Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve paint rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

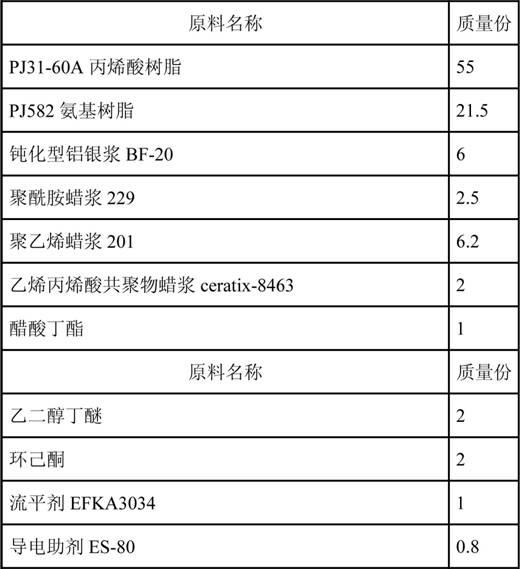

Acrylic resin metallic brilliant baking paint

The invention discloses acrylic resin metallic brilliant baking paint. The baking paint comprises the following components in parts by mass, 25 to 55 parts of acrylic resin, 10 to 35 parts of amido resin, 4 to 20 parts of aluminum paste, 5 to 25 parts of metal pigment alignment auxiliary agent, 0.2 to 2.0 parts of flatting agent, 0.1 to 2.0 parts of conductivity improver, and 5 to 25 parts of organic solvent. When the acrylic resin metallic brilliant baking paint is used for an auto spray coating line, punch-through cannot occur in a range that construction voltage is between 50 and 120kV in a working solution state of low impedance (1 to 10 M omega), and the acrylic resin metallic brilliant baking paint has the advantages of high varnishing rate of paint liquid, uniform and flat paint film appearance and excellent paint film performance, and can meet the requirement on paint film performance of most home appliance, ironware and artware.

Owner:JIANGMEN PAINT FACTORY

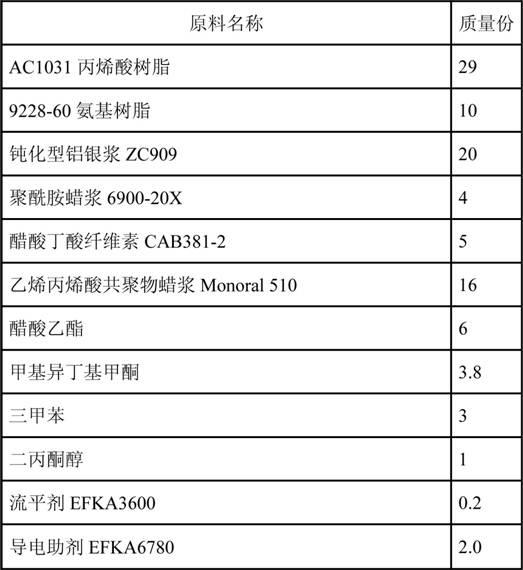

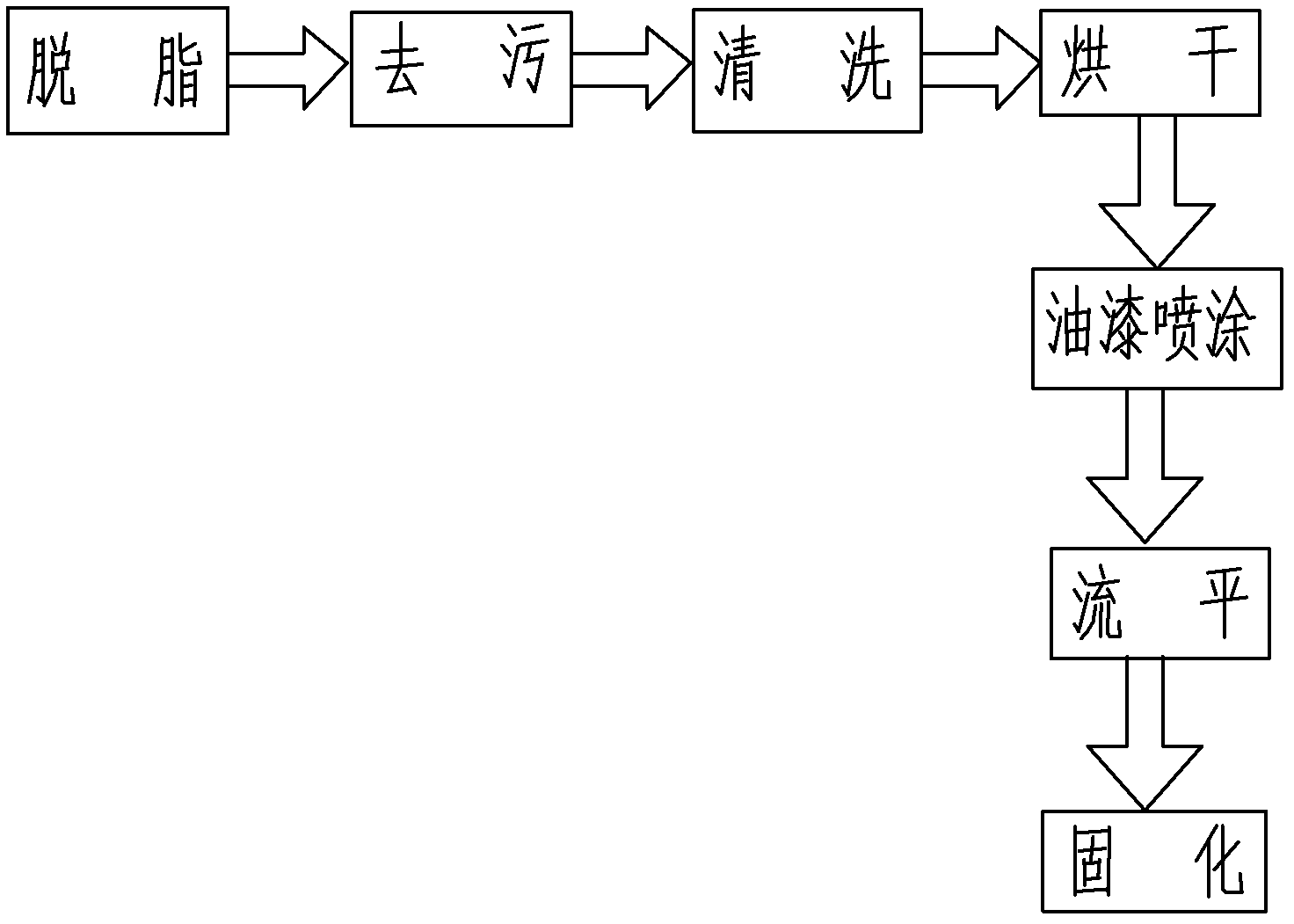

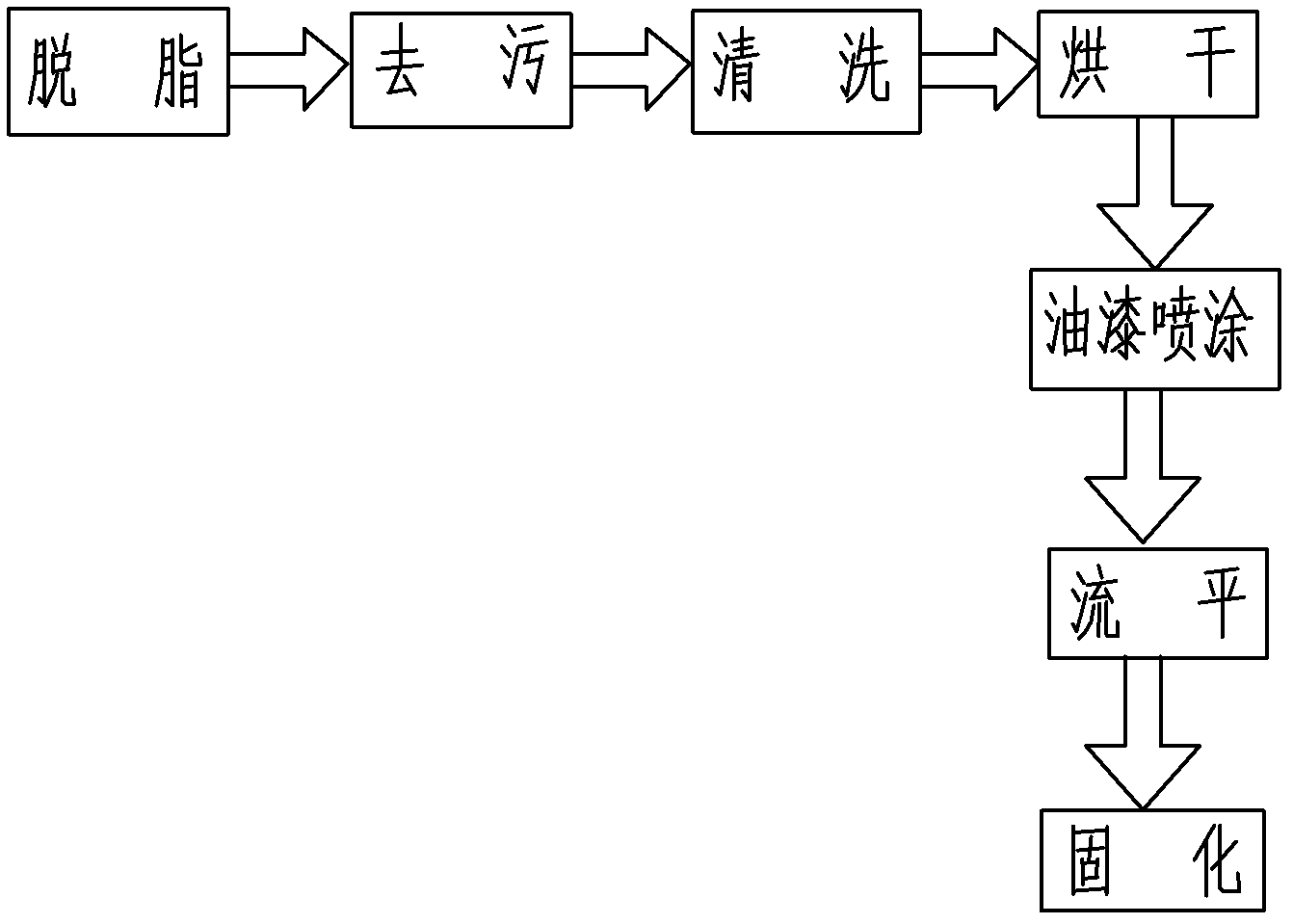

Coating process of carbon fiber fishing rod

InactiveCN102527596AUniform adsorptionReduce pollutionPretreated surfacesCoatingsFiberNumerical control

The invention provides a coating process of a carbon fiber fishing rod. The coating process of the carbon fiber fishing rod sequentially comprises the steps of: degreasing, decontaminating, cleaning and drying a fishing rod, sealing and plugging the mouth of the fishing rod by using a silicone head; vertically hanging the fishing rod on a hanger and spraying paint up and down by a numerical controlled DISK electrostatic spraying device, then entering a leveling region for leveling within 10-15 minutes, irradiating 8-15 minutes by far infrared rays to solidify the fishing rod. By adopting the method provided by the invention, the surface of the sprayed fishing rod is smooth and full, the painting rate of dead angles is high, the whole fishing rod is painted evenly, the brightness is high, the adhesive force is good, the stable product quality is ensured, bad phenomena such as color distortion and bubbling are avoided, the paint film is 50% thinner than the conventional paint and the whole fishing rod has less paint; besides, the painting way is lighter than the traditional way and is independent of skilled labors with high spraying seed and high efficiency.

Owner:湖北钓鱼王渔具有限公司

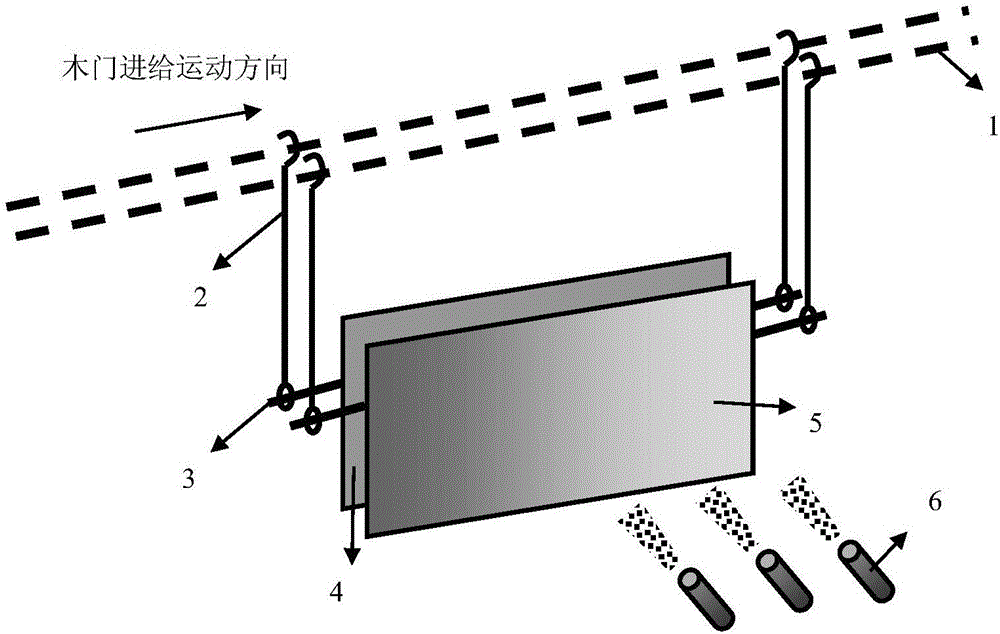

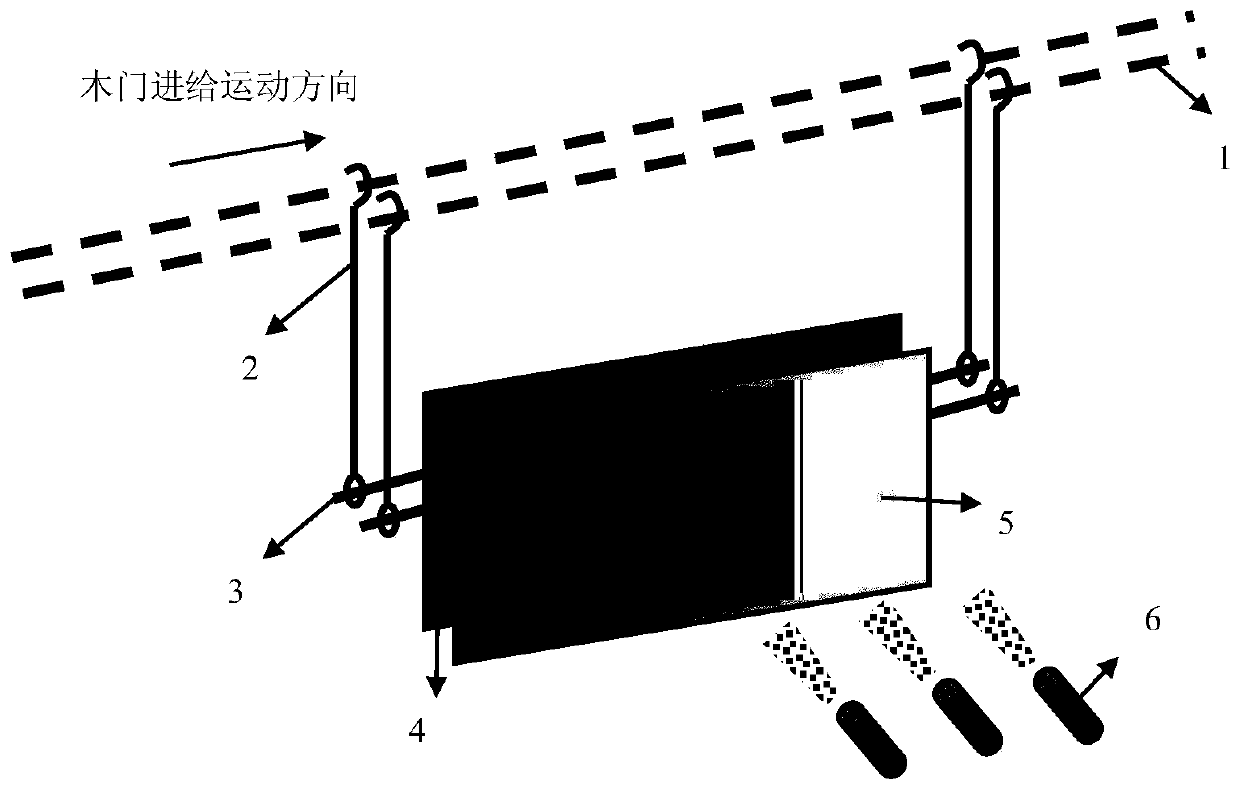

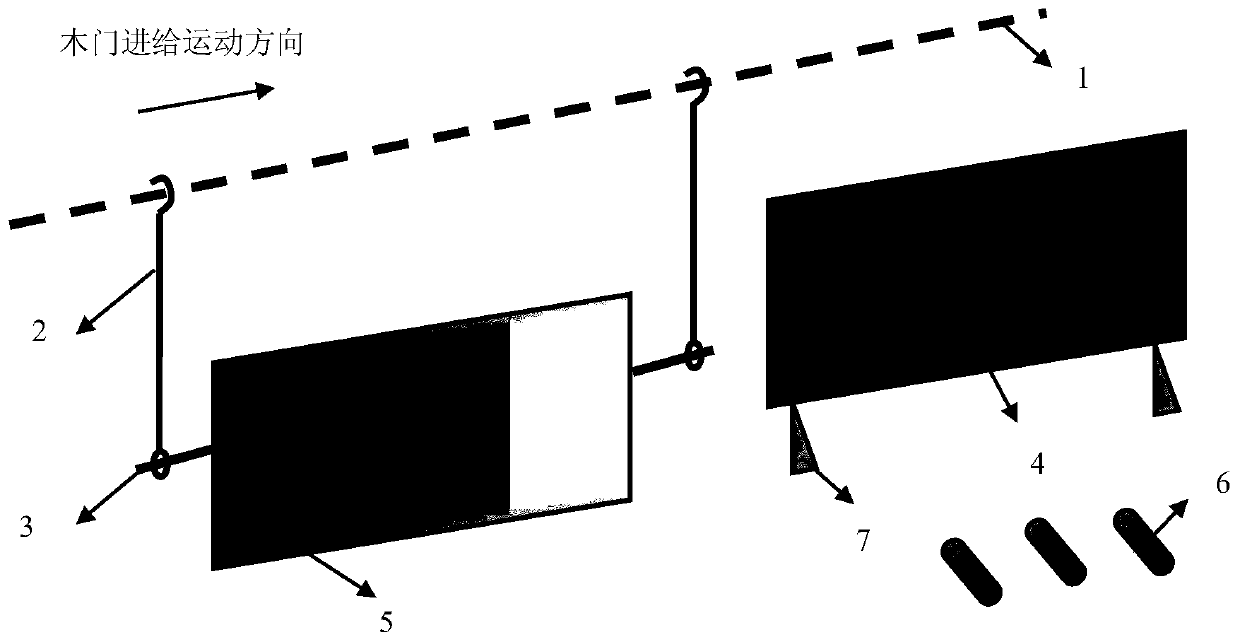

Method for improving quality of electrostatic surface coating of wooden door

ActiveCN106391428ADoes not reduce adhesionImprove the quality of electrostatic sprayingLiquid surface applicatorsCoatingsMechanical engineeringSurface coating

The invention discloses a method for improving the quality of an electrostatic surface coating of a wooden door. The method for improving the quality of the electrostatic surface coating of the wooden door comprises the steps that the wooden door is prepared; and spraying is conducted, specifically, a grounding conductive board is adopted to be placed on the back side of the wooden door during spraying, and in the electrostatic spraying process, the wooden door is located between an electrostatic spraying gun and the grounding conductive board. By adoption of the method for improving the quality of the electrostatic surface coating of the wooden door, the problems that in the conventional electrostatic spraying process of the wooden door, the thickness of a coating is nonuniform, the painting rate is instable, and painting is difficult during secondary spraying or finish paint spraying can be solved; and meanwhile, no humidification treatment needs to be conducted on the surface of the wooden door, so that the adhesive force of a paint film is not reduced, and the electrostatic spraying quality is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

