Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Improved arc burn resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

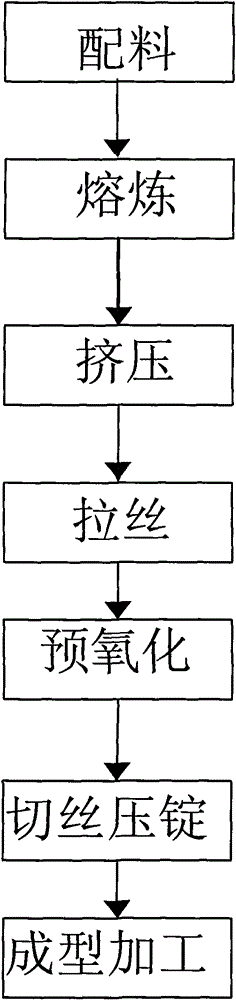

High-performance silver cadmium oxide material and manufacturing method thereof

The invention relates to a high-performance silver cadmium oxide material and a manufacturing method thereof, which are characterized in that the silver cadmium oxide material comprises the following components: 85 to 97 percent of silver, 2 to 15 percent of cadmium, 0.01 to 0.5 percent of nickel, 0.01 to 1 percent of tin and 0.01 to 0.5 percent of rear earth mixture. The manufacturing method of the high-performance silver cadmium oxide material is characterized in that: a given quantity of silver, cadmium, nickel, tin and rare earth mixture are measured to be arranged inside a middle-frequency induction furnace to be smelted and cast, the cast ingot is extruded by an extruding machine to be thick wires, the thick wires are stretched by a wire-drawing die to be thin wires, the thin wires are pre-oxidized by an internal oxidization furnace, then the thin wires are cut and preformed and finally is processed and formed. The anti-oxidization performance, electric-arc burning loss resistance and the abrasion resistance of the silver cadmium oxide material are improved, and the service life is prolonged, so the high-performance silver cadmium oxide material can be applied to different working environments, has low production cost, simple manufacturing method and low requirements on the device and the production.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

Prepn process of nanometer tin oxide material with surface decorating silver

The present invention relates to the preparation process of nanometer tin oxide material with surface decorating silver, and belongs to the field of electric contact material preparing technology. The preparation process includes the following steps: adding tin oxide powder of 20-30 nm size into anhydrous ethanol and adding polyglycol as dispersant; ultrasonic stirring at room temperature and stoving; adding the treated nanometer tin oxide powder into 10-30 % concentration silver nitrate solution via electromagnetic and ultrasonic stirring for homogeneous dispersion; adding reductant hydrazine hydrate to reduce silver ion and obtain silver coated nanometer tin oxide powder and stoving at 80-120 deg.c. The present invention has the advantages of simple technological process and being suitable for industrial production, and the surface decorated nanometer tin oxide may be used in producing electric contact with excellent mechanical performance and high conductivity.

Owner:TIANJIN UNIV

Silver-tin oxide electrical contact material and preparation method thereof

InactiveCN1624838APromote internal oxidationLower internal oxidation temperatureContact materialsRare-earth elementAlloy

The invention discloses silver tin oxide electrician contact material and its preparation method. Its chemical composition (weight ratio) is that the SnO2 is from three percent to ten percent; the mixed rare earth oxide (Sm2O3, Gd2O3, Y2O3) is from 0.1 percent to 2.0 percent; the surplus quantity is Ag. The preparation method is that the Ag, Sn, rare earth element are made up according to the alloy design proportion of ingredients, alloying in the vacuum melting furnace; then the AgSnRE is made after quickly solidification. At first the alloy is formed to thread, panel, profiled bar or rivet by extrusion, rolling, drawing, heat treatment. Then it is formed to AgSnO2 mixed rare earth oxide electrician contact material by produce internal operation. It can be used in AC and DC contactor, relay, controller, circuit breaker, switch, and so on.

Owner:KUNMING INST OF PRECIOUS METALS

Graphene reinforced copper-rare earth based electrical contact material and preparing method thereof

The invention relates to a graphene reinforced copper-rare earth based electrical contact material and a preparing method thereof. The electrical contact material comprises, by weight, 0.1-3.0% of graphene and 97.0-99.9% of copper-rare earth alloy, and rare earth accounts for 0.05-3.0% of the total weight of copper-rare earth alloy. The preparing method comprises the steps of powder atomization, ball milling and powder mixing, cold press molding, sintering, secondary forming and sintering. By adding a graphene reinforcing body to copper alloy to serve as the framework, the material has high hardness, high wear resistance, high mechanical impact resistance and high welding resistance. By adding rare earth, the oxidation resistance and electric arc erosion resistance of the copper alloy electrical contact material are improved.

Owner:UNIV OF JINAN

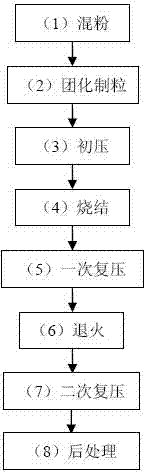

Special powder copper alloy electric contact material and method for making same

ActiveCN101145450AImprove antioxidant capacityImproved arc burn resistanceContactsLow voltageRare earth

The invention provides a method for producing Cu alloy electrical contact material with good antioxidant property. The alloy is composed of rare earth (at least one selected from La, Ce and Yt elements), boron, aluminum, silver, conductive ceramic (TiN2 and / or SnO2), diamond powder and copper. The alloy is processed by powdering, mechanical mixing, isostatic pressing, sintering, extrusion and shaping steps, to make various electrical contact elements. With the inventive method, the produced electrical contact element can overcome the disadvantage of poor antioxidant capability of the prior Cu alloy electrical contact elements, and can be used to replace the silver alloy electrical contact in the field of low-voltage electrical apparatuses, thereby solving the problems of the silver alloy electrical contact, such as high cost due to noble metal silver and bad influence on social sustainable development.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

