Silicon heterojunction solar cell structure and manufacturing method thereof

A solar cell and silicon heterojunction technology, which is applied in the manufacture of final products, sustainable manufacturing/processing, circuits, etc., can solve the problems of poor interface contact ability and easy peeling, and achieve the effect of improving the tension of the solder strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical content disclosed in this application more detailed and complete, reference may be made to the drawings and the following various specific embodiments of the present invention, and the same symbols in the drawings represent the same or similar components. However, those skilled in the art should understand that the examples provided below are not intended to limit the scope of the present invention. In addition, the drawings are only for schematic illustration and are not drawn according to their original scale.

[0039] The specific implementation manners of various aspects of the present invention will be further described in detail below with reference to the accompanying drawings.

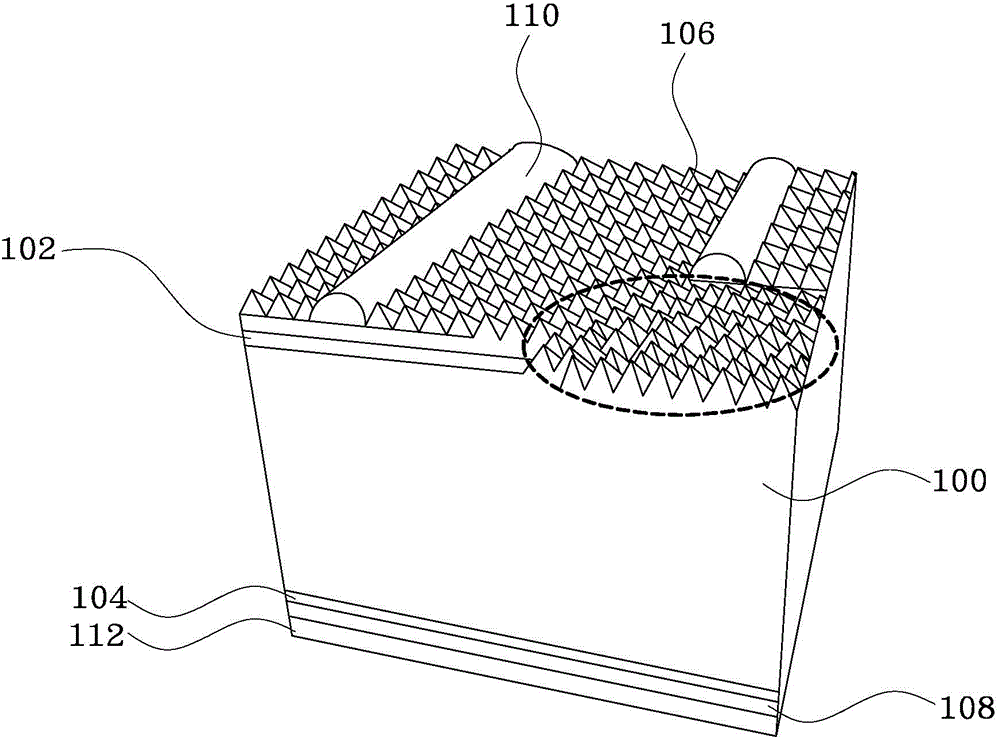

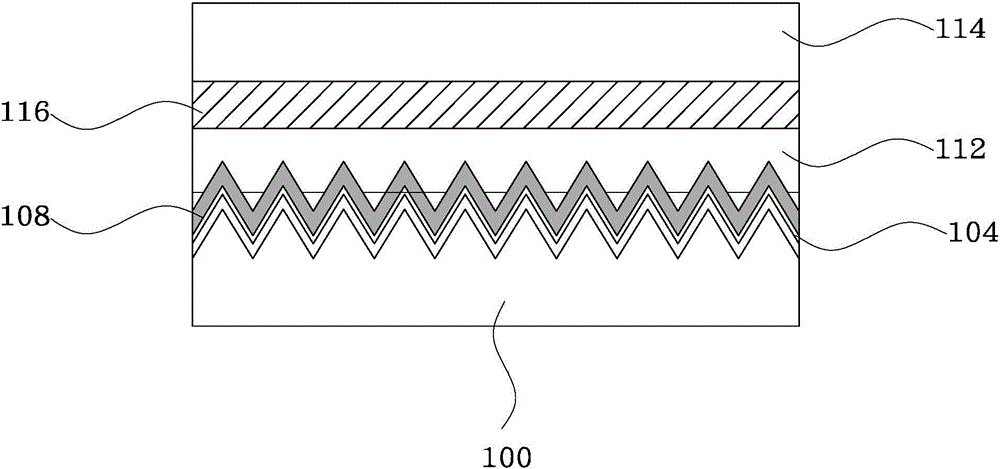

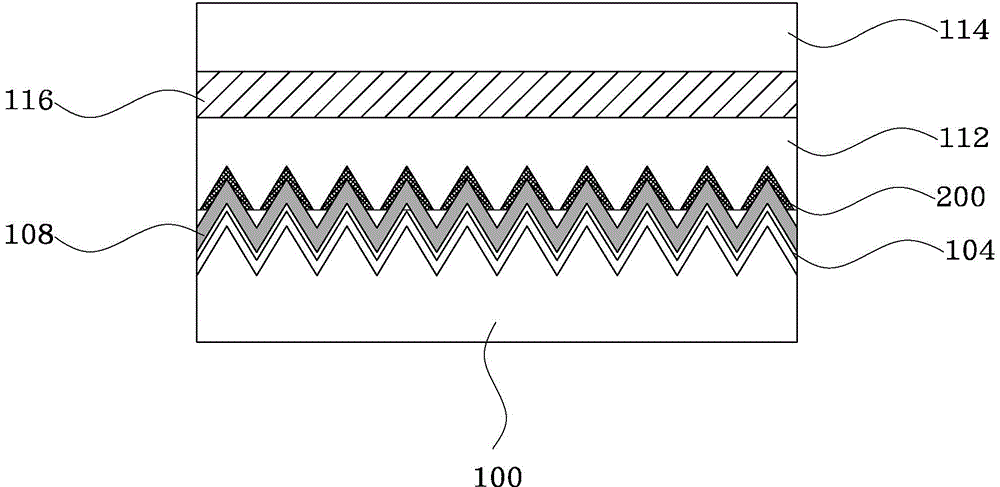

[0040] figure 1 A schematic structural diagram of a silicon heterojunction solar cell in the prior art is shown. figure 2 show figure 1 Schematic diagram of the interface contact between the transparent conductive oxide layer and the buffer silver film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com