Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Increase perfusion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

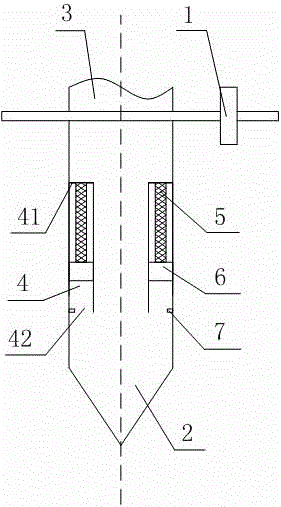

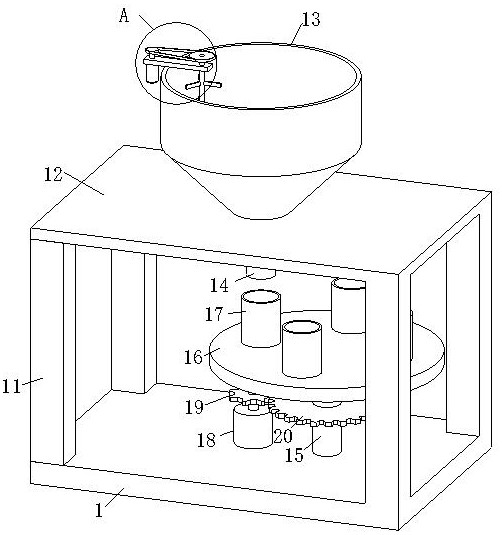

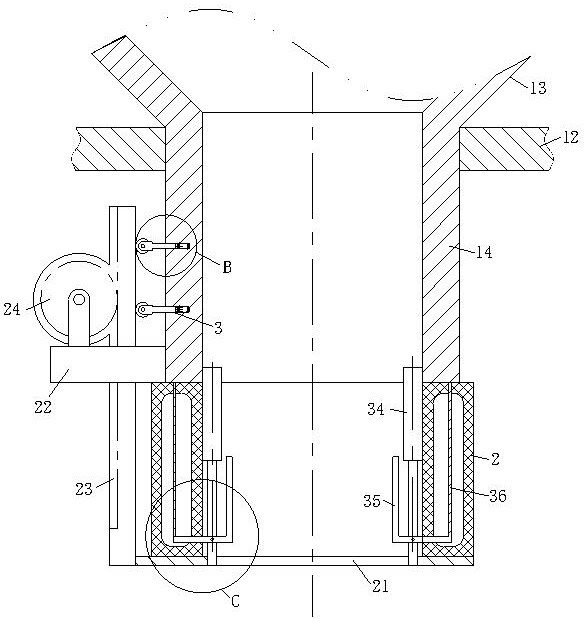

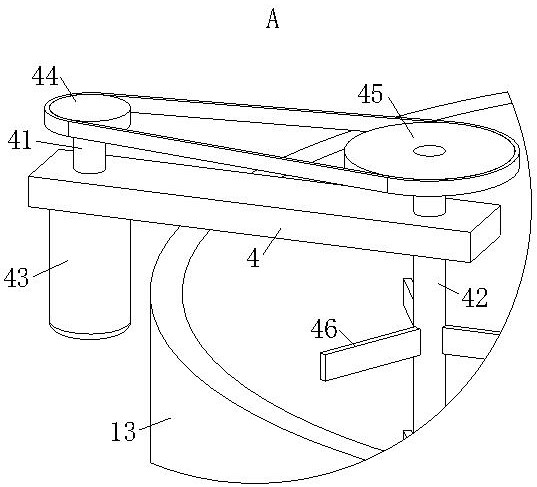

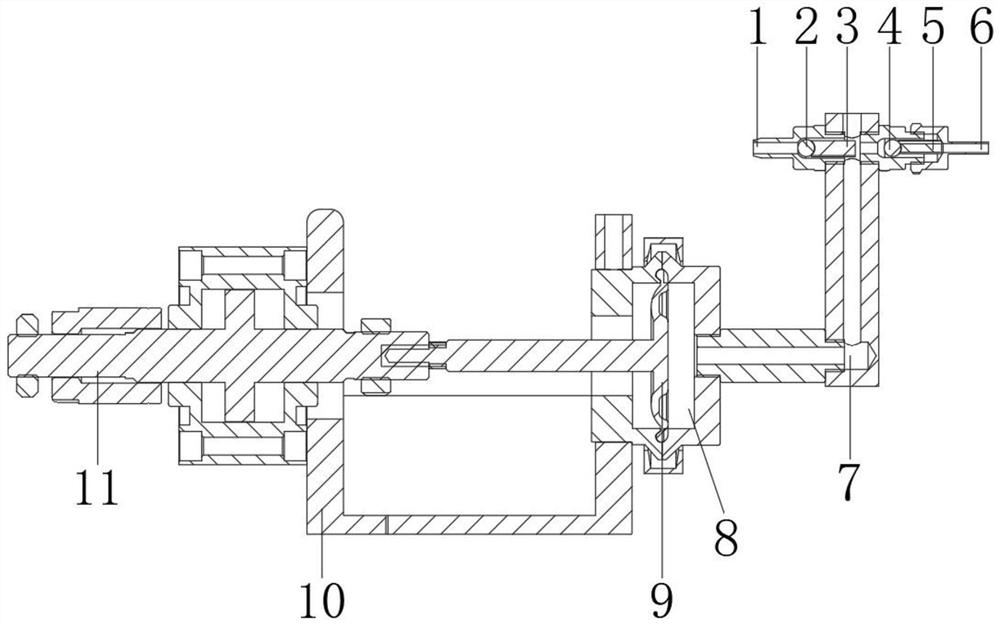

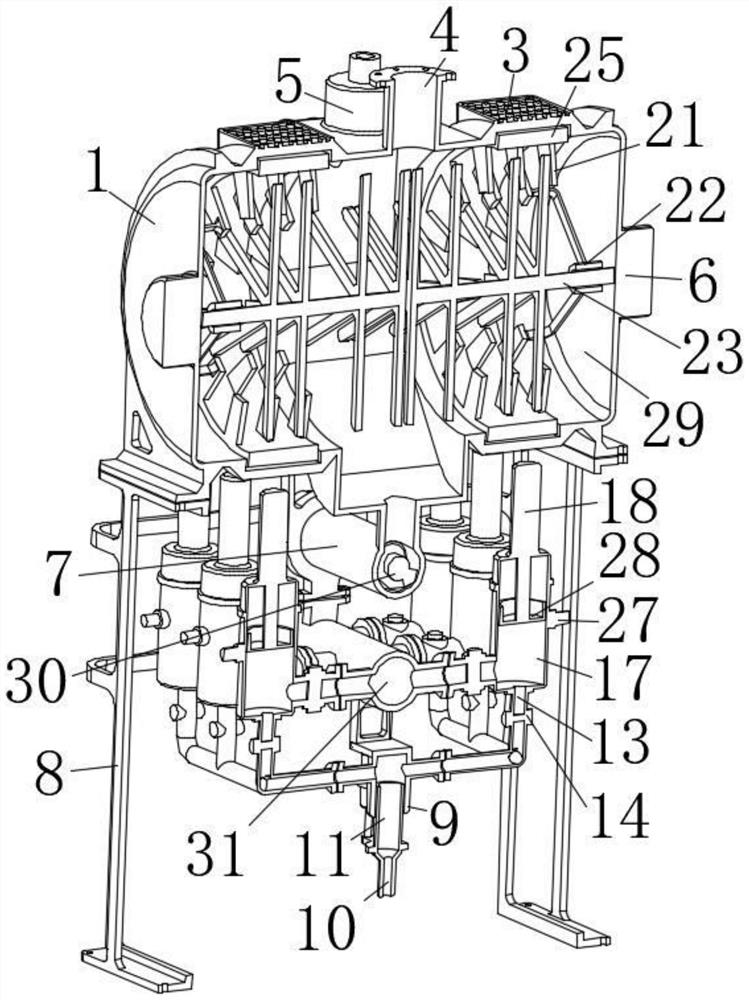

Dairy product filling and discharging structure capable of preventing fluid from dripping

InactiveCN106185762AIncrease perfusion rateImprove perfusion efficiencyLiquid bottlingEngineeringPiston

The invention discloses a dairy product filling and discharging structure capable of preventing fluid from dripping. The dairy product filling and discharging structure comprises a pipe body provided with a valve and a nozzle; an annular inner cavity is arranged in the pipe body and between the valve and the nozzle; one end, near the valve, of the inner cavity is enclosed, and one end, near the nozzle, of the inner cavity is unenclosed; the enclosed end of the inner cavity is fixedly provided with a drive rod facing the direction of the nozzle; and the drive rod is connected with an annular piston matched with the inner cavity. The dairy product filling and discharging structure capable of preventing the fluid from dripping provided by the invention aims at solving the problem that a residual dairy product is easy to drip into the filling system in the prior art, and therefore, the goals that waste of the dairy product is reduced, a sanitary condition of the filling system is improved, and meanwhile, the filling efficiency of the diary product is increased are achieved.

