Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115results about How to "Improve steaming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

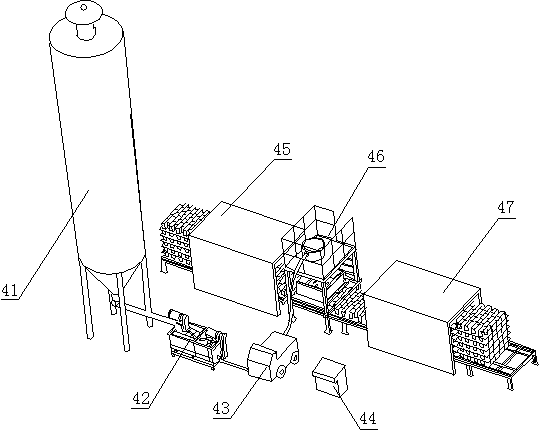

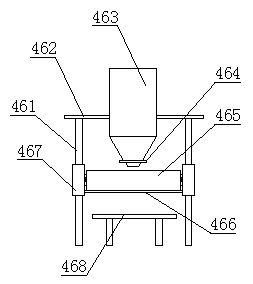

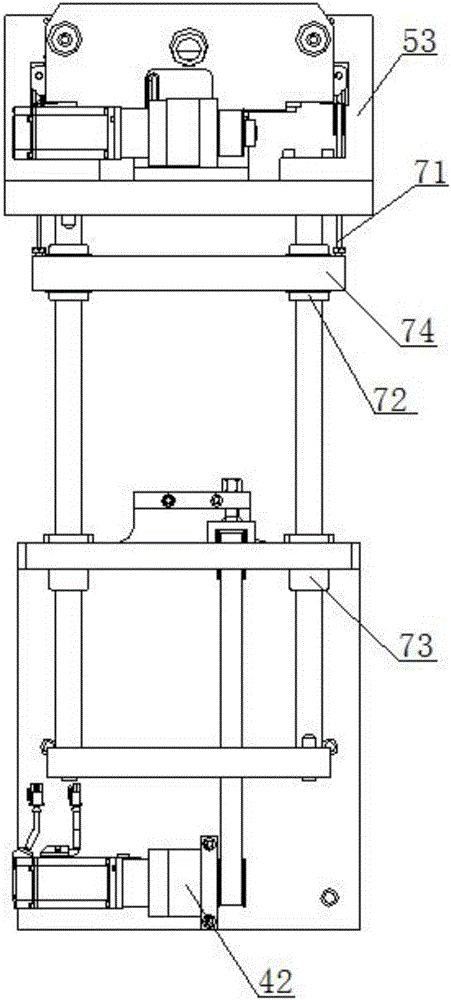

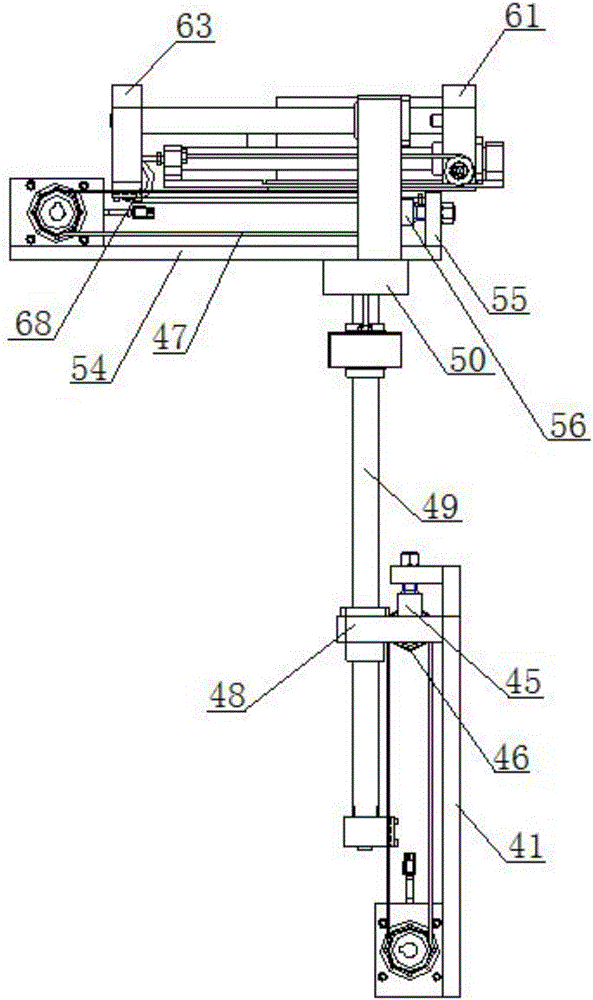

Production line for self-heat-insulation building blocks for walls

ActiveCN103128848AReduce waste lossEasy maintenanceCeramic shaping plantsProduction lineFoam concrete

The invention discloses an equipment production line for self-heat-insulation building blocks for walls. The equipment production line comprises a hollow brick production system, a steam curing system, a transfer system, a foam concrete pouring system and an automatic control system. The steam curing system is respectively connected with the hollow brick production system and the foam concrete pouring system by the transfer system, and the automatic control system is connected with the hollow brick production system, the steam curing system, the foam concrete pouring system and the transfer system by control circuits. Compared with the traditional production line, the equipment production line has the advantages that the steam curing efficiency is greatly improved, the energy cost is greatly saved, and the production cost is reduced; and distances from a filling plate and a filling groove to hollow bricks can be adjusted via lifting mechanisms, so that slurry can be effectively prevented from flowing out of the hollow bricks during pouring when the quantity of slurry in the filling groove is excessively high, waste of the slurry is reduced, and accordingly the production cost is saved.

Owner:河南华泰新材科技股份有限公司

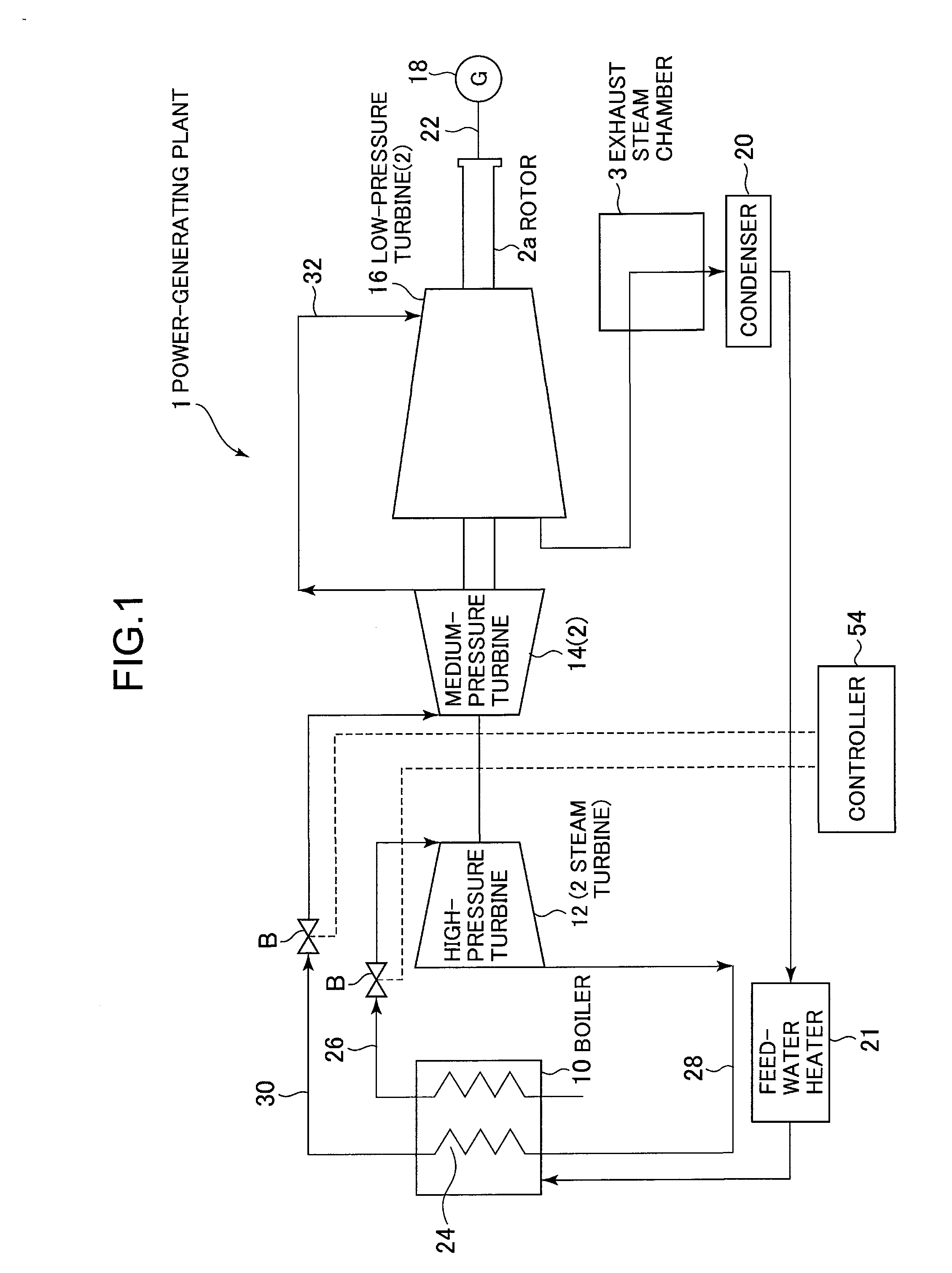

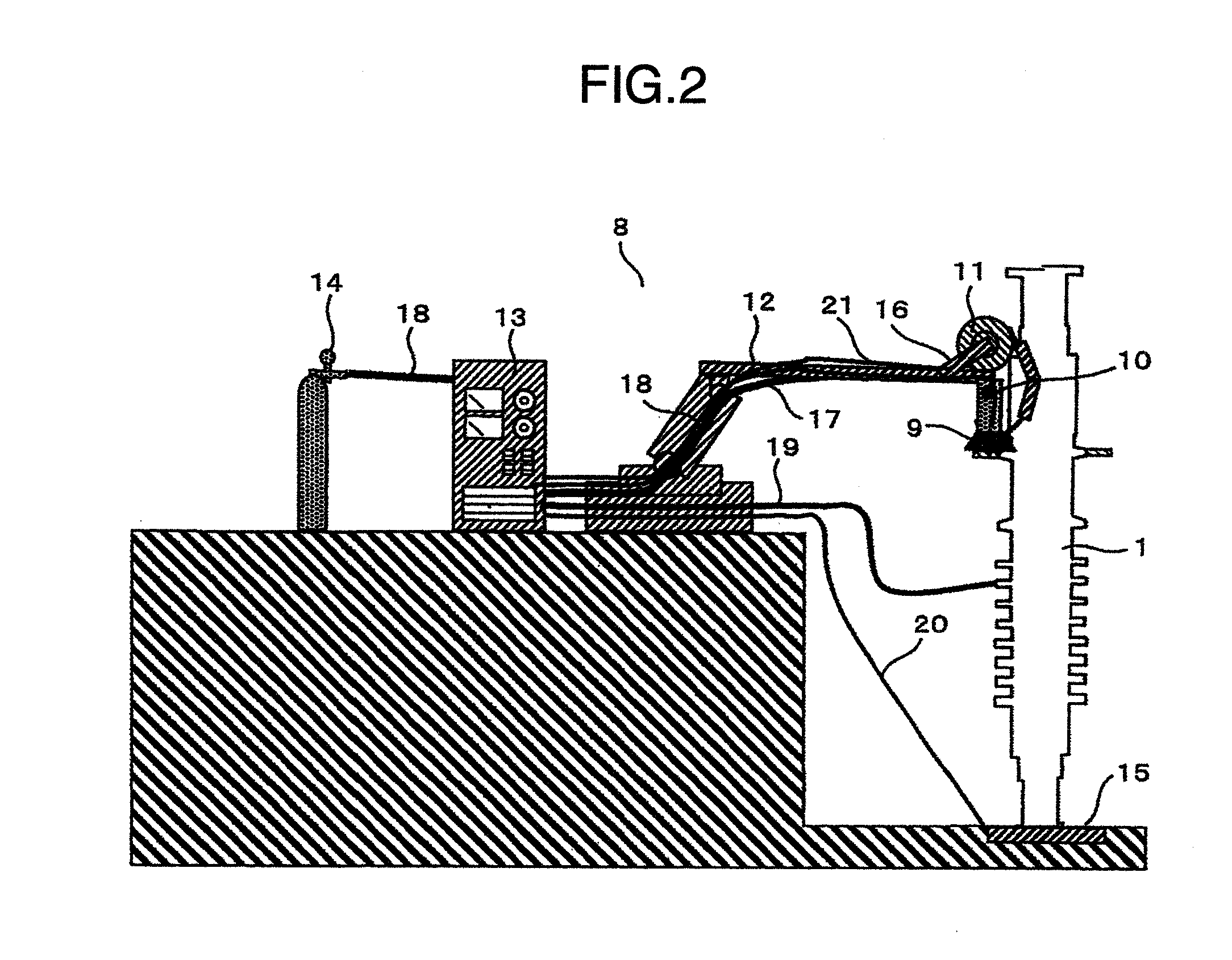

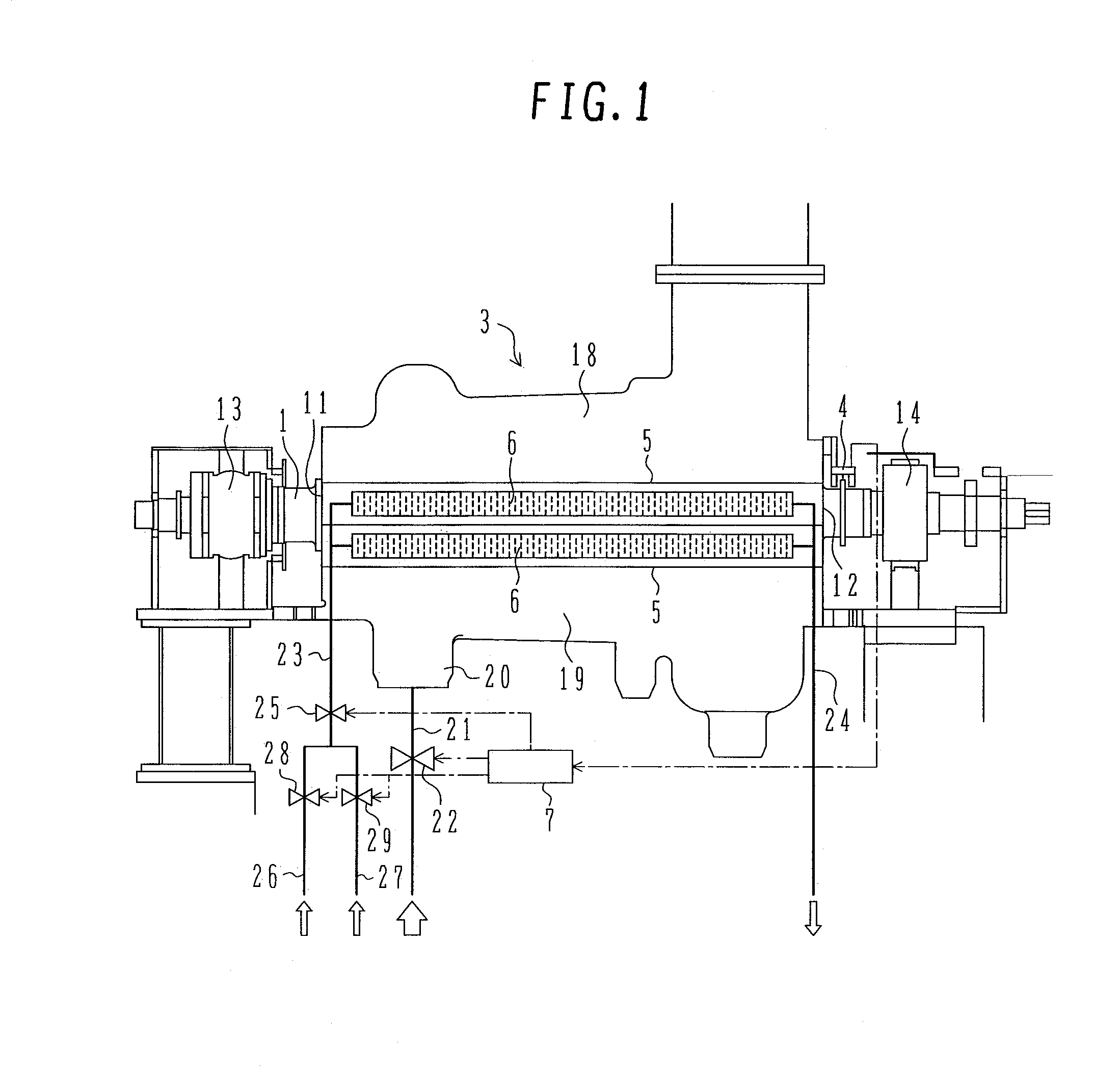

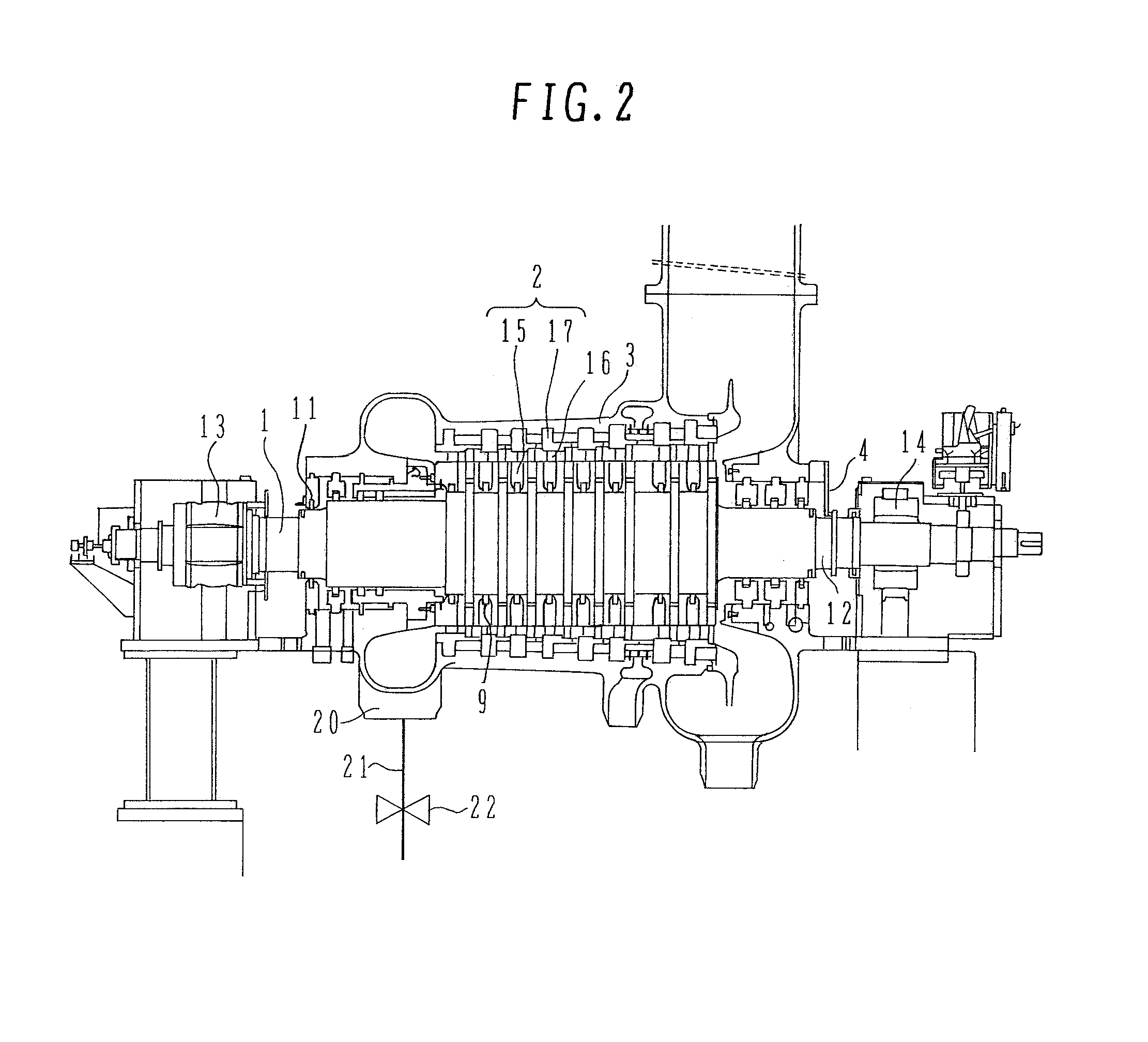

Steam turbines, seals, and control methods therefor

InactiveUS20080019821A1Shorten the timeImprove efficiencyWind motor controlPump componentsEngineeringThermal expansion

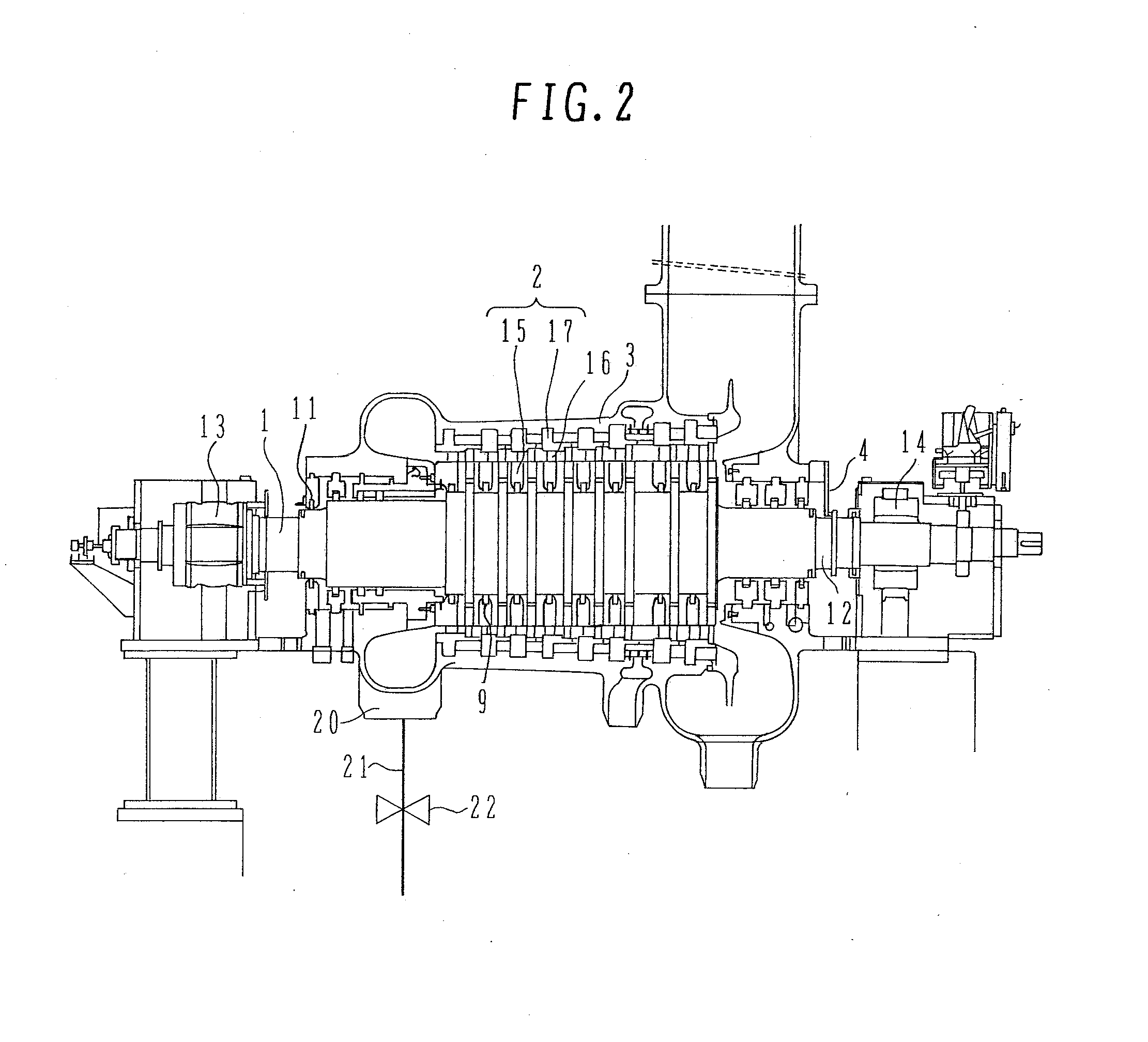

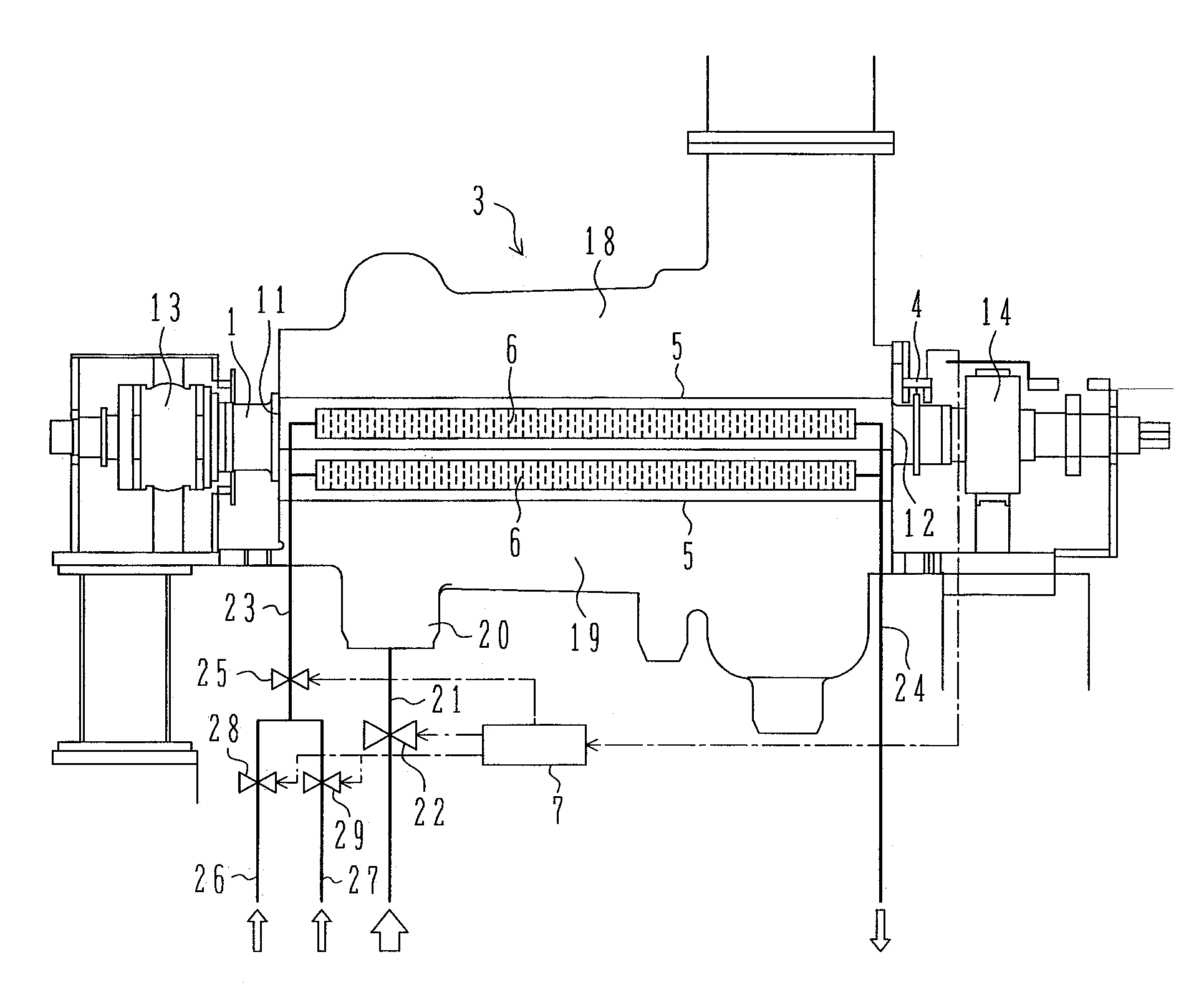

A steam turbine comprises a rotor with moving blades attached thereto; diaphragms which surround the rotor from an outer periphery side of the rotor; a casing which encloses the diaphragms and the rotor and has an upper half and a lower half clamped together through respective flanges; a displacement detector for measuring a difference d in thermal expansion in the rotor axis direction between the casing and the rotor; heating / cooling devices attached to the flanges respectively to heat and cool the flanges; and a controller which makes control so that the flanges are heated or cooled by the heating / cooling devices until a measured value obtained by the displacement detector reaches a preset value M or S in unsteady operation.

