Method for improving filling efficiency of PMVA

A liquid filling and efficient technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of slow rising speed of liquid crystal, high surface tension, and weakened capillary phenomenon, so as to improve perfusion efficiency, accelerate capillary phenomenon, shorten Effect of perfusion cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

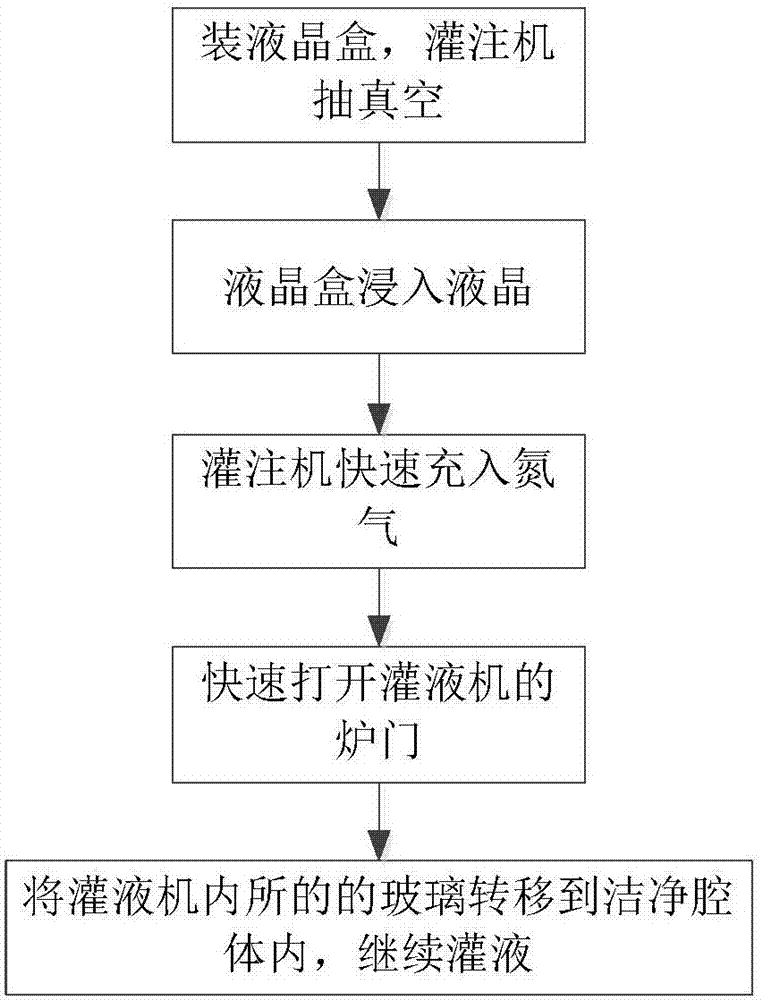

[0018] Such as figure 1 As shown, a method for improving the efficiency of PMVA filling includes the following steps: Step 1: Put the liquid crystal box with an opening into the filling machine, and vacuumize the inside of the filling machine; Step 2: Lower the liquid crystal box to the liquid crystal During the process, make the liquid crystal liquid surface submerge the filling port of the liquid crystal box; step 3: quickly fill nitrogen into the filling machine; step 3: quickly open the furnace door of the liquid filling machine, so that the inside and outside of the liquid crystal box reach the maximum pressure difference; Step 4: Transfer the liquid crystal glass obtained in the filling machine from the fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com