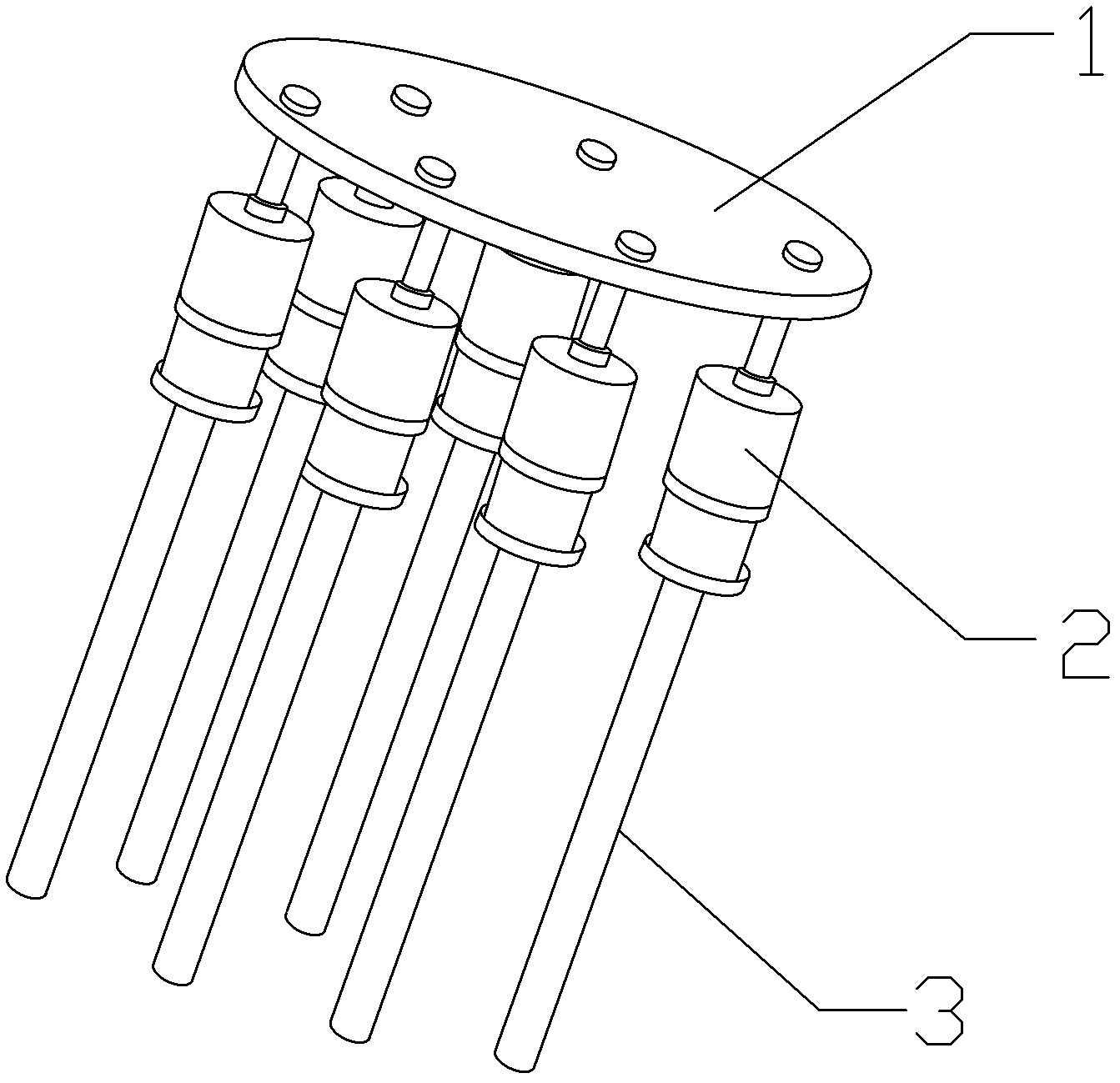

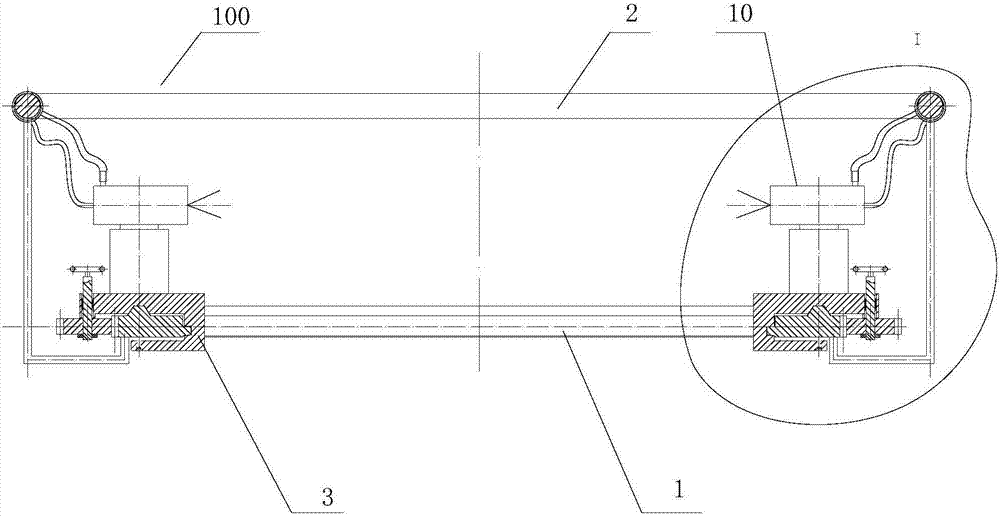

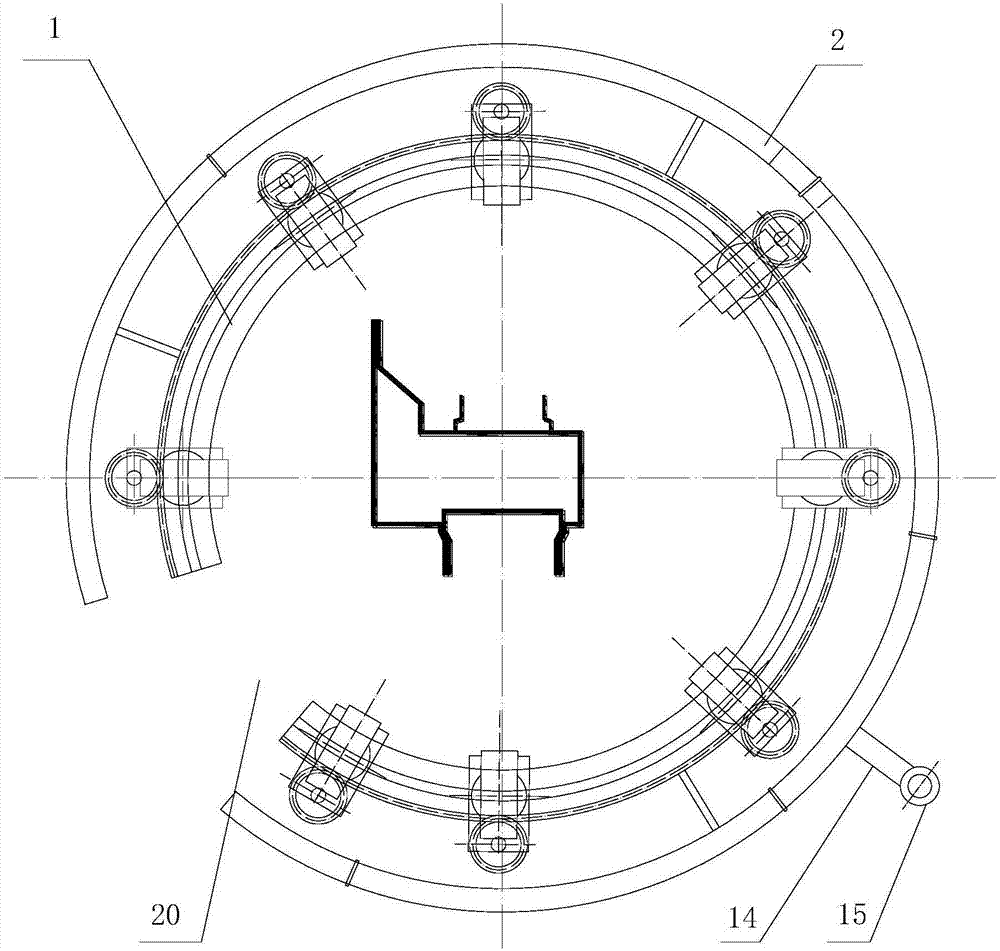

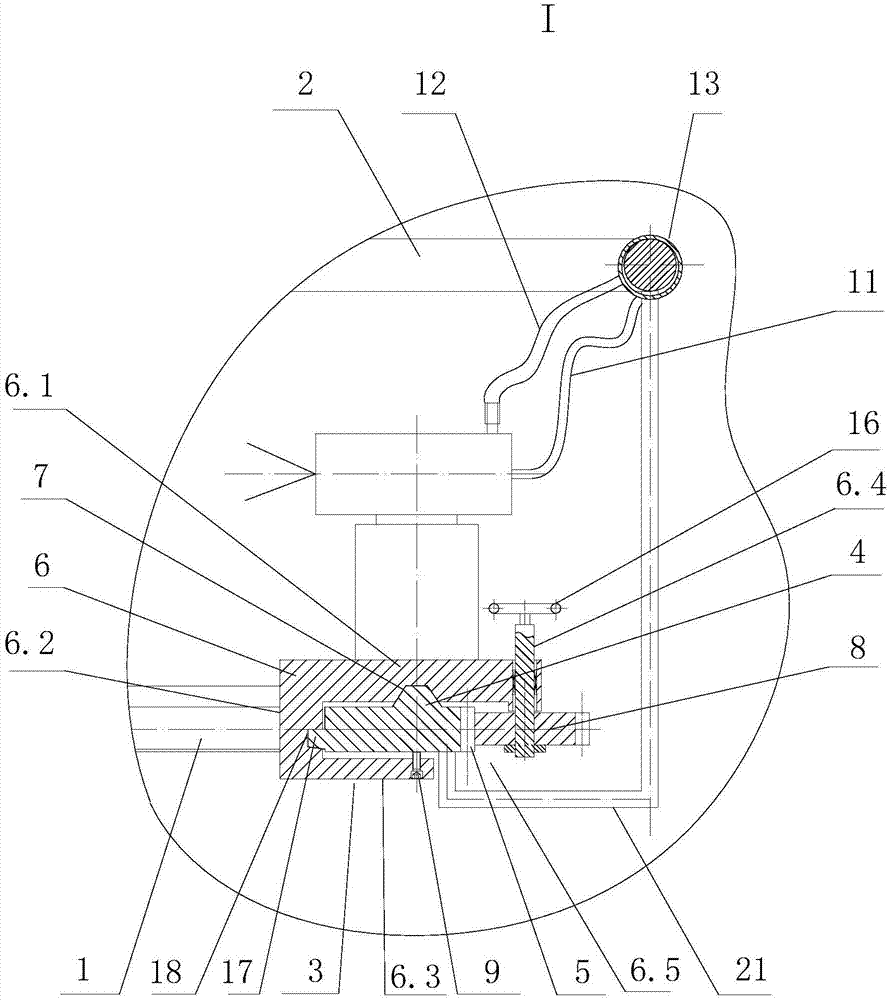

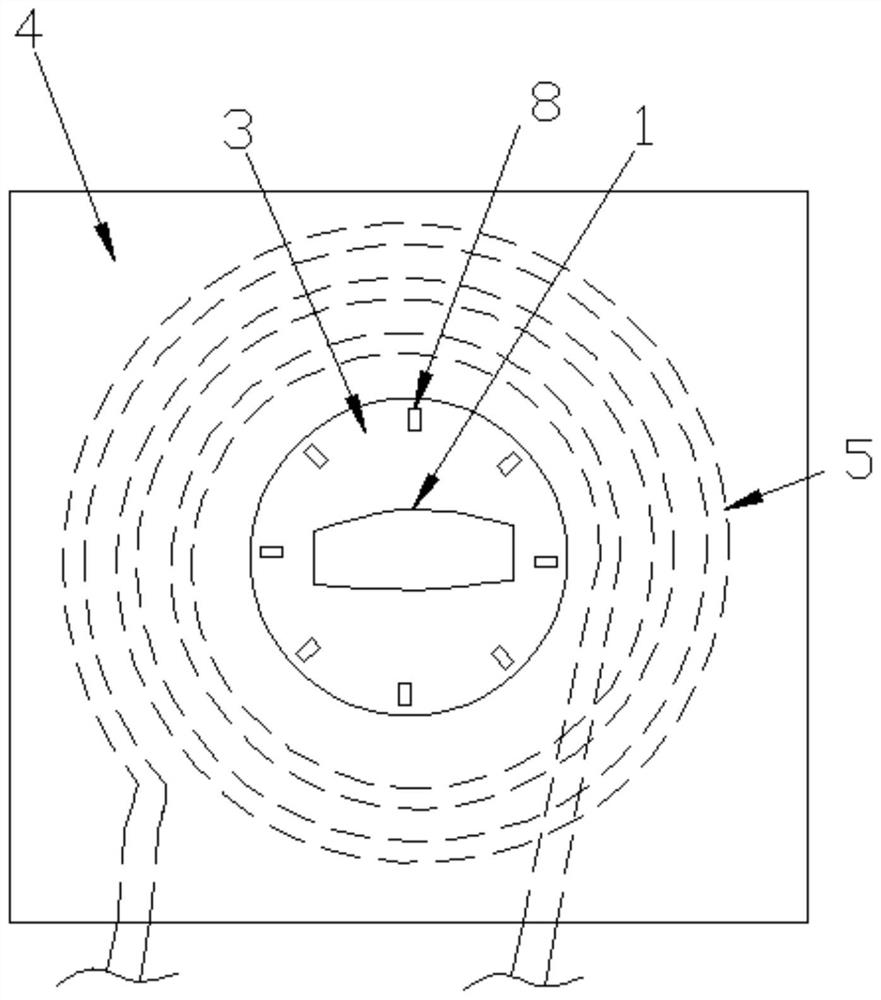

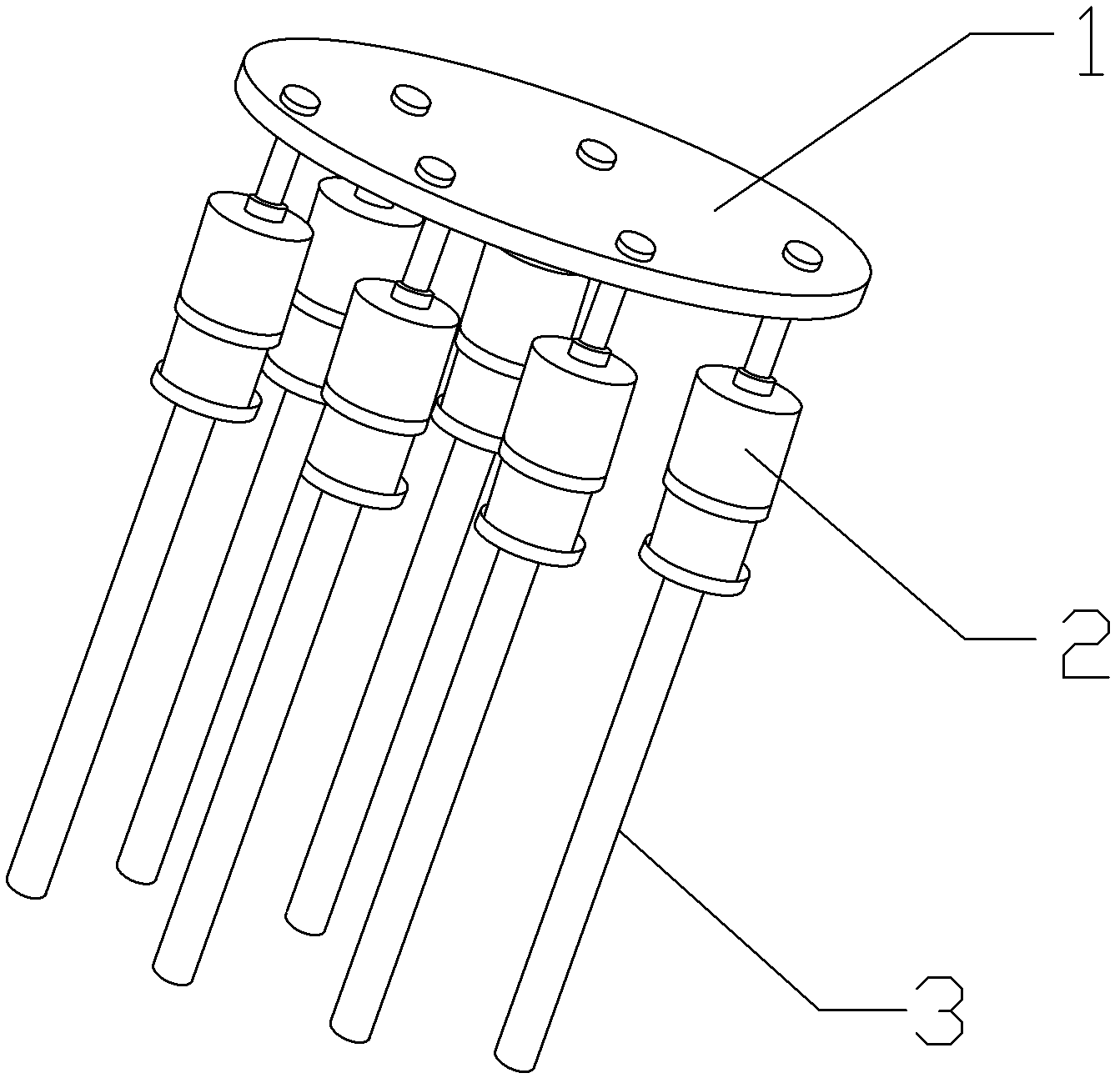

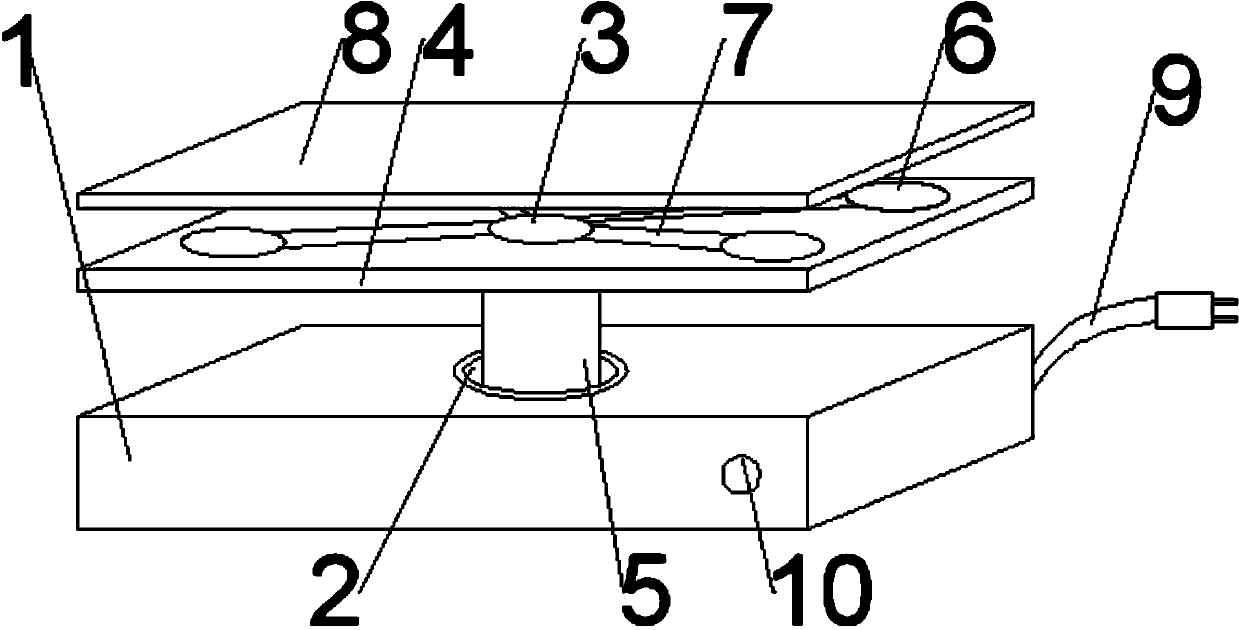

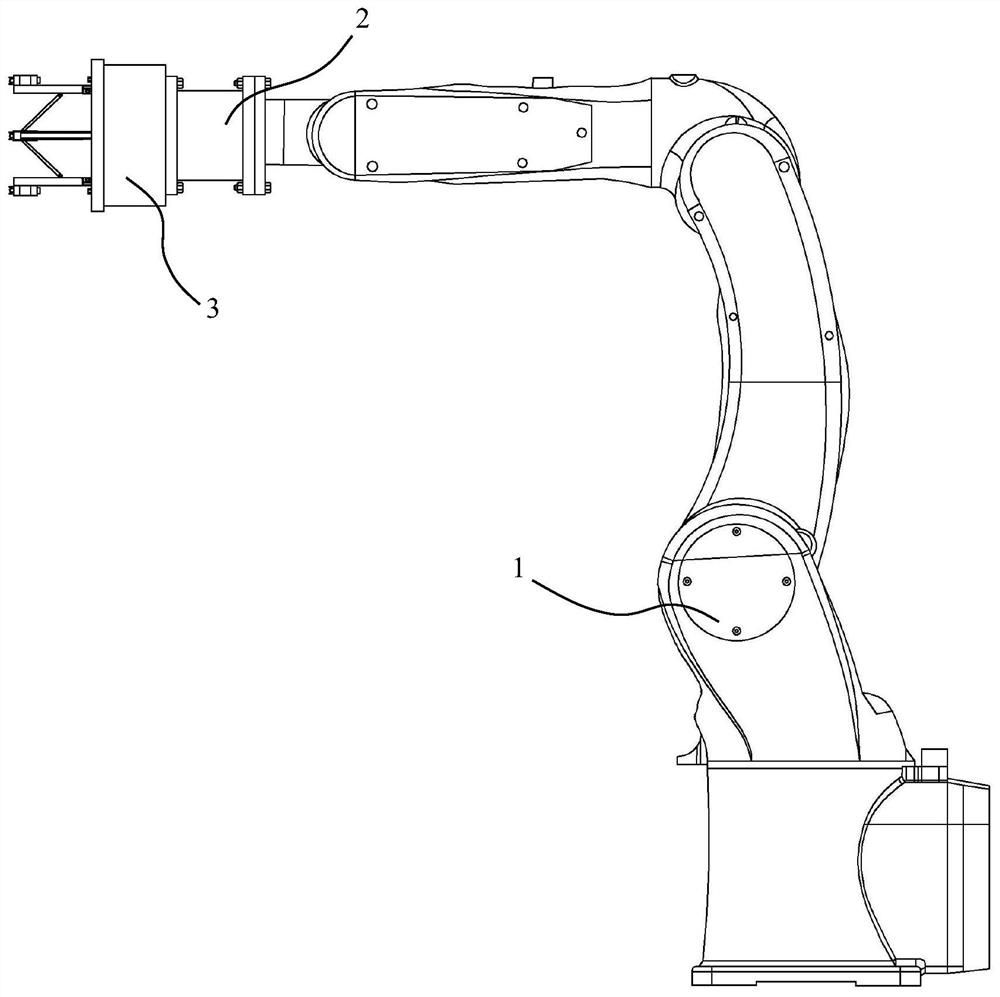

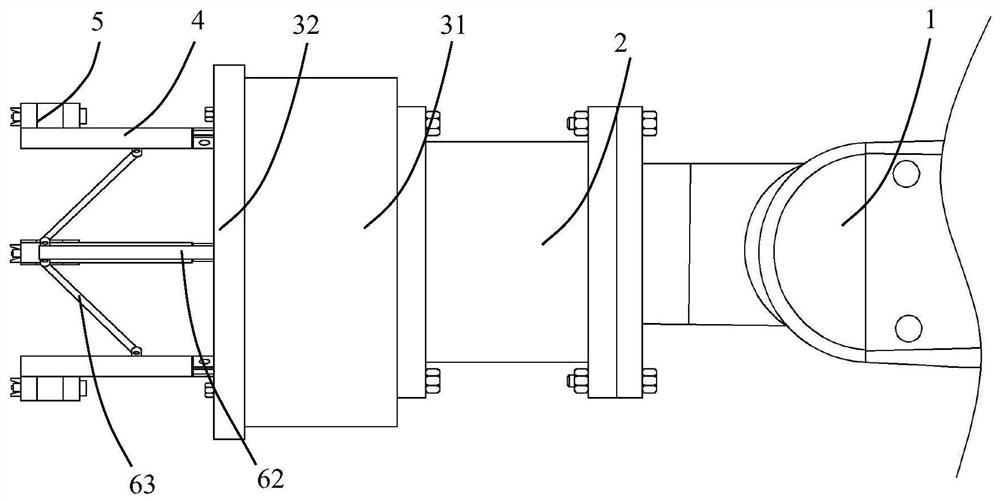

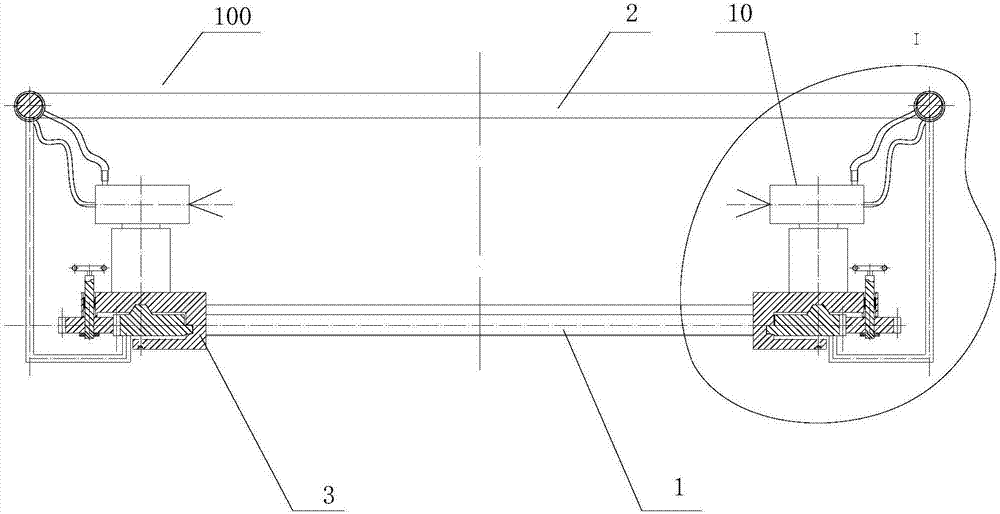

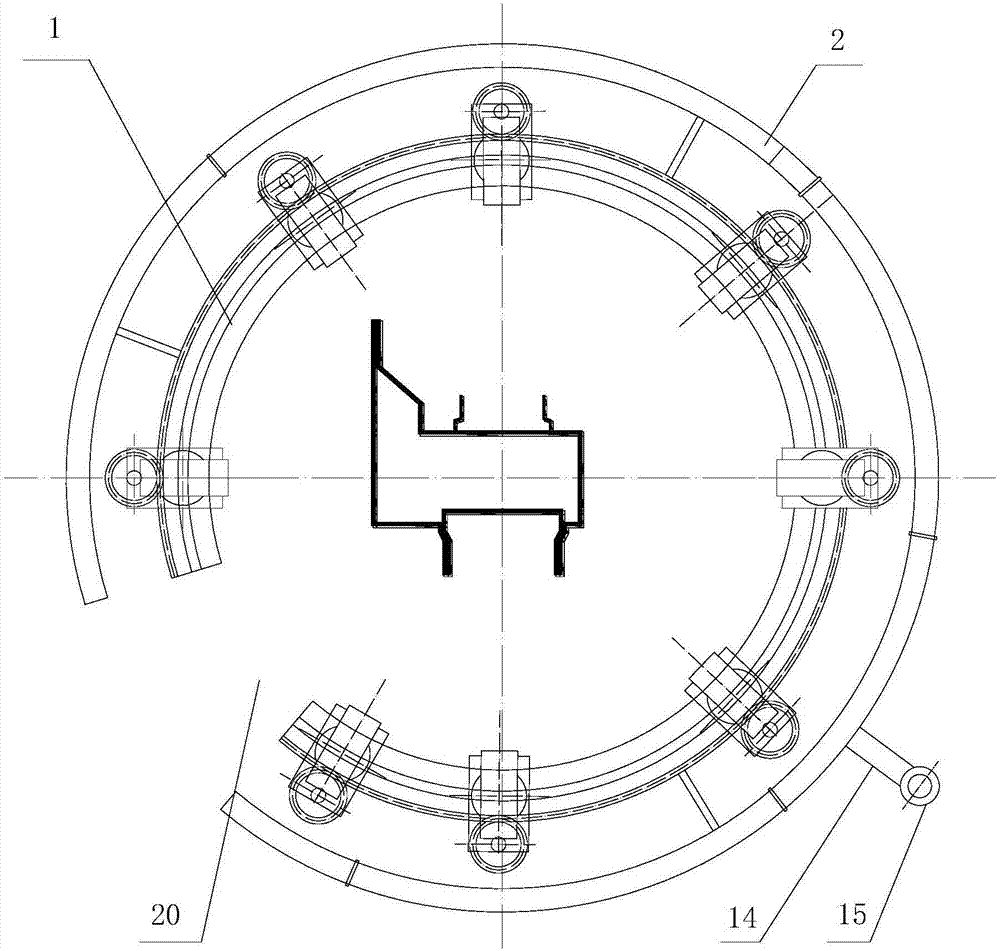

Spraying tool of long automobile interior trim part

ActiveCN107042182ASave the touch-up processImprove paint rateSpray discharge apparatusGear wheelCoating

A spraying tool of a long automobile interior trim part comprises at least three spraying guns (10) annularly arranged in a spaced manner. The spraying tool comprises an angle space adjusting mechanism (100) and a spraying sector adjusting mechanism (200); the angle space adjusting mechanism (100) comprises a first annular main body (1) which is provided with at least three nozzle bases (3) in a sliding manner, the spraying guns (10) are arranged on the nozzle bases (3) in a sliding manner in the radial direction of the first annular main body, the first annular main body (1) comprises a first guide rail (4), a second guide rail (17) and outer teeth (5), the outer teeth (5) are arranged on the outer edge of the first annular main body (1), each nozzle base (3) comprises a first guide groove (7), a second guide groove (18) and a walking gear (8), and the top side center point of each first guide groove (7), the top side center point of each second guide groove (18) and the axis of each walking gear (8) form the isosceles triangle. The spraying tool of the long automobile interior trim part is suitable for spraying a long workpiece, the coating supplementing process is removed, the painting rate is high, and the production cost is reduced.

Owner:江苏蔚金汽车零部件有限公司