Owner:MITSUBISHI POWER LTD

Laundry treating apparatus

ActiveUS20090288456A1Increase efficiencyPrevent removalOther washing machinesTextiles and paperLaundryEngineering

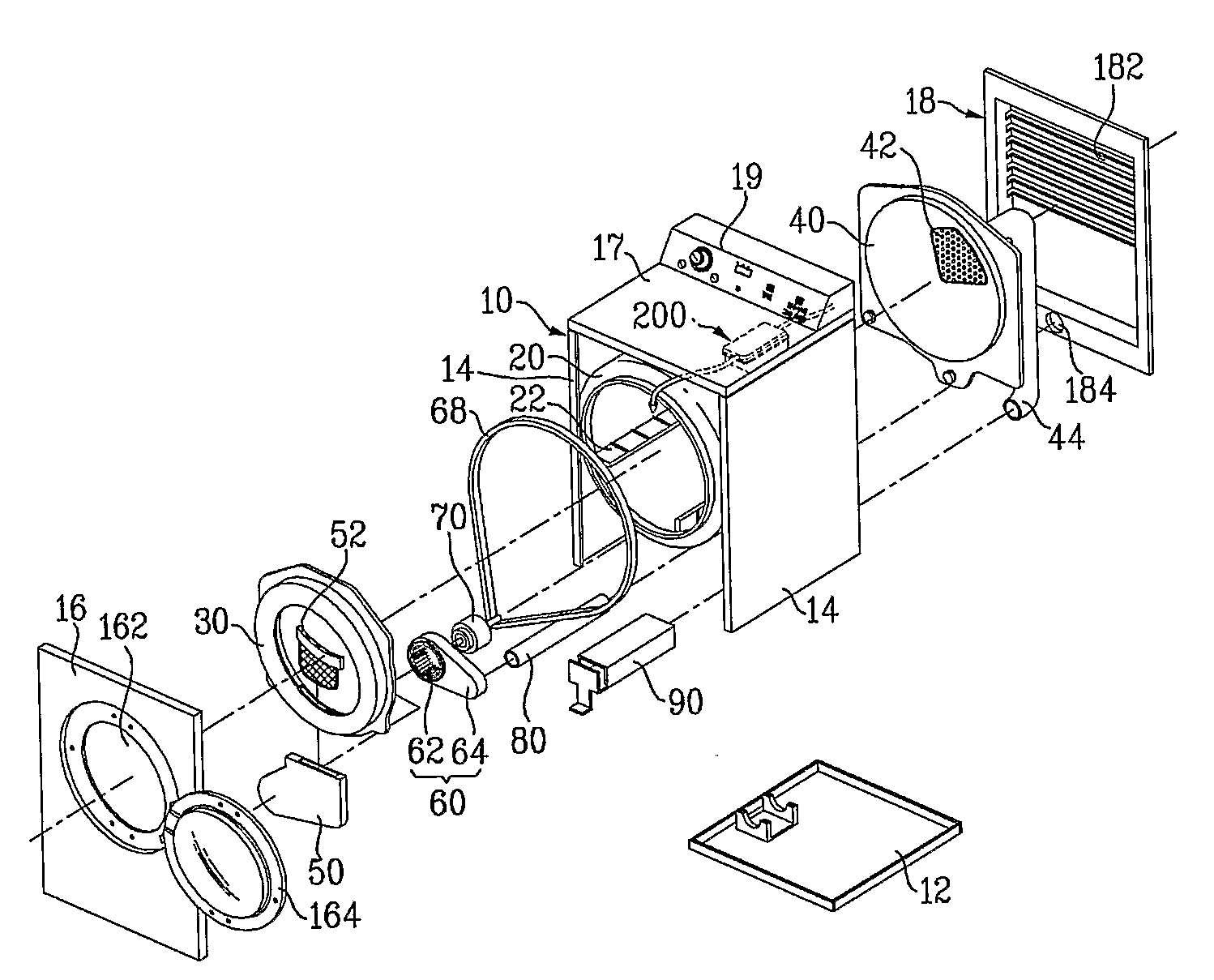

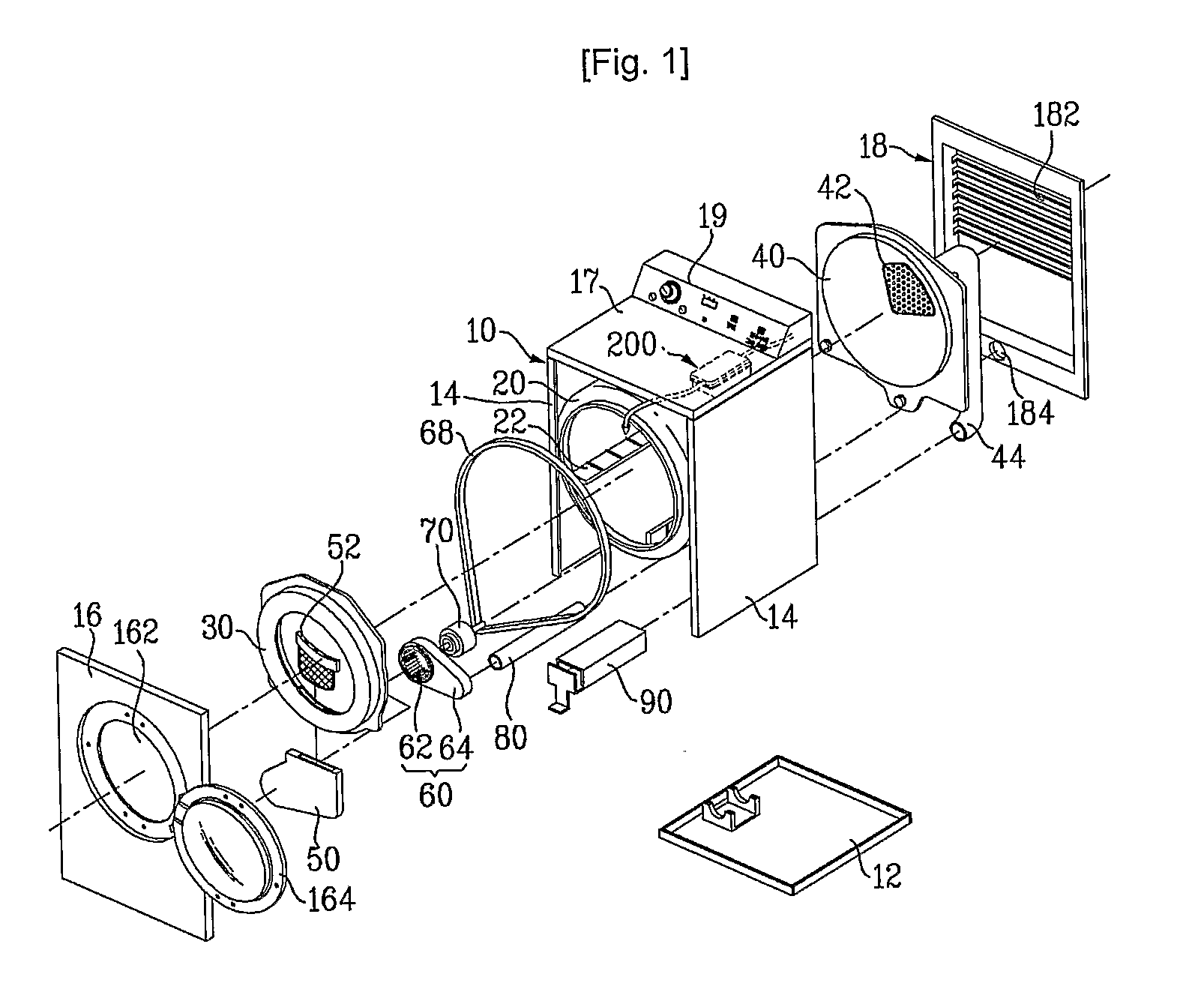

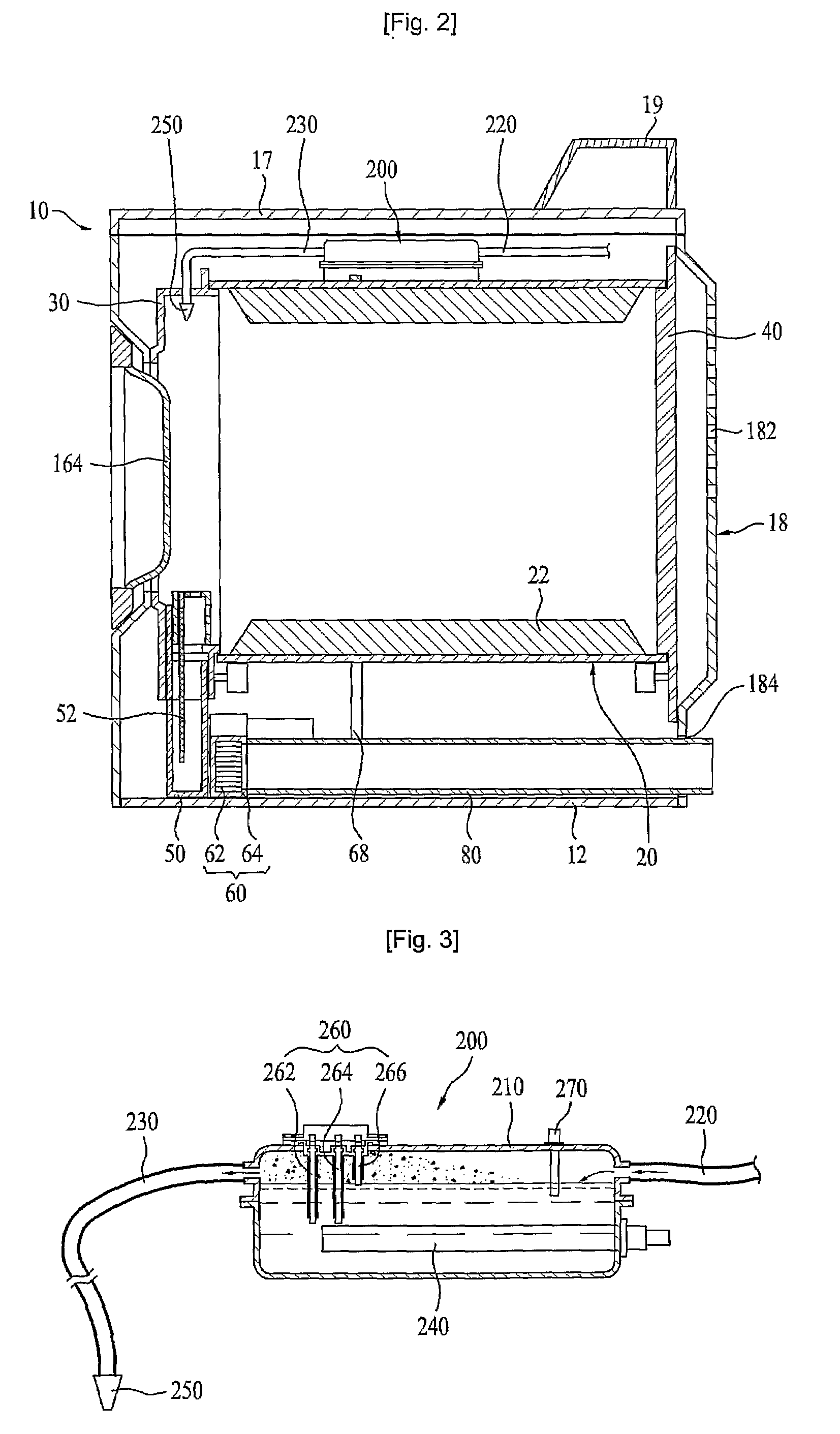

A laundry treating apparatus and a method of controlling the same are disclosed. The laundry treating apparatus includes a laundry receiving unit for receiving laundry, a steam generator for generating steam to be supplied to the laundry receiving unit, a water supply unit for supplying water to the steam generator, a water softening member for softening water to be supplied to the steam generator, and a control unit for controlling the replacement or regeneration time of the water softening member to be displayed on a display unit. According to the present invention, it is possible to effectively prevent and / or remove wrinkles or rumples on laundry. Furthermore, it is possible to replace or regenerate a water softening member at an appropriate point of time, thereby increasing convenience in use.

Owner:LG ELECTRONICS INC

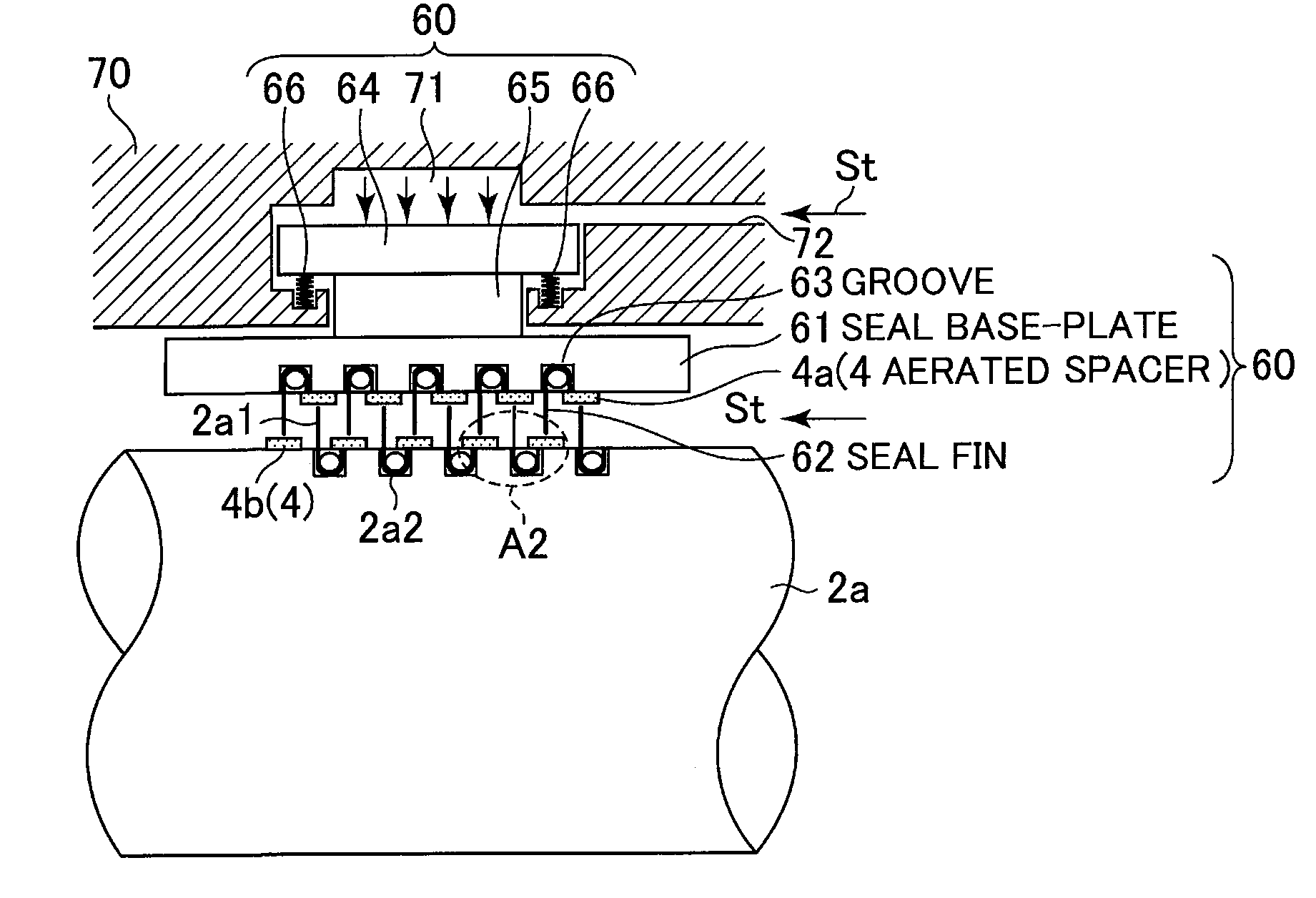

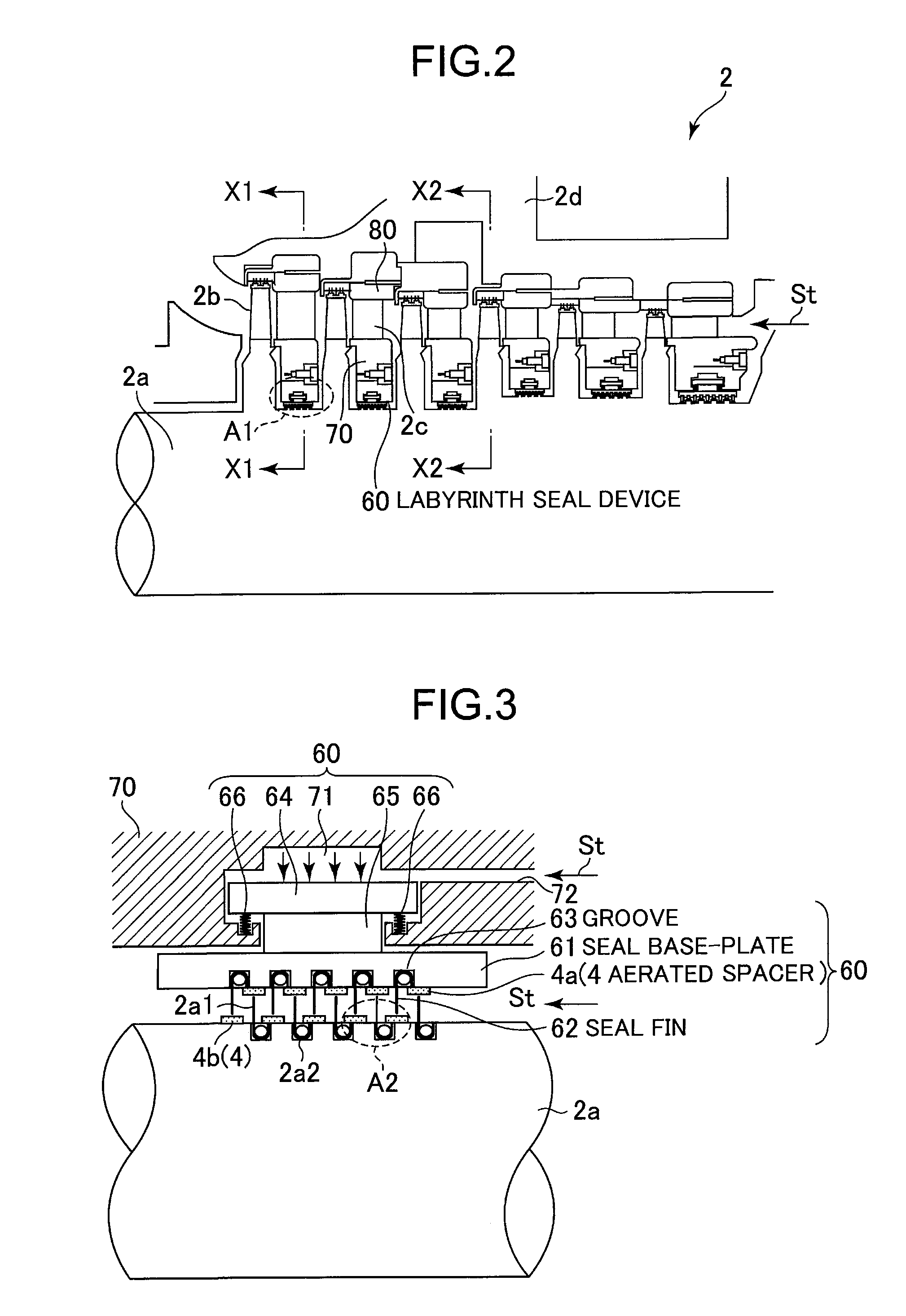

Seal Structure and Control Method Therefor

InactiveUS20100278645A1Improve sealingInhibit temperature risePump componentsLeakage preventionHigh pressureStart up

Provided are a seal structure and a control method therefor that can improve sealing performance between a rotating portion and a fixed portion, smoothly start up a steam turbine, and suppress the temperature rise of the rotating portion even if the rotating portion is continuously rotated for a long period of time.A seal structure is configured such that seal fins 62 on a seal base-plate 61 side and corresponding breathable spacers 4b on a rotor 2a side are opposed to each other and breathable spacers 4a on the seal base-plate 61 side and corresponding seal fins 2a1 on the rotor 2a side are opposed to each other. The seal base-plate 61 is installed shiftably in a direction coming close to or moving away from the rotor 2a. If steam St has low pressure, the seal fins 62 and the corresponding breathable spacers 4b are not in contact with each other and the seal fins 2a1 and the corresponding breathable spacers 4a are not in contact with each other. If the steam St has high pressure, the seal fins 62 and the corresponding breathable spacers 4b are in contact with each other and the seal fins 2a1 and the corresponding breathable spacers 4a are in contact with each other.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

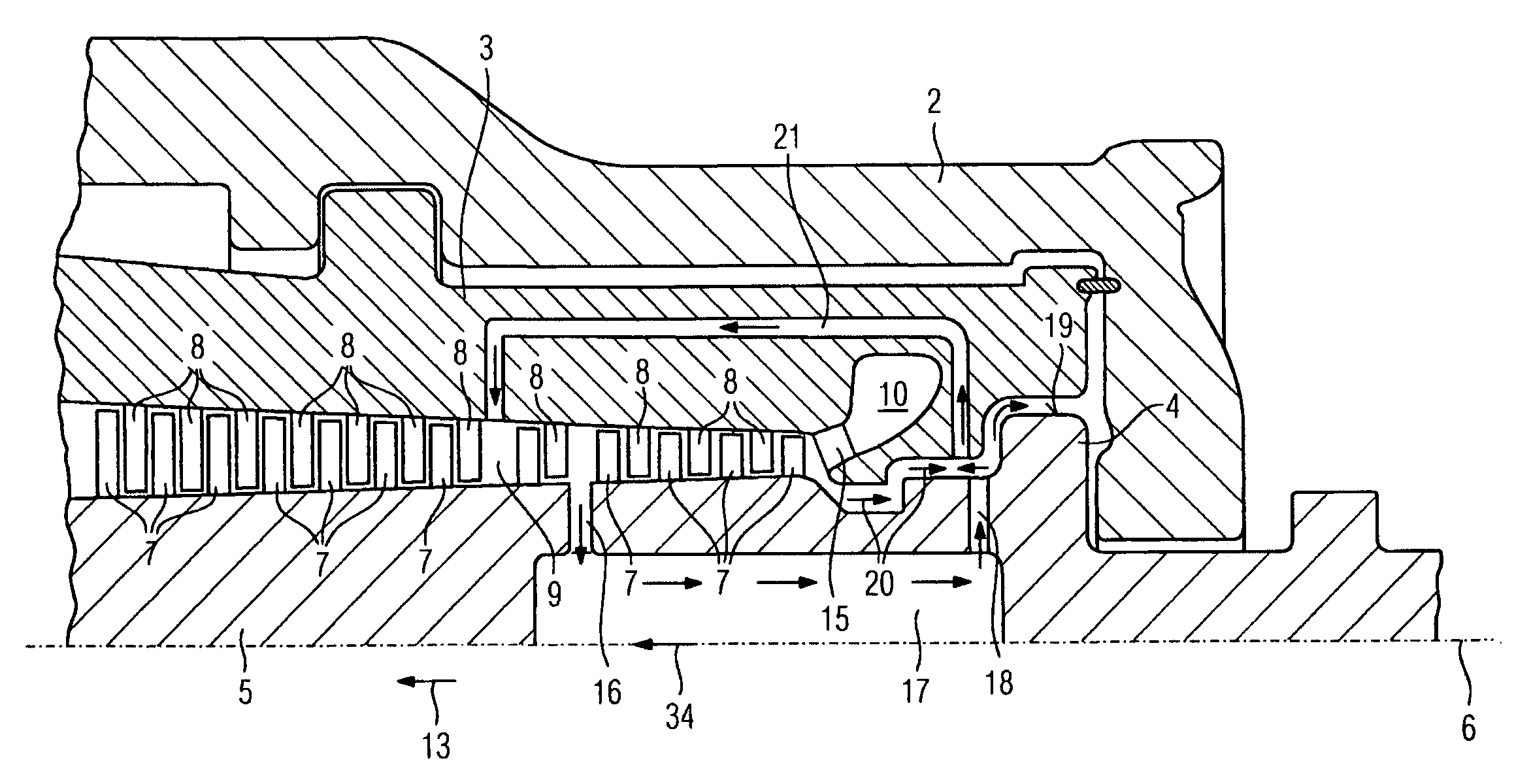

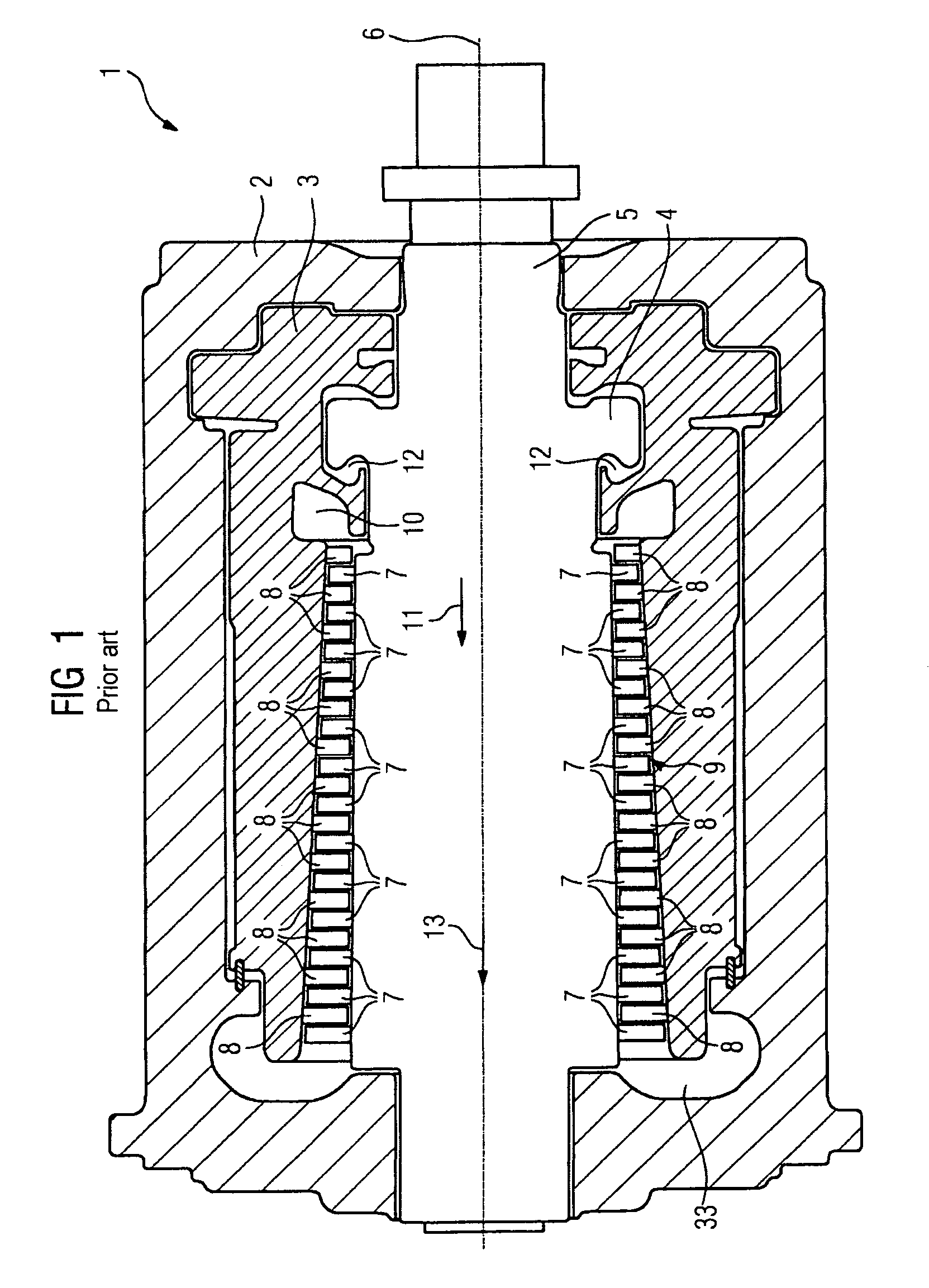

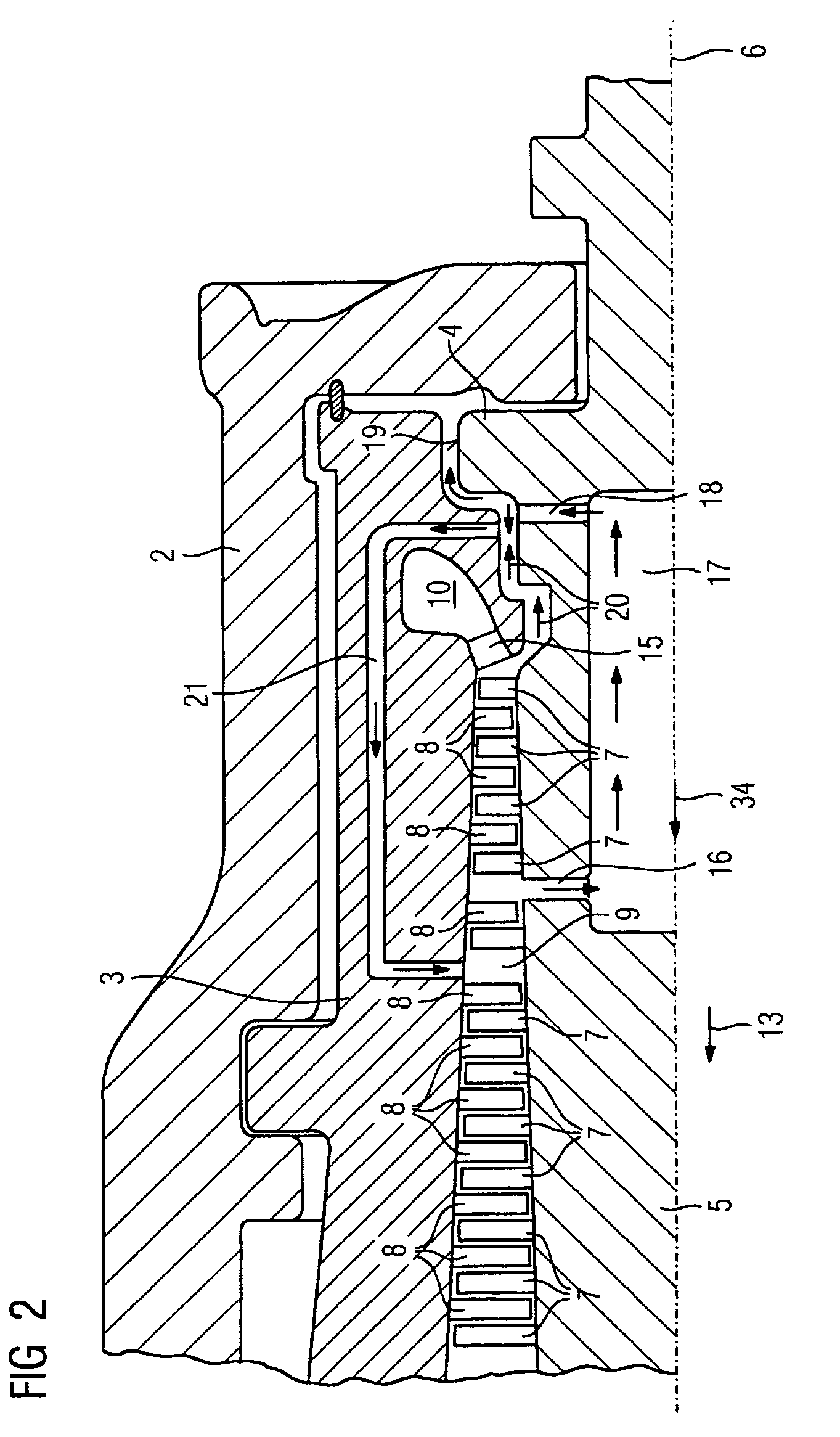

Steam turbine

InactiveUS8128341B2Reduce heat loadImprove steaming efficiencyEngine fuctionsBlade accessoriesLine tubingEngineering

Disclosed is a steam turbine with a casing, wherein a turbine shaft having a thrust-compensating piston is rotatably mounted inside the casing and directed along a rotation axis, wherein a flow passage is formed between the casing and the turbine shaft. The turbine shaft has in its interior a cooling line for directing cooling steam in the direction of the rotation axis. The cooling line, on one end, is connected to at least one inflow line for the inflow of cooling steam into the cooling line from the flow passage, and on the other end, is connected to an outflow line for directing cooling steam onto a lateral surface of the thrust-compensating piston. An essential aspect is, the cooling steam discharging onto the lateral surface of the thrust-compensating piston mixes with some of the live steam and is directed back into the flow passage via a return line arranged in the casing.

