Quick-hardening low-shrinkage colored cement grouting material and construction method thereof

A grouting material and colored cement technology, which is used in buildings, roads, and coagulating pavements laid on site. , to achieve the effect of great promotion and application potential, shortening the sealing time, and improving the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

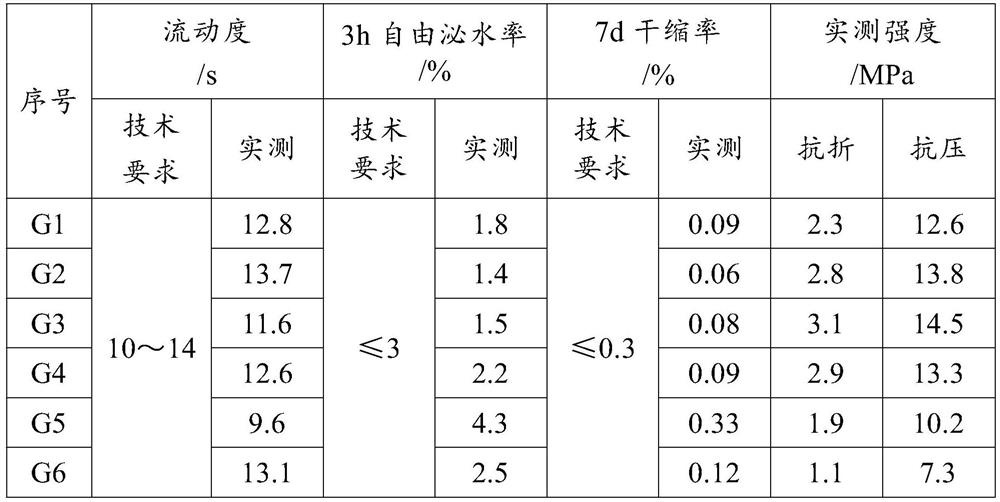

Examples

Embodiment 1

[0040] A fast-hardening and low-shrinkage colored cement grouting material, the raw materials of which are: 100 parts of white cement, 8 parts of silica fume, 15 parts of slag powder, 20 parts of heavy calcium powder, 40 parts of quartz sand, and 0.10 parts of water reducing agent , 0.025 parts of defoamer, 0.75 parts of activator, 3 parts of expansion agent, 0.11 part of cellulose ether, 3.6 parts of pigment and 55 parts of water; first mix all solid materials evenly, then add liquid materials and mix to obtain The product of the present invention is denoted as G1.

[0041] Among them, the white cement is 42.5-grade white Portland cement, the slag powder is S95 water-quenched blast furnace slag powder, and the quartz sand is made by mixing two kinds of quartz sand of 30-50 mesh and 70-100 mesh at a weight ratio of 1:2.5. , The activator is made of aluminum sulfate, calcium chloride and calcium formate in a weight ratio of 1:0.7:0.4, and the pigment is iron oxide red.

Embodiment 2

[0043] A fast-hardening and low-shrinkage colored cement grouting material, the raw materials of which are: 100 parts of white cement, 13 parts of silica fume, 19 parts of slag powder, 26 parts of heavy calcium powder, 30 parts of quartz sand, and 0.17 parts of water reducer , 0.018 parts of defoamer, 1.18 parts of activator, 4.5 parts of expansion agent, 0.08 part of cellulose ether, 5.6 parts of pigment and 67 parts of water; first mix all solid materials evenly, then add liquid materials and mix to obtain The product of the present invention is denoted as G2.

[0044] Among them, the white cement is 52.5-grade white Portland cement, the slag powder is S105 water-quenched blast furnace slag powder, and the quartz sand is made by mixing two kinds of quartz sand of 30-50 mesh and 70-100 mesh at a weight ratio of 1::3.0 The activator is made of aluminum sulfate, calcium chloride and calcium formate in a weight ratio of 1:0.5:0.4, and the pigment is iron oxide yellow.

Embodiment 3

[0046] A fast-hardening and low-shrinkage colored cement grouting material, the raw materials of which are: 100 parts of white cement, 17 parts of silica fume, 22 parts of slag powder, 35 parts of heavy calcium powder, 28 parts of quartz sand, and 0.20 parts of water reducer , 0.011 parts of defoamer, 1.55 parts of activator, 5.5 parts of expansion agent, 0.05 part of cellulose ether, 7.0 parts of pigment and 75 parts of water; first mix all solid materials evenly, then add liquid materials and mix to obtain The product of the present invention is denoted as G3.

[0047] Among them, the white cement is 52.5-grade white Portland cement, the slag powder is S105 water-quenched blast furnace slag powder, and the quartz sand is made by mixing two kinds of quartz sand of 30-50 mesh and 70-100 mesh at a weight ratio of 1:3.6. , The activator is made of aluminum sulfate, calcium chloride and calcium formate in a weight ratio of 1:0.5:0.2, and the pigments are iron oxide orange and iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com