Owner:欧德机械成都有限公司

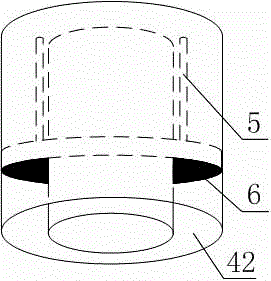

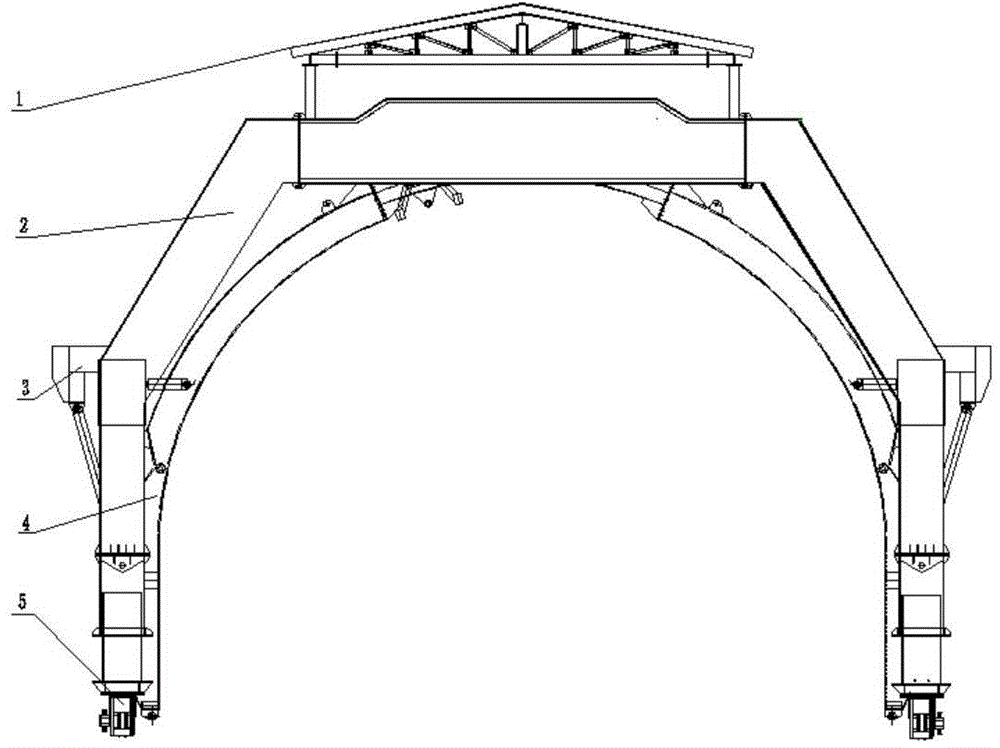

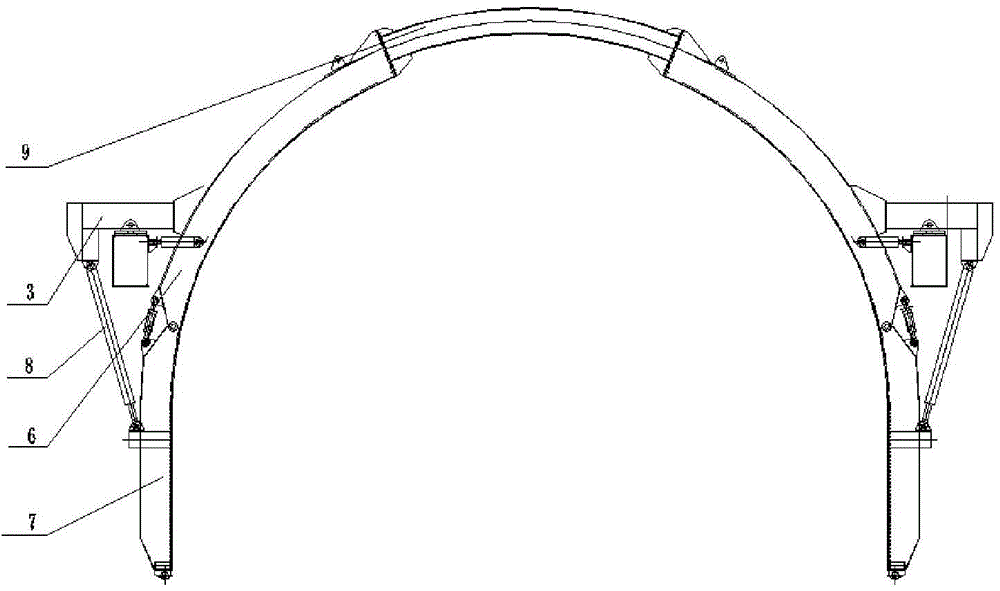

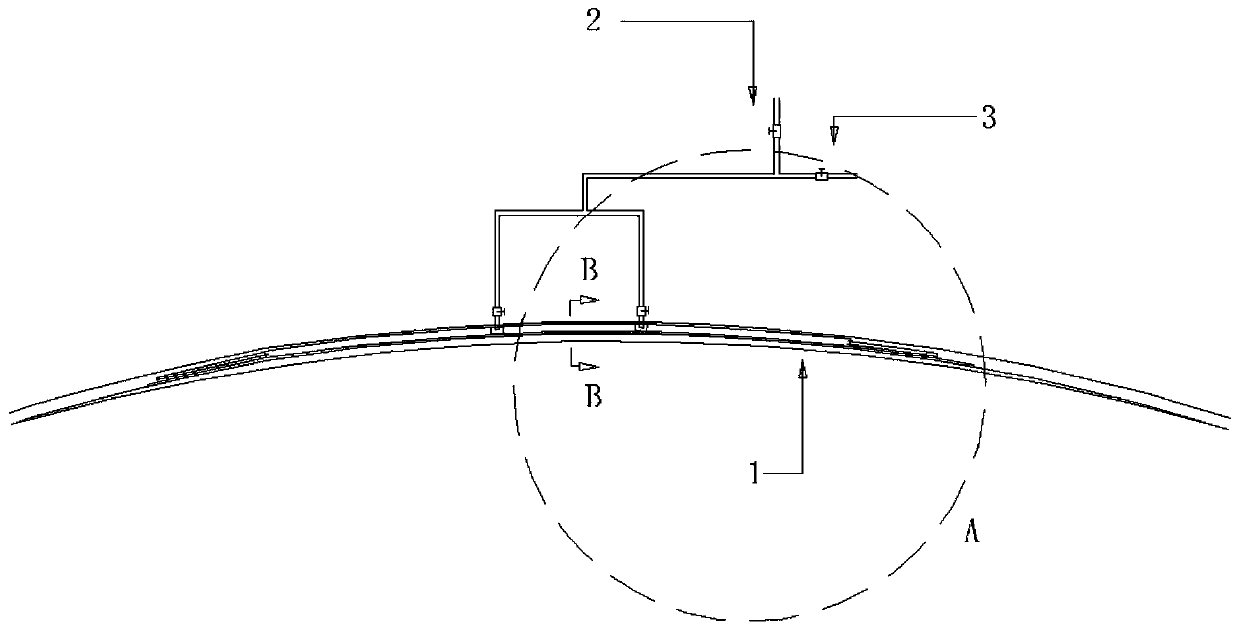

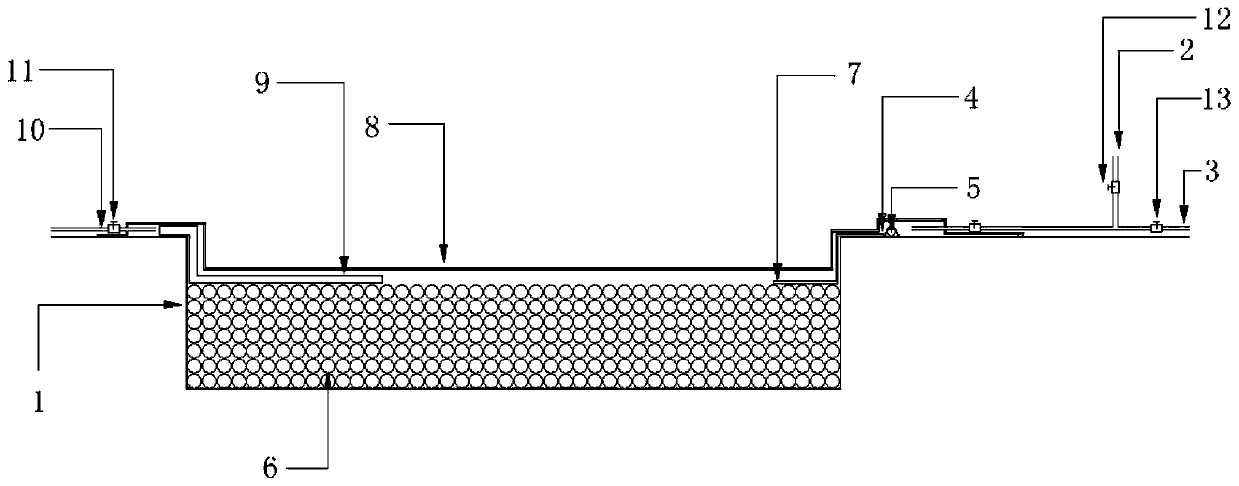

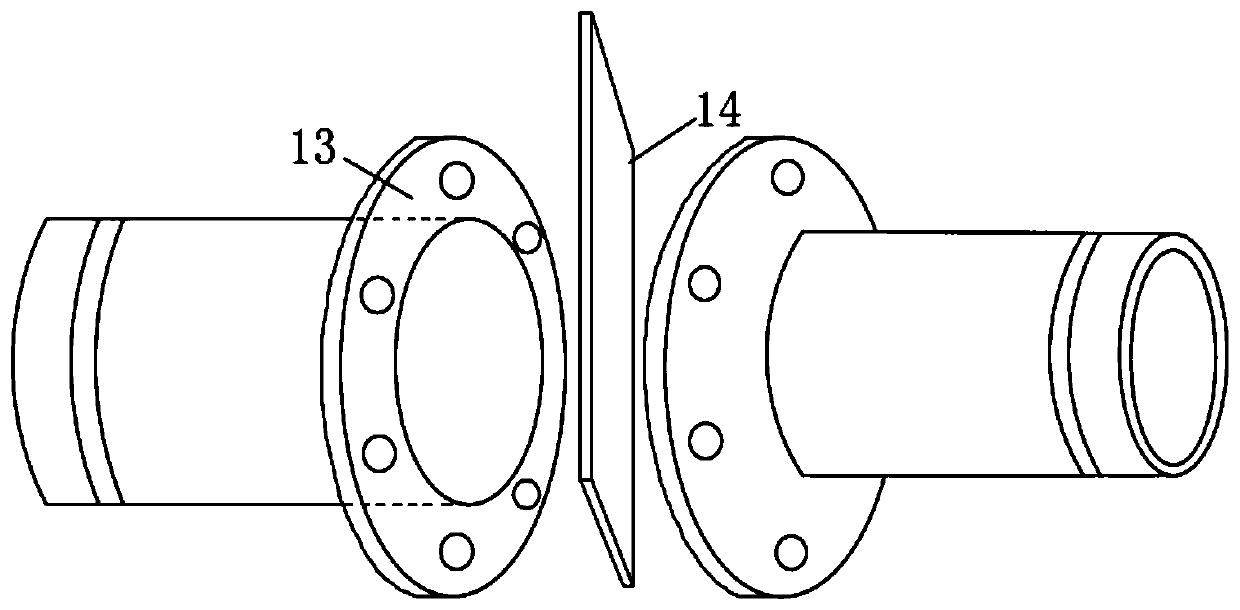

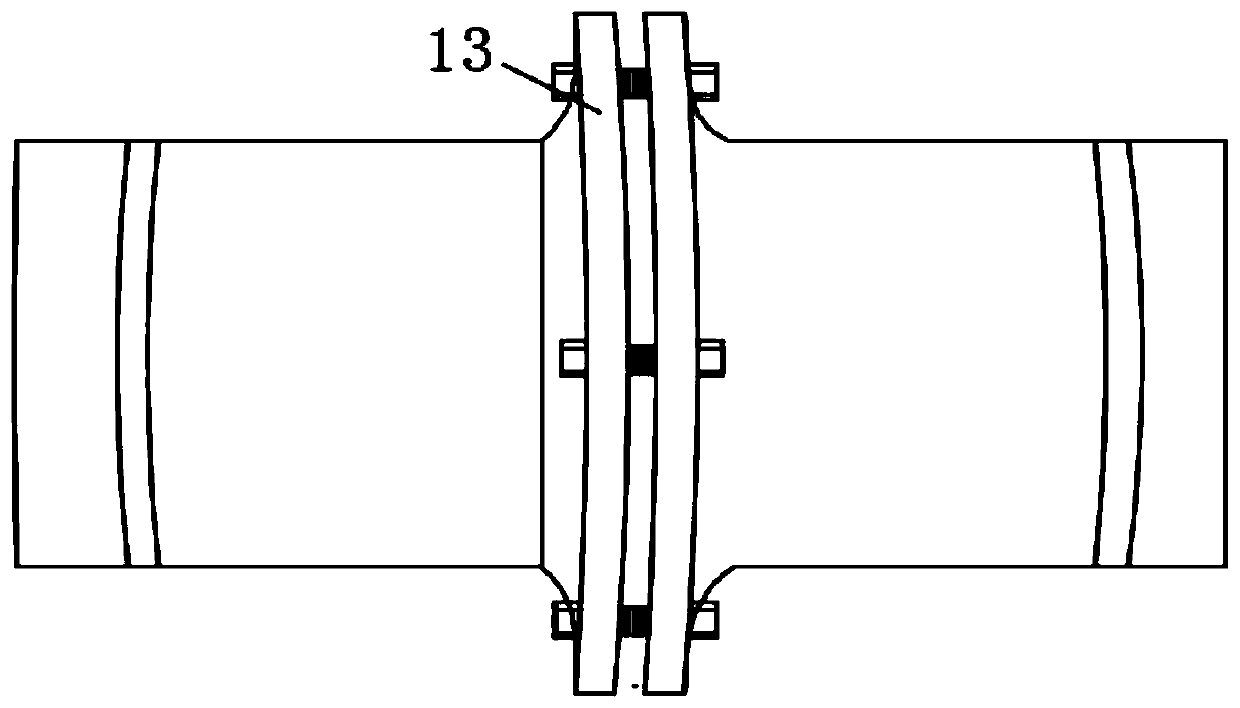

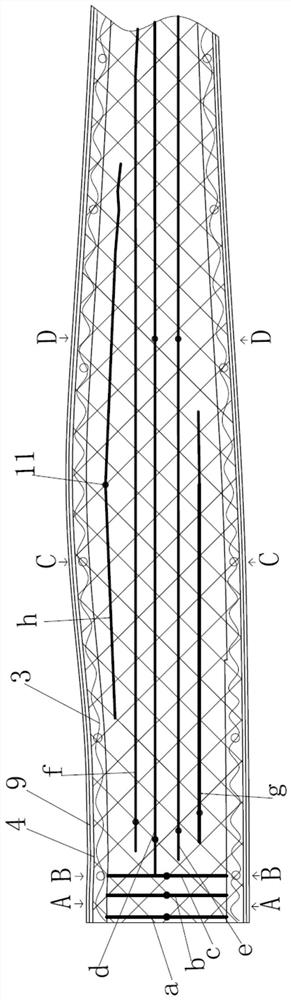

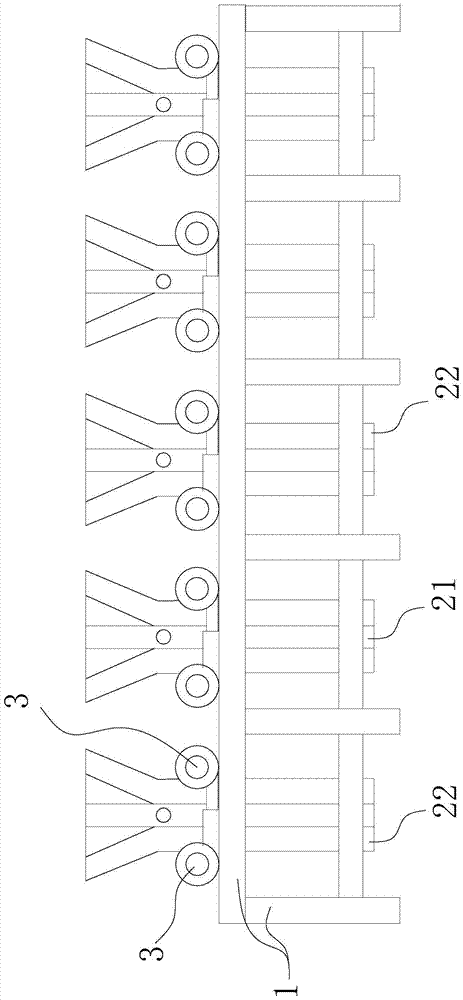

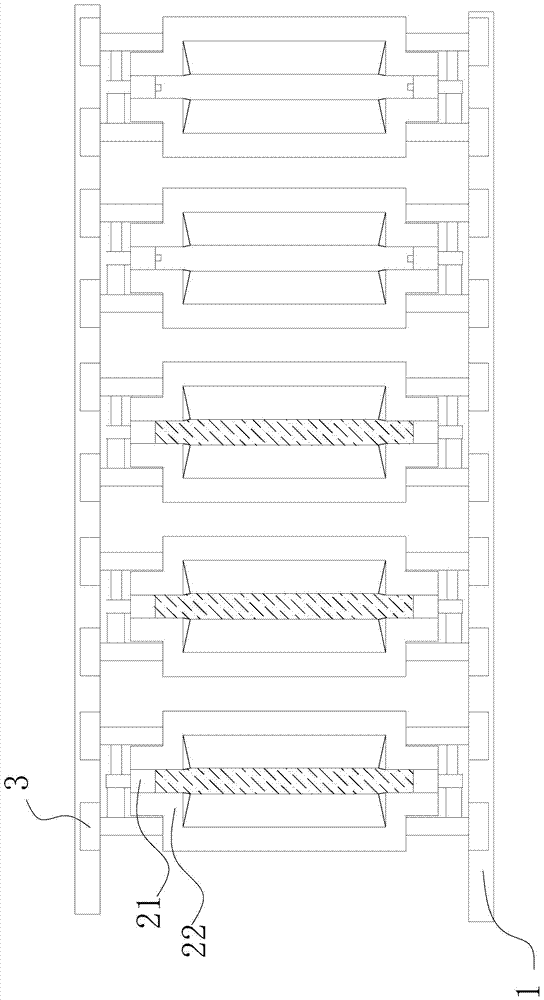

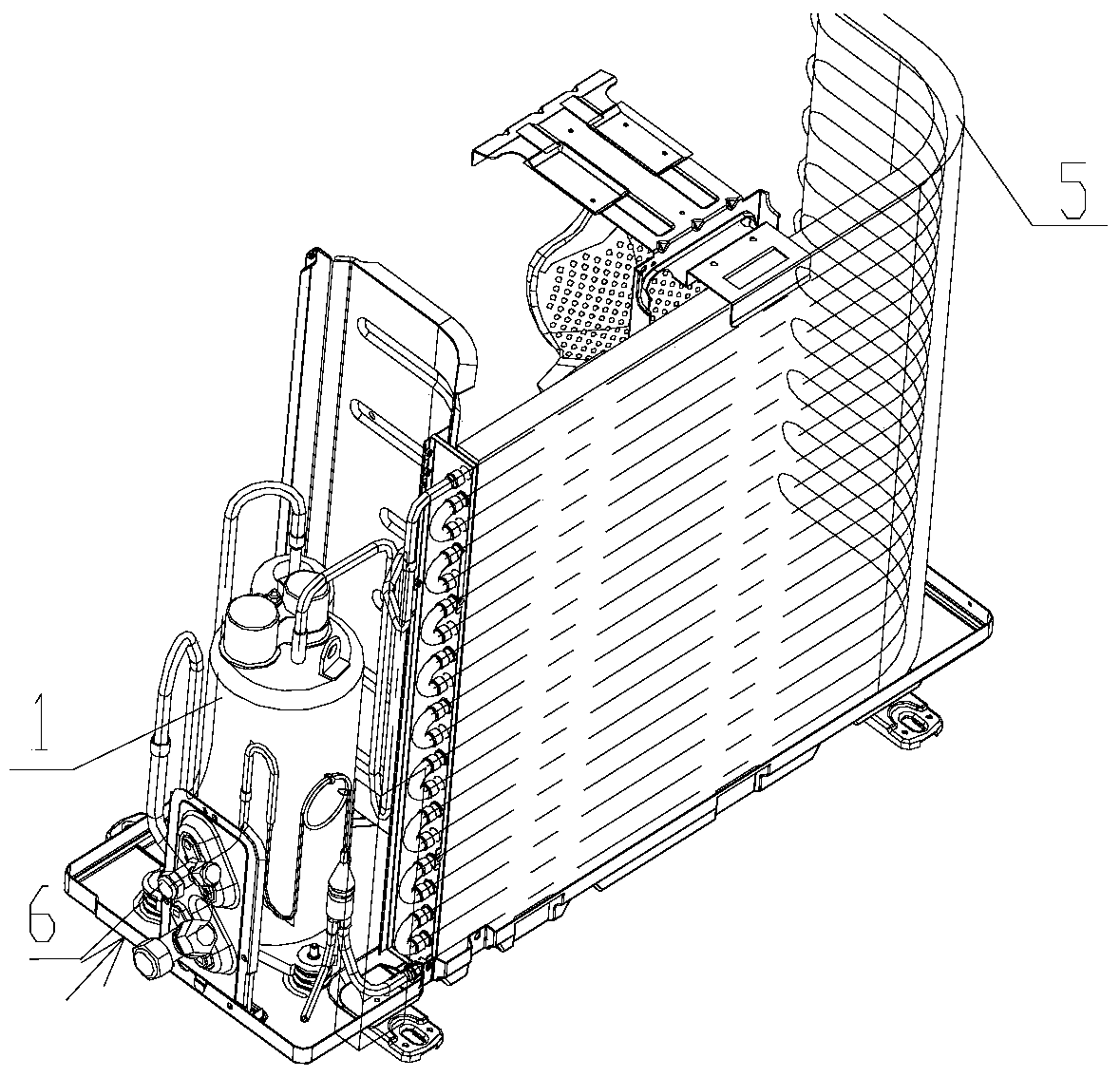

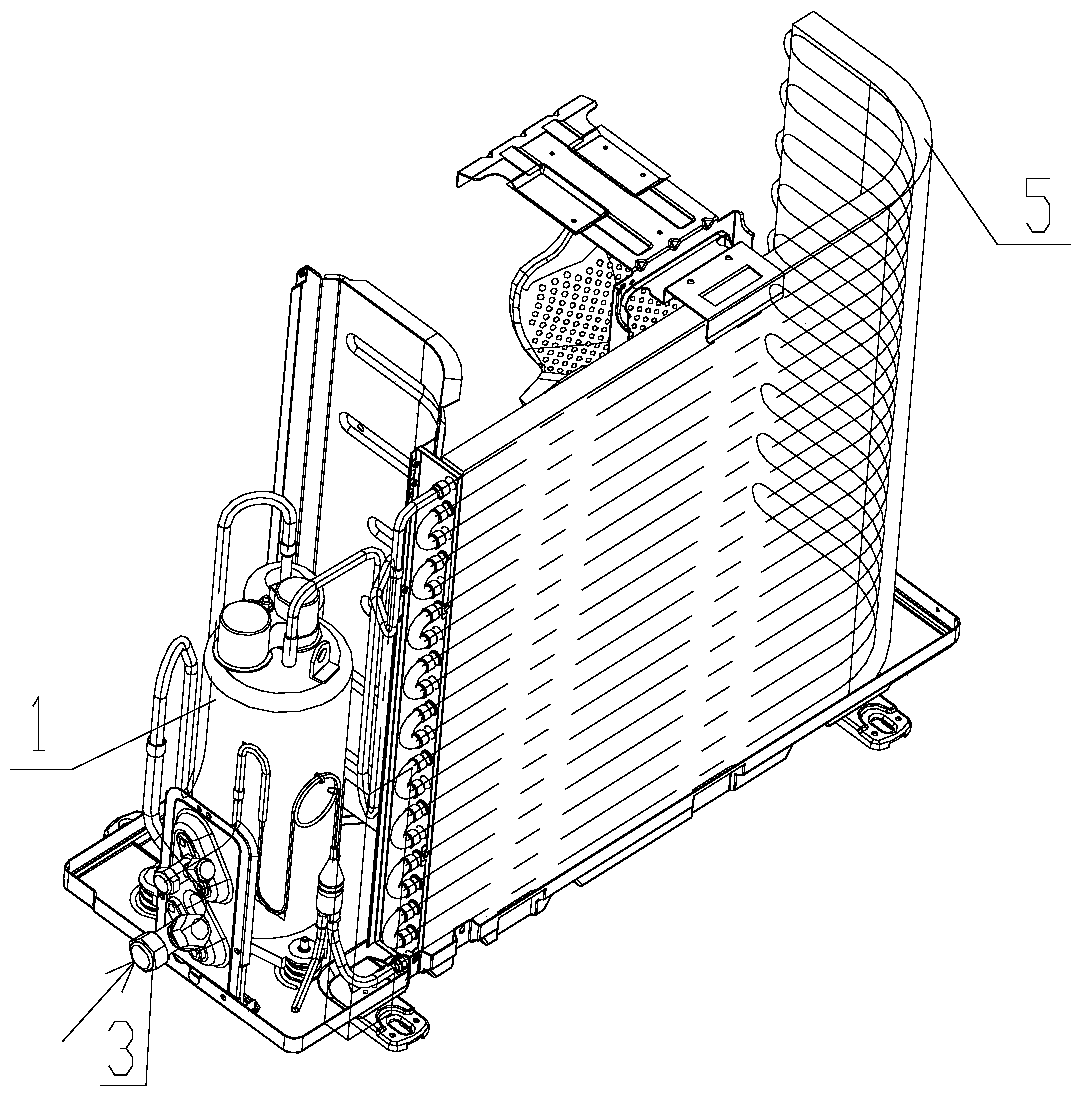

Formation and construction set for continuous open-cut tunnel

ActiveCN104929660AIncrease perfusion rateGood lining surface qualityUnderground chambersTunnel liningVehicle frameRailway tunnel

The invention discloses a formation and construction set for a continuous open-cut tunnel. The formation and construction set comprises a frame; the frame comprises two gantries; the gantries are connected together through a vertical beam; the vertical beam is connected with a formwork through a mechanical support; telescopic posts and travelling mechanisms are provided below the gantries. The formwork comprises a plurality of groups of tunnel arc forms vertically spliced; the tunnel arc forms in each group are in integrated large form structures, the tops of which fit the sectional shape of the tunnel; an arc slurry-lifting and leveling unit is arranged at the top of the tunnel arc forms. The formation and construction set is suitable for lining construction by a wall-first and arch-second method; the designed lining is suitable for use in highways, diversion tunnels, railway tunnels and the like, with less than 600mm of thickness. The formation and construction set is simple in structure and attractive in style, allows convenience for construction, and is of good integrity, high automation level, high form removal speed and high in-position speed.

