Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Improve length accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

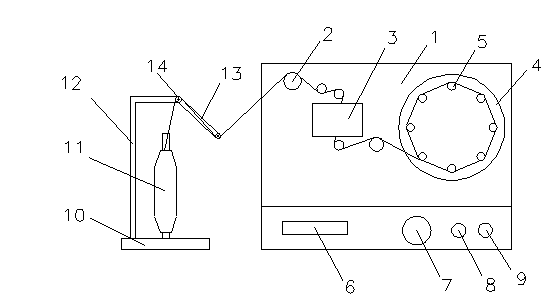

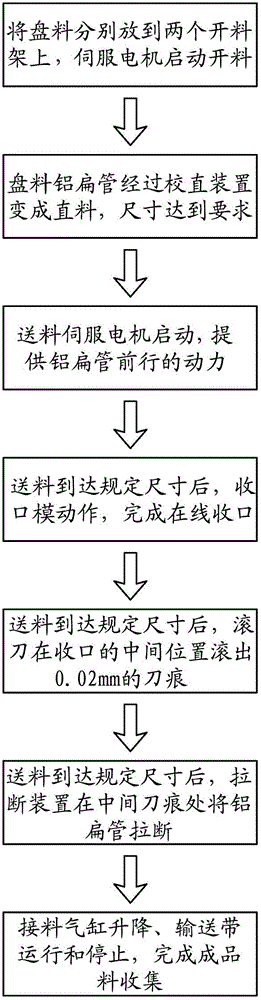

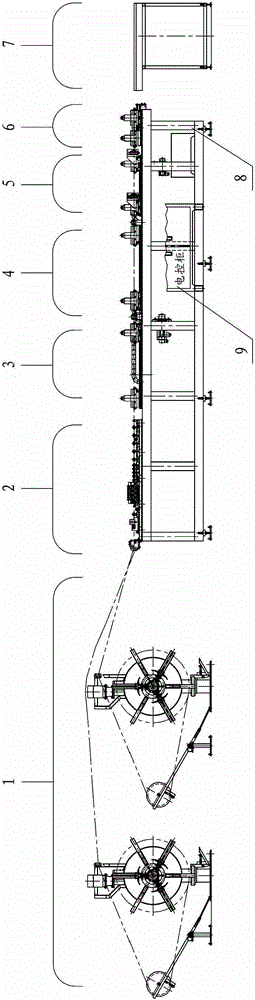

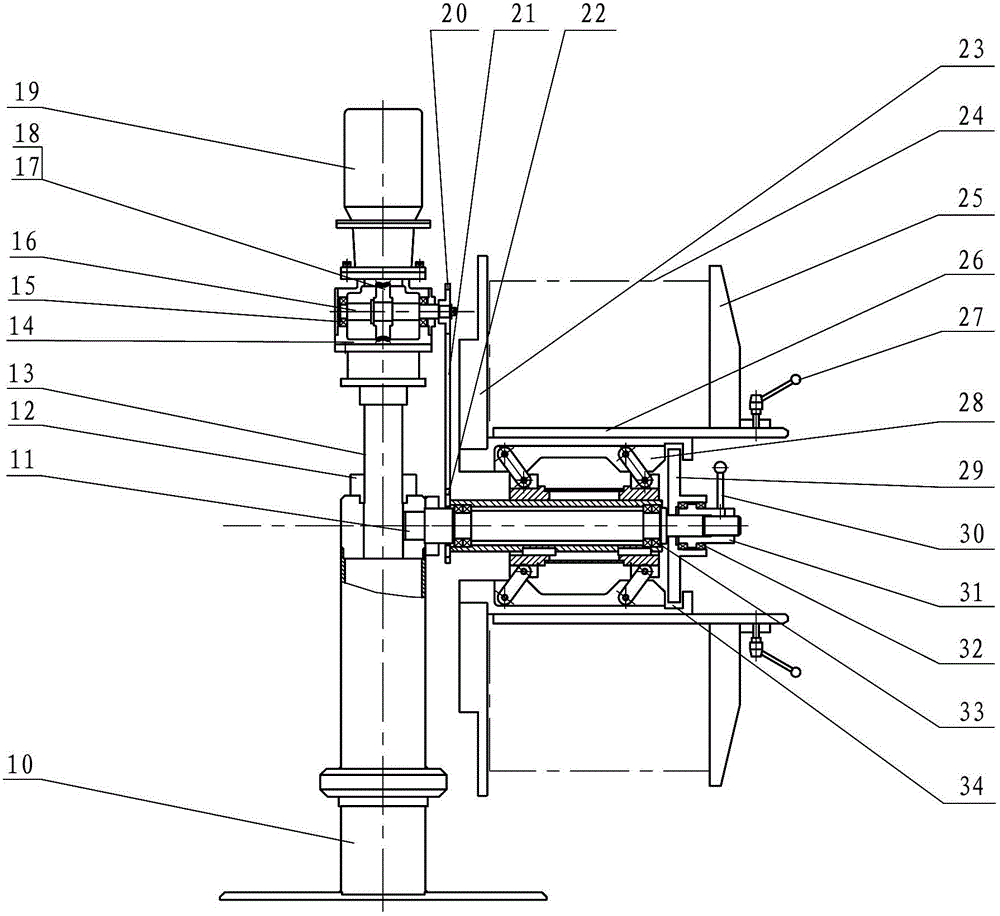

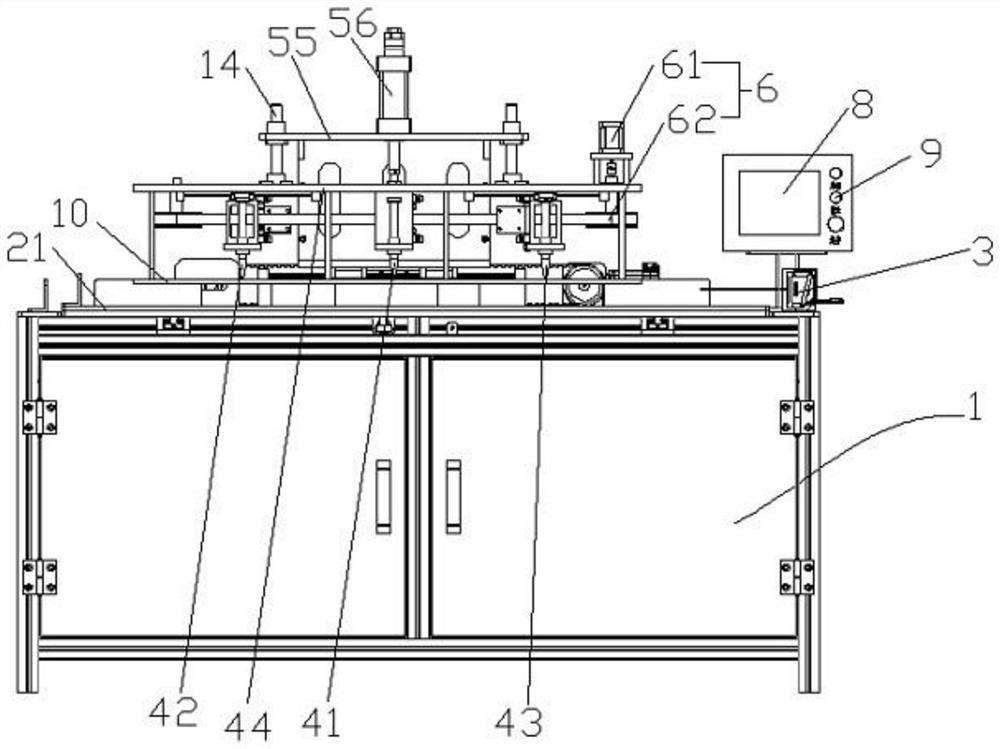

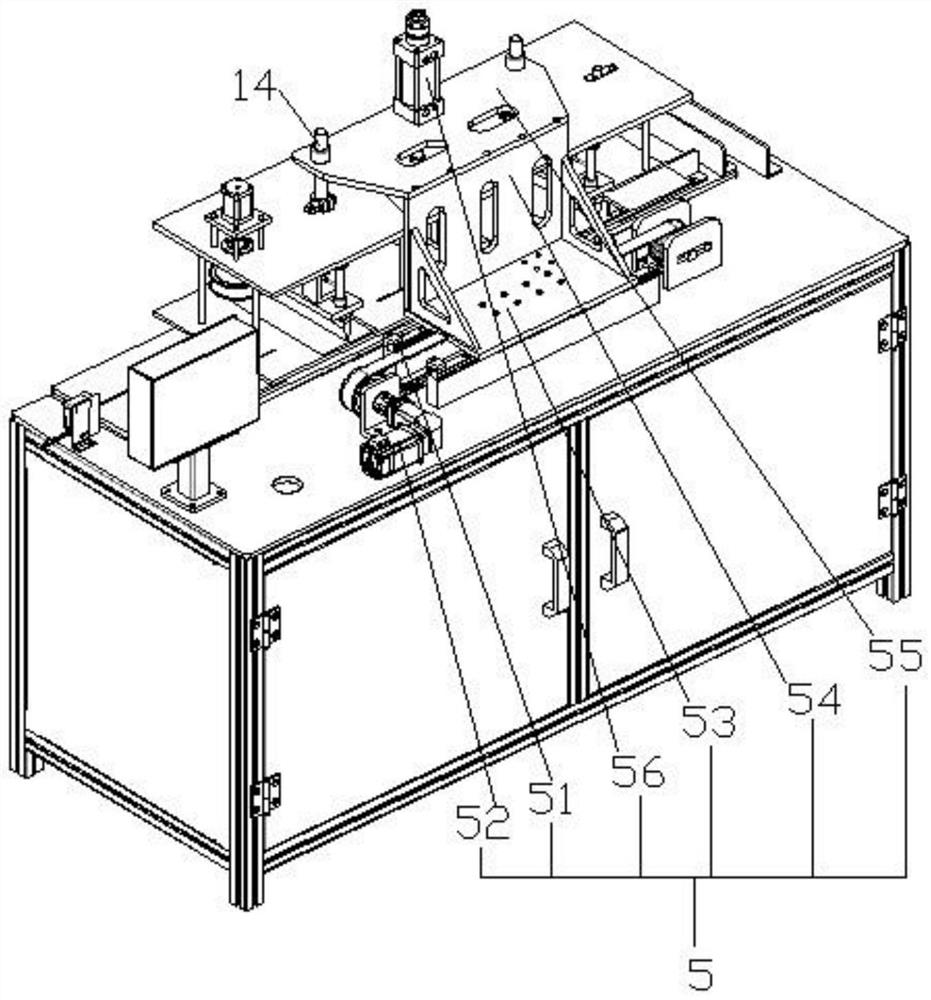

High-speed straightening dimensioning blanking process and equipment for aluminum flat pipe of automobile air conditioner

ActiveCN102689147AConsistency Error ReductionRealize automatic collectionOther manufacturing equipments/toolsControl systemAutomobile air conditioning

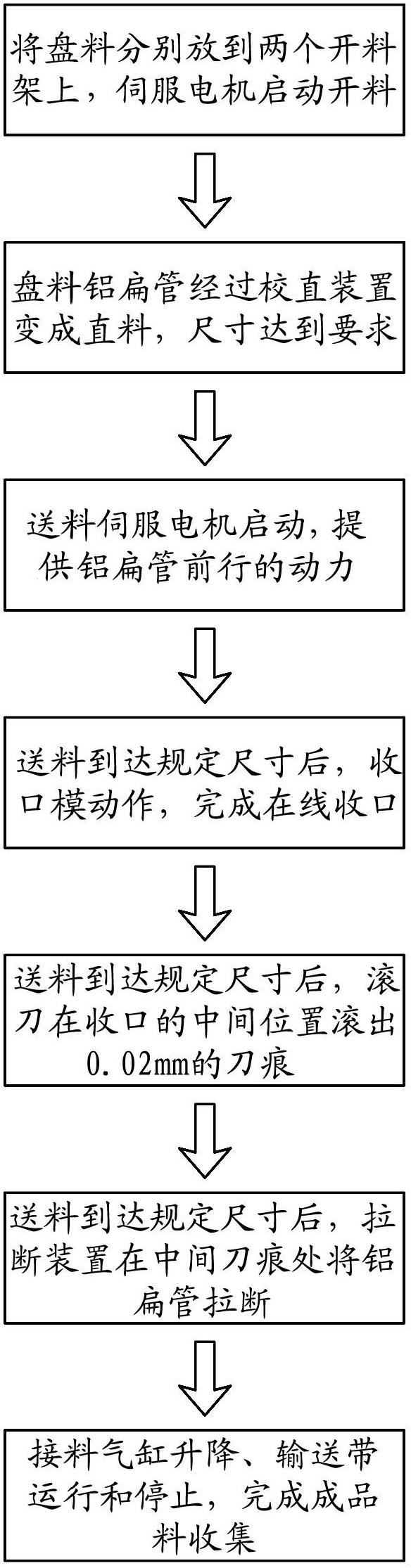

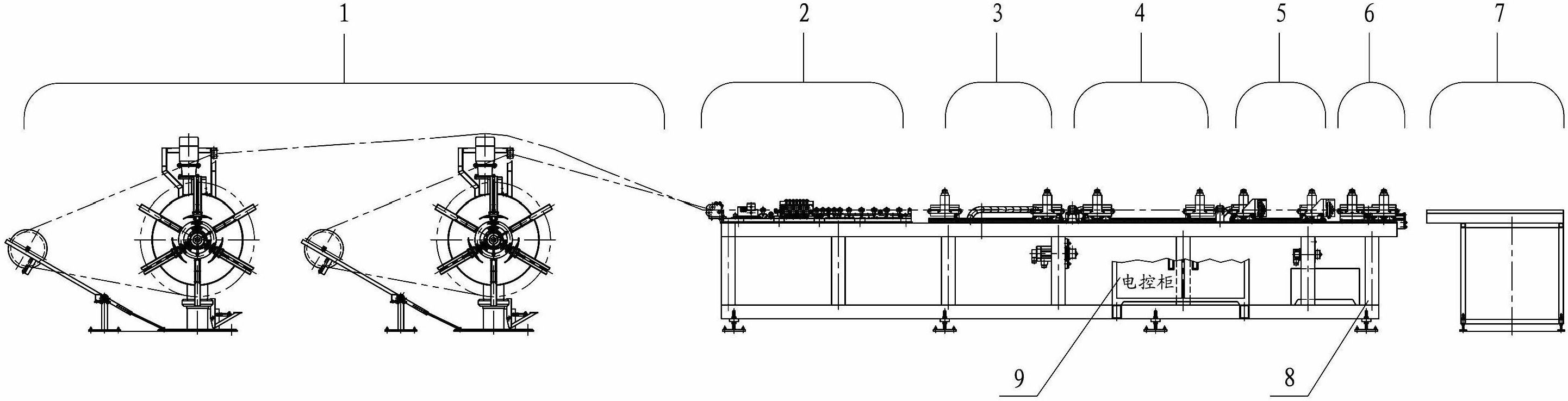

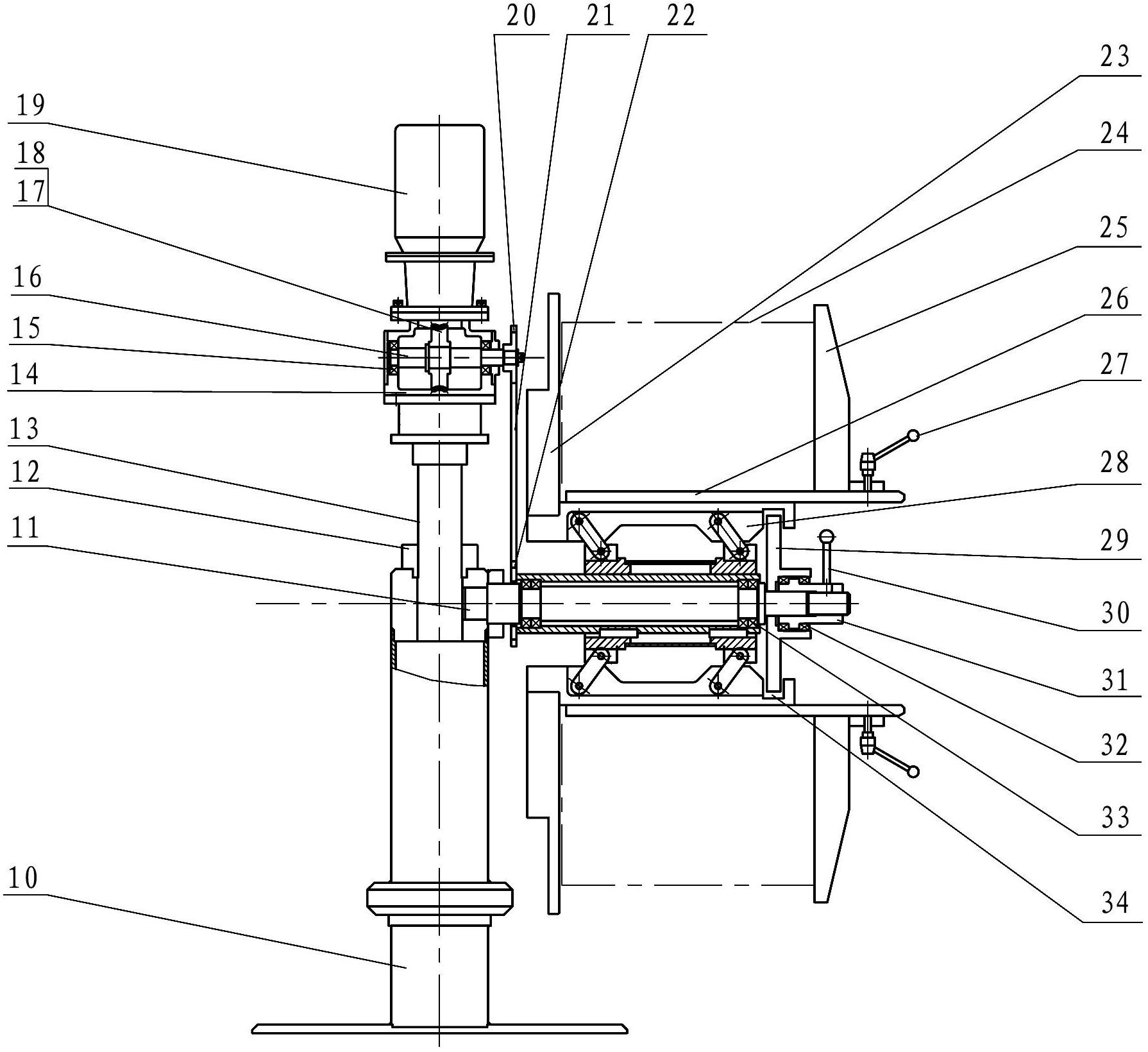

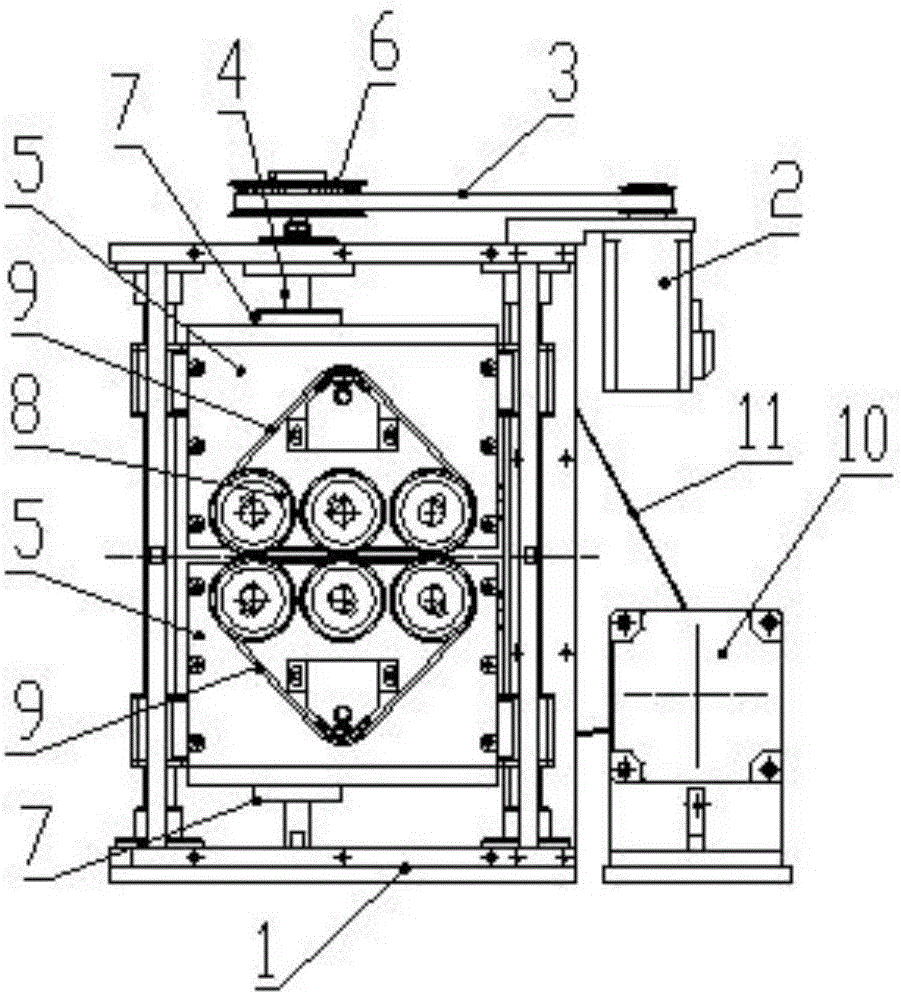

The invention provides a high-speed straightening dimensioning blanking process and equipment for an aluminum flat pipe of an automobile air conditioner. The equipment consists of a driving material cutting frame, a straightening device, a servo feeding device, a servo online necking device, a dimensioning cutting device, a clamping tension fracture device, a material collecting table, a machine body and an electric control system, and is characterized in that the whole processes of disc material cutting, straightening, necking, tension fracture and automatic finished product collection can be realized on the same production equipment, all servo motors in the whole equipment are respectively controlled by a programmable controller so that the immediate synchronous movement of actions of all devices is ensured, and three actions of necking, cutting and clamping tension fracture of the aluminum flat pipe can be simultaneously completed on three different devices of the equipment. When the equipment is adopted, the forming precision of the finished products of the aluminum flat pipes can be improved by three times, and the operation efficiency of the equipment is improved by five times.

Owner:沈阳智勤机器人系统工程有限公司

Medium and long term hydrologic forecasting method based on empirical mode decomposition

InactiveCN104091074AThe method steps are simpleReasonable designSpecial data processing applicationsKernel principal component analysisSupport vector machine

The invention discloses a medium and long term hydrologic forecasting method based on empirical mode decomposition. The medium and long term hydrologic forecasting method based on empirical mode decomposition comprises the steps that firstly, a hydrologic forecasting model is built according to the following procedures of (101) empirical mode decomposition, wherein empirical mode decomposition is carried out on a hydrologic time sequence s(t) of a forecast drainage basin, (102) kernel principle component analysis, wherein kernel principle component analysis is carried out on n intrinsic mode function components Fj obtained through empirical mode decomposition and a trend item rn, and p main components F'k are extracted, (103) building of a training sample set, wherein the training sample set is built according to the extracted p main components F'k, (104) building of a support vector machine model, and (105) training of the support vector machine model; secondly, annual runoff data of the years needing forecasting are forecast through the built hydrologic forecasting model. The medium and long term hydrologic forecasting method based on empirical mode decomposition is simple in step, convenient to realize, easy and convenient to operate, good in use effect and capable of effectively resolving the problem of low forecasting accuracy of an existing hydrologic forecasting method.

