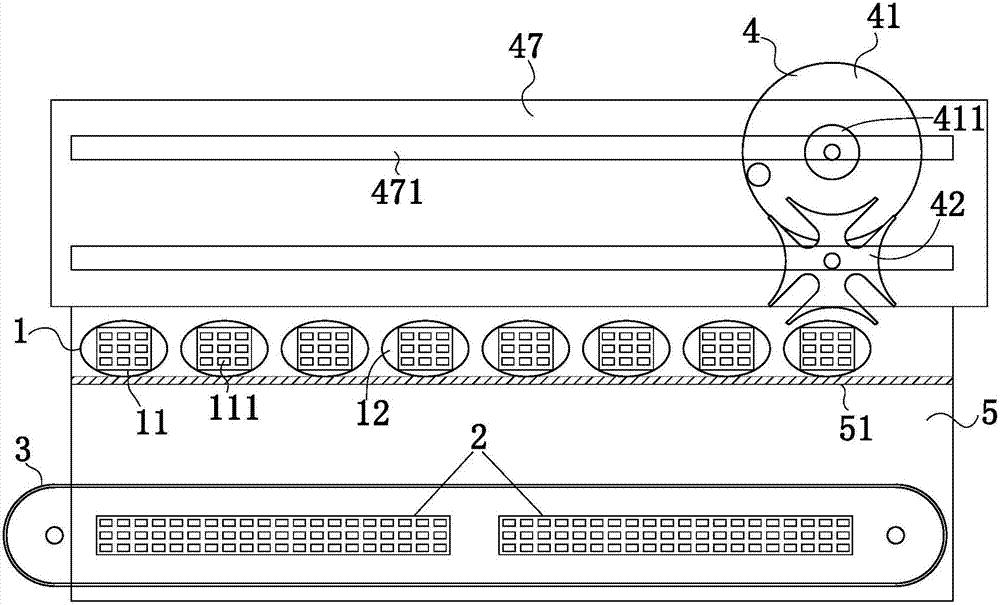

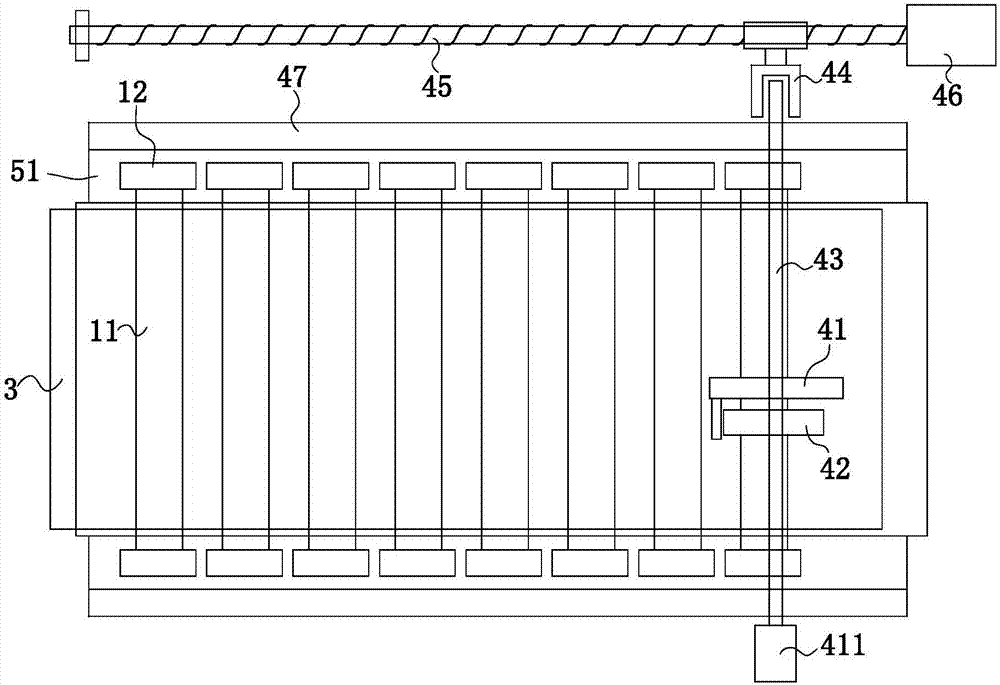

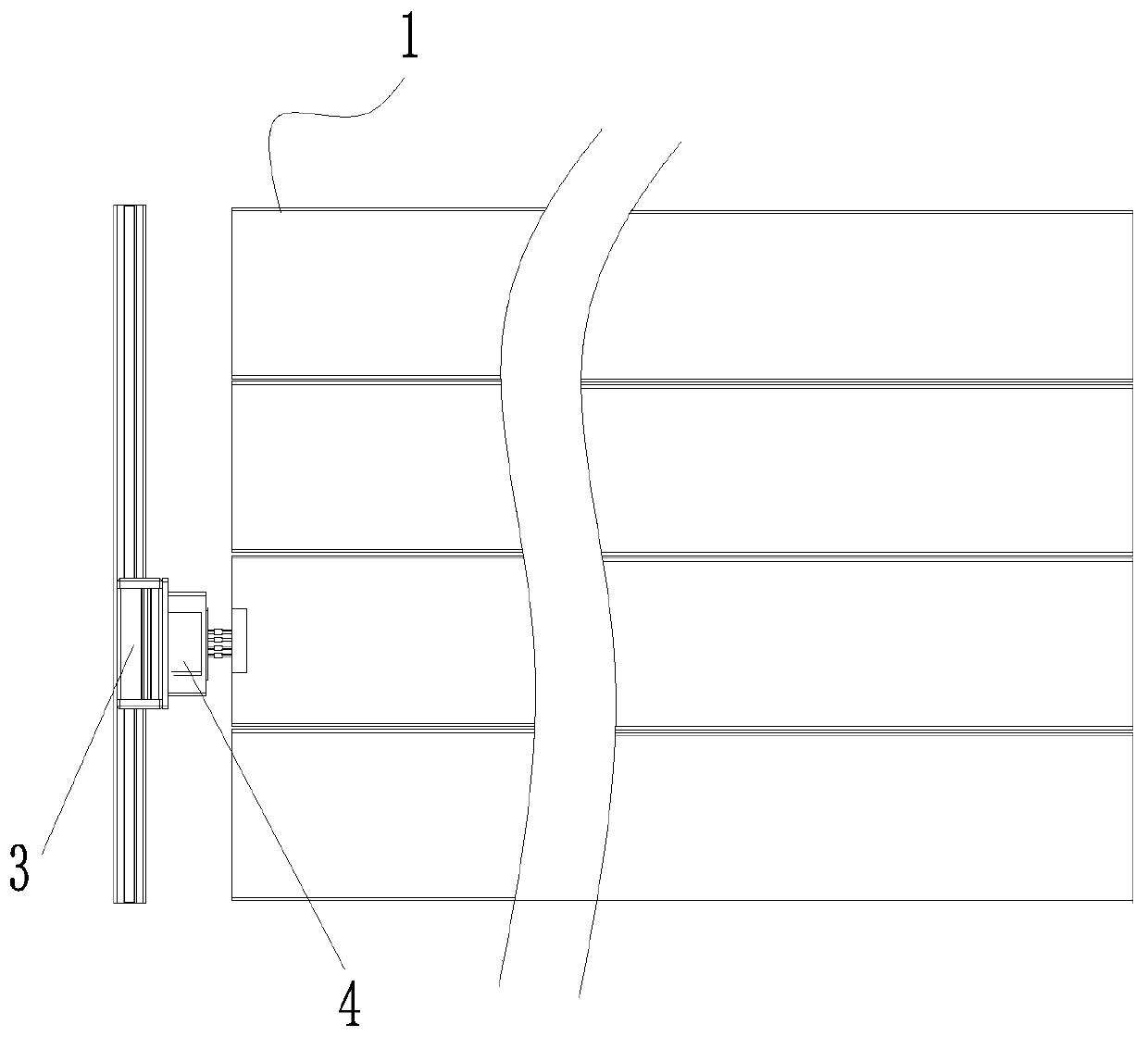

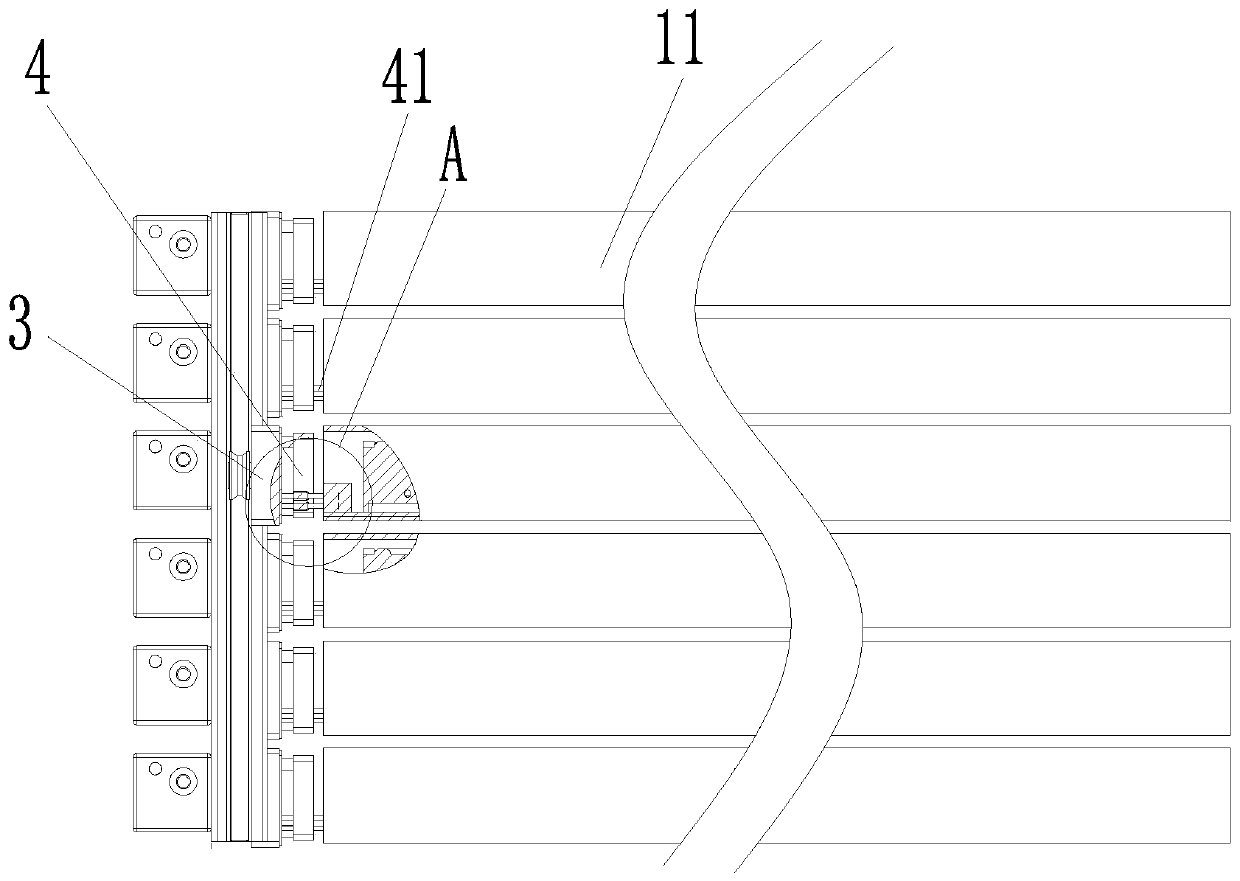

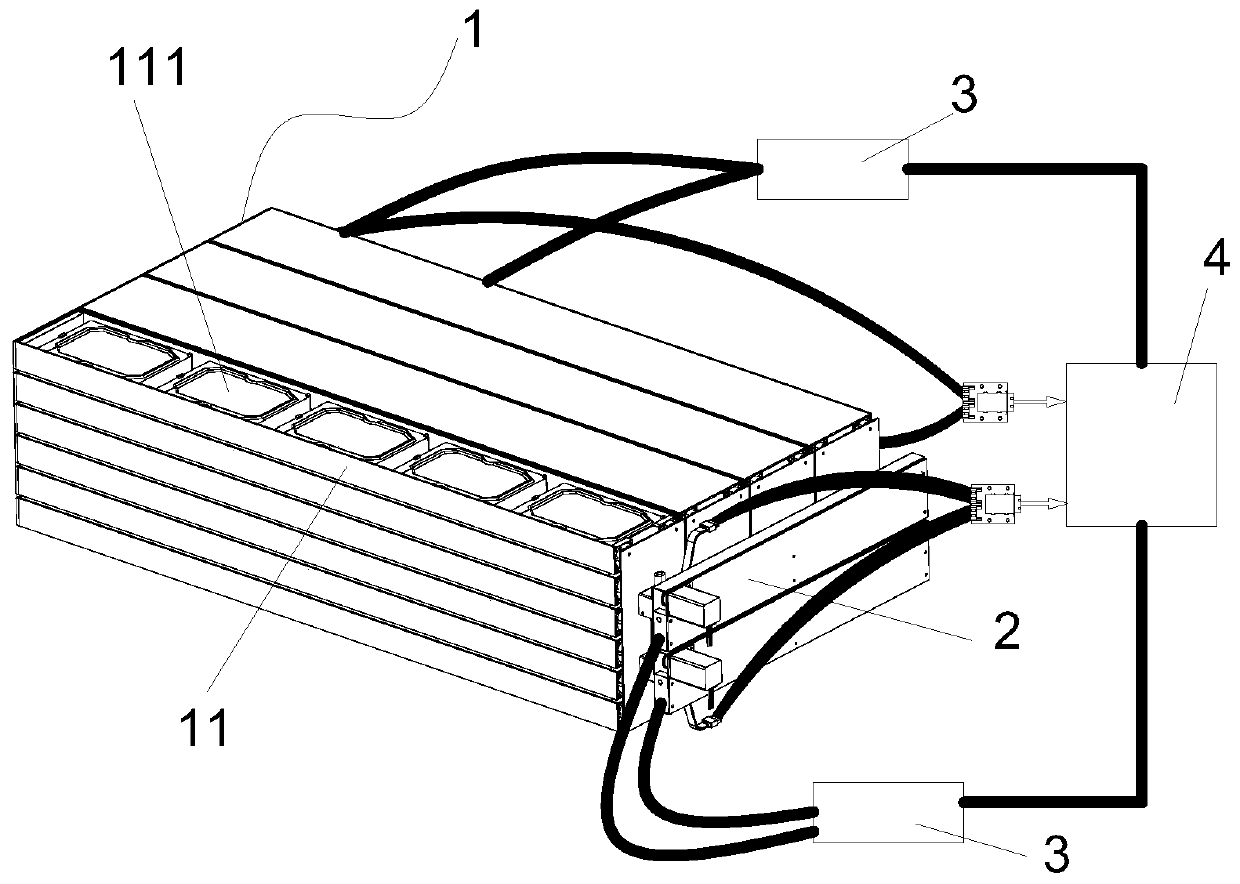

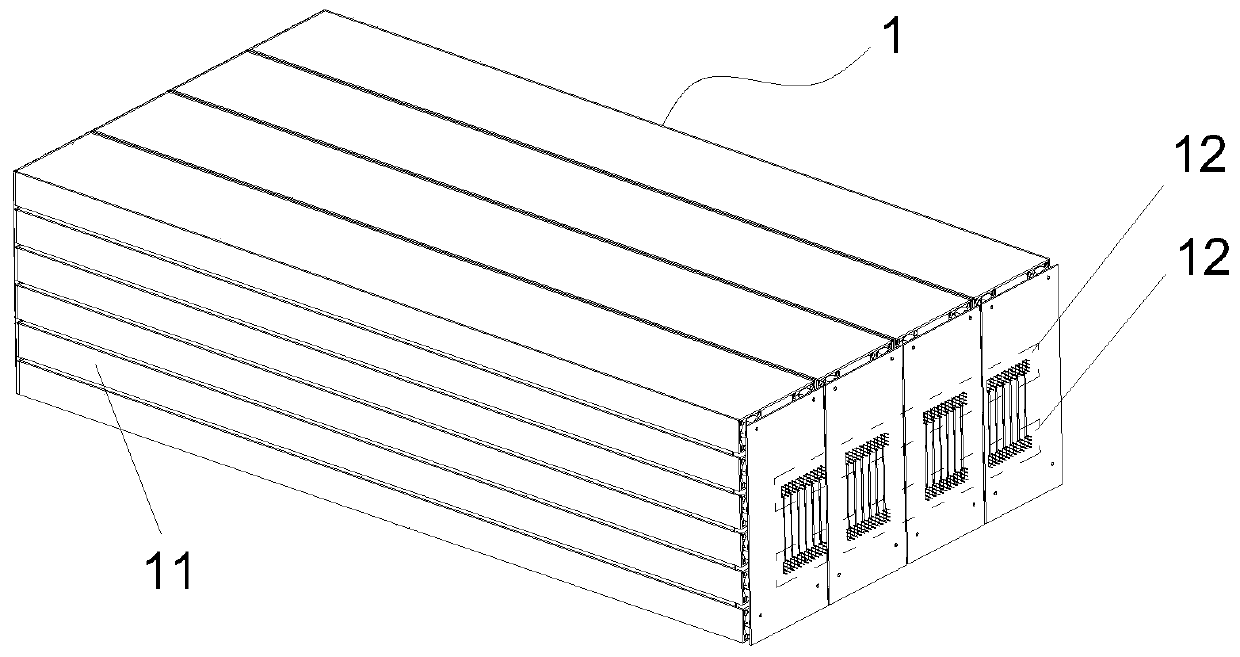

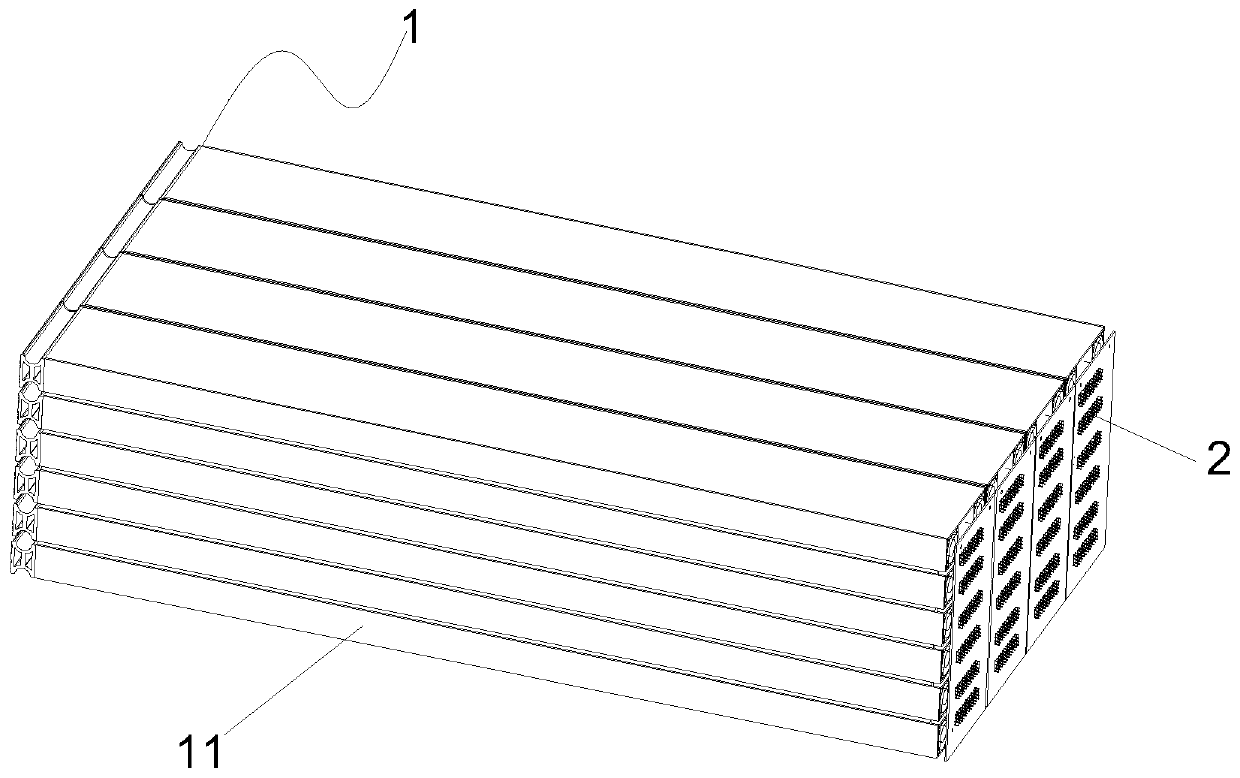

Data center server cooling equipment cabinet

ActiveCN103838337AContact heat transferExtended service lifePower supply for data processingHeat transmissionEngineering

The invention discloses a data center server cooling equipment cabinet which comprises a server equipment cabinet, a phase change heat transmission system, server machine shells and spring pieces for fixing the server machine shells. The phase change heat transmission system comprises a plurality of heat exchangers arranged in the server equipment cabinet, an outdoor cooling device and connecting pipelines. The heat exchangers are arranged on support layers for placing of servers in the server equipment cabinet respectively. The server machine shells are placed on the upper portions of the heat exchangers, the servers are sealed in the server machine shells, air cooling does not exist in the whole data center server cooling equipment cabinet, server heating units are in direct contact with the server machine shells, the server machine shells are in direct contact with the heat exchangers placed in the server machine cabinet, contact heat transmission is achieved, and heat transmission efficiency is improved. According to the data center server cooling equipment cabinet, server placing density can be increased, building cost is low, a building cycle is short, and the running cost of a whole data center is greatly lowered.