Owner:北京铁五院工程机械有限公司 +1

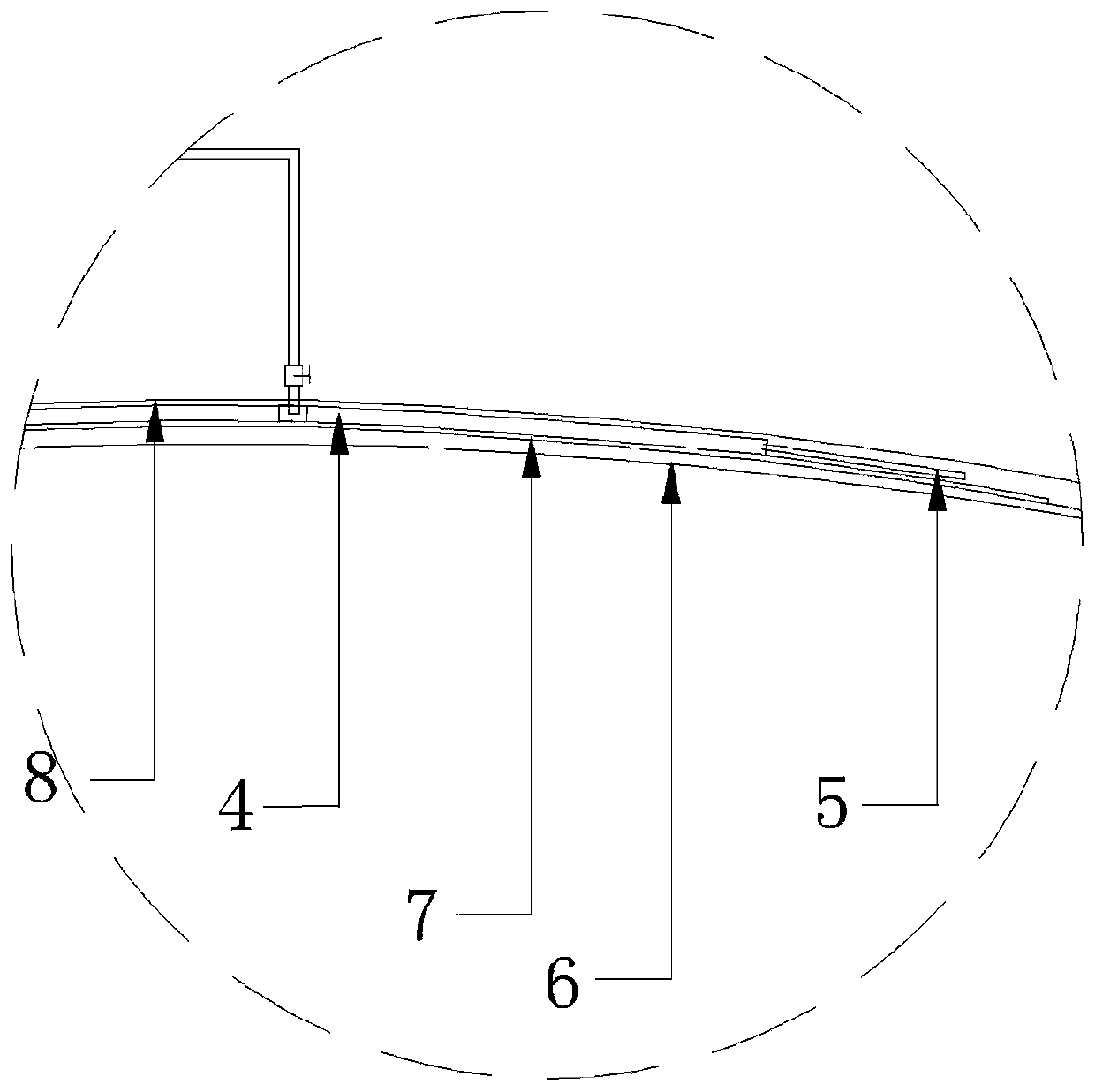

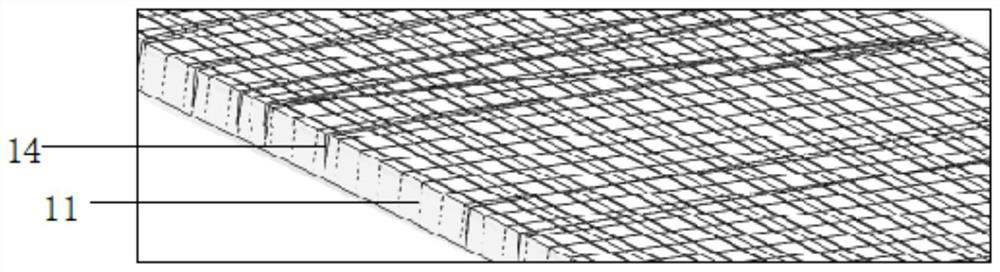

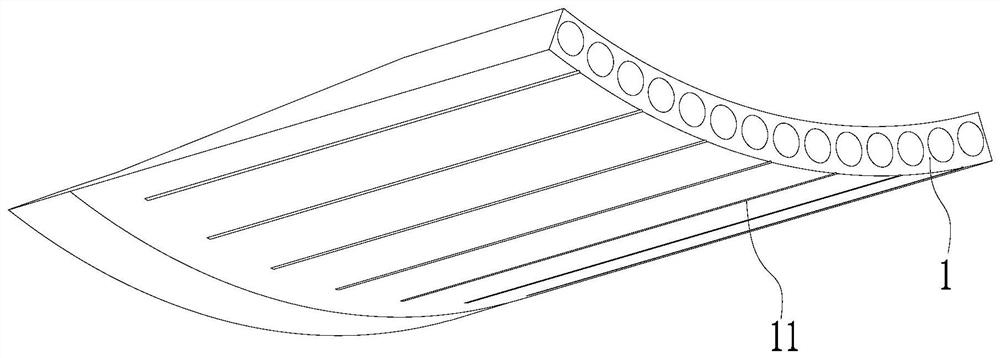

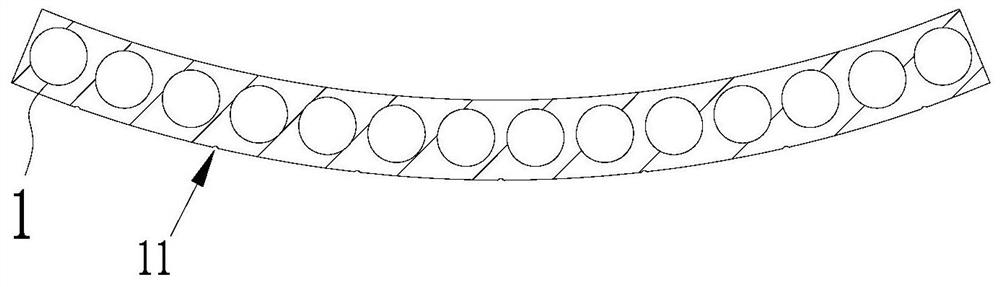

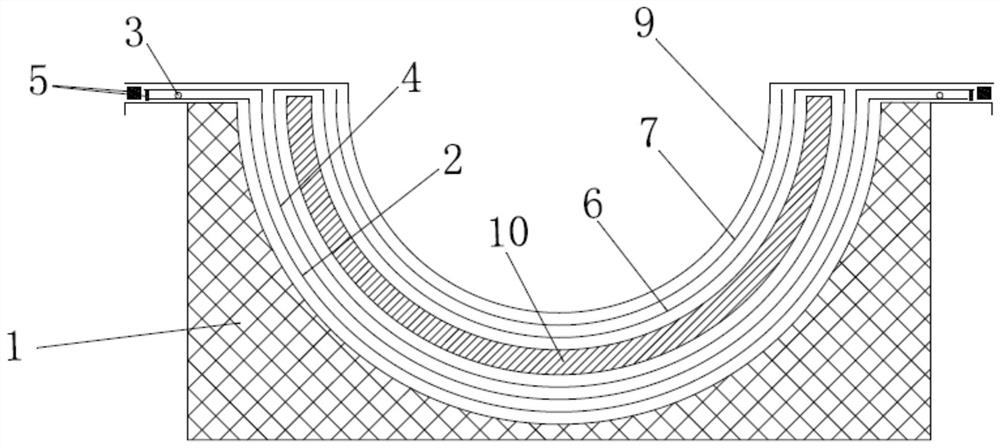

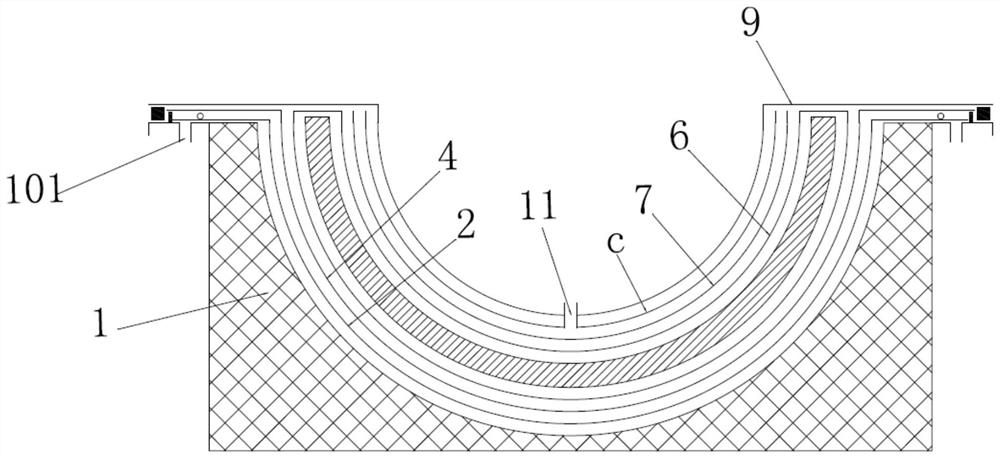

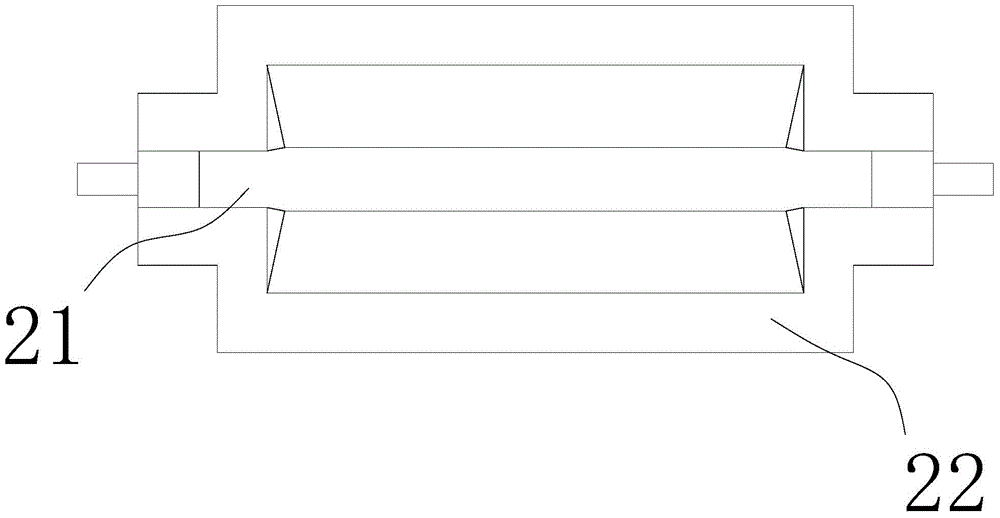

Blade root end pouring device for wind mill

ActiveCN101623932AImprove compactnessImprove product qualityDomestic articlesVacuum pumpingAir bubble

The invention relates to a blade root end pouring device for a wind mill, which comprises a root end structural laying layer, an air pervious isolating film and a vacuum pumping mechanism, wherein a guide net is arranged at the front end of the root end structural laying layer and a resin draft tube is arranged at the upper part at the upper front end of the guide net. The air pervious isolating film is covered on the guide net and between the outlet of the resin draft tube and the front side adjacent to the root end structural laying layer; and the root end structural laying layer, the guide net, the resin draft tube and the air pervious isolating film are arranged in the vacuum pumping mechanism. The device has the advantages that because the auxiliary air extracting mode of the air pervious film is added to a guide layer, residual air bubbles clamped in resin are eliminated so that the compactness of the products is improved, the resin is poured more completely, and the product quality is improved. Moreover, because an integral structural plane is exhausted, the pouring speed and the quality stability can be effectively improved.

Owner:SHANGHAI AEOLON WIND ENERGY TECH DEVGRP CO LTD +3

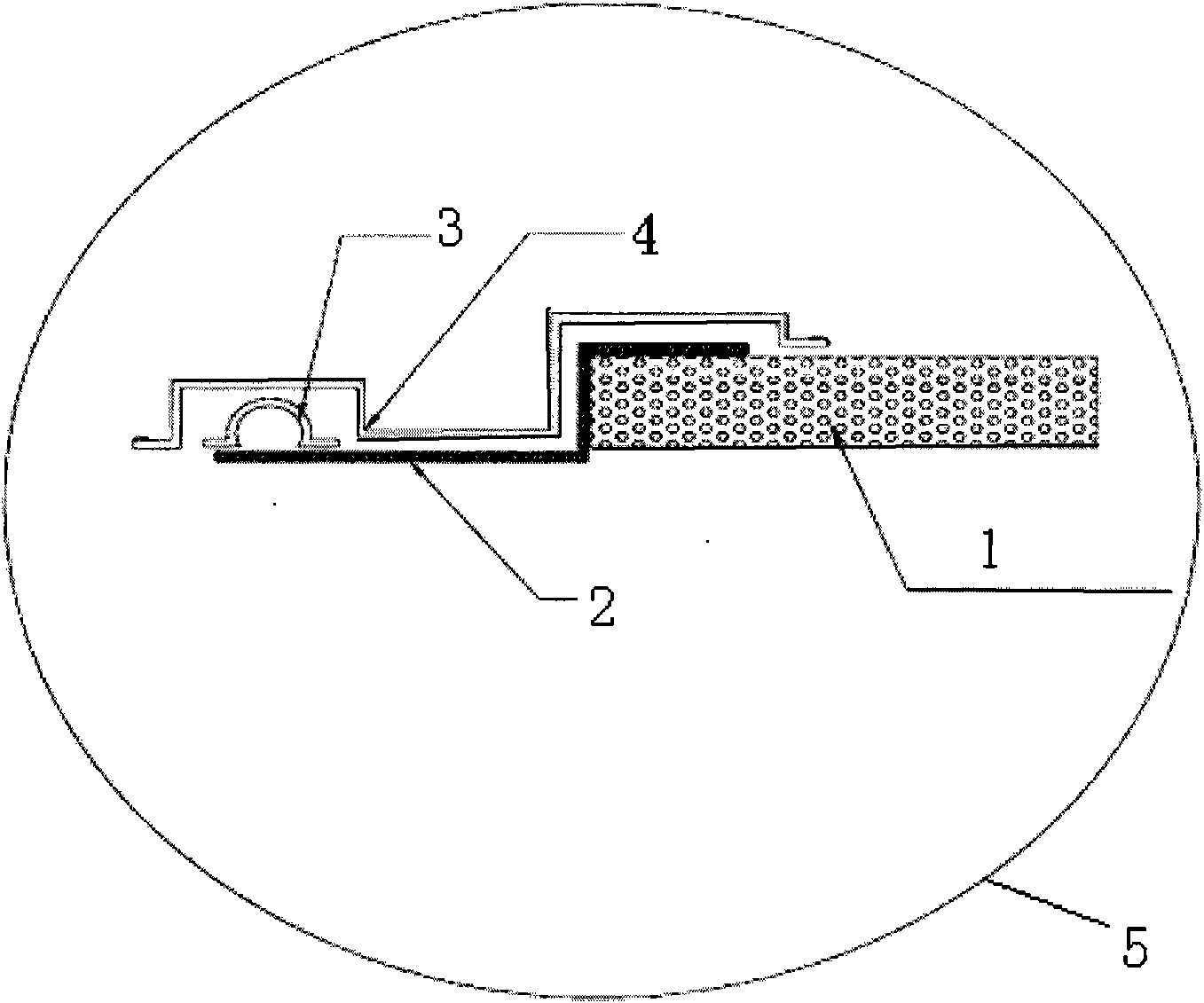

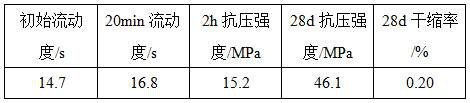

Large-flow-state cement-based grouting material for semi-flexible pavement and preparation method of large-flow-state cement-based grouting material

ActiveCN113135723AGive full play to the "ball effect"Improve mobilitySolid waste managementAluminateRoad engineering

The invention discloses a large-flow-state cement-based grouting material for a semi-flexible pavement and a preparation method of the large-flow-state cement-based grouting material. The large-flow-state cement-based grouting material comprises the components in parts by weight: 35-60 parts of quick-hardening sulfoaluminate cement, 15-40 parts of modified microbeads, 10-30 parts of fine aggregate, 0.01-0.3 part of an early strength agent, 0.1-0.5 part of a water reducing agent, 0.05-0.2 part of a water-retaining agent, 0.001-0.1 part of a defoaming agent, 4-5.5 parts of an expanding agent and 20-35 parts of water. Through cooperative matching of the components, on the basis of relatively high hour strength, the performance improvement of high fluidity, high flow velocity and high pouring rate is realized, and the concrete has the advantages of short construction period, no need of vibration, convenience in construction, high cost performance and the like, and meets the requirement of rapid traffic opening in road engineering.

Owner:CHINA CHEM TRANSPORTATION CONSTR GRP NO 4 ENG CO LTD +2

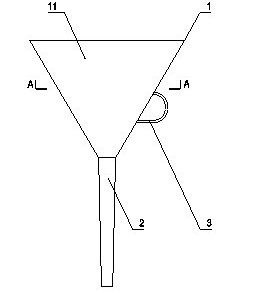

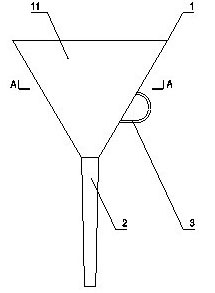

Funnel

The invention discloses a funnel capable of improving pouring speed and reducing labor intensity, comprising a conical bucket and intubation tubes connected with a lower port of the bucket, wherein the bucket comprises at least three side plates, and a plurality of sides of the lower port of the bucket downward extend to form the intubation tubes. Because the inlets of a majority of containers are circular, air returning channels are formed between the outer wall of the funnel and the inlets of the containers, thereby the intubation tubes are not used as the air returning channels any more, and liquid in the intubation tubes still keeps smooth so that the pouring speed is greatly improved; and moreover, in the whole pouring process, operators only need to care whether the liquid overflows the funnel or not so that the labor intensity of operators are greatly reduced.

