Handling system, control method thereof and floor tile laying system

A technology of a handling system and a control method, which is applied in the field of robots, can solve the problem that the robot cannot meet the requirements of tiling accuracy, and achieve the effects of improving the tiling accuracy, improving the accuracy, and overcoming the position deviation of floor tiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

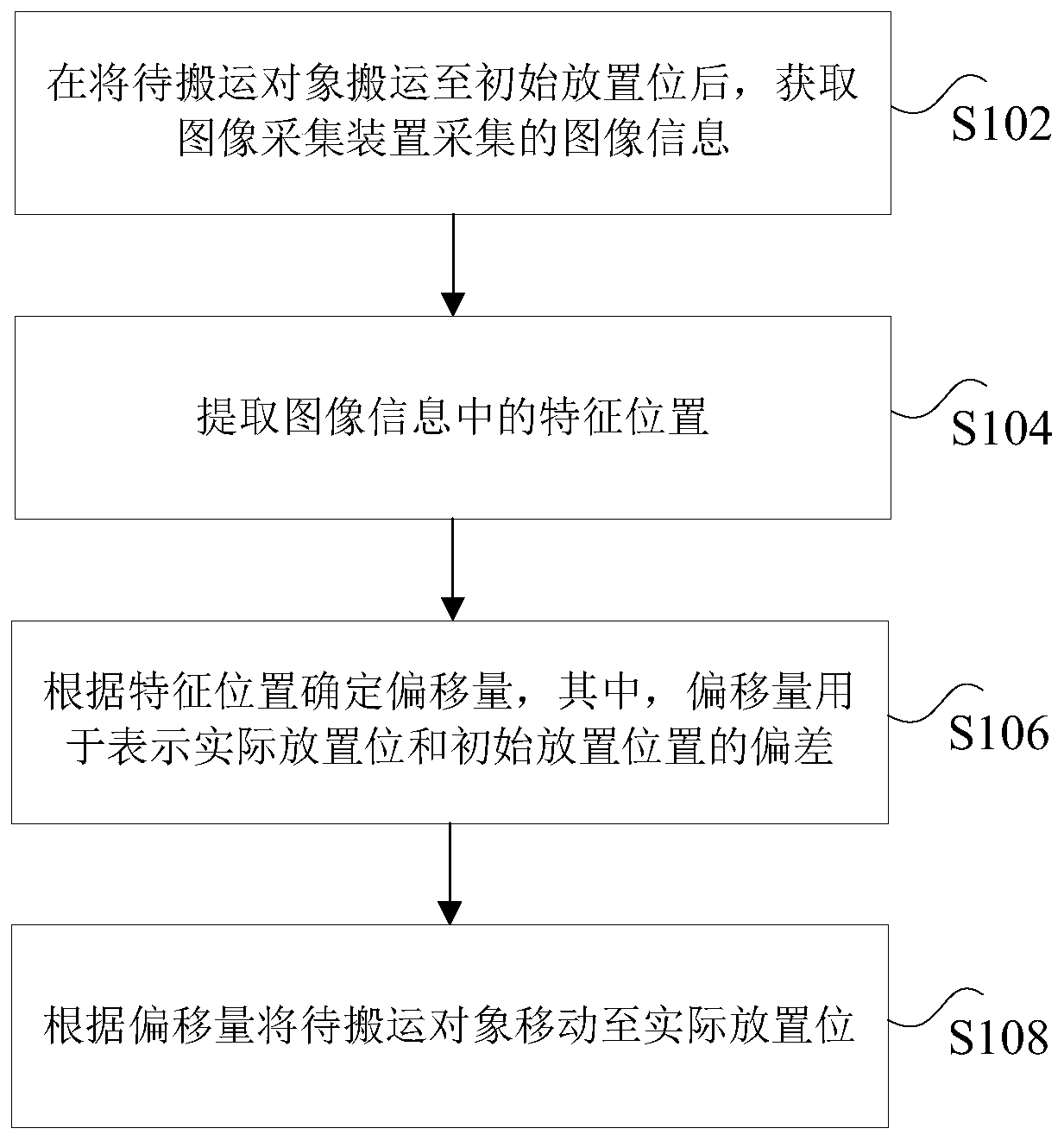

[0042] According to an embodiment of the present invention, an embodiment of a method for controlling a handling system is provided. It should be noted that the steps shown in the flowcharts of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, and , although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0043] figure 1 It is a flow chart of the control method of the transport system according to the embodiment of the present invention. The transport system includes an image acquisition device. The object to be transported in this embodiment may be a floor tile to be laid. In the following embodiments, the floor tile is taken as an example for illustration ,Such as figure 1As shown, the method includes the following steps:

[0044] Step S102, after the object to be transported is transported to t...

