Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Increase lighting power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

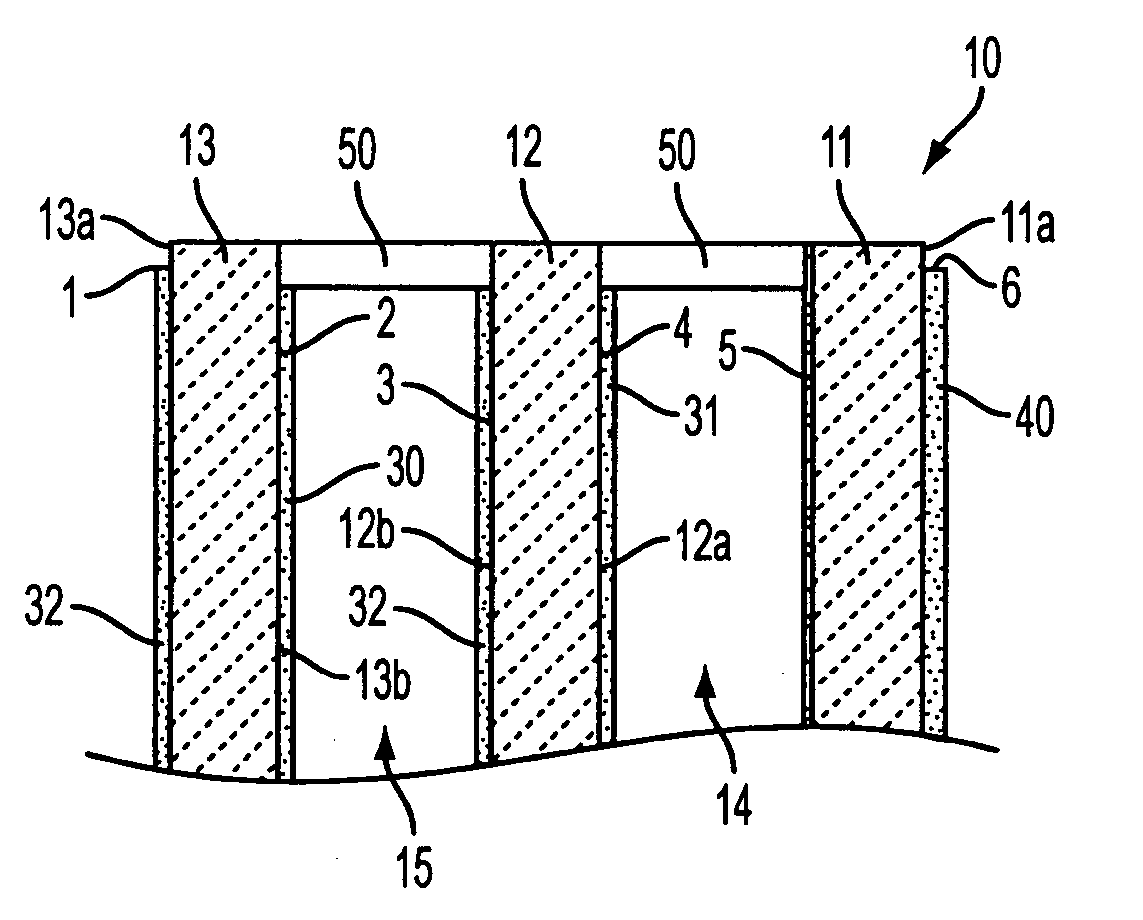

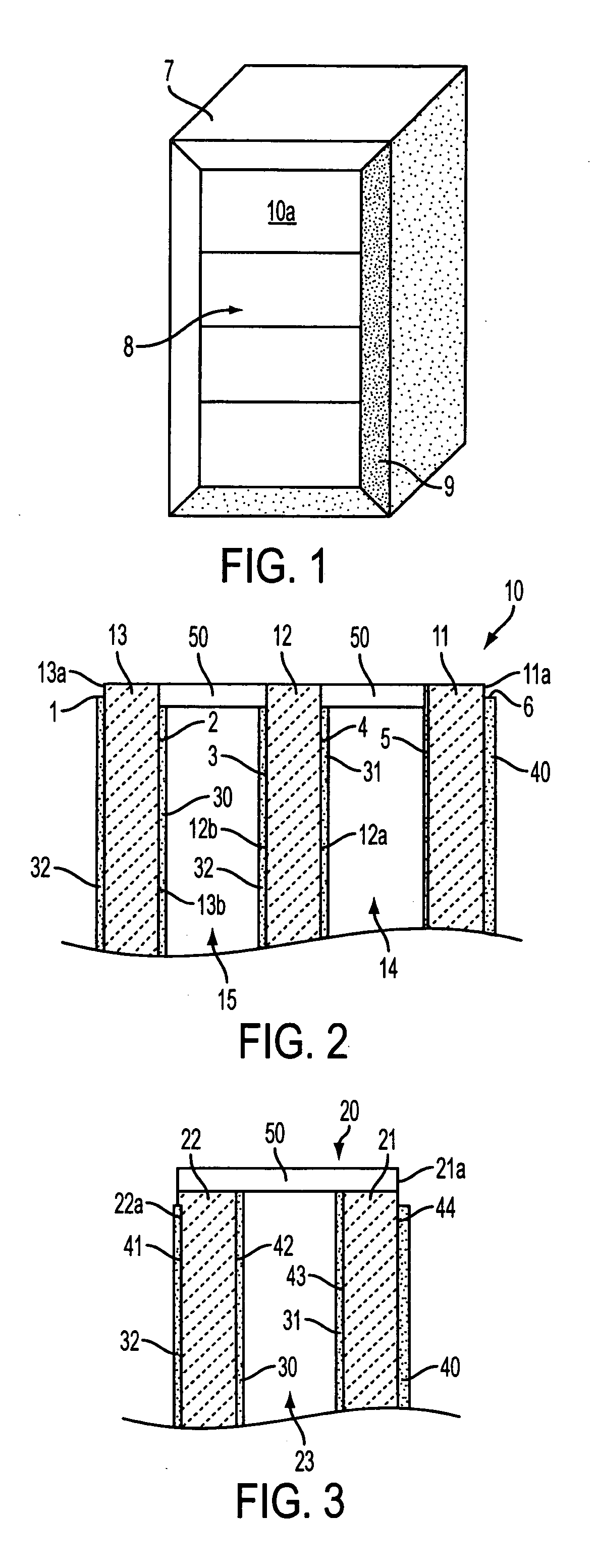

Refrigerated display case having a transparent insulating glazing unit

ActiveUS20060005484A1Improve thermal performanceSeen clearly and easilyShow cabinetsEnvelopes/bags making machineryFrostEngineering

