Leadframe having a heat sink supporting ring, fabricating method of a light emitting diodepackage using the same and light emitting diodepackage fabbricated by the method

A technology of light emitting diodes and heat sinks, applied in the field of lead frames, can solve the problems of unstable LED packaging structure, damage to LED packaging, separation of heat sinks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

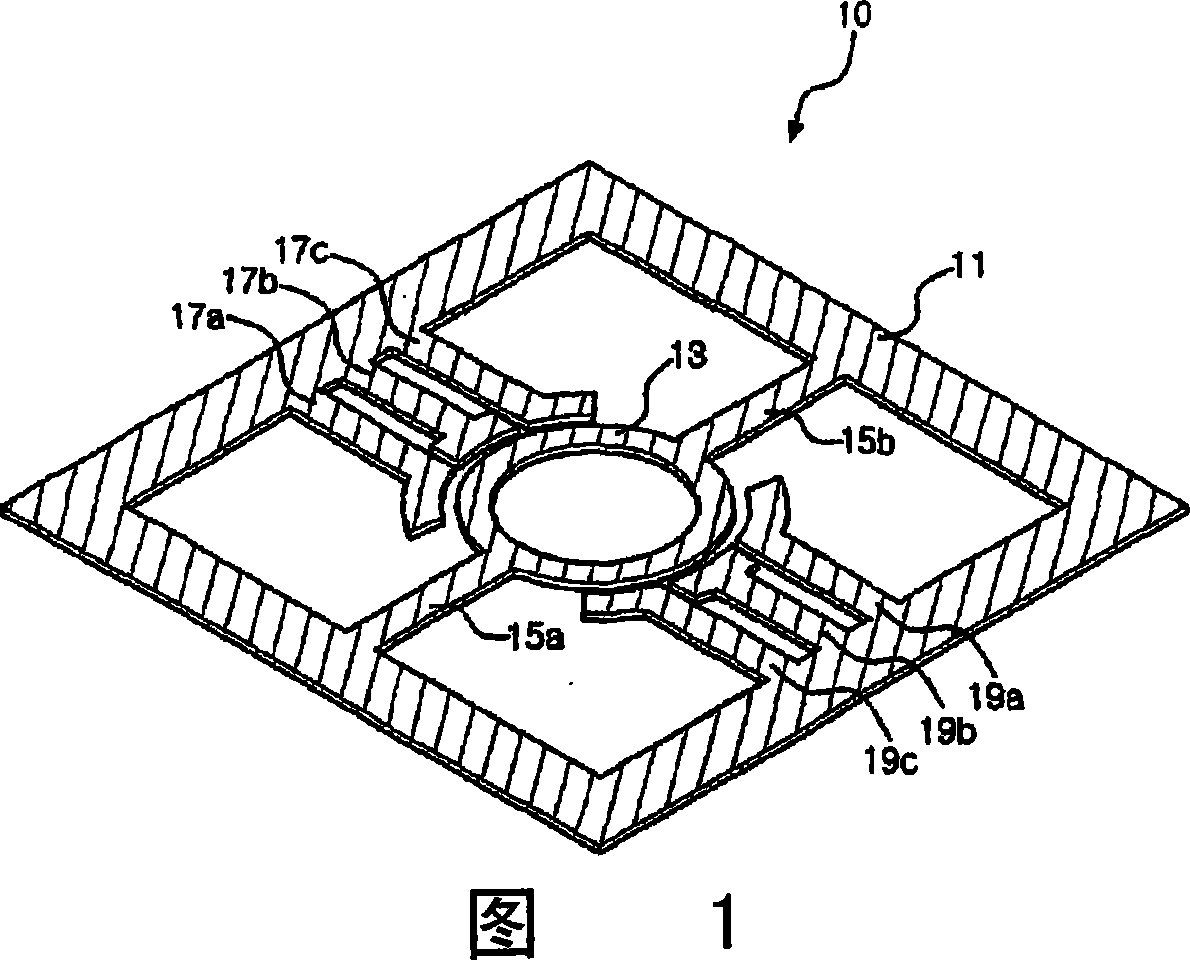

[0037] FIG. 1 is a perspective view of a lead frame according to one embodiment of the present invention.

[0038] Referring to FIG. 1 , the lead frame 10 includes a heat sink support ring 13 into which a heat sink can be inserted. The support ring 13 may be formed in a circular ring shape as shown in FIG. 1 , but its shape is not limited thereto, but may be formed in a polygonal ring shape.

[0039] The support ring 13 is enclosed by the outer frame 11 . The outer frame 11 is spaced apart from the support ring 13 . The outer frame 11 may be formed in a square shape as shown in FIG. 1, but its shape is not limited thereto, but may be formed in a circular shape or a polygonal shape.

[0040] The outer frame 11 and the support ring 13 are connected to each other via at least one support lead 15a and / or 15b. The support r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com