Concrete pouring system and pouring method for concrete filled steel tube bracket

A technology of steel pipe concrete and concrete, which is applied in the direction of earthwork drilling, pipe elements, pipes/pipe joints/fittings, etc., and can solve problems such as unsmoothness, support arch void, uneven and dense concrete pouring construction, etc., and achieve easy Effects of operation, improving load-carrying capacity, increasing fluidity and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

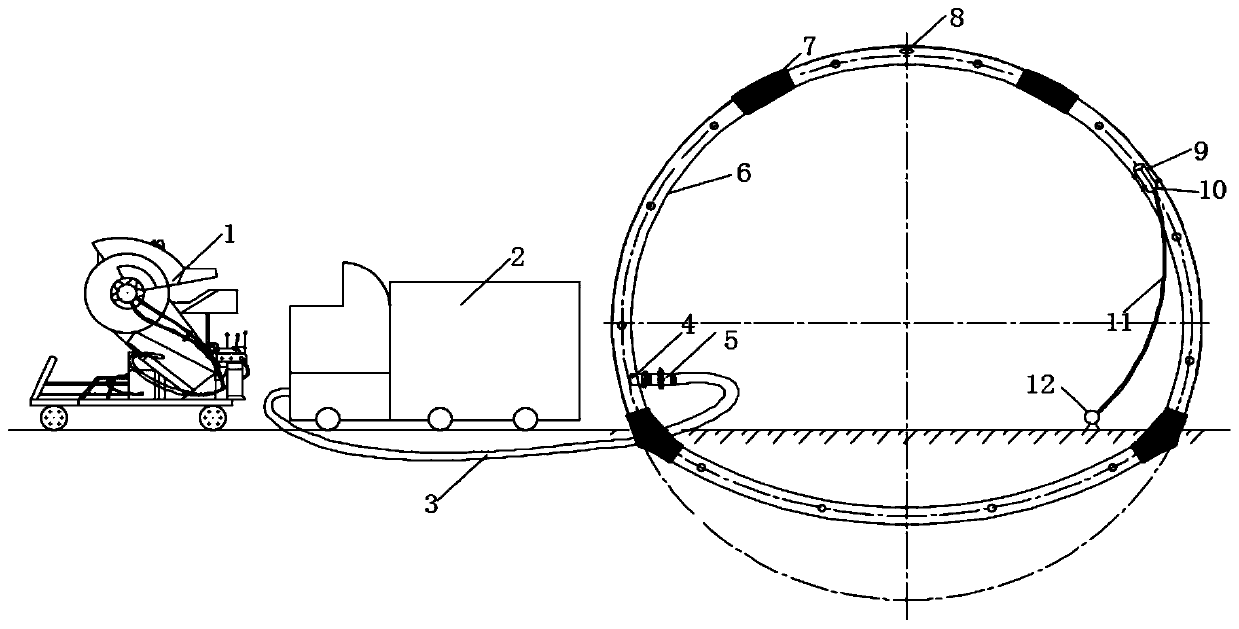

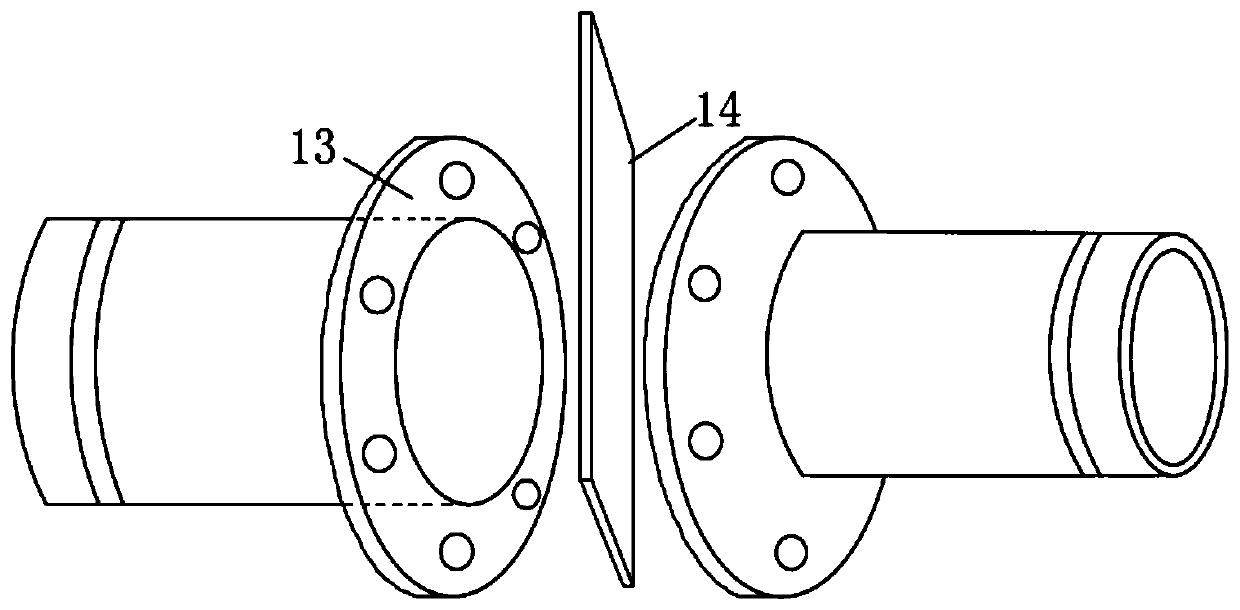

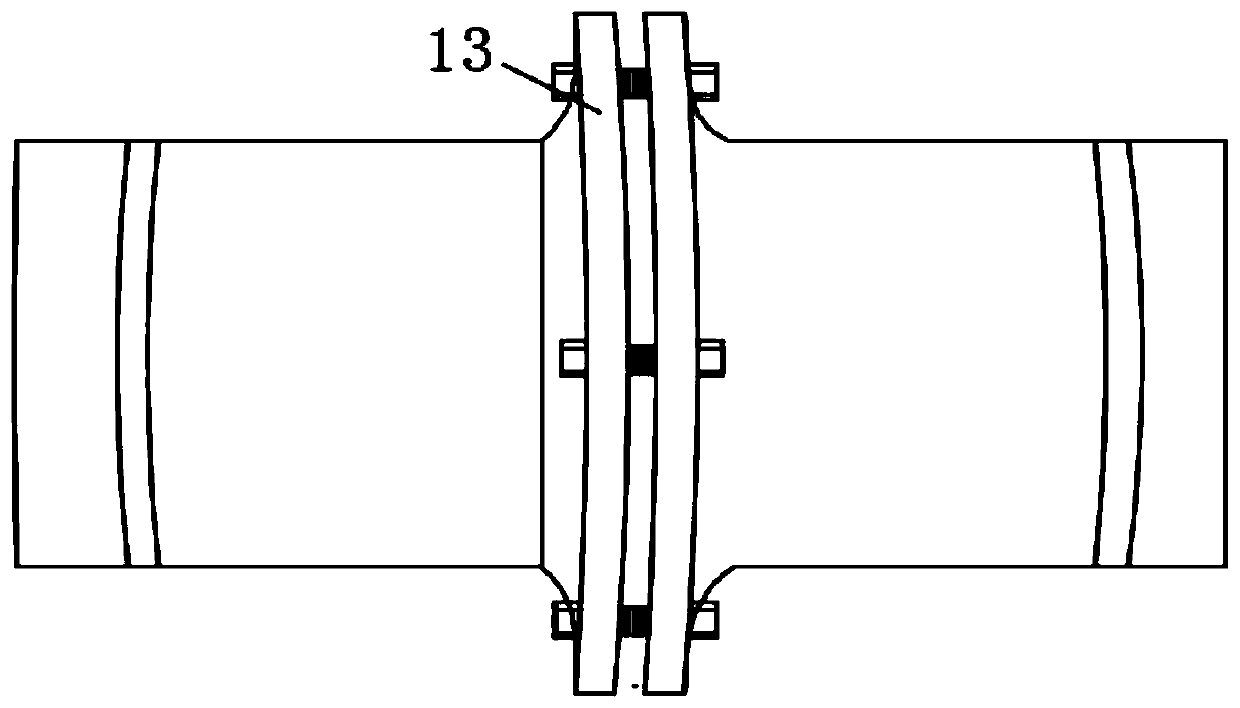

[0034] A concrete grouting system for a steel pipe concrete support, including a mixer, a delivery pump, a delivery pipeline, a check valve, an attached wind vibrator, and matching designed pouring holes and exhaust and grout holes on the support. At the bottom of one side, the exhaust and slurry discharge hole is located at the top of the bracket, the steel pipe on the side without the filling hole is connected with an attached pneumatic vibrator, and the delivery pump is connected to the filling hole through a delivery pipeline. The mixer mixes the concrete and transports the concrete to the delivery pump. The delivery pump is connected to the pouring hole through the delivery pipeline, and the concrete is poured into the steel pipe by pumping.

[0035] Concrete-filled steel tube brackets are composed of steel tubes and concrete, and are used for underground engineering support. Generally, there are various cross-sections such as straight wall semi-circular arches, shallow bo...

Embodiment 2

[0045] like Figure 5 shown.

[0046] (1) Put the concrete delivery pump flat on the roadway, and connect it to the pouring hole of the bracket through the delivery pipe.

[0047] (2) First, a group of personnel connects the cables and arranges the water pipes, and the delivery pump is empty for 15 to 20 minutes; another group of personnel goes to the stockyard to mix dry concrete, one mine car each time.

[0048] (3) Put the dry material into the mixer, add water, and mix the concrete with the mixer. The strength grade of the prepared concrete should reach C40. Add cement, sand, stones and admixtures strictly according to the ratio of C40. Take the on-site materials for trial mixing, simulate the internal environment of the steel pipe to maintain the concrete test block, fine-tune the mix ratio according to the concrete strength test results, and add the early strength agent, water reducing agent and FRP limiter to the concrete mixing according to a certain ratio. The conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com