Owner:SAINT-GOBAIN GLASS FRANCE

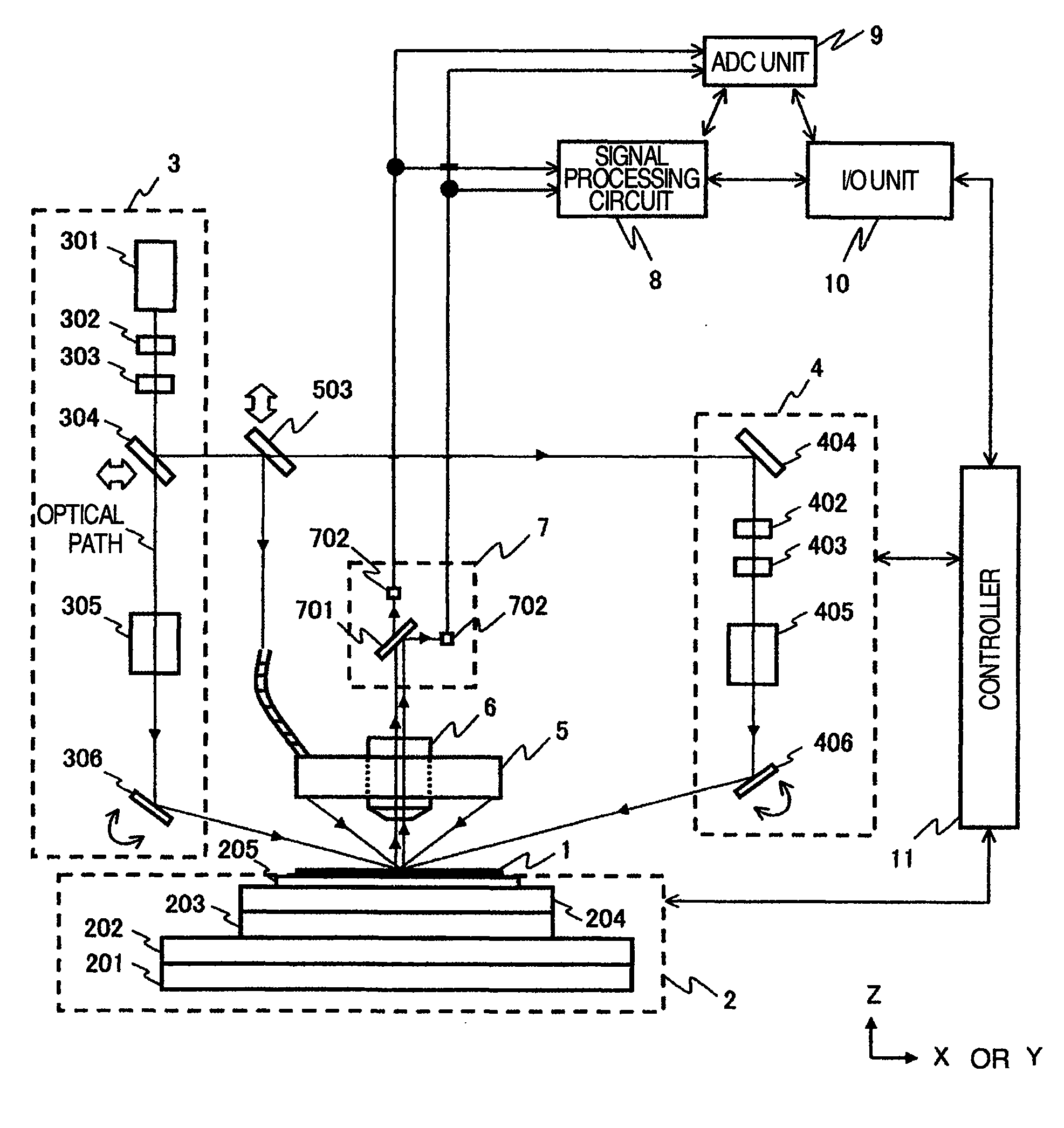

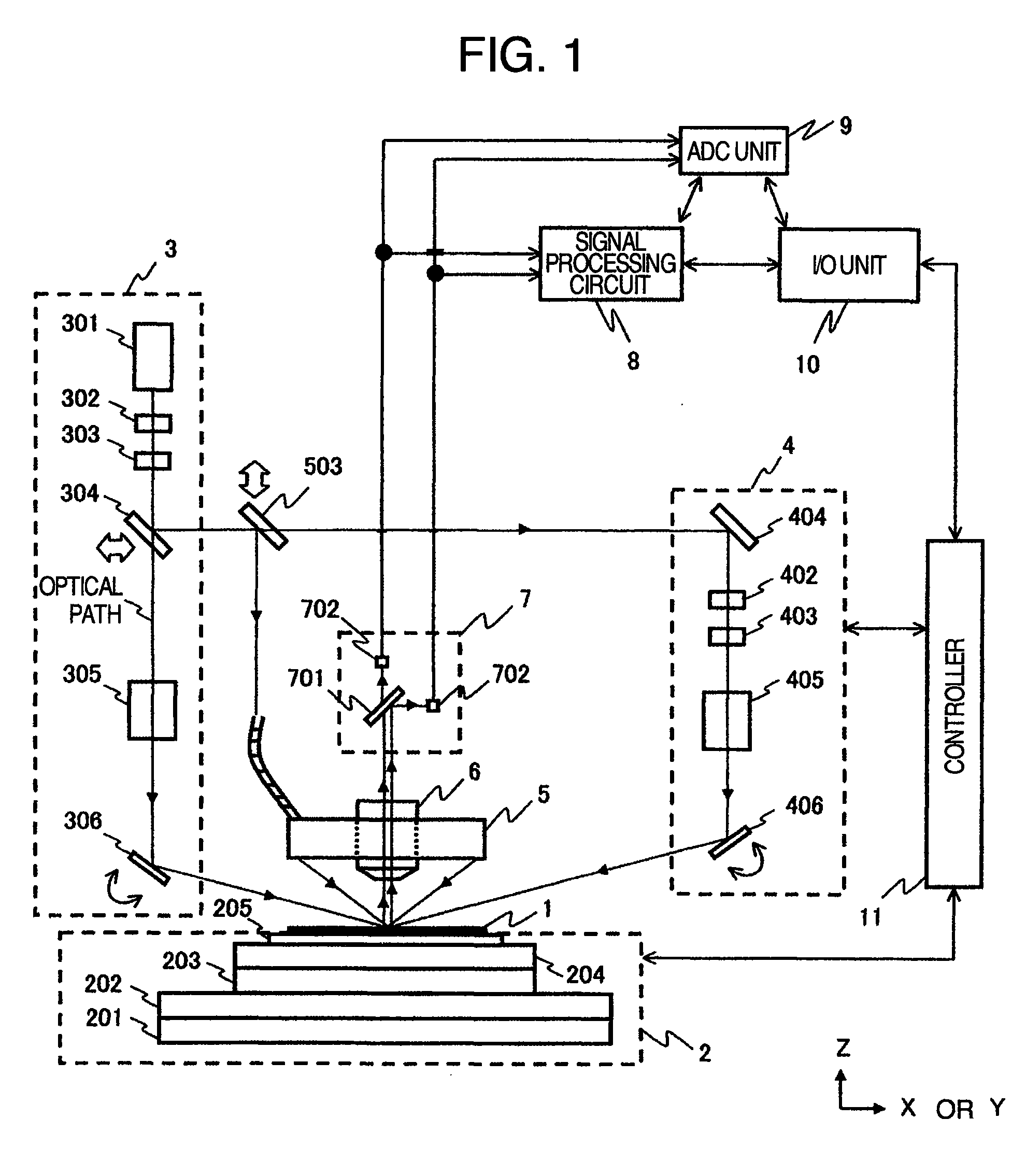

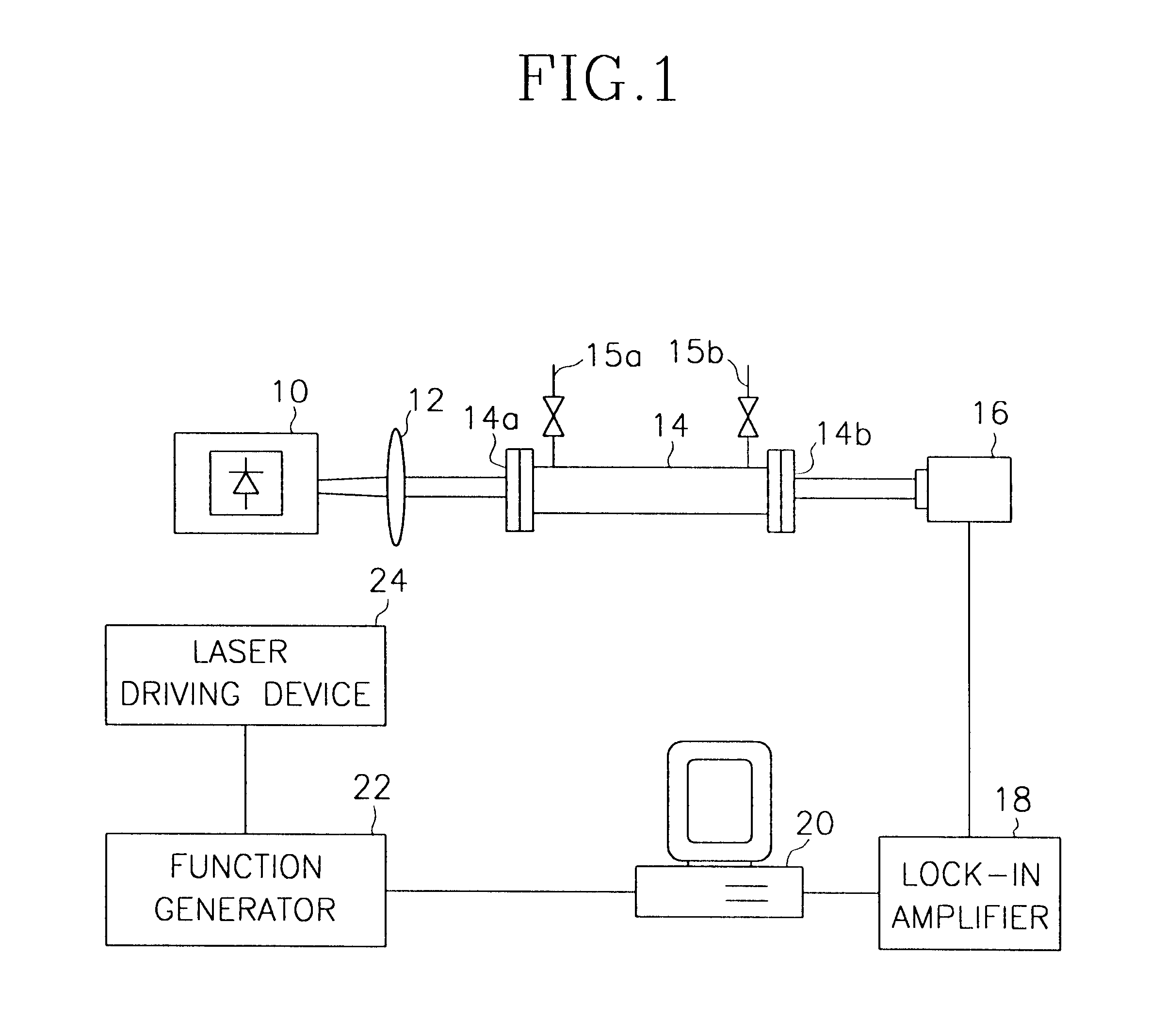

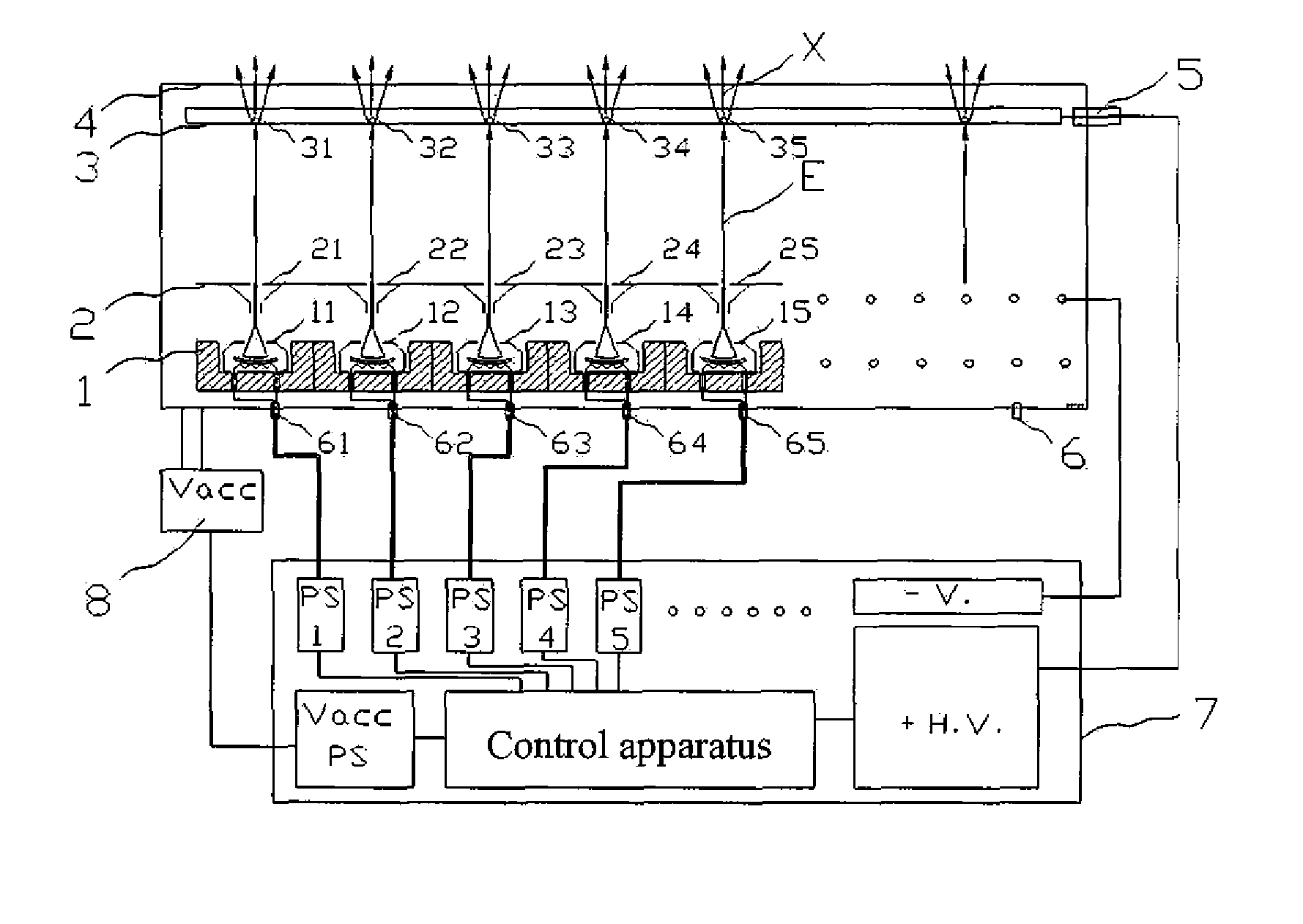

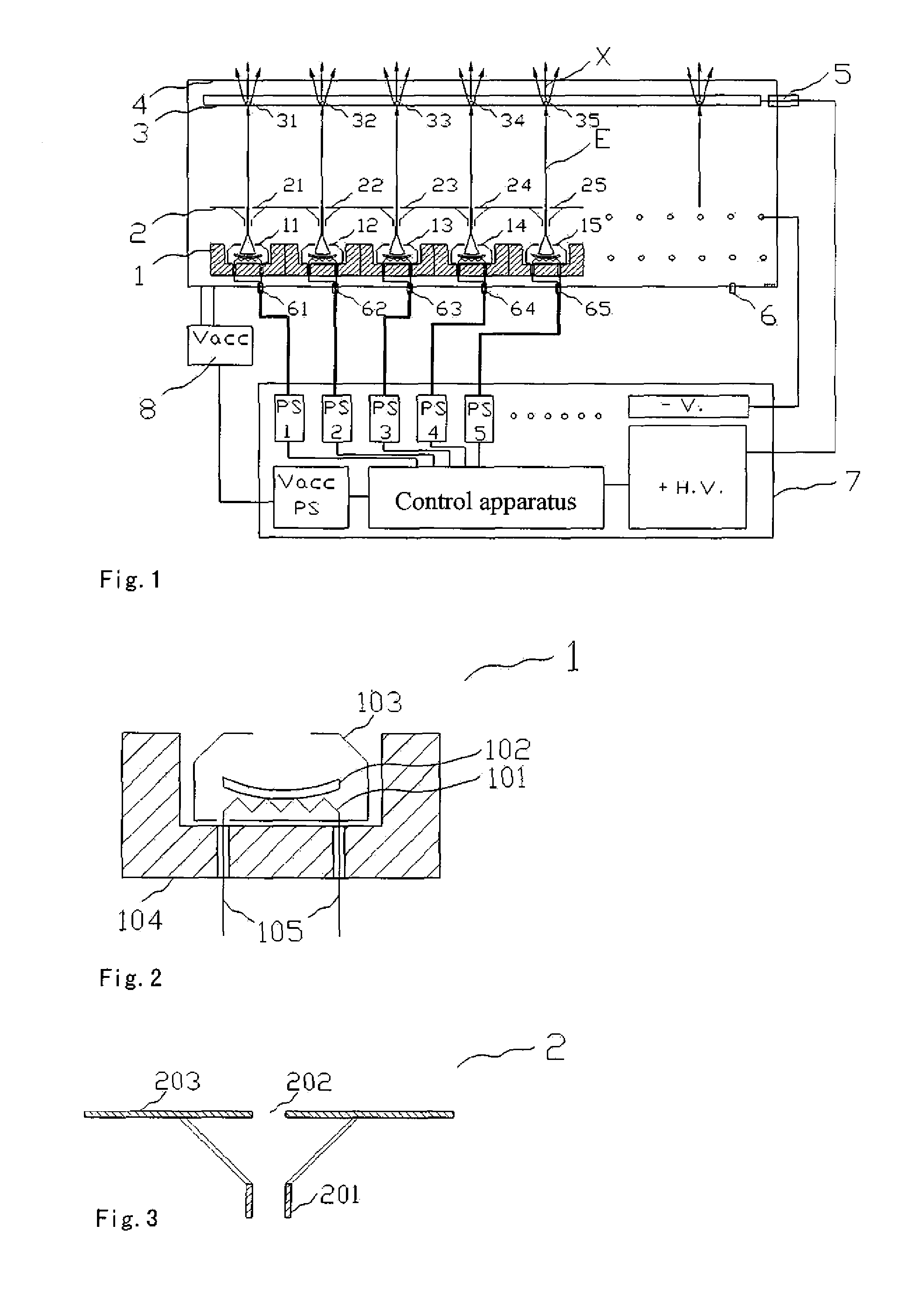

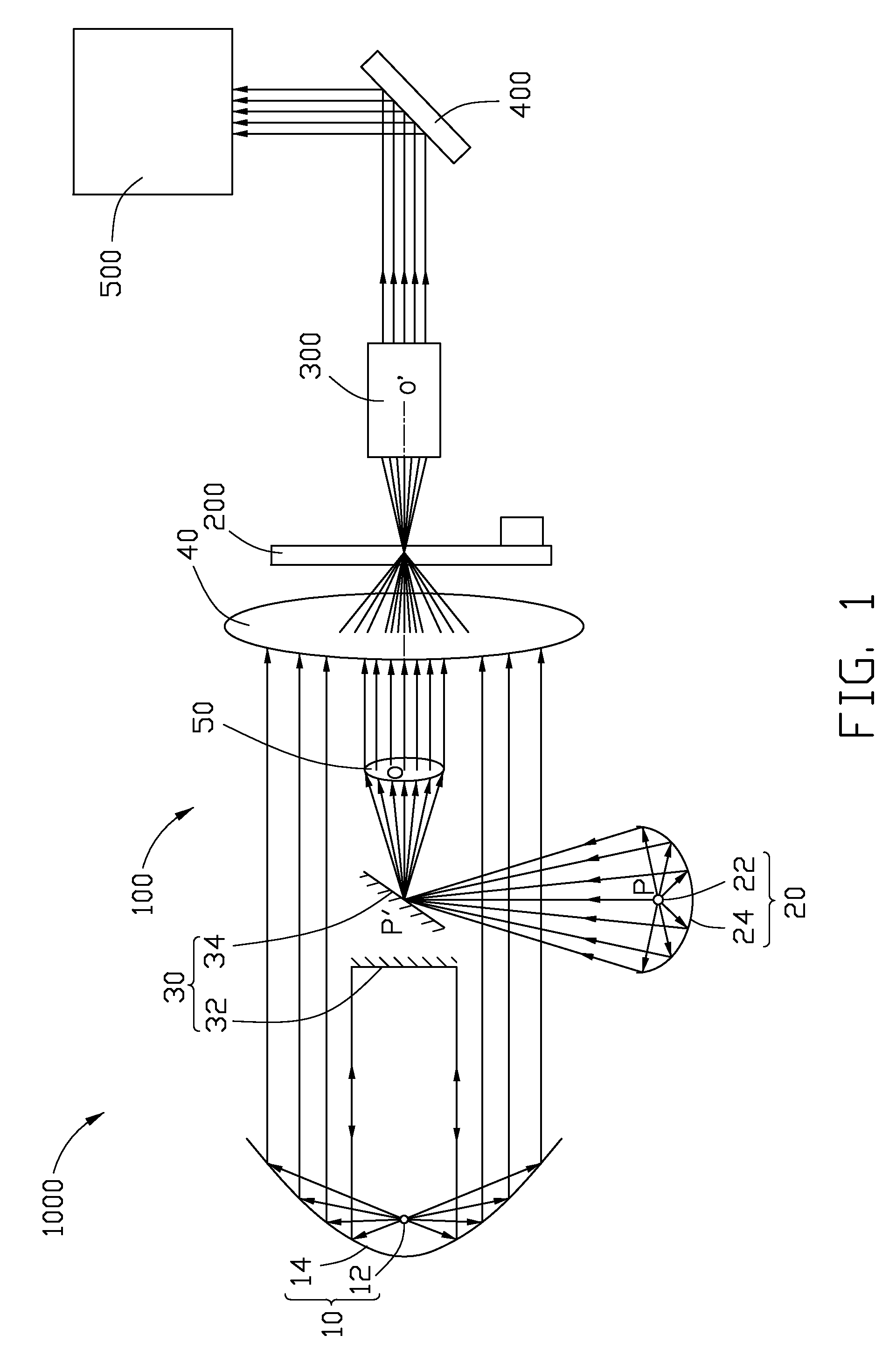

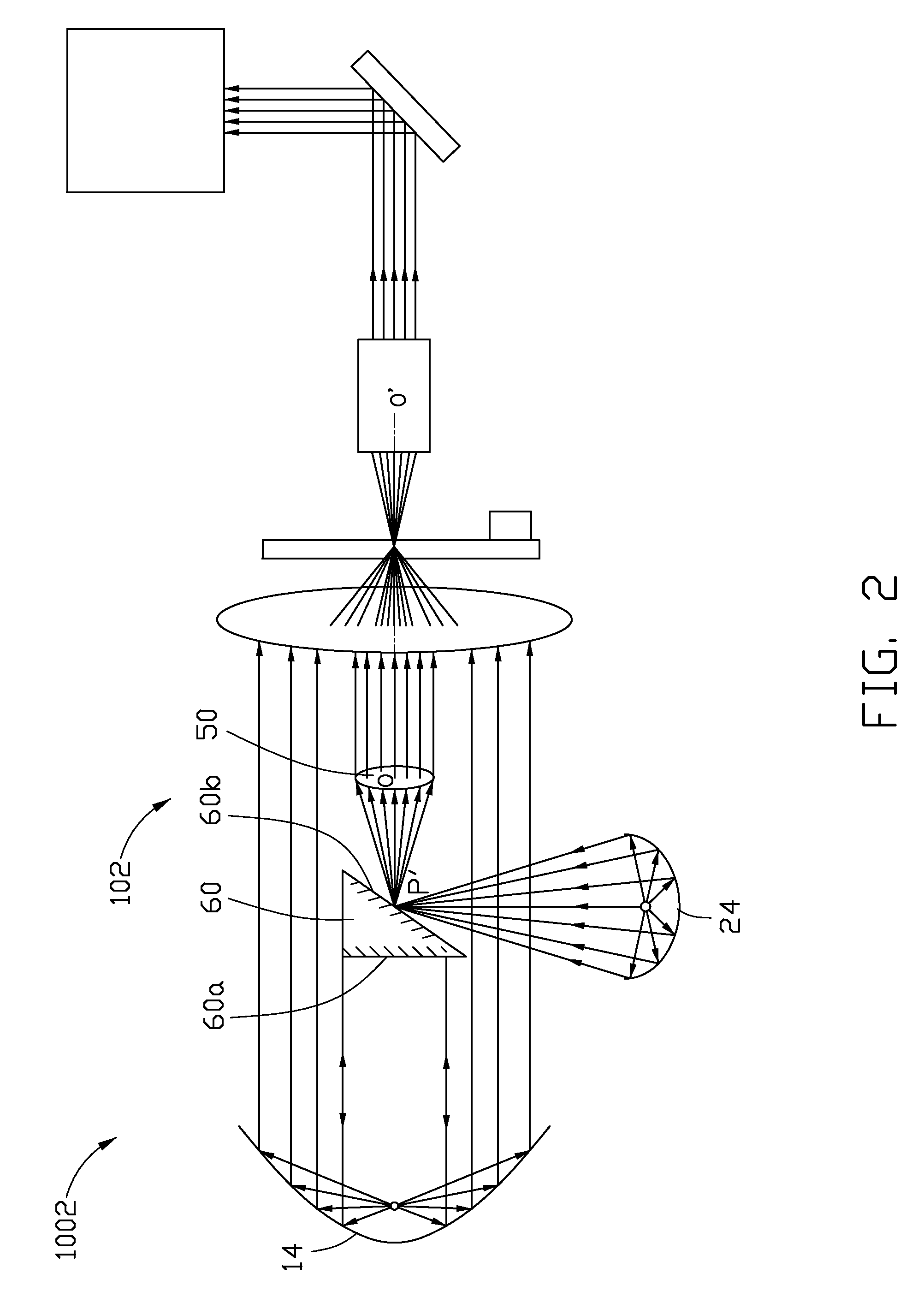

Pattern defect inspection apparatus and method

InactiveUS20080273193A1Increase brightnessIncrease lighting powerSemiconductor/solid-state device testing/measurementScattering properties measurementsSpeckle noiseAcoustics

A pattern defect inspection apparatus capable of detecting minute defects on a sample with high sensitivity without generating speckle noise in signals is realized. Substantially the same region on a surface of a wafer is detected by using two detectors at mutually different timings. Output signals from the two detectors are summed and averaged to eliminate noise. Since a large number of rays of illumination light are not simultaneously irradiated to the same region on the wafer, a pattern defect inspection apparatus capable of suppressing noise resulting from interference of a large number of rays, eliminating noise owing to other causes and detecting with high sensitivity minute defects on the sample without the occurrence of speckle noise in the signal can be accomplished.

Owner:HITACHI HIGH-TECH CORP

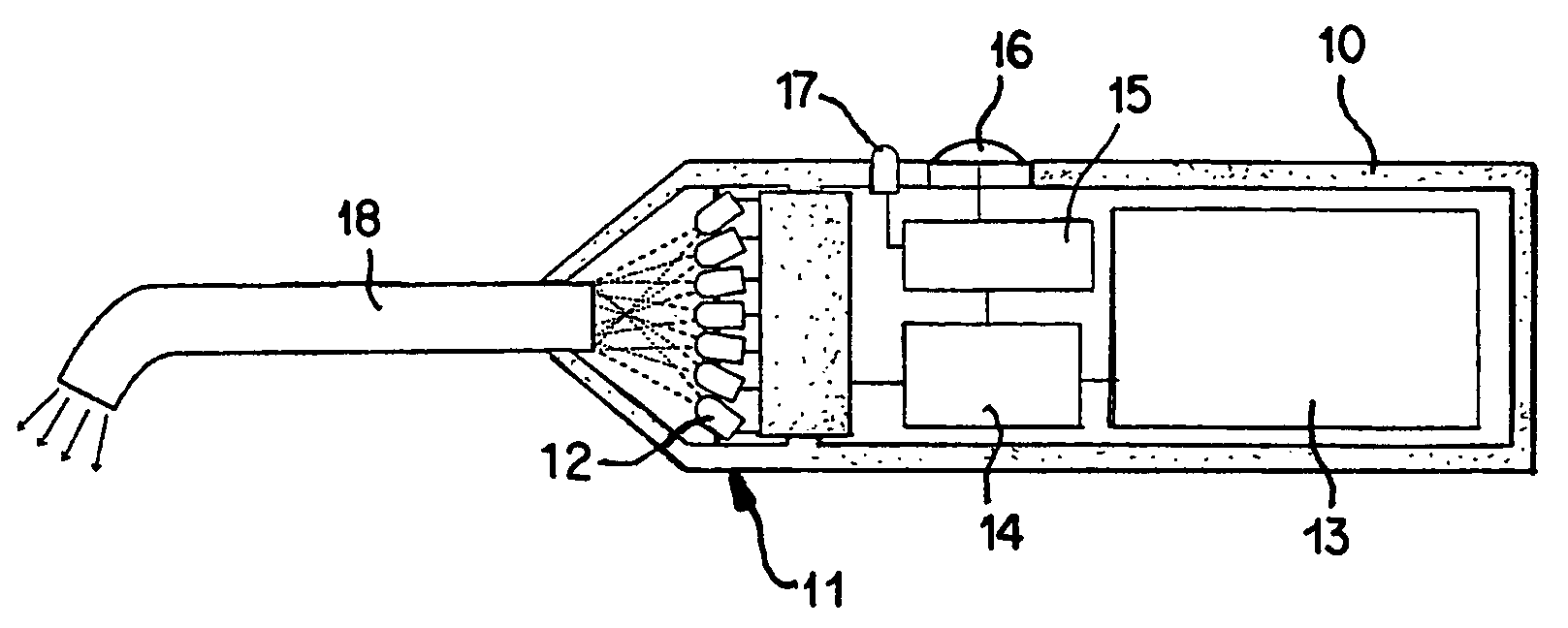

Irradiation unit

InactiveUS6932599B1Increase lighting powerQuick and reliableDental toolsDisplay meansLight beamIrradiation

