System for visually detecting surface flaws of small-diameter reflective spheres in batches

A technology for batch detection and surface flaws, which is applied in the direction of optical testing flaws/defects, etc., to achieve the effects of reducing costs, improving detection efficiency, and improving detection rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

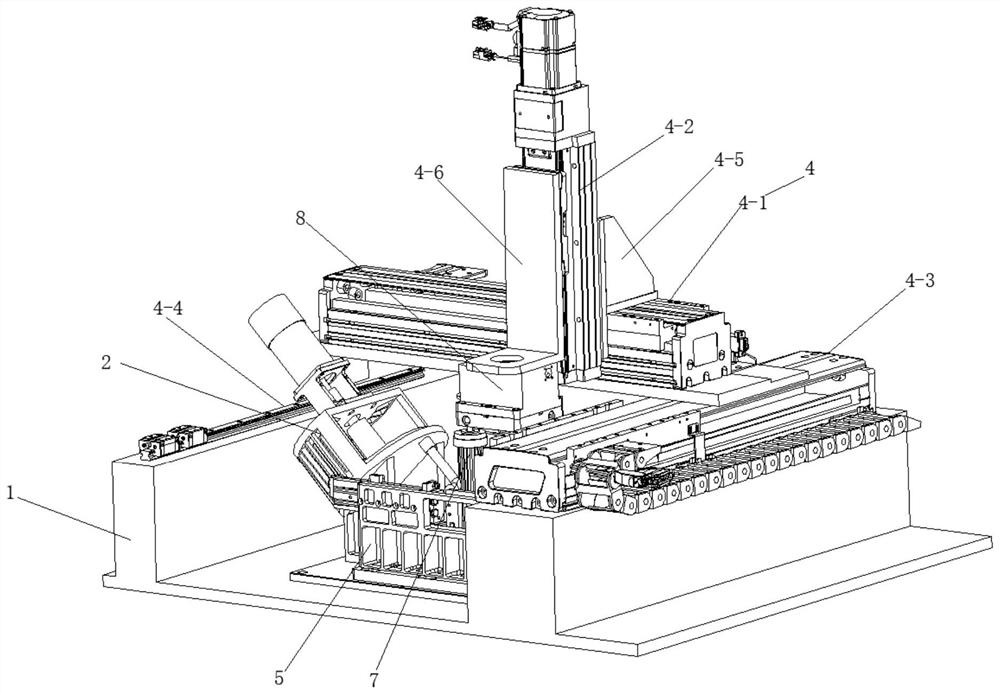

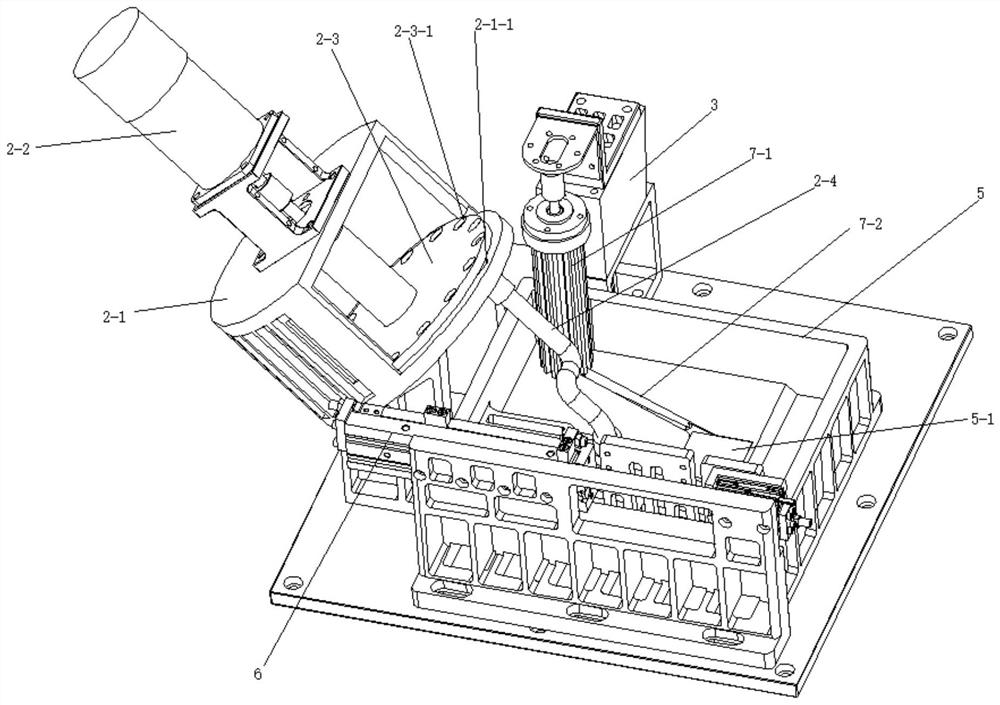

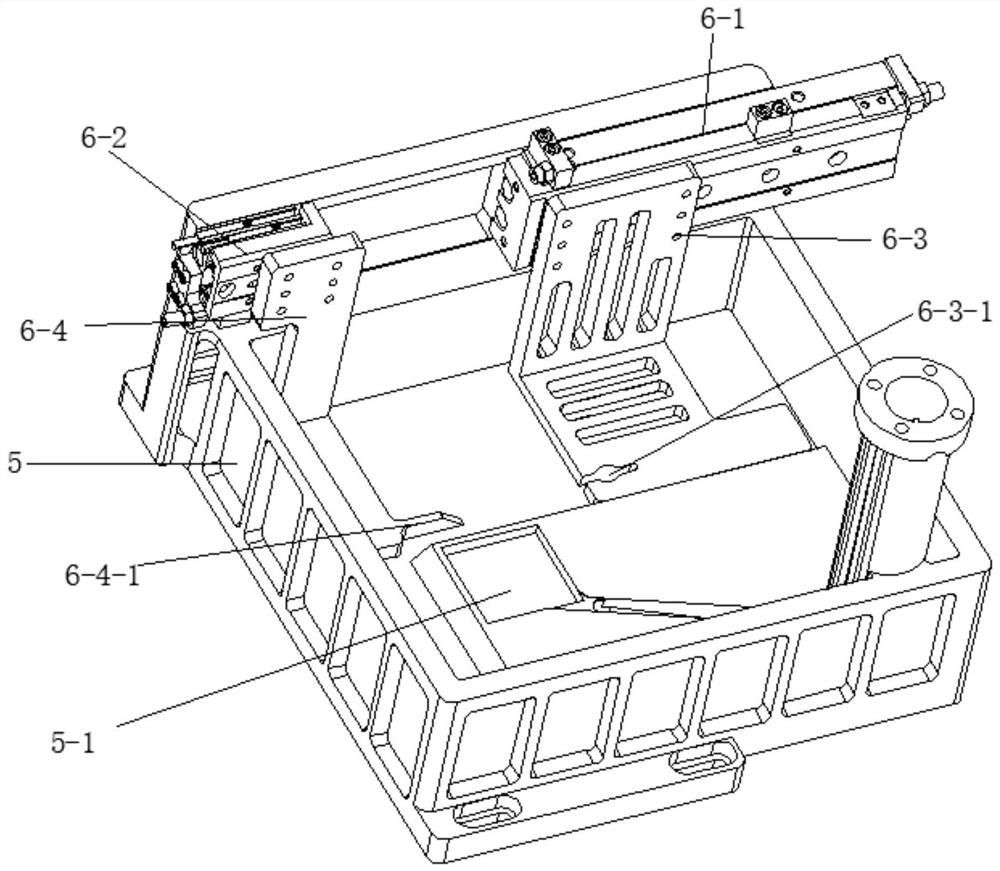

[0044] Such as Figure 1 to Figure 6 The visual batch detection system for surface defects of small-diameter reflective spheres shown includes a control system, a base plate 1, a goal unit 2 fixedly installed on the base plate 1, an automatic sphere classification unit 3, a light source and a visual drive unit 4, and an alcohol tank 5, A sphere lifting unit 6 and a sphere transmission unit 7 are fixedly installed in the alcohol tank 5, and a light source and a visual shooting unit 8 are fixedly installed on the light source and visual drive unit 4, wherein the scoring unit 2, the sphere automatic classification unit 3, the light source and the visual The drive unit 4 , the sphere lifting unit 6 , the sphere transmission unit 7 , the light source and the visual photographing unit 8 are all electrically connected to the control system. The scoring unit 2 communicates with the sphere lifting unit 6, the alcohol tank 5 is equipped with alcohol and a detection block 5-1 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com