Rope with spiral tooth

A technology of helical teeth and cables, applied in the direction of elements with teeth, belts/chains/gears, transmission belts, etc., can solve the problems of stop position error, stop error of driven moving member, damage to image reading accuracy, etc. Achieve the effect of improving adhesion, friction coefficient, and friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

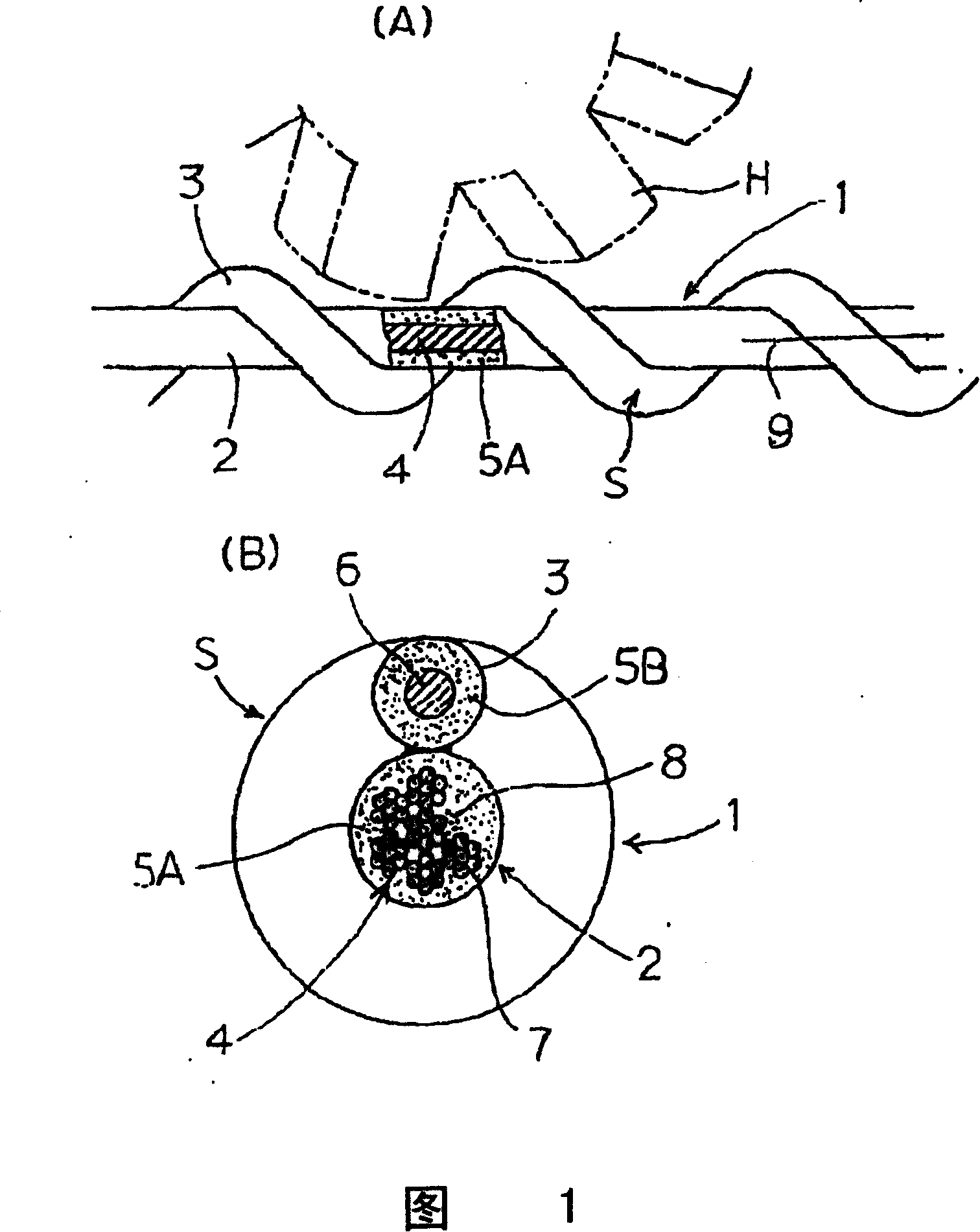

[0016] First, a helically toothed cable 1 (hereinafter referred to as a toothed cable 1 ) according to an embodiment of the present invention will be described with reference to FIG. 1 .

[0017] The toothed cable 1 is provided on the outer periphery of the cable main body 2 formed by providing the resin coating layer 5A on the core material steel wire rope 4, and has a spiral strip S formed by winding a linear body 3 in a helical shape. The linear body 3 is The resin coating layer 5B is provided on the wire material 6 as a core material, and the cable main body 2 is formed by twisting austenitic stainless steel wire materials so that one side strand 7 is missing (the twisted seven side strands 7 One of them), the steel wire rope 4 having a helical groove 8 on the outer circumference is used as a core material, and the groove 8 is filled to enclose the outer circumference of the steel wire rope 4 "made of metal fiber-containing resin or metal oxide fiber Resin cover layer 5A" ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com