Owner:BEIJING FULLLINK OREITH TECH CO LTD

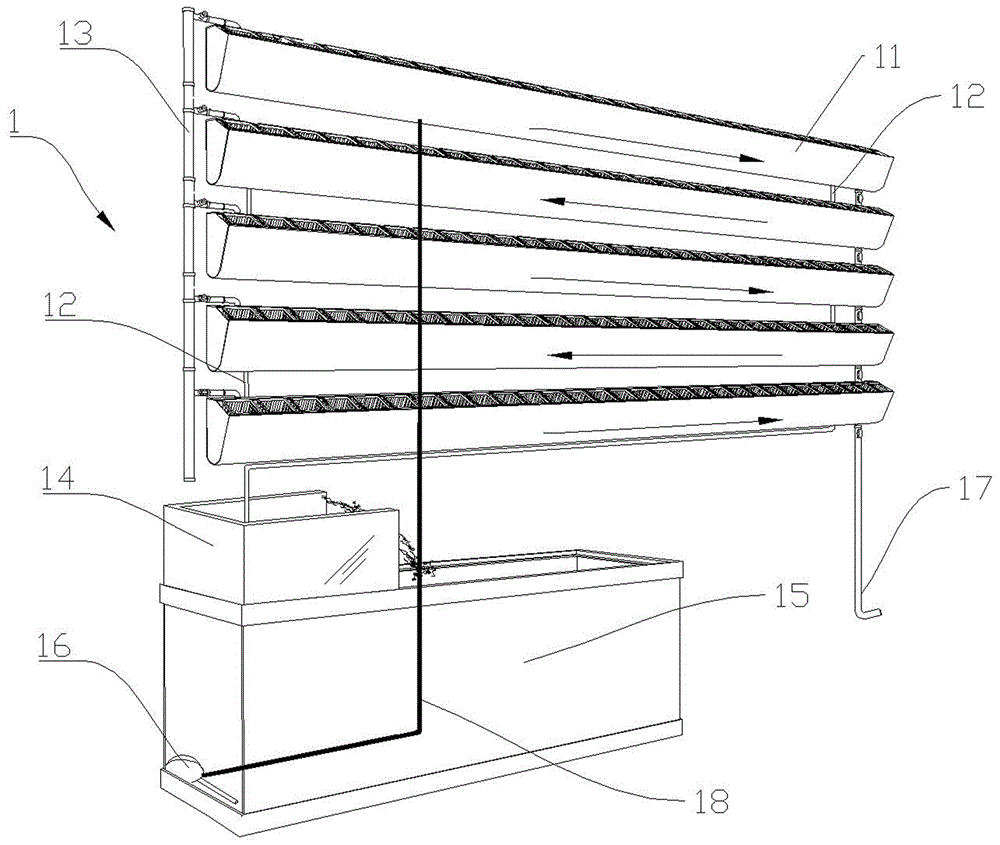

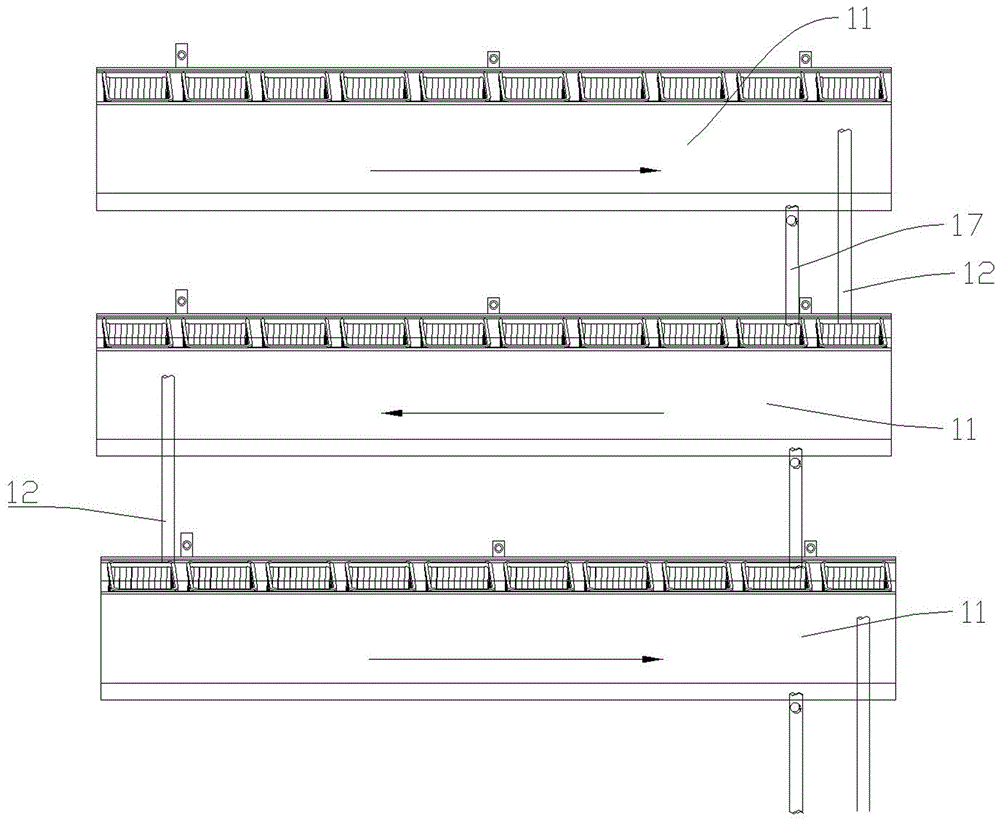

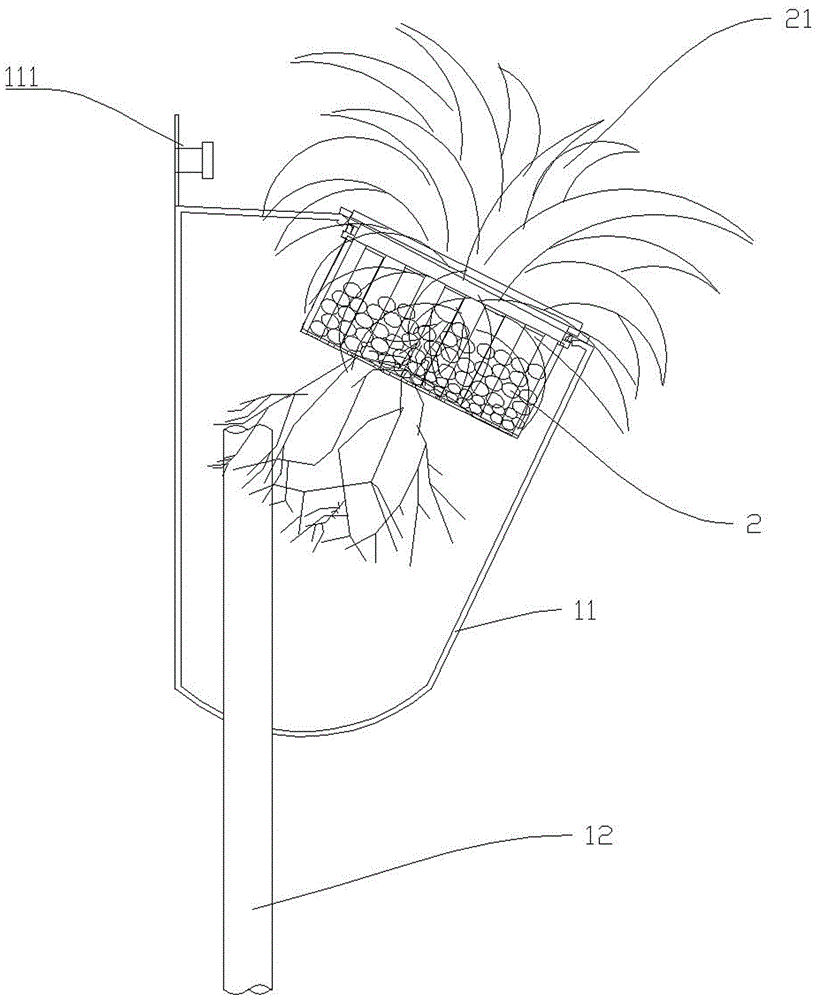

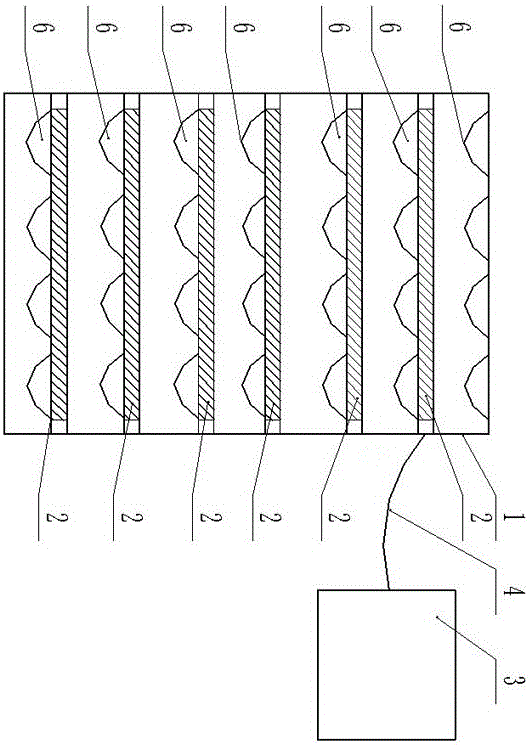

Hydroponic plant wall planting method and device

ActiveCN105684868AEasy to manageElegant managementPisciculture and aquariaAgriculture gas emission reductionLife qualityAir cleaning

The invention discloses a hydroponic plant wall planting method and device. The method comprises the following steps that formed hydroponic plants are adopted for planting; formed plant planting baskets are adopted for planting hydroponic plants; water of a circulating system is absorbed thoroughly through a hydroponic plant wall device with water tanks and a circulating water draining system for plant culture to form a hydroponic plant wall. Plants of different varieties can be combined and planted on the water tanks by adopting the formed plant planting baskets, a water pump pumps water in a fish tank or a fish pond to the top of the plant wall, the water of each-level water tank reaches the overflow opening and then naturally flows down to the next level, and water of the lowest-level water tank reaches the overflow opening position and then flows back to the fish tank or the fish pond to form water circulation. Air purification, clean planting and ecological environmental protection can be achieved, the life quality can be improved, modular production can be achieved, operation is convenient, maintenance is easy, and the practicability is high.

Owner:GUANGZHOU JINGRUN GARDEN GREENING CO LTD

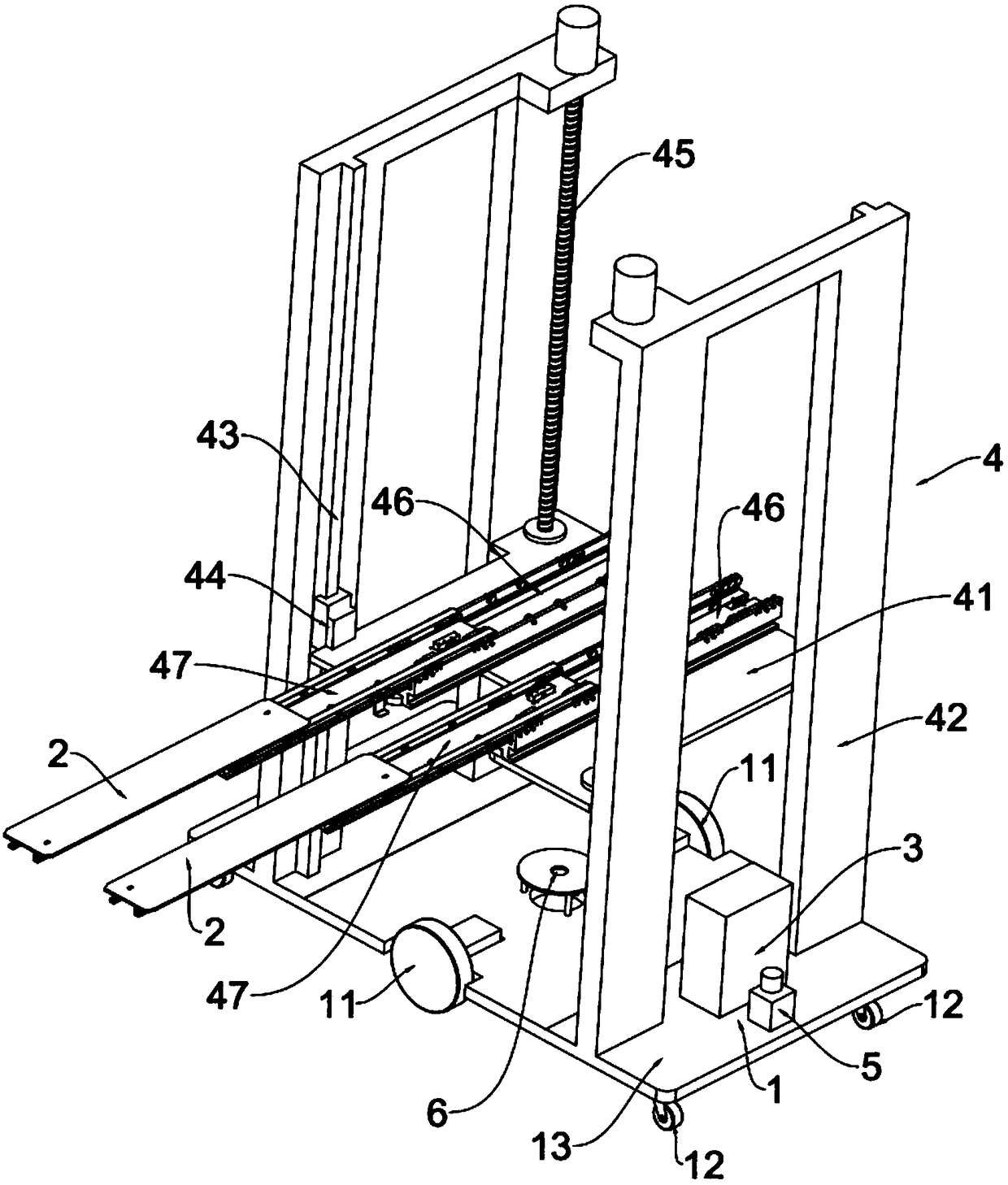

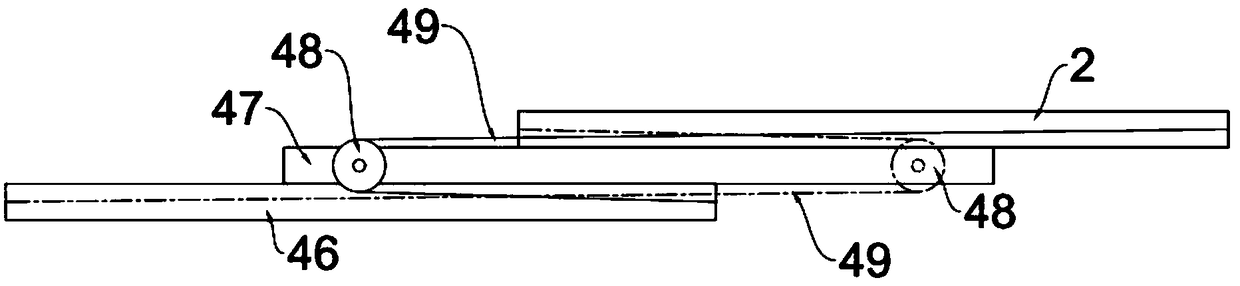

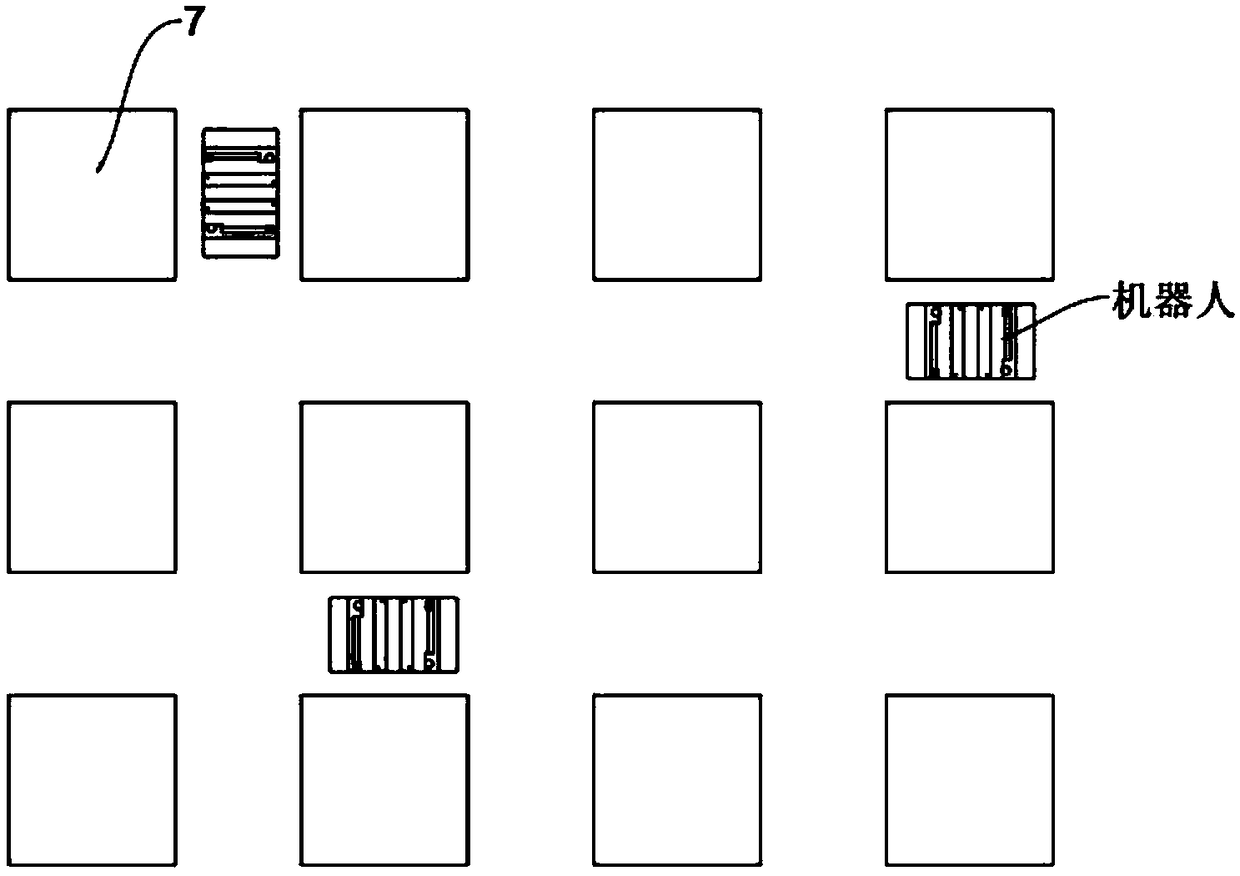

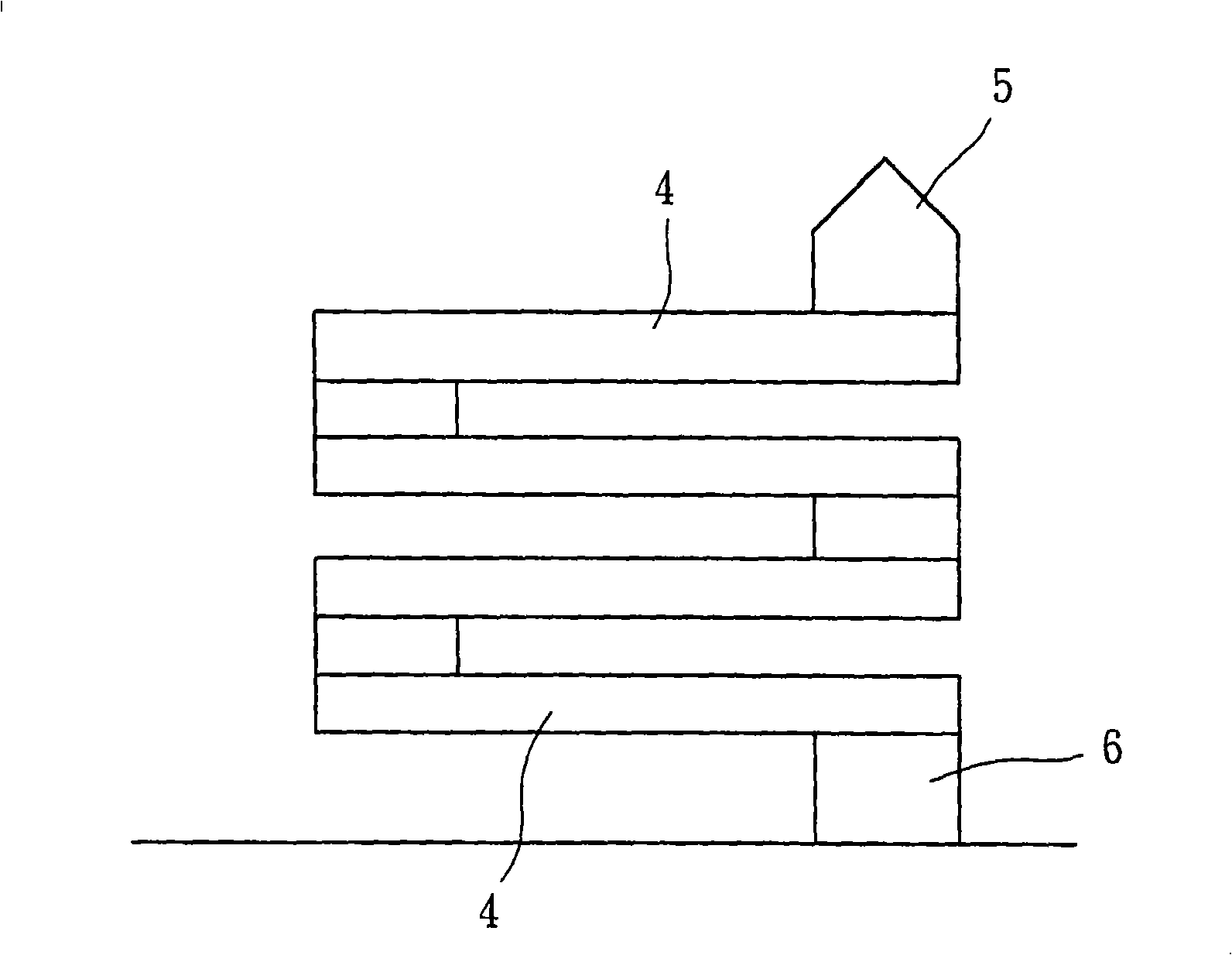

Autonomous mobile robots for picking and placing goods on shelves, and warehousing system and method

The invention discloses autonomous mobile robots for picking and placing goods on shelves, and a warehousing system and method. The autonomous mobile robots each comprise a moving base plate and a support body. The support bodies can rise and fall relative to the moving base plates and can stretch out of the moving base plates bi-directionally and horizontally, and the stretching-out directions ofthe support bodies are perpendicular to the linear motion directions of the moving bases. The autonomous mobile robots can walk in passages between shelf arrays for goods picking and placing. The autonomous mobile robots for picking and placing the goods on the shelves, and the warehousing system and method are suitable for carrying large materials, the autonomous mobile robots are low in manufacturing cost and compact in structure; the goods picking and placing directions of the support bodies of the autonomous mobile robots are perpendicular to the linear motion directions of the autonomousmobile robots, therefore, the robots do not need to frequently change the postures in the passages between the shelves, and the operation efficiency is improved; and the robots are compact in structure, therefore, the placing density of the goods in a warehouse can be increased, and the storage efficiency of the warehouse is improved.

