Vertical dies for ferroalloy pouring and cooling

A technology of ferroalloy and mould, which is applied in the field of vertical moulds. It can solve the problems of inability to meet the large-scale requirements of ferroalloy furnaces, troublesome demoulding and crushing of molds, poor automation effect, etc., and achieve less powder, less labor requirements and faster cooling speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing description:

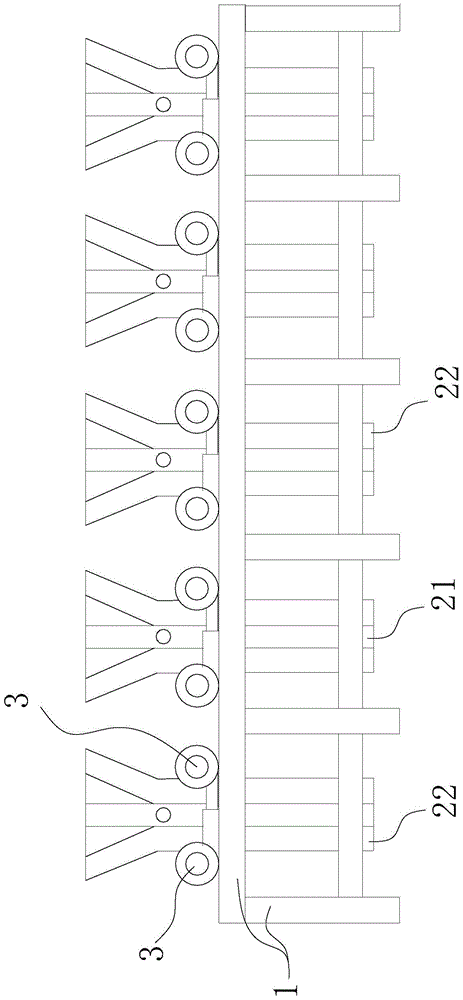

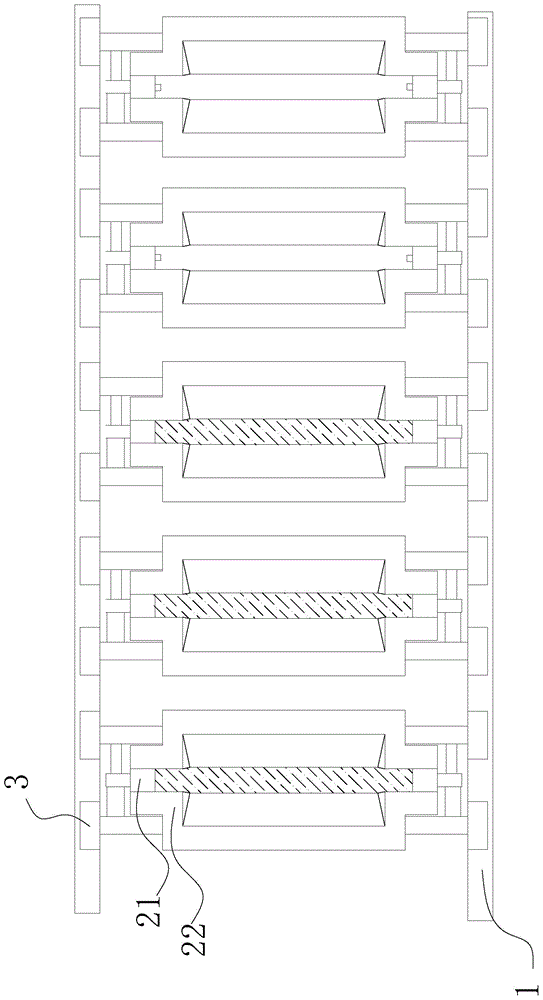

[0026] Such as Figure 1-9 Shown: it includes support frame 1, mold, opening and closing device 3, cooling device,

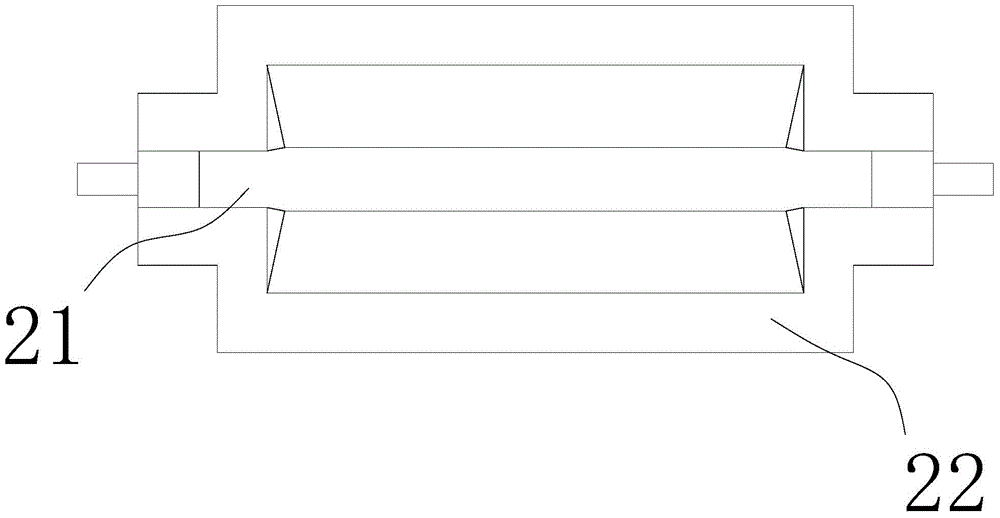

[0027] Described mold comprises support formwork 21 and side plate 22, and described support formwork is that front side, bottom, rear side are provided with baffle plate, and the mold that front side, bottom, rear side baffle plate are connected successively, in support formwork The front and rear side walls or / and the inner side walls of the bottom plate are provided with limiting projections 23. There are two side plates, which are respectively located on the left and right sides of the back form, and can be separated or merged with the back form, and when the side plates When combined with the support form, the support form 21 and the side plate 22 can form a container with an opening only on the top and a cavity in the middle;

[0028] The sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com