Owner:3M ESPE

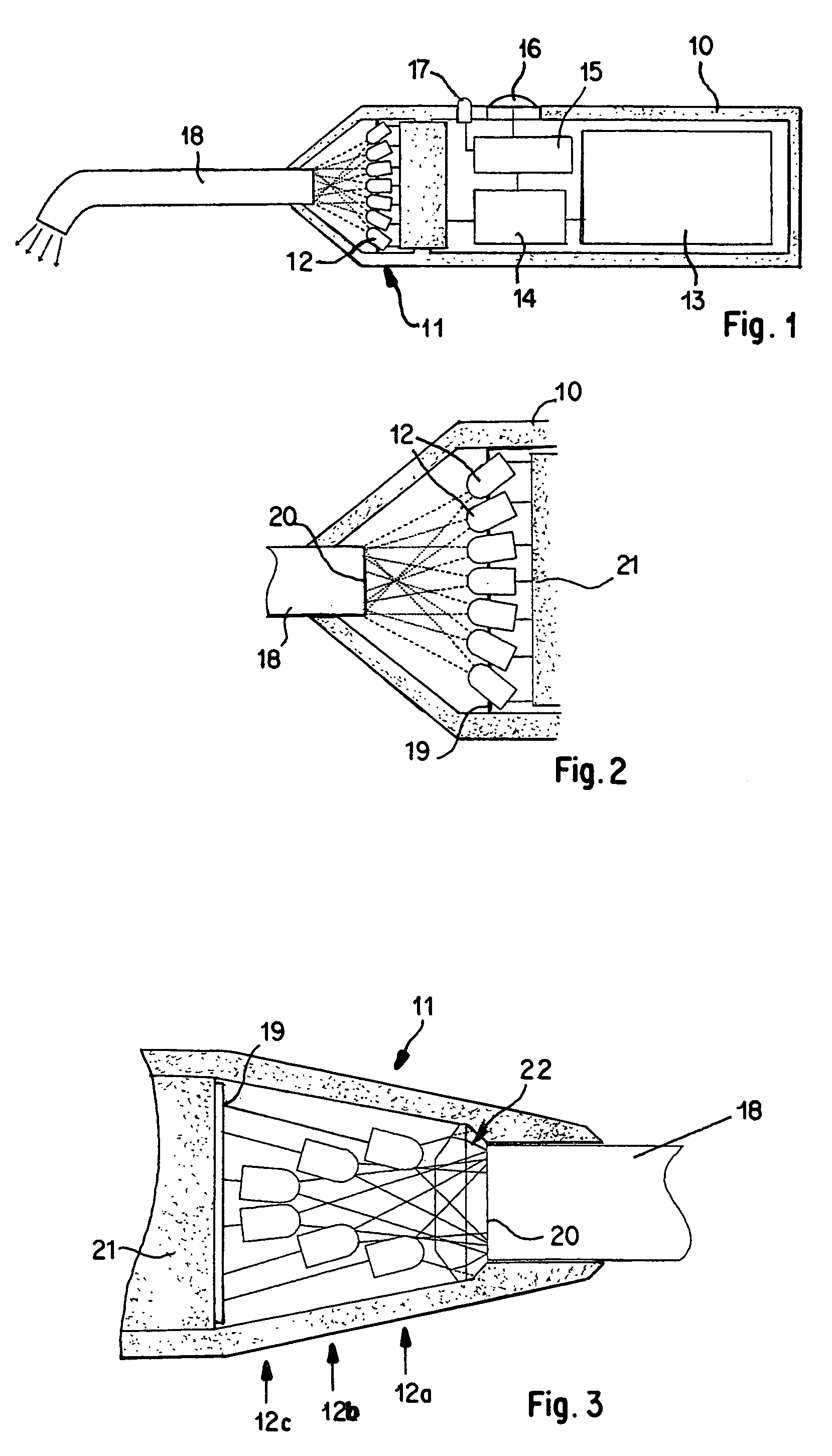

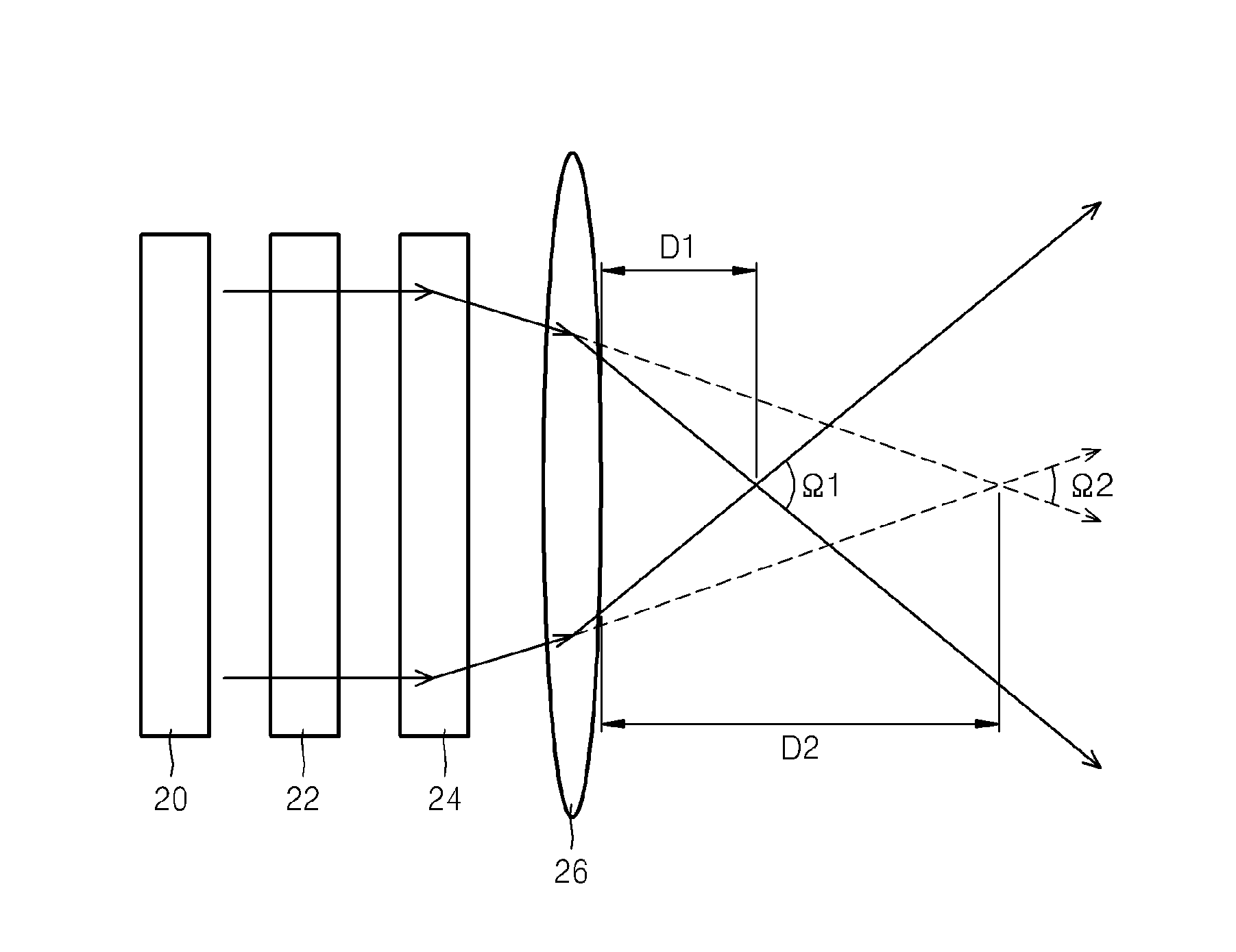

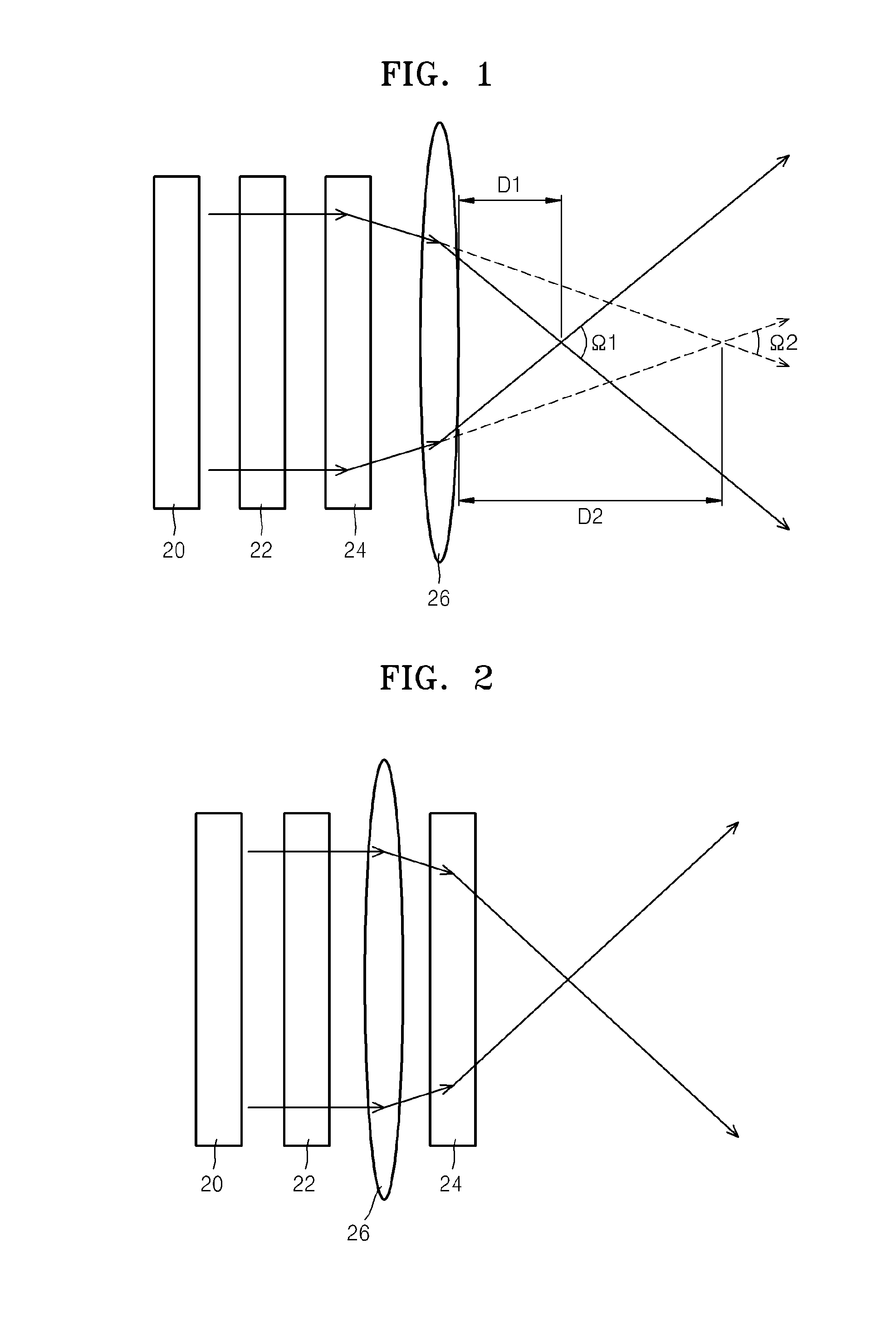

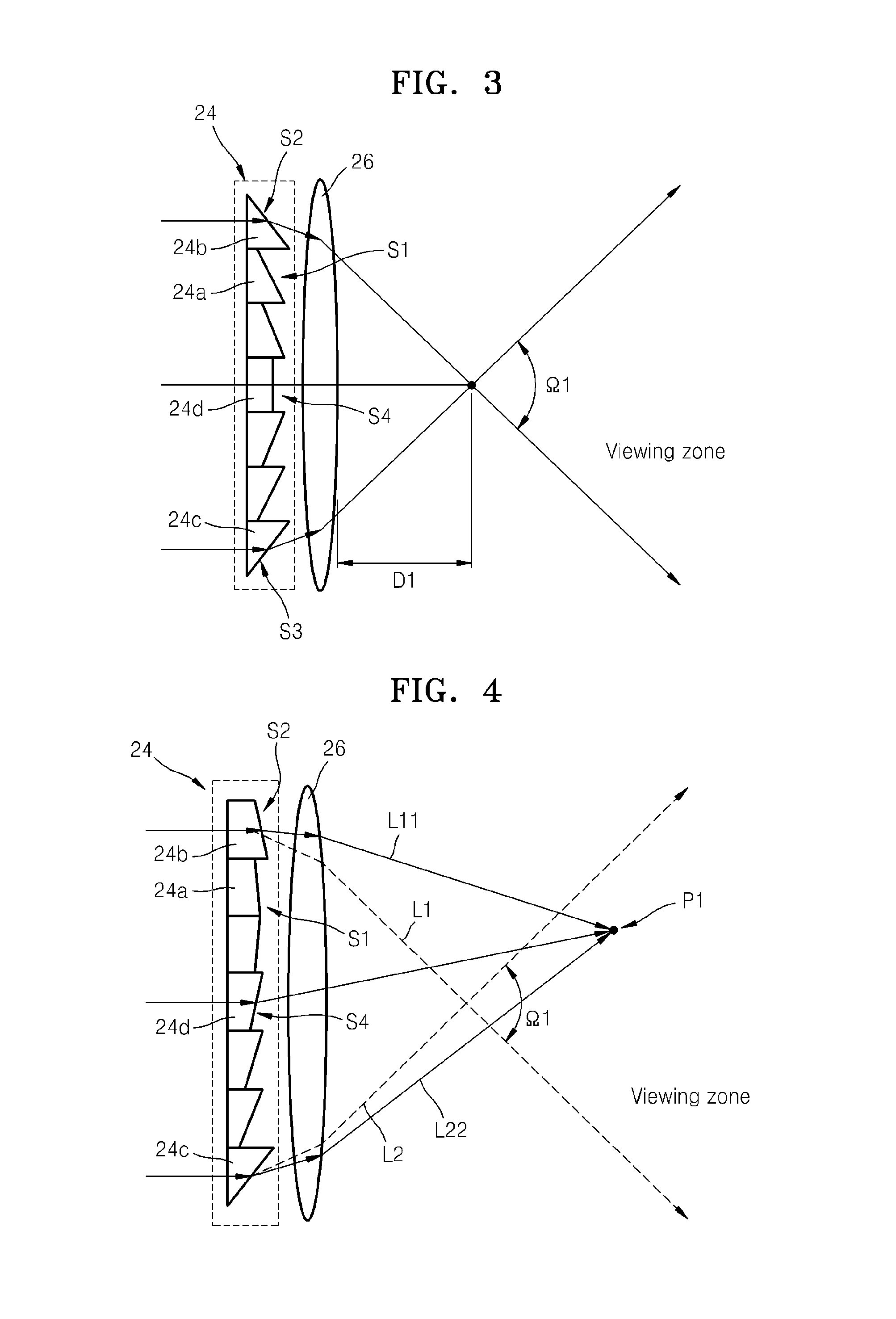

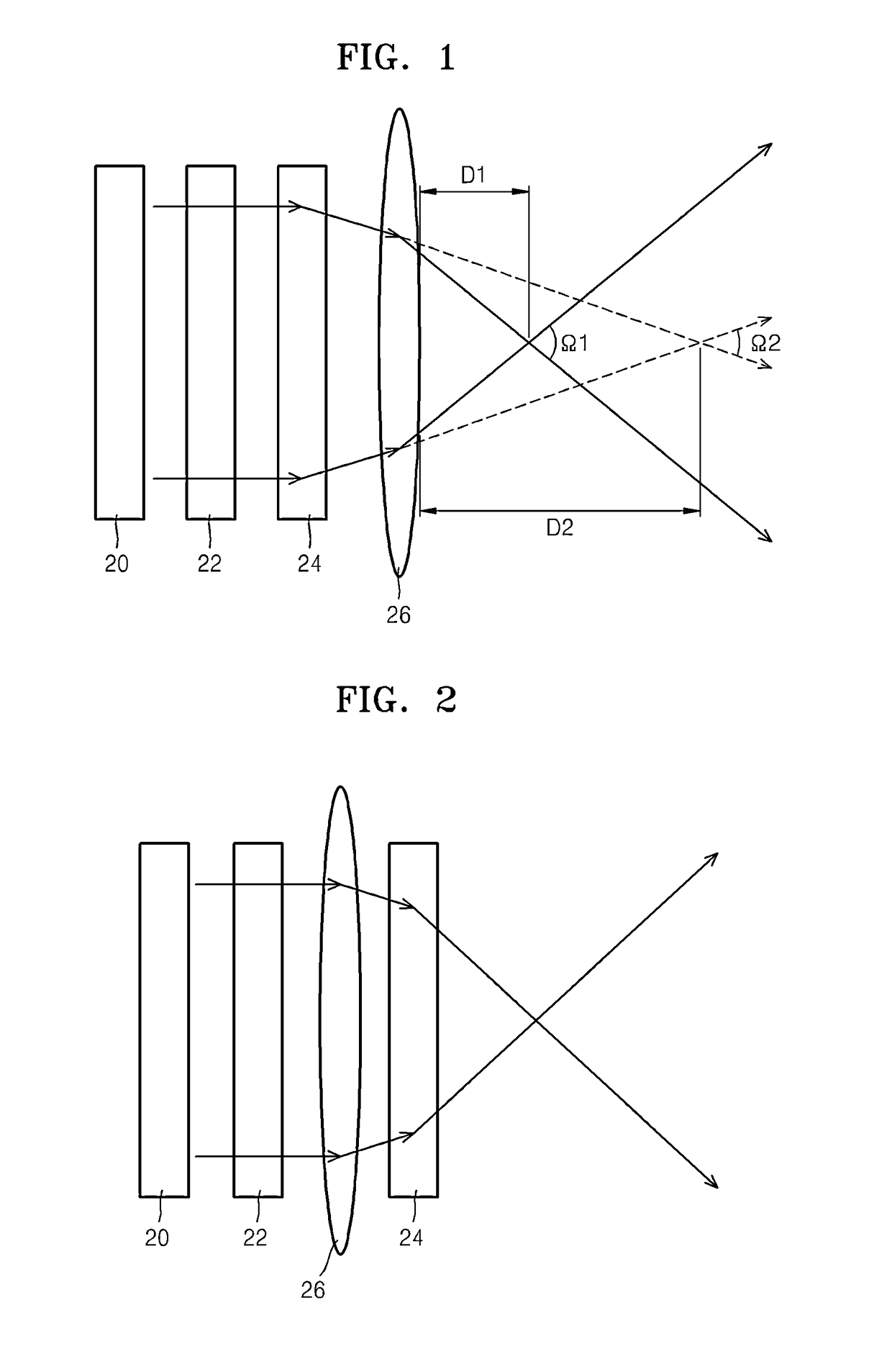

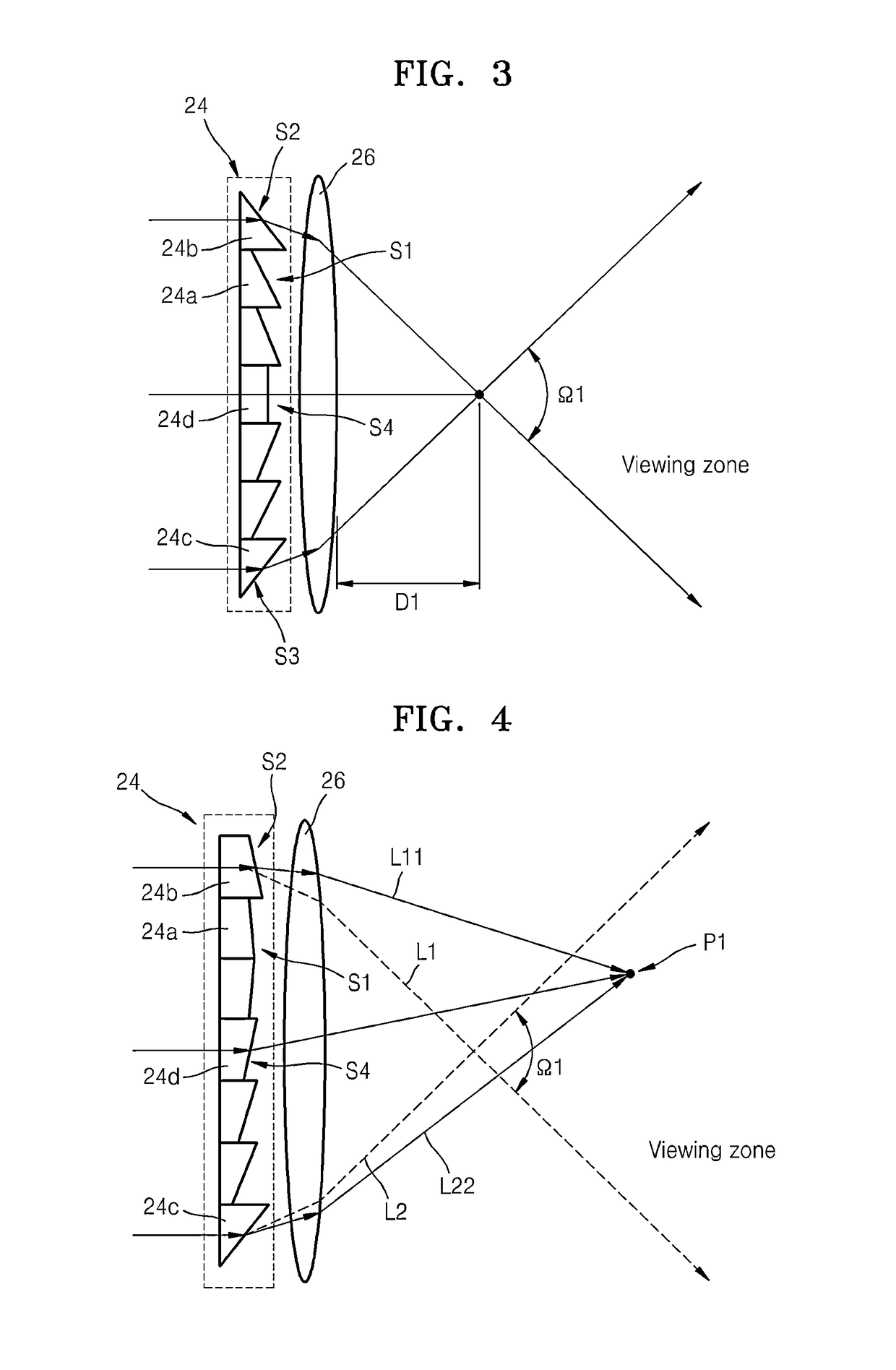

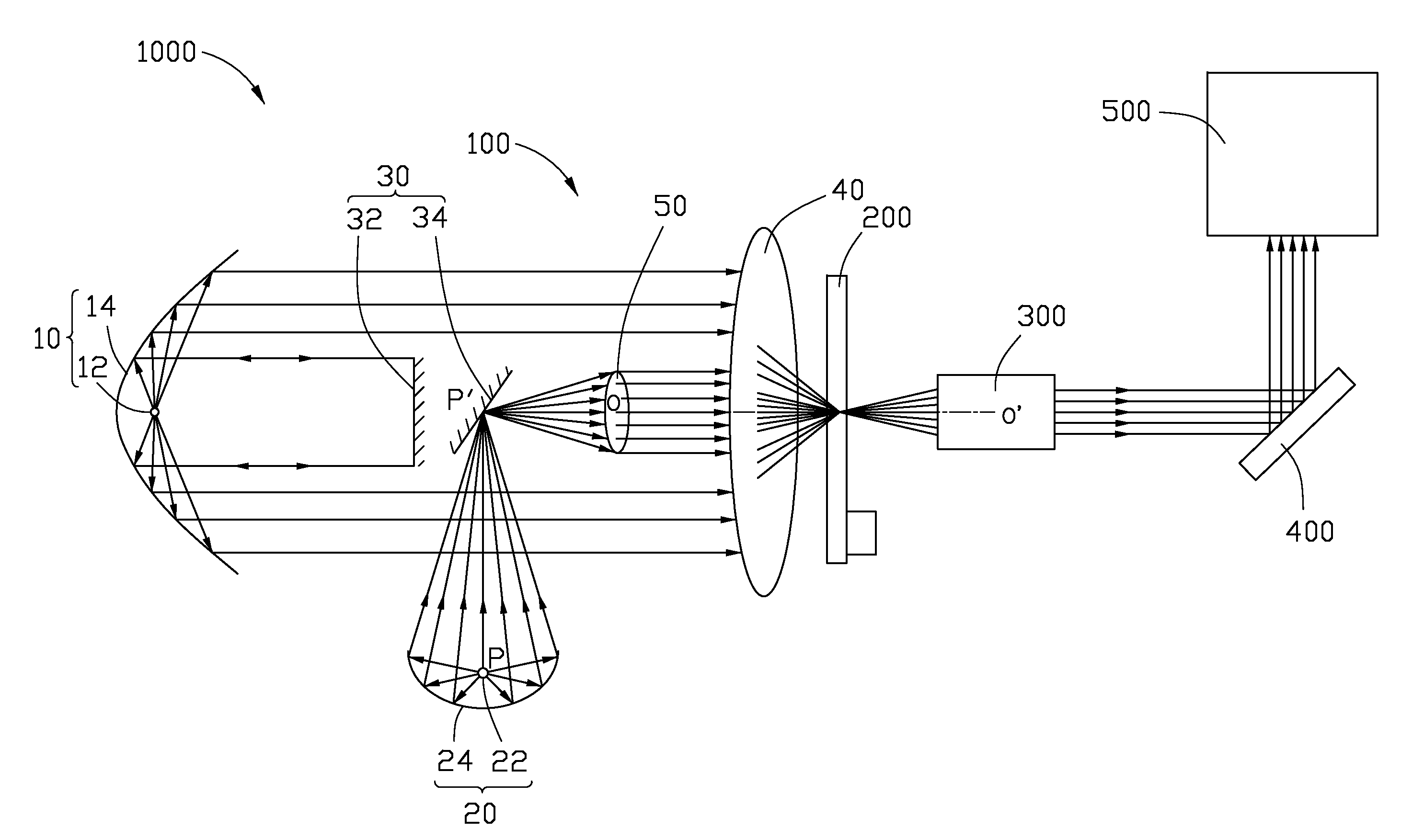

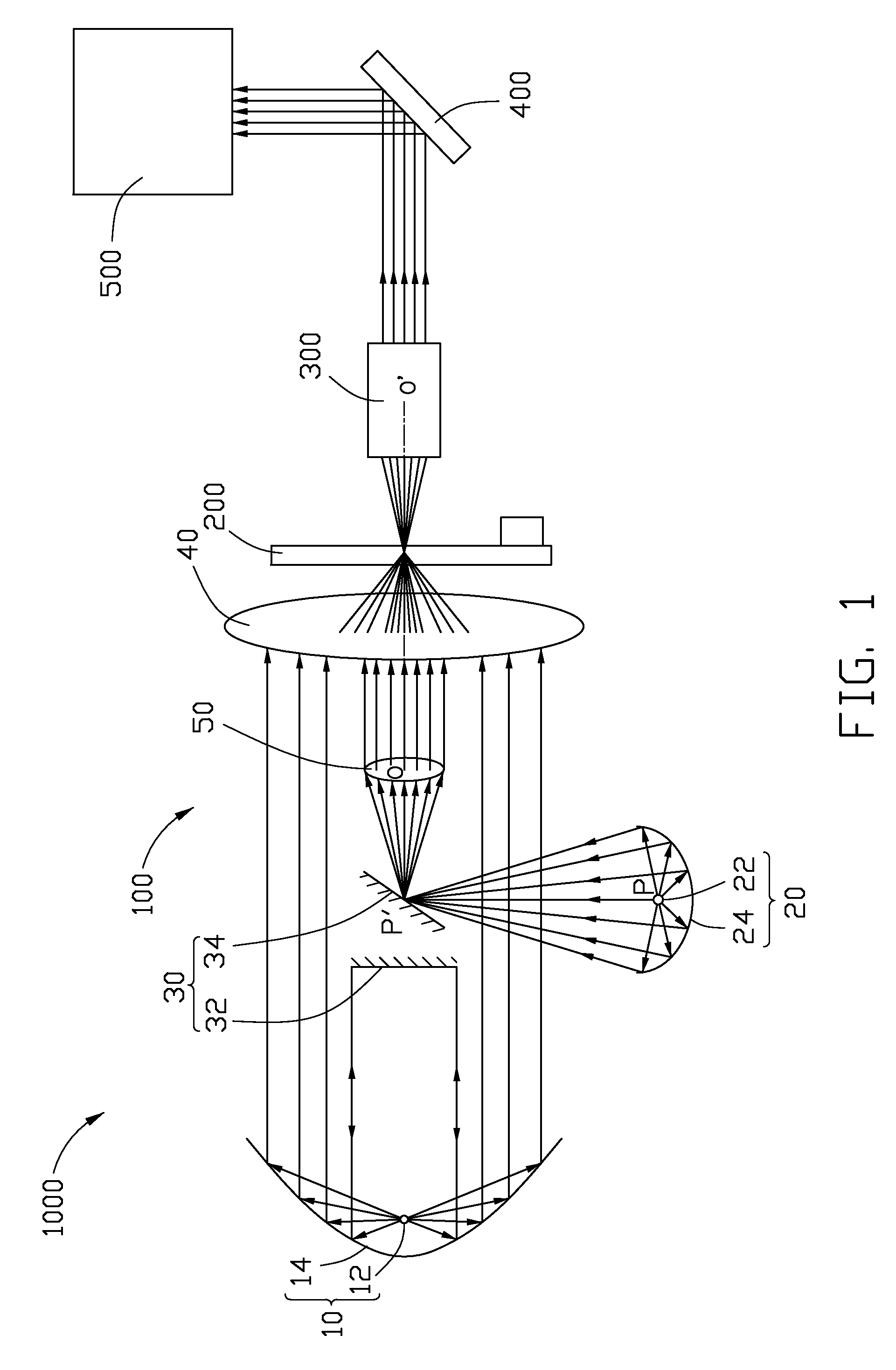

Display including electrowetting prism array

ActiveUS20140168754A1Increase lighting powerNon-linear opticsOptical elementsFresnel lensDisplay device

A display including an electrowetting prism array is provided. The display includes: a light source, a 2-dimensional (2D) display for providing an image using light from the light source, a prism array in which a refractive power of one or more prisms of the prism array is adjustablein real time, and an optical element which increases a refraction of light transmitted therethrough. In the display, the optical element may be disposed in front of or behind the prism array. The optical element may be a convex lens, a Fresnel lens, a holographic optical element (HOE), a diffraction optical element (DOE), or a second electrowetting prism array. The convex lens may be a variable focus lens.

Owner:SAMSUNG ELECTRONICS CO LTD

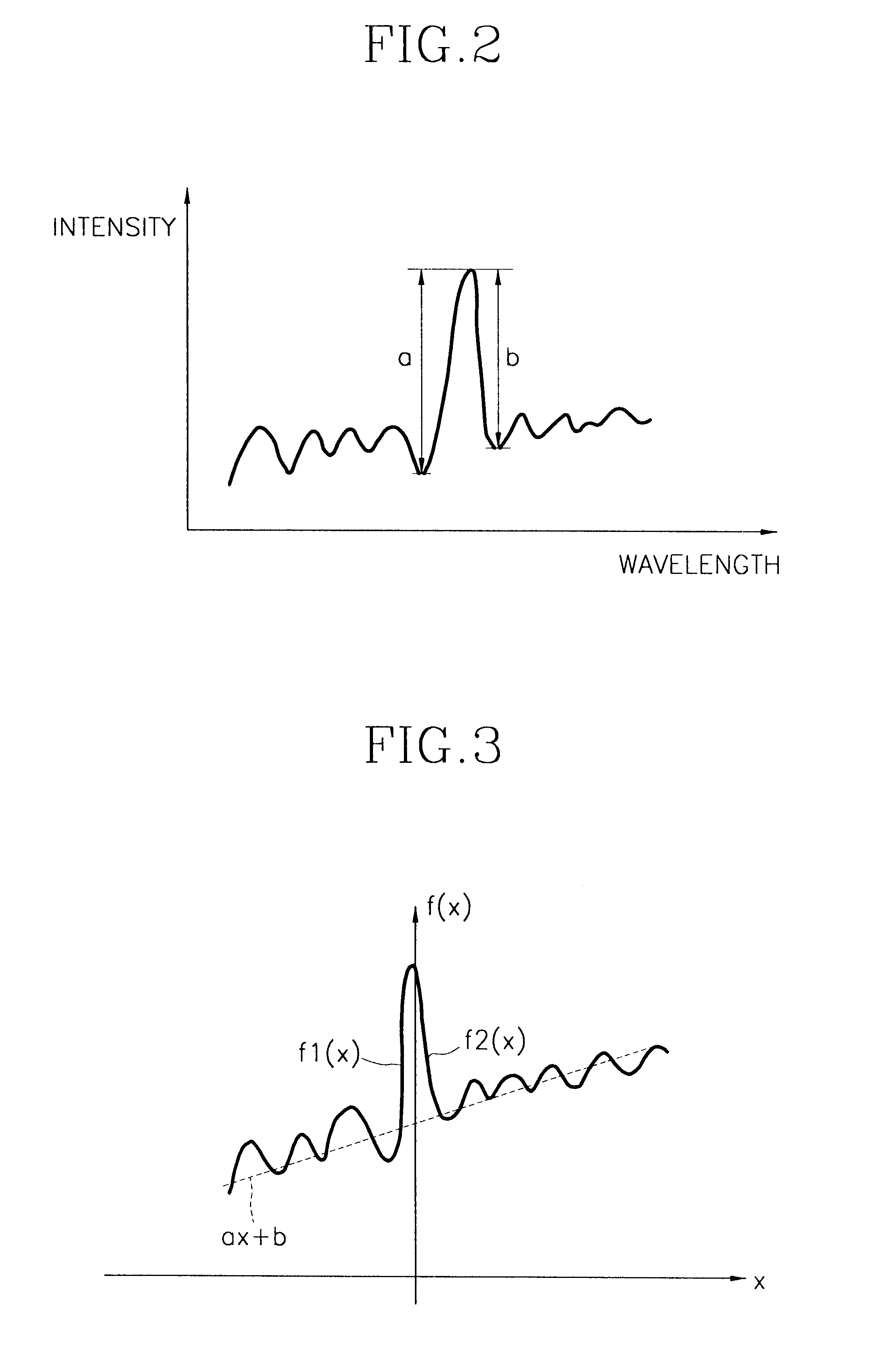

Method and apparatus for measuring light absorption spectra

InactiveUS6434496B1High sensitivityComponents increasedSpectral/fourier analysisRadiation pyrometryLaser beamsPhysics

The present invention provides a method and an apparatus for measuring a light absorption spectra which can remove a noise included in a measurement signal, and achieve a high sensitivity of a laser spectral in a good S / N ratio. According to the present invention, there is provided a method for measuring a light absorption spectra comprising the steps of: (i) conducting a Fourier transform of an absorption spectra measured by using a laser beam source; (ii) disassembling in a Fourier space the Fourier transformed signal into a signal resulted from a periodic vibration component and a signal resulted from a molecular absorption spectra; (iii) removing the Fourier component resulted from said periodic vibration component in a Fourier space; and (iv) conducting an inverse Fourier transform on the signal from which said periodic vibration component is removed, whereby reproducing an absorption spectra in a real space.