Owner:SUZHOU MUSHINY INTELLIGENCE TECH CO LTD

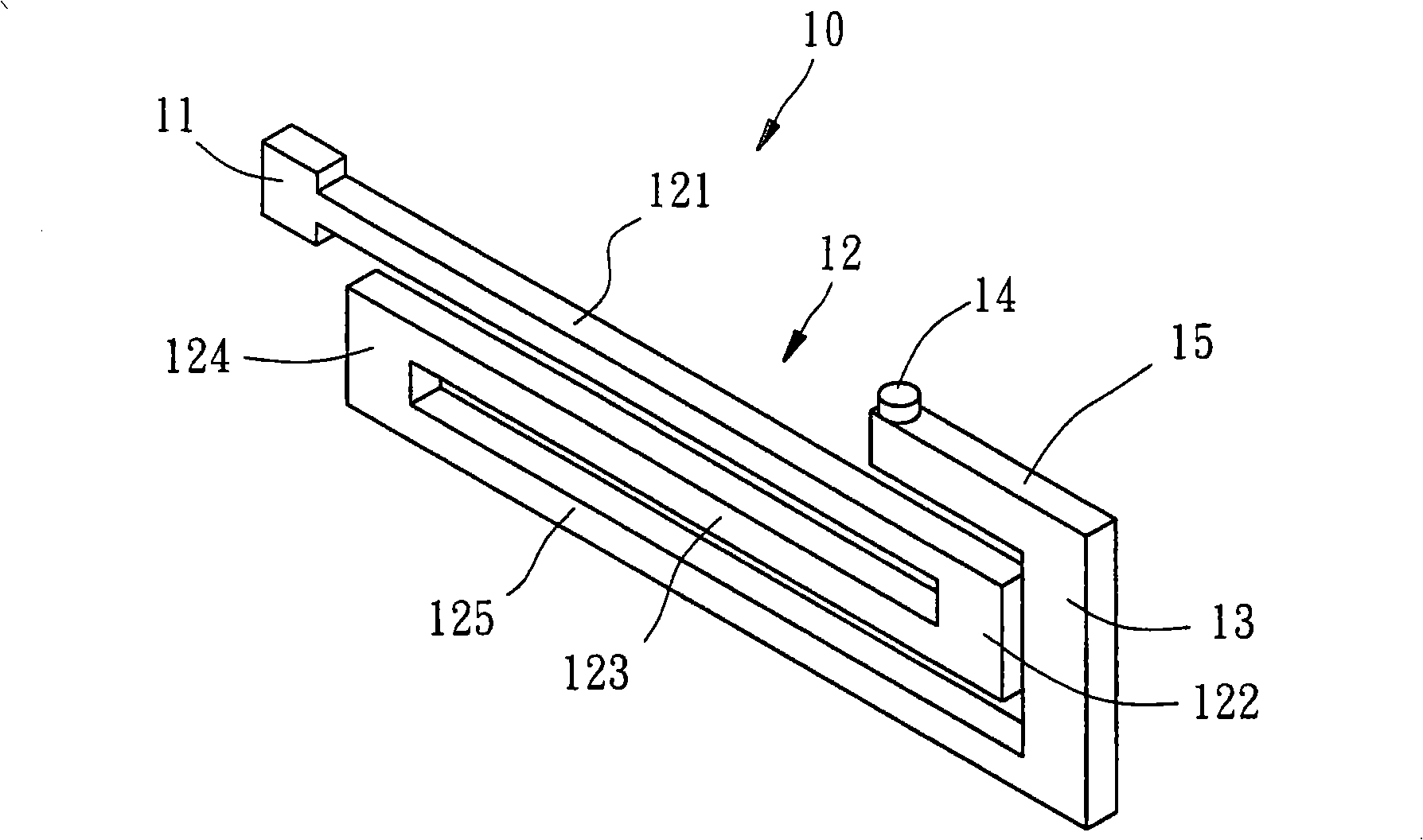

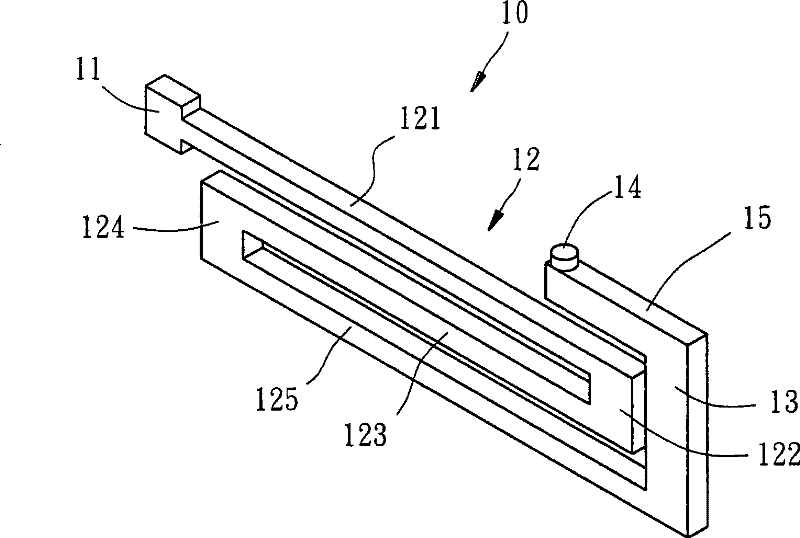

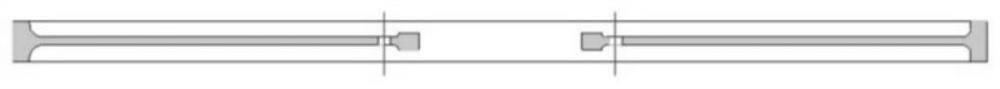

Stretching type folding probe

InactiveCN101315391AReduce maximum stressLarge elastic deformation rangeElectrical measurement instrument detailsElectrical testingHigh densityEngineering

The invention relates to a tensile foldable probe, which comprises a fixing part, a foldable part, and a probe point part. The foldable part is provided with a plurality of horizontal sections and a plurality of vertical sections which extend from one side of the fixing part to be in continuously reversed bent connection; the probe point part which is formed by vertically extending at the predetermined distance to the fixing part through the free ends of the horizontal sections at the end of the foldable part, and the probe point part and fixing part are positioned on different axial lines; when the probe point part is contacted with an object to be tested, the foldable part is driven to be stretched, stretching elastic force is provided to allow the probe point and the object to be tested to maintain the electrical contact; the stress can be dispersed by each horizontal section, so as to increase the elastic deformation amount; meanwhile, the tensile foldable probe has better structural stability, so as to meet the requirement of high density probe distribution of micro probe point distance.

Owner:MICROELECTRONICS TECH INC

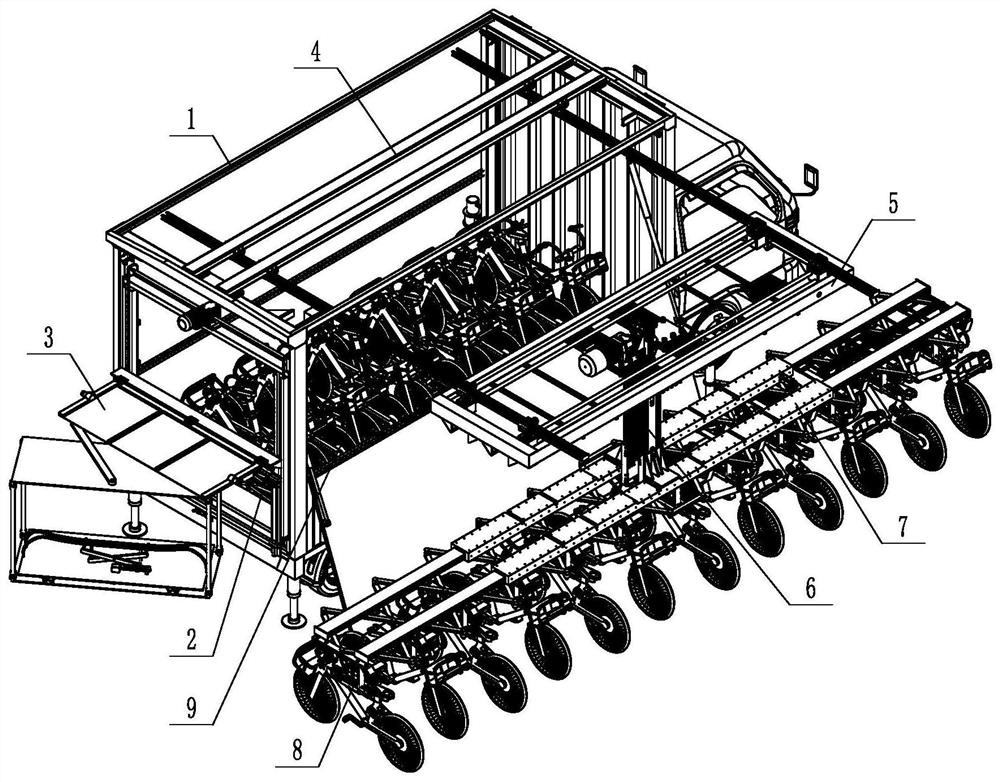

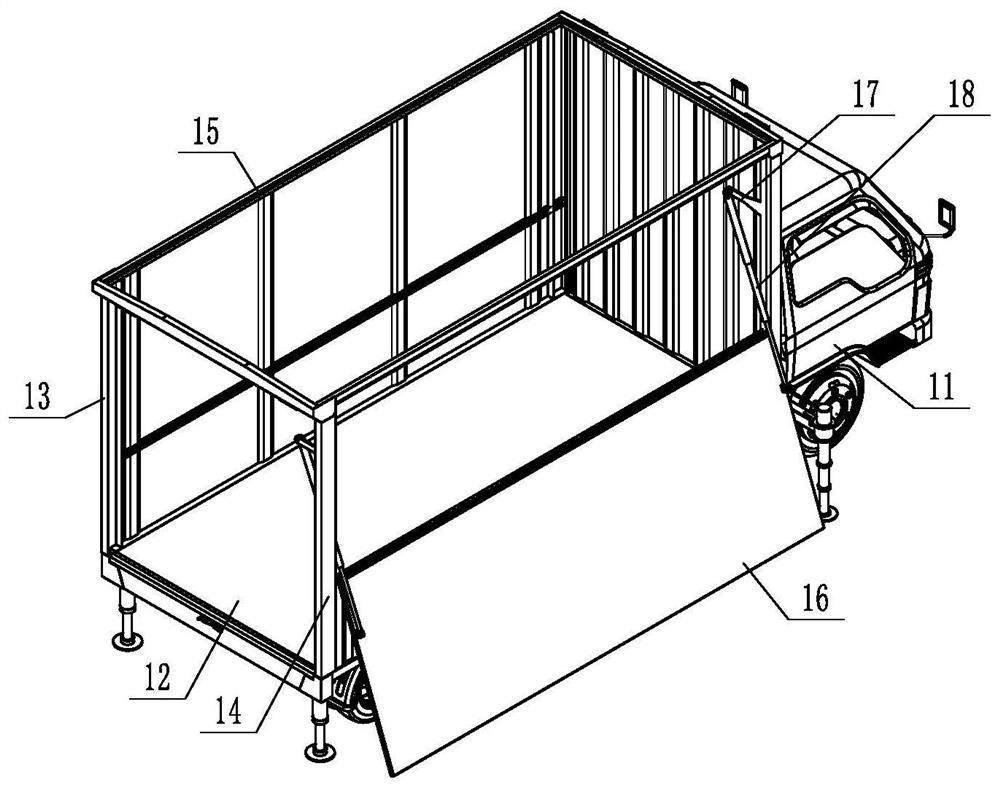

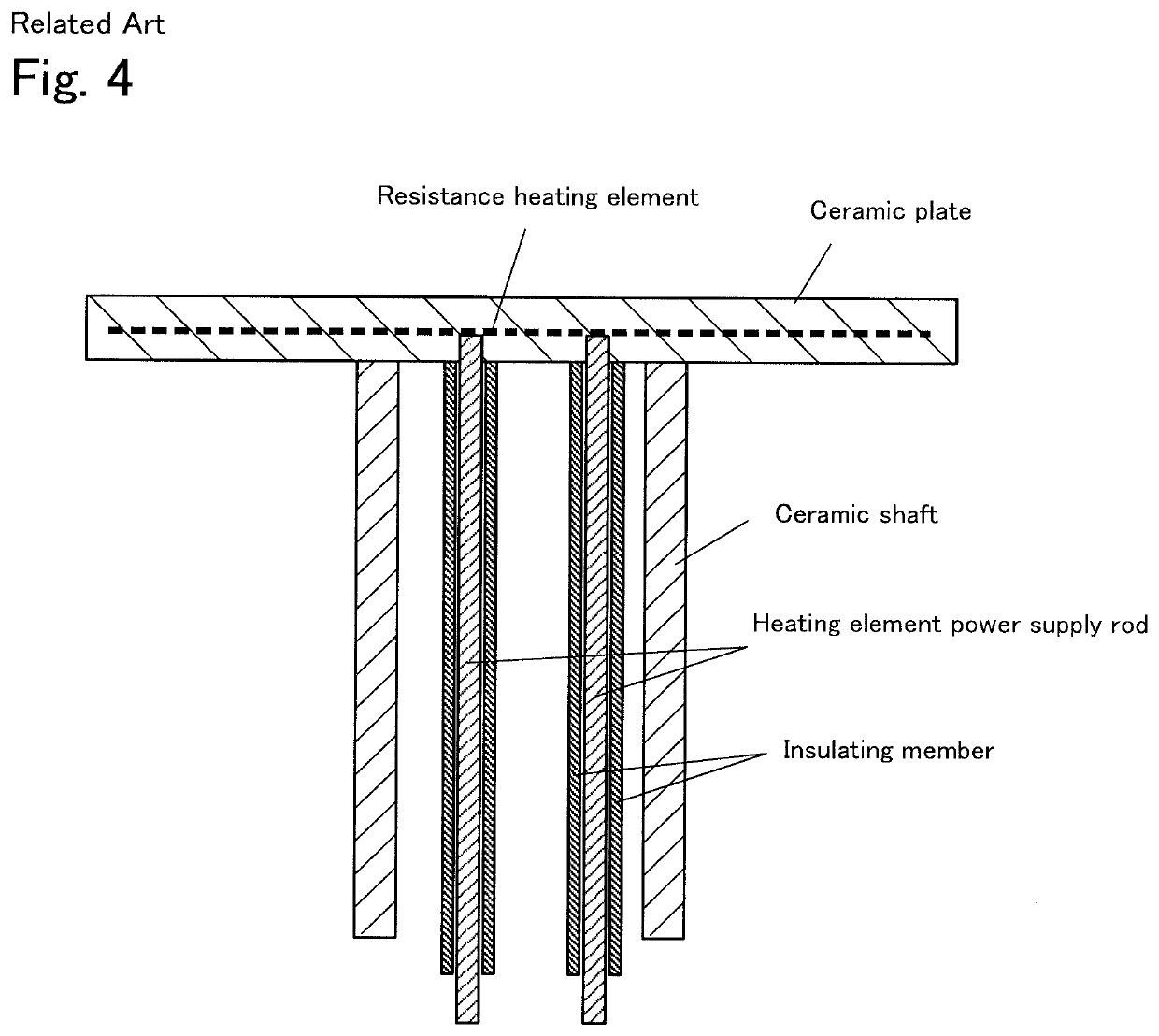

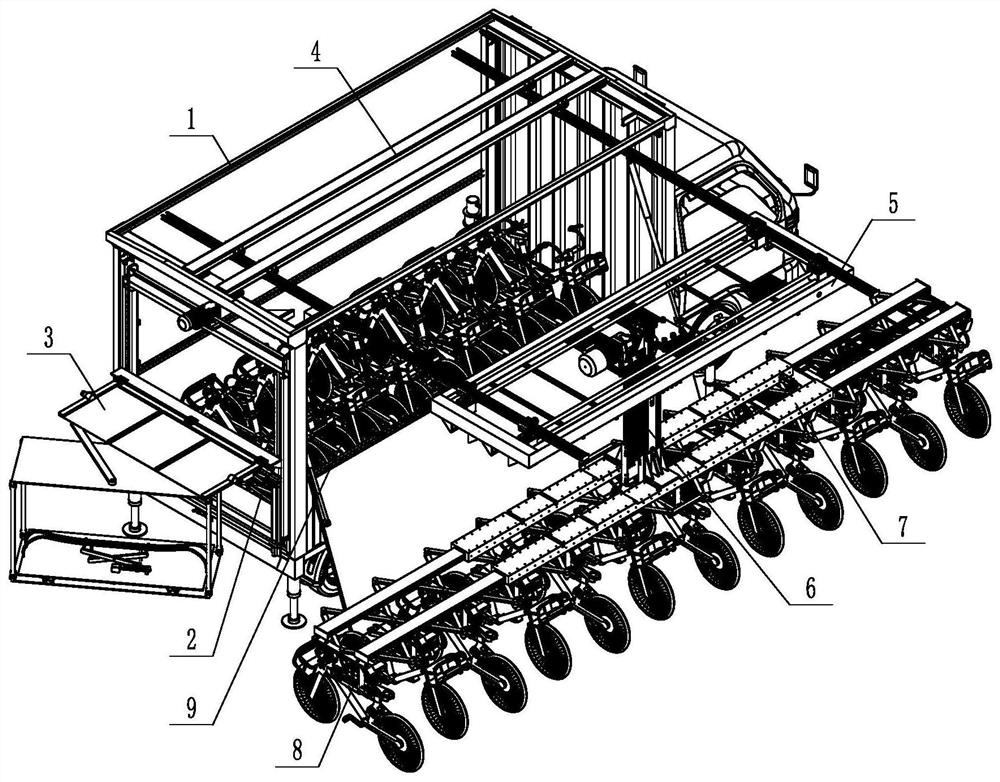

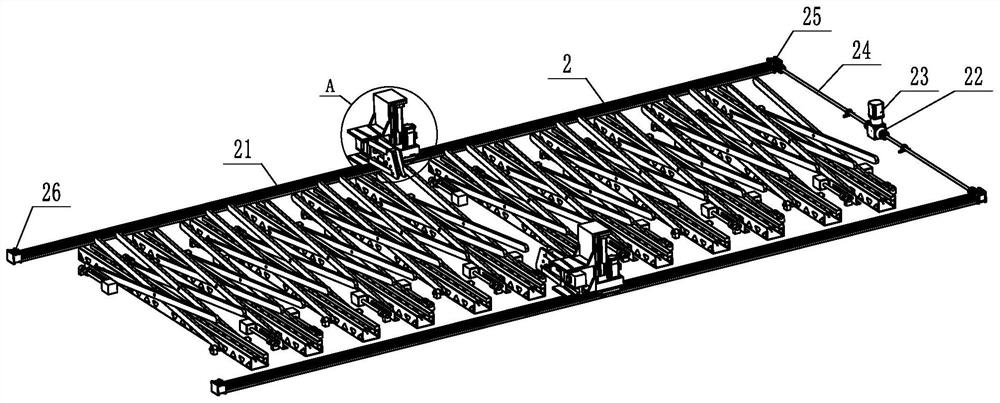

Shared bicycle transport vehicle based on van

ActiveCN112874422AEnable mobilityAchieve positioningLoading/unloading vehicle arrangmentItem transportation vehiclesRobot handEngineering

A shared bicycle transport vehicle based on a van relates to the field of automation equipment and comprises a carriage, the carriage comprises a carriage bottom plate, guide rail type bicycle clamping and placing devices are arranged at the two sides of the carriage bottom plate, a scissors fork type bicycle fixing device is arranged between the guide rail type bicycle clamping and placing devices, a foldable bicycle lifting and overturning device is arranged at the tail of the carriage, and a truss type multidirectional telescopic manipulator is arranged at the top of the carriage. Automatic grabbing and carrying of the shared bicycles can be achieved, labor is saved, and efficiency is improved. The bicycle lifting and overturning device achieves staggered placement of the shared bicycles in the mode that the heads face the tails of the shared bicycles, the guide rail type bicycle clamping and placing devices achieve horizontal movement and positioning placement of the shared bicycles in a compartment, and the multi-direction telescopic truss type mechanical arm achieves rapid unloading of the shared bicycles.

Owner:郑华康

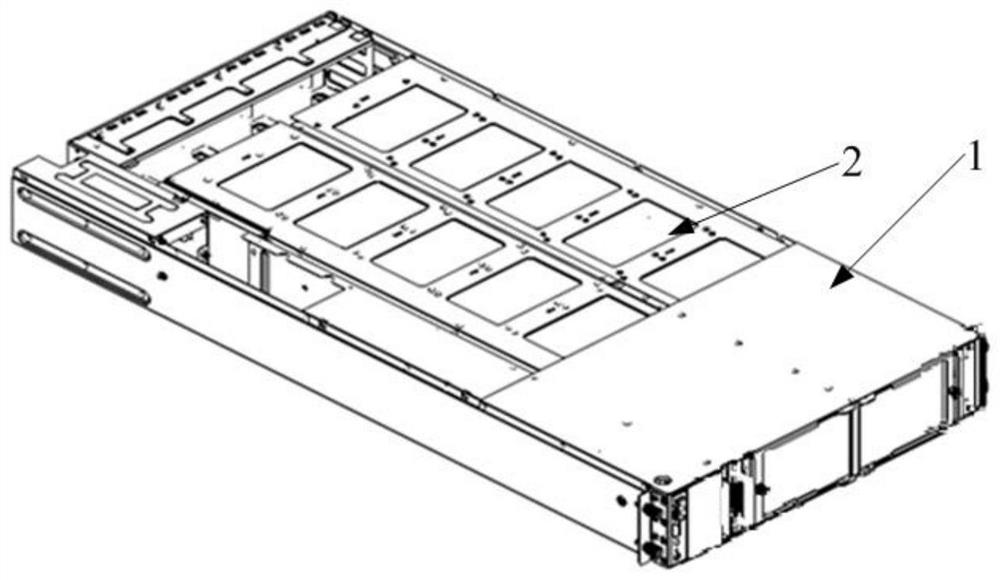

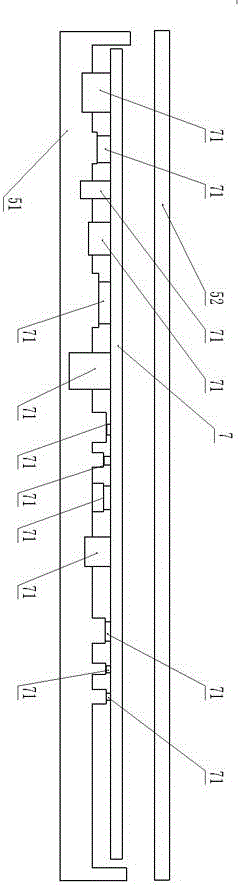

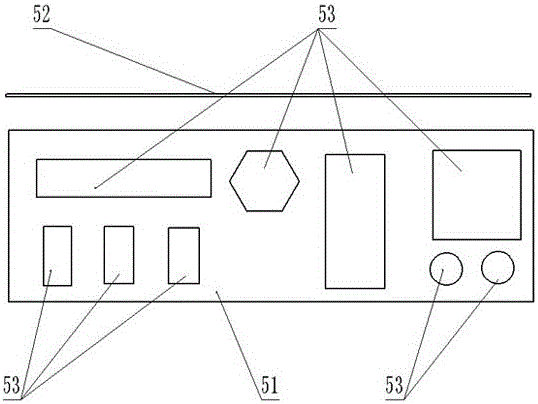

Server

PendingCN112969334AAchieve exposureRealize pluggingServersData center roomsComputer hardwareEngineering

The invention discloses a server. The server comprises a case capable of being installed on a cabinet, wherein a plurality of hard disk slots in which hard disks can be inserted and pulled are formed in the case; at least part of the case can be pulled relative to the mounting groove of the cabinet so as to expose the hard disk slots; and the hard disk slots are arranged in two rows in the drawing direction, the directions of notches of the two rows of hard disk slots are opposite, each row of hard disk slots are arranged in a matrix mode in the drawing direction, and the plugging direction of the hard disk slots is perpendicular to the thickness direction and the drawing direction of the case at the same time. According to the server, the two rows of disk slots are arranged in parallel on the case, and the whole case can be drawn relative to the mounting slot of the cabinet, or the part of the case provided with the disk slots can be drawn relative to other parts of the case, so that the disk slots are exposed, and the hard disks can be inserted into and pulled out of the disk slots; and due to the fact that the hard disk slots in each row are arranged in the drawing direction in the matrix arrangement mode, the hard disk slots can be arranged in the drawing direction as many as possible, and the placing density of the hard disks is improved.