Owner:谢金宝

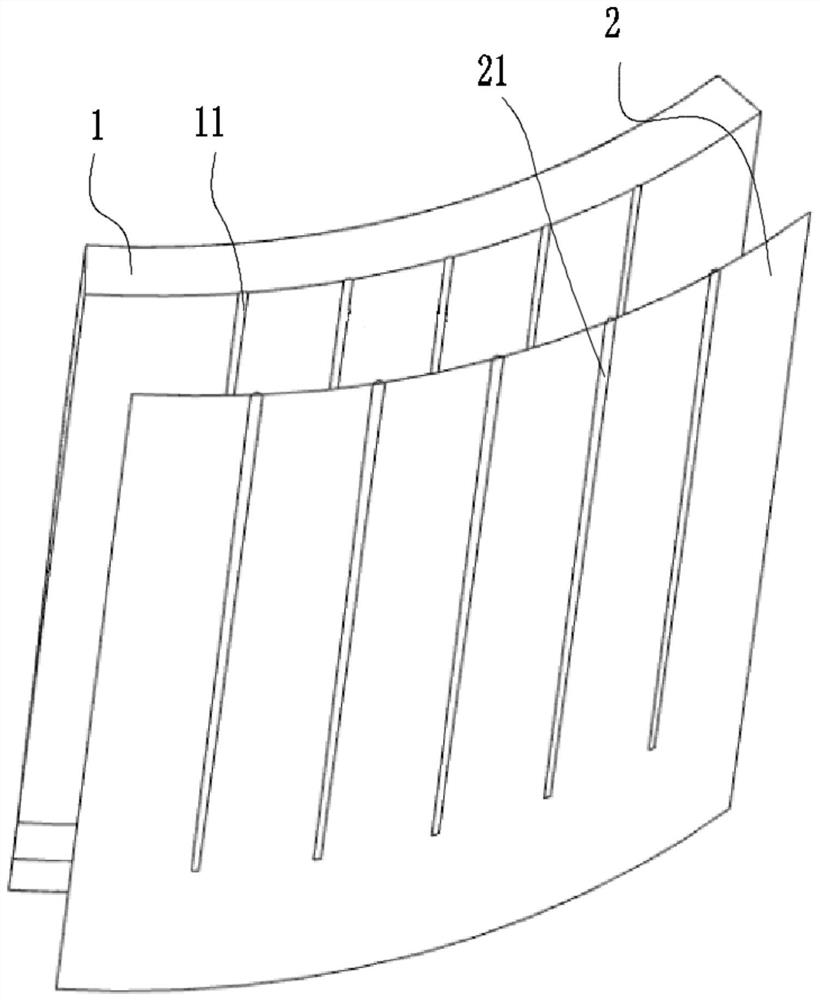

Polyurethane resin pouring structure of wind turbine blade, and forming method

ActiveCN110884167AControl propulsion speedMeet infusion molding requirementsFinal product manufactureDomestic articlesTurbine bladeLap joint

The invention discloses a polyurethane resin pouring structure of a wind turbine blade, and a forming method. The pouring structure comprises a bottom-layer diversion medium, a reinforcement material,an upper-surface diversion medium, a glue pouring pipeline, an Ohm pipe used for glue pouring and a spiral pipe, wherein the bottom-layer diversion medium is disposed on the bottommost layer of a die; the reinforcement material is paved on the bottom-layer diversion medium; the upper-surface diversion medium is disposed on the upper surface of the reinforcement material at a chordwise glue filling side and is in partial lap joint with the upper surface of the reinforcement material; the Ohm pipe is disposed on an edge of the upper-surface diversion medium along an extending direction; a sleeving tubular diameter of two ends of the Ohm pipe is smaller than the diameter of the spiral pipe of the Ohm pipe; and a glue pouring hole of the glue pouring pipeline is located at the middle of the extending direction of the die and is docked with the Ohm pipe. The pouring structure disclosed by the invention has the beneficial effects that an overall pouring speed is increased; prolonging of pouring time caused by irrational flow channel design at a few of positions is avoided, so production efficiency is increased; easy occurrence of pouring failure during manufacture of polyurethane composite material products can be improved; and risks in shaping are reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

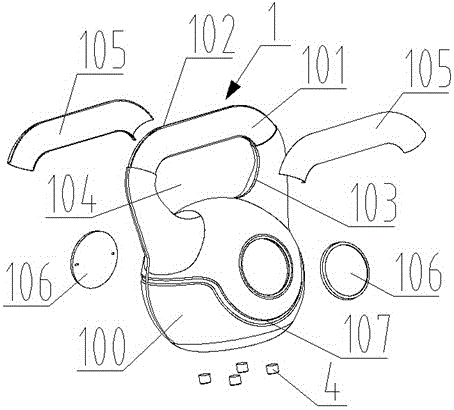

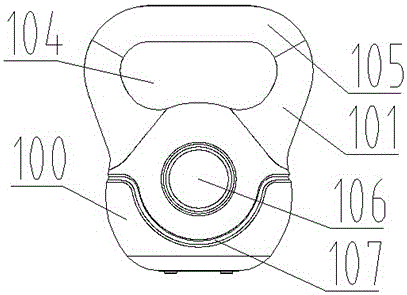

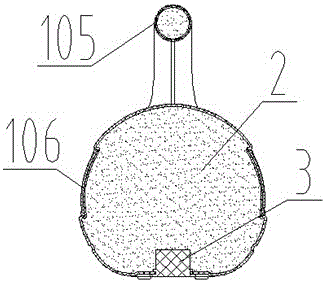

Kettle bell, kettle bell shell and production method of kettle bell

The invention provides a kettle bell, a kettle bell shell and a production method of the kettle bell. The kettle bell comprises a shell and a counter weight filling the inside of the shell, wherein an opening is formed at the bottom of the shell; a cover sealing the opening is arranged at the opening; the counter weight is classified into a liquid-state counter weight and a solid-state counter weight which are poured into the shell through the opening respectively; and the solid-state counter weight and the liquid-state counter weight are mixed and then condensed with the inner wall of the shell and the cover. In the invention, the counter weight of the kettle bell is classified into a liquid-state counter weight and a solid-state counter weight which are poured into the shell of the kettle bell through the opening respectively; the liquid-state counter weight and the solid-state counter weight have relatively high fluidity and are convenient to pour; and compared with existing technology of mixing the two into a thick fluid before pouring, the pouring speed can be at least doubled. Moreover, the liquid-state counter weight and the solid-state counter weight are poured separately, the hard-to-clear mixed solidified object of water and cement is not formed on the outer surface of the kettle bell, and convenience is provided for follow-up cleaning and shaping of the kettle bell.

Owner:南通鑫鑫体育运动用品有限公司

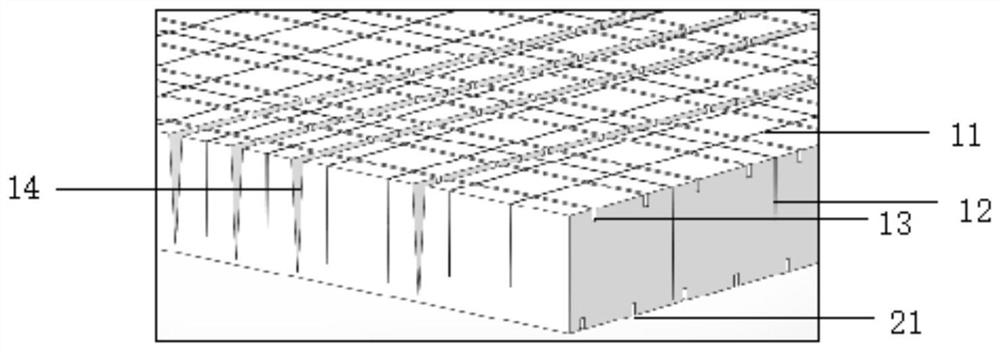

Wind turbine blade core material and machining method thereof

PendingCN112477189AIncrease productivityReduce gapDomestic articlesMetal working apparatusTurbine bladeStructural engineering

The invention discloses a wind turbine blade core material. A plurality of deep and shallow grooves are cut in the first surface of the core material, a plurality of shallow grooves are cut in the second surface of the core material, and a plurality of multi-angle V-shaped structure grooves are cut in the first surface or the second surface of the core material. The number of the cut grooves is increased, core material adapts to the specially-shaped cambered surface and the height difference of a mold when placed by the aid of the multi-angle V-shaped structure grooves, the defects such as gaps, wrinkles, protrusions and the like in the actual use process are reduced, the flow guide speed is increased in the pouring process, and the production efficiency of a wind turbine blade is improved.

Owner:ZHEJIANG LIANYANG NEW MATERIAL

Concrete pouring system and pouring method for concrete filled steel tube bracket

PendingCN110486054AImprove liquidityImprove compactnessUnderground chambersPipe elementsSlurryCheck valve

The invention relates to a concrete pouring system and pouring method for a concrete filled steel tube bracket.The concrete pouring system comprises a mixer, a delivery pump, a delivery pipeline, a check valve, a pouring hole and an exhaust slurry discharging hole matched withthe bracket andan attached pneumatic vibrator, concrete is prepared by the mixer, and delivered to the delivery pump, and the pouring hole is formed in the bracket, the pouring hole is located at the bottom end of one side of the bracket, the upper end of the other side of the bracket is connected with the attached pneumatic vibrator, the top end of the bracket is provided with theexhaust slurry discharging hole, and the delivery pump is connected with the pouring hole through the delivery pipeline. The concrete in the bracket first flows down from the pouring hole to an underground pipeline, after the concrete is filled,the concrete is poured into a pipeline above the pouring hole by pumping and jacking,when reaching the position of the exhaust slurry discharging hole of the bracket, the concrete is dropped at a high level,at the same time, the attached pneumatic vibrator drives the bracket to vibrate,and smooth and dense pouring of the concrete in the bracket is ensured. Bubbles and bleeding in the concrete in the bracket are avoided, density of the concrete is improved, and the fact that the concrete-filled steel tube bracket reaches the design bearing capacity is ensured.

Owner:SHANDONG JIANZHU UNIV

Prefabricated part, prefabricated part mold, wind power blade and manufacturing method of wind power blade

The invention provides a prefabricated part, a prefabricated part mold, a wind power blade and a manufacturing method of the wind power blade. One strip-shaped groove is formed in the lower surface ofa prefabricated part body and can extend from one end of the prefabricated part body to the other end of the prefabricated part body so that during subsequent blade machining and molding, poured resin materials can flow along the strip-shaped groove; a protruding part is directly arranged on the prefabricated part mold in a protruding mode, when a prefabricated part is machined, the strip-shapedgroove can be directly formed in the bottom of the prefabricated part body, secondary machining of the prefabricated part can be avoided, the influence on the performance of fibers on the lower surface of the prefabricated part body is avoided, and the machining process is simpler, so that the production cost of the prefabricated part is reduced; and the pouring speed and the pouring effect can beimproved, and the problem that a bottom layer cannot be completely poured through when pouring is carried out from top to bottom is solved, so that the possibility that a cloth layer is whitened is reduced, and the molding rate is increased.

Owner:SINOMATECH WIND POWER BLADE

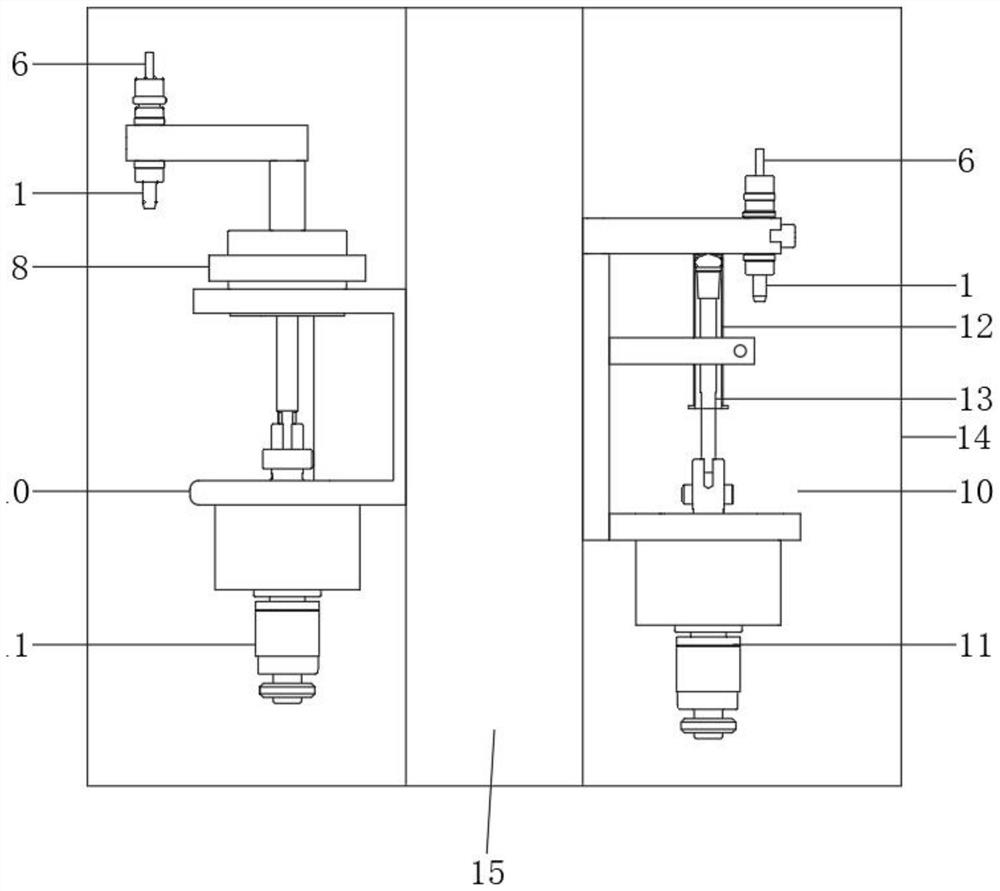

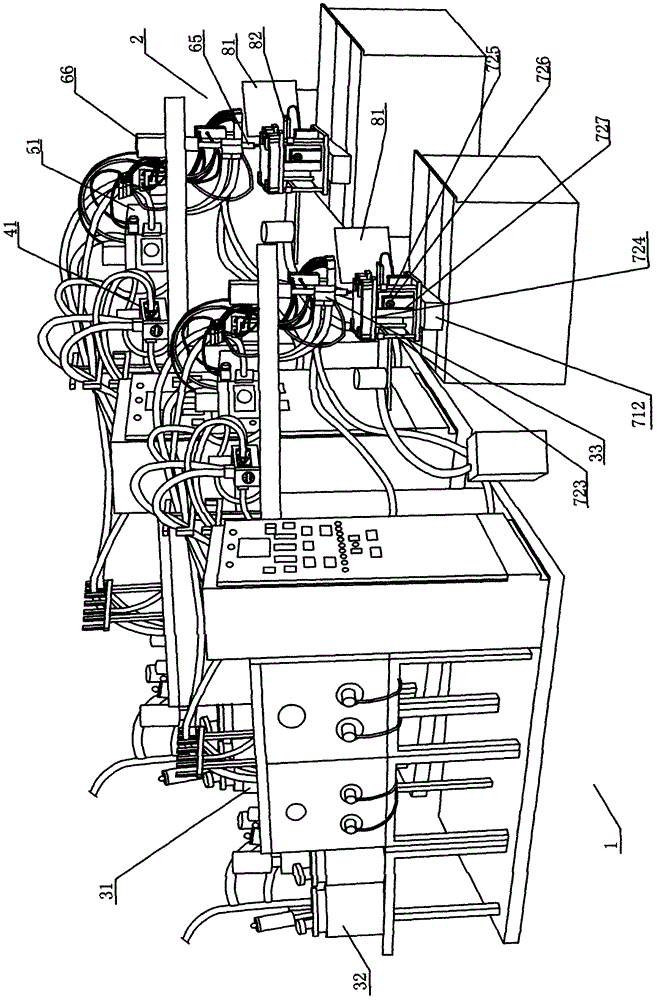

Rapid packaging machine for canned fruits

InactiveCN111977043AImprove packaging efficiencyIncrease perfusion rateLiquid materialBiotechnologyCanned fruit

The invention belongs to the technical field of canned fruit processing, and particularly relates to a rapid packaging machine for canned fruits. The rapid packaging machine comprises a base, whereinthe top of the base is fixedly connected with a platform through a group of vertical rods; a discharging cylinder is arranged at the top of the platform, and a discharging pipe communicating with thebottom of the discharging cylinder penetrates through the platform and extends to the bottom of the platform; the bottom of the discharging pipe is fixedly connected with an annular elastic ring, andthe bottom of the elastic ring is fixedly connected with a fixing ring; a first support is arranged on one side of the discharging pipe, a rack penetrates through the first support, and the bottom ofthe rack is fixedly connected with the fixing ring; a supporting unit is arranged between the rack and the discharging pipe; and one side of the first support is rotationally connected with a third gear through a support, the third gear is meshed with the rack, the third rack is driven by a servo motor, and the servo motor is connected with a power supply through a controller. According to the rapid packaging machine, the third gear drives the rack to move downwards, so that the fixing ring slides downwards to stretch the elastic ring and extend into a can body, and liquid splashing is reduced.