Electric contact material made of silver-tungsten carbide graphite and preparation method thereof

The invention relates to an electric contact material made of silver-tungsten carbide graphite and a preparation method thereof. The electric contact material comprises the following main components in percentage by weight: 11%-14% of tungsten carbide-zirconium carbide solid solution, 2%-6% of graphite, 0.3%-0.6% of additive and the balance of silver, wherein the added element is one or the combination of Ti, Co and Cr. The tungsten carbide and the zirconium carbide are added in form of solid solution with the ratio of (6:4)-(9:1). Compared with the traditional electric contact made of silver-tungsten carbide graphite, the electric contact material has higher welding resistance, electric arc burning resistance and high-temperature oxidation resistance. A low-voltage electric appliance adopting the electric contact material has lower contact resistance, longer electric service life and high reliability. Therefore, the novel electric contact material with high reliability is more suitable for being applied in various different plastic-shell circuit breakers, small high-interruption circuit breakers and alternating-current contactors.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

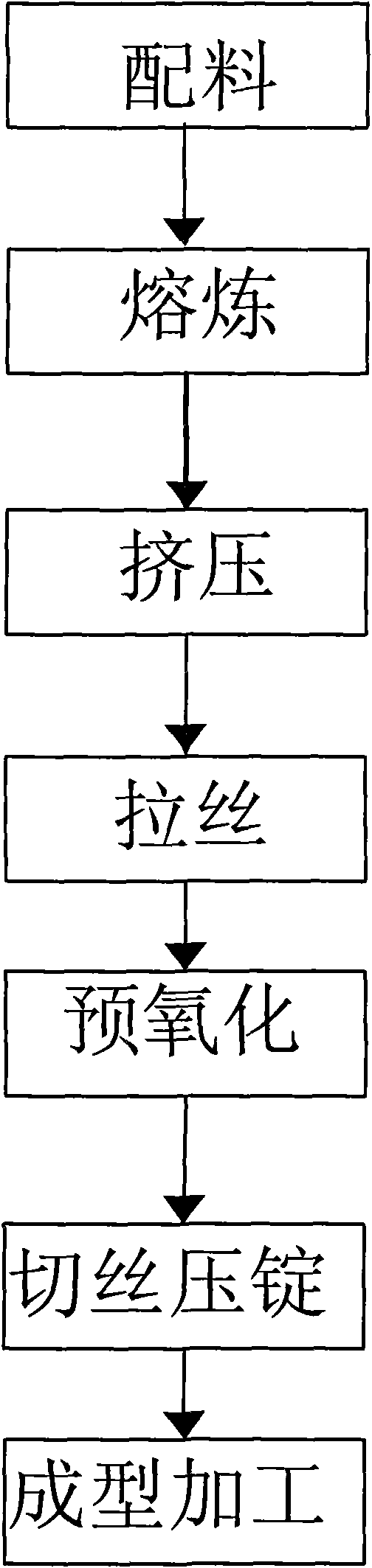

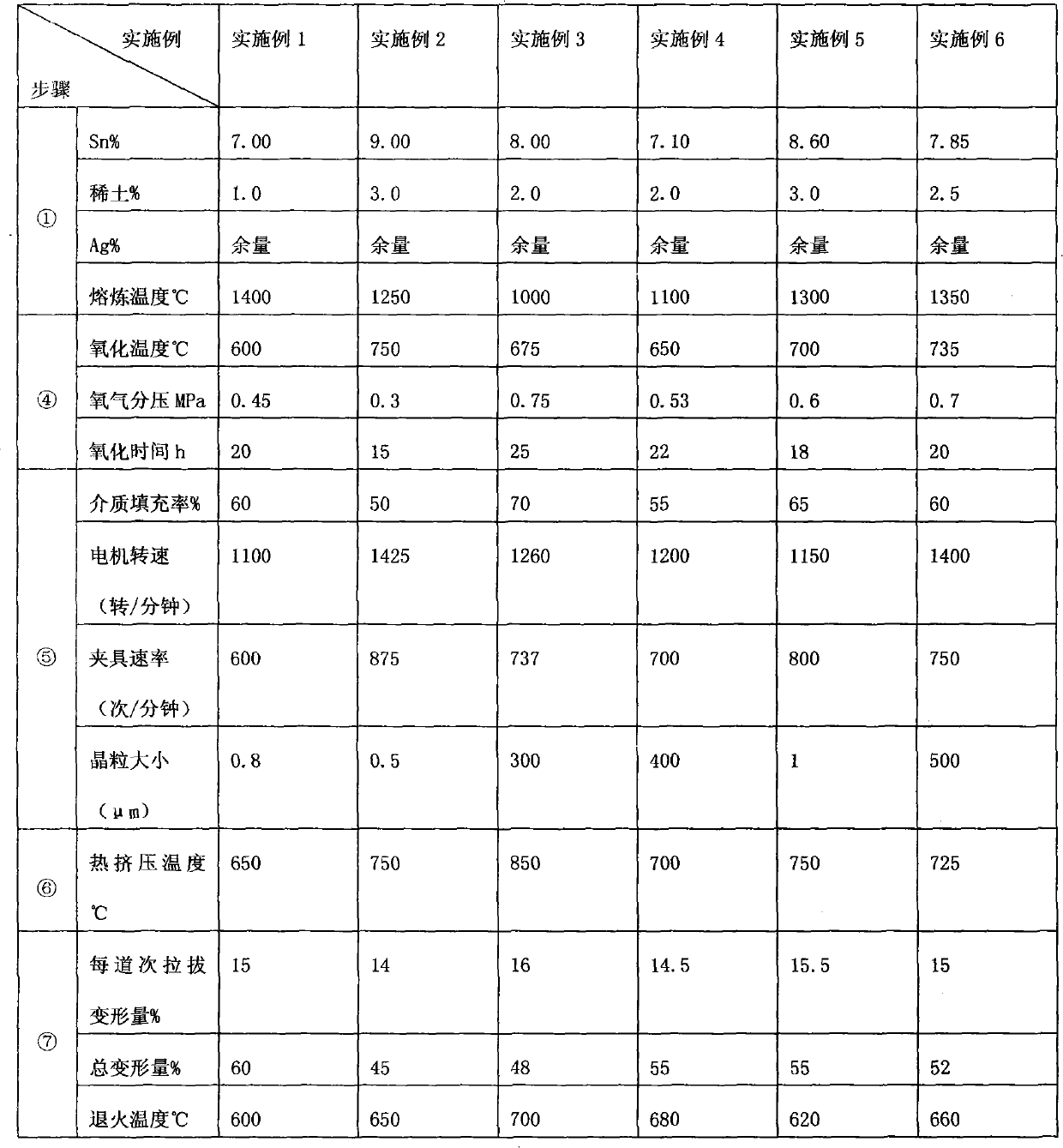

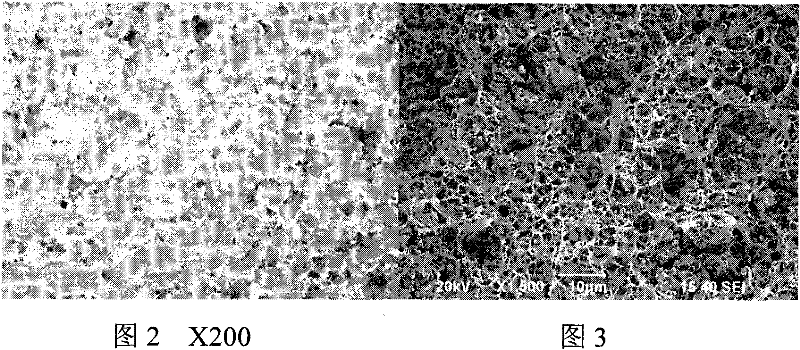

Manufacturing method of silver tin oxide contact alloy material and manufactured alloy thereof

The invention discloses a manufacturing method of a silver tin oxide contact alloy material and a manufactured alloy thereof. The method comprises the following steps: 1.smelting: smelting the ingredients at the preset temperature and continuing to stir in the process of smelting; 2. casting the ingredients into a round spindle and lathing the surface of the round spindle; 3. carrying out hot rolling and then cold rolling on the round spindle and then rolling the round spindle into sheets; 4. carrying out oxygenation processing on the sheets in an internal oxidation furnace; 5. crushing the sheets and then carrying out high energy crushing processing on the crushed sheets; 6. carrying out hot extrusion to obtain a wire stock blank; 7. carrying out drawing processing and annealing treatment; and 8. taking the obtained material as the finished product. The alloy comprises the following components in percentage by weight: 7%-9% of Sn, 1.0%-3.0% of rare earth additive and the balance of Ag. The invention has the advantages of more simplified technique, easy implementation and excellent product performance.

Owner:浙江乐银合金有限公司

Silver-nickel-based electrical contact material and preparation method thereof

ActiveCN101831571BHigh melting pointImprove welding resistanceContact materialsLow voltageBond strength

