Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Increase external force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

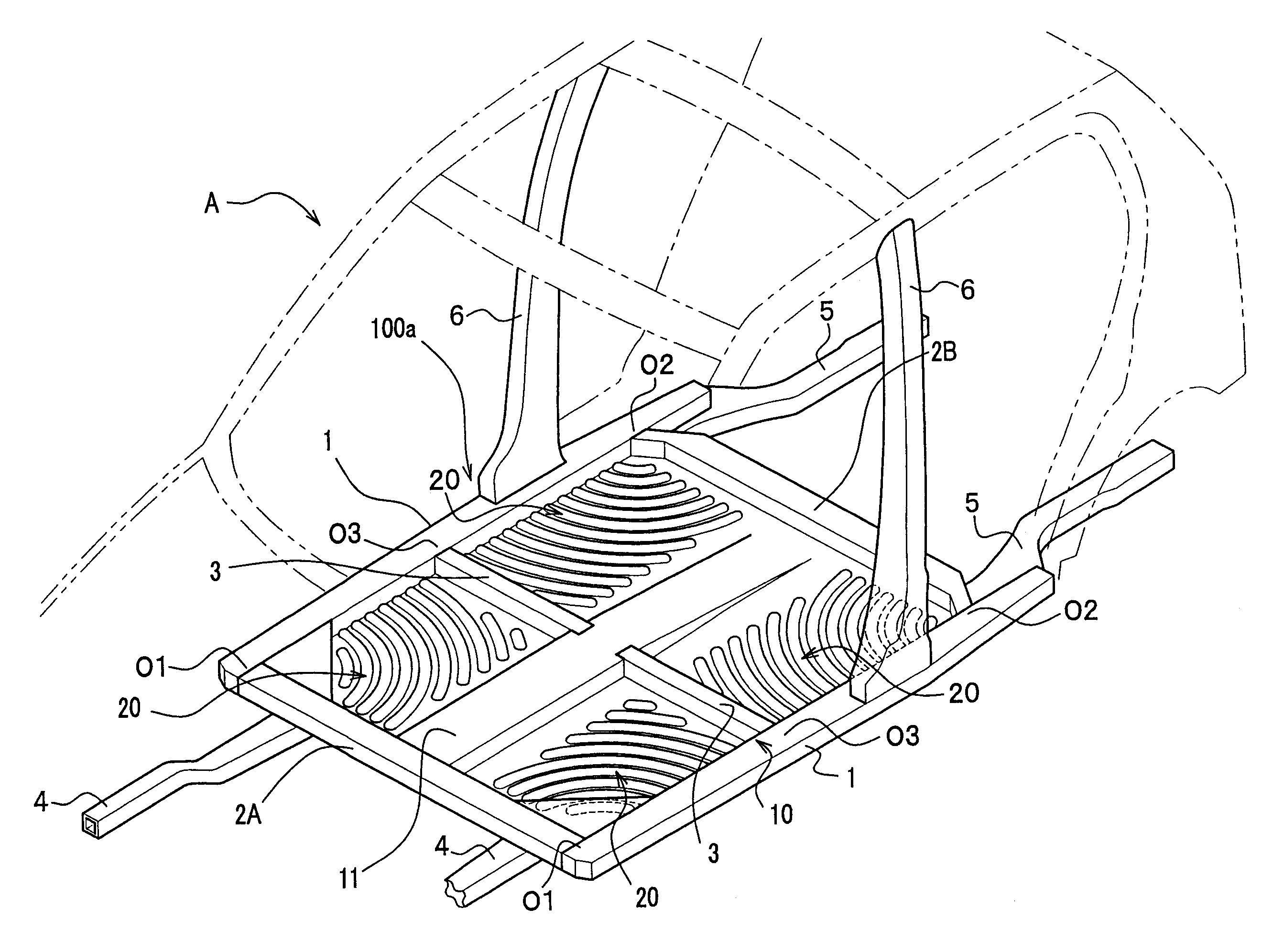

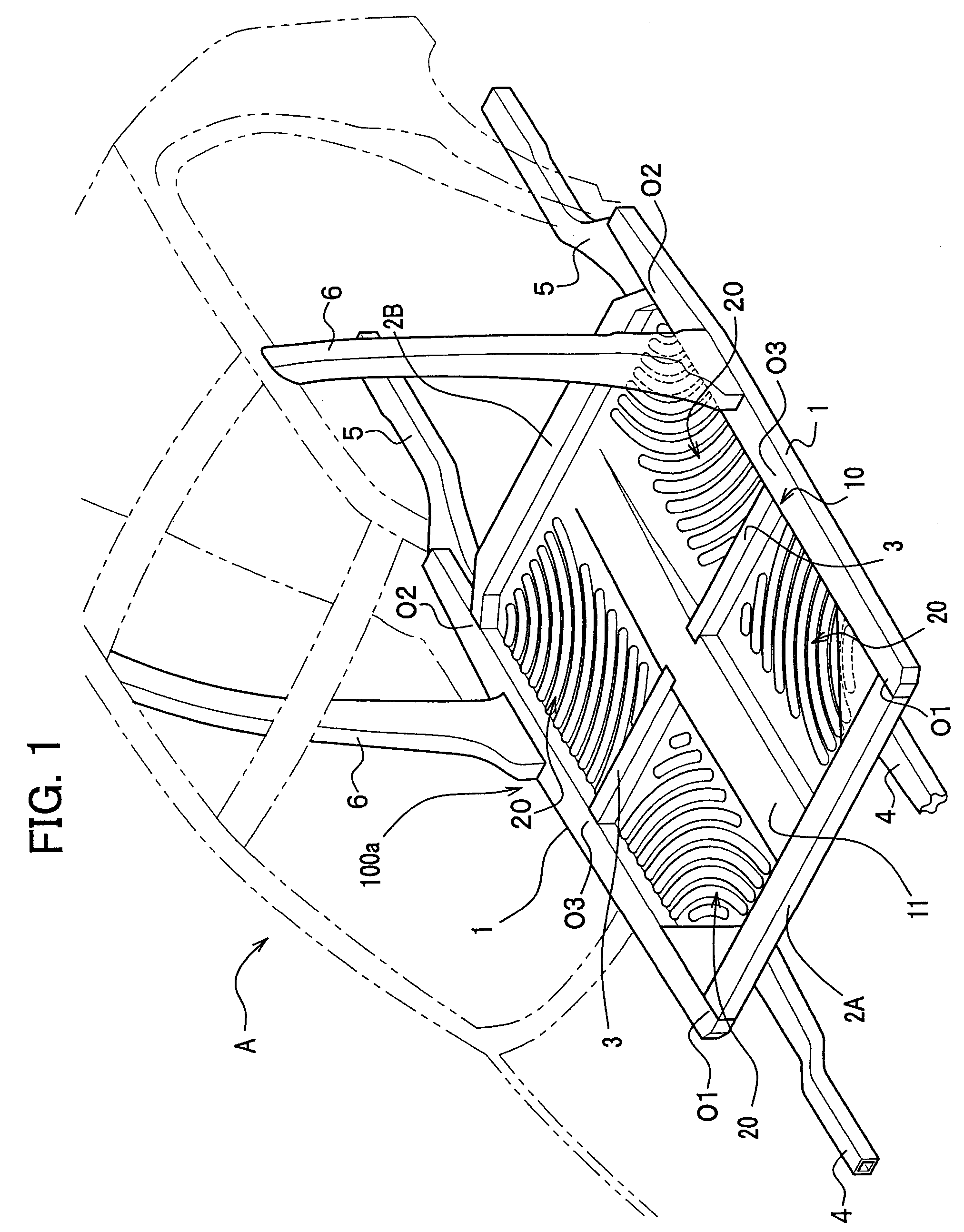

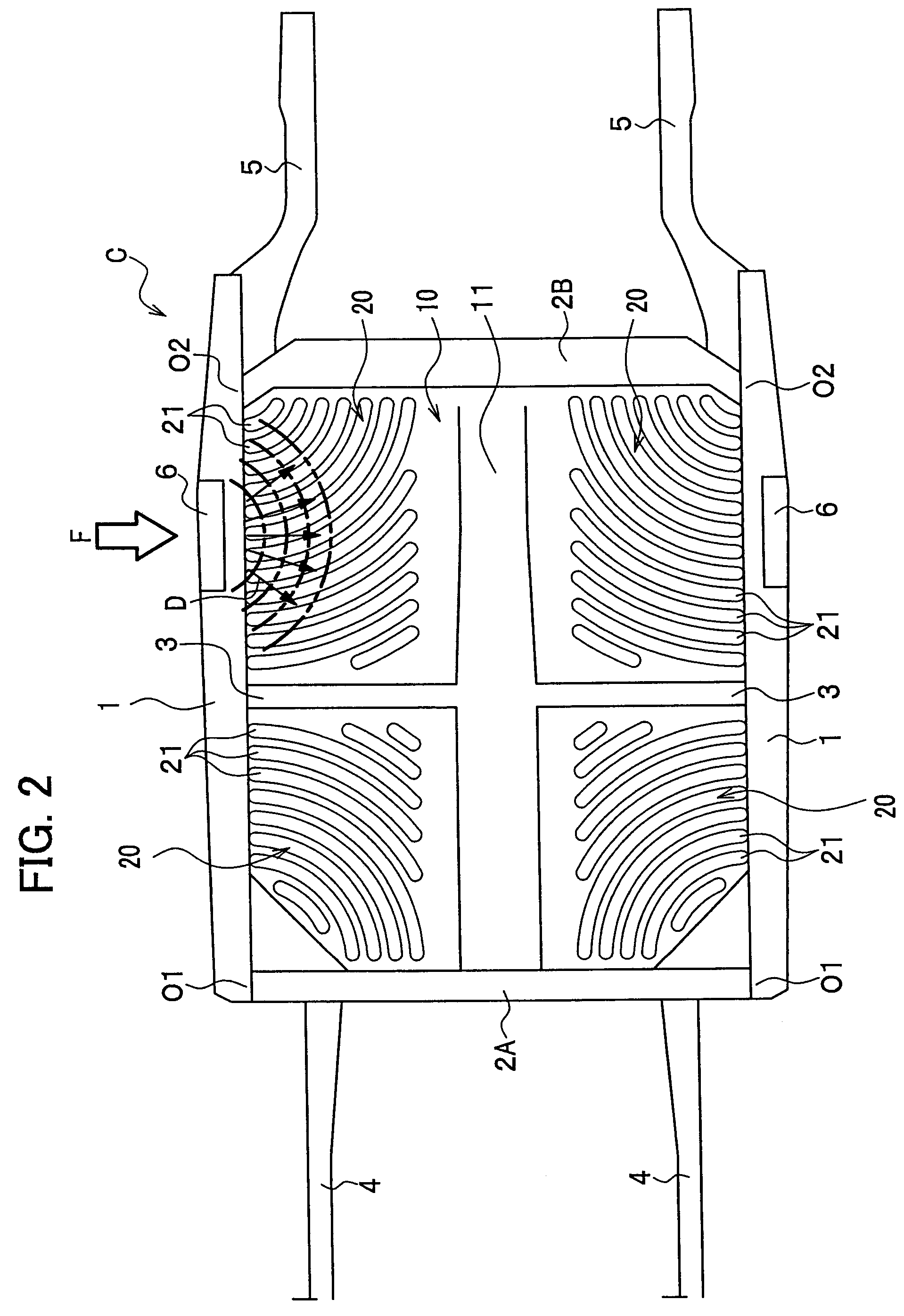

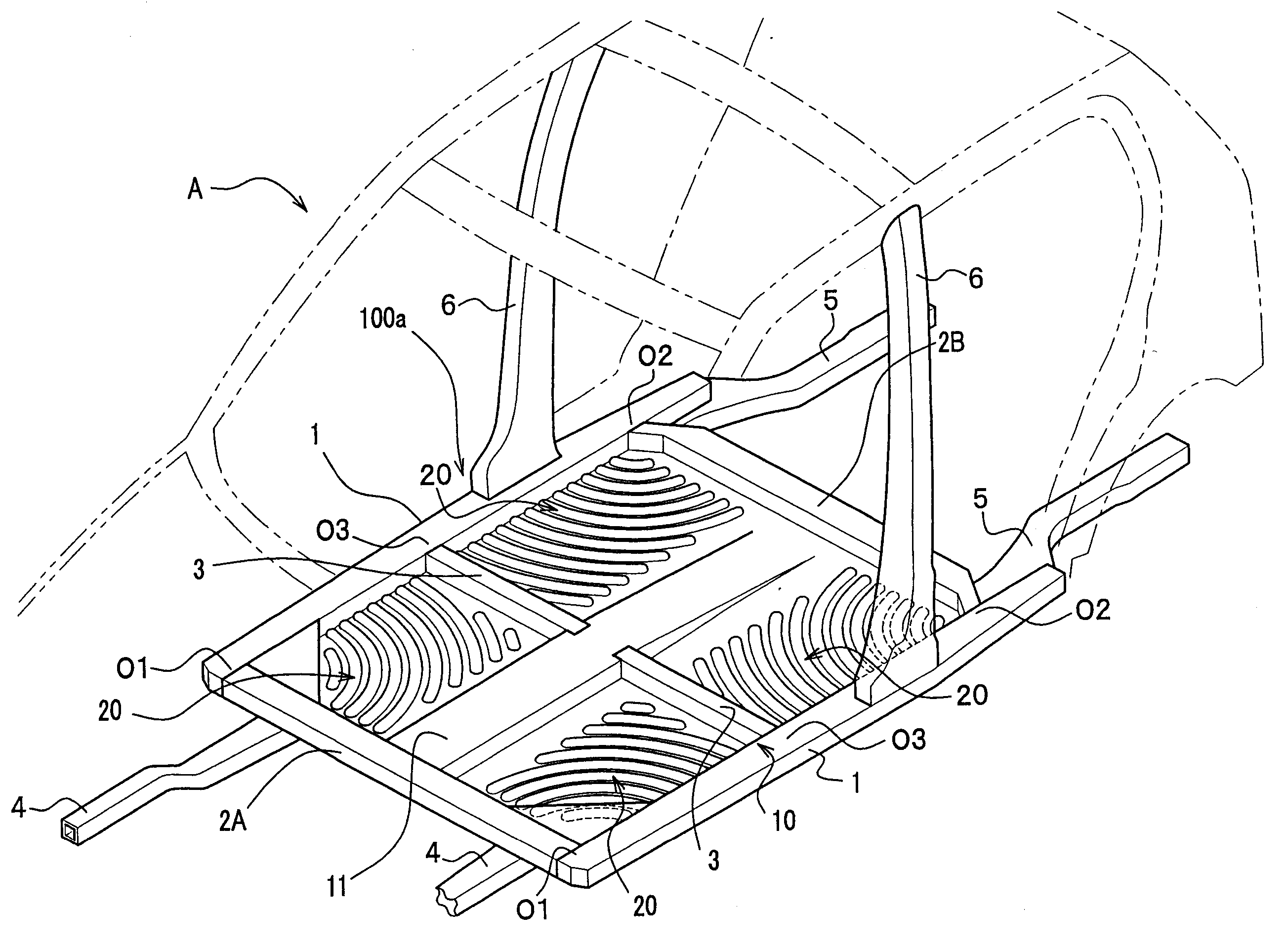

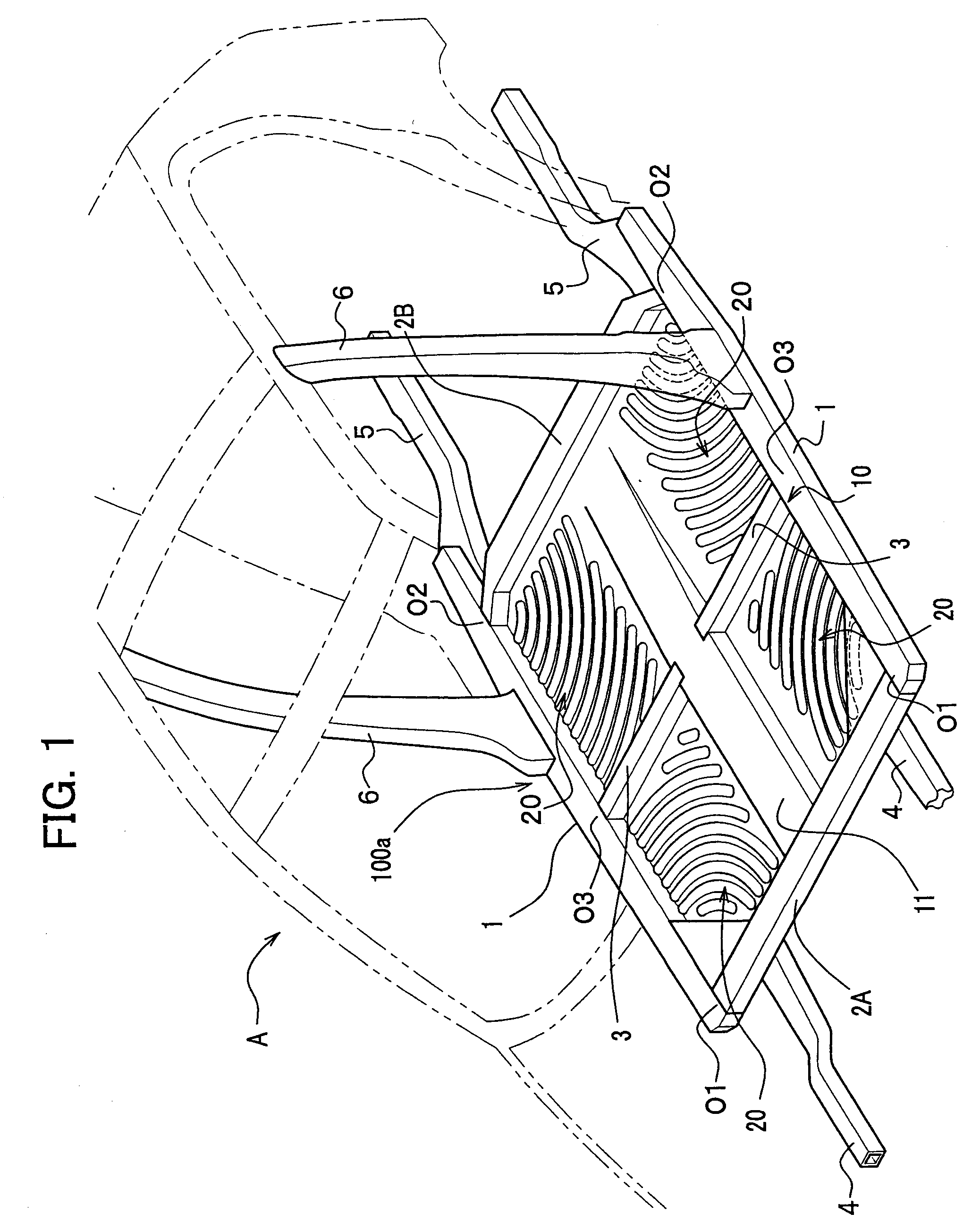

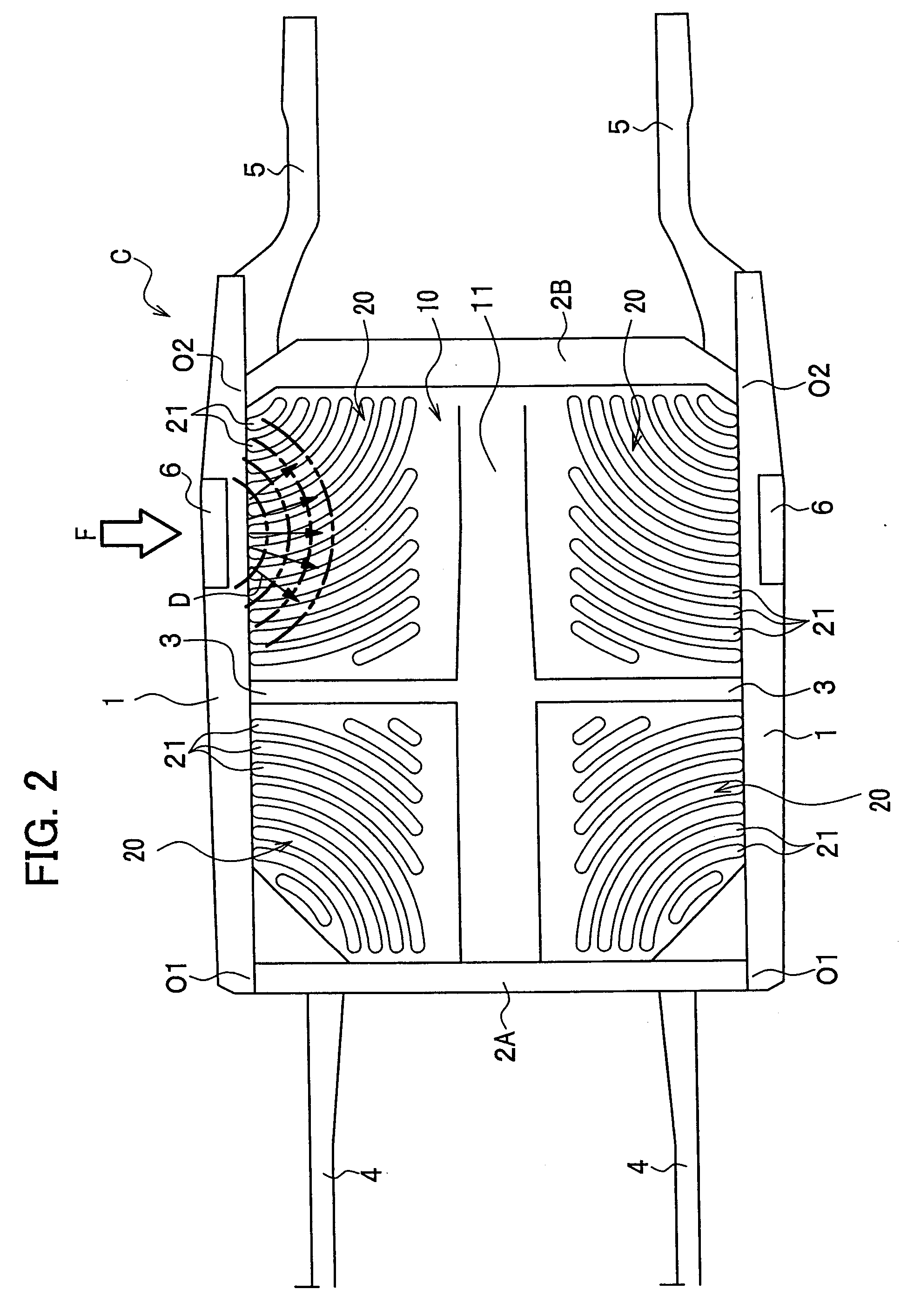

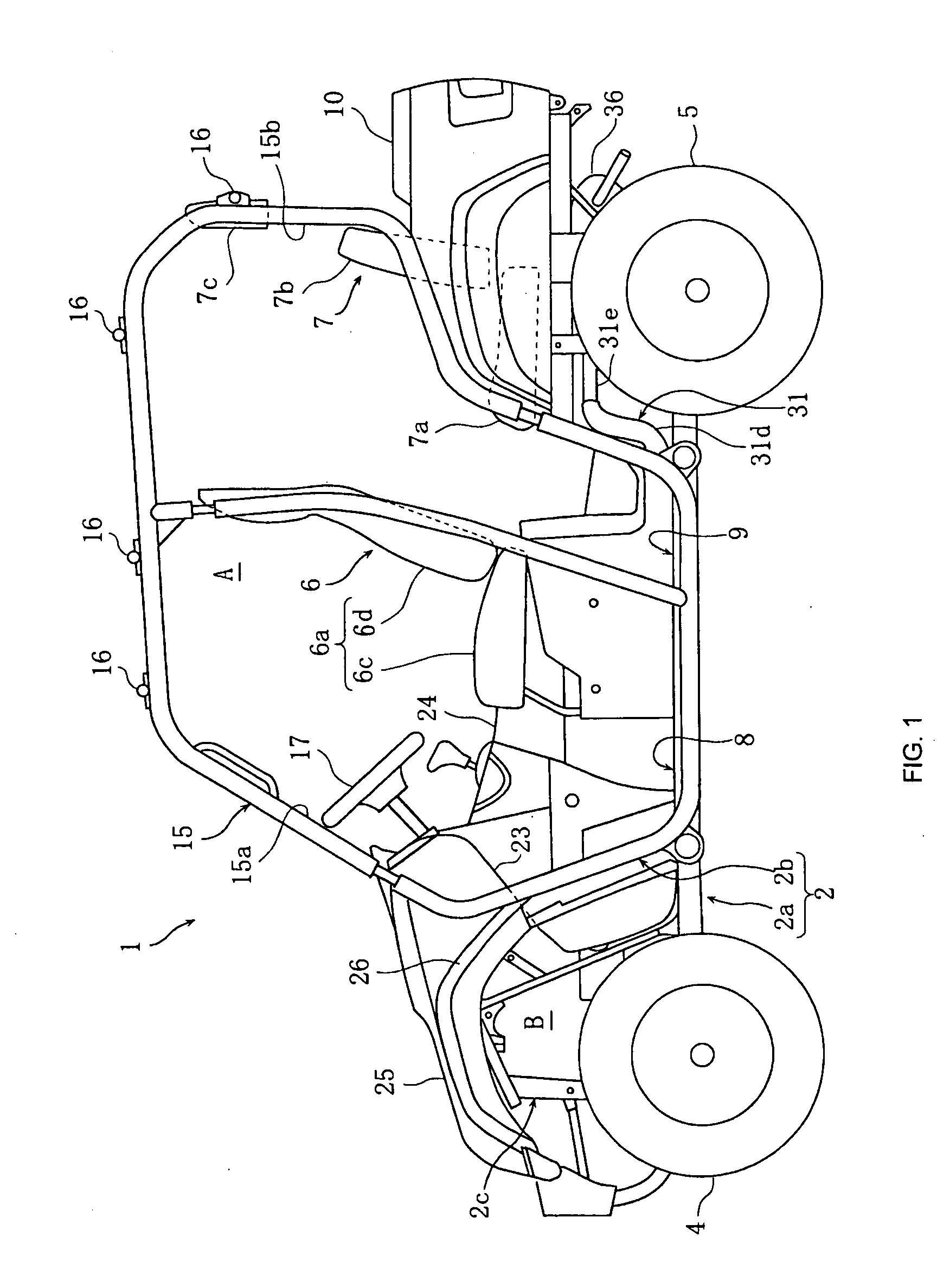

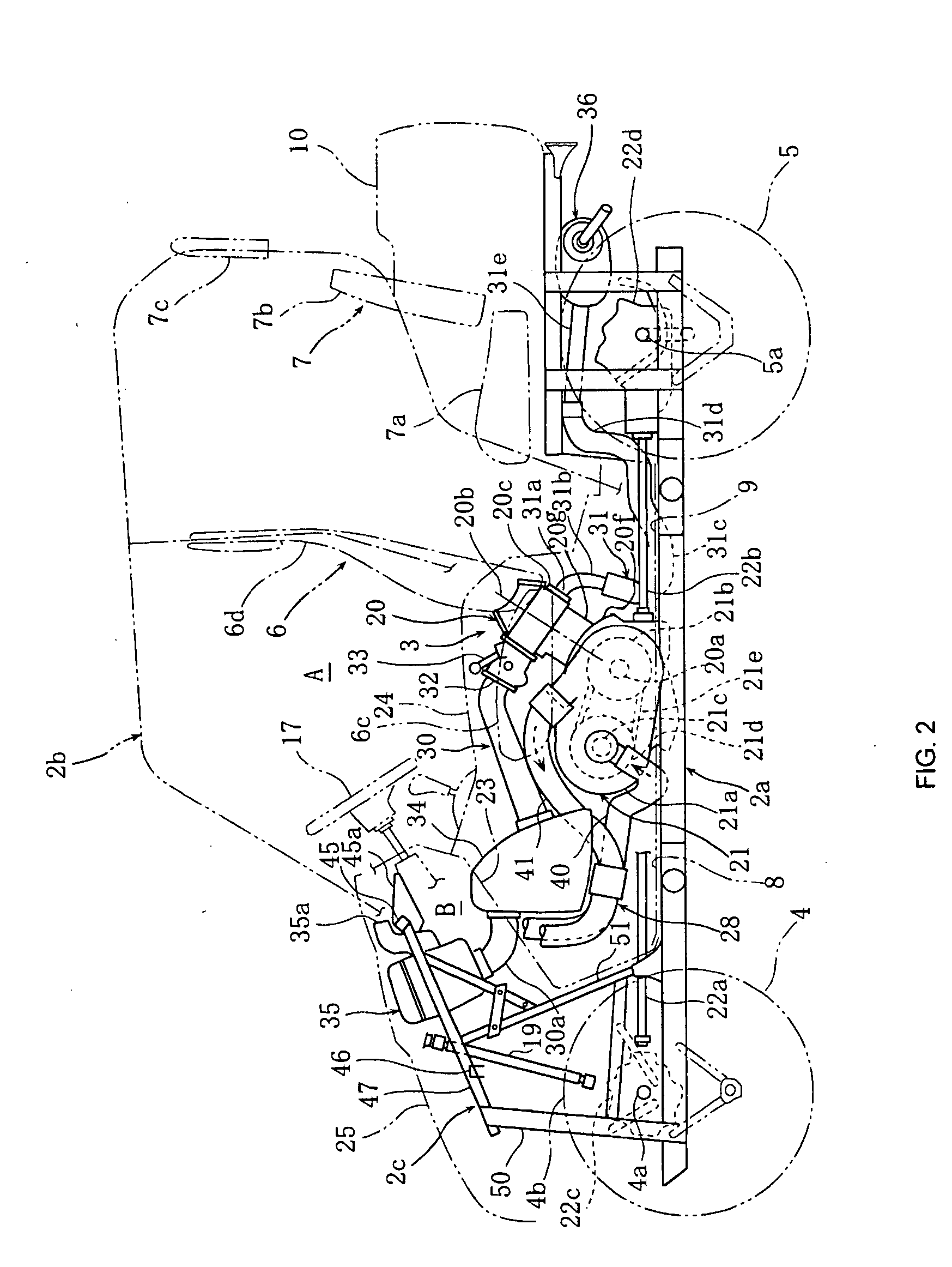

Floor structure of vehicle body

InactiveUS7195306B2Efficient disseminationReduce vehicle weightVehicle seatsUnderstructuresEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