Owner:NIPPON SANSO CORP

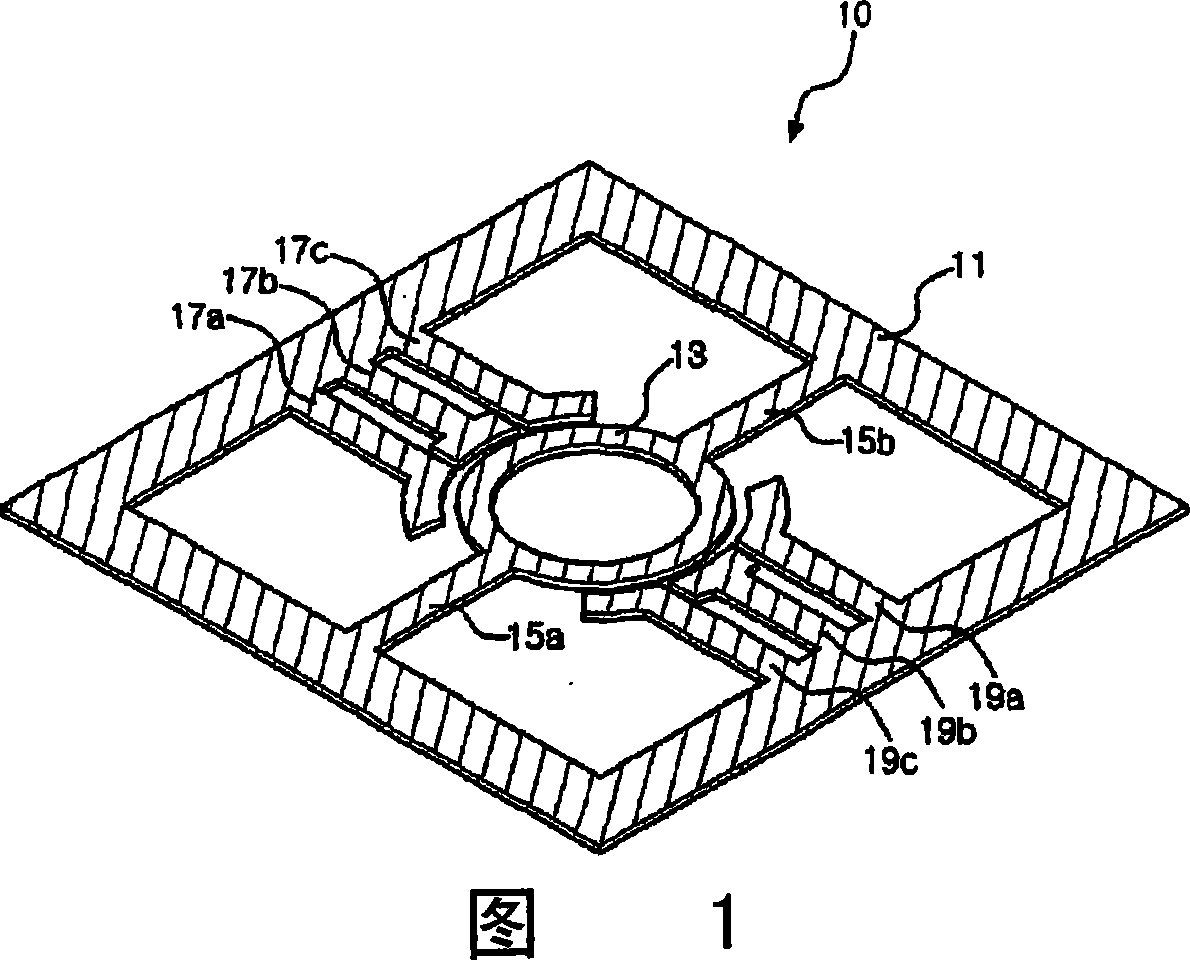

Leadframe having a heat sink supporting ring, fabricating method of a light emitting diodepackage using the same and light emitting diodepackage fabbricated by the method

ActiveCN101080822AIncrease lighting powerJunction temperature increaseSolid-state devicesSemiconductor devicesHeat sinkStructural stability

There are provided a leadframe, a method of fabricating a light emitting diode package using the leadframe, and the light emitting diode package fabricated by the method. The leadframe includes a heat sink supporting ring for supporting a heat sink. An outer frame is spaced apart from the heat sink supporting ring, and encloses the heat sink supporting ring. At least one supporting lead connects the heat sink supporting ring and the outer frame. A separated lead is extended from the outer frame toward the heat sink supporting ring, and is spaced apart from the heat sink supporting ring. Consequently, since the package body can be formed by an injection molding after a heat sink is inserted into the leadframe, a LED package having structural stability and good heat dissipation can be fabricated with ease.

Owner:SEOUL SEMICONDUCTOR

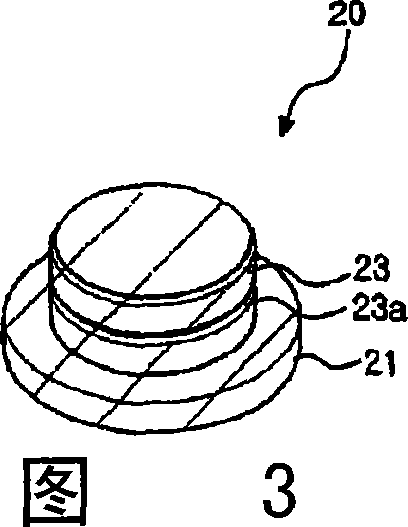

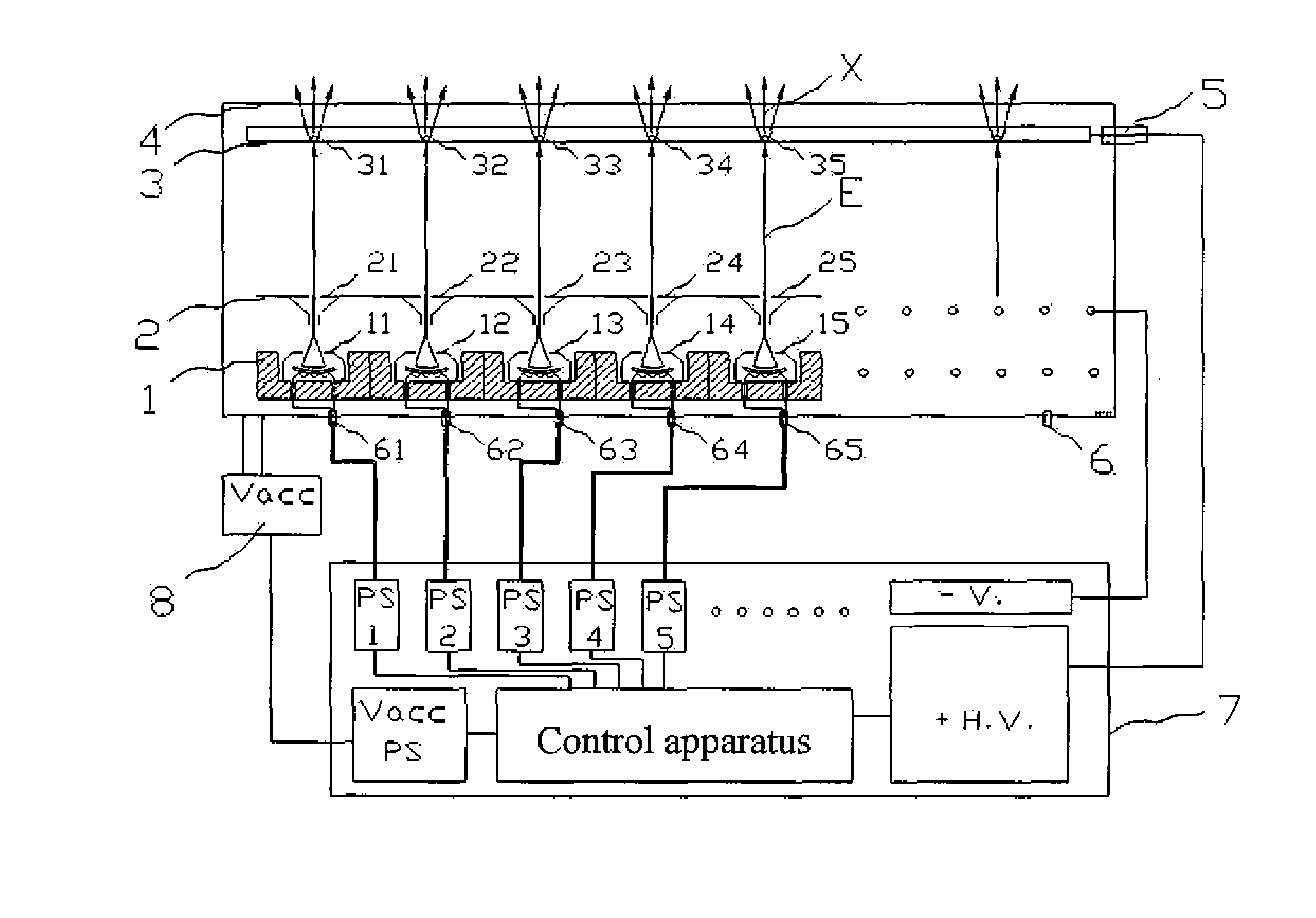

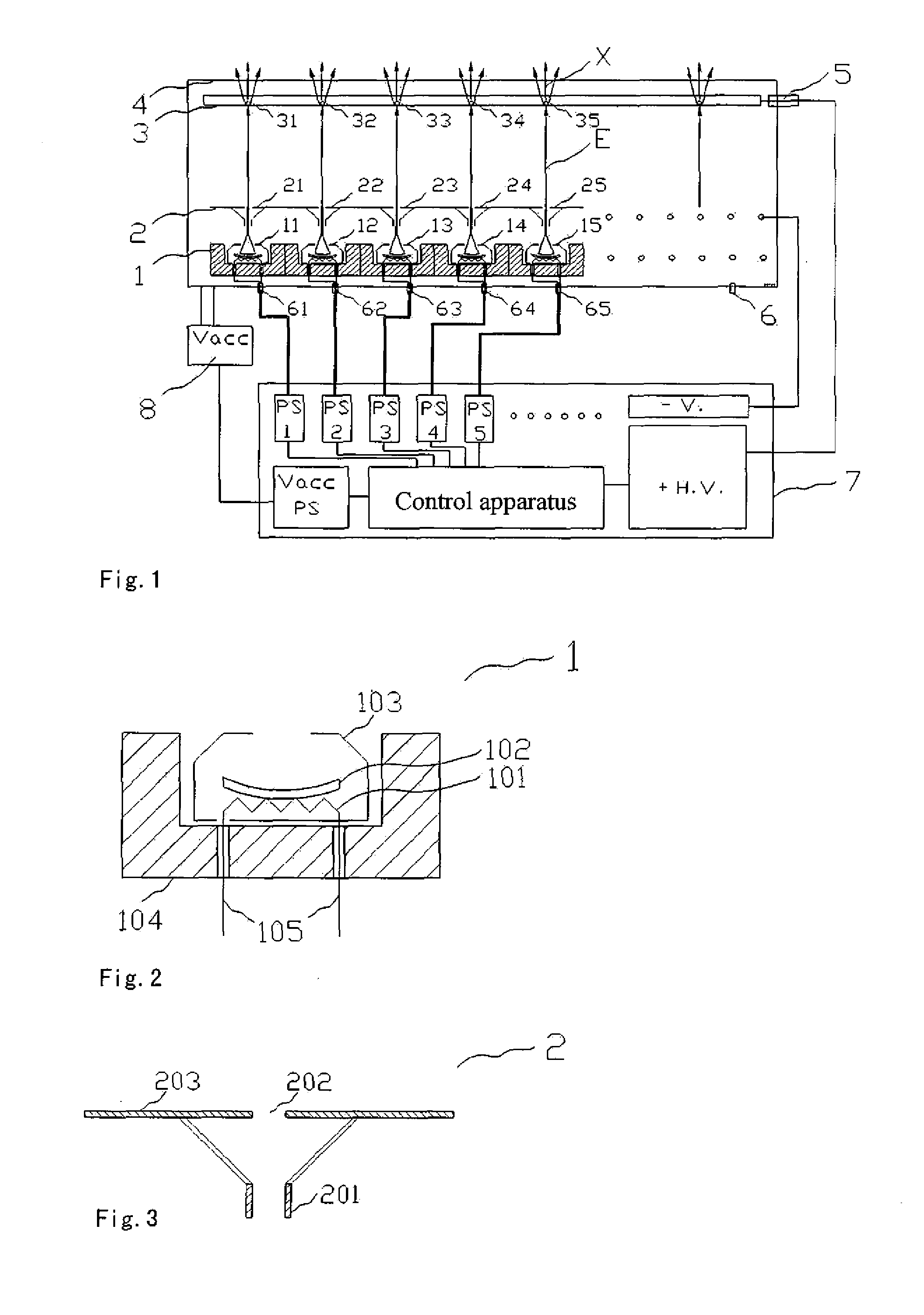

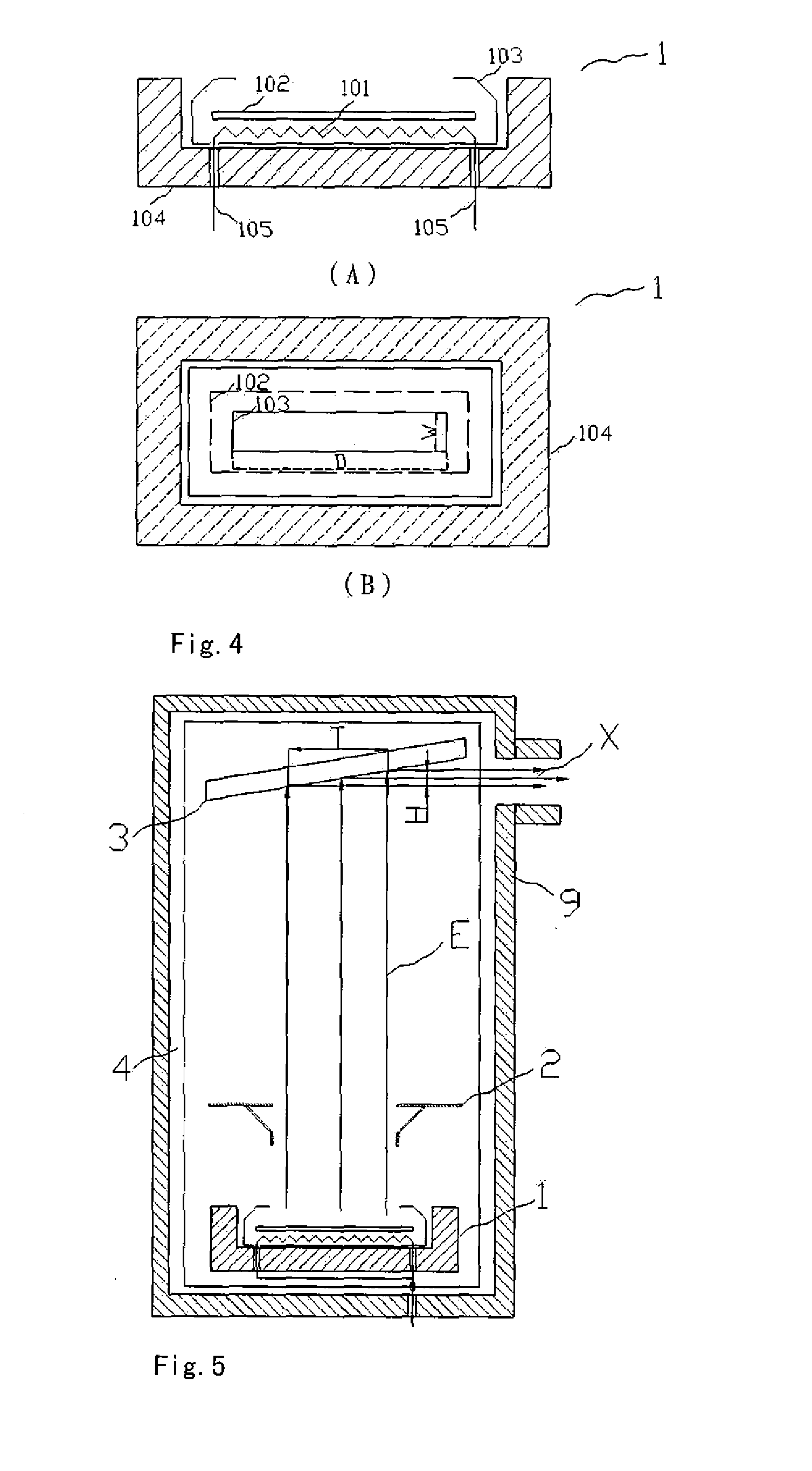

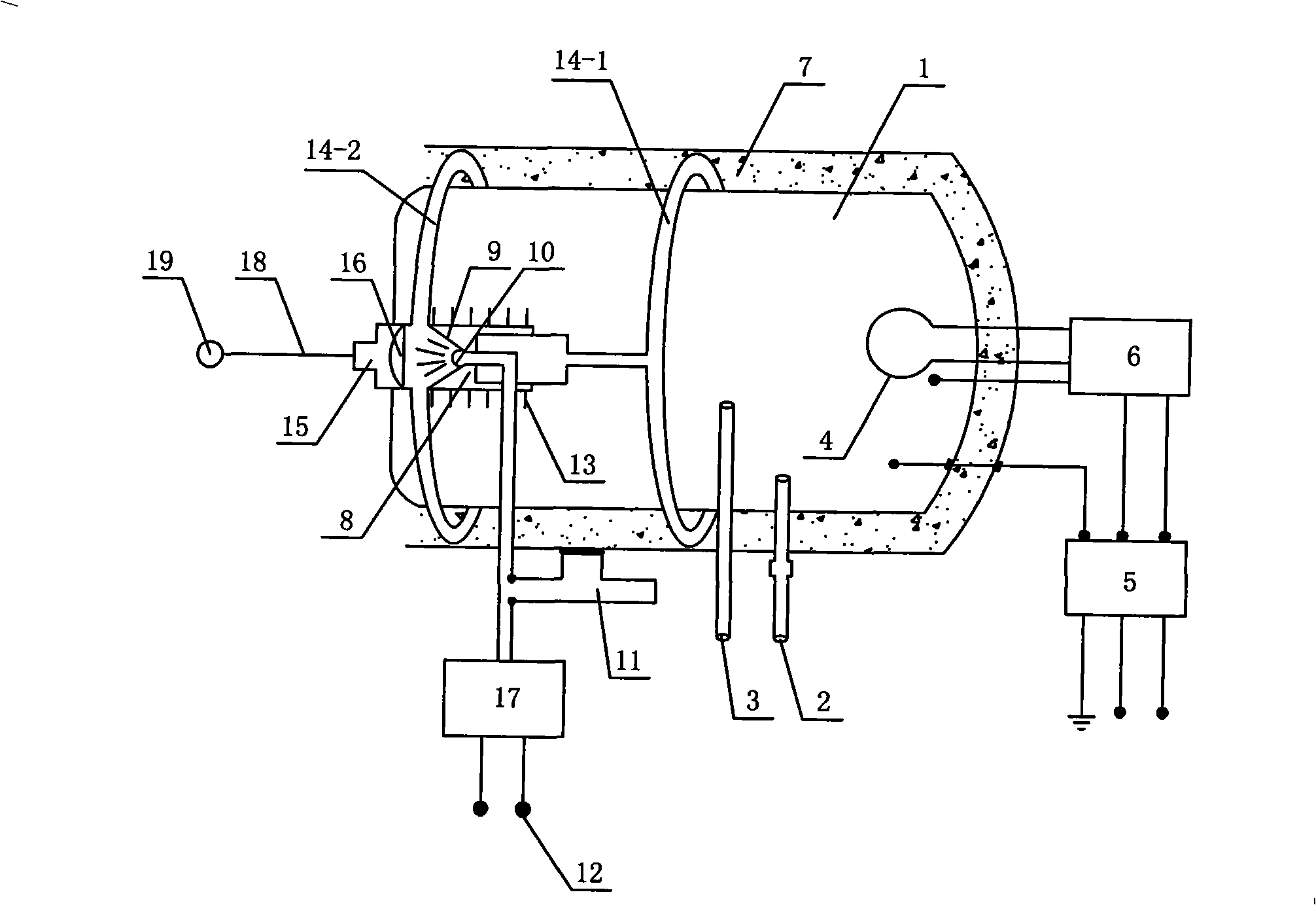

Cathode control multi-cathode distributed x-ray apparatus and ct device having said apparatus

ActiveUS20140185739A1Easy to controlHigh currentMaterial analysis using wave/particle radiationRadiation/particle handlingX-rayFocal position

This invention relates to an apparatus producing distributed X-ray, and in particular to a cathode control multi-cathode distributed X-ray apparatus, which produces X-ray that changes focal position in a predetermined order by arranging multiple independent hot cathodes and controlling cathodes in an X-ray source device, and a CT device having said X-ray apparatus.

Owner:NUCTECH CO LTD +1

Water storage type electro-optical dual-energy water heater

InactiveCN101261033AReduce energy consumptionLarge capacityMechanical apparatusWater heatersThermal energyWater storage tank

The invention discloses a water storage type electro-optical dual-energy water heater suitable for providing hot water and lighting and decorative effects for families, hotels and other business service places, which comprises a water storage tank, a water inlet with a reducing valve, a water outlet, an electric heater on one end of the water storage tank, a creepage protector, a temperature controller and an insulating course externally coated on the water storage tank; the other end of the water storage tank is provided with a lamp-house heater for optical fibre illumination; the periphery of the lamp-house heater is provided with circulating heat draft tubes which encircle inside the insulating course and outside the water storage tank; a lamp-house delivery port is arranged on the lamp-house heater and is transmitted to an optical fiber fitting by optical fiber. The water storage type electro-optical dual-energy water heater uses heat energy released by the lamp-house heater for heating and heat insulation of the water heater, transmits the lamp-house to other optical fibre fittings for illumination by optical fiber, greatly reduces the energy consumption needed for the heating and temperature constancy of the water heater, greatly saves energy and has the characteristic of safety, energy conservation and environmental protection.

Owner:严紫金

Cathode control multi-cathode distributed X-ray apparatus and CT device having said apparatus

ActiveUS9398677B2Reduce decreaseHigh currentX-ray tube electrodesX-ray tube multi-cathode assemblyX-rayFocal position

This invention relates to an apparatus producing distributed X-ray, and in particular to a cathode control multi-cathode distributed X-ray apparatus, which produces X-ray that changes focal position in a predetermined order by arranging multiple independent hot cathodes and controlling cathodes in an X-ray source device, and a CT device having said X-ray apparatus.