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Copper-plated graphene reinforced copper-based electrical contact material and preparation method thereof

ActiveCN105609159AHigh hardnessImprove wear resistanceNon-metal conductorsApparatus for manufacturing conducting/semi-conducting layersCopper platingRare earth

The invention relates to a copper-plated graphene reinforced copper-based electrical contact material and a preparation method thereof. The electrical contact material comprises 0.1-5.0 wt% of copper-plated graphene and 95.0-99.9 wt% of copper-rare earth alloy, and the weight ratio of rare earth in the copper-rare earth alloy accounts for 0.03-2.0%. The preparation method comprises the following steps of graphene copper plating, atomization for powder making, ball milling and power mixing, cold-press forming, sintering, secondary forming and sintering. A copper-plated graphene reinforced body is added into the copper alloy and taken as a framework, so that the material has the advantages of high hardness, high wear resistance, mechanical impact resistant performance and welding resistance; and with the addition of the rare earth, the oxidation resistance and the arc burning resistant capability of the copper alloy electrical contact material are improved.

Owner:UNIV OF JINAN

Arc extinguishing system and arc extinguishing chamber

PendingCN108320950AReduce burn rateImprove arc burn resistanceElectric switchesArc erosionMechanical engineering

The invention provides an arc extinguishing chamber, which comprises two side plates and an arc extinguishing grid plate group fixedly arranged between the two side plates. The arc extinguishing gridplate group comprises a plurality of first arc extinguishing grid plates and a plurality of second arc extinguishing grid plates. The plurality of first arc extinguishing grid plates are arranged under the plurality of second arc extinguishing grid plates; the thickness of each first arc extinguishing grid plate is larger than that of each second arc extinguishing grid plate; and the space betweentwo adjacent first arc extinguishing grid plates is larger than the space between two adjacent second arc extinguishing grid plates. The invention also provides an arc extinguishing system, which comprises the arc extinguishing chamber and a static contact and a moving contact opposite to the arc extinguishing chamber. The moving contact can be contacted with or separated from the static contact.By carrying out differentiated setting on the thickness of each arc extinguishing grid plate of the arc extinguishing grid plate group and the space between two adjacent arc extinguishing grid plates, arc erosion resistance is improved, and electrical life is improved.