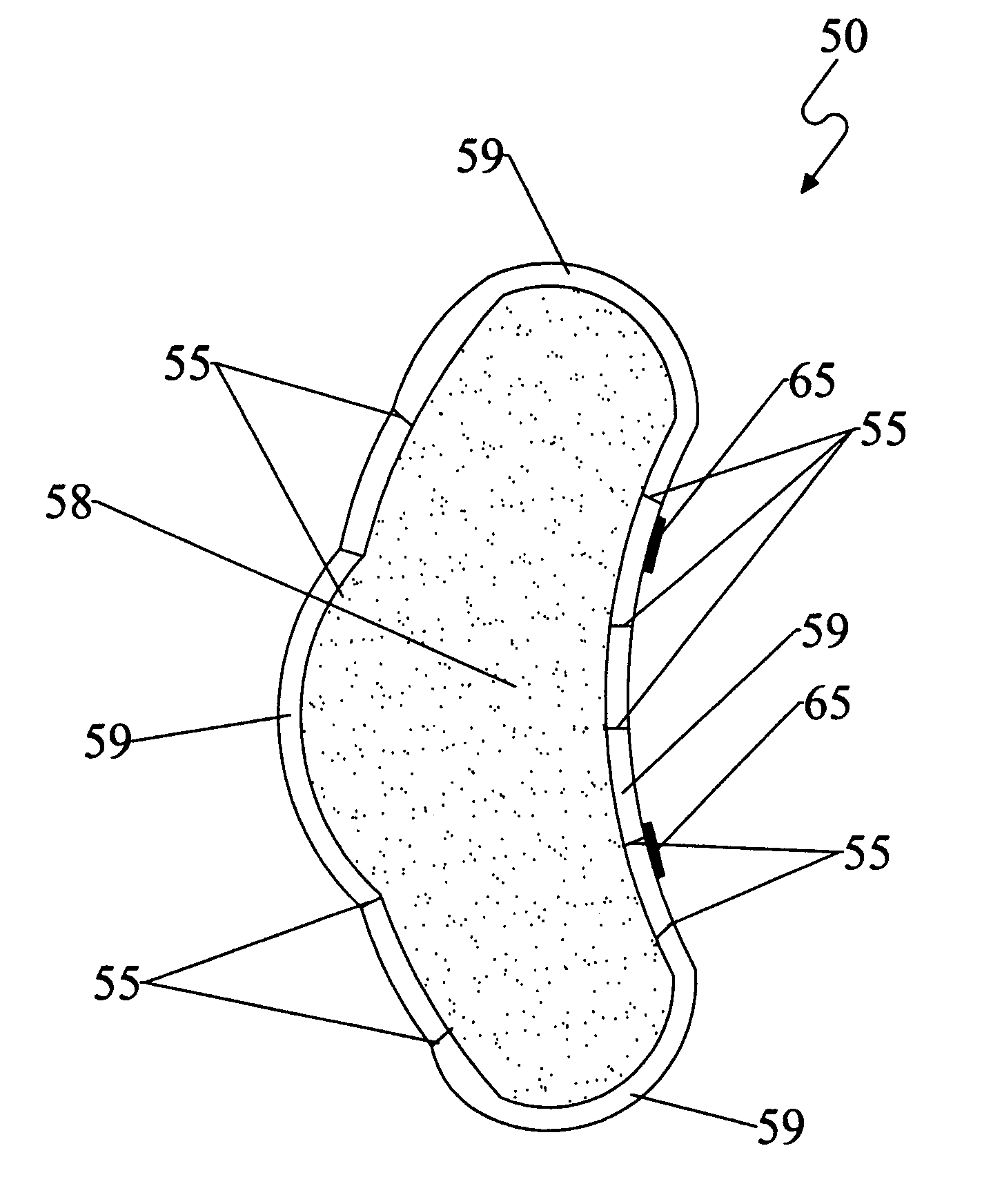

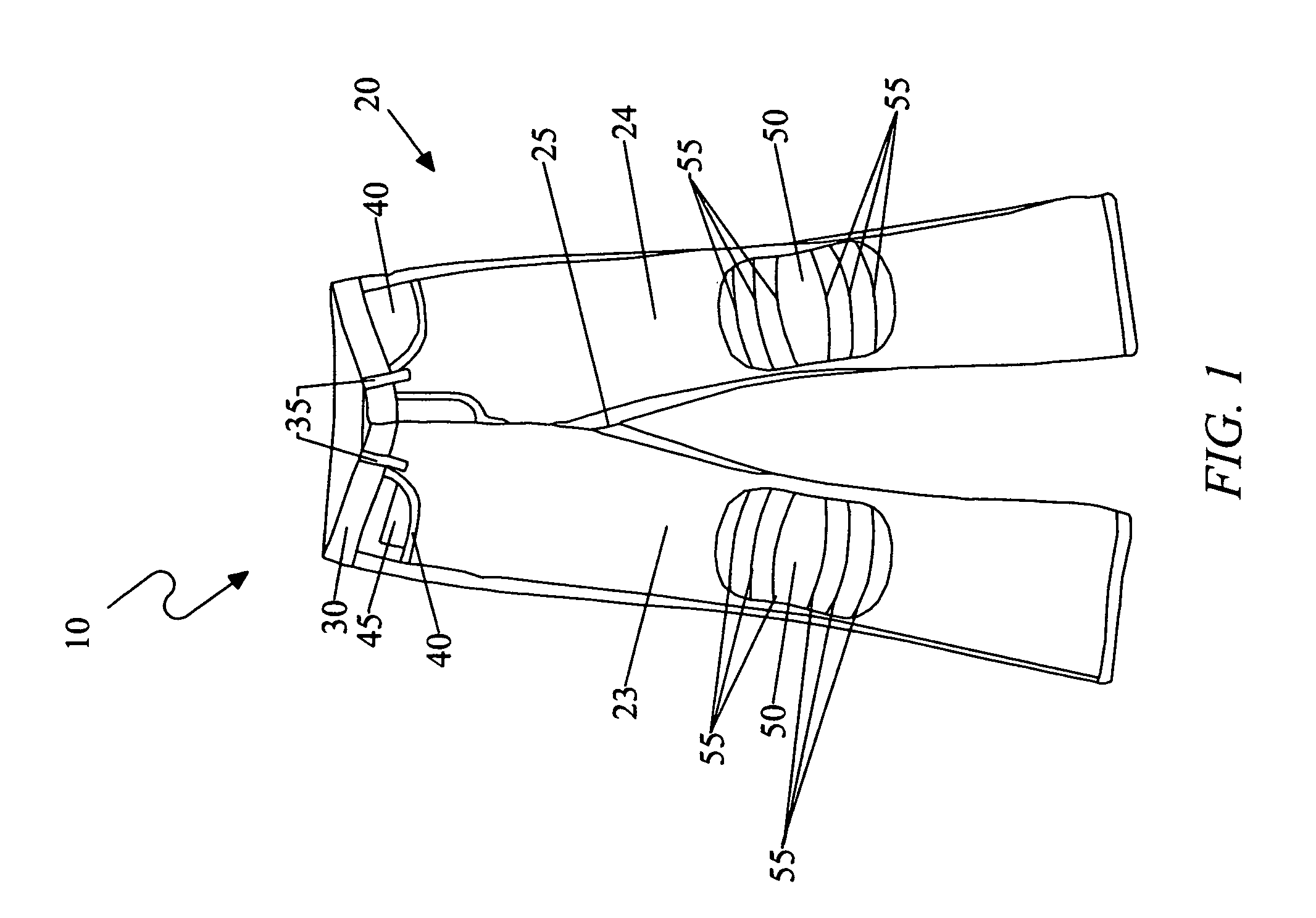

Knee pads for work pants and associated method

The present invention includes at least one knee pad and an associated method of attaching work quality external kneepads onto work pants by an attachment fastener. The attachment fastener preferably includes a commercial quality hook and loop fastener. The present invention adapts a pair of conventional work trousers to accept, when needed, conventional padded knee protectors. By using hook and loop fasteners, the kneepads can be quickly and simply attached and detached without having uncomfortable straps around the leg and therefore overcomes prior art shortcomings of hindering blood circulation. Thus, the direct attachment to the pants in lieu of straps means that there are no straps to cut into legs or cut off circulation. An additional benefit to this system is the convenience of laundering the work clothes.

Owner:DUMONT CLARENCE A

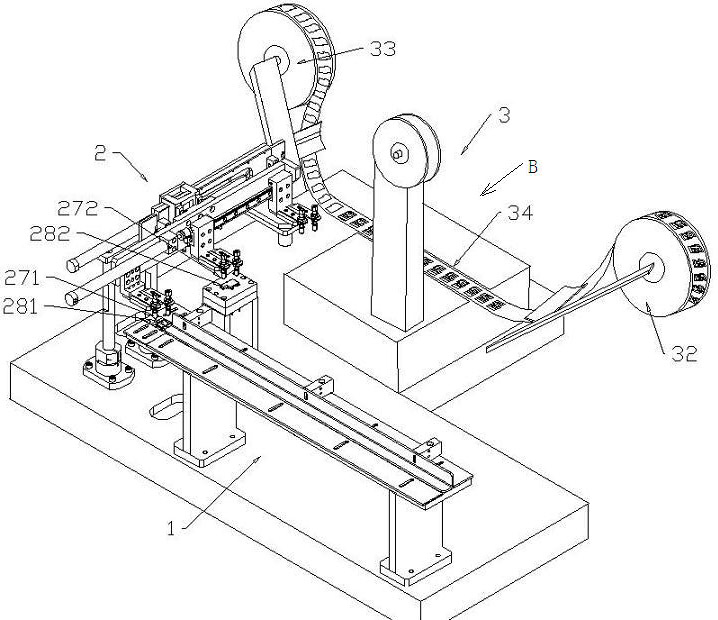

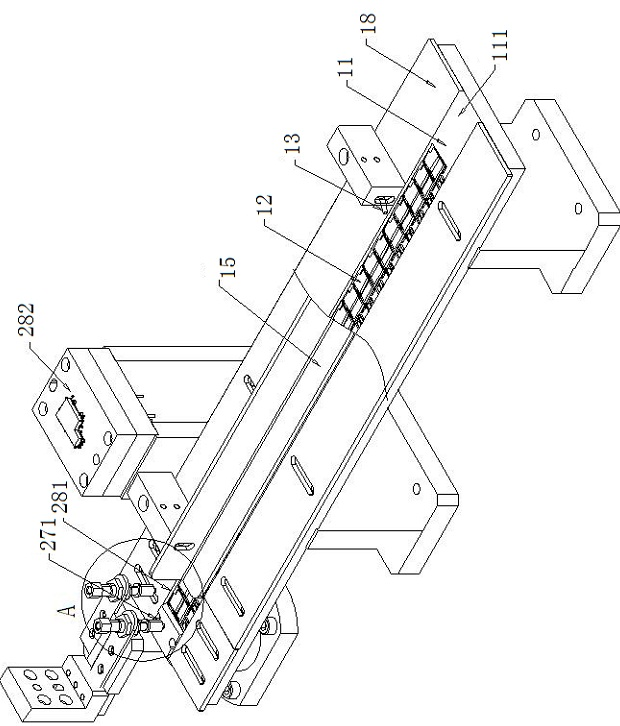

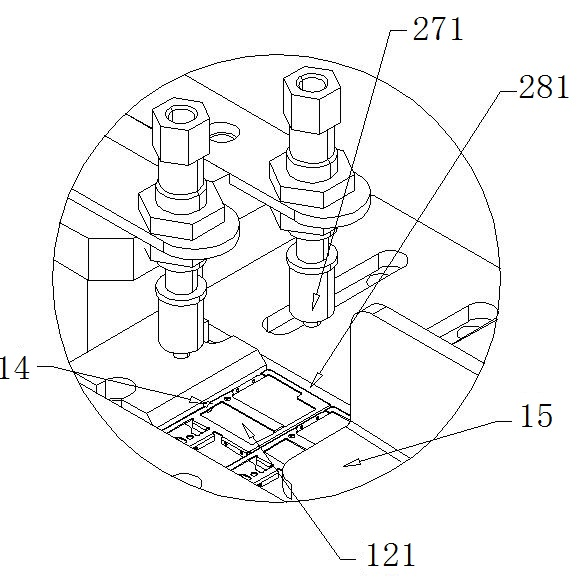

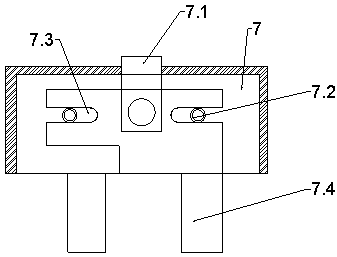

Integrated machine for automatically detecting flatness and packaging carrier belt for shielding case

ActiveCN102673822AFully automatedReduce quality impactPackaging automatic controlEngineeringAutomation

The invention discloses an integrated machine for automatically detecting flatness and packaging a carrier belt for a shielding case. The integrated machine comprises a blowing and feeding mechanism, a double stroke transmission mechanism, an automatic packaging mechanism and a controlling device. Shielding cases to be detected enter into a first work station in the blowing and feeding mechanism orderly, the controlling device controls the double stroke transmission mechanism to execute a first stroke, a first nozzle sucks the shielding cases at the first work station and conveys the shielding cases to a second work station for flatness detection, a second nozzle sucks the qualified shielding cases detected at the second work station and conveys the shielding cases to a third work station to be arranged on the carrier belt, and the carrier belt where the shielding cases are arranged is automatically packaged by an adhesive tape and coiled automatically by a receiving disc. The integrated machine provided by the invention detects and conveys the shielding cases automatically, sorts qualified and unqualified products and arranges the qualified products on the carrier belt automatically. The carrier belt is automatically packaged by the adhesive tape and operators do not contact with the detection and packaging process of the shielding cases, thereby realizing automation of the packaging process of the shielding cases.

Owner:南通诚业德精密组件有限公司

Oscillating-type generator

InactiveUS7157835B2Reduce the total massShorten the overall cycleRotary current collectorPiezoelectric/electrostriction/magnetostriction machinesElectricityEngineering

Owner:USC

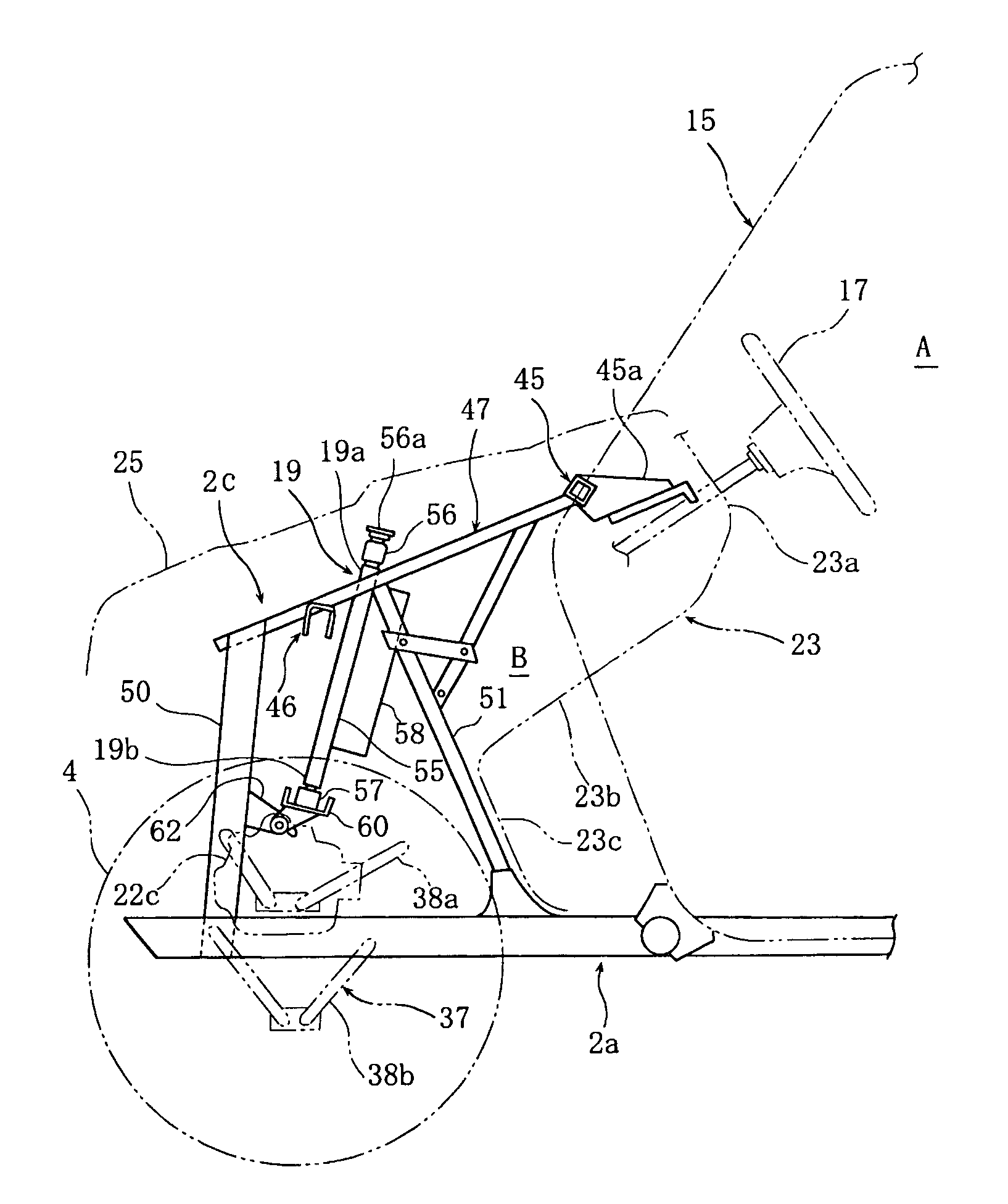

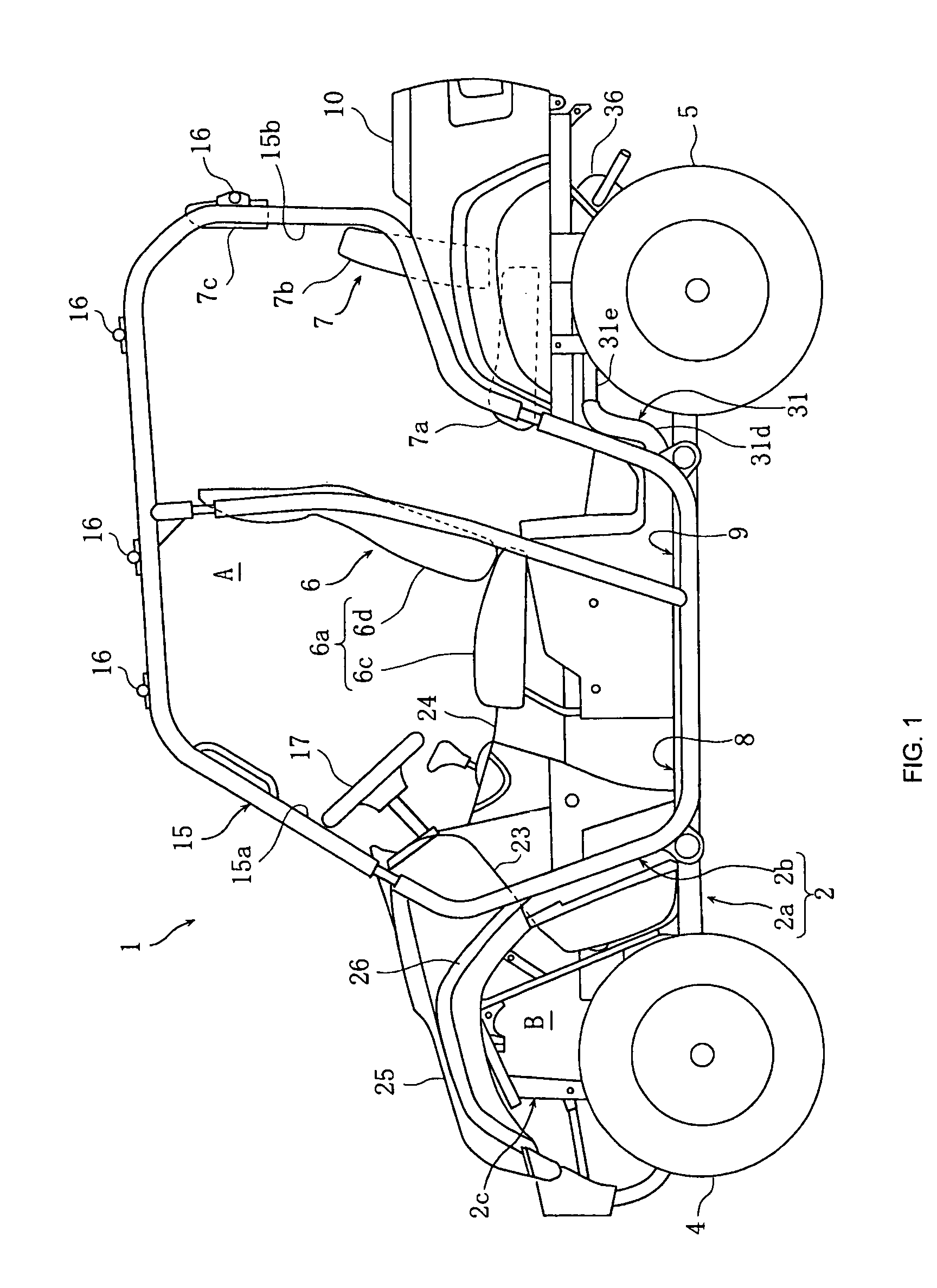

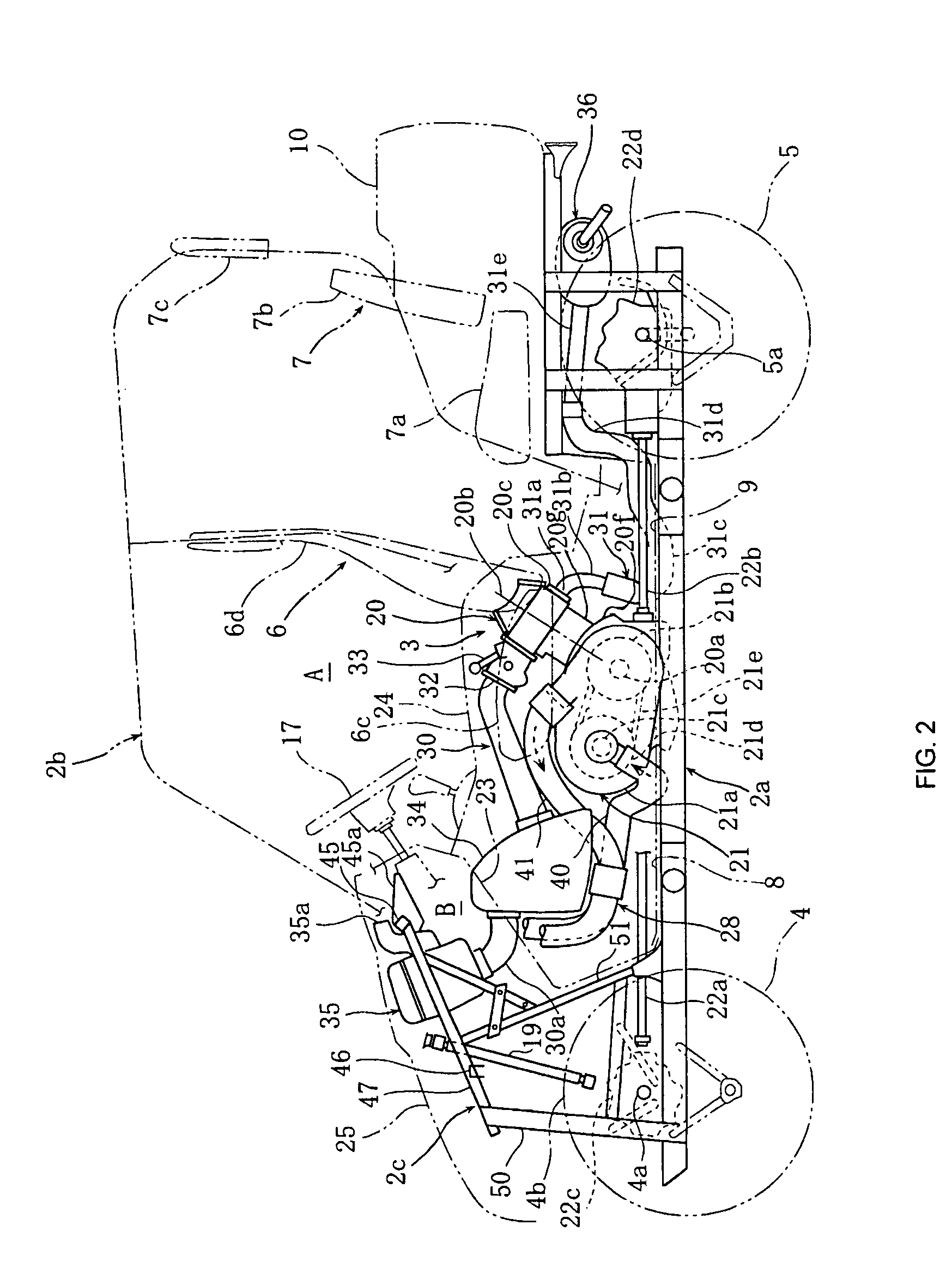

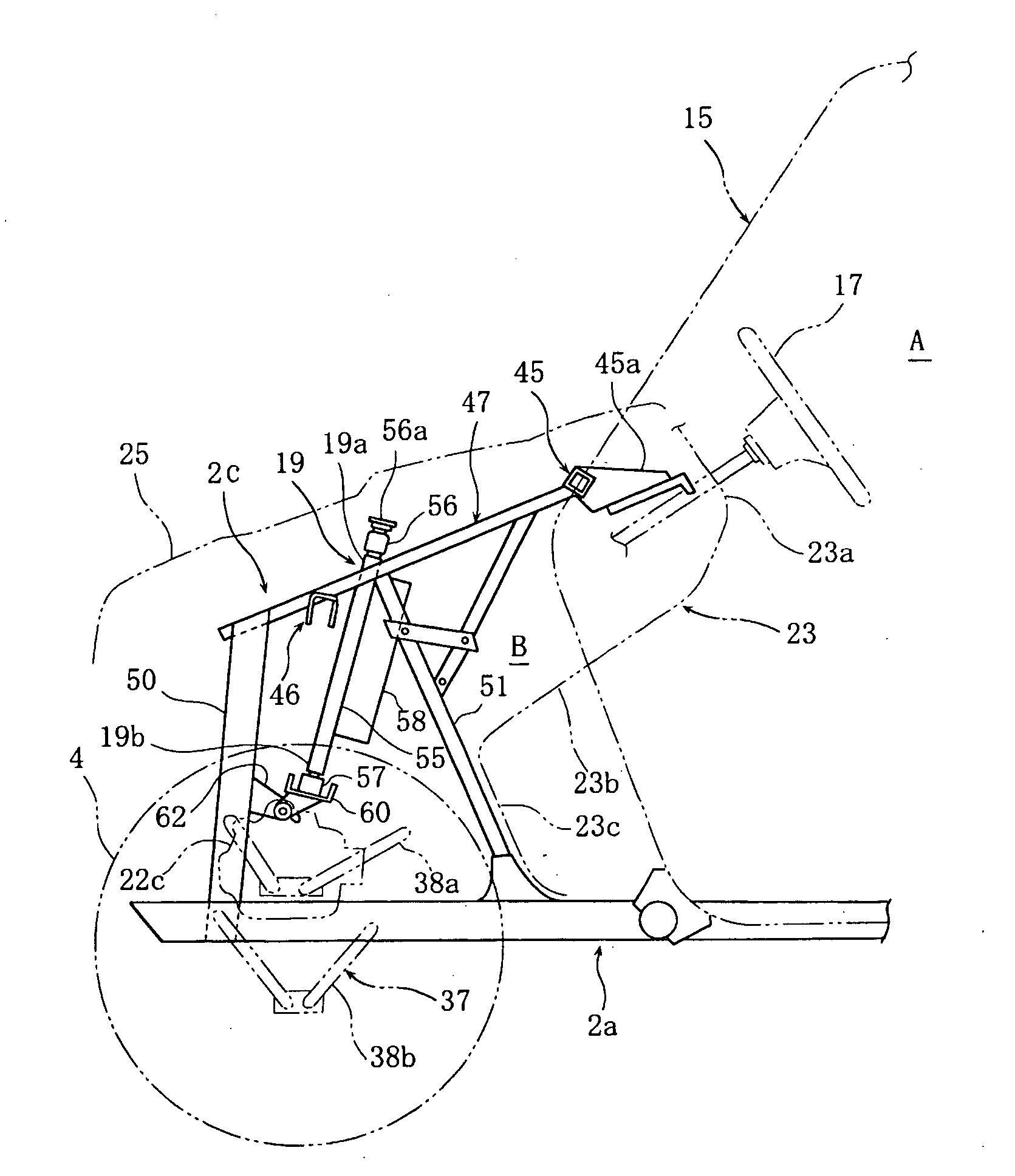

All terrain vehicle with radiator protection

ActiveUS8037959B2Improve protectionIncrease external forceVehicle body-frame connectionsUnderstructuresInterior spaceEngineering

A vehicle including a main body frame having a length direction and a width direction includes a front frame carried by the main body frame. The front frame includes a first front cross frame having a generally height and extends along said main body's width direction. A second front cross frame is disposed frontward and offset from the first cross frame at an elevational height less than the first front cross frame. A first and second side frame interconnect with the first cross frame and the second cross frame to define radiator cage having an interior space. A radiator is disposed within the interior space of said radiator cage.