Owner:CHANGAN UNIV +2

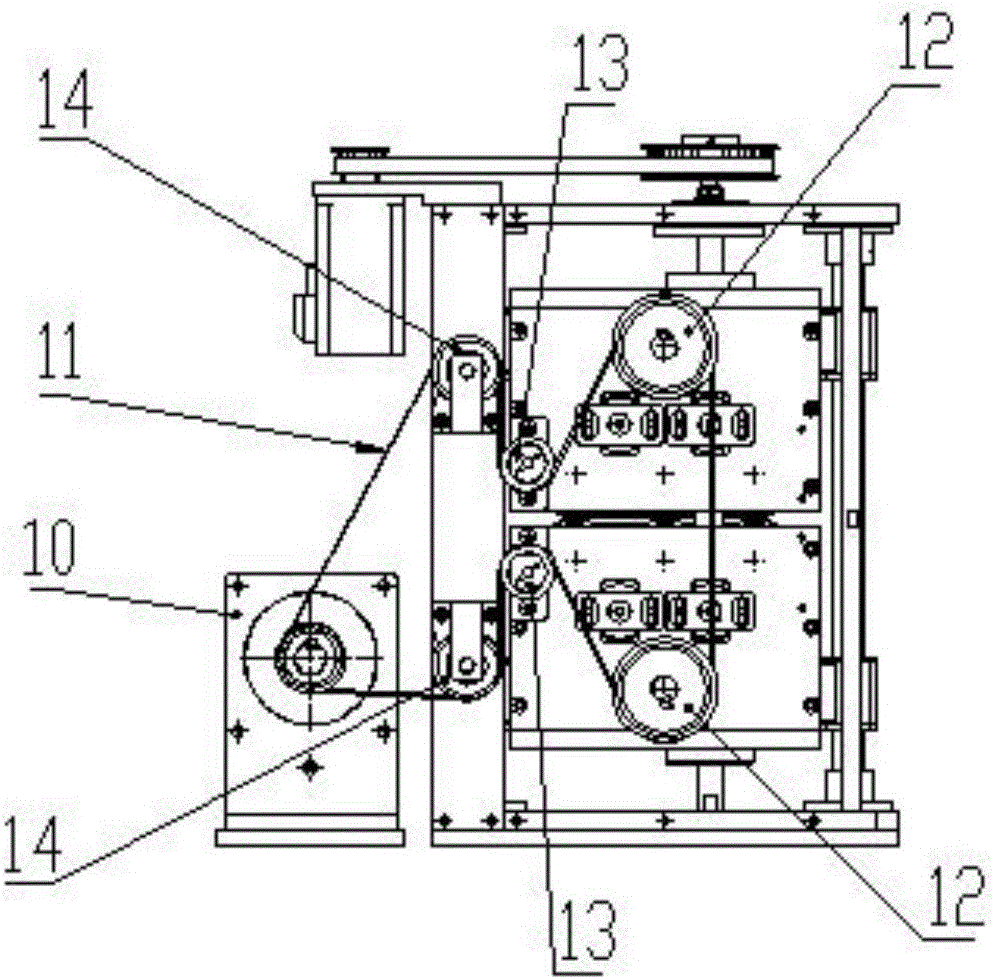

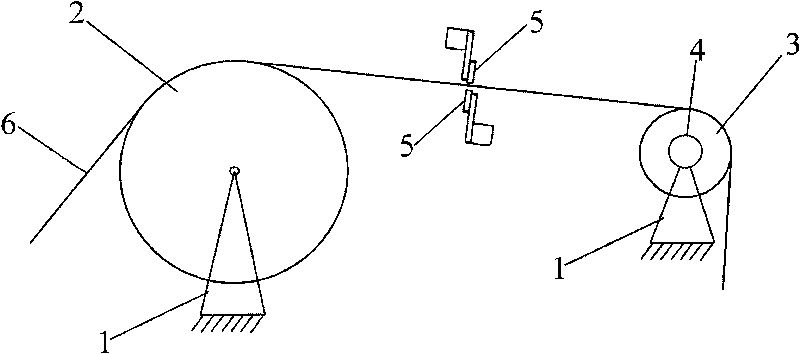

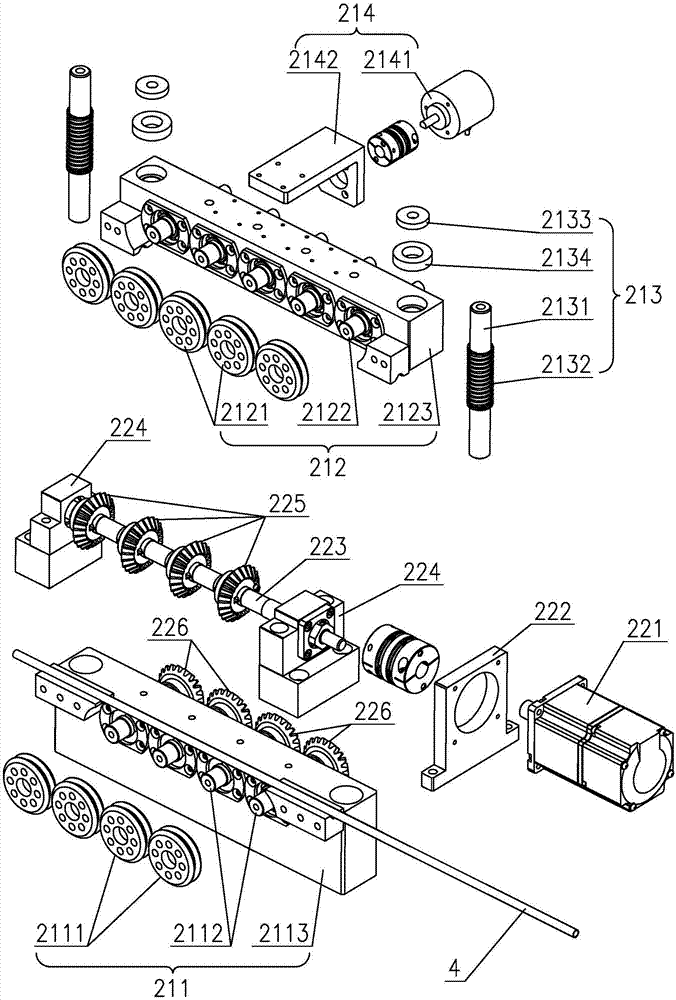

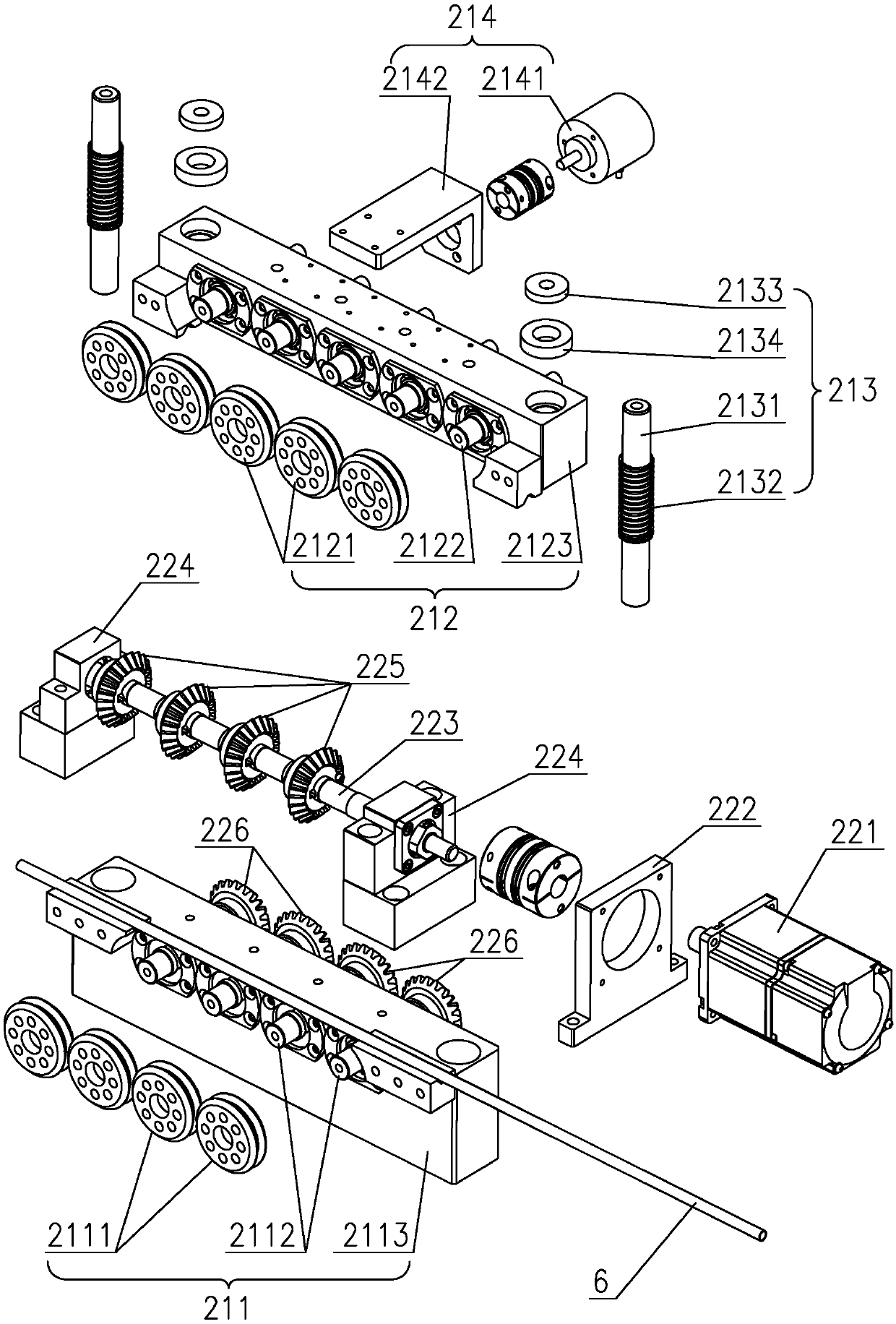

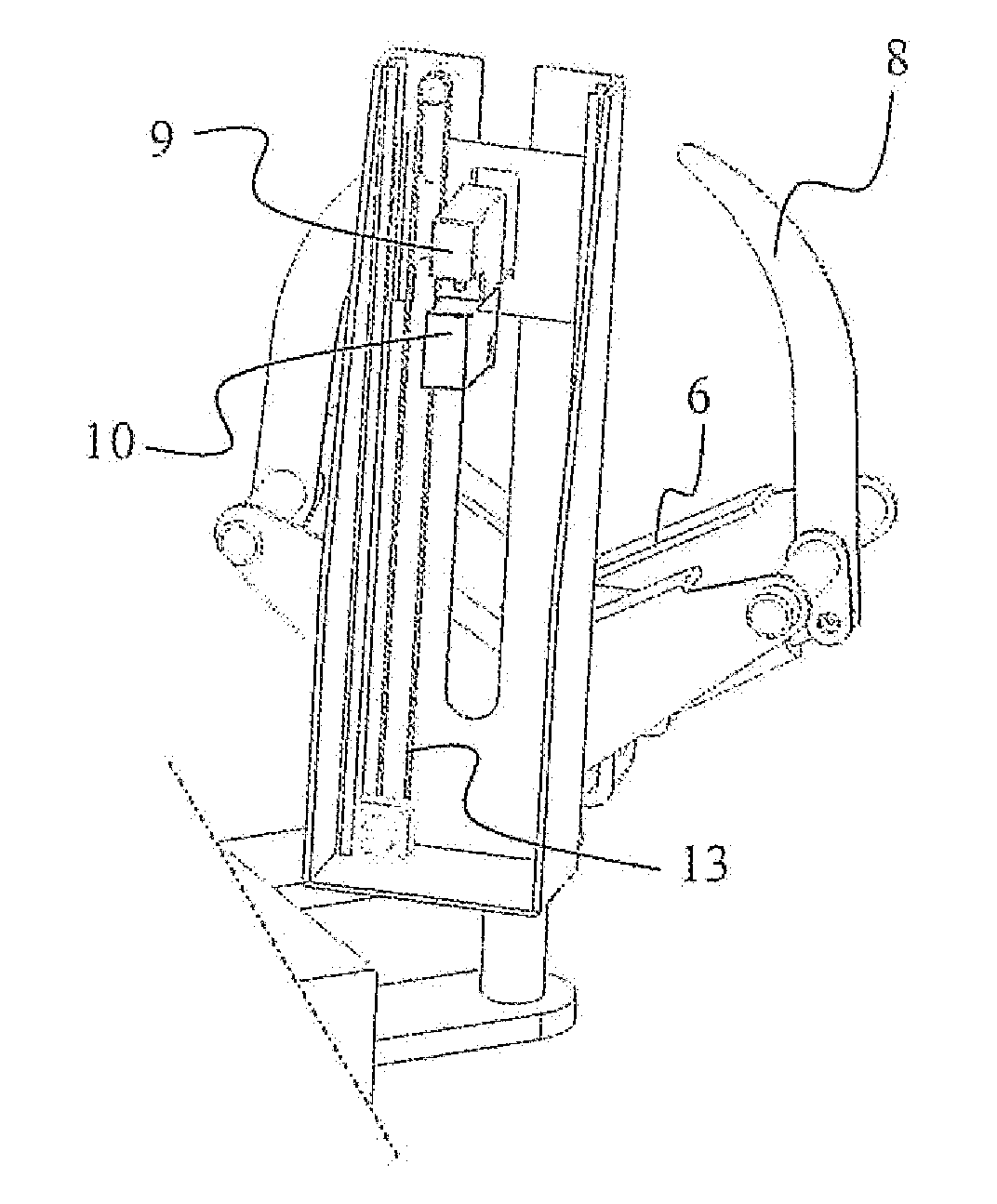

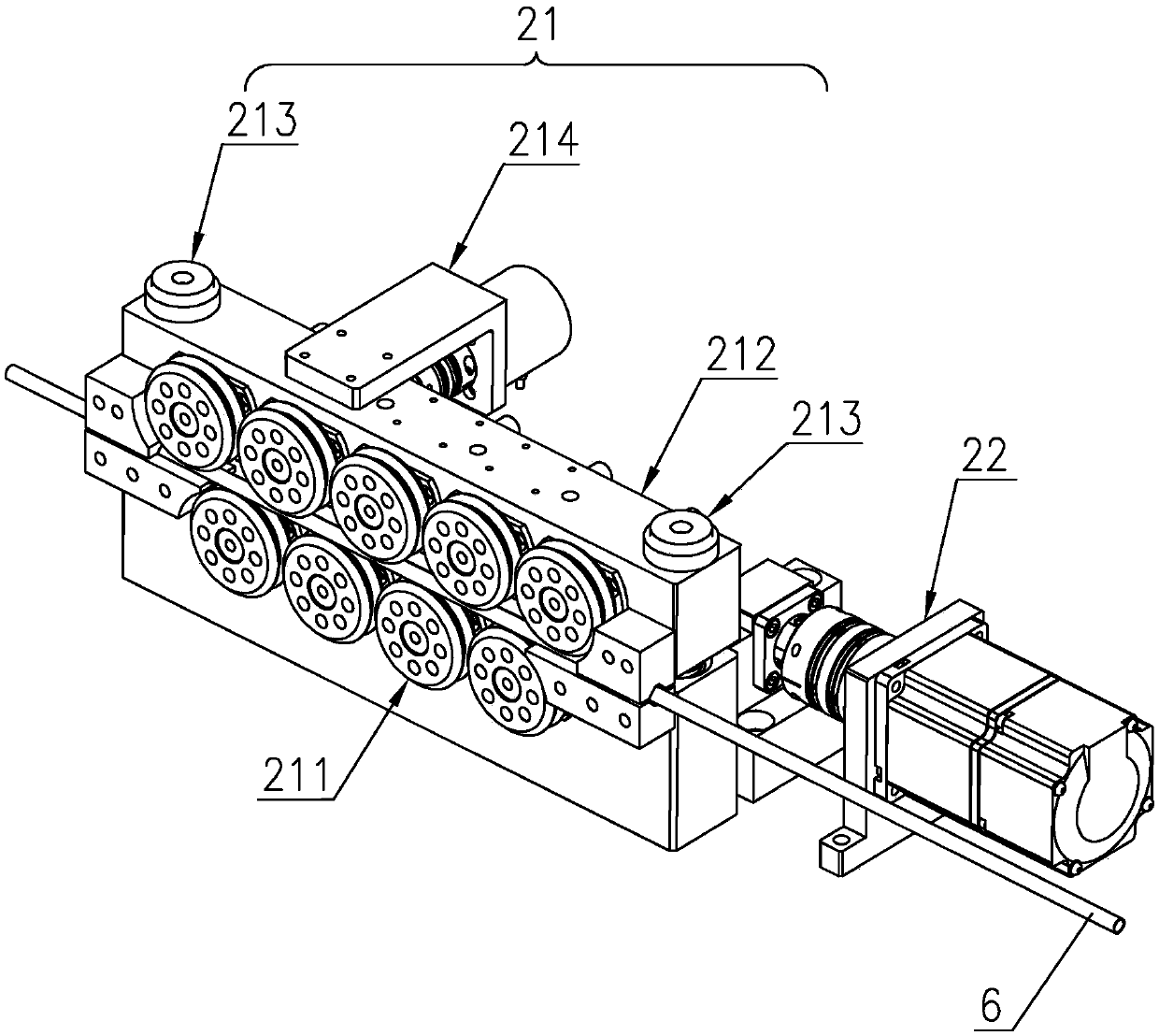

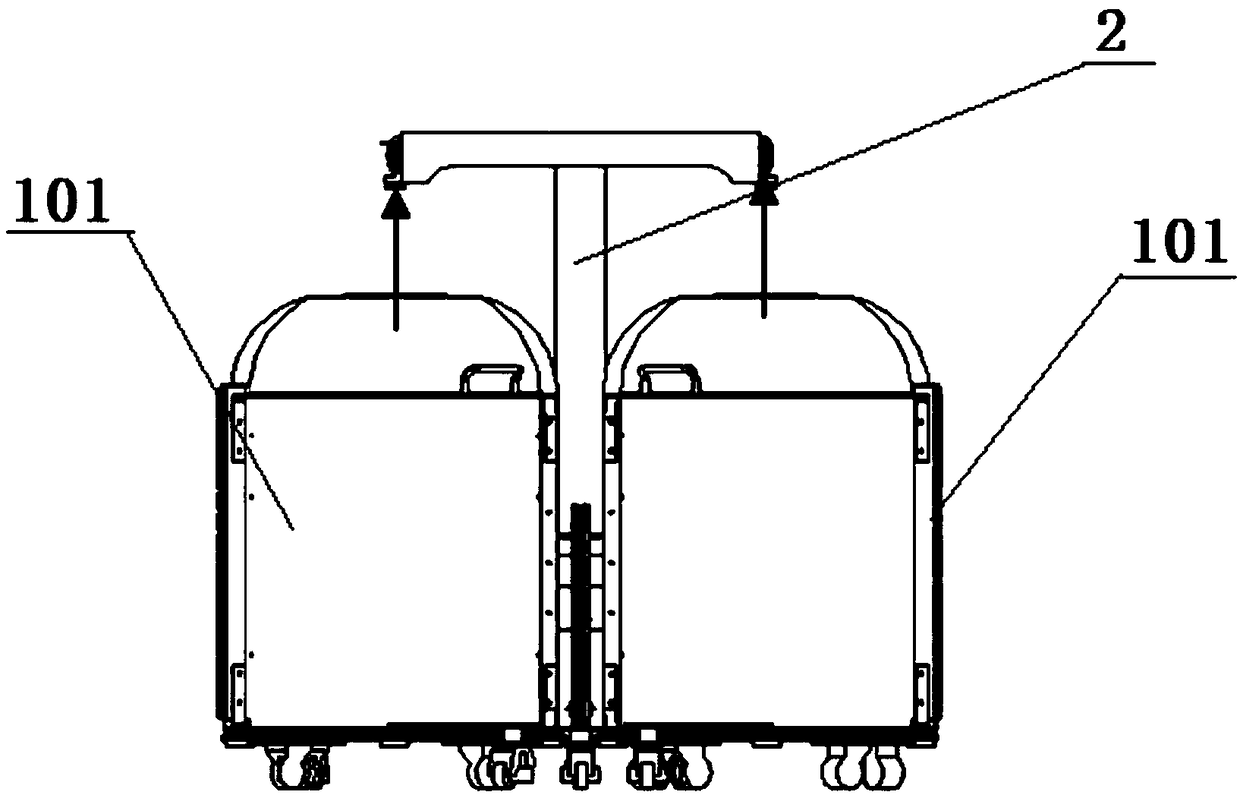

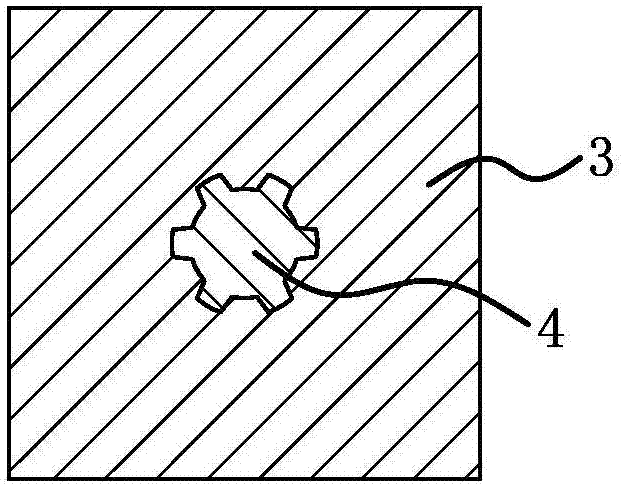

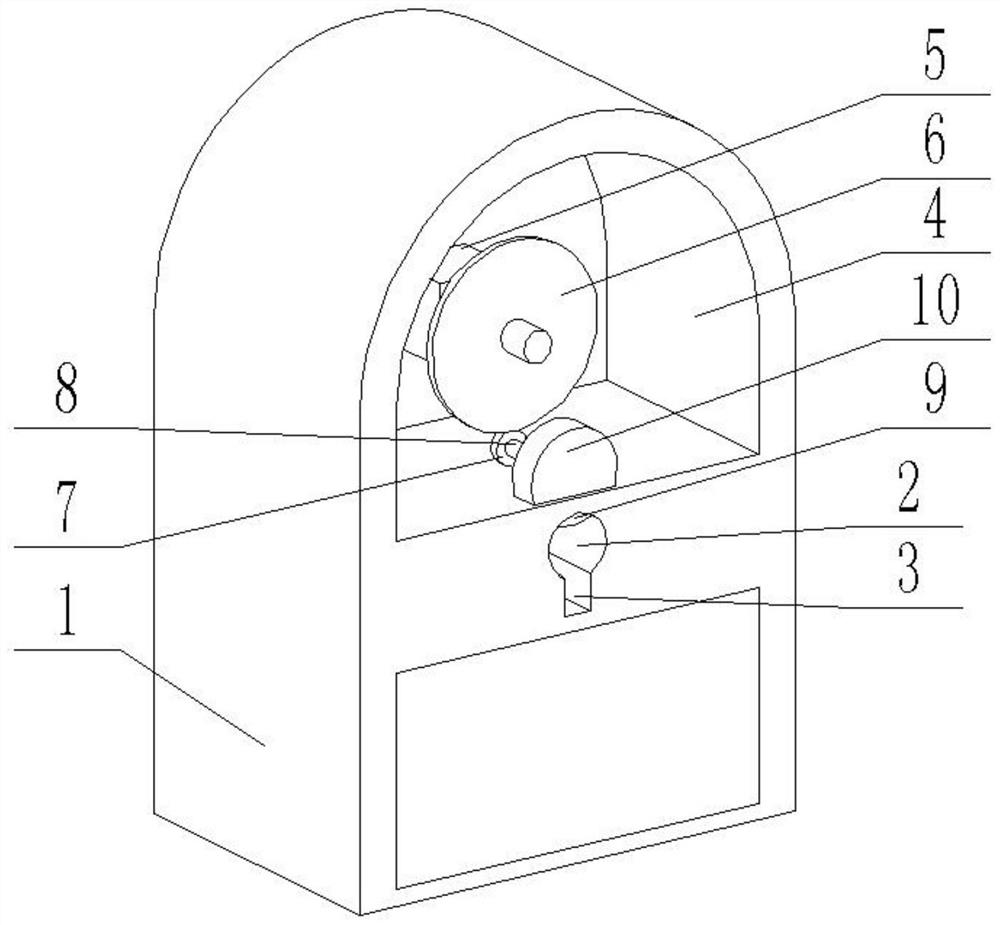

Wire stripping machine transmission mechanism with same power for multiple wheels and unchangeable center for different wire diameters

InactiveCN105775894AImprove length accuracyAvoid bevel phenomenonApparatus for cutting/splicing cablesFilament handlingMotor driveEngineering

The invention relates to a wire stripping machine transmission mechanism with the same power for multiple wheels and the unchangeable center for different wire diameters. A lifting motor drives a rotation wheel to rotate through a lifting drive belt, the rotation wheel drives a screw to rotate, and the screw drives two gearboxes to move in the opposite directions at the same time. All wire feeding wheels are driven through a set of motors and can be made to synchronously run, errors are reduced, and the upper wheels and the lower wheels are driven by one motor. After a wire is clamped, the position of the center face of the wire is not changed and is the same as the position of a cut center face. Wire feeding belts oppositely move at the same time, the moving distances are consistent, the types of machined wires cannot be affected by the diameters of the wires, all the wires can be machined, the wires are kept at the center position of a tool rest all the time, and the phenomenon of notch skew of a notch is avoided. One motor can drive two drive synchronous belt wheels to oppositely move at the same time in a drive belt winding direction manner while it is guaranteed that the driving torque is unchanged, the length precision of wire feeding is improved, and meanwhile the machining cost is reduced.

Owner:徐州领君自动化设备有限公司

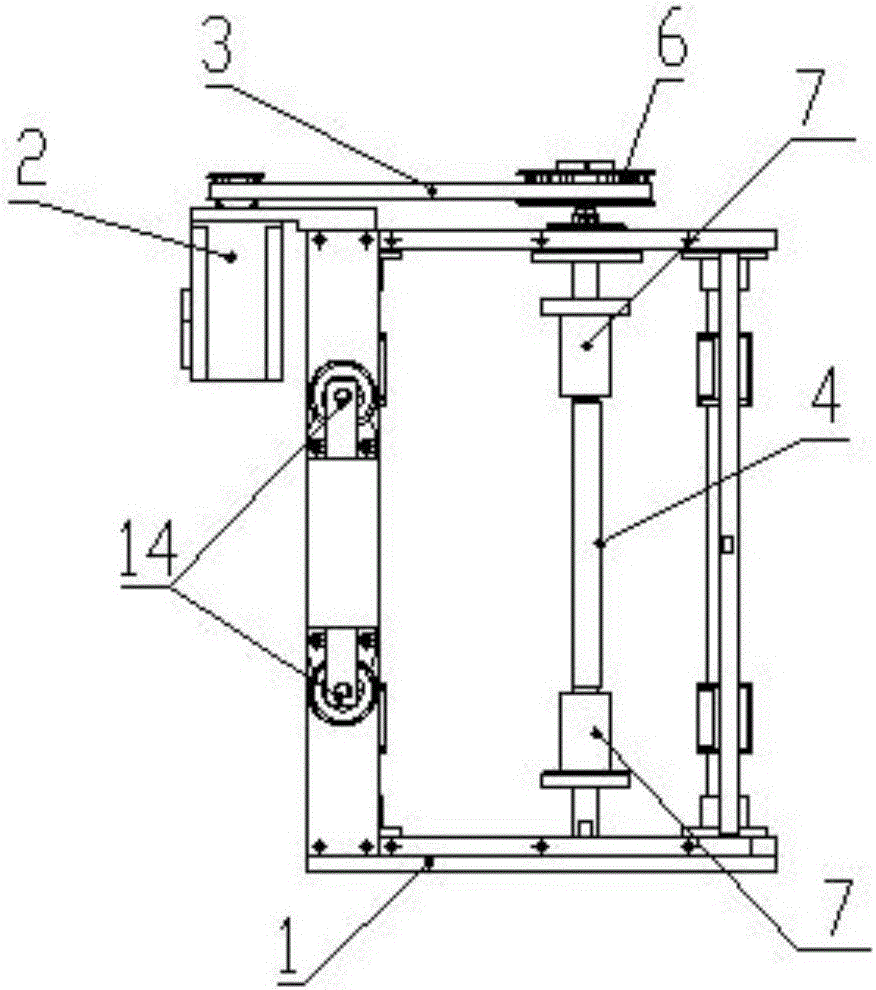

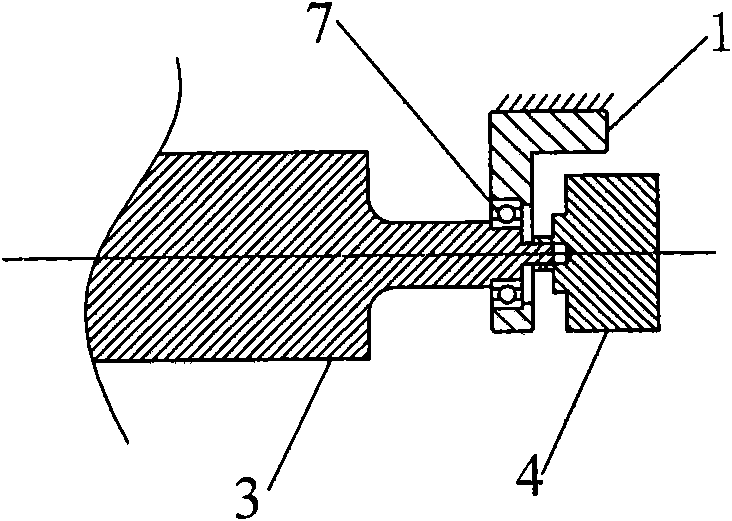

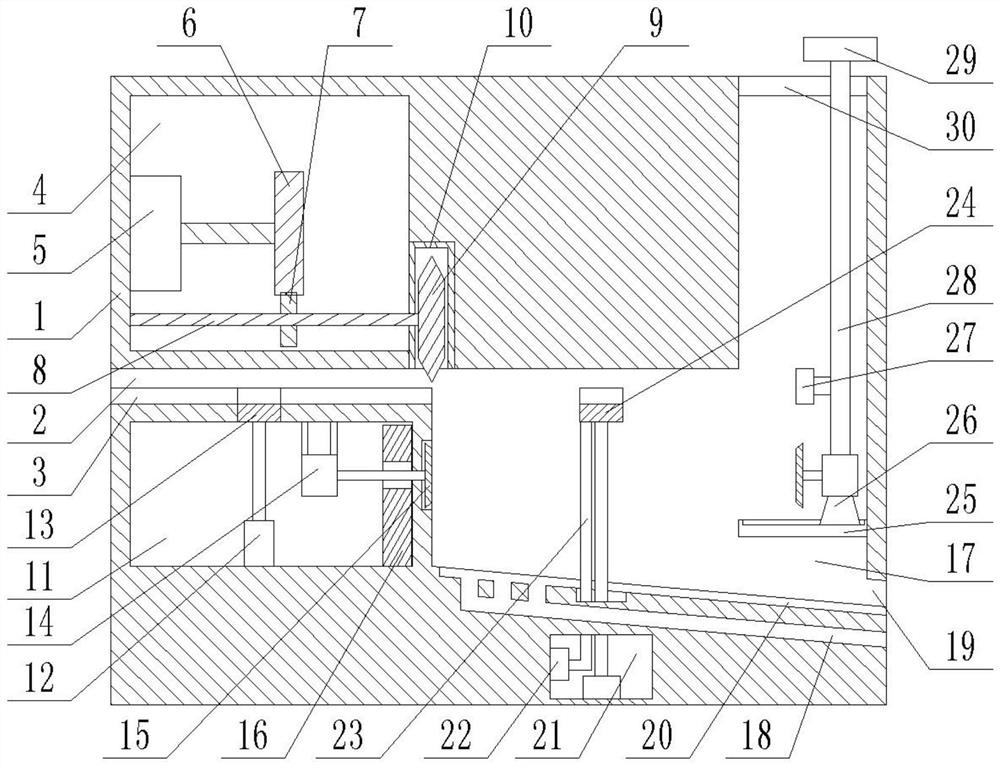

Precise and automatic cutting device and method for Teflon pipe

ActiveCN106863402AImprove length accuracyGood cut qualityMetal working apparatusEngineeringWater tanks

The invention provides a precise and automatic cutting device for a Teflon pipe. The precise and automatic cutting device comprises a base, a cooling water tank, a conveying mechanism, a clamping mechanism, a cutting mechanism, a cutting driving mechanism, a support frame, a U-shaped pipe length compensation mechanism and a rack, wherein the U-shaped Teflon pipe penetrates through the cooling water tank to be inserted into the conveying mechanism; the Teflon pipe with a fixed length is conveyed into the clamping mechanism to be clamped by the conveying mechanism; the cutting driving mechanism drives the cutting mechanism to cut the Teflon pipe in the clamping mechanism; and the U-shaped pipe length compensation mechanism drives the base to move upwards or downwards to compensate the length of the Teflon pipe which is inserted into the cooling water tank. The invention further discloses a precise and automatic cutting method for the Teflon pipe. The precise and automatic cutting method comprises the following method of A, preparing; B, inserting; C, compensating; D, conveying for clamping and outputting; E, rotating; F, cutting and resetting; G releasing; H re-conveying, ejecting-out, re-outputting and re-clamping; and returning to the step F for cutting repeatedly. By adopting the precise and automatic cutting device and method, the length precision of the cut pipes can be effectively improved; and phenomena of pipe bending or flattening are reduced or even eradicated.

Owner:南通正耀电气科技有限公司

Coating length measuring device

ActiveCN101728516AImprove length accuracyReduce measurement errorLiquid surface applicatorsCell electrodesMeasurement deviceTransducer

The invention discloses a coating length measuring device which is used for measuring the coating or / and interval length of the pole piece and the alignment length of the front side and the back side. The coating length measuring device comprises a bracket, a discharge glue roller and a first drum, wherein the discharge glue roller and the first drum are respectively rotatably connected with the bracket and are parallel to each other; two line linear optical fiber sensors are oppositely arranged between the discharge glue roller and the first drum; the linear optical fiber sensors are respectively and electrically connected with a processor; and the processor determines the coating or / and interval length and the alignment length of the front side and the back side according to the signal time difference between the input opening interruption and the closing interruption of the linear optical fiber sensors as well as the length electric signal of the rotary encoder. By utilizing the linear optical fibers, the invention can prevent the measurement data error when the pole piece coating trailings occur. Meanwhile, the coating or / interval length and the alignment length of the front side and the back side can be directly obtained because of adopting a rotary transducer, thereby reducing the error and enhancing the precision of the coating or / interval length and the alignment length of the front side and the back side.

Owner:SHENZHEN NEW KATOP AUTOMATION TECH

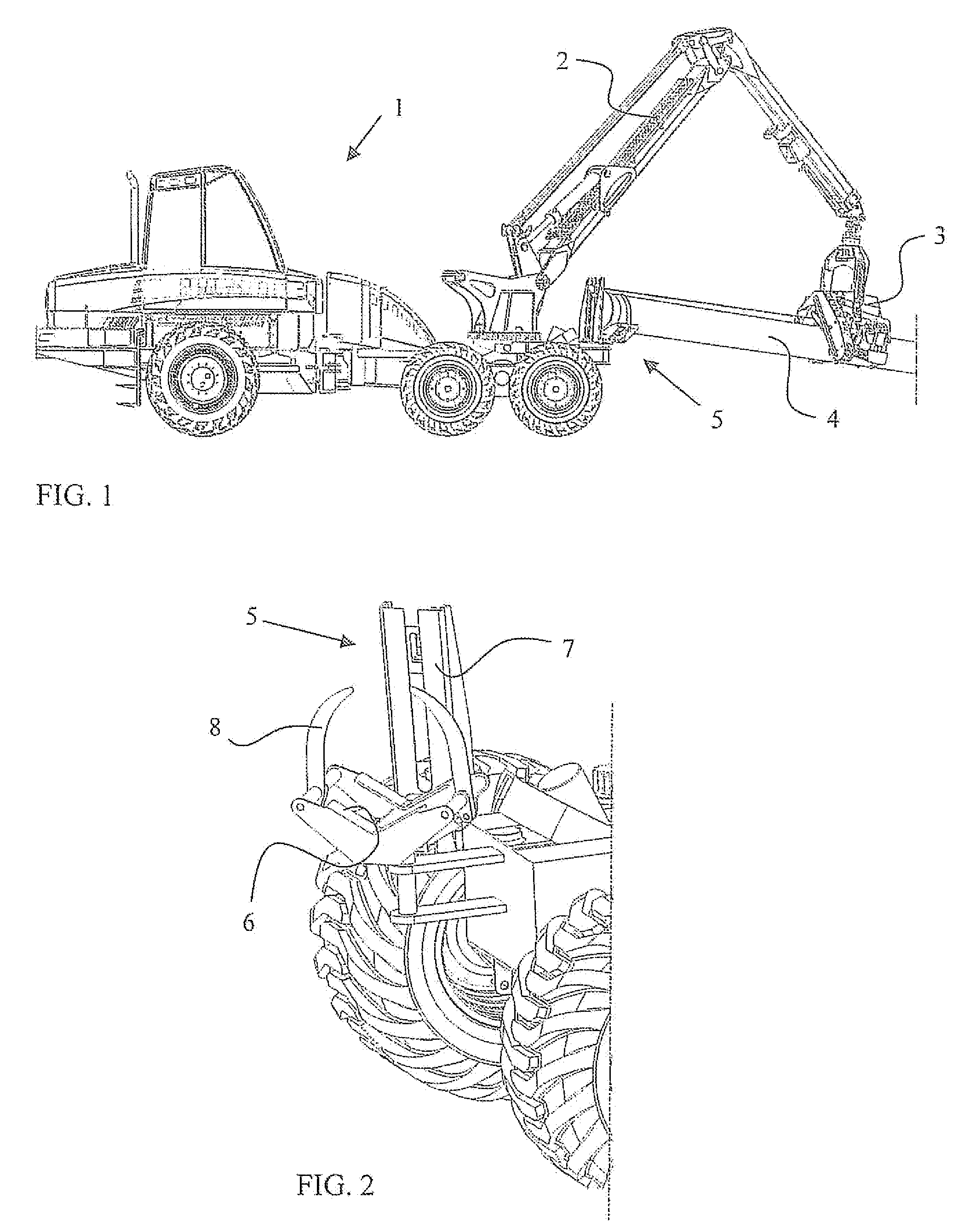

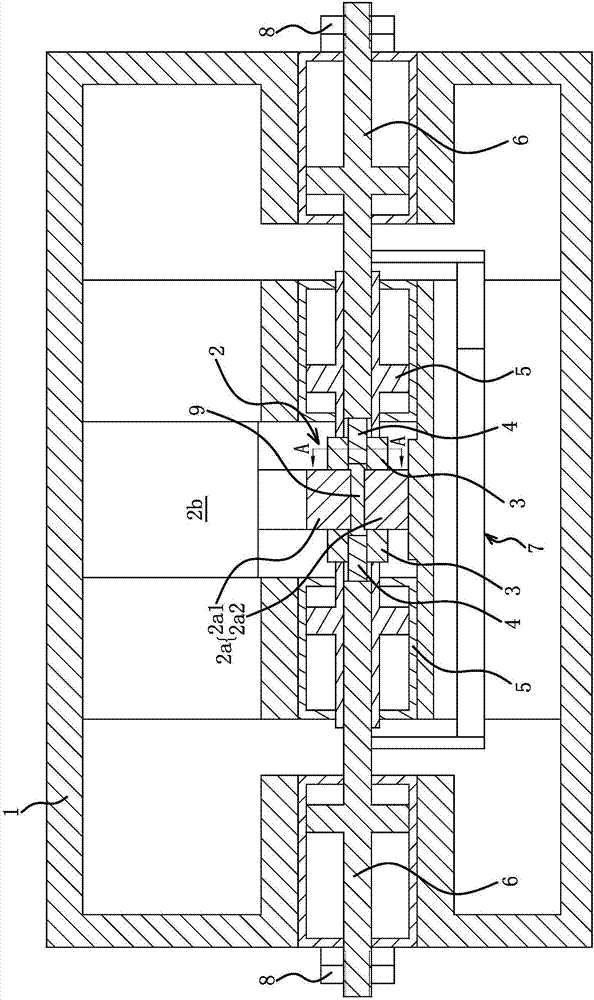

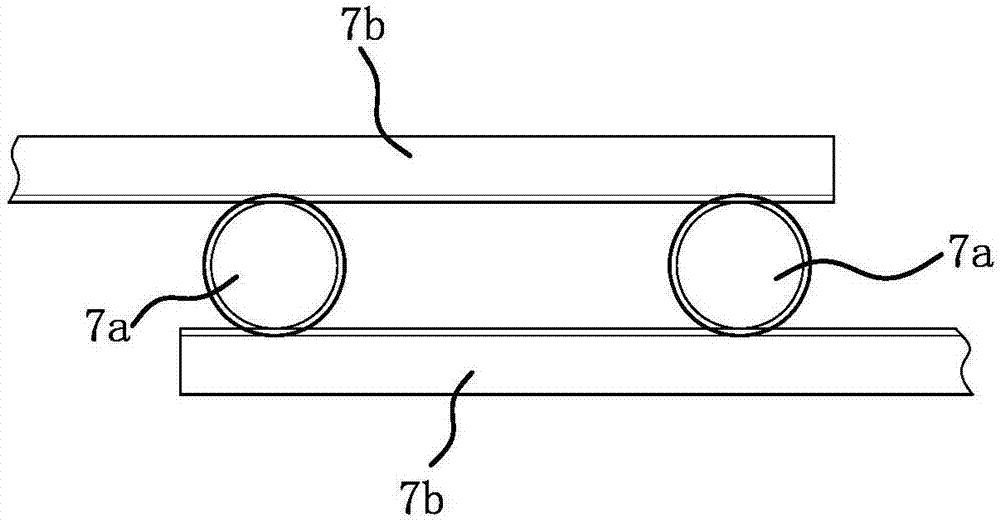

Pipe Assembly Unit With Built-In Flow Sensors

ActiveUS20070044574A1Improve versatilityEasy to optimizeLighting and heating apparatusCentral heating componentsFlow transducerEngineering

