Prepn process of nanometer tin oxide material with surface decorating silver

A nano-tin oxide and surface modification technology, which is applied in the field of preparation of nano-tin oxide materials, can solve the problems of poor plasticity and ductility of materials, increased contact resistance, limited popularization and application, etc. Simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

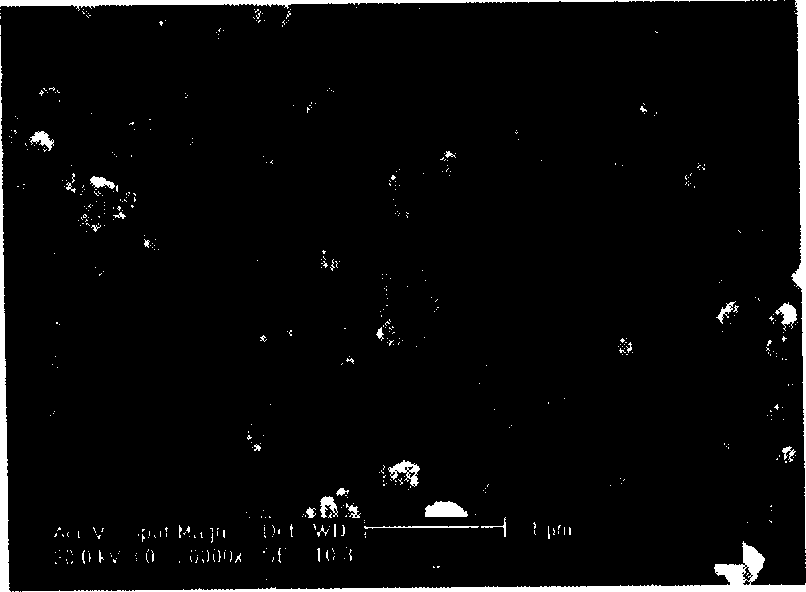

Image

Examples

Embodiment 1

[0012] (1) Decentralized processing

[0013] The prepared SnO with a particle size of 20-30 nm 2 Put 50 grams into a container, add 100 ml of absolute ethanol, then add 0.4 ml of surfactant polyethylene glycol as a dispersant, put it into an ultrasonic wave with a power of 2000W for 4 hours, dry it at 100°C and set it aside for use .

[0014] (2) Electroless plating treatment method of nano tin oxide powder

[0015] 50 grams of nano-tin oxide after the dispersion treatment is put into distilled water, and adding mass concentration is 15ml of 20% silver nitrate solution solution, and the method that combines electromagnetic stirring and vibration in ultrasonic wave makes nano-tin oxide and [Ag(NH 3 ) 2 ] + Disperse evenly, stir for 30 minutes; add 20ml reducing agent hydrazine hydrate (H 2 NNH 2 ×H 2 O) Reducing silver ions to obtain silver-coated nano-tin oxide powder, and then drying at 80°C to obtain a product.

[0016] (3) Mix the surface-modified nano-tin oxide pow...

Embodiment 2

[0020] (1) Decentralized processing

[0021] Put 80 grams of tin oxide with a particle size of 20-30 nanometers into a container, add 200 milliliters of absolute ethanol, then add 1.2 milliliters of surfactant polyethylene glycol as a dispersant, and put it into an ultrasonic wave with a power of 2000W for dispersion treatment After 6 hours, dry it at 80°C before use.

[0022] (2) Electroless plating treatment method of nano tin oxide powder

[0023] 80 grams of nano-tin oxide after dispersion treatment is put into distilled water, and adding mass concentration is 30% silver nitrate solution solution 30ml, the method that combines with electromagnetic stirring and vibration in ultrasonic wave makes nano-tin oxide and [Ag(NH 3 ) 2 ] + Disperse evenly, stir for 30 minutes; add 60ml reducing agent hydrazine hydrate (H 2 NNH 2 ×H 2 O) Reducing silver ions to obtain silver-coated nano-tin oxide powder, and then drying at 100° C. to obtain a product.

Embodiment 3

[0025] (1) Decentralized processing

[0026] Put 20 grams of the prepared tin oxide with a particle size of 20-30 nanometers into a container, add 200 ml of absolute ethanol, then add 0.24 ml of surfactant polyethylene glycol as a dispersant, and put it into an ultrasonic wave with a power of 2000W for dispersion treatment After 4 hours, dry it at 120°C before use.

[0027] (2) Electroless plating treatment method of nano tin oxide powder

[0028] 20 grams of nano-tin oxide after dispersion treatment is put into distilled water, and adding mass concentration is 20ml of 30% silver nitrate solution solution, and the method that combines with electromagnetic stirring and vibration in ultrasonic wave makes nano-tin oxide and [Ag(NH 3 ) 2 ] + Disperse evenly, stir for 20 minutes; add 40ml reducing agent hydrazine hydrate (H 2 NNH 2 ×H 2 O) Reducing silver ions to obtain silver-coated nano-tin oxide powder, and then drying at 100° C. to obtain a product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com