Owner:NUCTECH CO LTD +1

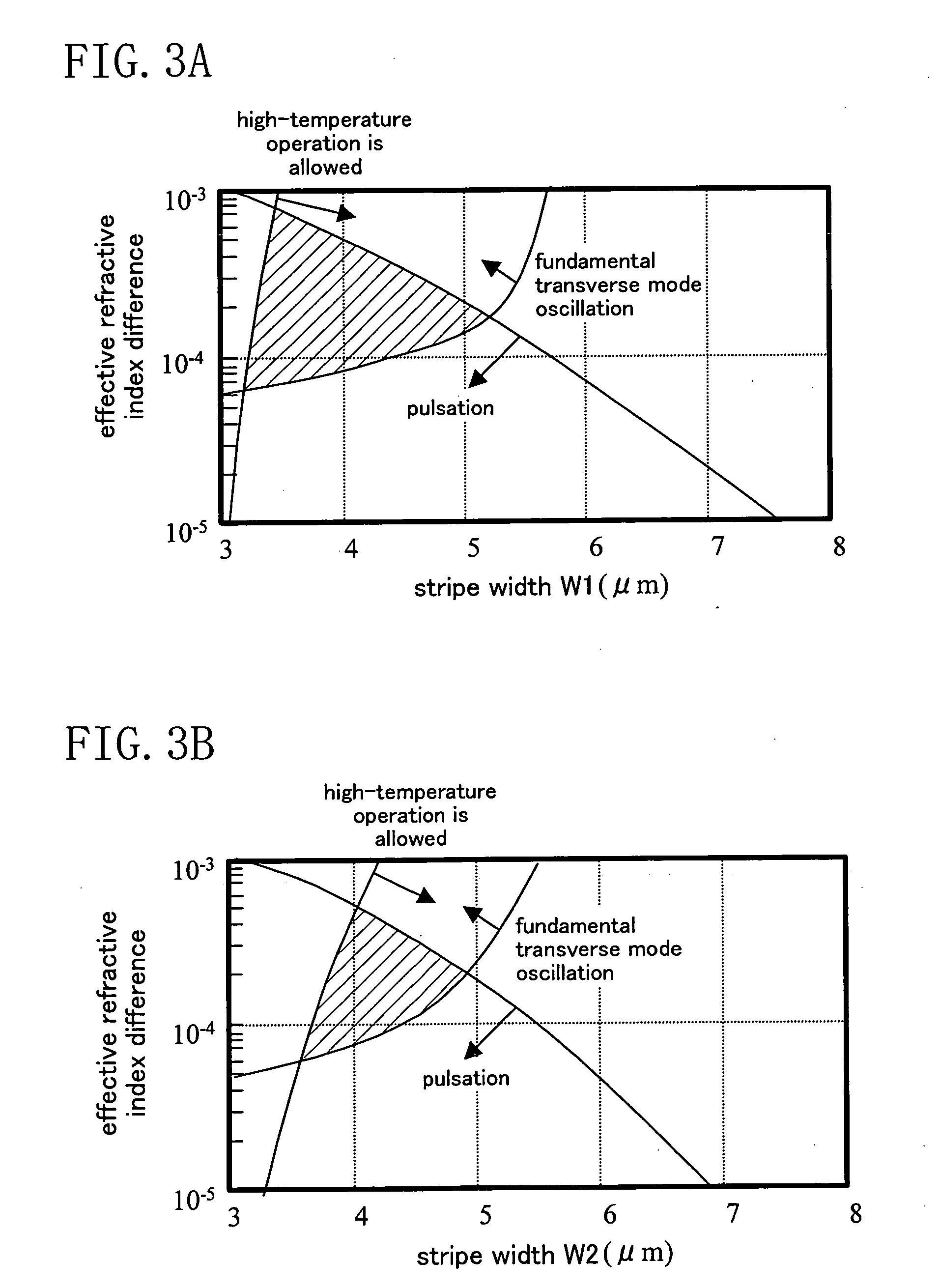

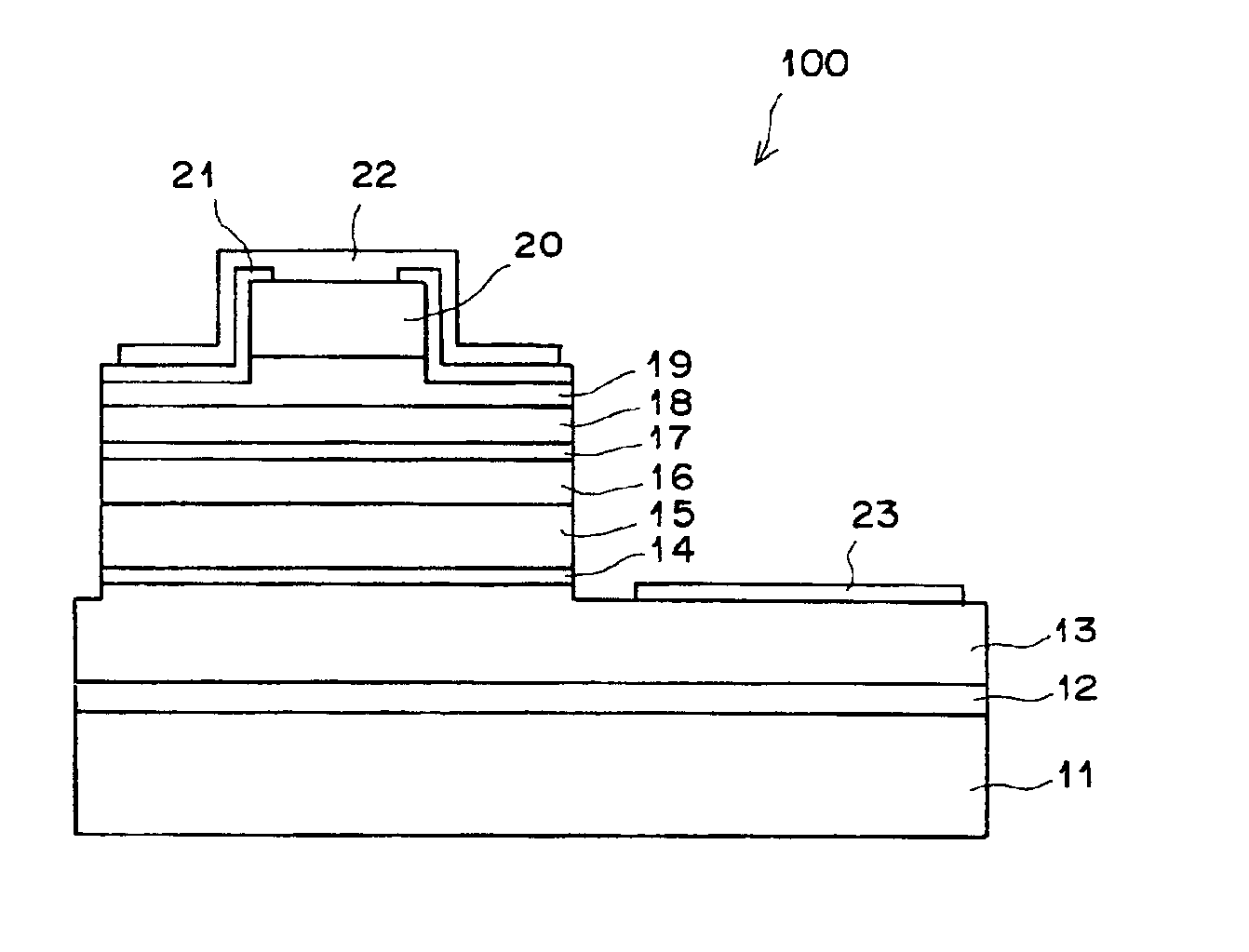

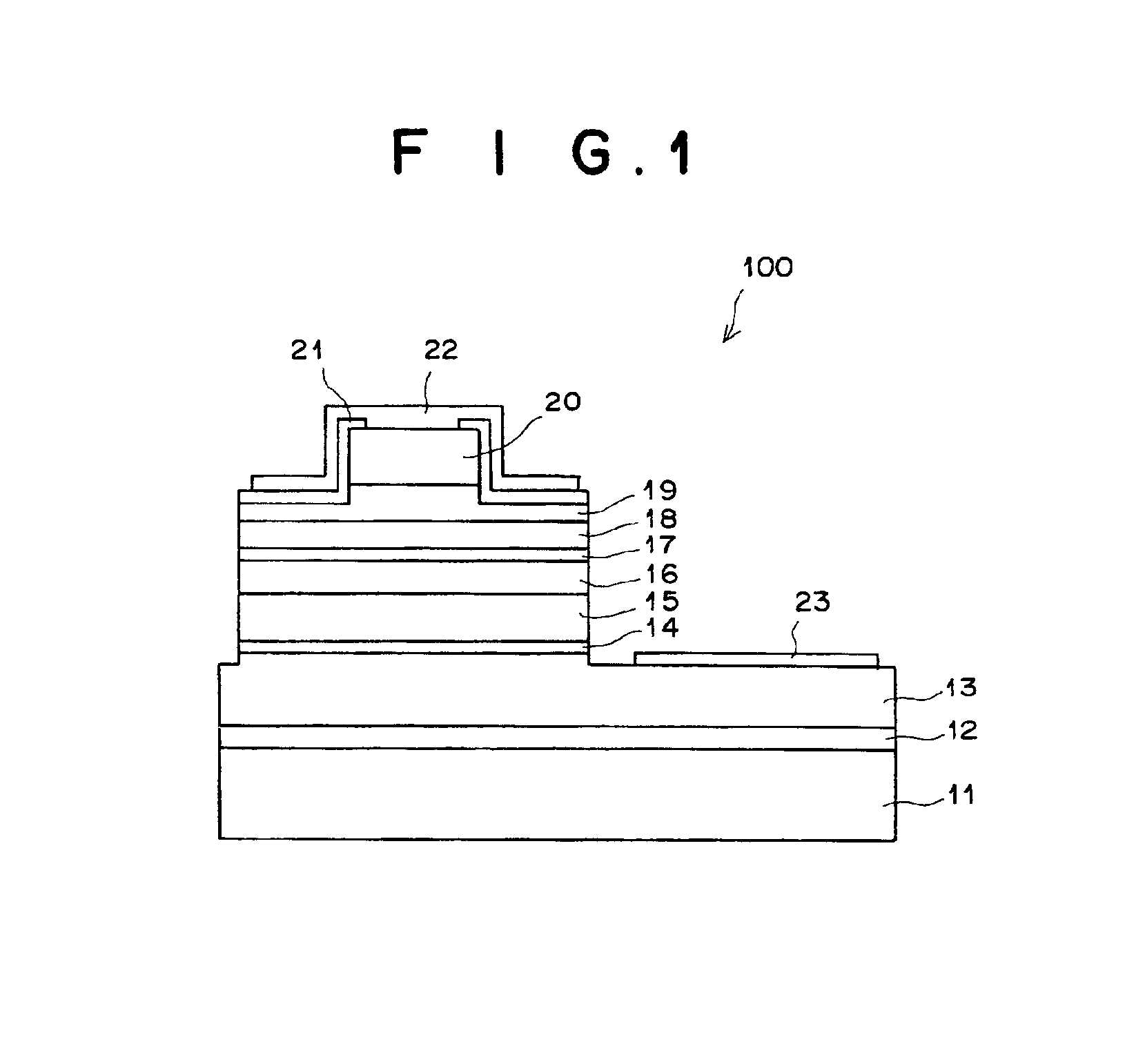

Semiconductor laser device and method for fabricating the same

ActiveUS20070147457A1High reproducibilityLarge threshold value variationLaser detailsNanoopticsLaserLength wave

In a semiconductor laser device, a plurality of light-emitting elements emitting light with different wavelengths are integrated on a substrate. Each of the light-emitting elements includes, on the substrate, an active layer and cladding layers respectively provided on top and bottom of the active layer. One of the cladding layers provided on top of the active layer is an upper cladding layer having a mesa ridge portion. An etching stopper layer for forming the ridge portion is interposed between the ridge portion and the other portion of the upper cladding layer. The thickness of the etching stopper layer varies among the light-emitting elements.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

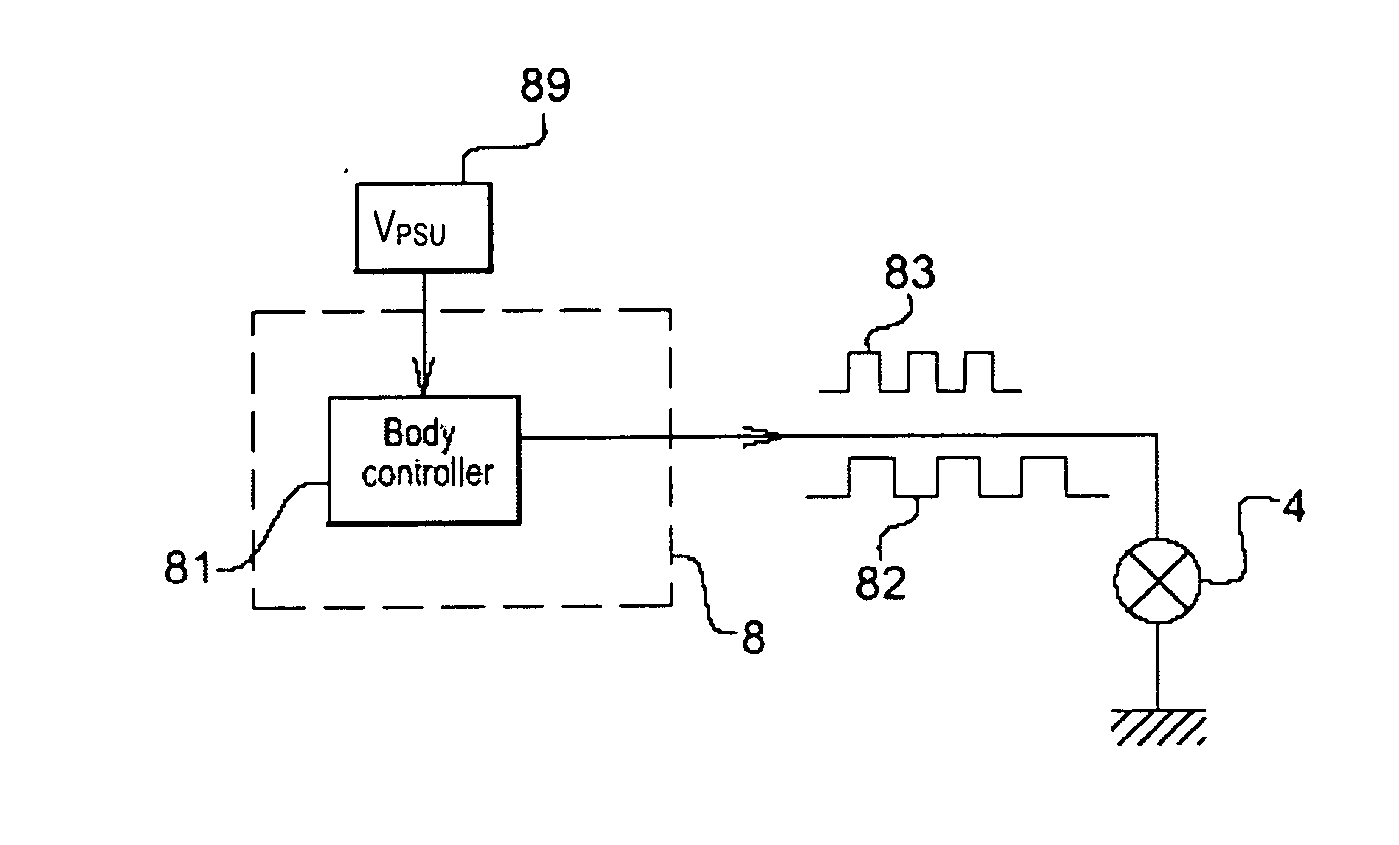

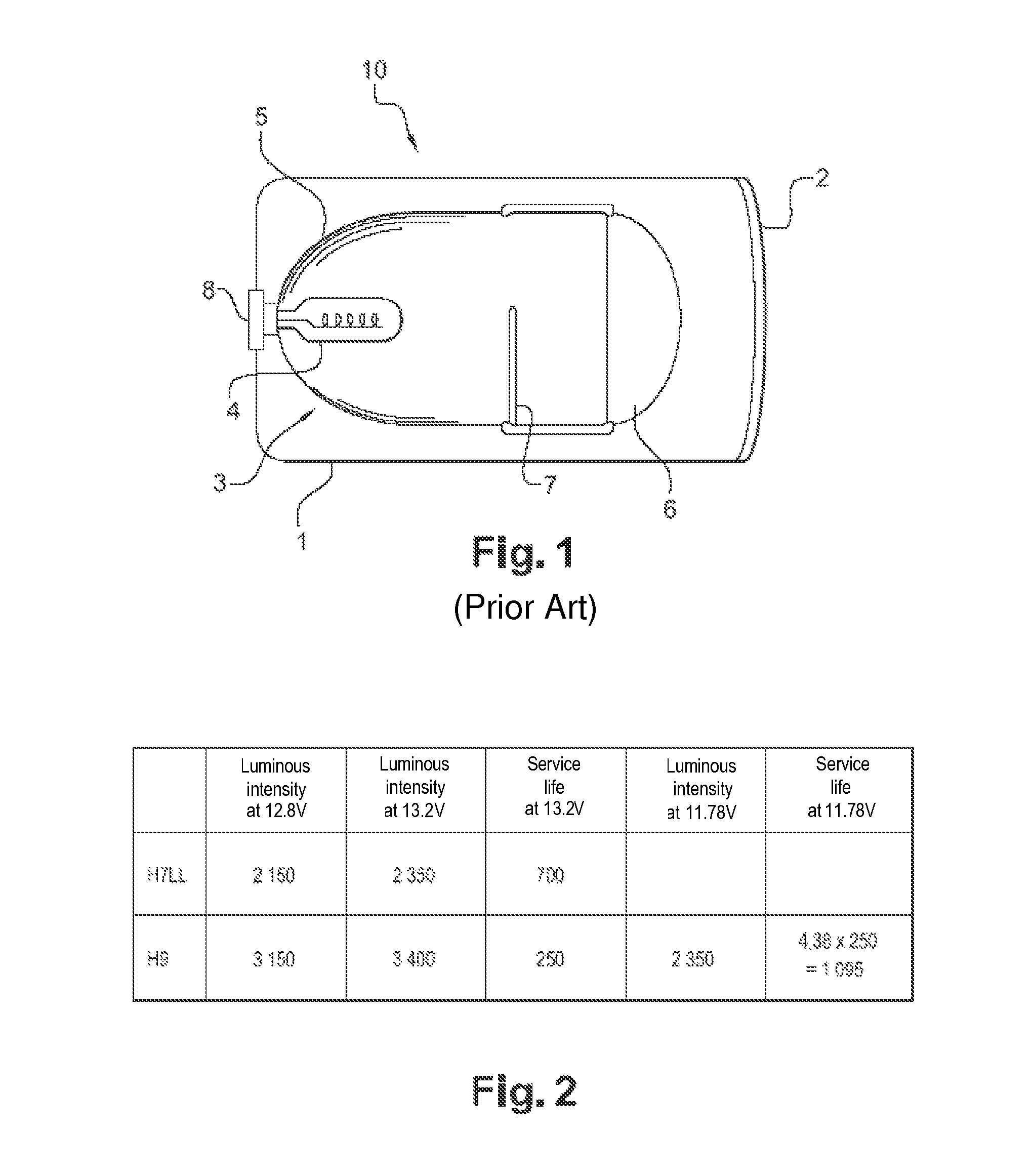

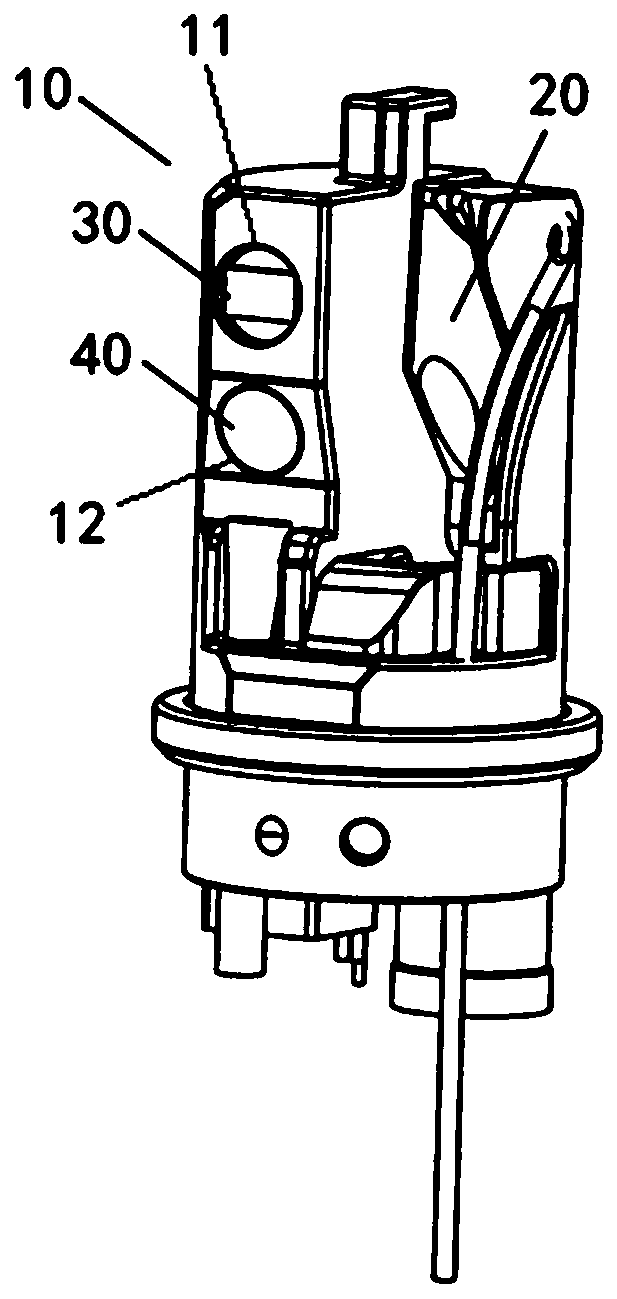

Method of supplying power to an automobile headlight lamp and headlight using that method

ActiveUS20090212705A1Service life of the light source is increasedIncrease lighting powerVehicle headlampsElectrical apparatusDual modeEffect light

A method and headlight adapted to supply power to a dual-mode automobile headlight light source able to provide either main beam mode lighting or dipped beam mode lighting, wherein the light source is supplied with electrical power at a first voltage when it is in main beam mode and at a second voltage when it is in dipped beam mode, the second voltage being lower than the first voltage.

Owner:VALEO VISION SA

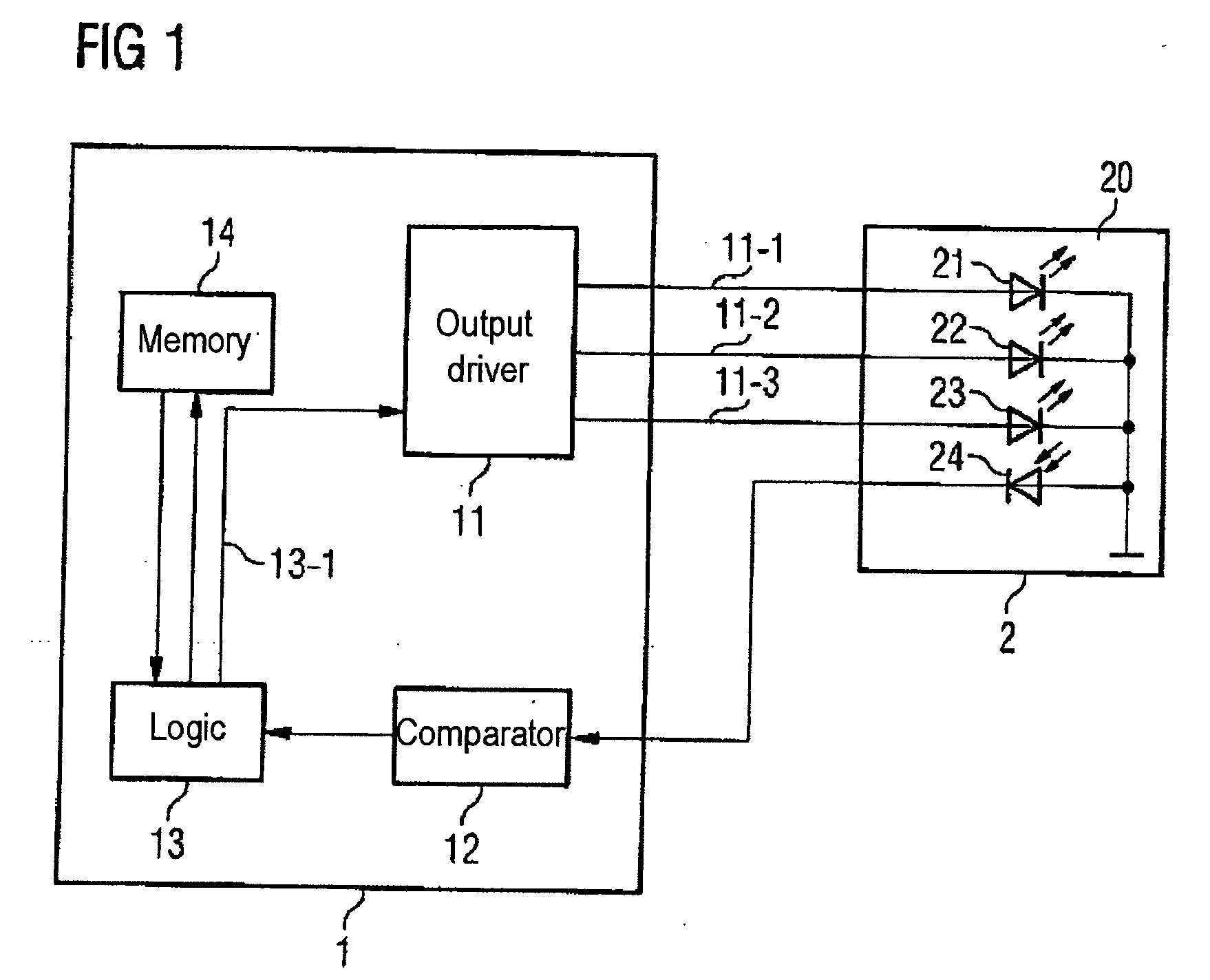

Method and device for operating an optical transmitting device having a plurality of optical transmitters that can be driven independently

InactiveUS20060245753A1Increase lighting powerSlow changePhotometry using reference valueLaser detailsOptical transmitterTransmitter

The invention relates to a method and a device for operating an optical transmitting device having a plurality of optical transmitters that can be driven independently. The method includes detecting the parameter values of the individual transmitters, comparing the parameter values determined with one another and / or with a prescribed comparison value, and selecting one of the transmitters for the communication operation of the transmitting device based on the comparison. The method further includes operating the transmitting device with the selected transmitter.

