Autonomous mobile robots for picking and placing goods on shelves, and warehousing system and method

An autonomous mobile and warehousing system technology, which is applied in the fields of putting, picking up goods, and warehousing logistics. It can solve the problems of high labor costs, difficult operation, and large volume of forklifts, and achieve increased placement density, improved operating efficiency, and increased storage efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

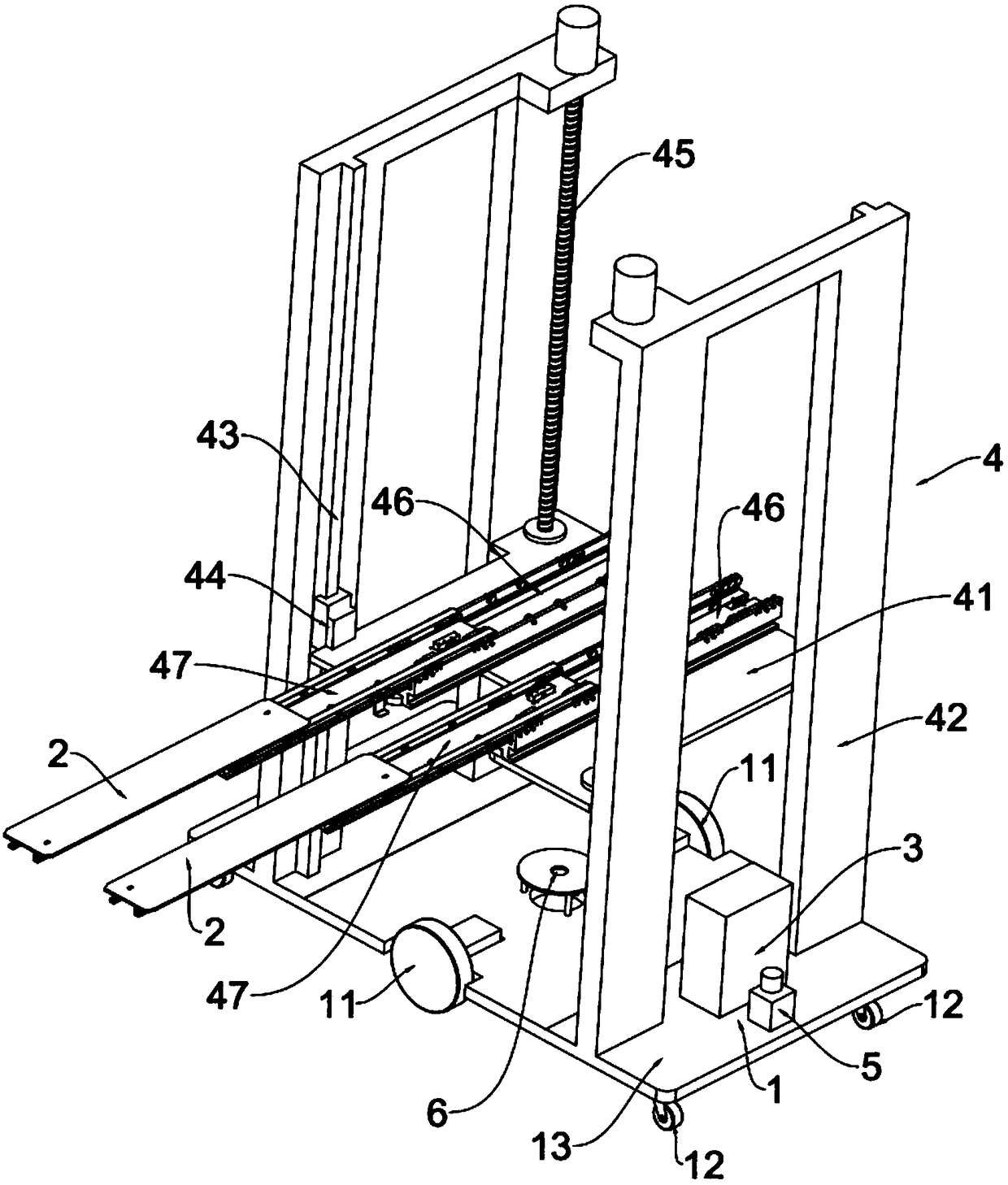

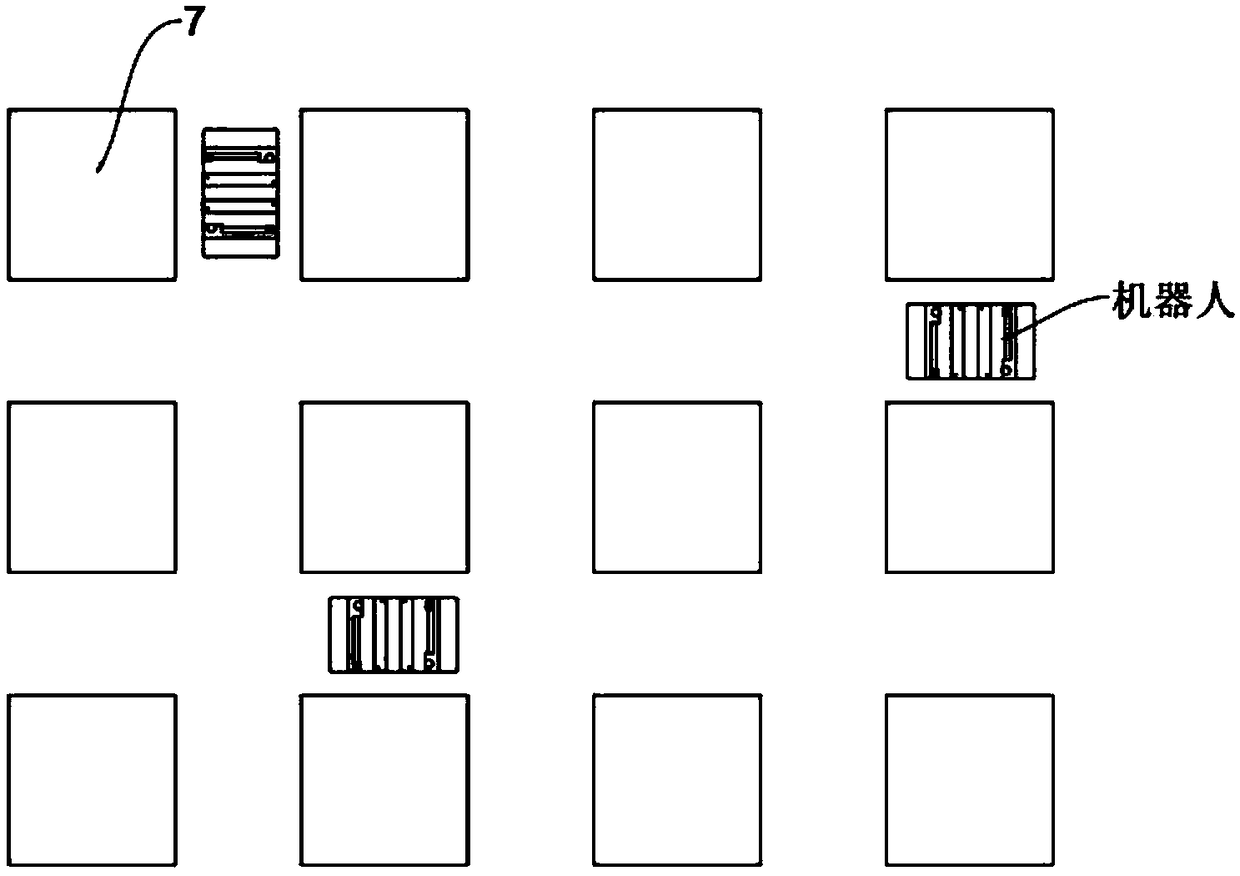

[0025] as attached figure 1 The shown autonomous mobile robot for picking and placing goods on a shelf includes a mobile chassis 1 on which a support body 2 is arranged; the support body 2 can be