Owner:YAMAHA MOTOR CO LTD

Floor structure of vehicle body

InactiveUS20060232105A1Improve rigidityEfficient disseminationVehicle seatsUnderstructuresMechanical engineering

Owner:HONDA MOTOR CO LTD

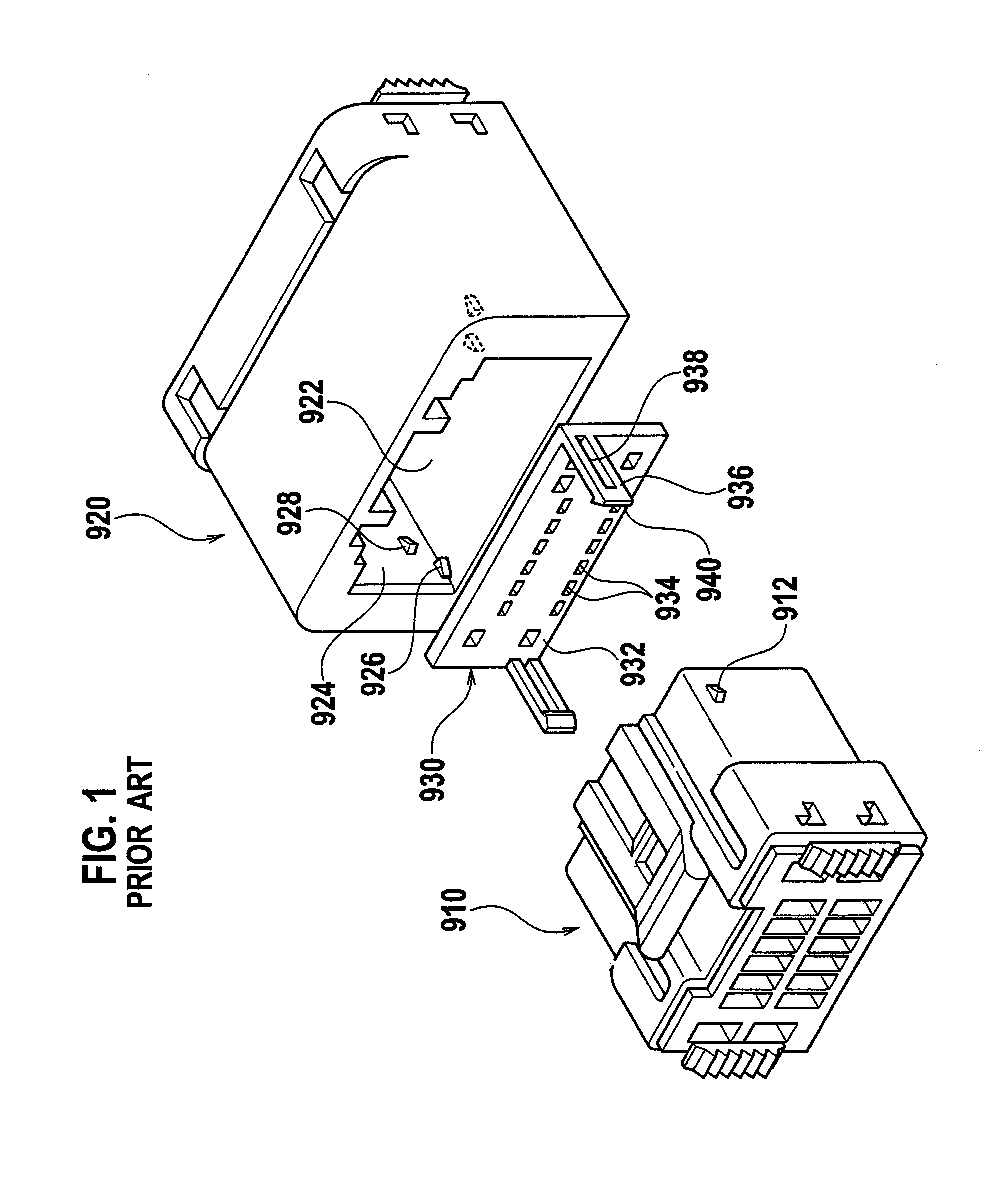

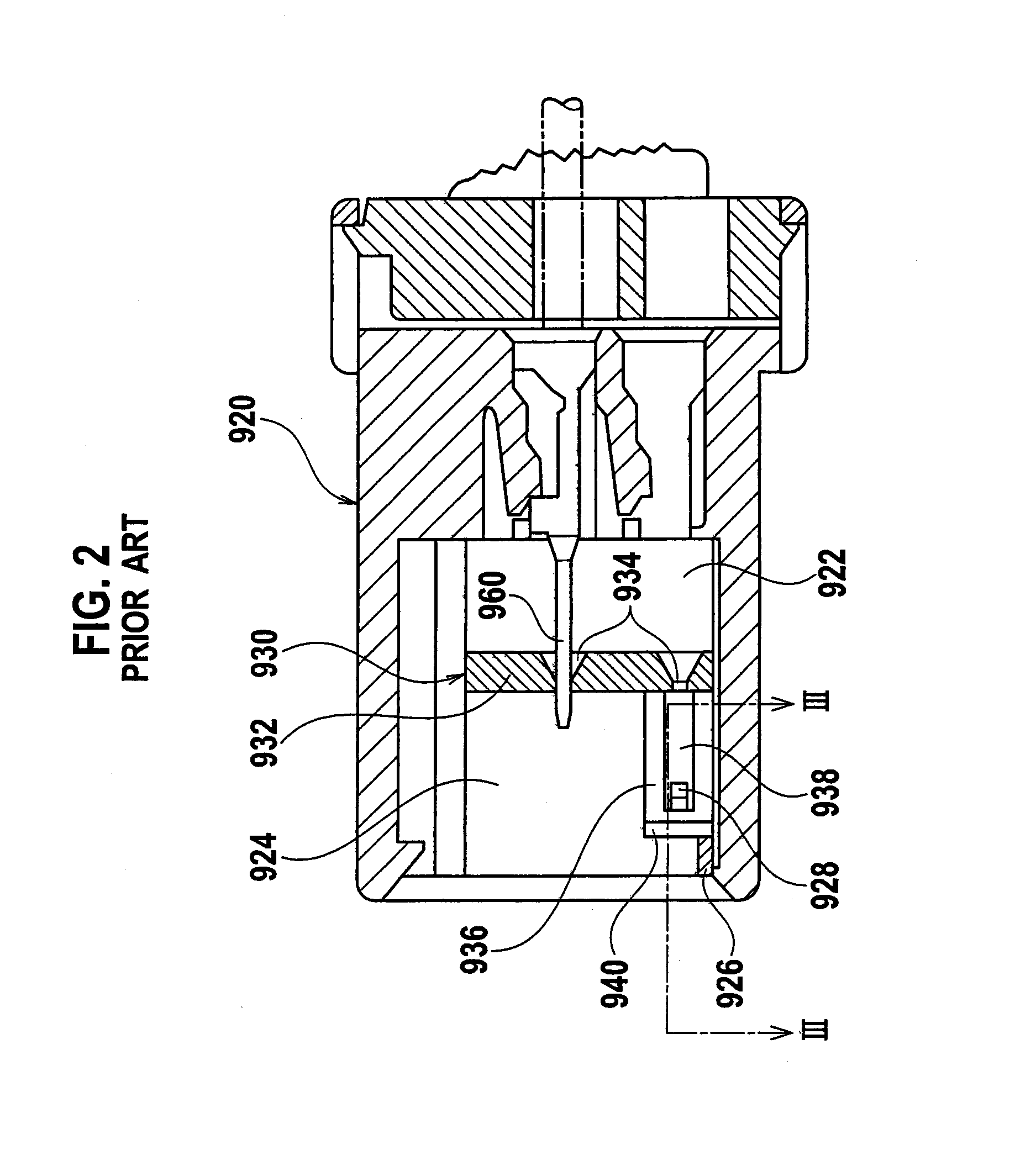

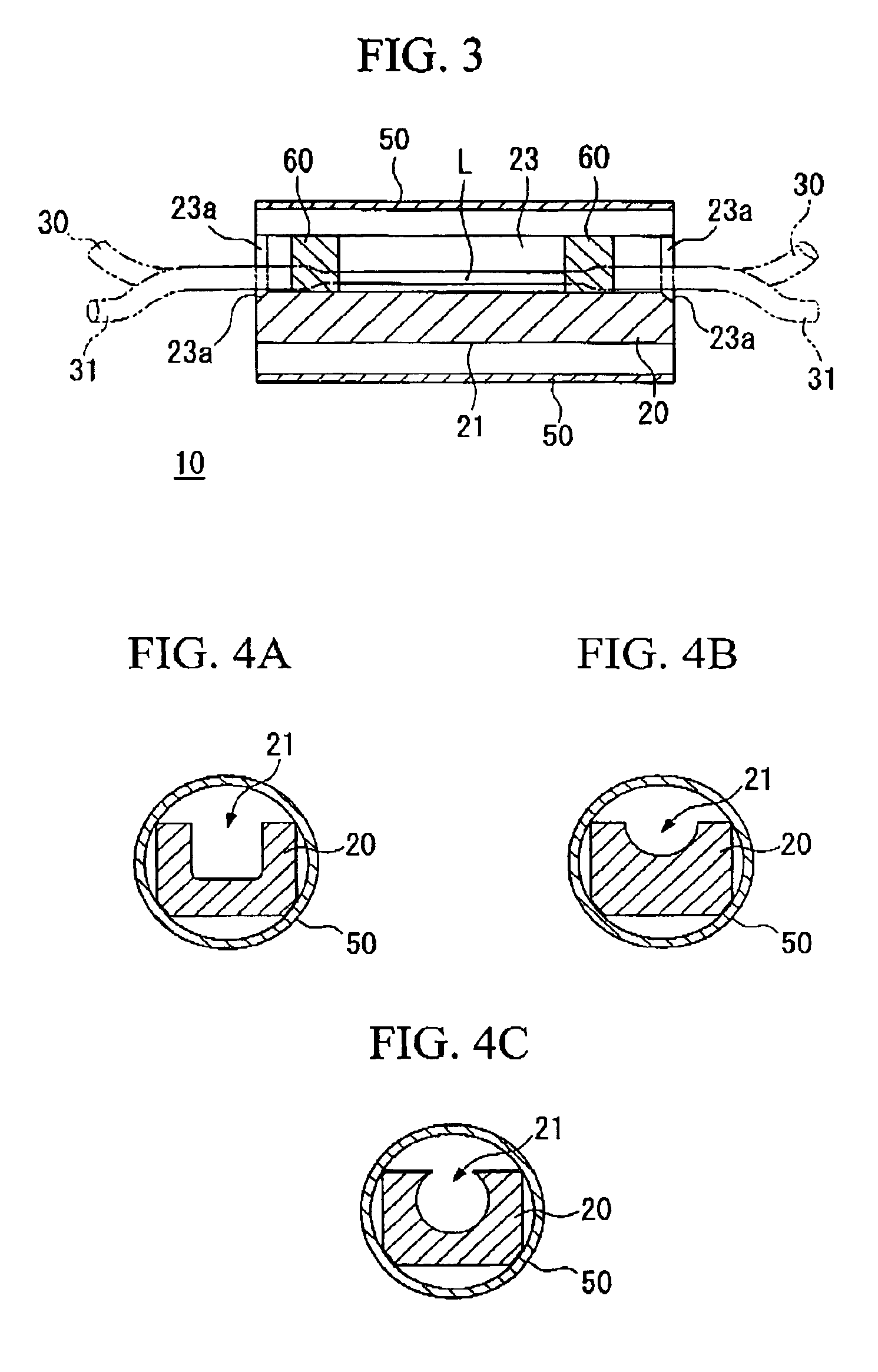

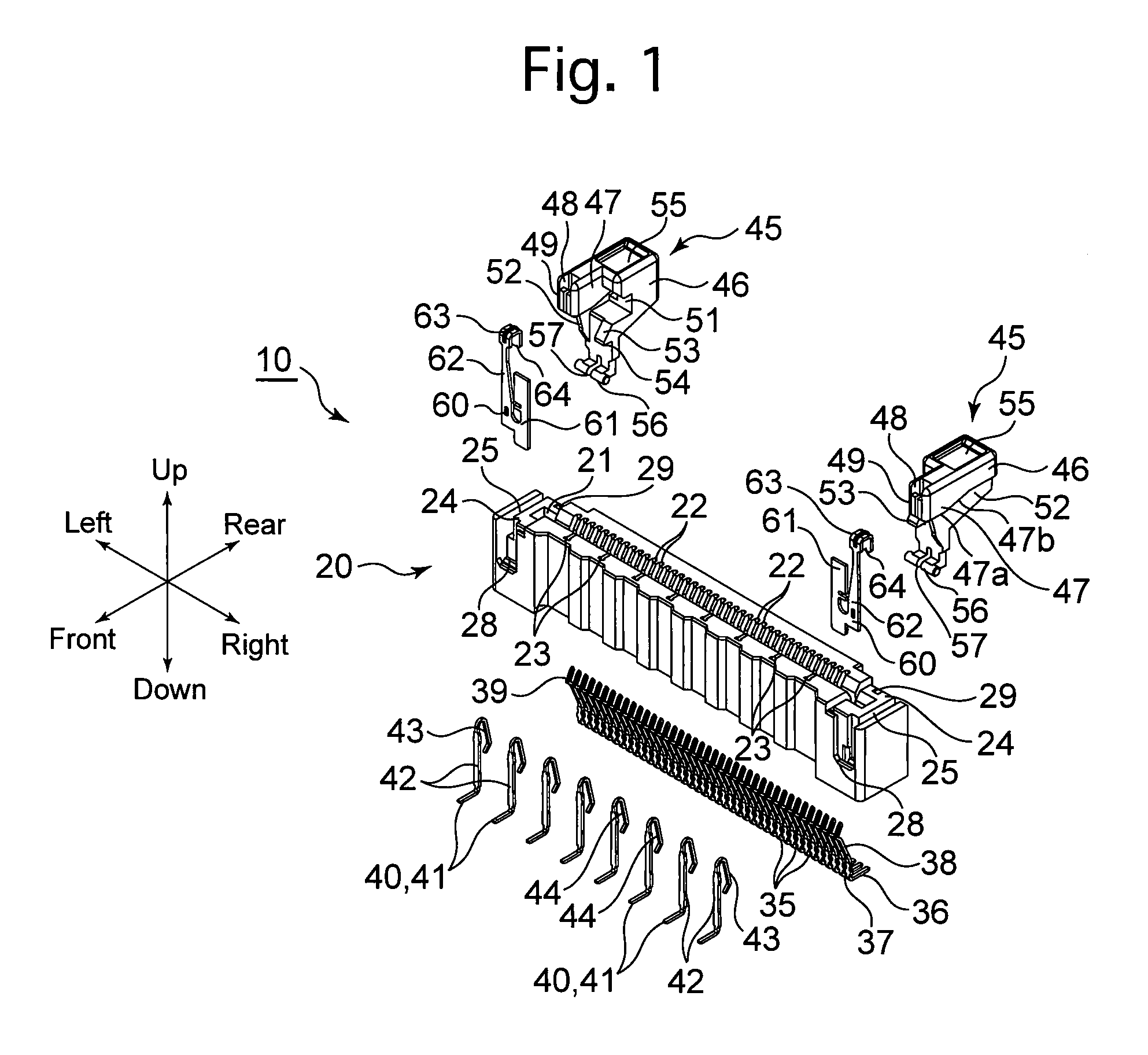

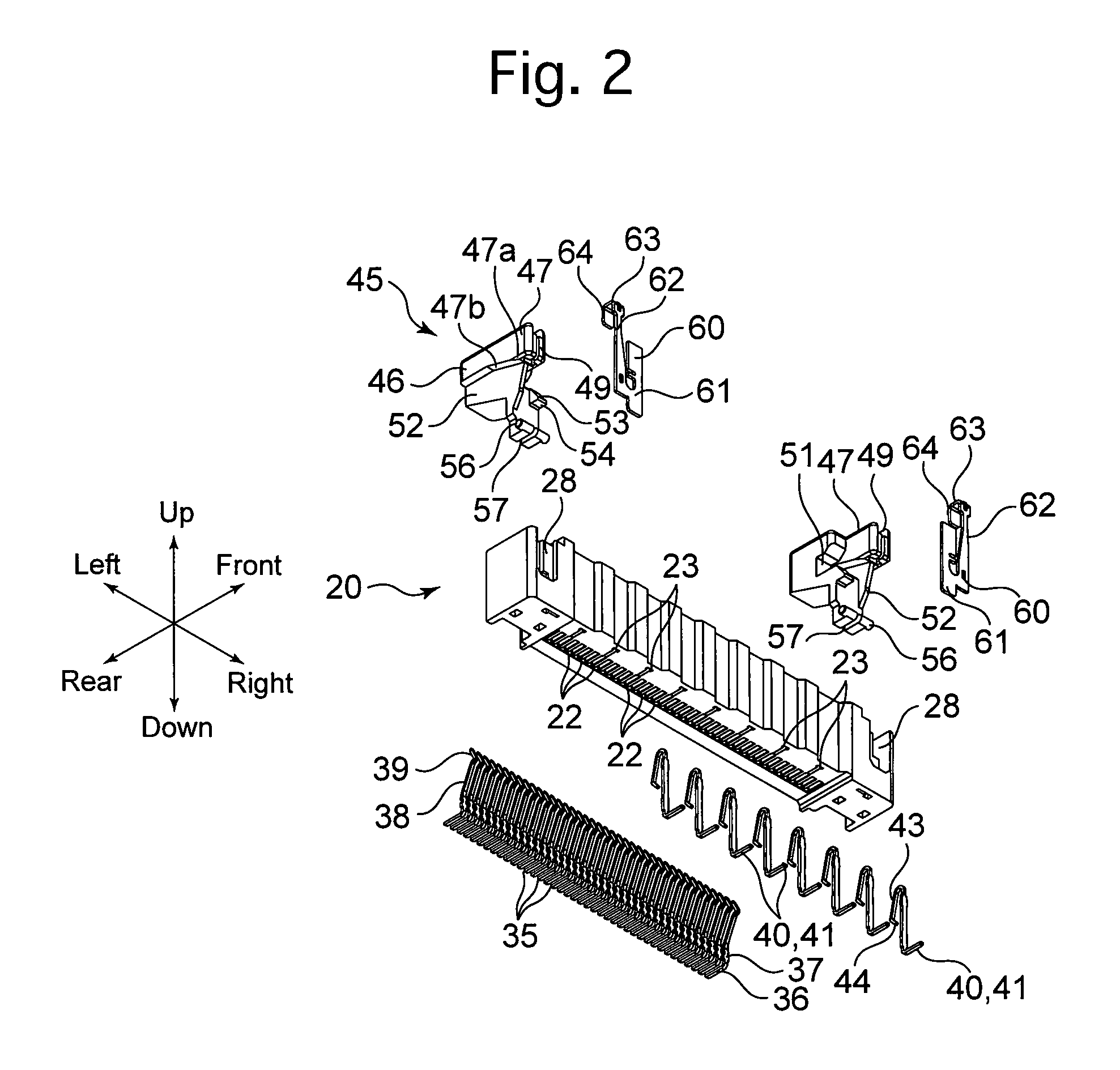

Lever Type Connector

InactiveUS20080102667A1Avoid plastic deformationReduction of temporary connecting performance is preventedEngagement/disengagement of coupling partsVehicle connectorsEngineeringMechanical engineering

Owner:YAZAKI CORP

All terrain vehicle with radiator protection

ActiveUS20100194087A1Improve protectionIncrease external forceVehicle body-frame connectionsUnderstructuresInterior spaceEngineering

A vehicle including a main body frame having a length direction and a width direction includes a front frame carried by the main body frame. The front frame includes a first front cross frame having a generally height and extends along said main body's width direction. A second front cross frame is disposed frontward and offset from the first cross frame at an elevational height less than the first front cross frame. A first and second side frame interconnect with the first cross frame and the second cross frame to define radiator cage having an interior space. A radiator is disposed within the interior space of said radiator cage.