Owner:SIEMENS AG

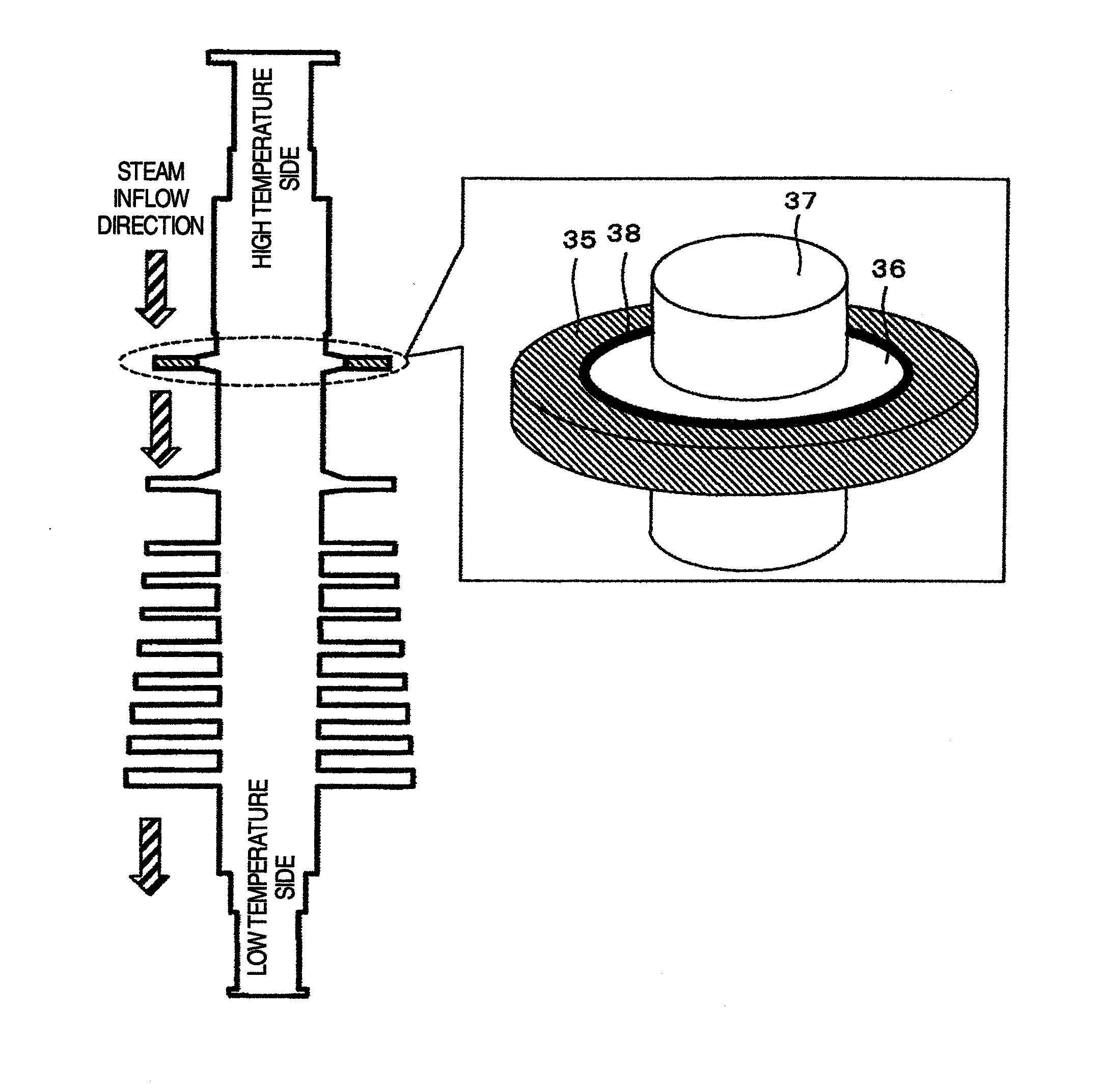

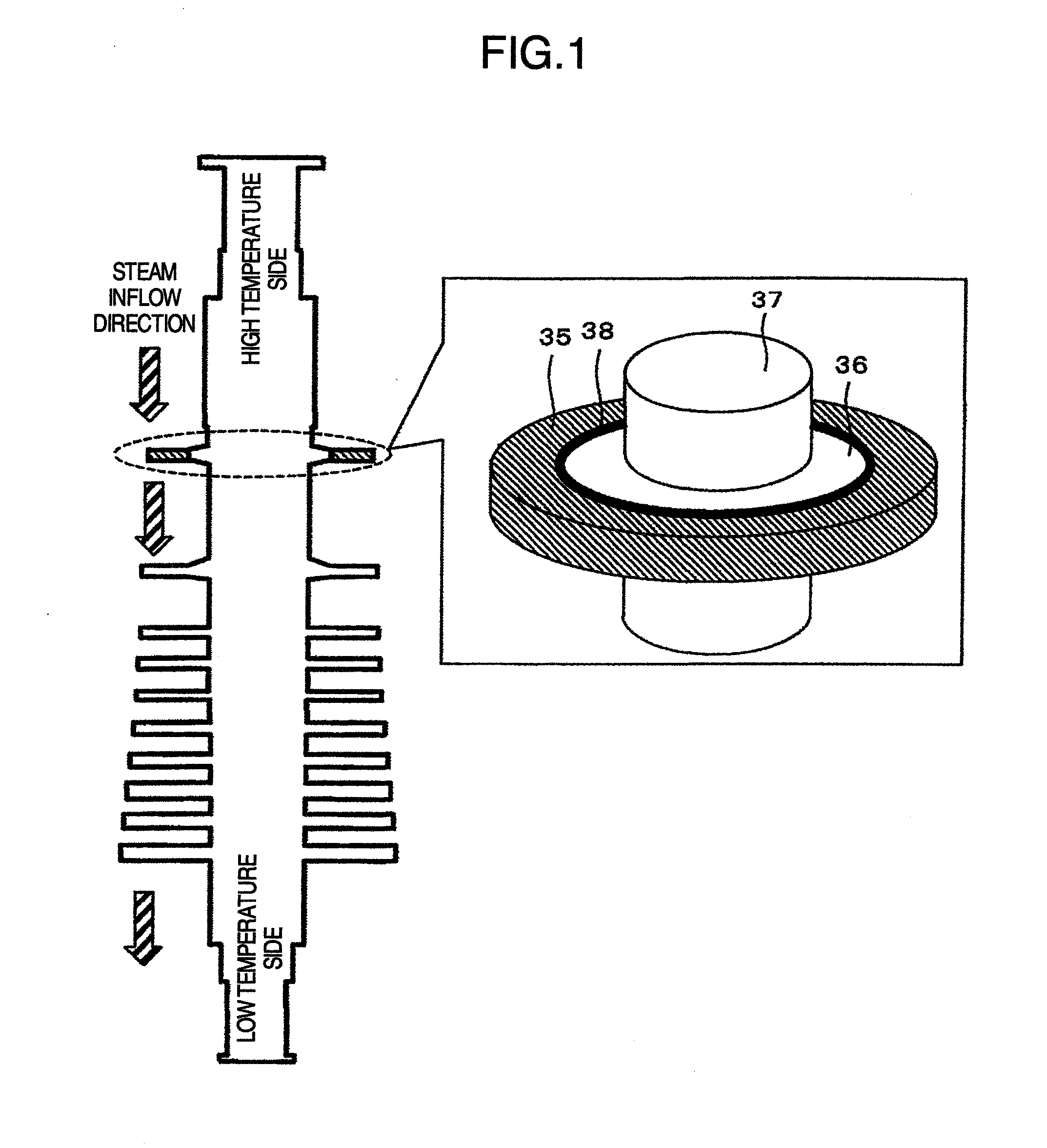

Turbine rotor

InactiveUS20100329849A1High tolerable temperatureEasy to manufacturePump componentsBlade accessoriesPower stationTurbine blade

A turbine rotor which is easy to manufacture and has a high tolerable temperature is provided. A highly efficient steam turbine power plant is also provided. The turbine rotor is configured from a rotor shaft, an inner rotor disc constructed integrally with the rotor shaft, and an outer rotor disc which is welded to the inner rotor disc via a weld metal part and has a structure for fixing a turbine blade. The outer rotor disc preferably has a cooling hole which extends in an axial direction to penetrate the outer rotor disc over the thickness of the outer rotor disc.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

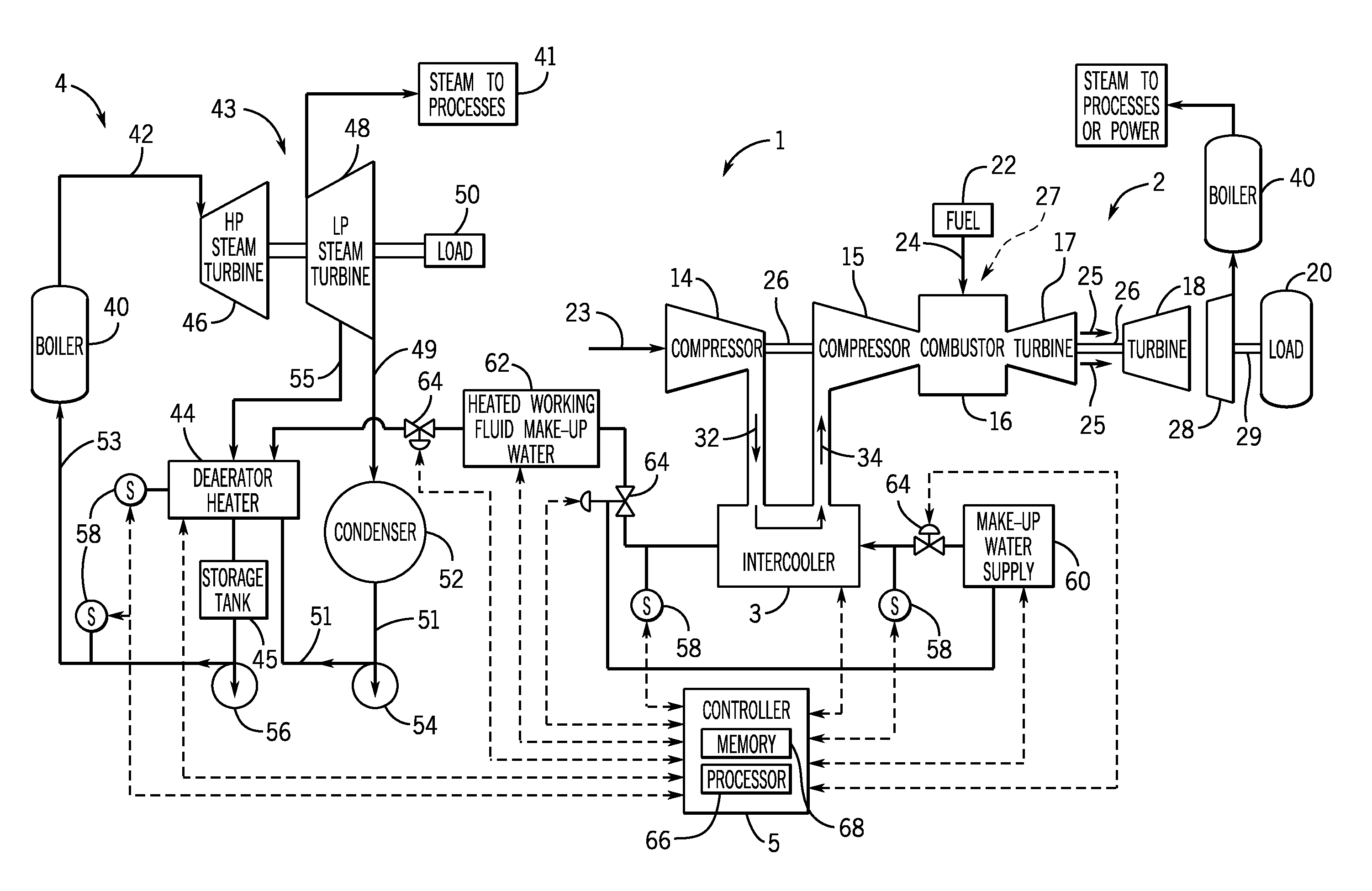

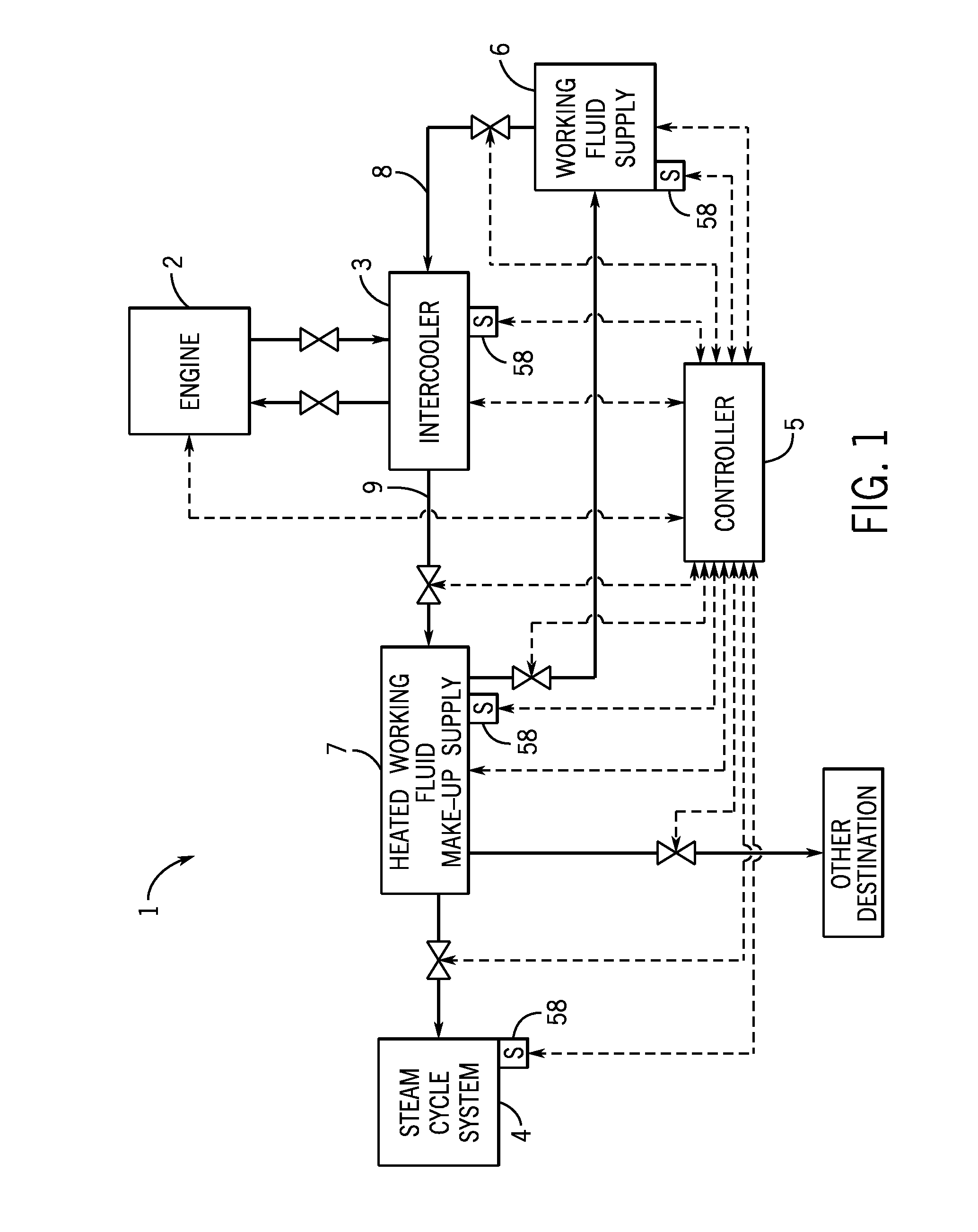

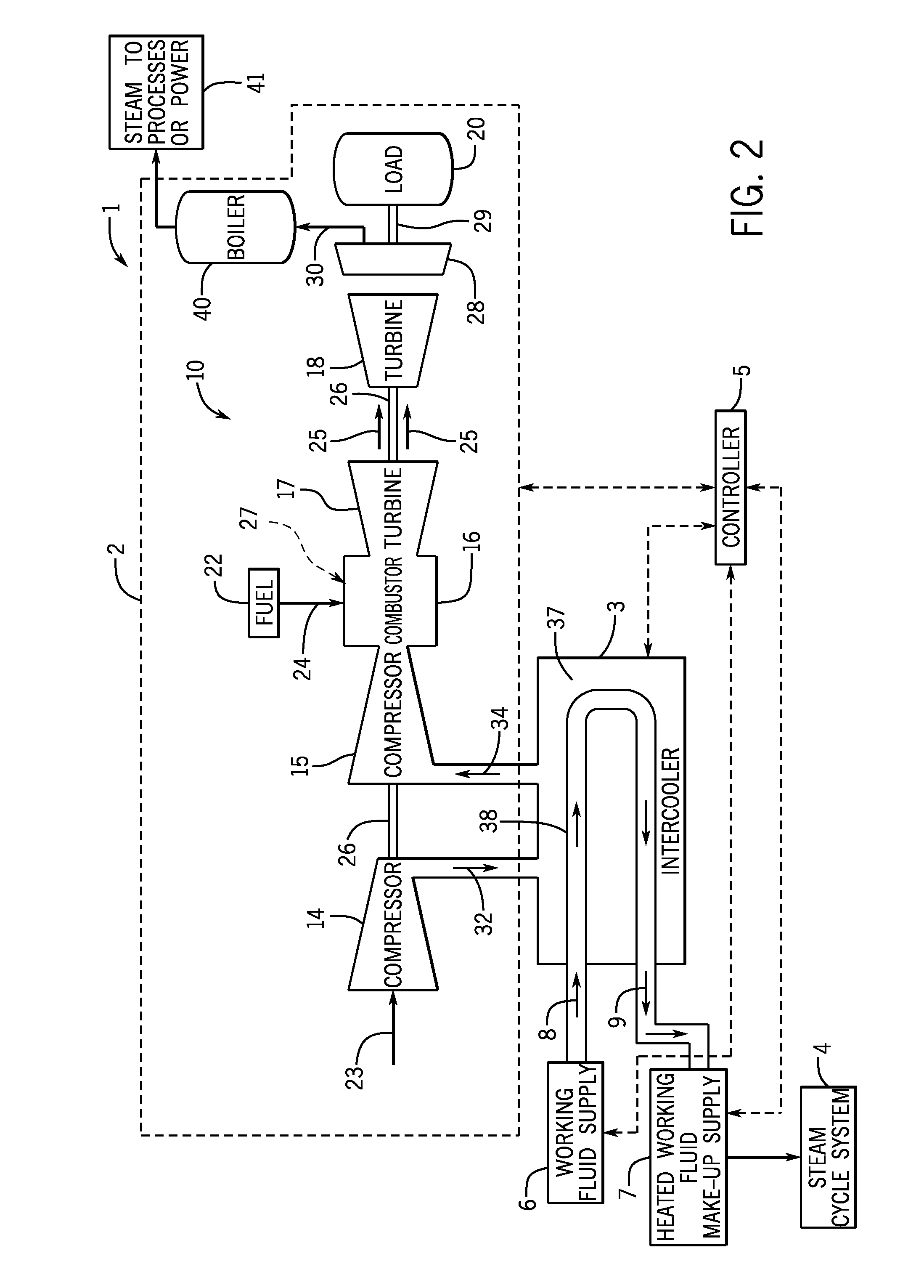

System and method for heating make-up working fluid of a steam system with engine fluid waste heat

ActiveUS20160245125A1Improve steaming efficiencyEngine fuctionsTurbine/propulsion engine coolingWorking fluidEngineering

A system including an engine and a heat exchanger coupled to the engine is provided. The engine includes an engine fluid and at least one of a compressor section configured to compress a gas, a lubricant path configured to circulate a lubricant, or a coolant path configured to circulate a coolant. The engine fluid comprises at least one of the gas, the lubricant, or the coolant, and the engine fluid is a source of heat derived from one or more operations of the engine. The heat exchanger is configured to receive the engine fluid from the engine and exchange heat between the engine fluid and a working fluid to produce a heated working fluid and a cooled engine fluid, and the heat exchanger is configured to export the heated working fluid to a steam system.

Owner:GENERAL ELECTRIC CO

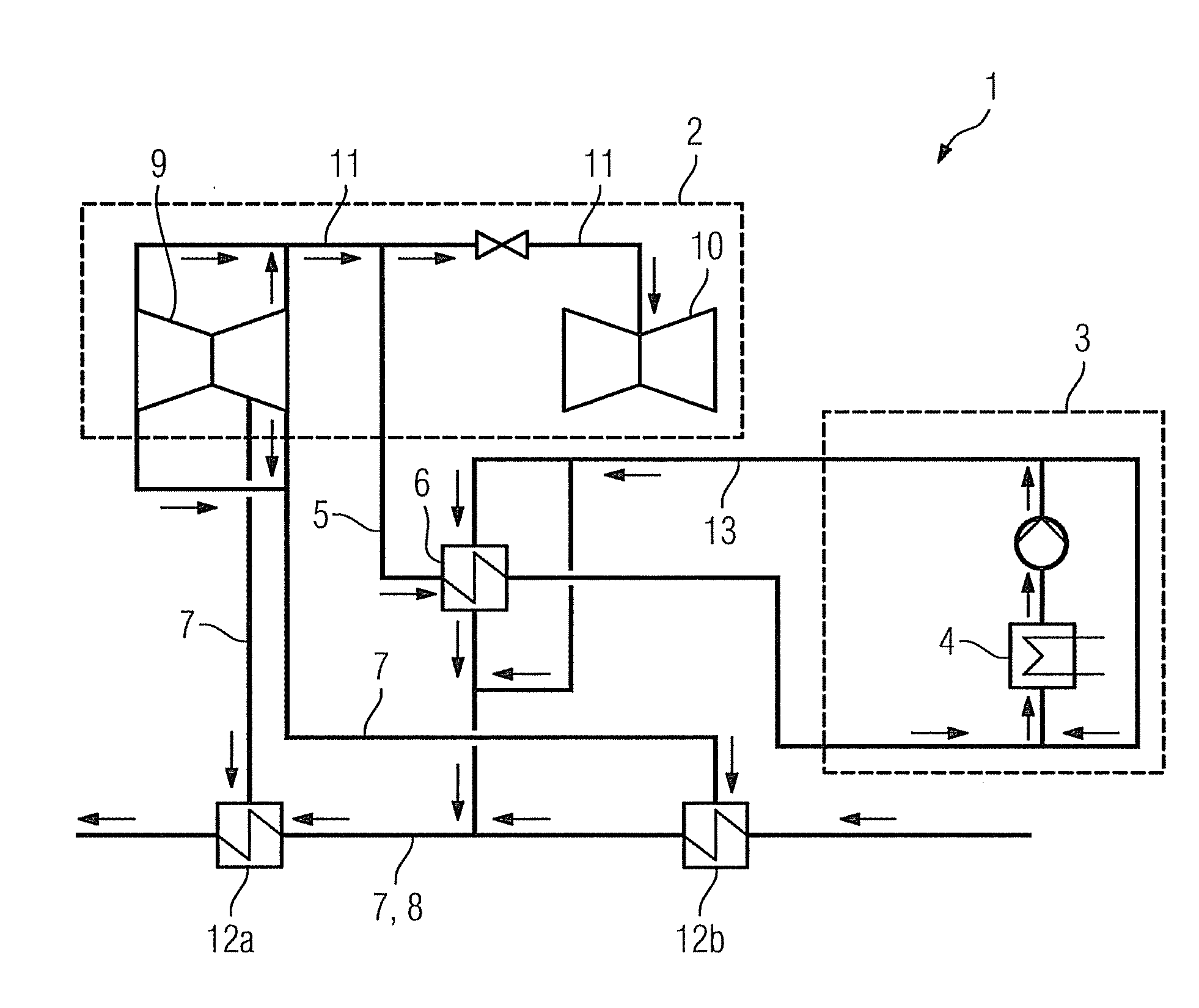

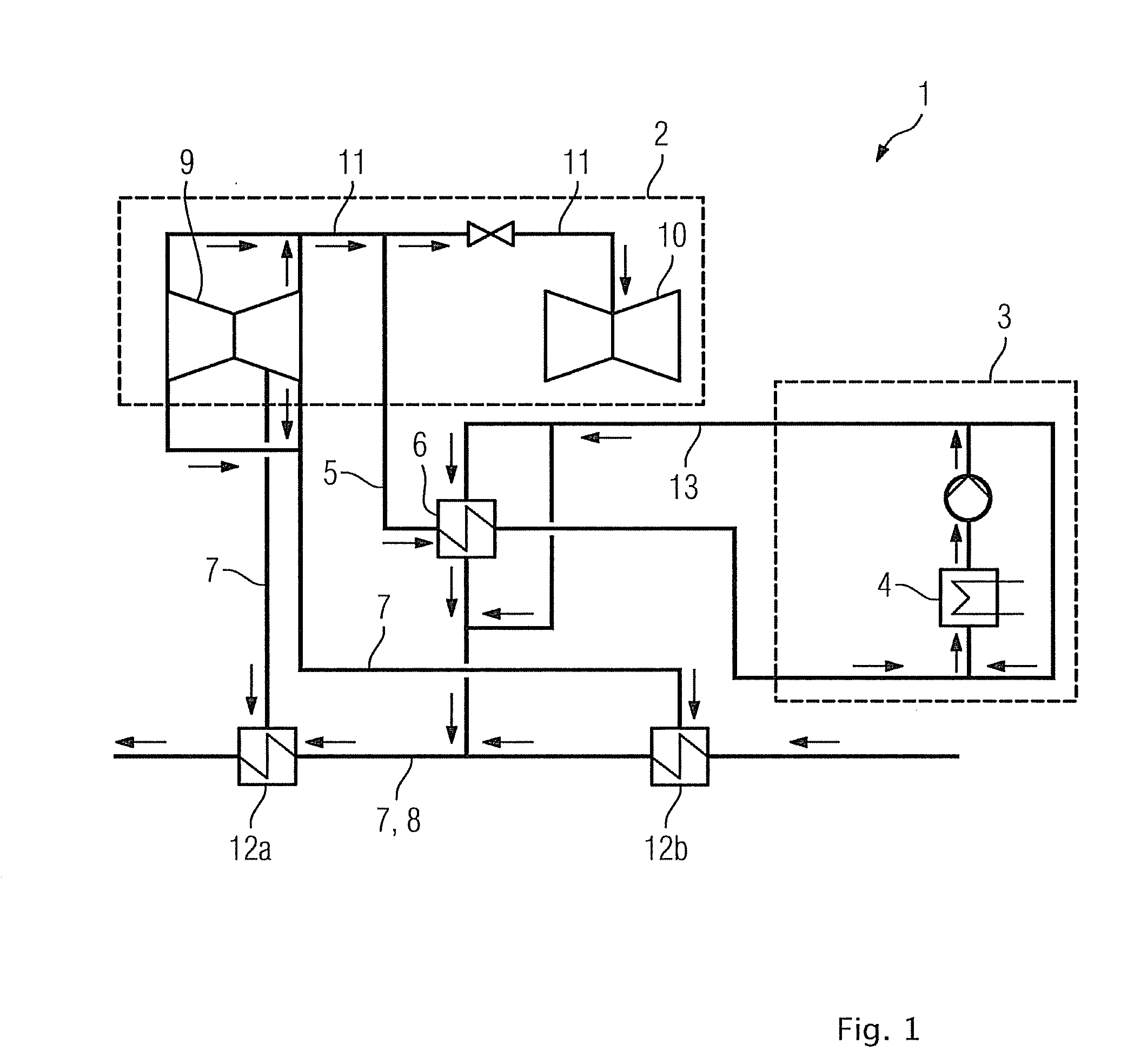

Steam power plant with steam turbine unit and process steam consumer, and method for operating a steam power plant with steam turbine unit and process steam consumer

InactiveUS20120111007A1Improve steaming efficiencyShorter piping routesSteam useDirect carbon-dioxide mitigationPower stationSteam line

A steam power plant having at least one steam turbine unit and a process steam consumer is provided. The process steam consumer includes a heat exchanger. The steam turbine unit is connected to a heat exchanger by means of a extraction steam line, and a desuperheater is connected in the primary side of the extraction steam line, so that process steam extracted through the extraction steam line of the turbine system may be conditioned by the desuperheater to the process conditions of the process steam consumer, and the heat energy removed in the desuperheater can be fed back into the steam power plant system.

