Adjustable core-pulling fixture for oil pump shaft

A technology for oil pump shafts and fixtures, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of clamp damage, cumbersome operation, and non-adjustable oil pump shaft core-pulling fixtures, etc., and achieve the effect of improving length accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

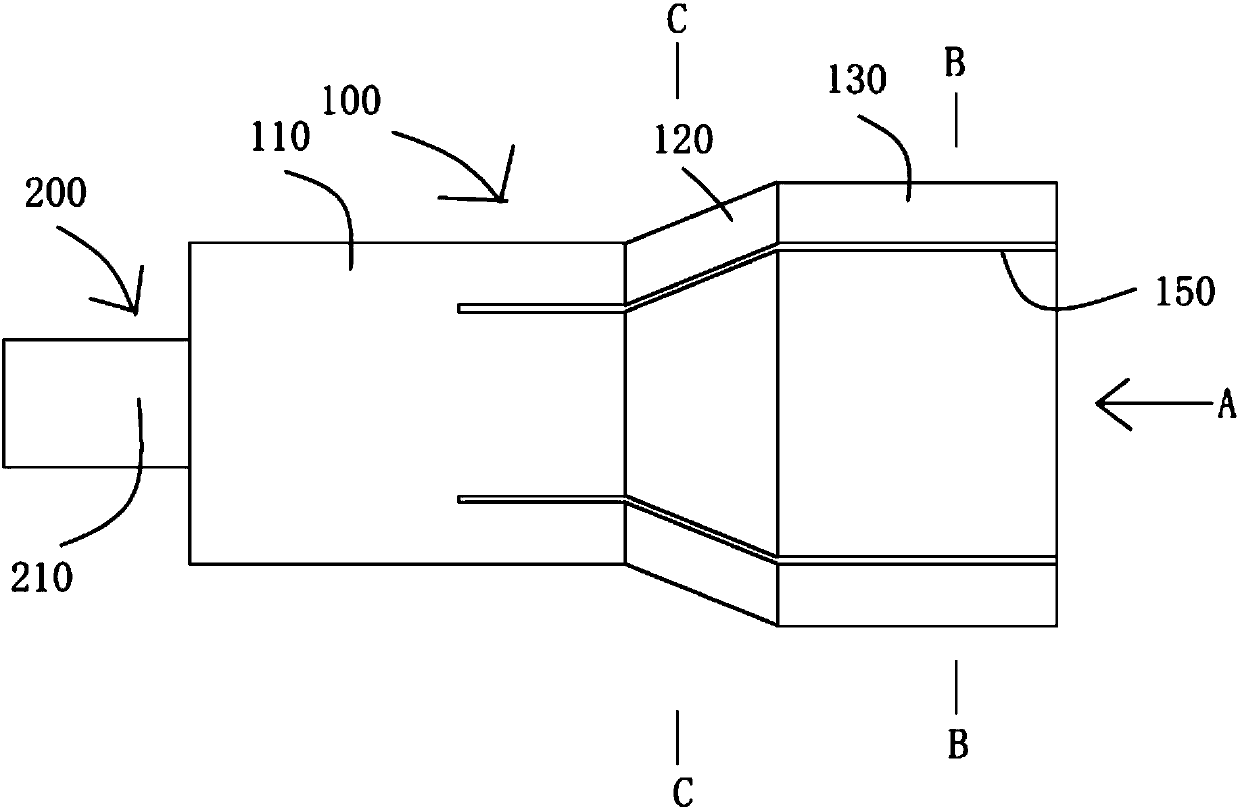

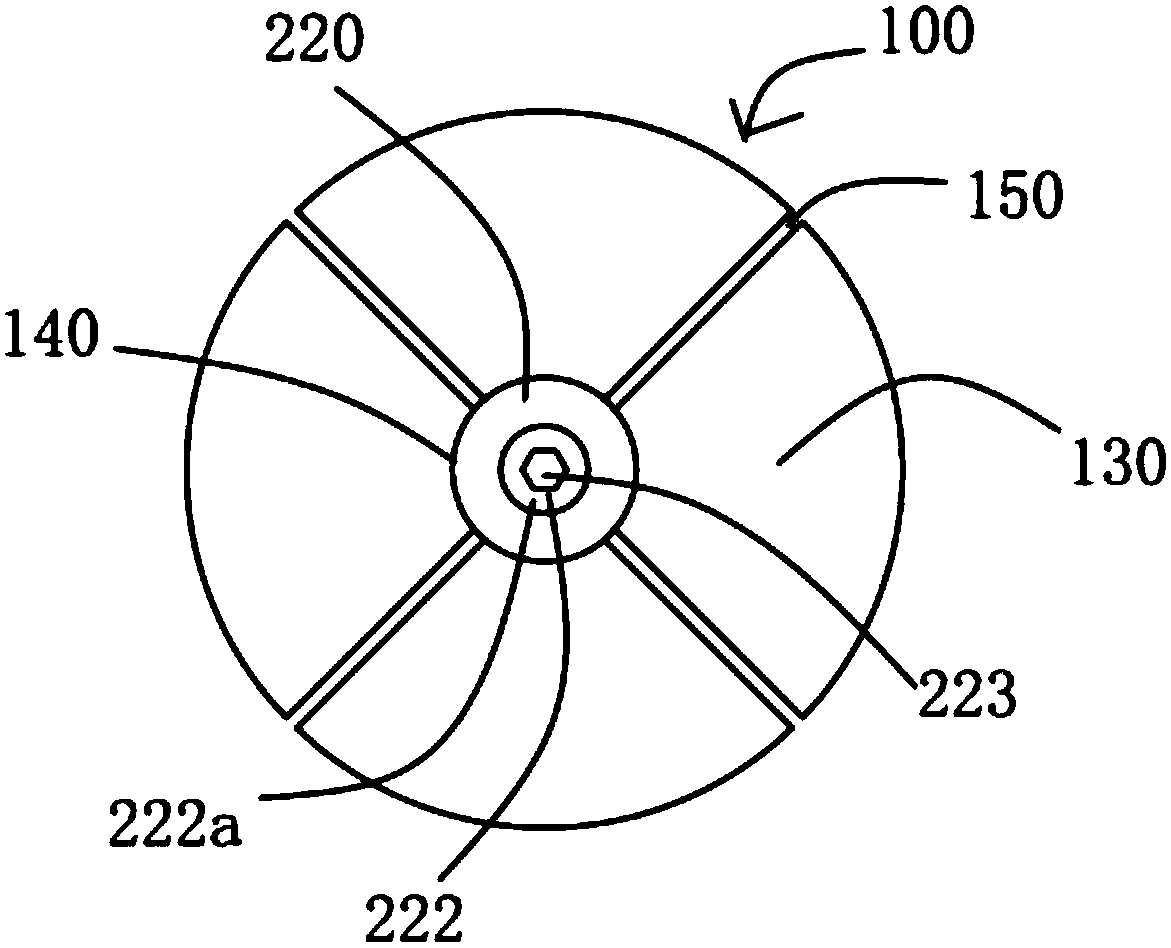

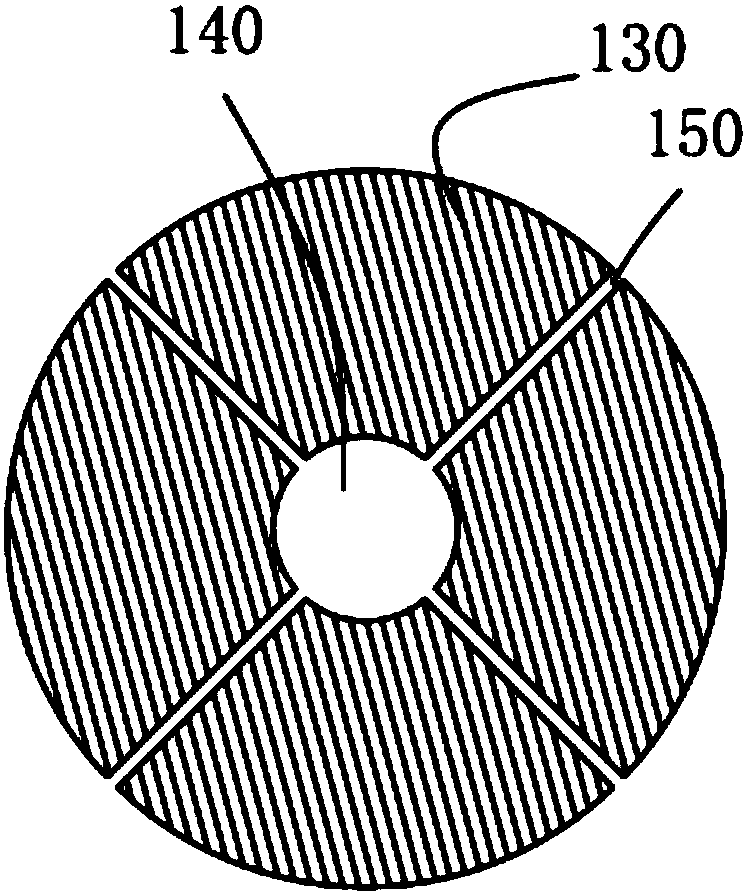

[0017] see Figure 1 to Figure 5 The shown adjustable jig for core pulling of the oil pump shaft includes a clamping cylinder 100 and a positioning mandrel 200 . The clamping cylinder 100 sequentially includes a small-diameter cylinder section 110 , a conical cylinder section 120 and a large-diameter cylinder section 130 arranged coaxially. The small-diameter end 121 and the large-diameter end 122 of the tapered barrel section 120 are respectively connected to the small-diameter barrel section 110 and the large-diameter barrel section 130 . The middle part of the tapered barrel section 120 and the large-diameter barrel section 130 is provided with a through hole 140 into which the shaft of the oil supply pump is inserted, and the barrel walls of the tapered barrel section 120 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com