Owner:YAMAHA MOTOR CO LTD

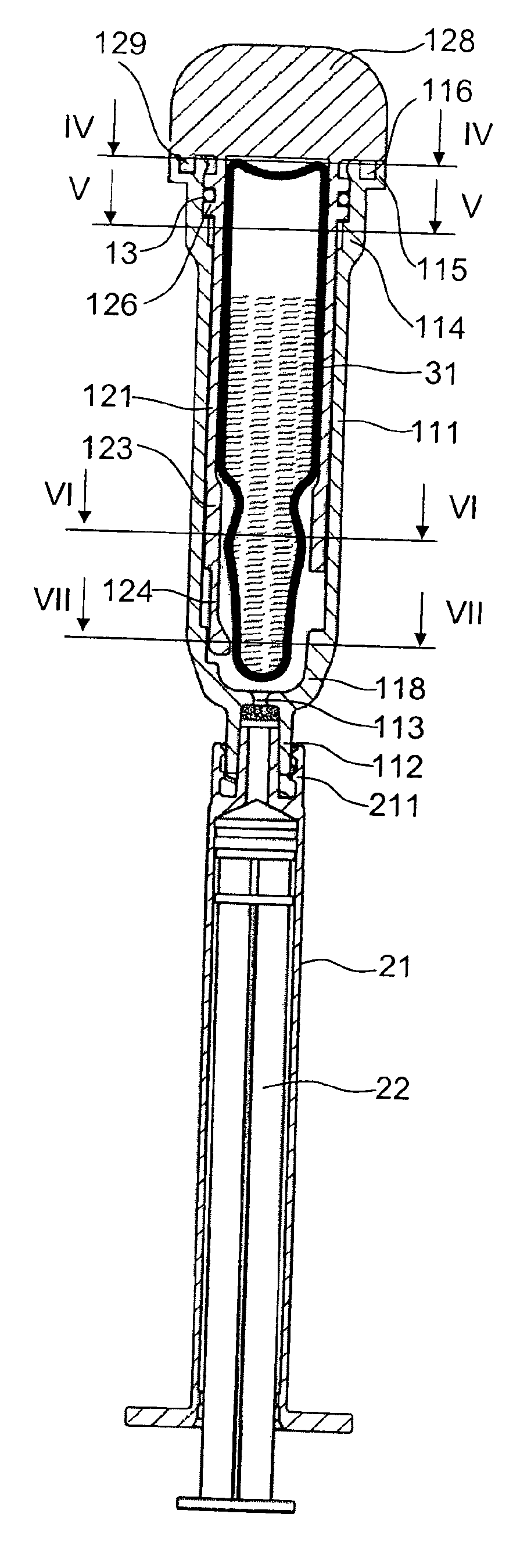

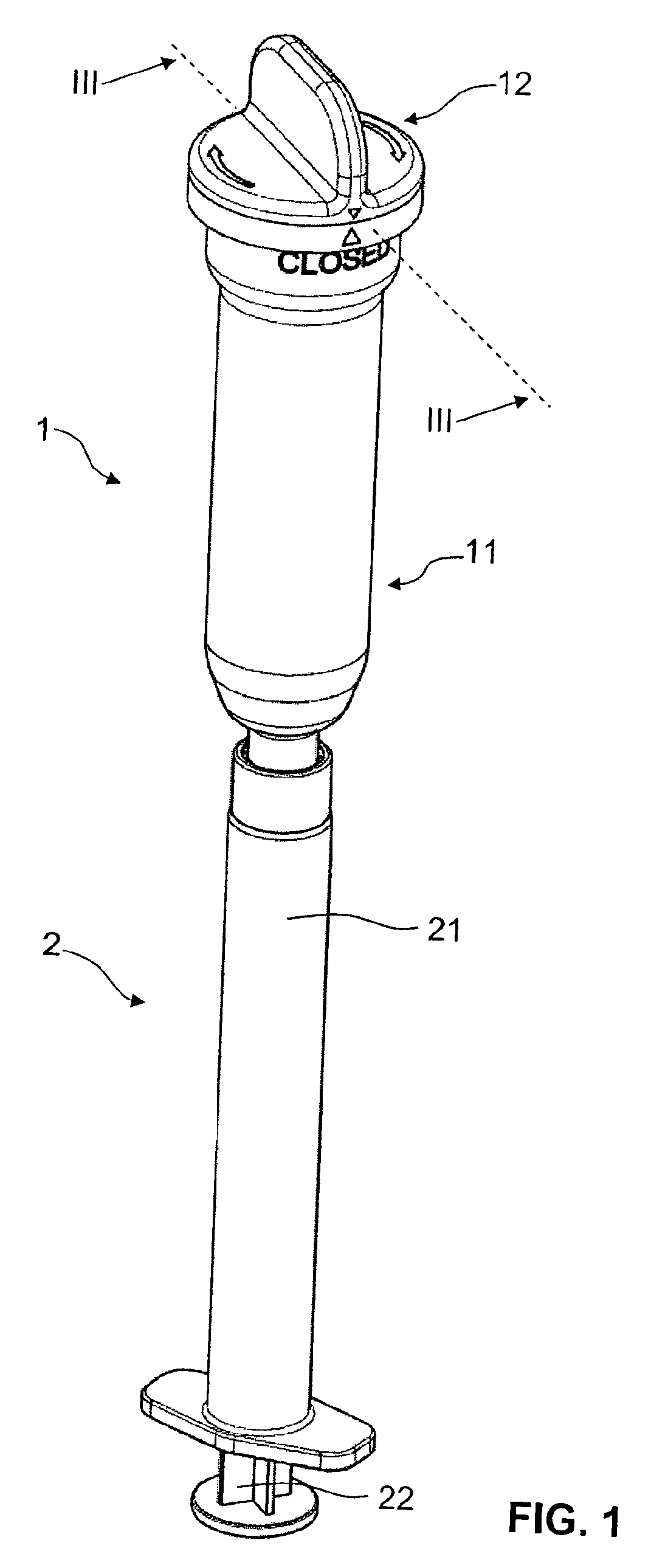

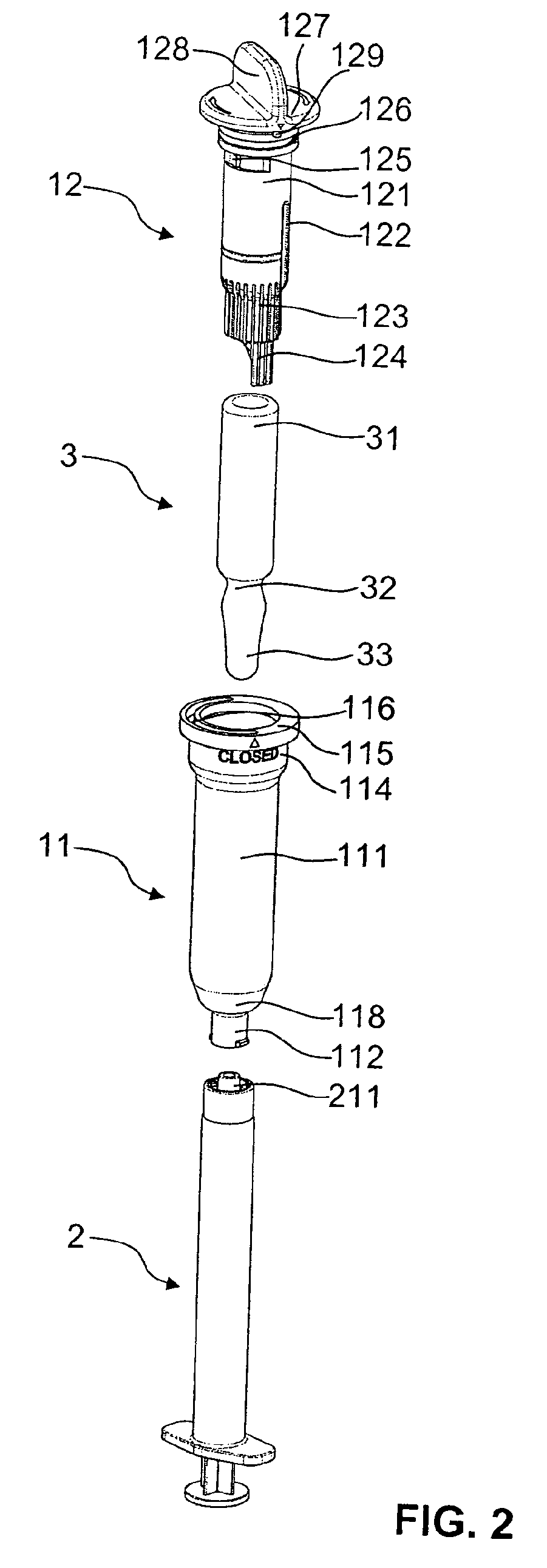

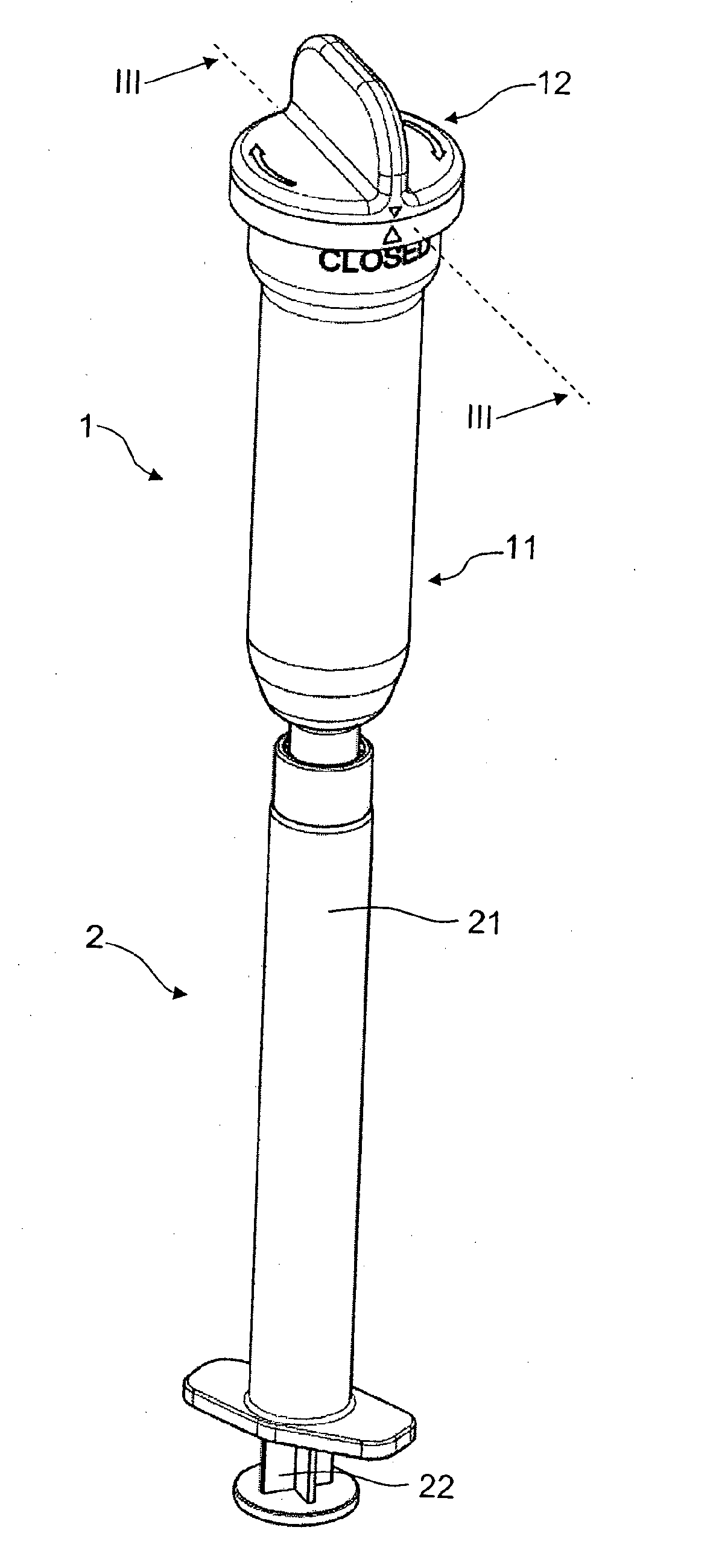

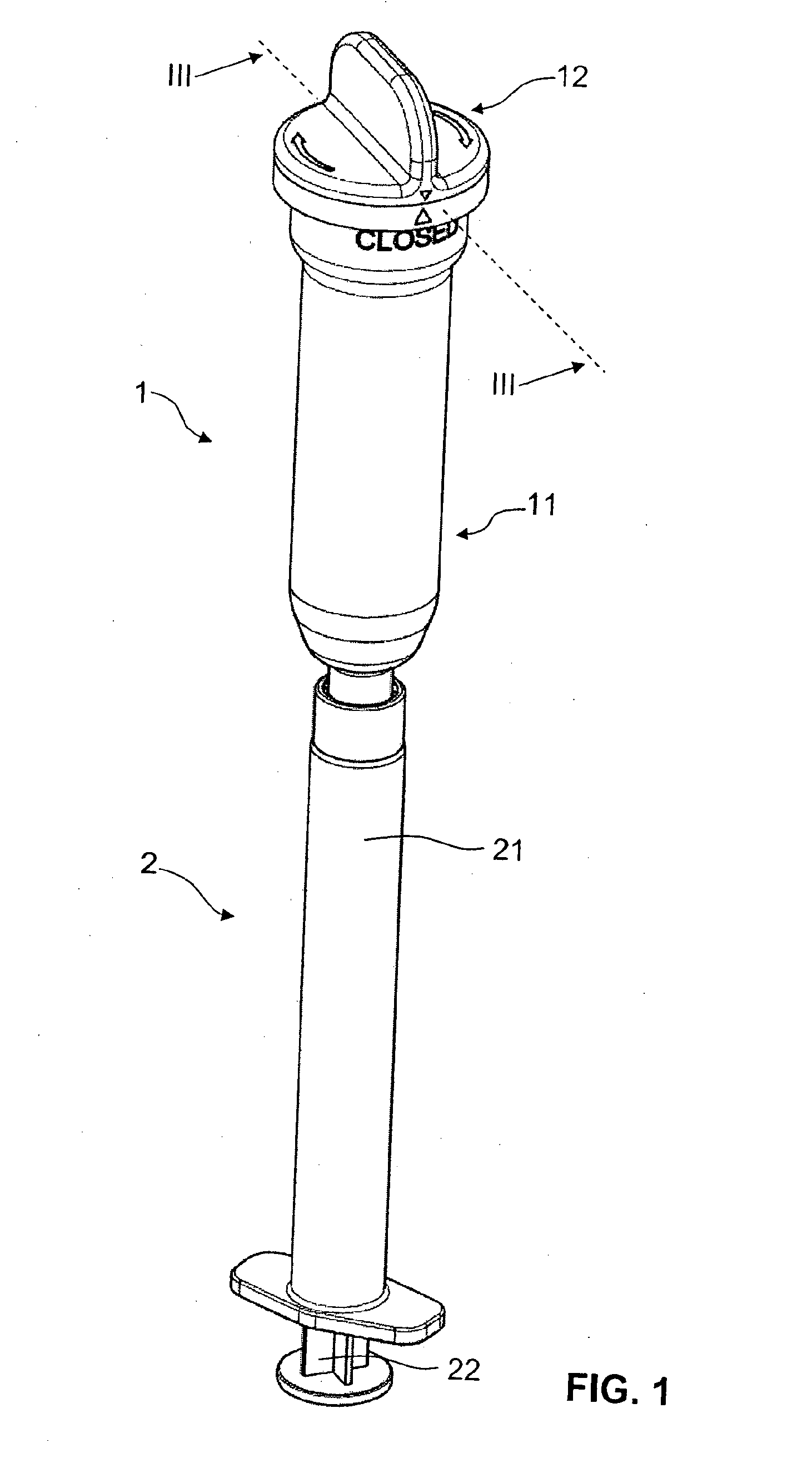

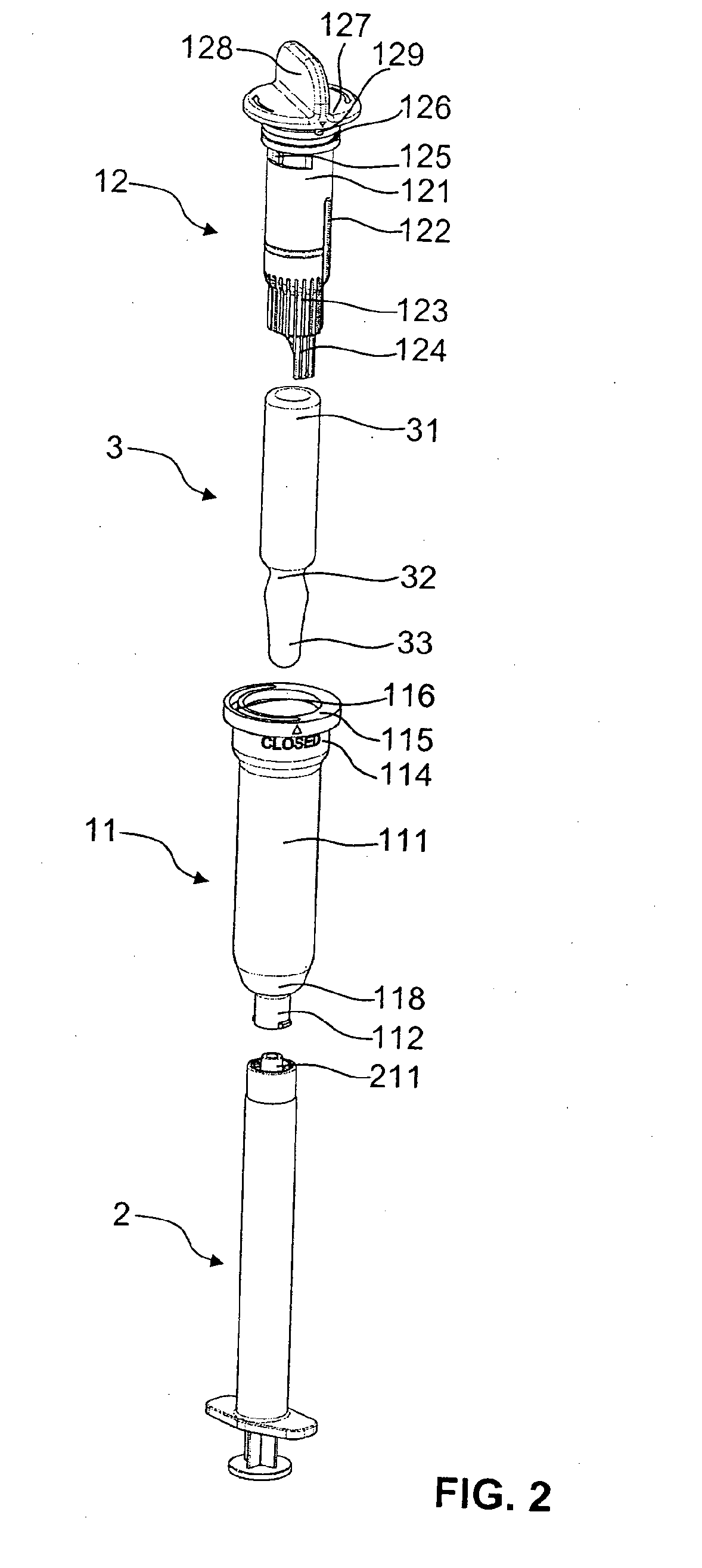

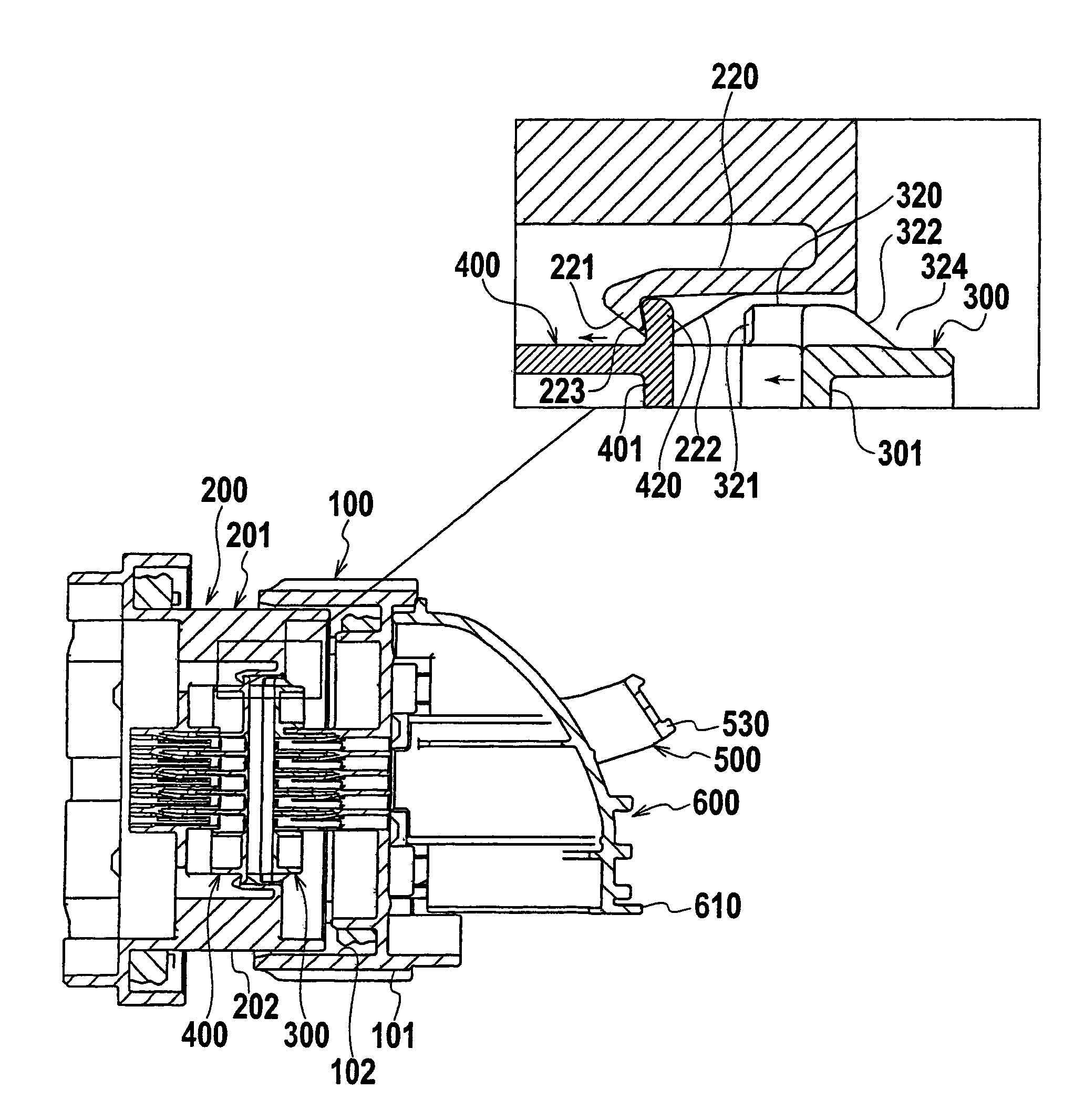

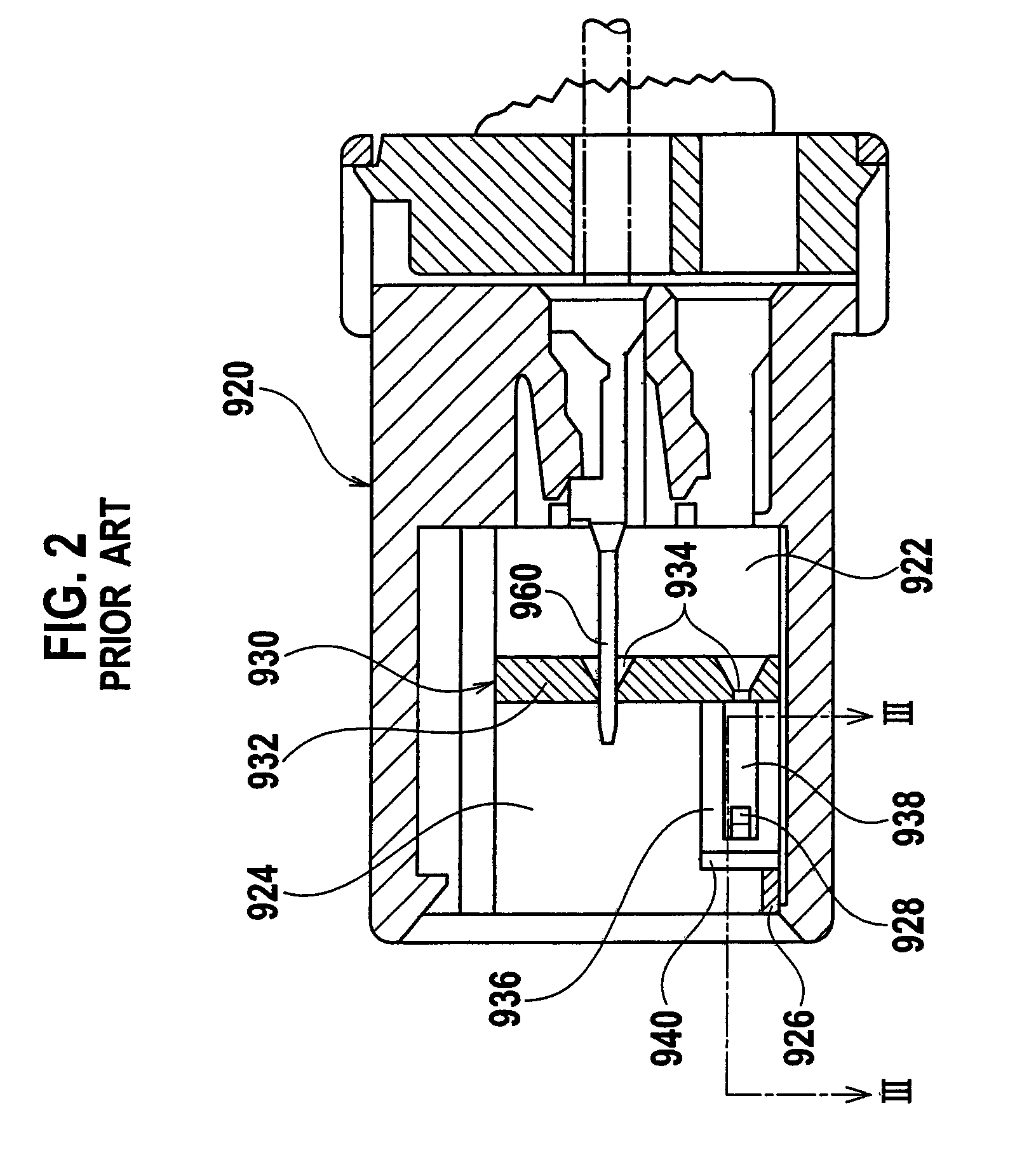

Device for opening an ampoule

InactiveUS8915413B2Easy to useCompact designOpening closed containersBottle/container closureEngineeringMechanical engineering

A device for opening an ampoule (3) comprises a hollow cylindrical housing (11) having an interior for accommodating the ampoule (3) and a rotary element (12) having a proximal section (121), to which a break-off section (124) extending in a distal direction is connected to. The break-off section (124) is flexible in a radial direction and is pivotably connected to the proximal section (121) in the radial direction. The rotary element (12) is rotatable relative to the housing (11) about the longitudinal axis. The housing (11) has a first guiding structure (119) for pressing the break-off section (124) inward during a rotation of the rotary element so that the break-off section (124) exerts a radial shear force on an ampoule head (33) of an ampoule (3) to break the ampoule head (33) off of the ampoule body (31).

Owner:MEDMIX SYST

Device for opening an ampoule

InactiveUS20130032623A1Increase flexibilityIncrease external forceOpening closed containersBottle/container closureEngineeringMechanical engineering

The invention relates to a device for opening an ampoule (3), said device comprising a substantially hollow cylindrical housing (11) having an interior for accommodating an ampoule (3). The device also comprises a rotary element (12) having a proximal section (121), to which a break-off section (124) extending in the distal direction is connected. The break-off section (124) is flexible in the radial direction and / or is pivotably connected to the proximal section (121) in the radial direction. The rotary element (12) can be rotated relative to the housing (11) about the longitudinal axis in an actuating direction from an initial position to an intermediate position. In the area of the side wall (111), the housing (11) has a first guiding structure (119), which is designed in such a way that the first guiding structure presses the break-off section (124) inward during a rotation from the initial position to the intermediate position so that the break-off section (124) exerts a radial shear force on the ampoule head (33) of an ampoule (3) accommodated in the interior in order to break the ampoule head (33) off of the ampoule body (31).

Owner:MEDMIX SYST

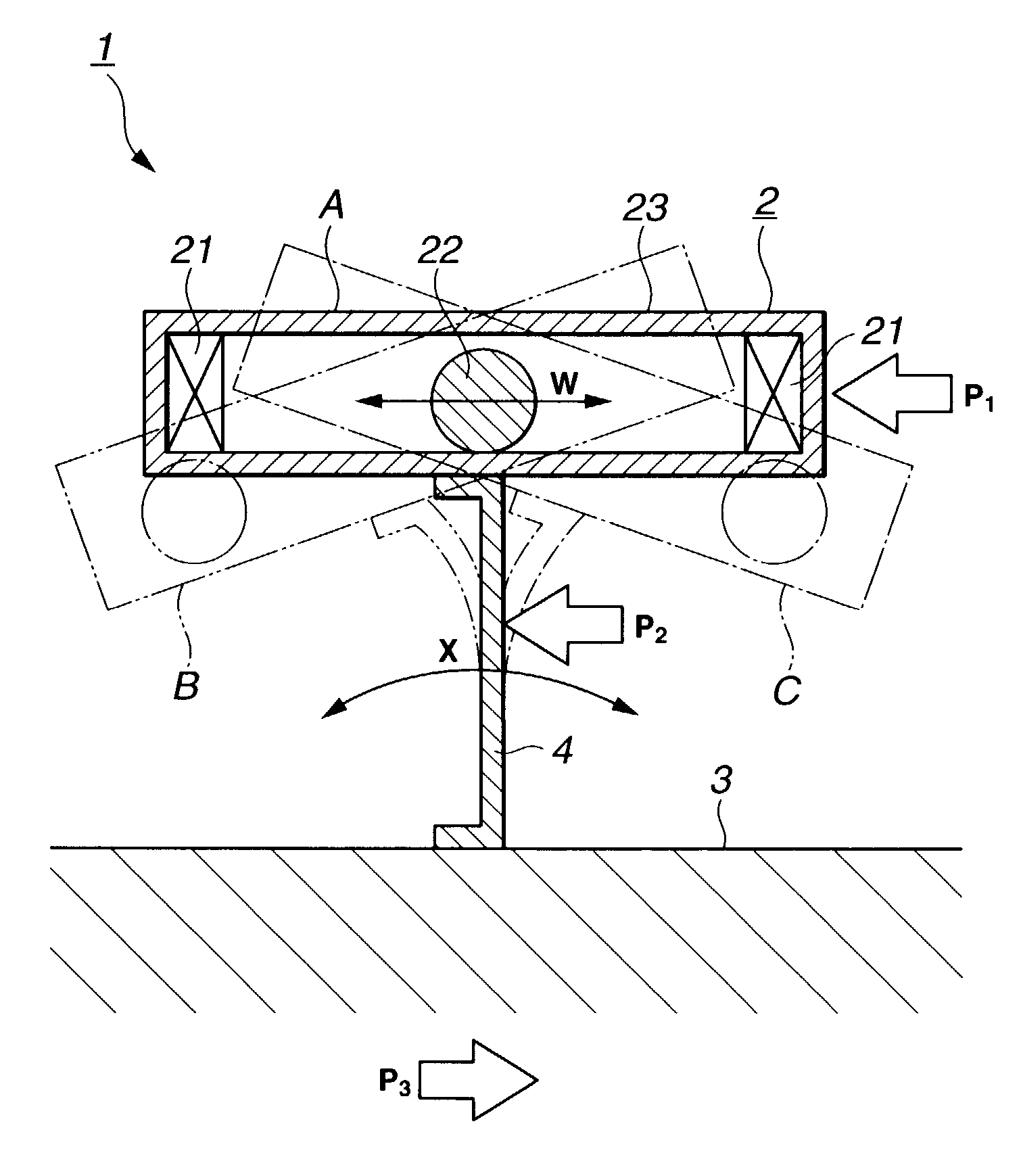

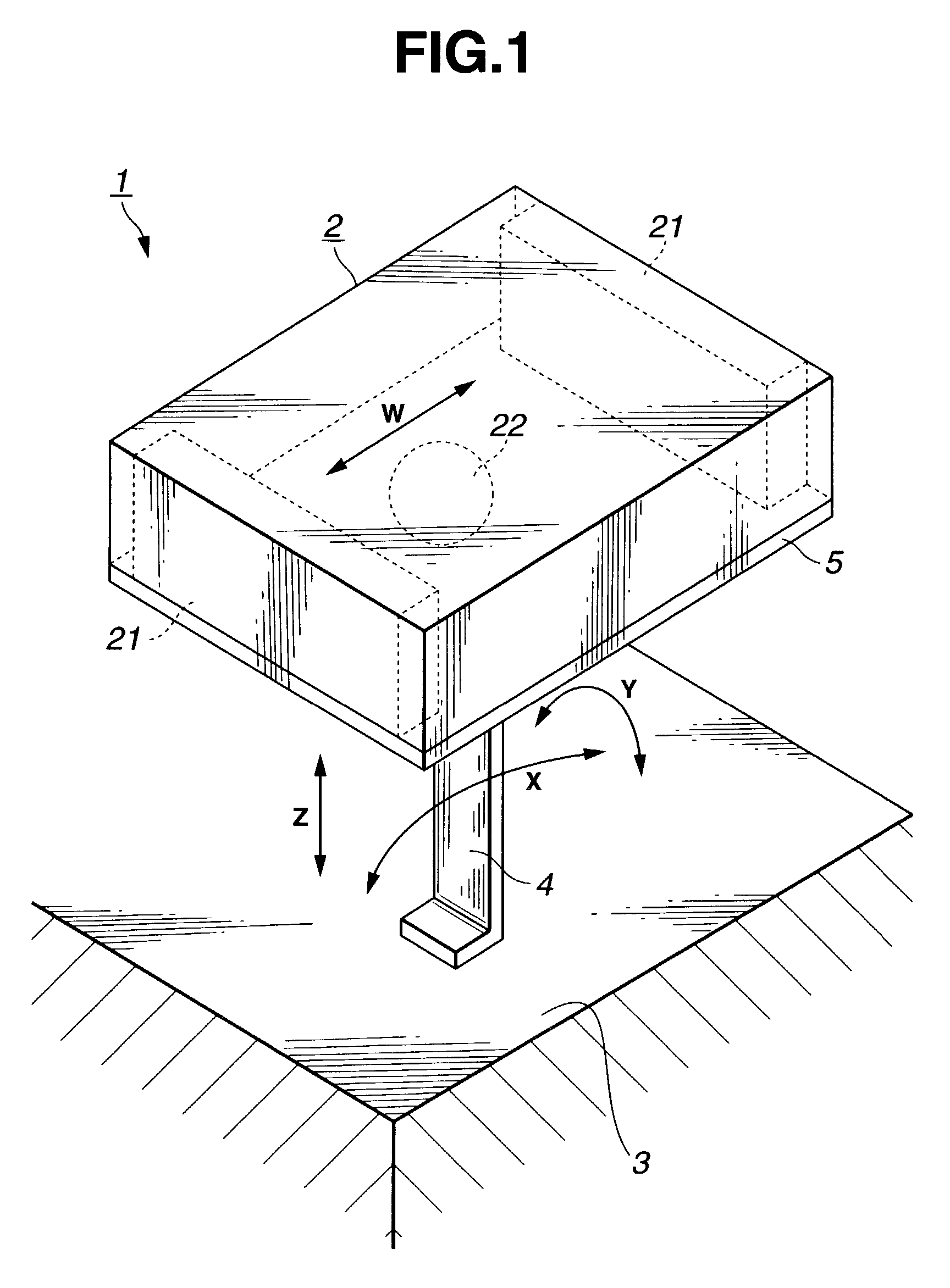

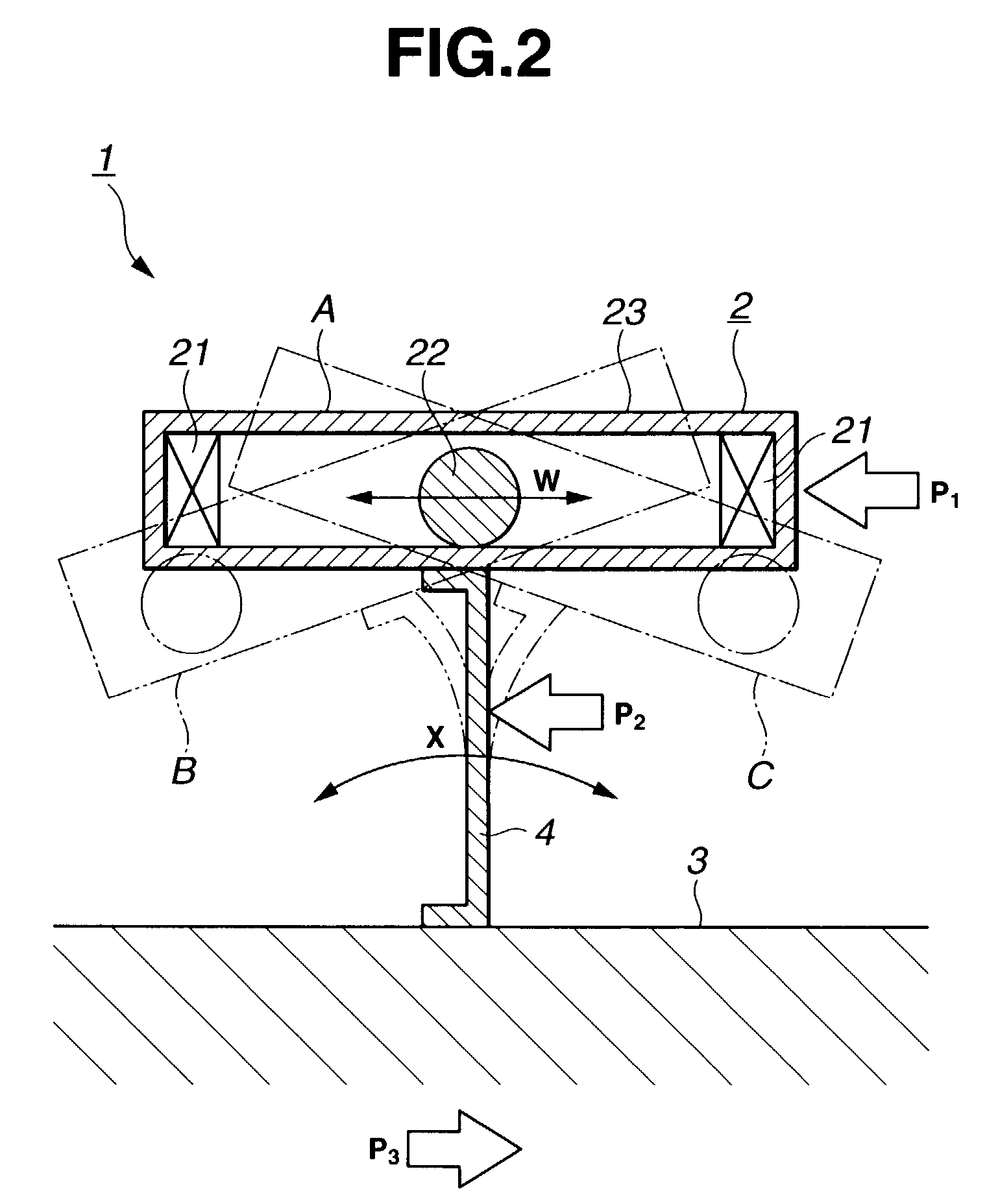

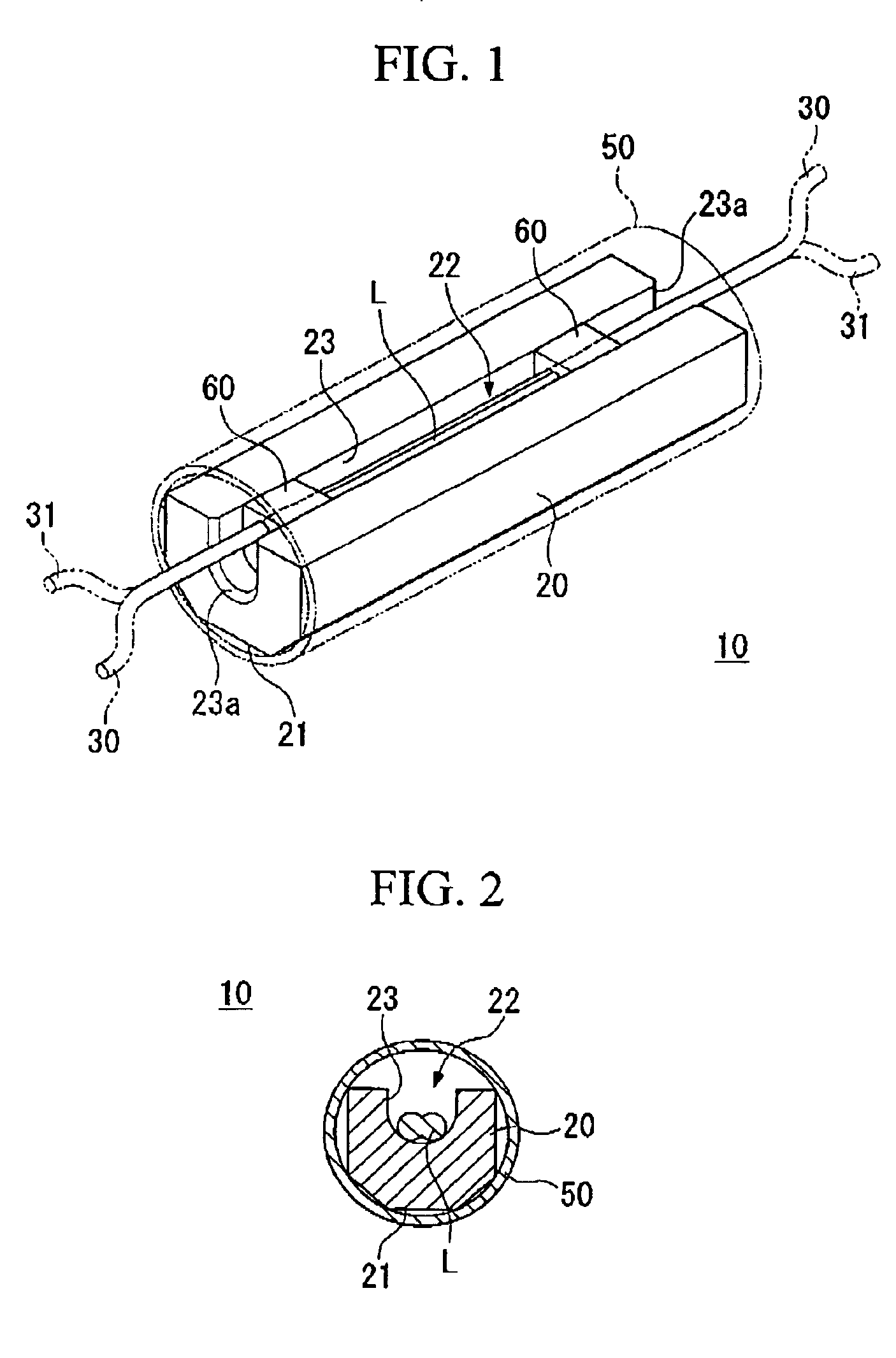

Optical fiber coupler reinforcing member and optical fiber coupler

An optical fiber coupler reinforcing member comprises an approximately rectangular member formed by a hard material, and has a flat surface along the longitudinal direction thereof. In addition, the shape thereof in cross-section is a hexagonal shape which inscribes a cylindrical member. Furthermore, a recess having a U-shaped cross-section is formed in the longitudinal direction of the above-mentioned approximately rectangular member and houses coupling section. The coupling section housed within the recess is fixed at both ends of the recess by an adhesive or the like. In addition, both ends of the inner wall surface of the recess have been given bevel sections. As a result, the optical fiber coupler reinforcing member having high reliability at low cost, with which the strength with respect to external force is improved and with which processability and the assembly operations of the optical fiber coupler are easy, are provided.