Owner:宿州市睿鼎信息科技有限公司

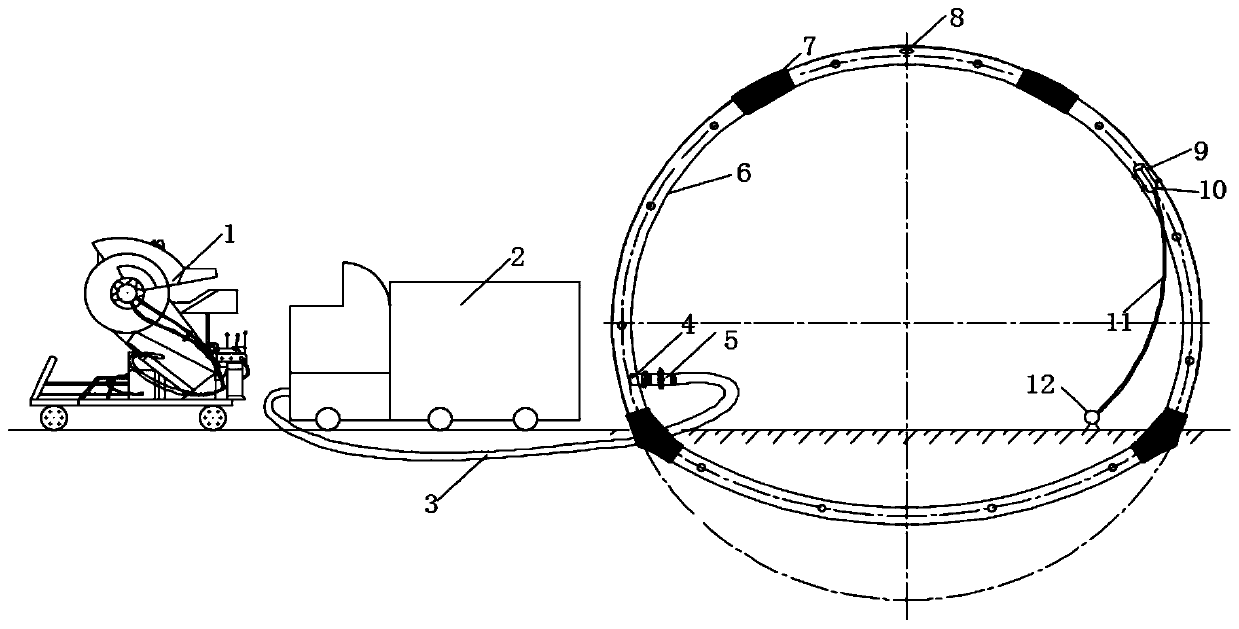

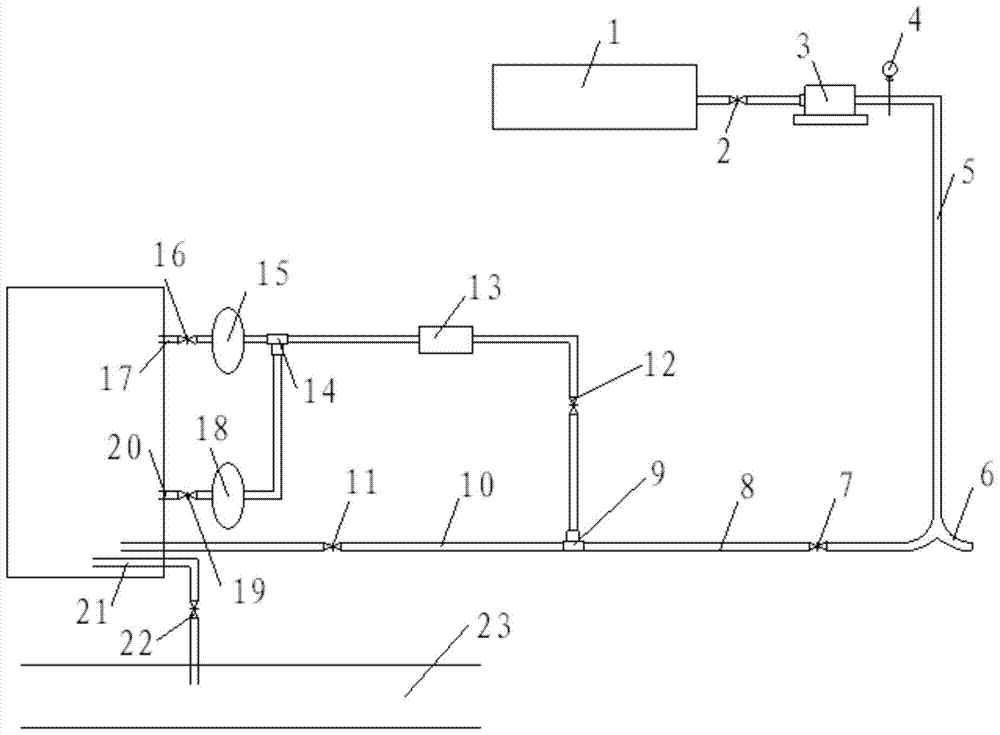

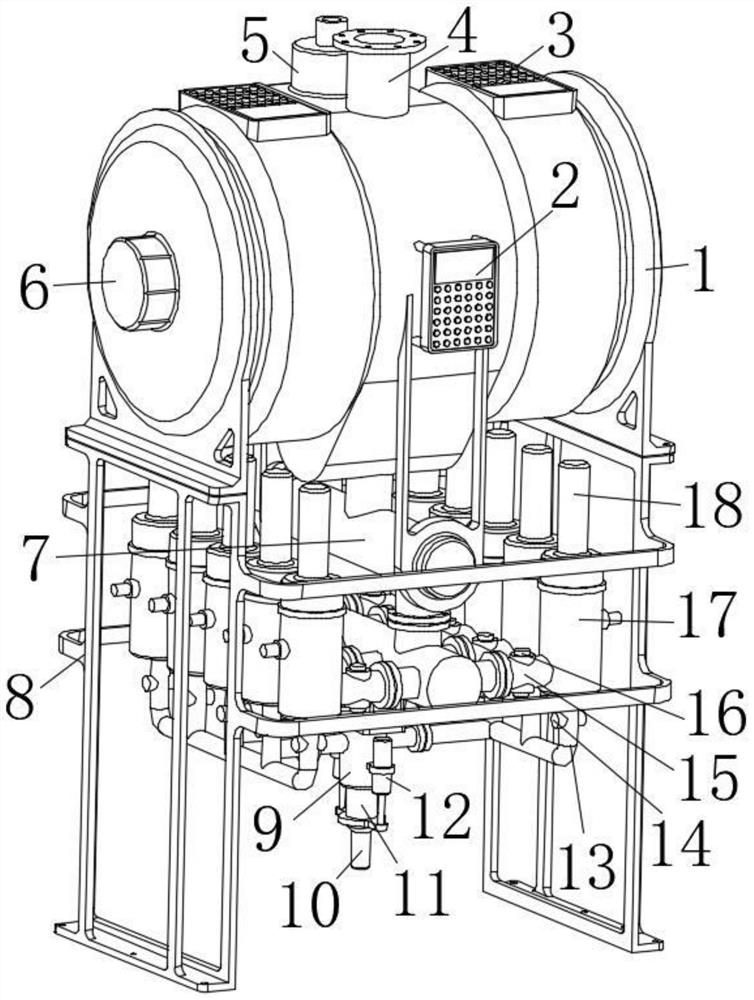

A liquid nitrogen fire extinguishing system and method

ActiveCN104775843BReduce pressureReduce perfusion resistanceDust removalFire preventionNitrogenHigh pressure

The invention discloses a liquid nitrogen fireproof fire extinguishing system, comprising a liquid nitrogen tank car; the liquid nitrogen tank car is connected with a pump, a vertical shaft and a liquid nitrogen conveying main pipe in sequence; the liquid nitrogen conveying main pipe is connected with a liquid nitrogen direct injection pipe for injecting liquid nitrogen into a goaf and a liquid nitrogen gasifying device for gasifying the liquid nitrogen into nitrogen and then injecting the nitrogen into the goaf; the goaf is integrally provided with an exhaust pipe connected with an air return pipeline; the exhaust pipe is provided with a first control valve; the goaf is internally provided with a sensor for monitoring pressure. The invention also discloses a liquid nitrogen fireproof fire extinguishing method. The liquid nitrogen fireproof fire extinguishing system and the method have the beneficial effects that the exhaust pipe is arranged in the goaf, when the pressure in the goaf is larger than a preset value, air in the goaf can be exhausted, so the pressure of the goaf is reduced, the nitrogen filling speed is improved, and inert gas and harmful gas in the goaf are prevented from escaping from cracks in upper edges corners of the goaf into a working area under action of high pressure.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

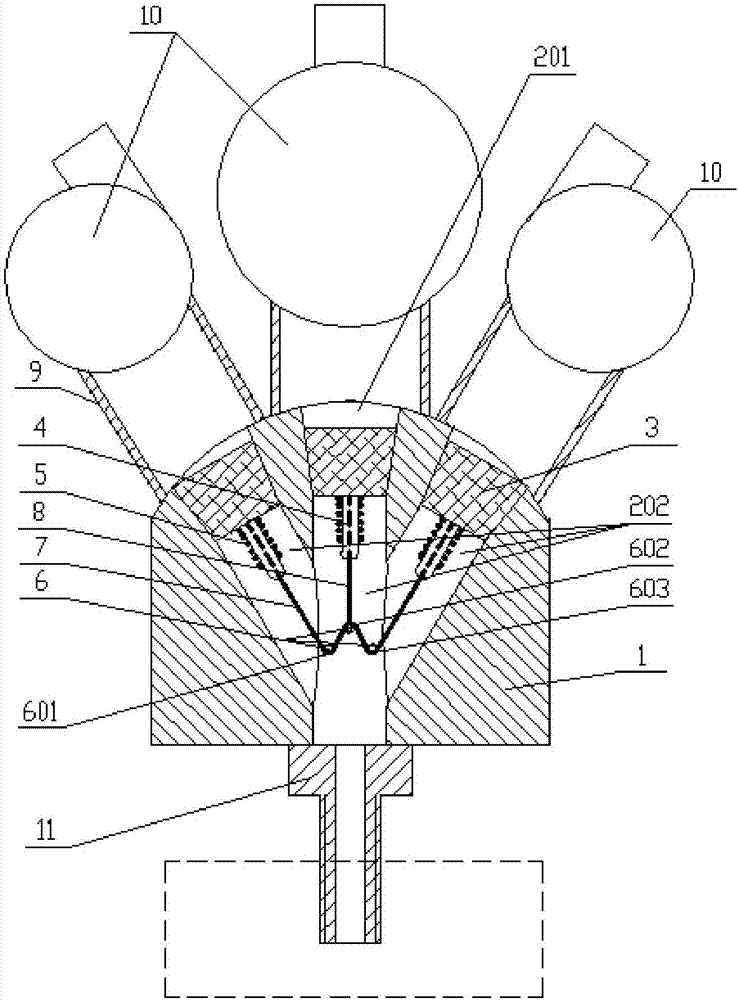

Multifunctional valve

InactiveCN106917883ALarge openingIncrease perfusion rateOperating means/releasing devices for valvesMultiple way valvesNatural stateBilateral symmetry

The invention discloses a multifunctional valve. Three communicated flow passages are arranged in a valve main body of the multifunctional valve; each flow passage comprises a conical hole and a cylindrical hole, wherein one flow passage is positioned on the axial line of the valve main body; the other two flow passages are in bilateral symmetry by using the flow passage positioned on the axial line as the symmetry axis; an identical conical piston is arranged in each flow passage; a fixing rod is arranged in the cylindrical hole; a spring sleeves a rod body at the section, coaxial with the cylindrical hole, of the fixing rod; the upper end of the spring is connected with the piston; the other end of the spring is welded at the surface of the fixing rod; three pulleys are arranged in the flow passage at the crossed and converged part of the three flow passages; a first elastic rope bypasses the three pulleys; the middle is connected with a second elastic rope connected with the small end surface of the piston positioned in the middle; in a natural state, the first elastic rope and the second elastic rope freely and straightly extend. The multifunctional valve has the advantages that the pressure intensity of each container after the filling can be enabled to be maintained in the identical range; the automatic regulation and flow division can also be realized; the filling efficiency is accelerated.

Owner:秦朝东

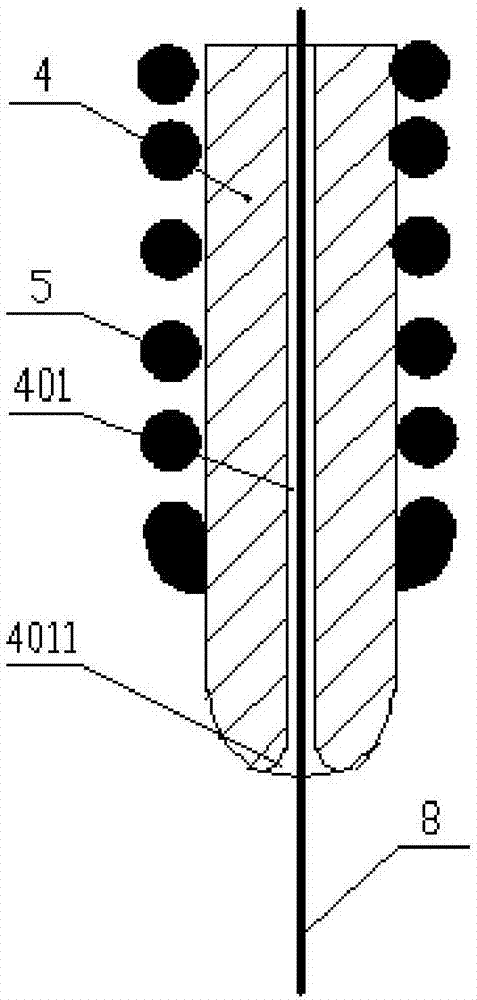

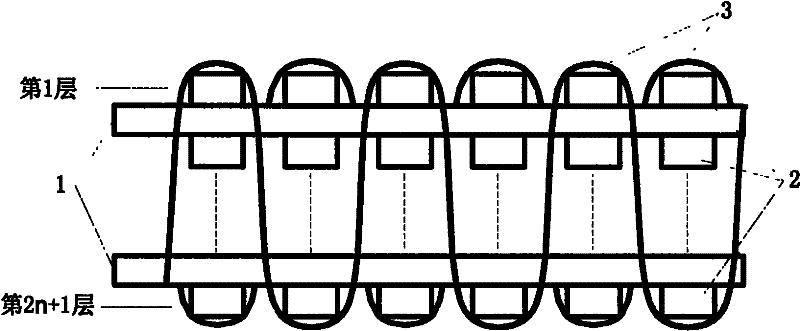

Enhanced permeable medium

The invention belongs to the technical field of composite molding process, relating to an enhanced permeable medium. The enhanced permeable medium is laid by odd layers of non-woven parallel yarns at a certain angle and is weaved by yarns used for weaving in low weaving density to form a three dimensional fabric with sparse weaving points; vast penetrating gaps or grooves are reserved in the fabric to provide channels for air and resin flow, so that the fabric has better permeably property of resin. The enhanced permeably medium of the invention can effectively increase flow rates of resins, realize sound immersion of fiber fabrics in resins, obviously increase reliability of pouring technique and improve uniformity of products. The products with smooth surfaces are directly obtained whenusing the medium without changing die structure, thus saving time and labor and being economical and efficient. The enhanced permeably medium of the invention has strong designability, and permeable media with demand structures are obtained by designing structural parameters such as material quality, yarns and angles, etc. according to the characteristics of the composite.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

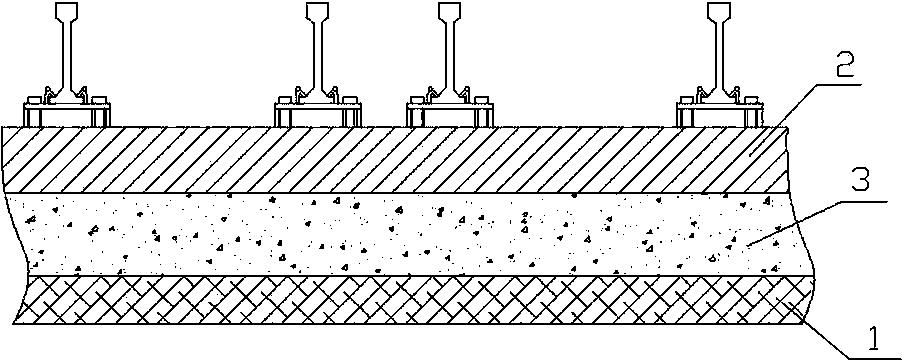

Concrete for railway switch base filling layer and pouring method

ActiveCN102617082AImprove liquidityExcellent self-filling performanceRailway track constructionLeaking waterRebar

The invention discloses concrete for a railway switch base filling layer. The concrete is mixed by raw materials including 370 parts of cement, 180 parts of mineral mixtures, 44 parts of expanding agent, 866 parts of river sand, 738 parts of broken stones, 184 parts of water and 7.7 parts of polycarboxylic copolymer according to 1M3 filling quantity standard. When the railway switch base filling layer is poured, a leveling blanket and switch slabs are constructed according to a conventional method at first, a pouring mode by the aid of a pump truck, a transfer hopper and a chute is adopted, and each switch slab is poured at one step. As the concrete has excellent mobility and a self-filling performance, the concrete can pass through an engineering portion with compact reinforcements and the complex structural section, is dense in filling, does not segregate or leak water, and has high homogeneity, engineering quality is guaranteed, durability of a concrete structure is improved, the problem that pouring of vibration operation components is not easy to be applied or cannot be applied is resolved, pouring speed is improved, a construction process of the concrete structure is simplified, construction efficiency and construction quality are improved, and construction period is shortened.