Owner:SOOAR TIANJIN ELECTRICAL EQUIP CO LTD

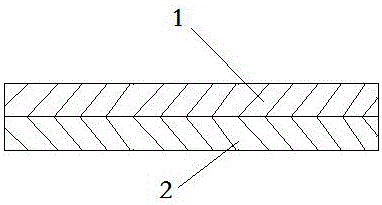

Composite contact with high fusion welding resistance for residual current protective breaker

InactiveCN106783240AStop splashImprove electrical lifeContact materialsCircuit-breaking switch contactsContact layerGraphite

The invention discloses a composite contact with high fusion welding resistance for a residual current protective breaker. The composite contact is characterized by comprising a silver alloy contact layer and a copper alloy contact layer, wherein the silver alloy contact layer comprises the following components in proportions by weight: 1-20% of yttrium oxide, 1-10% of diamond and the rest of silver; and the copper alloy contact layer comprises the following components in proportions by weight: 1-50% of molybdenum, 1-20% of graphite and the rest of copper. The thickness of the silver alloy contact layer is 5-50% of the thickness of the whole composite contact. The composite contact has the advantages of excellent performance, low silver content and low price.

Owner:沈阳新同正复合材料有限公司

Manufacturing method of silver tin oxide contact alloy material

The invention discloses a manufacturing method of a silver tin oxide contact alloy material and a manufactured alloy thereof. The method comprises the following steps: 1.smelting: smelting the ingredients at the preset temperature and continuing to stir in the process of smelting; 2. casting the ingredients into a round spindle and lathing the surface of the round spindle; 3. carrying out hot rolling and then cold rolling on the round spindle and then rolling the round spindle into sheets; 4. carrying out oxygenation processing on the sheets in an internal oxidation furnace; 5. crushing the sheets and then carrying out high energy crushing processing on the crushed sheets; 6. carrying out hot extrusion to obtain a wire stock blank; 7. carrying out drawing processing and annealing treatment; and 8. taking the obtained material as the finished product. The alloy comprises the following components in percentage by weight: 7%-9% of Sn, 1.0%-3.0% of rare earth additive and the balance of Ag. The invention has the advantages of more simplified technique, easy implementation and excellent product performance.

Owner:浙江乐银合金有限公司

Method for preparing mixed rare-earth oxide modified silver tin oxide electrical contact material

InactiveCN101984117ARealize industrial productionReduce processing costsContactsChemical treatmentRare-earth element

The invention discloses a method for preparing a mixed rare-earth oxide modified silver tin oxide electrical contact material, which comprises the following steps of: 1, treating Ag2O powder; 2, preparing alloy melt by alloying Sn, rare-earth element and Ag; 3, preparing a composite material by spray co-deposition; 4, performing in-situ chemical treatment on the composite material; and 5, preparing the mixed rare-earth oxide modified silver tin oxide electrical contact material by extruding, rolling and drawing. The preparation of the mixed rare-earth oxide modified silver tin oxide electrical contact material with short flow, near formation and enforced uniform solidification can be realized by integrating advanced processing technology of spray co-deposition, in-situ chemical reaction and the like. The mixed rare-earth oxide modified silver tin oxide electrical contact material prepared by adopting the method has high welding resistance and arc burning tolerance, and meanwhile has the characteristics of low temperature rise, simple subsequent processing, wide application range, long service life and capability of realizing industrialized production.