Owner:SIEMENS AG

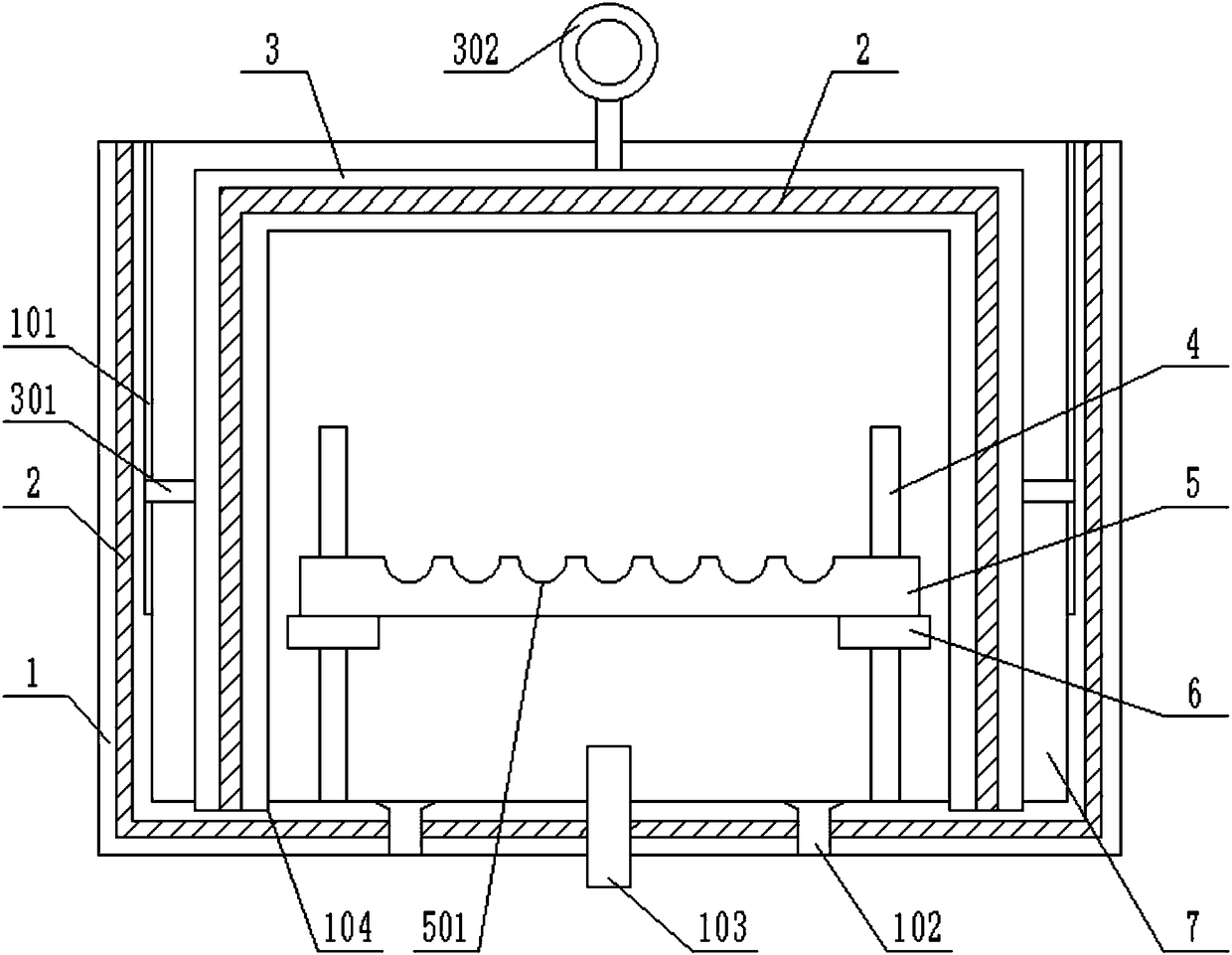

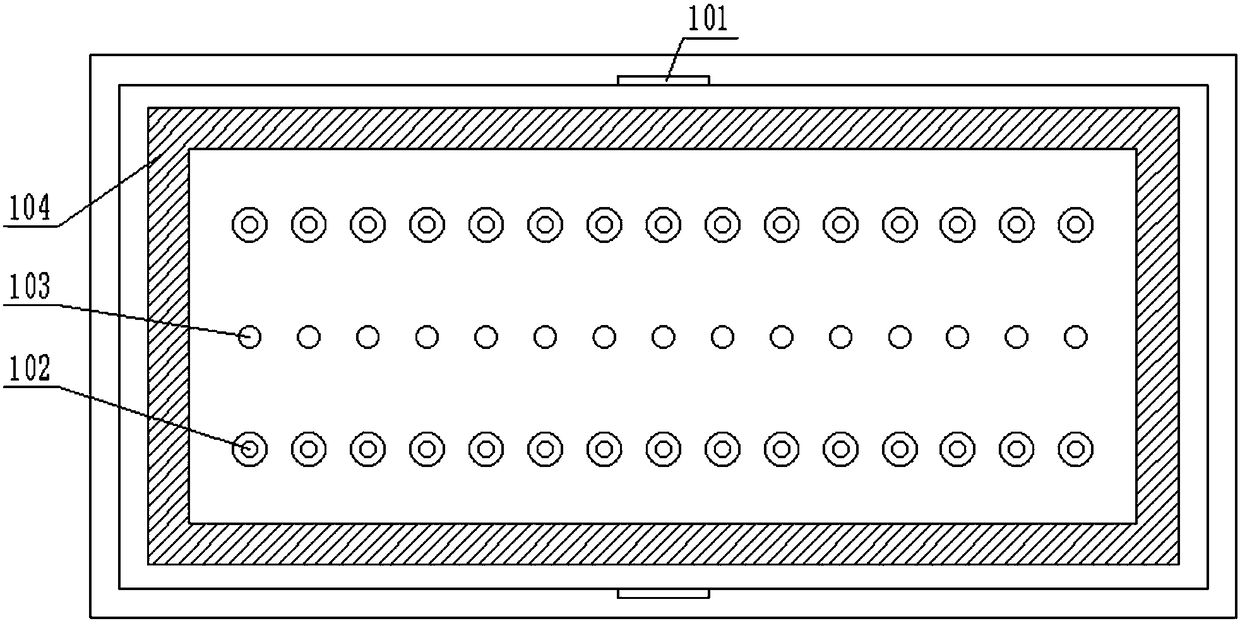

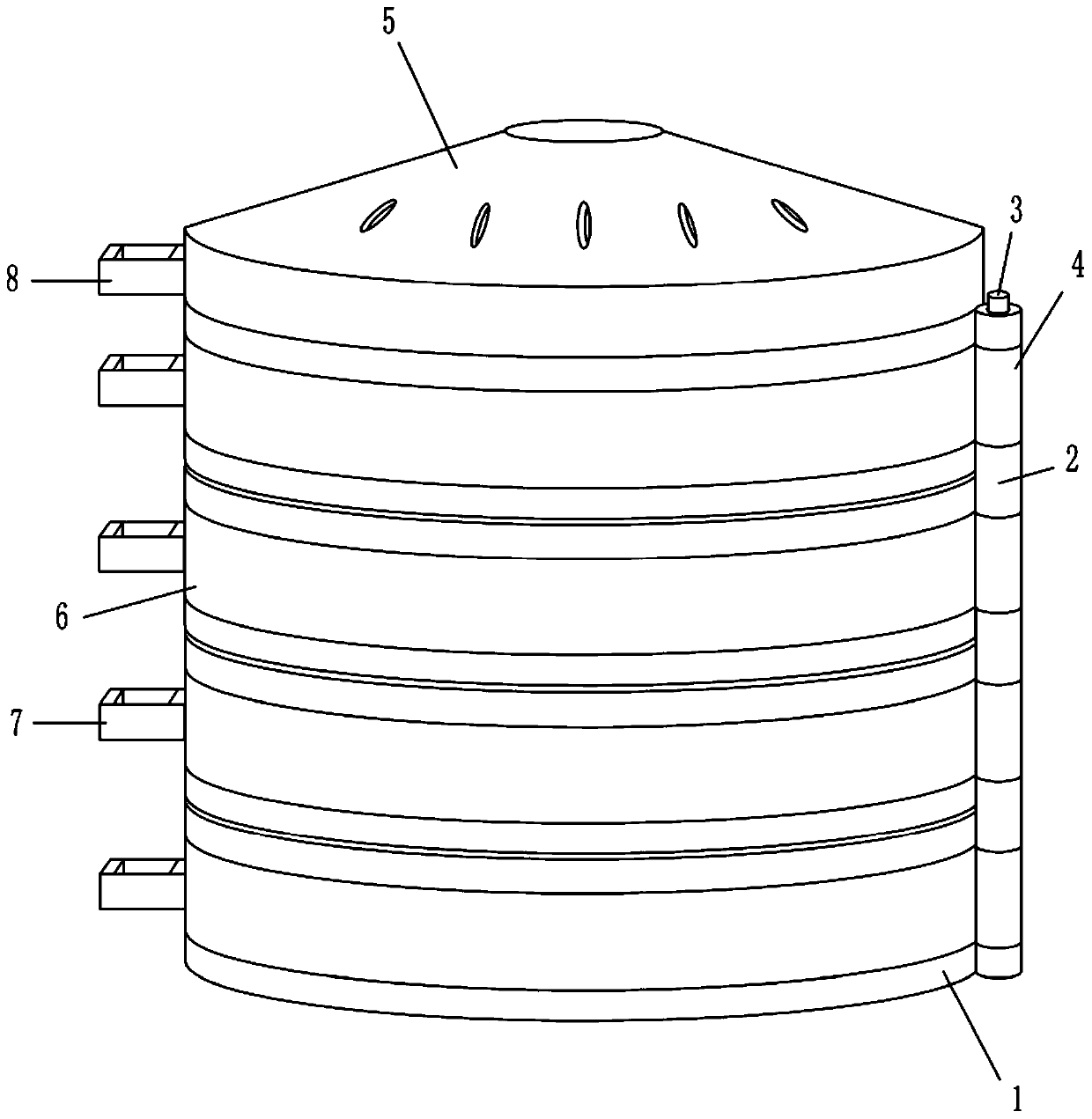

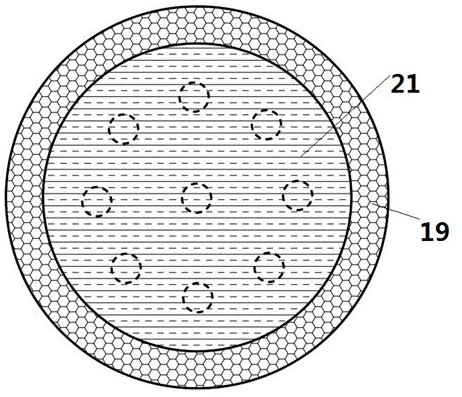

Evaporation pool for machining concrete electric poles

ActiveCN108453877AReduce lossesImprove insulation effectCeramic shaping apparatusWater storageThermal insulation

The invention discloses an evaporation pool for machining concrete electric poles. The evaporation pool comprises a pool body; a sealing groove is formed in the inner bottom surface of the pool body;a sealing cylinder is arranged in the sealing groove; the pool body and the sealing cylinder both adopt double-layer structures; thermal insulation layers fill the pool body and the sealing cylinder;a water storage cavity is formed between the pool body and the sealing cylinder; a steam injecting pipe and a drainage hole are arranged at the bottom of the pool body; a support frame is mounted at the bottom of the pool body; and an object carrying plate is mounted on the support frame through a limiting plate. The evaporation pool has the following beneficial effects: the pool body and the sealing cylinder are both of the double-layer structures, and the thermal insulation layers fill the pool body and the sealing cylinder, so that the thermal insulation effect of the device is improved; water is injected in the water storage cavity, so that the sealing performance of the device is improved, the device is excellent in overall insulation and sealing performance, and the heat loss can bereduced; and molds can be suspended in air through the support frame and the object carrying plate, so that steam is fully in contact with the molds, and the evaporation efficiency can be improved.

Owner:宁波雷阳工业科技有限公司

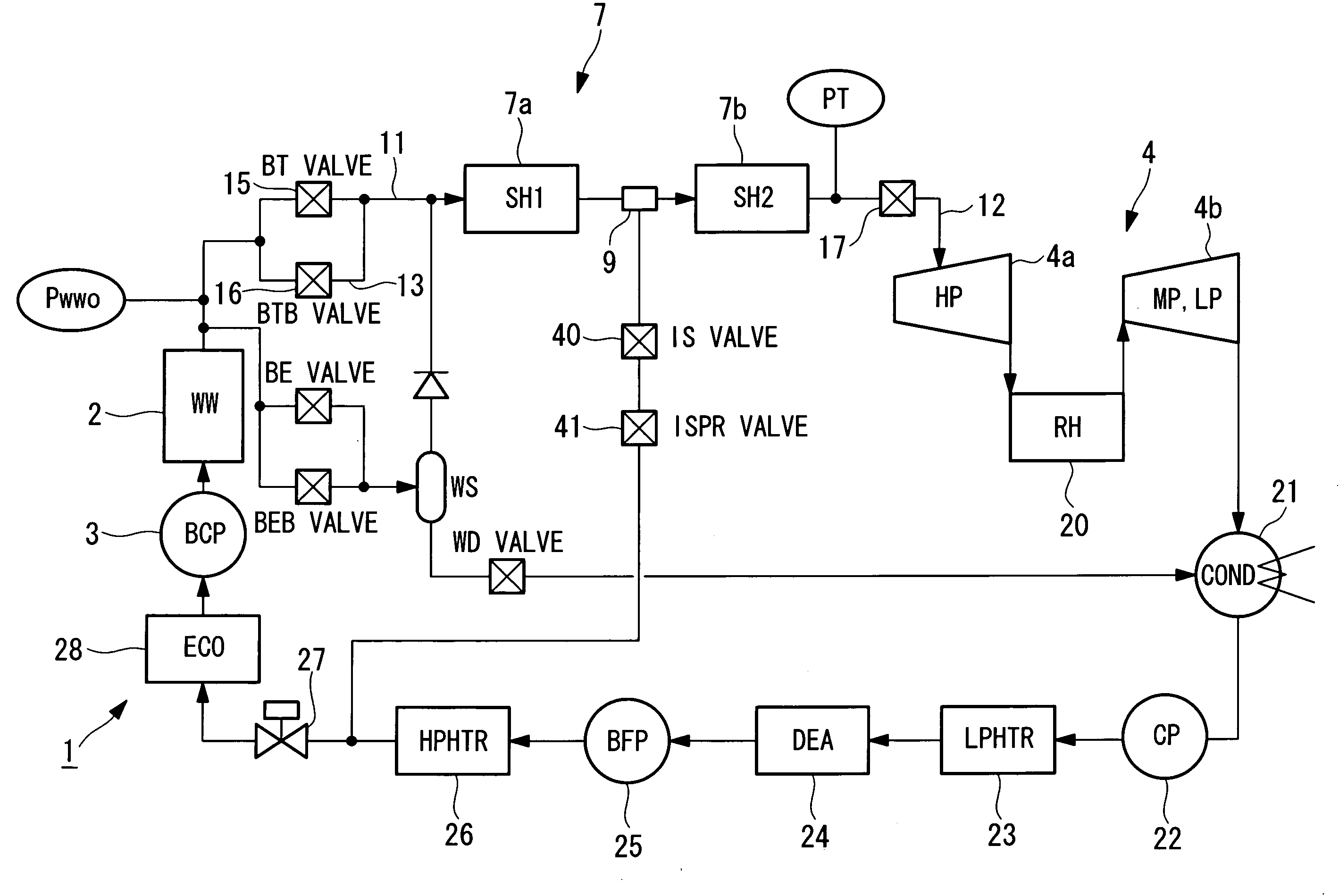

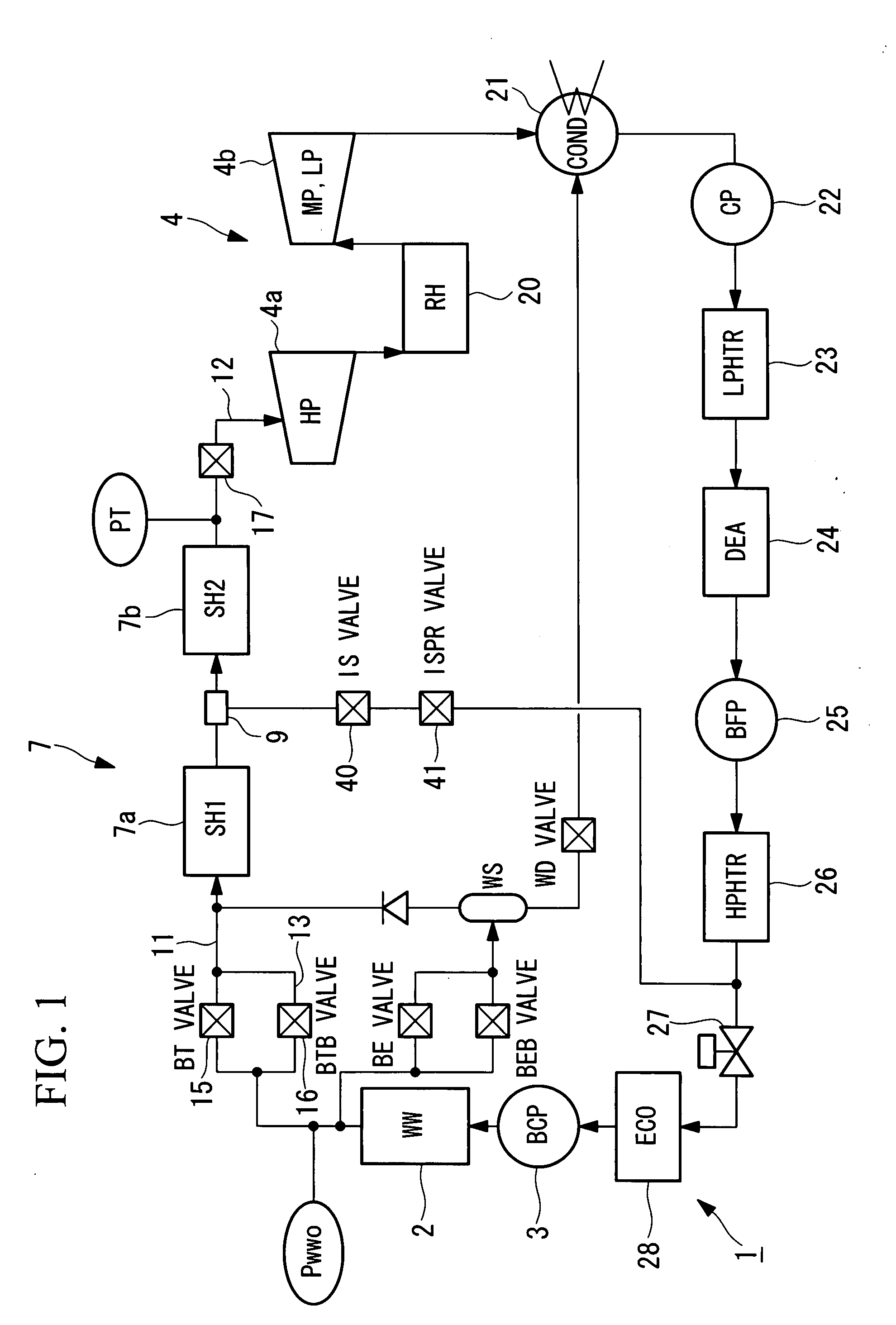

Steam turbine plant, combined cycle plant provided with same, and method of operating steam turbine plant

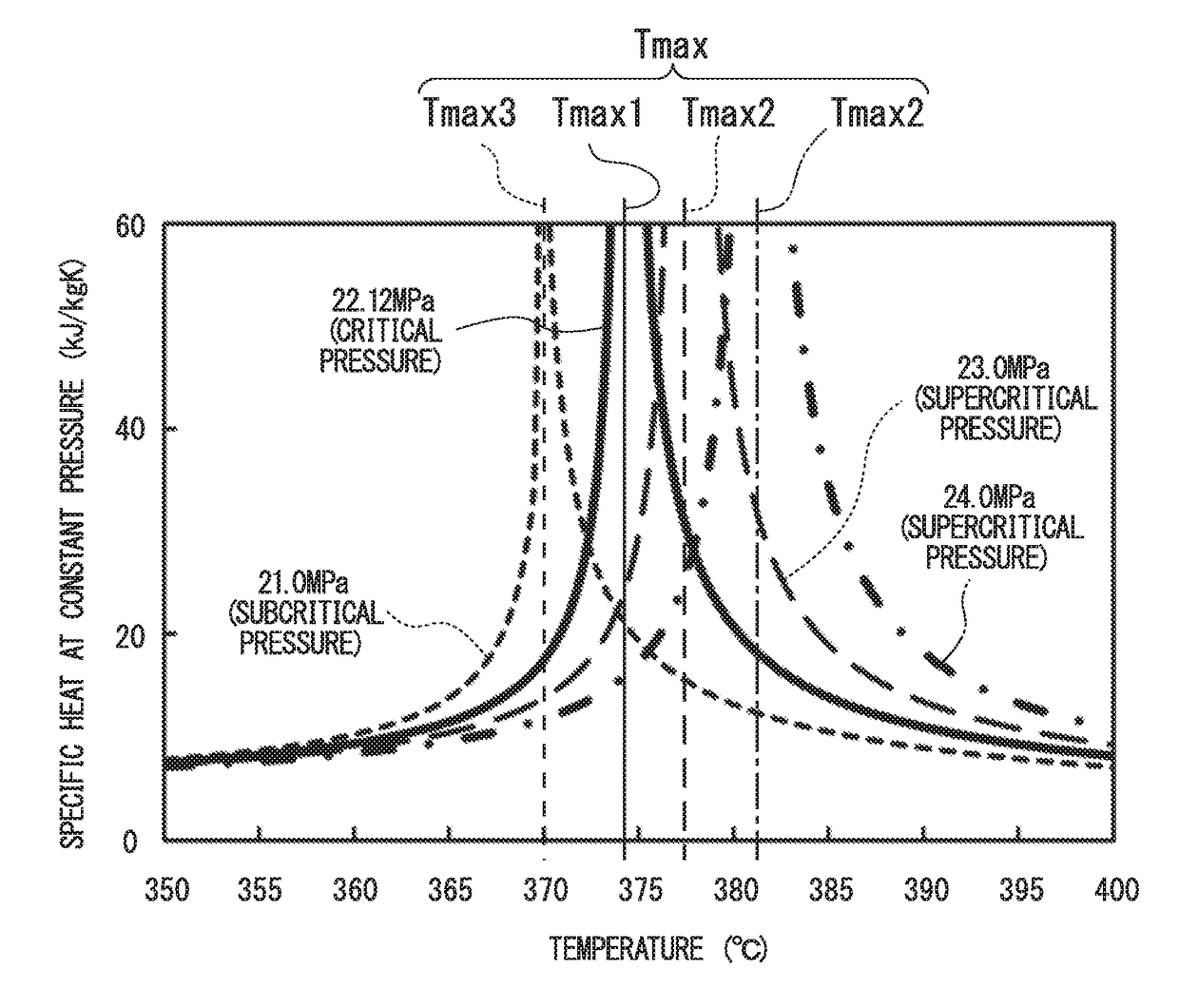

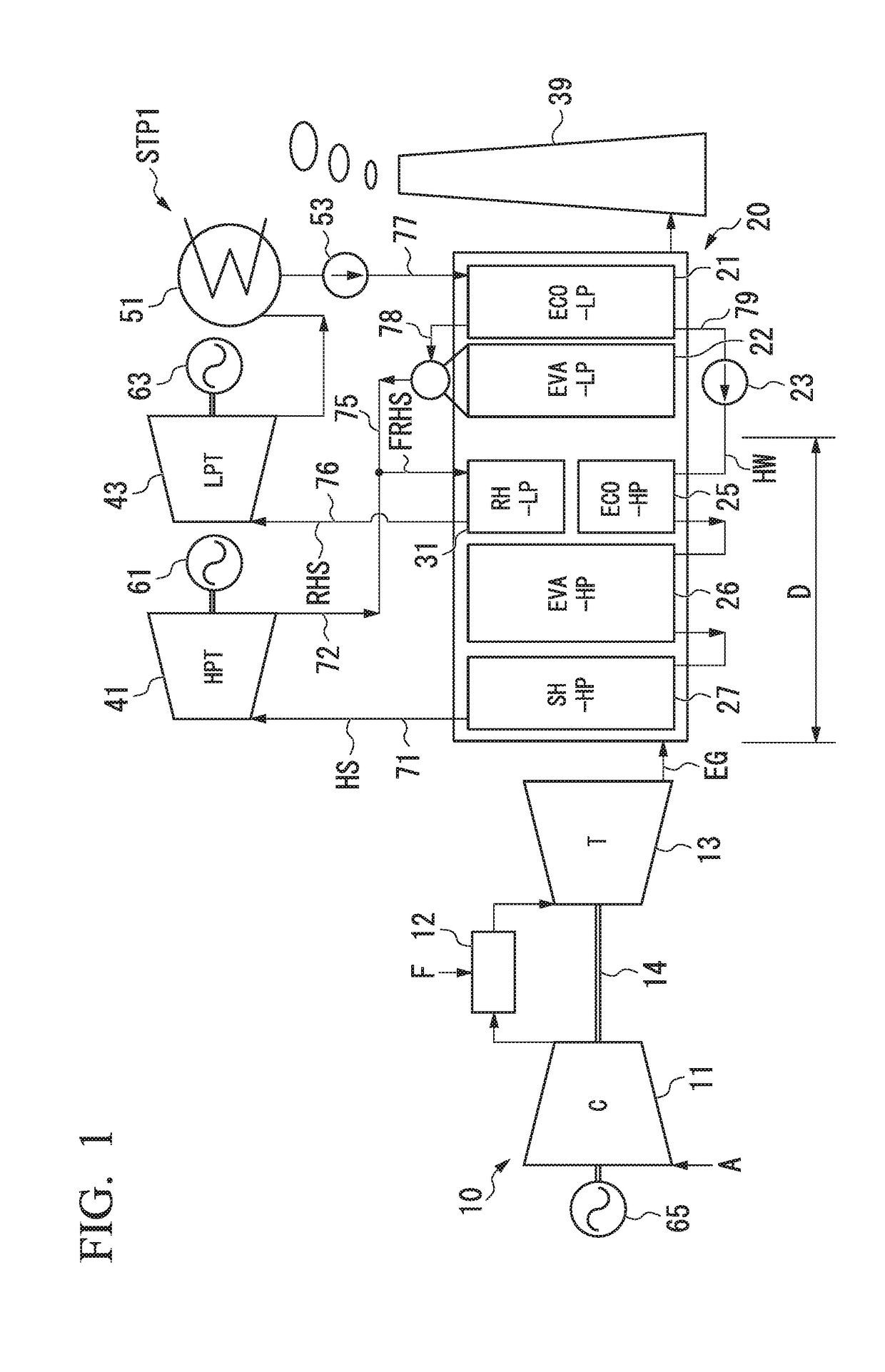

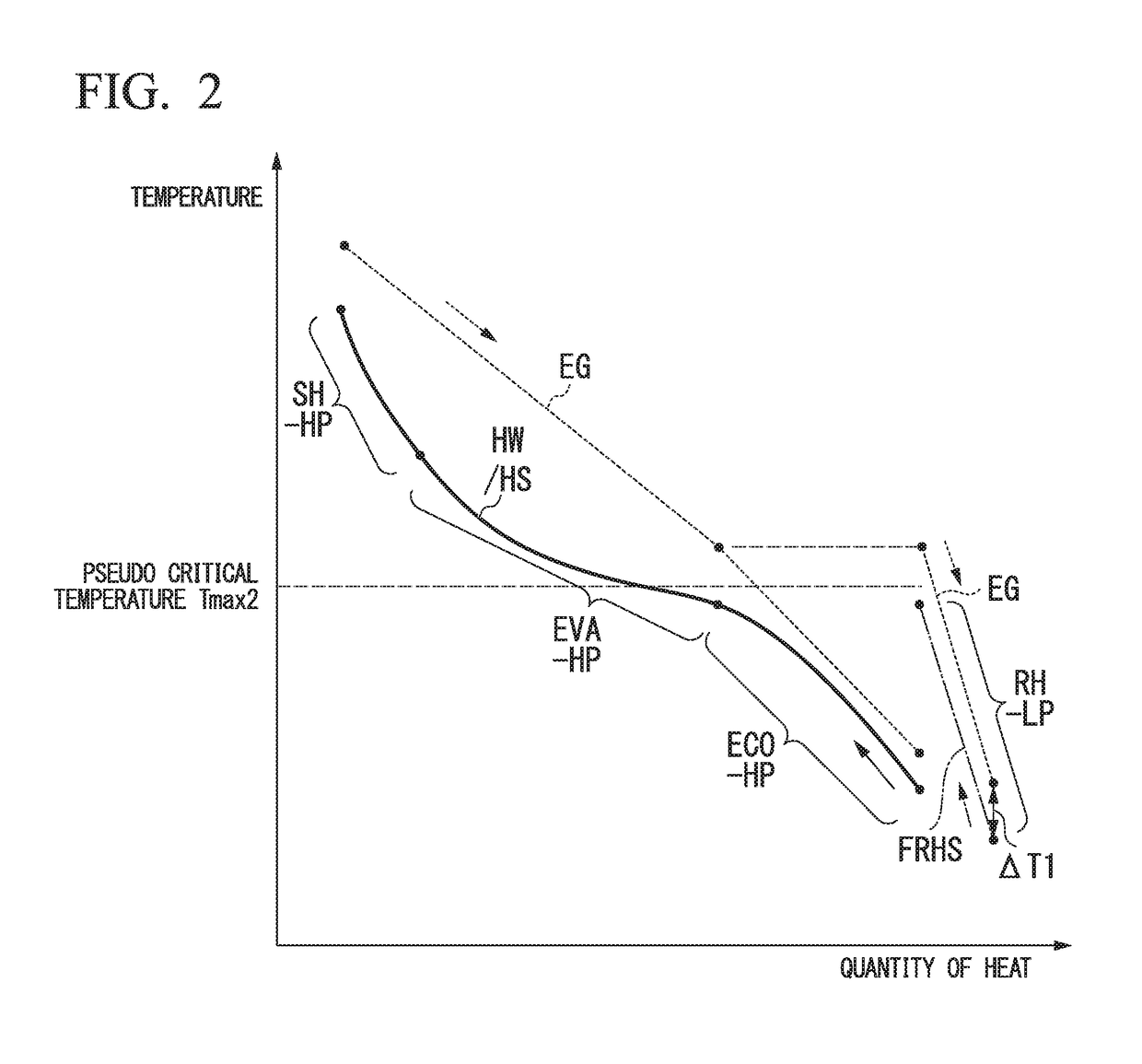

ActiveUS20180003085A1Cutting can not be obtainedImprove steaming efficiencyEngine componentsSteam engine plantsEngineeringHigh pressure

A boiler includes one or more evaporators configured to heat water which has flowed therein to a specific heat maximum temperature at constant pressure or more in which a specific heat at constant pressure is maximized using a heated fluid and one or more reheaters configured to heat the steam which has come from the boiler using the heated fluid. All the reheaters configured to supply steam to a low-pressure steam turbine are disposed only at a downstream side of the high-pressure evaporator. All the reheaters heat reheating steam (FRHS) containing steam which has passed through a high-pressure steam turbine configured to receive steam supplied from the high-pressure evaporator and having a temperature lower than a specific heat maximum temperature at constant pressure in the high-pressure evaporator to less than the specific heat maximum temperature at constant pressure.