Owner:ZHENGZHOU ENG CO LTD CHINA RAILWAY SEVENTH GRP

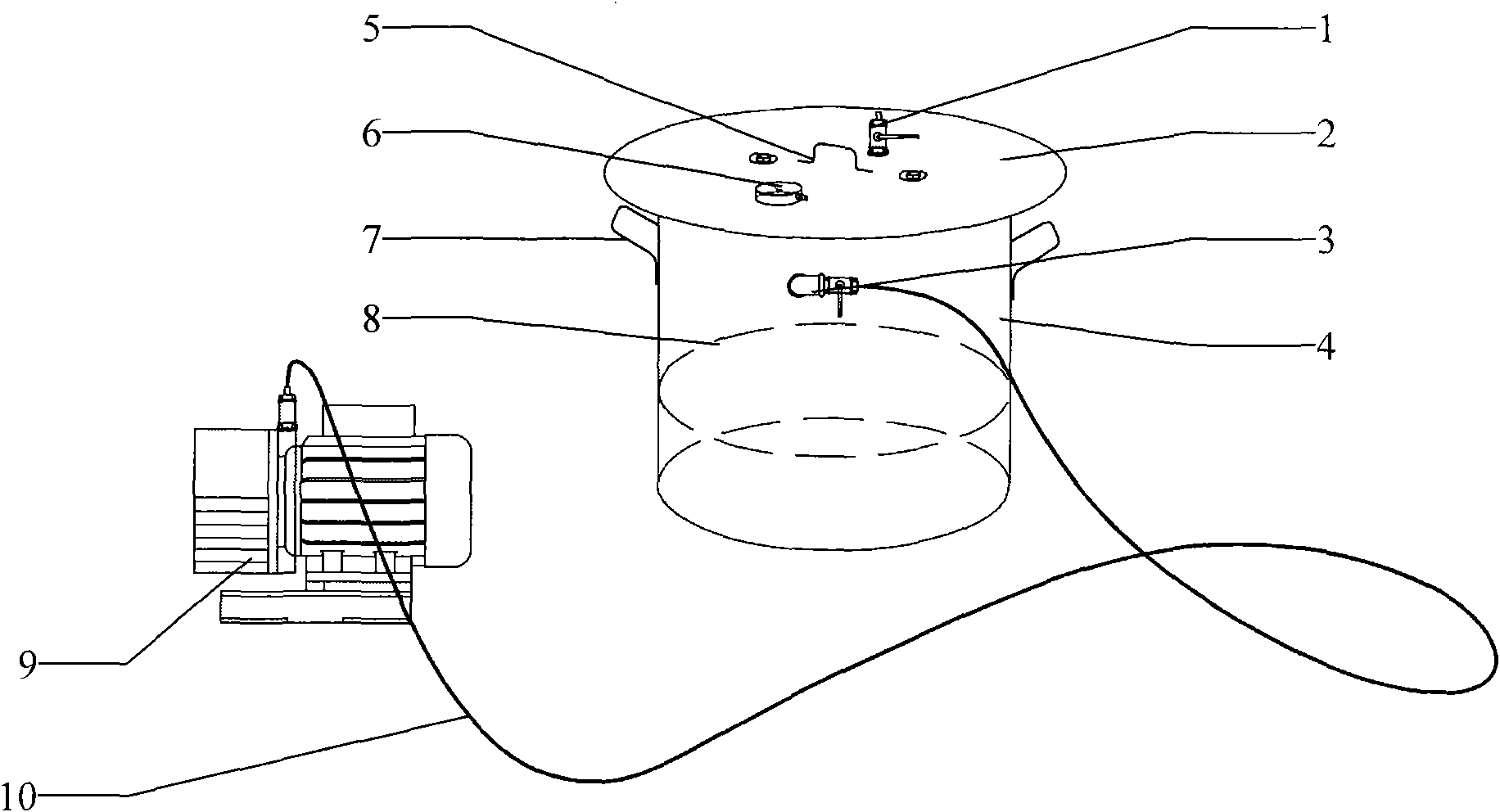

Negative-pressure infusion method and negative-pressure infusion device for cutflower preservation pipe

InactiveCN101624098AIncrease perfusion rateImprove perfusion efficiencyLiquid materialLiquid bottlingInfusion methodInlet valve

The invention relates to a negative-pressure infusion method for a cut flower preservation pipe. The method comprises the following steps: using a screen cover to press finger pipes which need to be infused and are provided with crack covers at the bottom of a infusion bucket to prevent the finger pipes from floating on a liquid level after liquid is added; infusing a sufficient amount of infusion liquid into the infusion bucket to immerse the finger pipes so that the infusion liquid can still immerse the finger pipes after all the finger pipes are filled with the infusion liquid; and vacuumizing the finger pipes to extract air remained in the finger pipes so that the infusion liquid is automatically infused into the finger pipes. The infusion device comprises the infusion bucket, a sealing cover, a vacuum pump, a conduit, and the like, wherein the sealing cover is provided with a sealing ring, an air inlet valve and a negative pressure gauge; the infusion bucket is provided with the screen cover; three protrusions are uniformly distributed on the inner wall in the one-half height of the infusion bucket to clamp the screen cover; and the conduit is connected with the vacuum pump and the infusion bucket. The invention aims to provide the finger pipe infusion method with high throughput and high effective infusion rate so as to increase the infusion speed, improve the infusion efficiency, realize the cut flower preservation effect, lessen manpower input and decrease the production cost.

Owner:海南出入境检验检疫局热带植物隔离检疫中心

Manufacturing and forming method of rapid vacuum injection system for blades of wind generating set

ActiveCN113386366AImprove vacuum infusion efficiencyImprove perfusion efficiencyFinal product manufactureWind energy generationProcess engineeringVacuum pump

The invention discloses a manufacturing and forming method of a rapid vacuum injection system for blades of a wind generating set, which comprises the following steps of: laying a gas guide medium, spiral exhaust pipes, a one-way ventilated membrane, demolding cloth and a flow guide net in an inner cavity of a blade mold in sequence, then laying a plurality of ohm pipes at set positions above the flow guide net, placing a glue injection port at a set position on each ohm pipe, covering the upper surfaces of the flow guide net, the ohm pipes and the glue injection ports with a vacuum bag film, then connecting external glue injection pipes with the glue injection ports, connecting an air exhaust port on a blade mold flange with an external vacuum pump, maintaining the pressure, and preheating the mold and a laying layer to a set temperature after qualification, then opening all the glue injection pipes, and injecting resin into the injection system through the glue injection ports; and after injection is completed, heating the mold, and after heating is maintained for a set time, completing curing. The method can effectively solve the problems that an existing blade injection manufacturing period is long, the process tolerance rate is small, resin spreading is uncontrollable, and the quality fluctuation of a finished product is large.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

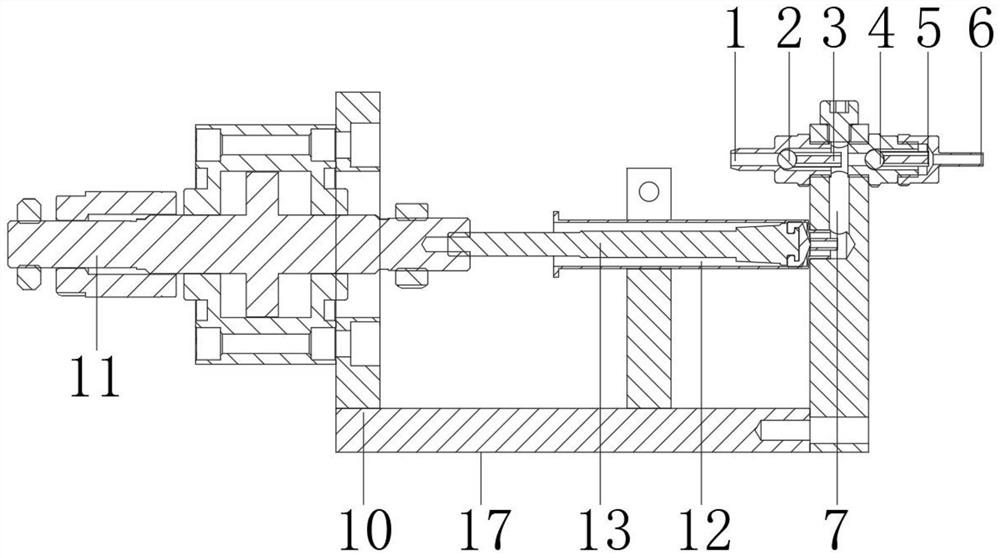

An adjustable glue filling pump

ActiveCN112849462BReduce pressureIncrease pressureLiquid surface applicatorsCoatingsAdhesive glueEngineering

The invention discloses an adjustable glue filling pump, which comprises a glue inlet, a first sealing steel ball, a first steel ball top block, a second sealing steel ball, a second steel ball top block, a glue outlet, a glue channel, a vacuum chamber, and an isolation film sheet, mounting bracket, adjustable cylinder, corrosion-resistant needle tube, sealed piston rod, bottom plate, partition, first glue filling mechanism and second glue filling mechanism, the upper surface of the bottom plate is provided with a partition, and the partition A first glue filling mechanism and a second glue filling mechanism are respectively fixed on the surfaces of both sides, and a glue channel is provided on the first glue filling mechanism and the second glue filling mechanism, and a glue inlet and a glue inlet are arranged at one end of the glue channel. outlet, the glue inlet communicates with the glue bucket, and the glue outlet communicates with the glue receiving device. The invention has the advantages of using an adjustable pneumatic needle tube glue filling pump for glue filling, which can realize the adjustment of the filling volume, fast and accurate filling, and the filling channel is not easy to be blocked, and the equipment maintenance is simple.

Owner:广东诺倍而自动化设备有限公司

Polymer coating quantitative filling equipment

InactiveCN112193459AHeating fastAvoid compromising qualityLiquid materialPolymer coatingsMechanical engineering

The invention relates to the technical field of material filling, in particular to polymer coating quantitative filling equipment which comprises a bottom frame. A material tank is fixedly installed on the bottom frame, a feeding pipe used for feeding materials into the material tank is integrally formed at the upper end of the material tank, a heater is fixedly installed at the upper end of the material tank, and a main heat conduction ring connected with the heat output end of the heater is fixedly mounted in the material tank. The polymer coating quantitative filling equipment has the beneficial effects that materials can be effectively and rapidly heated through the main heat conduction ring and an auxiliary heat conduction ring which are arranged in the material tank, so that the temperature suitable for filling can be rapidly reached; and in addition, the device can also cooperate with each unit cylinder through a conveying pipeline, so that quantitative high-pressure filling canbe carried out in a discontinuously supplied external container on the premise that the conveying pipeline works uninterruptedly, and the filling speed and the filling precision are effectively improved.

Owner:合肥厚为新材料技术有限公司

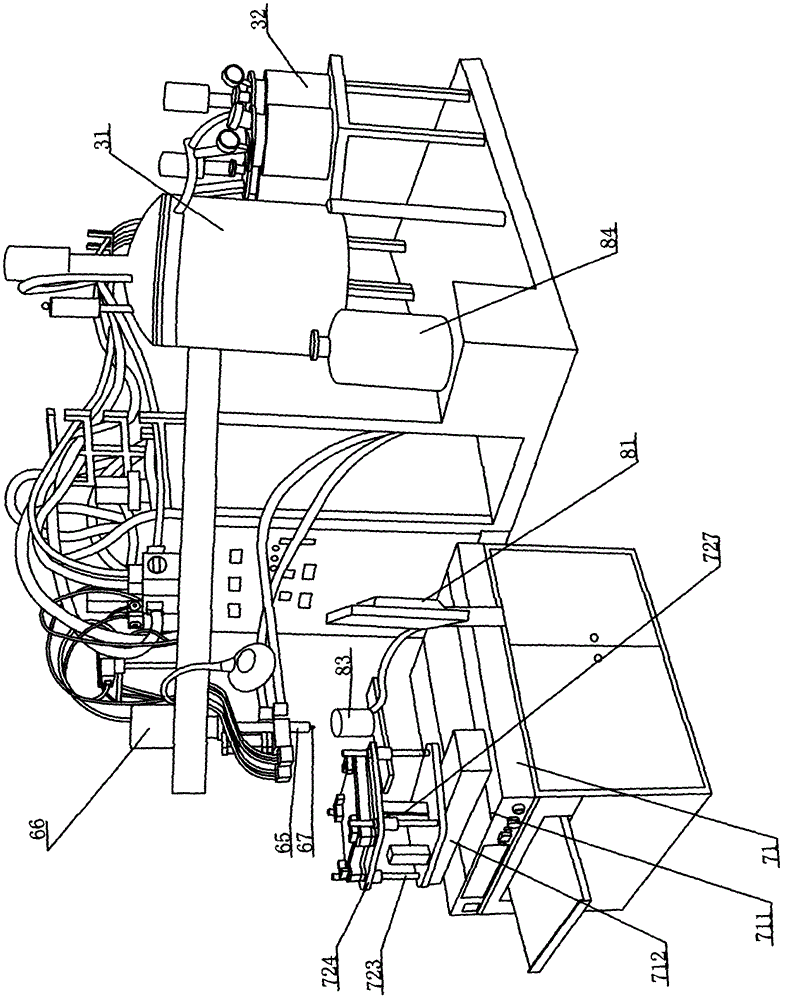

Color paste switching device of micro-scale polyurethane elastomer pouring machine

ActiveCN102653118BAvoid separationSolve the lack of hardnessDomestic articlesNumerical controlPolyurethane elastomer

Owner:海盐县于城丝绸印染股份有限公司

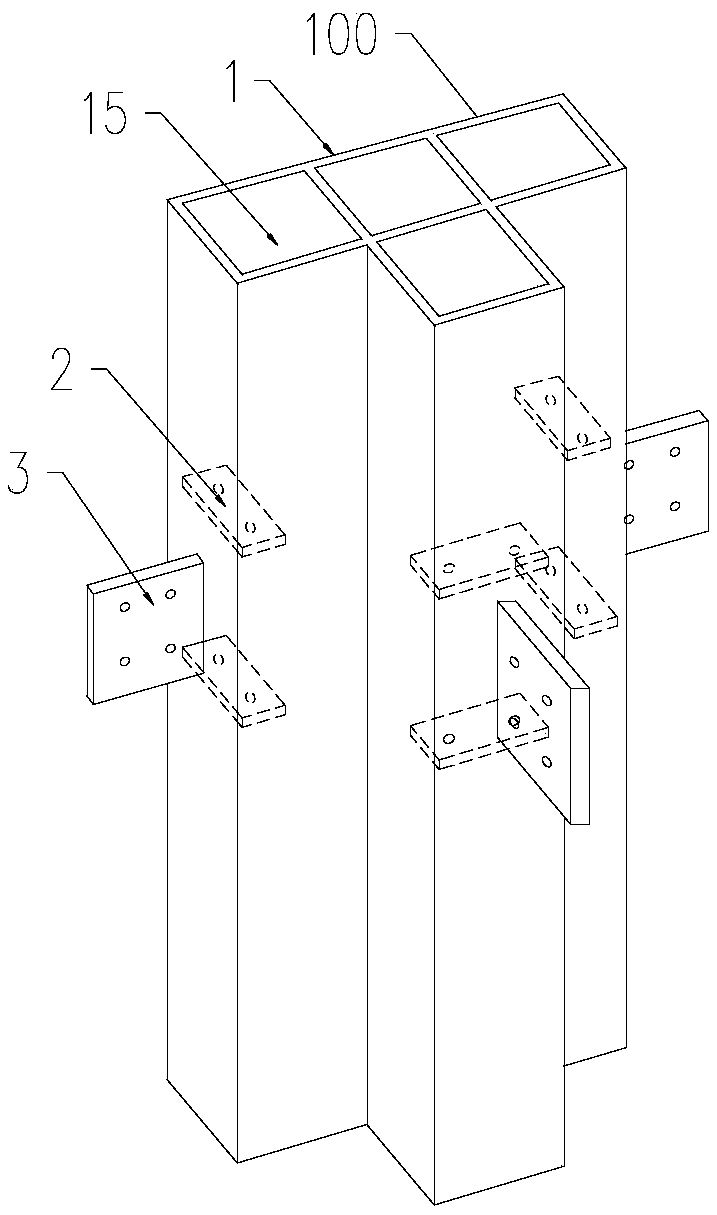

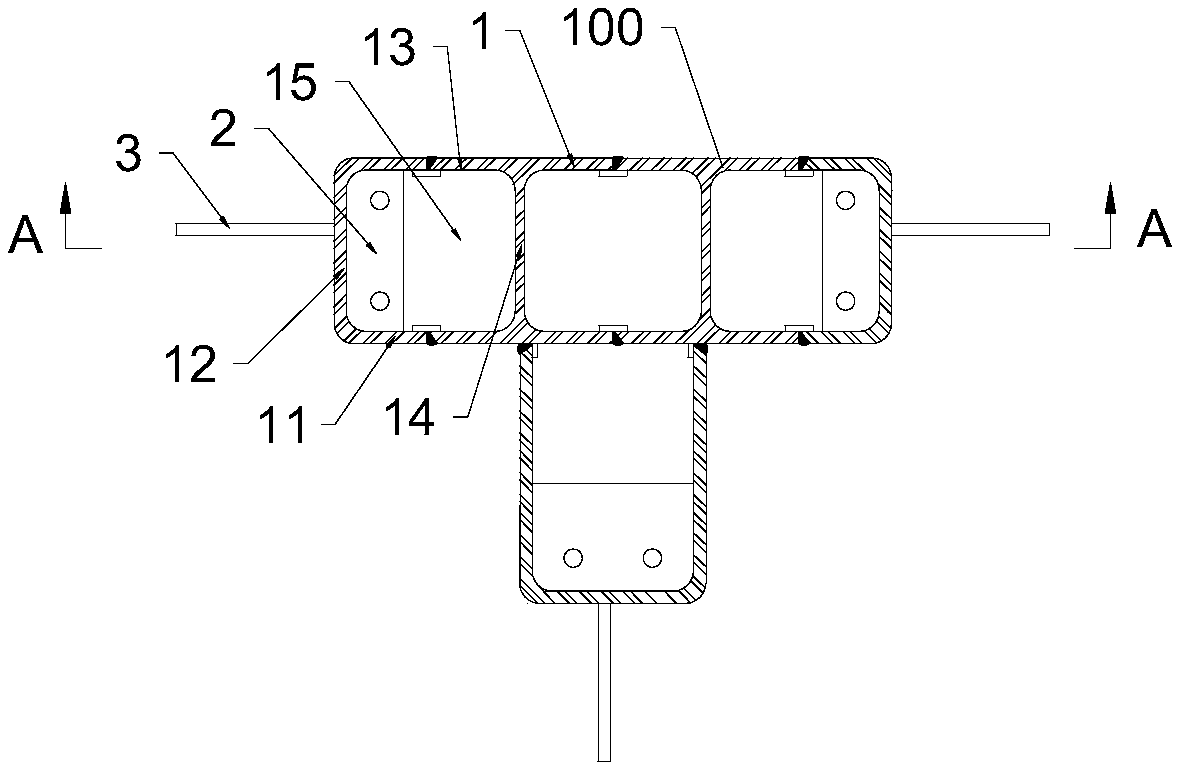

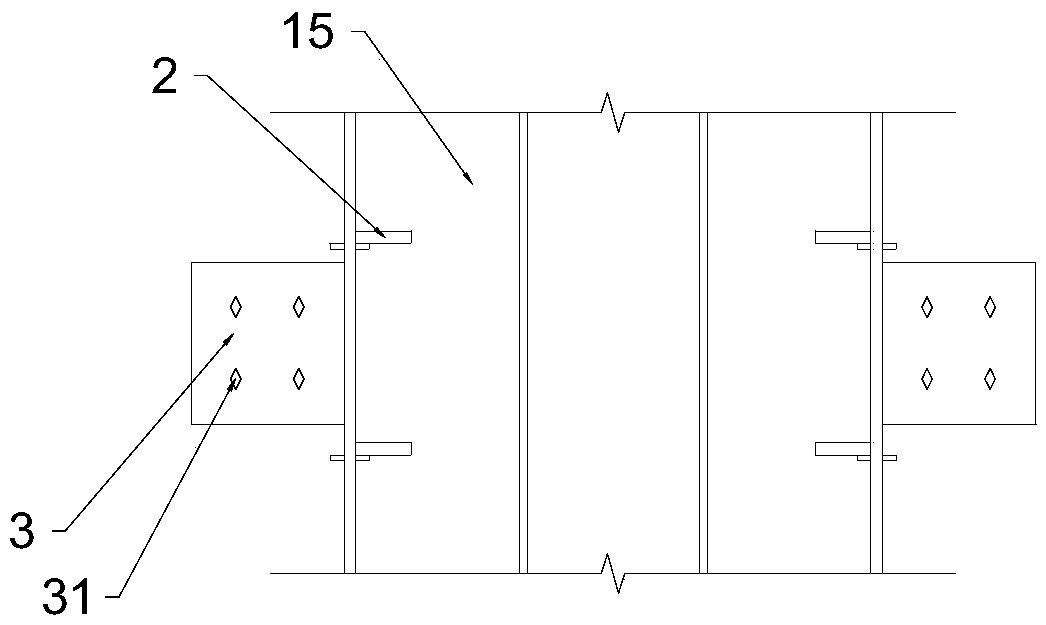

Special-shaped column assembly and beam column connecting joint structure

PendingCN109322440AGuaranteed structural strengthReduce weld lengthStrutsPillarsProject areaEngineering

The embodiment of the invention provides a special-shaped column assembly and a beam column connecting joint structure. The special-shaped column assembly comprises a special-shaped column and separating plates of a preset number, and the special-shaped column comprises at least one lateral plate. All the lateral plates enclose to form at least one cavity, or at least one lateral plate integrallyforms at least one cavity. A part of cavities is internally provided with at least one separating plate, and projected areas of the separating plates along lengths of the cavities are smaller than base areas of the cavities. The fact that the projected areas of the separating plates of the special-shaped column assembly along the lengths of the cavities are smaller than base areas of the cavitiesindicates that at least one marginal area existing in the separating plates is in a separating condition with one corresponding lateral plate or a part of thecorresponding lateral plate, and the marginal area and the corresponding lateral plate or the part of the corresponding lateral plate have intervals of certain distance and do not need to be connected in a weld mode, so that lengths of welding lines between the separating plates and the lateral plates which enclose to form the cavities are shortened, and welding workloads are reduced; and margins which are not connected with the lateral plates of the separating plates and the inner walls of the lateral plates enclose to form through holes used for pouring concrete, therefore, the separating plates do not need to be provided with pouring holes, and the own structural intensity of the separating plates is ensured.

