Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Improve laying accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

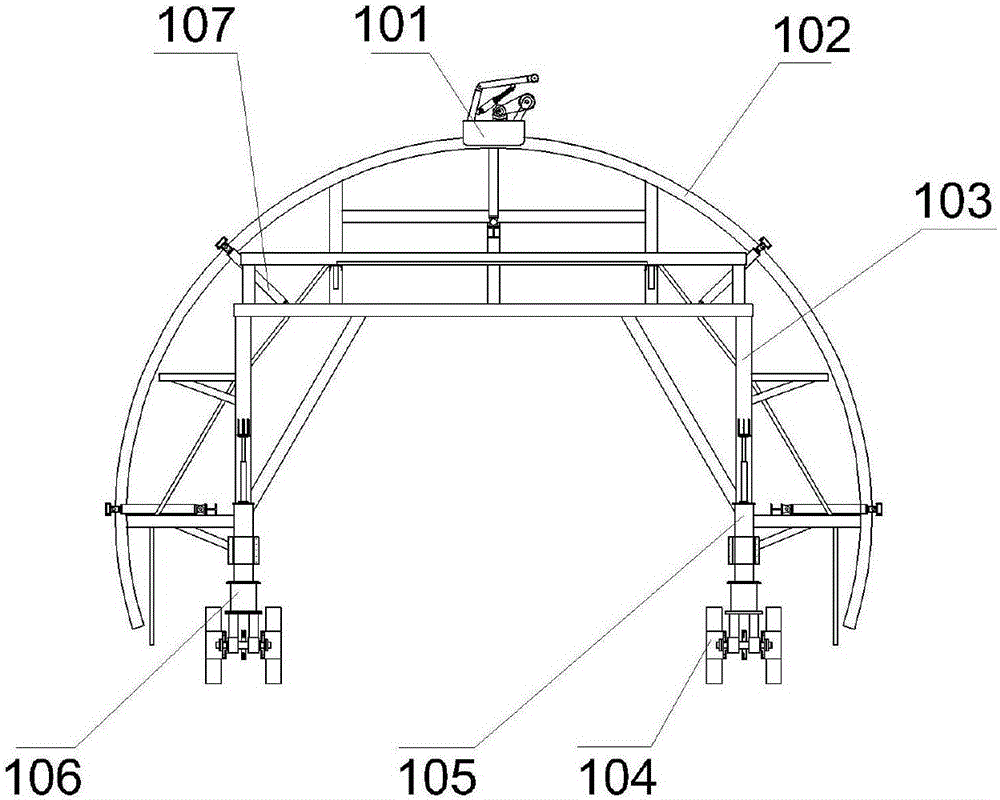

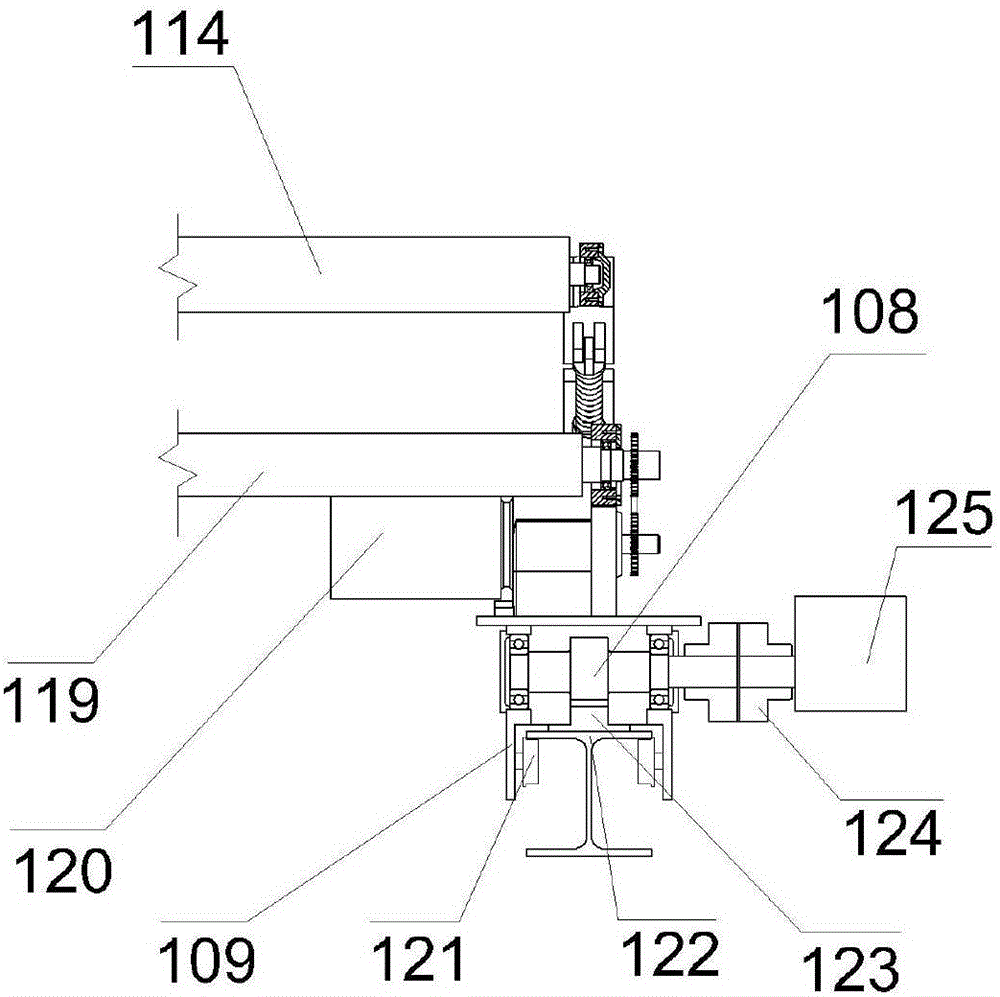

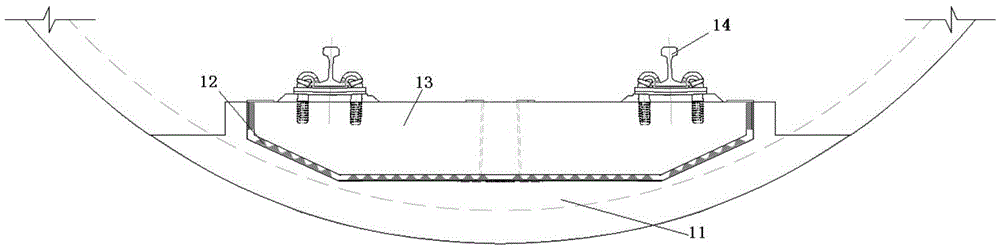

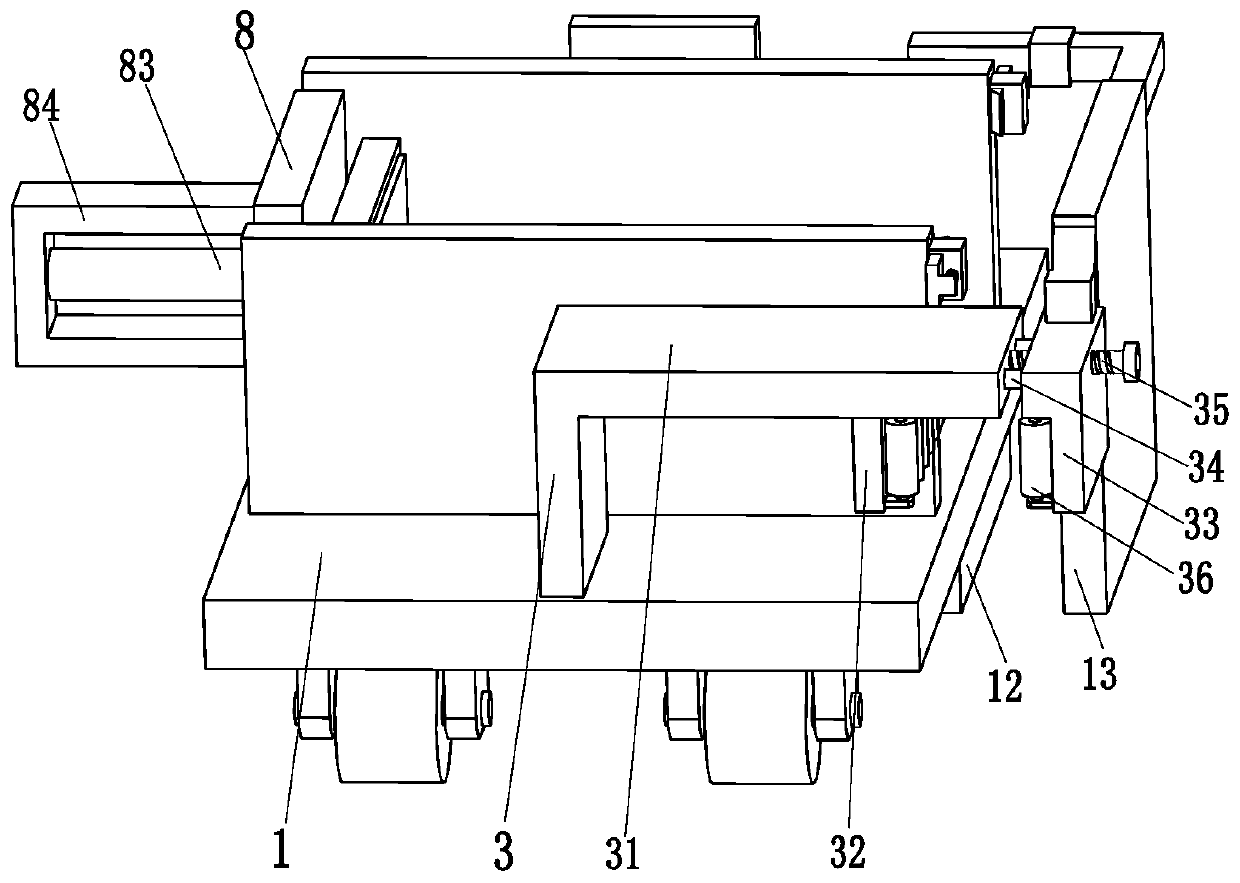

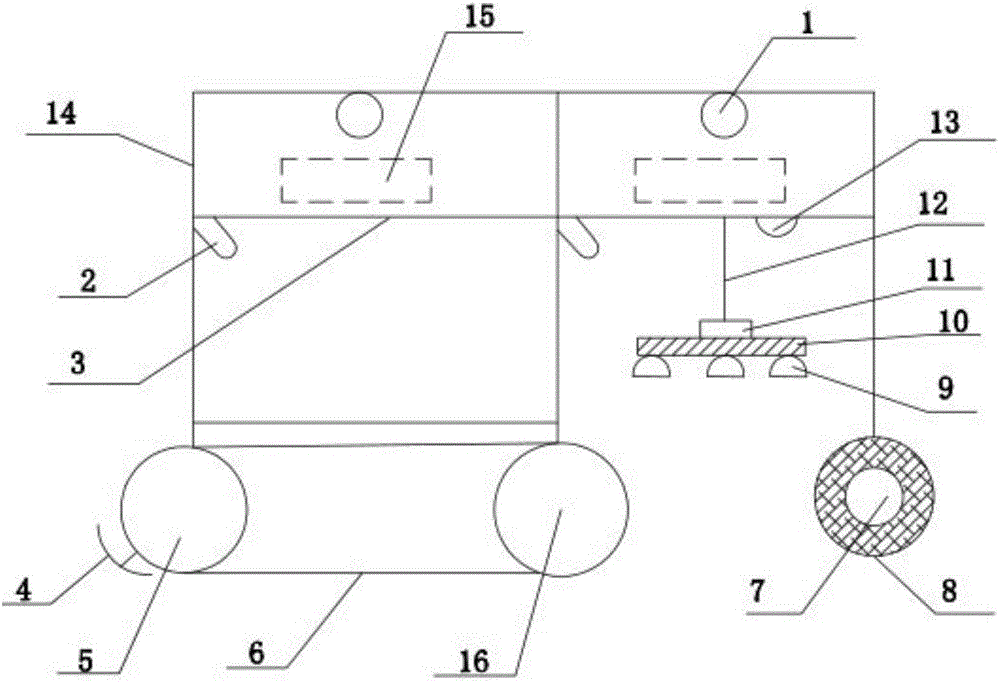

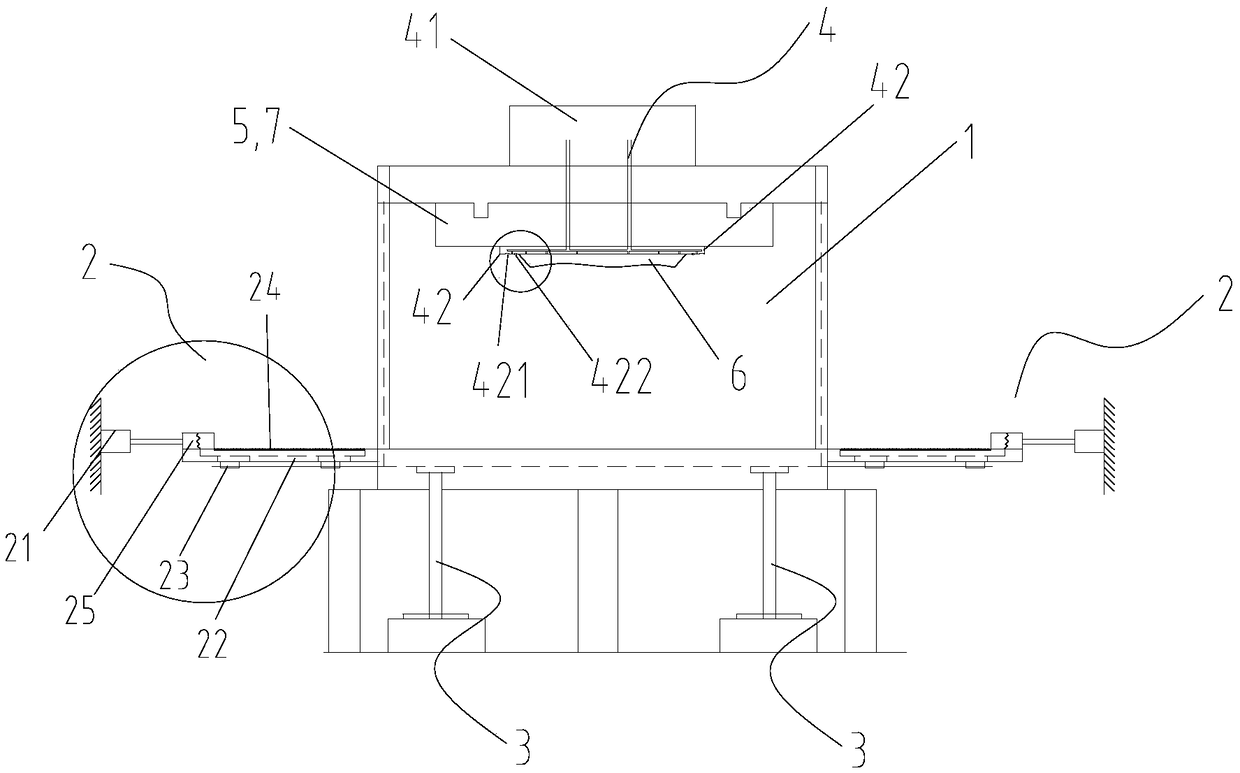

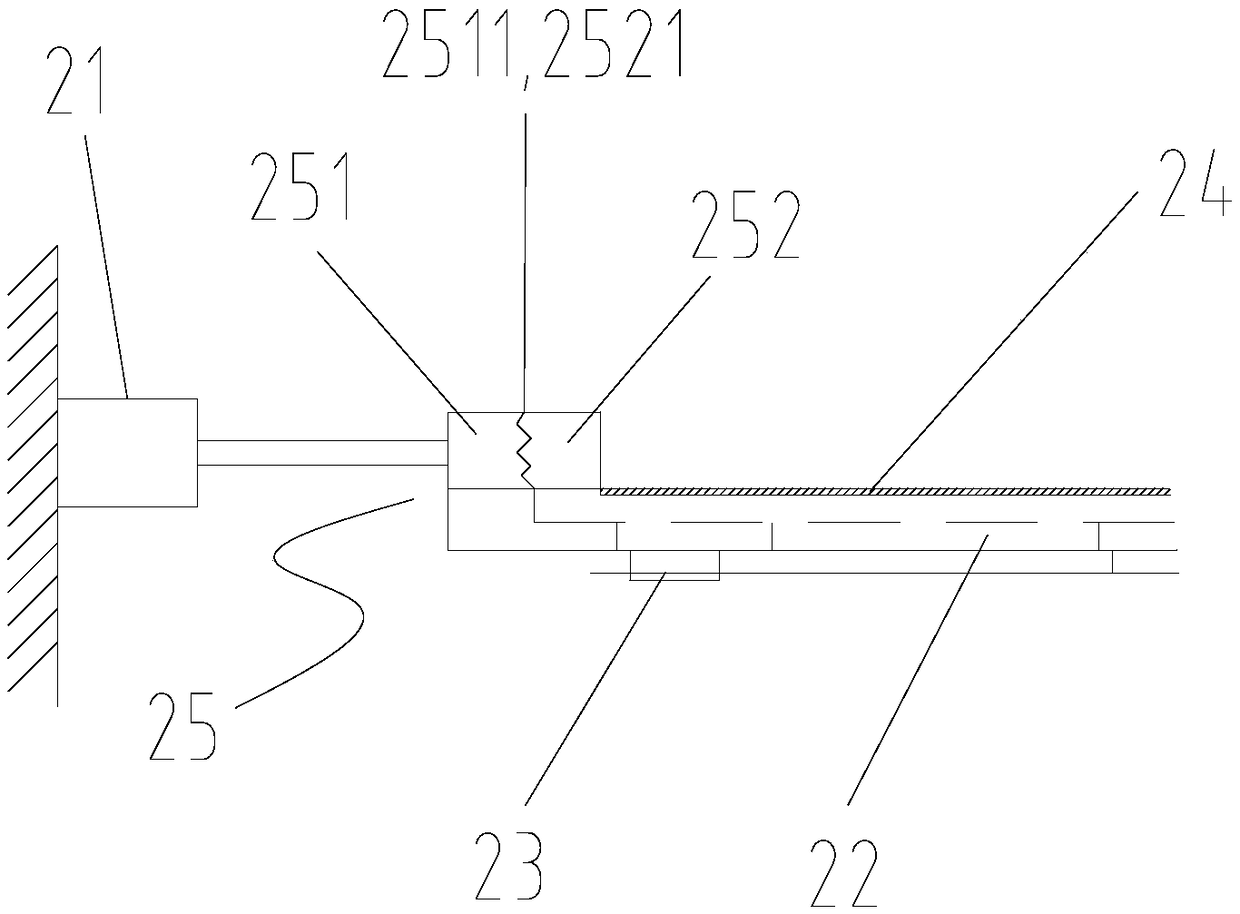

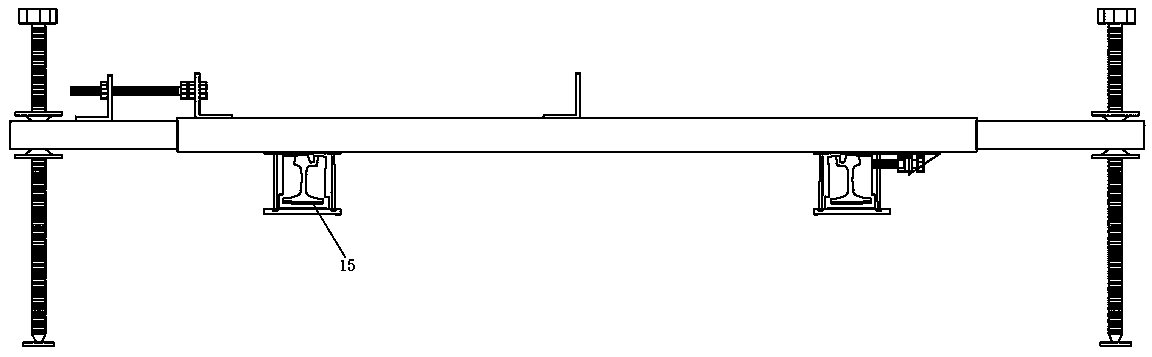

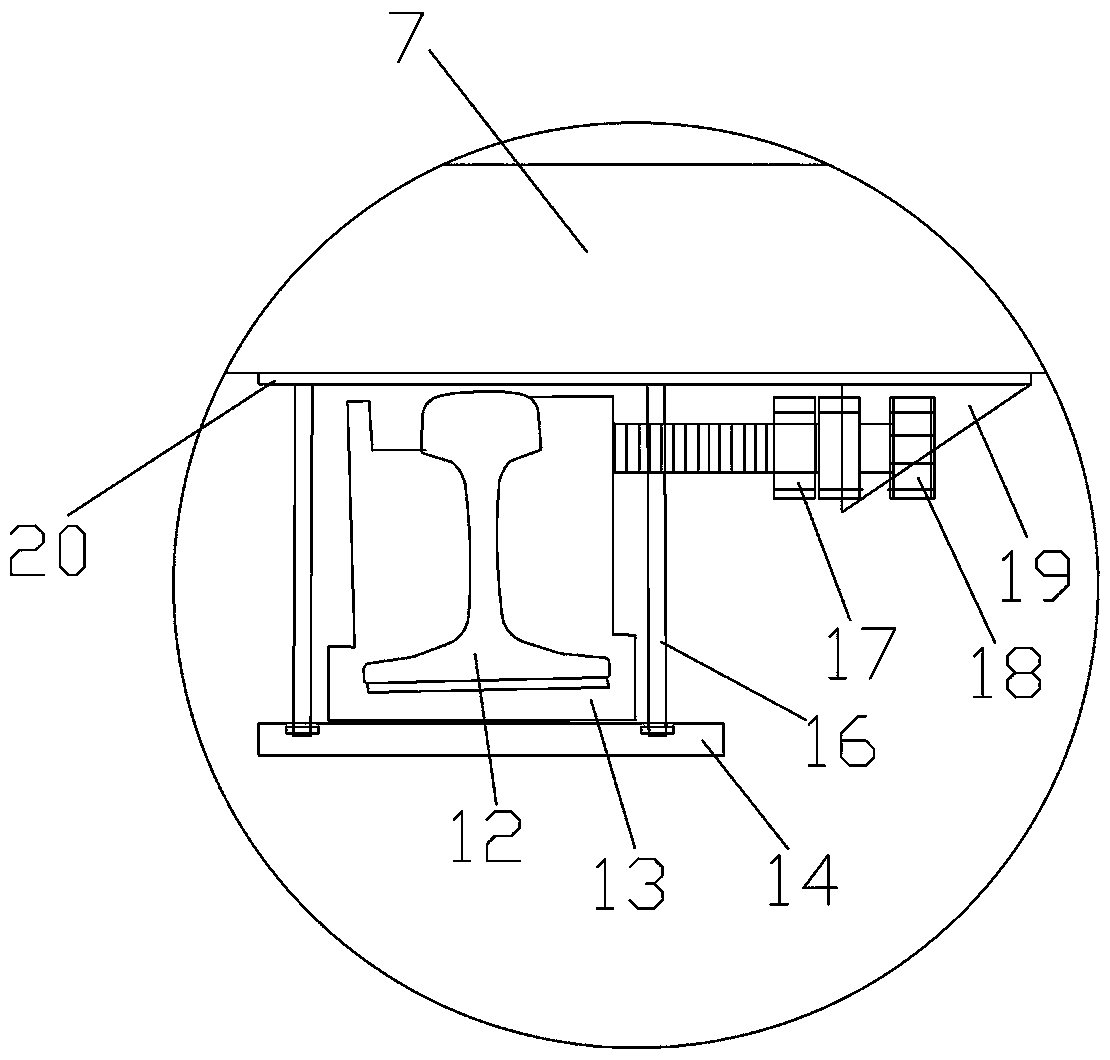

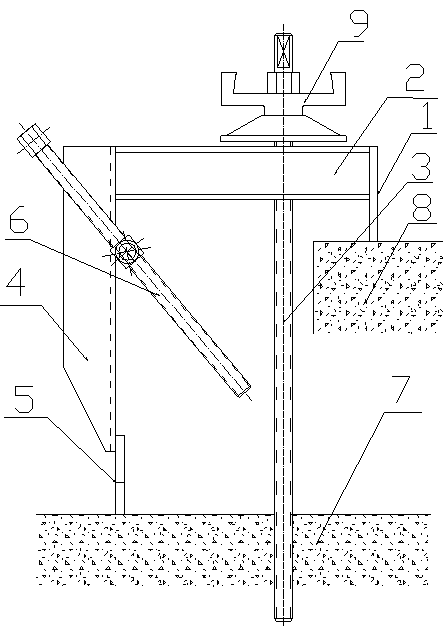

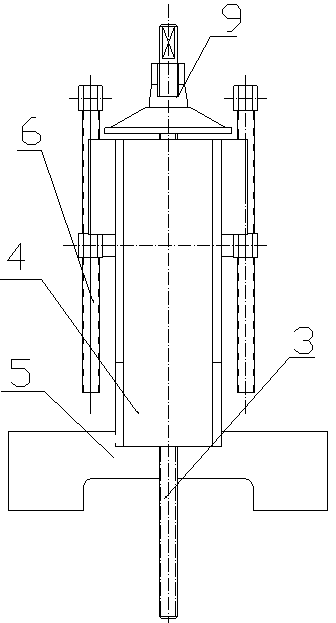

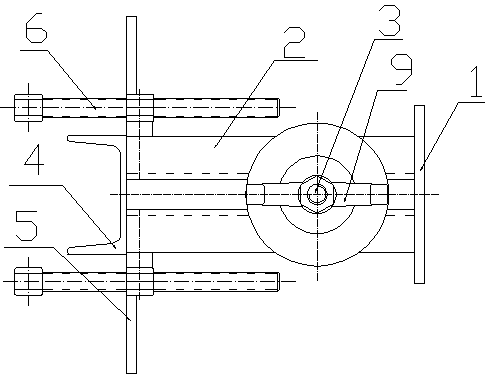

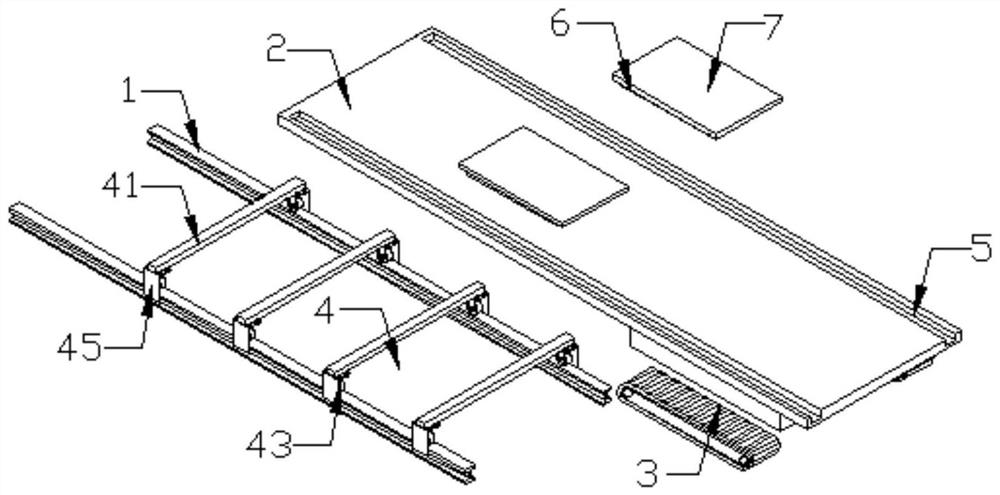

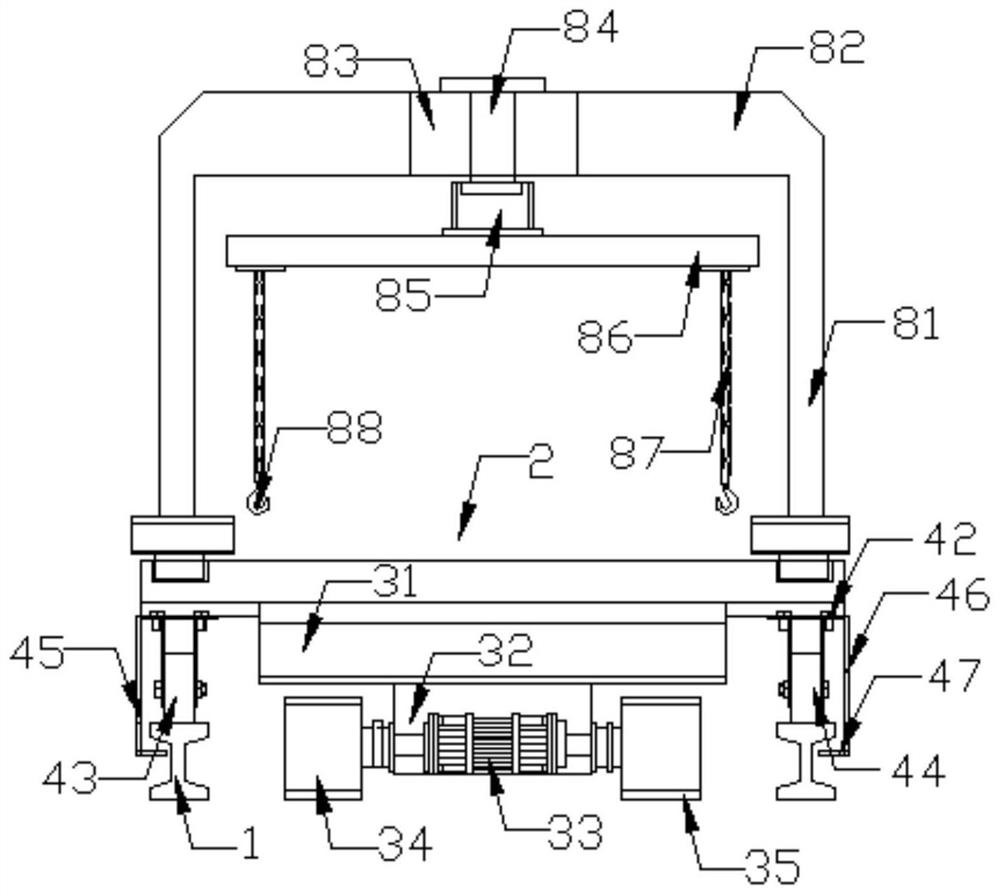

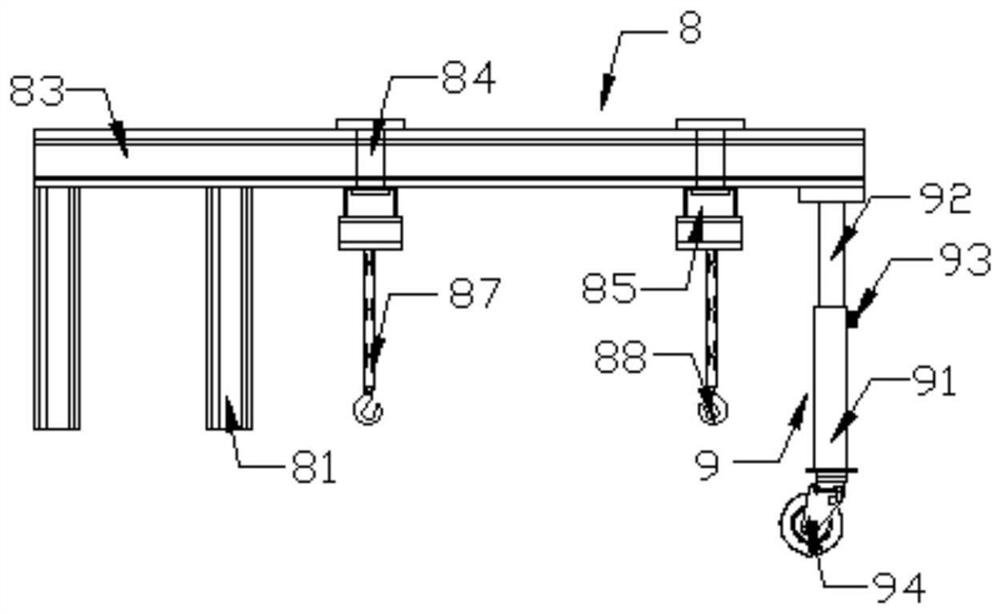

Tunnel automatic waterproof plate trolley

InactiveCN105736021AImplement autocastAvoid wrinklesUnderground chambersTunnel liningTunnel wallEngineering

The invention provides an automatic waterproof board trolley for tunnels, belonging to the technical field of tunnel construction, which includes a trolley main body, a walking trolley, a cloth rolling device, a rolling device and a trolley walking track; the trolley main body is provided with a road walking mechanism; The cloth device includes a driving device and a cloth rolling shaft; the driving device drives the cloth rolling shaft to work; the rolling device includes a bracket and a rolling roller. The tunnel automatic waterproof board trolley realizes the automatic release of the waterproof board through the rolling device, and rolls the deployed waterproof cloth and the tunnel wall tightly through the rolling device to avoid wrinkles of the waterproof board, and the rolling device can walk along The trolley moves along the trolley track and is suitable for the entire tunnel contour; therefore, it improves the laying accuracy of the waterproof board, so that the waterproof board can fit the tunnel wall completely according to the tunnel contour, without a large gap in the middle, and ensures the reserved sag, thereby improving the waterproof effect; at the same time, reducing the labor intensity of workers and improving work efficiency.

Owner:TUNNEL TANG TECH

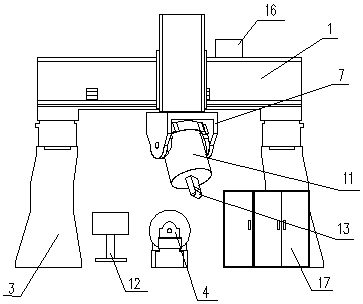

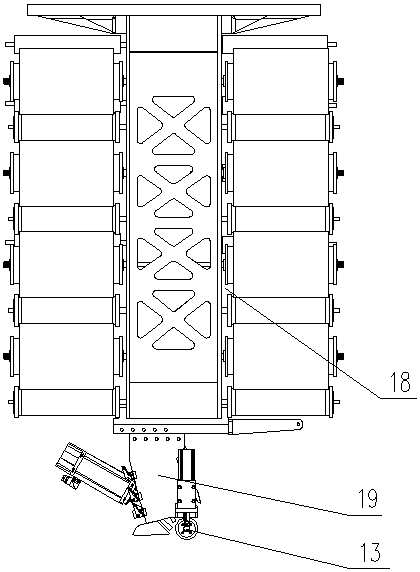

Automatic fiber placing device for placing fibrous composite material

PendingCN108422685ATurn freely and convenientlyGuaranteed rotation attitude at any angleHead pressingControl system

The invention discloses an automatic fiber placing device for placing a fibrous composite material. Two servo motors A drive two output gears to be rotated along an X-directional long rack, so a crossbeam is driven to be slid along a longitudinal beam; a servo motor B drives a sliding base to be slid along the cross beam; a servo motor C drives a Z-directional screw rod to be rotated, so a ram isdriven to be upwards and downwards slid along the sliding base; a C-axis rotation mechanism fixed on a fixing body drives a C-axis rotation body to be rotated along a C-axis of a center shaft of theC-axis rotation body; an A-axis rotation mechanism drives a swinging