Owner:联想(北京)信息技术有限公司

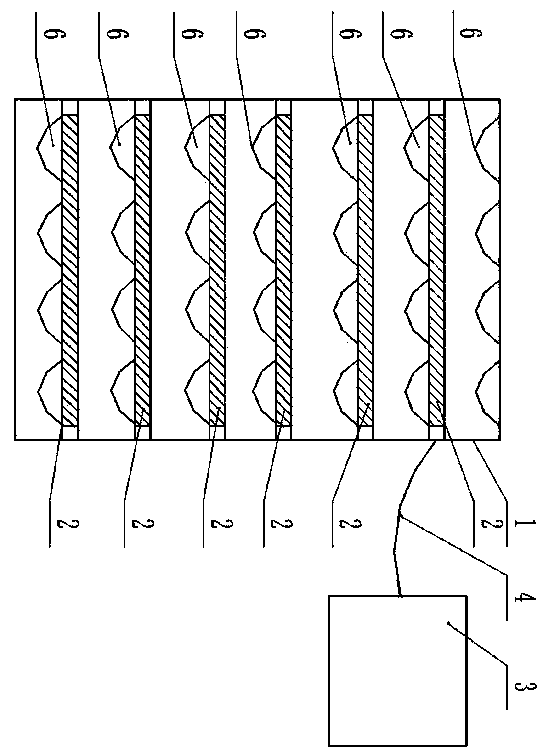

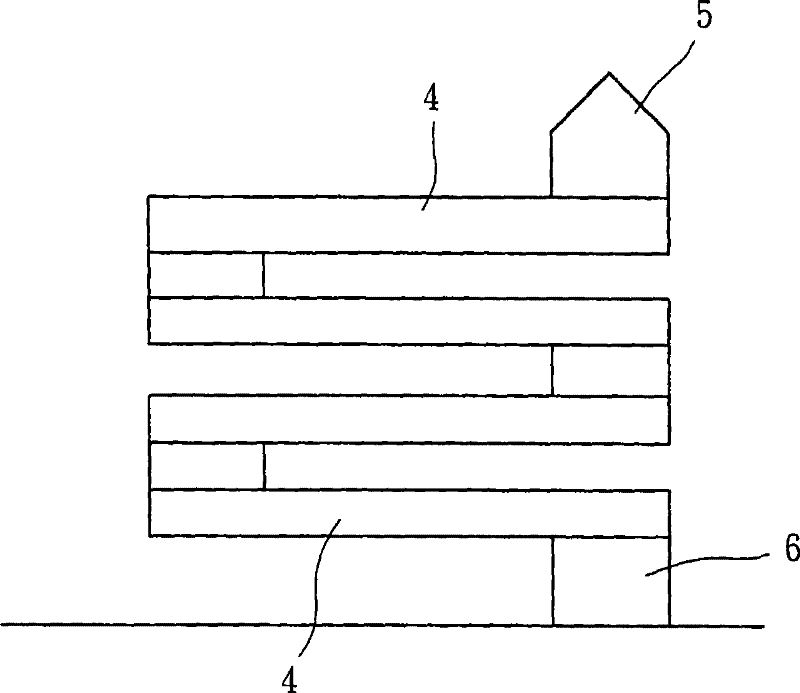

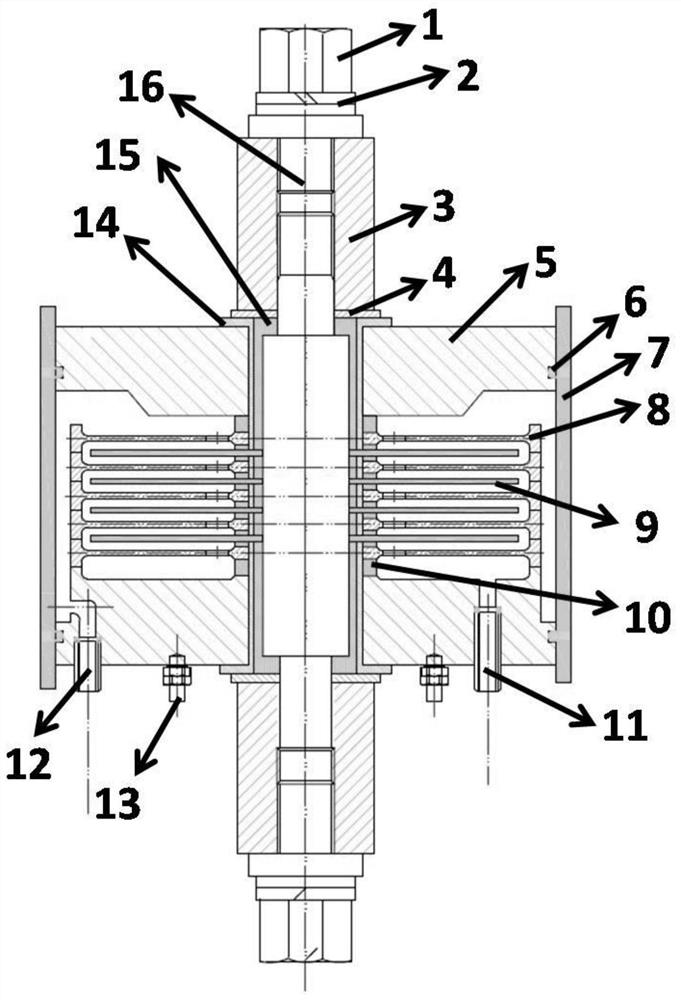

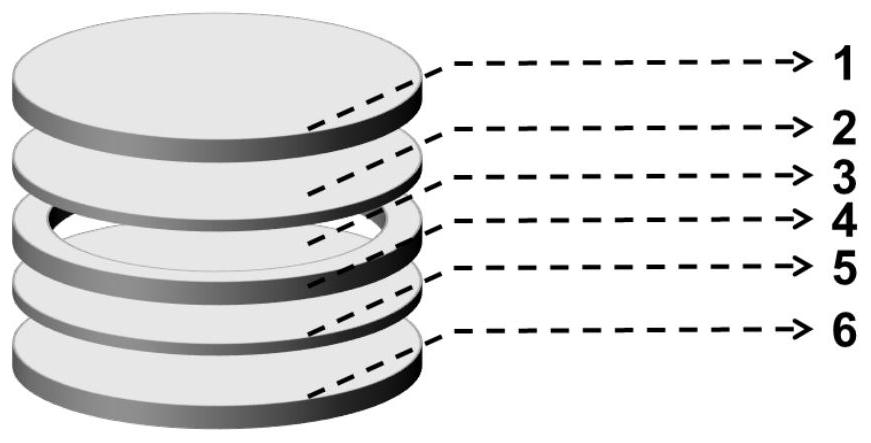

Ultrahigh-pressure sodium hypochlorite generator and preparation method of sodium chlorate

PendingCN112281179AReduce layout spacingIncrease mass transfer efficiency and reaction pathwaysCellsElectrode shape/formsUltra high pressureSodium hypochlorite

Disclosed are an ultrahigh-pressure sodium hypochlorite generator and a preparation method of sodium chlorate. The ultrahigh-pressure sodium hypochlorite generator comprises a shell with a water inletand a water outlet, a plurality of cathode pressing plates and a plurality of anode plates which are sequentially stacked at intervals are arranged in the shell, and the cathode pressing plates and the anode plates are provided with center holes. A center shaft penetrates through the center holes to position and press the cathode pressing plates and the anode plates to form a disc type structureand block the cathode pressing plates and the anode plates at the positions of the center holes. Strong brine enters from the water inlet, sequentially flows back between the cathode pressing plates and the anode plates to form a passage and flows out from the water outlet. The reaction mass transfer efficiency and the reaction path are increased by utilizing the disc type design, and the reactionefficiency of sodium hypochlorite production is improved; the electrodes adopt a cathode and anode staggered lamination mode, so that the reaction efficiency is enhanced; and the reactor shell and the internal electrodes adopt a high-pressure sealing mode, so that the dissolution rate of chlorine can be effectively improved, and chlorine leakage is avoided. The method has good sodium hypochloriteproduction capacity, and can significantly improve the concentration of sodium hypochlorite in water.