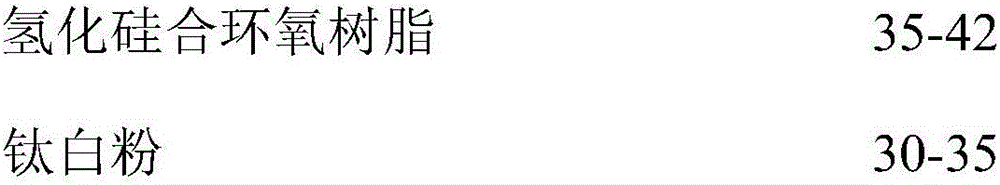

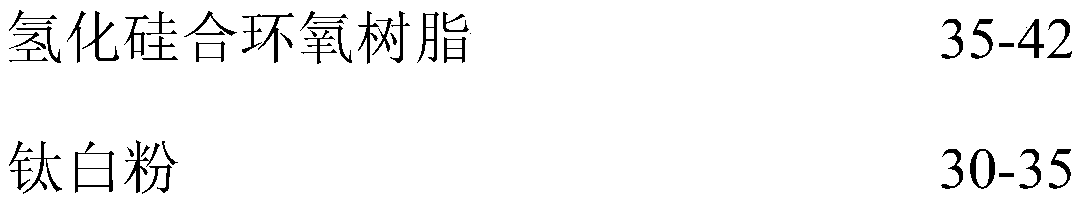

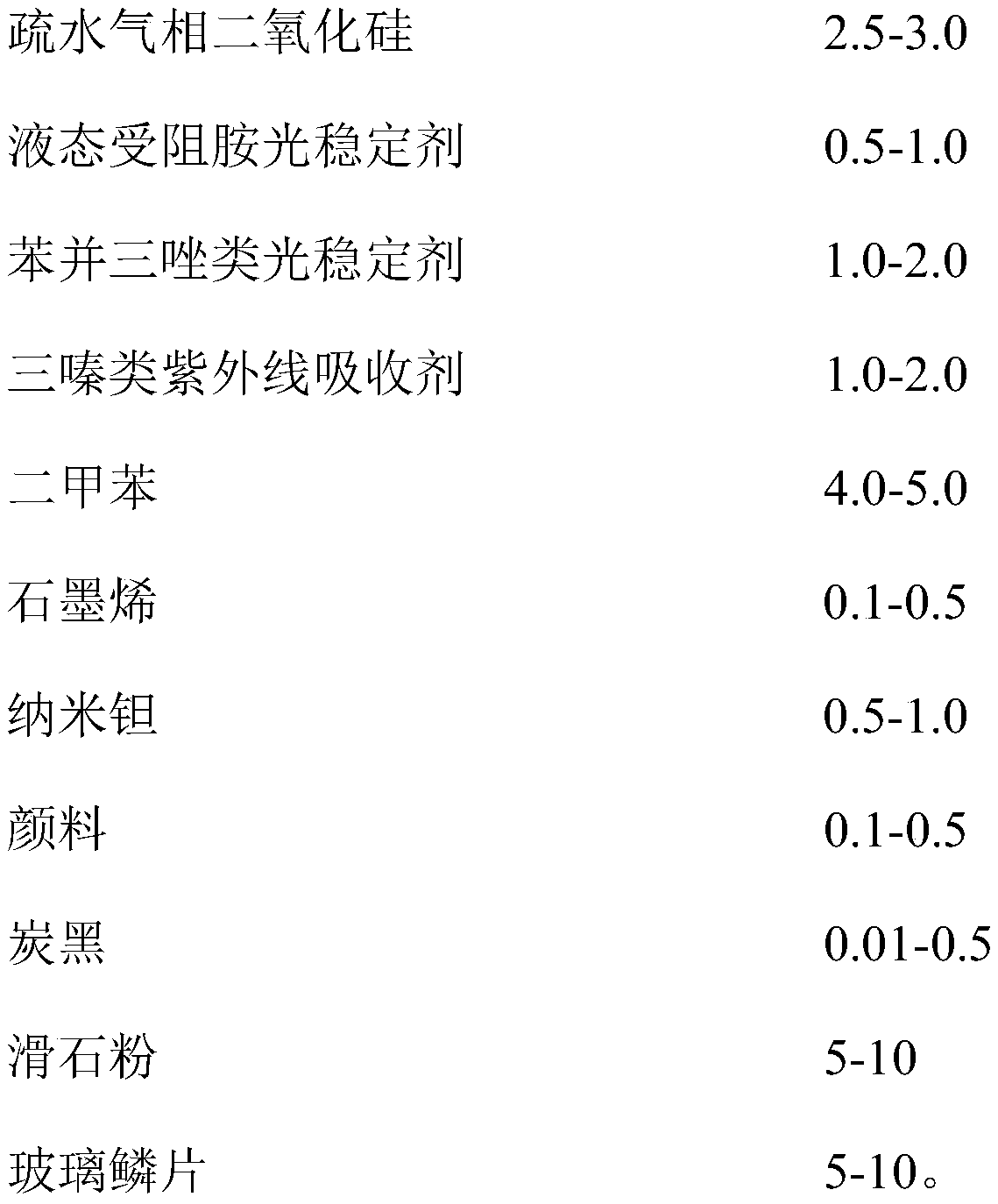

High-salt-fog-resistance and high-weather-resistance type protecting coating for magnesium alloy base material, preparation method and application method

ActiveCN107523193AGood weather resistanceGood resistance to salt sprayAnti-corrosive paintsEpoxy resin coatingsEpoxyCoating system

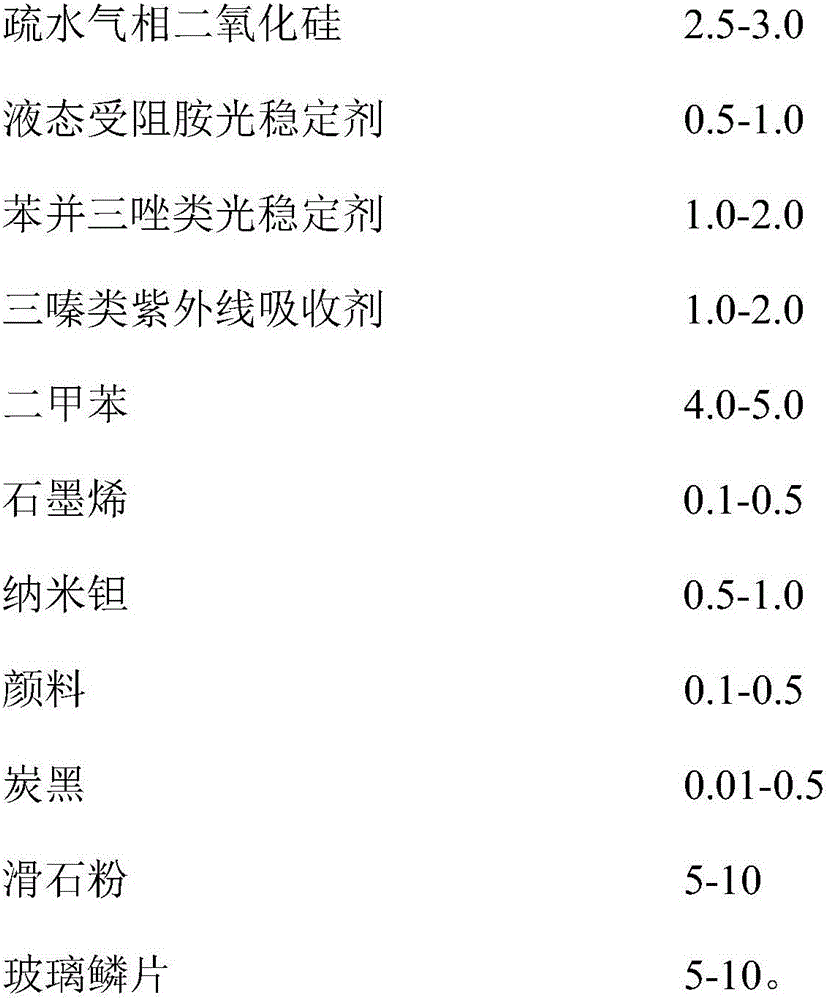

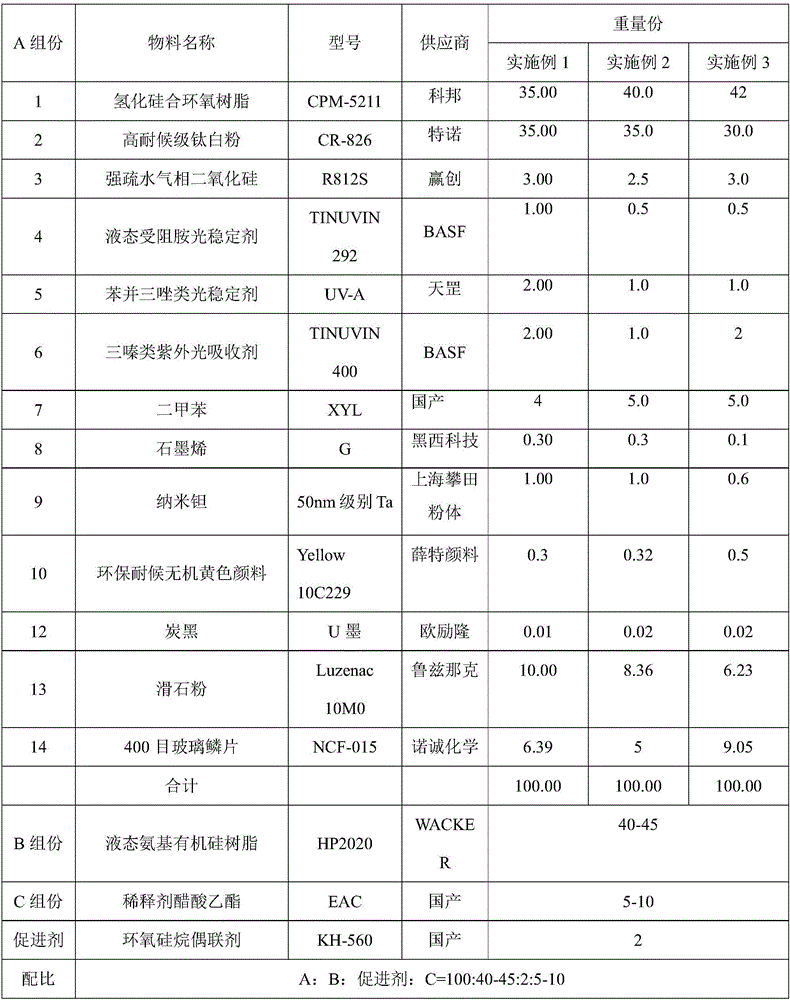

The invention provides a high-salt-smog-resistance and high-weather-resistance type protecting coating for a magnesium alloy base material, a preparation method and an application method. The high-salt-smog-resistance and high-weather-resistance type protecting coating is characterized in that hydrogenated silicon bonded epoxy resin is used as main resin, and enables a coating layer to meet the demands of indexes on basic salt smog resistance and weather resistance; strongly hydrophobic fumed silica provides high settling resistance of the coating in storage and outstanding sag resistance in construction; a light stabilizer is combined and matched with an ultraviolet absorbent to further ensure the high weather resistance of the coating layer; graphene, nano-tantalum and glass flakes are combined to enable the improvement on the high slag smog resistance and corrosion resistance of the coating layer; talcum powder in the formula acts together with a KH-560 epoxy silane coupling agent to greatly improve the wet adhesion of a coating film to the magnesium alloy coating; xylene is used for adjusting the viscosity of the whole coating system. Compared with the prior art, the prepared special protecting coating for the magnesium alloy is high in weather resistance, outstanding in salt smog resistance, high in solid content, low in viscosity, and uniform in the coating layer.