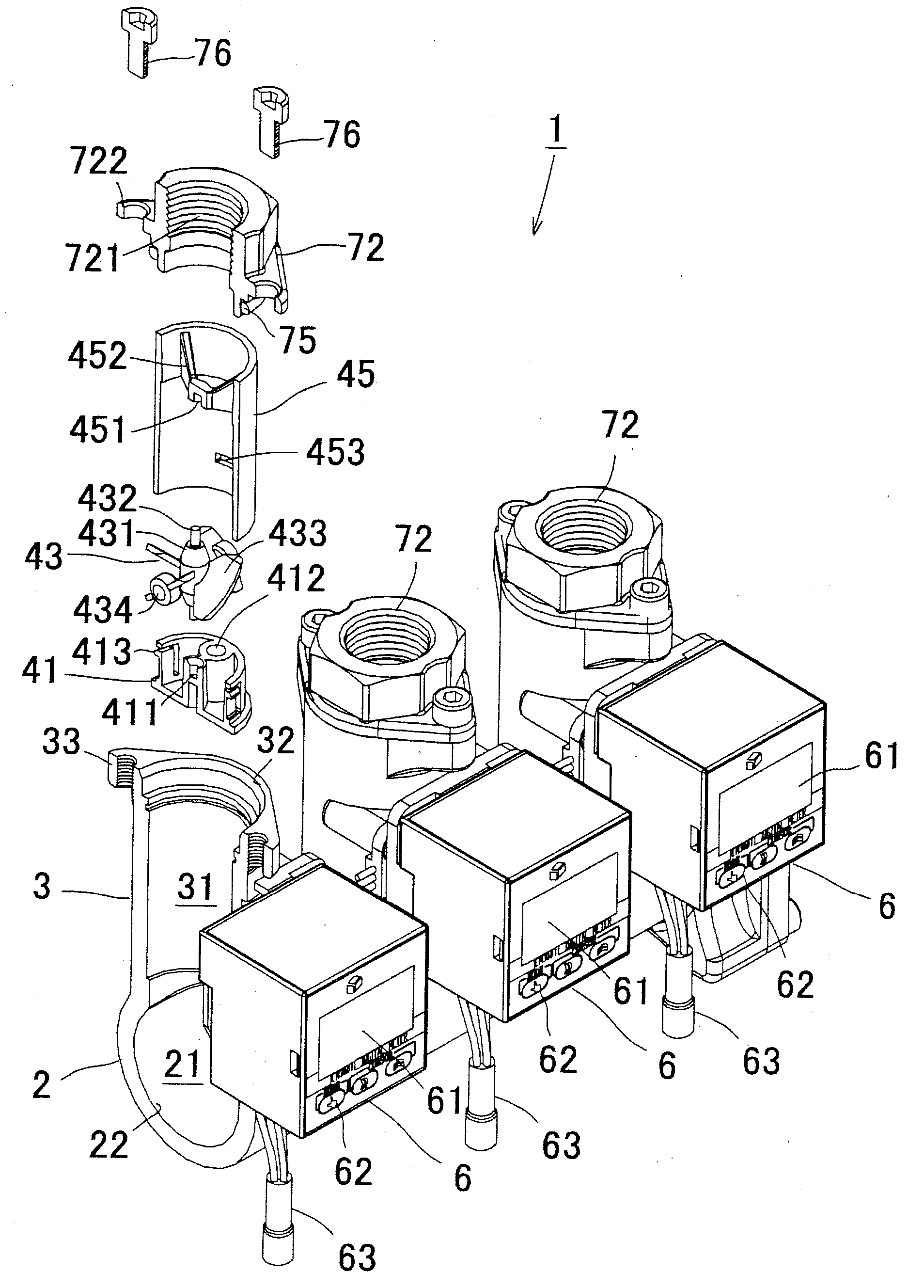

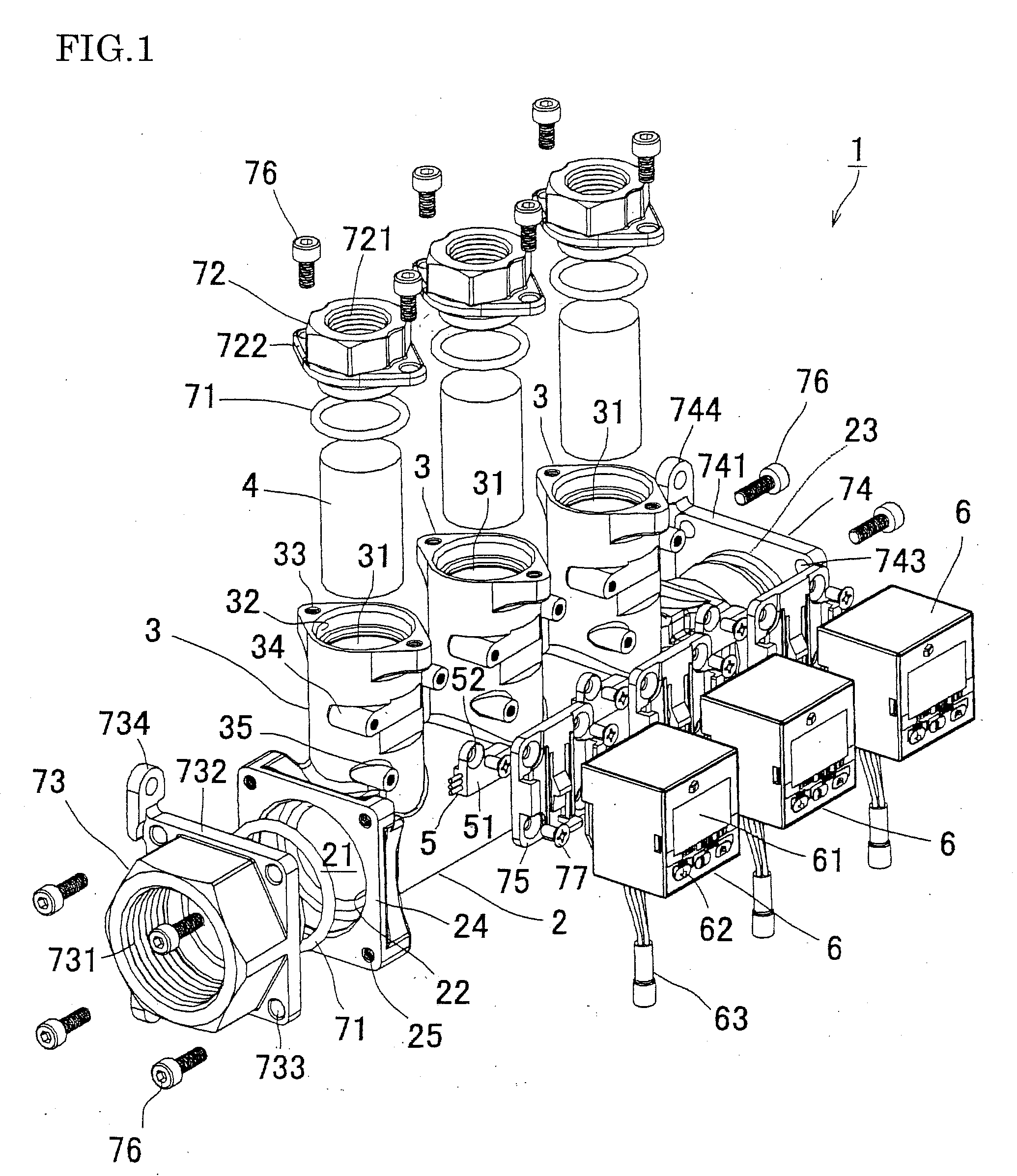

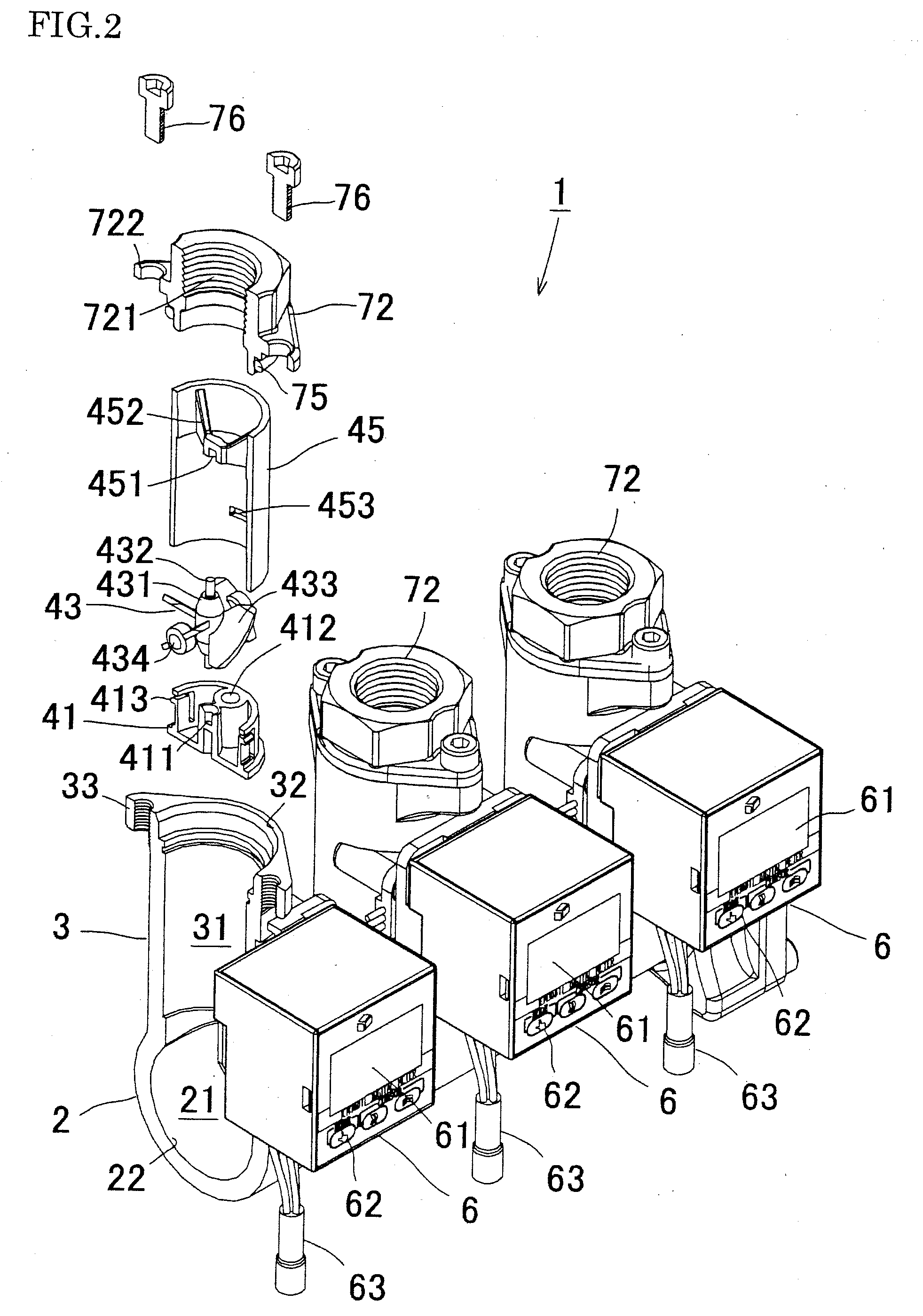

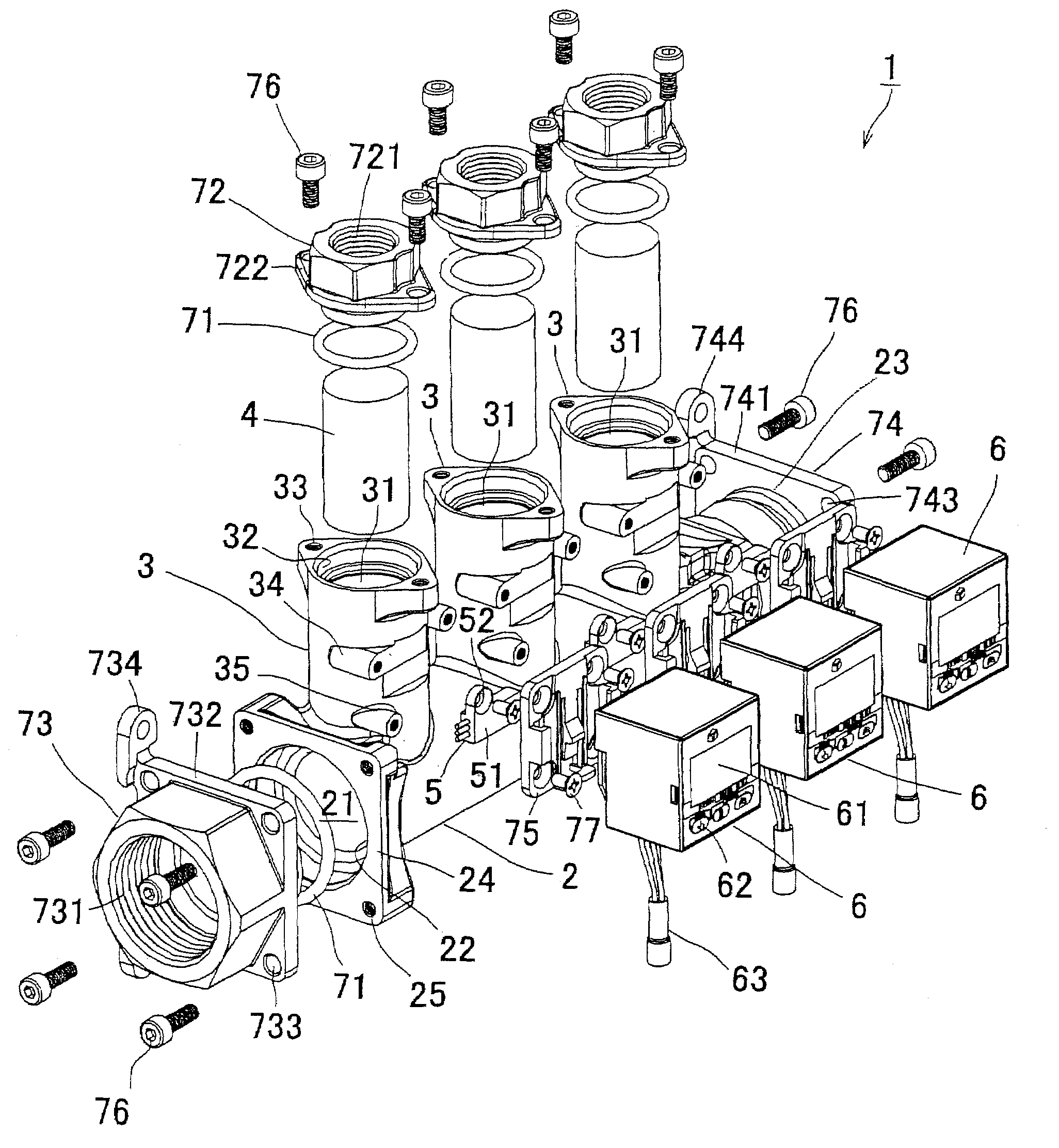

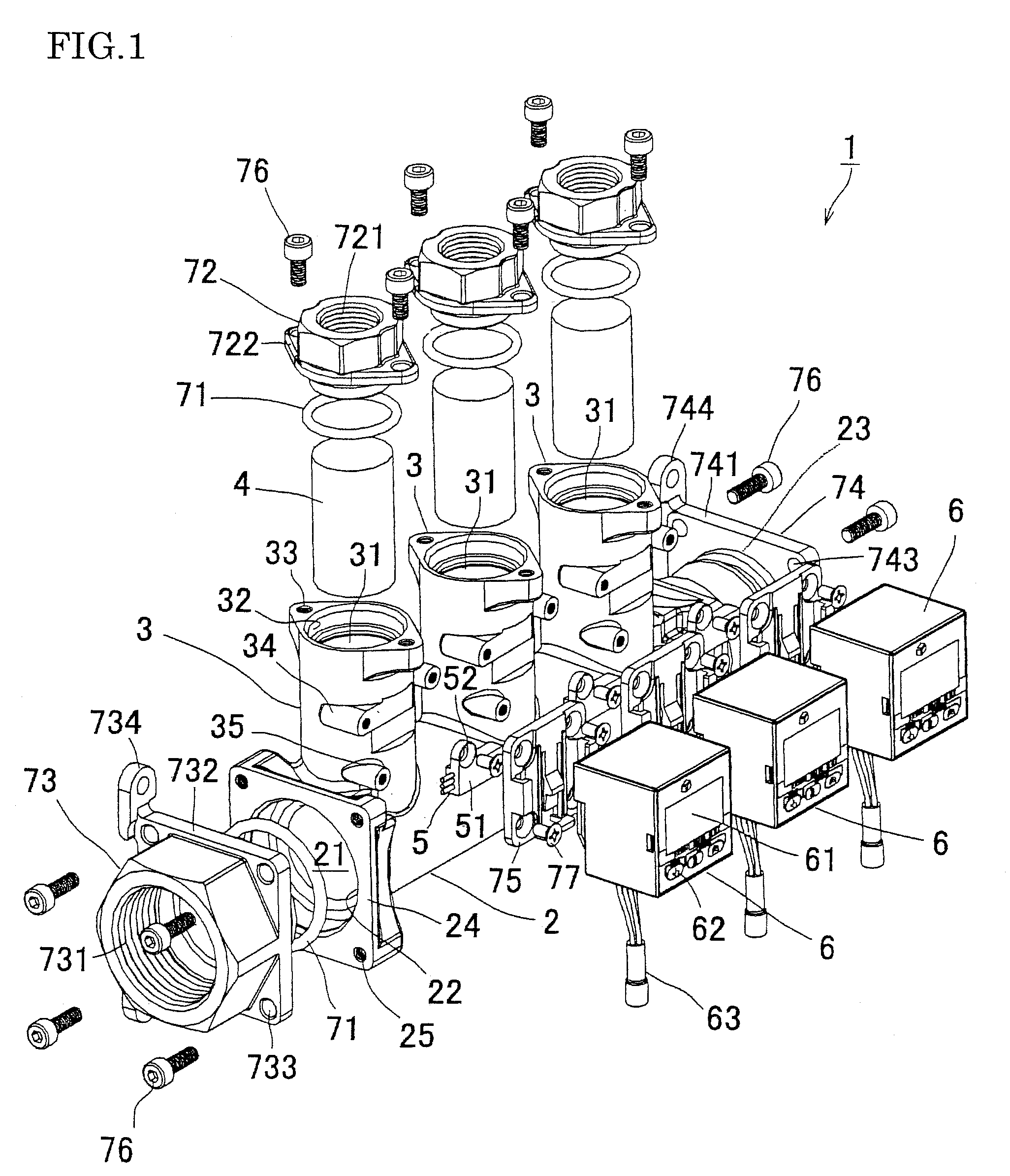

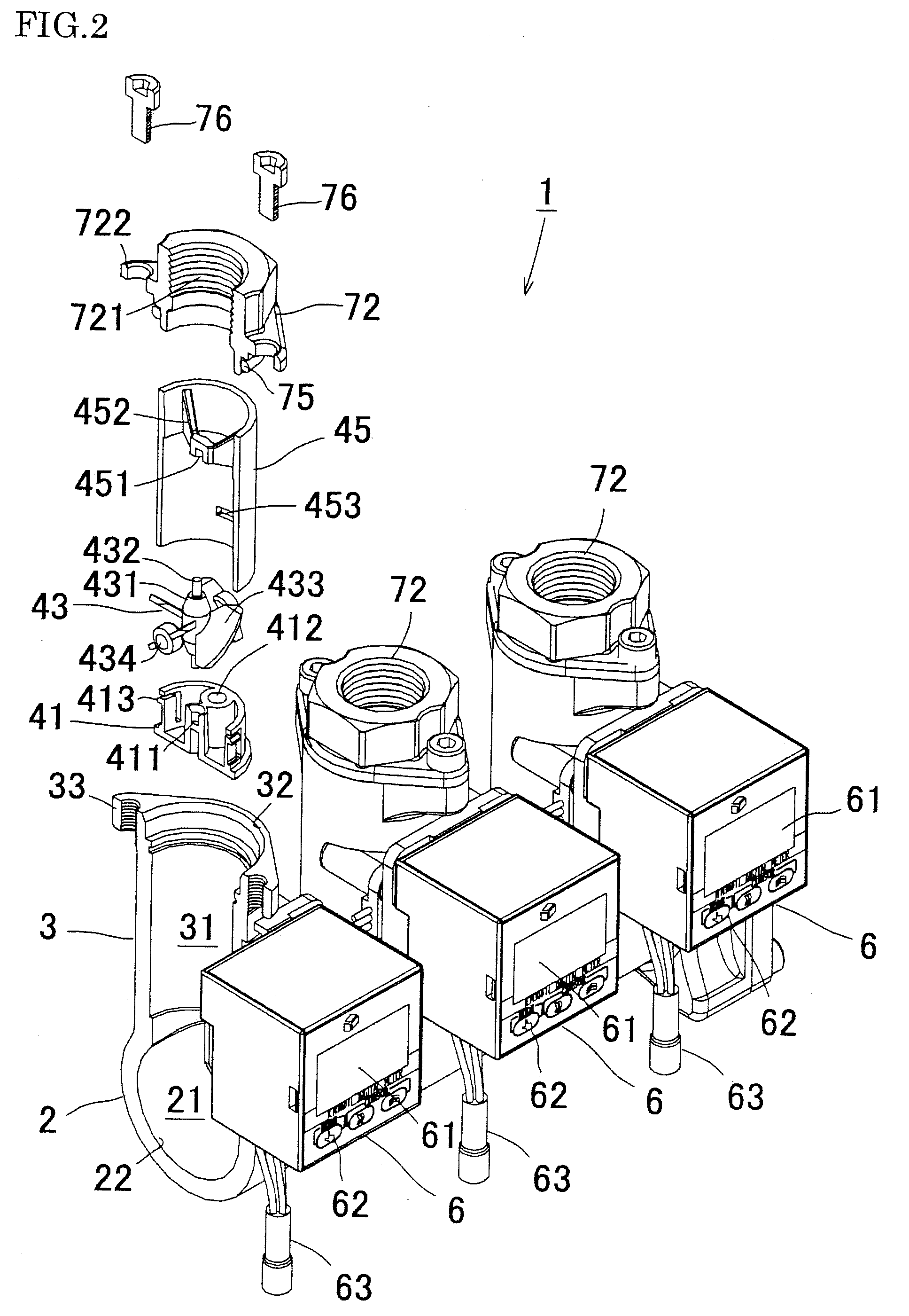

Cost is reduced by simplifying piping work and reducing the number of parts. At the same time, the degree of freedom in the arrangement of piping is raised by making the mounting posture of the piping variable. A pipe assembly unit with built-in sensors 1 is fabricated by integrating a main pipe 2 and multiple branch pipes 3, 3, . . . which branch from the main pipe 2 and by building, in the multiple branch pipes 3, 3, . . . , a flow sensor 4 which detects the flow rate of a fluid flowing through a conduit 31 of each of the branch pipes 3, and the use of a conventional seal construction using a nipple in connections between the main pipe 2 and the branch pipes 3 is abolished. A pipe adapter 73 having legs 734 is detachably attached to opening ends of the main pipe 2 and the legs 734 are fixed to an installation surface A by changing the orientation of the pipe adapter 73, whereby the mounting posture of the pipe assembly unit 1 is made variable.

Owner:TOFLO CORP

Pipe assembly unit with built-in flow sensors

ActiveUS7225685B2Avoid troubleReduce in quantityLighting and heating apparatusCentral heating componentsGuide tubeMass flow sensor

Cost is reduced by simplifying piping work and reducing the number of parts. At the same time, the degree of freedom in the arrangement of piping is raised by making the mounting posture of the piping variable. A pipe assembly unit with built-in sensors is fabricated by integrating a main pipe and multiple branch pipes, which branch from the main pipe and by building, in the multiple branch pipes a flow sensor which detects the flow rate of a fluid flowing through a conduit of each of the branch pipes, and the use of a conventional seal construction using a nipple in connections between the main pipe and the branch pipes is abolished. A pipe adapter having legs is detachably attached to opening ends of the main pipe and the legs are fixed to an installation surface A by changing the orientation of the pipe adapter, whereby the mounting posture of the pipe assembly unit is made variable.

