Chlorine removal method for recycle use

A technology for recycling and dechlorination, applied in the field of wet smelting, can solve problems such as incomplete dechlorination, and achieve the effects of significant social comprehensive benefits, simple process and improved comprehensive recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

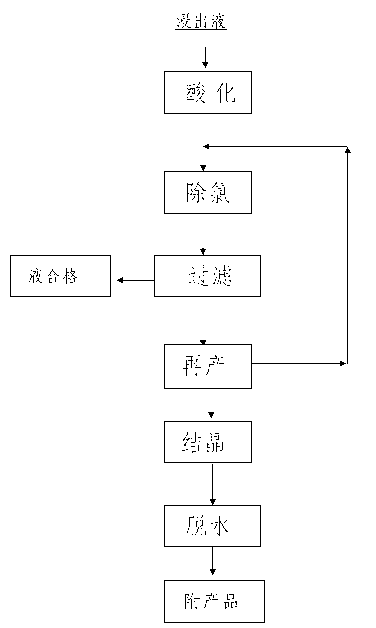

Image

Examples

Embodiment Construction

[0042] The present invention can be further described by the following examples, however, the scope of the present invention is not limited to the following examples. Contains high concentrations of chloride ions

[0043] Such as: hydrometallurgy zinc dechlorination

[0044] (1) Acidification: The pH value of the neutral leachate of zinc hydrometallurgy is generally >5.2; the pH value of the leachate of the neutral leachate should be adjusted to 2.0-3.5 with zinc electrolysis waste liquid.

[0045] (2) Chlorine removal: The neutral leaching solution requires the chlorine content to be less than 200mg / L. The neutral leaching solution is based on the chlorine content of the liquid plus 1-1.5 times the theoretical amount of Cu 2 O, reaction precipitation in acidification solution; precipitation temperature 2 O and CI 1- Insoluble Cu 2 CI 2 precipitation.

[0046] (3) Filtration: prevent oxidation, quickly separate and precipitate Cu 2 CI 2 , Washing with acid water can ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com