body to be rotated along an A-axis of an axial lead of two coaxial shafts; a C1-axis rotation mechanism fixed on the swinging bodydrives a creel to be rotated along a C1-axis of a center shaft of the creel; a fiber placing head and a fiber placing head press roller are fixed at the lower end of the creel; a control system controls the C-axis, C1-axis and A-axis rotation mechanisms and a brake device to be operated; and a servo motor D drives a workpiece to be rotated along a rotation principal axis of the workpiece. The automatic fiber placing device is high in placement precision, rapid in speed, high in placement working efficiency, and stable in placement quality.

Owner:BAODING BIAOZHENG MACHINE TOOL

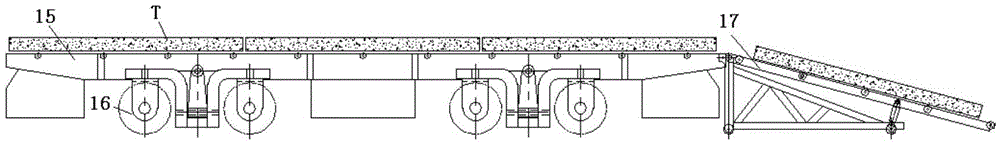

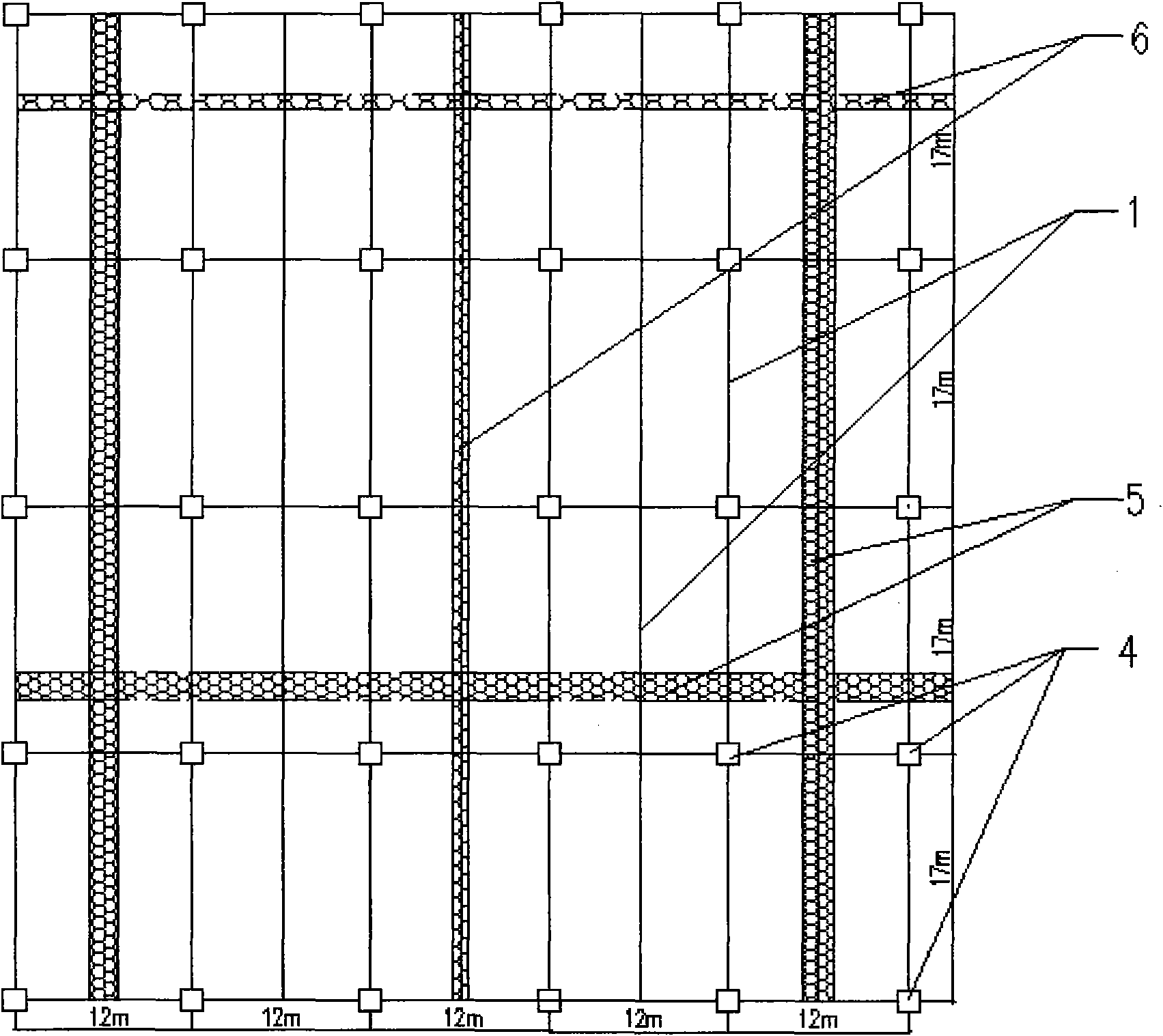

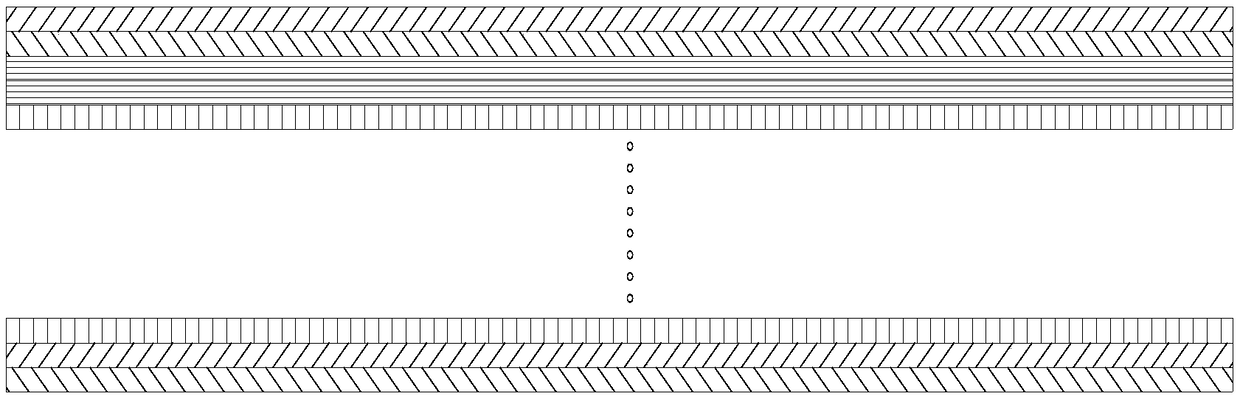

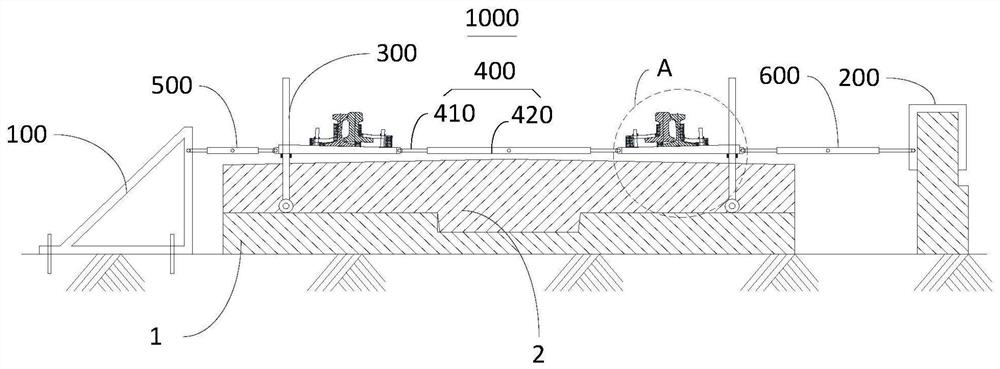

Construction method for precast type vibration damping track board

ActiveCN105625105AImprove laying efficiencyImprove laying accuracyBallastwayRailway track constructionEngineeringUltimate tensile strength

The invention relates to a construction method for a precast type vibration damping track board. The construction method comprises the steps such as track board prefabrication, plate cushion compounding, transportation, lifting and unloading, track board positioning, concrete pouring, concrete maintaining, accessory buckling, steel rail laying and the like. The method adopts an inverse construction method from top to bottom, so that no-rail type laying of the track board is realized; and the track board laying precision is high, the construction progress is quick and the labor intensity is low.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

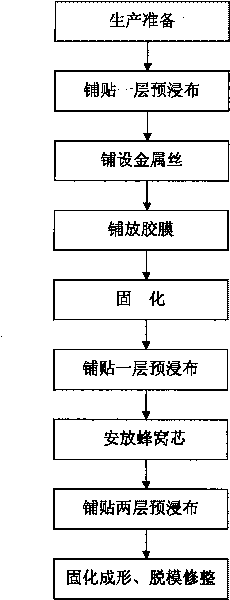

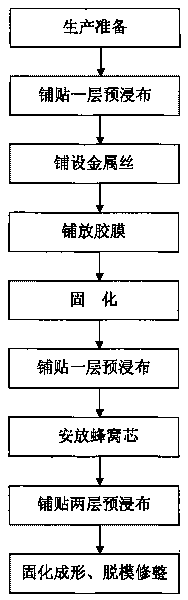

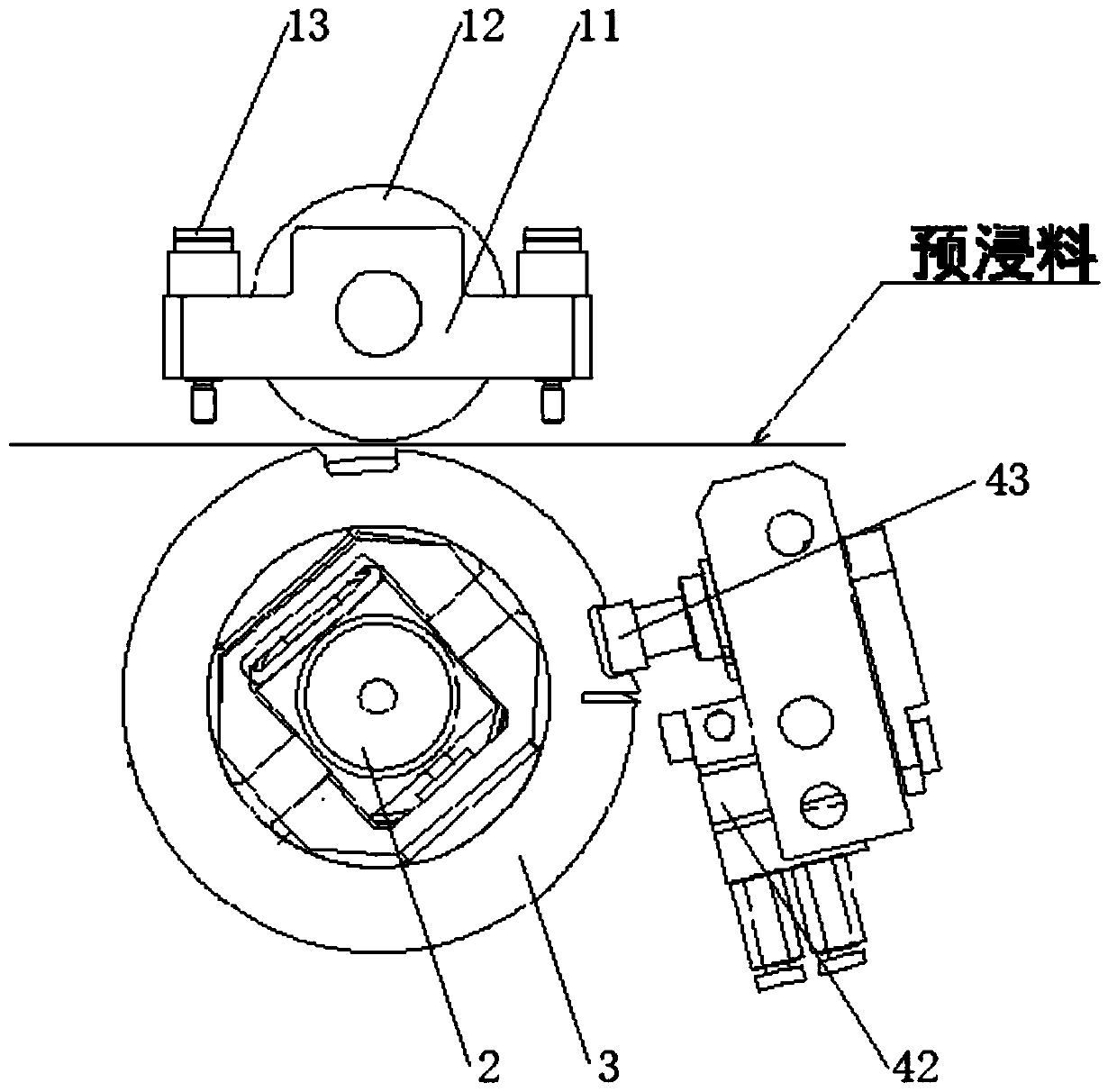

Metal wire laying method

The invention discloses a metal wire laying method, which is a process method for paying off along the coordinate system direction of the body surface and grooving and laying by adopting a numerical control machine through a metal wire laying device, and comprises the following steps: paying off along the coordinate system direction of the body surface and grooving and laying a metal wire (2) on the surface of a device for laying, molding and positioning; and after fixing the metal wire (2), molding the meal wire (2) on the device for laying, molding and positioning and transferring the metalwire (2) to the body surface of the product through laying, vacuum-pumping and curing on the surface of a prepreg. By using the characteristics of the numerical control machine, parallel lines or oblique lines in equivalent width / space change can be laid without being limited by the body, the metal wires which have a diameter phi of 0.1 to 1 mm and are made of different soft materials can be laidon the surface of any body, laying precision and speed are high, and the metal wire laying method effectively solves the problem that the metal wire cannot be laid on the surface of an uneven complexbody with larger curvature.