lifted and lowered relative to the mobile chassis 1, and the support body 2 can be The bidirectional horizontal translation extends out of the moving chassis 1 , and its extending direction is perpendicular to the linear movement direction of the moving chassis 1 .

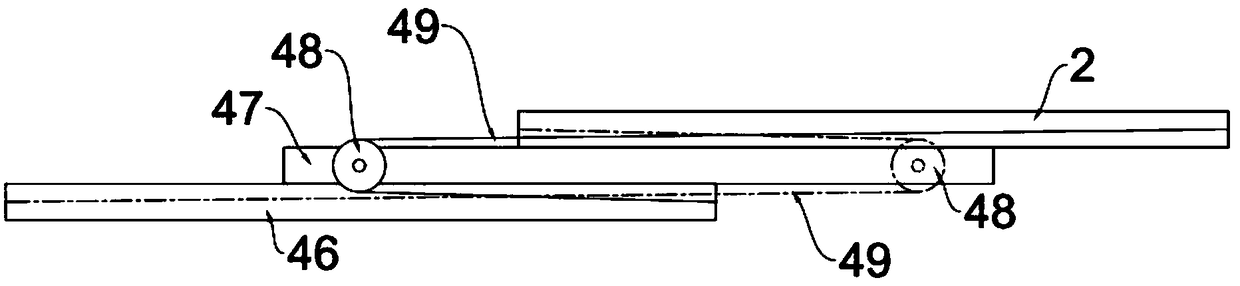

[0026] There are many structures that can realize the lifting of the support body 2 relative to the mobile chassis 1 and the horizontal bidirectional expansion and contraction. 41 and a frame body 42 installed on the mobile chassis 1 , the support body 2 is installed on the lift base 41 and can be horizontally translated in two directions relative to the lift base 41 , and the lift base 41 can be controllably rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com