Owner:TOFLO CORP

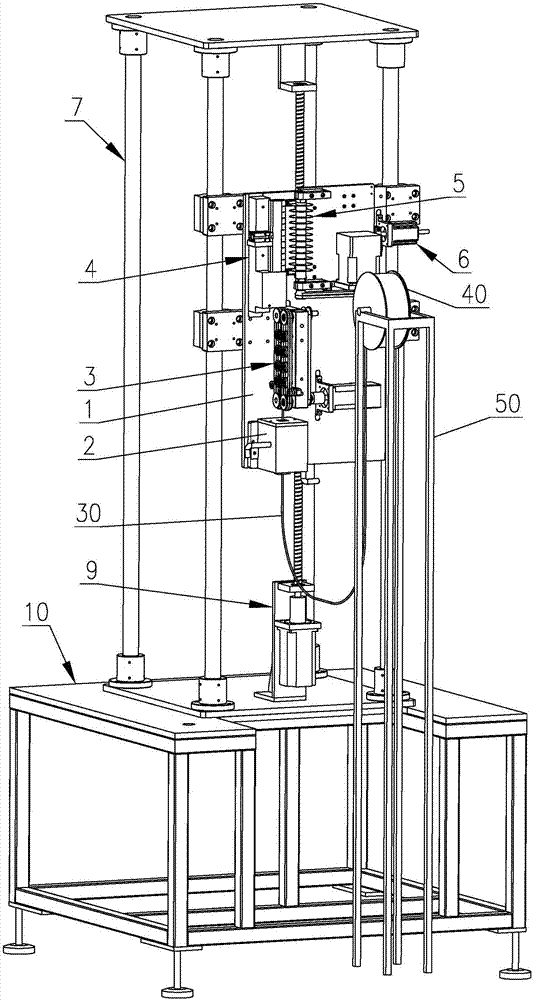

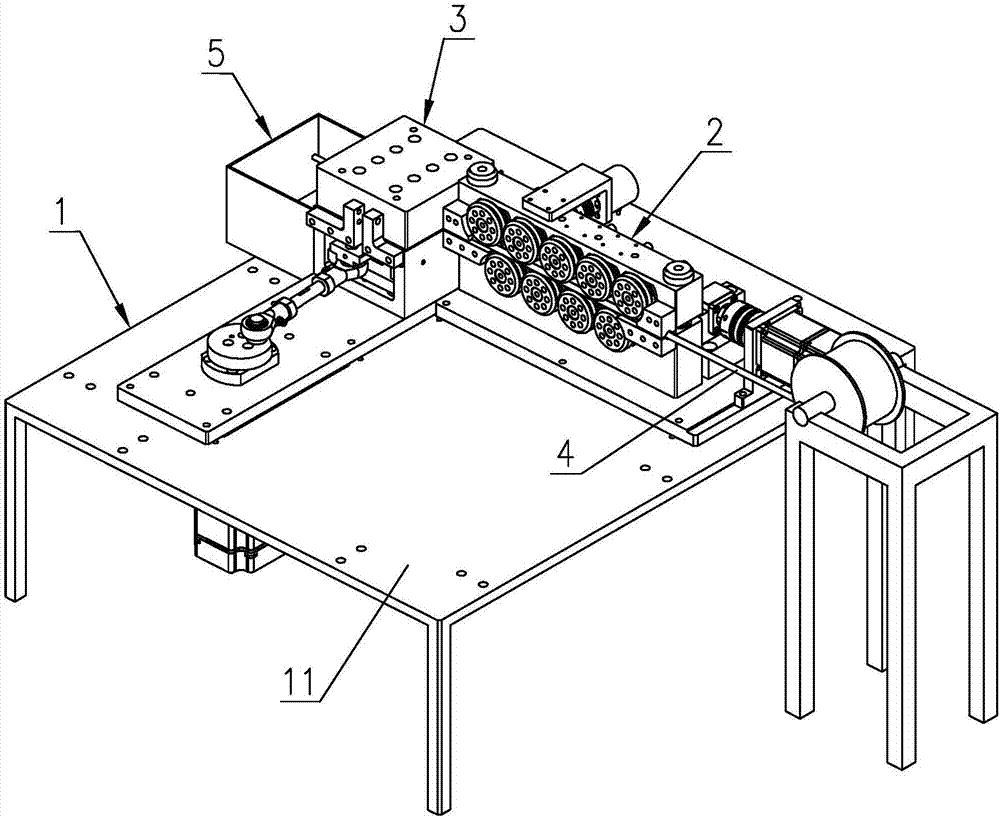

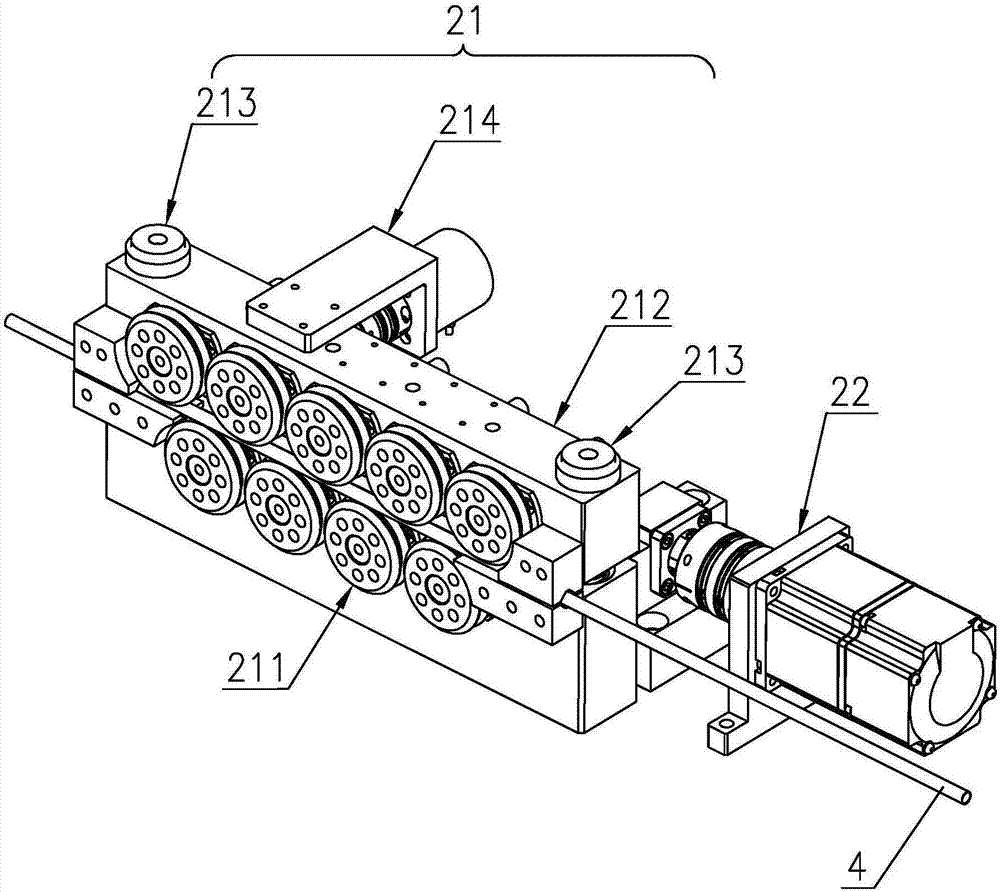

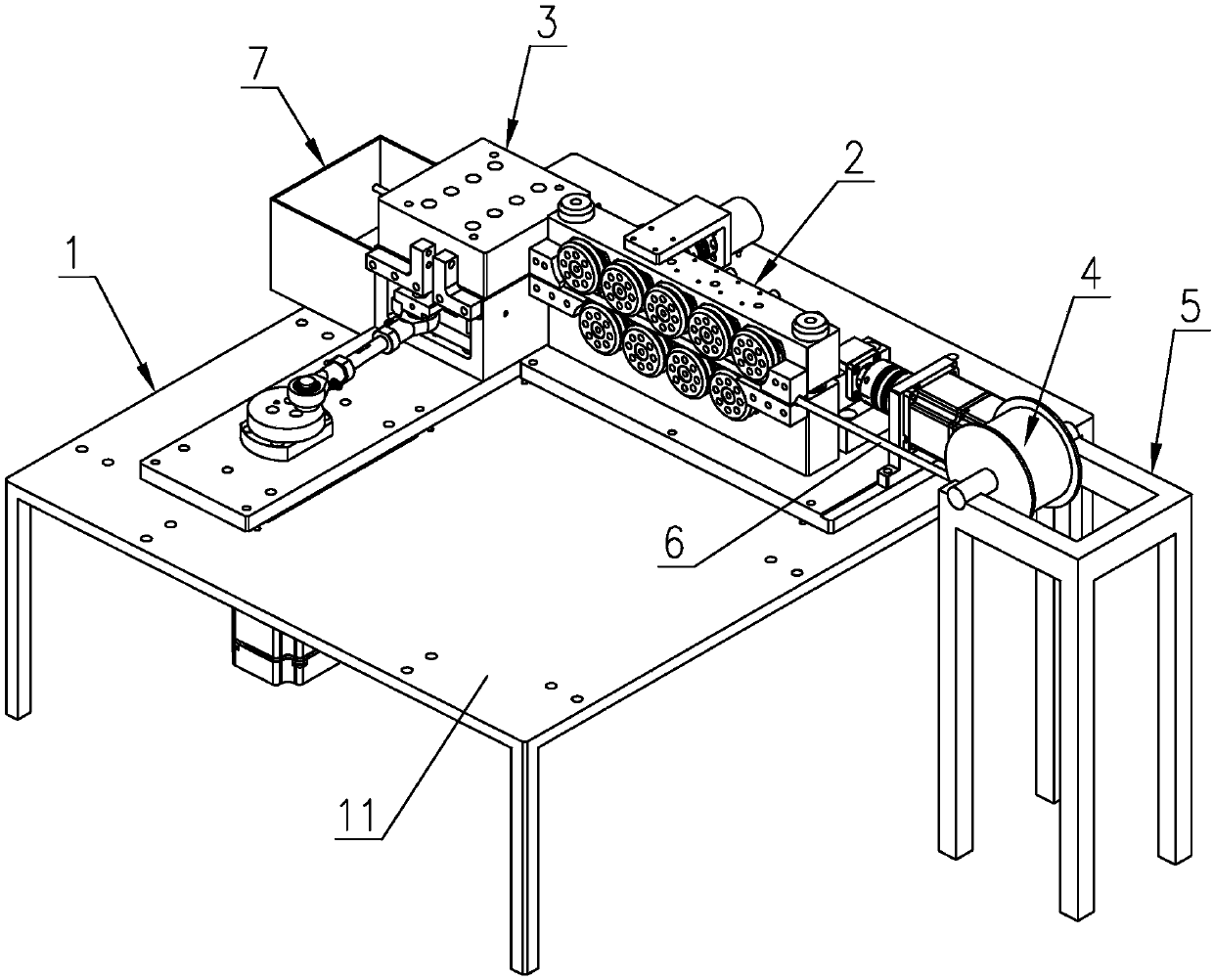

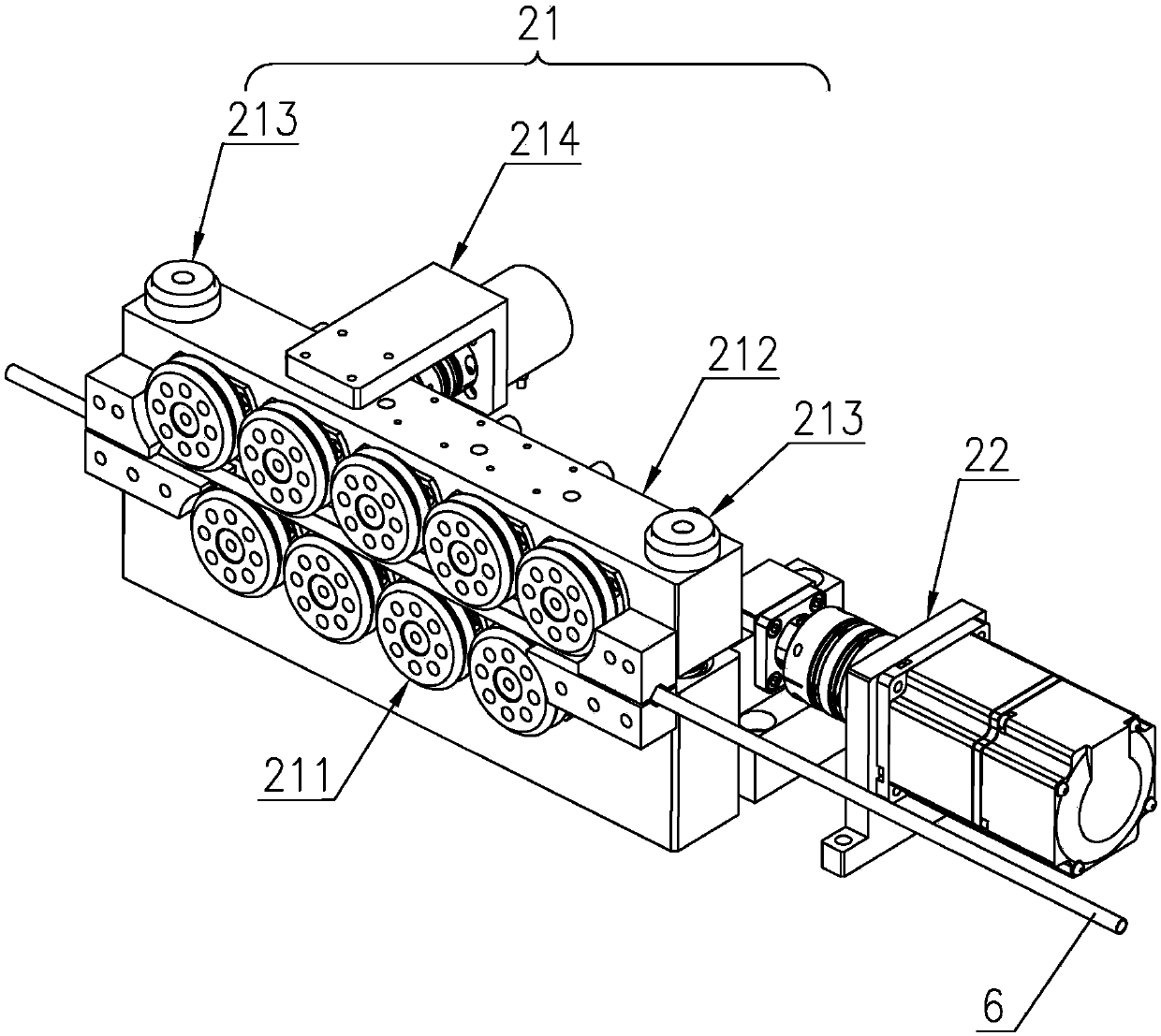

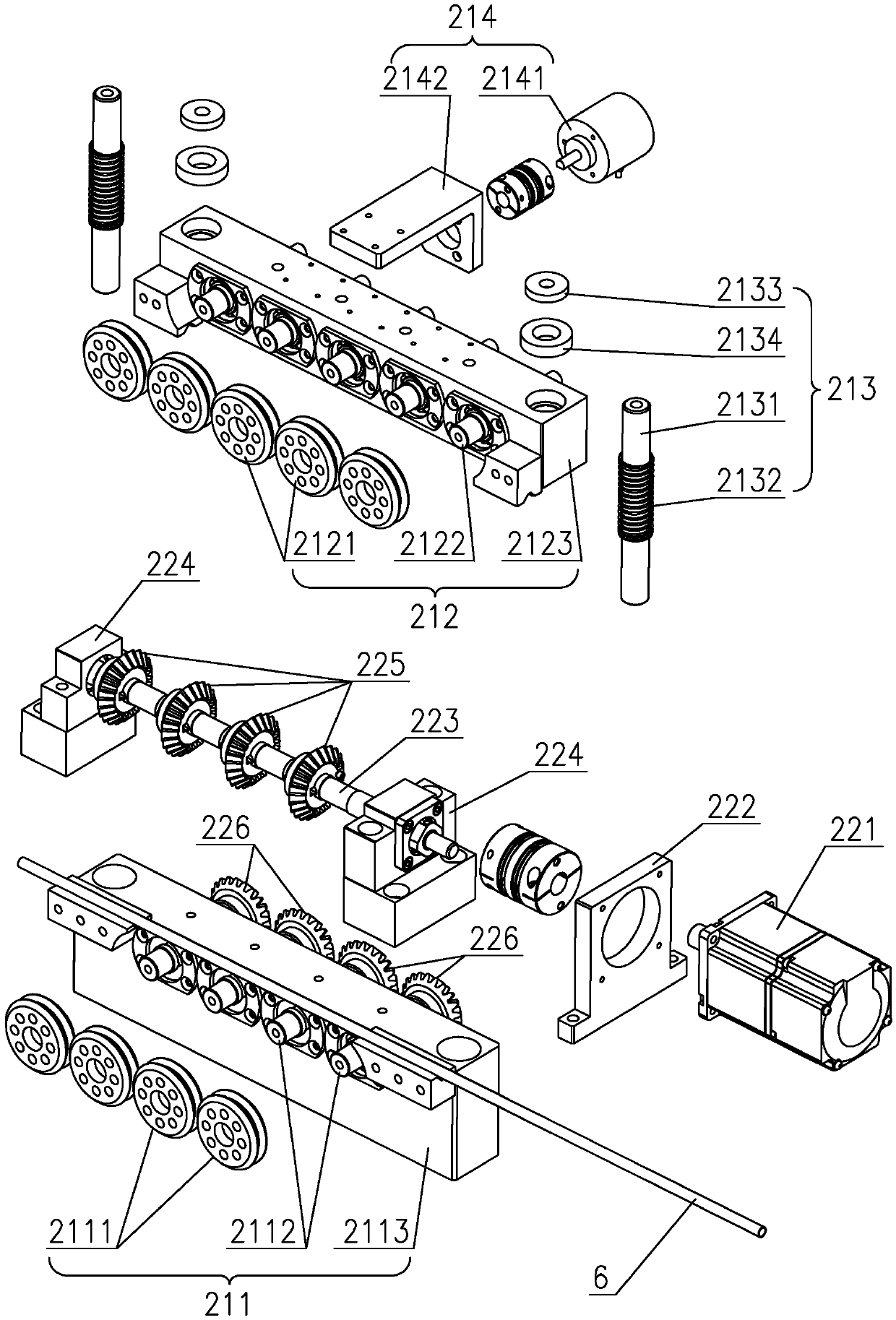

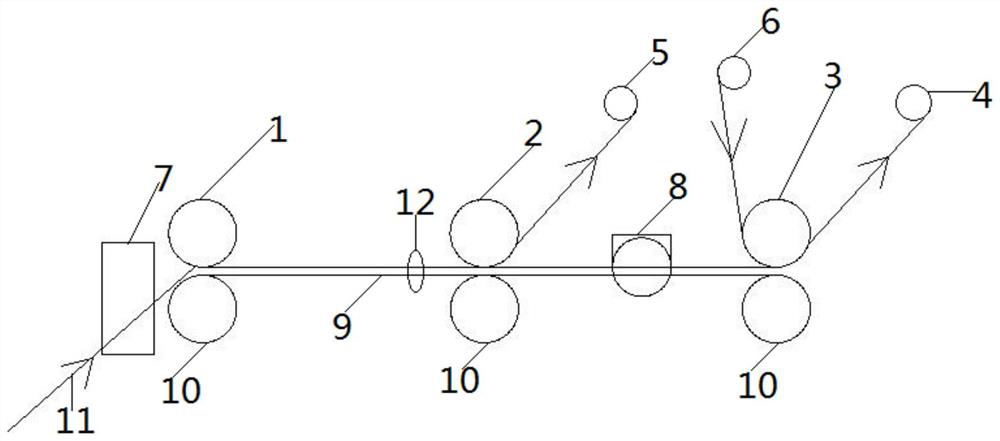

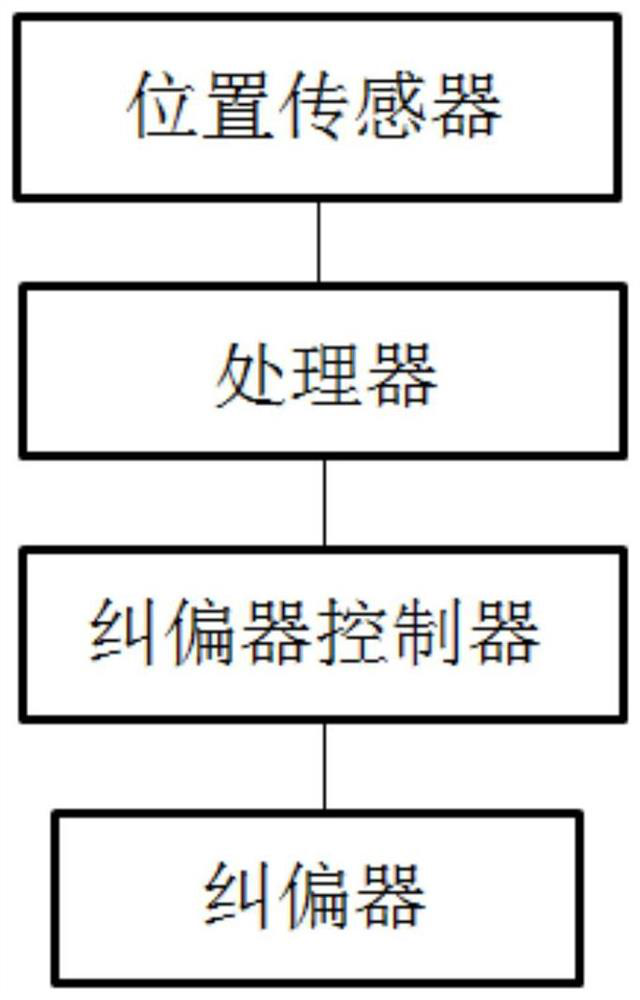

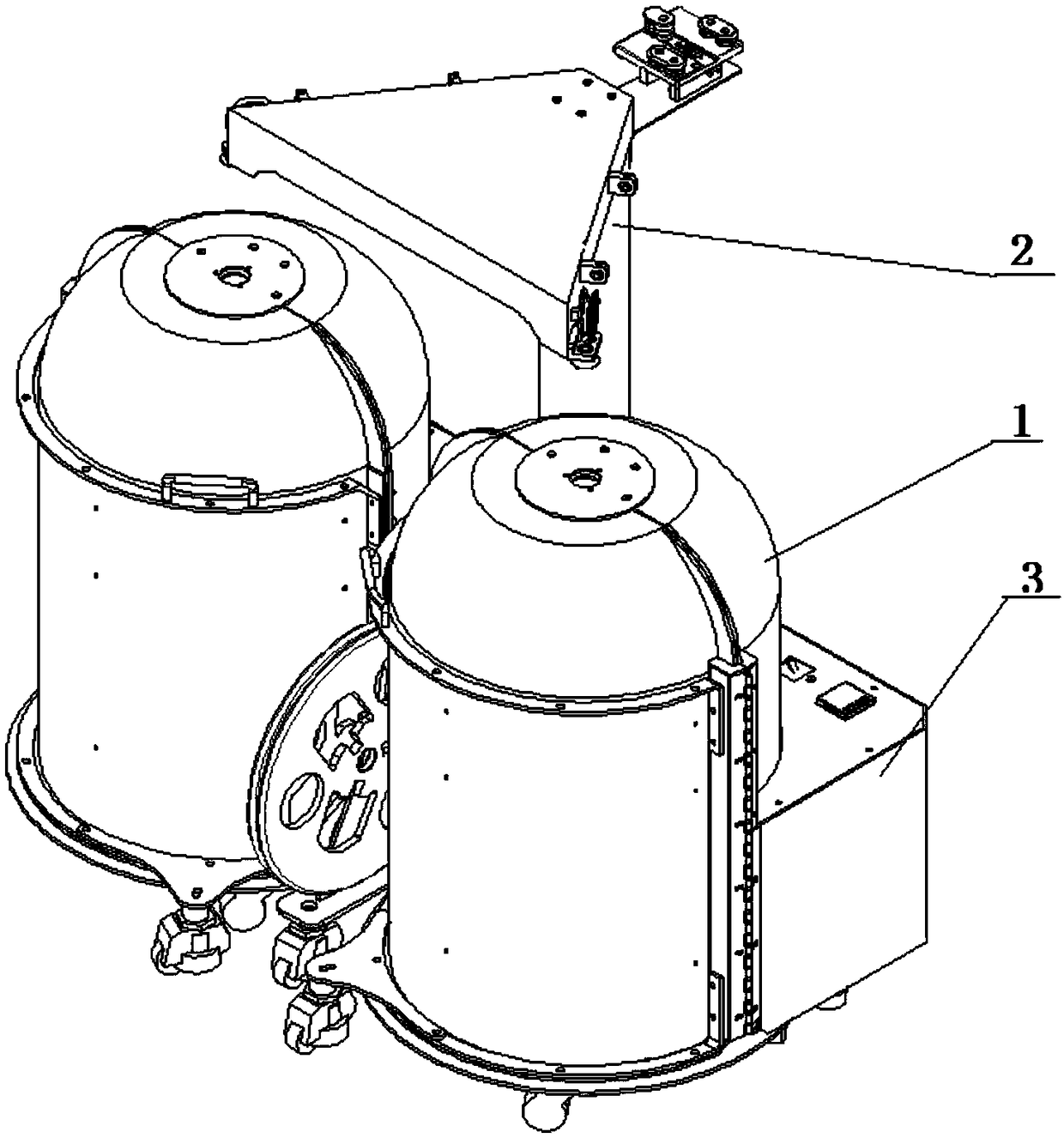

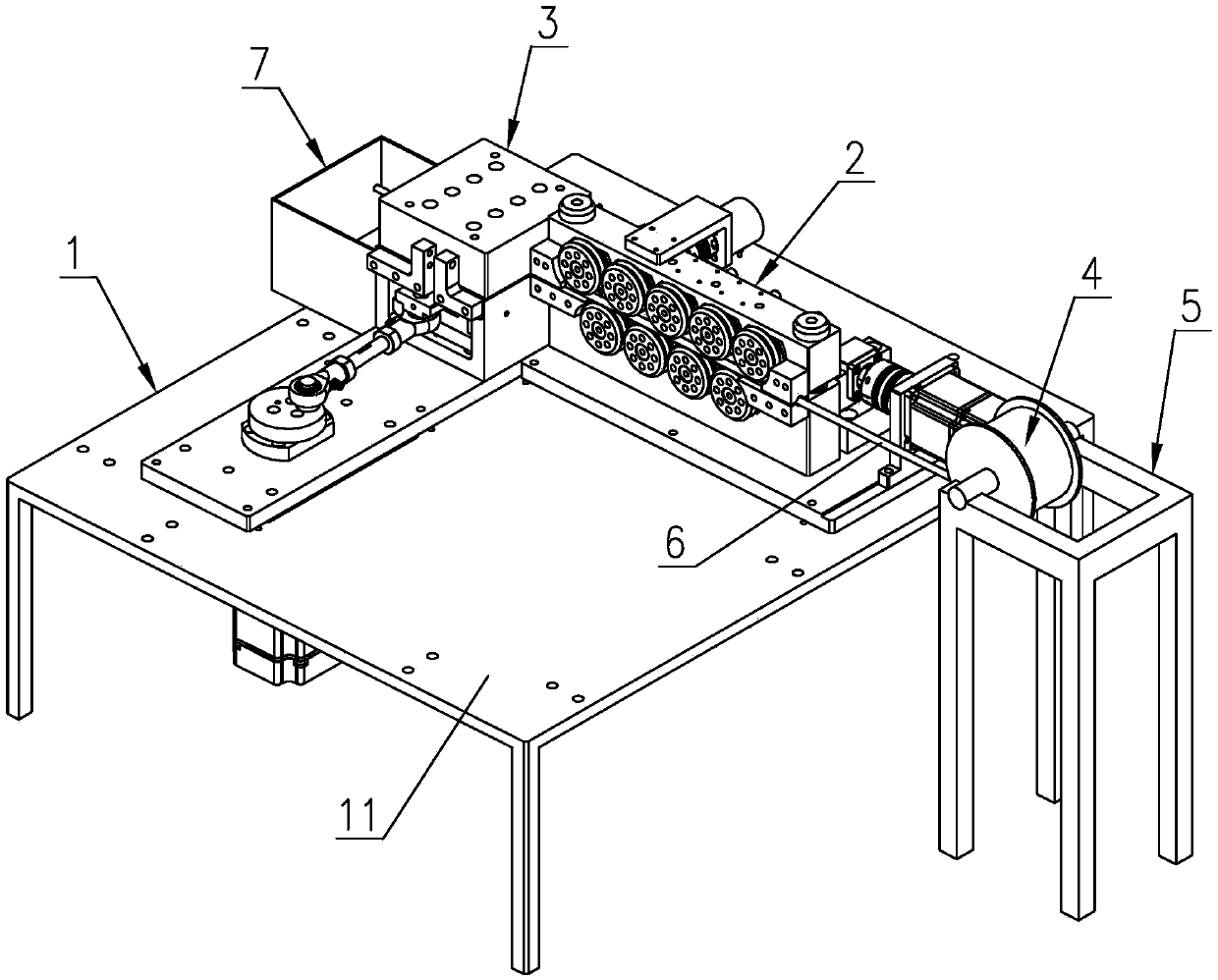

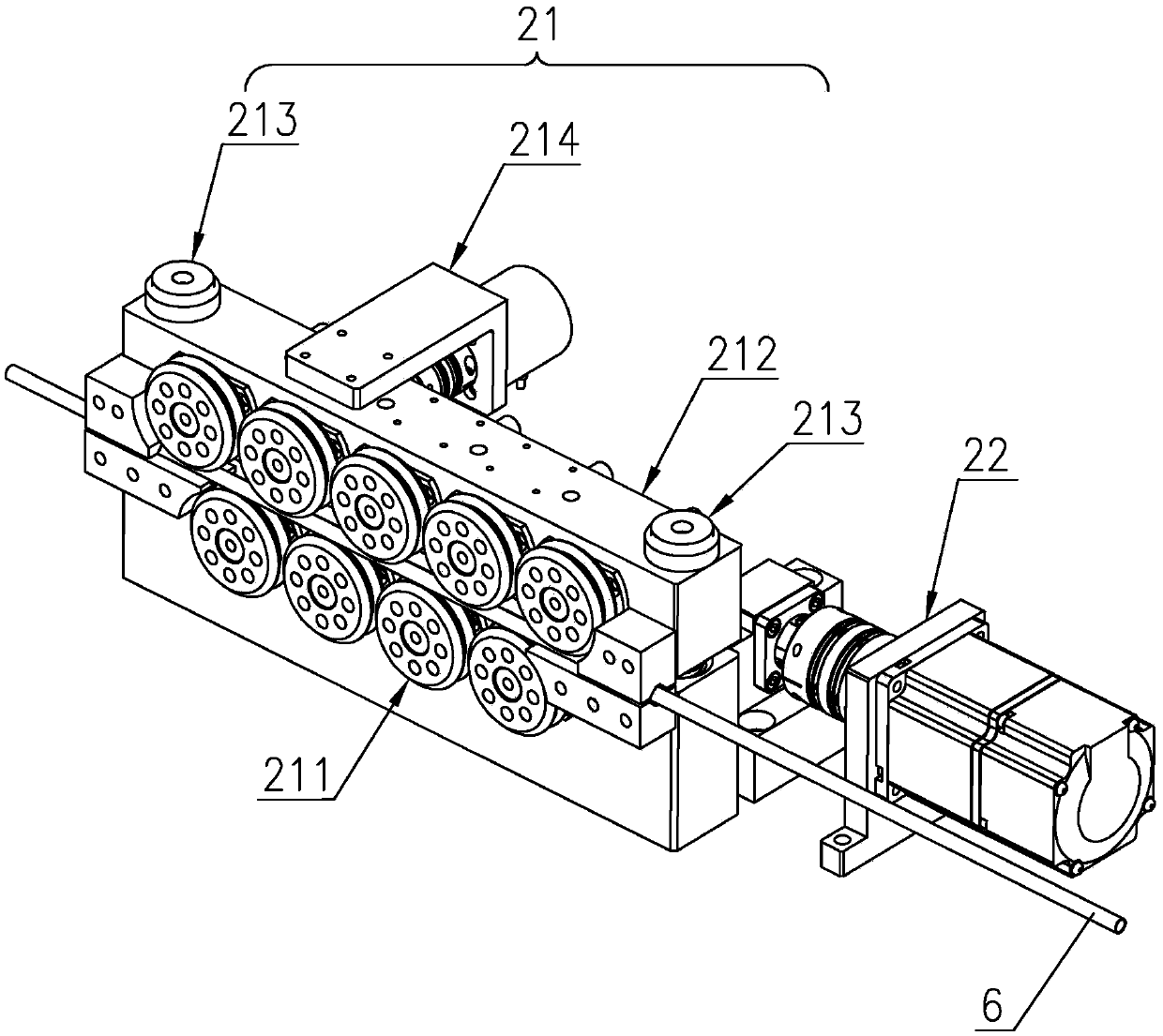

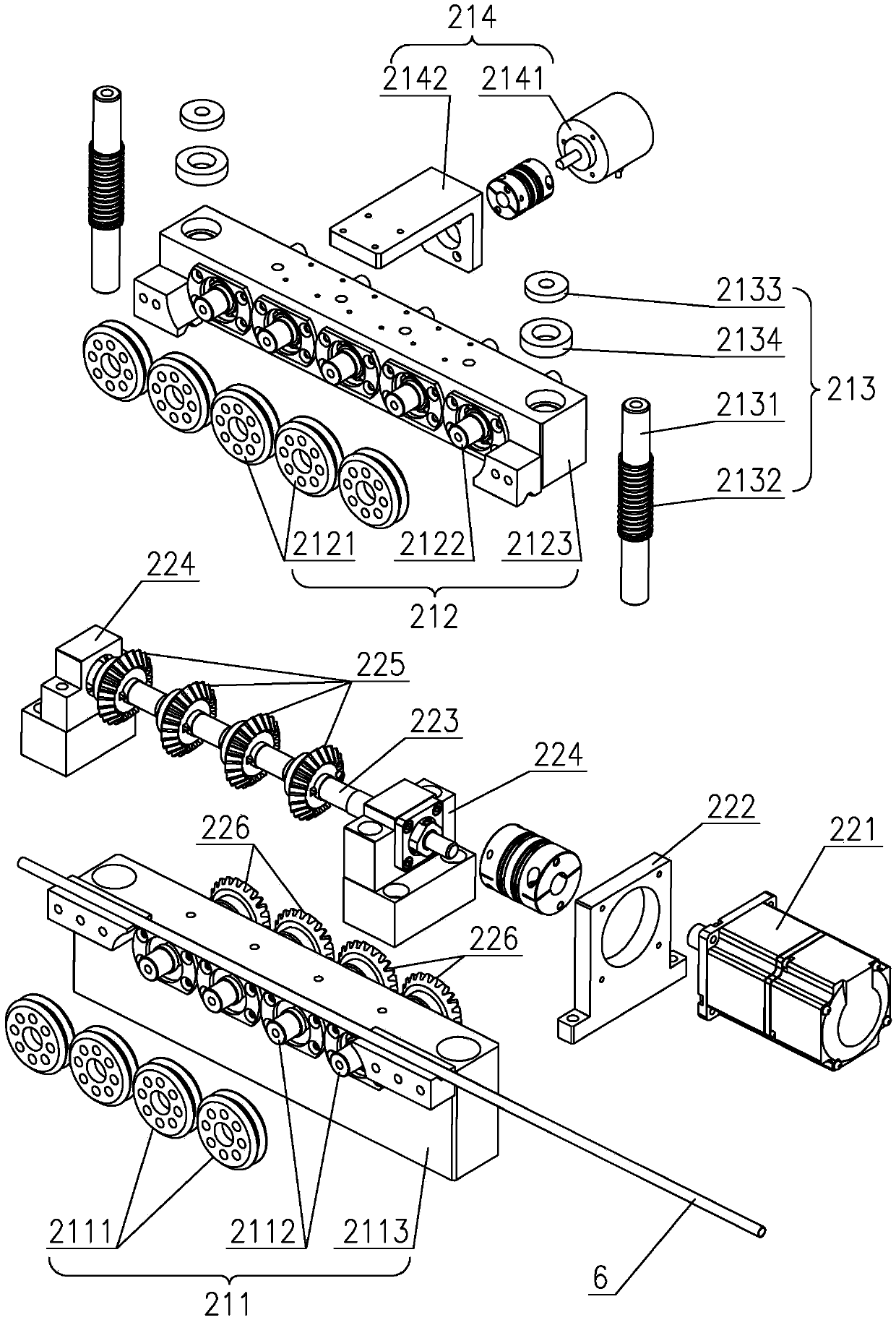

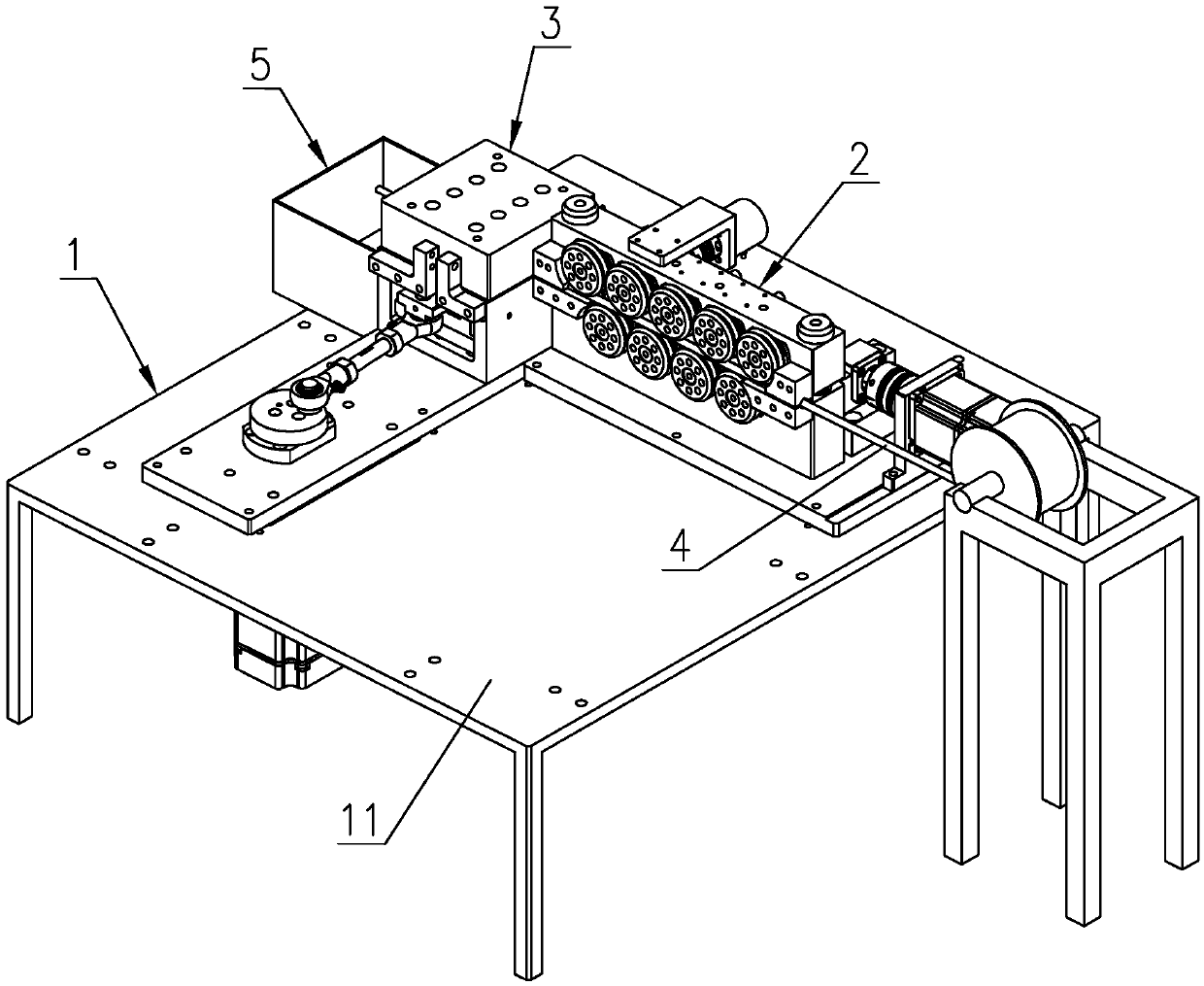

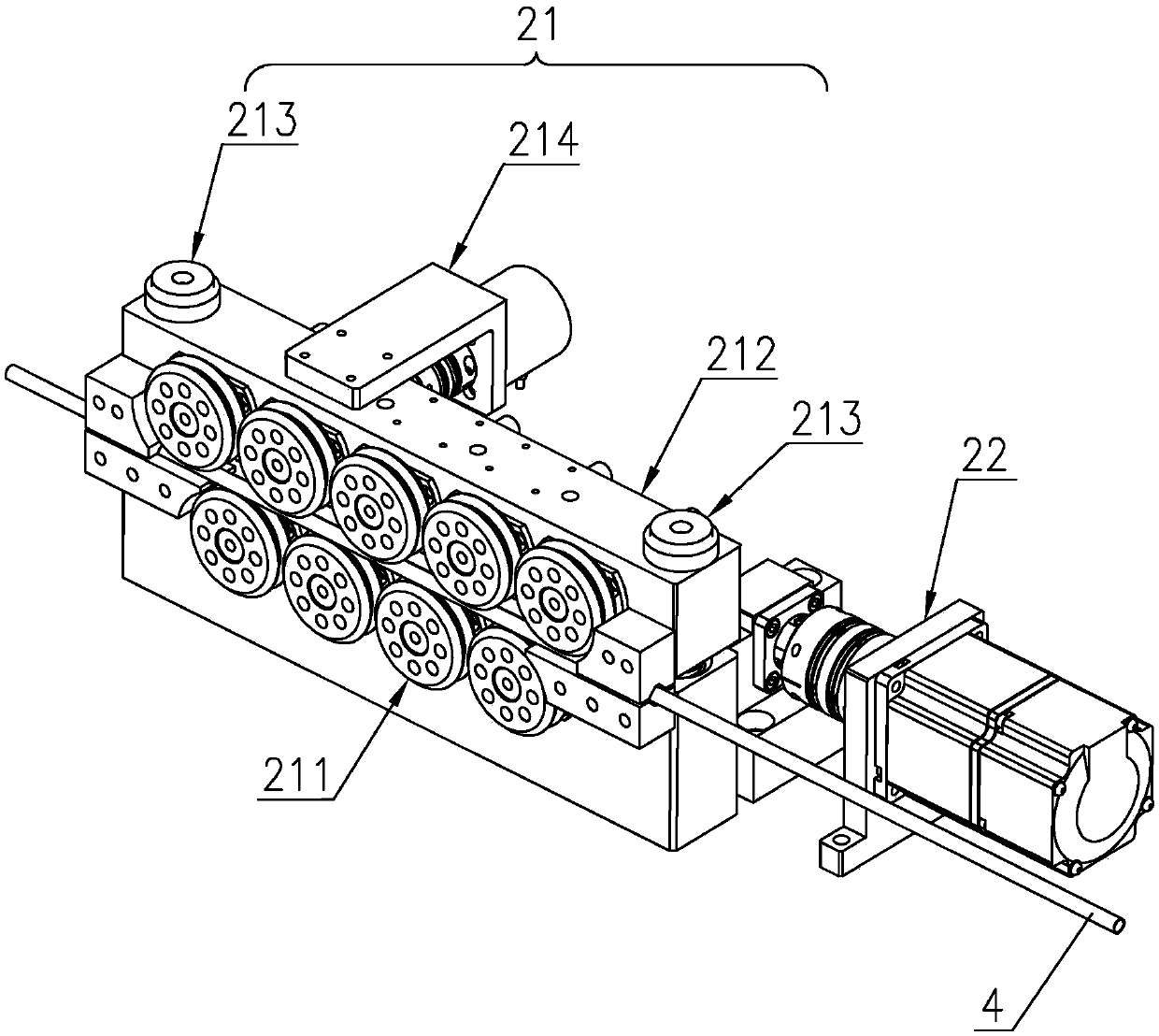

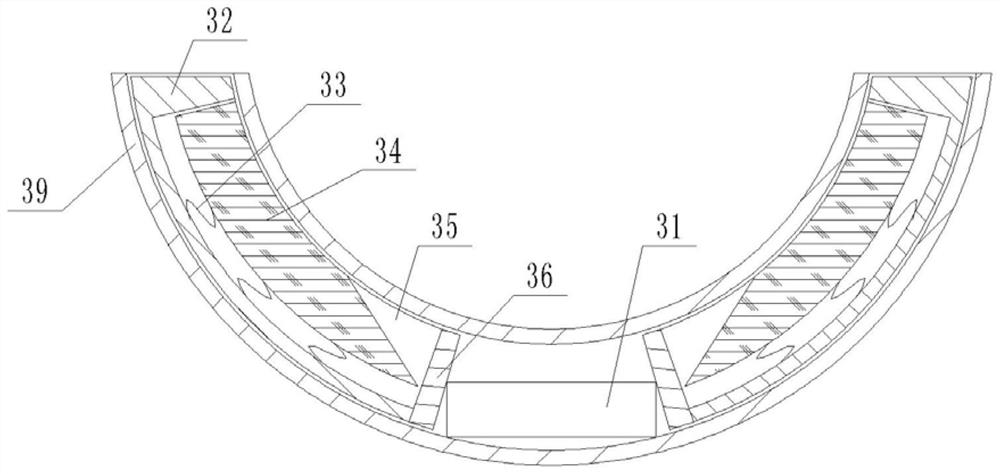

Teflon pipe precise cutting equipment and method

ActiveCN107877560AImprove length accuracyImprove cut qualityMetal working apparatusBiomedical engineeringFixed length

The invention provides teflon pipe precise cutting equipment. The teflon pipe precise cutting equipment comprises a rack (1), a teflon pipe conveying device (2) and a teflon pipe cutting device (3); and the rack (1) is provided with a rack table face (11); the teflon pipe conveying device (2) and the teflon pipe cutting device (3) are installed on the rack table face (11), the teflon pipe conveying device (2) conveys a teflon pipe in fixed length to enable the teflon pipe to enter the teflon pipe cutting device (3) to be cut off, and the teflon pipe is conveyed into a collecting box (5). The invention further provides a teflon pipe precise cutting method. By means of the teflon pipe precise cutting equipment and method, the precision of the length of the cut pipe can be effectively improved, the cutting notch quality is good, and the pipe bending or flattening condition can be reduced even eliminated.

Owner:上海伊川水塑料制品有限公司

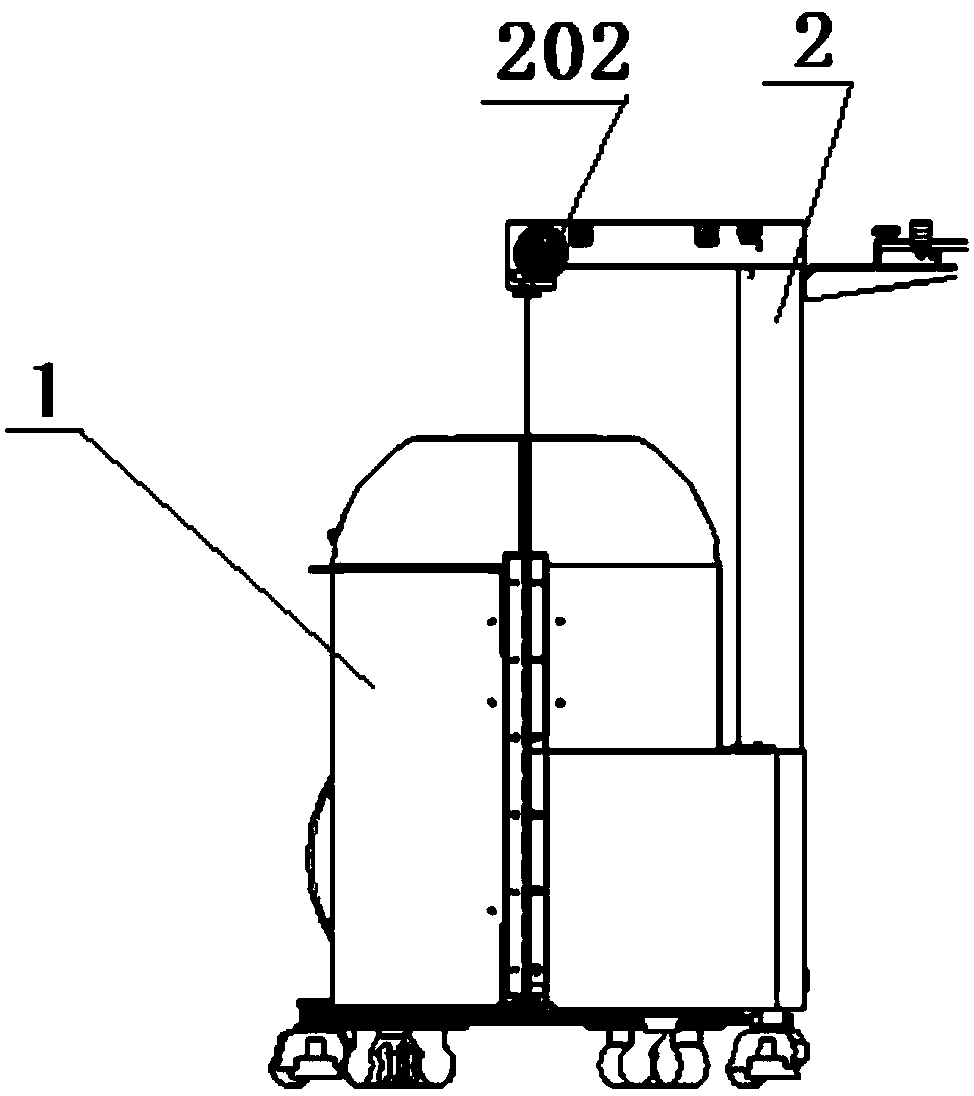

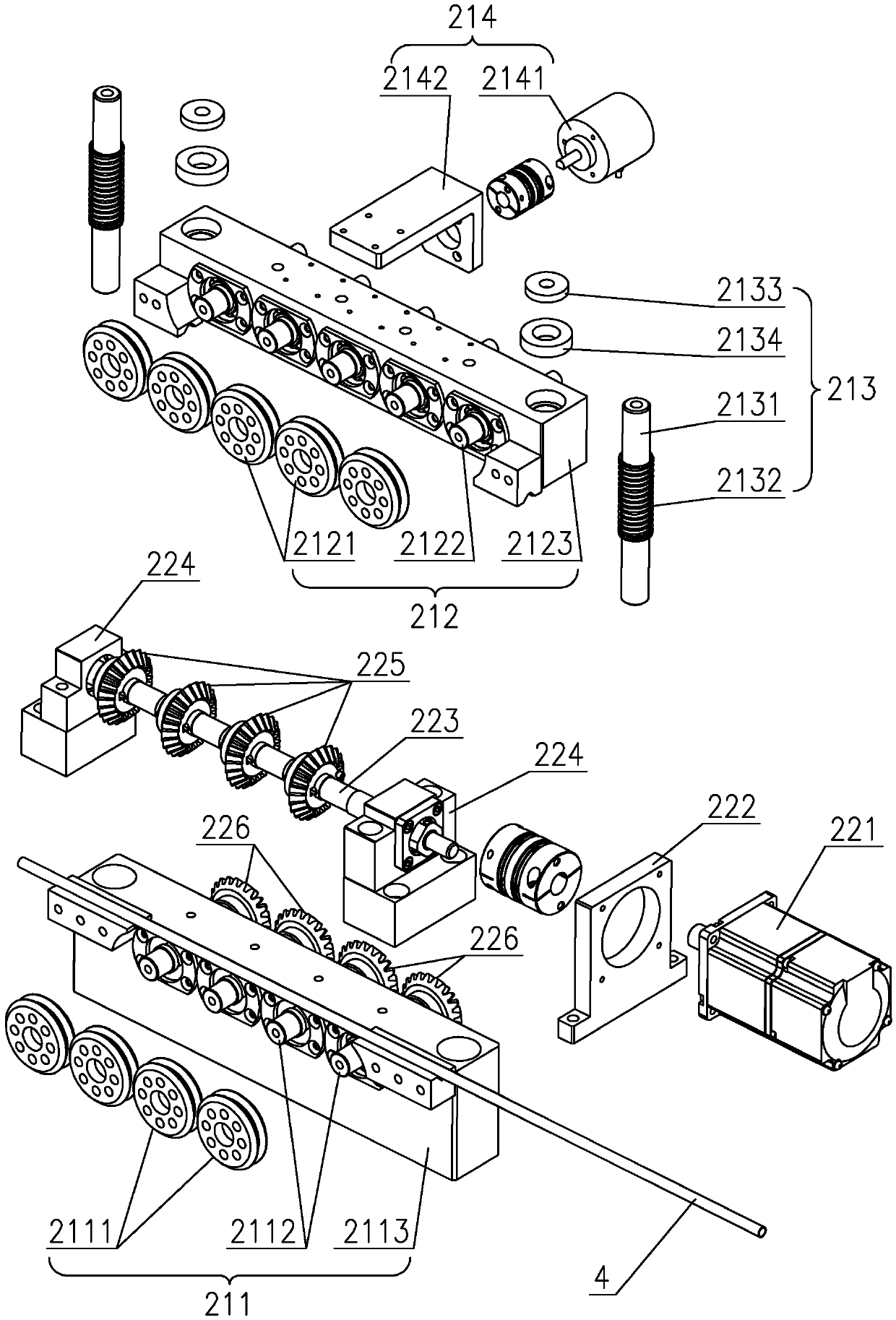

Precision automatic cutting equipment and method for teflon tube

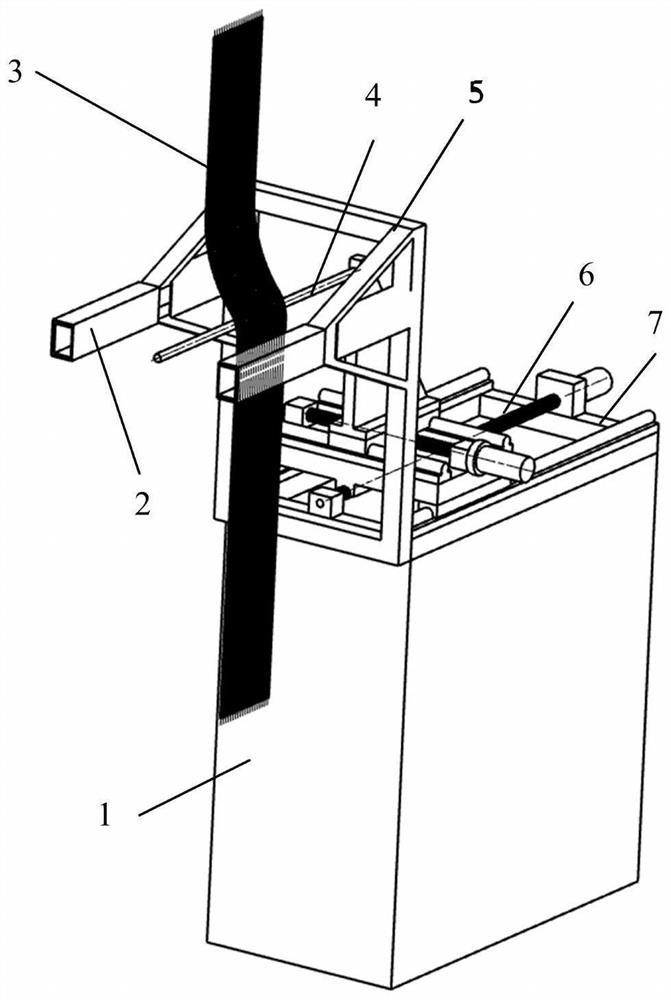

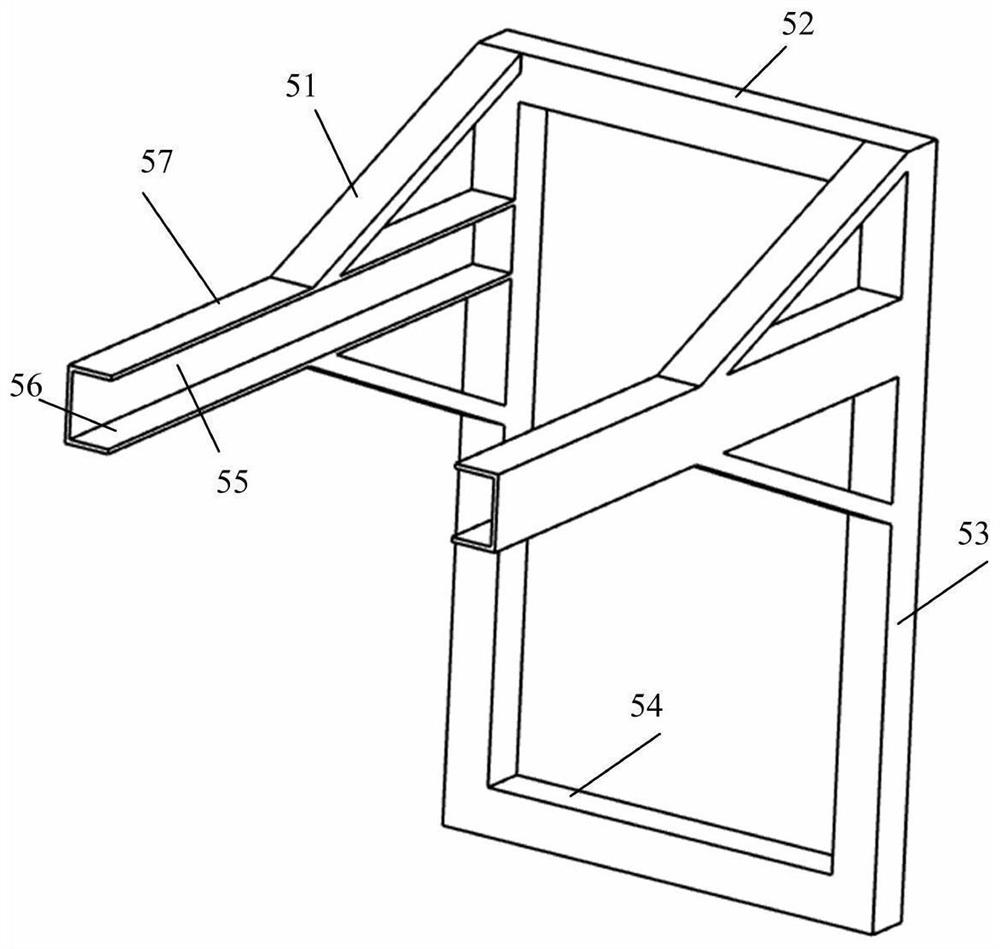

ActiveCN107627341AImprove length accuracyImprove cut qualityMetal working apparatusBiomedical engineeringFixed length

The invention provides precision automatic cutting equipment for a teflon tube and further provides a precision automatic cutting method for the teflon tube. The precision automatic cutting equipmentcomprises a rack (1), a teflon tube conveying device (2), a teflon tube cutting device (3), a teflon tube rotating table (4) and a rotating table frame (5); the rack (1) is provided with a rack tablesurface (11); the teflon tube conveying device (2) and the teflon tube cutting device (3) are mounted on the rack table surface (11), and the teflon tube rotating table (4) is rotatably mounted on therotating table frame (5); the rotating table frame (5) is placed in front of an inlet of the teflon tube conveying device (2); and the teflon tube is drawn out from the teflon tube rotating table andinserted into the teflon tube conveying device (2), the teflon tube conveying device (2) automatically conveys the teflon tube of the fixed length into the teflon tube cutting device (3), and the teflon tube is cut off. According to the precision automatic cutting equipment and method for the teflon tube, the tube length cutting precision can be effectively improved, the quality of a cut openingis good, and the situation that a tube material is bent or flattened can be reduced or even eliminated.

Owner:ZHEJIANG GAOAO SANITARY WARE CO LTD