Owner:XIAN AIRCRAFT IND GROUP

Railway laying device

ActiveCN109944122ARealize mobile crane layingImprove mobile stabilityRailway track constructionCivil engineering

Owner:林最隆

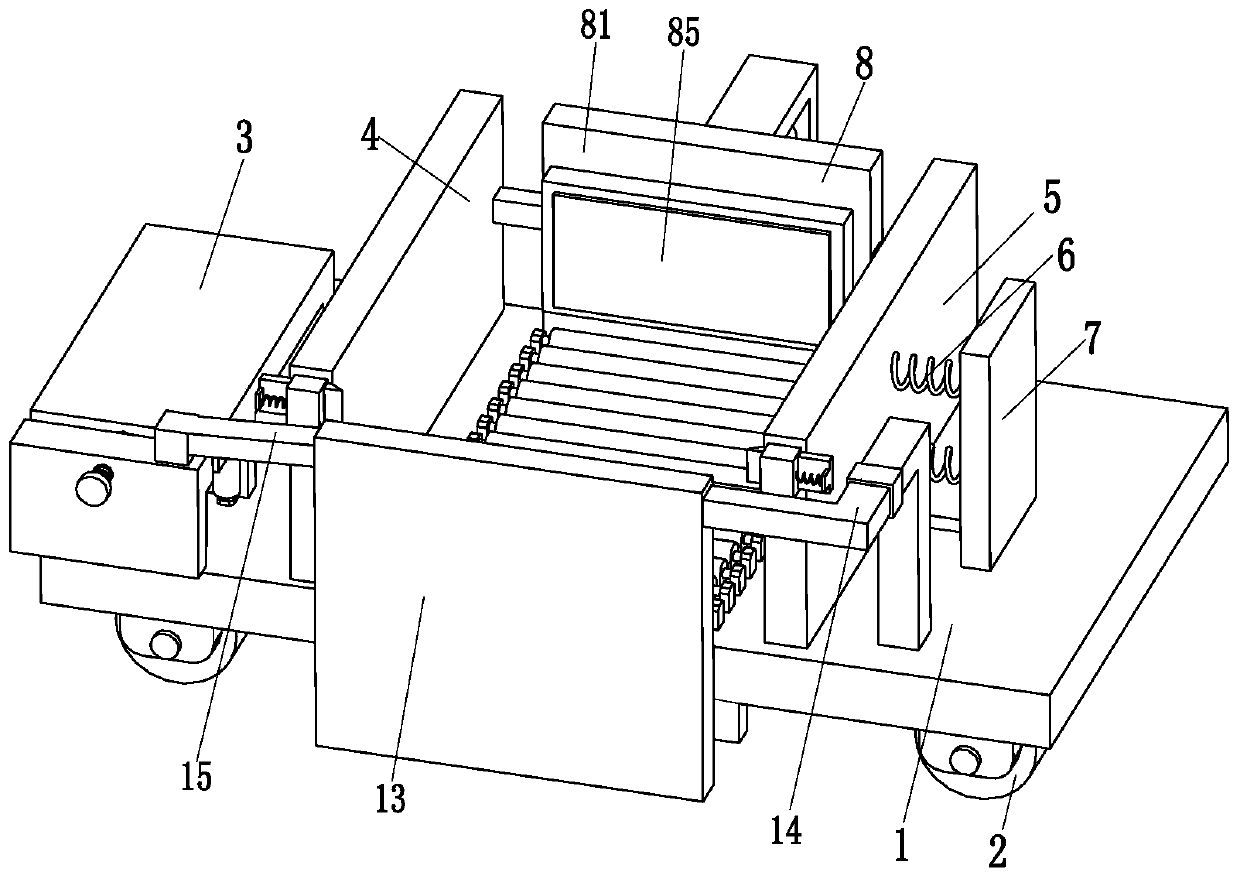

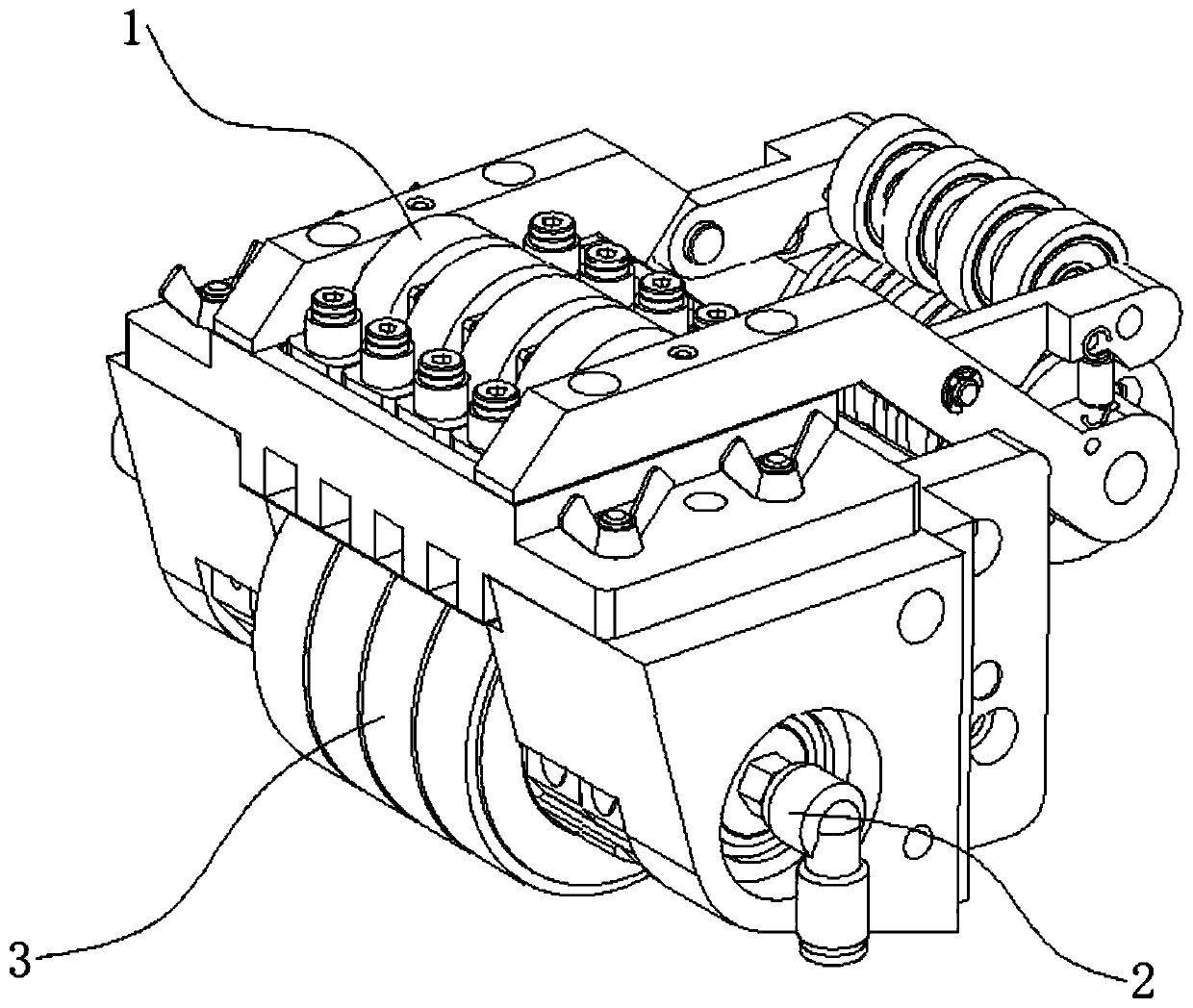

Ceramic tile clamping mechanism and ceramic tile laying robot

ActiveCN110905177AImprove laying accuracyPrevent slidingGripping headsBuilding constructionsCeramic tilesEngineering

The invention relates to the technical field of construction machinery, and discloses a ceramic tile clamping mechanism and a ceramic tile laying robot. According to the tile clamping mechanism provided by the invention, a sucking disc, a first clamping assembly and a second clamping assembly are arranged, and therefore, a tile can not only be sucked by the sucking disc, but also can be clamped bya first clamping piece and a second clamping piece, and the tile can be effectively prevented from sliding relative to the sucking disc through the cooperation of the first clamping piece and the second clamping piece, and accordingly the laying precision is improved advantageously; in addition, by arranging the first clamping piece and the second clamping piece to be liftable in the thickness direction of a mounting plate, that is, the first clamping piece and the second clamping piece can be moved in the thickness direction of the tile, the first clamping piece and the second clamping piececan be moved away from the tile in the direction close to the mounting plate when the tile is clamped in the laying position; and therefore, when tiles are laid, the first clamping piece and the second clamping piece are prevented from being inserted into gaps between adjacent tiles, and interference with tiles already laid beside is avoided.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

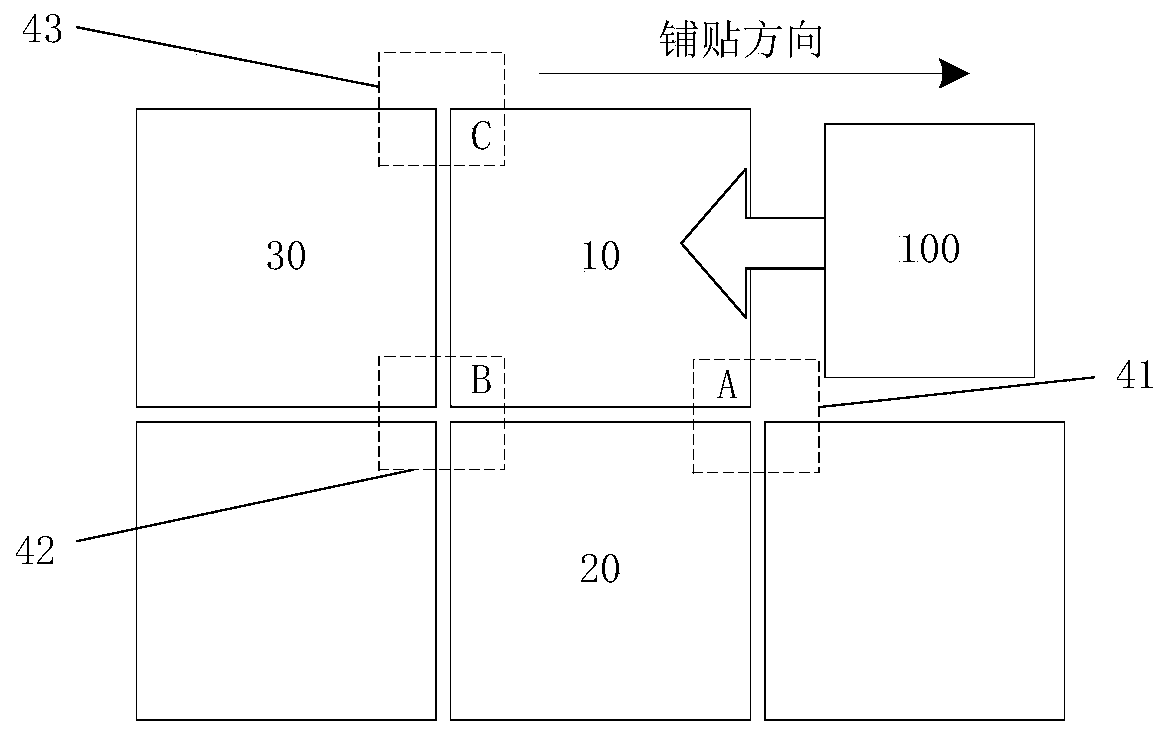

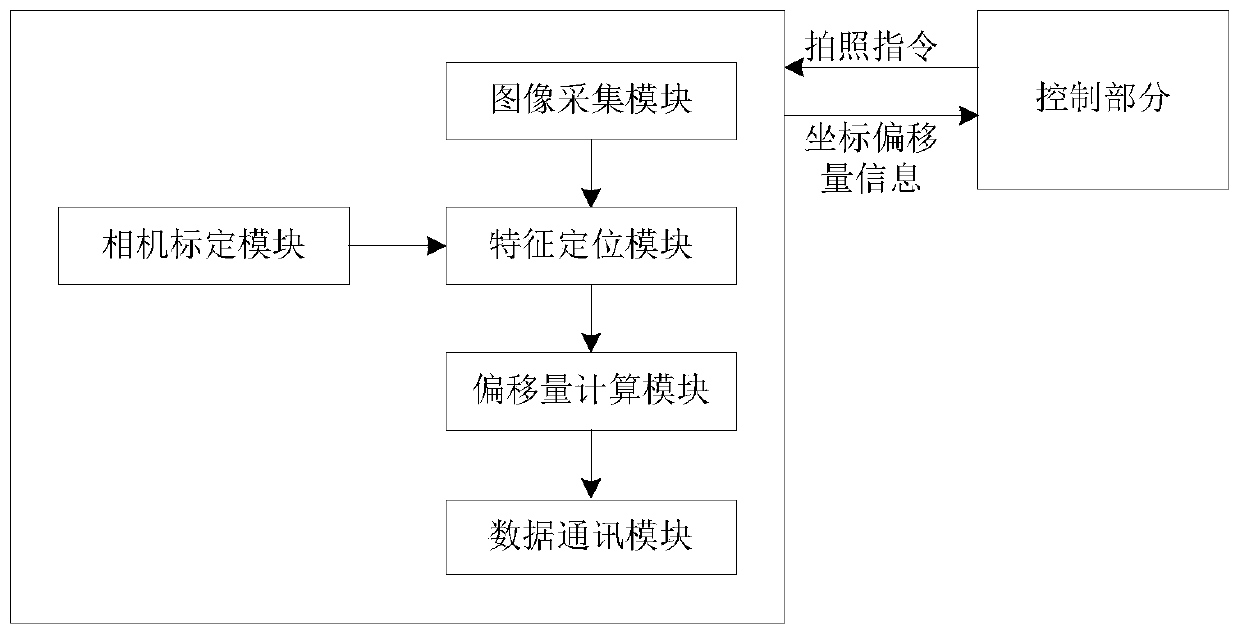

Handling system, control method thereof and floor tile laying system

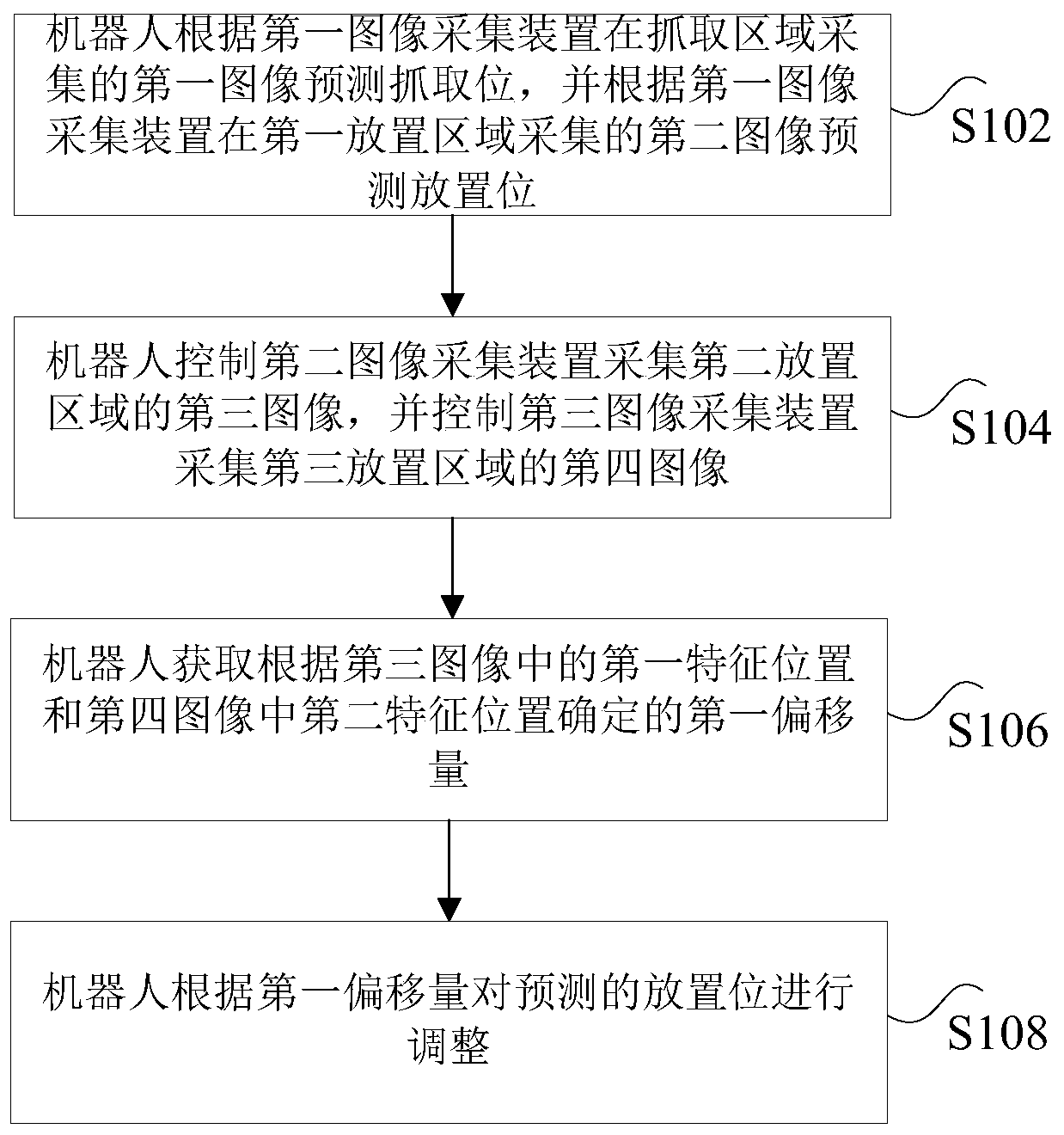

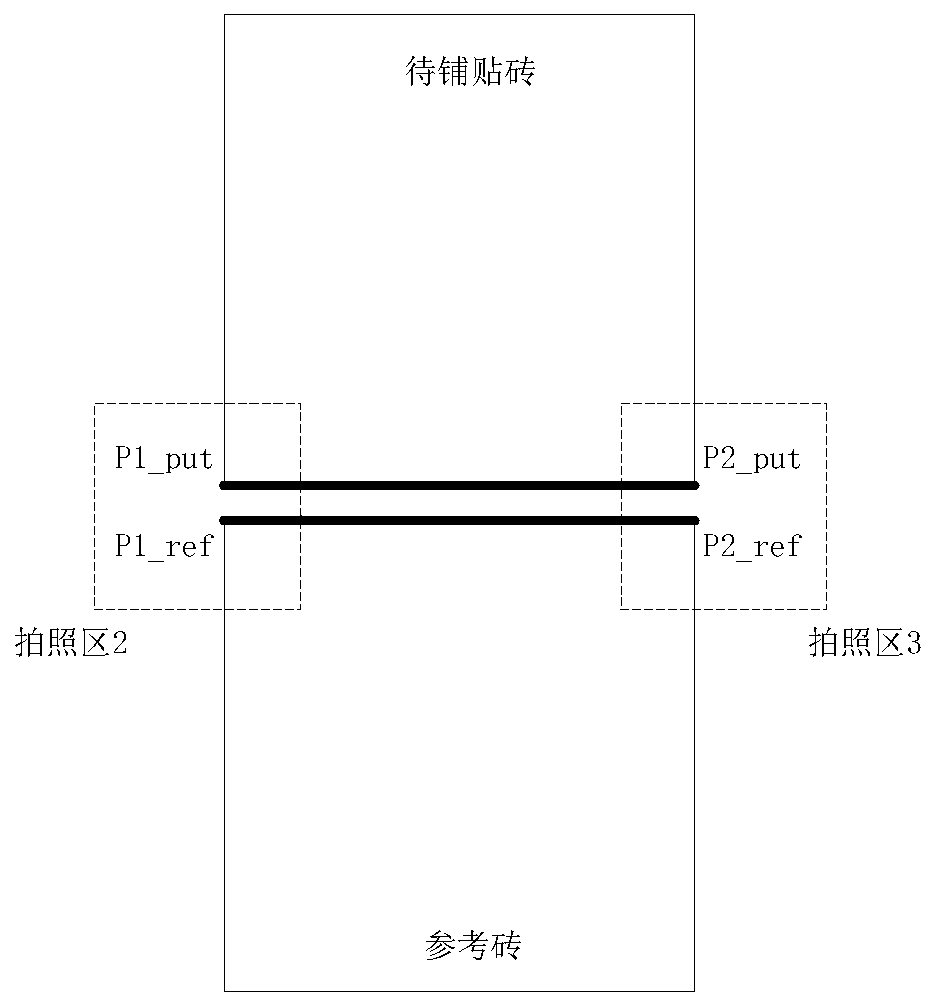

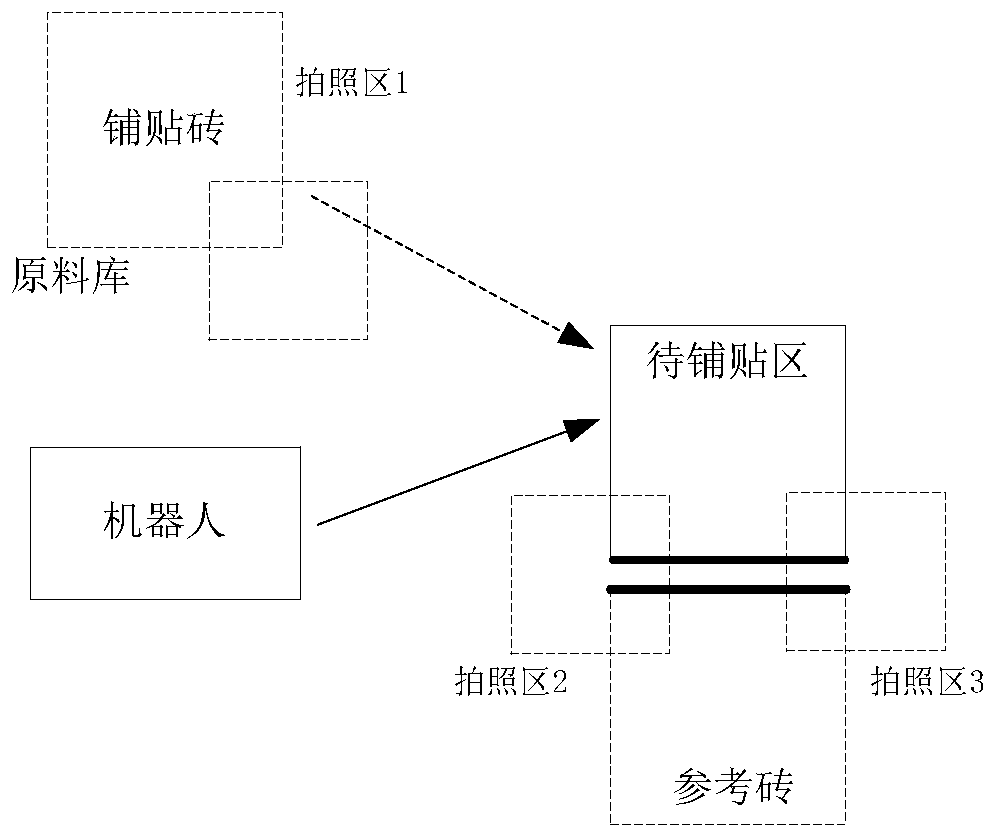

ActiveCN110303498AImprove laying accuracyProgramme-controlled manipulatorGripping headsBrickRobot control

The invention discloses a handling system, a control method thereof and a floor tile laying system. The control method of the handling system comprises the following steps: a robot predicts a grabbingposition according to a first image acquired by a first image acquisition device in a grabbing area, and predicts a placing position according to a second image acquired by the first image acquisition device in a first placing area; the robot controls a second image acquisition device to acquire a third image of a second placing area, and controls a third image acquisition device to acquire a fourth image of a third placing area, wherein the second placing area and the third placing area comprise two different feature positions of a placed object; the robot acquires a first offset determinedaccording to the first feature position in the third image and the second feature position in the fourth image, wherein the first offset is used for representing the deviation of the actual placing position from the predicted placing position; the robot adjusts the predicted placing position based on the first offset. According to the invention, the technical problem that the robot for laying floor tiles in the prior art cannot meet the laying precision requirement is solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Road kerb mounting and building equipment

ActiveCN111188247AHigh laying continuityImprove laying accuracyRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to road kerb mounting and building equipment which comprises a walking support plate, walking wheels, a limiting mechanism, a fixed plate, a sliding plate, sliding springs, a spring support plate and a pushing mechanism. The walking wheels are symmetrically mounted at the bottom of the walking support plate. The limiting mechanism is mounted at the top of the left end of thewalking support plate. The fixed plate is connected with the top of the walking support plate. A sliding groove is transversely formed in the top of the right end of the walking supporting plate, andthe sliding groove of the walking supporting plate is connected with the sliding plate in a sliding fit mode. The right side face of the sliding plate is connected with the spring support plate through the sliding springs, and the spring support plate is installed at the top of the right end of the walking support plate. The pushing mechanism is installed at the top of the rear end of the walkingsupport plate. The problems in existing kerb laying can be solved, namely, the kerbs need to be carried and placed manually, the kerb laying continuity is low, the manual workload is large due to manual carrying of the kerbs, and certain potential safety hazards exist.

