Novel guide device of multistage Stirling engine piston

A guiding device and Stirling machine technology, applied in the direction of hot gas variable displacement engine, internal combustion piston engine, mechanical equipment, etc., can solve the problems of increasing the complexity of the piston structure, increasing the overall height of the engine, and the demand for large space height, etc. Achieve the effect of wide applicability, simplification of internal structure and smooth movement change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in detail by the following examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations on the technical solutions of the present invention.

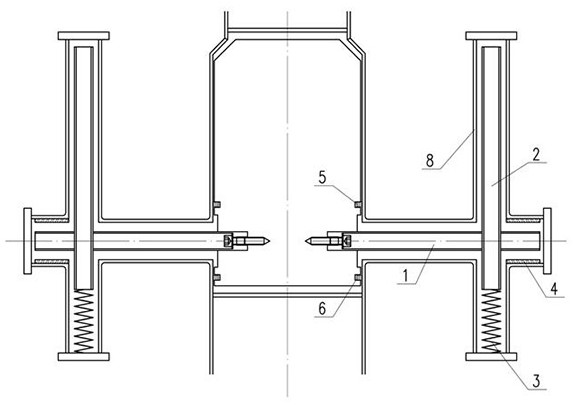

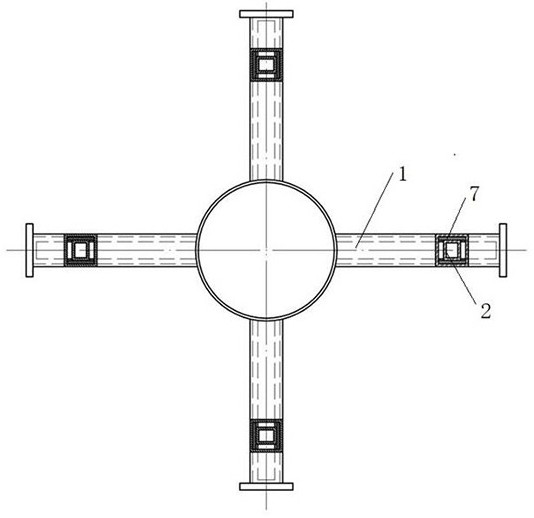

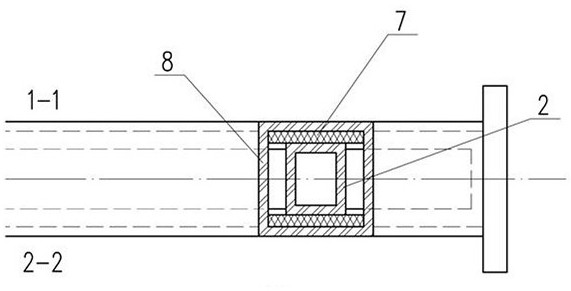

[0029] combine Figure 1-3 , a new type of guide for a multistage Stirling machine. For the multi-stage Stirling engine piston, four guide devices are symmetrically arranged in its horizontal position, and each guide device includes: a radially coordinated vibration connecting rod, an axially stabilizing guide rod, a piston positioning spring and an anti-collision damper. Vibration pad, with guide blocks arranged on both sides. Setting three guiding devices at a suitable position or setting them in a symmetrical manner can also achieve the required restraint effect, but it will increase the difficulty of installation and adjustment, so i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com