Owner:XIAN RAREALLOYS

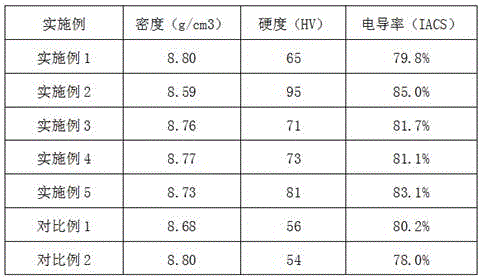

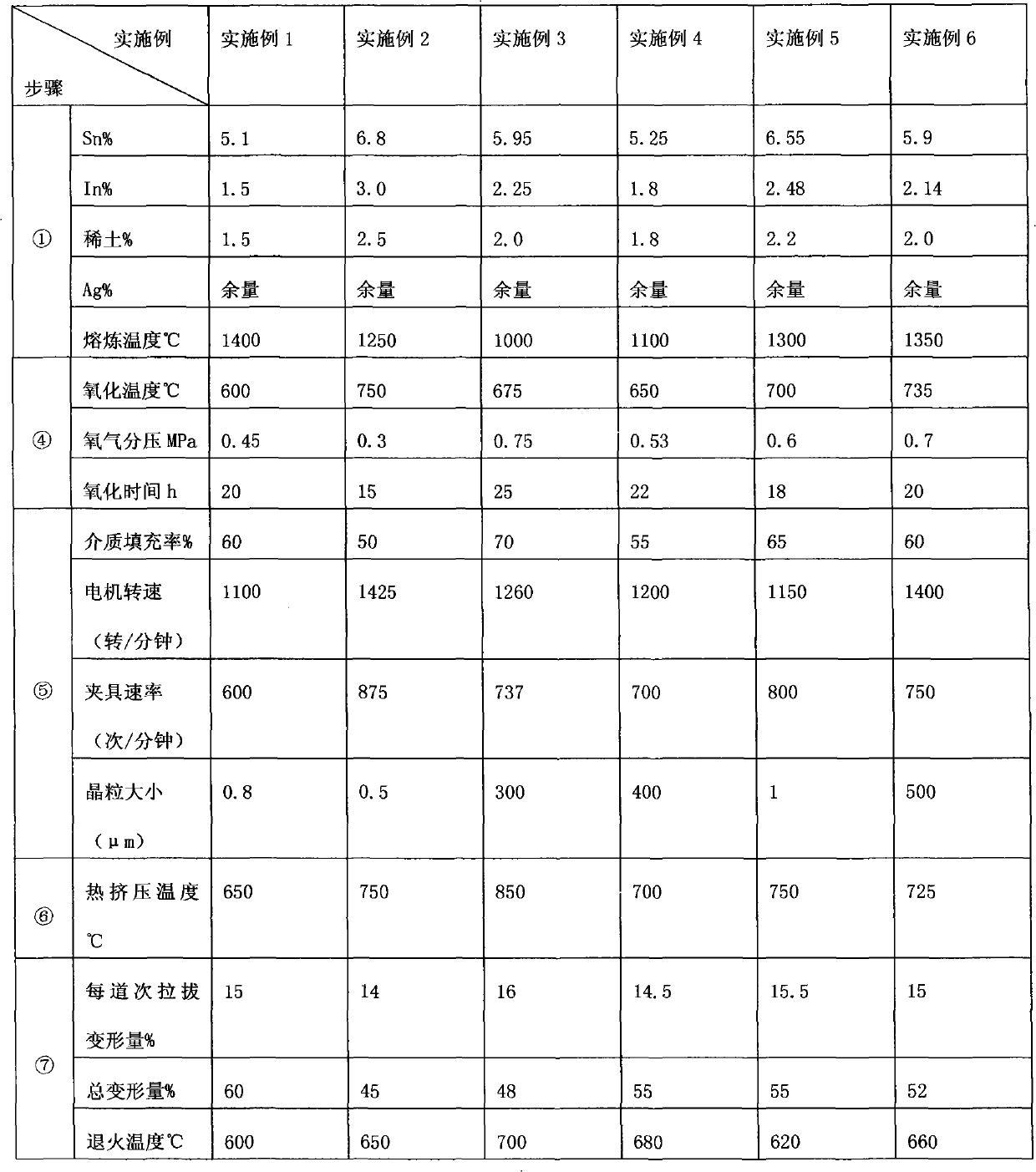

Method for manufacturing silver tin oxide indium oxide contact alloy material and manufactured alloy thereof

InactiveCN101950592AImprove heat workabilityGrain refinementMetal/alloy conductorsCable/conductor manufactureIndiumHigh energy

The invention discloses a method for manufacturing silver tin oxide indium oxide contact alloy material and a manufactured alloy thereof. The method comprises the following steps of: (1) smelting, namely smelting ingredients at the preset temperature, and continuously stirring in the smelting process; (2) casting into round ingots and turning external surfaces thereof; (3) performing hot rolling and cold rolling to form sheets; (4) performing oxygen-increasing treatment on the sheets in an inner oxidation furnace; (5) crushing and performing high-energy crushing treatment; (6) performing hot extrusion to prepare wire blanks; (7) drawing and annealing; and (8) using the obtained materials as finished products. The alloy comprises the following components in percentage by mass: 5.1 to 6.8 percent of Sn, 1.50 to 3.0 percent of In, 1.50 to 2.50 percent of rare earth additive and the balance of Ag. The method for manufacturing the silver tin oxide indium oxide contact alloy material has the advantages of simplified technology, easy implementation and excellent product performance.

Owner:浙江乐银合金有限公司

High-performance silver cadmium oxide material and manufacturing method thereof

The invention relates to a high-performance silver cadmium oxide material and a manufacturing method thereof, which are characterized in that the silver cadmium oxide material comprises the following components: 85 to 97 percent of silver, 2 to 15 percent of cadmium, 0.01 to 0.5 percent of nickel, 0.01 to 1 percent of tin and 0.01 to 0.5 percent of rear earth mixture. The manufacturing method of the high-performance silver cadmium oxide material is characterized in that: a given quantity of silver, cadmium, nickel, tin and rare earth mixture are measured to be arranged inside a middle-frequency induction furnace to be smelted and cast, the cast ingot is extruded by an extruding machine to be thick wires, the thick wires are stretched by a wire-drawing die to be thin wires, the thin wires are pre-oxidized by an internal oxidization furnace, then the thin wires are cut and preformed and finally is processed and formed. The anti-oxidization performance, electric-arc burning loss resistance and the abrasion resistance of the silver cadmium oxide material are improved, and the service life is prolonged, so the high-performance silver cadmium oxide material can be applied to different working environments, has low production cost, simple manufacturing method and low requirements on the device and the production.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

Nano silver-tin oxide electric contact and its prepn

InactiveCN1195308CImprove plasticityImprove conductivityContact materialsMetal/alloy conductorsElectrical resistance and conductanceMetallurgy

Owner:TIANJIN UNIV

Laminated silver-copper-brazing-filler-metal composite electrical contact material prepared by coating method and preparation method thereof

PendingCN106057527AImprove organizational structureImprove brazing resistanceContact materialsElectrical performanceFiller metal

The invention discloses a laminated silver-copper-brazing-filler-metal three-composite electrical contact material prepared by a coating method. Silver alloy powder is prepared by a coating method and copper alloy powder is prepared by a mechanical method; the silver alloy power, the copper alloy power, and a brazing filler metal material are prepared into a band material; and compounding is carried out to obtain a three-composite electrical contact material. Therefore, an electrical contact material having advantages of low material costs, excellent integrated electrical performances, and environmental protection is provided to replace the traditional copper-alloy contact material, silver-alloy contact material, and silver-copper-alloy contact material.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

Superfine oxide particle silver oxide ferroelectric contact material and preparation method thereof