Owner:AVAGO TECH INT SALES PTE LTD

Pattern defect inspection apparatus and method

InactiveUS7746453B2Increase brightnessIncrease lighting powerSemiconductor/solid-state device testing/measurementScattering properties measurementsAcousticsPhysics

A pattern defect inspection apparatus capable of detecting minute defects on a sample with high sensitivity without generating speckle noise in signals is realized. Substantially the same region on a surface of a wafer is detected by using two detectors at mutually different timings. Output signals from the two detectors are summed and averaged to eliminate noise. Since a large number of rays of illumination light are not simultaneously irradiated to the same region on the wafer, a pattern defect inspection apparatus capable of suppressing noise resulting from interference of a large number of rays, eliminating noise owing to other causes and detecting with high sensitivity minute defects on the sample without the occurrence of speckle noise in the signal can be accomplished.

Owner:HITACHI HIGH-TECH CORP

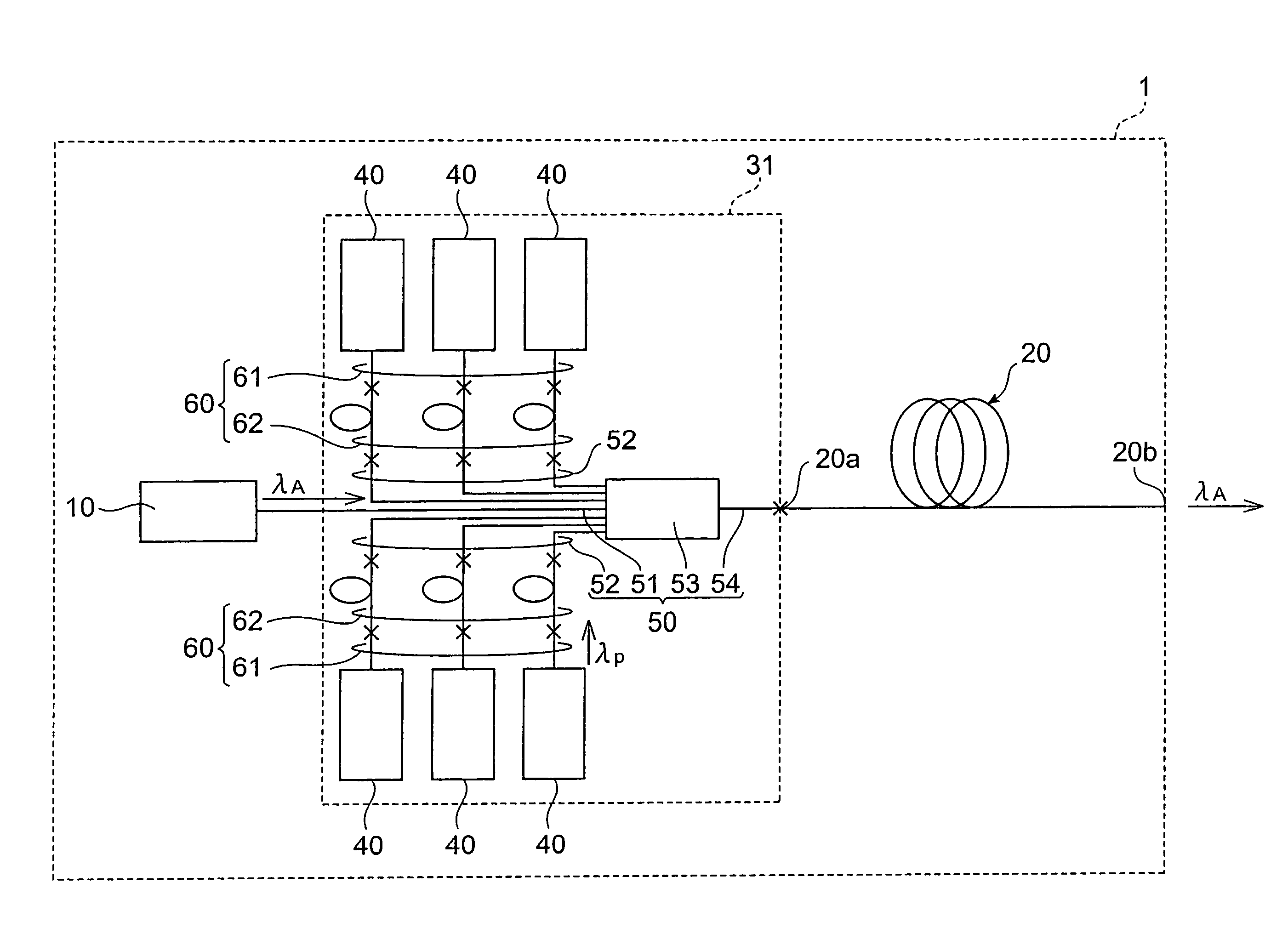

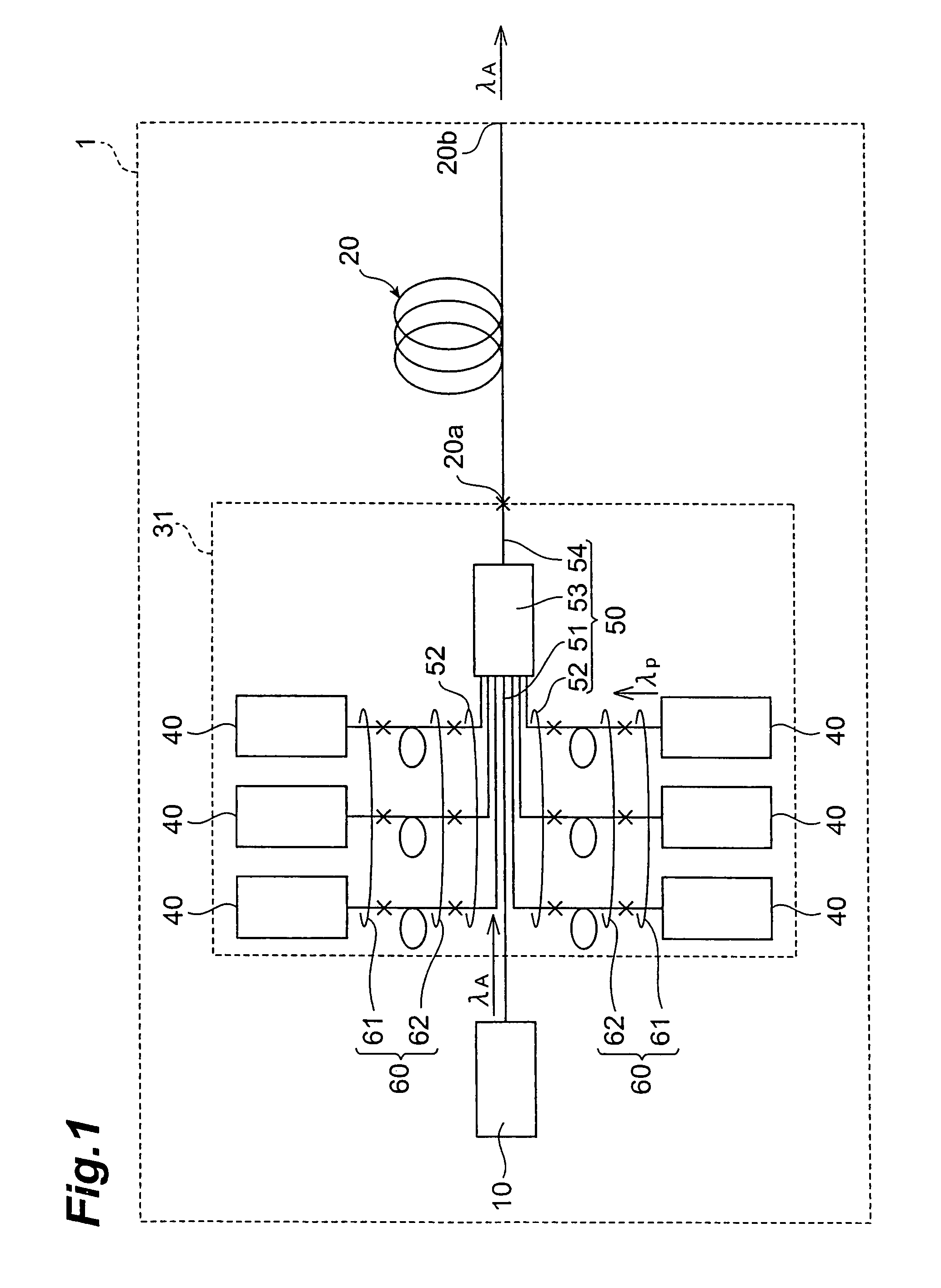

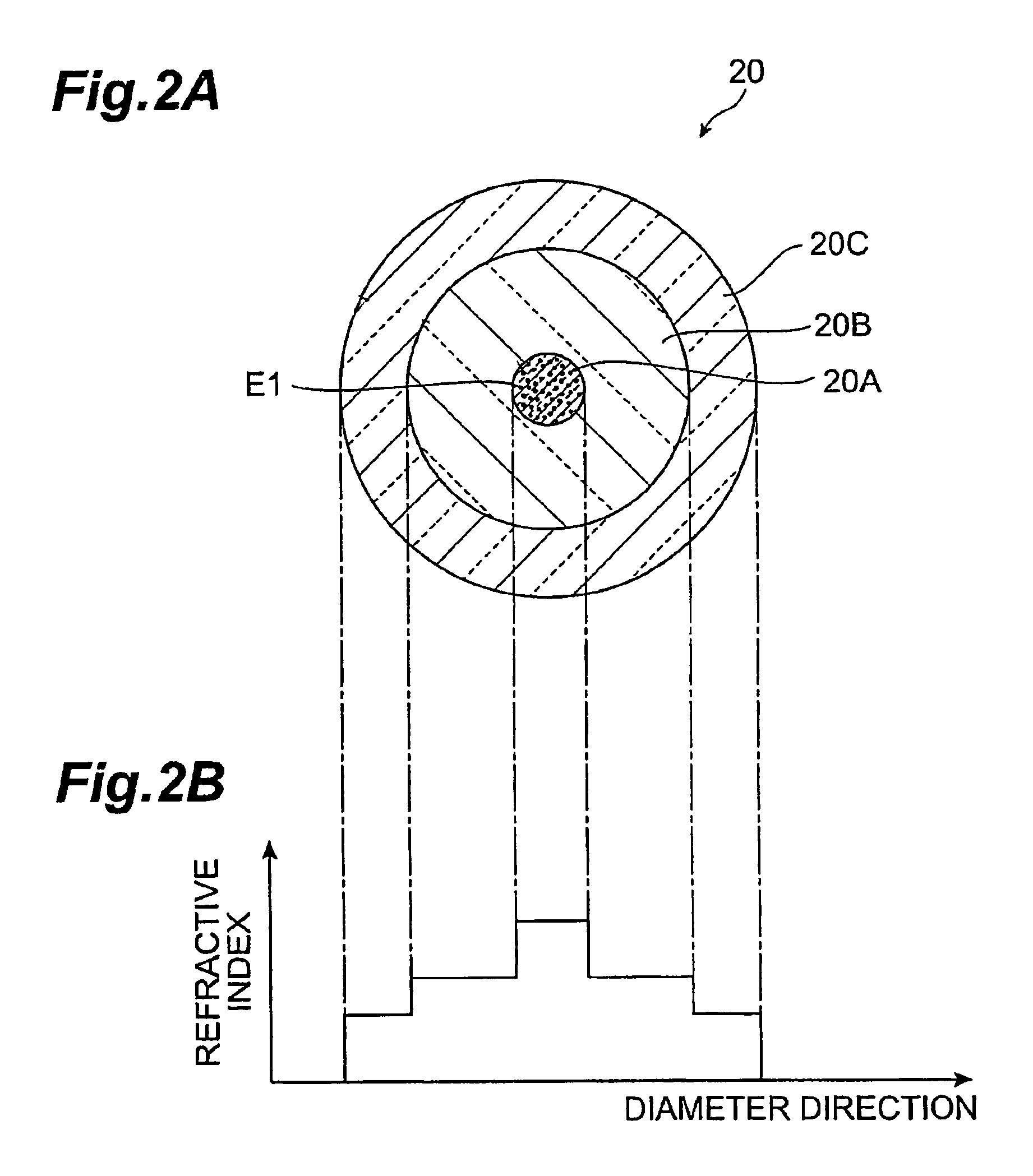

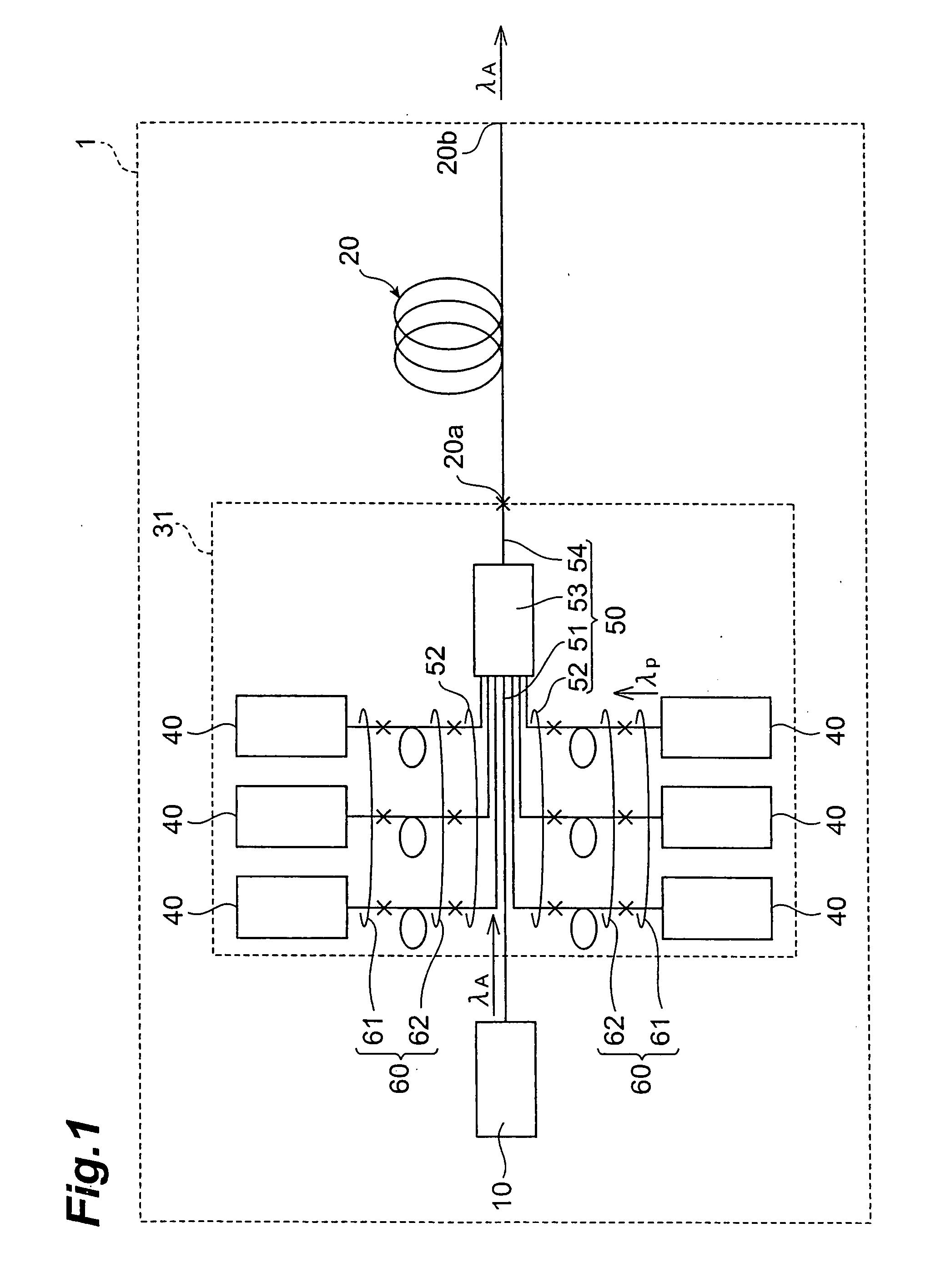

Optical module and optical amplification module

InactiveUS7724424B2Increase powerIncrease lighting powerLaser detailsFibre transmissionOptical ModuleEngineering

