Electrical excitation vibration pile hammer equipment of engineering machinery

A technology of vibrating pile hammer and construction machinery, which is applied in the direction of foundation structure engineering, sheet pile wall, soil protection, etc., can solve the problems of poor safety and durability, heavy and large machinery, and no new technology, etc., to achieve comprehensive The effect of technical scheme design, stable and small vibration, and light equipment design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

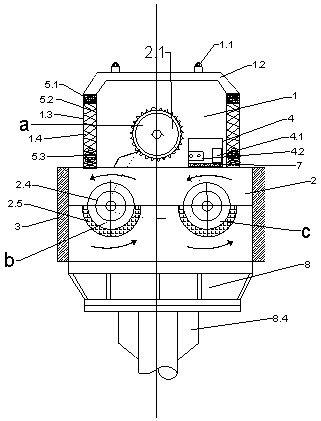

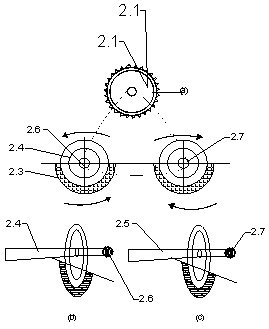

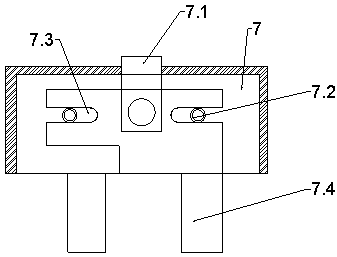

[0014] like Figure 1 to Figure 3 As shown, the present invention is a kind of electrical excitation vibrating pile hammer equipment of engineering machinery, comprising a vibration absorber 1, a vibrator 2, two vibration exciters 3 and an electrical device 4, and the vibration absorber 1 is composed of a lifting pulley 1.1, a damper The vibrating beam 1.2 and the vertical axis 1.3 are composed. Both ends of the damping beam 1.2 are welded with a vertical shaft 1.3, and the vertical shaft 1.3 is inserted into a compression spring 1.4 to form a group. The bottom of the vertical shaft 1.3 is fixedly connected to the upper surface of the vibrator 2, and the upper surface of the vibration damping beam 1.2 is welded with a lifting pulley 1.1. The vibrator 2 is composed of a motor 2.1, a box body 2.2, at least two pairs of eccentric weights 2.3, at least two driving shafts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com