Owner:SHAANXI UNIV OF SCI & TECH

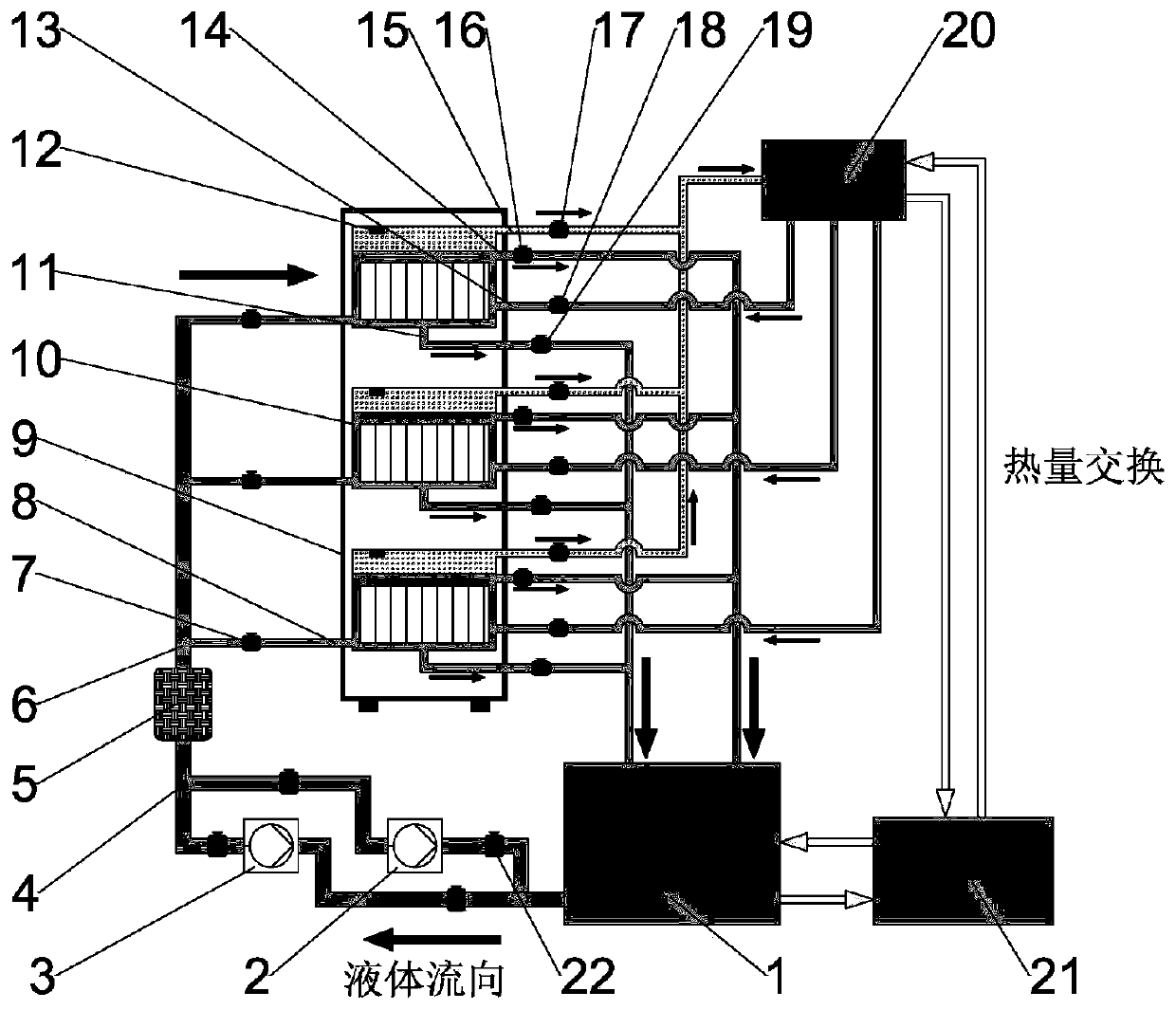

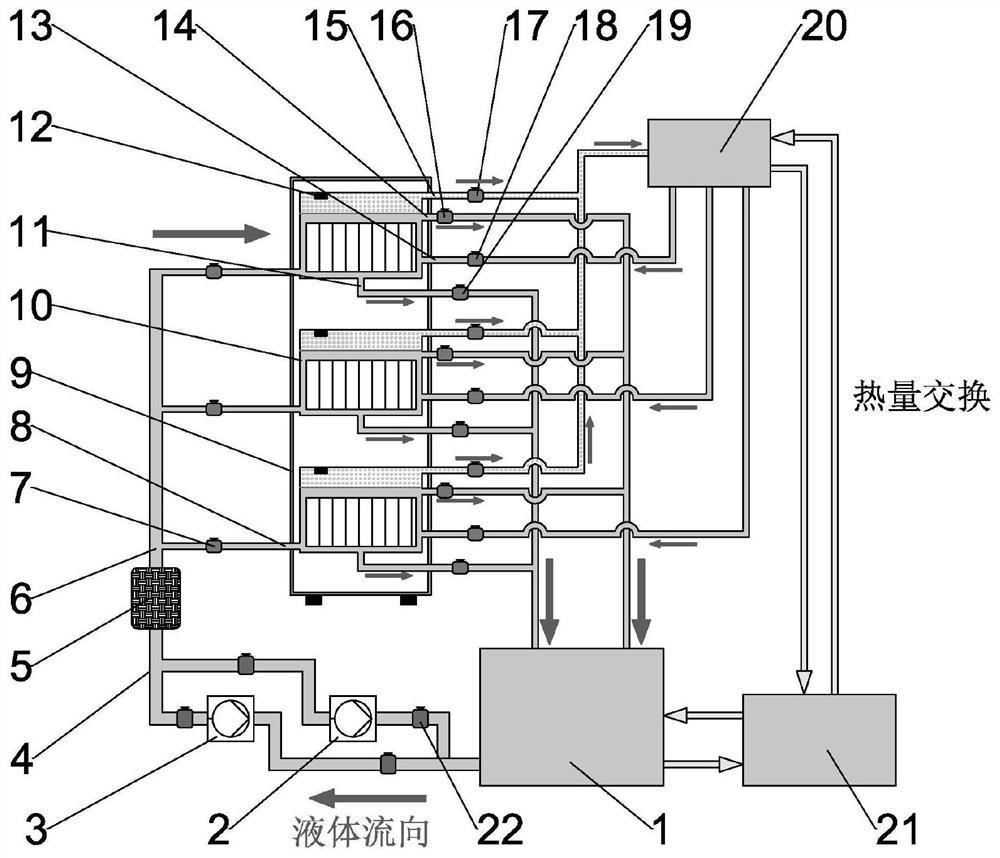

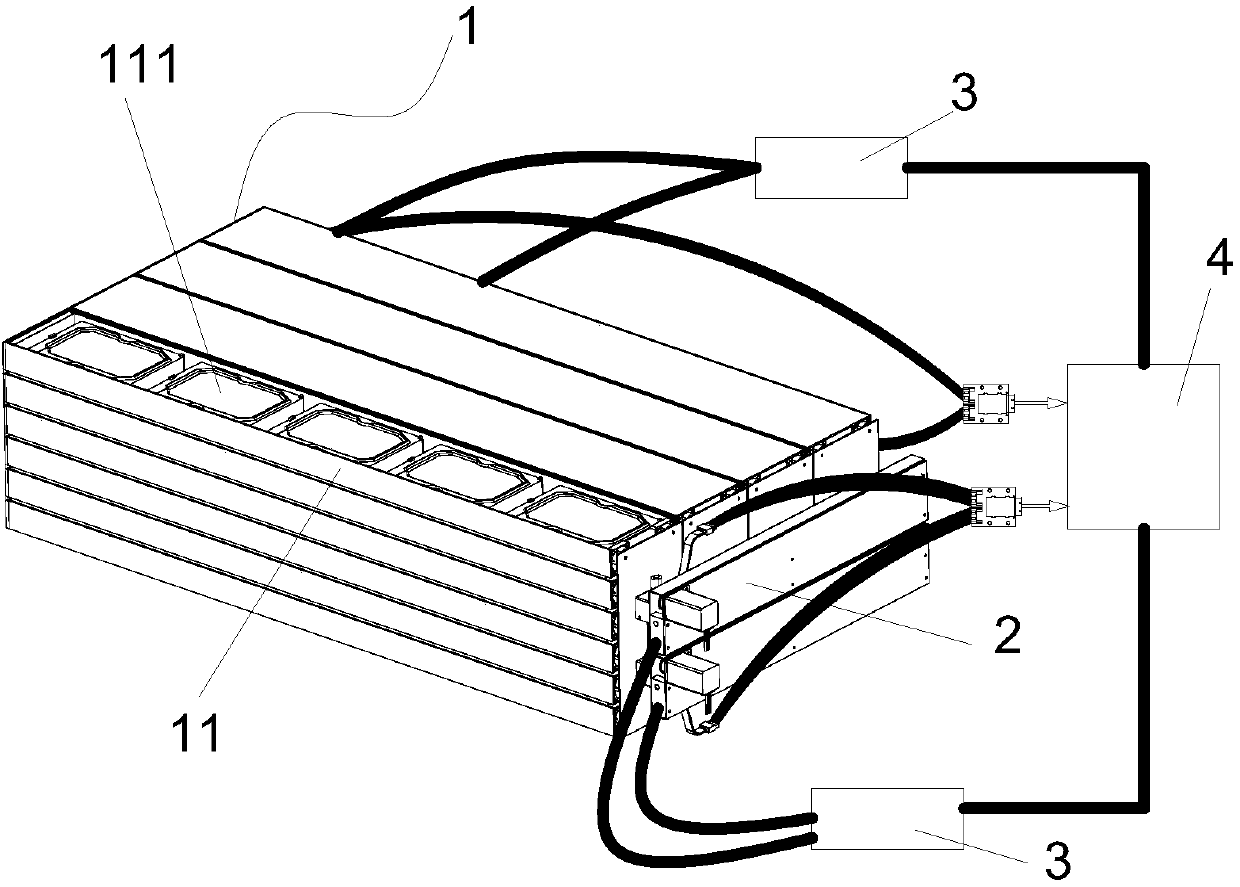

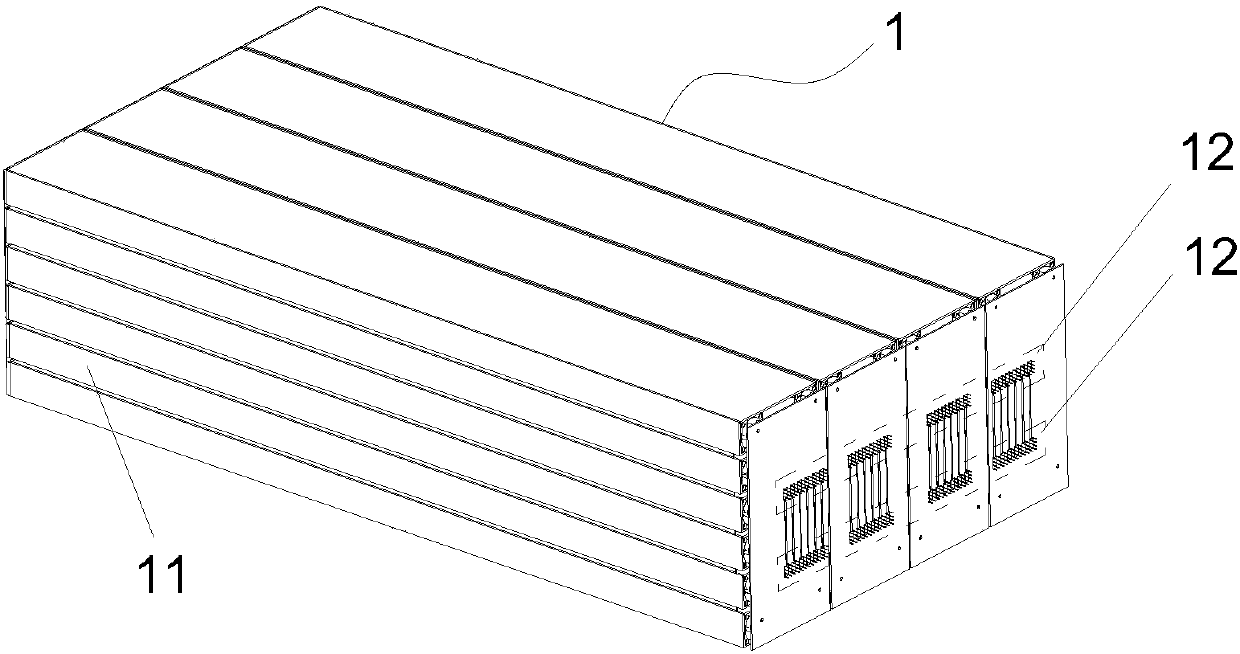

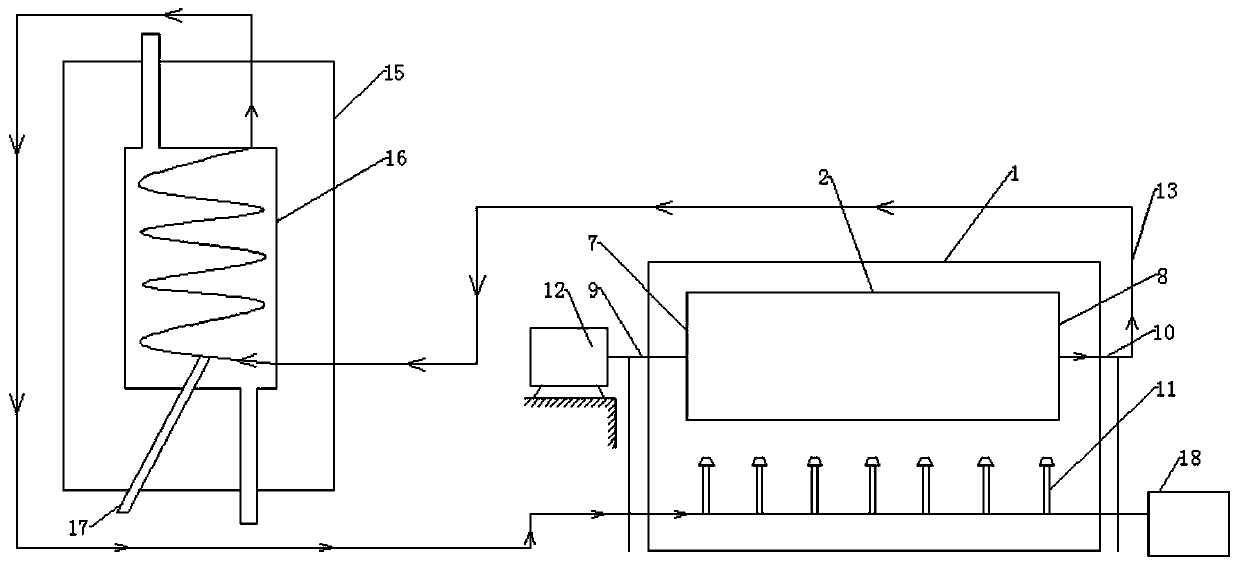

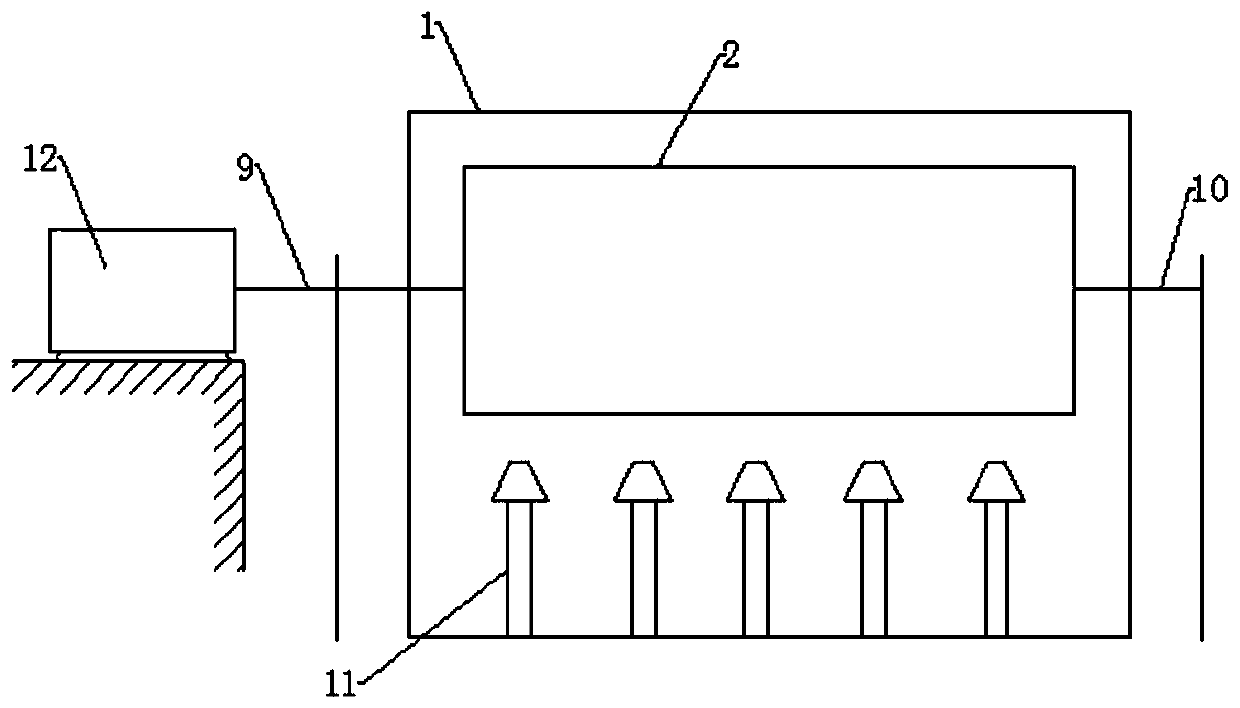

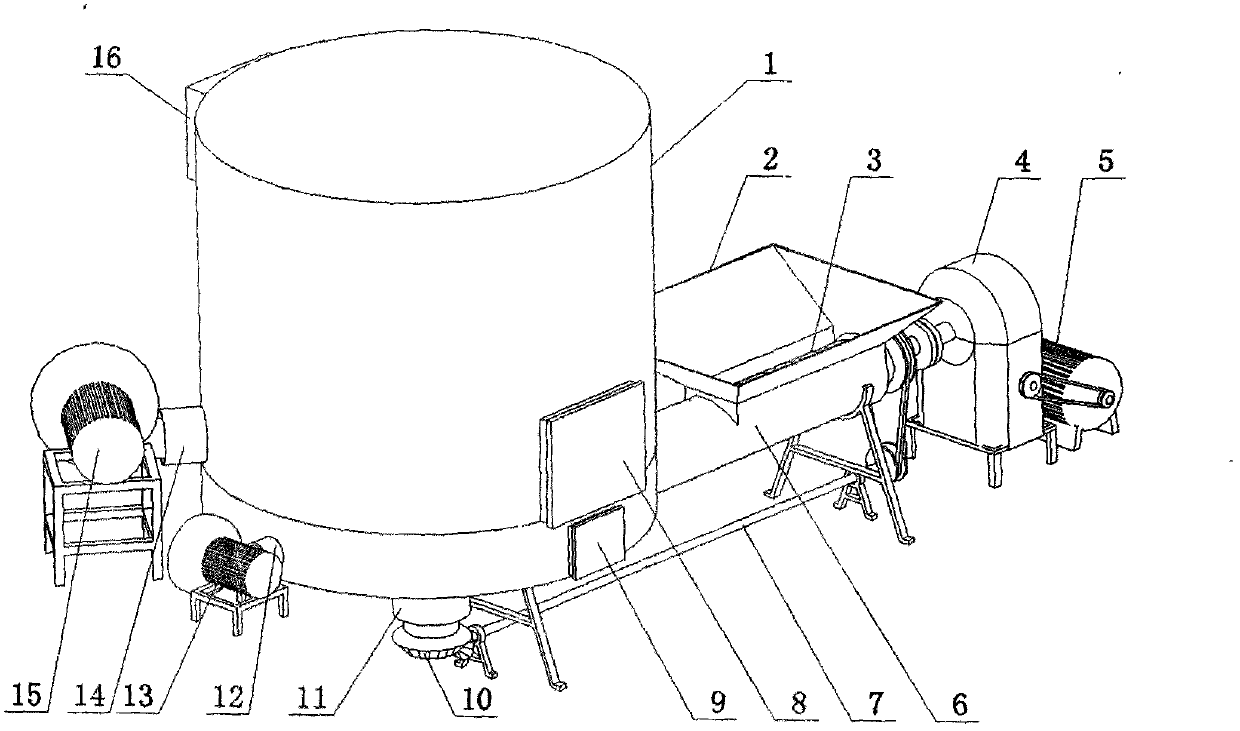

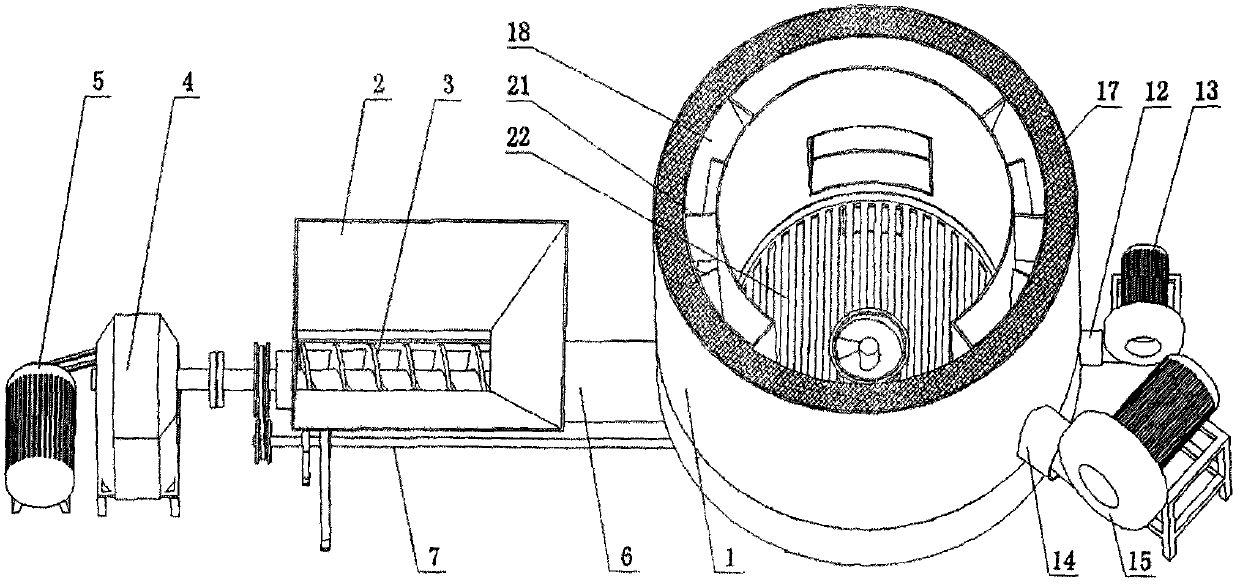

Fountain type double-circulation supercomputer cooling system

ActiveCN110366359AImprove stabilityIncrease usageCooling/ventilation/heating modificationsLow noiseSupercomputer

The invention relates to a fountain type double-circulation supercomputer cooling system, which comprises a subcooler, a circulating pump, a blade case, a condenser, a secondary cooling system, a pipeline and a valve, and is characterized in that an evaporative cooling medium is stored in the subcooler, the blade case and the connected pipeline. The cooling system is divided into two communicatedcycles. The steam in the blade case rises to the condenser through a collecting pipe and a collecting valve and is condensed into a liquid, and the liquid flows into the blade case via a liquid returnpipe to realize self circulation of the steam; and the high-temperature medium in the blade case enters the subcooler via an overflow pipe and then flows into the blade case via a liquid inlet pipe after being cooled so as to realize the controllable circulation of the evaporative cooling medium. The cooling system carries out heat exchange by medium phase change and forced convection, and well solves the problem of difficult heat dissipation of equipment. The cooling system is energy-saving and environment-friendly, has no electromagnetic radiation, no dust pollution and low noise to the outside. In addition, the cooling system is low in operation cost and high in heat dissipation efficiency, and can improve the equipment placement density and improve the utilization rate of a computer room.

Owner:TIANJIN SHENWEI SCI & TECH CO LTD

A data center server cooling cabinet

ActiveCN103838337BContact heat transferExtended service lifePower supply for data processingSoftware engineeringFixed service

The invention discloses a data center server cooling cabinet, which comprises a server cabinet, a phase change heat transfer system, a server case and a spring leaf for fixing the server case; the phase change heat transfer system includes multiple a heat exchanger, an outdoor cooling device, and connecting pipelines; the plurality of heat exchangers are respectively installed on each layer of support for placing servers in the server cabinet; the server casing is placed on the plurality of The upper part of the heat exchanger; the server is sealed inside the server cabinet; the entire data center server cooling cabinet has no air cooling, the server heating unit is in direct contact with the server cabinet, and the server cabinet is in contact with a plurality of servers installed in the server cabinet. The heat exchanger is in direct contact to achieve contact heat transfer and improve heat transfer efficiency; the data center server cooling cabinet of the present invention can increase the server placement density, low construction cost, short construction period, and the operating cost of the entire data center is also very high Reduced.

Owner:BEIJING FULLLINK OREITH TECH CO LTD

A spring-type dual-circulation supercomputer cooling system

ActiveCN110366359BImprove stabilityIncrease usageCooling/ventilation/heating modificationsSupercomputerThermodynamics

The invention relates to a fountain type double-circulation supercomputer cooling system, which comprises a subcooler, a circulating pump, a blade case, a condenser, a secondary cooling system, a pipeline and a valve, and is characterized in that an evaporative cooling medium is stored in the subcooler, the blade case and the connected pipeline. The cooling system is divided into two communicatedcycles. The steam in the blade case rises to the condenser through a collecting pipe and a collecting valve and is condensed into a liquid, and the liquid flows into the blade case via a liquid returnpipe to realize self circulation of the steam; and the high-temperature medium in the blade case enters the subcooler via an overflow pipe and then flows into the blade case via a liquid inlet pipe after being cooled so as to realize the controllable circulation of the evaporative cooling medium. The cooling system carries out heat exchange by medium phase change and forced convection, and well solves the problem of difficult heat dissipation of equipment. The cooling system is energy-saving and environment-friendly, has no electromagnetic radiation, no dust pollution and low noise to the outside. In addition, the cooling system is low in operation cost and high in heat dissipation efficiency, and can improve the equipment placement density and improve the utilization rate of a computer room.

Owner:TIANJIN SHENWEI SCI & TECH CO LTD

Stretching type folding probe

InactiveCN101315391BReduce maximum stressLarge elastic deformation rangeElectrical measurement instrument detailsElectrical testingHigh densityEngineering

The invention relates to a tensile foldable probe, which comprises a fixing part, a foldable part, and a probe point part. The foldable part is provided with a plurality of horizontal sections and a plurality of vertical sections which extend from one side of the fixing part to be in continuously reversed bent connection; the probe point part which is formed by vertically extending at the predetermined distance to the fixing part through the free ends of the horizontal sections at the end of the foldable part, and the probe point part and fixing part are positioned on different axial lines; when the probe point part is contacted with an object to be tested, the foldable part is driven to be stretched, stretching elastic force is provided to allow the probe point and the object to be tested to maintain the electrical contact; the stress can be dispersed by each horizontal section, so as to increase the elastic deformation amount; meanwhile, the tensile foldable probe has better structural stability, so as to meet the requirement of high density probe distribution of micro probe point distance.

Owner:MPI CORP

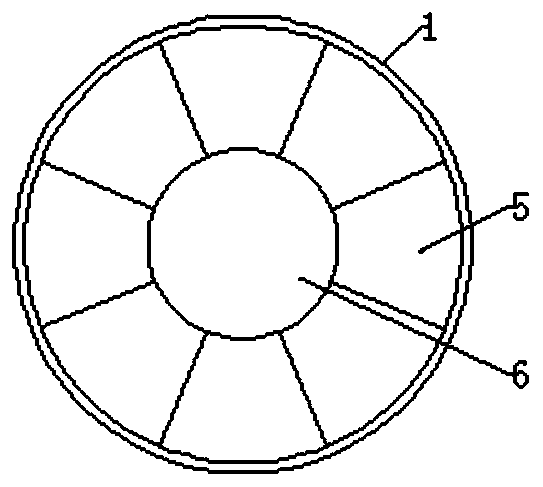

A disc-type electrocatalytic water treatment device

ActiveCN109279685BIncreased loading areaReduce layout spacingWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment apparatusElectrode placementAmmoniacal nitrogen

A dish-type electrocatalytic water treatment device, comprising a shell with a water inlet and a water outlet, the shell is provided with a plurality of cathode pressure plates and anode plates stacked at intervals in sequence, and both the cathode pressure plate and the anode plate have a central hole , the central axis passes through the central hole to position and compress the cathode plate and the anode plate to form a disc structure and block the two at the position of the center hole. The waste water to be treated enters from the water inlet and is sequentially between the cathode plate and the anode plate. The reentrant flow forms a pathway and exits the outlet. The present invention utilizes the disc design to increase reaction mass transfer efficiency and reaction path, and improve the reaction efficiency of electrocatalytic oxidation; the electrocatalytic electrode adopts a cathode and anode staggered lamination method, which increases the electrode placement density, thereby enhancing the reaction efficiency. The results of the treatment of salt-containing industrial wastewater show that the method has good electrocatalytic oxidation ability, can significantly improve the removal efficiency of chroma, ammonia nitrogen and COD in high-salt wastewater, and make the effluent meet the first-class standard of comprehensive sewage discharge.

Owner:陕西镐丰京诚环境科技有限公司

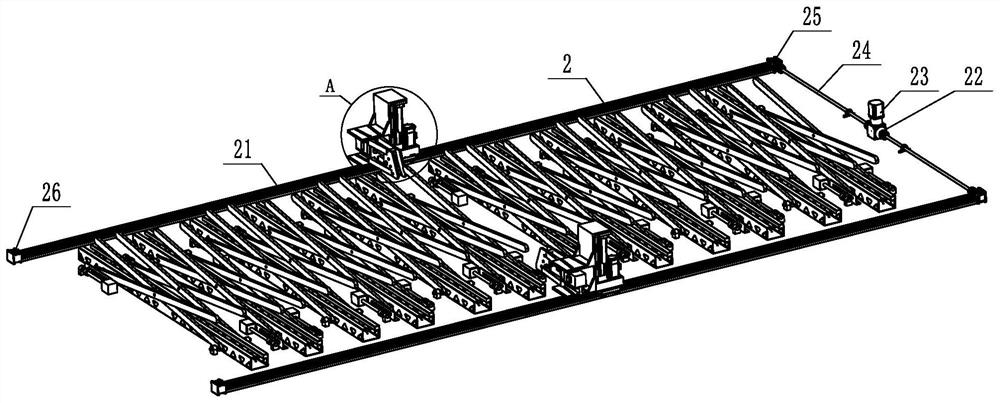

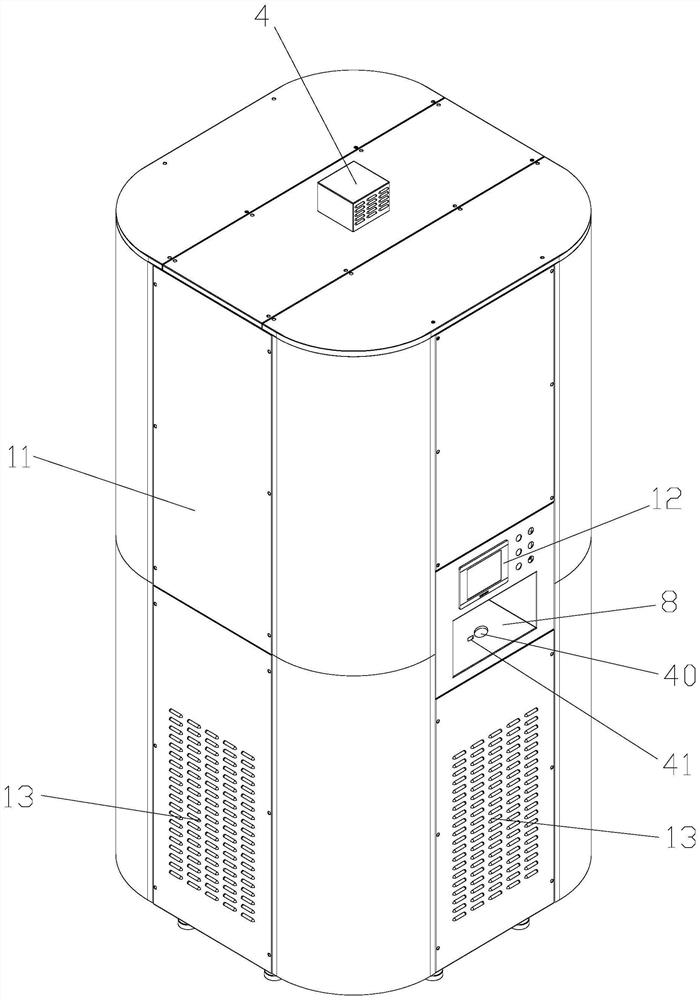

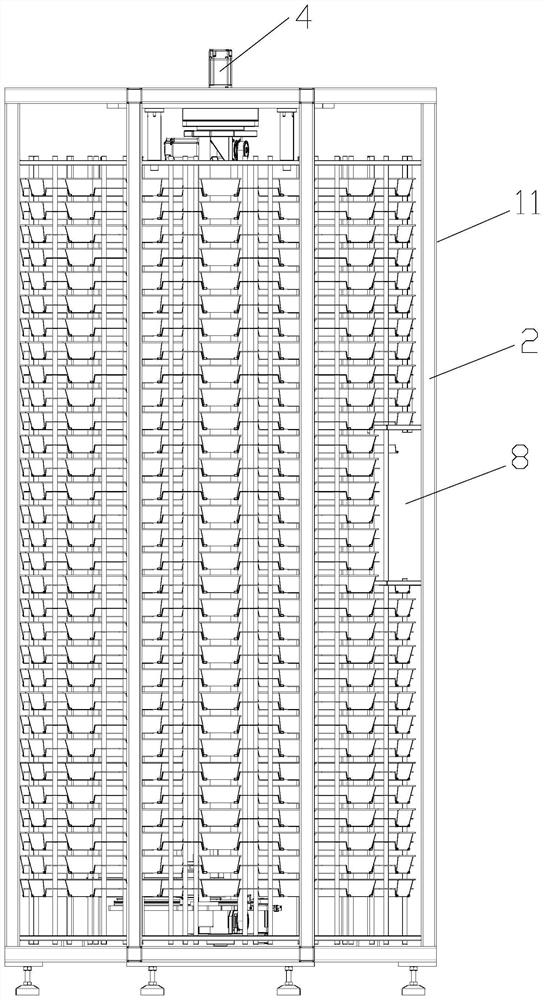

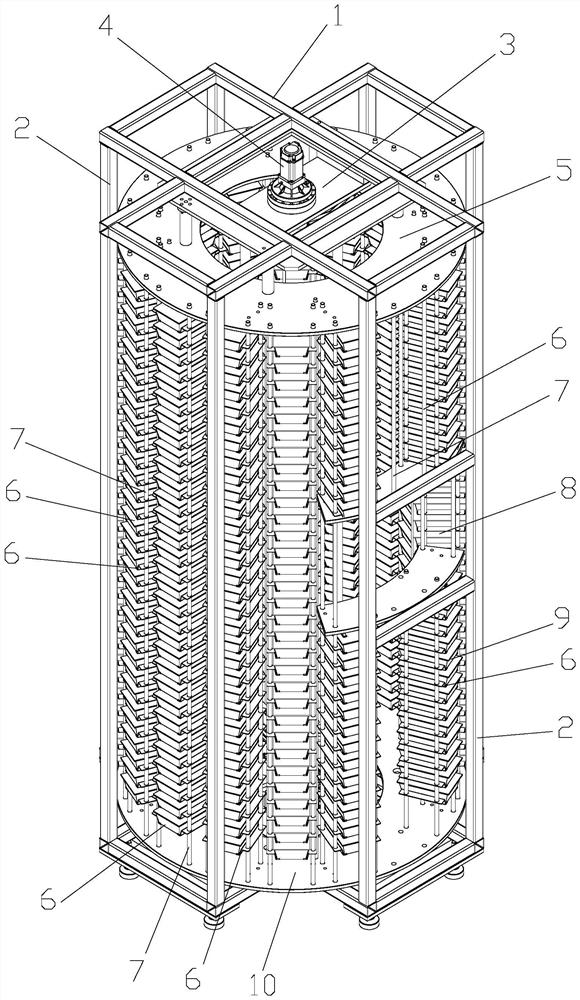

Rapid storage system for annular materials

PendingCN114313747AIncrease the placement densityMore storage boxesStorage devicesElectric machineryServo

The invention discloses an annular material rapid storage system which comprises a control unit and a rack, a frame connecting plate is arranged at the top of the rack, a first servo motor is arranged on the frame connecting plate, and an upper rotary plate is arranged below the frame connecting plate; an upper synchronous belt wheel and a second servo motor for driving the upper synchronous belt wheel to rotate are arranged on the upper rotary plate, a bottom plate mounting plate is arranged at the bottom of the rack, a rotary mounting plate is arranged between the upper rotary plate and the lower rotary plate, a clamping plate mechanism mounting plate is arranged on the rotary mounting plate, one side of the clamping plate mechanism mounting plate is fixed together with a first synchronous belt, and the other side of the clamping plate mechanism mounting plate is fixed together with a second synchronous belt. A lower supporting plate mounting seat is arranged on the clamping plate mechanism mounting plate, a lower supporting plate is mounted on the lower supporting plate mounting seat, a clamping plate mounting seat is arranged on the lower supporting plate mounting seat, an upper clamping plate is arranged on the clamping plate mounting seat, and a lead screw stepping motor is arranged on the lower supporting plate mounting seat. According to the storage system, the automation degree of storage and discharging of the material boxes can be high, the action is rapid, the efficiency is high, and the placement density of the material boxes is large.

Owner:昆山同日机器人智能科技有限公司

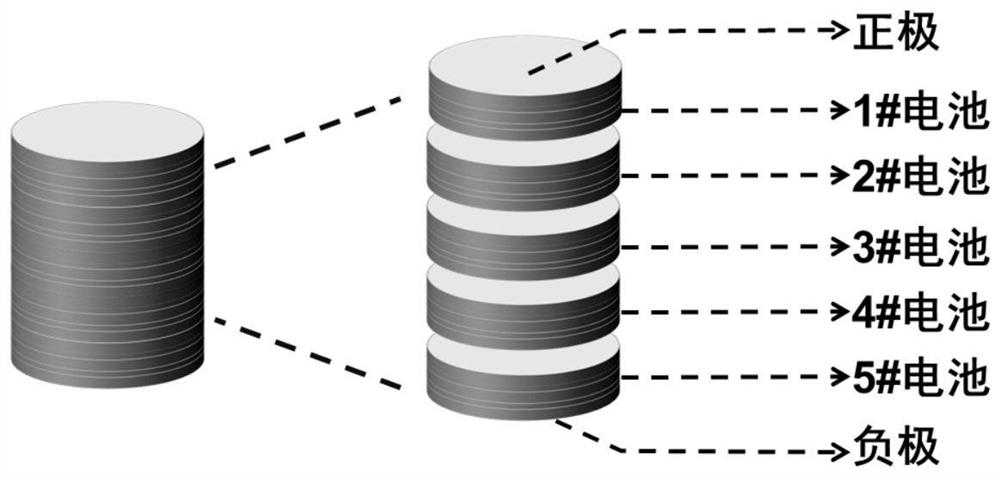

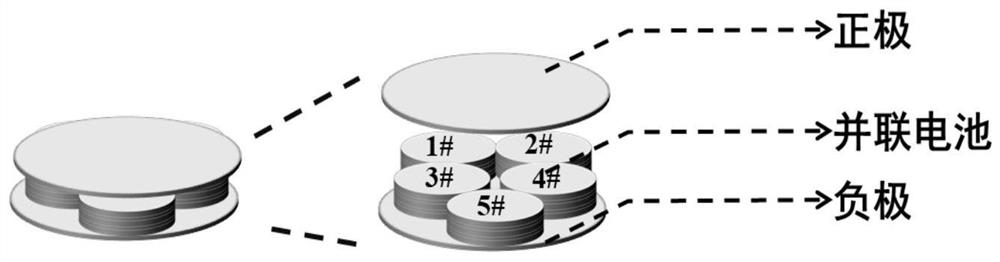

A fire-responsive temperature-controlled battery and its preparation method and application

ActiveCN112018404BPower output controlExtended service lifeDeferred-action cellsForest fire alarmsTemperature controlElectrical battery

The invention discloses a fire-responsive temperature-controlled battery, a preparation method and application thereof, and belongs to the technical field of fire monitoring. The temperature-controlled battery of the present invention includes an electrode and an electrolyte, and a phase change protection layer is arranged between the electrode and the electrolyte to isolate the contact between the electrolyte and the electrode. The temperature-controlled battery of the present invention has no electric energy output in a natural environment, but in a high-temperature environment, the phase change material changes to make the battery work and output electric energy, so that the temperature can control the power output of the battery. The temperature-controlled battery is low in cost, suitable for large-area control in a natural environment, and can effectively increase the placement density of fire monitoring nodes.