Owner:YAMAHA CORP +1

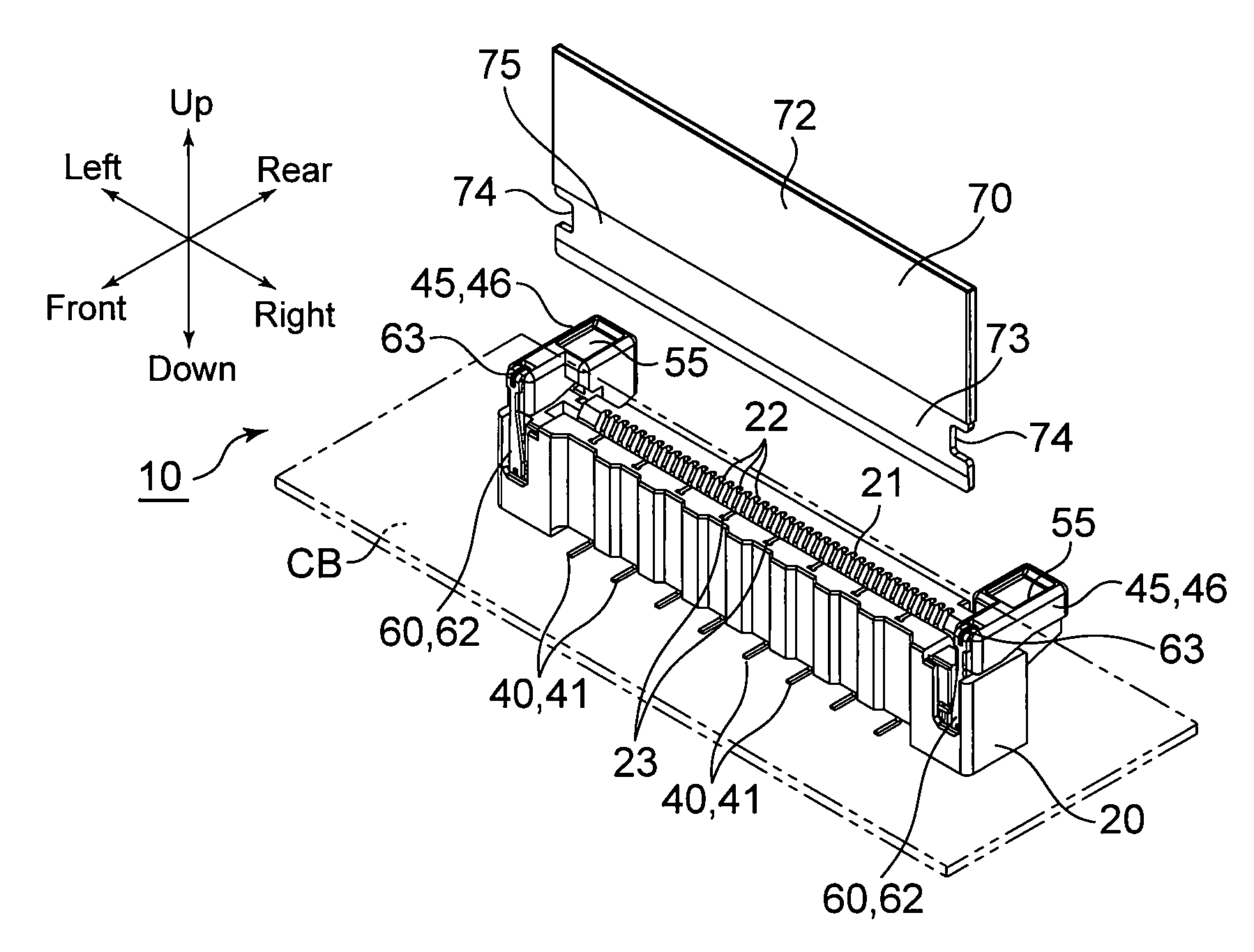

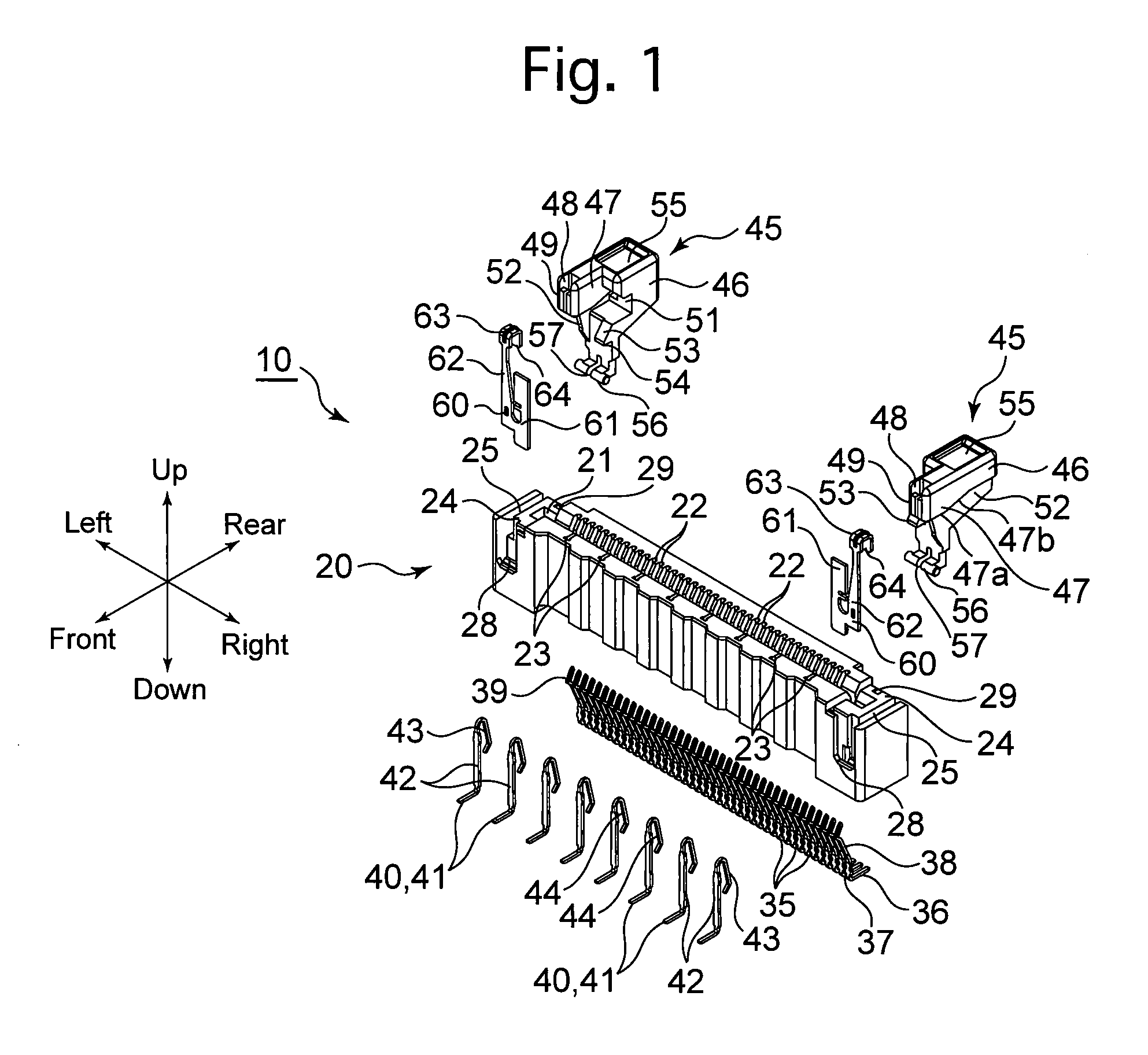

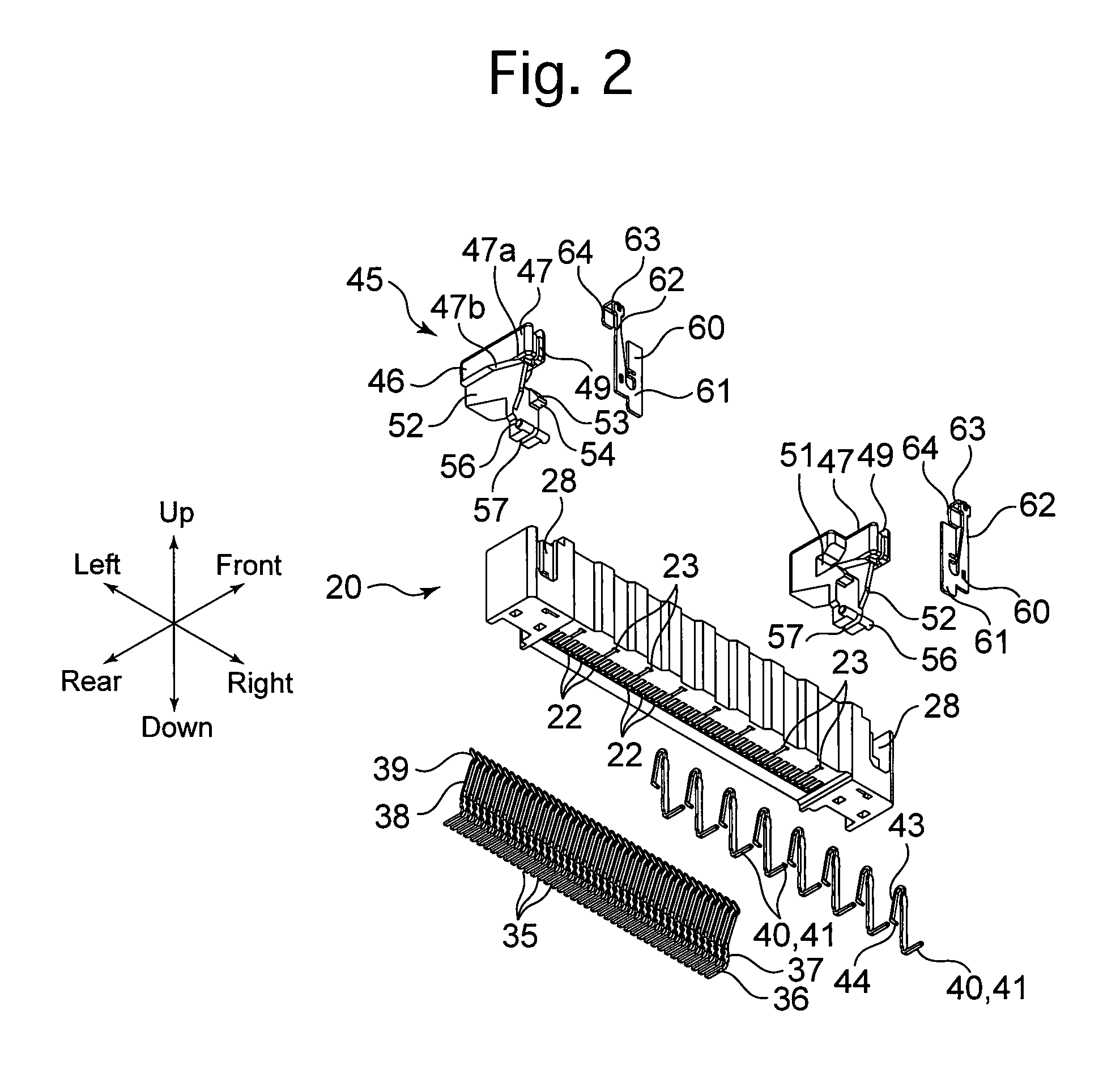

Cable connector

InactiveUS8845358B2Increase external forceIncrease the lengthCoupling device detailsElectrical and Electronics engineeringEngineering

A cable connector includes an insulator, signal contacts supported in the insulator, wherein the signal contacts come in contact with the cable when the cable is inserted into the insulator, a pair of lock members which are rotatable between a locked position and an unlocked position, and springs supported on the insulator, wherein the springs retain the locked position and allow rotation of the lock members to the unlocked position by elastic deformation of the springs. Each spring includes a base-plate portion supported on the insulator, an elastically deformable portion extending from the base-plate portion, an end-extending portion extending from an end of the elastically deformable portion, and an engaging portion which engages with an associated lock member to integrate the spring with the associated the lock member.

Owner:KYOCERA CORP

Gypsum hollow block and semi-dry production method of same

The invention proposes a gypsum hollow block, which is composed of the following raw materials in parts by weight: building gypsum powder: 80-90 parts, fly ash: 10-20 parts, water reducer: 0.2-0.5 parts, Coagulant: 0.6-0.8 parts, methyl cellulose: 0.1-0.2 parts, carboxymethyl cellulose: 0.2-0.3 parts, activator: 1-2 parts; wherein, the weight ratio of water to building gypsum powder is 0.3 -0.4:1, the water temperature is 5-25℃. In the semi-dry production method of the gypsum hollow block, the mixed powder and water mixture are added to a mixer for high-speed stirring at a stirring speed of 500-600r / min to obtain a semi-dry gypsum colloid, which is then uniformly distributed to Gypsum hollow block molding machine combined mold cavity, external pressure molding, and then hydraulically ejected from the mold cavity. The gypsum hollow block produced by the production method has a low water-to-paste ratio, and the free water of the gypsum block is very low after forming. After forming, the gypsum block can be sent to the construction site to directly build walls, saving storage yards and exempting from drying (natural and artificial drying).

Owner:ANHUI SENKE NEW MATERIAL

Lever type connector

InactiveUS7404722B2Avoid plastic deformationReduction of temporary connecting performance is preventedEngagement/disengagement of coupling partsVehicle connectorsEngineeringMechanical engineering

Owner:YAZAKI CORP

Cable connector

InactiveUS20130224986A1High lock retention abilityIncrease external forceCoupling device detailsElectrical and Electronics engineering

A cable connector includes an insulator, signal contacts supported in the insulator, wherein the signal contacts come in contact with the cable when the cable is inserted into the insulator, a pair of lock members which are rotatable between a locked position and an unlocked position, and springs supported on the insulator, wherein the springs retain the locked position and allow rotation of the lock members to the unlocked position by elastic deformation of the springs. Each spring includes a base-plate portion supported on the insulator, an elastically deformable portion extending from the base-plate portion, an end-extending portion extending from an end of the elastically deformable portion, and an engaging portion which engages with an associated lock member to integrate the spring with the associated the lock member.

Owner:KYOCERA CORP

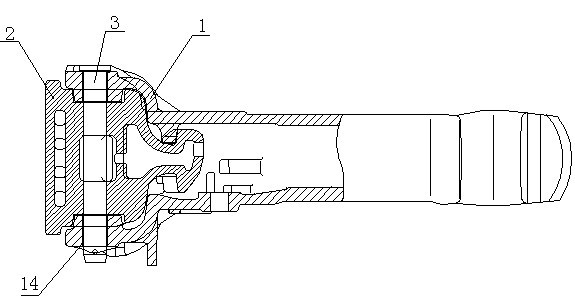

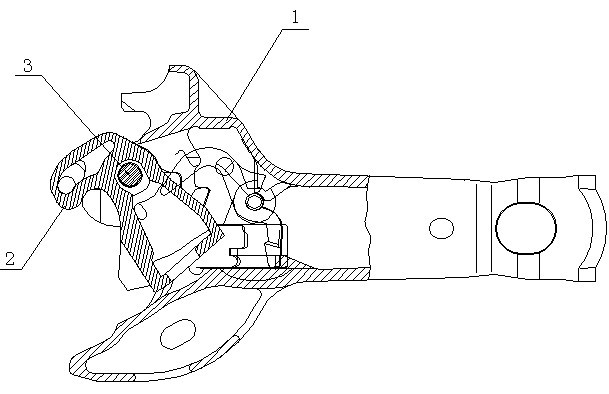

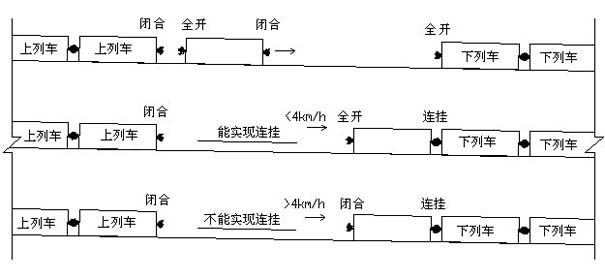

Vehicle coupler capable of preventing automatic locking

The invention discloses a vehicle coupler capable of preventing automatic locking, which comprises a coupler body, a coupler knuckle and a coupler knuckle pin. The coupler knuckle is articulated with the coupler body through the coupler knuckle pin arranged in a coupler knuckle pin hole of the coupler body, an elastic component is arranged in a cavity of the coupler knuckle, and the coupler knuckle pin and the coupler body are relatively fixed. Two plane sections are processed on the curved surface of the coupler knuckle pin, and a relatively protruding transition section is formed between the two plane sections. The head part of the elastic component is tightly attached to the plane sections after being bent toward the S face of the coupler knuckle, the tail part and the coupler knuckle are relatively fixed, and the folding point between the head part and the middle part of the elastic component is supported by a protrusion in the cavity of the coupler knuckle. An external force required for changing the vehicle coupler from the full open state to a locking state is effectively increased under the premise of not influencing the use performance of the traditional vehicle coupler assembly, the automatic locking phenomenon of coupler knuckle rotation caused by impact during coupling of a back-end vehicle coupler in vehicle rolling is greatly reduced, and thus, the efficiency of railway vehicle shunting work is increased.

Owner:CRRC MEISHAN

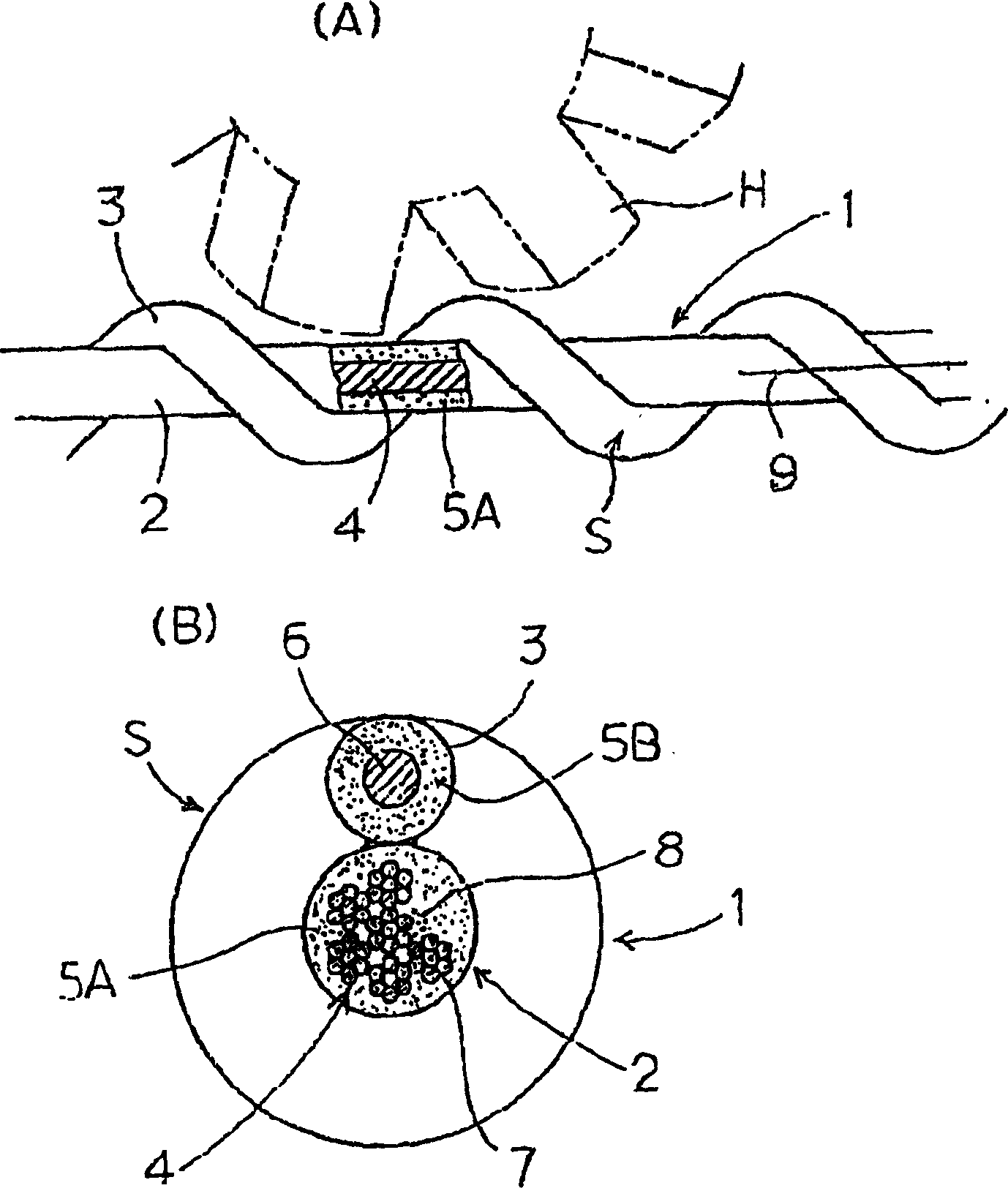

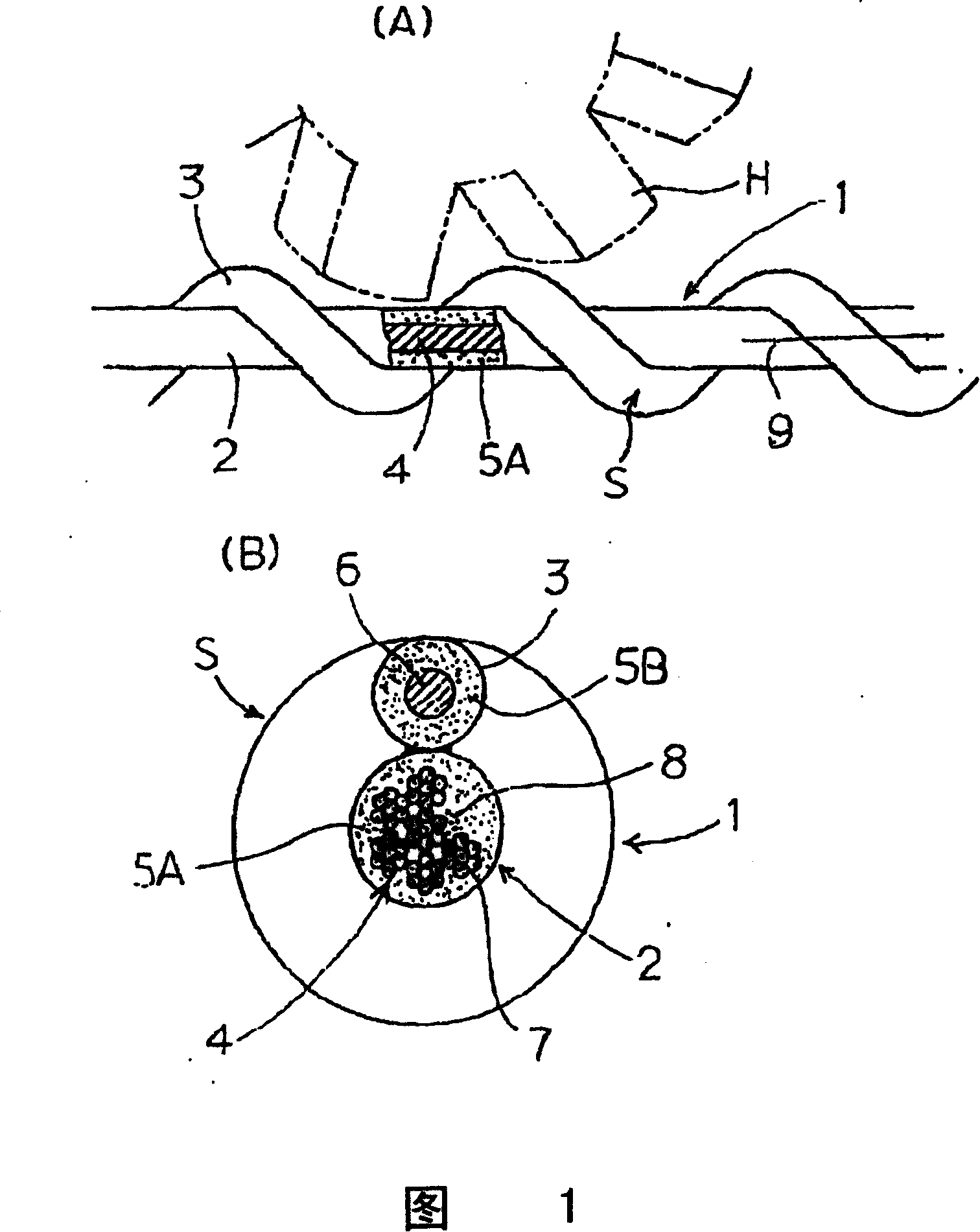

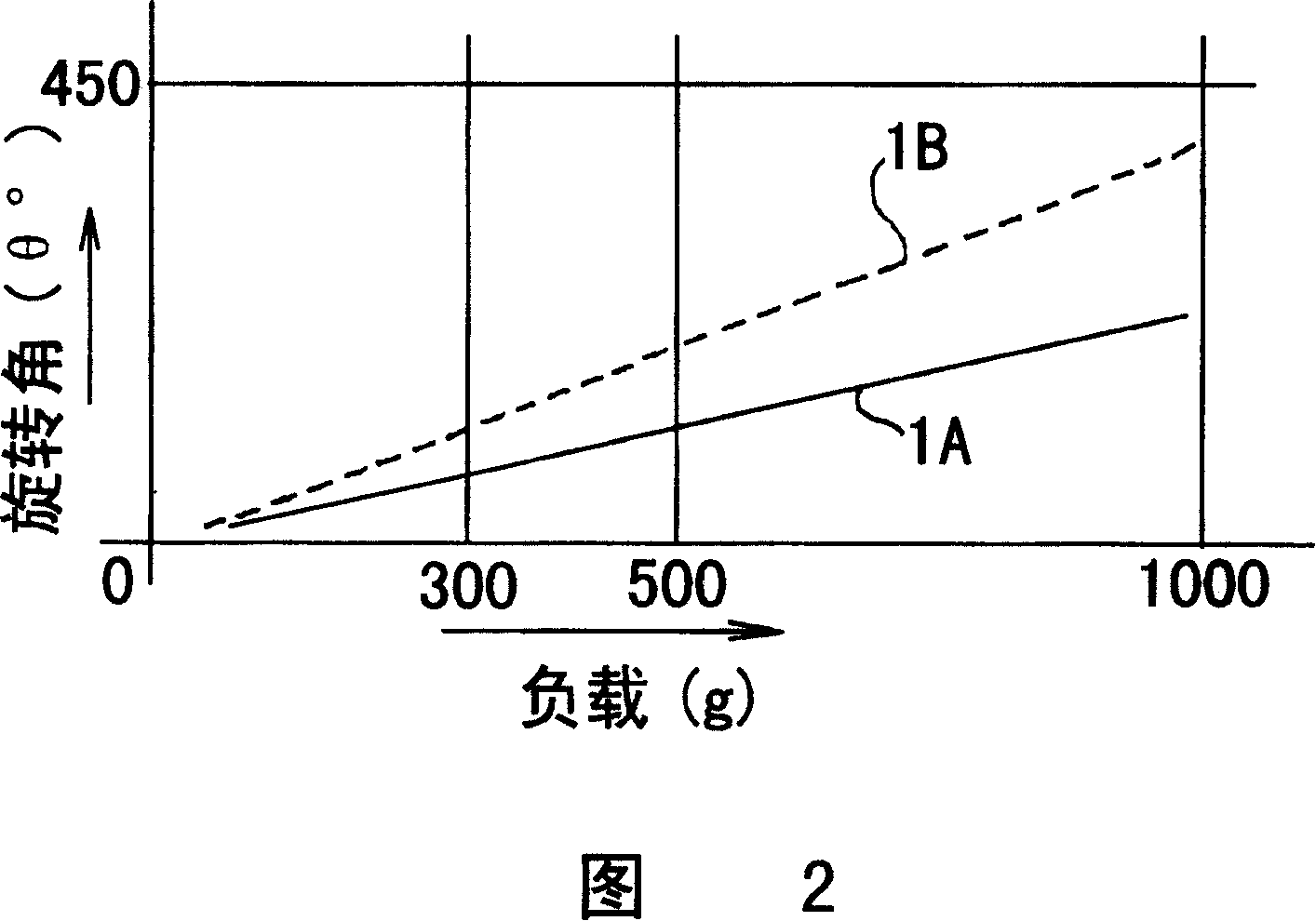

Rope with spiral tooth

InactiveCN1530490AGood adhesionIncrease coefficient of frictionRopes and cables for vehicles/pulleyPortable liftingMetal fiberFrictional coefficient

A cable with spiral teeth includes a core rope (4) having a recess groove (8) spirally continuous in the longitudinal direction, a resin covering layer (5a) installed on the outer periphery of the body (2) of the cable, a spiral strip (S) having a winding filament (3) and being installed with a resin covering layer (5B) on a linear core material, thereby increasing the relative frictional coefficient and the engagement power between the rope (4) and the resin covering layer (5A), the core material and the resin covering layer (5B), and the resin covering layers (5A)(5B), particularly increasing the accuracy of operation. The cable with spiral teeth is characterized in that the resin covering layer (5A) of the rope body (2) is consisted of a resin containing a metal fiber or a resin containing a metal oxide fiber, the resin covering layer (5B) of the filament (3) is consisted of a thermoplastic resin or elasticized resin, the rope body (2) is made of a material same as the core material contained in the resin covering layer (5A), and any of the resin covering layers (5A)(5B) of the rope body (2) and the filament (3) is consisted of a same resin material.

Owner:ASAHI INTECC CO LTD

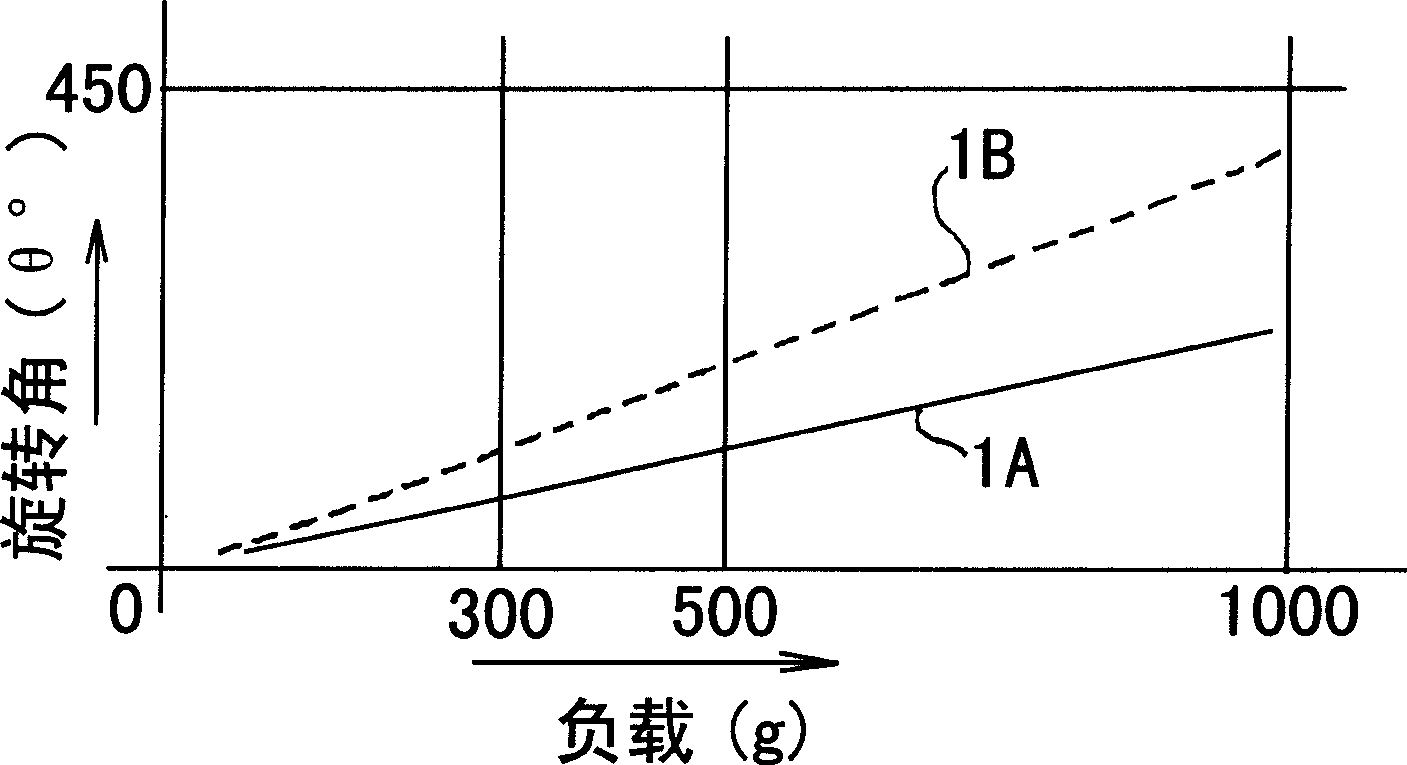

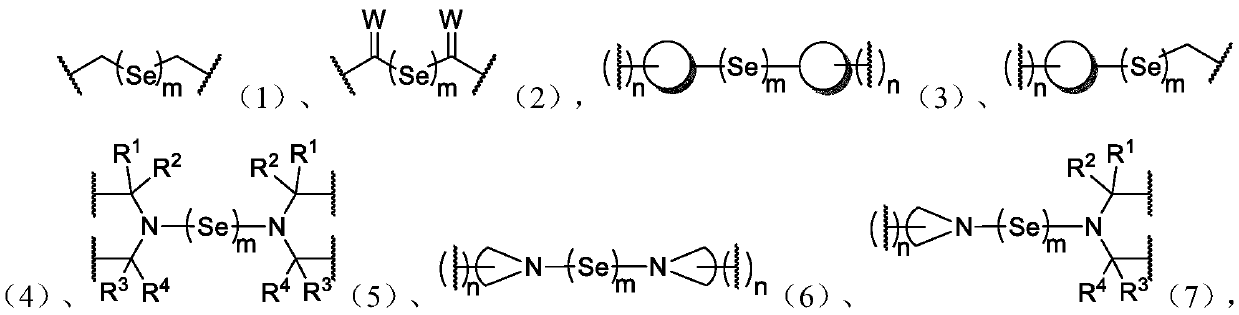

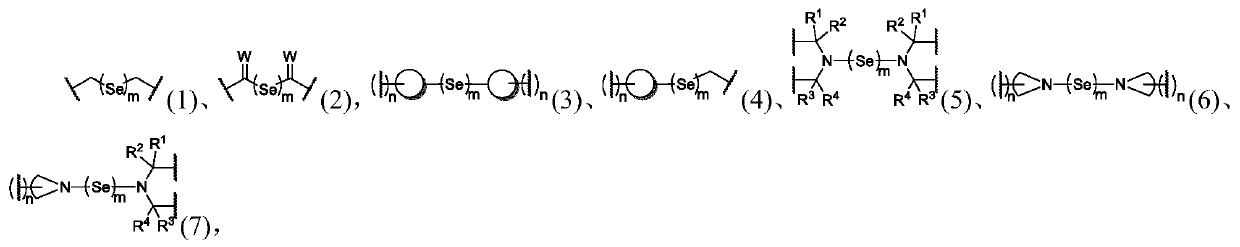

Energy absorption method based on hybrid dynamic polymer

InactiveCN111378154AAchieving dynamic reversibilityImprove dynamic performancePolymer scienceEnergy absorption

The invention discloses an energy absorption method based on a hybrid dynamic polymer. According to the method, the hybrid dynamic polymer containing a dynamic double-selenium bond and optional supramolecular hydrogen-bond interaction is used as an energy absorption material for energy absorption. The dynamic polymer combines respective advantages of a dynamic covalent bond and an optional supramolecular hydrogen bond; the dynamic covalent bond endows the polymer with certain strength and stability; and with the supramolecular hydrogen-bond interaction and strong dynamic reversibility of the dynamic covalent bond under certain conditions, the dynamic polymer has energy absorption characteristics such as energy dissipation and dispersion. The dynamic polymer can be applied to body protection in sports and daily life, military police body protection, explosion prevention, airborne landing and airdrop protection, automobile collision prevention, impact resistance protection of electronicand electrical products and the like.