Owner:WUHU CHUNFENG NEW MATERIAL

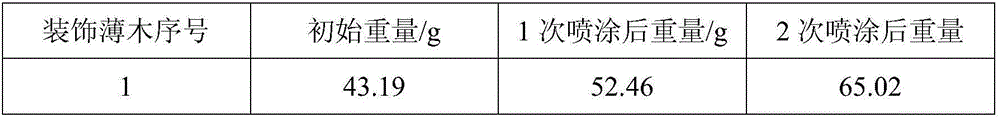

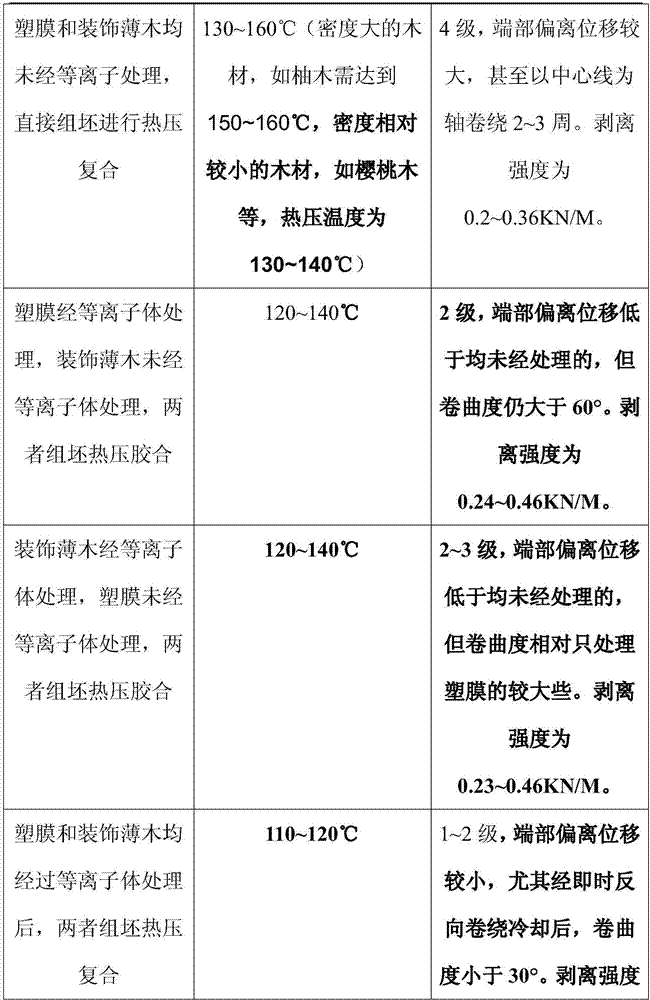

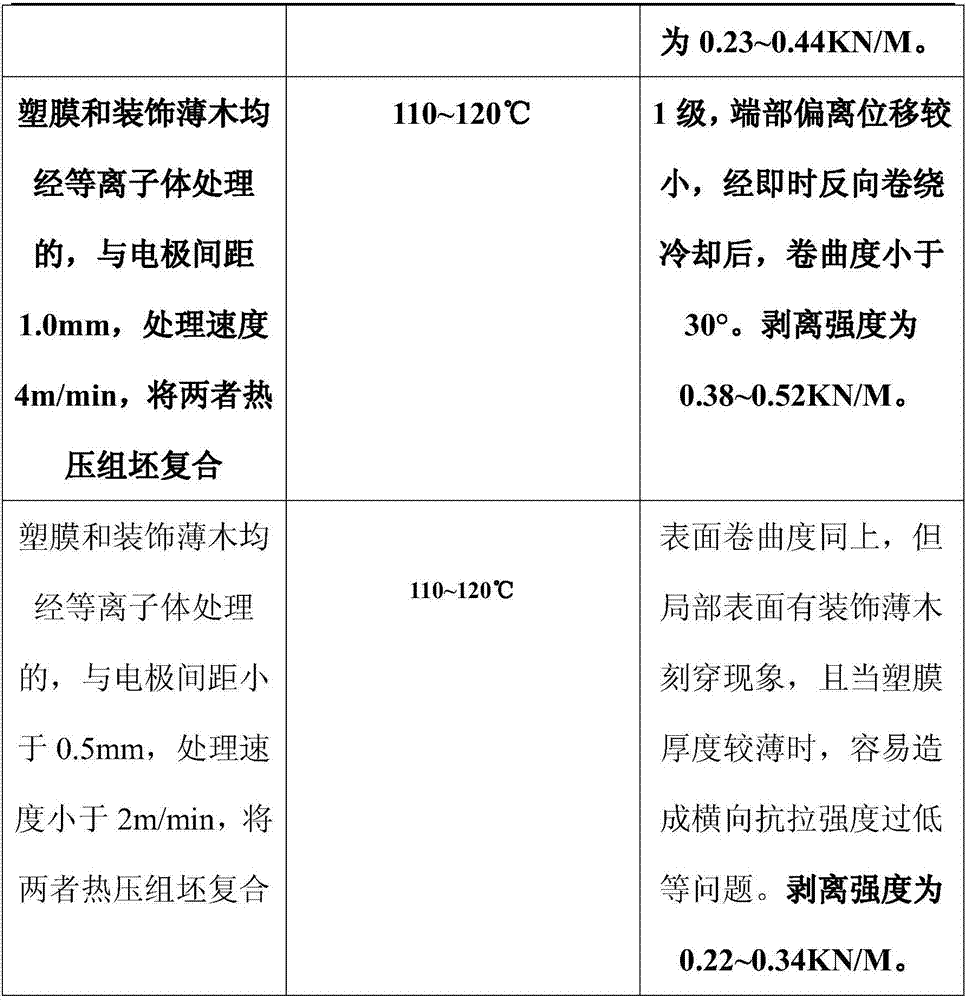

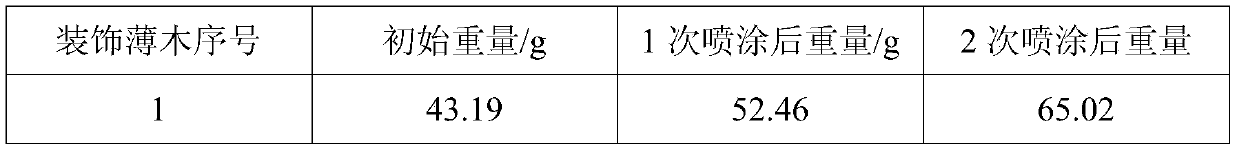

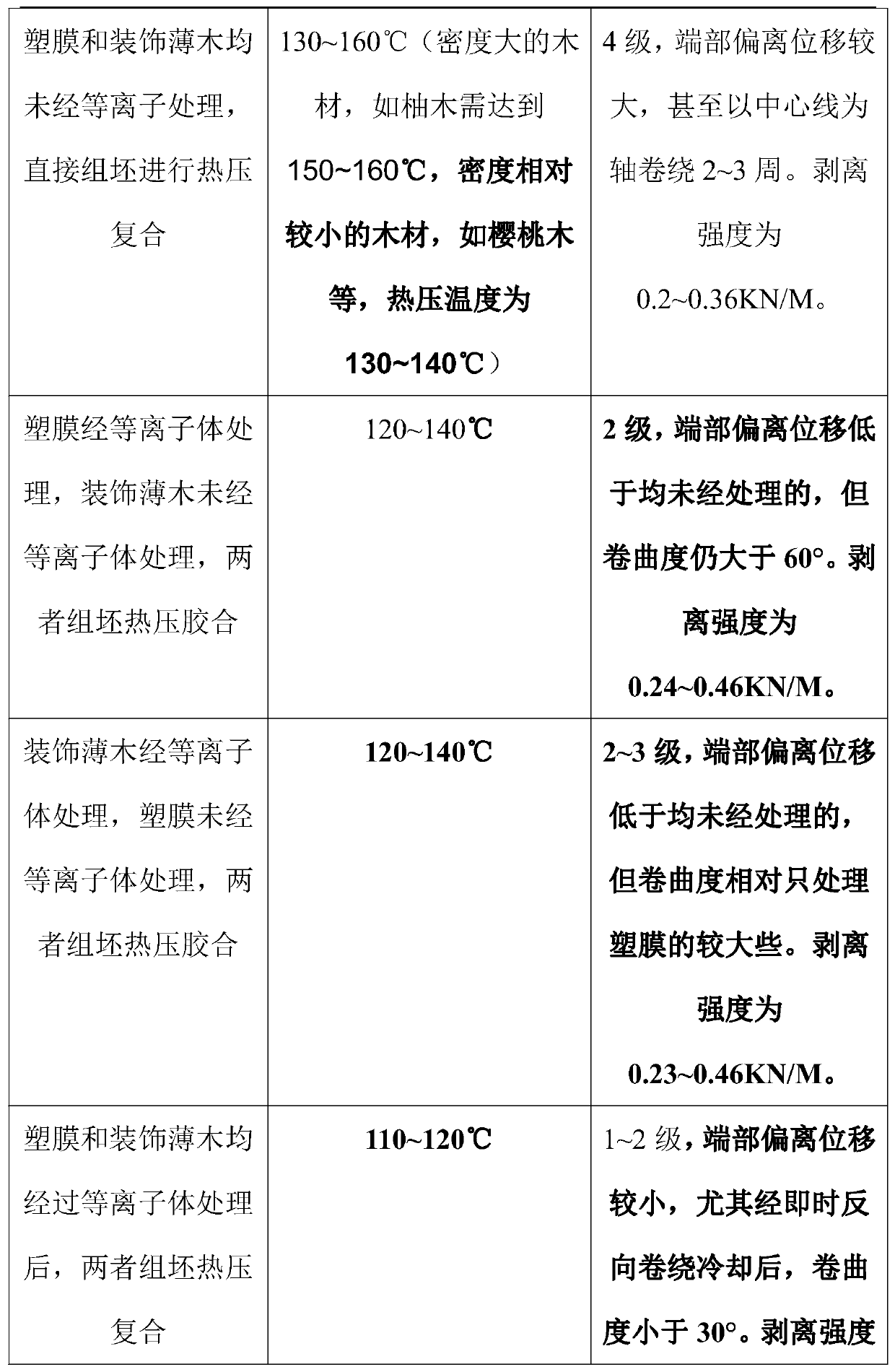

Method for improving interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification

ActiveCN107030802AResolve curlSolve discolorationLayered product treatmentElectric wood treatmentAdhesiveEngineering

The invention discloses a method for improving the interface bonding performance between composite flexible decorative veneer and surface facing through plasma modification. The method sequentially comprises the following technology steps that surface pretreatment of the decorative veneer, low-temperature plasma treatment of the surface of the decorative veneer, low-temperature plasma treatment of the surface of a plastic film, assembly and hot pressing of the decorative veneer and the plastic film, and facing hot-pressing of the plastic-film-reinforced flexible decorative veneer. By the adoption of the method for improving the interface bonding performance between the composite flexible decorative veneer and the surface facing through plasma modification, woodwork surface facing is conducted through the plastic-film-reinforced flexible decorative veneer manufactured through plasma modification treatment, an adhesive is not needed, the procedure of applying the adhesive can be omitted, the bonding strength of the facing surface of the product can be improved by 10%-70%, the adhesive force of a paint film can be improved by 20%-40%, the production cost can be reduced by 10%-50%, energy is saved, environmental friendliness is achieved, operation is easy and convenient, and efficiency is high.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

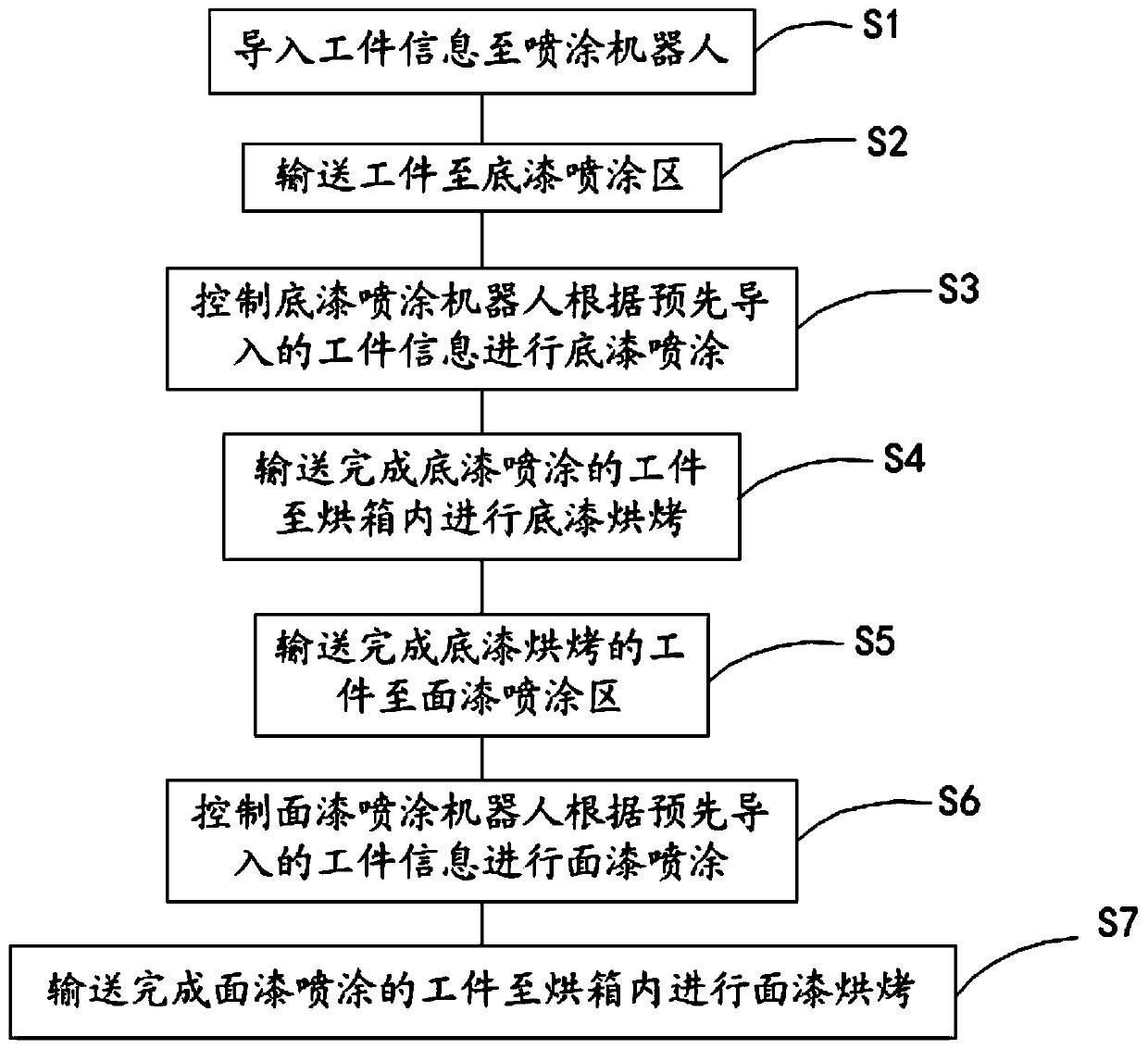

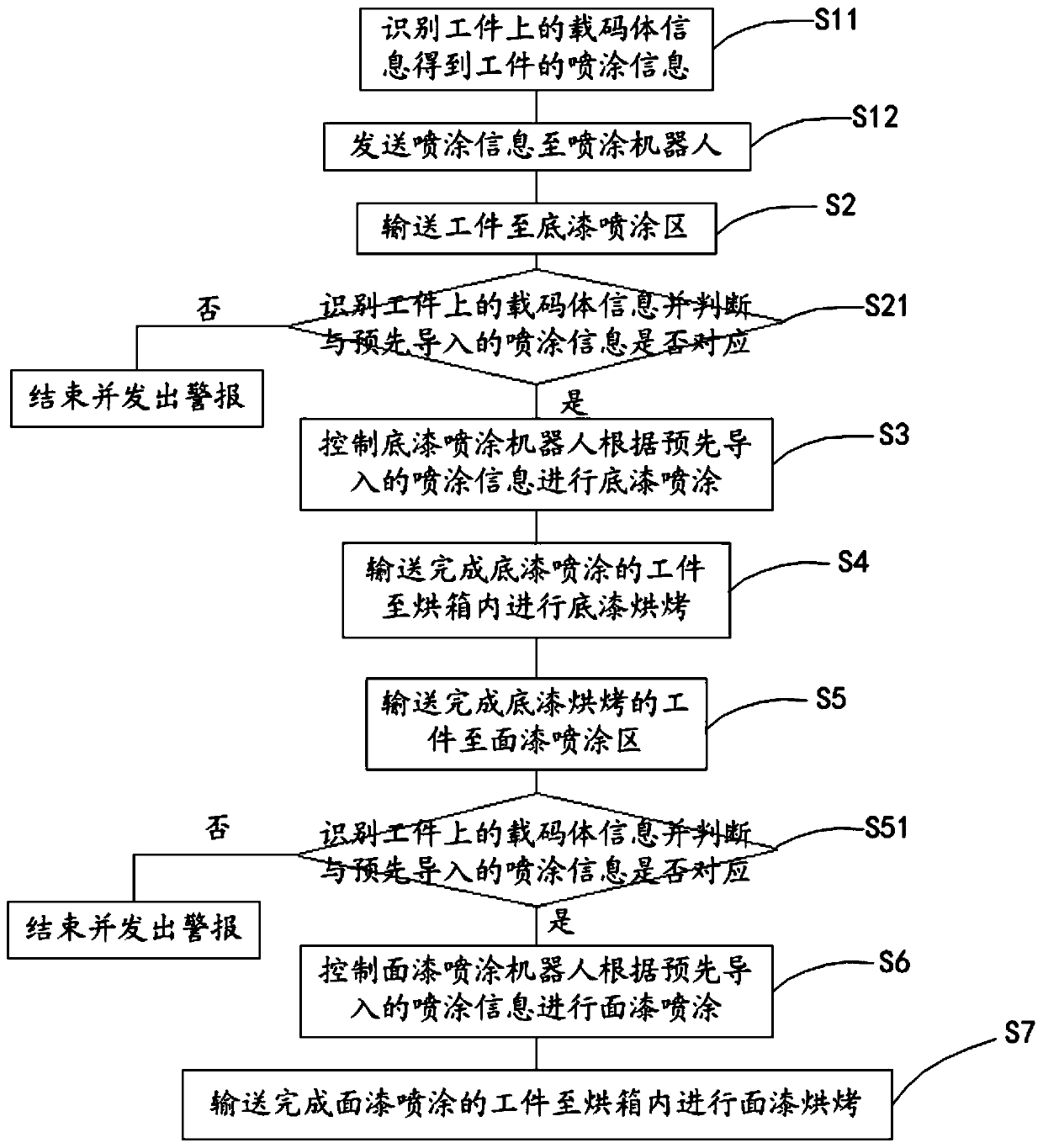

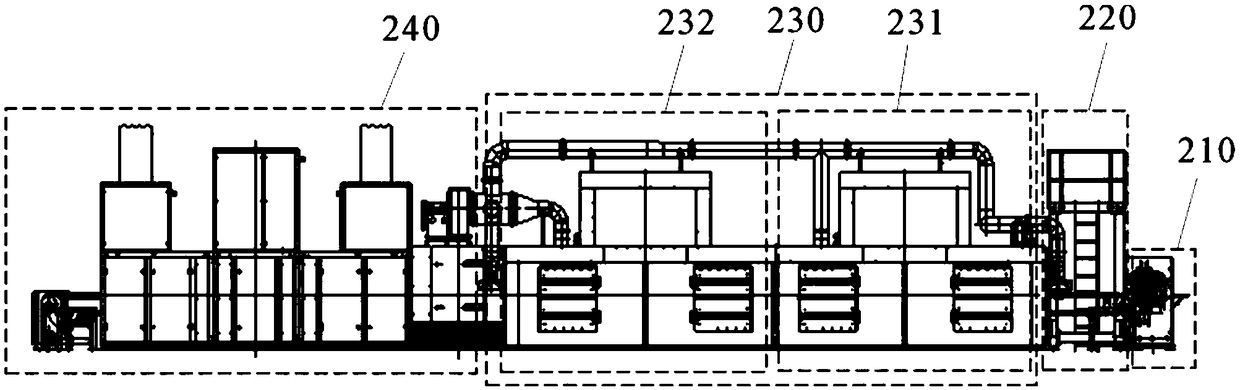

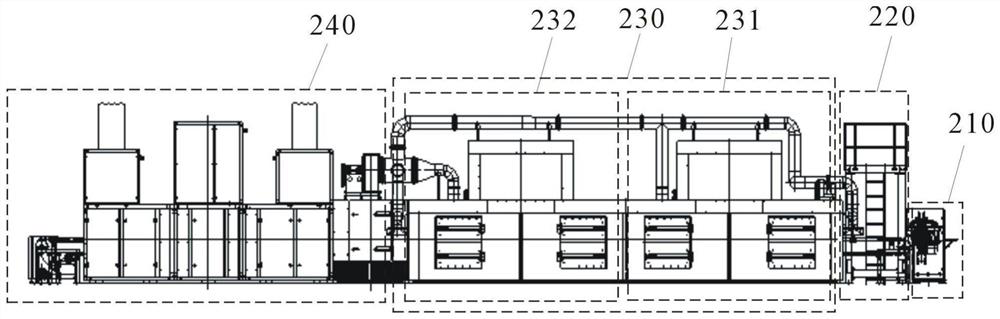

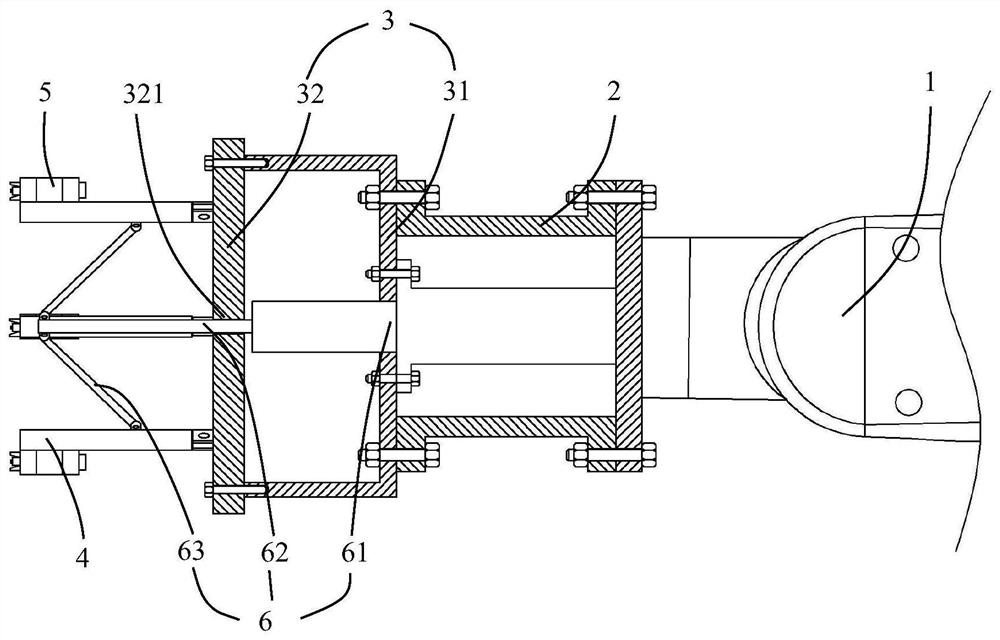

Engine coating spraying technology and system

InactiveCN109894338ARealization of automatic sprayingRealize automatic dryingLiquid surface applicatorsCoatingsAgricultural engineeringRobot

The invention discloses an engine coating spraying technology. The engine coating spraying technology comprises the steps that S1, workpiece information is guided to a primer spraying robot and a finishing coat spraying robot; S2, a workpiece is conveyed to the primer spraying area; S3, the primer spraying robot is controlled to conduct primer spraying according to the pre-guided-in workpiece information; fourthly, the workpiece obtained after primer spraying is conveyed into an oven, and the oven is controlled to conduct primer baking; S5, the workpiece obtained after primer baking is conveyed to the finishing coat spraying area; S6, the finishing coat spraying robot is controlled to conduct finishing coat spraying according to the pre-guided-in workpiece information; and S7, the workpiece obtained after finishing coat spraying is conveyed into the oven to be subjected to finishing coat baking. According to the provided engine coating spraying technology, full-automatic workpiece spraying can be achieved, hurt to bodies of spraying personnel in the spraying process is avoided, the spraying robots can conduct spraying according to the preset track and the preset scheme, and the paint painting rate can be greatly increased. The invention discloses an engine coating spraying system.