Owner:RENMIN UNIVERSITY OF CHINA

A double-layer heating furnace based on the principle of low-temperature long-distance running

The invention relates to the field of thermoplastic forming, in particular to a double-layer heating furnace based on the low-temperature long-distance race principle. The double-layer heating furnace comprises heating rods, heating plates, a feeding belt, a face overturning device and a furnace body. Each heating rod comprises a heating body and walking wheels, wherein a heating unit is arranged in the heating body, and the walking wheels are arranged at the two ends of the heating body. The face overturning device comprises a driving drive plate, a sheave, a cross shaft, a buckle, a spiral rod, a motor and a supporting plate with strip-shaped through holes. The cross shaft penetrates the through holes in the corresponding positions on the two sides. The sheave is fixed to the cross shaft. The driving drive plate is arranged above the sheave. One end of the spiral rod is connected with an output shaft of the motor. The cross shaft is clamped through one end of the buckle, and the other end of the buckle is arranged outside the spiral rod in a sleeving manner. According to the double-layer heating furnace, the low-temperature long-distance race design thought is adopted, the length of the heating plates is increased, plastic plates can be preheated in advance, and the plastic plates can be softened at the low temperature; and the overturning design is adopted for the top heating rods, top heat accumulation is avoided, and the heat utilization efficiency is higher.