Owner:MITSUBISHI HEAVY IND LTD

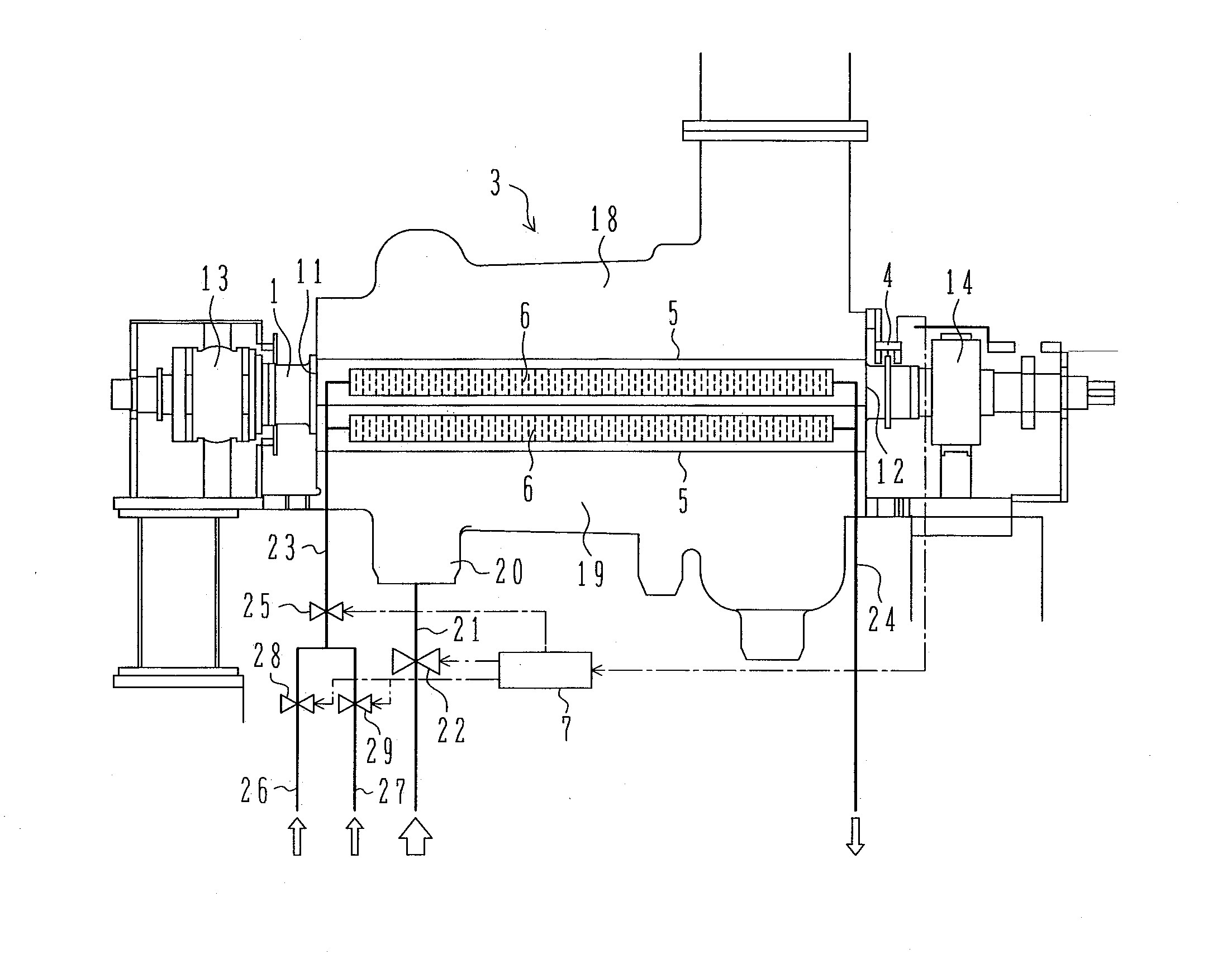

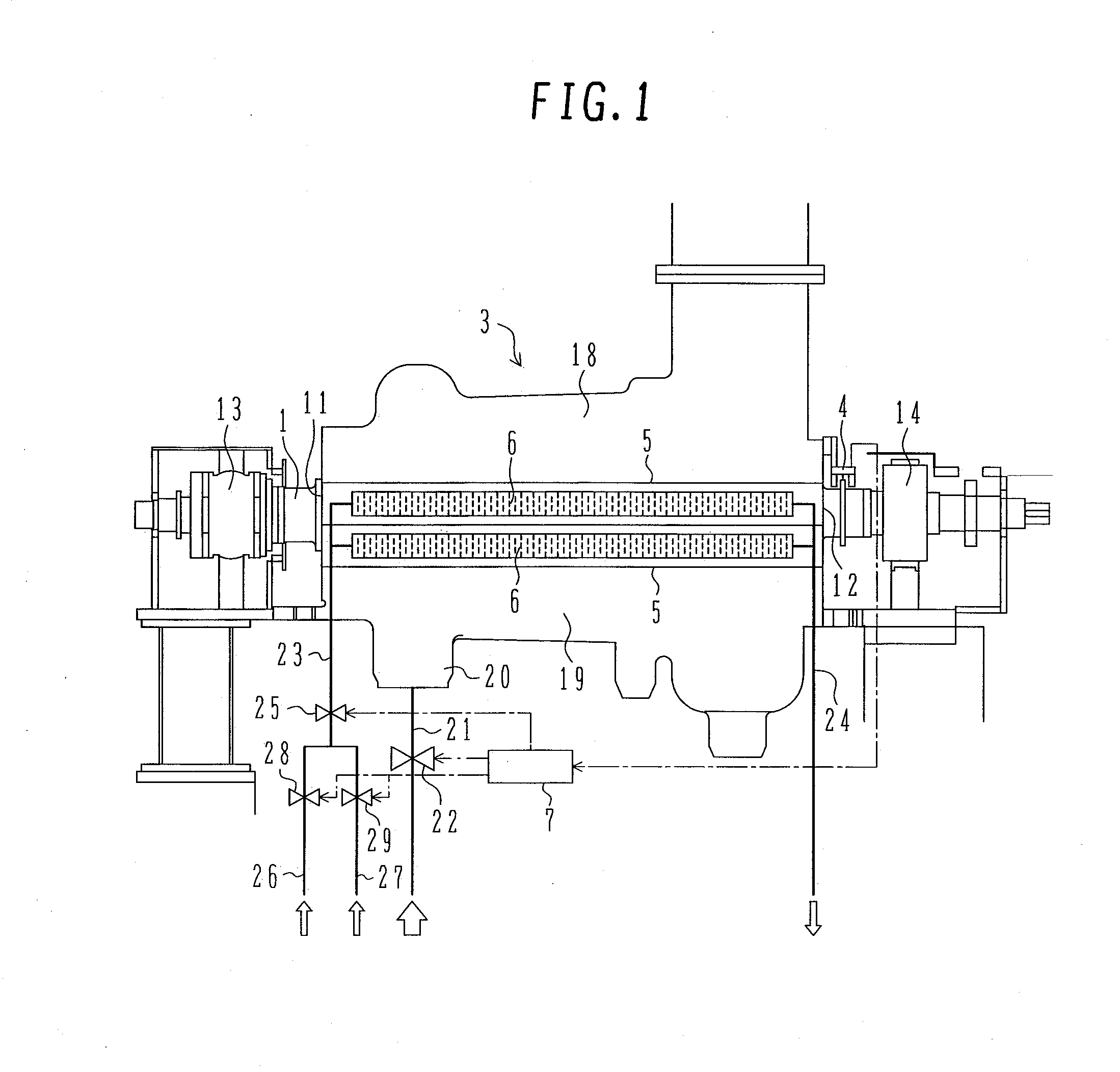

Steam turbines, seals, and control methods therefor

InactiveUS7985045B2Improve steaming efficiencySuppress leakageWind motor controlPump componentsThermal expansionEngineering

A steam turbine comprises a rotor with moving blades attached thereto; diaphragms which surround the rotor from an outer periphery side of the rotor; a casing which encloses the diaphragms and the rotor and has an upper half and a lower half clamped together through respective flanges; a displacement detector for measuring a difference d in thermal expansion in the rotor axis direction between the casing and the rotor; heating / cooling devices attached to the flanges respectively to heat and cool the flanges; and a controller which makes control so that the flanges are heated or cooled by the heating / cooling devices until a measured value obtained by the displacement detector reaches a preset value M or S in unsteady operation.

Owner:MITSUBISHI POWER LTD

Efficient and rapid steaming printing technology adopting reactive dyes

An efficient and rapid steaming printing technology adopting reactive dyes comprises processes as follows: pretreatment of grey cloth, blending of print paste, paste scraping and printing on a printer, efficient and rapid steaming, water washing, soap washing and drying.

Owner:HUBEI YABI HOME TEXTILES

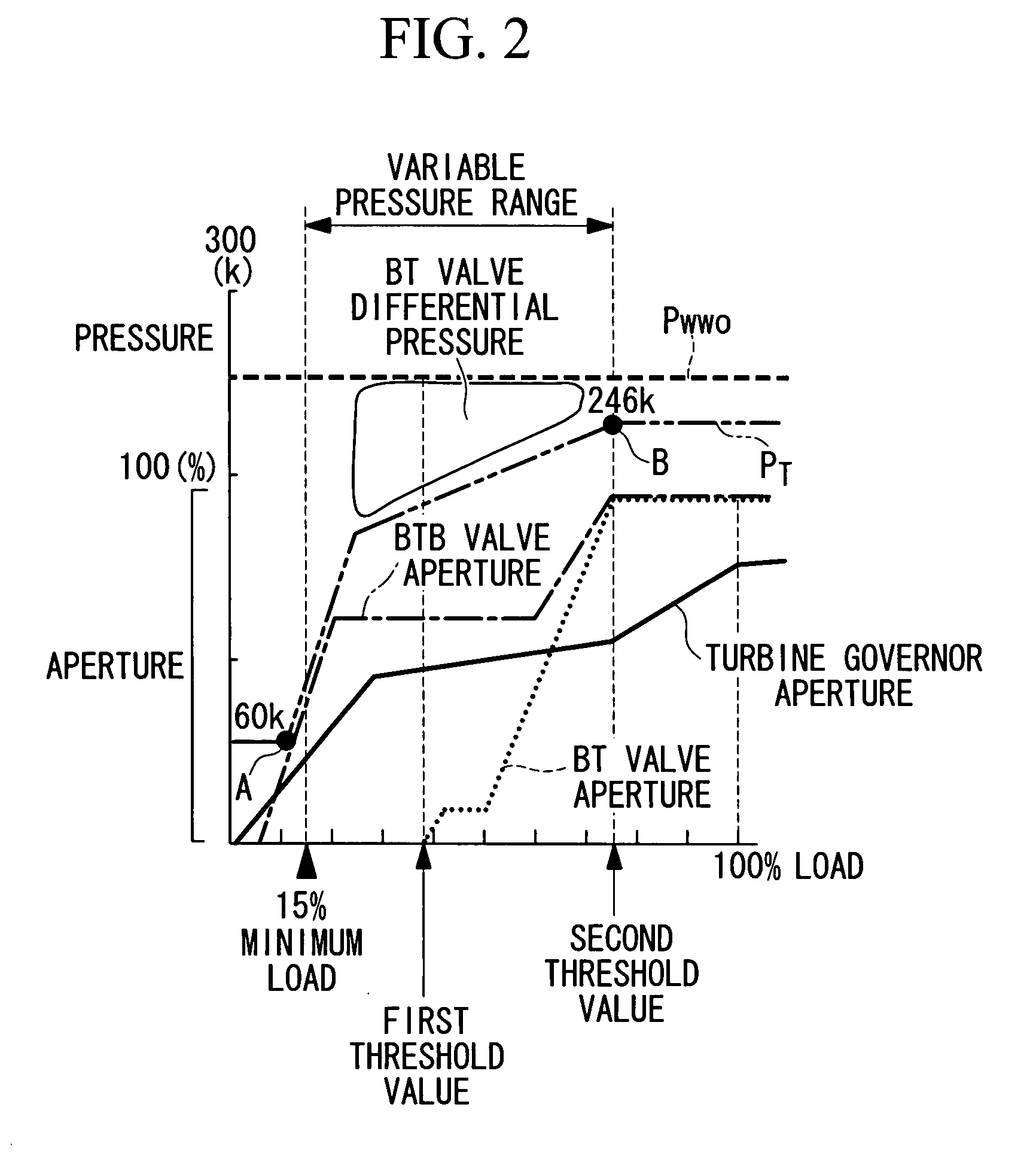

Power generation system

InactiveUS20080236139A1Prevents reduction in efficiency of steamLow efficiencyPropulsive elementsSteam engine plantsSolid fuelLiquid fuel

To provide a power generation system that prevents a reduction in the efficiency of a steam turbine due to an aperture adjustment of a turbine governing valve. There is provided a power generation system comprising: a furnace in which a solid fuel or a liquid fuel is combusted; a steam turbine that generates electric power by rotating a turbine rotor using steam generated by the furnace; a superheater that is provided between the furnace and the steam turbine and that superheats the steam; a first steam piping that connects the furnace to the superheater; a second steam piping that connects the superheater to the steam turbine; a first valve provided in the first steam piping; a turbine governing valve provided in the second steam piping; and a control section that adjusts an aperture of the first valve according to a load of the steam turbine.

Owner:THE TOKYO ELECTRIC POWER CO INC +1

Process for steaming and baking fresh bamboo through biomass gasification

InactiveCN102940168ALow costImprove steaming efficiencyFood processingFood preparationCooking & bakingEconomic benefits

The invention discloses a process for steaming and baking fresh bamboo through biomass gasification. The process comprises the following steps of: removing peels of the fresh bamboo, cutting the fresh bamboo into slices, putting the fresh bamboo into water, and after the quantity of the fresh bamboo meets the requirement, putting the fresh bamboo into a bamboo sieve of a commodity shelf; using a biomass gasification furnace, closing a moisture discharge hole and an air inlet, opening a hot air circulation door, combusting gas generated by the biomass gasification furnace through a combustion machine, entering the combusted gas into a heat exchange box and heating, feeding the heated gas into a baking chamber to steam the fresh bamboo slices, and controlling the steaming temperature to be 95-105 DEG C and the steaming time to be 1.5-2.5 hours; and after steaming the fresh bamboo slices, keeping running the gasification furnace, opening the moisture discharge hole and the air inlet, closing the hot air circulation door, controlling the temperature of hot air in the baking chamber to be 90-110 DEG C, baking the fresh bamboo slices, controlling the final baking temperature to be 55-60 DEG C after baking for 1.0-1.5 hours, gradually cooling, taking out, cooling and packing, wherein layer exchange and turning up need to be noted at any time when the fresh bamboo slices are steamed and baked. According to the steaming and baking process, the grade of the bamboo slices can be improved, the steaming and baking efficiency is improved, and the environmental protection benefit and the economic benefit are achieved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

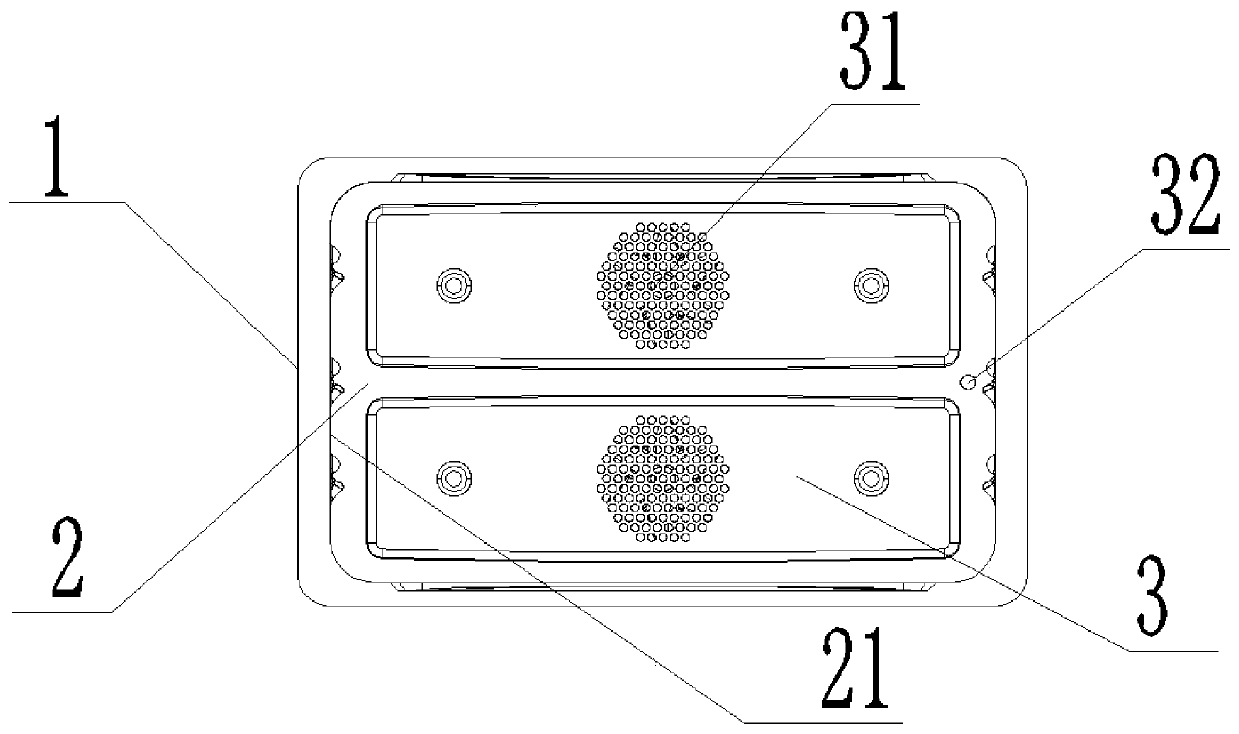

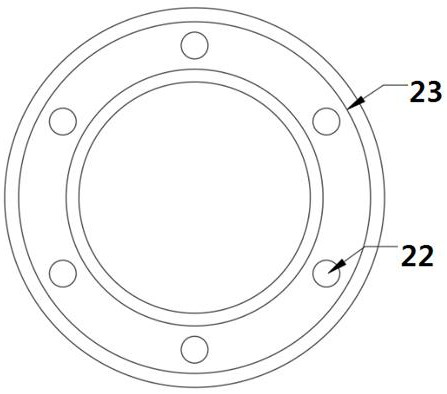

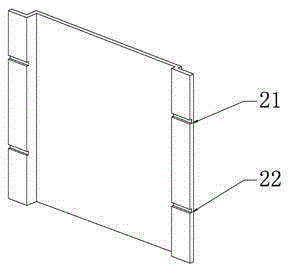

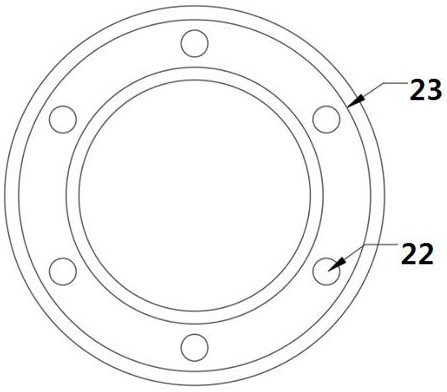

Tea base steaming device and in-mold steaming molding process

PendingCN106720558APressure range controllableQuality improvementPre-extraction tea treatmentSteam pressureBrick

The invention relates to a tea base steaming device and an in-mold steaming molding process, wherein the tea base steaming device comprises a compacting mold and a steaming component, and the in-mold steaming molding process comprises the following steps of mounting the tea base steaming device, steaming a tea base and compacting the tea base. During working, a well weighed raw material of the tea base is poured into a cavity to directly carry out steaming and compaction; the steaming time is adjustable and is further accurately controlled; the pressure range of steam is controllable; the automation is realized for a steaming procedure; the steaming efficiency is improved; the labor force is saved; further, the steaming extent is uniform and consistent; the pressure maintaining time of a tea brick is reduced; the quality of a finished-product brick is improved.

Owner:INST OF FRUIT & TEA HUBEI ACAD OF AGRI SCI

Radix angelicae sinensis traditional Chinese medicine decoction pieces and preparation method thereof

InactiveCN110368409ASimple processIncrease productivityPharmaceutical product form changePharmaceutical non-active ingredientsFreeze-dryingAdditive ingredient

The invention relates to the technical field of traditional Chinese medicine decoction pieces, in particular to radix angelicae sinensis traditional Chinese medicine decoction pieces and a preparationmethod thereof. The preparation method comprises the following steps of A, material selection and washing; B, infiltration; C, slicing and steaming; D, vacuum freeze drying and smashing; E, encapsulation; F, drying and tabletting. The preparation method is simple in process, the operation is easy to control, the production efficiency is high, and the cost is low; through encapsulation, active functional ingredients in radix angelicae sinensis are effectively protected, the water content is equal to or lower than 4.5%, the ligustilide content is 57.83%-58.64%, the ferulic acid content is 0.061-0.073%, the radix angelicae sinensis traditional Chinese medicine decoction pieces prepared by using the method are easy to dissolve and easy to digest and absorb, the dissolution rate is 97.25-98.88%, and bacteria are not easy to breed. The content of aflatoxin B1 is 1.6-2.3 microgram / kg, the shelf life is long, the quality is stable and the preparation method can be used for massive industrialproduction.

