Tunnel automatic waterproof plate trolley

An automatic waterproofing and pallet trolley technology, used in tunnels, tunnel linings, wellbore linings, etc., can solve the problems of the width limitation of the waterproof board, the inability to accurately align, and the inability to guarantee, so as to improve work efficiency, improve waterproof effect, and improve The effect of laying precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

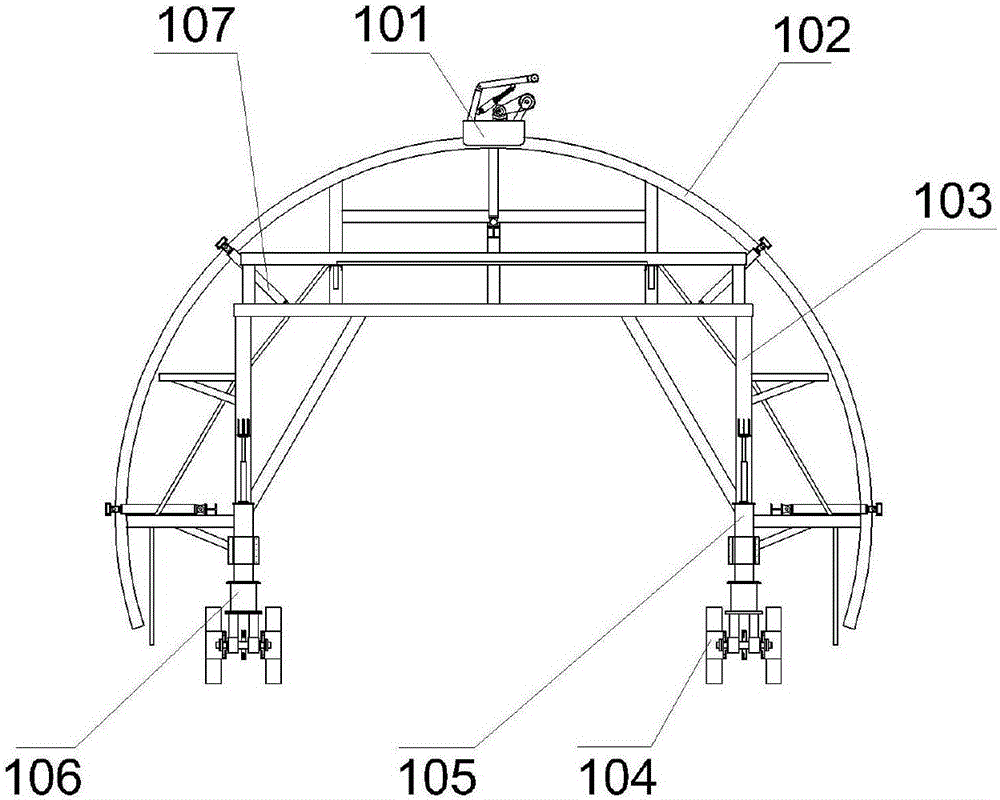

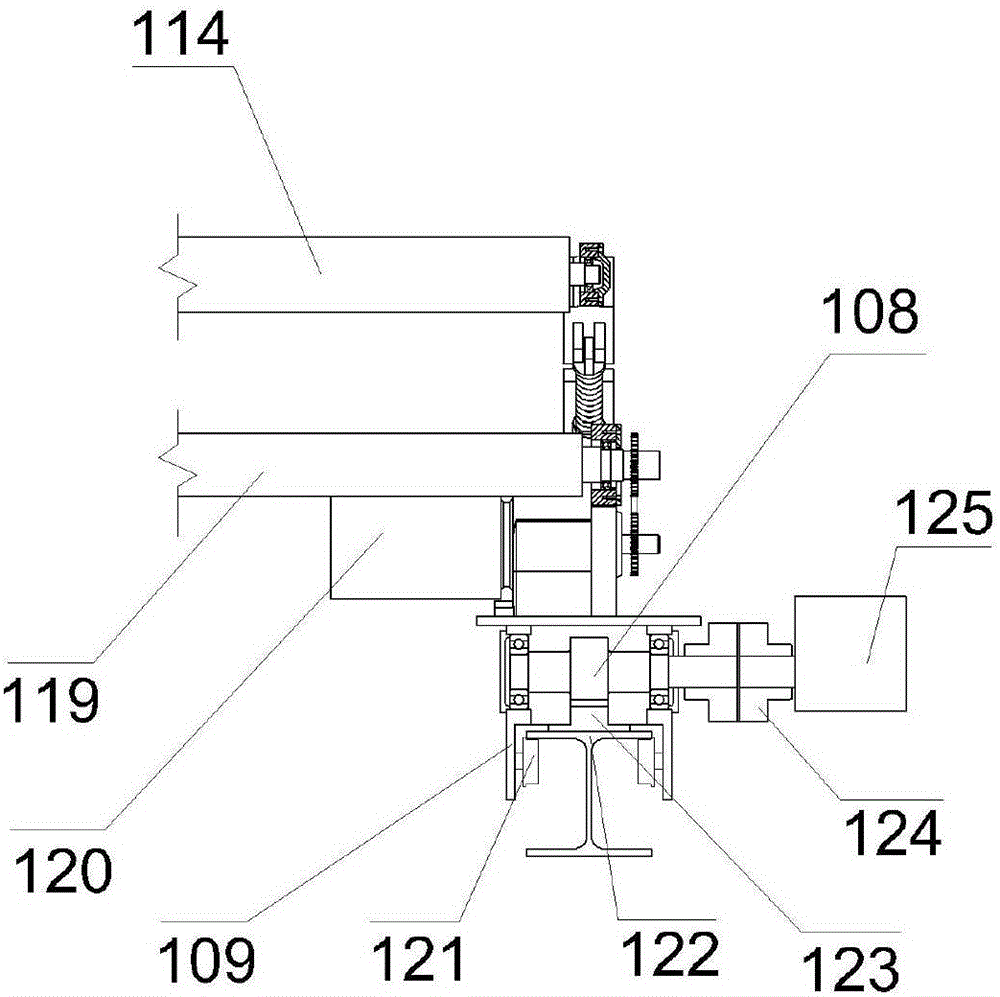

[0044] Such as figure 1 and figure 2 As shown, this embodiment provides a tunnel automatic waterproof board trolley, which includes: a trolley body, a walking trolley 101, a cloth rolling device, a rolling device, and a trolley walking track 102; the cloth rolling device includes a driving device and a cloth rolling device The rotating shaft 119; the driving device drives the cloth rolling shaft 119 to rotate, and is used to release the waterproof board 115 rolled on the cloth rotating shaft 119; the rolling device includes a bracket and a rolling roller 114, wherein the rolling roller 114 will release the waterproof board 115 Rolled on the tunnel wall to prevent the waterproof board 115 from wrinkling.

[0045] The trolley main body includes: a trolley base 106 and a trolley frame 103 arranged on the trolley base 106, and the bottom of the trolley base 106 is provided with a road running mechanism 104, which includes: walking rollers and a speed reducer; The rollers are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com