Steel rail lifting apparatus for track construction track laying, and application method thereof

An application method and rail technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of difficult ballastless track laying and accurate alignment, difficulty, and high precision, so as to improve laying efficiency, simple and reasonable device structure, Ease of manufacture and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

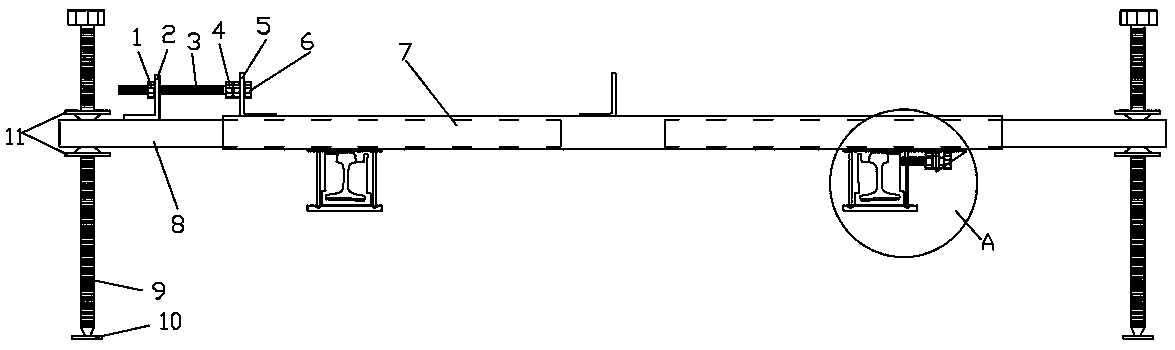

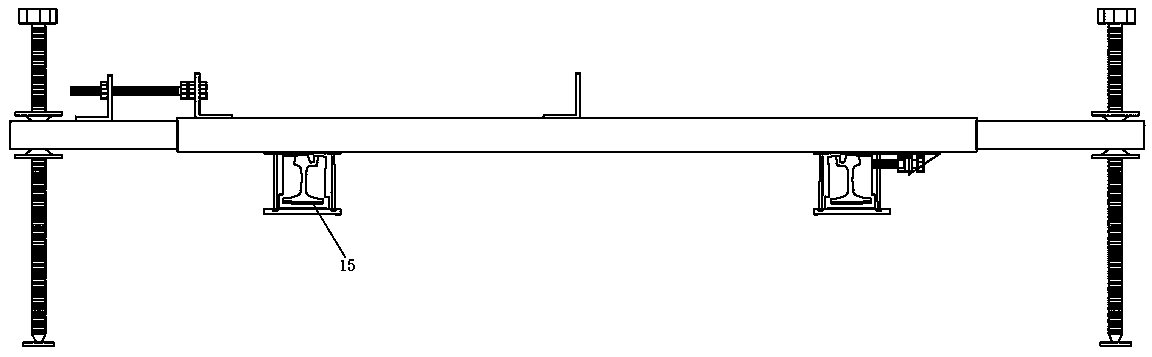

[0024] Embodiment one: if figure 1 As shown, in the rail lifting device used in track construction and laying provided by this embodiment, the main part of the device includes an outer sliding tube 7, an inner tube 8, an adjustable support and a bracket. Wherein, the two ends of the outer sliding tube 7 are respectively provided with an inner tube 8, the inner part of the inner tube 8 is partially sleeved inside the outer sliding tube 7, and the outer part protrudes outside the outer sliding tube 7; the inner tube 8 and the outer sliding Sliding fit is formed between the tubes 7 , that is, the inner tube 8 can protrude outward or retract inward along the extension direction of the tube body of the outer sliding tube 7 . The outer end of the inner tube 8 is connected with an adjustable support. The bracket is arranged at the bottom of the outer sliding tube 7 and is located at both ends of the outer sliding tube 7, and there is a bearing space for the rail in the bracket.

[...