Owner:中源宏宇建设集团有限公司

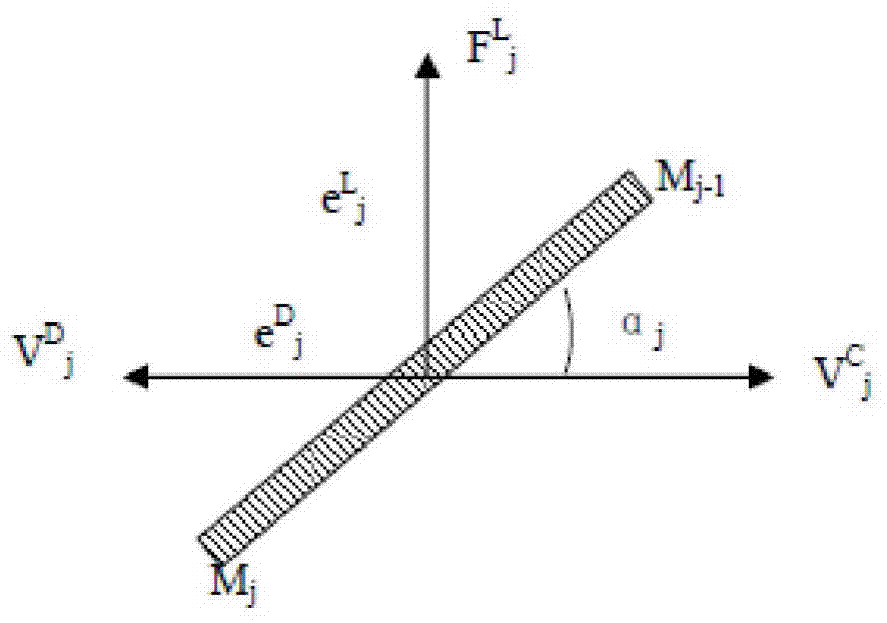

Coaxial double-rotor unmanned helicopter modeling method based on optical cable laying

Disclosed is a coaxial double-rotor unmanned helicopter modeling method based on optical cable laying. The method comprises flexible optical cable dynamics modeling at a constant tension release state and an optical cable laying unmanned helicopter dynamics model for a flight control system. The flexible optical cable dynamics modeling at the constant tension release state comprises stress calculating method of a single optical cable segment and a whole optical cable dynamics model establish method. The optical cable laying unmanned helicopter dynamics model for the flight control system comprises an unmanned helicopter platform dynamics model and an unmanned helicopter parameter identification test system, and it is set that: a), a whole optical cable to be laid is composed of N optical cable segments; b), each segment is sequentially released from a release mechanism, and the speed of the currently releasing optical cable segment is consistent with the speed of the just released optical cable segment; c), each optical cable segment is taken as a rigid rod, and the mass is concentrated at one end point of each optical cable segment; and d), the rigid rods are connected through twists. The coaxial double-rotor unmanned helicopter modeling method provided by the invention provides support for development of the flight control system of an unmanned helicopter.

Owner:SHENZHEN MINGXIN AVIATION TECH

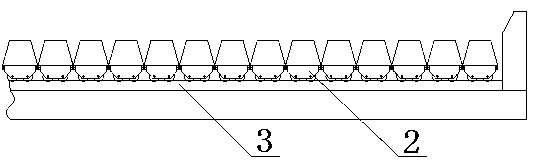

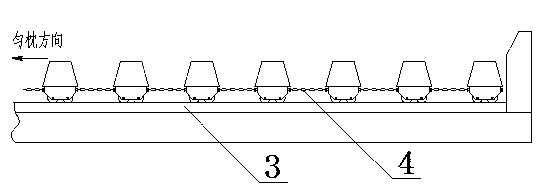

Sleeper evenly arranging device and evenly arranging construction method used for group-sleeper-type sleeper laying unit

ActiveCN103161103ARealize automatic leveling operationOvercoming the Technical Difficulties in Laying Ballasted Track LinesRailway track constructionNatural stateMechanization

The invention discloses a sleeper evenly arranging device and an evenly arranging construction method used for a group-sleeper-type tail laying unit. The sleeper evenly arranging device and the evenly arranging construction method used for the group-sleeper-type tail laying unit have the advantages that automatically and evenly arranging working of sleepers is achieved, foundation is established for successful development of a group-sleeper-type long-sleeper sleeper laying unit, a sleeper laying working manner of a ballast seamless track is radically changed, and due to the fact that during a sleeper laying construction process, the sleepers are horizontally conveyed in a natural state mode, the group-sleeper-type long-sleeper sleeper laying unit works stably, the phenomena of sleeper-clamping and sleeper-turnover are avoided, and impact on an sleeper laying mechanism caused by the sleepers is eliminated. Compared with a sleeper laying unit with a single sleeper method, the group-sleeper-type tail laying unit with the sleeper evenly arranging device eliminates a multi-level sleeper conveying mechanism, the structure is greatly simplified, various mechanisms are relatively independent, working is reliable, maintenance is convenient, sleeper laying accuracy is high, adaptability to the track is good, and a mechanization working degree is high.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +2

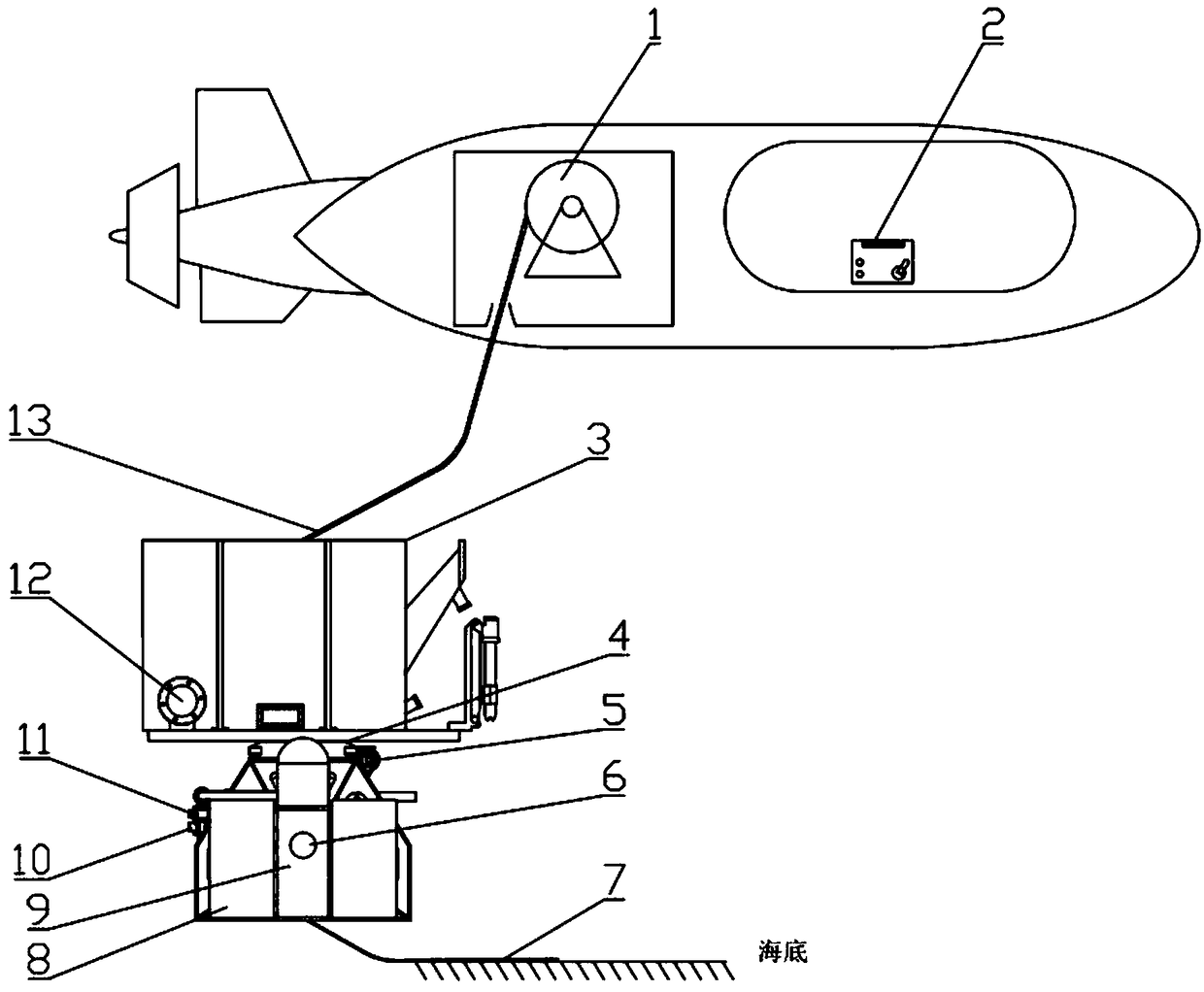

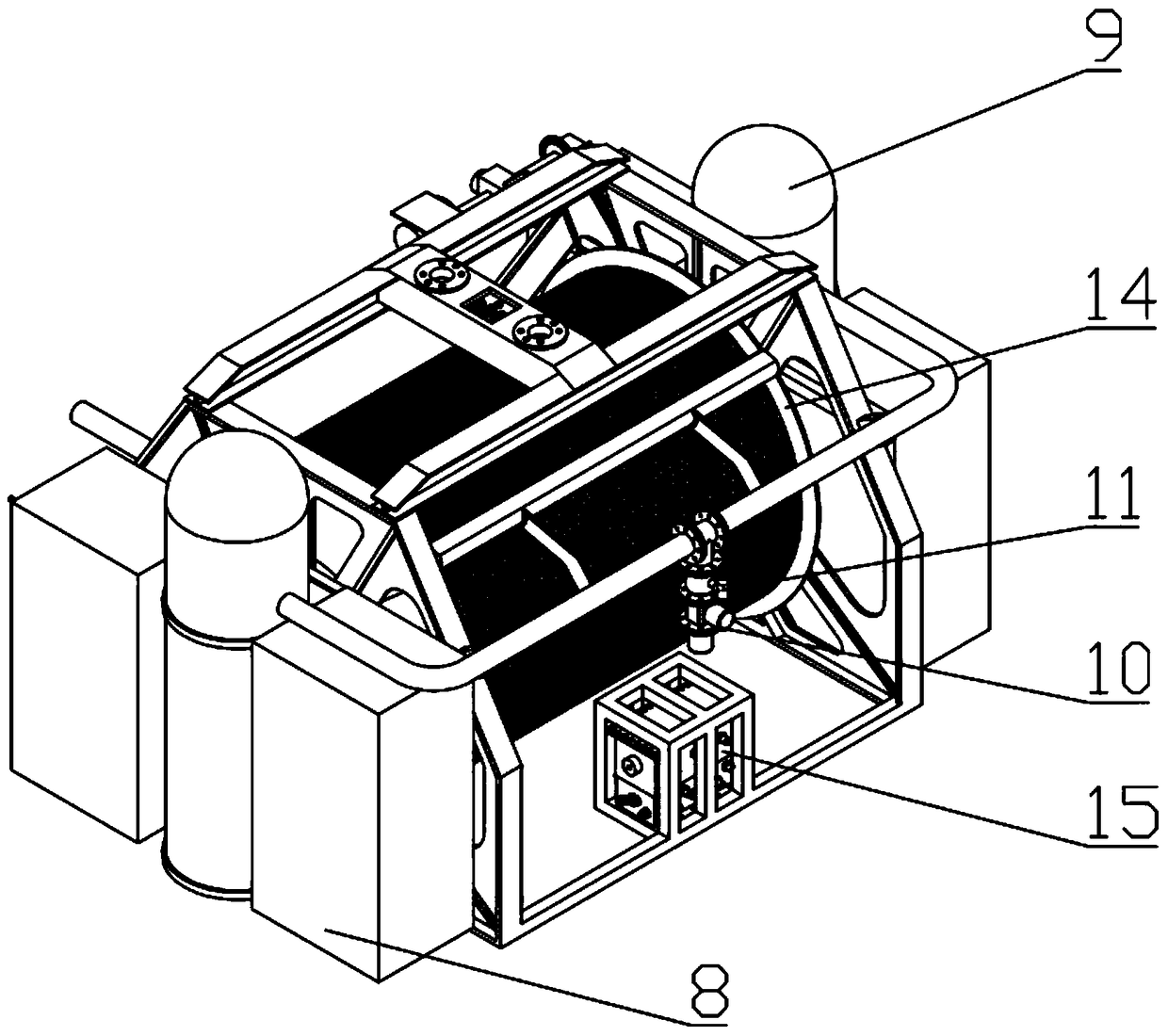

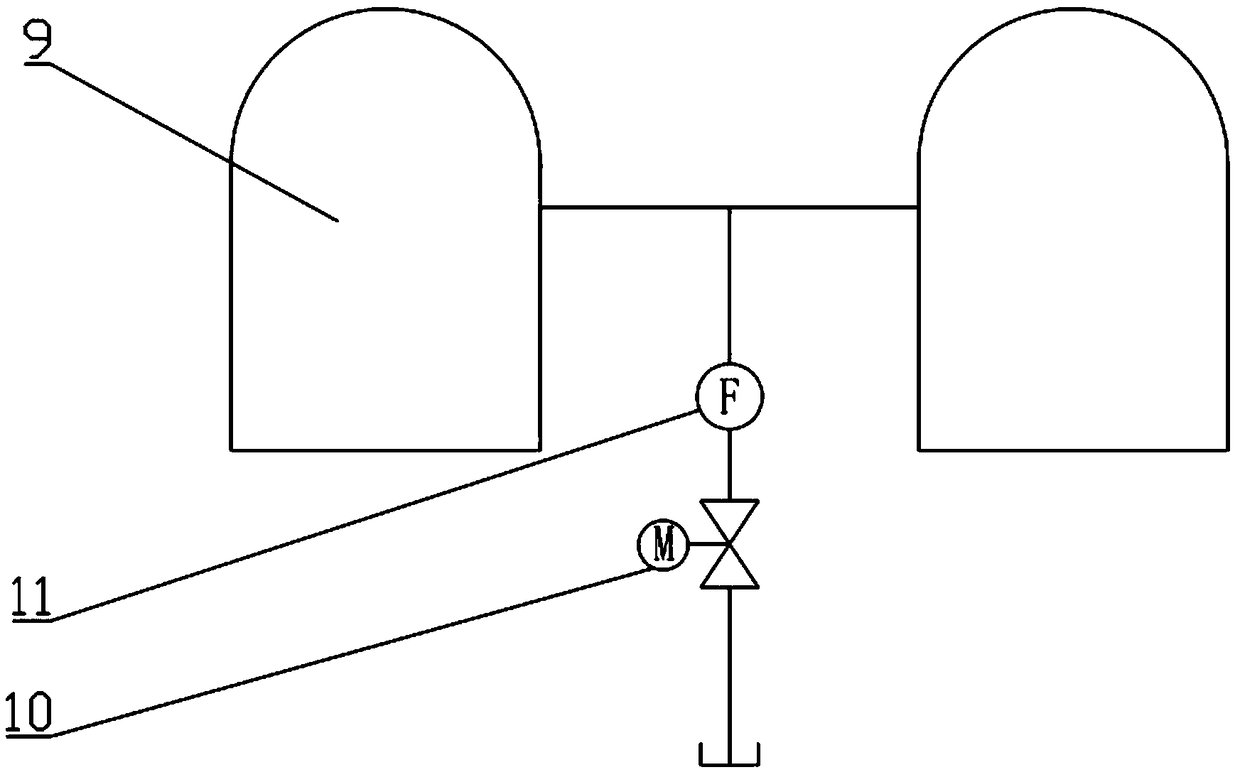

ROV deep-sea cable laying operating system for manned submersible

ActiveCN109230894AEnsure safetyGuaranteed zero buoyancyCable installations on groundApparatus for laying cablesOcean bottomElectricity

The invention relates to an ROV deep-sea cable laying operating system for a manned submersible. The system comprises a rendering winch and an ROV cable laying operation box which are arranged on themanned submersible, wherein one end of an umbilical cable winds a reel of the rendering winch and is electrically connected with the ROV cable laying operation box, and the other end of the umbilicalcable is connected with a remotely operated vehicle with a cable laying winch and a hydraulic source, so that signals among the remotely operated vehicle, the cable laying winch and the manned submersible are transmitted and controlled in time. The ROV deep-sea cable laying operating system for the manned submersible has the advantages that the structure is simple, and the use is convenient; the influence of sea weaves can be effectively avoided, the stealthiness is good, the security of submarine information network is ensured; a buoyancy adjusting mechanism can ensure the zero-buoyancy stateof the cable laying vehicle in water during cable laying, the consumption of ROV energy is reduced, and the laying precision of deep-sea submarine cables is greatly increased.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