Owner:ANQING LIXIANG IND & TRADE

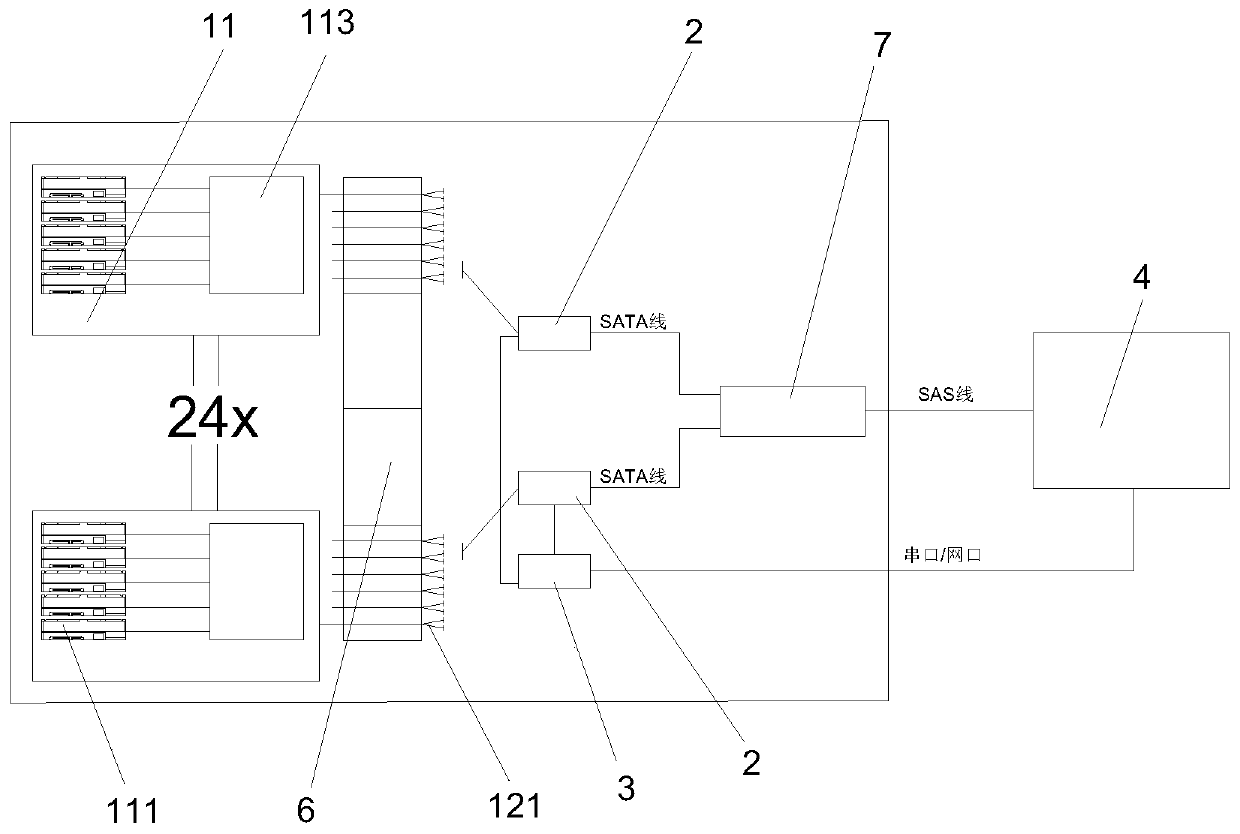

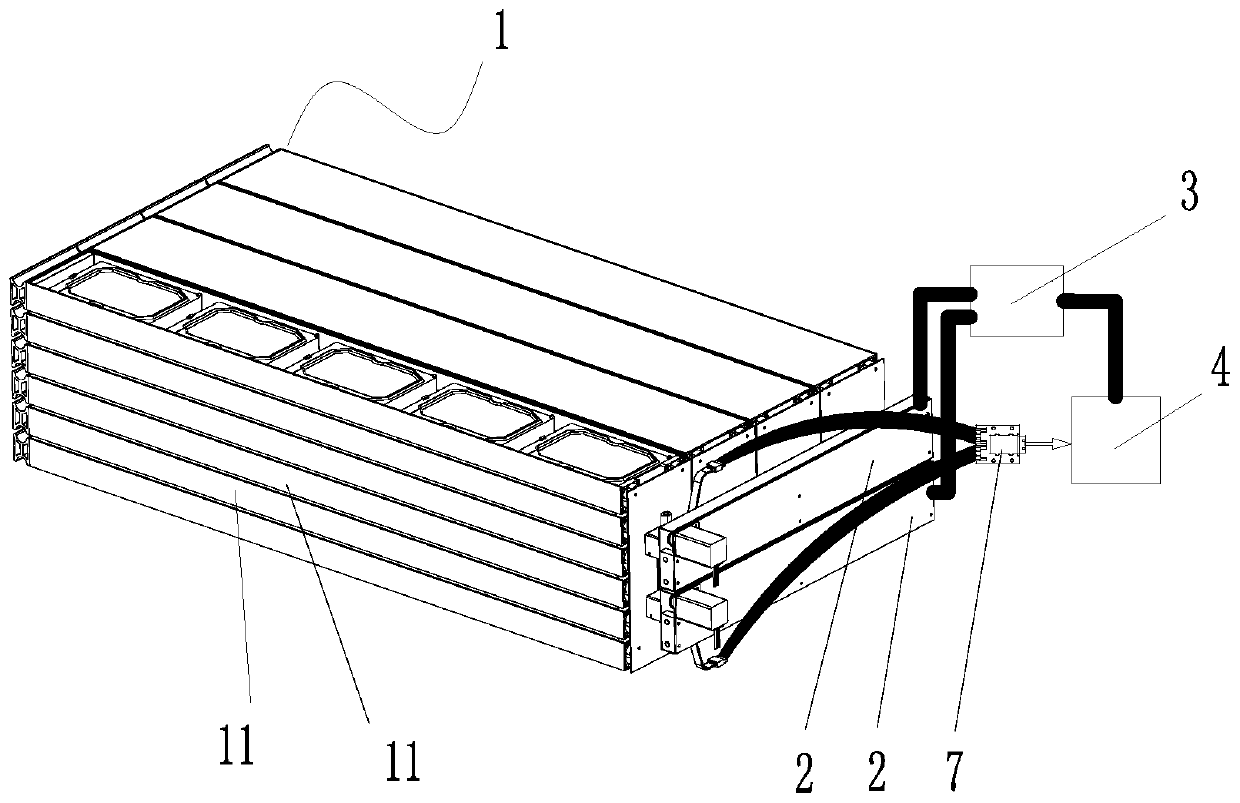

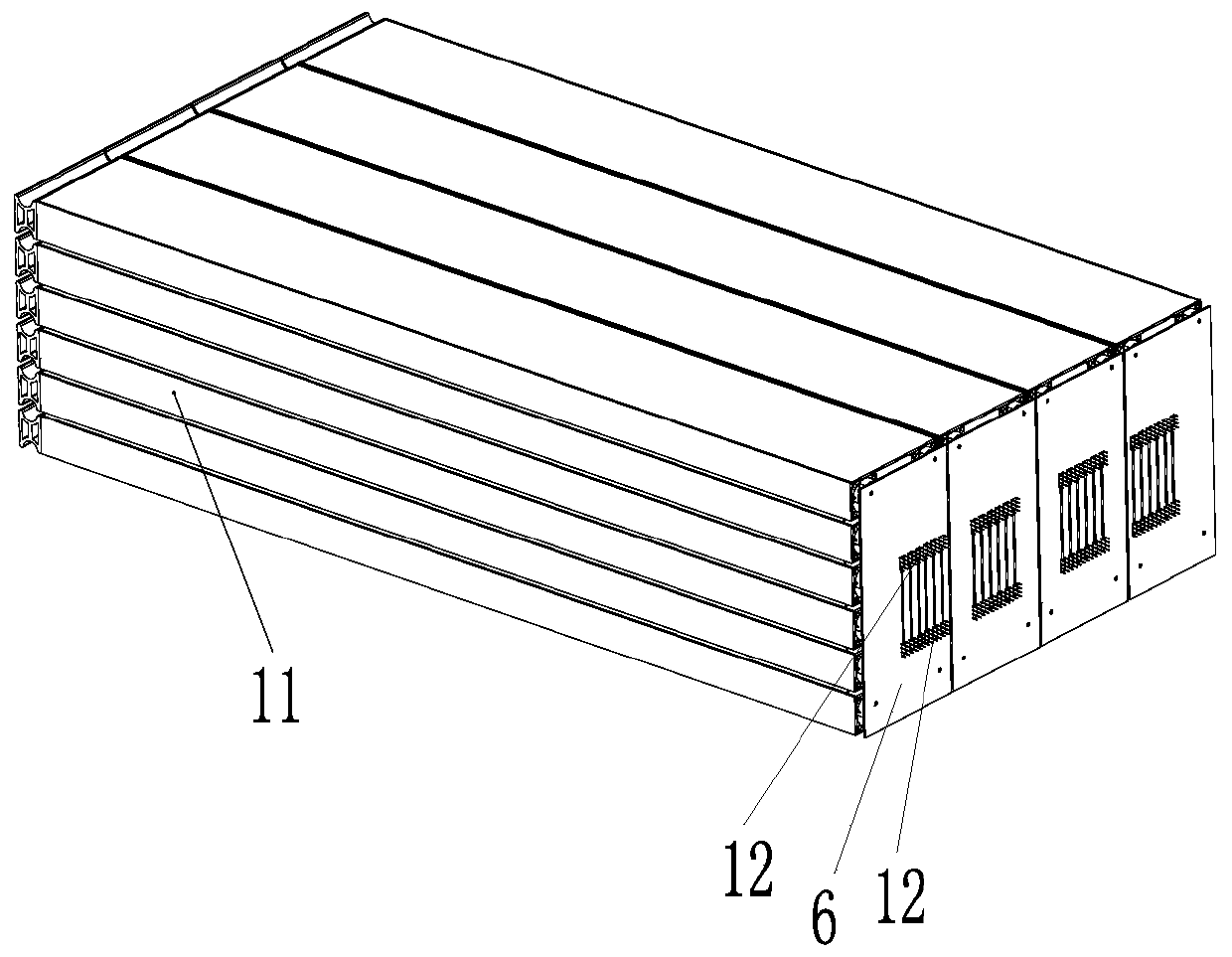

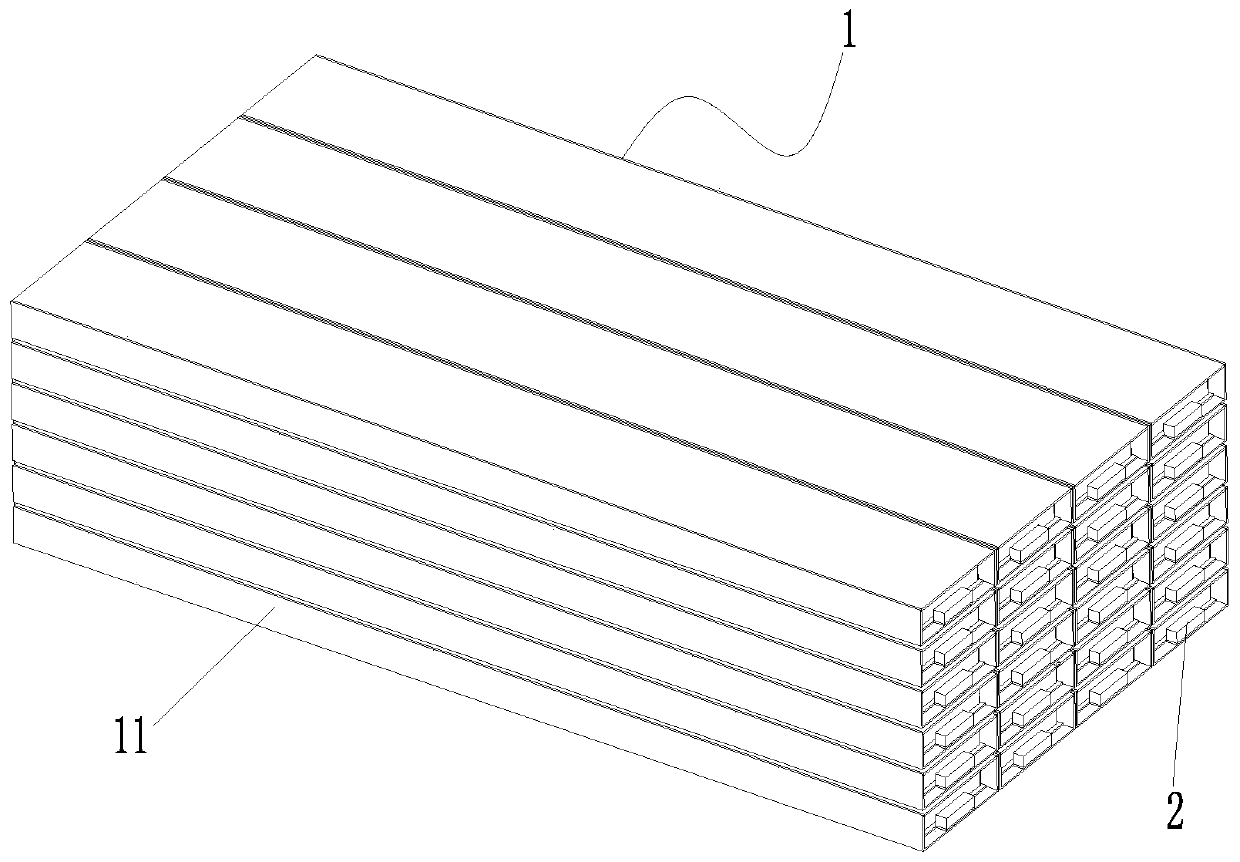

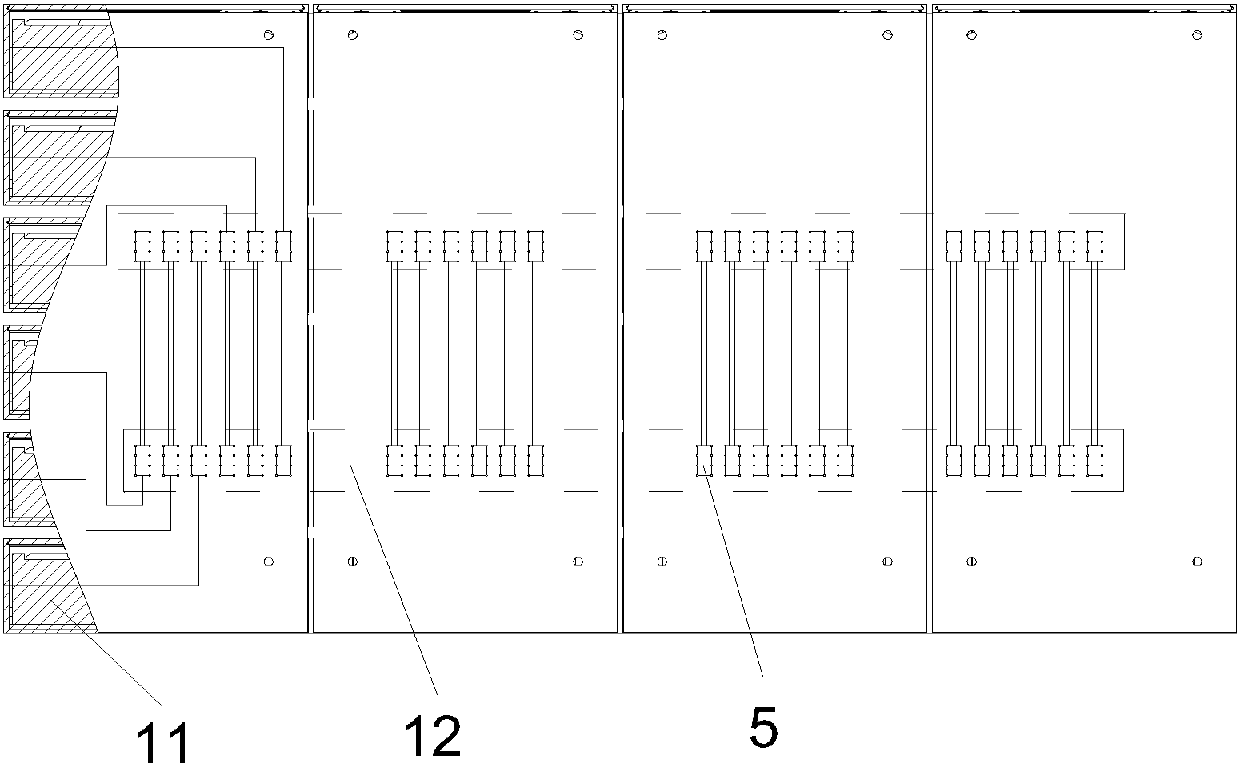

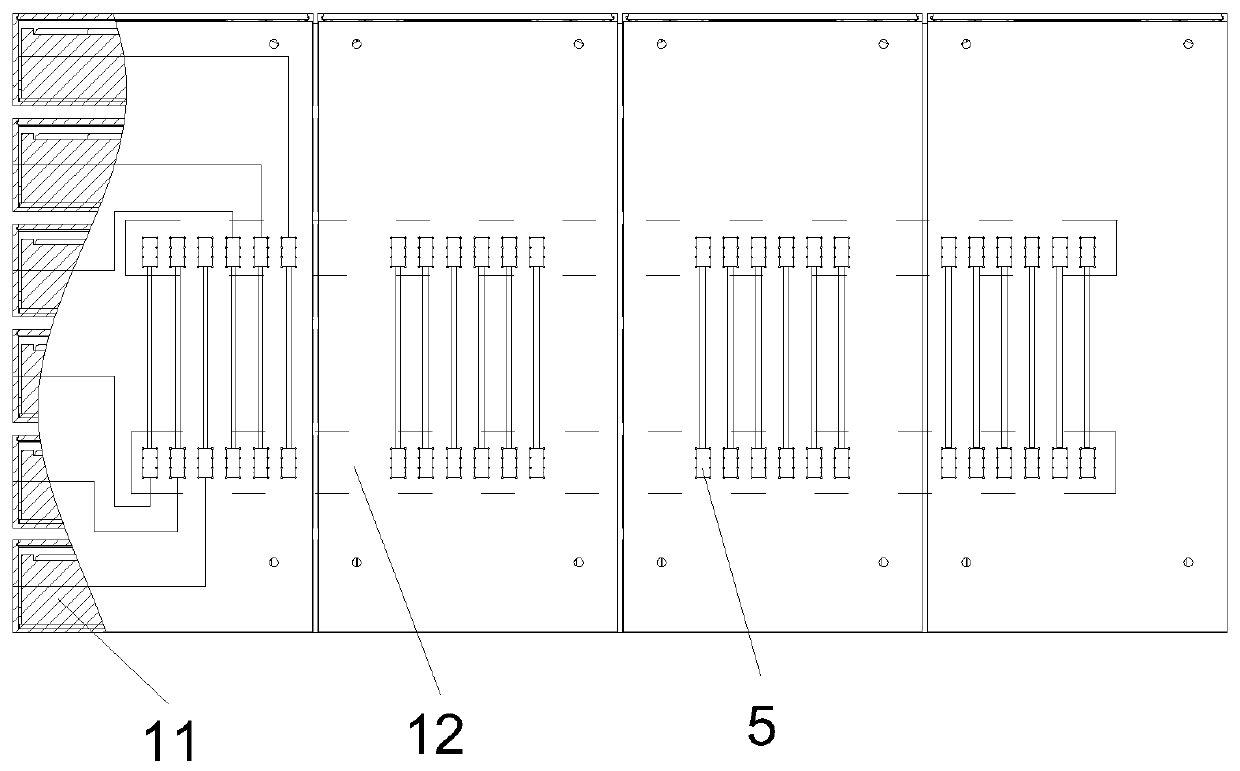

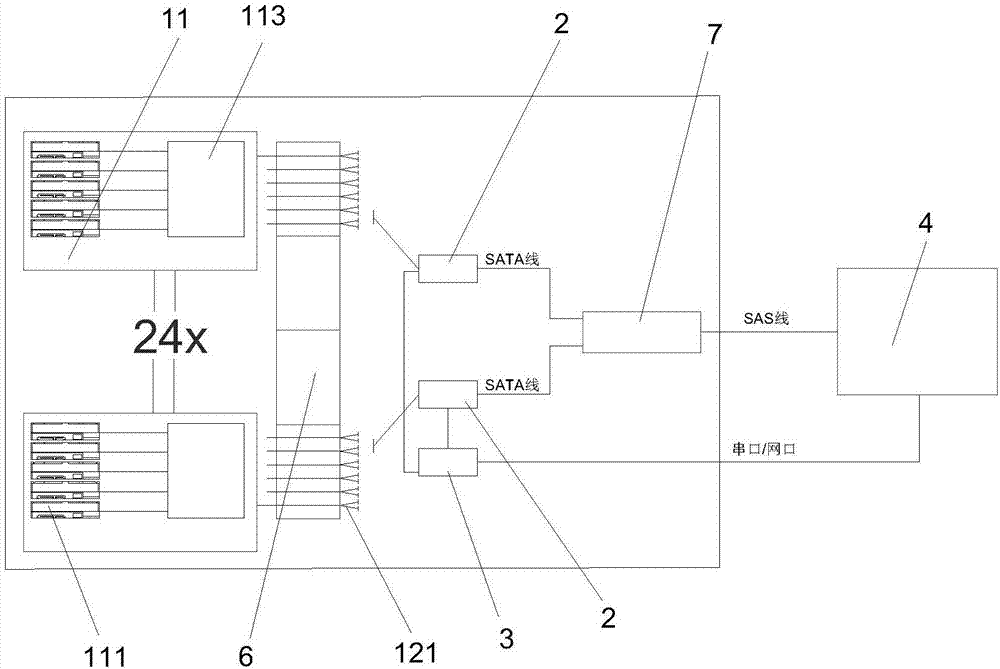

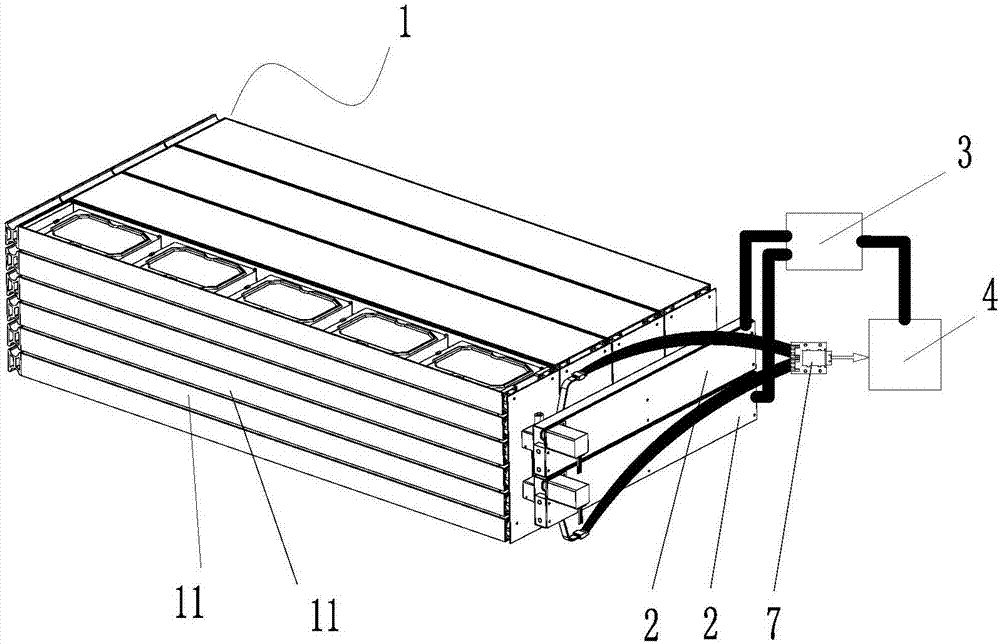

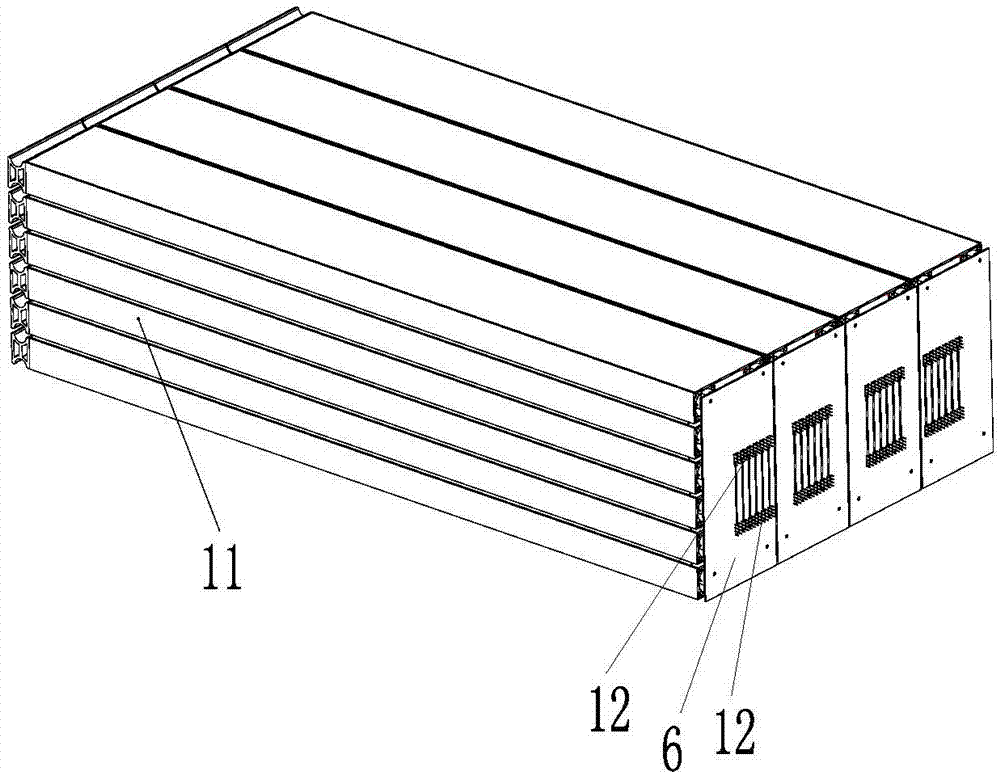

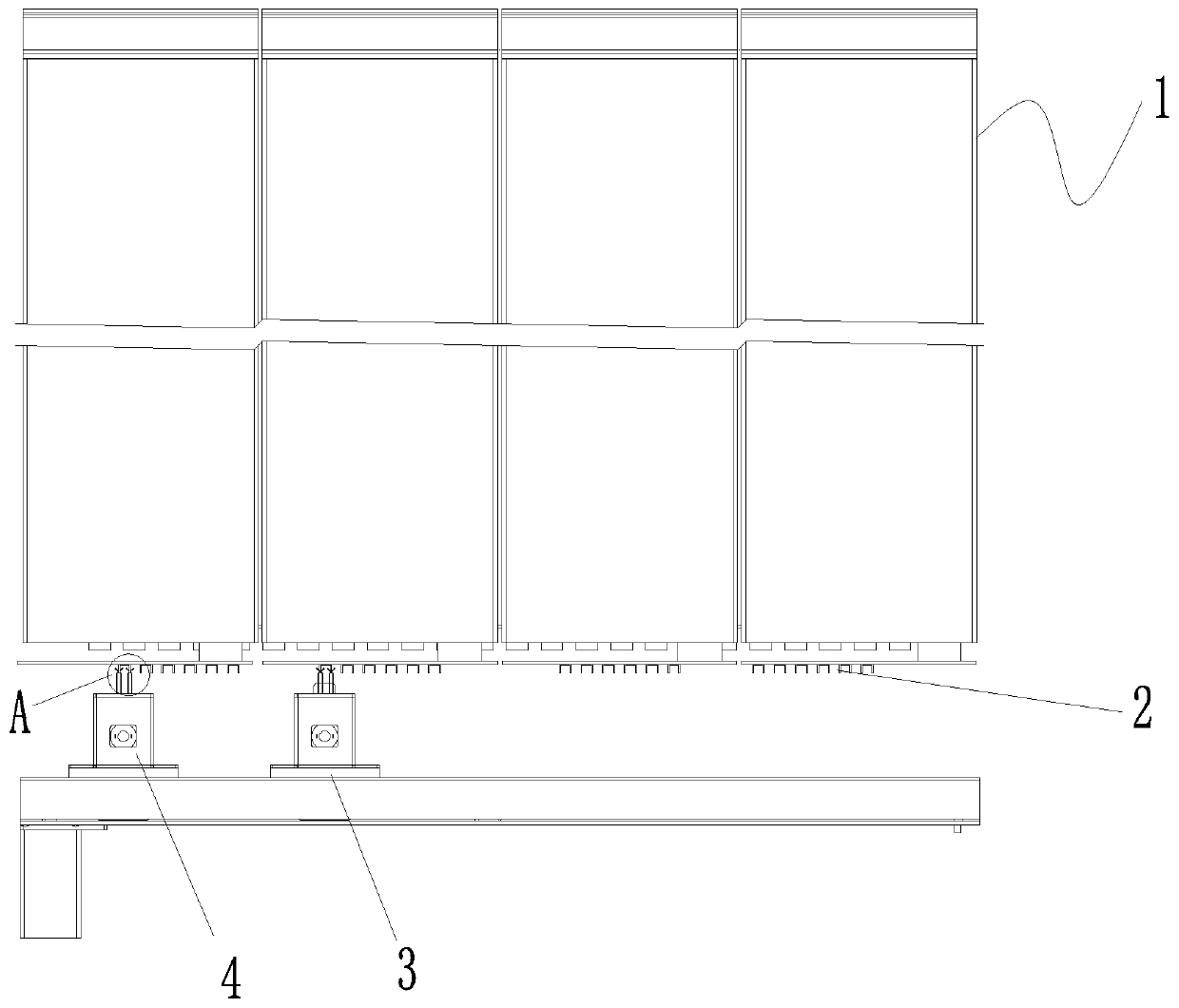

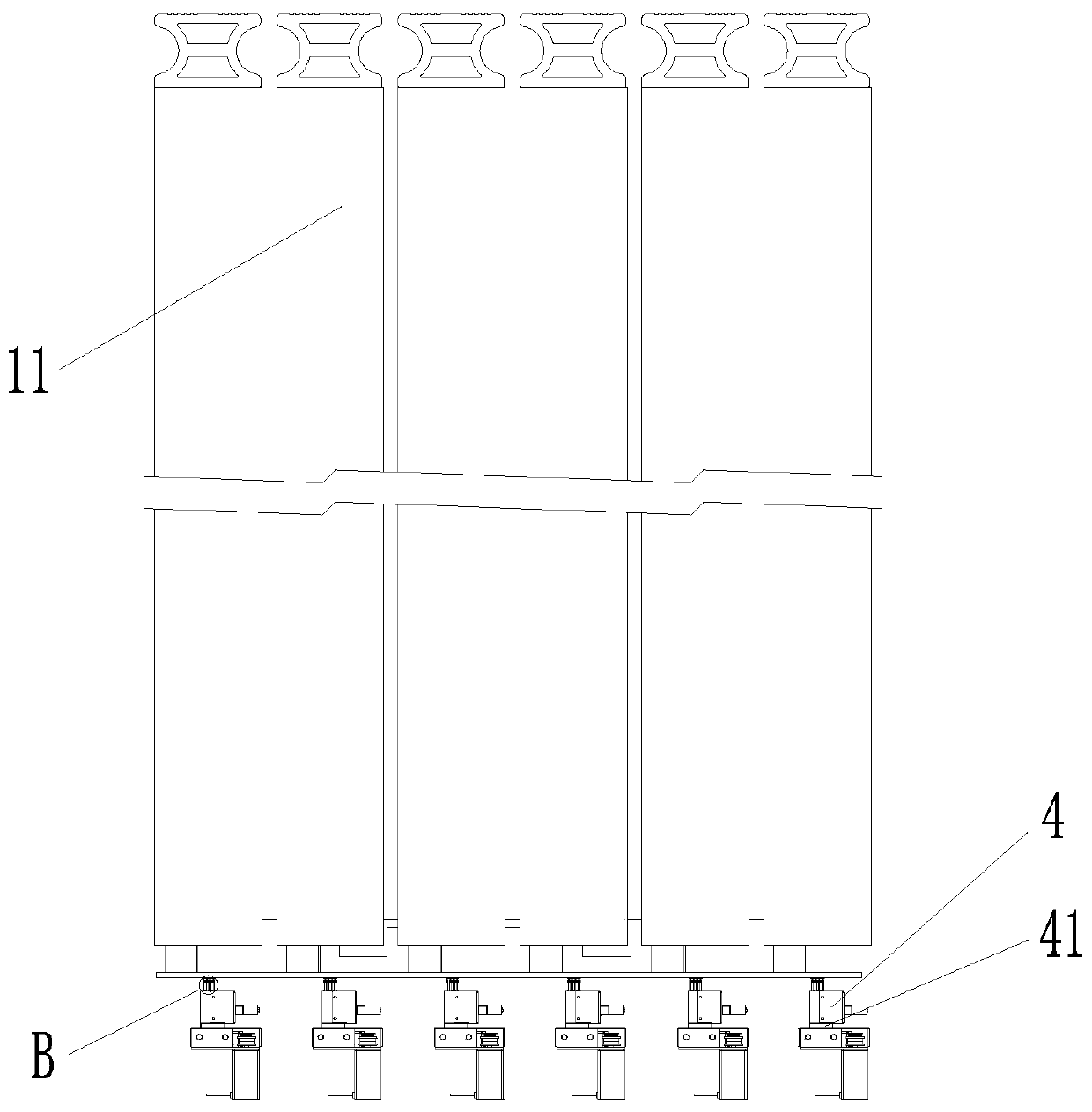

A nearline disk array library

ActiveCN107993681BLow form costImprove reliabilityCarrier constructional parts dispositionReducing physical parameters of carriersData acquisitionData management

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

A nearline disk array library with one-dimensional kinematic manipulator

ActiveCN108053843BLow form costImprove reliabilityApparatus modification to store record carriersRecord information storageData managementDisk array

The invention discloses a near line disk array library with one-dimensionally moving mechanical arms. The library comprises a completely independent driver set, which comprises multiple disk array modules that are arranged in M rows and N columns, wherein M and N are both an integer that is not less than 2; the front ends of the rear ends of the disk array modules are all outward arranged; and thefront ends of the disk array modules are provided with a read-write head. The library also comprises multiple mechanical arms, which can move in a row direction or a column direction in a plane thatis parallel to the front ends of the disk array modules; and a controller, which is used to control the mechanical arms to designated positions so as to connect a data management server and the disk array modules to finish data transmission. The library ahs the advantages of high reliability and convenient maintenance, compared with a typical disc array form, the cost is lower, and the facility stability is obviously enhanced.

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

Near-line magnetic disk array library with contact areas at two sides

ActiveCN108022608ASave human effortImprove work efficiencyCarrier constructional parts dispositionInput/output to record carriersComplete dataData management

The invention discloses a near-line magnetic disk array library with contact areas at two sides. The near-line magnetic disk array library comprises an all-independent driver set, a plurality of mechanical arms, a controller, and a data management server. The all-independent driver set consists of a plurality of magnetic disk array module groups arranged in M rows and N columns; the front ends andthe rear ends of the plurality of magnetic disk array module groups are arranged externally; first contact areas are arranged at the front ends of the plurality of magnetic disk array module groups;second contact areas are arranged at the rear ends of the plurality of magnetic disk array module groups; contact points are arranged in the first contact areas and the second contact areas; the firstcontact area at each row or each column corresponds to one mechanical arm; and the second contact area at each row or each column corresponds to one mechanical arm. The controller is used for controlling movement of the mechanical arm to a designated position and realizing connection between the data management server and the magnetic disk array module groups to complete data transmission. The near-line magnetic disk array library has advantages of high stability and low energy consumption; reading and writing on the independent disc drivers are carried out simultaneously; and the data are obtained conveniently.

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

A Nearline Disk Array Library with Contact Areas on Both Sides

ActiveCN108022608BSave human effortImprove work efficiencyInput/output to record carriersCarrier constructional parts dispositionComplete dataData management

The invention discloses a near-line magnetic disk array library with contact areas at two sides. The near-line magnetic disk array library comprises an all-independent driver set, a plurality of mechanical arms, a controller, and a data management server. The all-independent driver set consists of a plurality of magnetic disk array module groups arranged in M rows and N columns; the front ends andthe rear ends of the plurality of magnetic disk array module groups are arranged externally; first contact areas are arranged at the front ends of the plurality of magnetic disk array module groups;second contact areas are arranged at the rear ends of the plurality of magnetic disk array module groups; contact points are arranged in the first contact areas and the second contact areas; the firstcontact area at each row or each column corresponds to one mechanical arm; and the second contact area at each row or each column corresponds to one mechanical arm. The controller is used for controlling movement of the mechanical arm to a designated position and realizing connection between the data management server and the magnetic disk array module groups to complete data transmission. The near-line magnetic disk array library has advantages of high stability and low energy consumption; reading and writing on the independent disc drivers are carried out simultaneously; and the data are obtained conveniently.

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

Method for placing load-related virtual machine

ActiveCN102541622BImprove resource utilizationNo reduction in service qualityResource allocationSoftware simulation/interpretation/emulationVirtualizationResource utilization

The invention relates to a method for placing a load-related virtual machine. In a currently common virtualized environment, in order to ensure performance, resources are often excessively allocated, leading to a low resource utilization level and resulting in increase of the cost and resource waste. By utilizing a multi-iteration complementary pairing method provided by the invention, the problems of a low resource utilization ratio as well as unreasonable pairing caused by random pairing or one-time pairing can be solved; and the iteration degree is controlled by setting a saturation of the resource utilization ratio, so that the performance of the system and the service quality of a user are controlled within an acceptable range. By a multi-iteration virtual machine method, by utilizing the time complementarity of the resources, the resource utilization ratio of the virtual machine can be improved in a relatively deep level on the premise of not reducing the service quality of the user.

Owner:HANGZHOU DIANZI UNIV

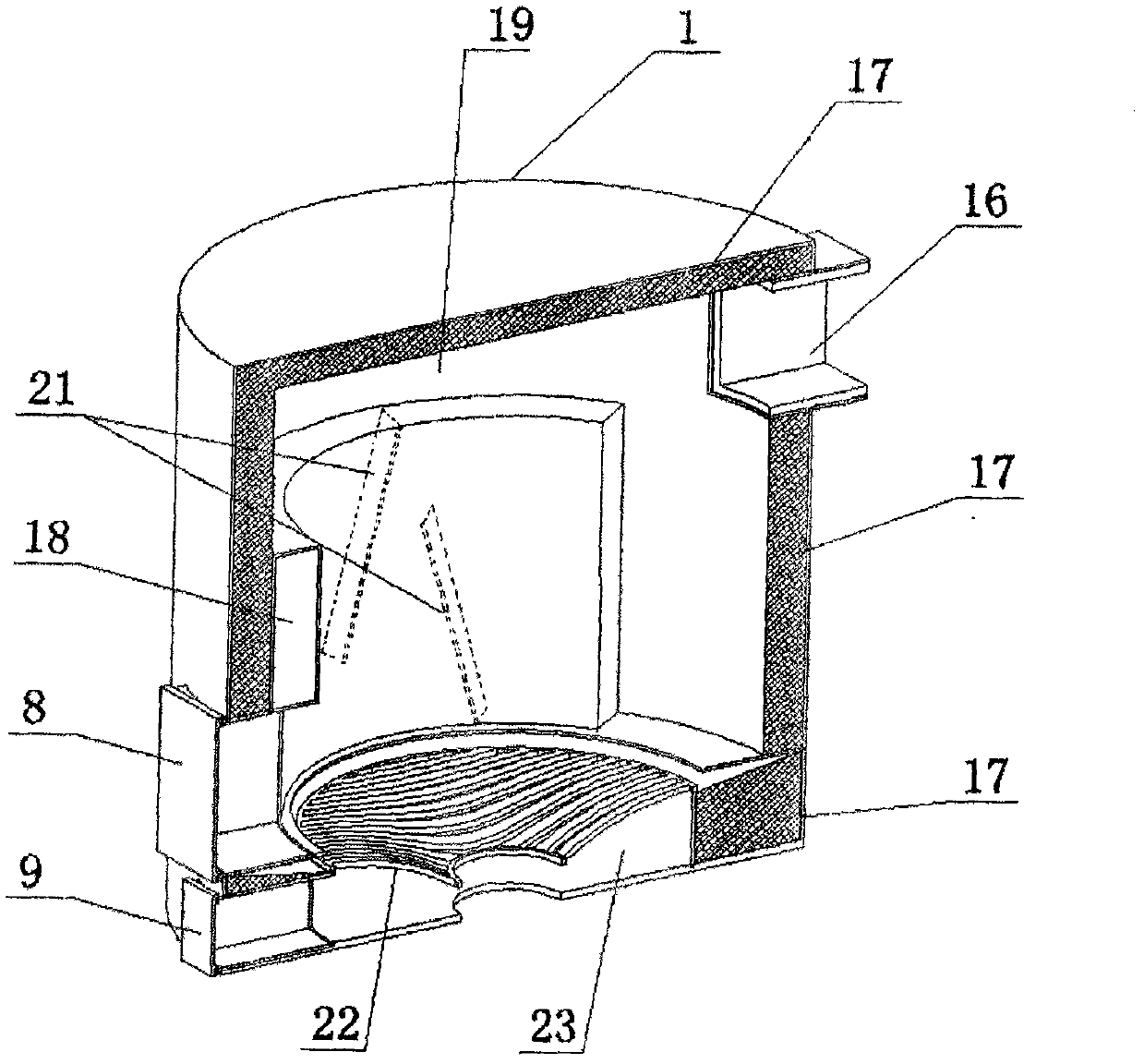

Continuous internal circulation dry distillation carbonization equipment

ActiveCN107325825BEasy accessLow densityBiofuelsIndirect heating destructive distillationProcess engineeringMechanical engineering

The invention discloses continuous inner-cycle dry distillation and carbonization equipment. The equipment comprises a combustion reaction chamber and a dry distillation kettle, wherein the combustion reaction chamber is hollow; the dry distillation kettle is a cylindrical column and is horizontally arranged in the combustion reaction chamber, a plurality of shin plates are arranged on the inner wall of the dry distillation kettle, rig plates are vertically arranged on two side plate surfaces of the shin plates, a first charcoal bin placed on the rig plates is arranged between each two adjacent shin plates, all the first charcoal bins form a circle coaxial with the dry distillation kettle, and meanwhile, second charcoal bins matched with the first charcoal bins are arranged in the circle; and a detachable first sealing cover and a detachable second sealing cover are respectively arranged at two ends of the dry distillation kettle, a rotating shaft is coaxially arranged at the outer end of the first sealing cover, and a flue is coaxially formed in the outer end of the second sealing cover and is communicated to the inside of the dry distillation kettle. The continuous inner-cycle dry distillation and carbonization equipment has the characteristics that the sintering time is saved, the uniform dry distillation and carbonization in a furnace body are realized, and the fetching and placement of an operator are facilitated.