Owner:北京和筑科技有限公司

Vertical mold for pouring and cooling ferroalloys

ActiveCN104889331BSmall footprintIncrease perfusion rateFoundry mouldsFoundry coresSmall footprintIron alloys

Owner:吴绍相

Blade root end pouring device for wind mill

The invention relates to a blade root end pouring device for a wind mill, which comprises a root end structural laying layer, an air pervious isolating film and a vacuum pumping mechanism, wherein a guide net is arranged at the front end of the root end structural laying layer and a resin draft tube is arranged at the upper part at the upper front end of the guide net. The air pervious isolating film is covered on the guide net and between the outlet of the resin draft tube and the front side adjacent to the root end structural laying layer; and the root end structural laying layer, the guide net, the resin draft tube and the air pervious isolating film are arranged in the vacuum pumping mechanism. The device has the advantages that because the auxiliary air extracting mode of the air pervious film is added to a guide layer, residual air bubbles clamped in resin are eliminated so that the compactness of the products is improved, the resin is poured more completely, and the product quality is improved. Moreover, because an integral structural plane is exhausted, the pouring speed and the quality stability can be effectively improved.

Owner:SHANGHAI AEOLON WIND ENERGY TECH DEVGRP CO LTD +3

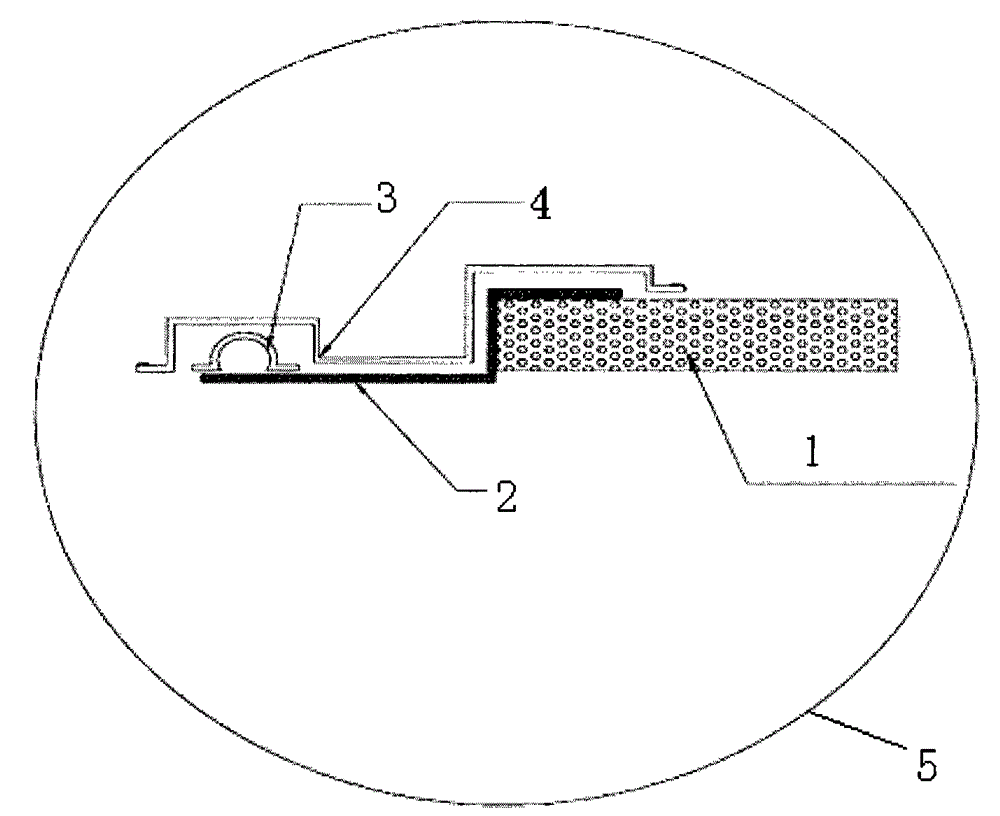

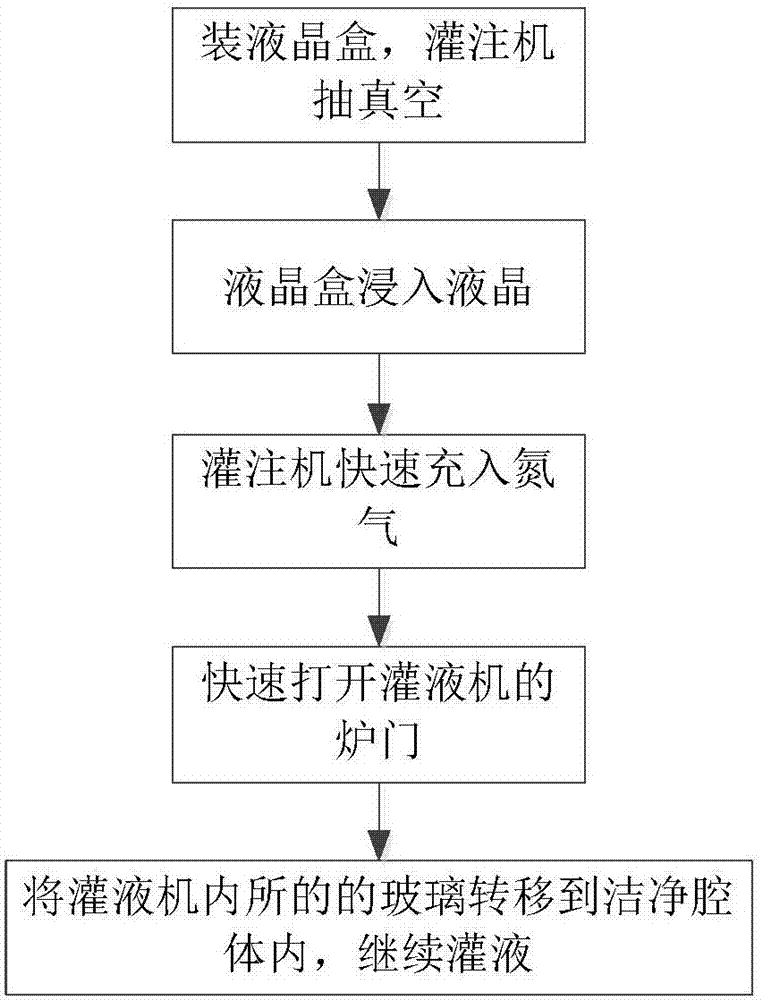

Method for improving filling efficiency of PMVA

InactiveCN107884999AAccelerated capillarityIncrease perfusion rateNon-linear opticsLiquid crystalNitrogen gas

The invention relates to a method for improving the filling efficiency of PMVA. The method includes the first step of placing a liquid crystal box with an opening into a filling machine and vacuumingthe filling machine; the second step of lowering the liquid crystal box into liquid crystal, and causing the liquid crystal liquid level to be higher than the filling opening of the liquid crystal box; the third step of quickly inflating the filling machine with nitrogen; the third step of quickly opening a furnace door of the filling machine, so that the maximum pressure difference is reached inside and outside the liquid crystal box; the fourth step of transferring liquid crystal glass obtained in the filling machine to a clean chamber, and continuing the filling. According to the technicalscheme, the peculiarities of the structure and material of PMVA filling can be overcome, the method capable of simply and quickly improving filling efficiency can be provided, and the filling efficiency of the large-size PMVA can be increased by 50% or above.

Owner:YONGZHOU XINHUIKAI TECH

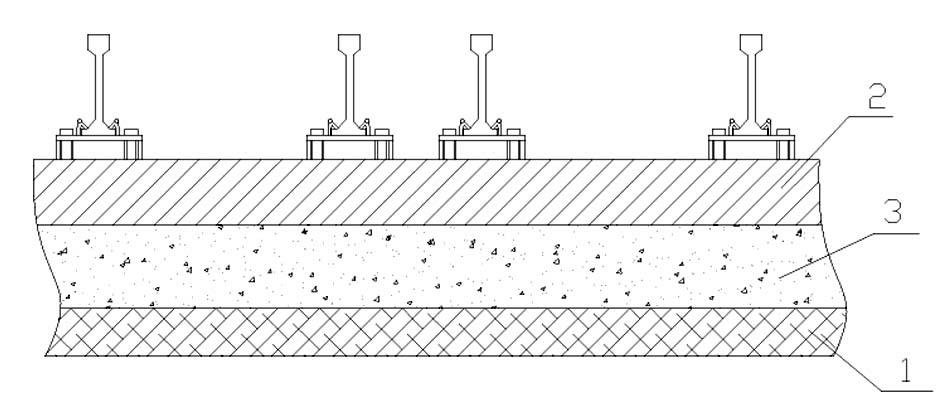

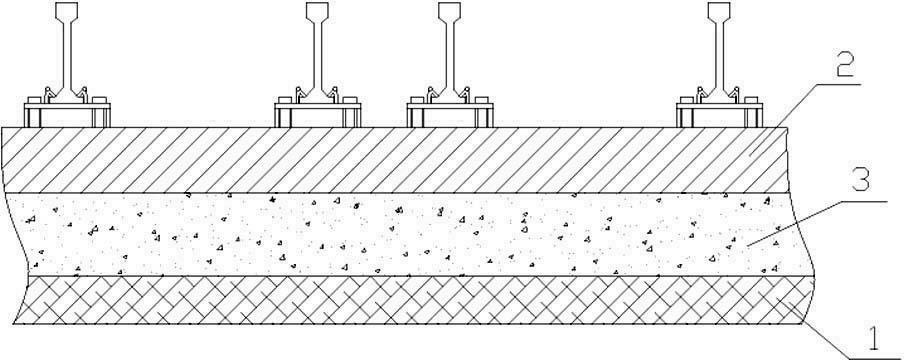

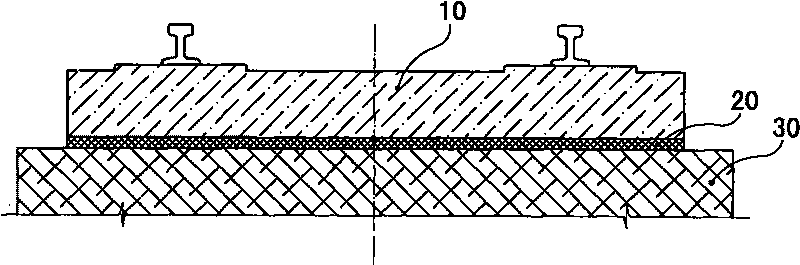

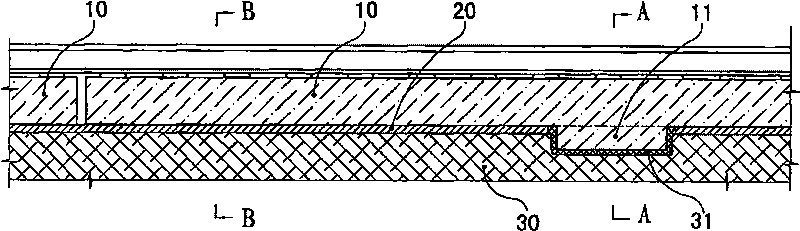

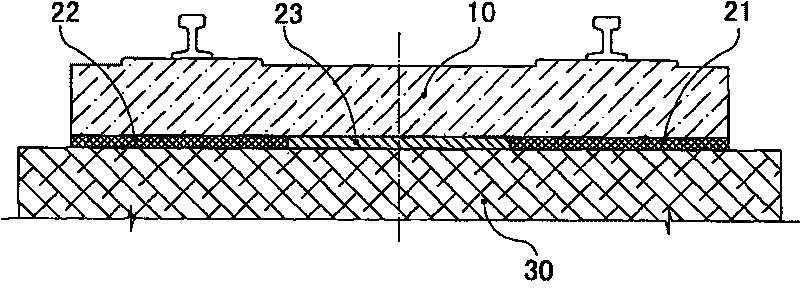

Unballasted track construction

The invention discloses a non-ballast track structure, which aims to effectively strengthen the integrity and the anti-vibration performance of a non-ballast track and reduce the maintenance and repair workload of a track structure. The non-ballast track structure comprises a track plate (10) adopting a prestressed reinforced concrete structure, a base (30) adopting a reinforced concrete structure, and a mortar adjustment layer positioned between the track plate (10) and the base (30), wherein the mortar adjustment layer is a resin mortar layer (20), and the resin mortar layer (20) is adheredto the track plate (10) and the base (30) to form an integral structure. The non-ballast track structure has the advantages that the resin mortar layer has good elasticity and adhesive property and canfirmly connect the track plate and the base into a whole, thereby improving the integrity and the anti-vibration performance of the non-ballast track structure; and the non-ballast track structure ca n effectively accelerate the pouring rate of the mortar adjustment layer and ensure the construction quality, so the non-ballast track structure has the characteristic of convenient site constructionand can realize rapid maintenance.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Quick-hardening low-shrinkage colored cement grouting material and construction method thereof

PendingCN112094086AIncrease perfusion rateShorten closing timeIn situ pavingsRoads maintainenceCelluloseUltimate tensile strength

The invention provides a quick-hardening low-shrinkage colored cement grouting material and a construction method thereof. The colored cement grouting material mainly comprises the following raw materials in parts by weight: 100 parts of white cement, 8-20 parts of silica fume, 15-25 parts of slag powder, 20-35 parts of ground calcium carbonate powder, 25-40 parts of quartz sand, 0.75-1.80 parts of an excitant, 0.10-0.25 part of a water reducer, 0.008-0.020 part of a defoamer, 3-7 parts of an expanding agent, 0.04-0.11 parts of cellulose ether, 3.6-8.0 parts of pigment and 55-80 part of water.The strength of the cement grouting material is rapidly increased, the cement grouting material has the advantages of being good in workability and small in shrinkage deformation, and the high-temperature anti-rutting performance of a semi-flexible pavement is improved; and the product has the characteristics of adjustable color and simple construction process.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +1

Pouring method of concrete for railway switch base filling layer

ActiveCN102617082BImprove liquidityIncreased durabilityRailway track constructionMaterials scienceRaw material

The invention discloses concrete for a railway switch base filling layer. The concrete is mixed by raw materials including 370 parts of cement, 180 parts of mineral mixtures, 44 parts of expanding agent, 866 parts of river sand, 738 parts of broken stones, 184 parts of water and 7.7 parts of polycarboxylic copolymer according to 1M3 filling quantity standard. When the railway switch base filling layer is poured, a leveling blanket and switch slabs are constructed according to a conventional method at first, a pouring mode by the aid of a pump truck, a transfer hopper and a chute is adopted, and each switch slab is poured at one step. As the concrete has excellent mobility and a self-filling performance, the concrete can pass through an engineering portion with compact reinforcements and the complex structural section, is dense in filling, does not segregate or leak water, and has high homogeneity, engineering quality is guaranteed, durability of a concrete structure is improved, the problem that pouring of vibration operation components is not easy to be applied or cannot be applied is resolved, pouring speed is improved, a construction process of the concrete structure is simplified, construction efficiency and construction quality are improved, and construction period is shortened.

Owner:ZHENGZHOU ENG CO LTD CHINA RAILWAY SEVENTH GRP

Refrigerant filling method for outdoor unit of air conditioner

ActiveCN105674435BImprove operational efficiencyIncrease productivityRefrigeration componentsAir conditioning systemsInfusion methodControl theory

The invention provides a refrigerant pouring method of an air conditioner outdoor unit. The air conditioner outdoor unit comprises a compressor (1) and an outdoor unit heat exchanger (5); and the compressor (1) comprises an air suction cavity and an exhausting cavity. The outdoor unit further comprises an air suction cavity and / or an exhausting cavity communicating with the compressor (1) through a communicating pipeline and / or a large valve (3) and a small valve (6) of the outdoor unit heat exchanger (5); and the large valve (3) is used for pouring refrigerants into the exhausting cavity and / or the air suction cavity of the compressor (1). By means of an air conditioner system, the pouring speed of the refrigerants ( especially R32) of the air conditioner system can be effectively increased, and therefore the running and producing efficiency of the air conditioner system is improved; and the pouring precision of the refrigerants (especially R32) of the air conditioner system can also be effectively improved, the pouring precision is more accurate, and the running and producing efficiency of the air conditioner system is further improved.