Owner:ANHUI HUALING AUTOMOBILE

Plastic paint and preparation method thereof

The invention provides a plastic paint and a preparation method thereof. The plastic paint is composed of the following raw materials in parts by weight: 50-60 parts of acrylic resin, 10-15 parts of filler, 2-5 parts of auxiliaries, 7-10 parts of pigment, 1-3 parts of curing agent, 5-10 parts of graphene dispersion liquid, 0.5-1 part of fatty alcohol phosphate diethanolamine salt, and 15-20 parts of solvent. The plastic paint prepared by the invention has the features of being high in rigidity, good in glossiness, and strong in adhesive force, convenient for construction, free from primer painting, and can be extensively applied to the product coating of the plastic substrate.

Owner:陈少双

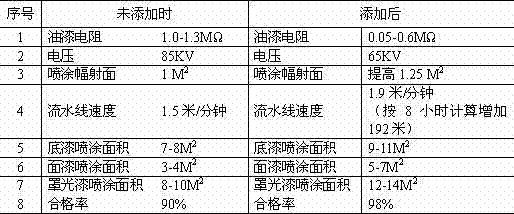

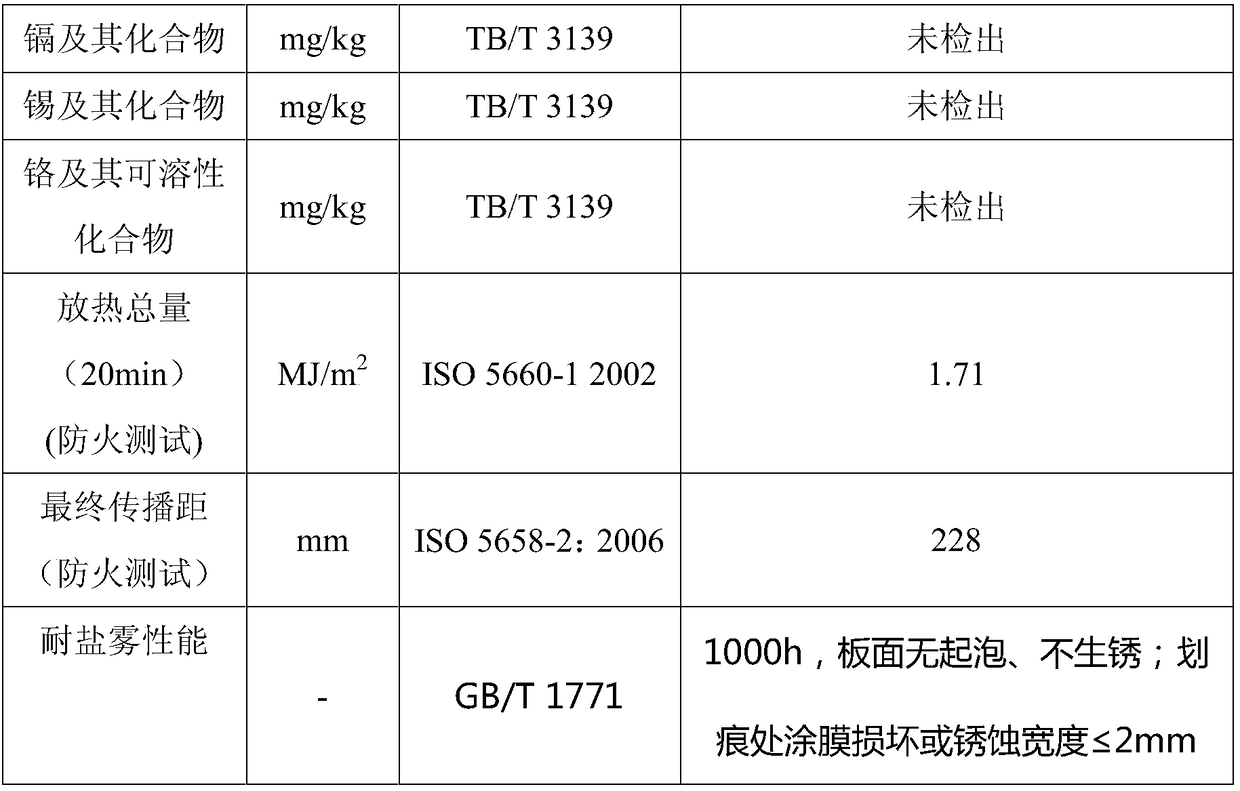

Additive capable of improving electrostatic effect for spraying fluorocarbon paint

ActiveCN102268210BLower resistanceImprove conductivityElectrically-conductive paintsDiethylene glycol monobutyl etherButyl acetate

The invention belongs to the technical field of fluorocarbon paints, and particularly relates to an additive capable of improving the electrostatic effect for spraying fluorocarbon paint. The additive consists of the following components in percentage by weight: 15-25 percent of methyl ethyl ketone, 10-20 percent of diethylene glycol monobutyl ether, 2-4 percent of methyl isobuthyl ketone, 3-6 percent of butyl acetate and 45-70 percent of alkane main solution. The additive can be used for overcoming the defects of low atomizing efficiency of a spray gun, low adsorption force, low painting efficiency and non-uniform distribution of metal fine particles and the like caused by weak electrostatic effect and poor electric conductivity in the spraying process of the fluorocarbon paint at present.

Owner:上海新大余氟碳喷涂材料有限公司

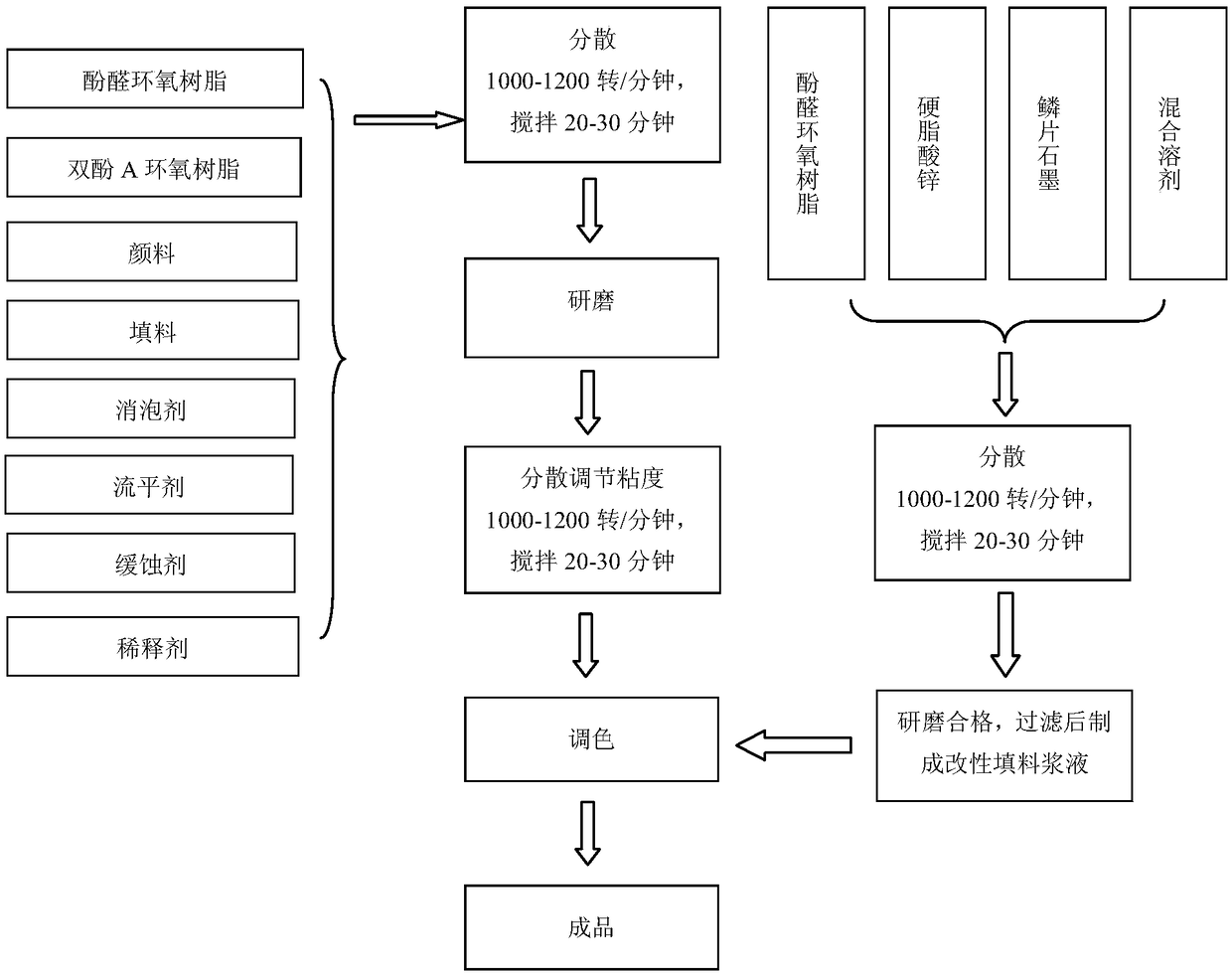

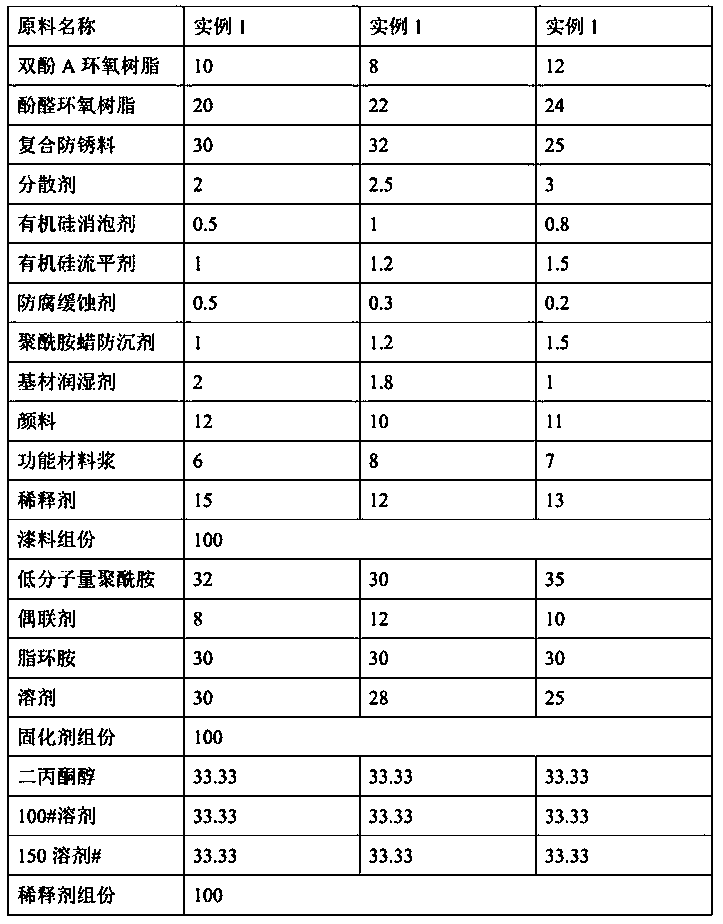

Epoxy primer for electrostatic spraying of rail traffic bogie, and preparation method thereof

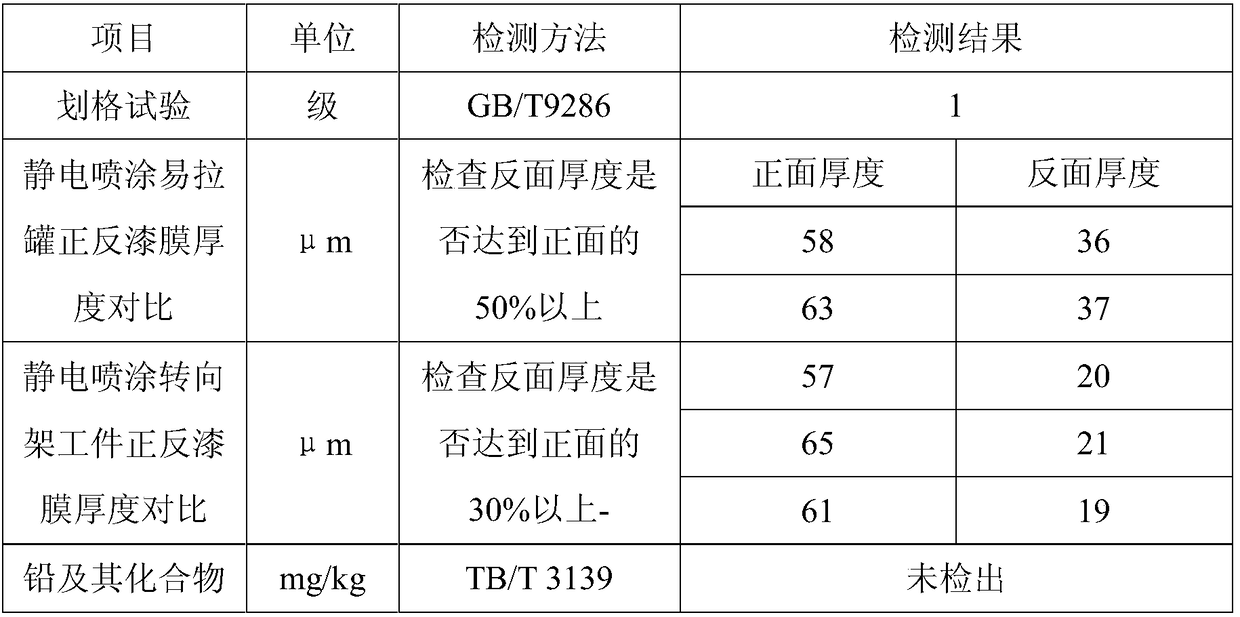

ActiveCN108129958AEasy electrostatic spray applicationStrong adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyBogie

The invention relates to an epoxy primer for electrostatic spraying of a rail traffic bogie, and a preparation method thereof. Epoxy resin, a composite antirust material, a coloring pigment, a functional material slurry, an assistant and a solvent form a paint; low-molecular polyamide, alicyclic amine, an assistant and a solvent form a curing agent; and the primer is prepared from the paint and the curing agent according to a weight ratio of 100:20 when constructed, and a proper amount of a diluent is added to adjust the construction viscosity in order to facilitate construction. The epoxy primer can adapt to mixed gas electrostatic spray gun spraying and electrostatic adsorption, and has the advantages of good environmental protection effect, small paint mist spray, high painting rate, good conductivity in a dry film, no influences on the electrostatic spraying, and realization of a coating layer with the performances meeting technical requirements of the primer for rail traffic bogie, and the epoxy primer can reduce the use amount of a paint by 30% or more when used in the mixed gas spray gun electrostatic spraying construction of the rail traffic bogie in order to reduce paint mist and the emission of VOCs, so the epoxy primer is an environmentally-friendly coating.

Owner:株洲市九华新材料涂装实业有限公司

Additive for fluorocarbon paint spraying that can increase electrostatic effect

ActiveCN102268210ALower resistanceImprove conductivityElectrically-conductive paintsDiethylene glycol monobutyl etherButyl acetate

The invention belongs to the technical field of fluorocarbon paints, and particularly relates to an additive capable of improving the electrostatic effect for spraying fluorocarbon paint. The additive consists of the following components in percentage by weight: 15-25 percent of methyl ethyl ketone, 10-20 percent of diethylene glycol monobutyl ether, 2-4 percent of methyl isobuthyl ketone, 3-6 percent of butyl acetate and 45-70 percent of alkane main solution. The additive can be used for overcoming the defects of low atomizing efficiency of a spray gun, low adsorption force, low painting efficiency and non-uniform distribution of metal fine particles and the like caused by weak electrostatic effect and poor electric conductivity in the spraying process of the fluorocarbon paint at present.

Owner:上海新大余氟碳喷涂材料有限公司

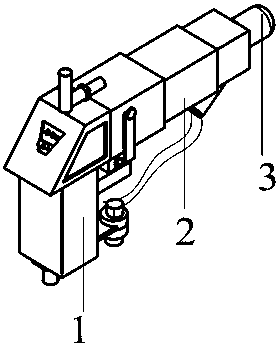

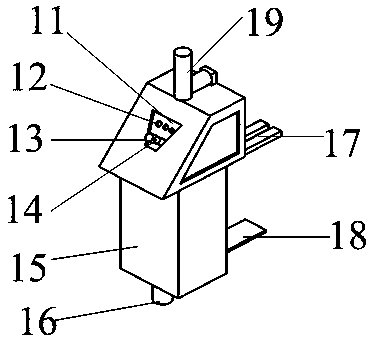

Electrostatic paint spraying gun and using method thereof

InactiveCN110918281AImprove paint rateExtended service lifeSpray discharge apparatusStructural engineeringElectric cables

The invention discloses an electrostatic paint spraying gun and a using method thereof. The electrostatic paint spraying gun comprises a gun tail; the gun tail comprises a control panel, an indicatinglamp, a spraying width atomization adjusting button, a high-voltage switch, a handle, an air interface, a trigger lock and a cable; the control panel is located above the handle; the indicating lampis fixed to the control panel; the spraying width atomization adjusting button is fixed to the control panel; the high-voltage switch is fixed to the control panel; the handle is fixed to the air interface; the air interface is located below the handle; the trigger lock is connected with the handle; and the cable is connected with the air interface. The structure is simple, the operation is convenient, the painting rate of a painted object is increased, and paint waste is reduced.

Owner:七星瓢虫环境科技(苏州)有限公司

Dual-curing varnish, and preparation method and application thereof

ActiveCN112358816AImprove rigidityHigh hardnessLiquid surface applicatorsCoatingsDual curePolymer science

The invention provides a dual-curing varnish which comprises the following components in percentage by mass: 40-46% of unsaturated resin and 40-46% of fatty acid resin, wherein the unsaturated resin is acrylic acid esterification unsaturated resin. A paint film formed by the dual-curing varnish provided by the invention has excellent properties of high hardness, high fullness, high gloss, high adhesive force and high wear resistance, also has good drying property even under a low-temperature condition, and is not easy to generate prickly heat even under a high-temperature condition, therefore,the varnish has high smoothness during construction, and the formed paint film has favorable appearance.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

A kind of water-based primer and construction technology thereof

ActiveCN110330875BReduce pollutionAvoid damageLiquid surface applicatorsPolyurea/polyurethane coatingsFilm resistancePolymer science

The invention discloses a water-based primer, which comprises water-based polyolefin resin, unsaturated carboxylic acid or acid anhydride modified polyolefin, water-based epoxy resin, water-based acrylic resin, and the weight ratio of primer and curing agent is 100:10 , Unsaturated carboxylic acid or acid anhydride modified polyolefin is polyolefin modified with maleic acid or maleic anhydride, the mass ratio of each component is calculated based on solid content: 10 to 30 parts of water-based polyolefin resin, 25-40 parts of unsaturated carboxylic acid or acid anhydride modified polyolefin, 5-10 parts of water-based epoxy resin, 15-20 parts of water-based acrylic resin; the curing agent is at least one polyolefin with a weight percentage of 40-70 parts An isocyanate curing agent and 15-70 parts of γ-butyrolactone. The present invention greatly reduces air pollution and greatly reduces the damage to human health; the dry film resistance is high, and the paint rate of the colored paint is increased, thereby reducing the use of colored paint; the present invention has strong covering ability and reduces the cost of polishing .