Owner:MEGAOPTO

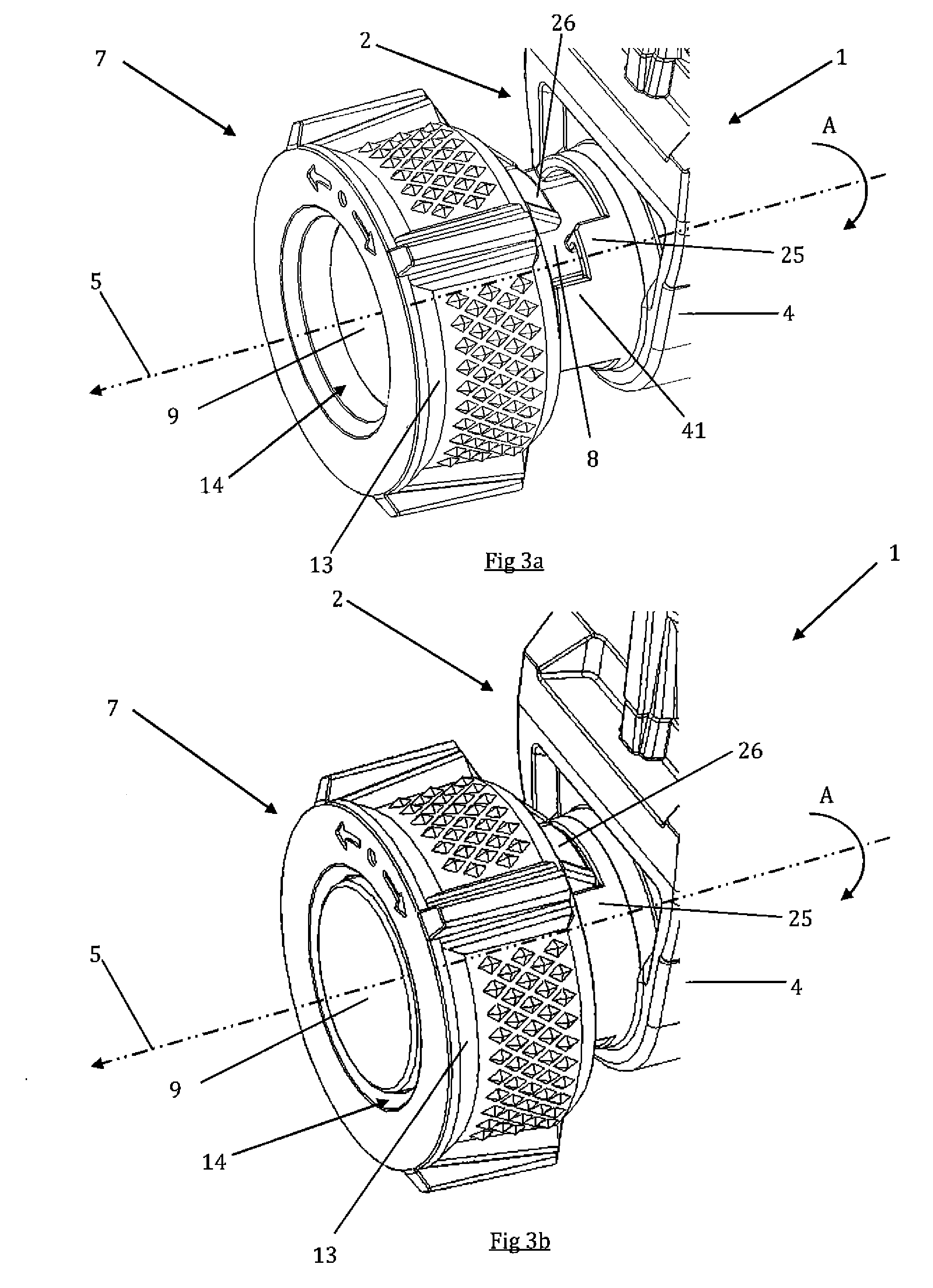

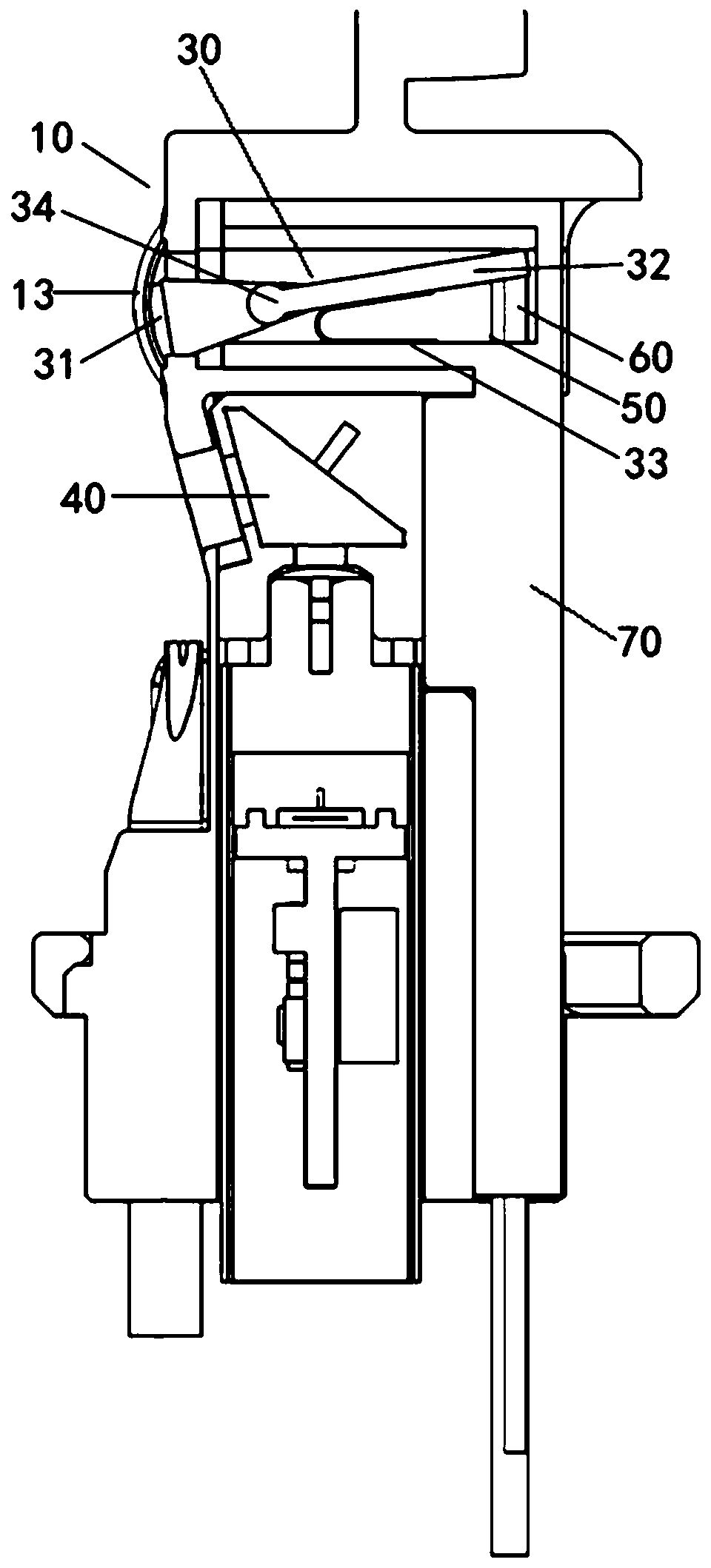

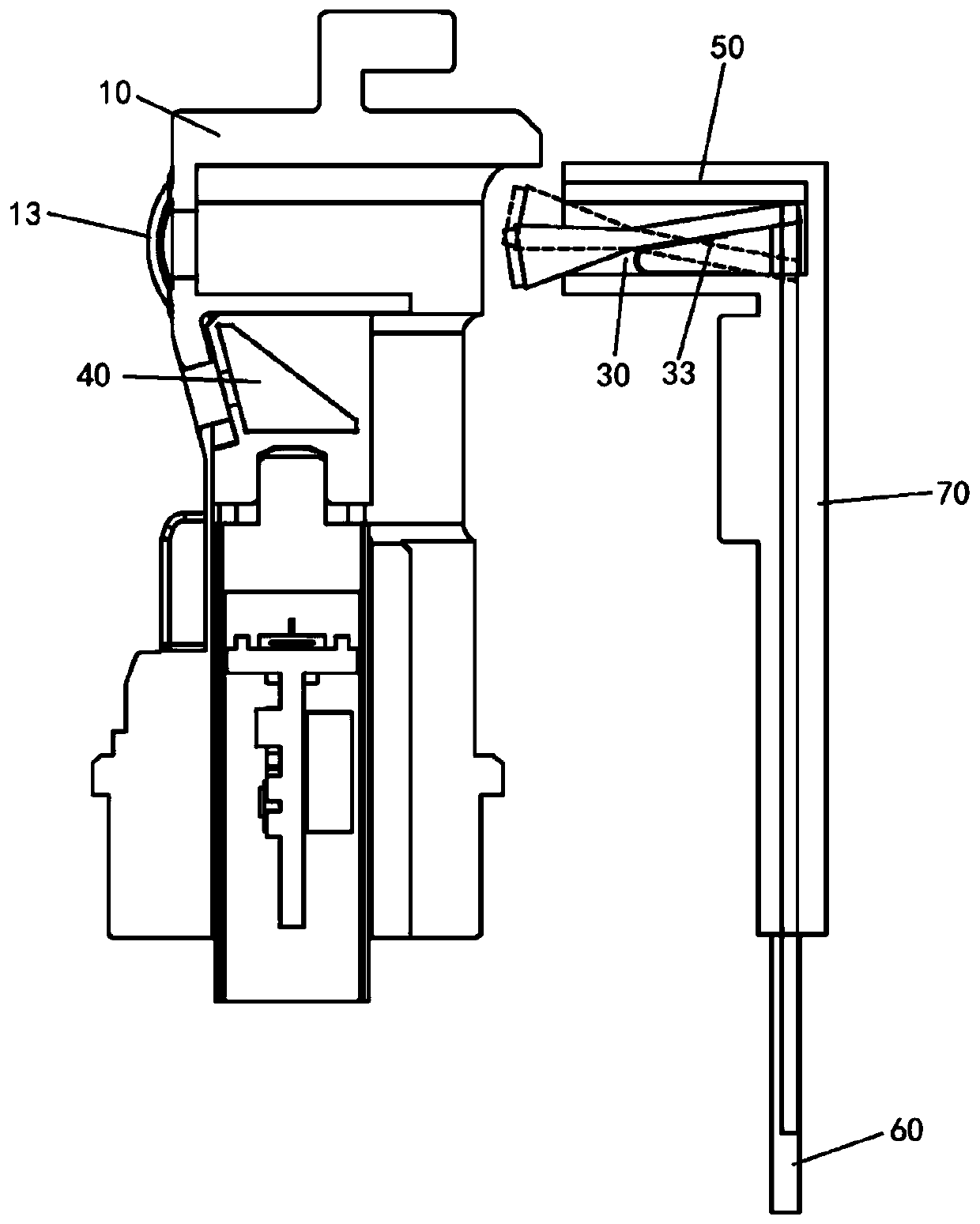

Portable electric lamp with a compact casing housing a lighting module controlled by a rotary actuator

ActiveUS20130242545A1Simple and efficient to useIncrease lighting powerPoint-like light sourceElectric circuit arrangementsEngineeringControl switch

A portable electric lamp with a compact casing housing a lighting module and an electric circuit coupled to the lighting module and provided with a controlled switch, comprising an actuator rotating around an axis of rotation and mounted fixed in translation in the direction of said axis of rotation to control the switch, and a control knob rotating around the axis of rotation of the actuator, the control knob further being mounted movable in translation along the axis of rotation of the actuator between a driving position in which the control knob drives the actuator in rotation and at least one blocking position in which the control knob prevents rotation of the actuator in at least one direction of rotation.

Owner:ZEDEL CORP

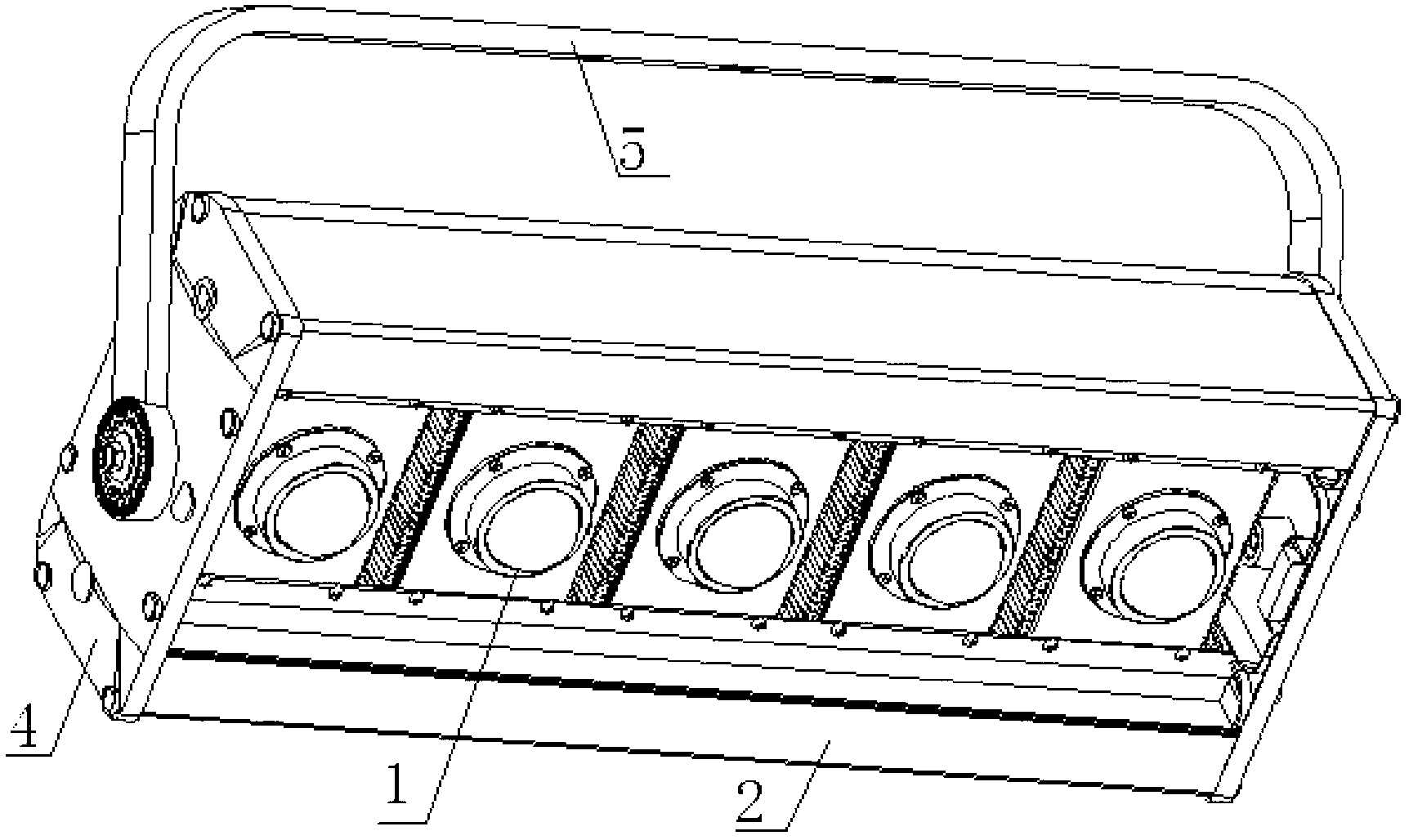

High-power light-emitting diode (LED) high-pole lamp

InactiveCN103234163ADistribute quicklyIncrease lighting powerPoint-like light sourceElongate light sourcesEngineeringLED lamp

The invention relates to a high-power light-emitting diode (LED) high-pole lamp which comprises a light source module. A lamp body is respectively arranged at the upper end and the lower end of the light source module, a lamp insertion piece is arranged at the back end of the light source module, an end cover is respectively arranged at the front end and the back end of the light source module, an installation support is arranged between the end covers, and a dial is respectively arranged at two ends of the installation support. The high-power LED high-pole lamp is compact in structure, good in radiating performance and long in service life.

Owner:HONGLI LIGHTING GRP

Light source device and projector having same

InactiveUS8066388B2Increase brightnessIncrease lighting powerTelevision system detailsNon-electric lightingOptical axisLight beam

A light source device includes a first light source, a second light source, a reflective assembly, and a condensing lens defining an optical axis. The first light source includes a first lamp and a first reflector reflecting light beams generated by the first lamp as first parallel light beams. The second light source includes a second lamp and a second reflector reflecting light beams generated by the second lamp. The first light source, the reflective assembly and the condensing lens are arranged in order along the optical axis. The second light source corresponds to the reflective assembly deviated from the optical axis. The reflective assembly reflects light beams reflected by the first reflector back to the first reflector, and reflects light beams from the second reflector to the condensing lens. The condensing lens condenses the first parallel light beams and the light beams reflected by the reflective assembly.

Owner:HON HAI PRECISION IND CO LTD

Light-emitting diode

InactiveUS6888165B2Increase productionIncrease the amount of lightSolid-state devicesSemiconductor devicesActive layerLight-emitting diode

An n-GaN low-temperature buffer layer, an n-GaN buffer layer, an n-In0.05Ga0.95N buffer layer, an n-Al0.15Ga0.85N clad layer, an n-GaN optical guide layer, an undoped active layer, a p-GaN optical guide layer, a p-Al0.15Ga0.85N clad layer, and a p-GaN cap layer, are grown on a sapphire substrate. Then, an epitaxial layer other than a light-emitting region is etched until the n-GaN buffer layer is exposed. Next, in a similar process, etching is performed up to anywhere within the p-Al0.15Ga0.85N clad layer so that a 4-μm-wide stripe region in the form of a ridge remains. The length from the light-emitting facet to the opposite facet is between 30 and 250 μm.

Owner:FUJIFILM HLDG CORP +1

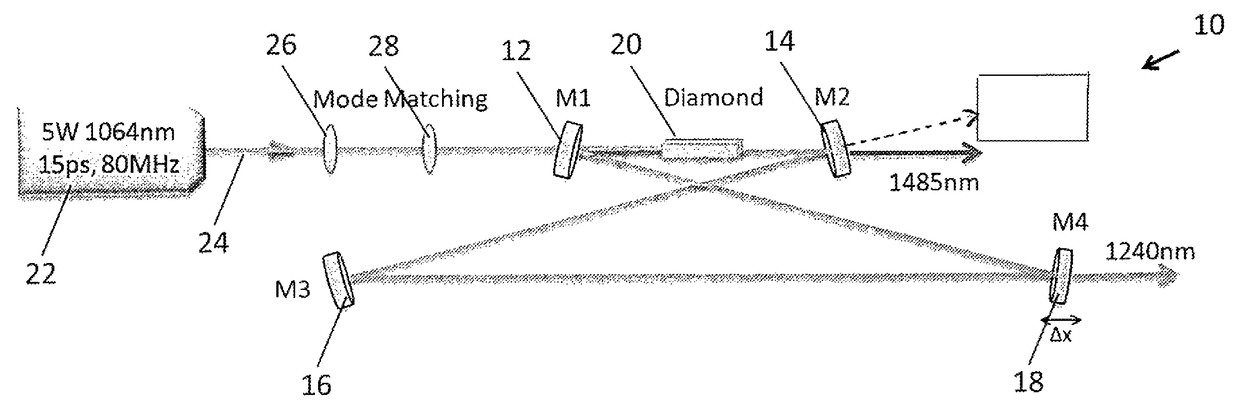

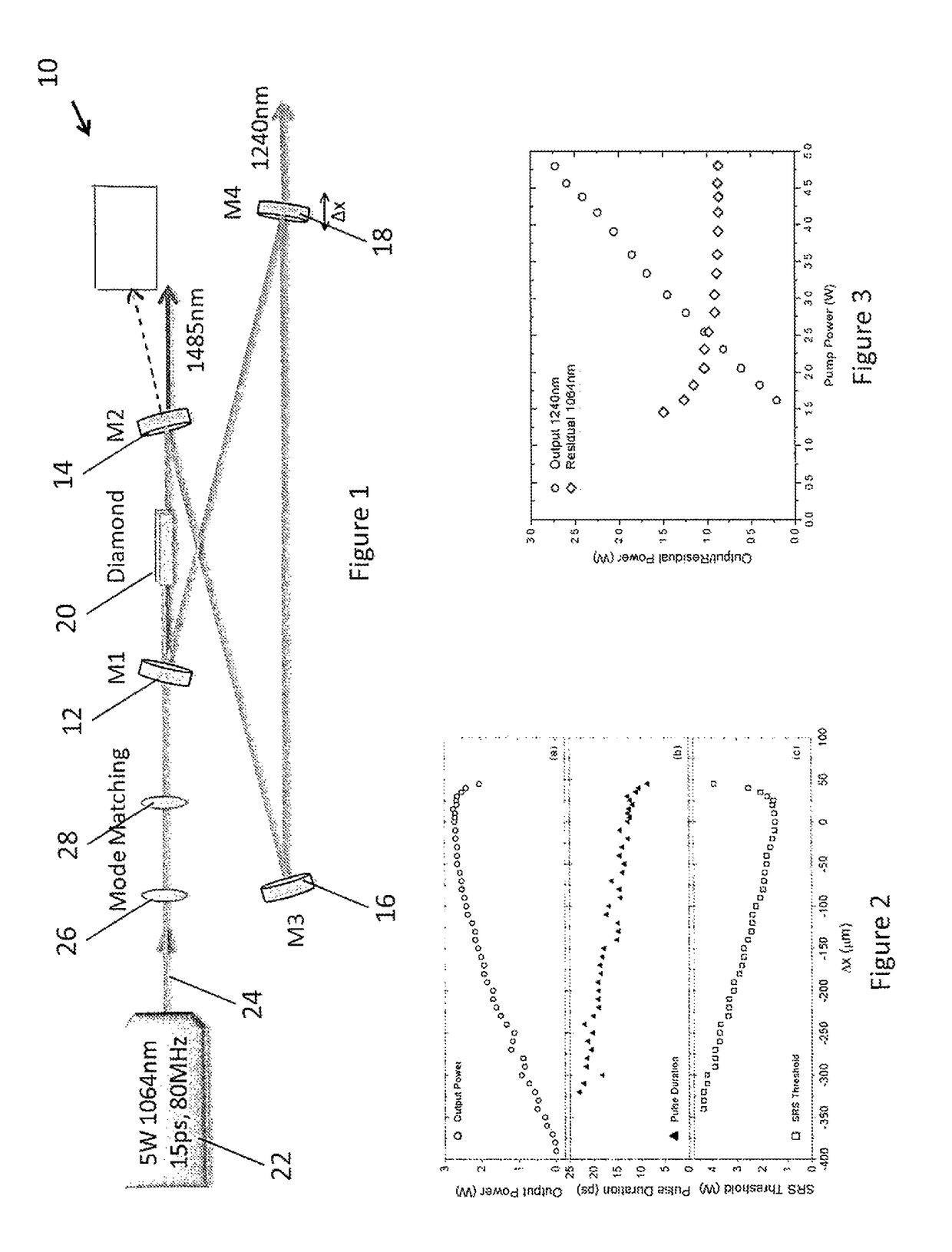

Method and a system for generating a Raman second Stokes light to a source light

ActiveUS9837787B2Lower the thresholdSignificant simplificationLaser using scattering effectsNonlinear opticalMolecular physics

A method and system for generating a Raman second Stokes light to a source light comprising generating a Raman first Stokes light from the source light by a Raman interaction in a nonlinear optical medium disposed in an optical resonator, and resonating the Raman first Stokes light in the optical resonator; generating a seed light at the frequency of the Raman second Stokes light from the source light and the Raman first Stokes light by a four wave mixing process which is not phase matched in the nonlinear medium; amplifying the seed light by transferring power from the first Stokes light resonating in the optical resonator to the seed light using a Raman amplification process in the nonlinear medium; and extracting from the optical resonator a majority of the power of the seed light so amplified.

Owner:MACQUARIE UNIV

Method and device for operating an optical transmitting device having a plurality of optical transmitters that can be driven independently

InactiveUS7792426B2Increase lighting powerAvoid dataPhotometry using reference valueLaser detailsEngineeringOptical transmitter

The invention relates to a method and a device for operating an optical transmitting device having a plurality of optical transmitters that can be driven independently. The method includes detecting the parameter values of the individual transmitters, comparing the parameter values determined with one another and / or with a prescribed comparison value, and selecting one of the transmitters for the communication operation of the transmitting device based on the comparison. The method further includes operating the transmitting device with the selected transmitter.

Owner:AVAGO TECH INT SALES PTE LTD

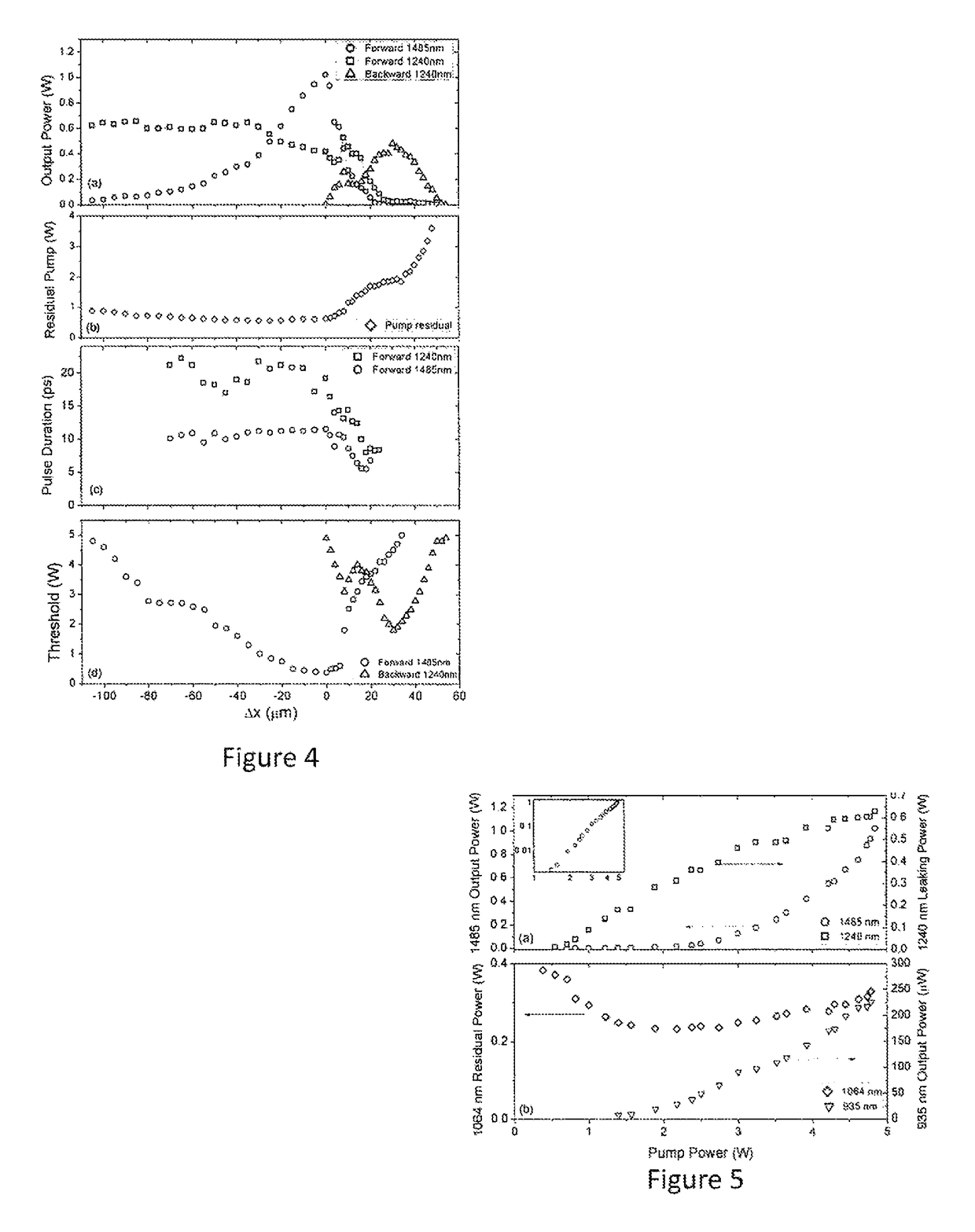

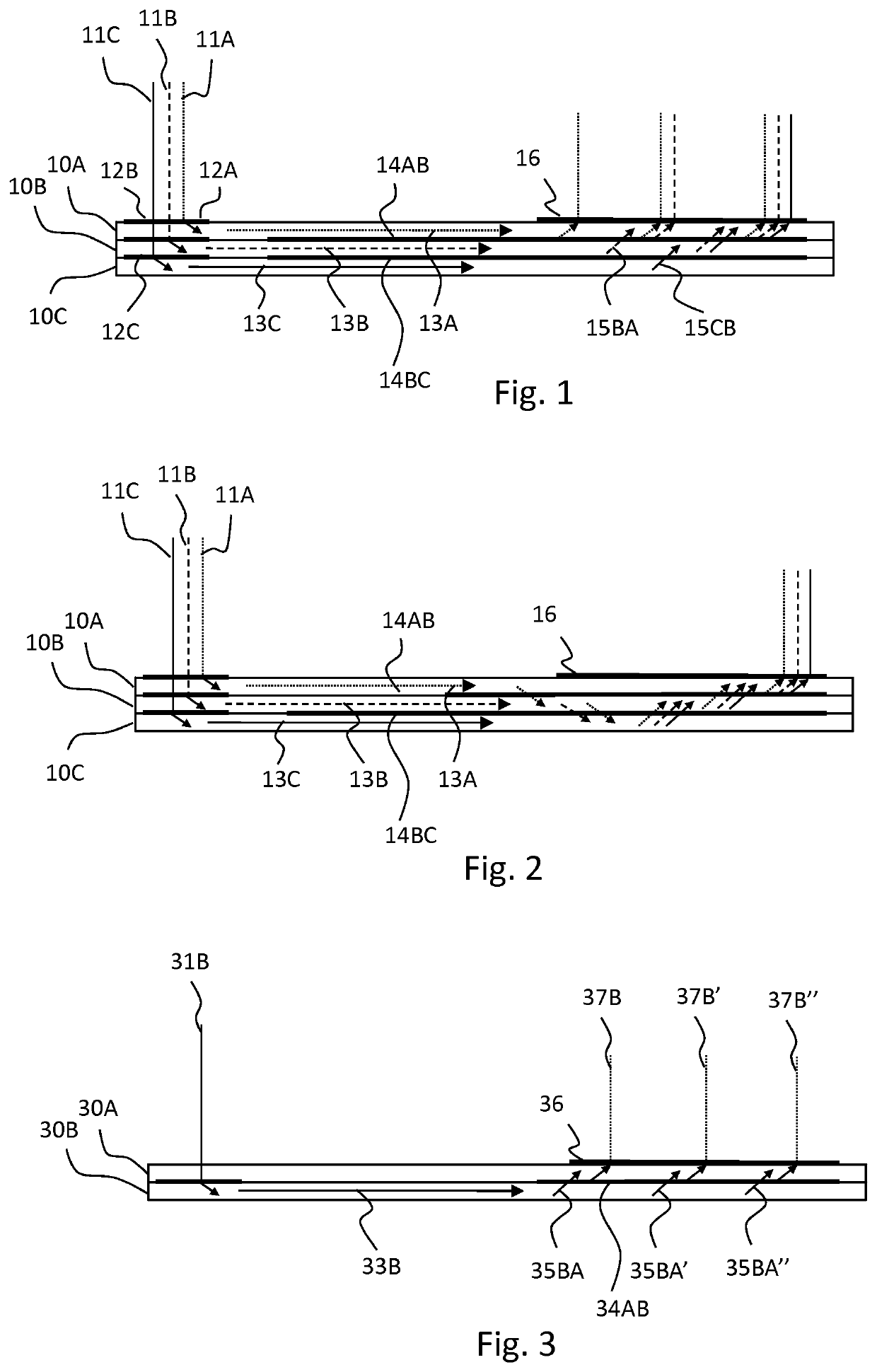

Multilayer waveguide display element

ActiveUS20200333614A1New freedom of designSignificant comprehensive benefitsDiffraction gratingsOptical light guidesDisplay deviceEngineering

The invention relates to a waveguide display element for guiding an image from a first lateral zone of the element to a second lateral zone of the element, the element comprising a plurality of waveguide layers (40A-E) on top of each other. The element further comprises at least one intermediate diffractive optical element (44AB, 44BC, 44AD, 44DE) arranged between two of said waveguide layers. The intermediate diffractive optical element (44AB, 44BC, 44AD, 44DE) is adapted to change the distribution of propagating light power between the layers. The invention also concerns a diffractive display device comprising such element.