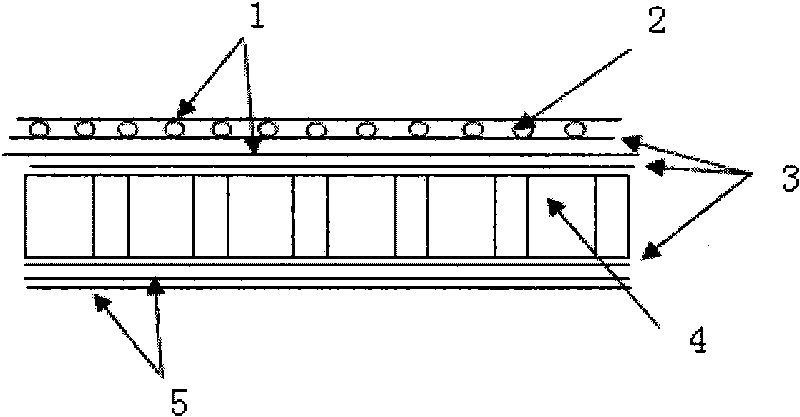

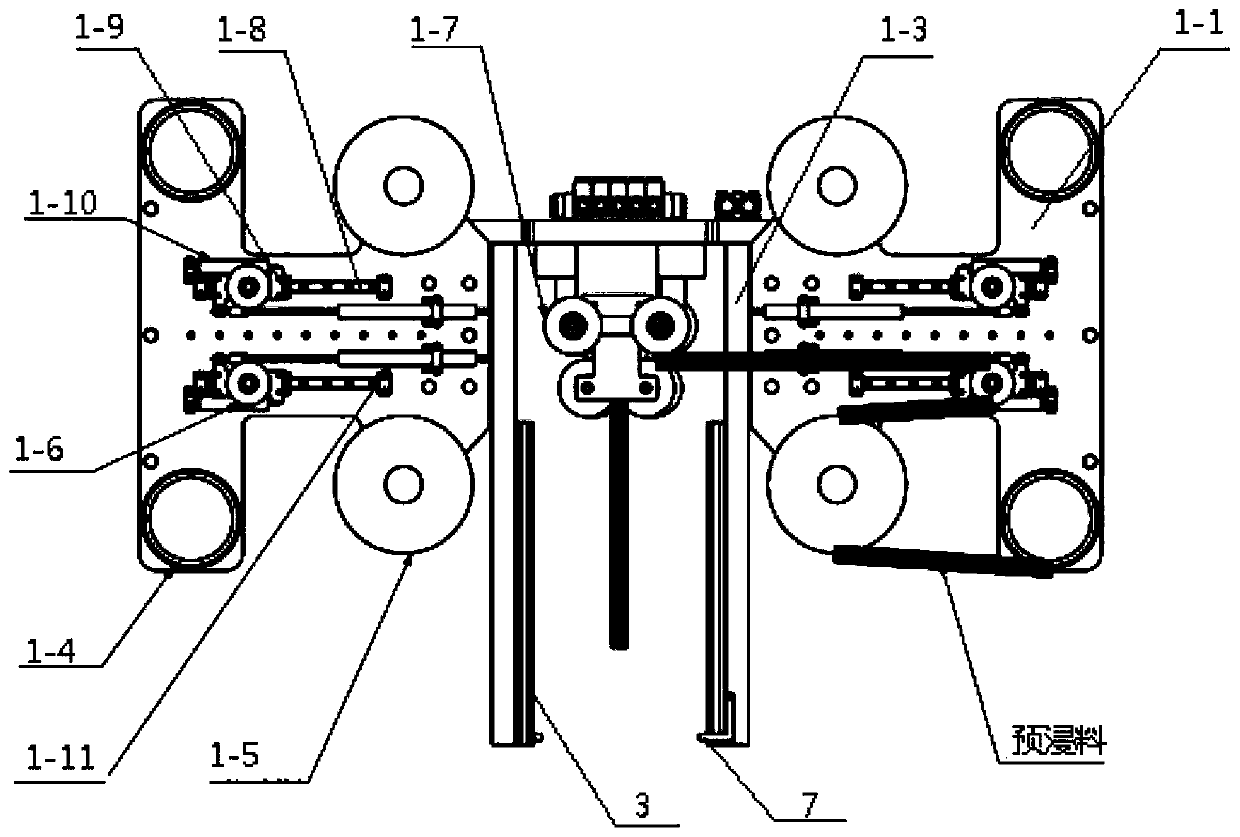

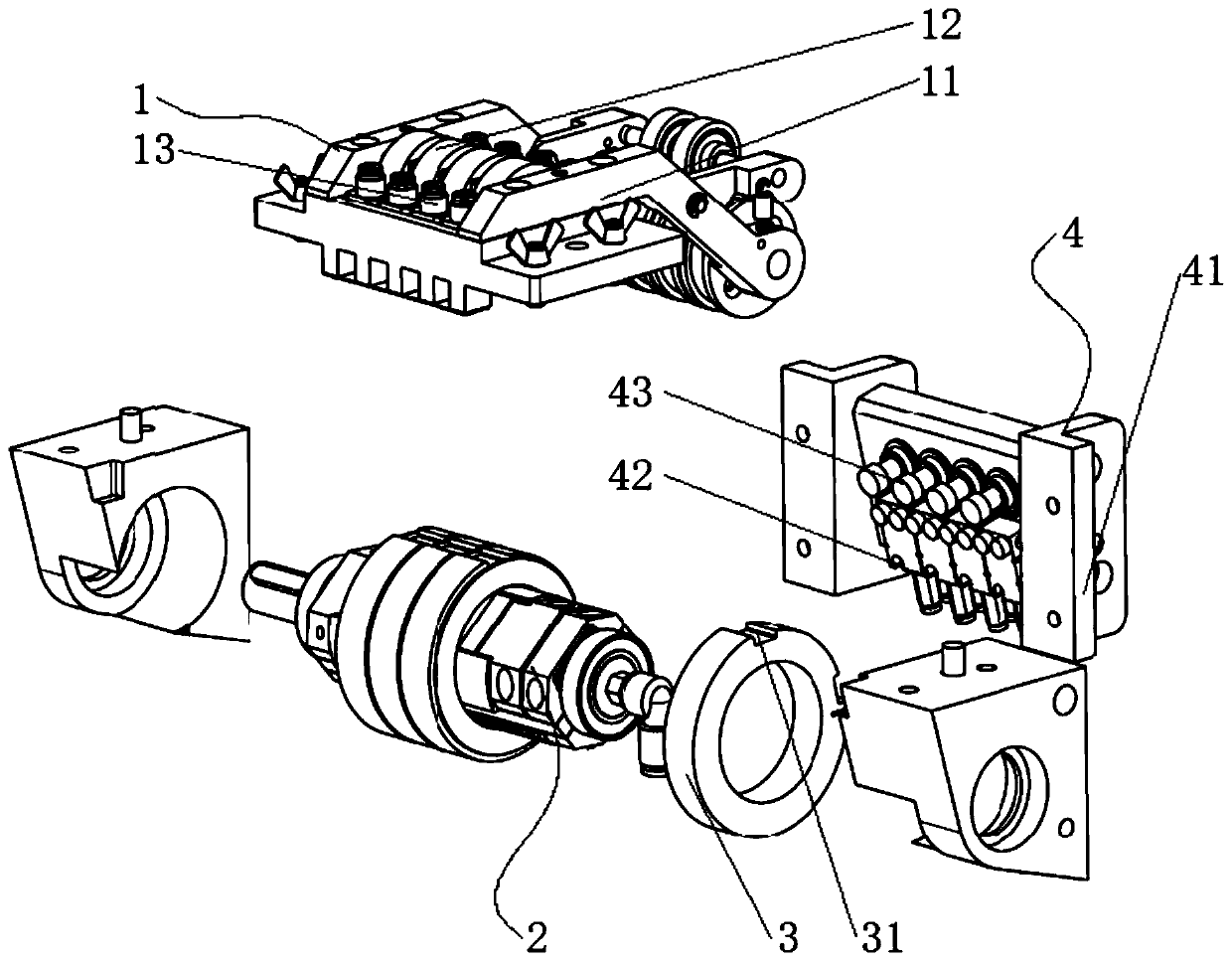

Novel fiber placement head

The invention relates to a novel fiber placement head, and belongs to the technical field of fiber placement machines. The novel fiber placement head comprises a yarn box and a fiber placement head floating mechanism, wherein two linear guide rails are arranged on the yarn box in parallel; sliding blocks are mounted on the fiber placement head floating mechanism; the fiber placement head floatingmechanism is used in match with the linear guide rails through the sliding blocks; one end of a compaction air cylinder is connected with the yarn box while the other end of the compaction air cylinder is connected with the fiber placement head floating mechanism; the fiber placement head floating mechanism is driven by the compaction air cylinder to be slid on the linear guide rails. According tothe yarn box disclosed by the invention, paying-off of yarns of four groups of prepreg rolls, that is, eight prepreg rolls can be realized simultaneously and cannot interfere with each other; two mounting plates which are parallel to each other are arranged on the left side and the right side of a U-shaped connecting plate; and two yarn paying-off film-collecting mechanisms are arranged on each of the mounting plates. Due to the arrangement, the whole size of the yarn box is greatly reduced, so that the phenomenon that interference between a concave curved surface and a die occurs when the concave curved surface with a narrow space can be prevented. According to the novel fiber placement head disclosed by the invention, a novel filament bundle actuation device is adopted, so that a wrapangle of the fiber placement head is reduced, and the technical problem of lack of accessibility is further solved.

Owner:肖睿

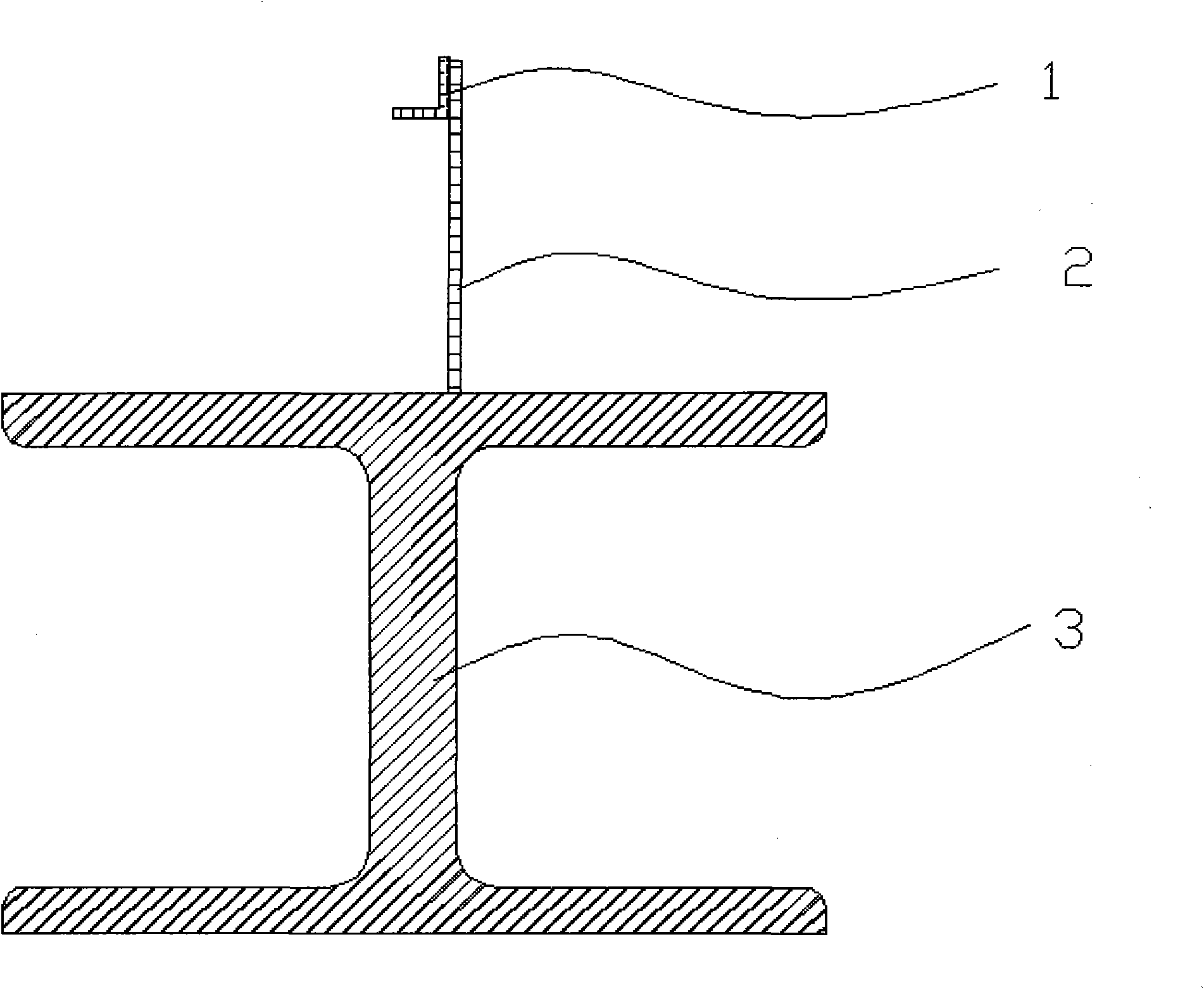

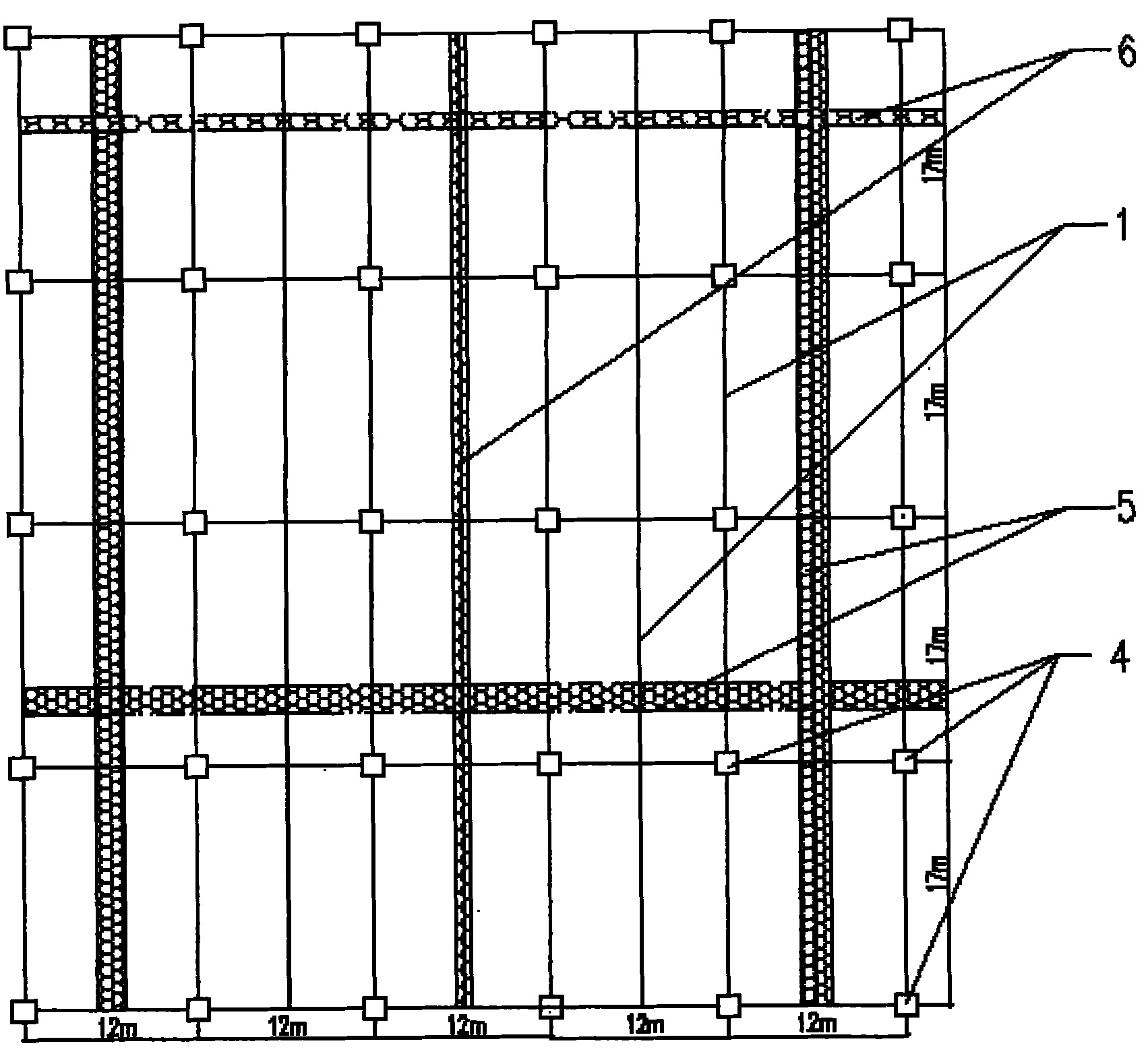

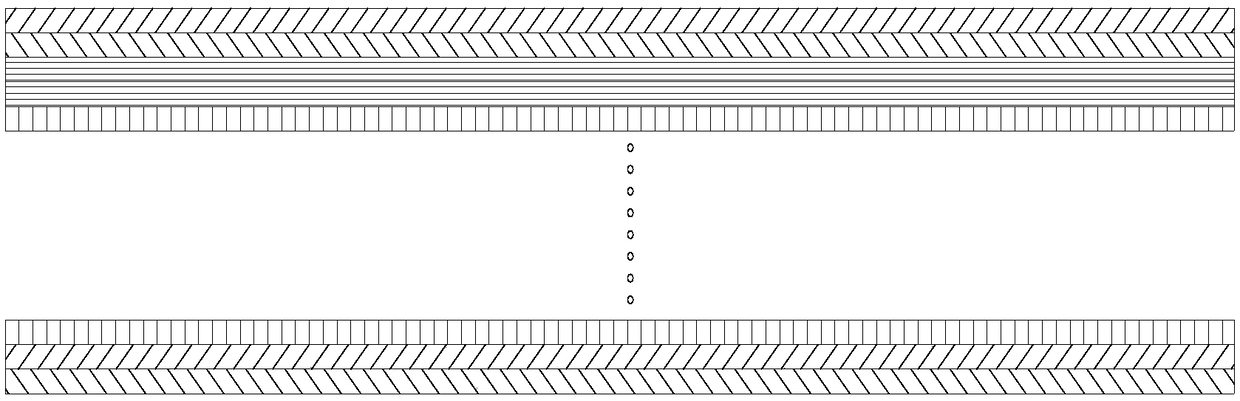

Method for controlling concrete planeness of large-area steel bar truss template

ActiveCN101967884AGuaranteed flatnessImprove laying accuracyBuilding material handlingSteel barSpot welding

The invention belongs to the technical field of building construction, in particular relating to a method for controlling concrete planeness of a large-area steel bar truss template. The method for controlling concrete planeness of the large-area steel bar truss template comprises the following steps of: firstly, arranging a horizontal angle steel guide rail, i.e. carrying out spot welding installation on the horizontal angle steel guide rail and a vertical short angle steel; then arranging the angle steel guide rail according to width of a steel beam; and then pouring structural concrete, compactly vibrating, and flat-pressing and compacting the vibrated concrete by using a roller along an angle steel track in a reciprocating way. In the method for controlling concrete planeness of the large-area steel bar truss template, the truss template and a concrete cast-in-place plate are combined as a structural layer and the planeness is arranged in a pouring region to control the angle steel guide rail, therefore, the planeness of a cast-in-place plate of the large-area steel bar truss template is effectively ensured about 2mm to 2m and the qualified rate is more than 90 percent when the large-area concrete is poured, and the laying precision of floor concrete of a large factory is enhanced.

Owner:ANHUI HUALI CONSTR GRP

Optical cable laying based coaxial double-rotor-wing unmanned helicopter parameter identification test system

ActiveCN104391364AImprove laying accuracyAccurate controlOptical fibre/cable installationNavigation instrumentsGlobal Positioning SystemData records

An optical cable laying based coaxial double-rotor-wing unmanned helicopter parameter identification test system comprises an aircraft platform and a ground device; an inertia measuring unit, a global positioning system, a magnetic heading meter, a laser height indicator, a data recorder and a controller are respectively installed on the aircraft platform; the inertia measuring unit, the global positioning system, the magnetic heading meter, the laser height indicator and the data recorder are connected to the controller; the controller processes signals and outputs the signals to the control unit; the ground device comprises a wireless remote control transmitter, a data transmission terminal and a ground control computer system; the ground control computer system is connected with a RC (Remote Control) transmitter; the ground control computer system is also connected with the data transmission terminal; a sensor is integrated on the aircraft platform; the sensor measures the triaxial angular speed, the linear acceleration, the course angle, the triaxial positions and the triaxial linear speed of the aircraft platform.

Owner:SHENZHEN MINGXIN AVIATION TECH

Prepreg laminating high-pressure pre-forming process

The invention provides a prepreg laminating high-pressure pre-forming process. The prepreg laminating high-pressure pre-forming process comprises the following steps that S1, a single layer of prepregis laid on each of two stations; S2, one of the stations is driven into a pre-forming cavity, an electromagnet is powered off, and the station and a corresponding frame body are separated; S3, the corresponding frame body is jacked by a lifting device, and is tightly pressed against the bottom end of a vacuum adsorption device, the vacuum adsorption device performs vacuumizing, elastic rubber deforms to be attached to a mold, meanwhile, the corresponding single layer of prepreg is also pressed on the mold, and the pressure is maintained for a period of time; S4, the lifting device is reset, the other station is driven into the pre-forming cavity, the step S3 is repeated, and at the moment, the station in the step S2 undergoes prepreg laying synchronously; S5, the steps S2 to S4 are repeated; and S6, laying is finished. Compared with the prior art, the prepreg laminating high-pressure pre-forming process has the advantages that the laying precision is high, the laying efficiency is high, in the case of the finally obtained product, the quality is good, the porosity is small, carbon fiber is free of wrinkles, and bubbles are not prone to being generated between the layer and the layer.

Owner:常州新创航空科技有限公司

Material laying system and method

InactiveCN109483880AImprove efficiencyHigh precision3D object support structuresManufacturing data aquisition/processingNew materials3D printing

The invention provides a material laying system and method. The material laying system and method are applied to a material laying program of a 3D printing process. The material laying system comprises a material bed, a material laying device and a drive device, wherein an annular material laying area is formed on the material bed; the material laying device and the material bed can carry out relative movement in a first direction, so that the material laying device can carry out cyclic material laying along the annular material laying area; and the drive device is used for driving relative movement in a second direction, between the material laying device and the material bed, a distance between the material laying device and the material bed is increased in a material laying process, andprinting material layers are laid on the material bed in a stacking manner. The invention provides a new material laying system and method. An annular laying method is adopted, and an idle stroke canbe cancelled, so that the material laying efficiency is greatly increased.

Owner:YUANZHI TECH SHANGHAI CO LTD

Handling system, control method thereof and floor tile laying system

InactiveCN110397257AHigh precisionSolve technical problems that cannot meet the accuracy requirements of tilingBuilding constructionsBrickHandling system

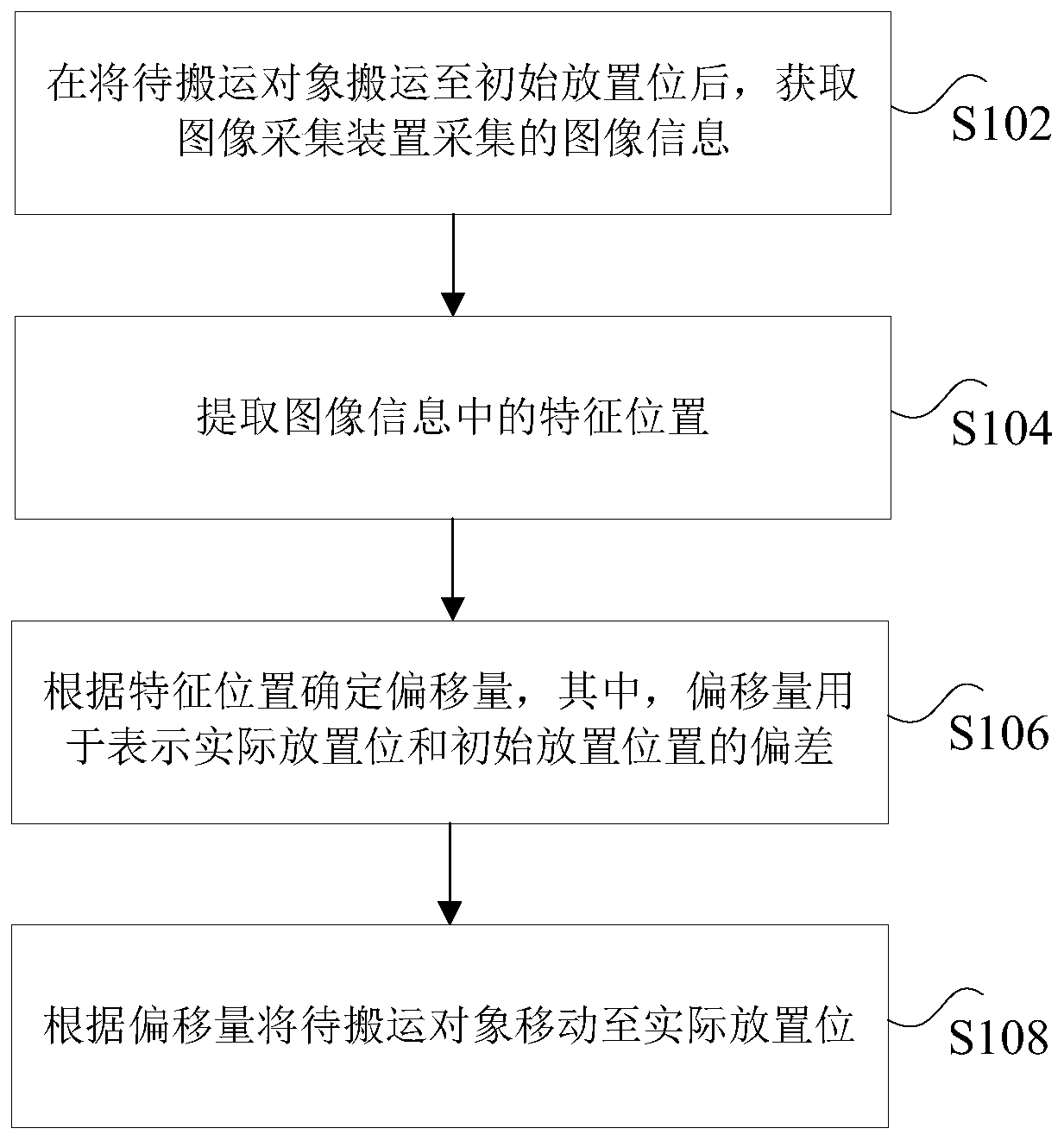

The invention discloses a handling system, a control method thereof and a floor tile laying system. The handling system includes an image capture device. The method includes the steps of acquiring image information collected by the image capture device after an object to be transported is transported to an initial placement position, wherein the image information at least includes the actual placement position of the object to be transported and three adjacent angles of two adjacent reference objects; extracting a feature position in the image information; determining an offset according to the feature position, wherein the offset is used for representing a deviation between the actual placement position and the initial placement position; and moving the object to be transported to the actual placement position according to the offset. The technical problem that in the prior art, a robot for tile laying cannot meet the tile laying precision requirement is solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Carbon fiber prepreg actuating device for carbon fiber automatic filament paving machine

The invention relates to a carbon fiber prepreg actuating device for a carbon fiber automatic filament paving machine, and relates to the technical field of carbon fiber automatic silk paving machines. The carbon fiber prepreg actuating device for a carbon fiber automatic filament paving machine particularly relates to a chopping board wheel component, the chopping board wheel component comprisesa group of chopping board wheel frames, the chopping board wheel frames are arranged on the automatic filament paving machine, a plurality of groups of chopping board wheels are arranged on the chopping board wheel frames side by side, an air shaft is arranged below the chopping board wheel component, one end of the air shaft is connected with a motor main shaft, the two ends of the air shaft arearranged on the automatic filament paving machine through bearing seats, a plurality of groups of cams are arranged on the air shaft, the carbon fiber prepreg yarns penetrate between the cams and thechopping board wheels, a group of carbon fiber prepreg cutter is further arranged on the cams, and a group of trigger cylinder components are arranged beside the air shaft. According to the carbon fiber prepreg actuating device for the carbon fiber automatic filament paving machine, the part almost has no impact load during working, therefore the cutting chip is less, so that the requirement of the cutter material is reduced, and the service life of a cutter and a chopping board is prolonged.