Owner:江阴名鸿车顶系统有限公司

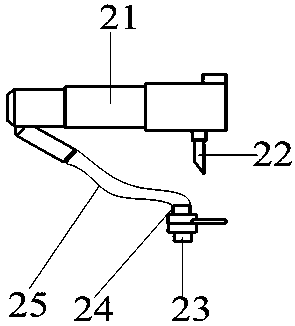

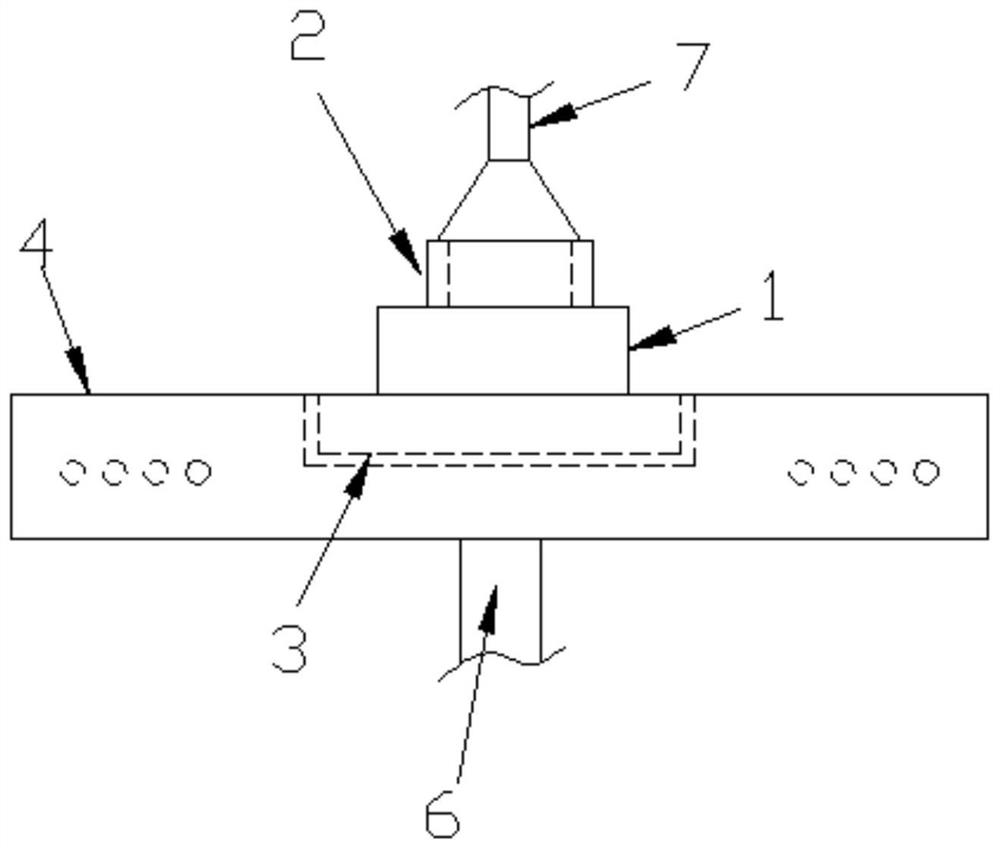

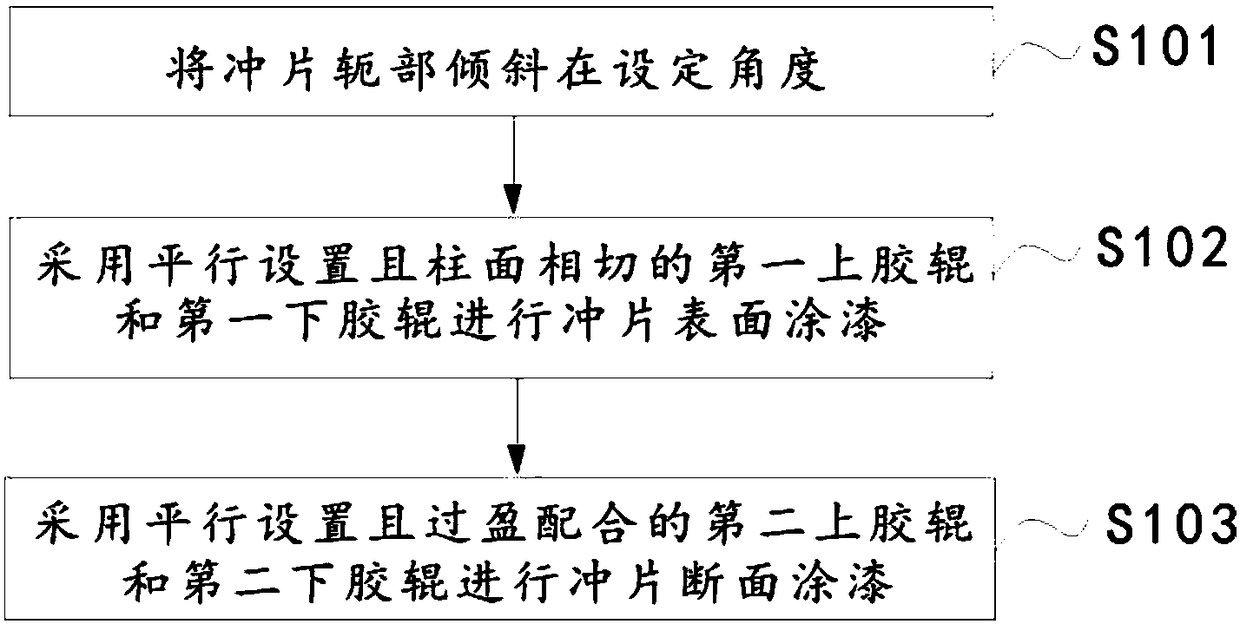

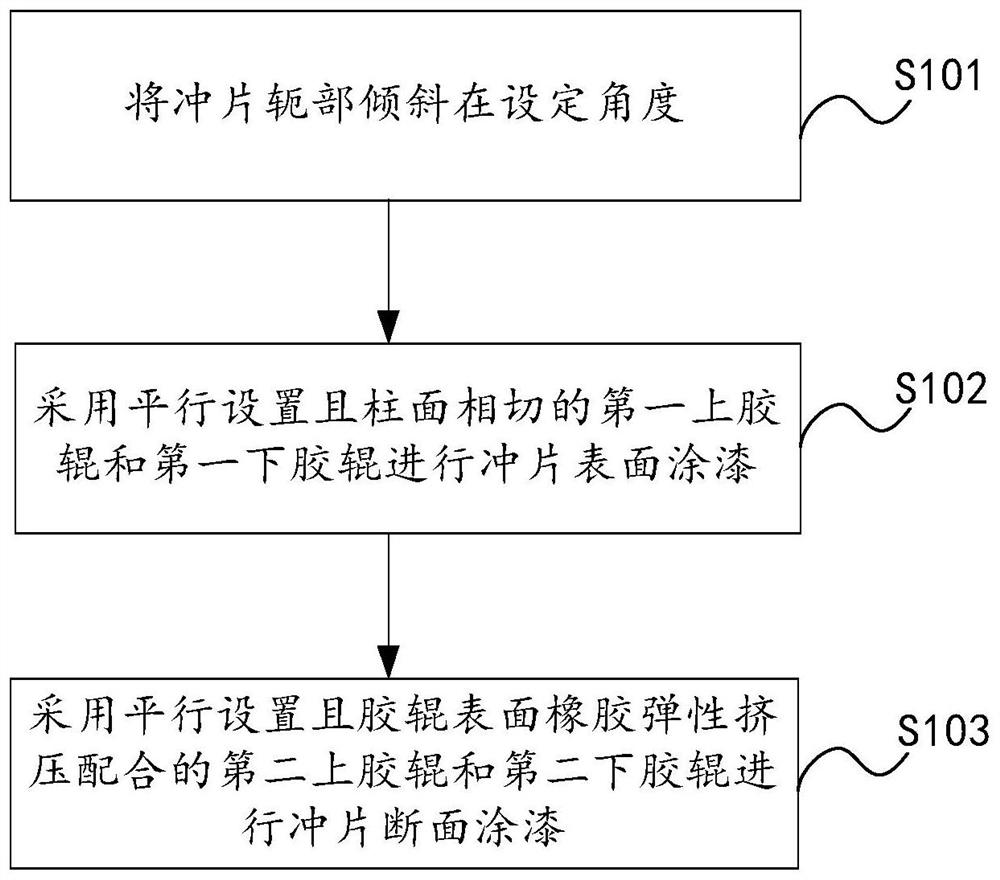

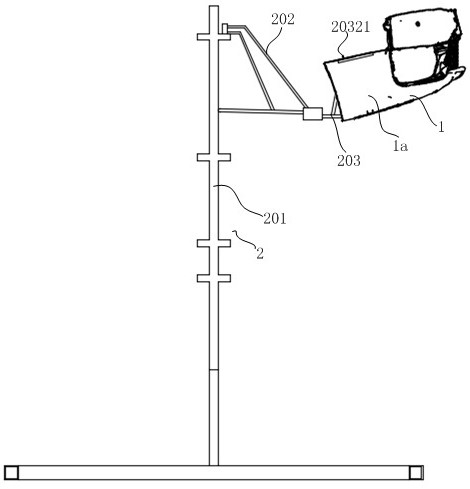

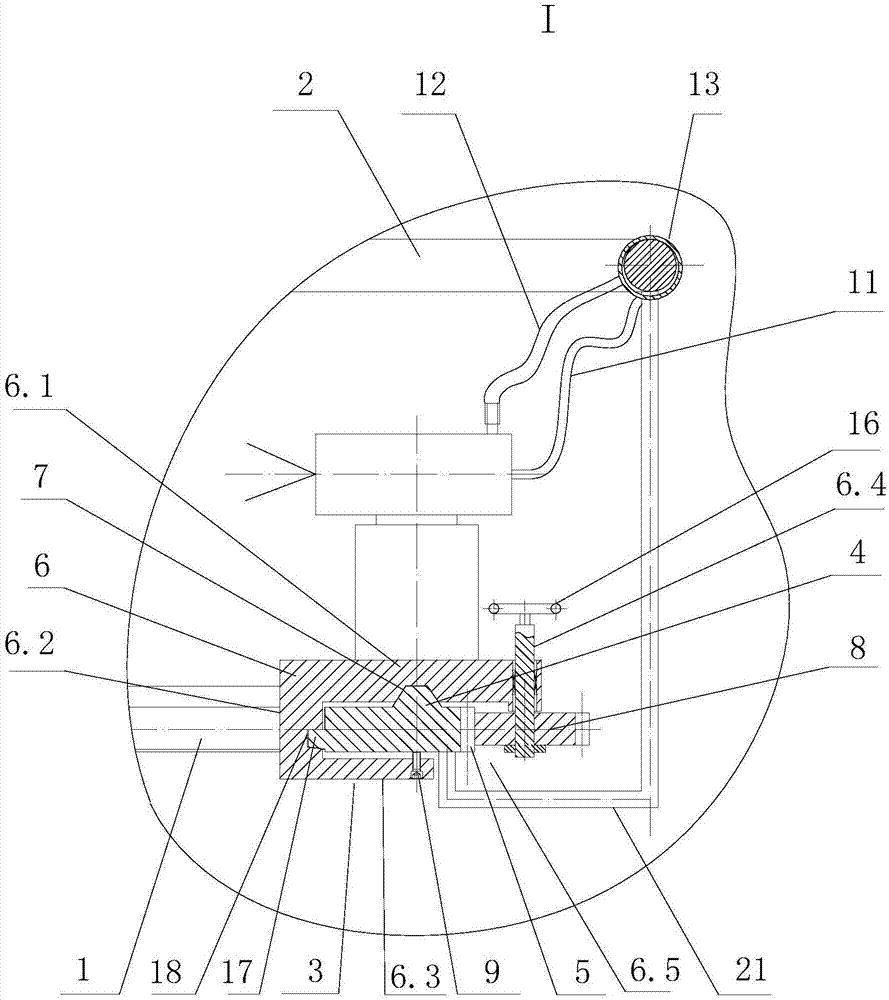

Stator core punching sheet surface painting method and device

ActiveCN108654919APrevent rustImprove paint rateLiquid surface applicatorsCoatingsInterference fitPunching

The invention discloses a stator core punching sheet surface painting method and device and belongs to the technical field of high-voltage motors. The stator core punching sheet surface painting method comprises the following steps: inclining the yoke part of a punching sheet at a set angle; adopting a first upper rubber roller and a first lower rubber roller to paint the surface of the punching sheet, wherein the first upper rubber roller and the first lower rubber roller are parallel, and the cylindrical surface of the first upper rubber roller is tangent with that of the first lower rubberroller; and adopting a second upper rubber roller and a second lower rubber roller to paint the fracture surface of the punching sheet, wherein the second upper rubber roller and the second lower rubber roller are parallel and are in interference fit. The stator core punching sheet surface painting device comprises a control mechanism and a painting handpiece, wherein the control mechanism is usedfor controlling the painting handpiece; the painting handpiece comprises a first pair of rubber rollers and a second pair of rubber rollers; the first pair of rubber rollers comprises the first upperrubber roller and the first lower rubber roller, the first upper rubber roller and the first lower rubber roller are parallel and are used for painting the surface of the punching sheet, and the cylindrical surface of the first upper rubber roller is tangent with that of the first lower rubber roller; and the second pair of rubber rollers comprises the second upper rubber roller and a second lower rubber roller, the second upper rubber roller and the second lower rubber roller are parallel, are in interference fit and are used for painting the fracture surface of the punching sheet. With adoption of the stator core punching sheet surface painting method and device, the coating rate of the stator core punching sheet is effectively increased and the painting rate is high.

Owner:北京北重汽轮电机有限责任公司

Coating process of carbon fiber fishing rod

InactiveCN102527596BUniform adsorptionReduce pollutionPretreated surfacesCoatingsNumerical controlFiber

The invention provides a coating process of a carbon fiber fishing rod. The coating process of the carbon fiber fishing rod sequentially comprises the steps of: degreasing, decontaminating, cleaning and drying a fishing rod, sealing and plugging the mouth of the fishing rod by using a silicone head; vertically hanging the fishing rod on a hanger and spraying paint up and down by a numerical controlled DISK electrostatic spraying device, then entering a leveling region for leveling within 10-15 minutes, irradiating 8-15 minutes by far infrared rays to solidify the fishing rod. By adopting the method provided by the invention, the surface of the sprayed fishing rod is smooth and full, the painting rate of dead angles is high, the whole fishing rod is painted evenly, the brightness is high, the adhesive force is good, the stable product quality is ensured, bad phenomena such as color distortion and bubbling are avoided, the paint film is 50% thinner than the conventional paint and the whole fishing rod has less paint; besides, the painting way is lighter than the traditional way and is independent of skilled labors with high spraying seed and high efficiency.

Owner:湖北钓鱼王渔具有限公司

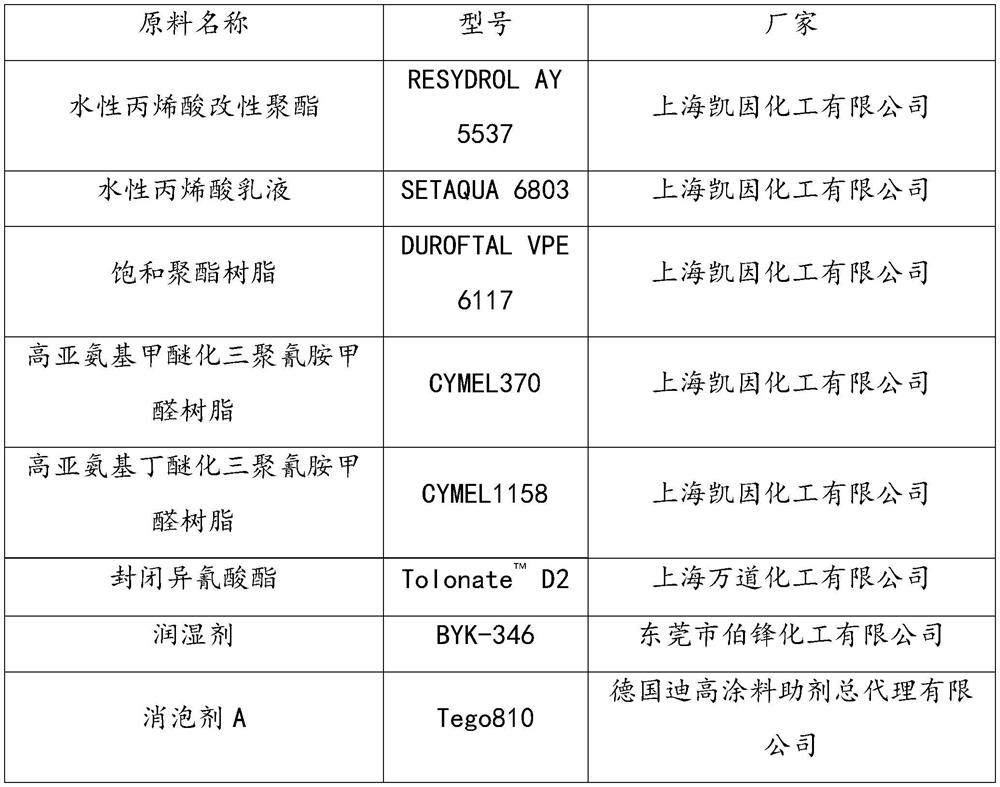

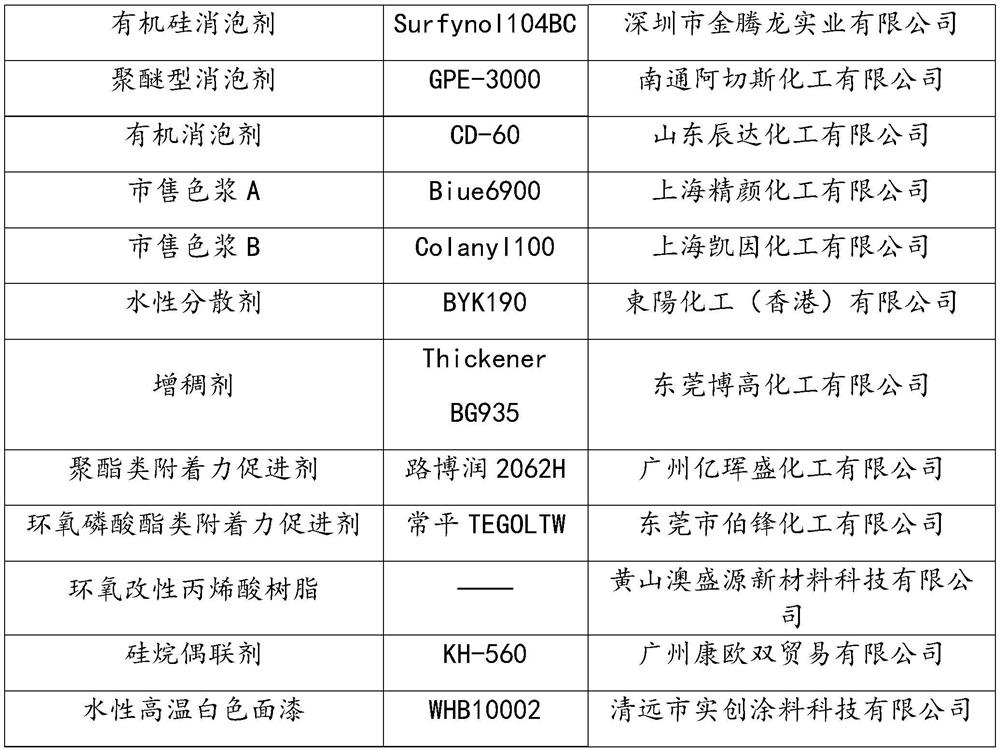

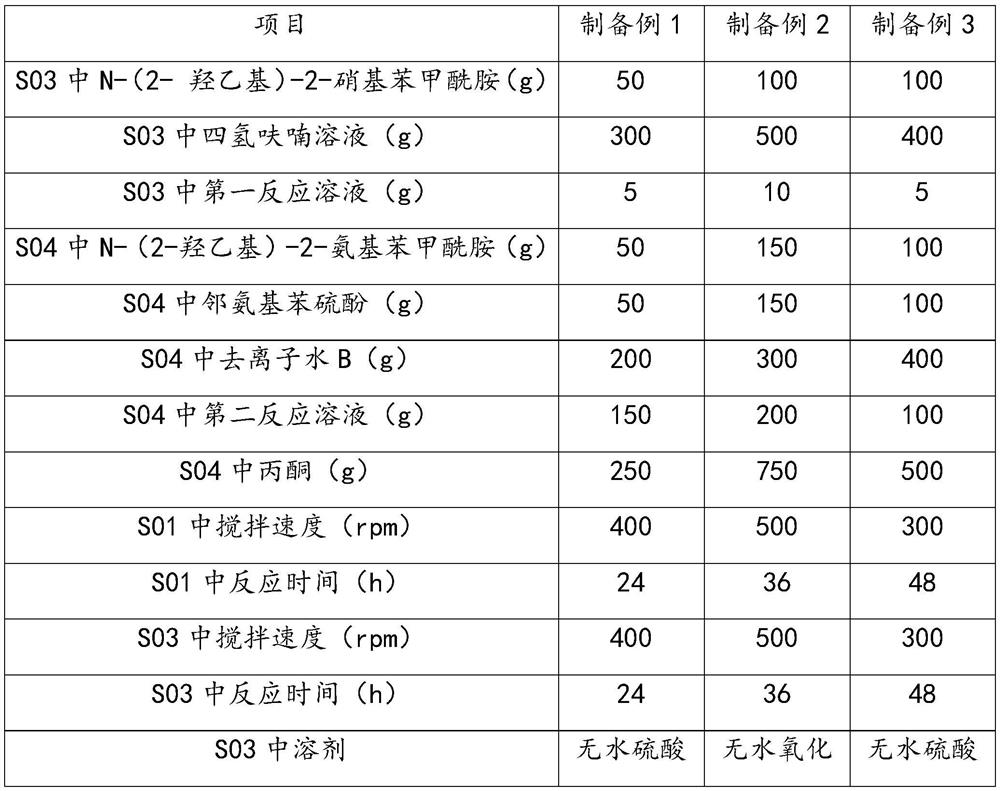

Preparation method of water-soluble polyaniline, water-soluble polyaniline-containing water-based high-temperature conductive primer for glass fiber reinforced plastics and preparation method thereof

PendingCN113667117AImprove paint rateImprove flexibilityPolyurea/polyurethane coatingsElectrically-conductive paintsO-aminothiophenolDichloromethane

The invention discloses a preparation method of water-soluble polyaniline, a water-soluble polyaniline-containing water-based high-temperature conductive primer for glass fiber reinforced plastics and a preparation method, and relates to the field of water-based high-temperature stoving varnish. The preparation method of polyaniline comprises the following steps: preparing N-(2-ethoxyl)-2-nitrobenzamide from o-nitrobenzoyl chloride, dichloromethane, ethanolamine and triethylamine; treating N-(2-ethoxyl)-2-nitrobenzamide by using iron powder, concentrated sulfuric acid and tetrahydrofuran to obtain N-(2-ethoxyl)-2-aminobenzamide; and then preparing the water-soluble polyaniline with o-aminothiophenol. The preparation method of the conductive primer comprises the step of mixing the water-based acrylic modified polyester, the water-based acrylic emulsion, the saturated polyester resin, the amino resin, the blocked isocyanate, the water-soluble polyaniline and the like to prepare the conductive primer. The solubility of polyaniline in the water-based conductive primer is improved, the conductive primer reduces the surface resistance of glass fiber reinforced plastic, electrostatic spraying of finish paint is achieved, and the painting rate is improved.