Owner:广东元德中药饮片有限公司

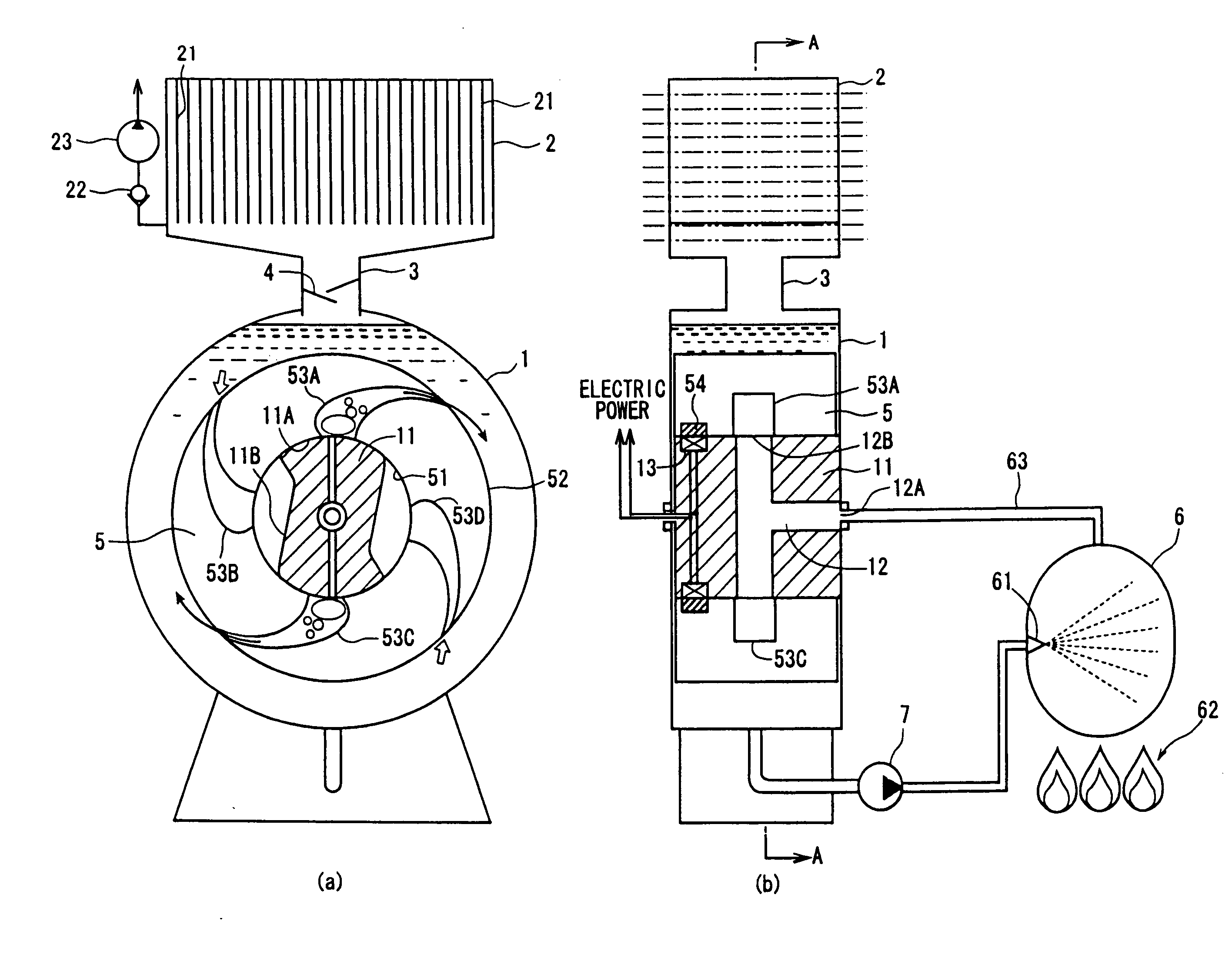

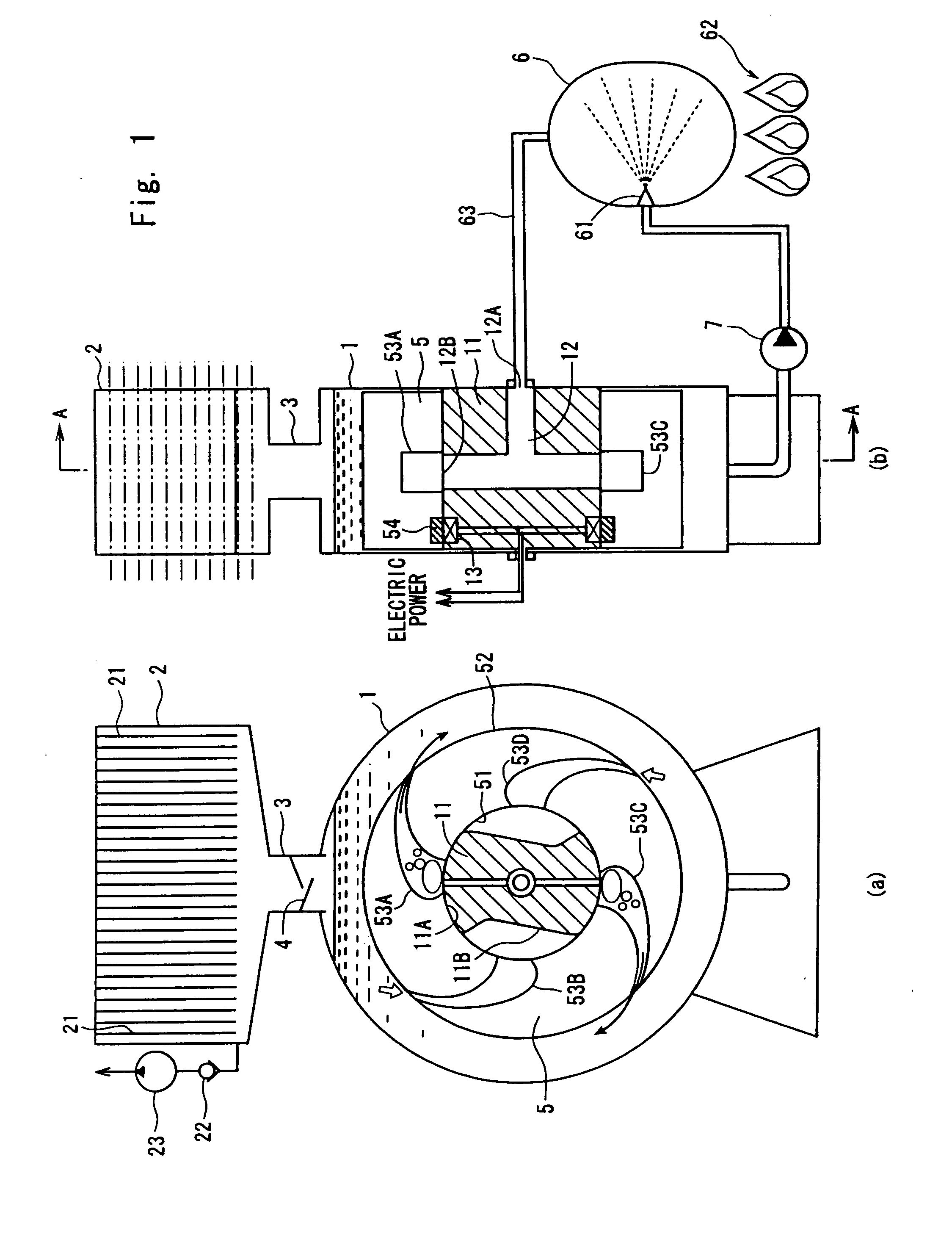

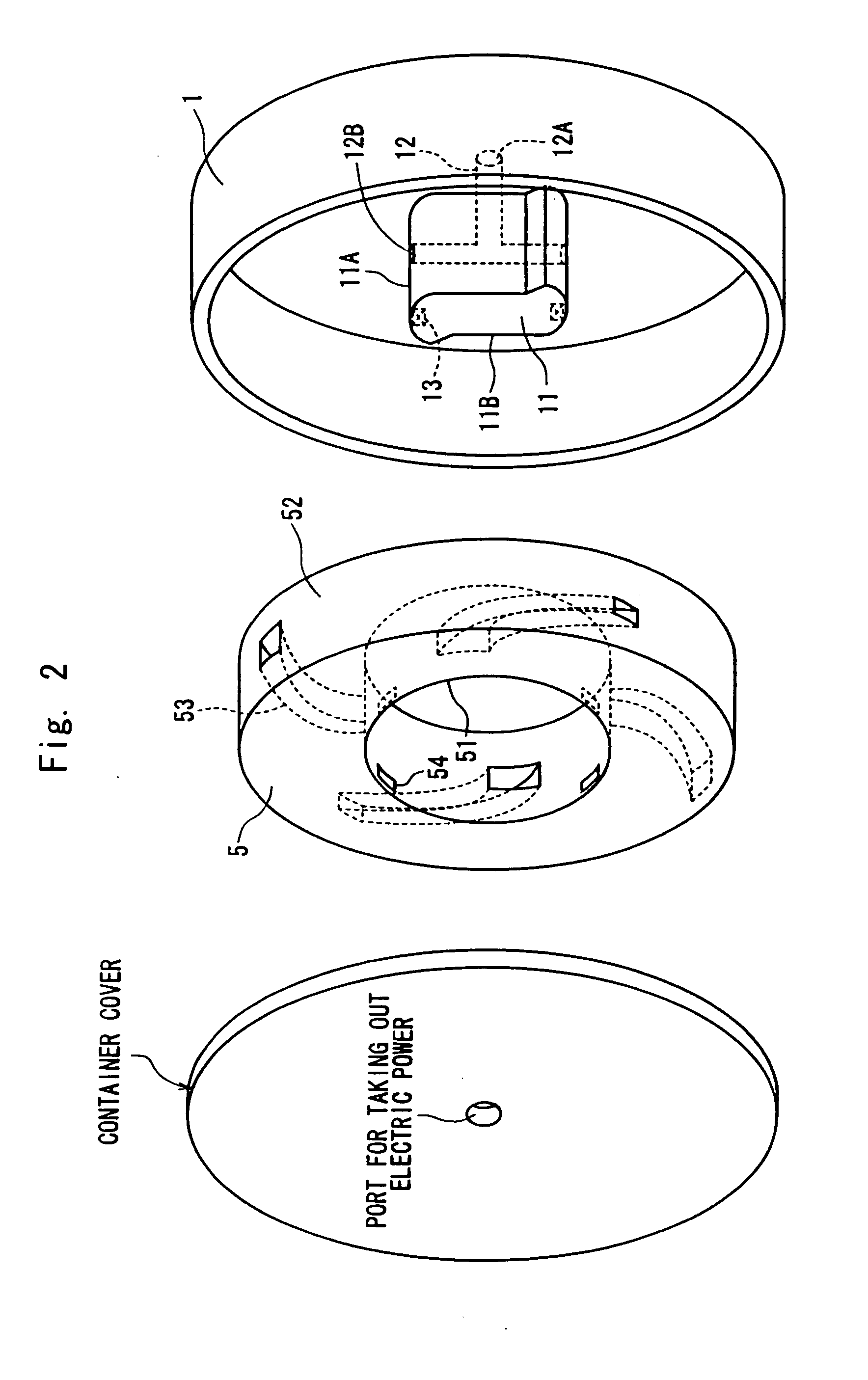

Steam-jet engine

InactiveUS20110107762A1High torqueEasy to operateFlash steam boilersSteam engine plantsJet engineEngineering

A steam engine in which a liquid and a steam are jetted so that a rotor is turned by the reaction thereof, and the rotor having a well-balanced simple structure. In the steam engine, the rotor 5 having a plurality of bent flow paths 53A to 53D arranged at regular intervals therein is rotatably supported in a closed container 1 filled with the liquid being fitted onto a boss portion 11 of the closed container 1. The boss portion 11 is alternately forming slide-contact portions 11A having a steam feed port and recessed portions 11B. The steam fed into the bent flow path 53 from the steam feed port causes the liquid in the flow path to be jetted outward to rotate the rotor 5. The rotor 5 is of a point-symmetrical shape in cross section free of unbalanced weight, has no moving part, and is simple in structure. When the bent flow path 53 communicates with the recessed portion 11B, the steam remaining in the flow path is cooled and disappears, and the flow path is filled with the liquid.

Owner:ISUZU MOTORS LTD

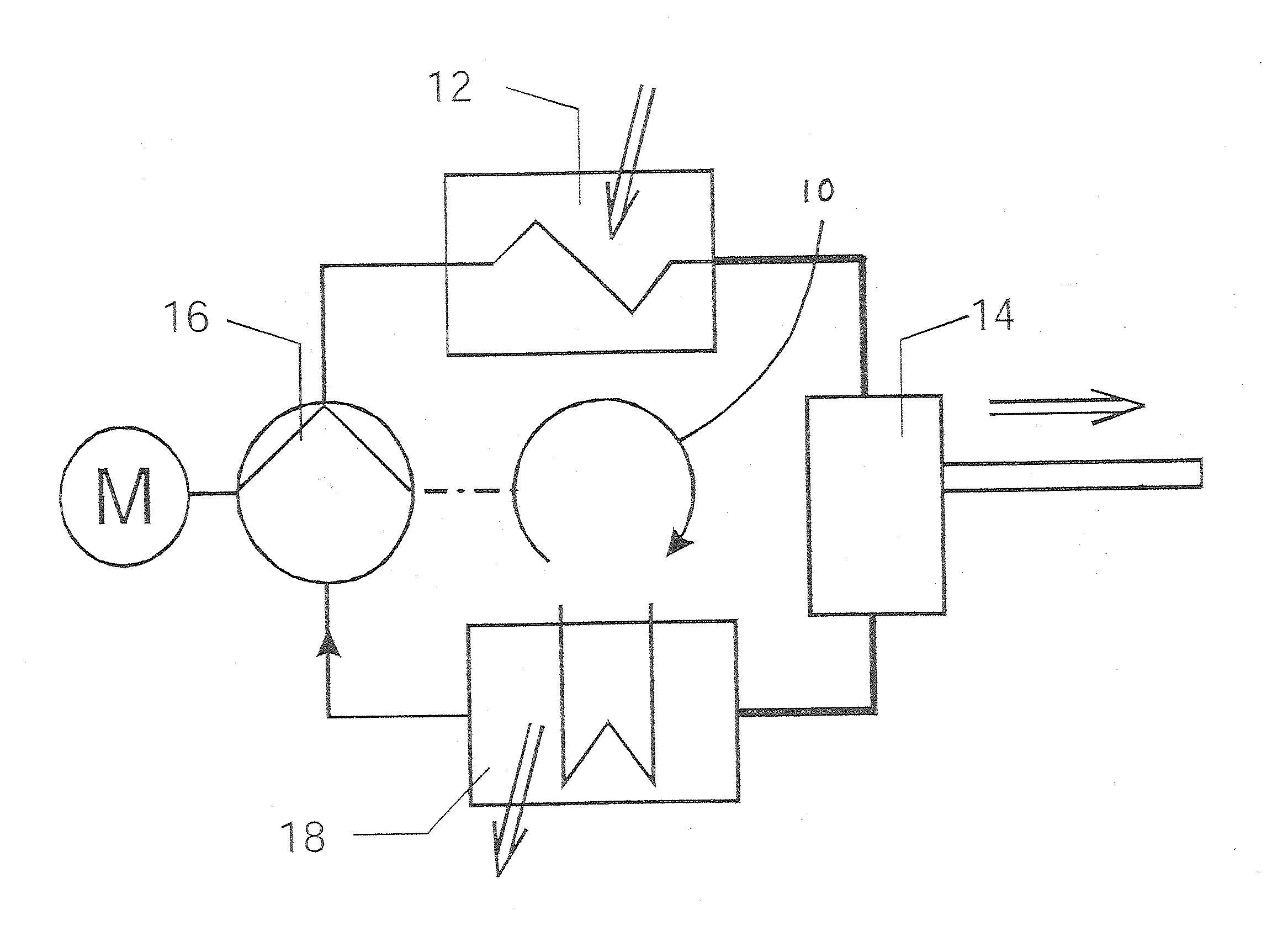

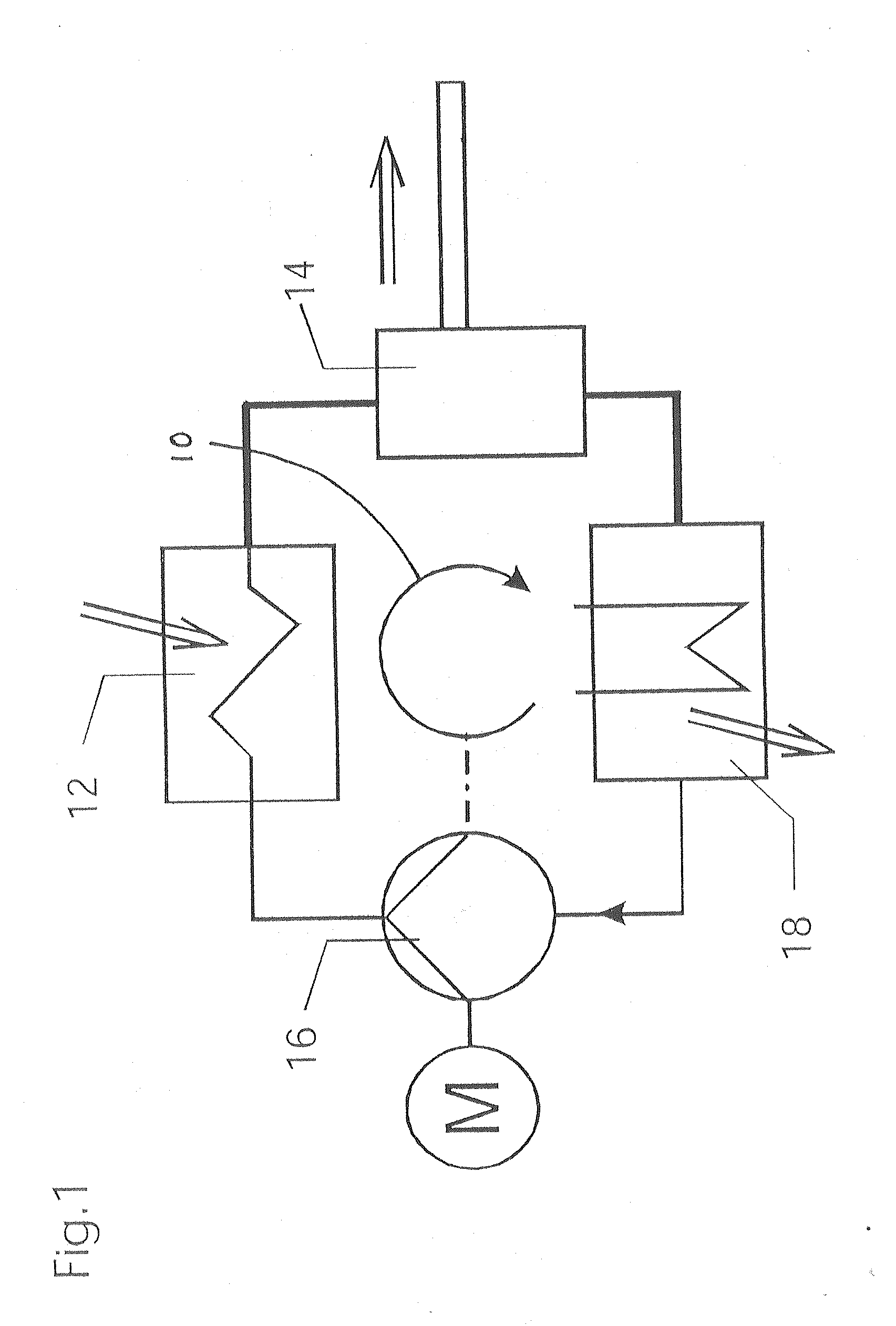

Working medium mixture for steam engines

InactiveUS20150240668A1Improve efficiencyImprove solution stabilitySteam engine plantsPower stationSteam power

The invention relates to the use of a working medium in steam power plants having a steam generator for generating working medium vapor, a pump for generating an increased pressure in the working medium vapor, an expansion machine for generating mechanical and / or electrical work by expansion of the working medium from an elevated pressure to a lower pressure level under working conditions and a condenser for condensing the working medium, wherein the working medium contains a lubricant. The invention is characterized in that the working medium contains acetone and a lubricant.

Owner:MAHLE INT GMBH

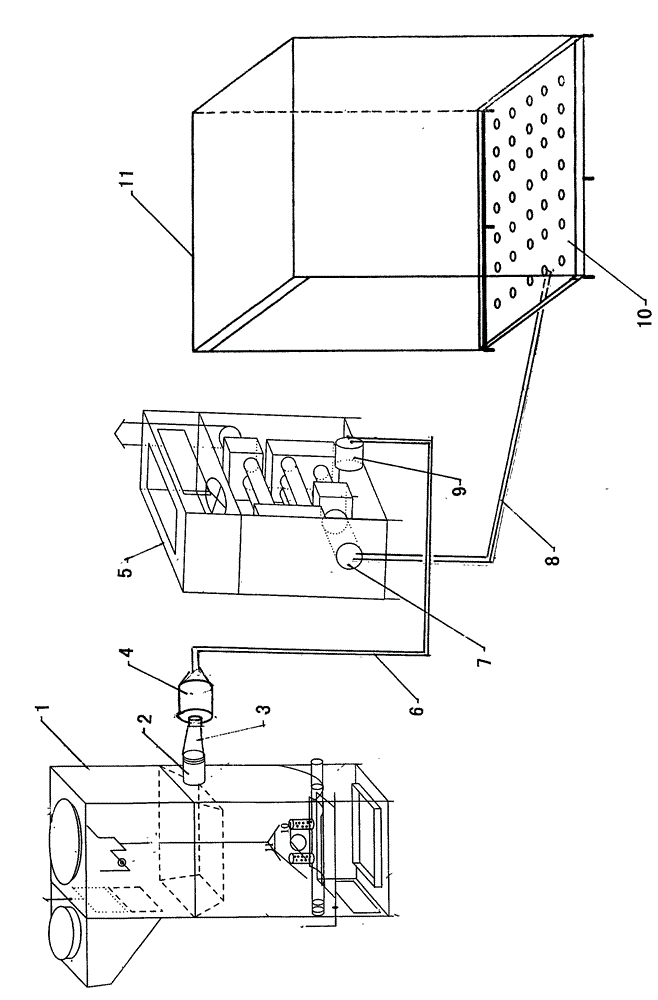

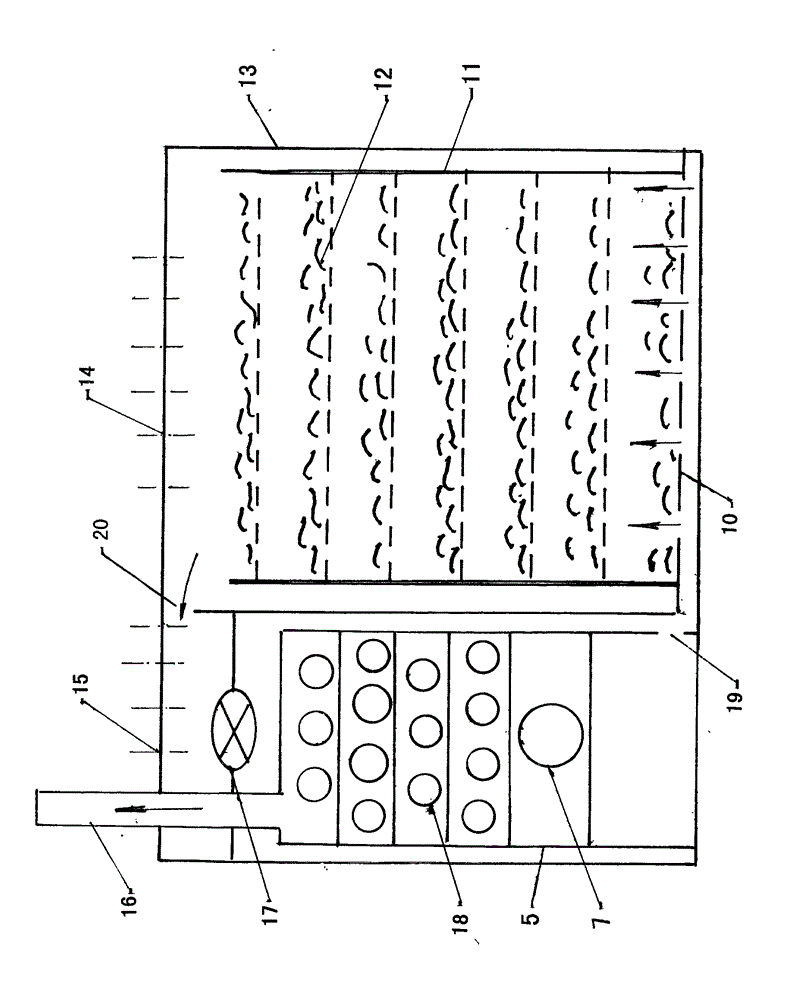

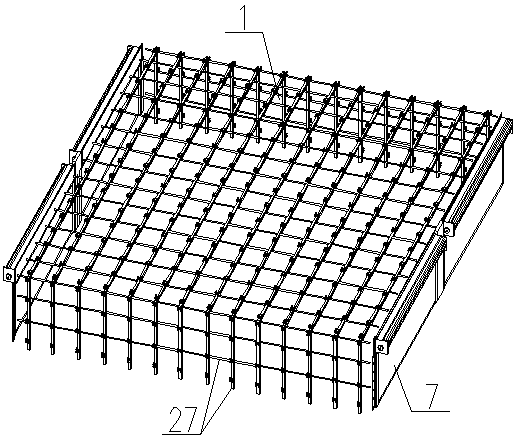

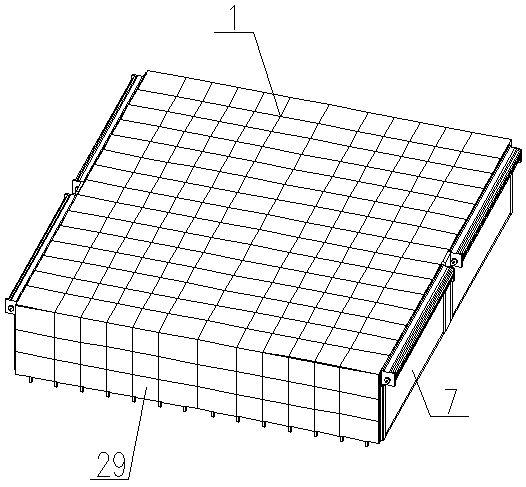

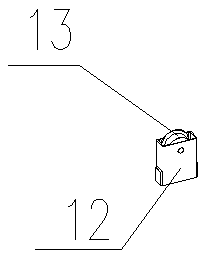

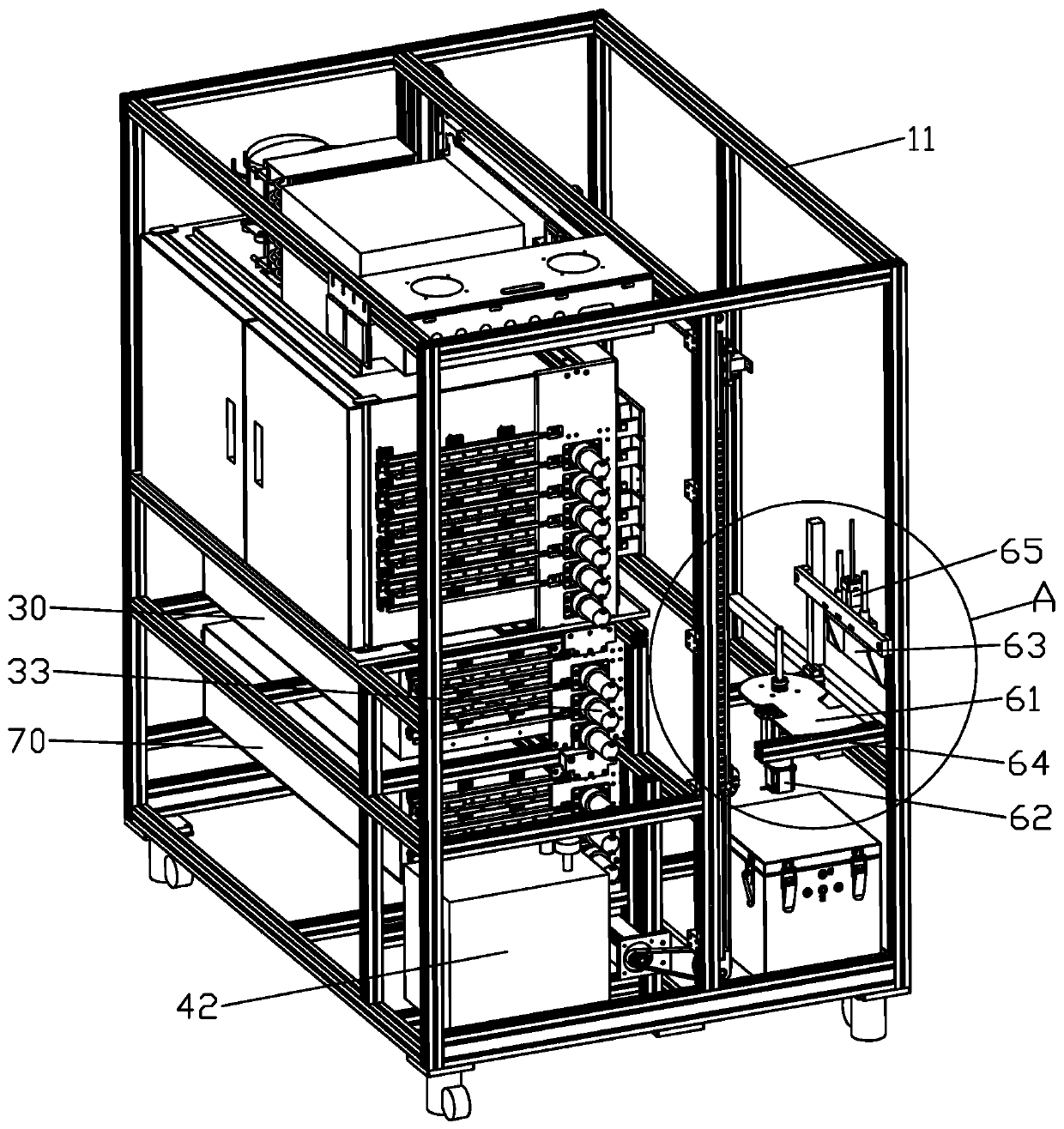

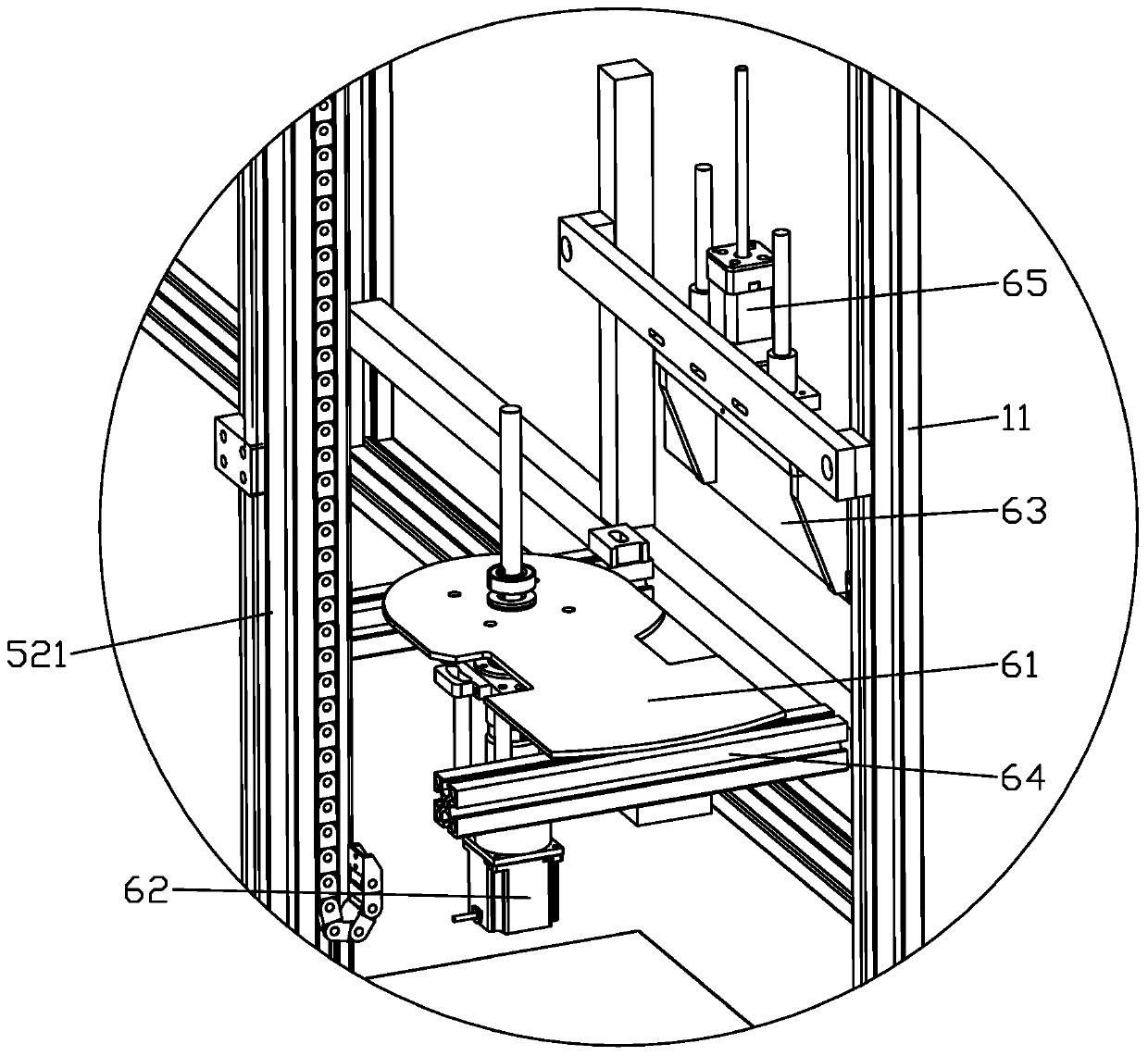

Modularized movable type prefabricated part multilayer steam curing production system and installation production method

PendingCN109291228AReduce overhead costsLow priceCeramic shaping plantsAutomotive engineeringDrive motor

The invention discloses a modularized movable type prefabricated part multilayer steam curing production system and an installation production method. An existing prefabricated part curing kiln generally adopts coal and fuel gas curing, coal and other fossil resources belong to non-renewable energy sources, and serious pollution is caused while the heat is generated through combustion. The systemcomprises a steam-curing shed (1), a mold table moving line (5), a ferry vehicle (6) and a moving machine (19), the steam-curing shed is a linear-shaped closed space, an opening type shed door (7) isarranged on the steam-curing shed, the mold table moving line is composed of two linear-shaped arranging ground wheels (10) and a driving motor (11), the ground wheels are arranged on a supporting frame (12) of the ground wheels, a wheel (13) is arranged at the top of the supporting frame, the driving motor is arranged between the ground wheels, a driving motor wheel is of an annular friction surface, the ferry vehicle is a mold table horizontal moving device, the ferry vehicle is provided with a frame body (15), and a jacking device (16) is arranged at the top of the frame body. The modularized movable type prefabricated part multilayer steam curing production system and the installation production method are provided.