Owner:DISPELIX OY

Semiconductor laser device and method for fabricating the same

ActiveUS7433380B2Reduce light absorptionIncrease lighting powerLaser detailsNanoopticsLength waveActive layer

In a semiconductor laser device, a plurality of light-emitting elements emitting light with different wavelengths are integrated on a substrate. Each of the light-emitting elements includes, on the substrate, an active layer and cladding layers respectively provided on top and bottom of the active layer. One of the cladding layers provided on top of the active layer is an upper cladding layer having a mesa ridge portion. An etching stopper layer for forming the ridge portion is interposed between the ridge portion and the other portion of the upper cladding layer. The thickness of the etching stopper layer varies among the light-emitting elements.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Optical module and optical amplification module

InactiveUS20080002251A1Stable supplyEfficient amplificationLaser detailsFibre transmissionFiberOptical Module

An optical module for supplying pump light for amplifying to-be-amplified light includes an pump light source, optical coupling means, and an optical guide section. The optical guide section optically connects the pump light source and the optical coupling means, and propagates the pump light from the pump light source, in multi-transverse-mode. The optical coupling means output the pump light from the optical guide section in multi-transverse-mode, and at least one of (i) at least one of end faces where the optical guide section and the optical coupling means are connected, (ii) an area between the end faces, and (iii) the optical guide section, has a loss medium of which transmission loss is greater in a wavelength of the to-be-amplified light than in a wavelength of the pump light. By this, an optical module which can stably supply the pump light to the optical amplification fiber can be provided.

Owner:MEGAOPTO

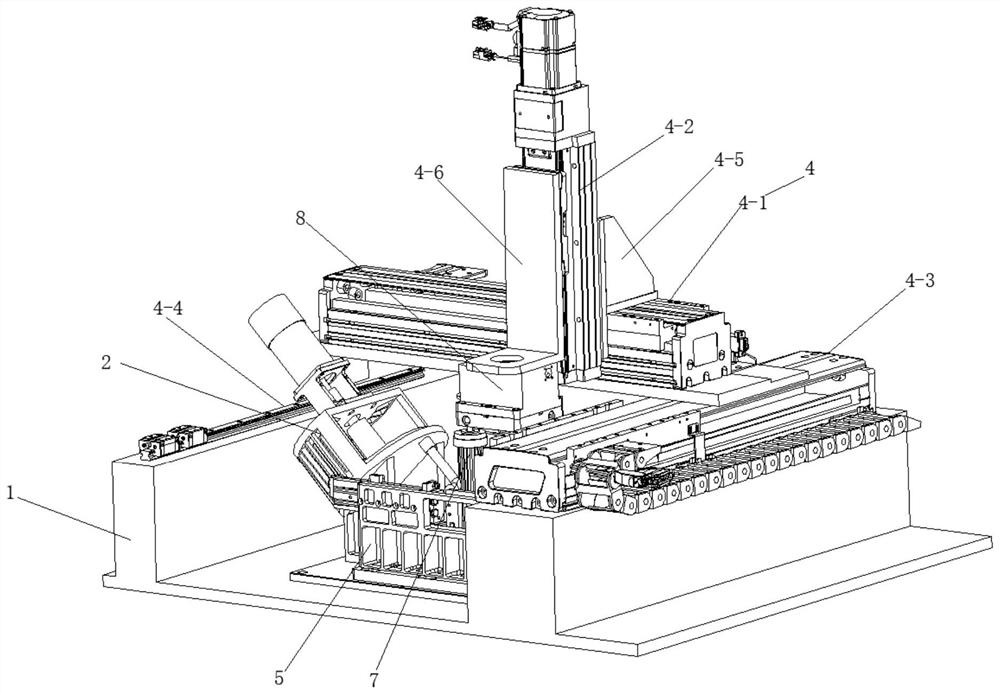

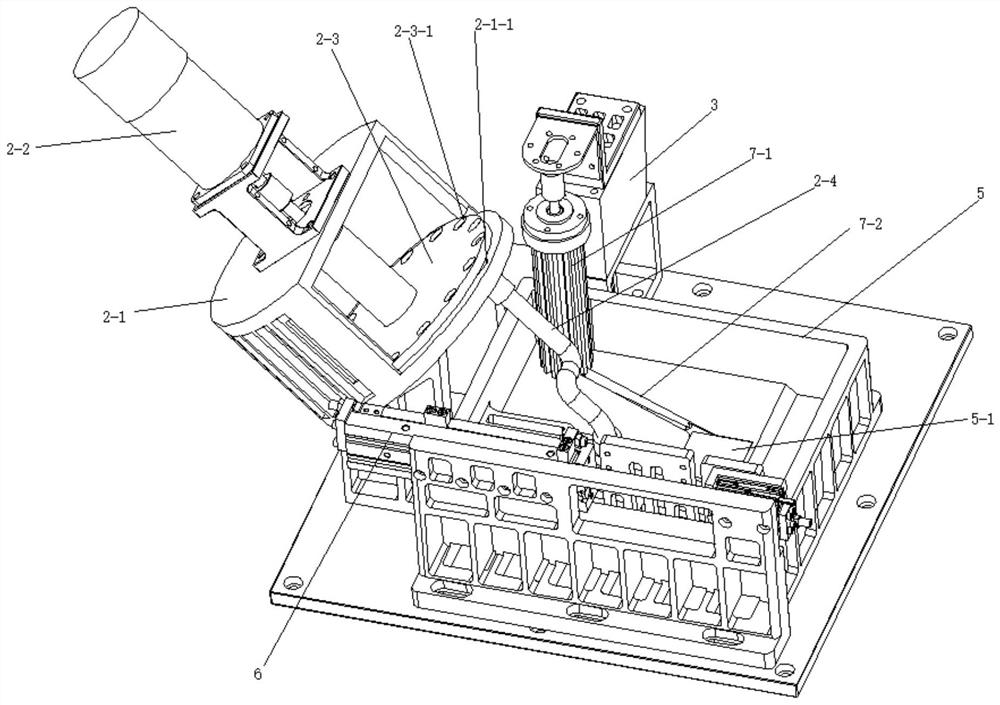

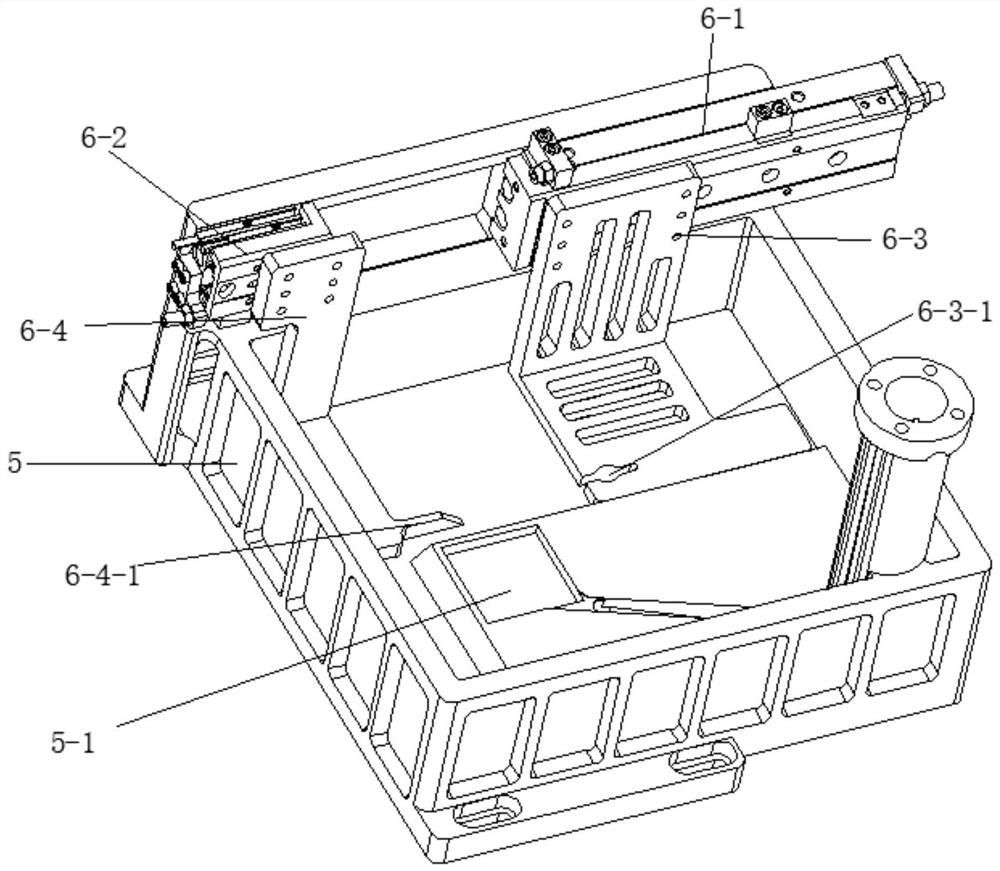

System for visually detecting surface flaws of small-diameter reflective spheres in batches

PendingCN114088720AImprove defect detection rateImprove detection accuracyOptically investigating flaws/contaminationNuclear energy generationControl systemEngineering

The invention discloses a system for visually detecting the surface flaws of the small-diameter reflective spheres in batches. The system comprises a control system, a bottom plate, an alcohol tank fixedly installed on the bottom plate, and a sphere feeding unit, a sphere automatic classifying unit, a light source and visual driving unit which are controlled by the control system. A sphere lifting unit and a sphere transmission unit which are electrically connected with the control system are fixedly installed in the alcohol tank, the sphere feeding unit is communicated with the sphere lifting unit, and a detection block is arranged in the alcohol tank; a light source and visual shooting unit is suitable for moving the small spheres on the sphere lifting unit to the detection block for surface unfolding shooting and transmitting the shot pictures to the control system for analysis, meanwhile the detected small spheres are moved to the sphere transmission unit, and the output end of the sphere transmission unit is communicated with a sphere automatic classification unit. The system has the advantages of safety, reliability, continuous detection, high detection rate, high precision and the like, the cost is saved, and the system has broad markets and urgent demands in bearing sphere production enterprises.

Owner:CHANGZHOU INST OF OPTOELECTRONICS TECH

Display including electrowetting prism array

ActiveUS10036884B2Increase lighting powerNon-linear opticsOptical elementsFresnel lensDisplay device

Owner:SAMSUNG ELECTRONICS CO LTD

Light source device and projector having same

InactiveUS20100097578A1Increase brightnessIncrease lighting powerTelevision system detailsNon-electric lightingOptical axisLight beam

A light source device includes a first light source, a second light source, a reflective assembly, and a condensing lens defining an optical axis. The first light source includes a first lamp and a first reflector reflecting light beams generated by the first lamp as first parallel light beams. The second light source includes a second lamp and a second reflector reflecting light beams generated by the second lamp. The first light source, the reflective assembly and the condensing lens are arranged in order along the optical axis. The second light source corresponds to the reflective assembly deviated from the optical axis. The reflective assembly reflects light beams reflected by the first reflector back to the first reflector, and reflects light beams from the second reflector to the condensing lens. The condensing lens condenses the first parallel light beams and the light beams reflected by the reflective assembly.

Owner:HON HAI PRECISION IND CO LTD

Method of supplying power to an automobile headlight lamp and headlight using that method

ActiveUS8154208B2Service life of the light source is increasedIncrease lighting powerVehicle headlampsLighting support devicesDual modeLight beam

A method and headlight adapted to supply power to a dual-mode automobile headlight light source able to provide either main beam mode lighting or dipped beam mode lighting, wherein the light source is supplied with electrical power at a first voltage when it is in main beam mode and at a second voltage when it is in dipped beam mode, the second voltage being lower than the first voltage.

Owner:VALEO VISION SA

Variable lighting structure and endoscope

InactiveCN110916601ACompact structureStructure does not changeGastroscopesOesophagoscopesEngineeringImage View

The invention discloses a variable lighting structure and an endoscope. According to the scheme, the variable lighting structure is formed through the cooperation of a lighting part, a transmission part and a light field adjusting part, wherein the lighting part can be movably arranged; the transmission part is in drive connection with the lighting part, and can drive the lighting part to move; the light field adjusting part is in drive connection with the transmission part; the light field adjusting part adjusts and controls the moving distance of the transmission part, the lighting part is driven by the transmission part to move, and then the area of a lighting field generated by the lighting part is adjusted. In the endoscope, it can be achieved that the direction of the lighting fieldand the lighting range are adjusted by using the variable lighting structure, an operator can adjust a lighting window according to actual operation conditions, and the problems are effectively solvedthat a visual lighting window and an image view field in an existing endoscope are incompletely overlapped, a non-overlapped part cannot be lighted in an surgical process, and unclear imaging can becaused only depending on reflected lighting.

Owner:SHANGHAI AOHUA PHOTOELECTRICITY ENDOSCOPE

Multilayer waveguide display element

ActiveUS11409122B2New freedom of designPrevent peelingDiffraction gratingsOptical light guidesDisplay deviceWaveguide

The invention relates to a waveguide display element for guiding an image from a first lateral zone of the element to a second lateral zone of the element, the element comprising a plurality of waveguide layers (40A-E) on top of each other. The element further comprises at least one intermediate diffractive optical element (44AB, 44BC, 44AD, 44DE) arranged between two of said waveguide layers. The intermediate diffractive optical element (44AB, 44BC, 44AD, 44DE) is adapted to change the distribution of propagating light power between the layers. The invention also concerns a diffractive display device comprising such element.

Owner:DISPELIX OY

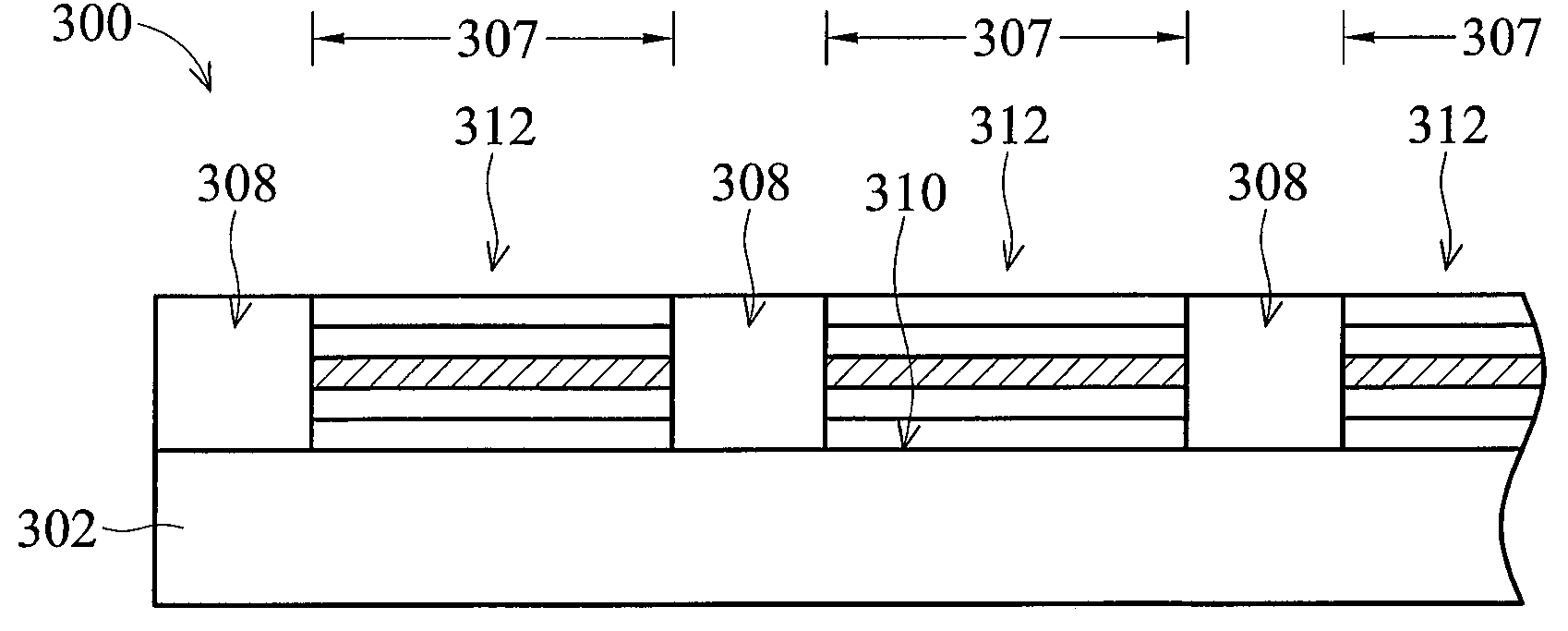

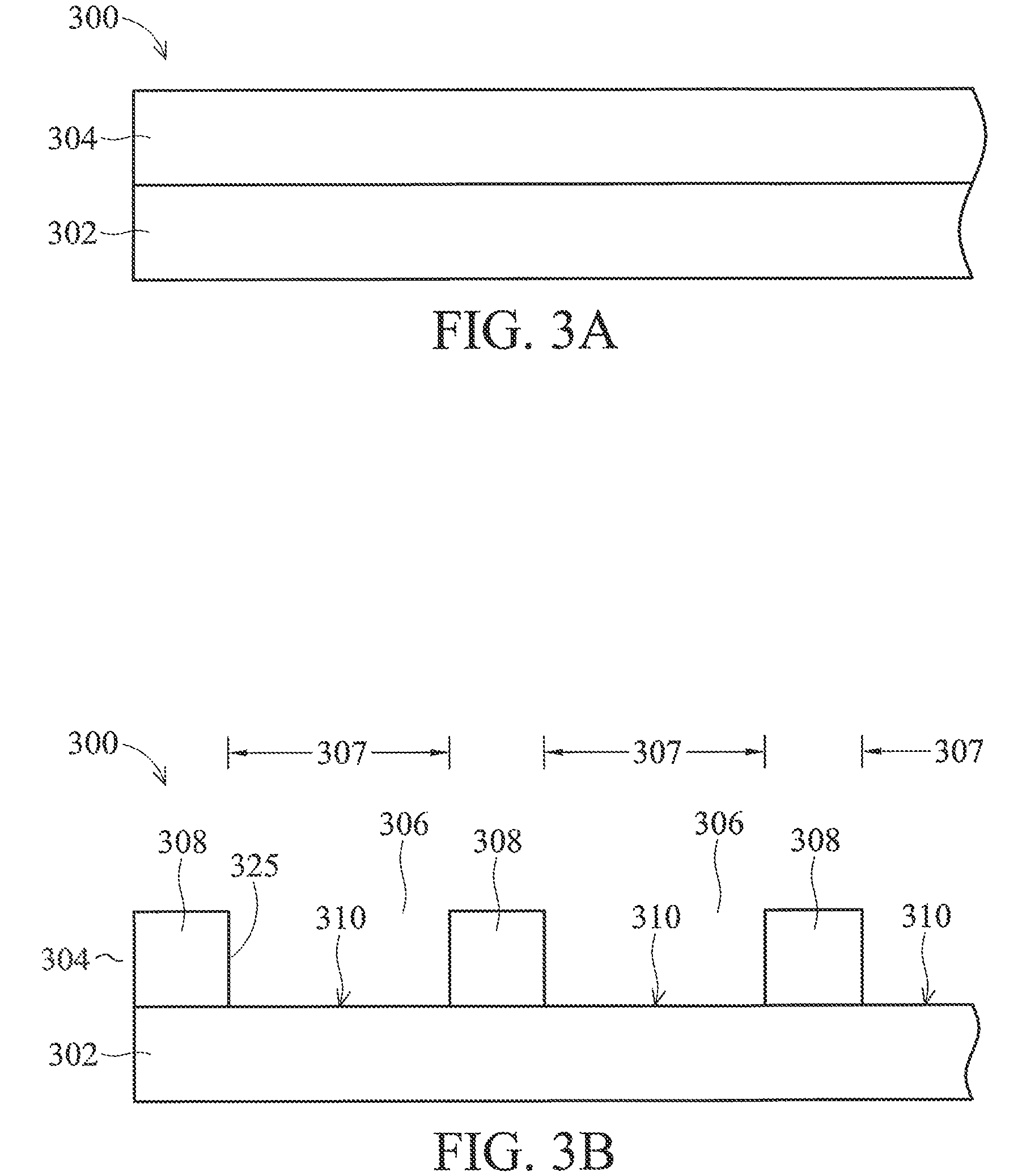

Stress-alleviation layer for LED structures

ActiveUS8779445B2Reduce residual stressAvoiding pressure injuriesSemiconductor devicesStress alleviationLight-emitting diode

A light emitting diodes (LEDs) is presented. The LED includes a stress-alleviation layer on a substrate. Open regions and stress-alleviation layer regions are formed on the substrate. Epitaxial layers are disposed on the substrate, at least in the open regions therein, thereby forming an LED structure. The substrate is diced through at least a first portion of the stress-alleviation regions, thereby forming the plurality of LEDs.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com