Embodiment 2

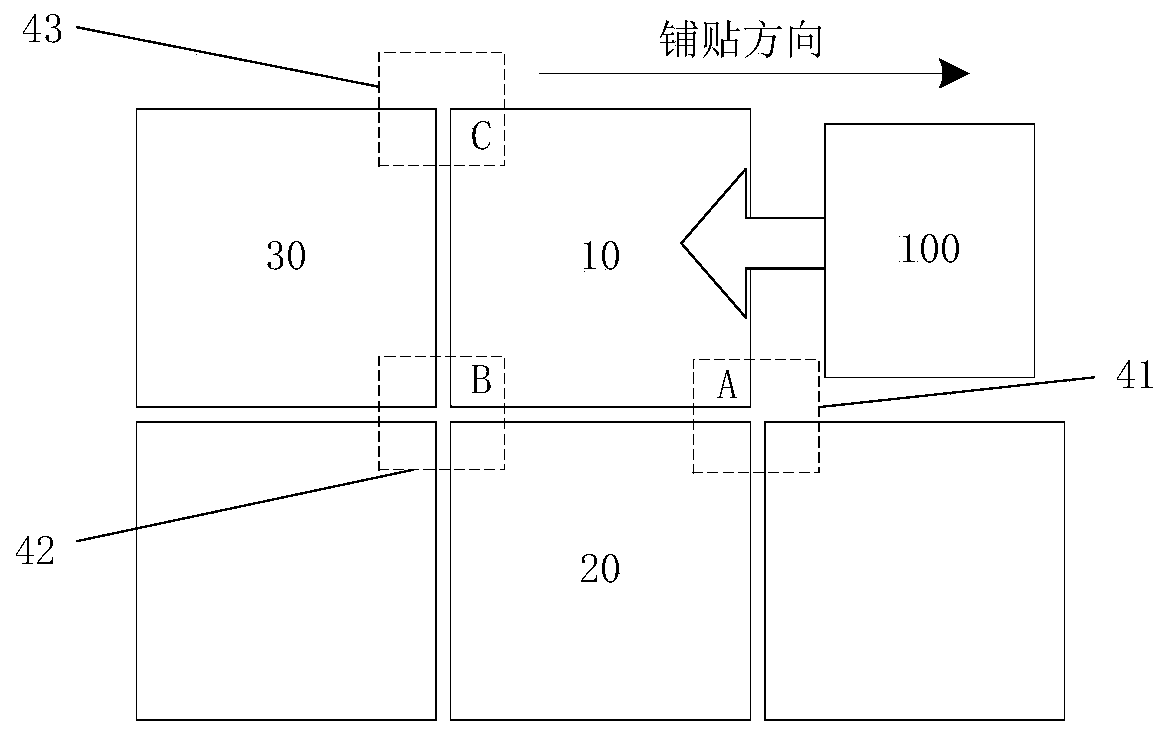

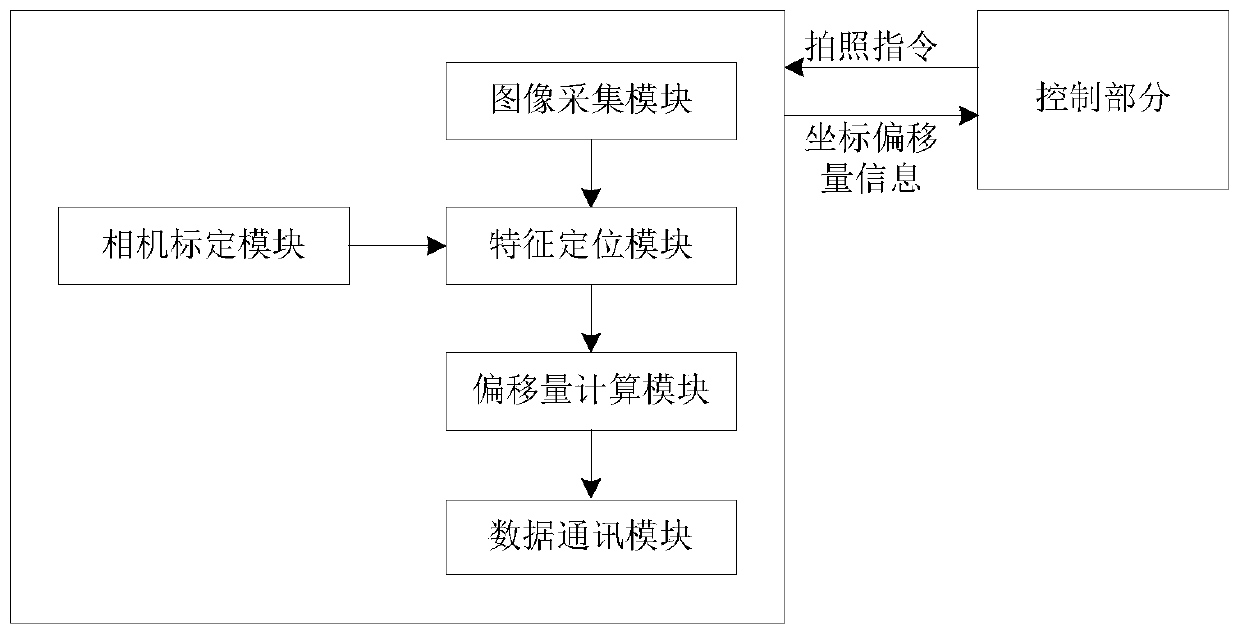

[0086] According to an embodiment of the present invention, an embodiment of a handling system is provided, Figure 10 is a schematic diagram of a handling system according to an embodiment of the present invention, combined with Figure 10 As shown, the system includes:

[0087] The image acquisition device 102 is used to obtain the image information collected by the image acquisition device after the object to be transported is transported to the initial placement position, wherein the image information at least includes the actual placement position of the object to be transported and the three-dimensional position of two adjacent reference objects. adjacent corners.

[0088] The above-mentioned initial placement position is near the actual placement position, and the robot can run to the initial placement position according to the automatic navigation operation.

[0089] The above-mentioned image acquisition device can be an industrial camera, which is arranged on the ma...

Embodiment 3

[0109] According to an embodiment of the present invention, a system for laying floor tiles is provided, including the handling system described in Embodiment 1.

[0110] The serial numbers of the above embodiments of the present invention are for description only, and do not represent the advantages and disadvantages of the embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com