Novel yarn hairiness testing device

The invention discloses a novel yarn hairiness testing device which comprises a tester body and a fixed bracket; a display screen is arranged on the lower end of the tester body; a control switch is arranged on one side of the display screen; a yarn is fixedly arranged on the fixed bracket; a plurality of guide wheels are fixedly arranged on the upper end of the tester body; a detector is arranged on one side of each guide wheel; a rotating disc is arranged on the output end of each detector; the yarn passes through the detectors through the guide wheels; and the end of the yarn is fixedly connected with the rotating discs. According to the novel yarn hairiness testing device, a design integrating light, mechanics and electronics is adopted, the precision in setting the hairiness length is high, the yarn runs stably, a computer automatically carry out detecting, correcting, displaying and calculating operations, the hairiness test data is stable, and the error is small.

Owner:YANGZHOU FENGDENG PRECISION MACHINERY

Transverse cutting device of extruded polystyrene foam plate production equipment

InactiveCN104162899AReduce dustReduce energy consumptionMetal working apparatusVehicle frameElectric machinery

The invention discloses a transverse cutting device of extruded polystyrene foam plate production equipment. The transverse cutting device comprises a frame, a transverse cutting dolly, a dolly servo driving motor, a blade, a blade driving motor, a lead screw, a cylinder, a fixed plate, a controller and an encoder, wherein the transverse cutting dolly is arranged above an extruded polystyrene foam plate channel, is mounted on the frame through a longitudinal guide rail, and is connected with the lead screw; the lead screw is connected with the dolly servo driving motor; the blade is mounted at the end of the transverse cutting dolly through a transverse guide rail; the cylinder is mounted on the transverse cutting dolly; the fixed plate is arranged at the lower end of the cylinder; the dolly servo driving motor, the blade driving motor and the cylinder are respectively connected with the controller; the controller is connected with the encoder; and the encoder is mounted on the extruded polystyrene foam plate channel. The transverse cutting device can guarantee the preciseness in any state, and has no need to use an electric heating wire for secondary processing, so that the manpower is reduced, and the energy consumption is decreased.

Owner:NANJING OURGREEN ENERGY SAVING TECH

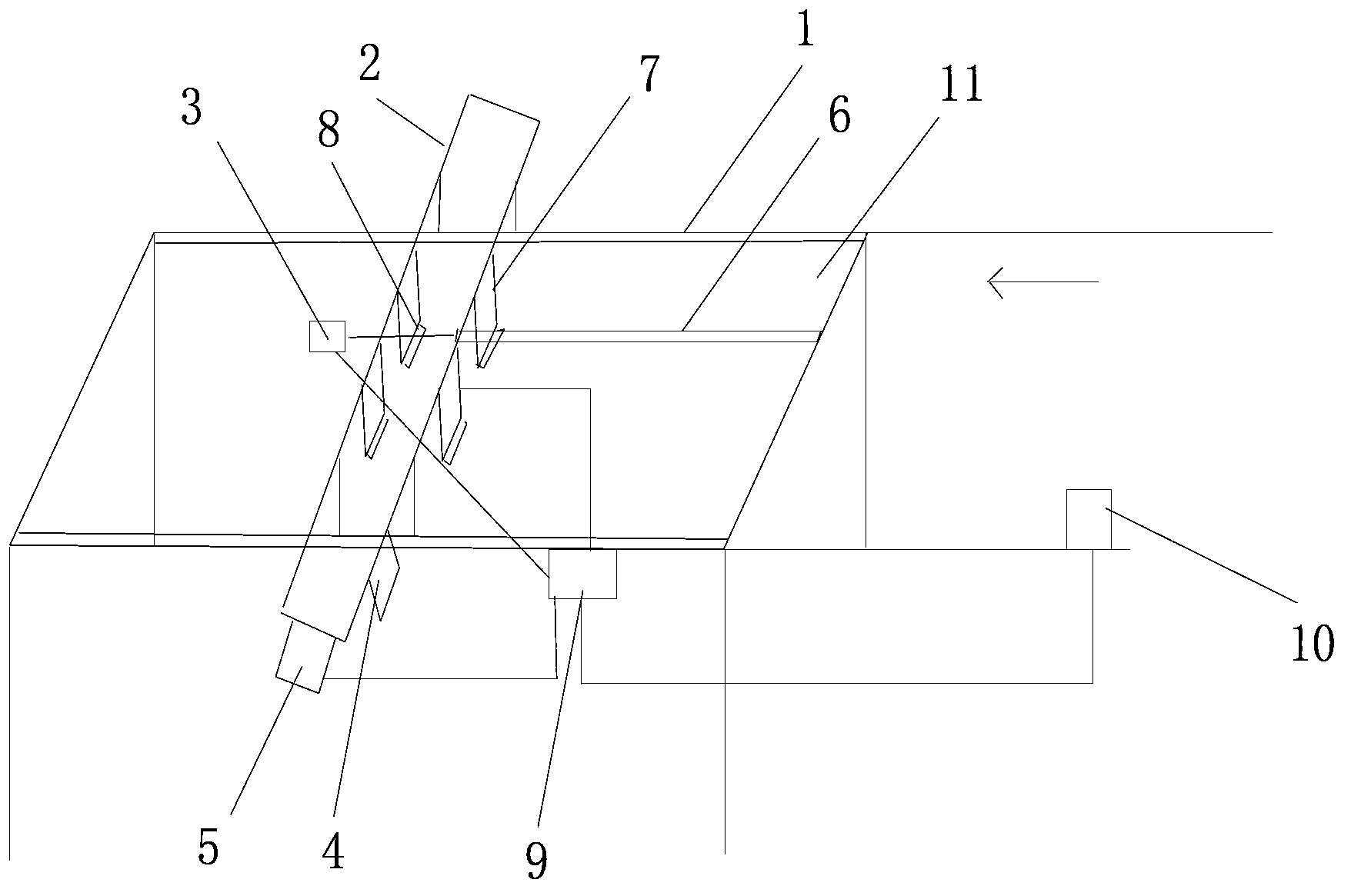

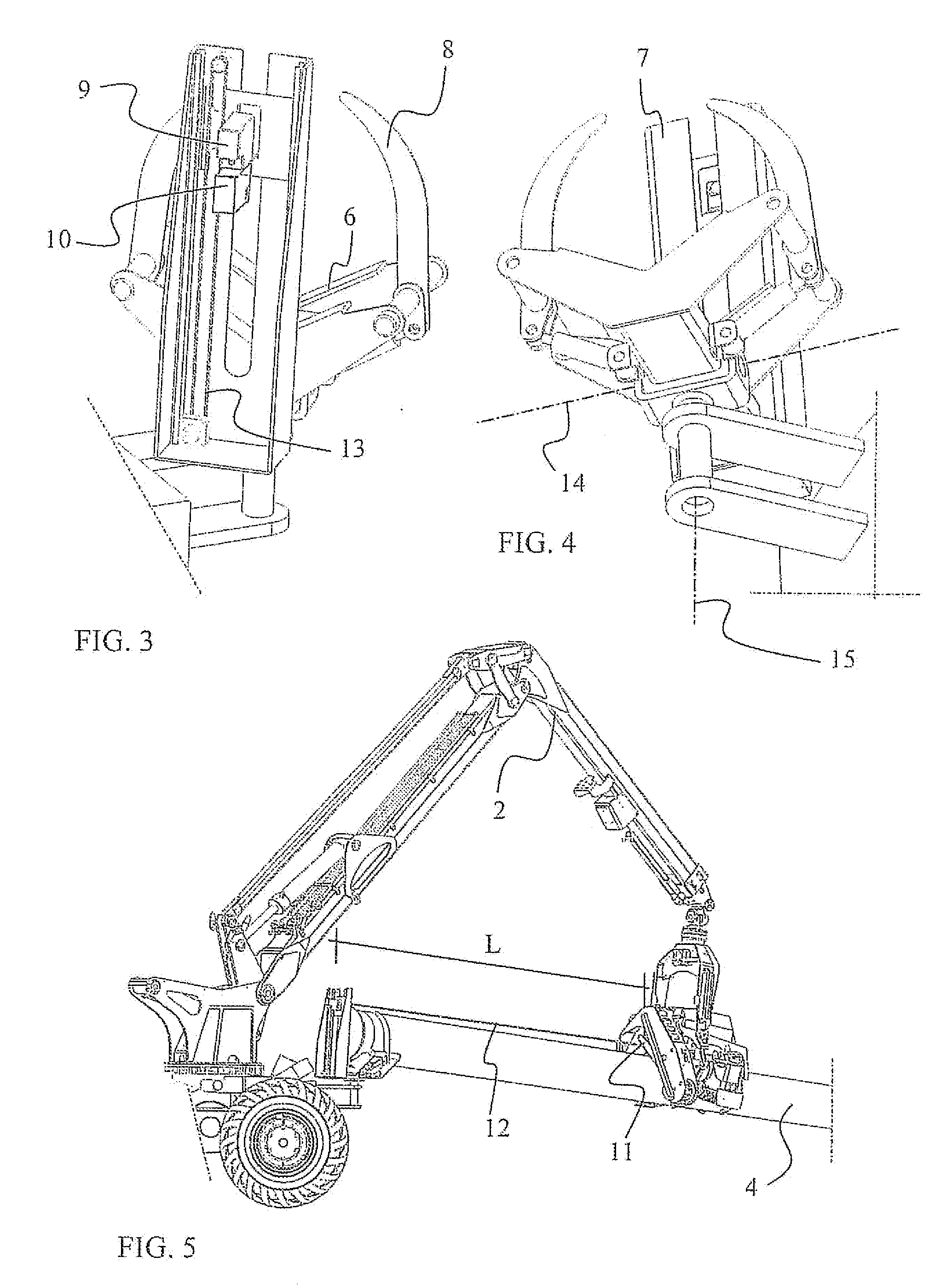

Method and arrangement for measuring timber piece

ActiveUS20100027034A1Reduce the impactEliminate errorsAutomatic control devicesPrecision positioning equipmentWoodchipsMechanical engineering

The invention relates to a method and arrangement for measuring a timber piece (4) in a wood handling machine (1). Such a wood handling machine comprises booms (2) arranged in a base machine and a wood handling device (3) operating therein. In such a wood handling machine (1), a wood handling device (3) grips the timber piece (4) to be handled, after which one end of the timber piece is guided into a measuring carriage (5) in the wood handling machine by the wood handling device. The timber piece arranged in the measuring carriage is subjected to one or more observation measures by observation means provided in the measuring carriage.