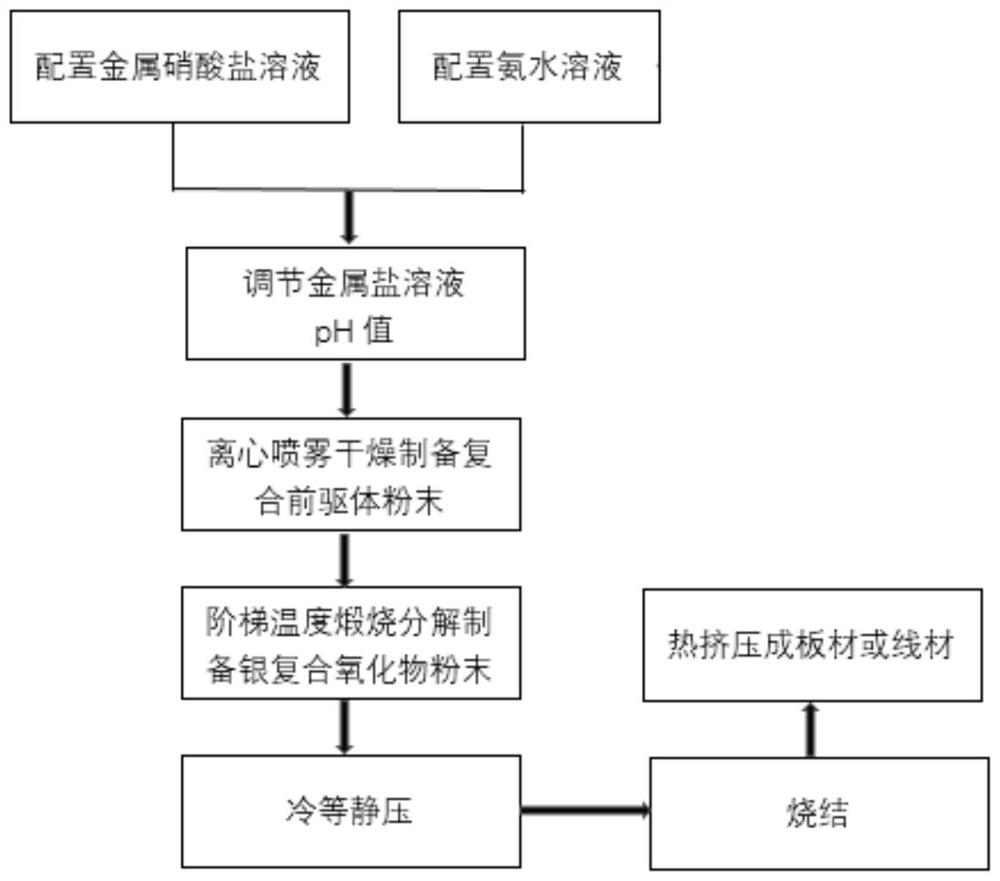

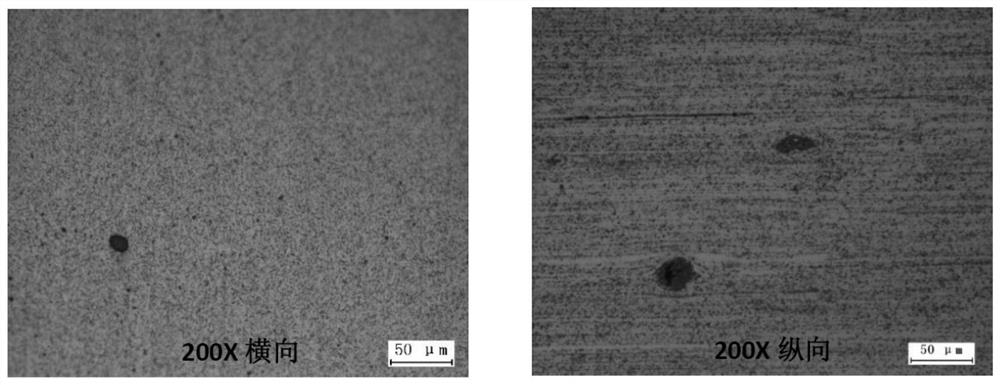

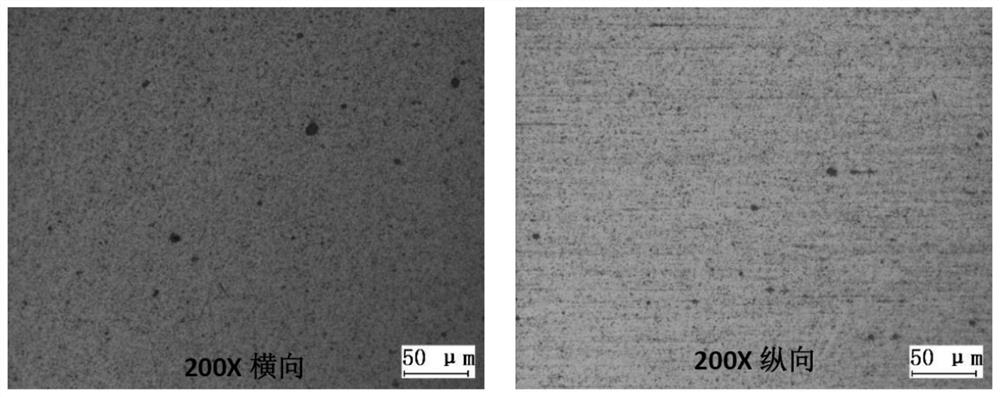

ActiveCN112355323AGuaranteed uniformityElimination of agglomeration defectsContactsMetal impuritiesSpray dried

The invention discloses a superfine oxide particle silver oxide ferroelectric contact material and a preparation method thereof. The preparation method comprises the following steps of: (1) preparingcomposite metal salt precursor powder, uniformly mixing a metal salt solution, and then preparing the composite metal salt precursor powder from the metal salt solution subjected to pH adjustment on spray drying equipment; (2) calcining and decomposing the composite metal salt precursor powder prepared in the step (1) through step heating to prepare silver oxide composite powder, wherein the silver oxide composite powder contains superfine oxide particles; and (3) performing cold isostatic pressing, sintering, re-pressing and hot extrusion on the silver oxide composite powder prepared in the step (2) to form a plate or a wire of the superfine oxide particle silver oxide ferroelectric contact material. According to the scheme, uniform dispersion and superfine particle size of the oxide particles can be realized, and low-melting-point metal impurities are not introduced in the preparation process of the material.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