Owner:肖睿

Mechanical device for automatically laying floor tiles

InactiveCN106499162AImprove laying accuracyQuality assuranceBuilding constructionsUltrasonic sensorDrive wheel

Owner:HEZE UNIV

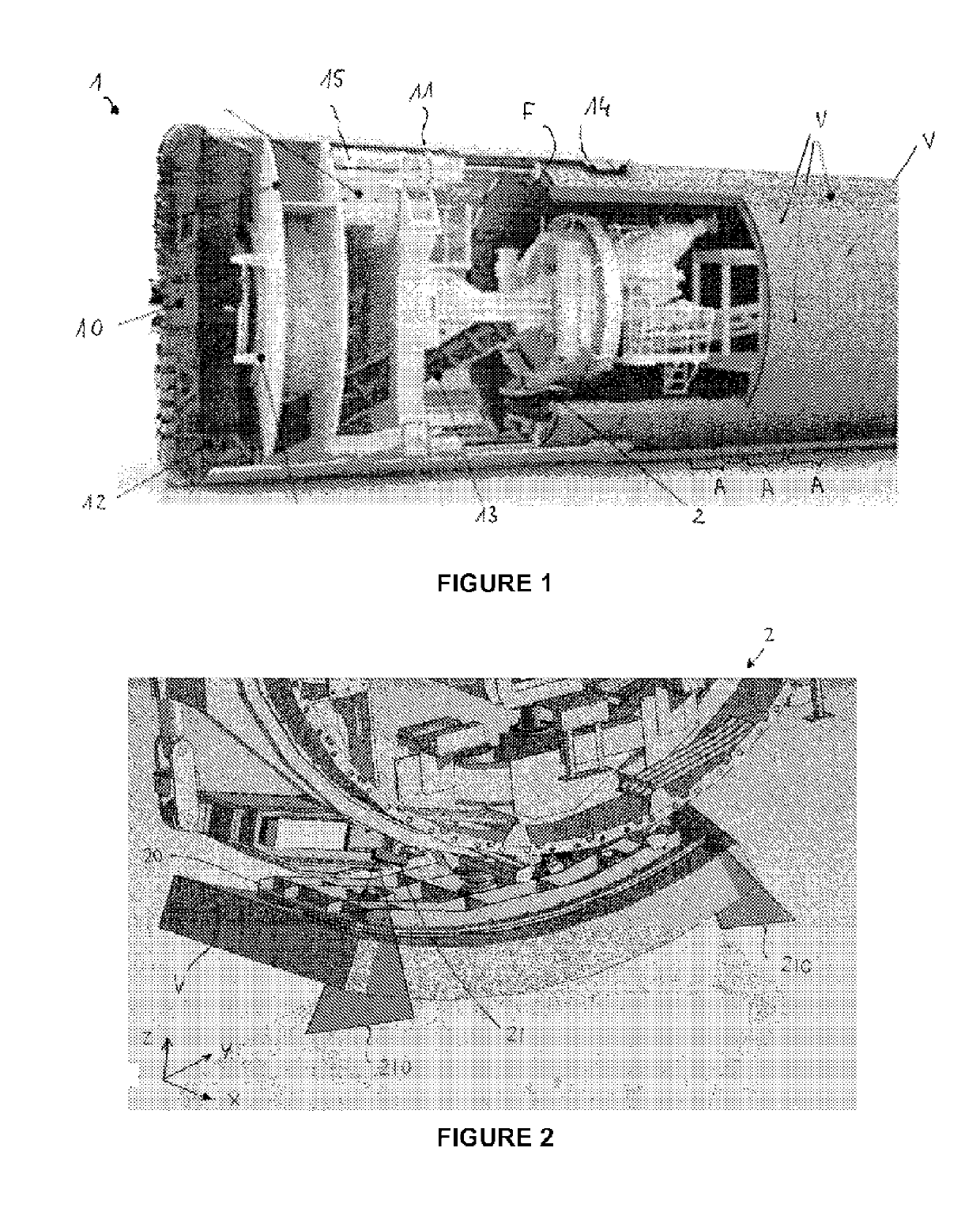

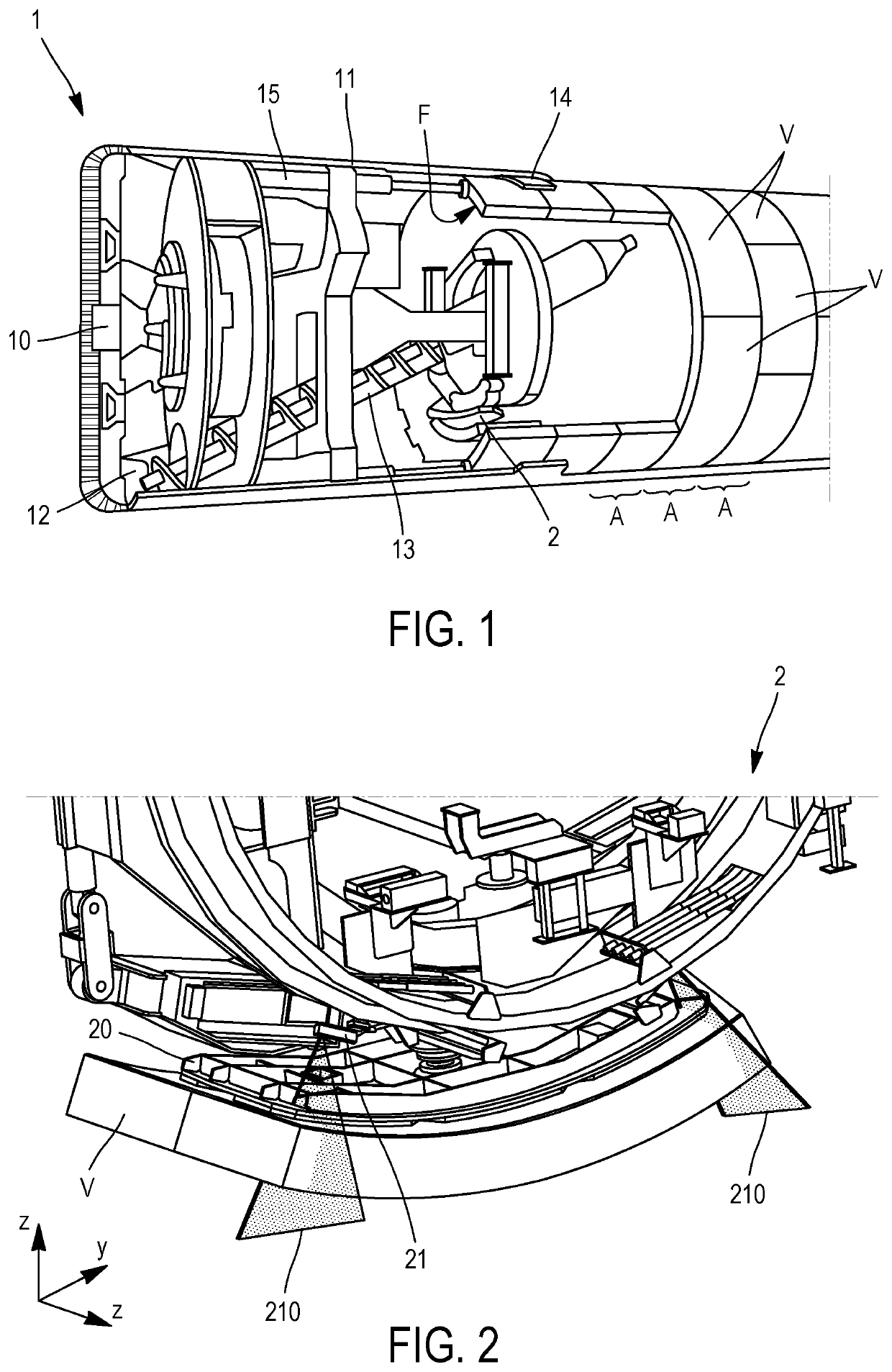

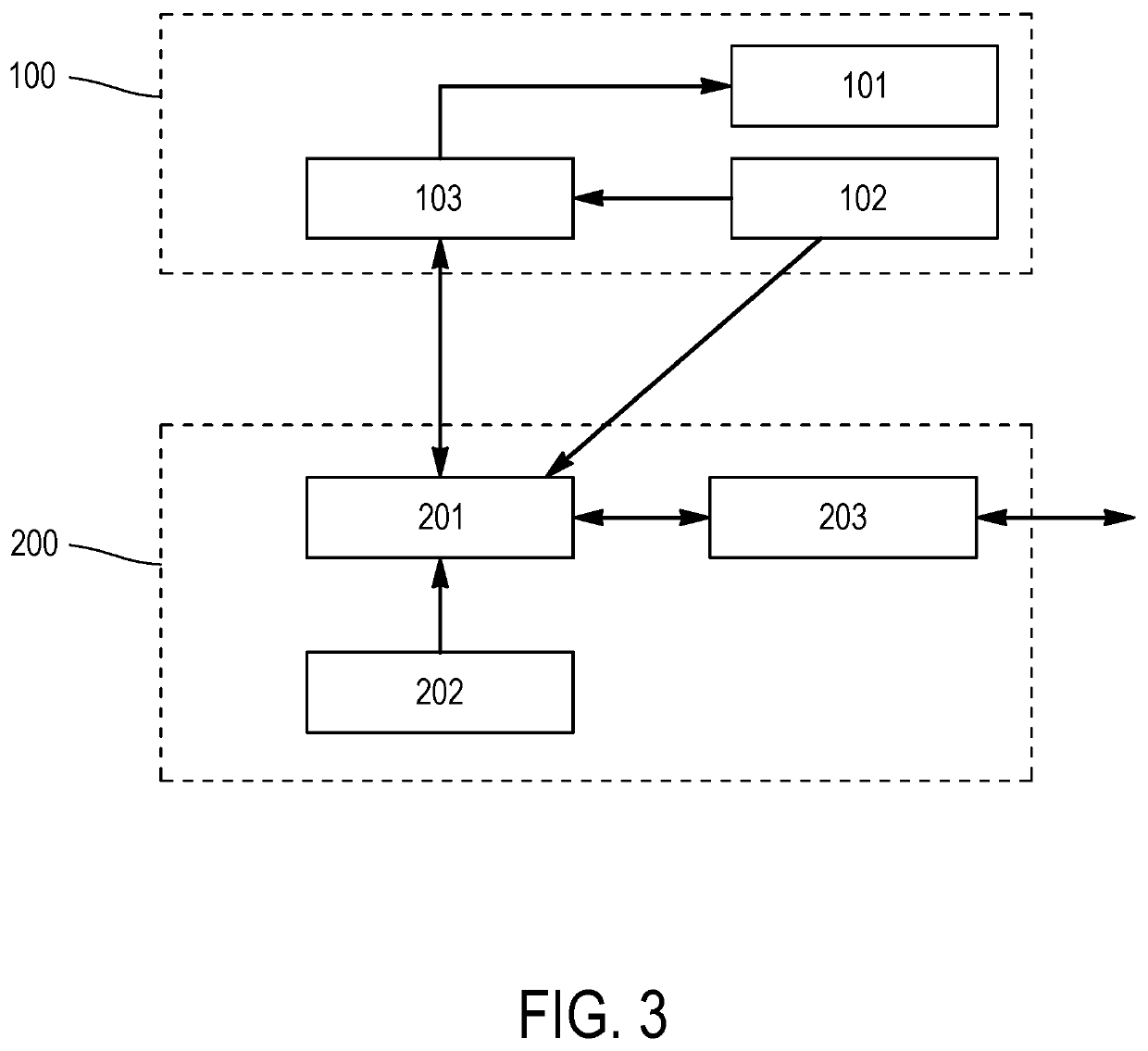

Device and method for the automated picking up and laying of a segment to form a lining of a tunnel

ActiveUS20190234214A1Increase productivityImprove securityUnderground chambersUsing optical meansController designAnalysis data

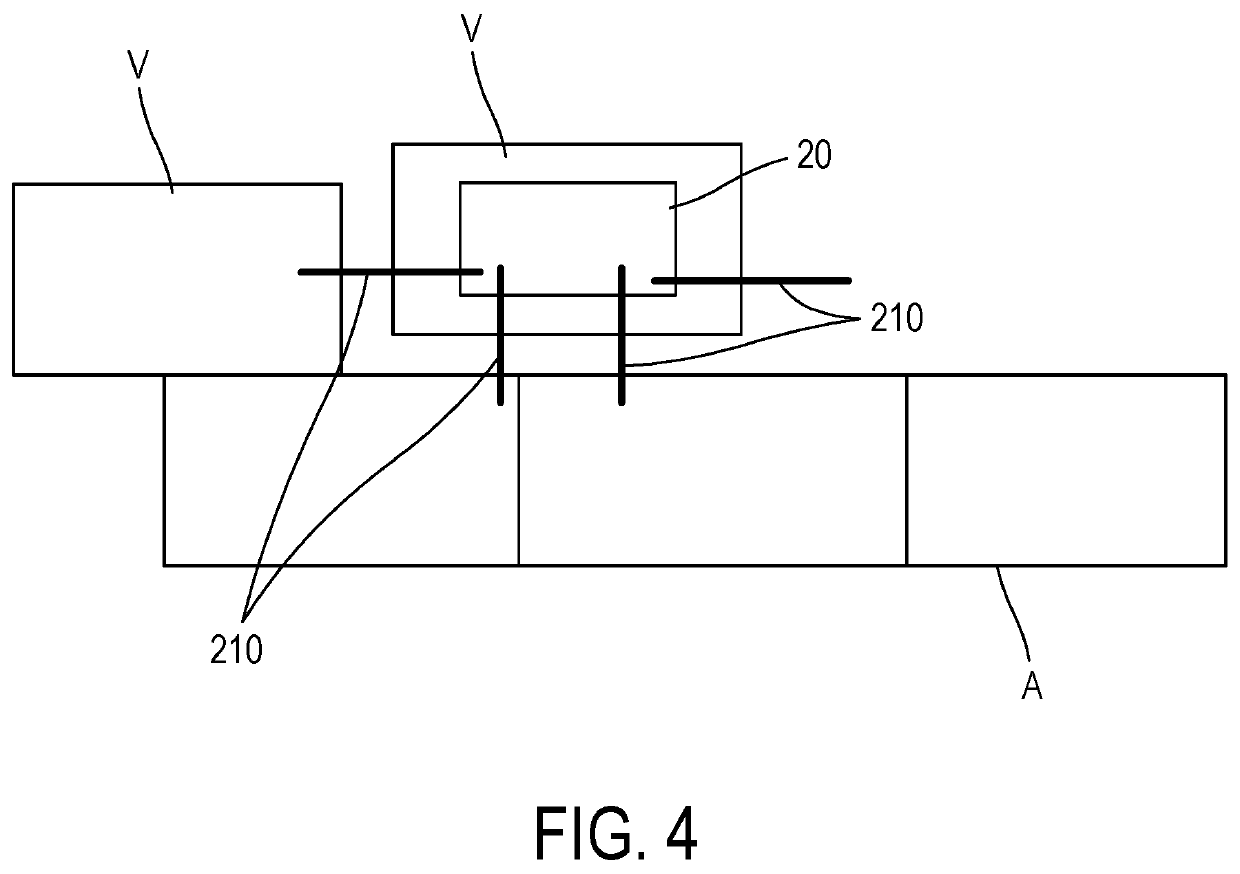

The invention relates to a device for the automated picking up and placing of a segment forming the lining of a tunnel, intended to be coupled to a tunnel-boring machine (1) provided with a segment erector (2), comprising: —a controller designed to communicate with an automated system of the tunnel boring machine, suitable for controlling the actuation of the erector; and —a three-dimensional vision system comprising at least four laser profilometers; the controller is designed to receive a segment positioning plan and to determine, from the analysis data of the three-dimensional vision system, the measurement data of the erector sensors and the segment positioning plan, an erector trajectory for positioning the segment (V) to be placed in alignment with a segment and / or ring (A) of segments already placed, and to communicate movement commands to the automated system of the tunnel boring machine, for actuating the erector to pick up the segment to be placed and move it according to the above trajectory.

Owner:BOUYGUES TRAVAUX PUBLICS SA

Device and method for the automated picking up and laying of a segment to form a lining of a tunnel

ActiveUS10472962B2Increase productivityImprove securityUnderground chambersUsing optical meansControl engineeringTunnel boring machine

The invention relates to a device for the automated picking up and placing of a segment forming the lining of a tunnel, intended to be coupled to a tunnel-boring machine (1) provided with a segment erector (2), comprising:—a controller designed to communicate with an automated system of the tunnel boring machine, suitable for controlling the actuation of the erector; and—a three-dimensional vision system comprising at least four laser profilometers; the controller is designed to receive a segment positioning plan and to determine, from the analysis data of the three-dimensional vision system, the measurement data of the erector sensors and the segment positioning plan, an erector trajectory for positioning the segment (V) to be placed in alignment with a segment and / or ring (A) of segments already placed, and to communicate movement commands to the automated system of the tunnel boring machine, for actuating the erector to pick up the segment to be placed and move it according to the above trajectory.

Owner:BOUYGUES TRAVAUX PUBLICS SA

Double-station prepreg stacklamination high-pressure pre-shaping equipment

PendingCN109228407AAvoids problems with bonding that is difficult to layNot easy to produceEngineeringHigh pressure

The invention provides double-station prepreg laminationstack high-pressure pre-shaping equipment, which comprises a pre-shaping cavity, two stations, an ascending and descending lifting device, a vacuum adsorption device and a heating device, wherein the two stations are respectively arranged at the two sides of a the pre-shaping cavity and are used for conveying the prepreg into the pre-shapingcavity; the vacuum adsorption device is arranged on the top end of the pre-shaping cavity and can be used for adsorbing the prepreg from the upper side; the ascending and descendinglifting device is arranged at the bottom end of the pre-shaping cavity and is used for jacking the prepreg to the bottom end of the vacuum adsorption device; the heating device is used for ensuring the temperature constancy in the pre-shaping cavity. Compared with the prior art, the equipment has the advantages that through the arrangement of the stations at the two sides of the pre-shaping cavity, the vacuum adsorption device is arranged above the pre-shaping cavity; , and the ascending and descendinglifting device is arranged under the pre-shaping cavity; , and through the ascending and descending device, jacking the single layer prepreg layers on the stations is jacked onto the vacuum adsorption device one layer by one layerone by one by the lifting device,; the laying precision is high.