Owner:翁秋梅

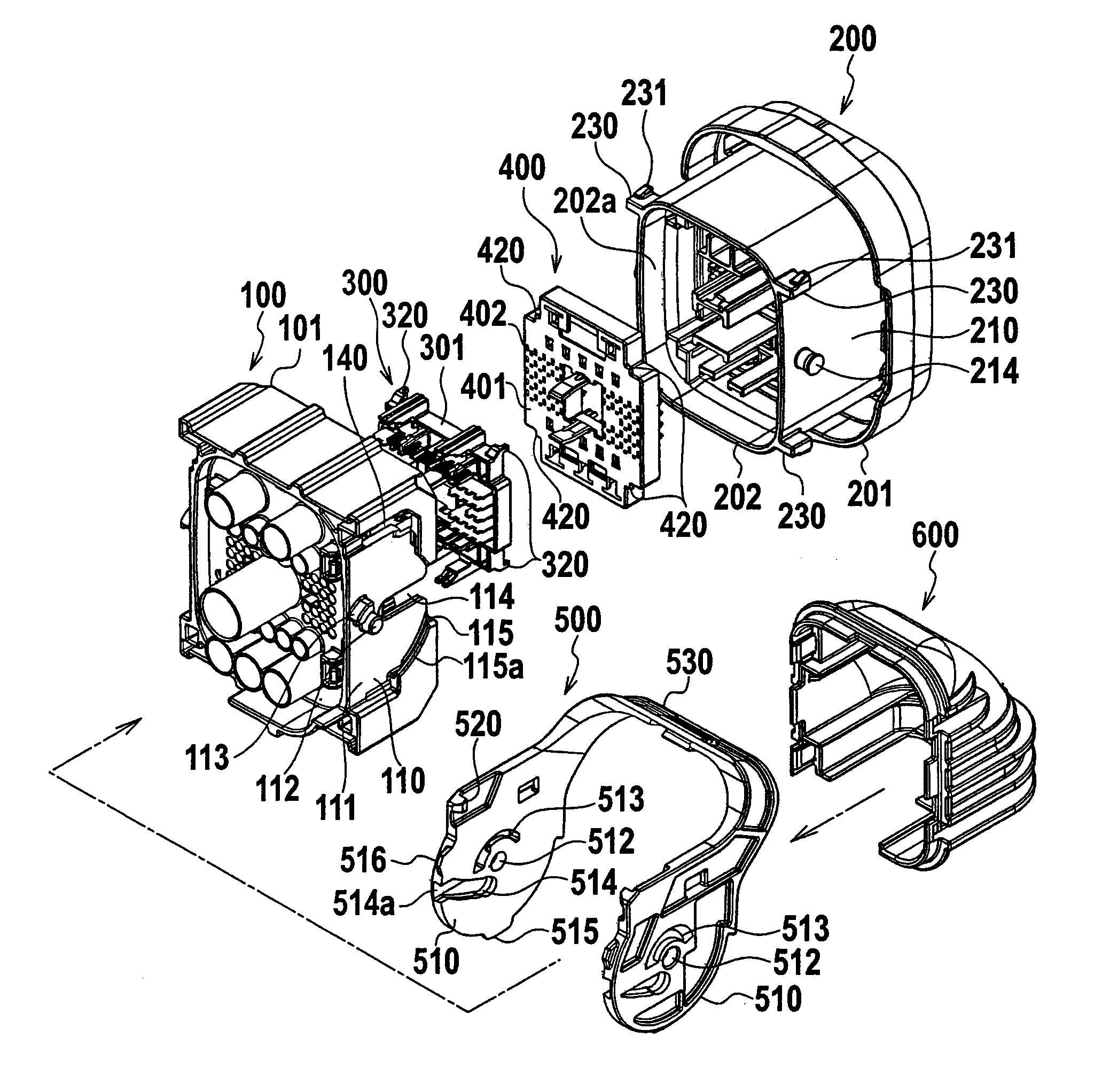

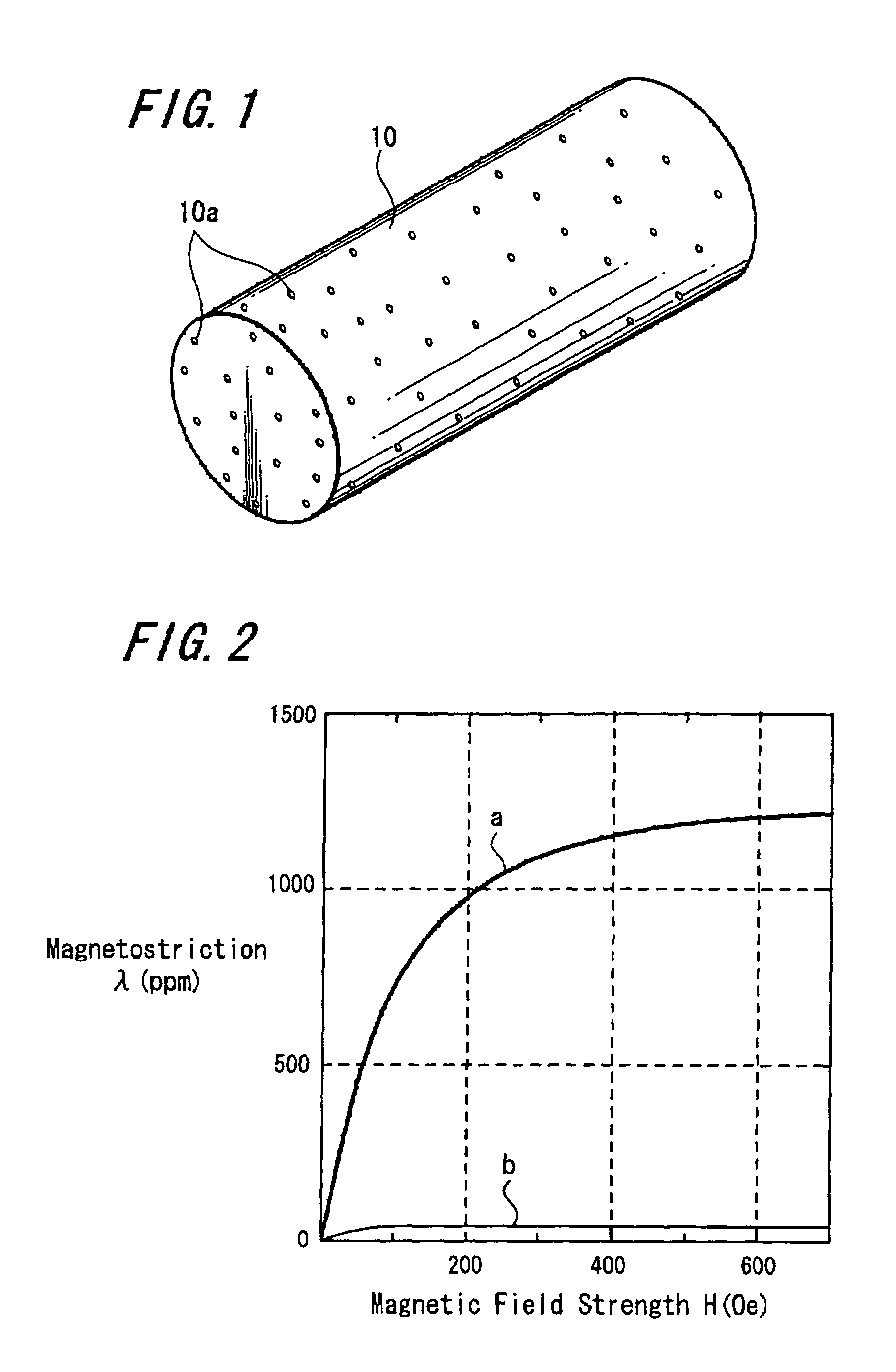

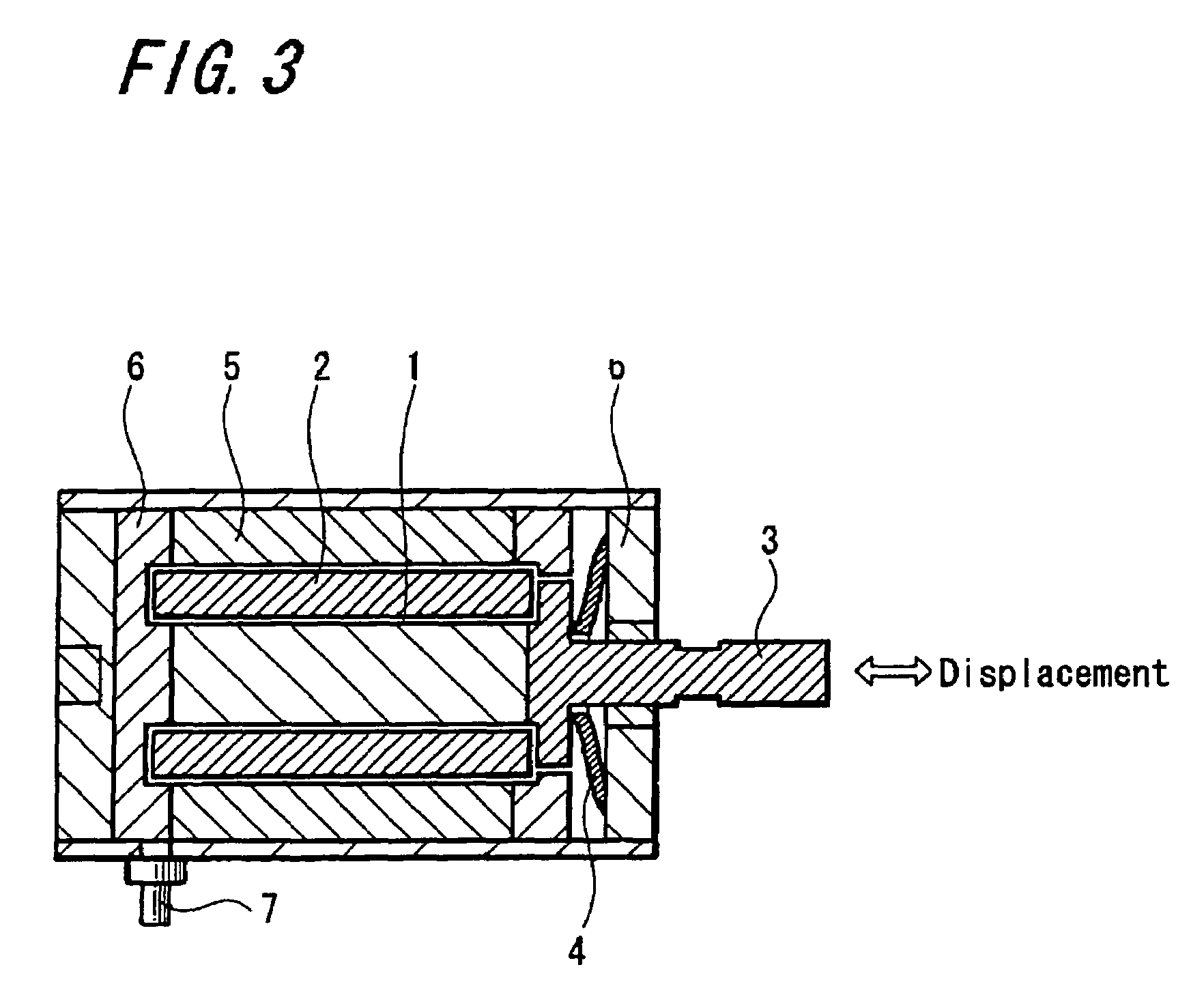

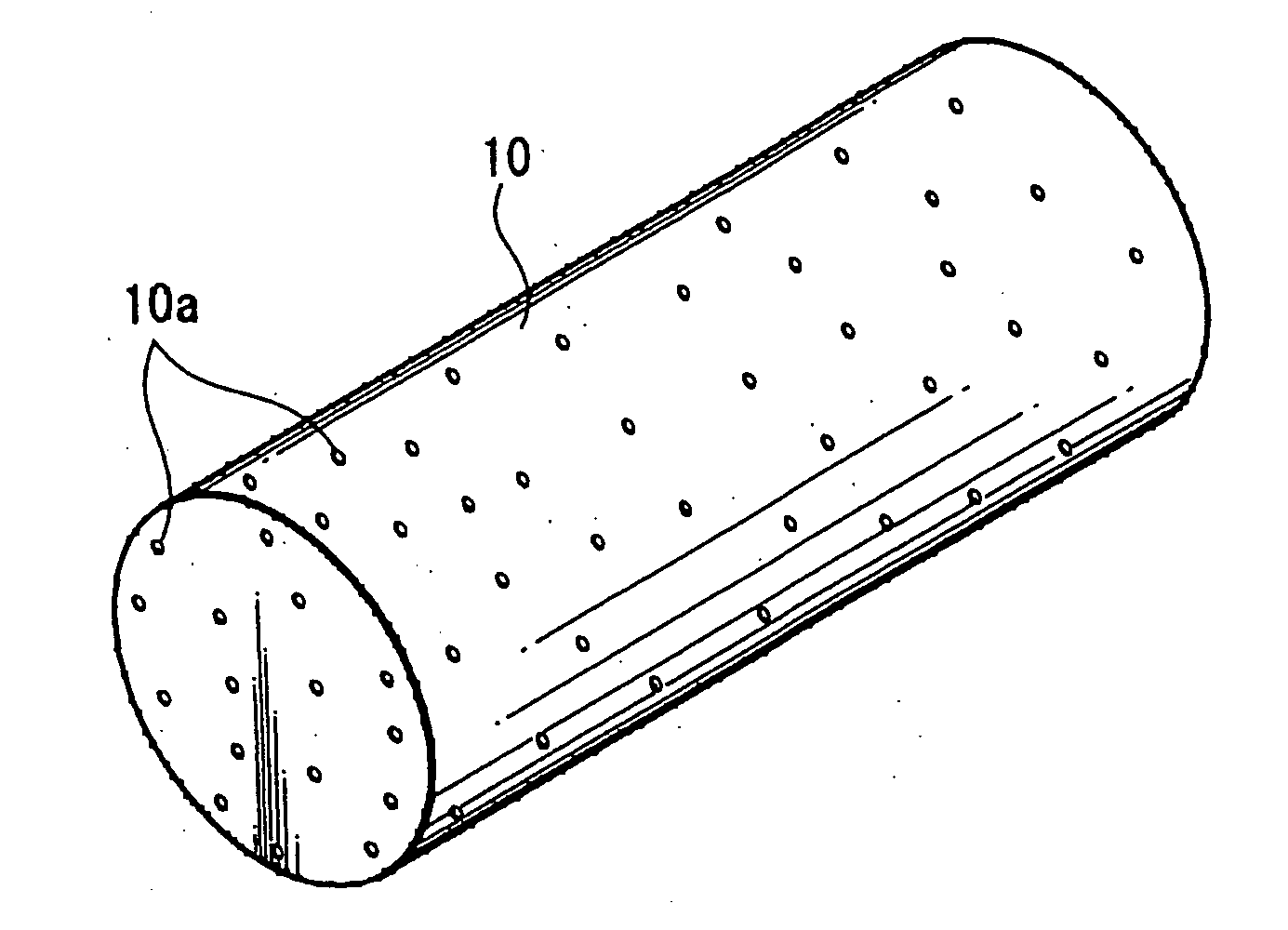

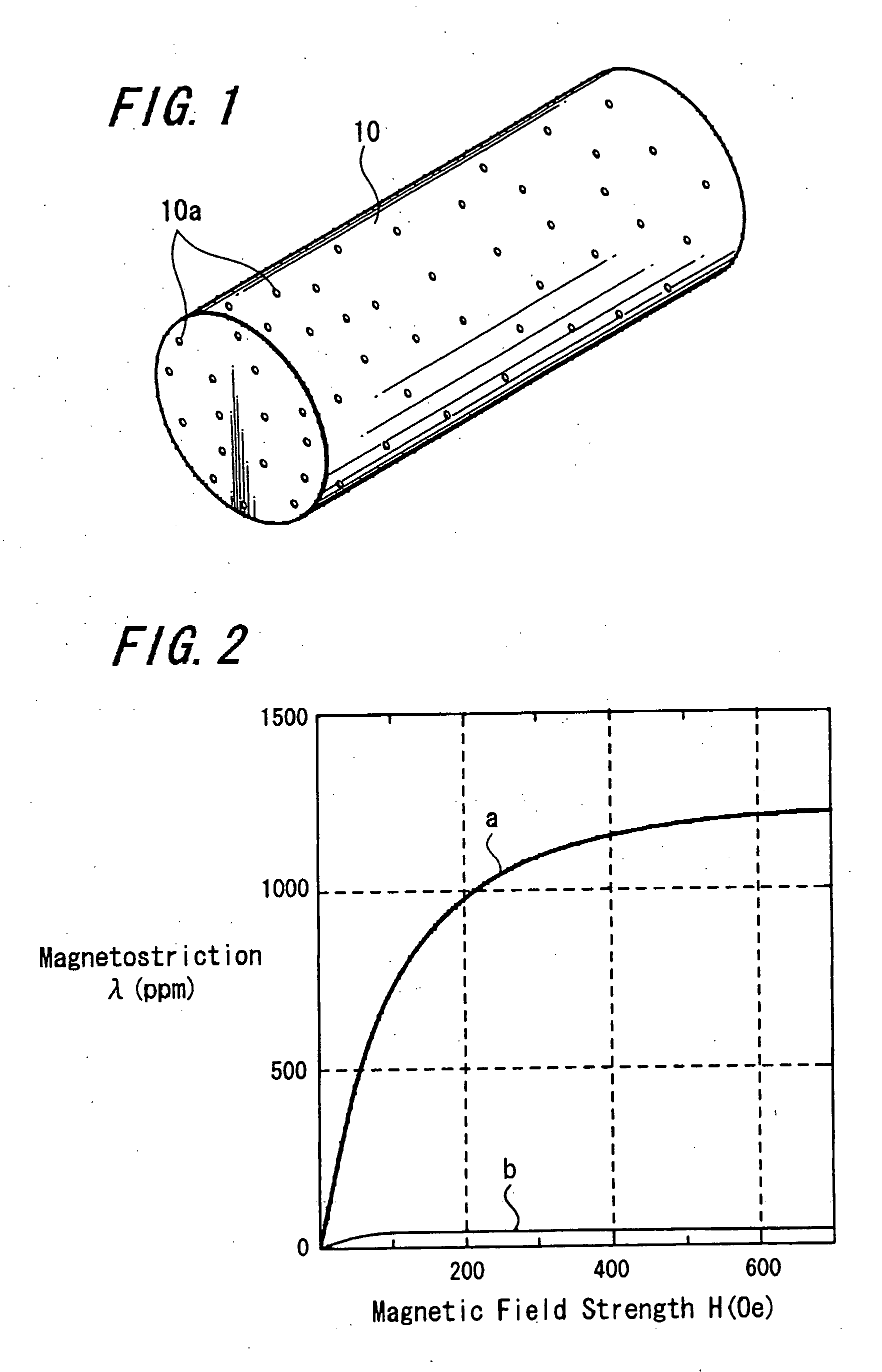

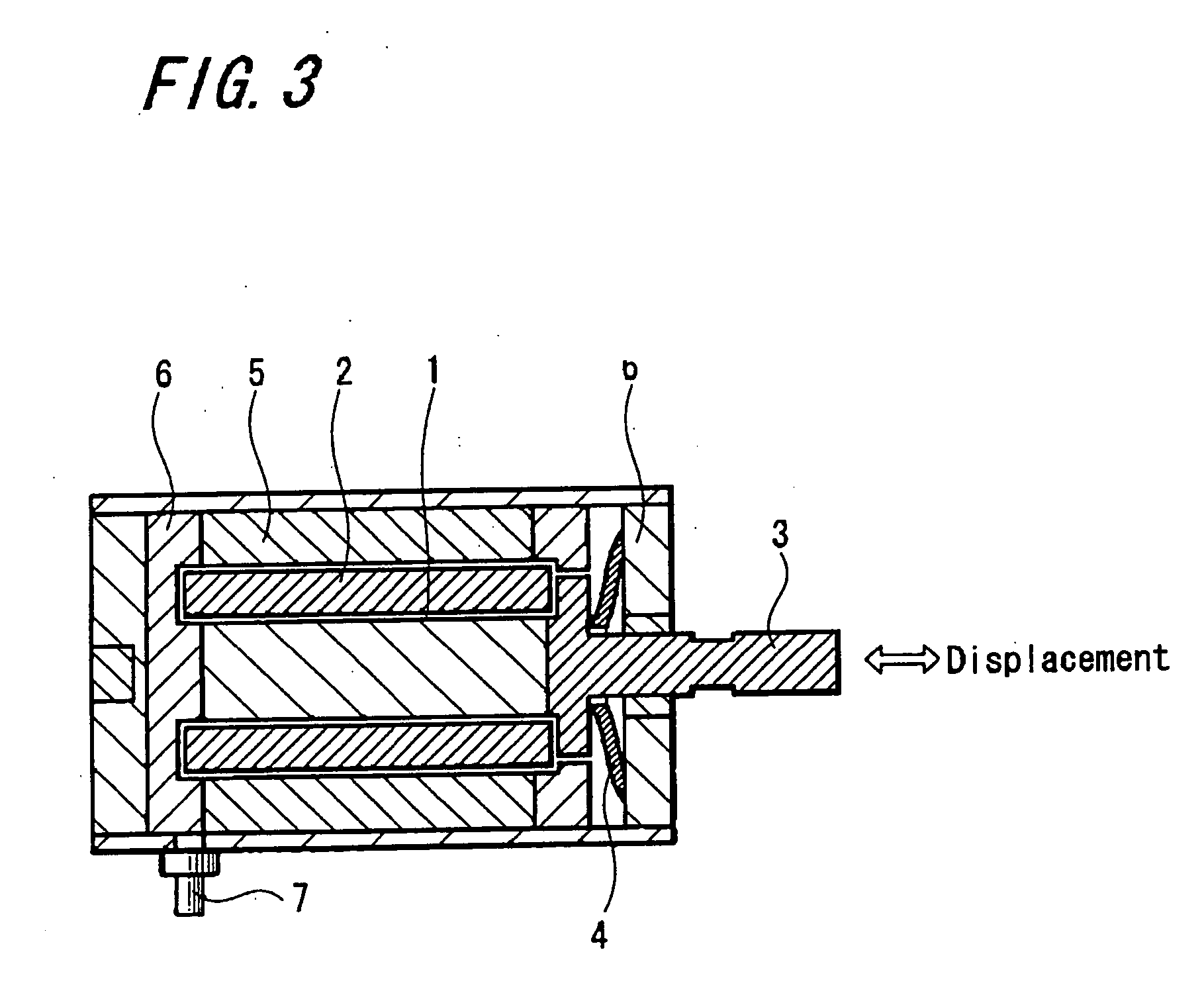

Magnetostriction device

InactiveUS7488369B2Increase external forceImprove permeabilityPiezoelectric/electrostriction/magnetostriction machinesMagnetsEpoxyAcrylic resin

A magnetostriction device is made such that an impregnated composition material, such as phenol resin, a resin in which an inorganic material such as silica is dispersed into a phenol resin, an epoxy based resin, or an acrylic resin is impregnated and caked into holes of a magnetostrictive sintered material manufactured by a powder metallurgy method. This magnetostriction device has improved mechanical strength against external force.

Owner:SONY CORP

Rope with spiral tooth

InactiveCN100343443CIncrease external forceRopes and cables for vehicles/pulleyPortable liftingFrictional coefficientEngineering

A cable with spiral teeth includes a core rope (4) having a recess groove (8) spirally continuous in the longitudinal direction, a resin covering layer (5a) installed on the outer periphery of the body (2) of the cable, a spiral strip (S) having a winding filament (3) and being installed with a resin covering layer (5B) on a linear core material, thereby increasing the relative frictional coefficient and the engagement power between the rope (4) and the resin covering layer (5A), the core material and the resin covering layer (5B), and the resin covering layers (5A)(5B), particularly increasing the accuracy of operation. The cable with spiral teeth is characterized in that the resin covering layer (5A) of the rope body (2) is consisted of a resin containing a metal fiber or a resin containing a metal oxide fiber, the resin covering layer (5B) of the filament (3) is consisted of a thermoplastic resin or elasticized resin, the rope body (2) is made of a material same as the core material contained in the resin covering layer (5A), and any of the resin covering layers (5A)(5B) of the rope body (2) and the filament (3) is consisted of a same resin material.

Owner:ASAHI INTECC CO LTD

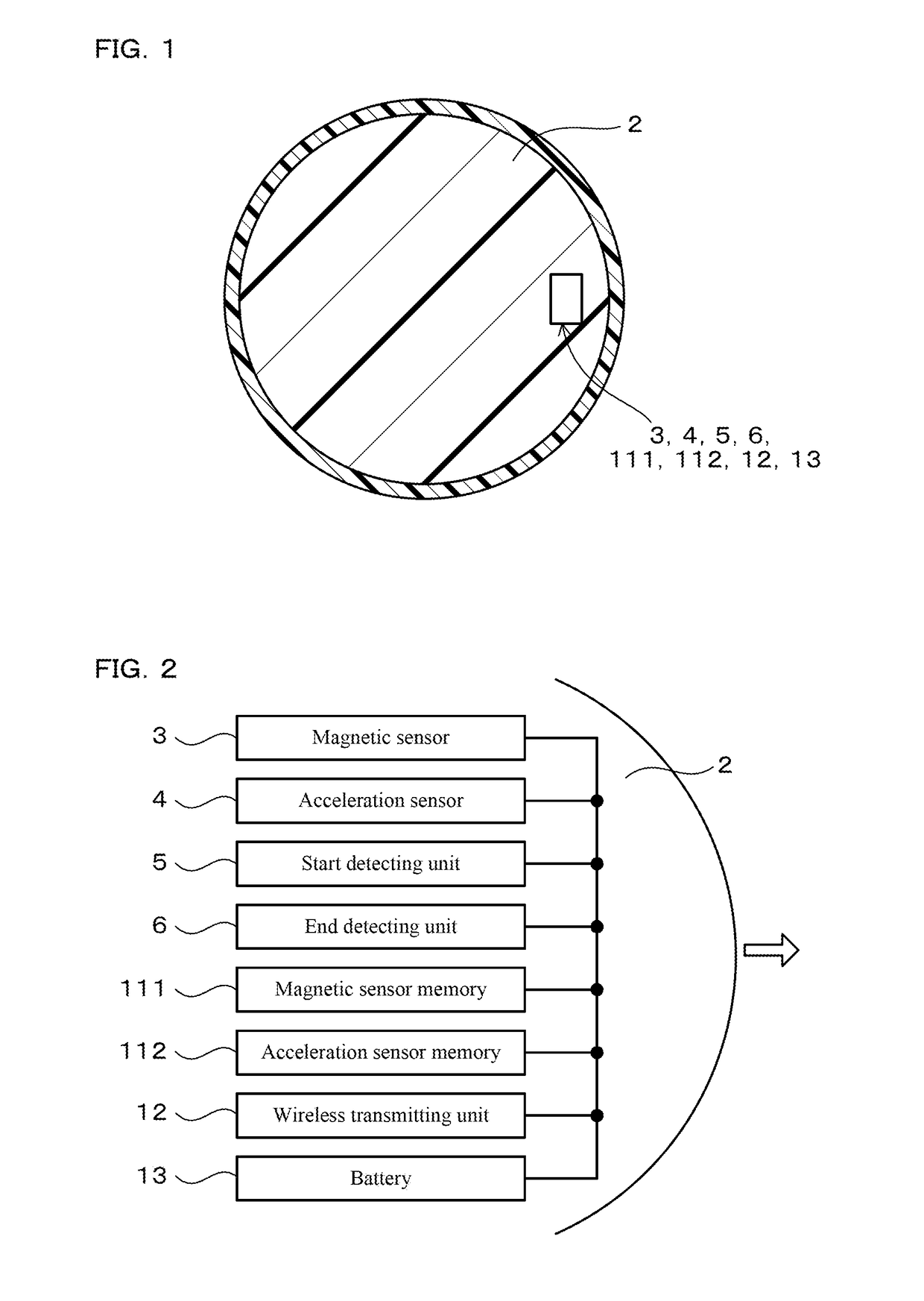

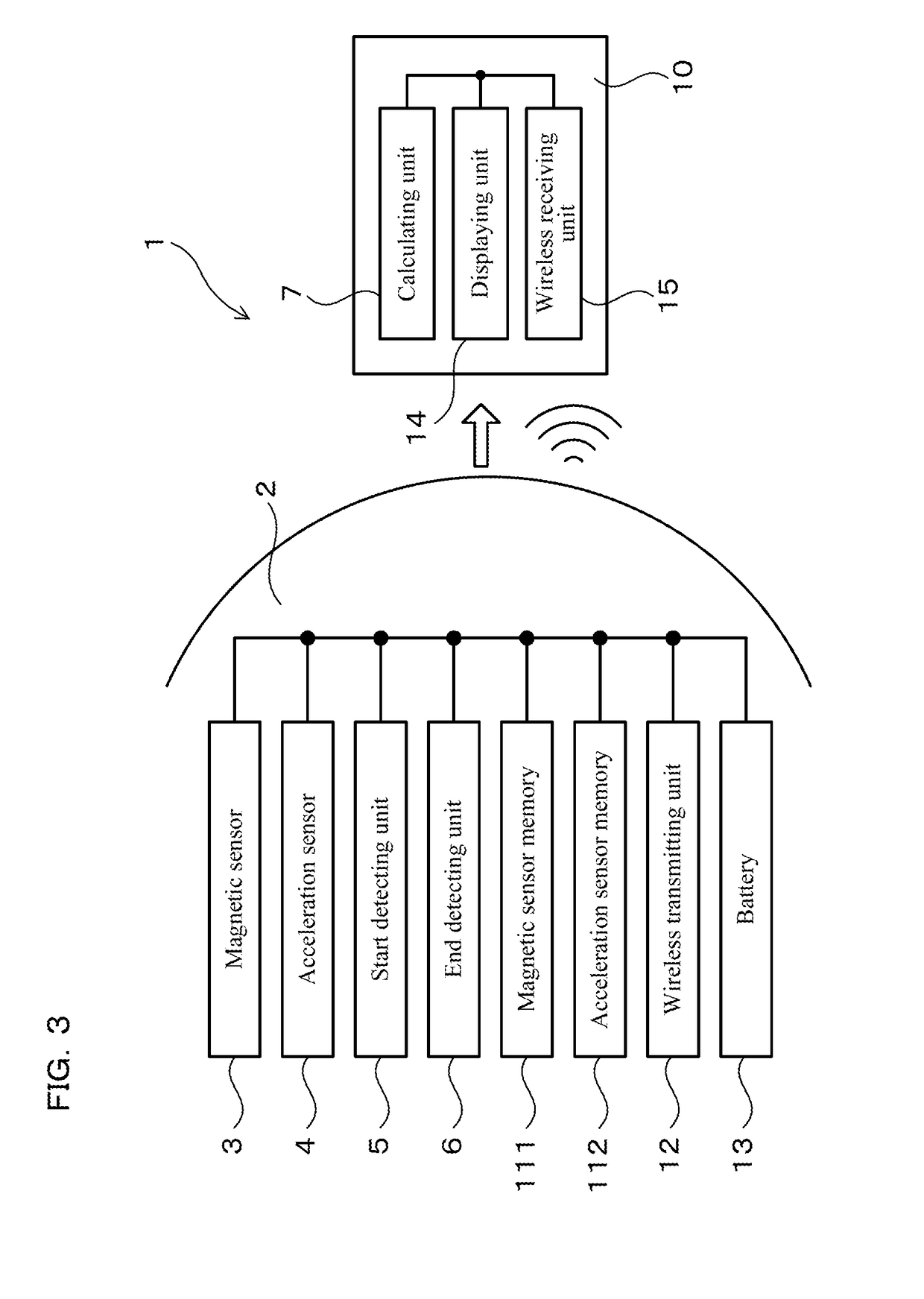

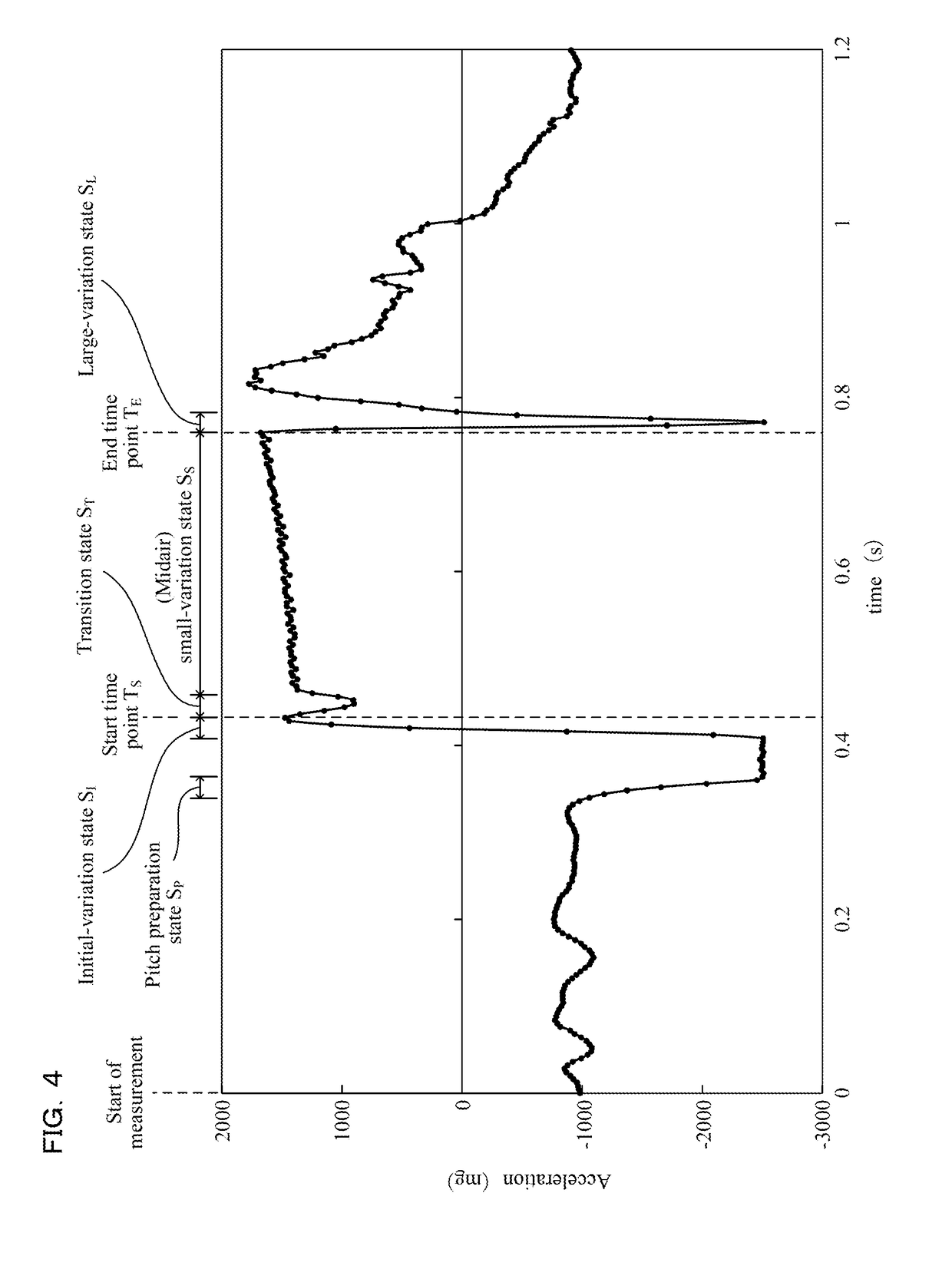

Rotation speed measuring system

ActiveUS10184992B2Automatic detectionIncrease changeAcceleration measurement using interia forcesMagnetic field measurement using galvano-magnetic devicesRotation velocityClassical mechanics

A rotation speed measuring system includes a magnetic sensor, an acceleration sensor, an end detecting unit, and a calculating unit. The magnetic sensor measures earth magnetism in at least one axis direction. The acceleration sensor measures acceleration in at least one axis direction. The end detecting unit detects a time point of a switch at which an acceleration variation is switched to a large-variation state after a small-variation state, wherein the small-variation state corresponds to a state in which the acceleration variation is equal to or below a predetermined first threshold value and the large-variation state corresponds to a state in which the acceleration variation is equal to or above a predetermined second threshold value. The calculating unit calculates the rotation speed of the ball moving in midair by analyzing a frequency of measurement data on the earth magnetism acquired by the magnetic sensor until the end time point.