A kind of preparation method of graphene-reinforced copper-based electrical contact material

ActiveCN105695776BPrevent floatingEvenly distributedElectric switchesIntermediate frequencyRare earth

The invention relates to a preparation method for a graphene reinforced copper-matrix electrical contact material. The preparation method comprises the steps that 1.0%-5.0% by weight of graphene and 95.0%-99.0% by weight of copper powder are subjected to ball milling for powder mixing and cold press molding, copper is smelted in an intermediate frequency furnace, copper-graphene intermediate alloy is added into molten copper, a composite is prepared through a casting process, and the composite is subjected to stress relief annealing and processing molding. According to the preparation method, graphene reinforcements are added into copper alloy to be used as a framework, so that the material has high hardness, high abrasion resistance, mechanical shock resistance and fusion-welding resistance. By adding rare earth, the oxidation resistance and electric arc burning resistance of the copper-alloy electrical contact material are improved.

Owner:冷金凤

Compound contact with higher welding resistance and high arc burning loss resistance

InactiveCN106356265AImprove welding resistanceEnhanced ability to resist arc burnCircuit-breaking switch contactsContact layerGraphite

The invention relates to a compound contact with higher welding resistance and high arc burning loss resistance. The compound contact is characterized by comprising a silver alloy contact layer and a copper alloy contact layer; the silver alloy contact layer is composed of the following components by weight percent: 1-20% of yttrium oxide, 1-10% of diamond and the balance of silver; and the copper alloy contact layer is composed of the following components by weight percent: 1-50% of molybdenum, 1-20% of graphite and the balance of copper. The compound contact provided by the invention has high welding resistance, high breaking capacity and obviously improved arc burning loss resistance.

Owner:沈阳新同正复合材料有限公司

Method for preparing mixed rare-earth oxide modified silver tin oxide electrical contact material

InactiveCN101984117BRealize industrial productionReduce processing costsContactsChemical treatmentRare-earth element

The invention discloses a method for preparing a mixed rare-earth oxide modified silver tin oxide electrical contact material, which comprises the following steps of: 1, treating Ag2O powder; 2, preparing alloy melt by alloying Sn, rare-earth element and Ag; 3, preparing a composite material by spray co-deposition; 4, performing in-situ chemical treatment on the composite material; and 5, preparing the mixed rare-earth oxide modified silver tin oxide electrical contact material by extruding, rolling and drawing. The preparation of the mixed rare-earth oxide modified silver tin oxide electrical contact material with short flow, near formation and enforced uniform solidification can be realized by integrating advanced processing technology of spray co-deposition, in-situ chemical reaction and the like. The mixed rare-earth oxide modified silver tin oxide electrical contact material prepared by adopting the method has high welding resistance and arc burning tolerance, and meanwhile has the characteristics of low temperature rise, simple subsequent processing, wide application range, long service life and capability of realizing industrialized production.

Owner:XIAN RAREALLOYS

Electric contact material made of silver-tungsten carbide graphite and preparation method thereof

The invention relates to an electric contact material made of silver-tungsten carbide graphite and a preparation method thereof. The electric contact material comprises the following main components in percentage by weight: 11%-14% of tungsten carbide-zirconium carbide solid solution, 2%-6% of graphite, 0.3%-0.6% of additive and the balance of silver, wherein the added element is one or the combination of Ti, Co and Cr. The tungsten carbide and the zirconium carbide are added in form of solid solution with the ratio of (6:4)-(9:1). Compared with the traditional electric contact made of silver-tungsten carbide graphite, the electric contact material has higher welding resistance, electric arc burning resistance and high-temperature oxidation resistance. A low-voltage electric appliance adopting the electric contact material has lower contact resistance, longer electric service life and high reliability. Therefore, the novel electric contact material with high reliability is more suitable for being applied in various different plastic-shell circuit breakers, small high-interruption circuit breakers and alternating-current contactors.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Silver-based alloy material and application thereof

ActiveCN101787460BHigh strengthImproved arc burn resistanceContact materialsElectrical resistance and conductanceHardness

The invention discloses a silver-based alloy material and application thereof. The silver-based alloy material can be used as sliding electric contact material for a light and medium load micromotor and improves the hardness and softening temperature of Ag-Cu alloy, thereby improving the electric arc burning resistance, fusion welding resistance and metal transfer resistance of the material and improving the electric contact reliability of the Ag-Cu alloy. Therefore, the material can solve the problems of unstable contact resistance, reduced contact reliability and low hardness and abrasive resistance under higher temperature of the AgCu4 alloy.

Owner:深圳市深汕特别合作区中金岭南新材料有限公司

Silver-iron oxide electric contact material with dispersed oxide particles and preparation method thereof

ActiveCN112475295ASolving Dispersion Uniformity IssuesSolve the uniformity of dispersionOxide conductorsFurnace typesBrown iron oxideInternal oxidation

The invention discloses a silver-iron oxide electric contact material with dispersed oxide particles and a preparation method of the silver-iron oxide electric contact material. The preparation methodcomprises the following steps: (1) smelting silver and modified additive metal, and carrying out water atomization to form alloy powder; (2) drying and sieving the alloy powder through a 200-mesh sieve to prepare -200 mesh alloy powder; (3) mixing the -200 mesh atomized alloy powder with iron powder; (4) performing powder rolling on the powder mixed in the step (3) to form a strip; (5) annealingthe strip, and then further performing cold rolling; and (6) carrying out internal oxidation on the rolled strip, then carrying out punching, ingot pressing, sintering and re-pressing on the strip subjected to internal oxidation, and further carrying out hot extrusion to form a plate or a wire. The silver-iron oxide electric contact material prepared by the method is fine in oxide particle size and uniform in structure, the material yield is remarkably improved compared with that of a conventional multi-extrusion process, and the method is suitable for mass production.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