Owner:常州新创航空科技有限公司

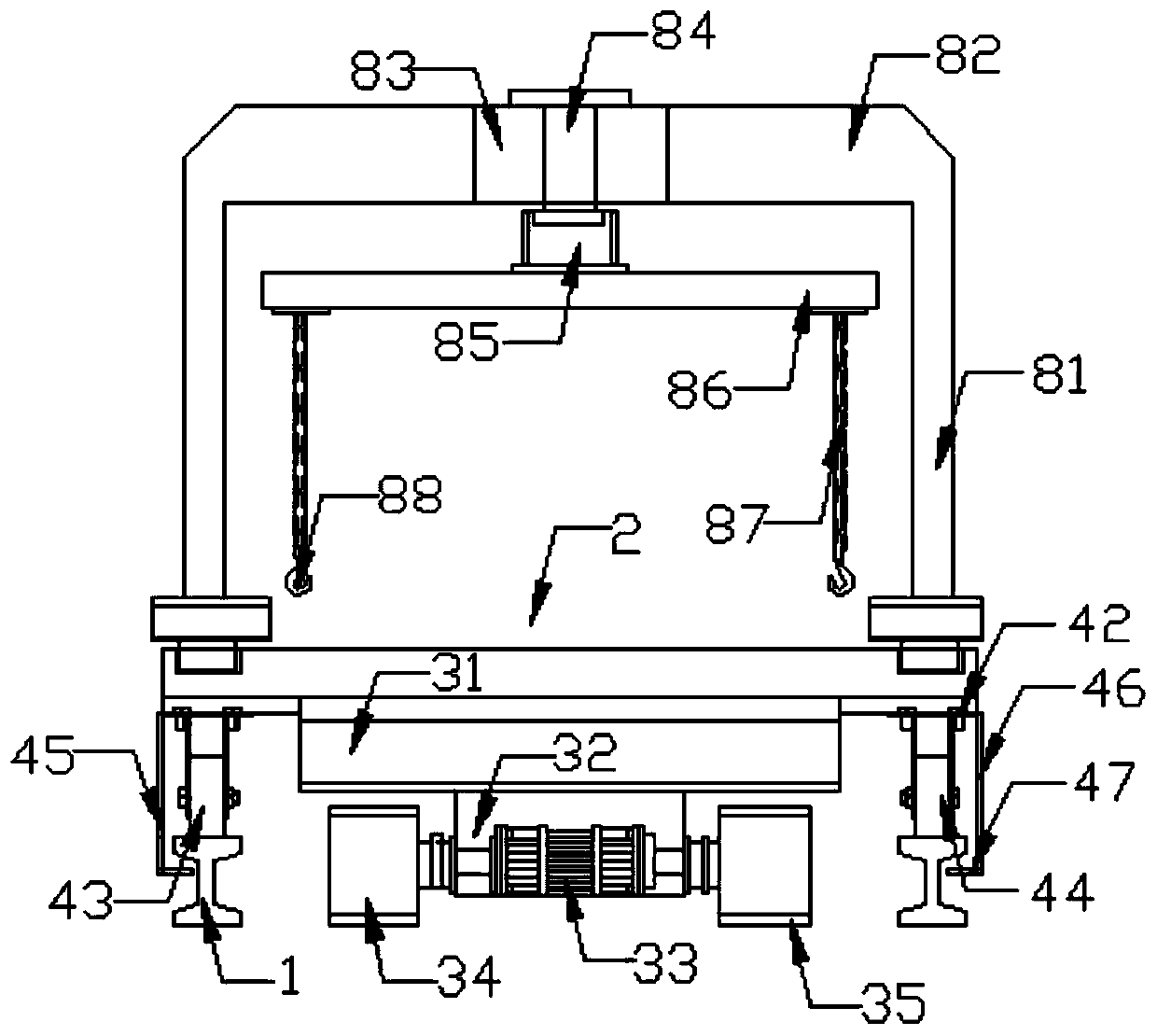

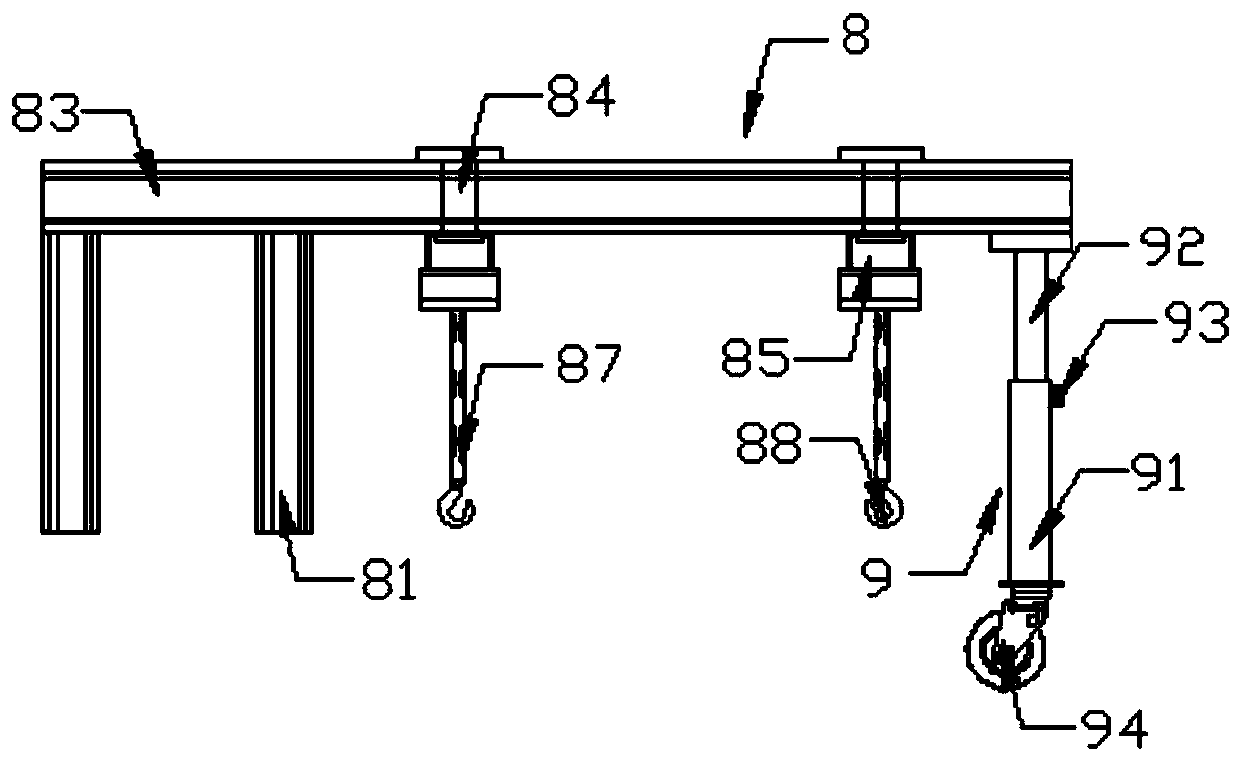

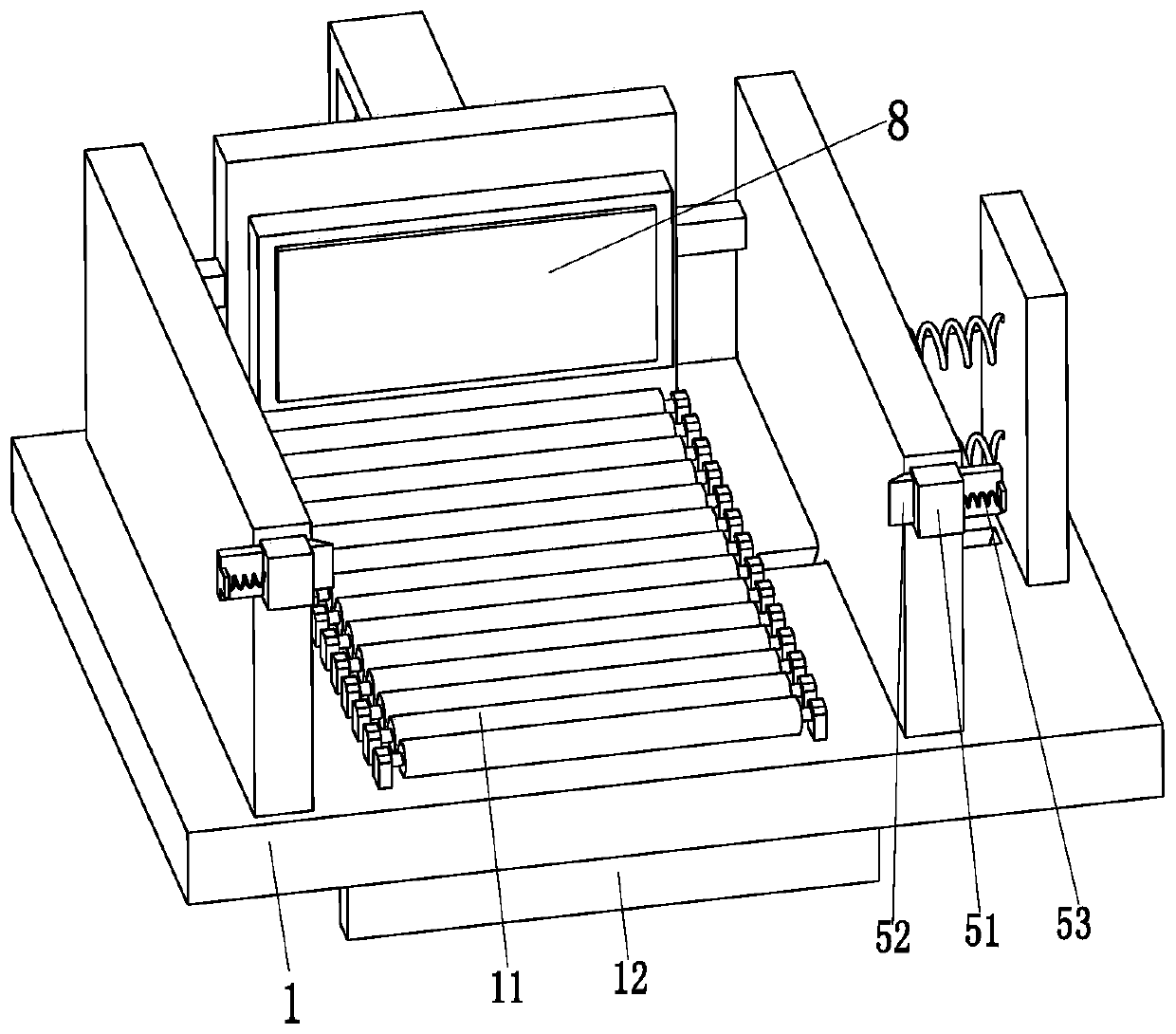

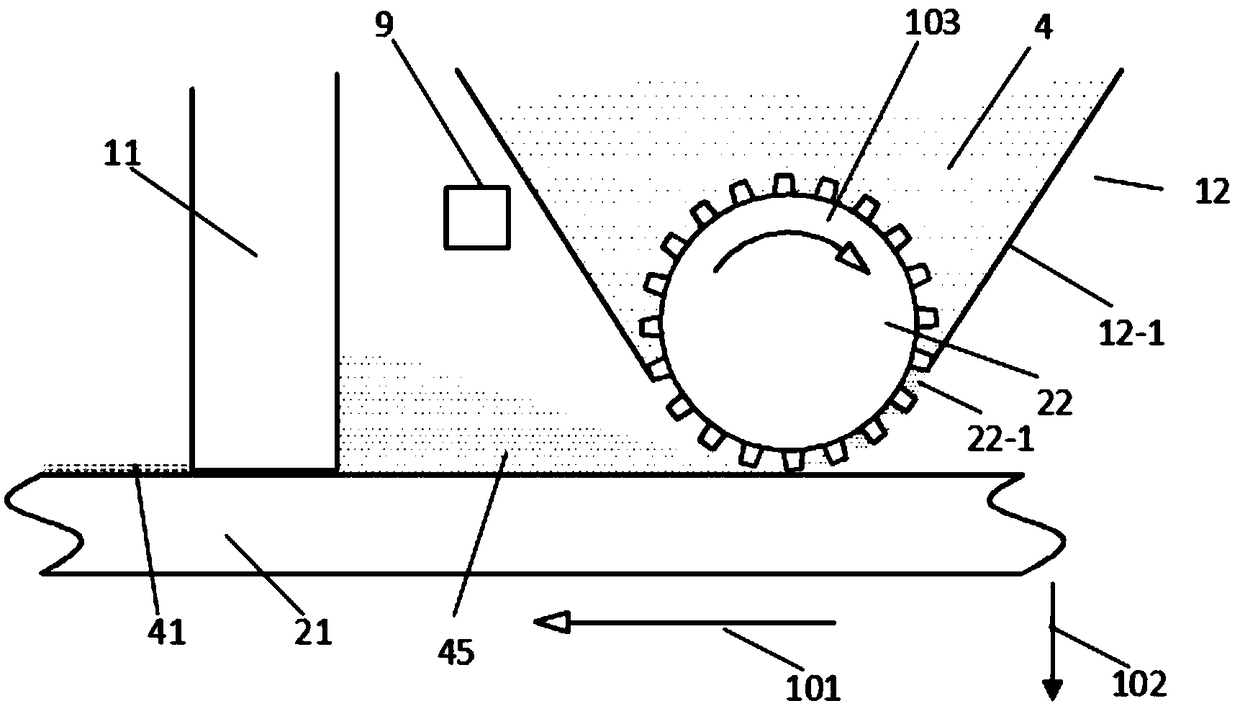

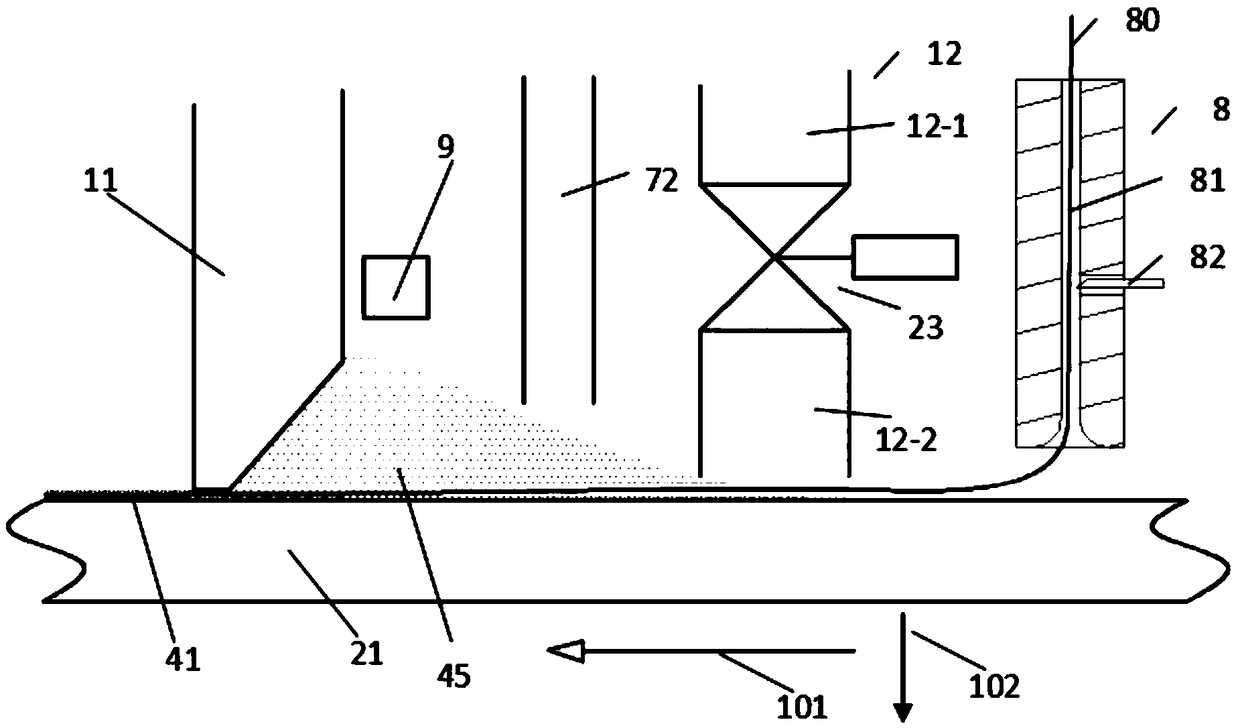

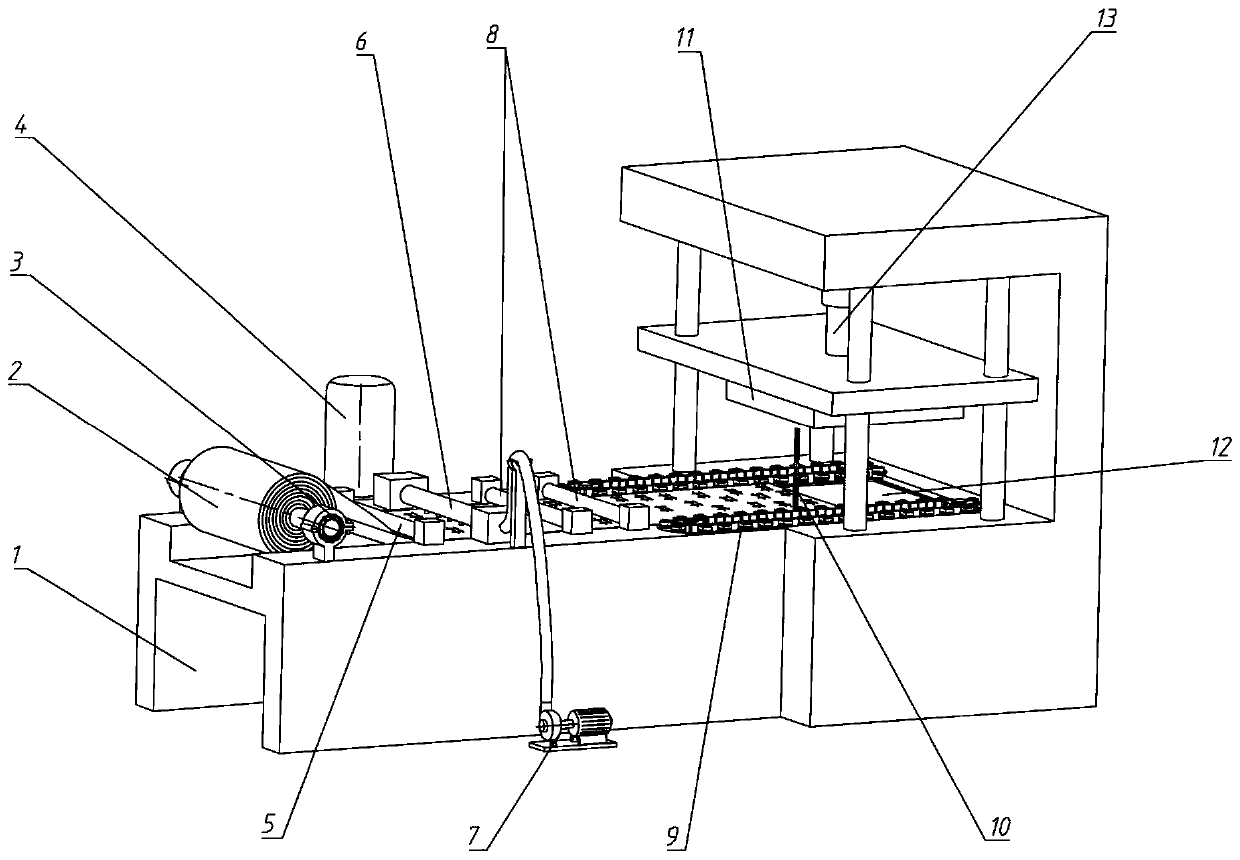

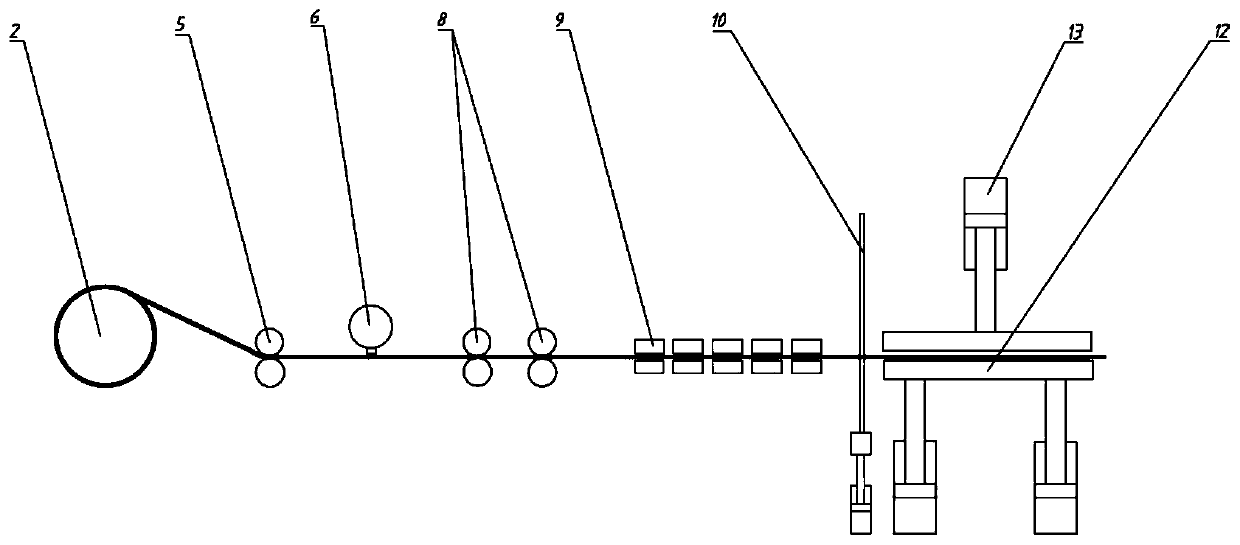

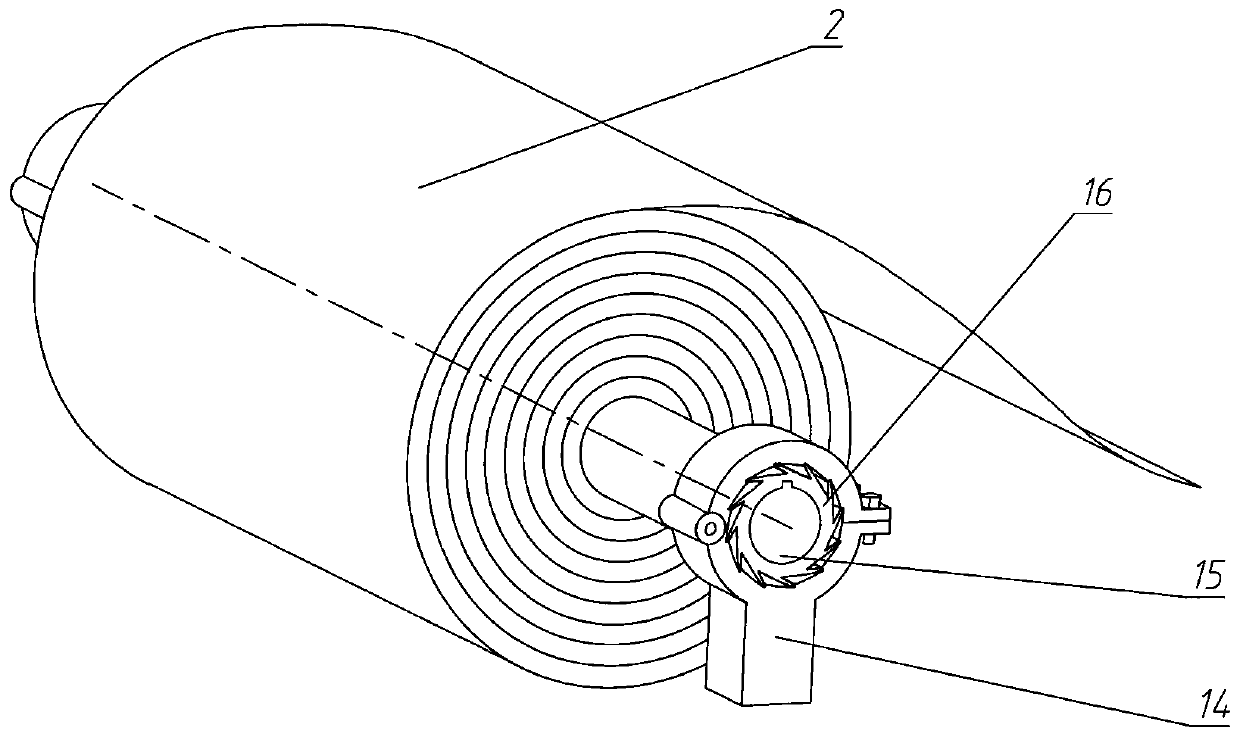

Rapid preparation device for plant fiber reinforced composite laminate plate

ActiveCN111469243AFully automatedReduce labor intensityWood working apparatusFlat articlesGear driveGear wheel

The invention relates to a rapid preparation device for a plant fiber reinforced composite laminate plate. The rapid preparation device for the plant fiber reinforced composite laminate plate comprises a working table (1), and a fiber cloth supporting device (3), a resin extruding device, a resin rolling device, a prepreg clamping and dragging device (9), a cutting device (10) and a mould liftingdevice (12) arranged on the working table and arranged sequentially, wherein a mould is placed above the mould lifting device (12). Compared with the prior art for the hand lay-up type preparation ofthe plant fiber reinforced composite laminate plate, according to the device, a prepreg can be automatically laid up and compacted, so that the composite laminate plate is integrally prepared, and thelabor intensity and the operation error of operating personnel are reduced; and through the cooperation of a resin roller shaft and a gear drive device, a fiber woven fabric is ensured to be tensioned without shrinkage, resin is uniformly applied, and the dimension precision of a composite workpiece is ensured.

Owner:SHANGHAI UNIV OF ENG SCI

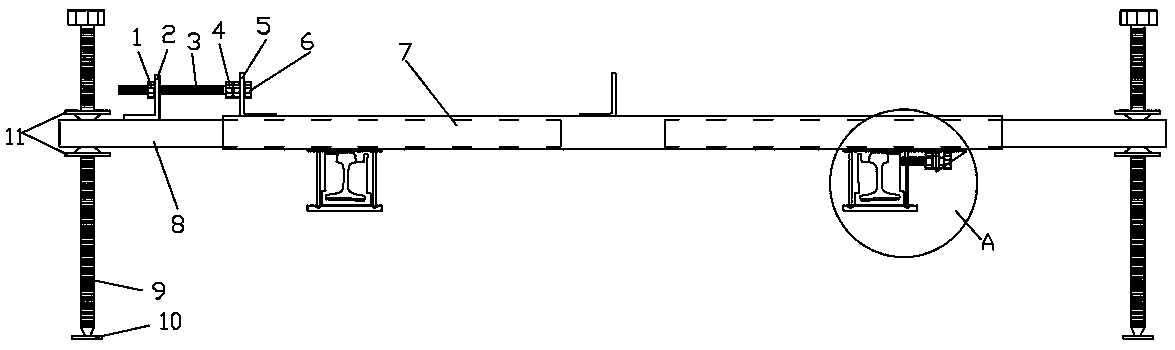

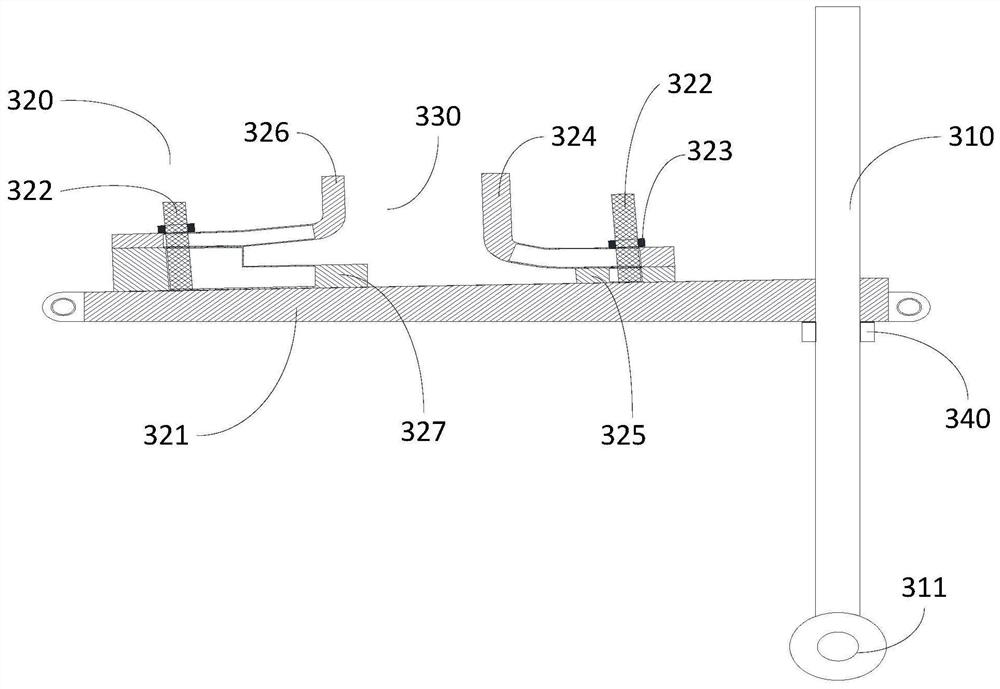

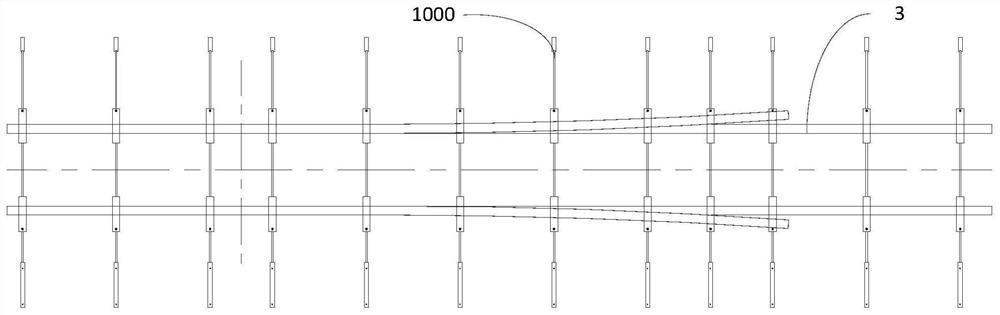

Steel rail lifting apparatus for track construction track laying, and application method thereof

PendingCN110983879AImprove laying accuracyImprove laying efficiencyRailway track constructionTrackwayEngineering

The invention relates to the technical field of track laying devices, and especially relates to a steel rail lifting apparatus for rail construction rail laying, and an application method thereof. Theapparatus comprises an outer sliding pipe, an inner pipe, an adjustable support and brackets, the adjustable support is used for adjusting the overall height of the inner pipe and the outer sliding pipe, a lateral movement locking device is arranged between the outer sliding pipe and the inner pipe, the lateral movement locking device can lock the relative position between the outer sliding pipeand the inner pipe so as to adjust the horizontal position of the steel rail, a pushing device is arranged in the lateral direction of at least one bracket, and the pushing device adjusts the positions of the steel rails in the brackets so as to adjust the distance between the steel rails in the two brackets. The apparatus has the advantages of completion of ballastless track laying and accurate alignment in a narrow space, remarkable improvement of the steel rail laying precision, improvement of the steel rail laying efficiency, simple and reasonable structure, and convenience to use, manufacture and carry.