Owner:QINGYUAN SHICHUANG COATING TECH CO LTD

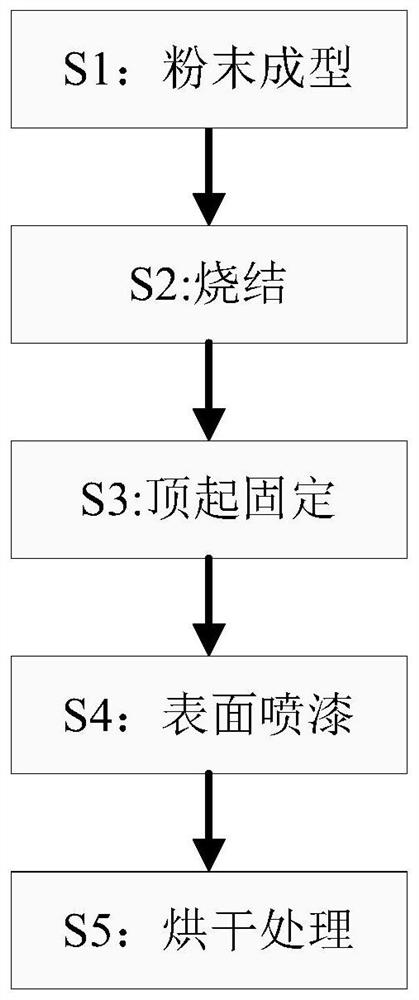

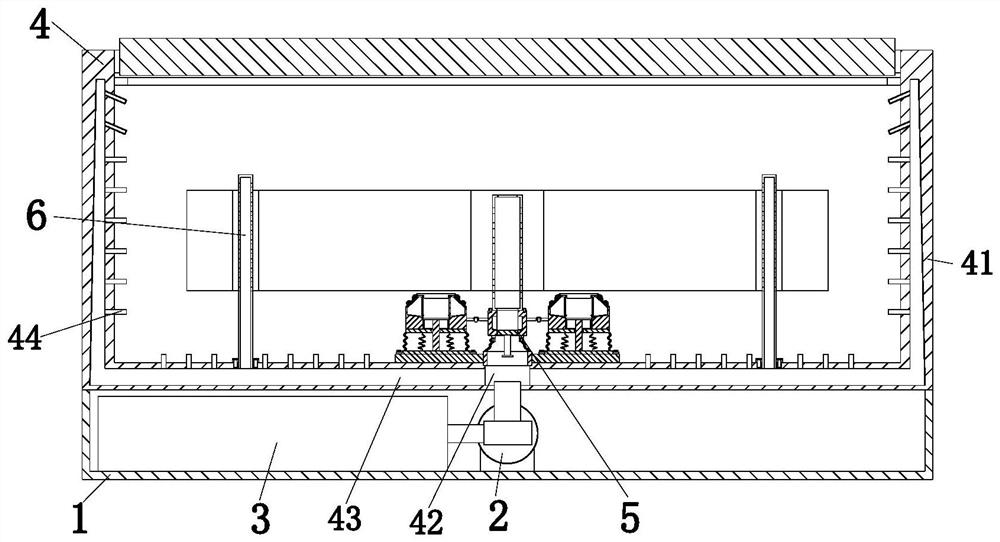

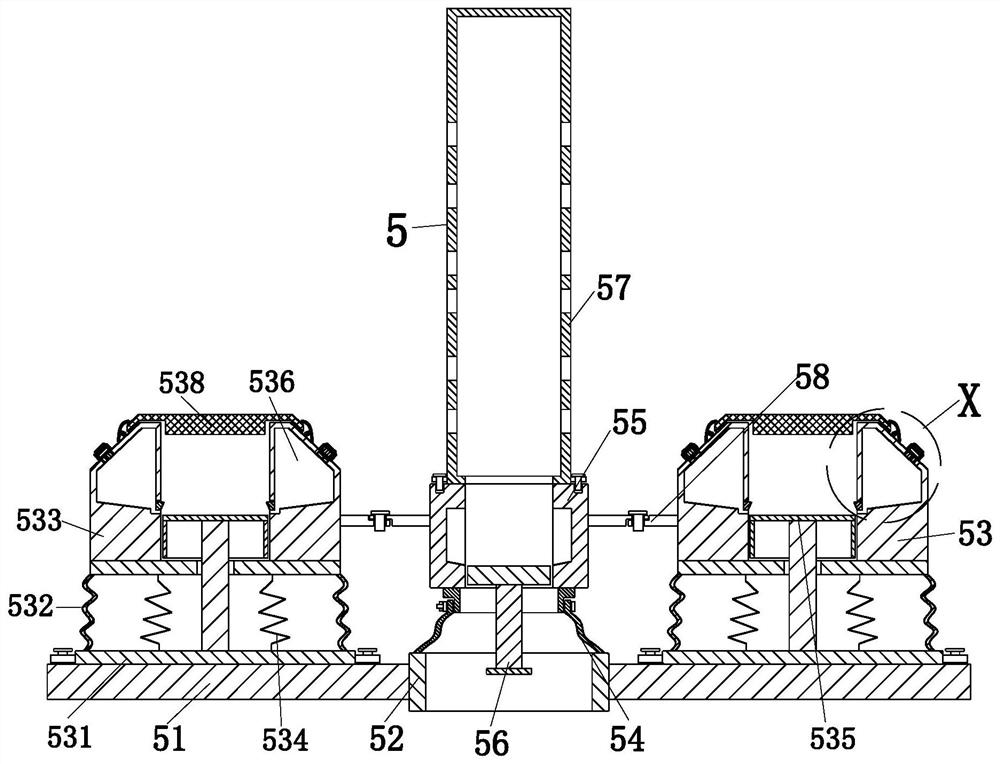

A method for manufacturing a powder metallurgy stainless steel flange

ActiveCN110421159BImprove paint rateIncrease the areaLiquid surface applicatorsCoatingsMetallurgyHydraulic pump

The invention provides a method for manufacturing a powder metallurgy stainless steel flange. The operation is completed by the cooperation of a base, a hydraulic pump, a material frame, a paint spray booth, a jacking device and a material spray pipe. During the process, it needs to be clamped with the help of a fixture. However, there are many contact surfaces between the fixture and the flange, so that the flange at this part cannot be sprayed, and it needs to be adjusted for a second time after adjusting its position. Touch-up painting is a complex operation process, and the position of the existing paint layer may be damaged when the position is adjusted. Because the internal space of the bolt hole of the flange is small, it is often difficult to spray the interior of the flange when spraying paint.

Owner:山西金宇粉末冶金有限公司

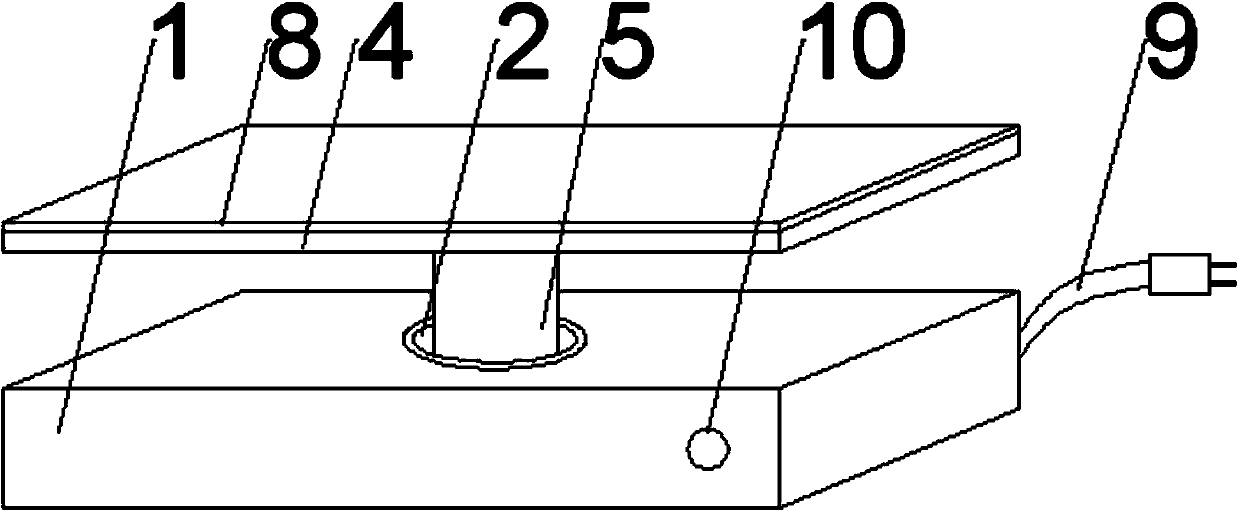

Heating base for mobile phone shell painting machines

InactiveCN104175710ASpeed up dryingImprove paint ratePrinting press partsElectricityInsulation layer

The invention relates to a heating base for mobile phone shell painting machines. The heating base comprises a base body, an inner cavity is arranged inside the base body, a circular through hole communicated with the inner cavity is formed in the upper surface of the base body, an electric heating unit is fixedly connected to the interior of the base body, a heat conducting pipe is fixedly connected on the electric heating unit, a support plate is fixedly connected above the base body, the upper end of the heat conducting pipe penetrates the through hole to be fixedly connected with the bottom of the support plate, a ceramic heat insulation layer is fixedly connected to the outer wall of the heat conducting pipe, a plurality of circular heat conducting pieces are fixedly connected to the upper surface of the support plate and are connected to the top end of the heat conducting pipe through heat conducting blocks, and a heat conducting plate used for conducting heat to heating the surface of a mobile phone shell is fixedly connected to the upper surface of the support plate. By the arrangement, the bottom of the mobile phone shell is heated while the mobile phone shell is painted, quick drying speed of painting on the surface of the mobile phone shell is greatly increased, and painting material rate is increased while color fastness is improved.

Owner:JIANGSU JUNYUN MACHINERY TECH CO LTD

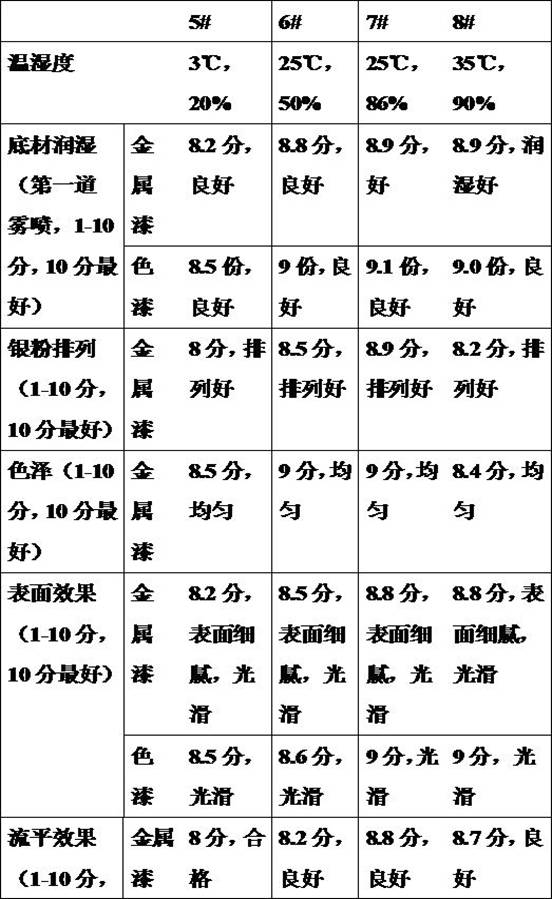

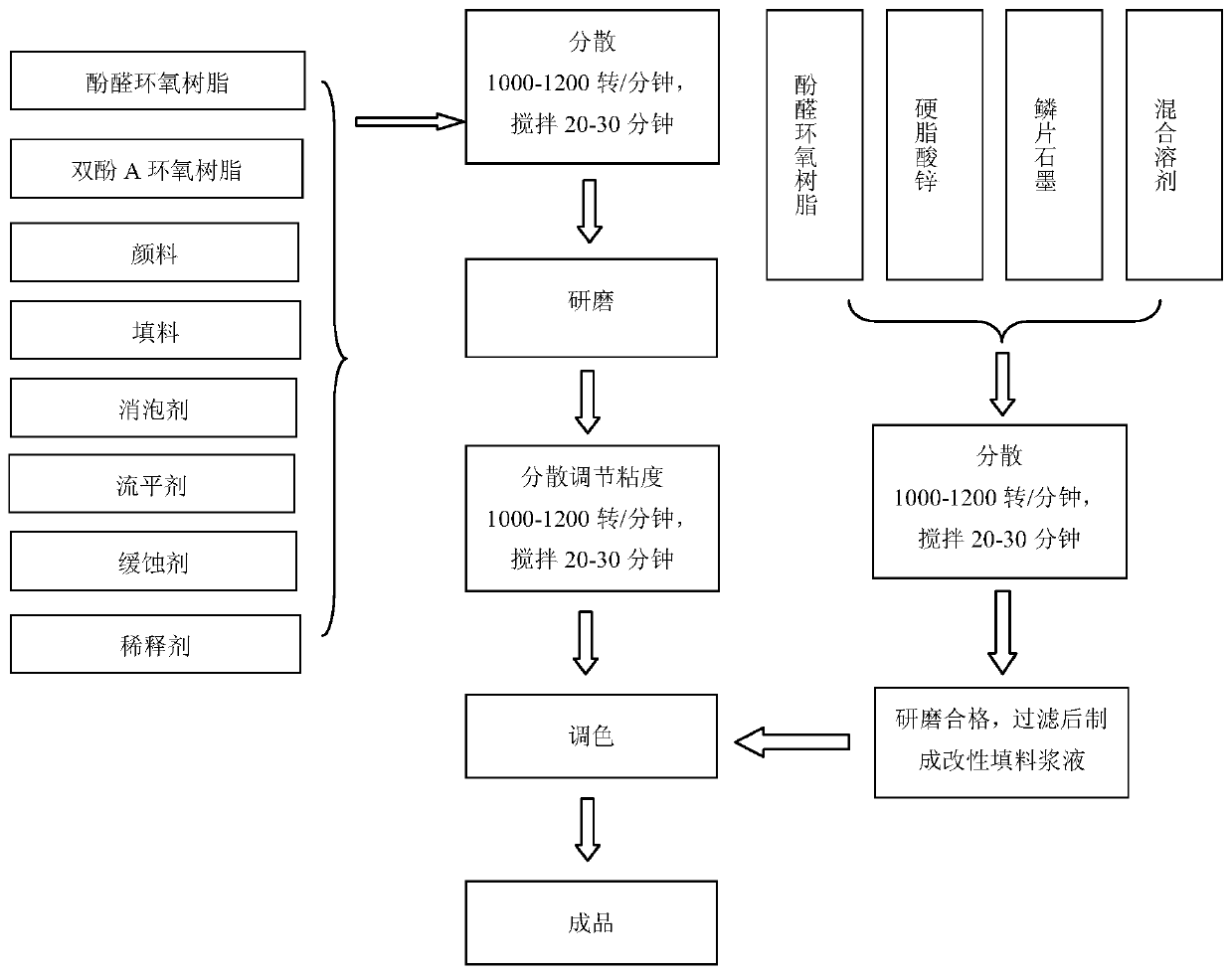

Superfineatomized all-weather low-viscosity multipurpose water-based blended water and preparation method thereof

The invention relates to the technical field of coatings, in particular to superfine atomized all-weather low-viscosity multipurpose water-based blended water and a preparation method thereof. The water-based blended water is composed of coating resin, n-amyl alcohol, a cosolvent, a base material wetting agent, an auxiliary and the like, the water-based blended water is matched with corresponding metallic paint or plain paint, the practical spray gun air pressure range is wide, the practical temperature and humidity range is wide, and after thinning, the spraying viscosity is low, normal spraying can still be carried out, the arrangement, the surface effect and the like of the metallic paint are not influenced, and the application range is wide.

Owner:GUANGDONG YATU CHEM

Epoxy primer for electrostatic spraying of rail transit bogie and preparation method thereof

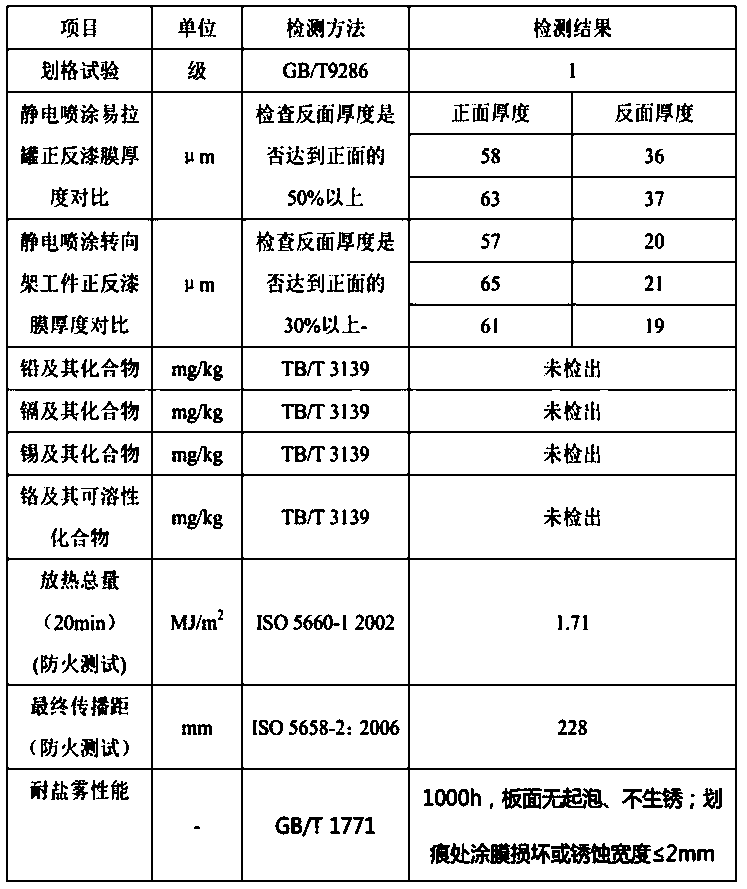

ActiveCN108129958BEasy electrostatic spray applicationStrong adhesionAnti-corrosive paintsEpoxy resin coatingsBogieFirming agent

The invention relates to an epoxy primer for electrostatic spraying of a rail traffic bogie, and a preparation method thereof. Epoxy resin, a composite antirust material, a coloring pigment, a functional material slurry, an assistant and a solvent form a paint; low-molecular polyamide, alicyclic amine, an assistant and a solvent form a curing agent; and the primer is prepared from the paint and the curing agent according to a weight ratio of 100:20 when constructed, and a proper amount of a diluent is added to adjust the construction viscosity in order to facilitate construction. The epoxy primer can adapt to mixed gas electrostatic spray gun spraying and electrostatic adsorption, and has the advantages of good environmental protection effect, small paint mist spray, high painting rate, good conductivity in a dry film, no influences on the electrostatic spraying, and realization of a coating layer with the performances meeting technical requirements of the primer for rail traffic bogie, and the epoxy primer can reduce the use amount of a paint by 30% or more when used in the mixed gas spray gun electrostatic spraying construction of the rail traffic bogie in order to reduce paint mist and the emission of VOCs, so the epoxy primer is an environmentally-friendly coating.