Owner:梧州元泓机械设备有限公司

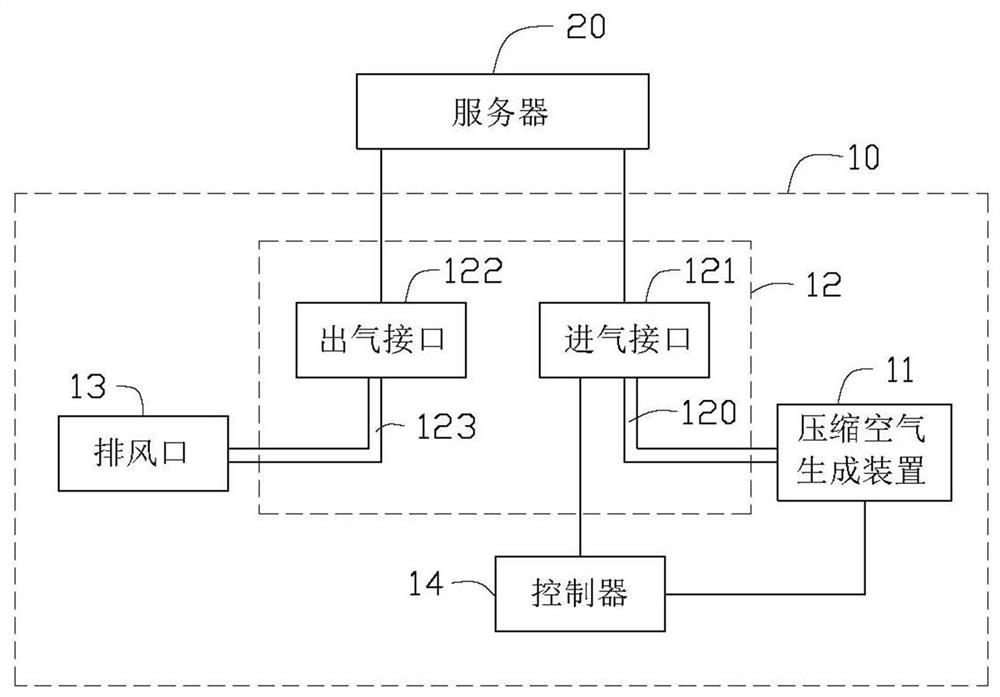

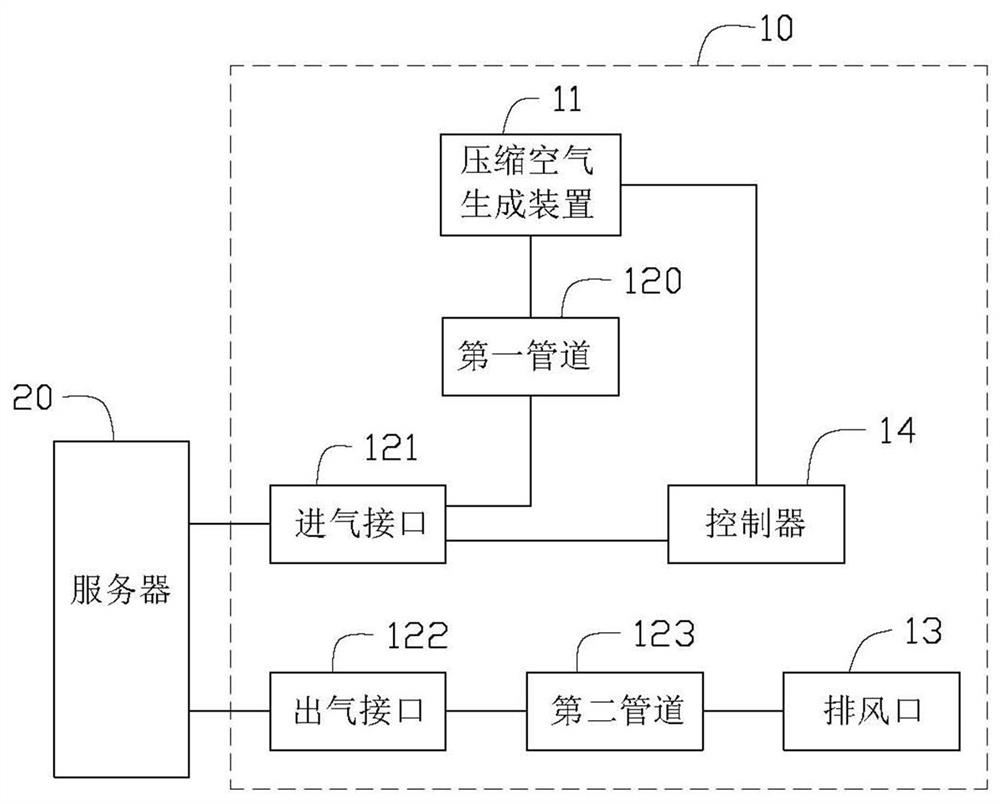

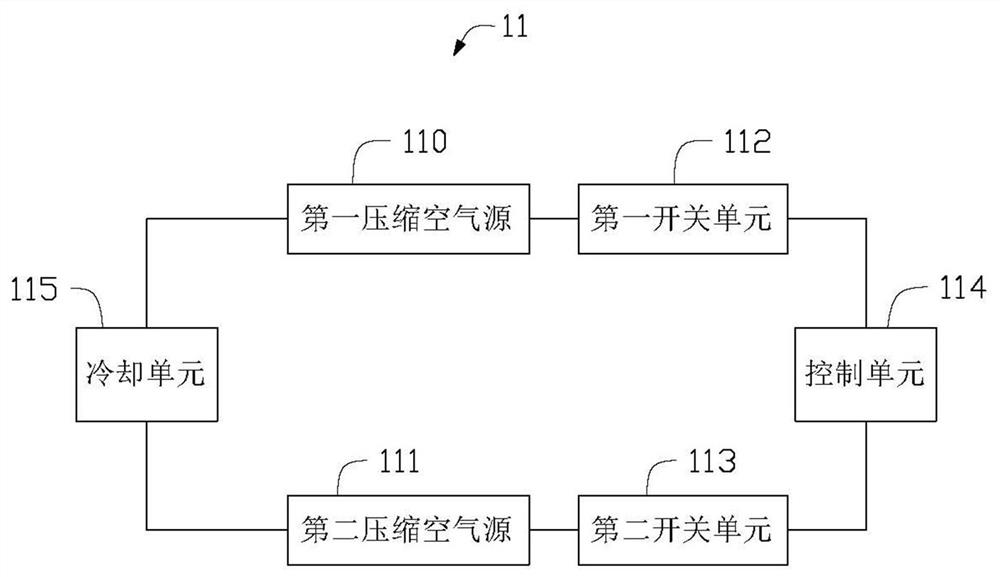

Server Cooling System

InactiveCN106468940BIncrease the placement densityReduce cooling needsDigital data processing detailsElectrical apparatus contructional detailsEngineeringHeat control

Owner:WARECONN TECH SERVICE (TIANJIN) CO LTD

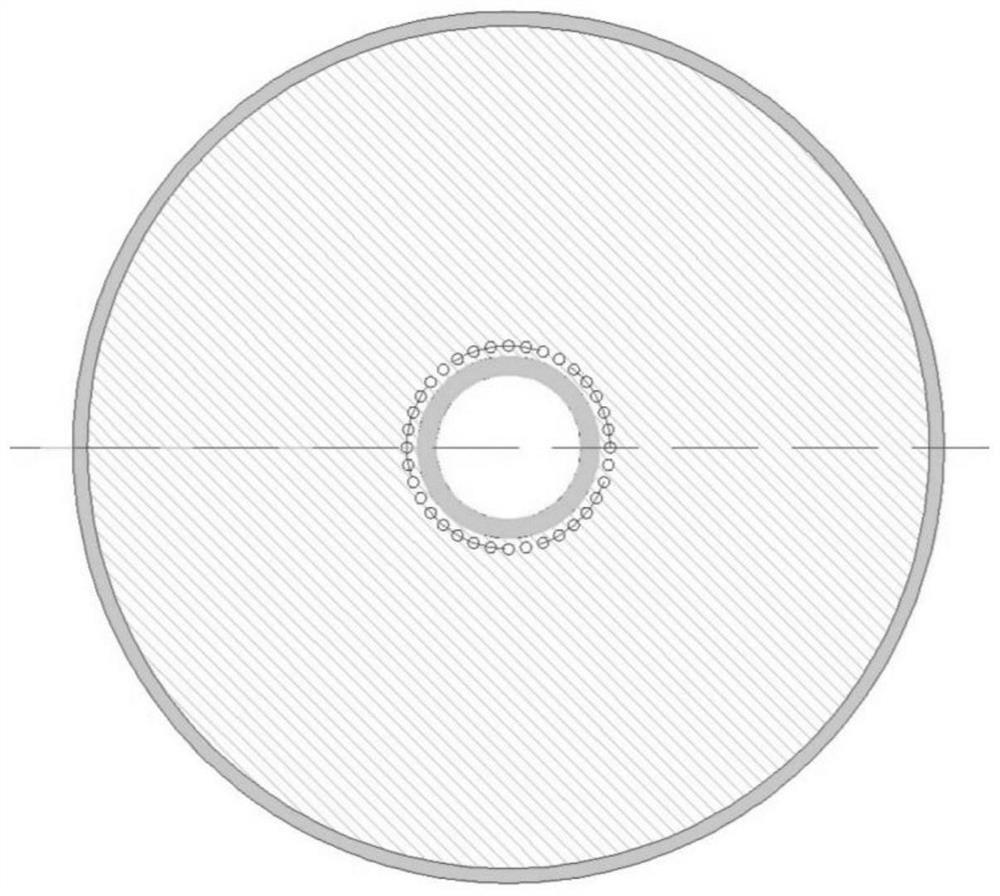

Cyclone electrocatalytic water treatment method

InactiveCN110835148AIncrease the placement densityReduce in quantityWater treatment parameter controlWater/sewage treatment apparatusElectrode placementCatalytic oxidation

The invention relates to the technical field of water treatment, and concretely relates to a cyclone electrocatalytic water treatment method. A hydrocyclone technology with an electrocatalytic oxidation technology are combined; the reaction mass transfer efficiency and the reaction path are improved by utilizing the hydrocyclone effect, so the reaction efficiency of electrocatalytic oxidation is increased; and electrocatalytic anode electrodes and electrocatalytic cathode electrodes are arranged in a cyclone reactor shell in a staggered manner to form an annular structure. The electrocatalyticelectrodes adopts the electrocatalytic anode electrodes and the electrocatalytic cathode electrodes which are arranged in the staggered manner, and the electrode placement density is increased, so that the reaction efficiency is enhanced, and the application of the electrocatalytic oxidation technology in the actual water treatment process is favorably realized; and an antifoaming gent is used todigest steam bubbles generated by electrocatalysis to a certain extent, so the quantity of the steam bubbles is reduced, and the reaction efficiency of electrocatalytic oxidation is further improved.

Owner:LULIANG UNIV

Near-line magnetic disk array library

ActiveCN107993681ALow form costImprove reliabilityCarrier constructional parts dispositionReducing physical parameters of carriersMaintainabilityData acquisition

The invention provides a near-line disk array library, which comprises all independent driver sets, mechanical arms, a controller and a data management server. All the independent driver sets comprisea plurality of magnetic disk array modules arranged in M rows and N columns. A contact area which extends in the row direction or in the column direction is arranged on one side of all the independent driver sets. The contact area comprises contact points which are in one-to-one correspondence with the M * N magnetic disk array modules, wherein M and N are integers greater than or equal to 2. Each row or each column of contact area corresponds to one mechanical arm. The controller is used for controlling the mechanical arms to move, achieving the connection of the data management server and the disk array modules and then realizing the data transmission. According to the invention, compared with the form of a typical magnetic disk array, the above near-line disk array library is low in cost, high in reliability and good in maintainability. The double-path or multi-path read-write operation can be performed on independent disk drivers. Meanwhile, the data acquisition is convenient, andthe equipment stability is good. The energy consumption is low.

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

A nearline disk array library with touchpoints

ActiveCN108022607BLow form costImprove reliabilityInput/output to record carriersCarrier constructional parts dispositionComplete dataMaintainability

The invention discloses a near-line magnetic disk array library with contact points. The near-line magnetic disk array library comprises an all-independent driver set, a plurality of mechanical arms,and a controller. The all-independent driver set consists of a plurality of magnetic disk array module groups arranged in M rows and N columns, wherein the M and the N are integers larger than or equal to 2; the front ends and the rear ends of the plurality of magnetic disk array module groups are arranged externally; contact points are arranged at the front ends of the plurality of magnetic diskarray module groups and are provided with complete signal channels for connection with data management servers. The multiple mechanical arms can move along a row direction or column direction in a plane parallel to the front ends of the magnetic disk array module groups. The controller is used for controlling the mechanical arms to move to designated positions to realize connection between the data management servers and the magnetic disk array module groups, thereby completing data transmission. The near-line magnetic disk array library has advantages of high reliability and maintainability;and compared with the typical magnetic disk array formation, the library has the lowered cost and the stability of the equipment is increased obviously.

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

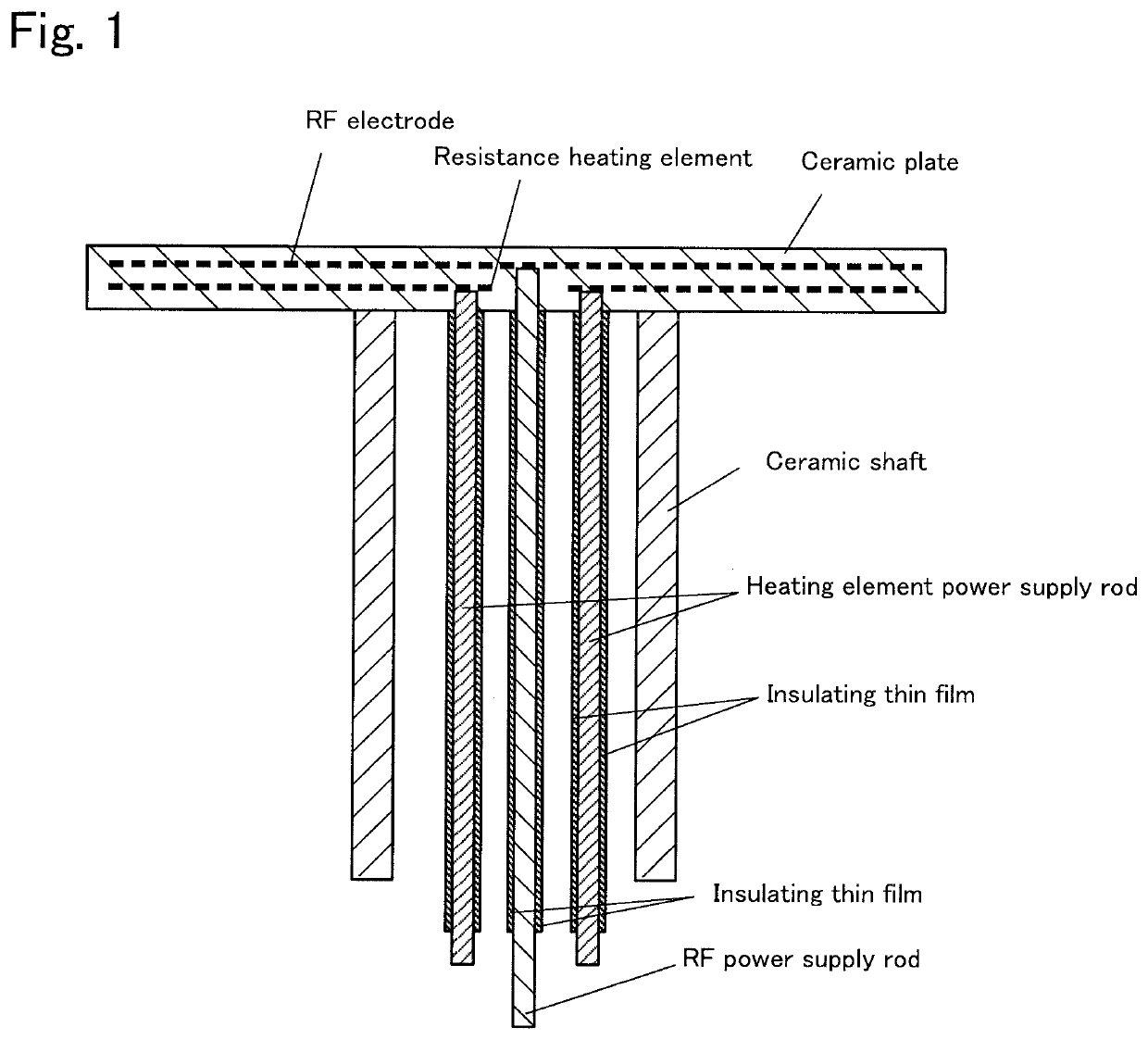

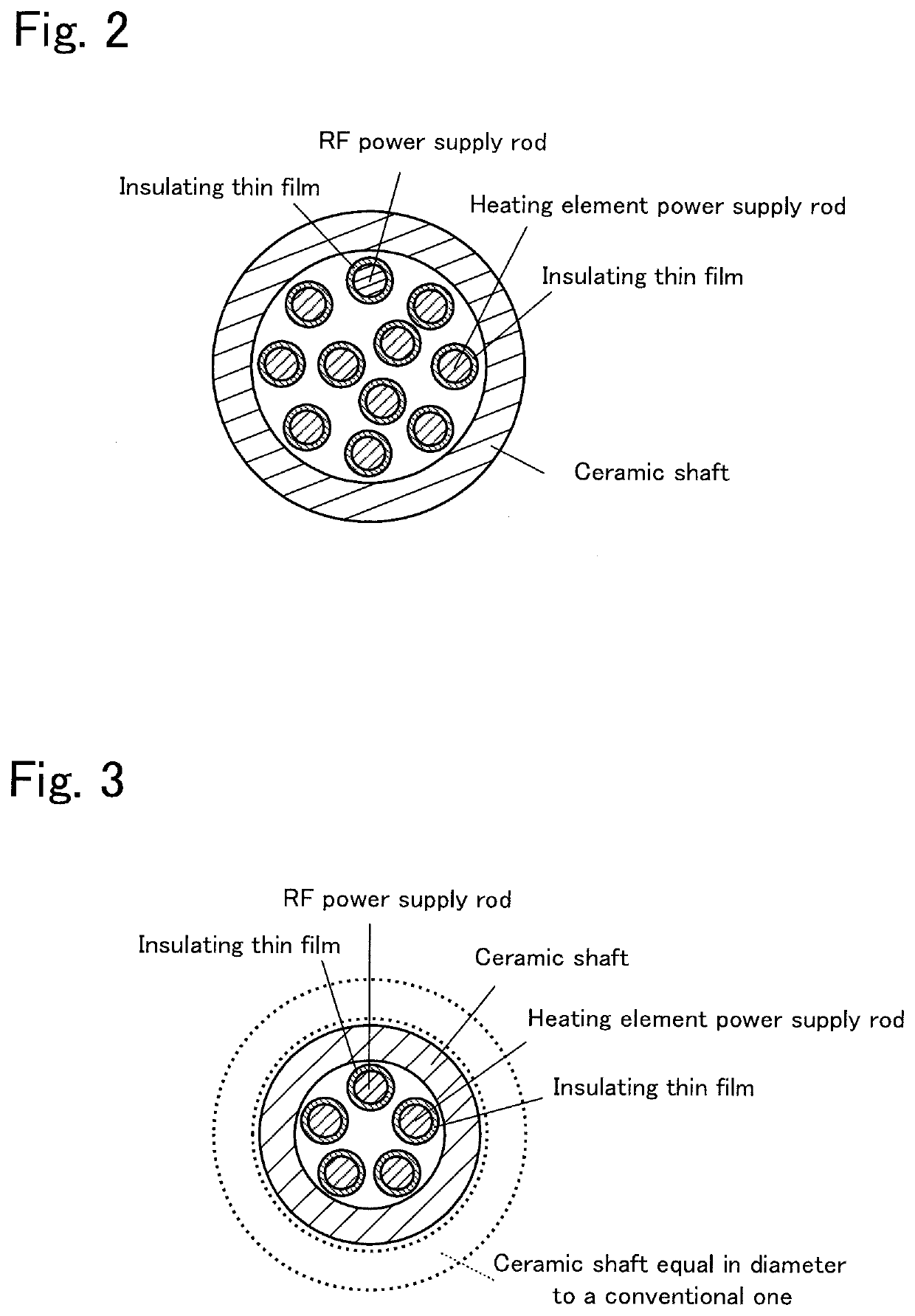

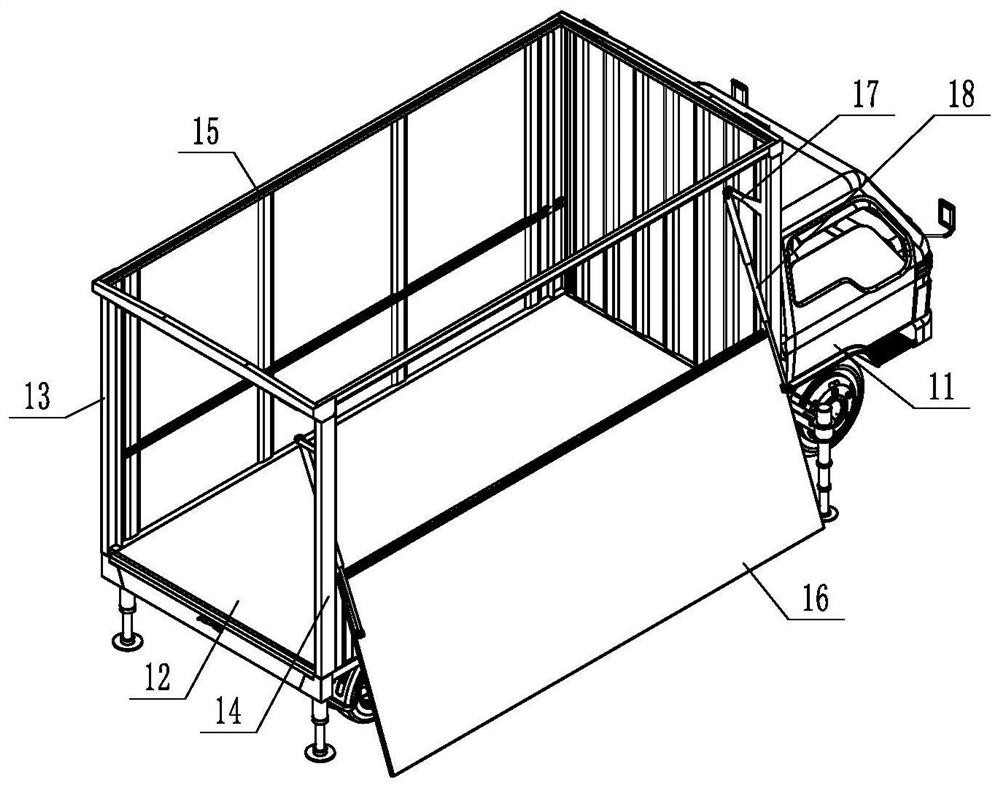

Ceramic heater with shaft

PendingUS20220030669A1Improve power densityIncrease the number ofOhmic-resistance electrodesHeater elementsWaferingAerosol deposition

A ceramic heater with a shaft includes a ceramic plate in which an RF electrode and a resistance heating element are embedded; a hollow ceramic shaft provided on a surface on an opposite side of a wafer placement surface of the ceramic plate; an RF power supply rod which is housed in an inner space of the ceramic shaft, and a heating element power supply rod which is housed in the inner space of the ceramic shaft, wherein an outer circumferential surface of a portion of at least one of the RF power supply rod and the heating element power supply rod is covered with an insulating thin film which is an aerosol deposition film or a thermal spray film, the portion being located in the inner space of the ceramic shaft.

Owner:NGK INSULATORS LTD

A shared bicycle transport vehicle based on a van

ActiveCN112874422BEnable mobilityAchieve positioningLoading/unloading vehicle arrangmentItem transportation vehiclesRobot handCarriage

A shared bicycle transport vehicle based on a van, relating to the field of automation equipment, including a carriage, the carriage includes a carriage floor, and guide rail type bicycle clamping and placing devices are provided on both sides of the carriage floor, and the guide rail type bicycle clamp There is a scissor-type bicycle fixing device in the middle of the taking and placing device, a foldable bicycle lifting and turning device at the rear of the carriage, and a truss-type multi-directional telescopic manipulator on the top of the carriage. The invention can realize automatic grabbing and handling of shared bicycles, save labor and improve efficiency. The bicycle lifting and turning device realizes the "front-to-rear" staggered placement of shared bicycles, the guide-rail bicycle clamping and placing device realizes the horizontal movement and positioning of shared bicycles in the compartment, and the multi-directional telescopic truss-type manipulator realizes Fast unloading of shared bicycles.

Owner:郑华康

Tornadic hot air underfeed automatic stoking quenching furnace

InactiveCN102618704BImprove insulation effectReduce lossesHeat treatment process controlQuenching devicesCombustion chamberQuenching

The invention discloses a tornadic hot air underfeed automatic stoking quenching furnace. The furnace includes a quenching furnace chamber and a coal-fired heater for jetting flames to the quenching furnace chamber; the lower part inside a coal-fired heater furnace body is a cylindrical ash chamber, the upper edge of which supports a bell mouth shaped furnace grate having a coal feeding port in the center, and a combustion chamber is positioned above the furnace grate; a C-shaped air feeding channel that supplies air directly to the combustion chamber and has a preheating function is arrangedaround the combustion chamber, a flame jet orifice communicated with the quenching furnace chamber is installed at a notch of the C-shaped air feeding channel on the upper part of the combustion chamber; a furnace bottom air inlet communicated with the outside of the heater furnace body is disposed on one side or at the bottom of the ash chamber; the bottom of the heater furnace body is provided with a longitudinal coal feeding pipe that extends to the central coal feeding port of the bell mouth shaped furnace grate, and automatic stoking is realized by coal feeding motor driven screw rods. The automatic stoking quenching furnace provided in the invention has the characteristics of simple structure, high coal-fired thermal efficiency, controllable quenching temperature and time, and conformance to environmental protection requirements.

Owner:张磊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com