Owner:CHINA RAILWAY 24TH BUREAU GRP

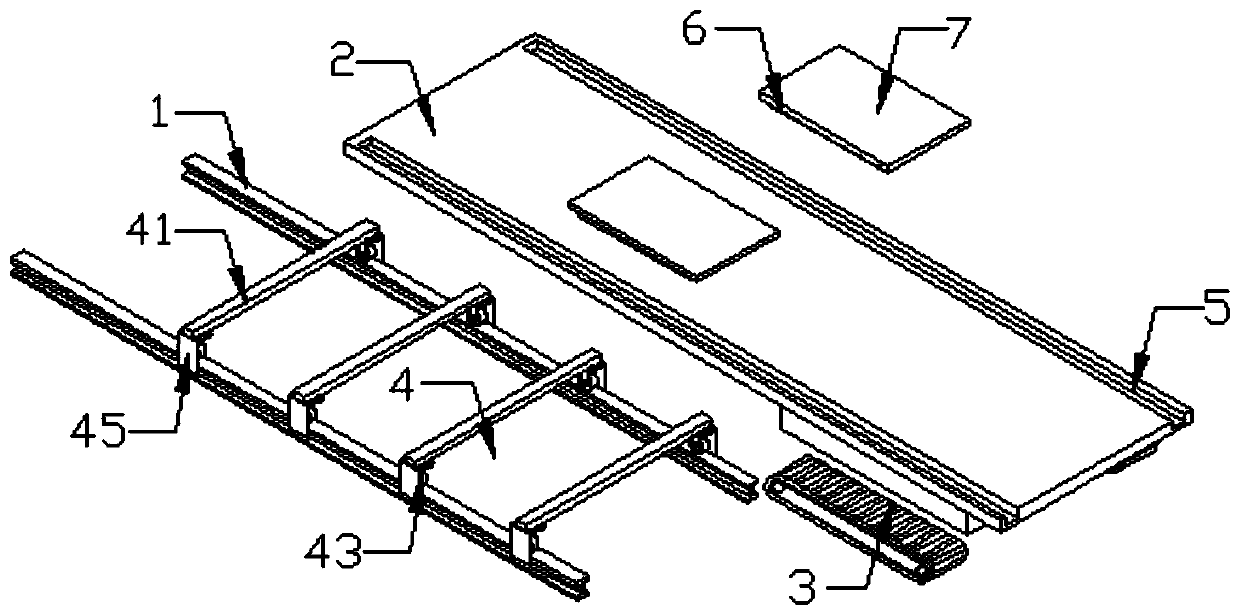

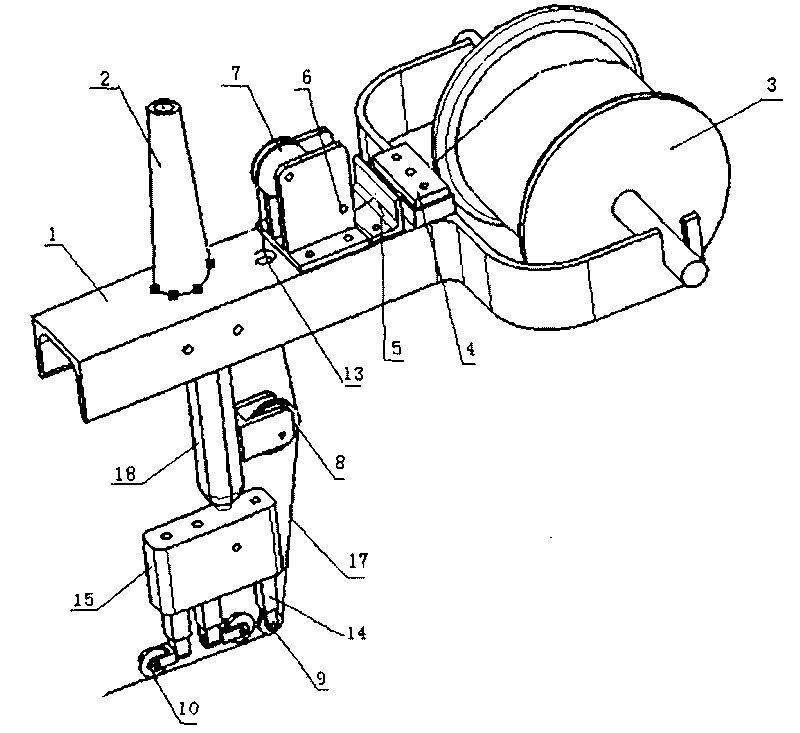

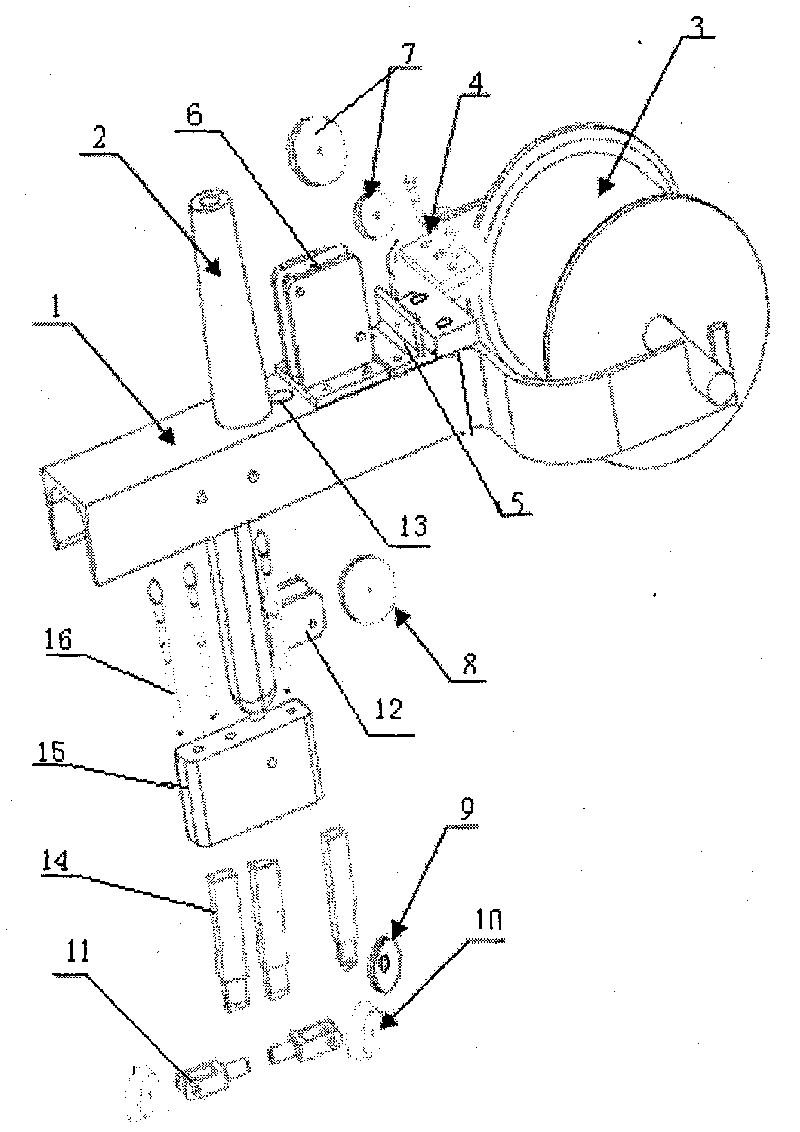

Metal wire laying device

The invention provides a metal wire laying device. A metal wire roller is arranged at one end of a bracket (1); a tension adjusting plate (4), a lead wire plate (5), a dual-lead wire wheel set (7) and a machine tool connecting handle (2) are arranged on the bracket; and a metal wire through hole (13) is arranged between the dual-lead wire wheel set (7) and the machine tool connecting handle (2). A single-lead wire wheel set bracket (12) is arranged at one side of a supporting block connecting rod (18). A wire releasing wheel (9) and a single-lead wire wheel set are arranged on the same vertical plane. A metal wire (17) penetrates the metal wire through hole (13) by the tension adjusting plate, a wire through hole on the lead wire plate and the dual-lead wire wheel set, is laid on the surface of a presoaked cloth on formed tooling equipment through the signal-lead wire wheel set (8) and the wire releasing wheel (9), and is compacted by two wire pressing wheels (10). The metal wire laying device can lay flexible metal wires which are made of different materials and have the diameter of within Phi 0.1mm to Phi 1mm. With high laying precision and speed, the metal wire laying device effectively solves the difficult problem that the metal wire cannot be laid on the surface of a convex-concave complicated body with high curvature.

Owner:XIAN AIRCRAFT IND GROUP

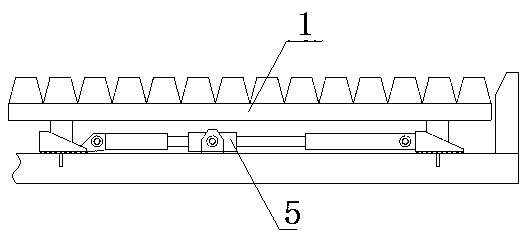

Side compression device for laying ballastless track sleeper

InactiveCN103174070AImprove laying accuracyAffect displacementRailway track constructionCompression deviceEngineering

The invention discloses a side compression device for laying a ballastless track sleeper. The device comprises a door-shaped support, a first bolt assembly and at least one set of second bolt assembly, wherein the door-shaped support is provided with a first side column (1), a top beam (2) and a second side column (4) which are sequentially and fixedly connected; the top beam (2) is provided with an axial slotted hole; a threaded rod (3) of the first bolt assembly penetrates through the slotted hole, and a nut (9) of the first bolt assembly is positioned on the outer side of the top beam (2) of the door-shaped support; and a threaded rod (6) of the second bolt assembly passes through the nut to be hinged with the second side column (4). The provided side compression device is contributed to improving the precision when a ballastless track sleeper is laid.

Owner:CHANGSHA COUNTY KEYUAN MACHINERY

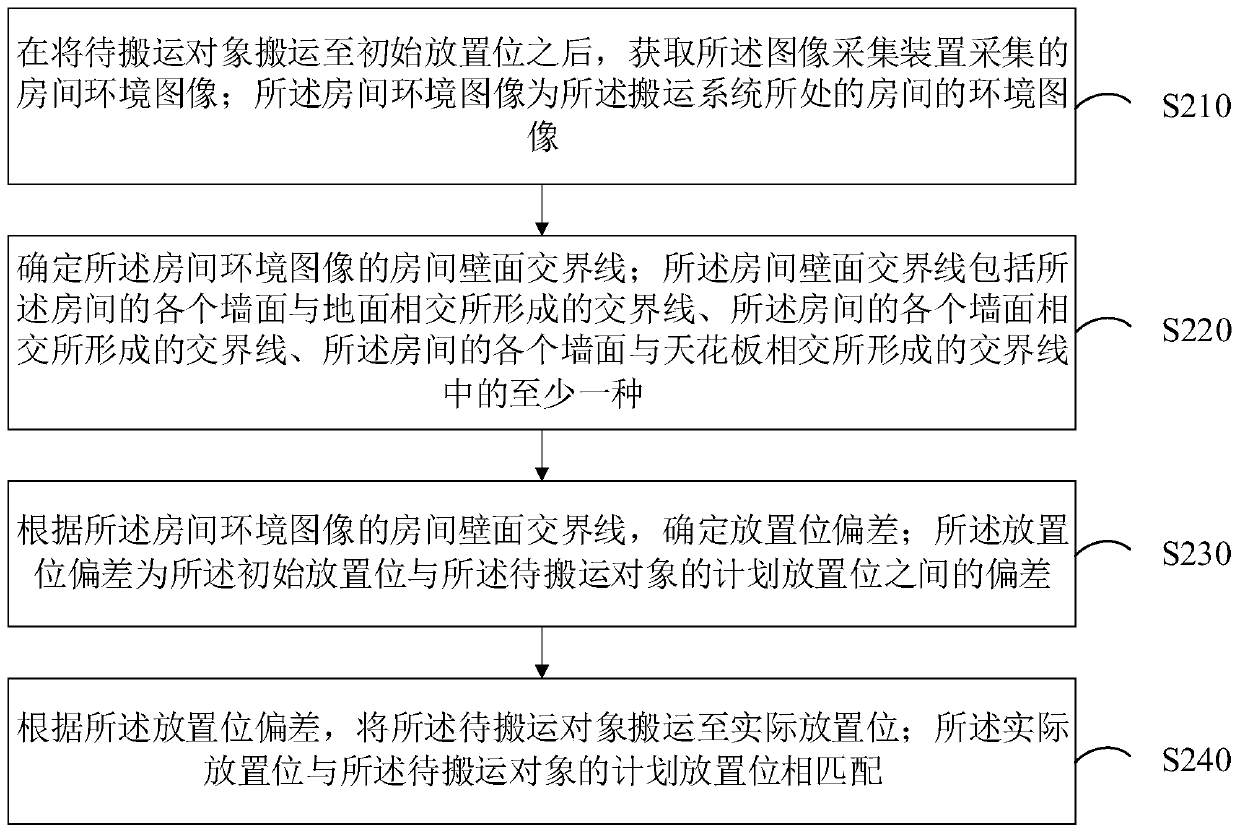

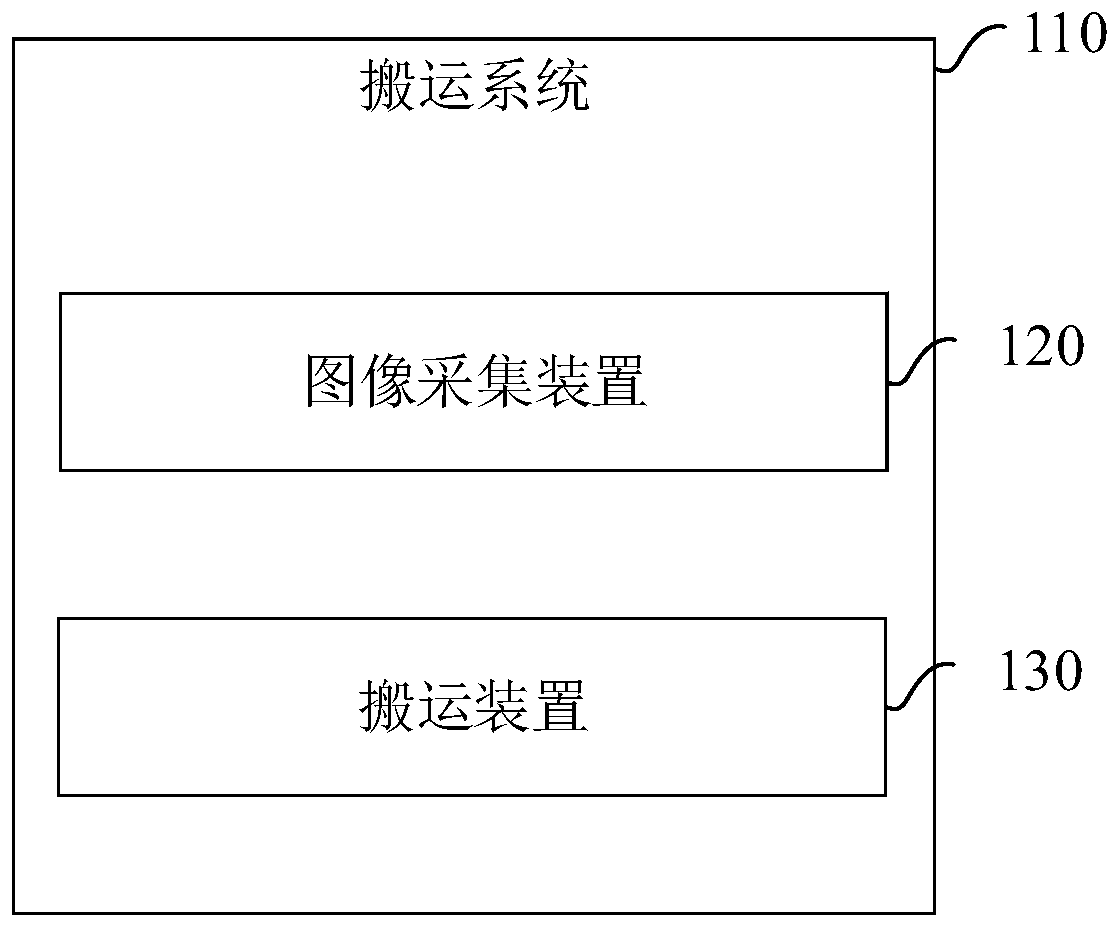

Control method and device of carrying system, computer equipment and storage medium

ActiveCN110989581AAvoid errorsReduce Global Cumulative ErrorPosition/course control in two dimensionsComputer hardwareSimulation

The invention relates to a control method and device of a carrying system, computer equipment and a storage medium. The carrying system comprises an image acquisition device, and the method comprisesthe steps that after a to-be-carried object is carried to an initial placement position, acquiring a room environment image acquired by the image acquisition device, wherein the room environment imageis an environment image of a room where the carrying system is located; determining a room wall surface intersection line of the room environment image; determining placement position deviation according to the room wall surface intersection line of the room environment image, wherein the placement position deviation is a deviation between the initial placement position and a planned placement position of the to-be-carried object; according to the placement position deviation, carrying the to-be-carried object to an actual placement position, wherein the actual placement position matches theplanned placement position of the to-be-carried object. The floor tile paving precision can be improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

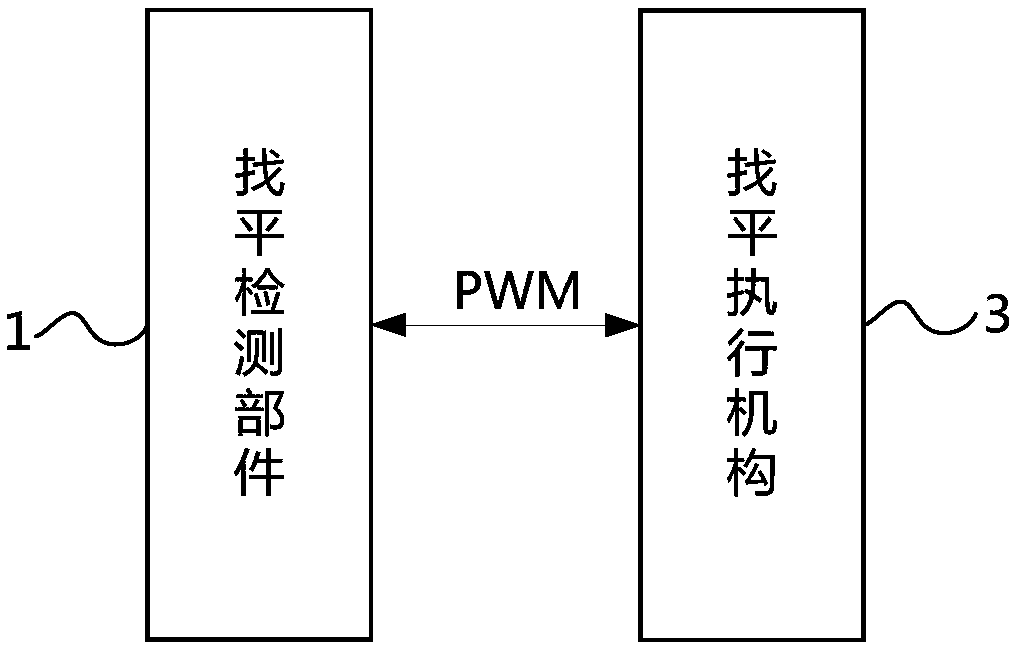

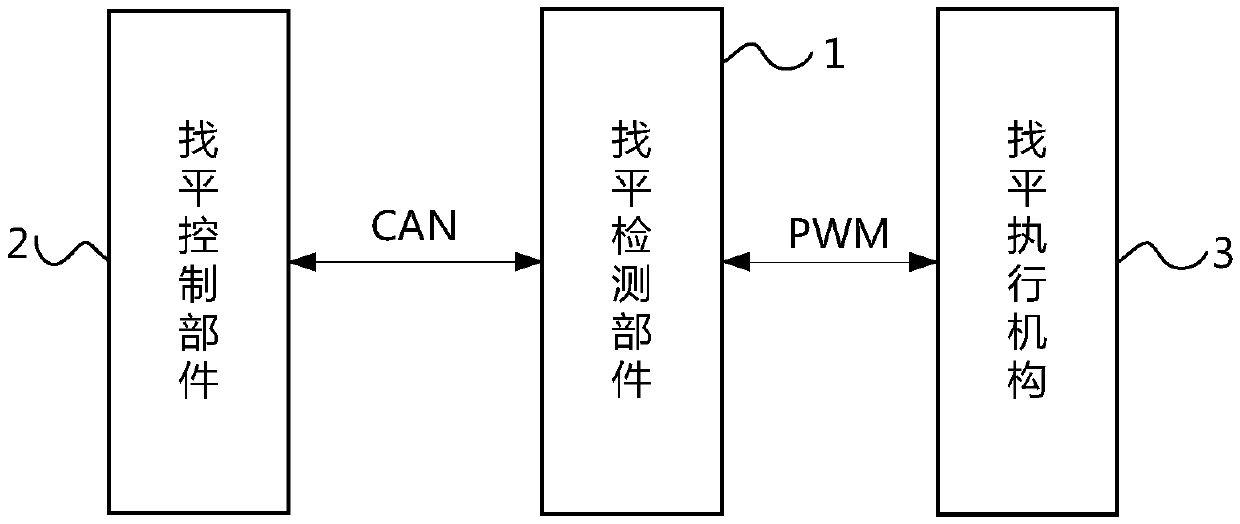

Paver longitudinal slope automatic leveling control device and method and paver

PendingCN107741719AImprove laying efficiencyImprove laying accuracyProgramme controlComputer controlLoop controlMode control

The invention relates to a paver longitudinal slope automatic leveling control device and method and a paver. The paver longitudinal slope automatic leveling control device comprises a leveling control part and a leveling detection part, at least one of the leveling control part, the leveling detection part and a whole paver control part is provided with a setting unit, and the leveling control part is used for selecting the working mode controlling a leveling execution mechanism according to road paving grade requirements, and the working mode comprises the steps that the leveling detection part is matched with the leveling control part to achieve independent leveling and is matched with the whole paver control part to achieve on-line leveling, and the leveling detection part is used fordetecting the height deviation between the paver and leveling reference to make the control device achieve leveling in the selected working mode. The paver longitudinal slope automatic leveling control device can flexibly select the appropriate working mode according to the road paving requirements, on occasions with low paving requirements, the road paving efficiency is improved, and the cost issaved; on occasions with high paving requirements, whole paver closed-loop control is achieved, and the road paving precision is improved.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

A railway track laying device

ActiveCN109944122BRealize mobile crane layingImprove mobile stabilityRailway track constructionStructural engineeringMechanical engineering

Owner:林最隆

Construction supporting device for steel rail telescopic adjuster and construction system

ActiveCN112376331ARealize left and right adjustmentImprove construction accuracyRailway tracksStructural engineeringMechanical engineering

The invention discloses a construction supporting device for a steel rail telescopic adjuster. The construction supporting device comprises a left fixing piece and a right fixing piece which are oppositely arranged; a left supporting unit and a right supporting unit which are oppositely arranged, wherein the left supporting unit and the right supporting unit are each provided with a single-side steel rail telescopic adjuster fixing groove, the left supporting unit is connected to the left fixing piece, the left supporting unit can reciprocate relative to the left fixing piece in the horizontaldirection, and the right supporting unit is connected to the right fixing piece, and the right supporting unit can reciprocate relative to the right fixing piece in the horizontal direction; and a first transverse connecting rod which is arranged between the left supporting unit and the right supporting unit, wherein the two ends of the first transverse connecting rod are connected with the leftsupporting unit and the right supporting unit correspondingly, and the length of the first transverse connecting rod is adjustable. The invention further provides a steel rail telescopic regulator construction system. The supporting device aims at improving the laying precision of the steel rail telescopic adjustor.

Owner:CHINA RAILWAY 20 BUREAU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com