Owner:GREE ELECTRIC APPLIANCES INC

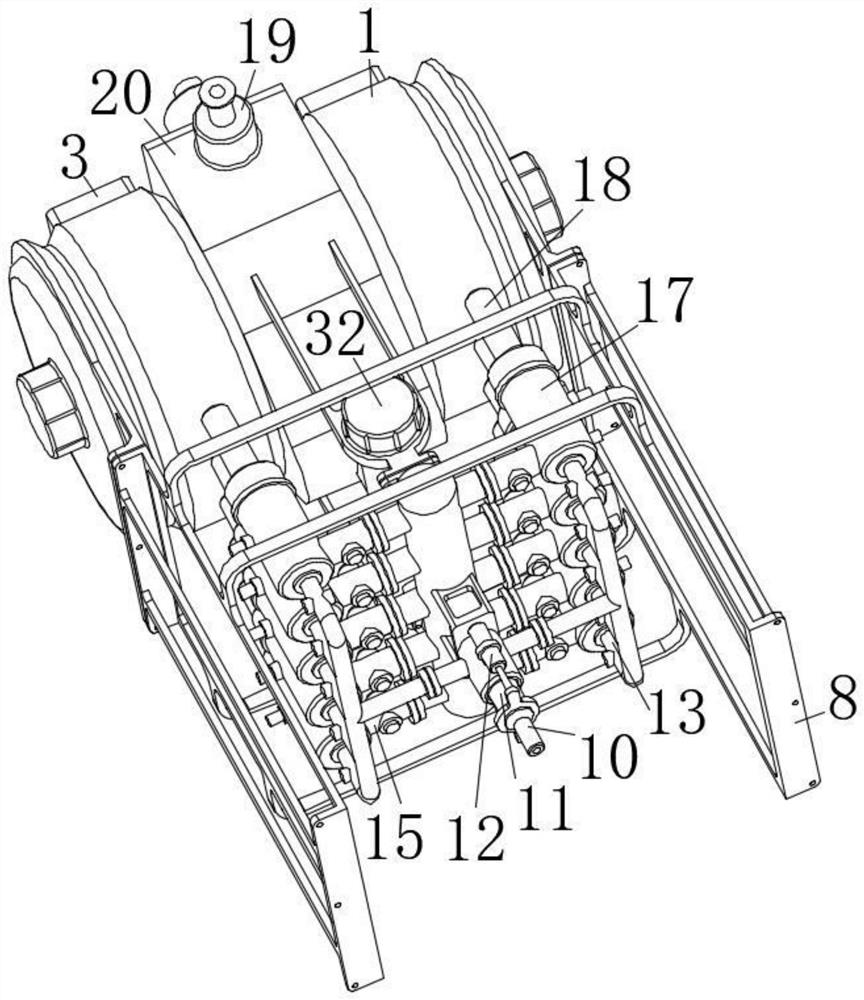

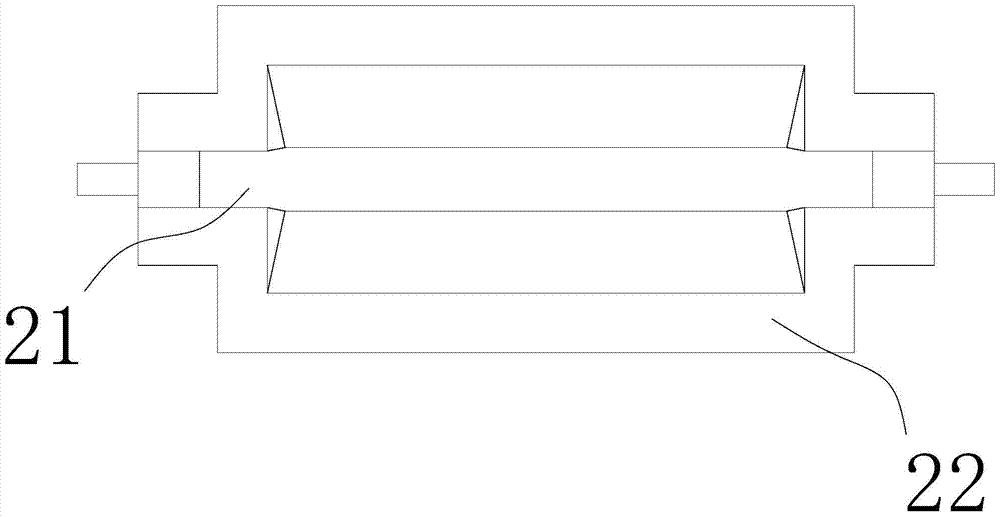

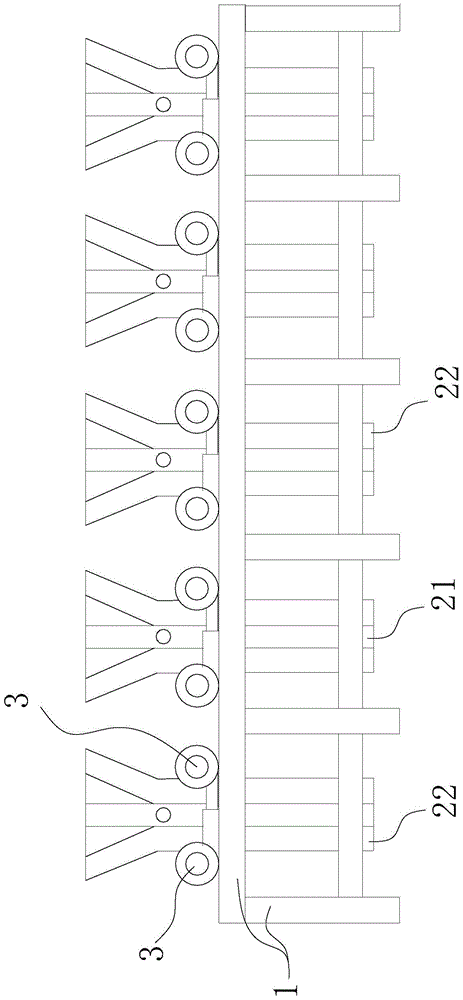

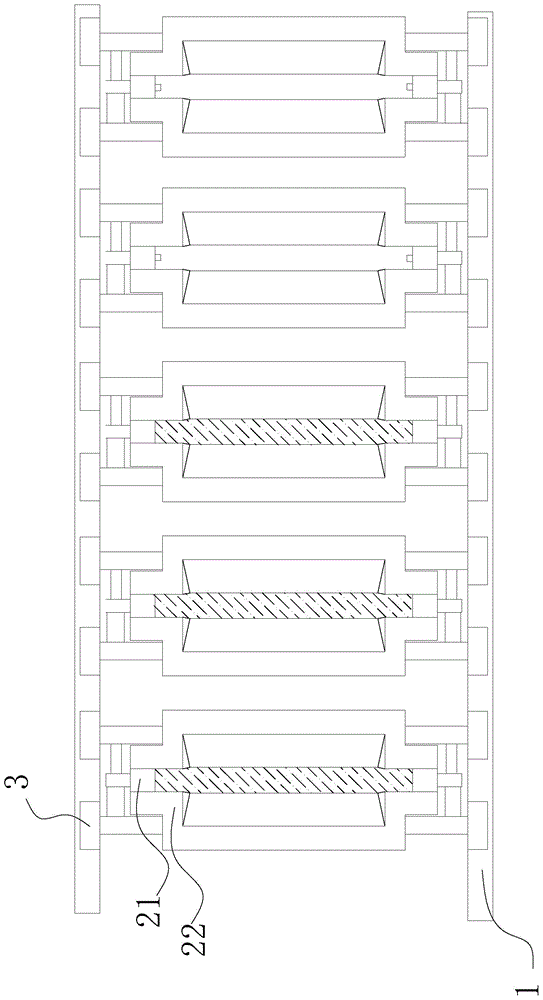

Vertical dies for ferroalloy pouring and cooling

ActiveCN104889331ASmall footprintIncrease perfusion rateFoundry mouldsFoundry coresSmall footprintIn degree

The invention provides vertical dies for ferroalloy pouring and cooling. The vertical dies comprise a supporting frame, die bodies, open-close devices and cooling devices, wherein the die bodies comprise supporting dies and side plates; the supporting dies are the die bodies of which the front sides, the bottoms and the rear sides are provided with baffles being sequentially connected with one another; limiting bulges are arranged on the front and rear side walls of the supporting dies or / and the inner wall surfaces of baseplates of the supporting dies; two side plates are respectively positioned on the left and right sides of each supporting die, and can be separated from or combined with the supporting die; when two side plates are combined with the corresponding supporting die, a container with an opening in the upper part and a cavity in the middle can be defined by the supporting die and the side plates; supporting die brackets are arranged on the supporting frame; the side plates are connected onto the supporting frame through the open-close devices; the open-close devices are used for controlling the open-close of the side plates. The vertical dies have the advantages of being small in occupied area, lower in labor cost, high in degree of automation, safety factor, cooling speed, and finished product quality, and low in product segregation possibility.

Owner:吴绍相

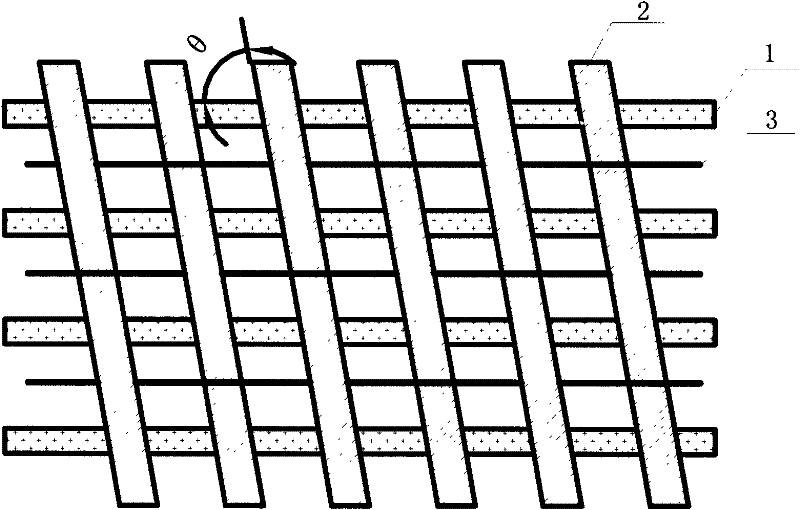

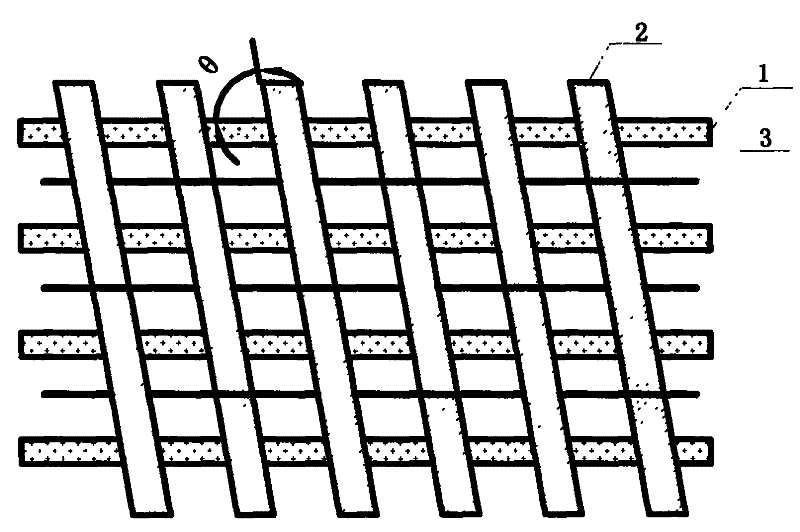

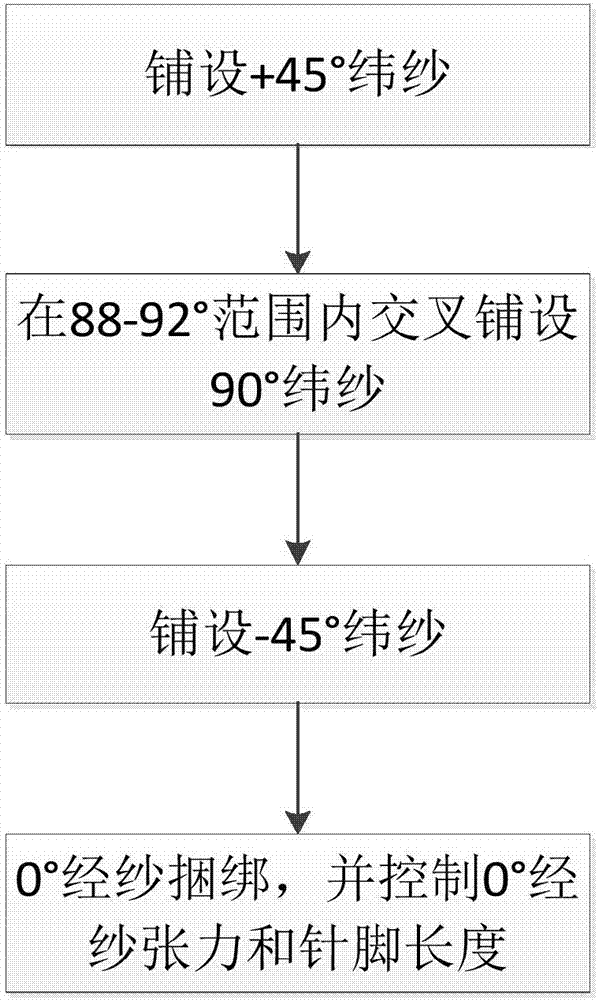

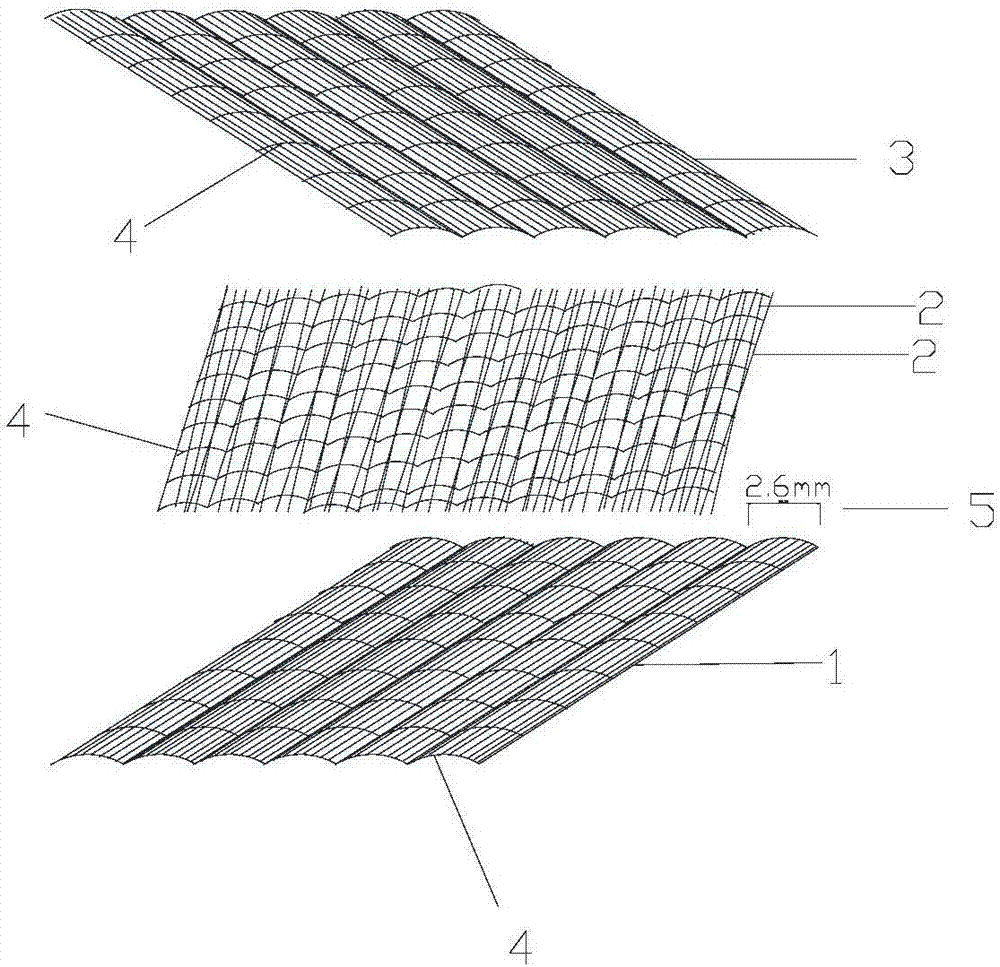

Fabric with high penetration rate, and preparation method and application of fabric

ActiveCN107151859AHigh penetration rateHigh porosityOrnamental textile articlesWarp knittingPorosityYarn

The invention provides fabric with a high penetration rate. The fabric comprises +45-degree weft yarns, 90-degree weft yarns, -45-degree weft yarns and 0-degree warp yarns, wherein the +45-degree weft yarns, the 90-degree weft yarns and the -45-degree weft yarns are bound together by means of the 0-degree warp yarns. The invention also provides a preparation method of the fabric with the high penetration rate. The method sequentially comprises the following steps: A. laying the +45-degree weft yarns; B. laying the 90-degree weft yarns; C. laying the -45-degree weft yarns; D. using the 0-degree warp yarns to bind the +45-degree weft yarns, the 90-degree weft yarns and the -45-degree weft yarns which are respectively laid in the step A, the step B and the step C, wherein the lengths of stitch-knitting stitches of the 0-degree warp yarns in the step A and the step C are 2.6-3.0mm. The invention also relates to application of the fabric in preparation of wind turbine blades. The fabric prepared by the method is high in porosity; resin filling channels are yarn clearances and holes of the bound yarns; when being filled with resin, the fabric is high in penetration rate, thus avoiding the problem that the roots of foliums become white; furthermore, the time for filling the roots of the foliums is short, and the filling speed is accelerated by 20% or above.

Owner:ZHEJIANG HENGSHI FIBER FOUND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com