A kind of copper-coated graphene/copper-based electrical contact material and preparation method thereof

ActiveCN105551839BHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingCvd grapheneCopper plating

The invention relates to a copper-plated graphene / copper-based electrical contact material and a preparation method thereof. The electrical contact material comprises the following components in percentage by weight: 0.1-2.0% of copper-plated graphene, and 98.0-99.9% of copper-rare earth alloy, wherein the weight ratio of rare earth to the copper-rare earth alloy is 0.03-3.0%. The preparation method comprises the following steps: plating copper on graphene, pulverizing to produce powder, ball-mixing and mixing powder, cold pressing and forming, and performing electric arc melting in vacuum. According to the invention, a copper-plated graphene reinforcing body as a framework is added into the copper alloy; therefore, the material has high hardness, abrasive resistance, mechanical shock resistance and melting-welding resistance; and, due to addition of the rare earth, the oxidation resistance and the electric arc erosion resistance capability of the copper alloy electrical contact material are improved.

Owner:UNIV OF JINAN

Method for manufacturing silver tin oxide indium oxide contact alloy material and manufactured alloy thereof

InactiveCN101950592BAccurate operationEasy to implementMetal/alloy conductorsCable/conductor manufactureIndiumHigh energy

The invention discloses a method for manufacturing silver tin oxide indium oxide contact alloy material and a manufactured alloy thereof. The method comprises the following steps of: (1) smelting, namely smelting ingredients at the preset temperature, and continuously stirring in the smelting process; (2) casting into round ingots and turning external surfaces thereof; (3) performing hot rolling and cold rolling to form sheets; (4) performing oxygen-increasing treatment on the sheets in an inner oxidation furnace; (5) crushing and performing high-energy crushing treatment; (6) performing hot extrusion to prepare wire blanks; (7) drawing and annealing; and (8) using the obtained materials as finished products. The alloy comprises the following components in percentage by mass: 5.1 to 6.8 percent of Sn, 1.50 to 3.0 percent of In, 1.50 to 2.50 percent of rare earth additive and the balance of Ag. The method for manufacturing the silver tin oxide indium oxide contact alloy material has the advantages of simplified technology, easy implementation and excellent product performance.

Owner:浙江乐银合金有限公司

A kind of copper-coated graphene-reinforced copper-based electrical contact material and preparation method thereof

ActiveCN105609159BHigh hardnessImprove wear resistanceNon-metal conductorsApparatus for manufacturing conducting/semi-conducting layersCopper platingRare earth

The invention relates to a copper-plated graphene reinforced copper-based electrical contact material and a preparation method thereof. The electrical contact material comprises 0.1-5.0 wt% of copper-plated graphene and 95.0-99.9 wt% of copper-rare earth alloy, and the weight ratio of rare earth in the copper-rare earth alloy accounts for 0.03-2.0%. The preparation method comprises the following steps of graphene copper plating, atomization for powder making, ball milling and power mixing, cold-press forming, sintering, secondary forming and sintering. A copper-plated graphene reinforced body is added into the copper alloy and taken as a framework, so that the material has the advantages of high hardness, high wear resistance, mechanical impact resistant performance and welding resistance; and with the addition of the rare earth, the oxidation resistance and the arc burning resistant capability of the copper alloy electrical contact material are improved.

Owner:UNIV OF JINAN

A layered silver-copper brazing three-composite electrical contact material prepared by atomization method

ActiveCN106067391BImprove organizational structureImprove welding resistanceContactsElectricityElectrical performance

The invention discloses a layered silver-copper-brazing three-laminated electric contact material and a preparation method thereof. According to the method, silver alloy powders, copper alloy powders and solders are prepared firstly. After that, strip materials are prepared by utilizing the silver alloy powders, the copper alloy powders and the solders. Finally, the strip materials are compounded to obtain the three-laminated electric contact material. The obtained electric contact material is low in material cost, excellent in comprehensive electrical performance, energy-saving, and environment-friendly, which can be used for replacing the materials of traditional copper alloy contacts, silver alloy contacts and silver-copper alloy contacts.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

Silver-tin oxide electrical contact material and preparation method thereof

InactiveCN1299307CPromote internal oxidationLower internal oxidation temperatureContact materialsRare-earth elementChemical composition

The invention discloses silver tin oxide electrician contact material and its preparation method. Its chemical composition (weight ratio) is that the SnO2 is from three percent to ten percent; the mixed rare earth oxide (Sm2O3, Gd2O3, Y2O3) is from 0.1 percent to 2.0 percent; the surplus quantity is Ag. The preparation method is that the Ag, Sn, rare earth element are made up according to the alloy design proportion of ingredients, alloying in the vacuum melting furnace; then the AgSnRE is made after quickly solidification. At first the alloy is formed to thread, panel, profiled bar or rivet by extrusion, rolling, drawing, heat treatment. Then it is formed to AgSnO2 mixed rare earth oxide electrician contact material by produce internal operation. It can be used in AC and DC contactor, relay, controller, circuit breaker, switch, and so on.

Owner:KUNMING INST OF PRECIOUS METALS

A kind of graphene-reinforced copper-rare earth-based electrical contact material and preparation method thereof

The invention relates to a graphene reinforced copper-rare earth based electrical contact material and a preparing method thereof. The electrical contact material comprises, by weight, 0.1-3.0% of graphene and 97.0-99.9% of copper-rare earth alloy, and rare earth accounts for 0.05-3.0% of the total weight of copper-rare earth alloy. The preparing method comprises the steps of powder atomization, ball milling and powder mixing, cold press molding, sintering, secondary forming and sintering. By adding a graphene reinforcing body to copper alloy to serve as the framework, the material has high hardness, high wear resistance, high mechanical impact resistance and high welding resistance. By adding rare earth, the oxidation resistance and electric arc erosion resistance of the copper alloy electrical contact material are improved.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com