Owner:株洲市九华新材料涂装实业有限公司

Paint spraying method

PendingCN111589667AImprove the safety of useDoes not change solids contentPretreated surfacesWater heatersSpray methodSpray painting

The invention relates to the technical field of paint spraying, and particularly relates to a paint spraying method. The paint spraying method comprises the steps that step 1, cleaning operation is conducted, specifically, surface cleaning treatment is conducted on a to-be-sprayed workpiece; step 2, preheating operation is conducted, specifically, preheating treatment is conducted on paint, so that the paint is heated to the first viscosity; step 3, heating operation is conducted, specifically, after preheating is completed, the paint is pumped into a paint container of a spraying machine through a pump body and heated, so that the paint is heated to the second viscosity; step 4, spraying operation is conducted, specifically, after heating is completed, the paint is sprayed to the surfaceof the workpiece through a spraying gun on the spraying machine, and the paint spraying thickness meets the paint thickness requirement of the workpiece; and step 5, drying operation is conducted, specifically, after spraying is completed, the workpiece is put into a drying channel, so that the paint on the surface of the workpiece is solidified into a film. According to the paint spraying method,paint spraying operation can be completed without adding a cosolvent or a diluent, so that the paint using safety is improved, and the spraying efficiency is improved.

Owner:深圳市莱莉雅环保科技有限公司

A method and device for painting the surface of stator core punching sheet

ActiveCN108654919BPrevent rustReduce thickeningLiquid surface applicatorsCoatingsPunchingRubber elasticity

Owner:北京北重汽轮电机有限责任公司

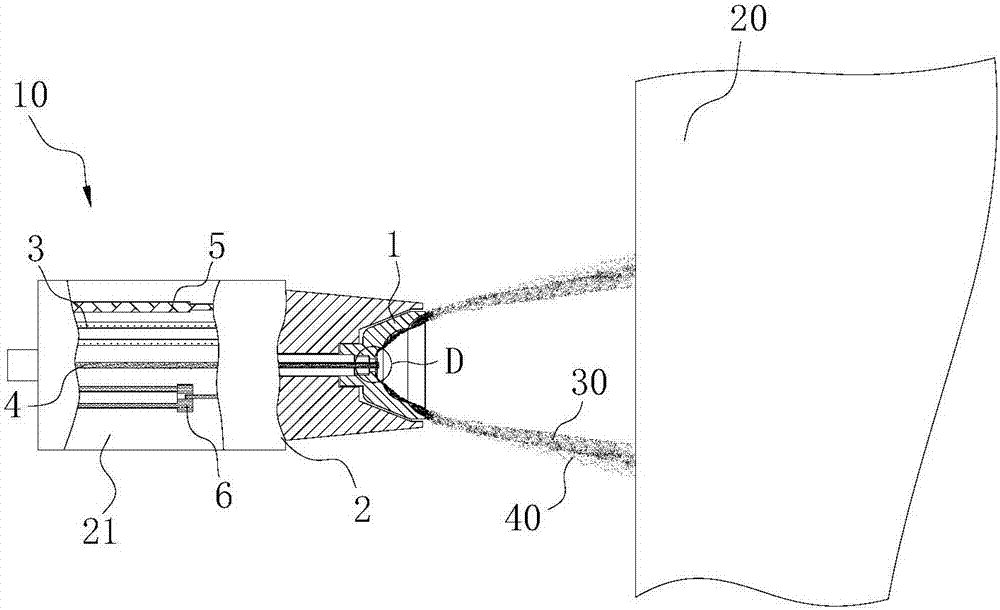

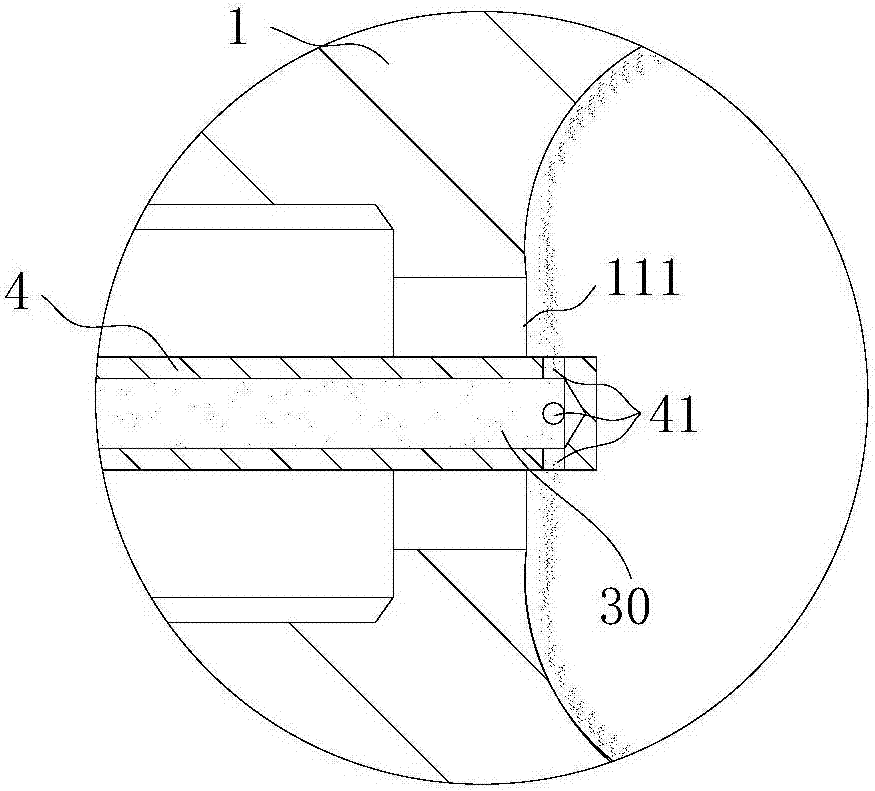

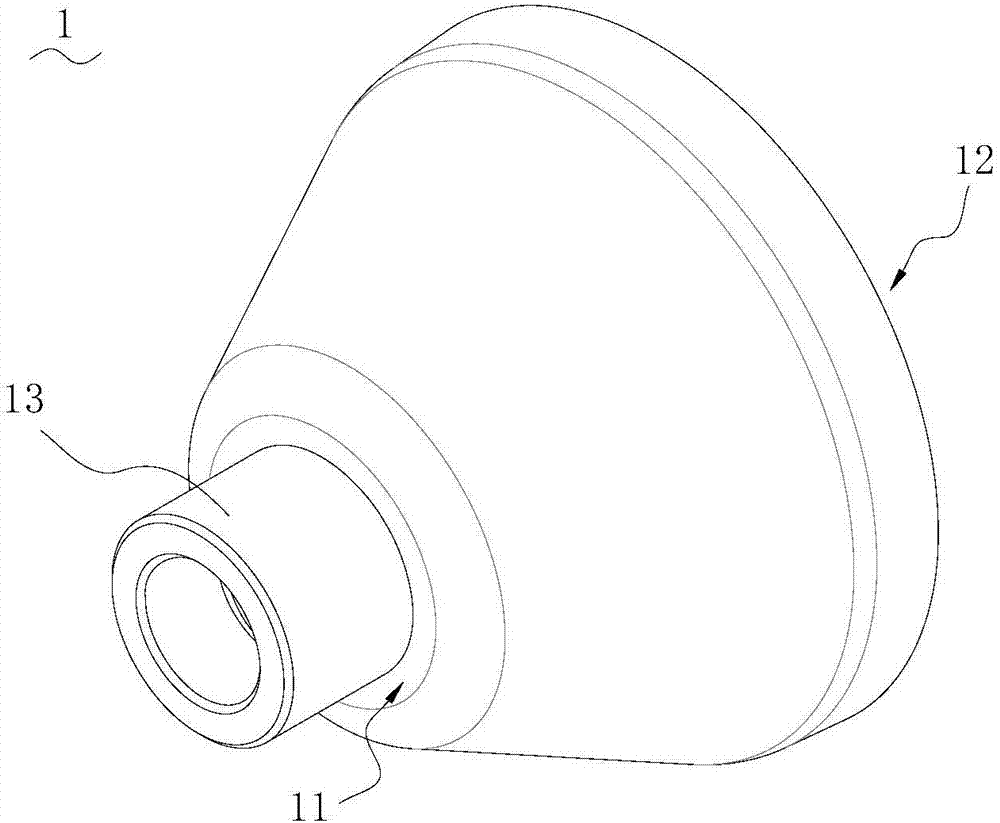

Electrostatic spraying equipment and rotary cup thereof

PendingCN107486349AImprove atomization effectSpray evenlySpray discharge apparatusMechanical engineeringCoating

The invention provides electrostatic spraying equipment and a rotary cup thereof. The rotary cup is used for atomizing coating conveyed into the rotary cup from the cup bottom and then spraying the coating out from a cup opening, and the area of the opening of the rotary cup is gradually increased in the direction from the cup bottom to the cup opening. The inner side wall surface of the rotary cup comprises multiple sections of inwards-concaved curved surfaces. The inwards-concaved curved surfaces are sequentially connected in the direction from the cup bottom to the cup opening. Through the rotary cup, the coating entering the rotary cup can be fully atomized after being impacted for multiple times, the atomizing effect of the coating is effectively improved, and the lacquering rate is increased, specifically, the lacquering rate can be increased by 15% or above according to practical verification and comparison. Meanwhile, the diameter and the angle of the bottom of the rotary cup can be smaller through the design of the multiple sections of inwards-concaved curved surfaces of the inner side wall of the rotary cup, and the defect that the coating is not atomized through the rotary cup and directly rebounds, and consequently, the atomizing effect of part of the coating is poor is avoided.

Owner:东莞南方中集物流装备制造有限公司 +2

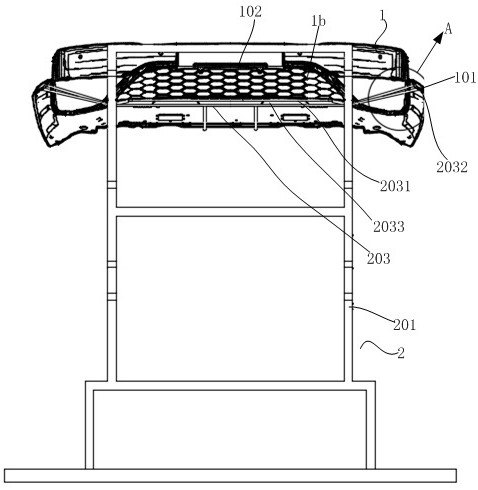

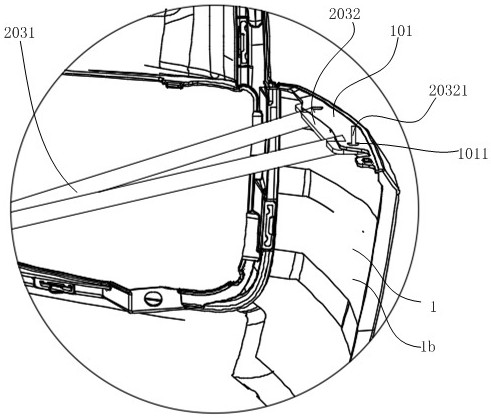

Integrated spraying process for bumper and grille of automobile

PendingCN114260166AEasy to sprayImprove adhesionSpraying apparatusCoatingsMechanical engineeringVarnish

The invention relates to an integrated spraying process for a bumper and a grille of an automobile, which is characterized by comprising the following steps of: (1) positioning a product: hanging the bumper and the grille which are integrally formed on a turnover mounting bracket, and arranging the outer surfaces of the bumper and the grille outwards; (2) primer is sprayed, specifically, the robot sprays a layer of primer to the bumper and the grating from the outer side, and the primer contains conductive carbon powder; (3) colored paint is sprayed; and (4) varnish spraying: after the colored paint is leveled, firstly, the robot sprays a first layer of varnish to the bumper and the grating from the outer side together, after the first layer of varnish is leveled, the mounting bracket is adjusted and overturned, so that the inner surfaces of the bumper and the grating are arranged upwards, and then the robot sprays a second layer of varnish to the grating from the upper side. The robot spraying device facilitates robot spraying, and the phenomena of spraying missing, orange peel and the like are avoided.

Owner:WUHAN LIAOYUAN MOLDING

A method for improving the surface coating quality of wooden door electrostatic spraying

ActiveCN106391428BDoes not reduce adhesionImprove the quality of electrostatic sprayingLiquid surface applicatorsCoatingsElectrostatic coatingEngineering

The invention discloses a method for improving the quality of an electrostatic surface coating of a wooden door. The method for improving the quality of the electrostatic surface coating of the wooden door comprises the steps that the wooden door is prepared; and spraying is conducted, specifically, a grounding conductive board is adopted to be placed on the back side of the wooden door during spraying, and in the electrostatic spraying process, the wooden door is located between an electrostatic spraying gun and the grounding conductive board. By adoption of the method for improving the quality of the electrostatic surface coating of the wooden door, the problems that in the conventional electrostatic spraying process of the wooden door, the thickness of a coating is nonuniform, the painting rate is instable, and painting is difficult during secondary spraying or finish paint spraying can be solved; and meanwhile, no humidification treatment needs to be conducted on the surface of the wooden door, so that the adhesive force of a paint film is not reduced, and the electrostatic spraying quality is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

A magnesium alloy base material with high salt spray resistance and strong weather resistance protective coating, preparation method and application method

ActiveCN107523193BGood weather resistanceGood resistance to salt sprayAnti-corrosive paintsEpoxy resin coatingsEpoxyGas phase

The invention provides a high-salt-smog-resistance and high-weather-resistance type protecting coating for a magnesium alloy base material, a preparation method and an application method. The high-salt-smog-resistance and high-weather-resistance type protecting coating is characterized in that hydrogenated silicon bonded epoxy resin is used as main resin, and enables a coating layer to meet the demands of indexes on basic salt smog resistance and weather resistance; strongly hydrophobic fumed silica provides high settling resistance of the coating in storage and outstanding sag resistance in construction; a light stabilizer is combined and matched with an ultraviolet absorbent to further ensure the high weather resistance of the coating layer; graphene, nano-tantalum and glass flakes are combined to enable the improvement on the high slag smog resistance and corrosion resistance of the coating layer; talcum powder in the formula acts together with a KH-560 epoxy silane coupling agent to greatly improve the wet adhesion of a coating film to the magnesium alloy coating; xylene is used for adjusting the viscosity of the whole coating system. Compared with the prior art, the prepared special protecting coating for the magnesium alloy is high in weather resistance, outstanding in salt smog resistance, high in solid content, low in viscosity, and uniform in the coating layer.

Owner:WUHU CHUNFENG NEW MATERIAL

Plasma modification method to improve the bonding performance of decorative veneer and veneer interface

ActiveCN107030802BResolve curlSolve discolorationLayered product treatmentElectric wood treatmentAdhesiveEngineering

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

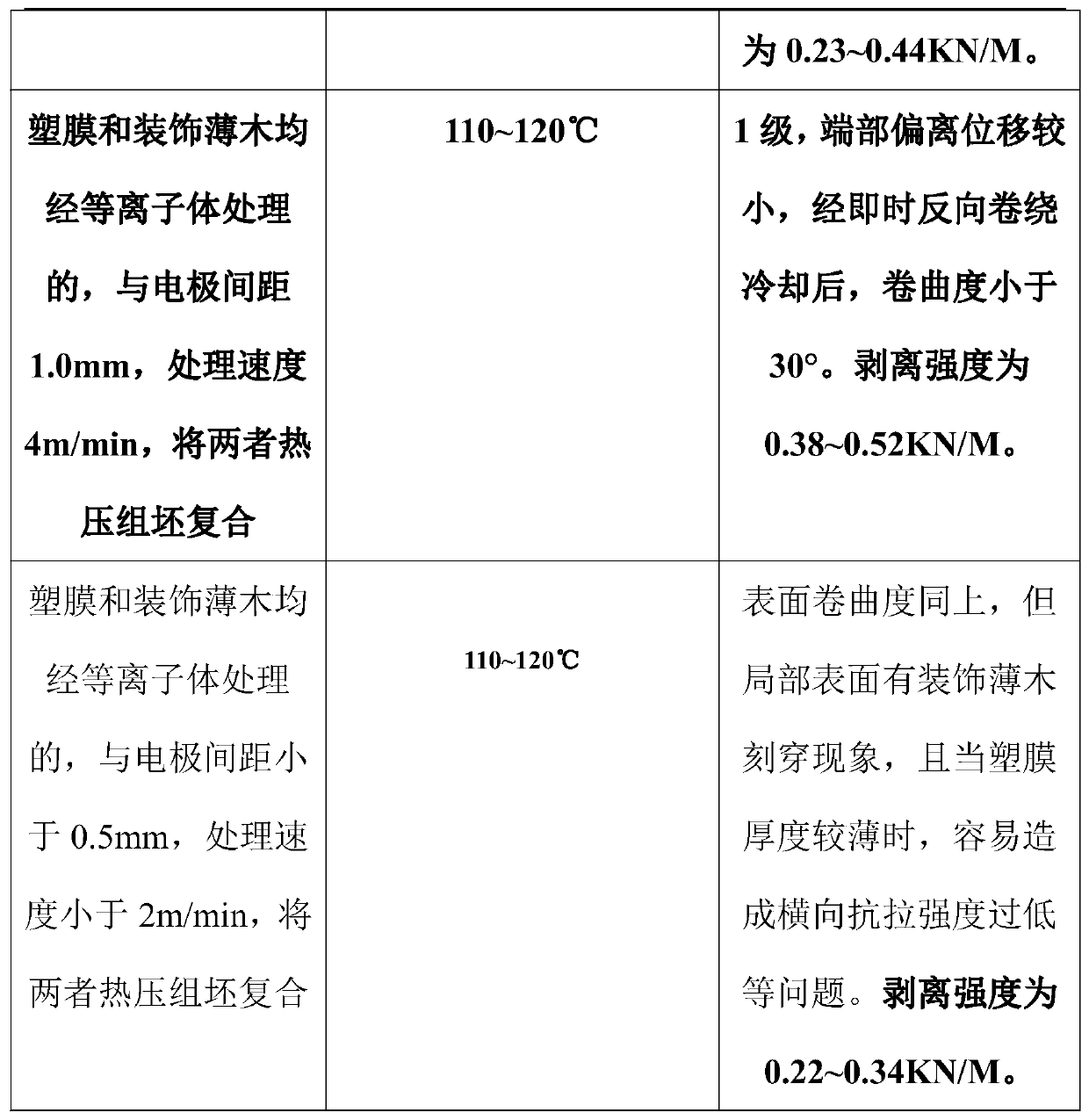

An automatic spraying device

ActiveCN110694831BImprove paint rateHigh degree of spraying automationSpraying apparatusManipulatorStructural engineeringSpray painting

The invention discloses an automatic spraying device, which comprises a six-axis robot, a connecting frame, a mounting frame, a fixed rod, a spray gun and a driving assembly; the connecting frame is fixedly connected to the mounting end of the six-axis robot; one end of the mounting frame is fixedly connected to the connecting frame; The number of fixed rods is multiple, and the end is hinged with the other end of the mounting frame, and the connection points of multiple fixed rods and the mounting frame are evenly spaced along the edge of the mounting frame; the spray gun is fixed at the end of the free end of the fixed rod; the drive assembly It is connected with the installation frame, and is used to simultaneously drive multiple fixed rods to expand outward or contract inward. The present invention improves the painting rate of the painted parts by arranging multiple spray guns on the same mounting frame. Since the spray surfaces of the spray guns are on the same horizontal plane, there will be no uneven spray thickness, and through the control of the drive assembly, It can realize the adjustment of multiple spray guns at different angles, and then adapt to spraying products with different needs, with high spraying efficiency and low cost.

Owner:YANGZHOU POLYTECHNIC COLLEGE

A spraying tool for elongated automotive interior parts

ActiveCN107042182BSave the touch-up processImprove paint rateSpray discharge apparatusGear wheelCoating

A spraying tool of a long automobile interior trim part comprises at least three spraying guns (10) annularly arranged in a spaced manner. The spraying tool comprises an angle space adjusting mechanism (100) and a spraying sector adjusting mechanism (200); the angle space adjusting mechanism (100) comprises a first annular main body (1) which is provided with at least three nozzle bases (3) in a sliding manner, the spraying guns (10) are arranged on the nozzle bases (3) in a sliding manner in the radial direction of the first annular main body, the first annular main body (1) comprises a first guide rail (4), a second guide rail (17) and outer teeth (5), the outer teeth (5) are arranged on the outer edge of the first annular main body (1), each nozzle base (3) comprises a first guide groove (7), a second guide groove (18) and a walking gear (8), and the top side center point of each first guide groove (7), the top side center point of each second guide groove (18) and the axis of each walking gear (8) form the isosceles triangle. The spraying tool of the long automobile interior trim part is suitable for spraying a long workpiece, the coating supplementing process is removed, the painting rate is high, and the production cost is reduced.

Owner:江苏蔚金汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com