Owner:AICHI STEEL

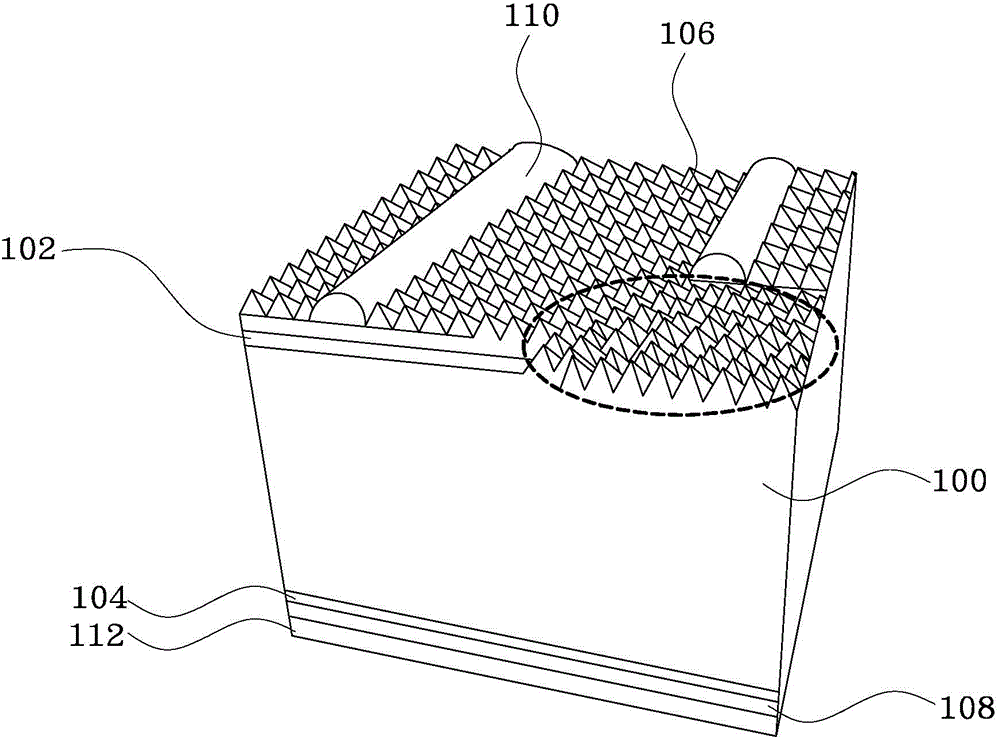

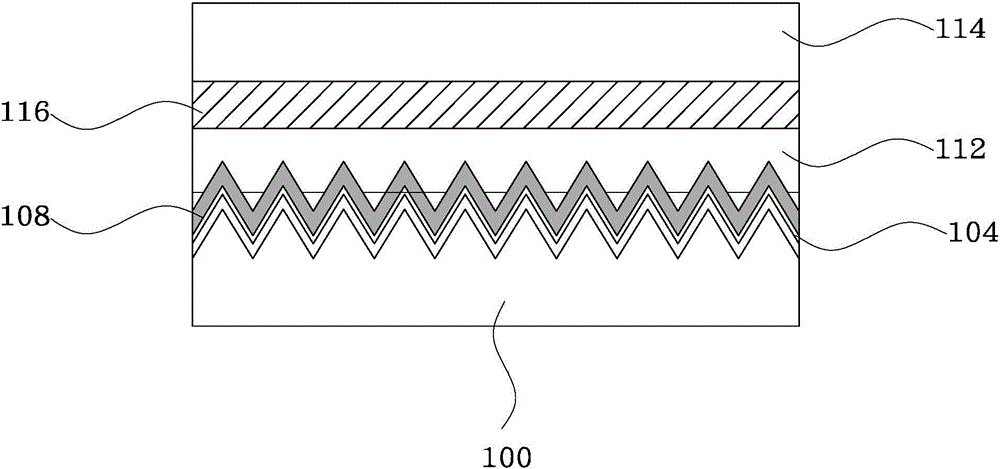

Silicon heterojunction solar cell structure and manufacturing method thereof

InactiveCN104638039AIncrease ribbon tensionDoes not affect energy conversion efficiencyFinal product manufacturePhotovoltaic energy generationSilver oxideConductive oxide

The invention provides a silicon heterojunction solar cell structure and a manufacturing method thereof. The structure comprises n-type crystalline silicon, a p-type hydrogenated amorphous silicon layer, an n-type hydrogenated amorphous silicon layer, a first TCO (Transparent Conductive Oxide) layer, a second TCO layer, an amorphous TCO layer, a silver colloid layer and a buffer thin film layer, wherein both the front face and the back face of the n-type crystalline silicon are passivated by using hydrogenated amorphous silicon; the first TCO layer is positioned on the upper side of the p-type hydrogenated amorphous silicon layer; the second TCO layer is positioned on the lower side of the n-type hydrogenated amorphous silicon layer; the amorphous TCO layer is formed on a surface of the second TCO layer; the silver colloid layer is grid-shaped; the buffer thin film layer is formed on a surface of the amorphous TCO layer through sputtering. Compared with the prior art, the structure and the method have the advantages that the amorphous TCO layer is additionally arranged between the second TCO layer and the buffer thin film layer on one side of a back electrode, and silver oxide is formed by using the amorphous TCO layer and the sputtered Ag thin film, so that sputtered Ag and the amorphous TCO layer can react chemically to form an oxygen-silver bond, and further the welding strip tension during series welding of a module is improved.

Owner:AU OPTRONICS CORP

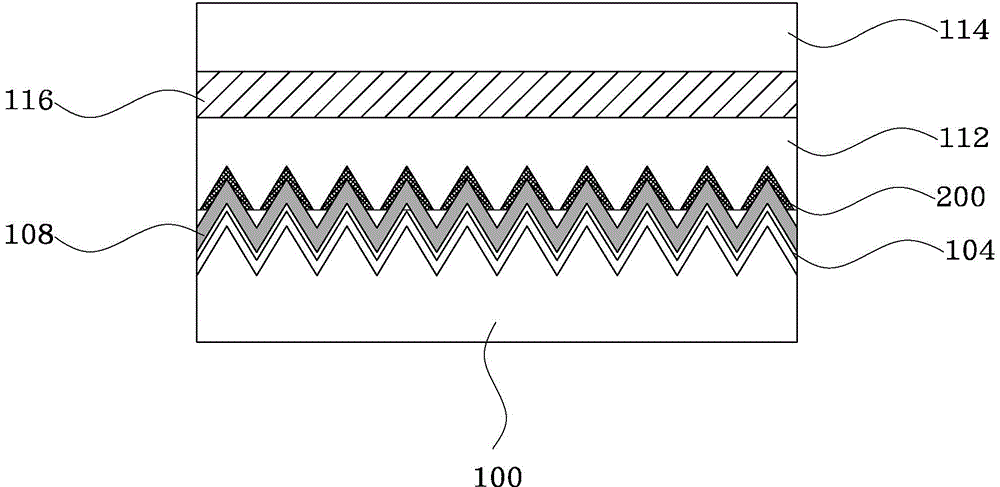

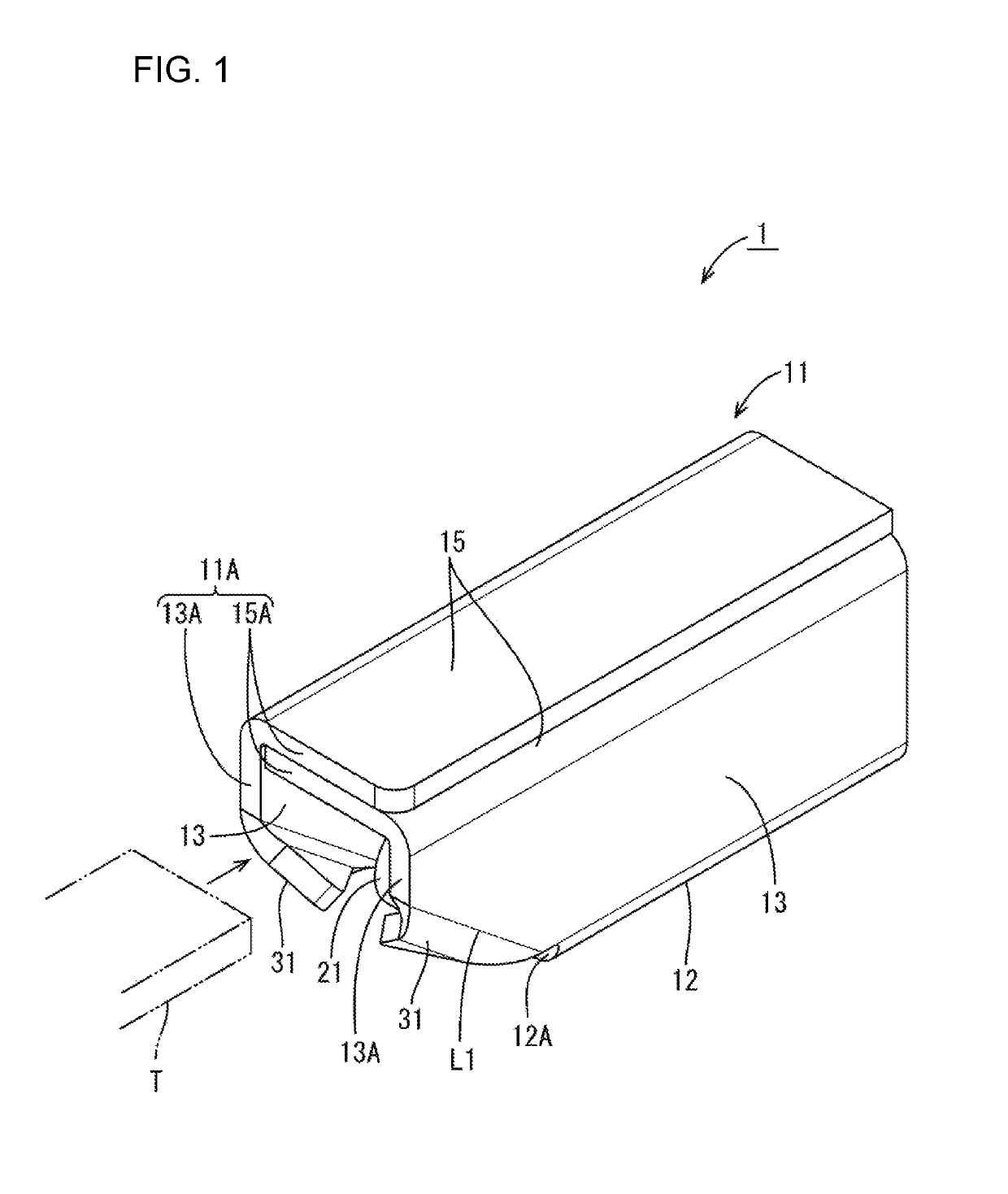

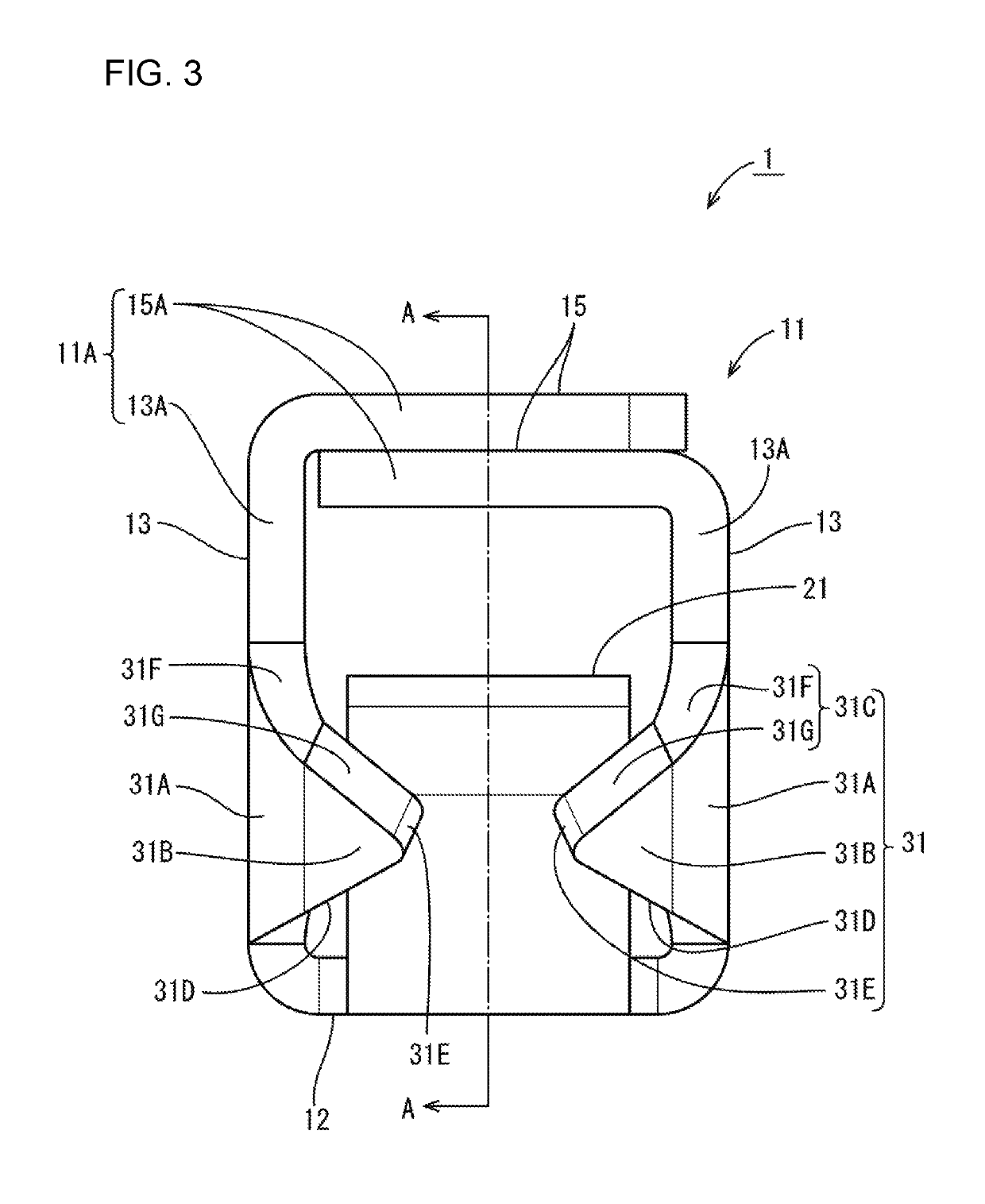

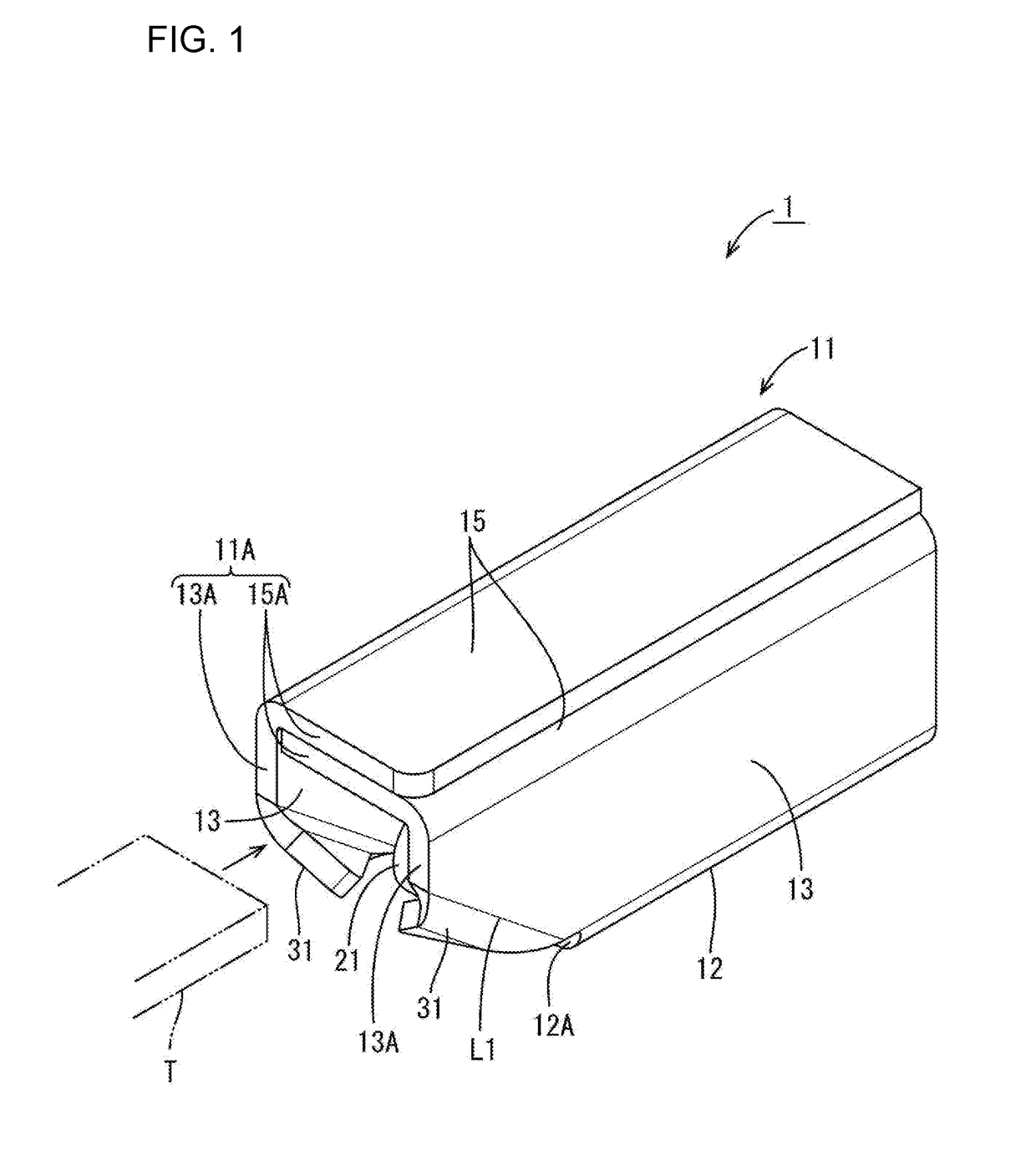

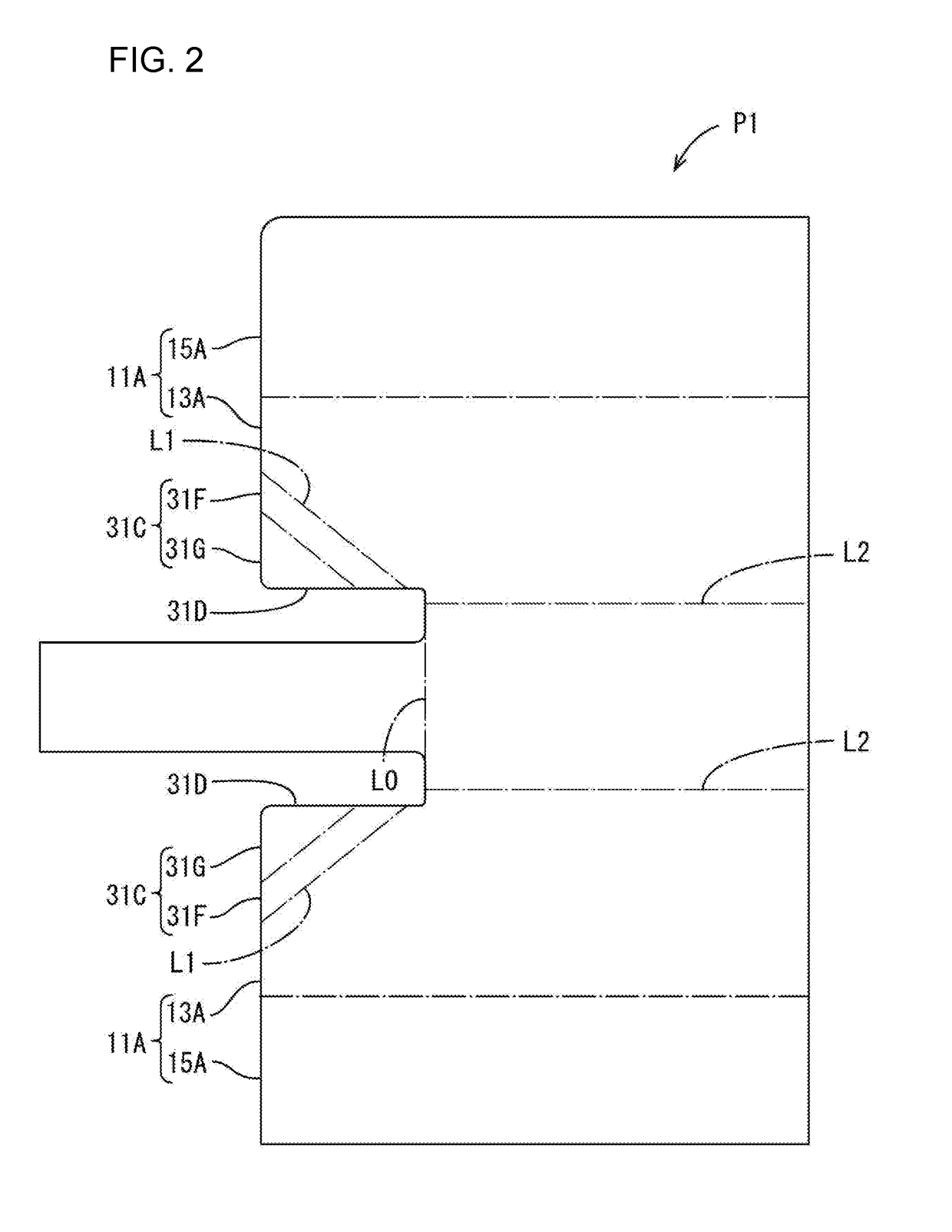

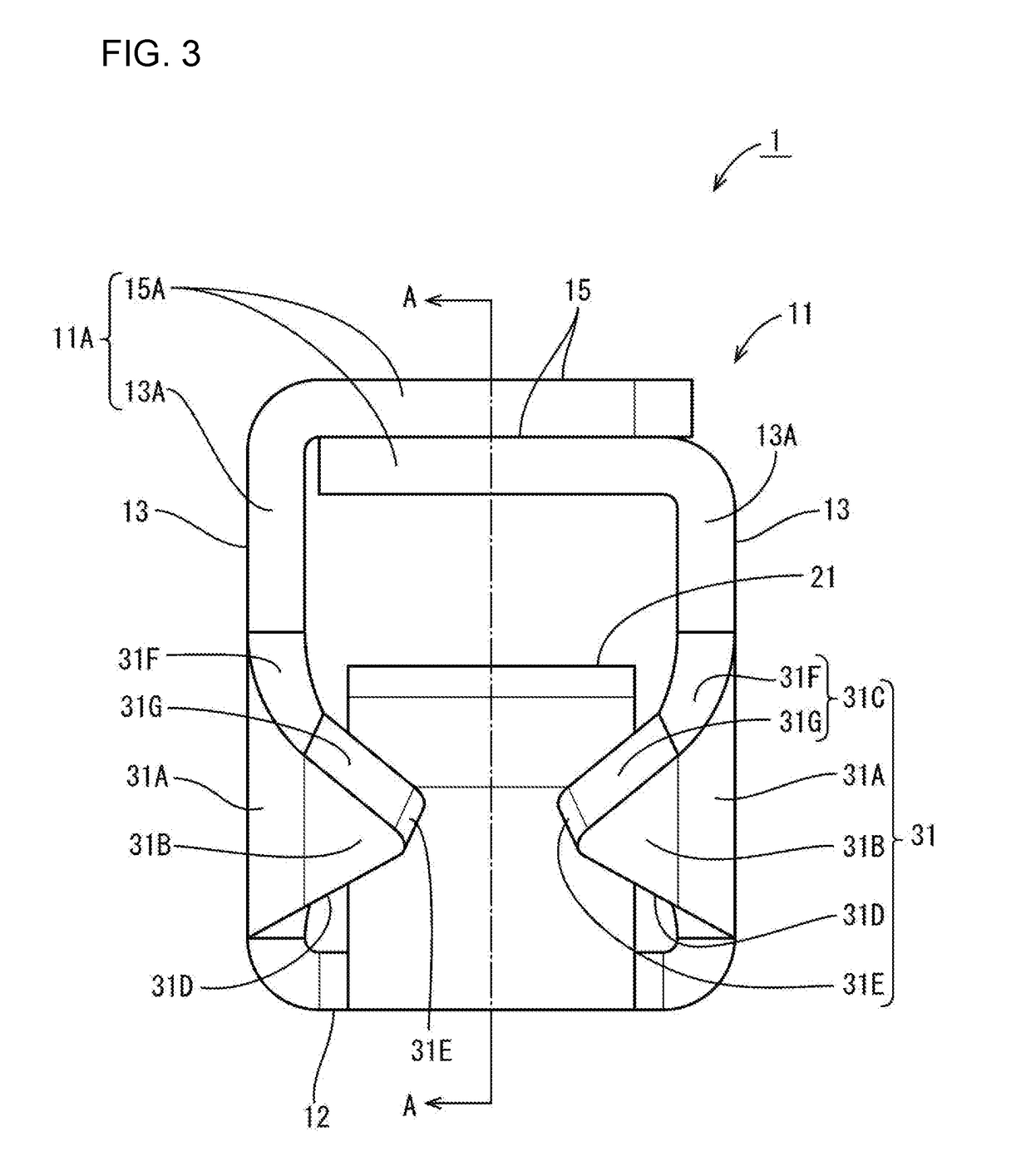

Terminal fitting

ActiveUS10374348B2Improve rigidityIncrease the areaSecuring/insulating coupling contact membersCoupling contact membersStructural engineeringEngineering

Owner:SUMITOMO WIRING SYST LTD

Terminal fitting

ActiveUS20190036258A1Well formedImprove rigiditySecuring/insulating coupling contact membersCoupling contact membersStructural engineeringEngineering

A terminal fitting to be connected to a mating terminal fitting with a tab (T) includes a rectangular tube (11) composed of a bottom wall (12), two side walls (13) rising from the bottom wall (12) and a ceiling wall (15) facing the bottom wall (12). A resilient contact (21) extends along the bottom wall (12) inside the rectangular tube (11). A protection wall (31, 131) has bending edge (L1) continuous with one of the side walls (13) is before a front end (12A) of the bottom wall (12) and extends from the bending edge (L1) toward the other side wall (13). A clearance for receiving the tab (T) is between the protection wall (31, 131) and the ceiling wall (15). The bending edge (L1) approaches the ceiling wall (15) from a front end (12A) of the bottom wall (12) toward a front end (13A) of the side wall (13).

Owner:SUMITOMO WIRING SYST LTD

Magnetostriction device

InactiveUS20060213325A1Increase external forceImprove permeabilityMagnetostrictive material selectionMagnetic materialsEpoxyPHENOL LIQUID

A magnetostriction device is made such that an impregnated composition material, such as phenol resin, a resin in which an inorganic material such as silica is dispersed into a phenol resin, an epoxy based resin, or an acrylic resin is impregnated and caked into holes of a magnetostrictive sintered material manufactured by a powder metallurgy method. This magnetostriction device has improved mechanical strength against external force.

