Unballasted track construction

A ballastless track and structure technology, applied in the field of railway ballastless track, can solve the problems of reducing construction cost, slow strength increase, poor integrity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

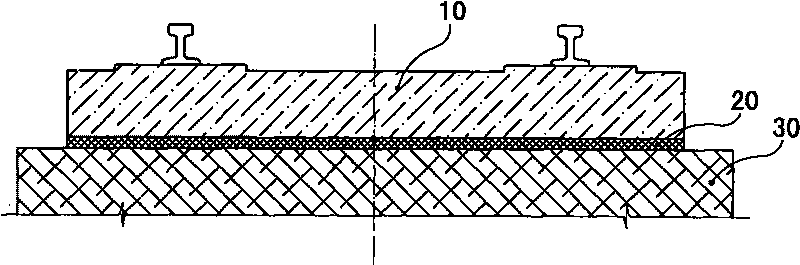

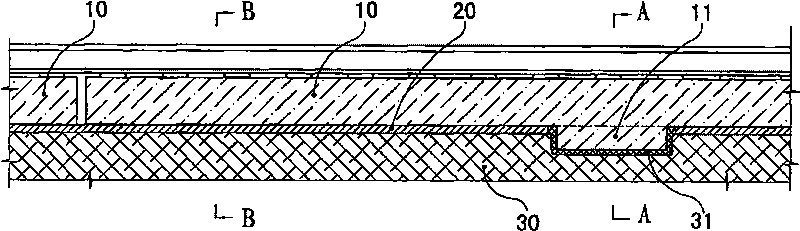

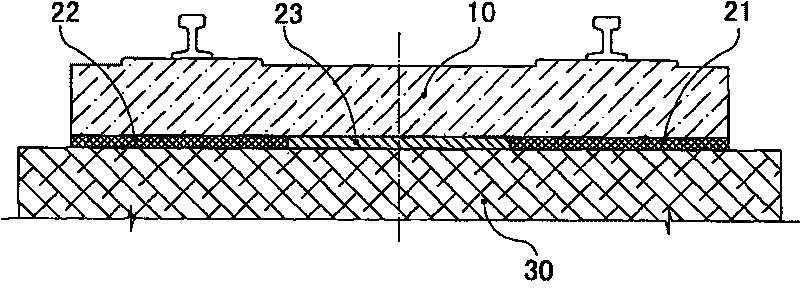

[0018] Figure 5 with Image 6 The existing ballastless track configuration is shown. refer to Figure 5 , the existing ballastless track structure includes three main structural layers, the track slab 10, the CA mortar adjustment layer 40, and the base 30, which are sequentially arranged from top to bottom. The track slab 10 adopts a prestressed reinforced concrete structure, and the base 30 adopts reinforced concrete structure. The advantage of the CA mortar adjustment layer 40 is that it can be easily maintained and replaced. However, since the CA mortar adjustment layer 40 cannot connect the track plate 10 and the base structure layer 30 as a whole, the structure of the ballastless track has poor integrity and cannot meet the needs of improving Requirements for track seismic performance. refer to Figure 5 with Image 6 , in order to constrai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com