Owner:湖北宇辉智能科技有限公司

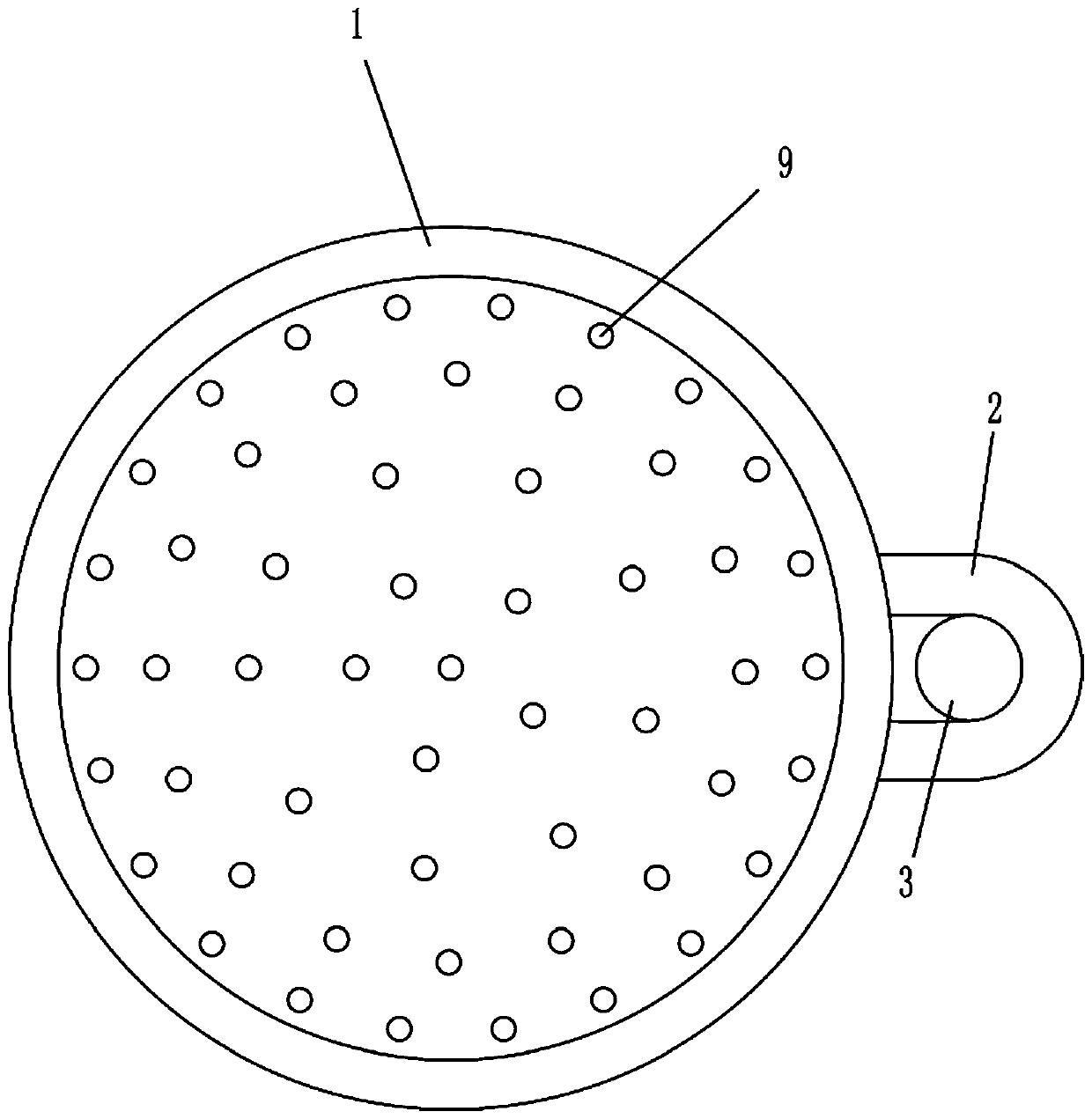

Food steamer applicable to processing of various kinds of steaming food

InactiveCN110074660AControllable EmissionsImprove applicabilitySteam cooking vesselsEngineeringFood item

The invention relates to the field of food processing, in particular to a food steamer applicable to processing of various kinds of steaming food. The invention aims at solving the technical problemsto provide the food steamer applicable to processing of various kinds of steaming food. By using the food steamer, pastries can be fast and conveniently steamed, and the steam discharging quantity canbe controlled. The food steamer applicable to processing of various kinds of steaming food comprises a fixed sieve disc, a fixing ring, a fixing rod, a rotating component, a regulating component, a steaming disc, a first rotating handle and a second rotating handle, wherein the fixing ring is uniformly and fixedly connected onto the fixing rod; the fixing sieve disc is fixedly connected onto thefixing ring; ventilation holes are uniformly formed in the inner bottom surface of the fixed sieve disc; the rotating component is fixedly connected with the fixing rod, and is positioned above the fixing ring; the steaming disc is in transmission connection with the output end of the rotating component, and is attached to the fixed sieve disc; steam holes are uniformly formed in the inner bottomsurface of the steaming disc; the first rotating handle is fixedly connected with the outer wall of the steaming disc. The effects of conveniently and fast steaming the pastry and controlling the discharging quantity are achieved.

Owner:蔡晓忠

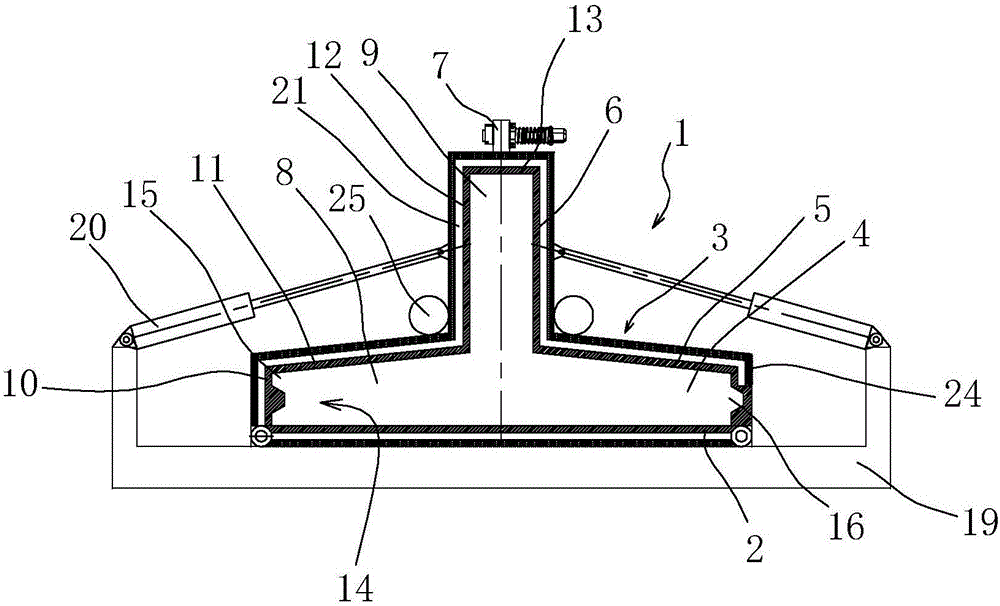

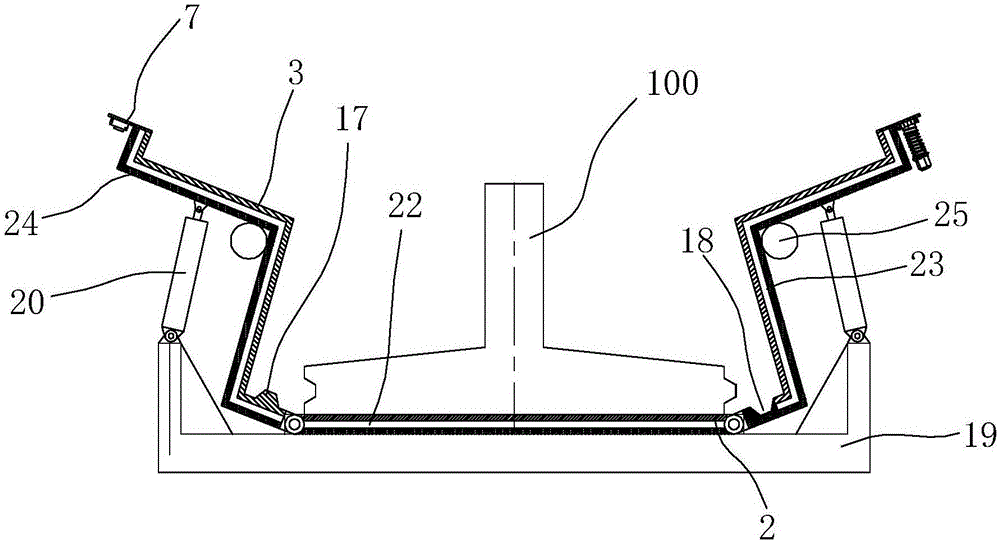

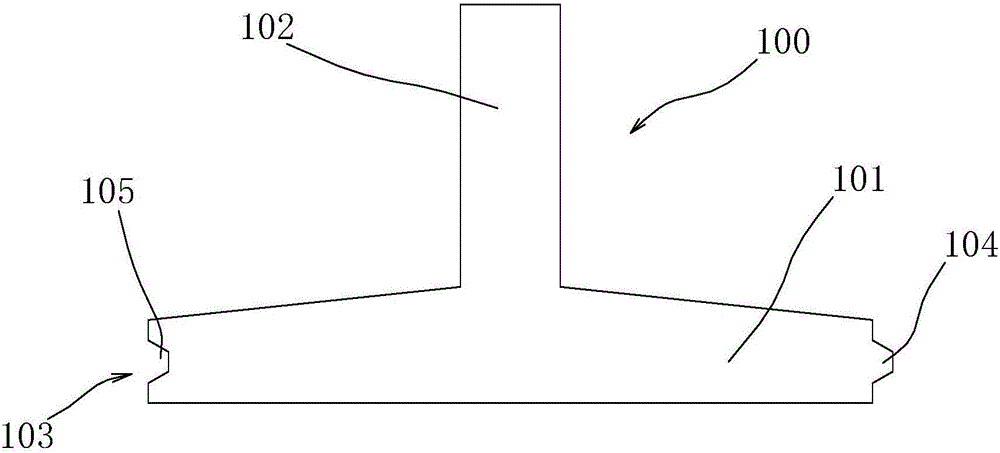

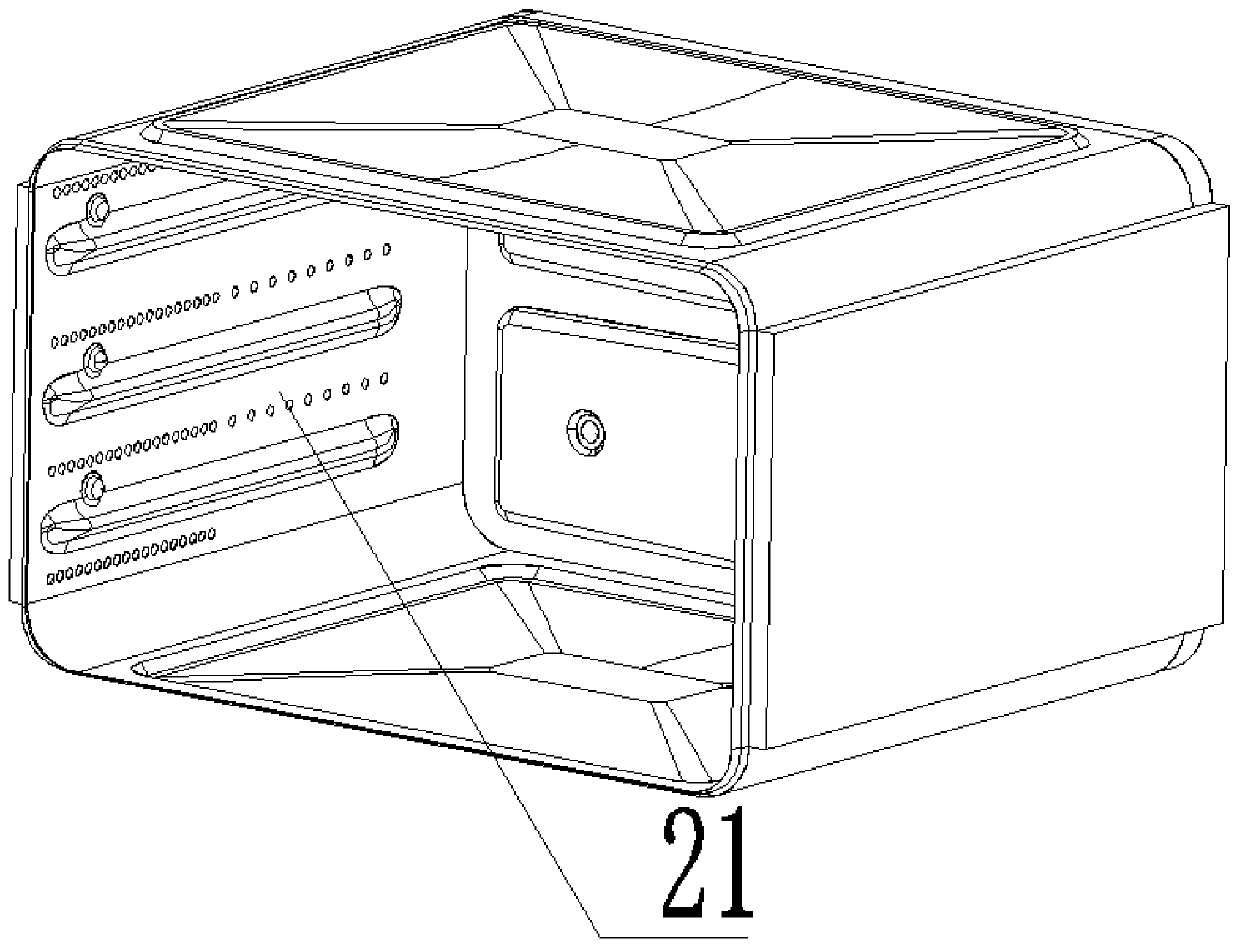

In-situ opening/closing type T-shaped pile mold

InactiveCN106272911AEasy to open and closeIncrease productivityMouldsMould fastening meansTongue and grooveMechanical engineering

The invention belongs to the technical field of buildings and relates to an in-situ opening / closing type T-shaped pile mold. The in-situ opening / closing type T-shaped pile mold comprises a mold body, wherein the mold body comprises a bottom mold plate; each of two ends of the bottom mold plate is hinged with a side mold strip component; the two side mold strip components are symmetrically distributed along the central line of the bottom mold plate; each side mold strip component can rotate along the position hinged with the bottom mold plate; when the two side mold strip components are close to each other, the end, far away from the bottom mold plate, of one side mold strip component can be connected with the end, far away from the bottom mold plate, of the other one side mold strip component in a mutually detachable mode, so that a T-shaped forming cavity is formed in the mold body; when the two side mold strip components are far away from each other, a T-shaped pile in the forming cavity is separated from the side mold strip component. The bottom mold plate is hinged with the side mold strip components, so opening and closing are facilitated; connecting tongue-and-groove plates of the side mold strip components are fixedly connected to form mold closing; the opening and closing processes are conducted in situ without using a lifting tool, and are very convenient, so that the production efficiency can be improved.

Owner:周兆弟

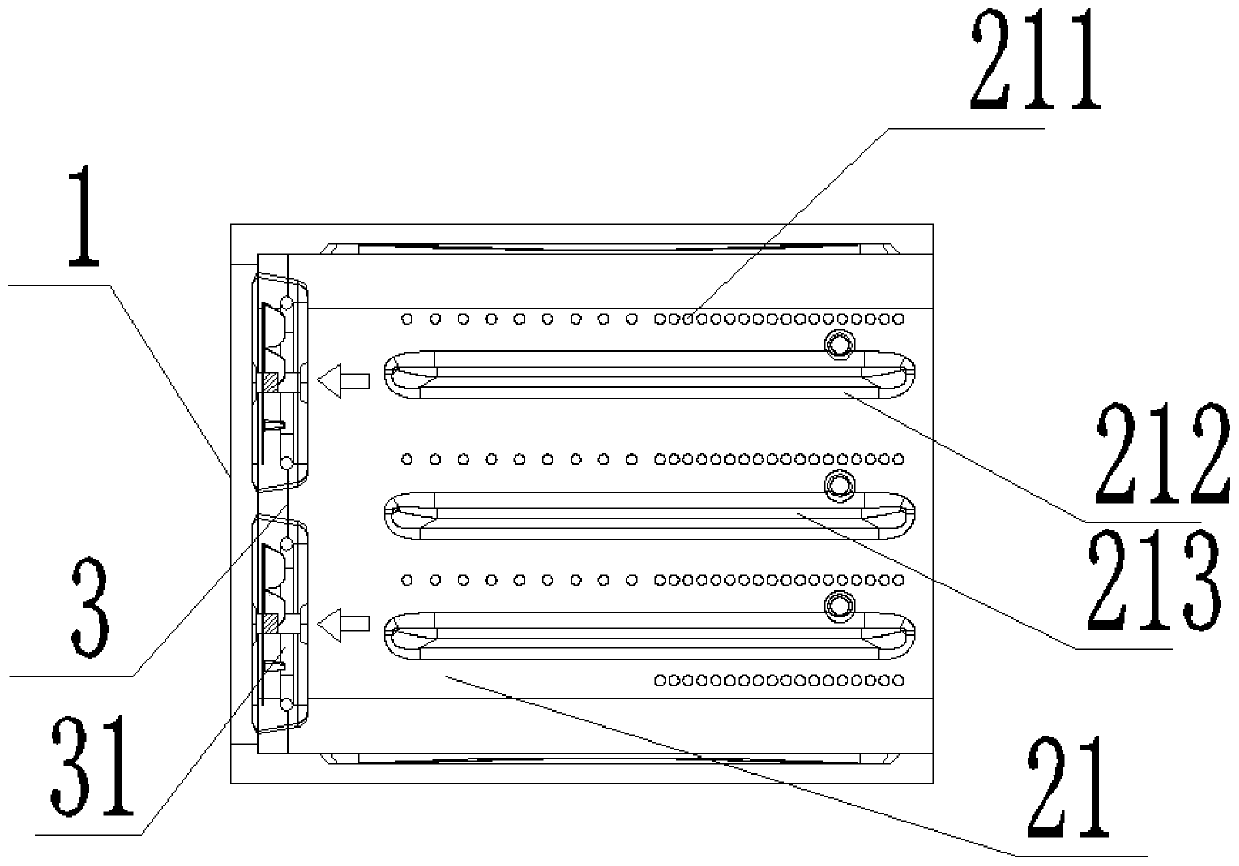

Steaming oven

PendingCN110693347AReduce lossExtended heating areaDomestic stoves or rangesLighting and heating apparatusEngineeringCooked food

The invention provides a steaming oven. The oven comprises an outer shell and an oven door installed on the outer shell. A heating cavity is formed in the outer shell. An air return port is formed inthe inner wall, opposite to the oven door, of the heating cavity; the air return port is communicated with a heating device and an air guide device, a flow channel is formed between the inner side wall of the heating cavity and the outer shell and communicated with the heating cavity, a communication part is arranged at the position, corresponding to the inner side wall, of the flow channel, and the communication area of the communication part is gradually increased in the unit area in the direction towards the oven door. The communicating area of the communicating part is gradually increasedin unit area in the direction towards the oven door; heat away from a heat source position is increased; according to the steaming oven, the temperature difference of the heating cavity can be effectively reduced, the temperature is more uniform, repeated debugging is not needed, the reliability of temperature uniformity is high, the heat cycle range is wider, the influence of the number of air inlets is avoided, more to-be-cooked food areas can flow through, and the defects that in the prior art, the temperature difference of baking areas of an inner cavity of a steam oven is large, and baking is uneven are overcome.