Owner:PONSSE

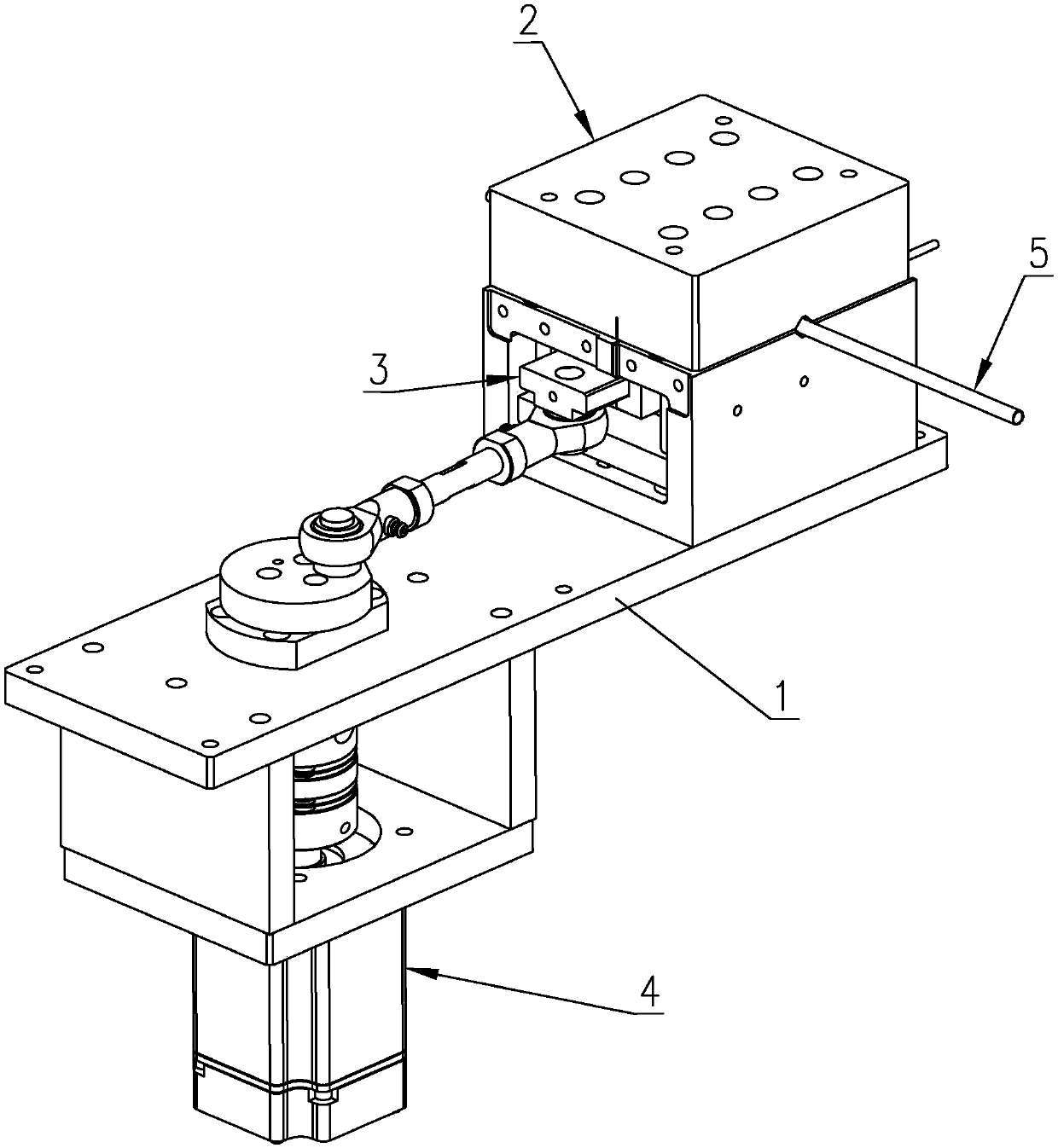

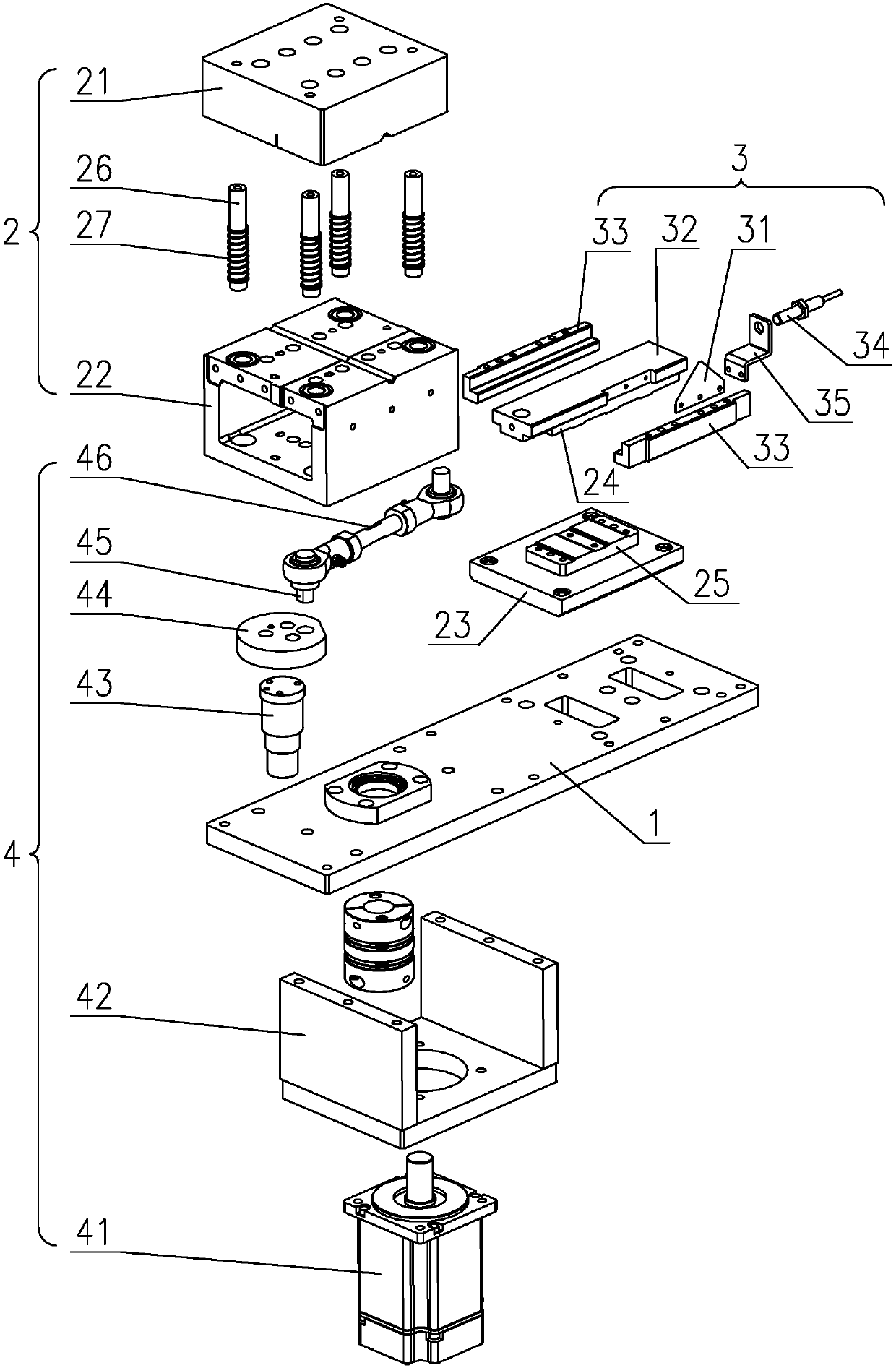

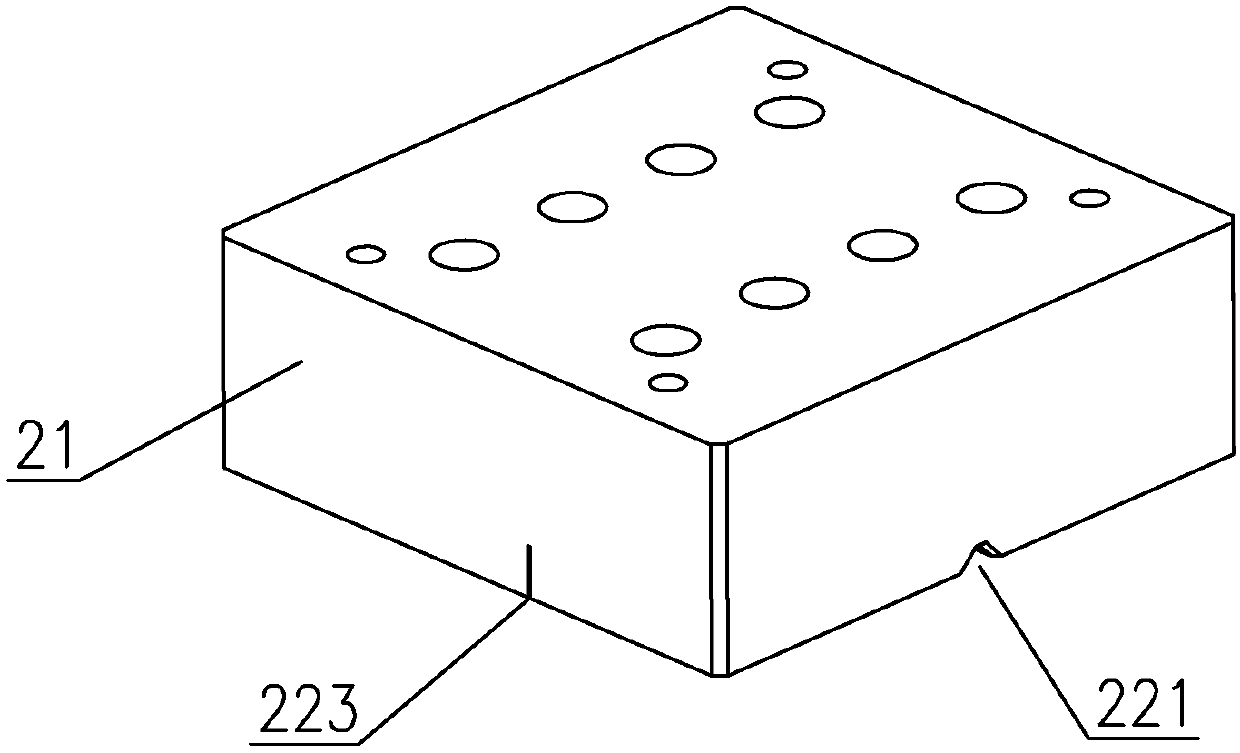

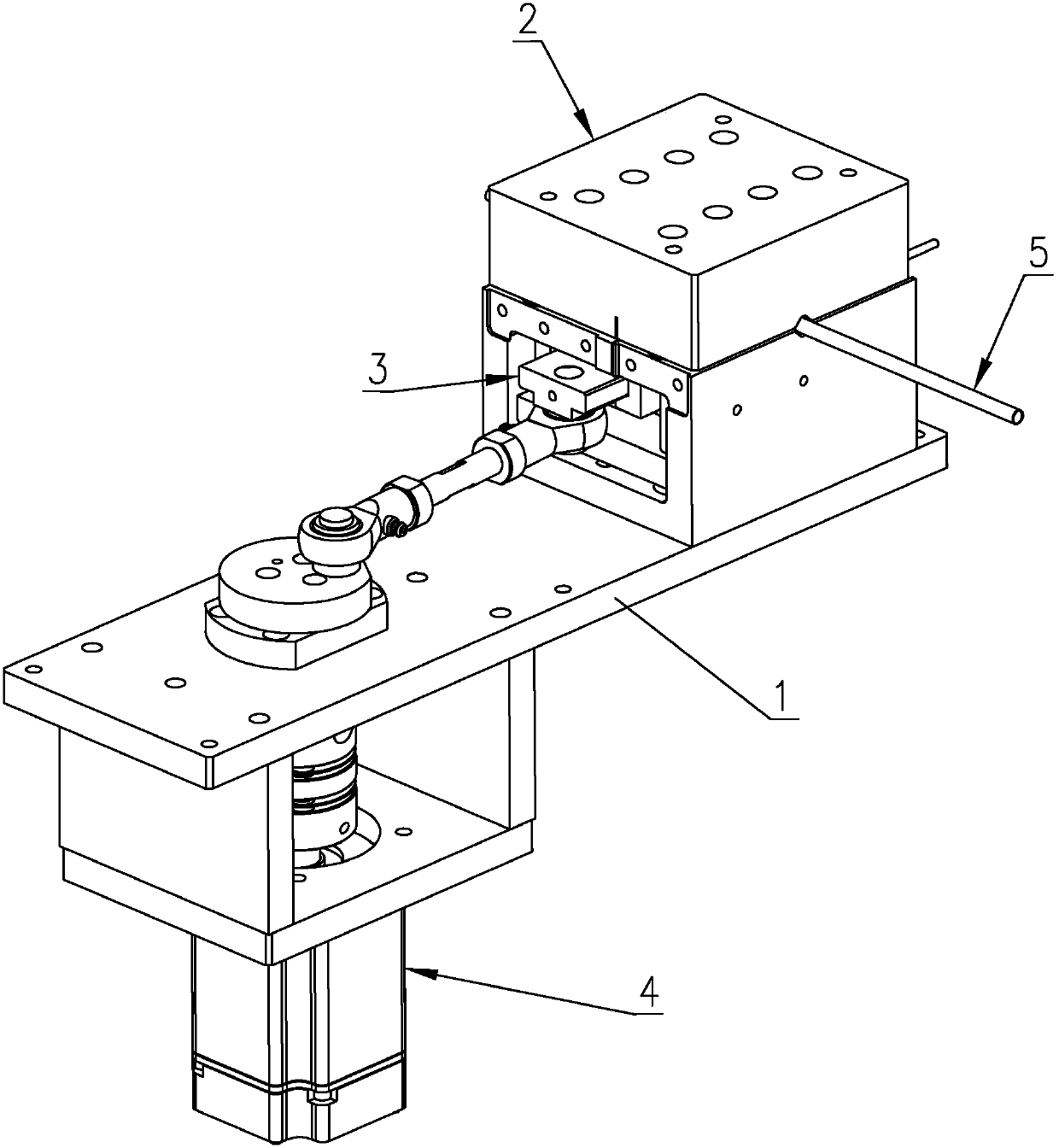

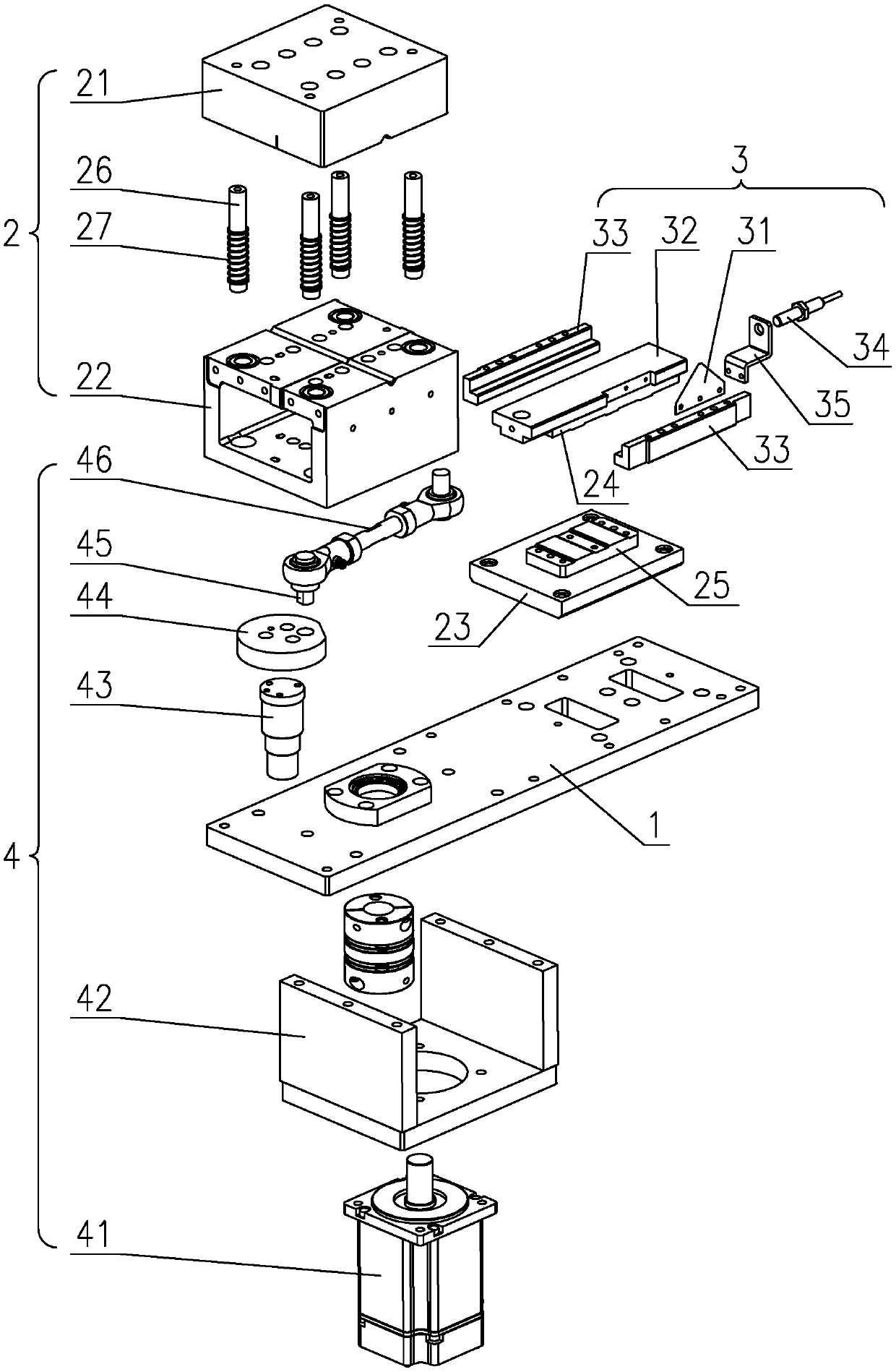

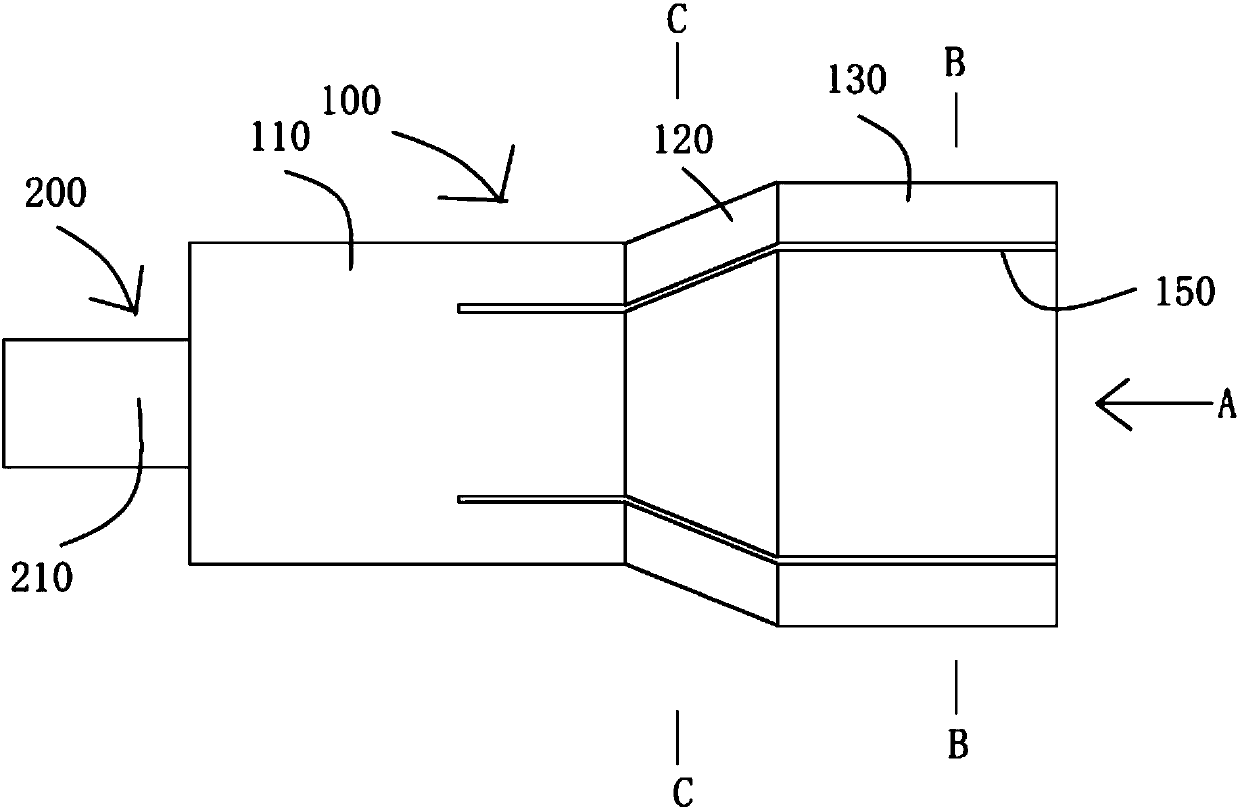

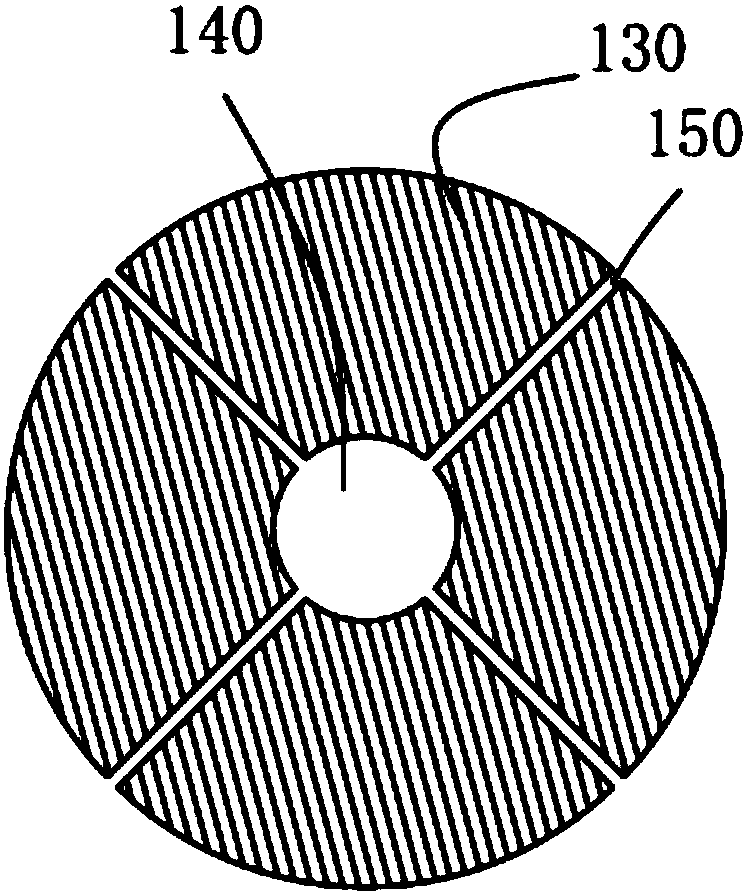

Teflon pipe precise cutting device and method

ActiveCN107825483AImprove length accuracyImprove cut qualityMetal working apparatusEngineeringMechanical engineering

The invention provides a teflon pipe precise cutting device. The teflon pipe precise cutting device comprises a frame, a clamping mechanism (2), a cutting mechanism (3) and a cutting driving mechanism(4); a frame tabletop (1) is arranged on the frame; the clamping mechanism (2) is mounted on the frame tabletop (1); the cutting mechanism (3) is positioned in the clamping mechanism (2); and the cutting driving mechanism (4) is mounted on the frame tabletop (1), and drives the cutting mechanism (3) to work to cut off teflon pipes clamped in the clamping mechanism (2). The invention further provides a teflon pipe precise cutting method. The teflon pipe precise cutting device and method can effectively improve the length precision of the cut pipes, are excellent in incision quality, and reduceor even eliminate the bending or flattening conditions of the pipes.

Owner:徐州莱益精密机械有限公司

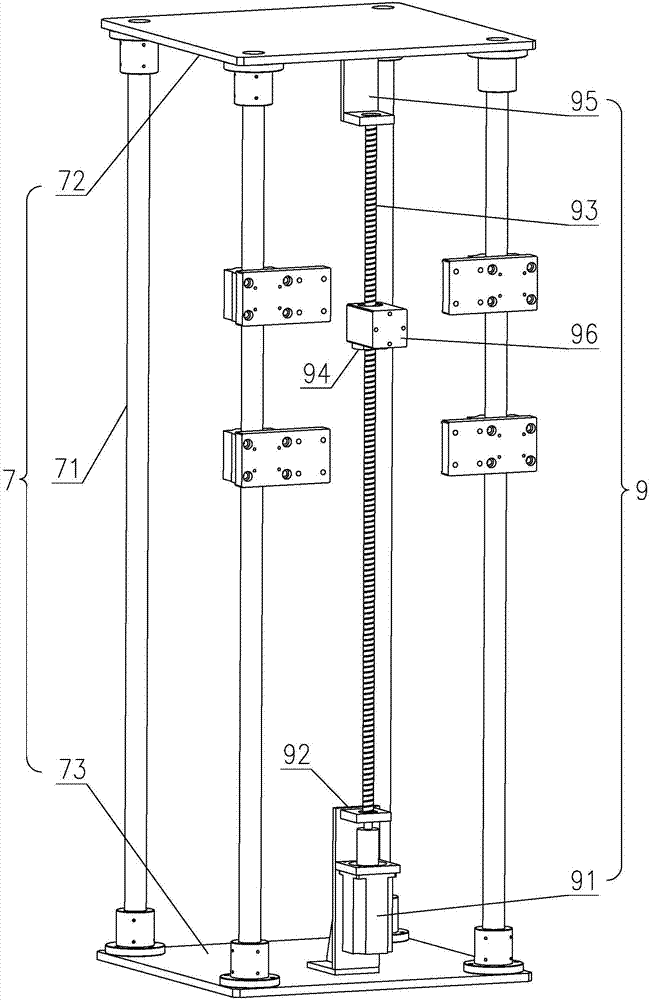

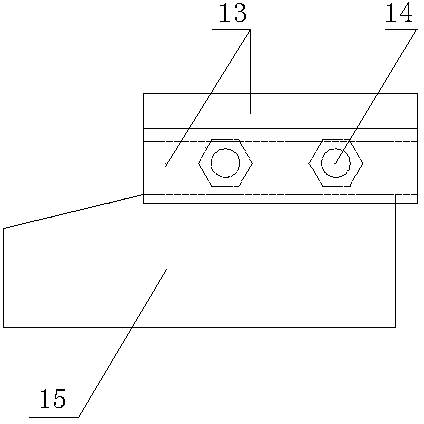

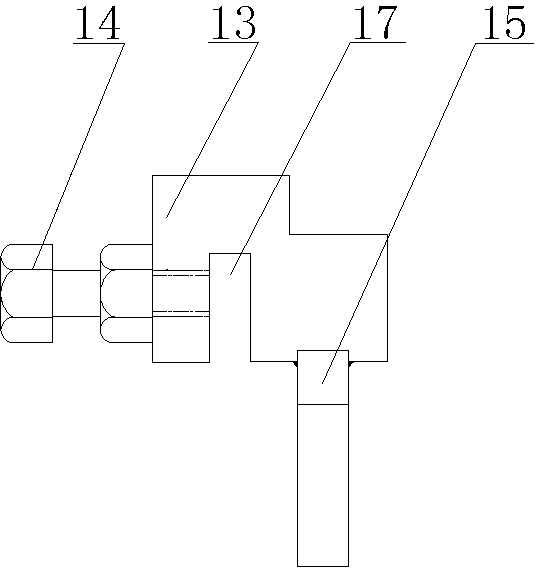

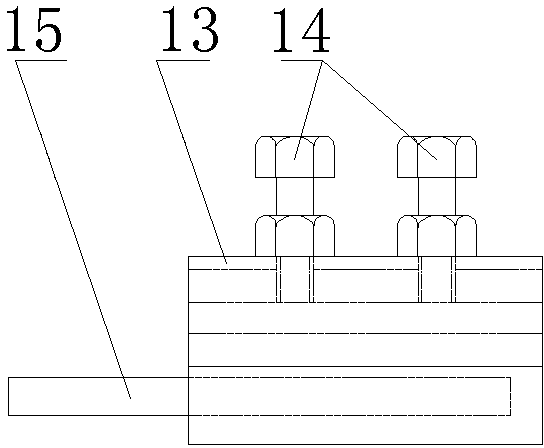

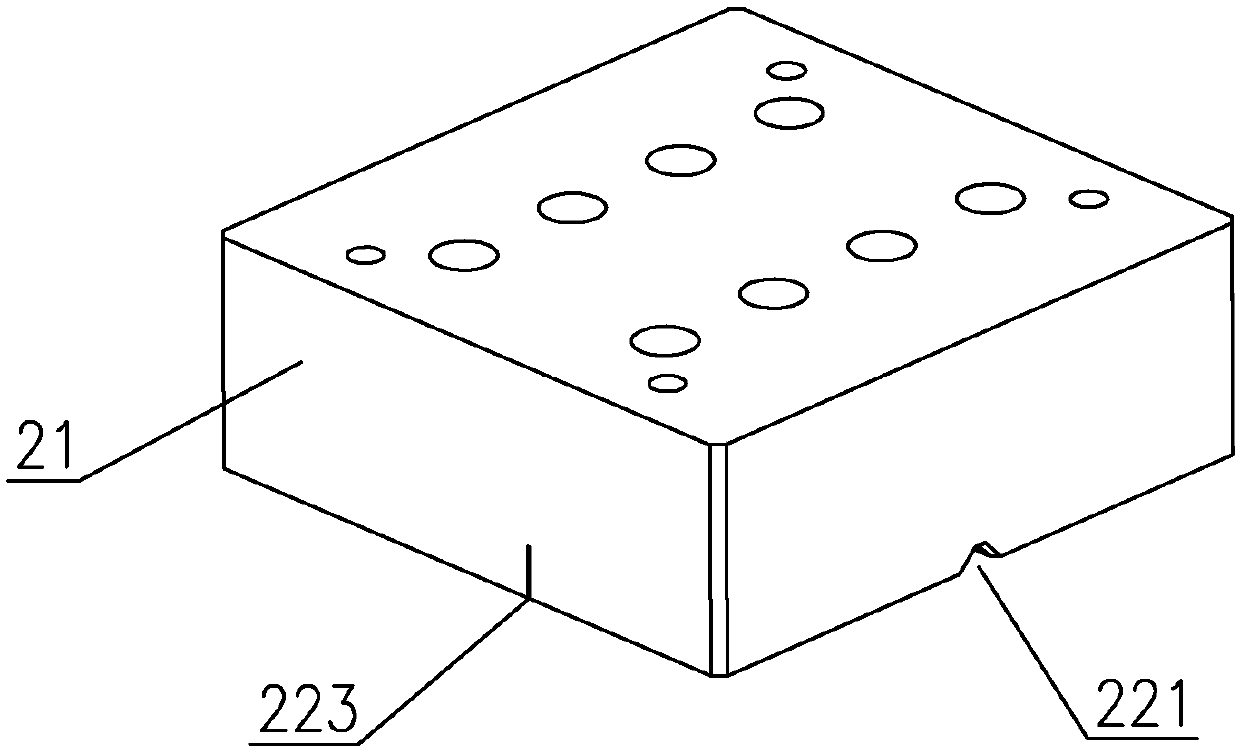

High-precision positioning device for reinforcement straightening cutting-off machine

The invention relates to a high-precision positioning device for a reinforcement straightening cutting-off machine and belongs to a reinforcement straightening cutting-off machine. The high-precision positioning device is characterized by also comprising a baffle seat body, a baffle and fixing bolts II, wherein the baffle seat body is a cuboid; the front upper part of the baffle seat body is transversely provided with a rectangular through undercut groove; the rear lower part of the baffle seat body is transversely provided with a through clamping groove; the groove width of the through clamping groove is slightly greater than the width of a guide rail; the rear groove wall of the through clamping groove is uniformly provided with left and right screw holes, and the fixing bolts II are correspondingly screwed in the left and right screw holes; the front bottom part of the baffle seat body is transversely provided with a rectangular straight slot, and the rectangular baffle which is vertically arranged is correspondingly embedded into the rectangular straight slot and is welded with the rectangular straight slot into one whole body; the left section of the baffle extends out of the baffle seat body. When in use, the high-precision positioning device is fixedly arranged on the guide rail, and the baffle is correspondingly positioned in an operation groove of a reinforcement, so that accuracy of the fabrication length of the reinforcement is ensured, and production efficiency is improved.

