Missile-borne floating air ball system

A balloon and bomb-borne technology, which is applied to balloon vehicles and other directions, can solve problems such as application limitations and aerostats are vulnerable to attack, achieve good practical value, and be beneficial to military and emergency applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

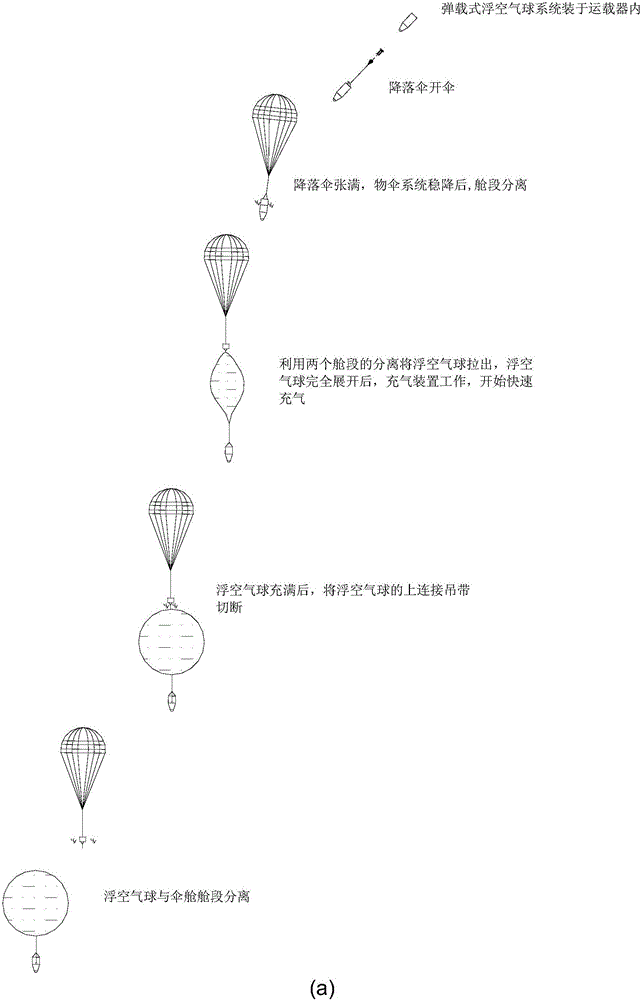

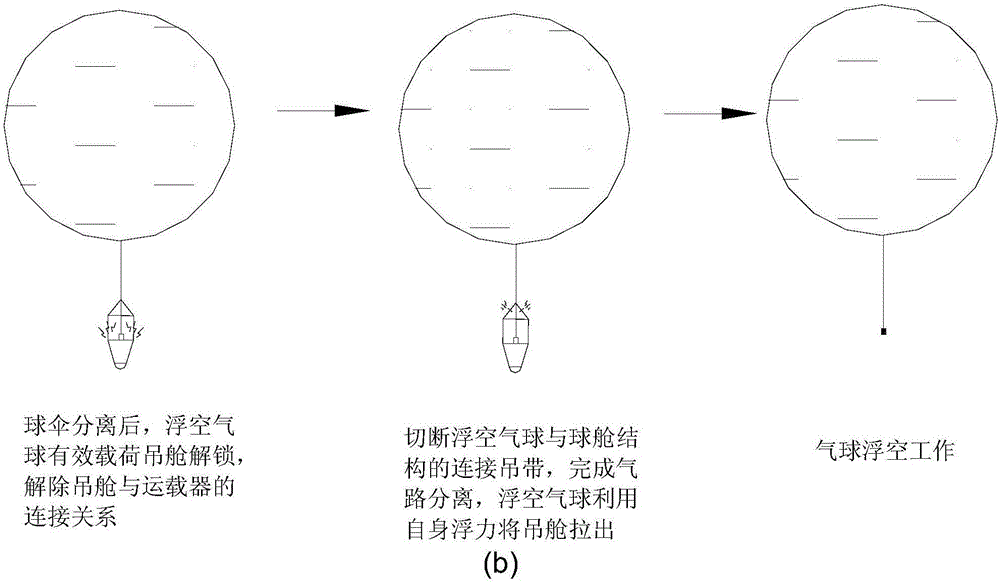

[0025] Aiming at the deficiencies of the prior art, the present invention proposes a missile-borne floating air balloon system, which solves the problem of rapid deployment of floating air balloons in battlefield environments and emergency conditions, and changes the bottom-up deployment method of traditional floating air balloons , using the carrier to realize automatic deployment on the battlefield from top to bottom, it is especially suitable for special purposes such as investigation, early warning, and earth observation. The present invention will be described in detail below in conjunction with the accompanying drawings.

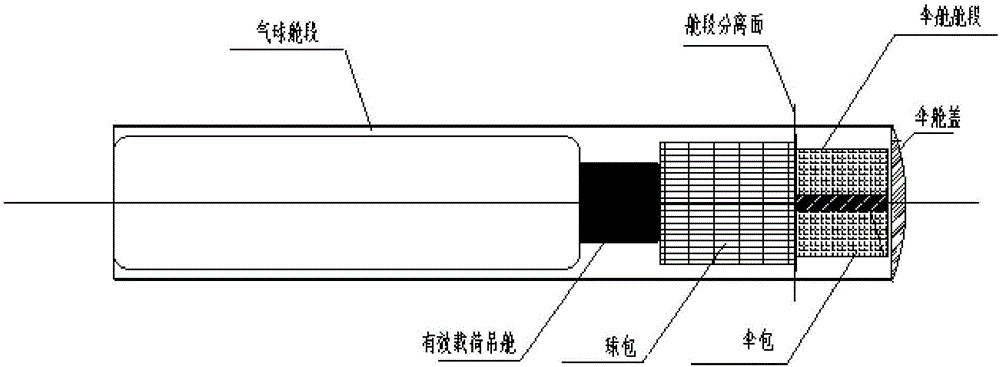

[0026] A bomb-loaded floating air balloon system of the present invention includes an umbrella cabin structure, a parachute, a floating air balloon, a catapult, a separation nut, a ball umbrella separation cutter, a ball cabin separation cutter, a pipeline separation device, an inflation device, and a ball cabin Cabin section, umbrella cabin section.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com