Owner:GREE ELECTRIC APPLIANCES INC

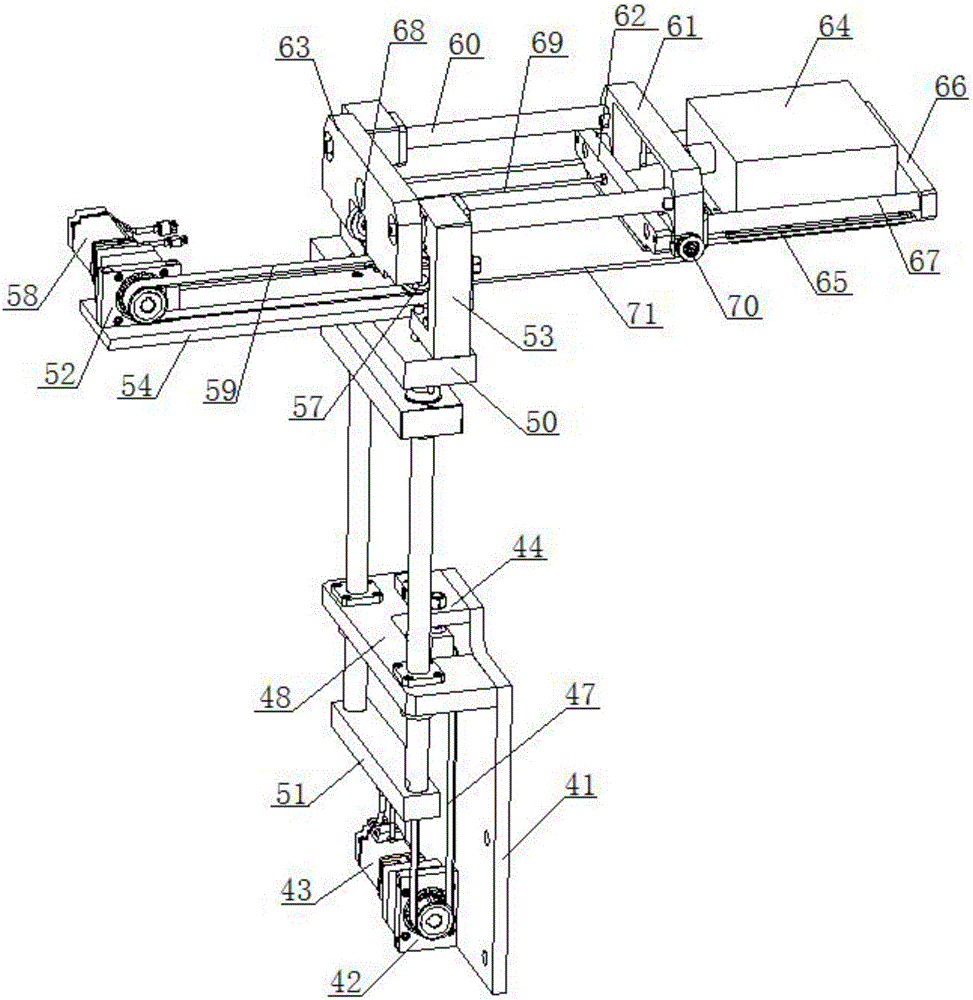

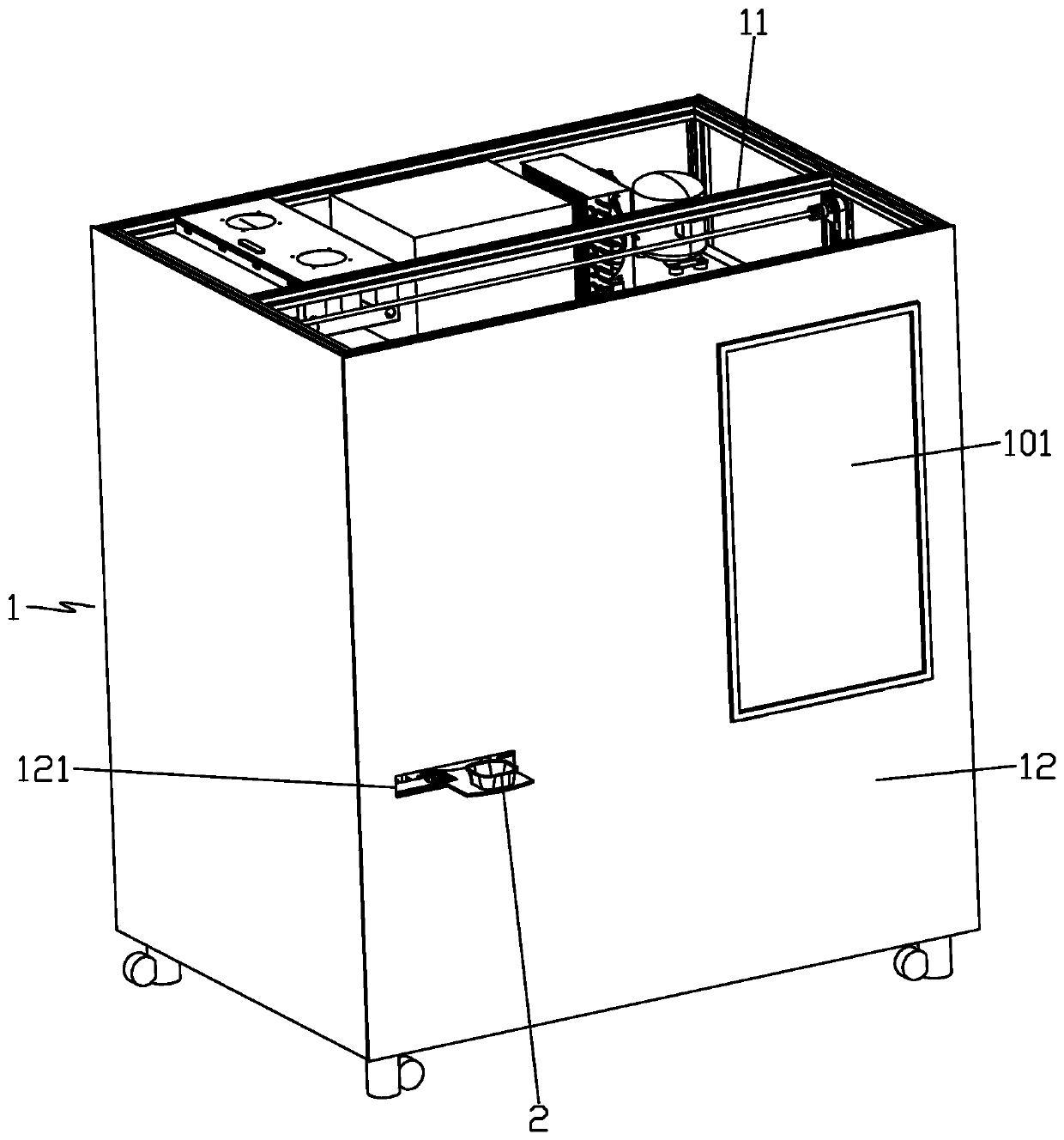

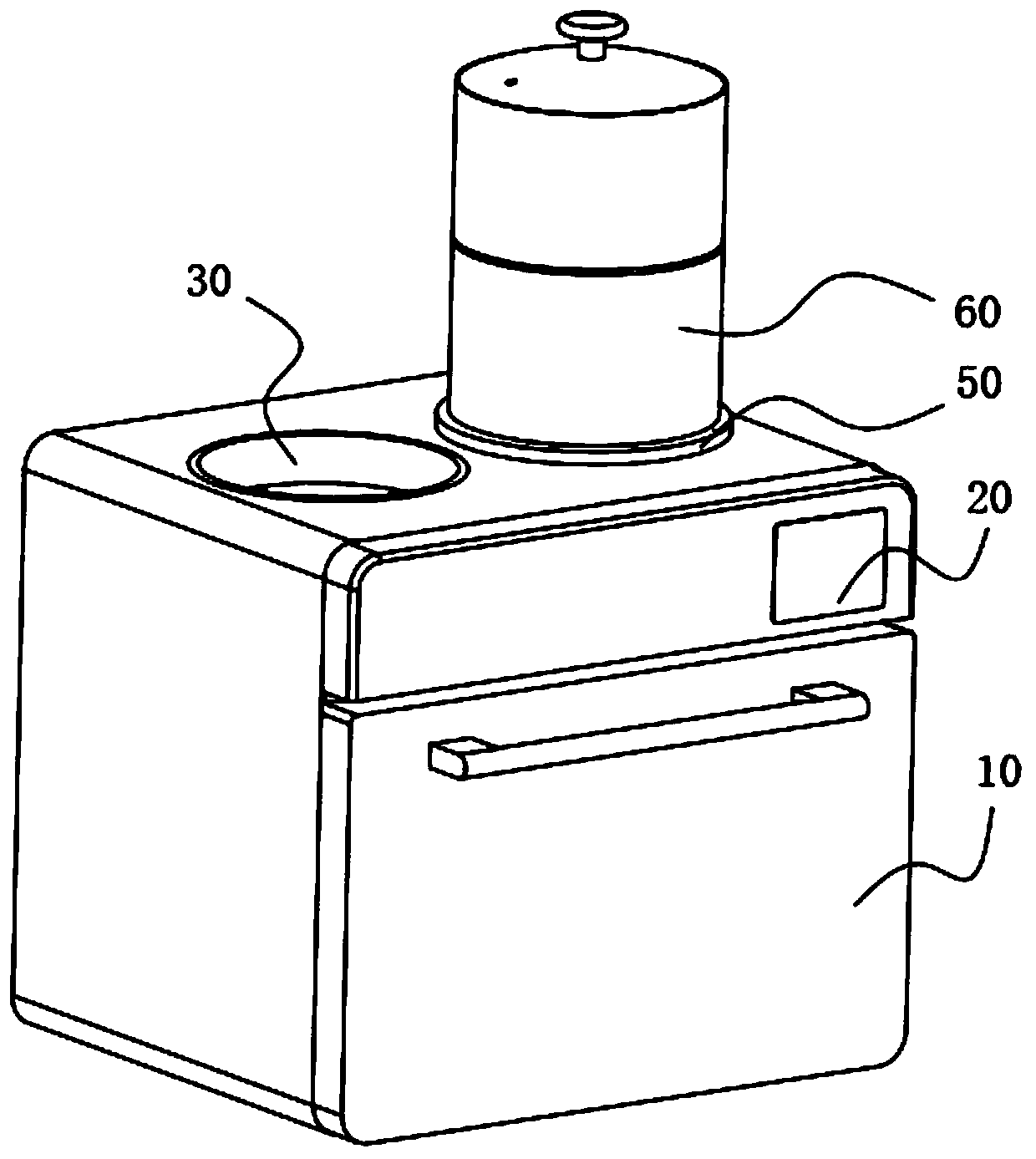

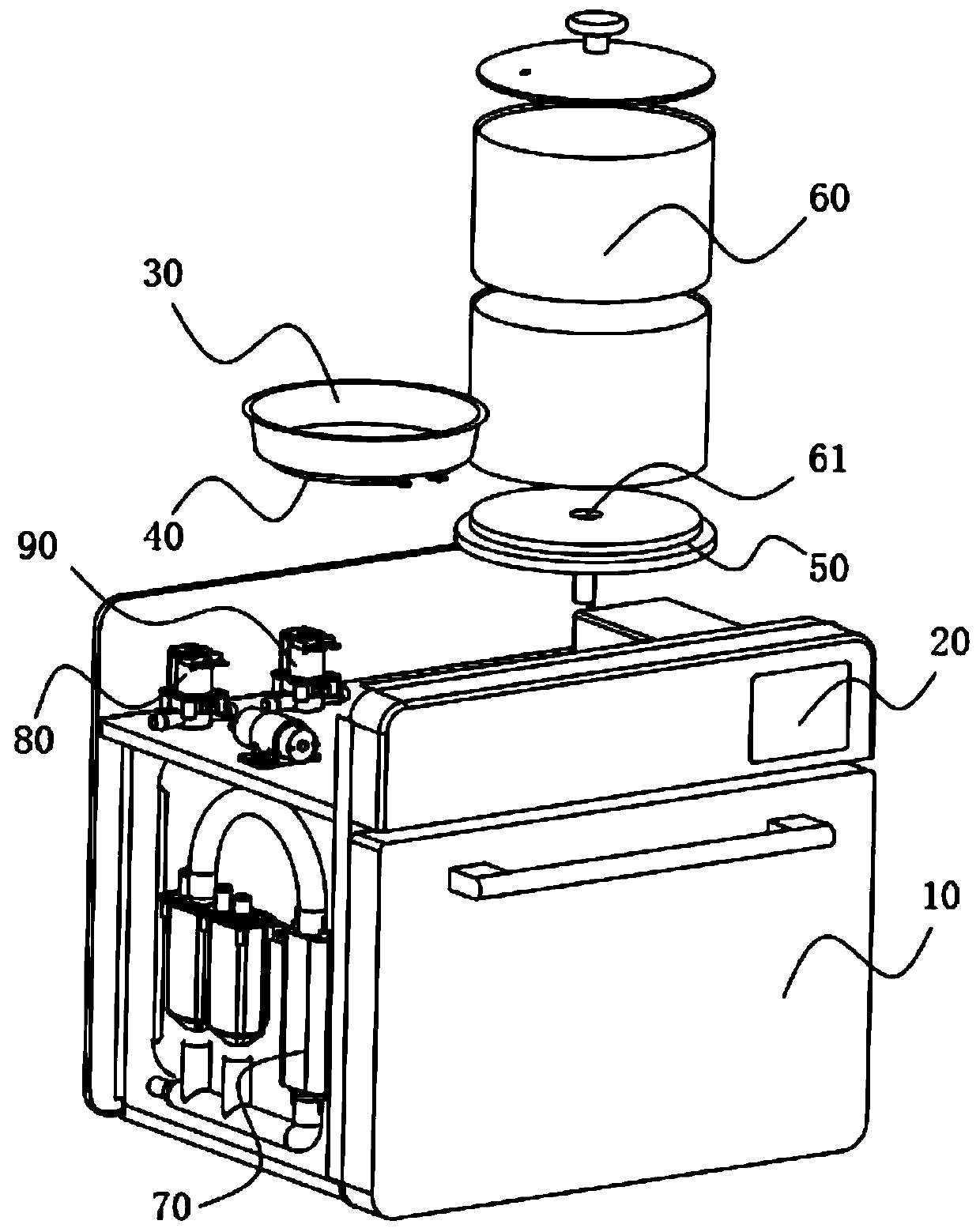

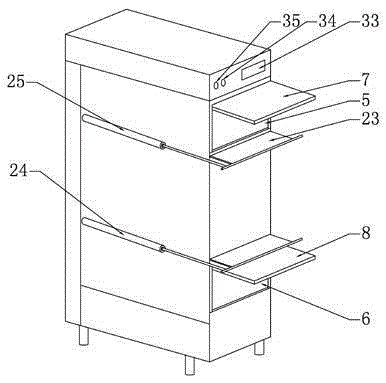

Automatic food steaming and vending machine

PendingCN110338645ACompact structureAccurate and stable transmissionSteam cooking vesselsApparatus for dispensing fluids/granular materialsFood contact materialsControl system

The invention discloses an automatic food steaming and vending machine; the automatic food steaming and vending machine comprises a machine body with a control system, wherein a storage space capableof containing a food container is arranged in the machine body, a feeding device capable of adding a liquid material into the food container, a steaming device capable of steaming the food in the foodcontainer, and a carrying system, wherein the carrying system is controlled by the control system, so that the food container can be conveyed among in the storage space, the feeding position of the feeding device and the steaming device, and the food container in the steaming device can be conveyed to a meal taking position. According to the requirements of users, the corresponding food containeris taken out, a proper amount of liquid material is added into the liquid material, and then the food container is put into the steaming device for automatic steaming and automatic vending, so that the machine has high market prospect.

Owner:深圳极客开饭科技有限公司

Processing method of day lily flowers

InactiveCN105341134ANatural colorNatural aromaMeat/fish preservation by dryingCooking & bakingMicrowave

The invention relates to a processing method of day lily flowers. The processing method comprises the following steps of picking and spreading for cooling: picking fresh day lily flowers, and spreading for cooling the picked day lily flowers; steam fixation: performing steam fixation on the cooled day lily flowers; primary baking: sending the day lily flowers after the fixation to a hot air dryer for primary baking, so that the water ratio of the obtained day lily flowers is reduced to 45%-48%; and secondary baking, sending the day lily flowers after primary baking to a microwave drier for secondary baking, so that the water ratio of the obtained day lily flowers is reduced to 13%-16%.Through the processing method of the day lily flowers, the day lily flowers can maintain a good shape, the color of the day lily flowers can also be improved, the quality of the day lily flowers can be greatly improved, and the effect of preventing the day lily flowers from being damaged by worms is achieved. In addition, according to the processing method, additives, such as essence, are not added, so that the safe and healthy consumption trend for the day lily flowers can be met.

Owner:HUIZHOU YULUMING AGRI DEV CO LTD

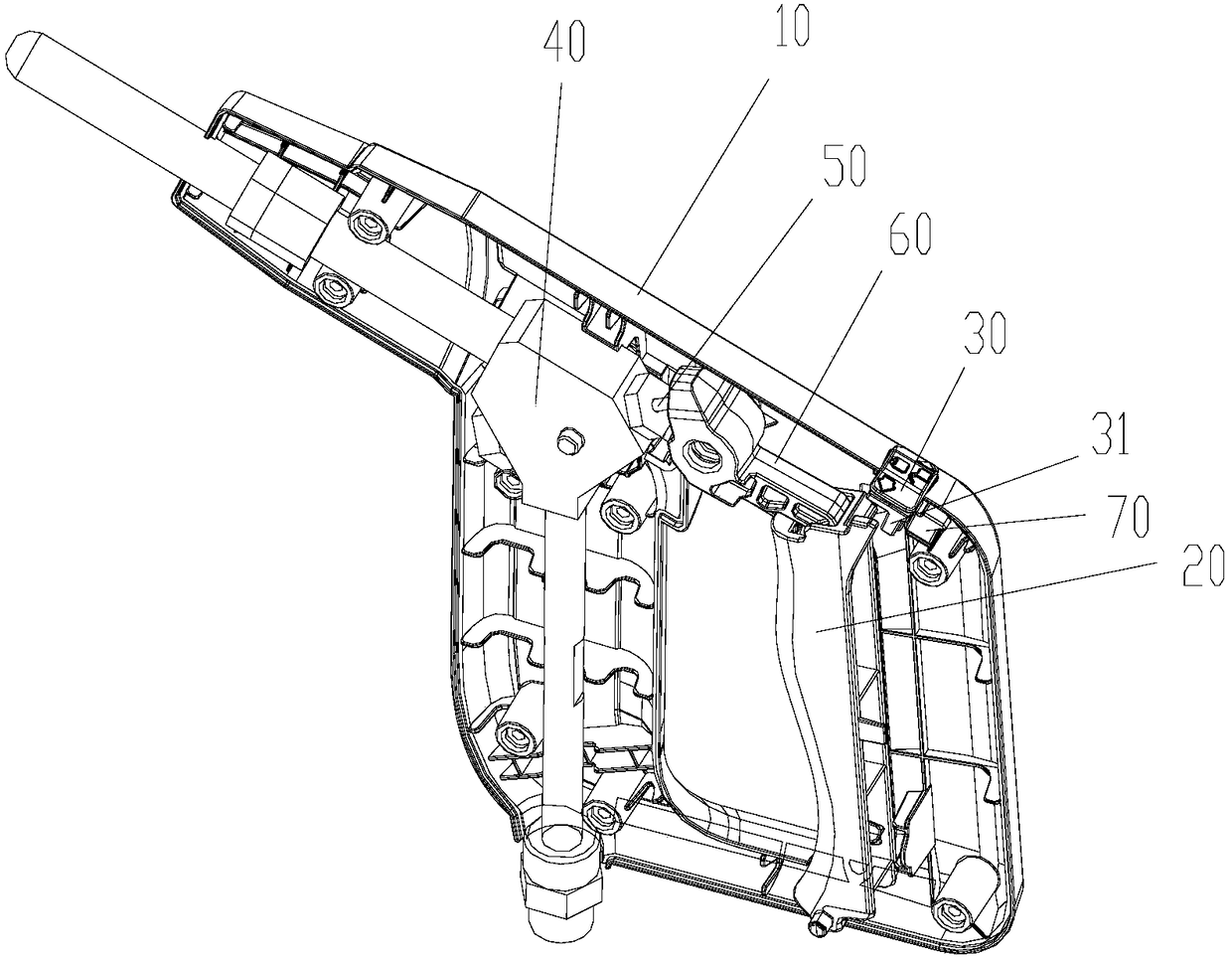

Cooking device with steaming function

PendingCN111568166ASave kitchen spaceStrong choice flexibilitySteam cooking vesselsWarming devicesProcess engineeringFrying-pans

The invention relates to the technical field of cooking equipment, in particular to a cooking device with a steaming function. The cooking device with the steaming function comprises a body with a main cooking cavity, an auxiliary cooking assembly and a steam generator. The auxiliary cooking assembly comprises a food steamer assembly, a frying pan and a heating piece, the food steamer assembly andthe frying pan are both installed outside the body, and the heating piece is used for heating food materials in the frying pan; the steamer assembly is communicated with a steam outlet of the steam generator through a first control valve; and the main cooking cavity is communicated with a steam outlet of the steam generator through a second control valve. According to the cooking device with thesteaming function, food materials can be fried, the trouble that a user purchases a frying pan independently is avoided, and kitchen space is saved for the user; in addition, the cooking efficiency can be improved when a small amount of food materials are cooked, energy is saved, and the amount of the food materials steamed at the same time can be increased.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

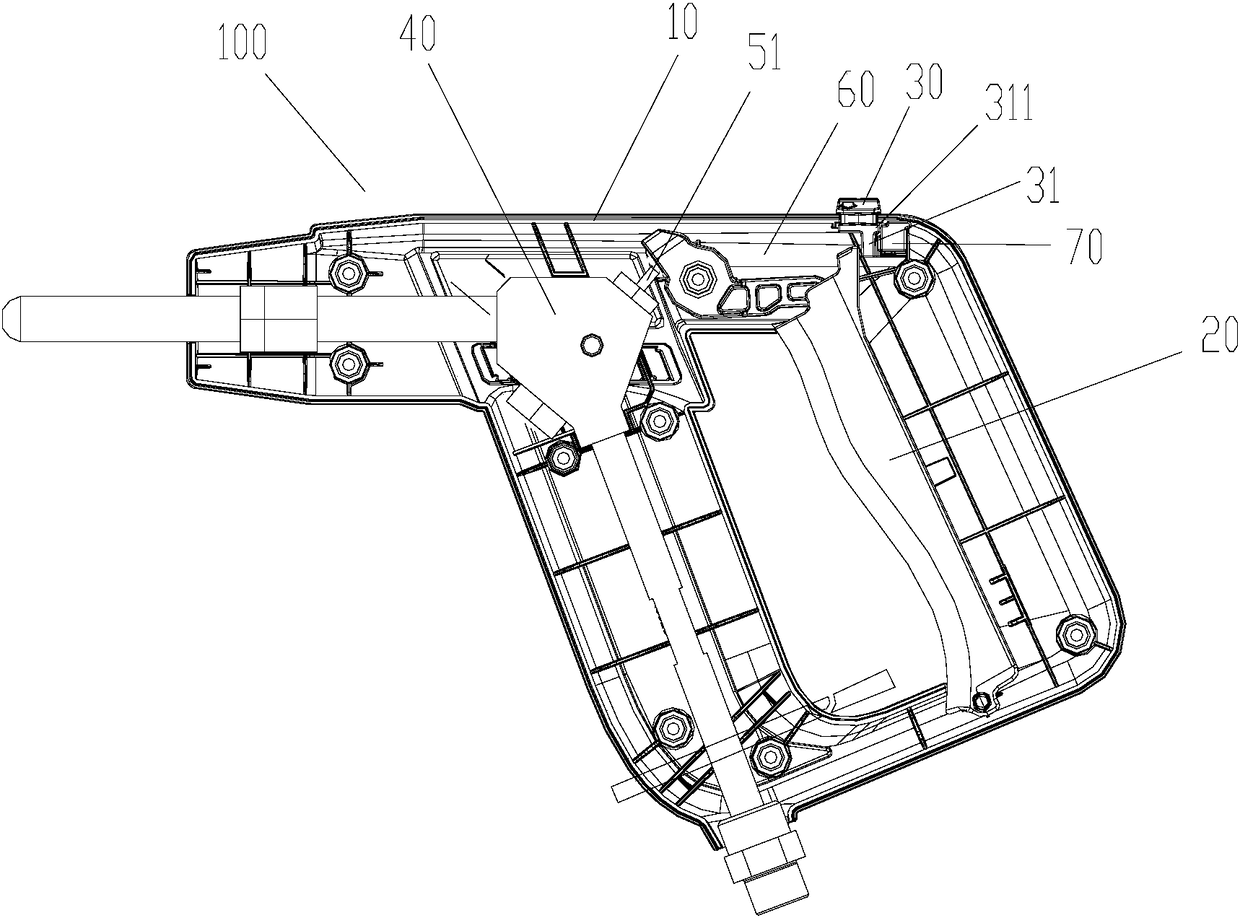

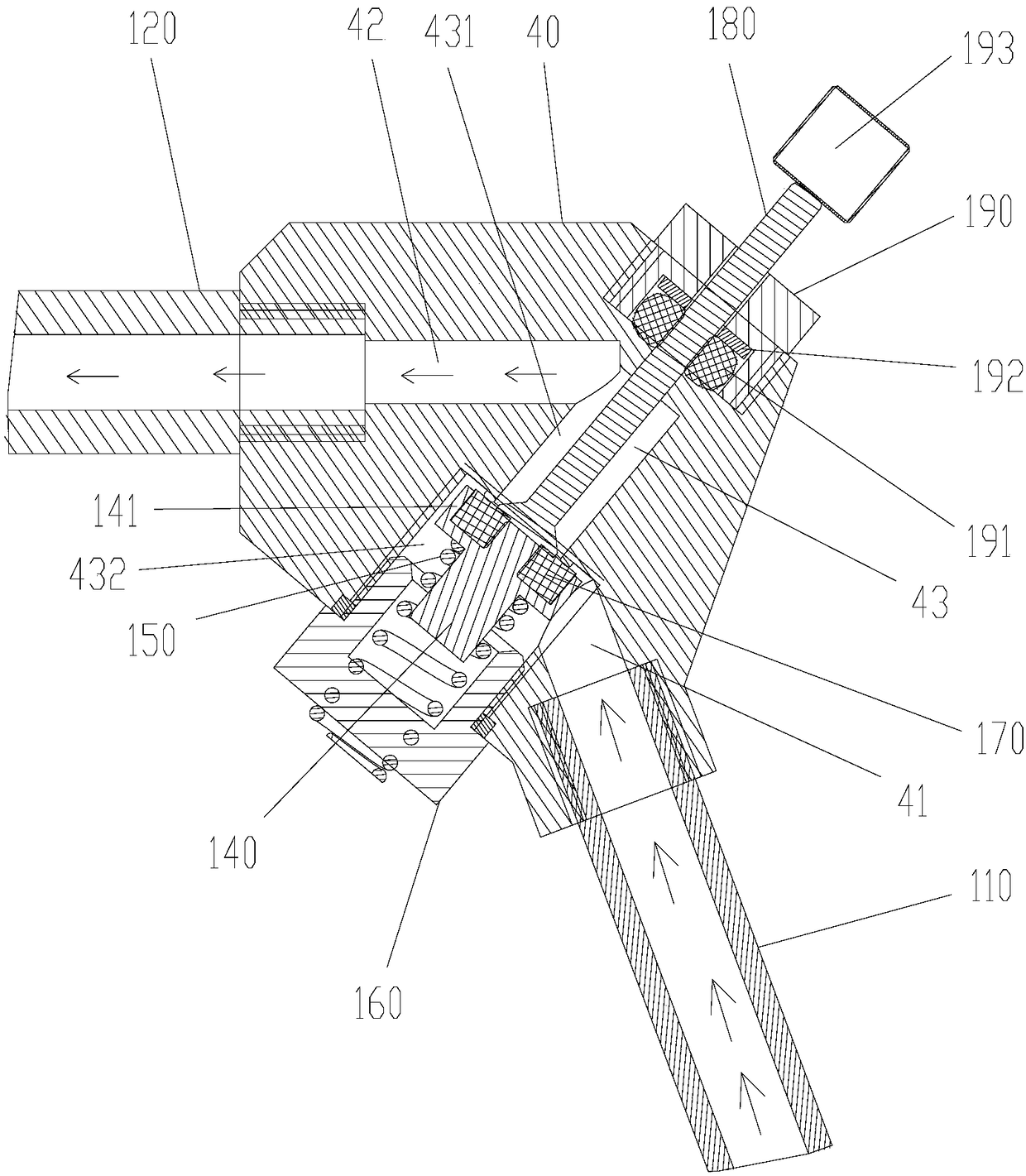

Car washing machine

PendingCN108128282AImprove heating efficiencyImprove steaming efficiencySpray nozzlesCleaning apparatus for vehicle exteriorsInlet channelCombustion chamber

The invention provides a car washing machine. The car washing machine comprises a steam generator and a spray gun connected with the steam generator, and the steam generator is provided with a gas outlet for gassing; the spray gun comprises a spray gun shell and an operating handle, and the operating handle is arranged on the spray gun shell; the steam generator comprises a boiler body, an inner cover and an outer cover, the boiler body is provided with a combustion chamber communicating with the gas outlet, the outer side of the boiler body is sleeved with the inner cover, and a gap between the inner cover and the boiler body forms a gas outlet channel used for enabling the combustion chamber to communicate with the gas outlet; the outer side of the inner cover is sleeved with the outer cover, and a gap between the inner cover and the outer cover form a gas inlet channel; and the spray gun further comprises a locking switch, the locking switch is mounted on the spray gun shell in a position adjustable mode, and the locking switch is located on one side of the operating handle and matched with the operating handle in a limited mode. The car washing machine solves the problem of lowsteam heating efficiency of a steam generator of a car washing machine in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Production process of autoclaved aerated concrete slab with high superior product rate

PendingCN112159244AImprove physical and chemical indicatorsGood chemical stabilityCeramic shaping plantsCeramicwareProcess engineeringMaterials processing

The invention discloses a production process of an autoclaved aerated concrete slab with a high superior product rate, and belongs to the technical field of building material processing and production. The autoclaved aerated concrete slab is prepared from the following raw materials in parts by mass: 49-52 parts of silica sand, 3.5-5 parts of gypsum, 18-21 parts of cement, 9-12 parts of lime and water, and the preparation stage, the pouring molding stage, the demolding cutting stage and the slotting steam curing stage are subjected to process optimization respectively, so that the problem thatthe superior product rate is relatively low in the process of producing the autoclaved aerated concrete slab in the current process is effectively solved.

Owner:贵州长通装配式建材有限公司

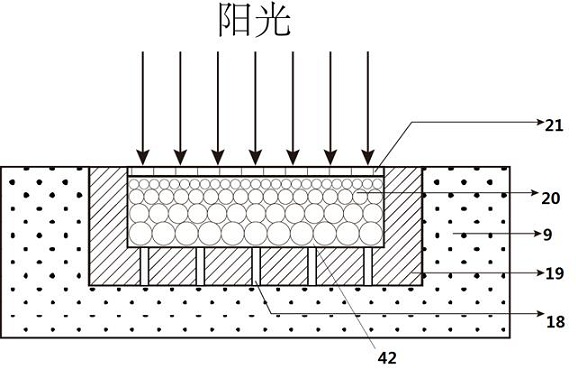

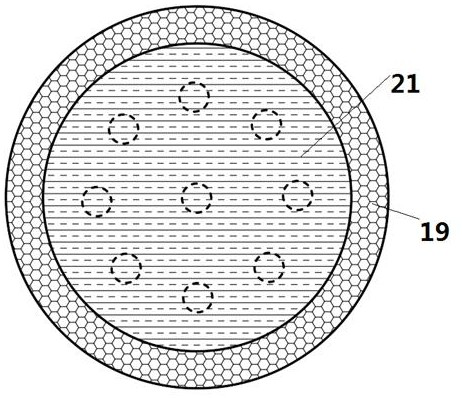

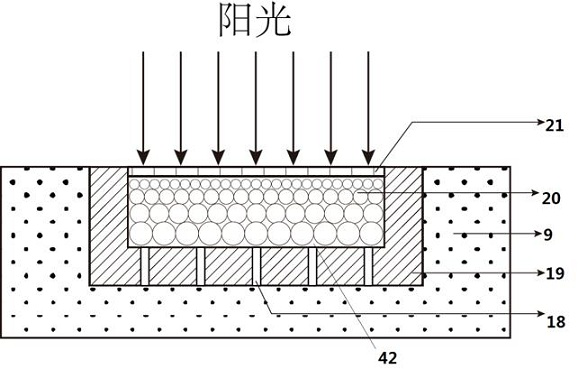

Active solar tracking heat collecting device and air cylinder structure thereof

ActiveCN112303934ASuppress dissipationImprove steaming efficiencySolar heating energySolar heat collector controllersNew energyEngineering

The invention provides an active solar tracking heat collecting device and an air cylinder structure thereof. The device comprises a water tank and a photo-thermal conversion element, wherein the upper end of the water tank is of an opening structure, the photo-thermal conversion element floats on the upper portion of the water tank, the photo-thermal conversion element comprises a base body formed by a foaming material, a groove with an opening in the upper side is formed in the base body, a heat collecting tube box comprises a first tube opening and a second tube opening, the first tube opening is connected with an inlet of a left heat release tube set, the second tube opening is connected with an inlet of a right heat release tube set, an outlet of the left heat release tube set is connected with an upper tube, and an outlet of the right heat release tube set is connected with the upper tube; and the first tube opening and the second tube opening are formed in one side of the heat collecting tube box. According to the active solar tracking heat collecting device and the air cylinder structure thereof, a large amount of steam is generated without the assistance of a heating device, the floating foam material supports a photo-thermal conversion layer out of the water surface, dissipation of generated heat energy from a film to a lower-layer liquid is restrained, therefore thevaporization efficiency of the device is improved, and the great potential of the device as a photo-thermal conversion new energy material is shown.

Owner:山东百帝气动科技股份有限公司 +1

steam box

InactiveCN104082635BRealize continuous operationAvoid wastingCooking insertsFood scienceAutomatic controlHigh rate

The invention aims to provide a steaming box which is high-rate, space-saving, accurate in mechanical transmission and capable of automatically controlling and monitoring; the steaming box comprises a box body, a power source and at least one tray, the box body is provided with a work room, the front side or / and the rear side of the body body is / are provided with a tray inlet or / and a tray outlet; the tray inlet and the tray outlet are correspondingly provided with a movable door, the left and right side walls of the work room are respectively provided with at least one supporting mechanisms, each supporting mechanism comprises two brackets which are oppositely arranged, at least two rotating shafts are arranged between the two brackets, a supporting table is horizontally arranged on each rotating shaft, each rotating shaft is provided in the a reset spring, one end of the reset spring is fixedly connected to one corresponding supporting table, the rear side wall of the work room is provided with a steam inlet, the left and right side walls of the work room are respectively provided with at least one lifting mechanisms corresponding to the power source; and the steaming box has the advantages of simple operation, high degree of automation, higher steam utilization rate and the like.

Owner:许春雁

Solar heat collection device and sewage treatment method thereof

ActiveCN113028656AAchieve vibrationAchieve descalingSolar heating energyGeneral water supply conservationThermodynamicsProcess engineering

The invention provides a solar heat collection device and a sewage treatment method thereof. The solar heat collection device comprises a reflecting mirror, the reflecting mirror is divided into two parts along the middle, the two parts are the first part and the second part separately, a supporting piece is arranged on the lower portion of a heat collection pipe box, and two hydraulic telescopic rods stretch out of a supporting column to be connected to the first part and the second part separately. The two hydraulic telescopic rods are used for driving the first part and the second part to separate or combine. When the first part and the second part are combined together, the reflecting mirror bodies form the complete reflecting mirror, and the heat collection pipe box is located at the focus position of the reflecting mirror and used for collecting heat of the heat collection pipe box; and when the first part and the second part are separated, the heat collection pipe box is not located at the focus of the first part and the second part, and heat collection is not conducted on the heat collection pipe box. The heat collection device of a novel structure is provided, and vibration and descaling of the heat collection device can be achieved by judging whether heat collection is conducted on the heat collection device or not.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com