Owner:SONY CORP

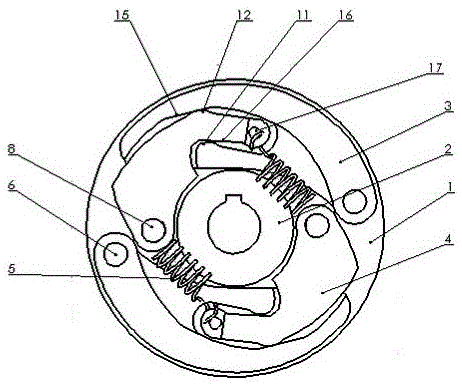

Lever Centrifugal Automatic Clutch

The lever centrifugal automatic clutch includes a driving disc, at least two sets of centrifugal mechanisms and a driven disc, a power sleeve is arranged in the center of the driving disc, a driven disc buckle is set on the edge of the centrifugal mechanism, and a power output mechanism is arranged on the driven disc. The adjacent two groups of centrifugal mechanisms are connected end to end and evenly distributed on the drive plate. The centrifugal mechanism is composed of a centrifugal body, a special-shaped lever, a tension spring, a centrifugal body positioning post and a special-shaped lever positioning post. This invention effectively reduces the The energy loss of the clutch during operation, especially in the low-speed working state, the output torque (power) is relatively large. At the same time, under the condition of ensuring the function, its structure is simplified.

Owner:嘉善陶庄再生资源有限公司

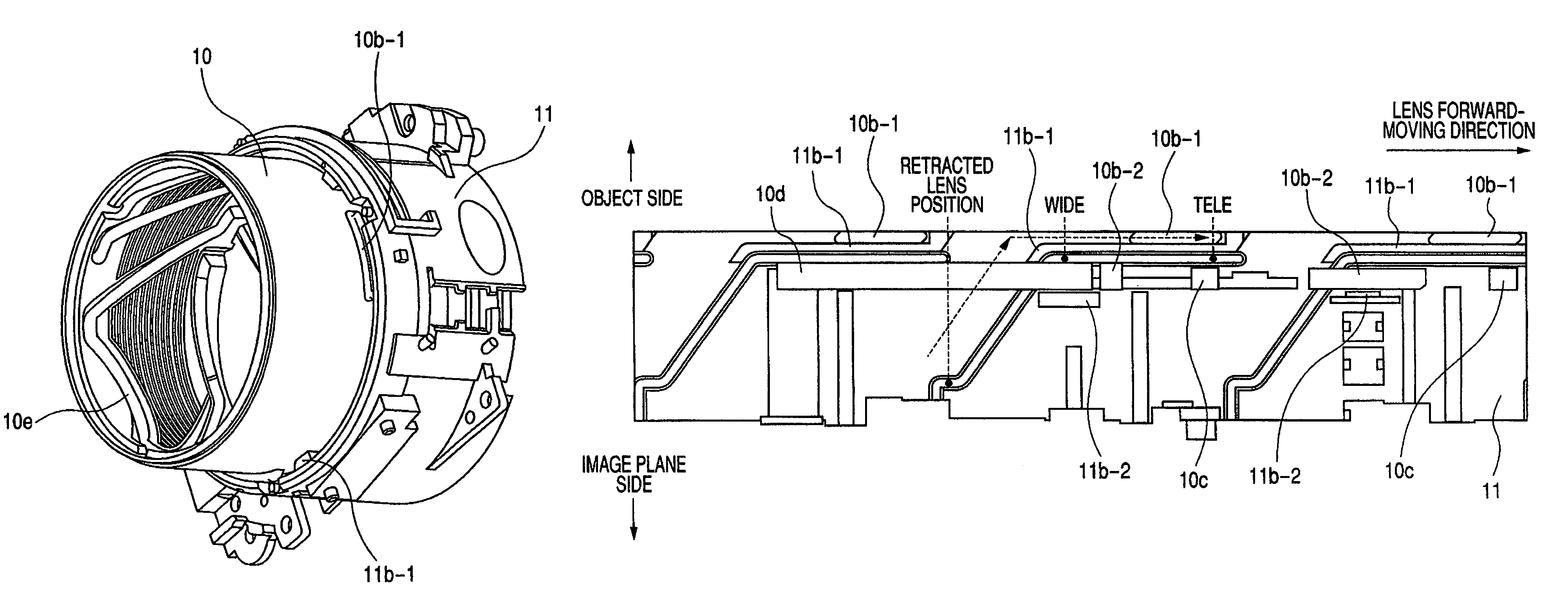

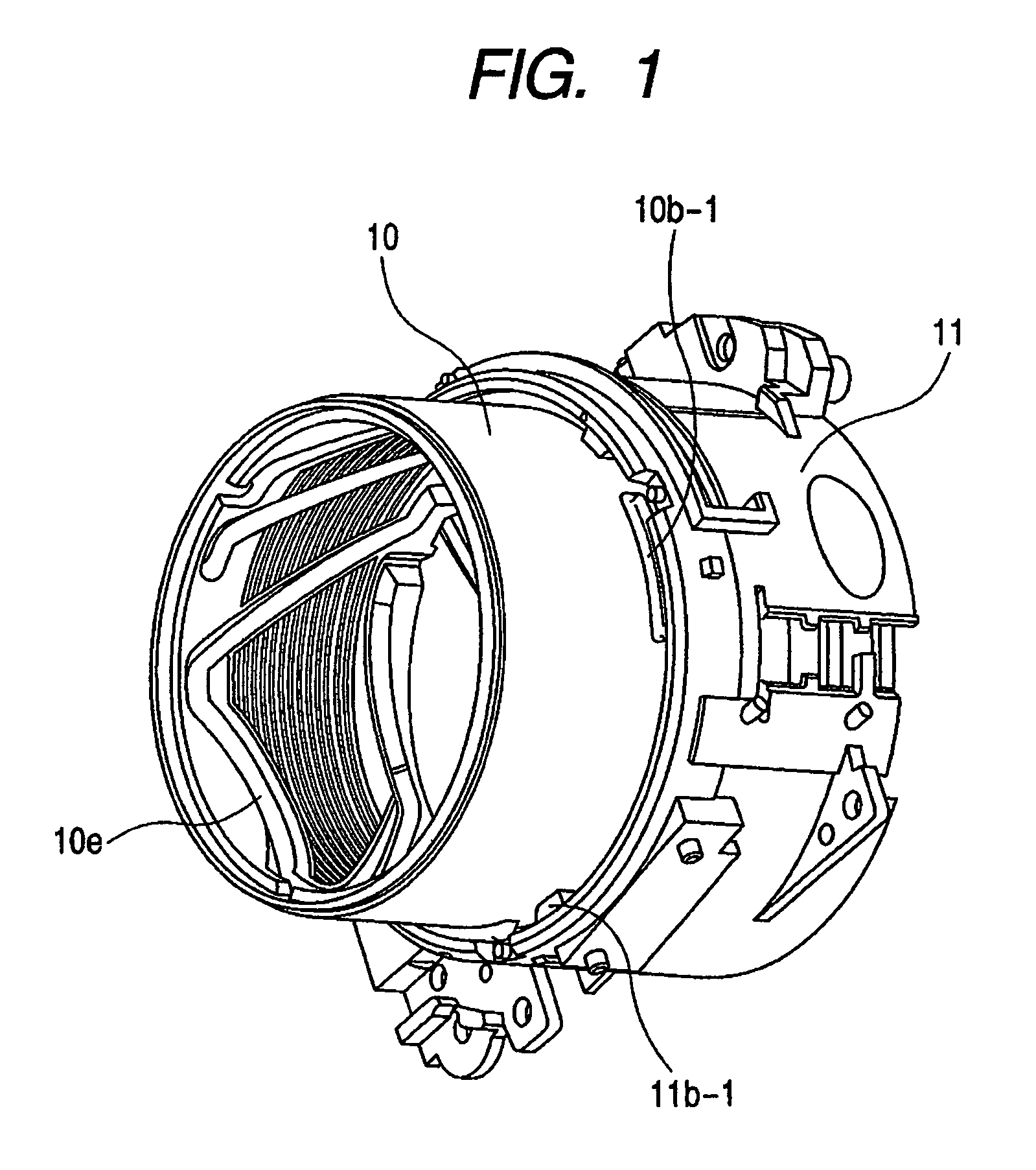

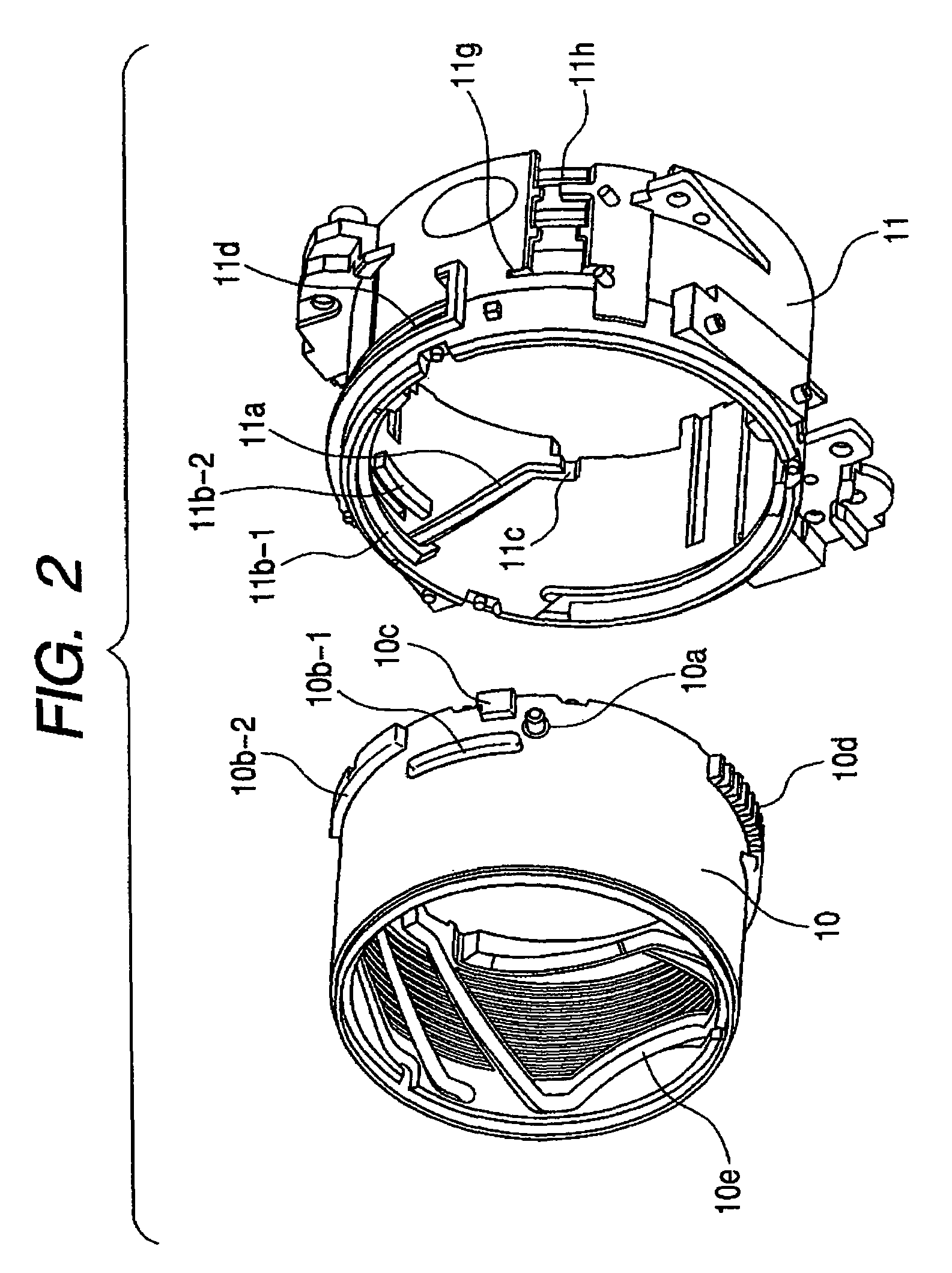

Optical apparatus such as digital still camera, video camera, and interchangeable lens

InactiveUS7321472B2Increase in sizeIncrease external forceTelevision system detailsCamera body detailsCamera lensOptical axis

An optical apparatus having a first member and a second member rotating about an optical axis with respect to the first member. One of the members has a cam portion; the other has a cam follower portion engaged with the cam portion which drives the first and second members relatively in an optical axis direction. The first member has first and second portions protruding toward the second member side separated from each other in the optical axis direction; the second member has third and fourth portions protruding toward the first member side separated from each other in the optical axis direction and abuts on the first and second portions, respectively; and the fourth portions are provided in a circumferential direction of the second member and include protruding portions for transmitting power.

Owner:CANON KK

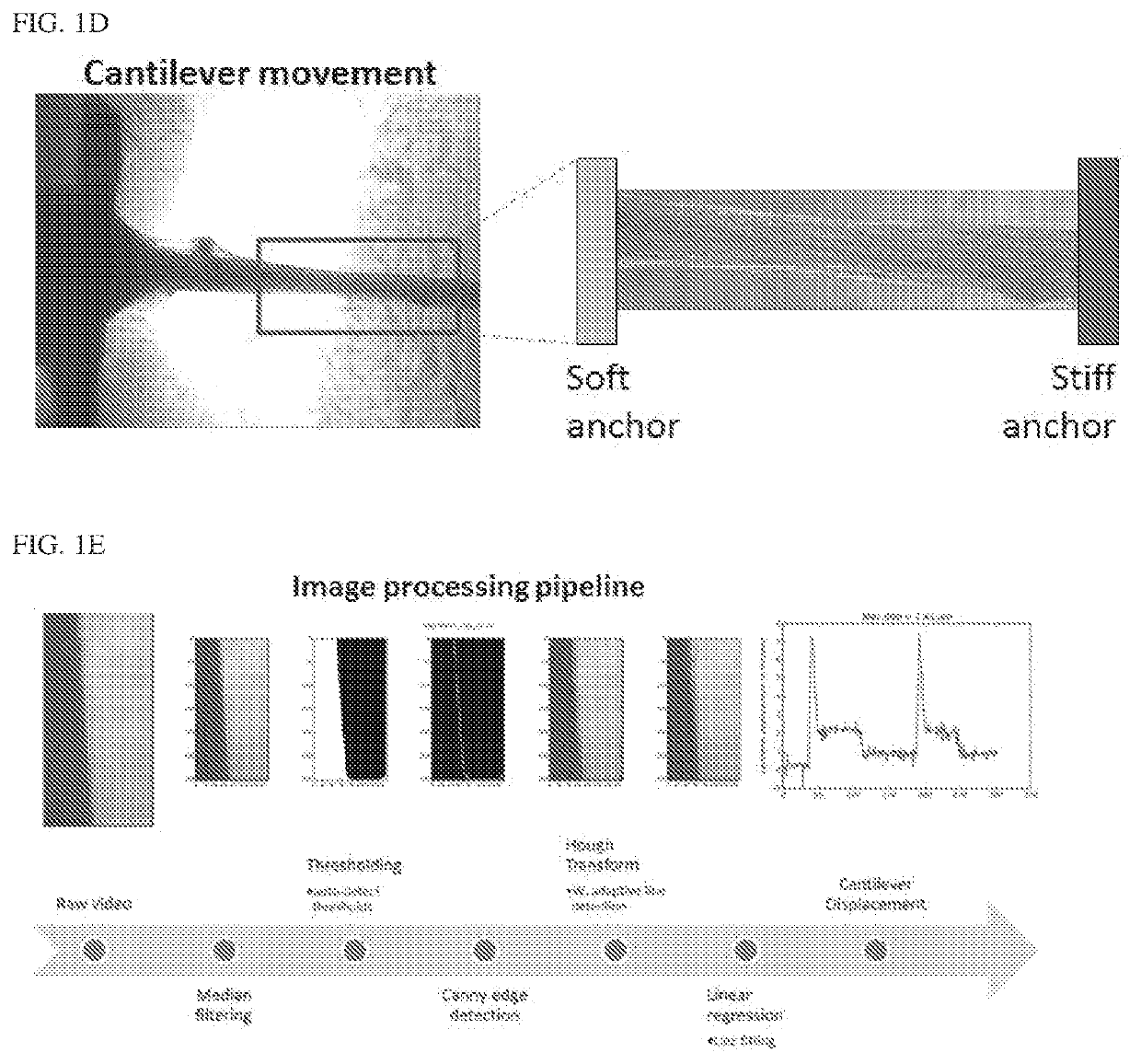

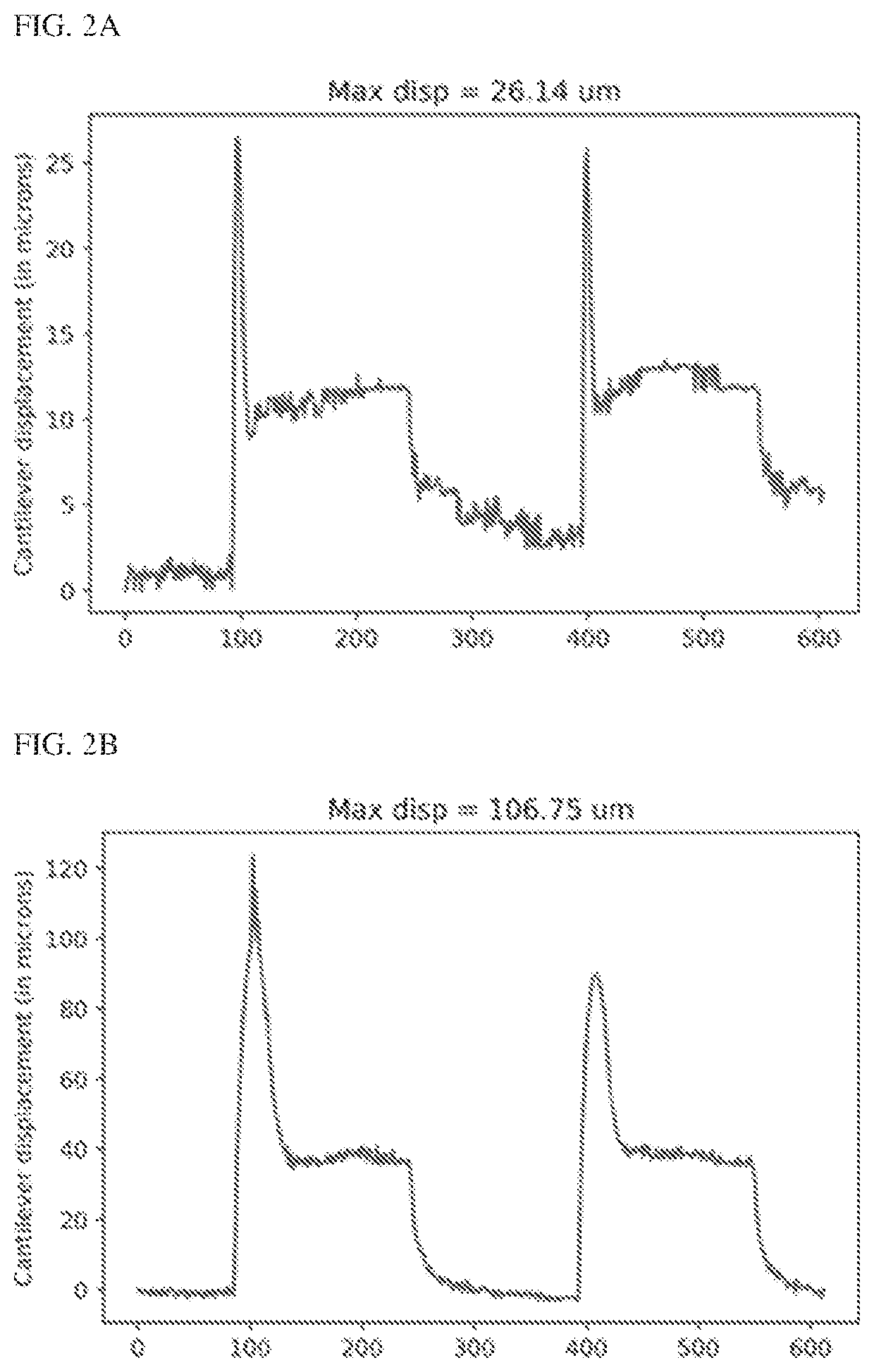

Compositions and methods to increase muscular strength

PendingUS20200352940A1Increase external forceImprove efficiencyOrganic active ingredientsMetabolism disorderMuscle strengthWeakness

Owner:MASSACHUSETTS INST OF TECH

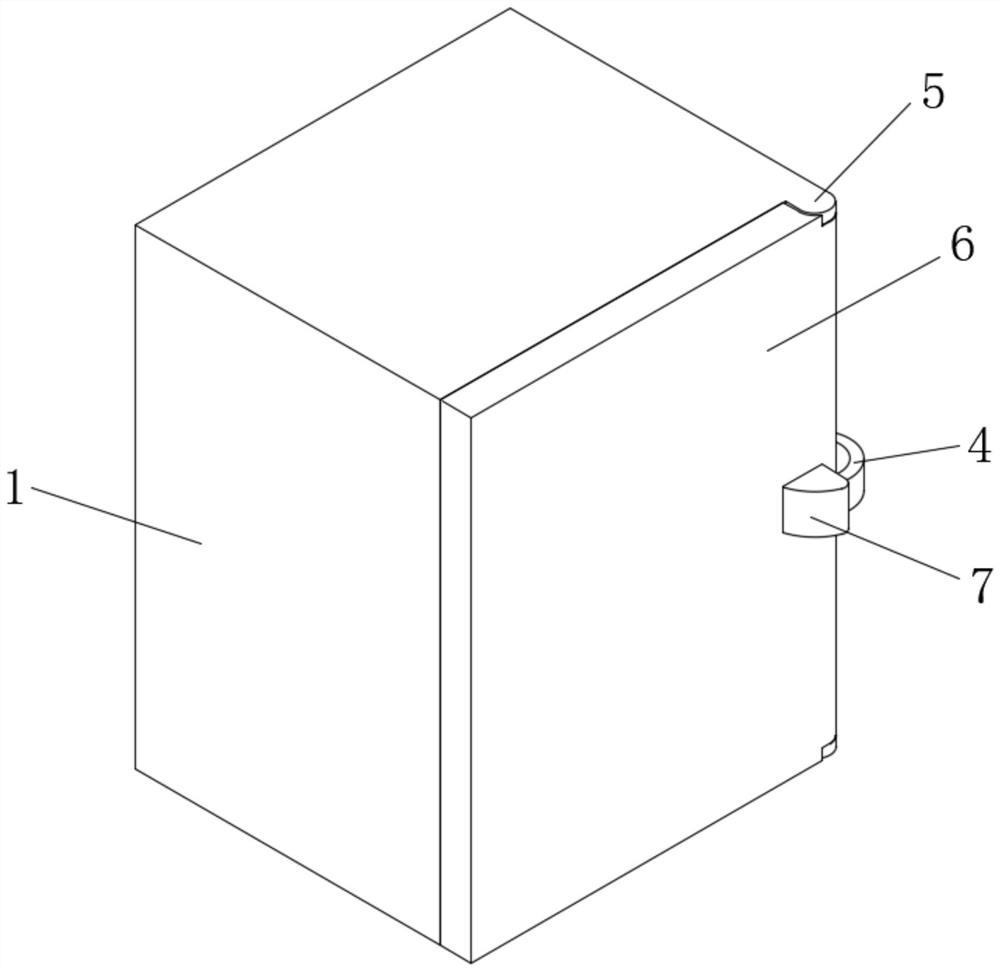

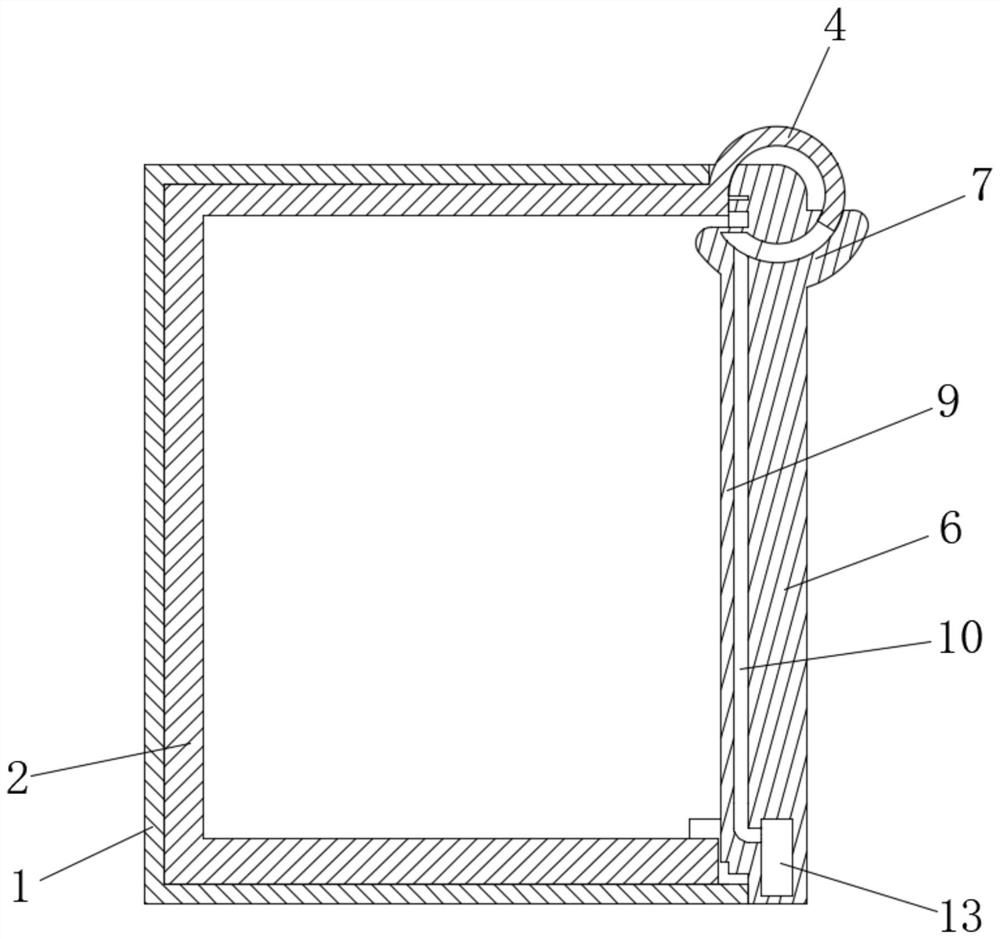

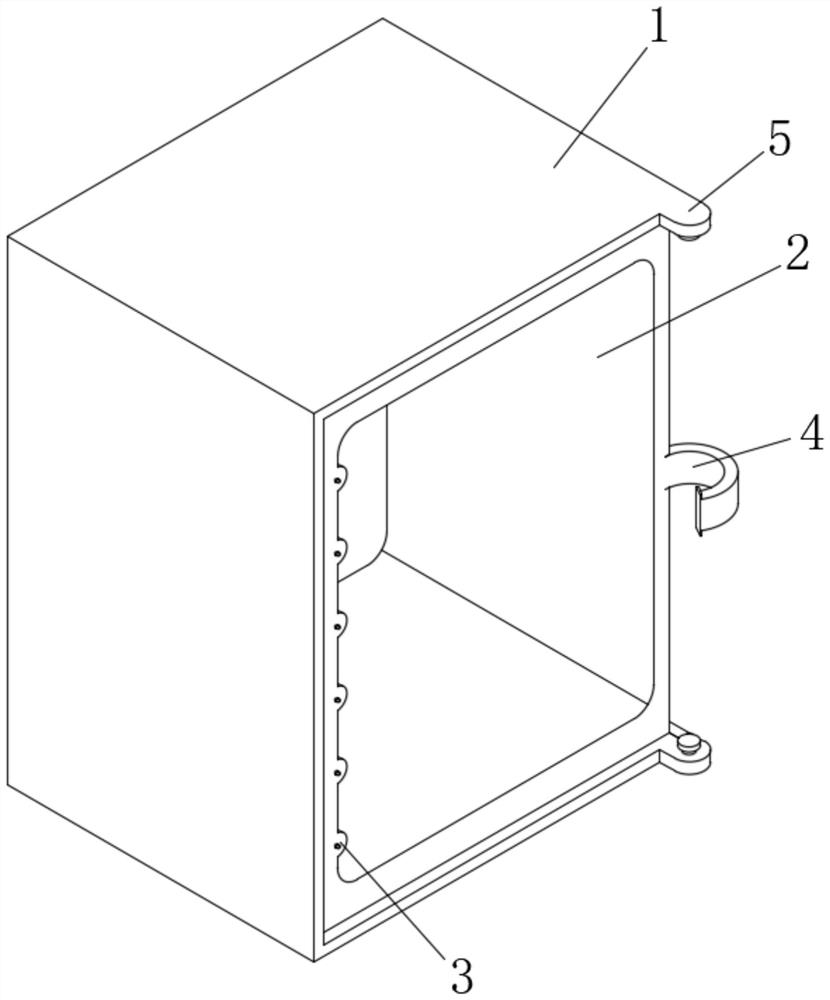

Self-suction sealing door of refrigerator

ActiveCN111964343AReduce the chance of being opened by mistakeImprove the function of preventing accidental openingLighting and heating apparatusCooling fluid circulationEngineeringElectrical and Electronics engineering

The invention relates to the technical field of household appliances, and discloses a self-suction sealing door of a refrigerator. The air pressure inside a negative pressure cavity is reduced by extracting an arc-shaped extrusion rod from the negative pressure cavity, and the effect is transmitted to flow-limiting devices through an air guide hole and an air guide groove at the same time; due tothe fact that the cross-sectional shape of a flow-limiting hole in each flow-limiting device is funnel-shaped, and an outer aperture R1 is larger than an inner aperture R2 which is larger than a middle aperture R3, each flow-limiting hole has a gas flow restriction, and the closing speed is high; the external air is difficult to enter the air guide groove and the air guide hole through the flow-limiting holes; and when a refrigerator door is completely closed, outer accommodating cavities make contact with the flow-limiting devices so as to abut against and open the flow-limiting holes and toenable the internal low air pressure to act on locking devices, bullet-shaped shooting needles are subjected to suction force to move, the tip of each bullet-shaped shooting needle enters the R3 of the corresponding flow-limiting hole and makes contact with a flow-limiting plate, the external force required by the door opening is improved, the probability that the refrigerator door is mistakenly opened is reduced, and the effect of the mistaken opening prevention function of the device is improved.

Owner:温岭市鸿露橡胶制品有限公司

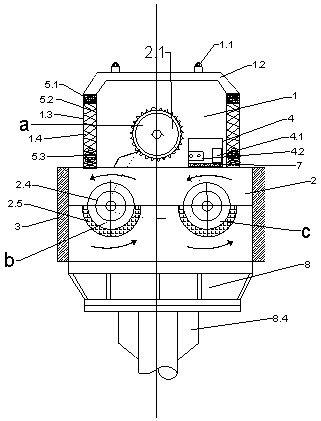

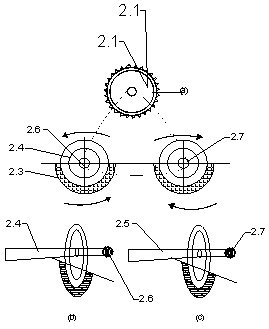

Electrical excitation vibration pile hammer equipment of engineering machinery

InactiveCN110552341ALightweight device designImprove efficiencyBulkheads/pilesSoil preservationElectric machineryEngineering

The invention discloses electrical excitation vibration pile hammer equipment for engineering machinery. The electrical excitation vibration pile hammer equipment comprises a vibration absorber, a vibrator, vibration exciters and an electrical device, wherein the vibration absorber is composed of a hoisting pulley, a vibration damping cross beam and vertical shafts. The vibration damping cross beam is fixedly connected with the upper part of the vibrator, the two sides of the vibration damping cross beam are provided with two vertical shafts correspondingly, each vertical shaft is sleeved witha compression spring in a sleeved mode to form a group, the vibration damping cross beam is fixed at the upper parts of the vertical shafts, the vibrator is composed of a motor, a box body, eccentricblocks, a driving shaft, a driven shaft and a gear, the power is transmitted to the box body through a triangular belt, the drving shaft and the driven shaft are meshed with each other through a pairof column gears, four eccentric blocks are arranged on the shaft, the two sides of the vibrator are fixedly connected with the vibration exciters correspondingly, the electrical device consists of adistribution box and a wire, and the power distribution box is connected with external power supply equipment. According to the equipment, the vibration damping of the two groups of springs of the vibration absorber of the equipment greatly reduces the amplitude of the equipment, and the four eccentric blocks increase the amplitude intensity.

Owner:徐州贝峰机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com