Owner:安徽天宇金属股份有限公司

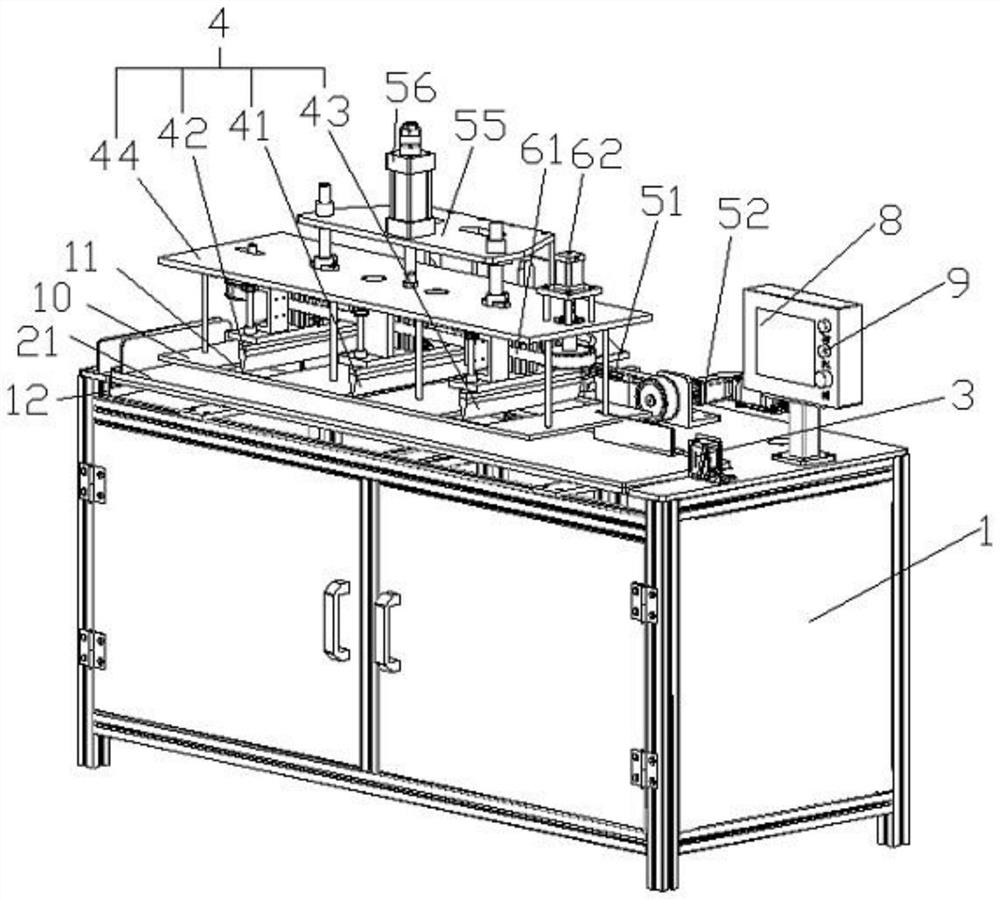

Precise and automatic cutting equipment of Teflon pipes

ActiveCN109591071AImprove length accuracyImprove cut qualityMetal working apparatusEngineeringFixed length

The invention provides precise and automatic cutting equipment of Teflon pipes. The precise and automatic cutting equipment comprises a rack (1), a Teflon pipe conveying device (2), a Teflon pipe cutting device (3), a Teflon pipe rotating disc (4) and a rotating disc frame (5). The rack (1) is provided with a rack table board (11). The Teflon pipe conveying device (2) and the Teflon pipe cutting device (3) are mounted on the rack table board (11). The Teflon pipe rotating disc (4) is rotationally mounted on the rotating disc frame (5), and the rotating disc frame (5) is placed in front of an inlet of the Teflon pipe conveying device (2). The Teflon pipes are drawn out from the Teflon pipe rotating disc to be inserted into the Teflon pipe conveying device (2), and the Teflon pipes of fixedlength are automatically conveyed by the Teflon pipe conveying device (2) into the Teflon pipe cutting device (3) and are cut off. By means of the precise and automatic cutting equipment, the length precision of pipe cutting can be effectively improved, the quality of cutting openings is good, and the situation that pipes are bent or flattened is reduced and even eliminated.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

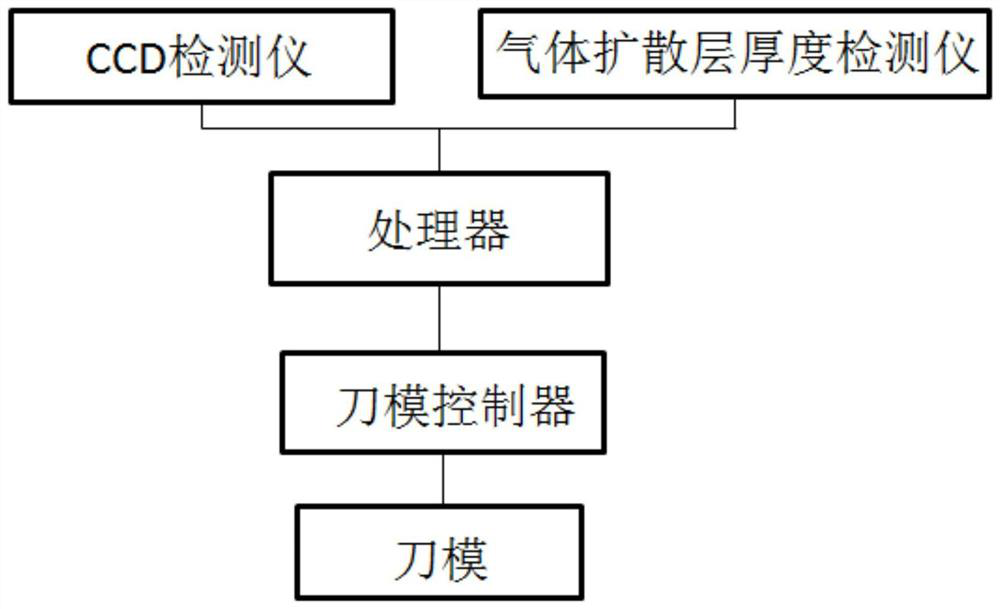

Structure of cutting die stamping gas diffusion layer

PendingCN114434554AMeet the precision requirementsImprove length accuracyMetal working apparatusEngineeringMechanical engineering

The invention provides a structure for stamping a gas diffusion layer by a cutting die, which comprises a conveying roller, the cutting die and a protective film laminating piece, and is characterized in that the conveying roller is used for conveying the gas diffusion layer to be cut to the cutting die; the cutting die is used for cutting the gas diffusion layer and transmitting the cut gas diffusion layer to the protective film laminating piece; the protective film attaching part is used for attaching a protective film to the surface of the cut gas diffusion layer to obtain a product, so that the size, appearance and broken filament length precision of the product obtained by cutting the gas diffusion layer are improved, the precision requirement of the product obtained by cutting the gas diffusion layer is met, and the production cost is reduced.

Owner:SUZHOU ANJIE TECH

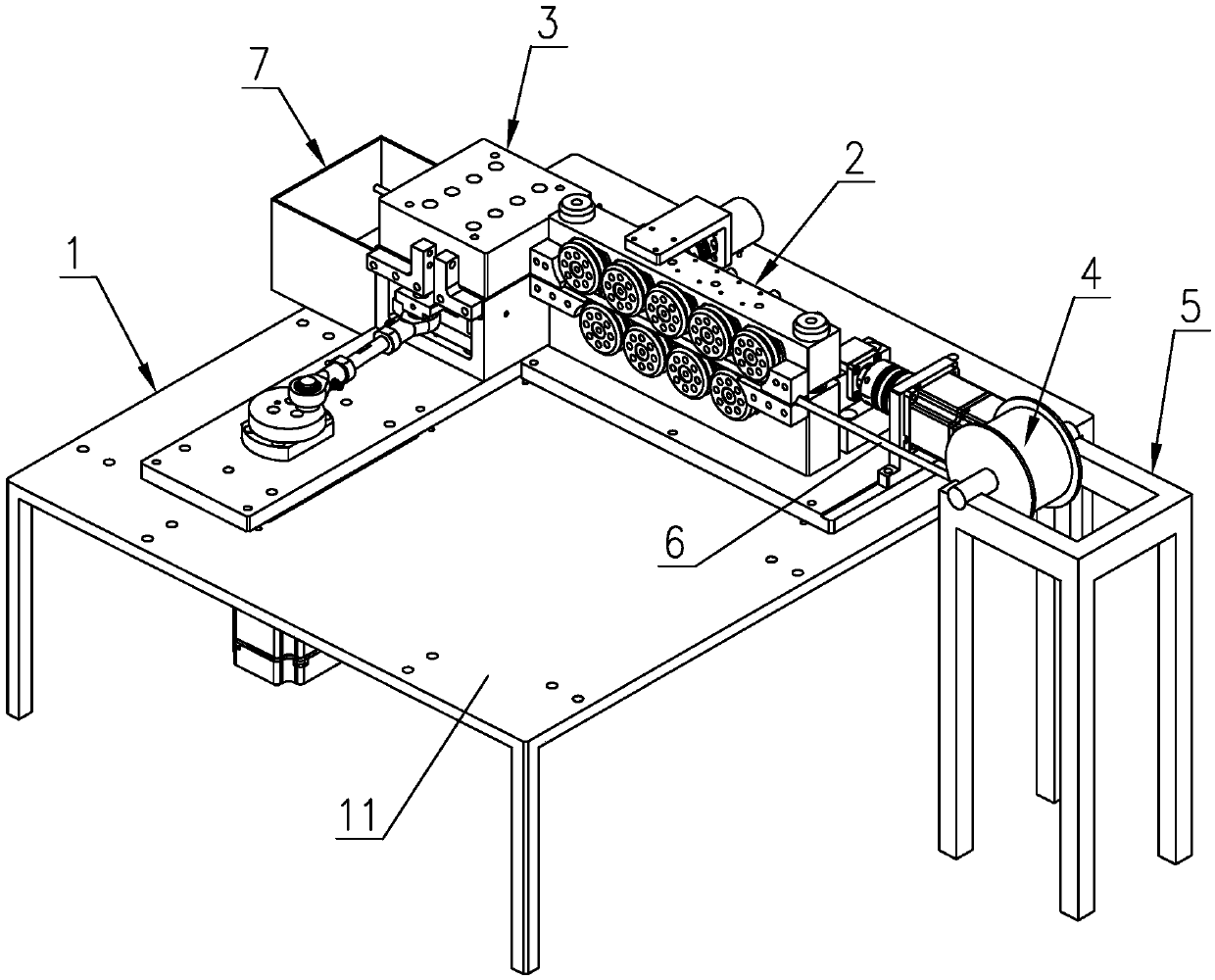

High-speed straightening dimensioning blanking process and equipment for aluminum flat pipe of automobile air conditioner

ActiveCN102689147BImprove length accuracyHigh precisionOther manufacturing equipments/toolsControl systemAutomobile air conditioning

The invention provides a high-speed straightening dimensioning blanking process and equipment for an aluminum flat pipe of an automobile air conditioner. The equipment consists of a driving material cutting frame, a straightening device, a servo feeding device, a servo online necking device, a dimensioning cutting device, a clamping tension fracture device, a material collecting table, a machine body and an electric control system, and is characterized in that the whole processes of disc material cutting, straightening, necking, tension fracture and automatic finished product collection can be realized on the same production equipment, all servo motors in the whole equipment are respectively controlled by a programmable controller so that the immediate synchronous movement of actions of all devices is ensured, and three actions of necking, cutting and clamping tension fracture of the aluminum flat pipe can be simultaneously completed on three different devices of the equipment. When the equipment is adopted, the forming precision of the finished products of the aluminum flat pipes can be improved by three times, and the operation efficiency of the equipment is improved by five times.

Owner:沈阳智勤机器人系统工程有限公司

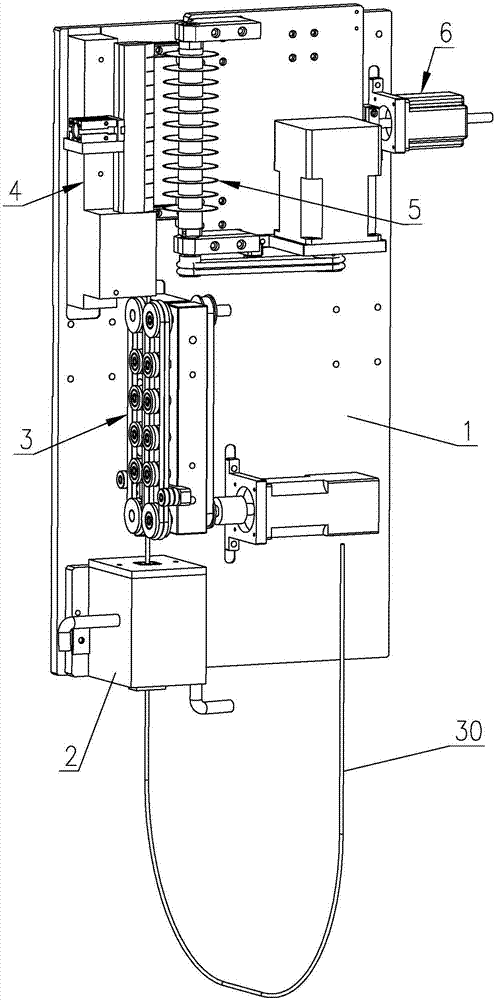

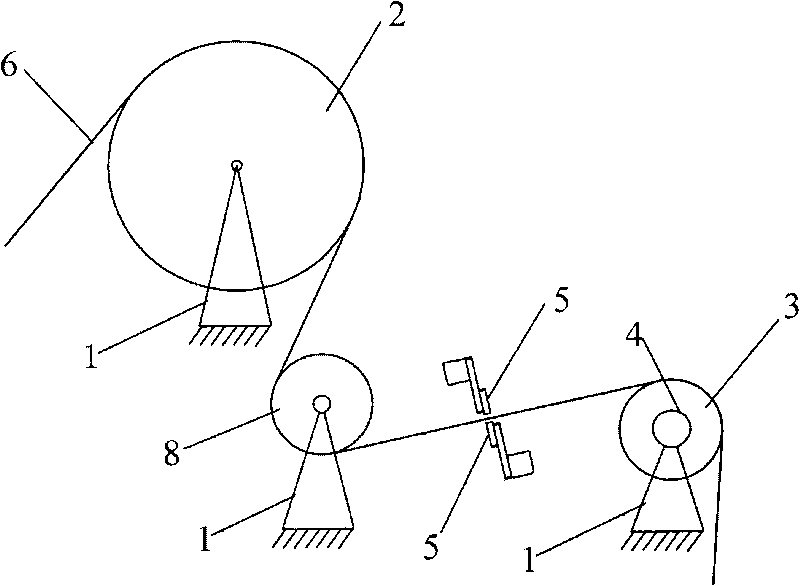

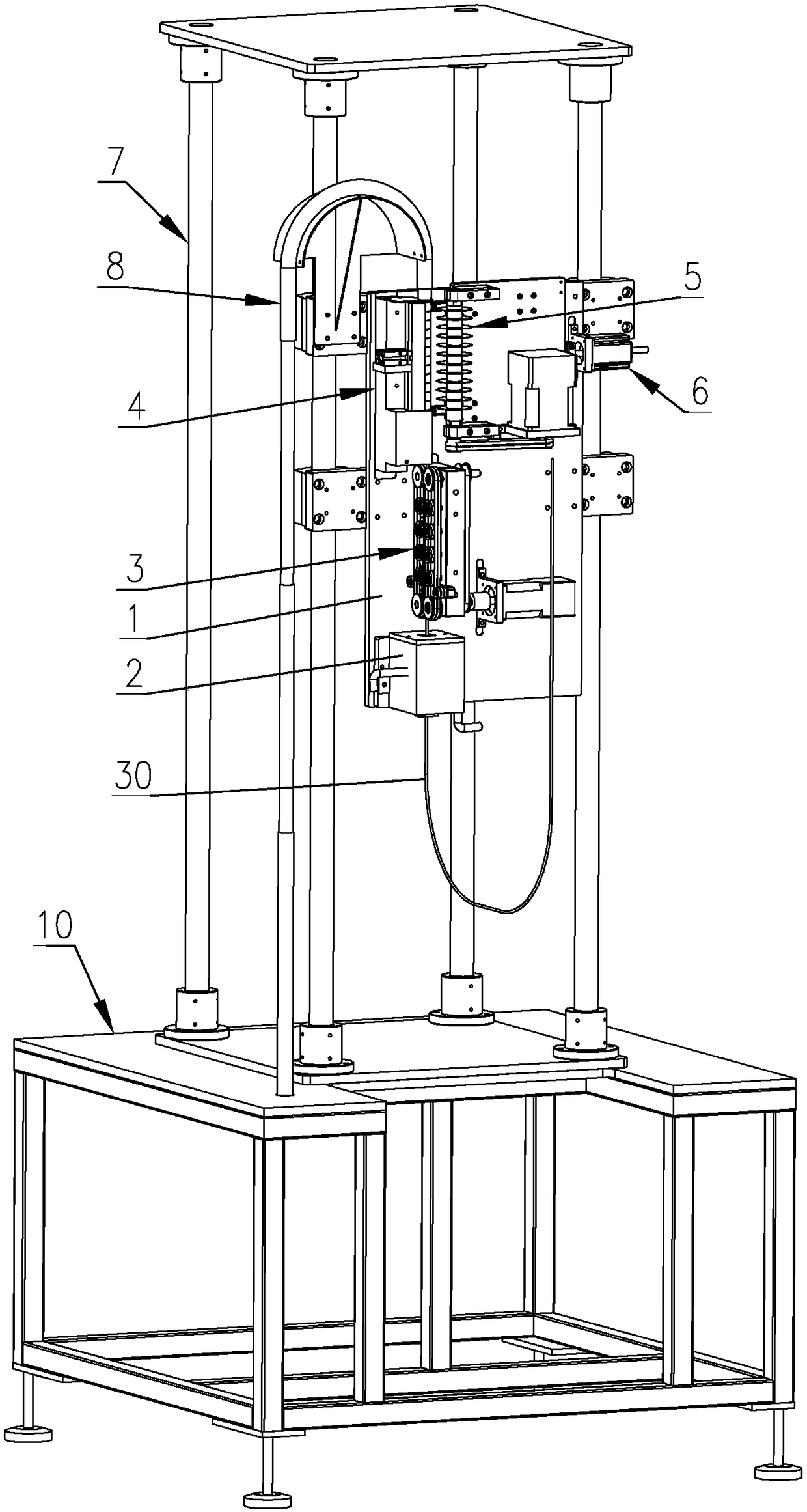

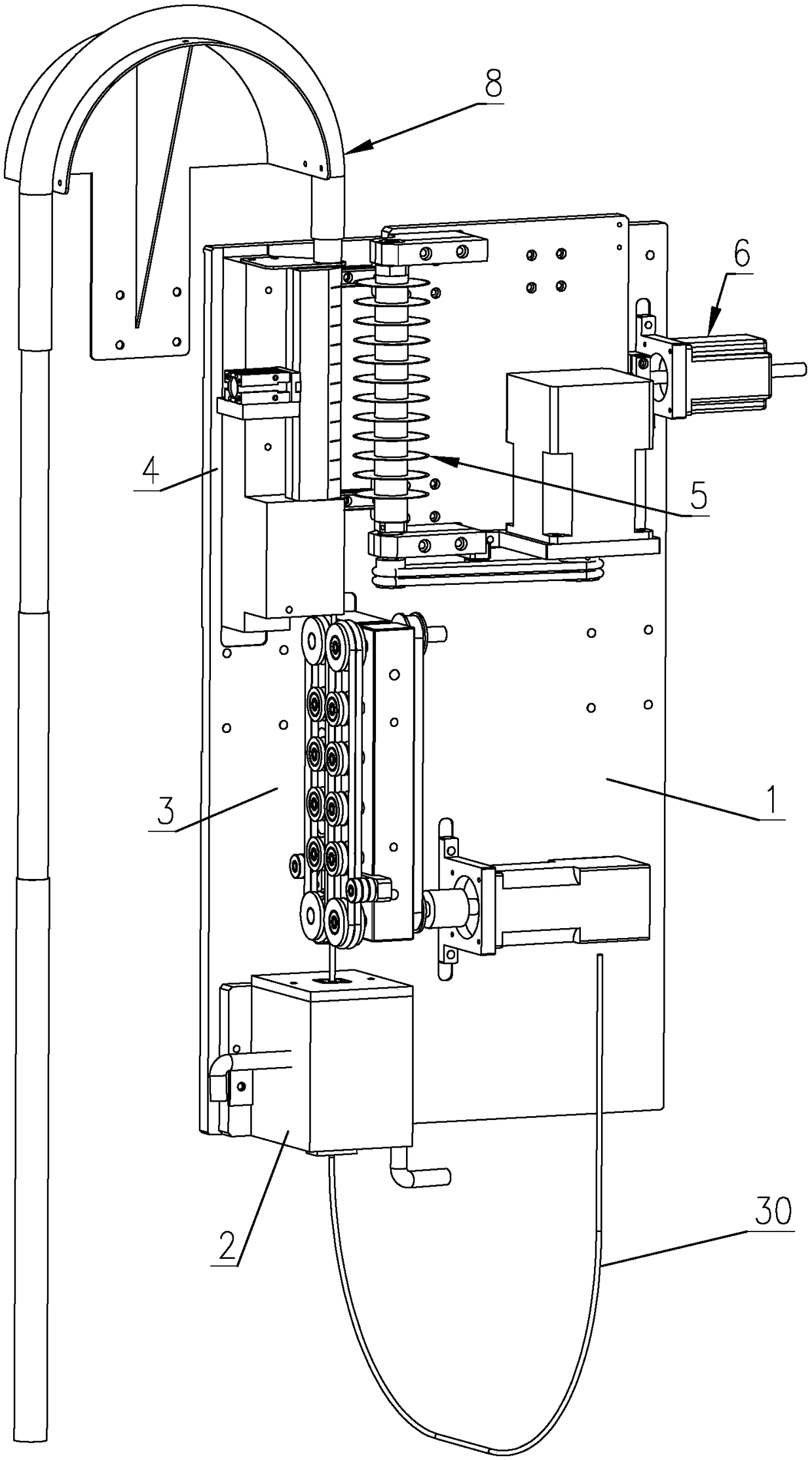

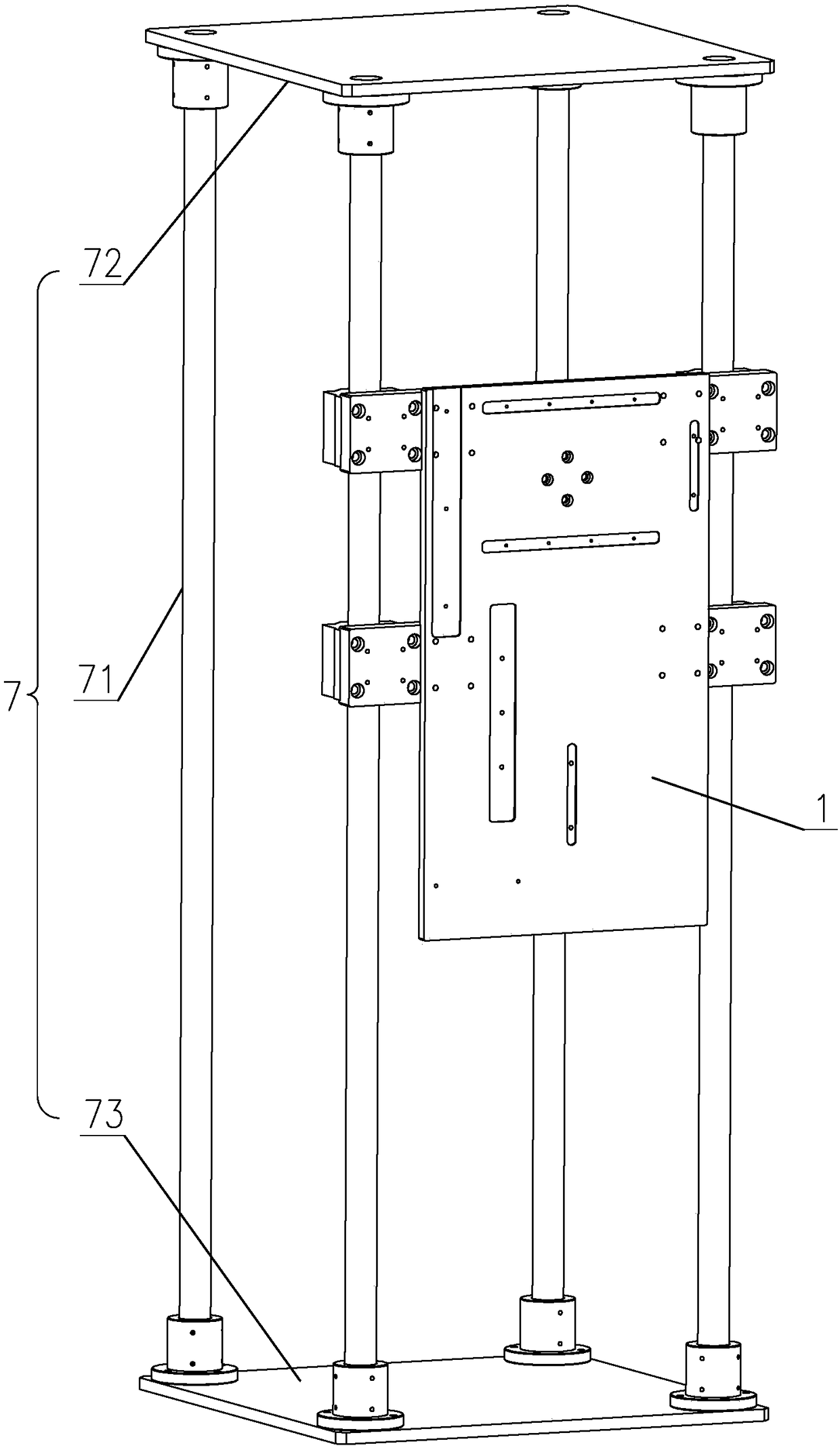

Teflon fine tube cutting equipment

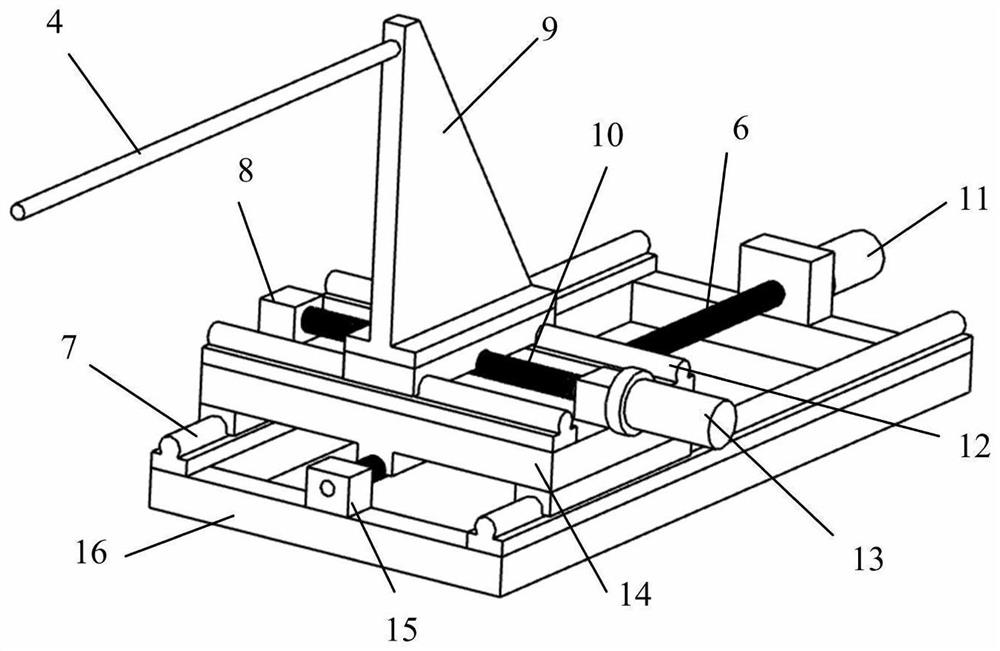

ActiveCN108555375ALess bendingImprove length accuracyTube shearing machinesMaintainance and safety accessoriesEngineeringFixed length

The invention provides teflon fine tube cutting equipment. The equipment comprises a base (1), a cooling water tank (2), a delivering mechanism (3), a clamping mechanism (4), a cutting mechanism (5),a cutting driving mechanism (6), a supporting framework (7), an output mechanism (8), a machine frame (10) and a collecting box; a teflon fine tube(30) penetrates through the cooling water tank (2) and is inserted into the delivering mechanism (3), the teflon fine tube (30) with a fixed length is delivered into the clamping mechanism (4) by the delivering mechanism (6) to be clamped, the cutting mechanism (5) is driven by the cutting driving mechanism (4) to cut the teflon fine tube (30) in the clamping mechanism, and the cut teflon fine tube (30) is output by the output mechanism (8) to the collecting box. By means of the equipment, the length precision of tube cutting can be effectively improved, the incision quality is good, and the bending or crushing of piping materials can be reducedor even eliminated.