Embodiment 2

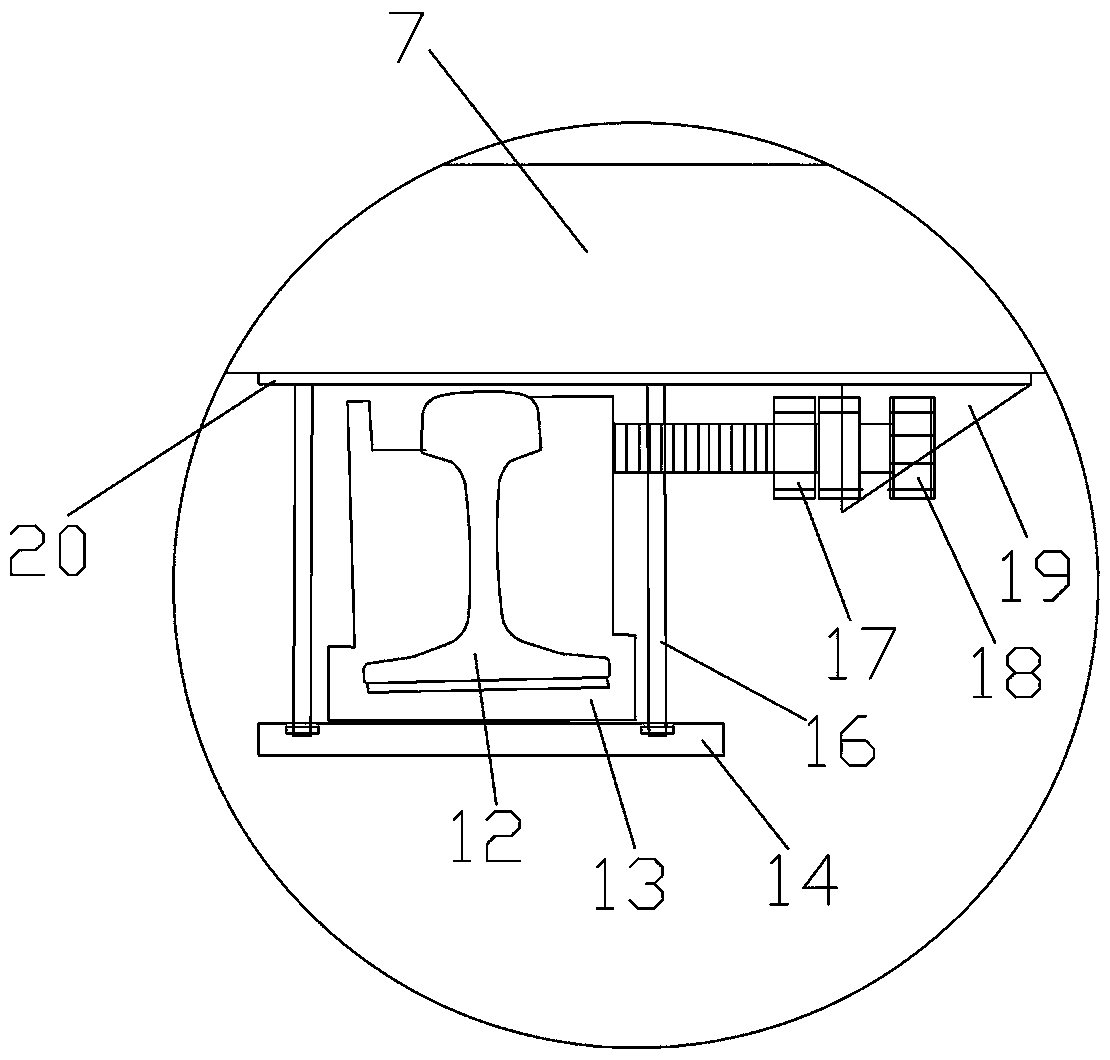

[0039] Embodiment 2: Compared with Embodiment 1, this embodiment differs in that: Figure 4 or Figure 5 As shown, in this embodiment, a fine-tuning sliding device is arranged between the outer sliding tube 7 and the bracket. Specifically, one or two fine-tuning nuts 21 are movable at the bottom of the outer sliding tube 7, and an oblong hole is arranged on the top plate 20. The oblong hole is located directly below the fine-tuning nuts 21. Fitting connection, the metal bolt head 22 is fixed on the bottom of the outer sliding tube 7 by tightening the connecting thread between the fine-tuning nut 21 and the metal bolt head 22, and the metal bolt is fixed by loosening the connecting thread between the fine-tuning nut 21 and the metal bolt head 22 The head 22 and the fine adjustment nut 21 can move left and right.

[0040] Such as Figure 5 As shown, the upper part of the metal bolt head 22 is provided with a thread matched with the fine-tuning nut 21, and the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com