Owner:新沂市新南环保产业技术研究院有限公司

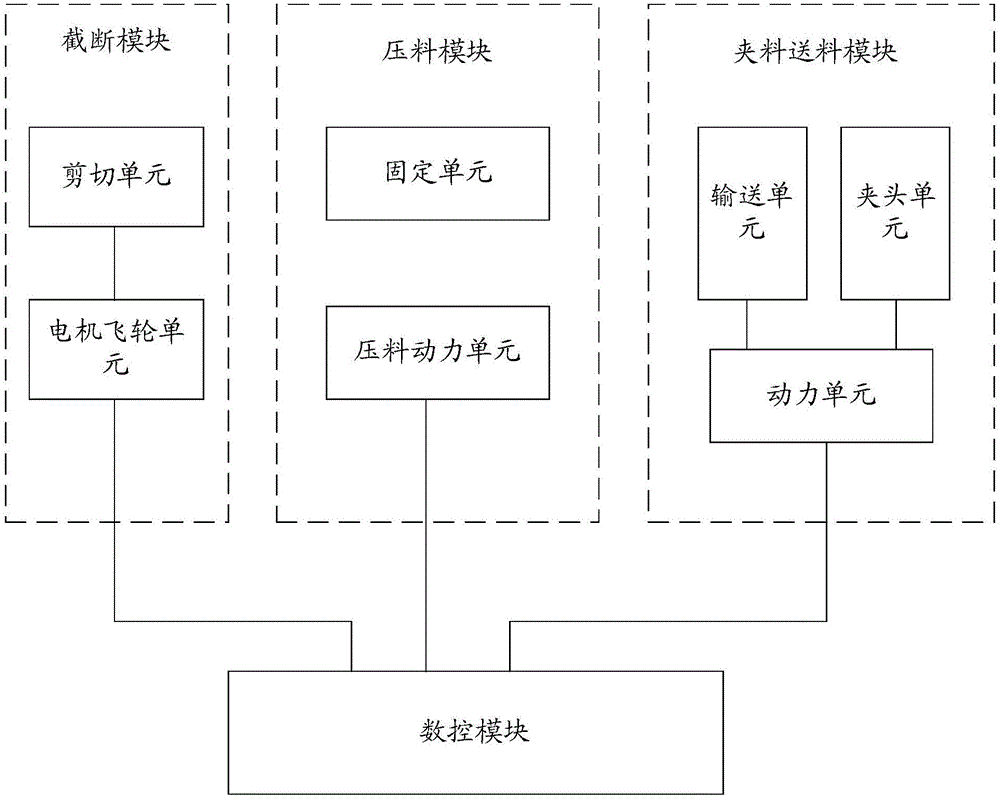

Work linkage system of round steel cutting-off machine

InactiveCN105108239AImprove consistencyImprove length accuracyMetal working apparatusPositioning apparatusNumerical controlEngineering

The invention discloses a work linkage system of a round steel cutting-off machine. The work linkage system comprises a clamping and feeding module, a cutting-off module and a numerical control module. The clamping and feeding module is used for clamping long round steel and feeding the long round steel forwards. The cutting-off module is used for cutting off and resetting the long round steel. The numerical control module is used for controlling the clamping action, the horizontal moving action, the cutting-off action and the resetting action to be conducted successively according to a preset time sequence. As the numerical control module is used for controlling the clamping action, the horizontal moving action, the cutting-off action and the resetting production action to be conducted, feeding operation does not need to be directly conducted manually, and therefore labor is greatly saved; due to the fact that the numerical control module is used for controlling the time sequence of the actions, smooth and continuous conduction of working procedures is guaranteed, production efficiency is improved, and production cost is reduced. By the adoption of the numerical control technical scheme, the length consistency of cut-out round steel sections is greatly improved, and the length accuracy of output products is improved. According to the technical scheme, the problems that working efficiency is low and accuracy is low due to the fact that round steel cutting off is directly operated manually are effectively solved.

Owner:CHONGQING QILONG IND & TRADE CO LTD

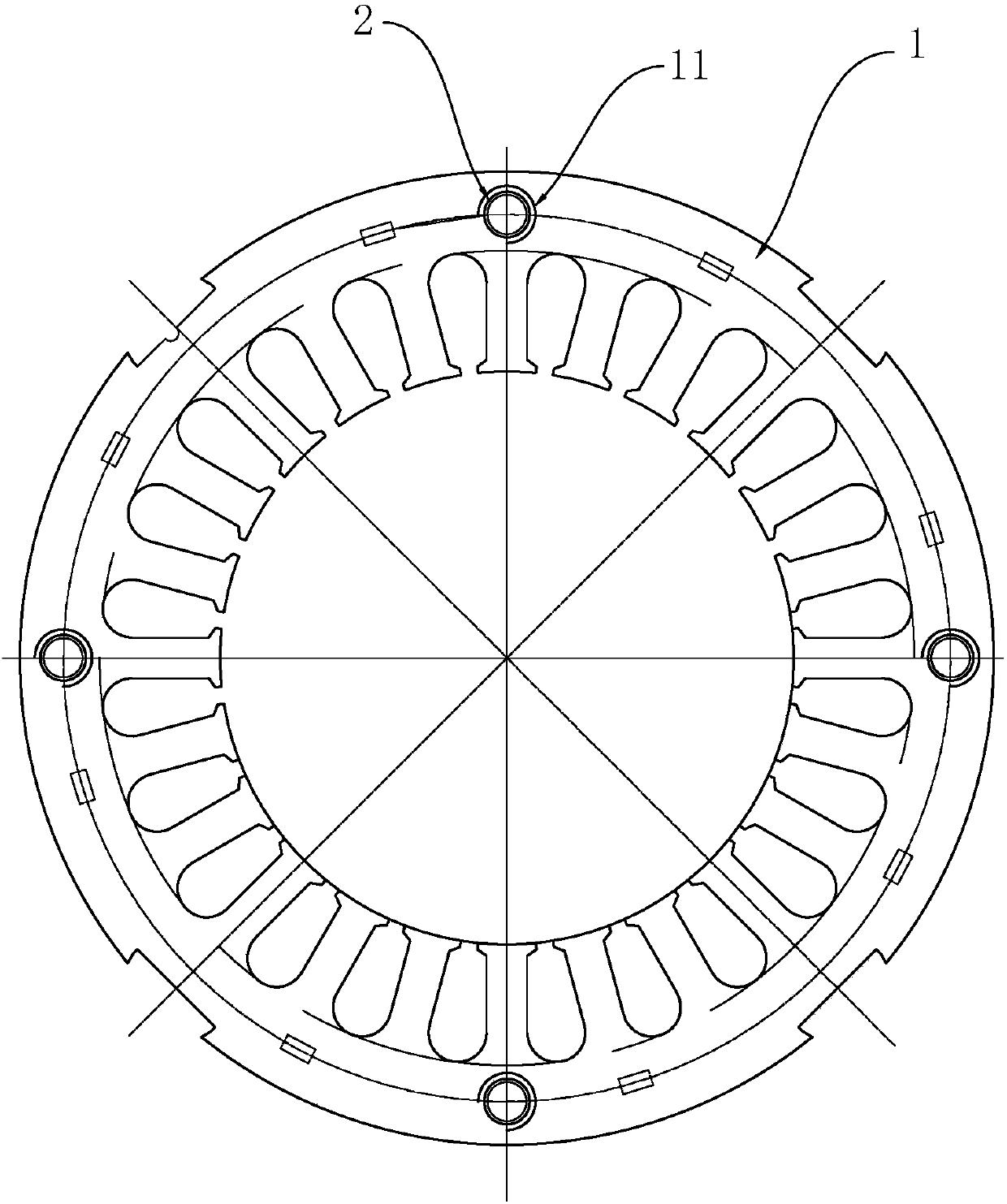

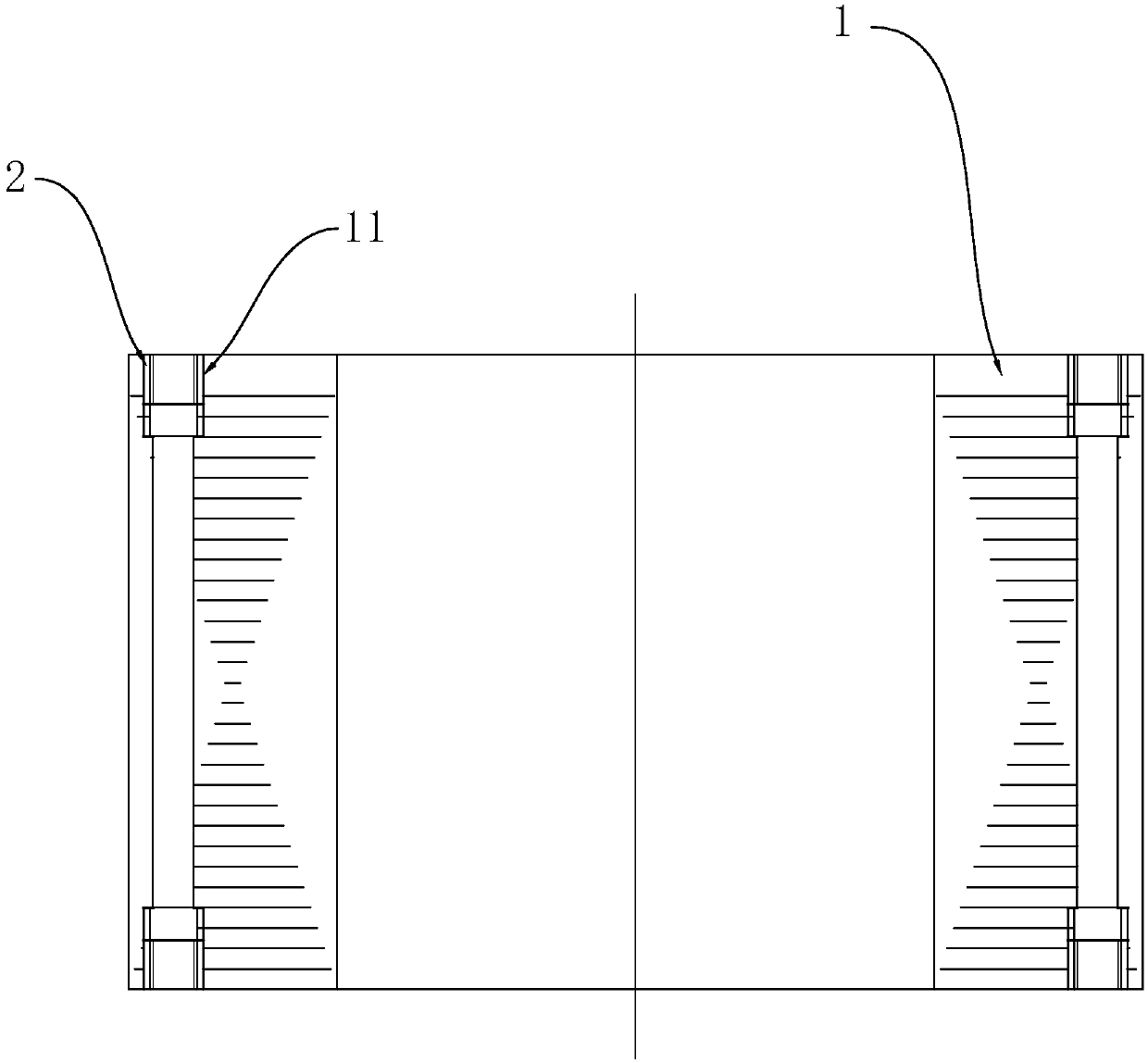

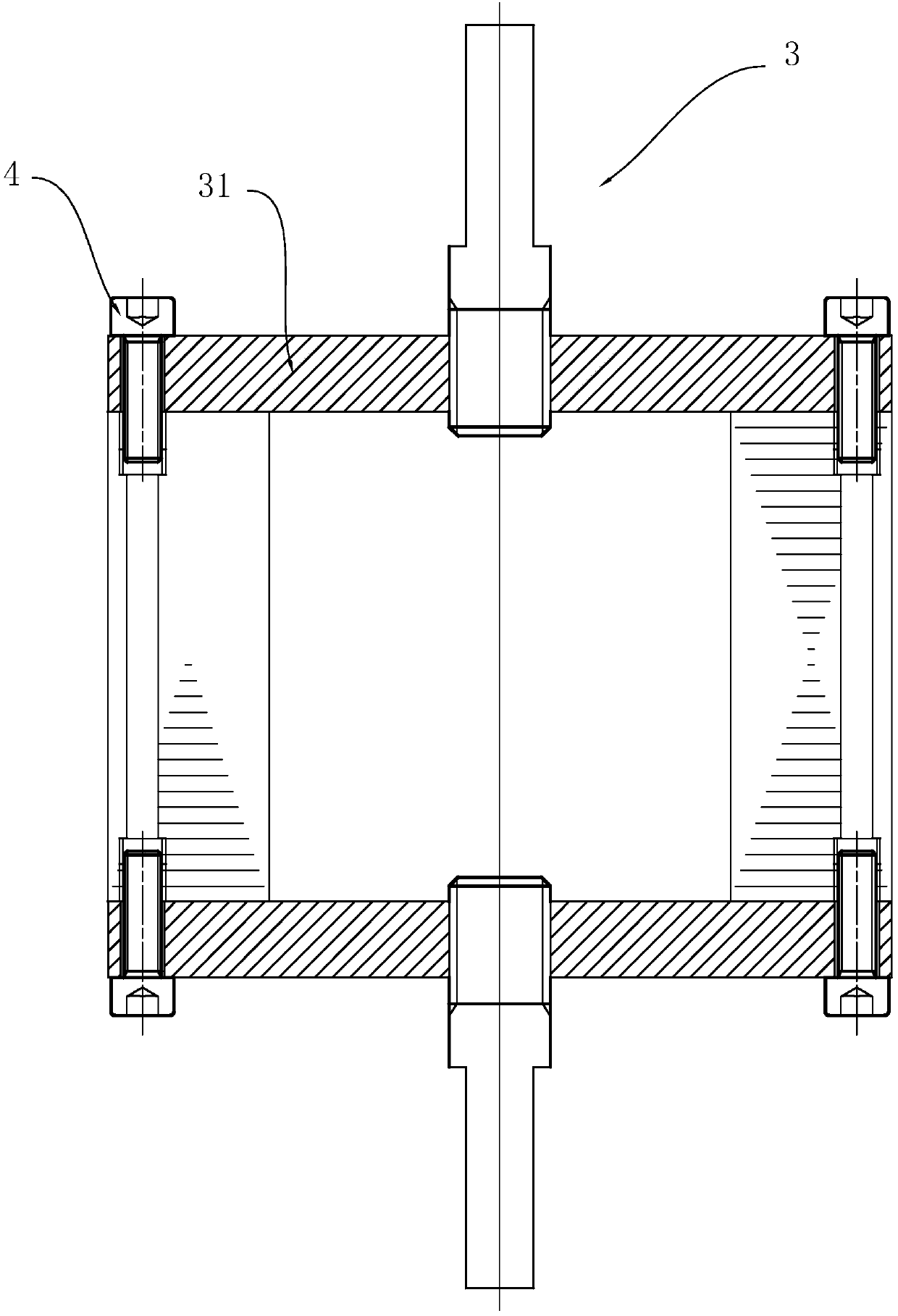

Auto-buckled motor core laminated riveting force testing mechanism and method

InactiveCN107764648AImprove rigidityEven by forceMaterial strength using tensile/compressive forcesEngineeringTensile testing

The invention relates to an auto-buckled motor core laminated riveting force testing mechanism and method. The problems that the conventional testing mechanism is unfavorable for balanced force measurement and large in test errors and the like are solved. With the adoption of the technical scheme, the testing mechanism comprises a wire thread insert and a tensile tool, wherein an axial wire threadinsert assembling hole is formed in an auto-buckled core; the wire thread insert is arranged in the wire thread insert assembling hole and is screwed with the wire thread insert assembling hole; anda bottom plate of the tensile tool is respectively buckled to two ends of the auto-buckled core and passes through a wire thread insert inner hole corresponding to the bottom plate by virtue of a screw so as to form screw joints in one-to-one correspondence with the wire thread insert. The testing mechanism has the technical effects that the wire thread insert is a whole, is fixed in a core screwhole and is tightly combined with the screw hole, and the overall rigidity of the core thread is excellent. During stretching, tension applied to the screw is transferred to the thread of the core screw hole by virtue of the wire thread insert, the stress of each punch is uniform, and the tensile testing precision is high.

Owner:SHIMGE PUMP IND GRP CO LTD

Heating wire supply device

ActiveCN108856599AReduce the accuracy of subsequent processingGuarantee the accuracy of subsequent processingProcessing accuracyInertia force

The invention discloses a heating wire supply device, and belongs to the technical field of wire harnesses. The heating wire supply device comprises a base, a lifting device and a heating insulation device, wherein the lifting device is arranged on the base, and the heating insulation device is fixed onto the base. A wire harness to be processed can be heated in a box to reach preset temperature by the heating insulation device, so that the wire harness can be sufficiently straightened by a straightener when in output, processed finished product length precision is improved, the rate of defective products is reduced, subsequent processing accuracy of the wire harness is ensured, a noise reduction strip is arranged on an insulation barrel, inertia force generated in wire looseness can be effectively decreased, collision and scratching with the insulation barrel are reduced, noise is reduced, excessive wire looseness is prevented, and a convection hot air inlet is formed in the insulation barrel to ensure uniform heating in the insulation barrel.

Owner:青岛凯睦自动化设备有限公司

Torsion rod forming machine and method for machining torsion rod by using torsion rod forming machine

The invention provides a torsion rod forming machine and a method for machining a torsion rod by using the torsion rod forming machine, belongs to the technical field of machine tools, and solves the problem of high manufacturing cost in a traditional vehicle safety belt force limiting torsion rod machining device. The torsion rod forming machine comprises a frame; the frame is provided with a clamping mechanism with a clamping mold and used for clamping a torsion rod blank; forming molds with end forming holes and extrusion rods inserted in the end forming holes are arranged on two sides of the clamping mold; and the frame is provided with a first hydraulic cylinder capable of driving the forming molds to butt against the side surface of the clamping mold and a second hydraulic cylinder capable of driving the extrusion rods to move in a direction of approaching the clamping mold. The torsion rod forming machine saves a lot of molds and punching mechanisms to largely reduce the manufacturing cost of the torsion rod forming machine; and the torsion rod forming machine is used for machining torsion rods to achieve the advantages of guaranteeing consistent quality of the torsion rods and improving the production efficiency.

Owner:玉环加鑫汽车配件有限公司

Automatic precision cutting equipment for Teflon pipe

InactiveCN109591064AImprove length accuracyImprove cut qualityMetal working apparatusEngineeringFixed length

Owner:东莞市元鹏五金电子科技有限公司

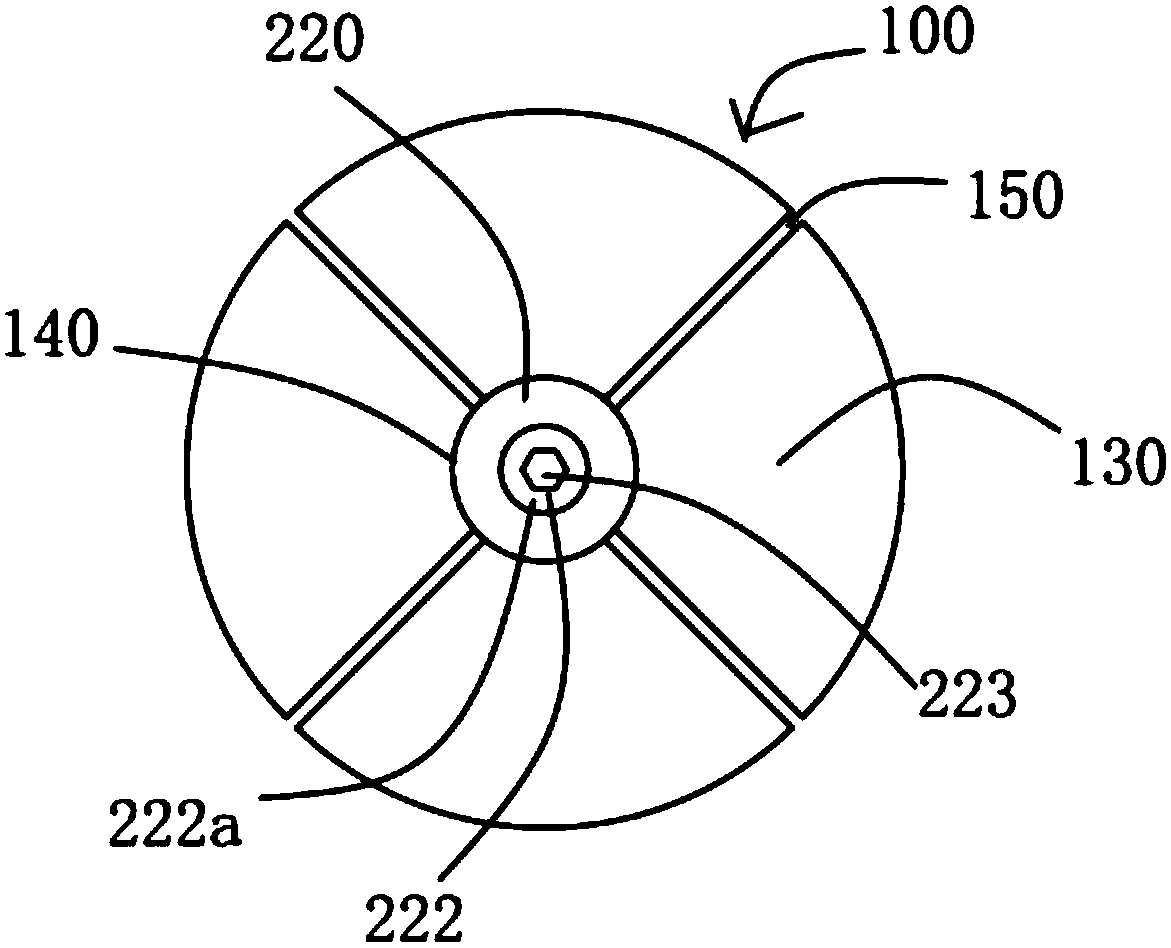

Precision cutting method for Teflon pipe

InactiveCN109591070AImprove length accuracyImprove cut qualityMetal working apparatusEngineeringFixed length

The invention provides a precision cutting method for a Teflon pipe. The precision cutting method comprises the following steps of A, preparing, B, conveying, C, cutting and D, outputting; in the stepA, the Teflon pipe (4) is pulled out of a Teflon pipe rotating disc and inserted into a conveying wheel conveying mechanism (21); in the step B, a conveying wheel driving mechanism (22) drives the conveying wheel conveying mechanism (21) to forward convey the Teflon pipe with a fixed length into the clamping mechanism (31); in the step C, a cutting driving mechanism (33) operates to drive a cutting mechanism (32) to operate to cut the Teflon pipe clamped in the clamping mechanism (31); in the step D, the conveying wheel driving mechanism (22) operates again to drive the conveying wheel conveying mechanism (21) to forward convey the Teflon pipe with the fixed length into the clamping mechanism (31) and to push forward the cut Teflon pipe into a collecting box (5); and the step C is returned, cutting and outputting are repeated. The length precision of the cut pipe can be effectively improved, the cutting quality is good, and the bending or flattening situation of the pipe is reduced oreven eliminated.

Owner:东莞市元鹏五金电子科技有限公司

Flour product length equal-division cutting device

PendingCN114393609AImprove work efficiencySmall footprintMetal working apparatusElectrical controlElectric control

The invention relates to a flour product length equal-division cutting device, relates to the technical field of flour product cutting, and solves the problems of tedious and redundant actions, non-uniform cutting length, inclined cutting surface, non-vertical lower cutter, low efficiency and the like during manual cutting of flour products in the prior art. The upper end of the control cabinet is provided with a placing assembly for placing flour products, a measuring sensor, a cutting assembly for equally cutting the flour products and a first driving part for driving the cutting assembly to move along the length direction of the control cabinet; the electric control device is used for controlling the placing assembly, the measuring sensor, the cutting assembly and the first driving piece, and the electric control device is arranged in the control cabinet; the device has the effects of improving the working efficiency, making the cut flour products tidy and attractive and occupying small space.

Owner:张林鹏

Precision cutting device of teflon pipe

ActiveCN109591067AImprove length accuracyImprove cut qualityMetal working apparatusEngineeringMechanical engineering

Owner:东台市高科技术创业园有限公司

Adjustable core-pulling fixture for oil pump shaft

The invention discloses an adjustable core-pulling fixture for an oil pump shaft. The adjustable core-pulling fixture comprises a clamping cylinder and a positioning core bar. The clamping cylinder sequentially comprises a small-diameter cylinder section, a conical cylinder section and a large-diameter cylinder section which are arranged coaxially. The small-diameter end and the large-diameter endof the conical cylinder section are connected with the small-diameter cylinder section and the large-diameter cylinder section correspondingly in a butting mode. Through holes allowing the oil pump shaft to be inserted are formed in the middles of the conical cylinder section and the large-diameter cylinder section. A plurality of deformation receding grooves are circumferentially formed in the cylinder walls of the conical cylinder section and the large-diameter cylinder section at intervals. An inner thread is arranged on the inner wall of the small-diameter cylinder section. An outer thread matched with the inner thread is arranged on the peripheral face of the positioning core bar. The first end of the positioning core bar is connected with a main machine, and a positioning face making contact with the end face of the oil pump shaft is arranged at the second end of the positioning core bar. The adjustable core-pulling fixture adapts to the oil pump shafts with the different lengths and outer diameters, and positioning precision is improved.

Owner:衡山同远机械有限公司

An automatic hanging device for propellant and explosive sticks

ActiveCN111196749BImprove length accuracyRealize human-machine isolation operationExplosive working-up apparatusExplosive AgentsReciprocating motion

Owner:XIAN MODERN CHEM RES INST

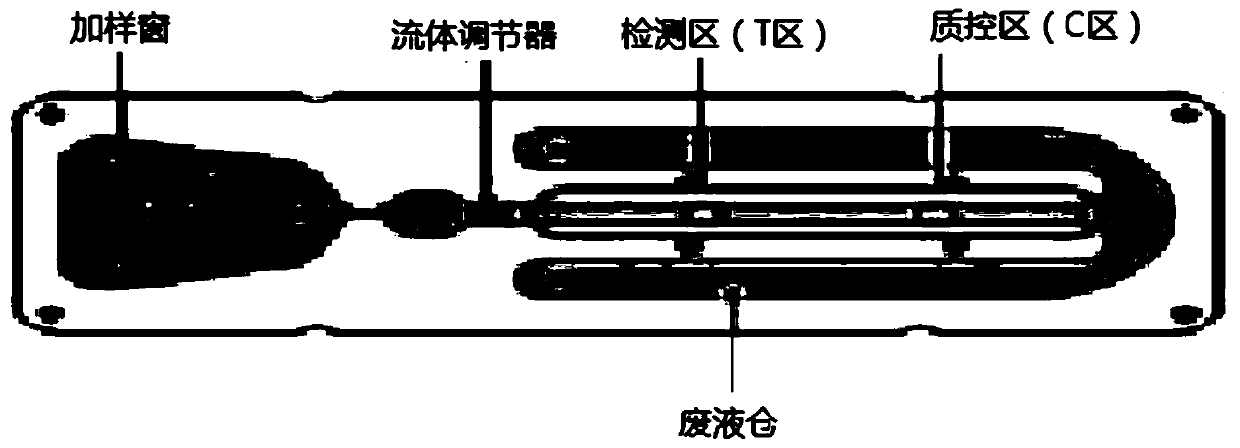

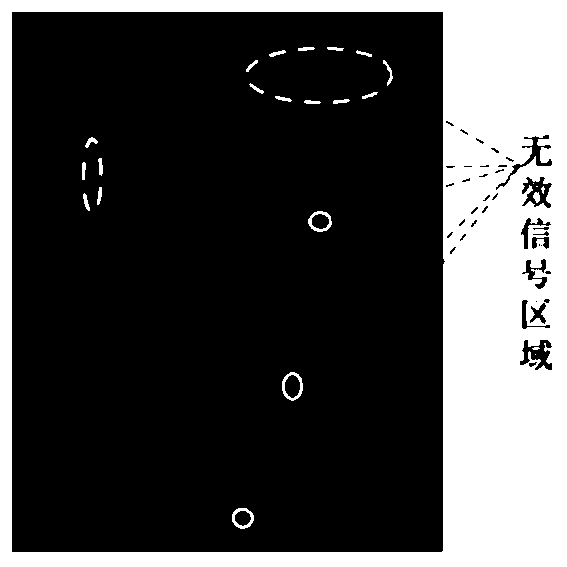

Micro-fluidic biochip scanning signal detection device

ActiveCN110208229AImprove length consistency and accuracyImprove reliabilityLaboratory glasswaresFluorescence/phosphorescencePhysicsFluorescence

The invention discloses a micro-fluidic biochip scanning signal detection device. The micro-fluidic biochip scanning signal detection device comprises an acquisition and filtering module of an original scanning signal for acquiring scanning signals of induced fluorescent signals on a micro-fluidic biochip to-be-tested area and a flow channel; a wavelet transform module of the scanning signals foracquiring the lengths of the scanning signals in T and C areas; an equal time length determination module of the scanning signals for acquiring the lengths of effective signals of the T area and the Carea; a signal extraction module for extracting effective scanning signals of the T area and the C area; a signal homogenization reconstruction module for homogenizing and reconstructing the effective scanning signals of the T and C areas; and a concentration calculation module of a tested object for acquiring the concentration of the tested object according to the area of the scanning signals after reconstruction of the T and C areas. The above device is applied to a micro-fluidic biochip scanning type detection process, and can solve the problem of inconsistent lengths of extracted signalsin the T area and the C area of the induced fluorescence, non-uniform distribution of measured signals in the areas and the like.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV +1

Hardware processing equipment

ActiveCN109396859BPrevent splashImprove cleanlinessOther manufacturing equipments/toolsPipe fittingEngineering

The invention belongs to the technical field of machining of hardware and particularly discloses hardware machining equipment. The hardware machining equipment comprises a base; the base is horizontally provided with a machining hole; the base is further internally provided with an upper chamber, a lower chamber and a grinding chamber; the machining hole is positioned between the upper chamber andthe lower chamber; a cutting knife is arranged inside the upper chamber; the lower part of the cutting knife extends to a position above the machining hole; the lower chamber and the grinding chamberare each internally provided with a lifting mechanism; the lifting mechanism inside the lower chamber is provided with first fixing claws which can be used for fixing a pipe part; the lifting mechanism inside the grinding chamber is provided with second fixing claws which can be used for fixing the pipe part; the first fixing claws and the second fixing claws both extend into the machining hole;the upper end of the grinding chamber communicates with the machining hole; the second fixing claws are positioned inside the grinding chamber; the two sides of the grinding chamber are each providedwith a circular platform-shaped grinding block; and each grinding block is provided with abrasive paper. The invention aims to provide the hardware machining equipment which can be used for implementing both cutting and grinding of the pipe part.

Owner:宁波隆锐机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com