Material laying system and method

A technology of material spreading and material spreading device, applied in the field of material spreading system, can solve the problems of material waste, heavy recycling workload, affecting material spreading speed, etc., and achieve the effect of improving efficiency and precision, improving utilization rate, and improving balanced utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

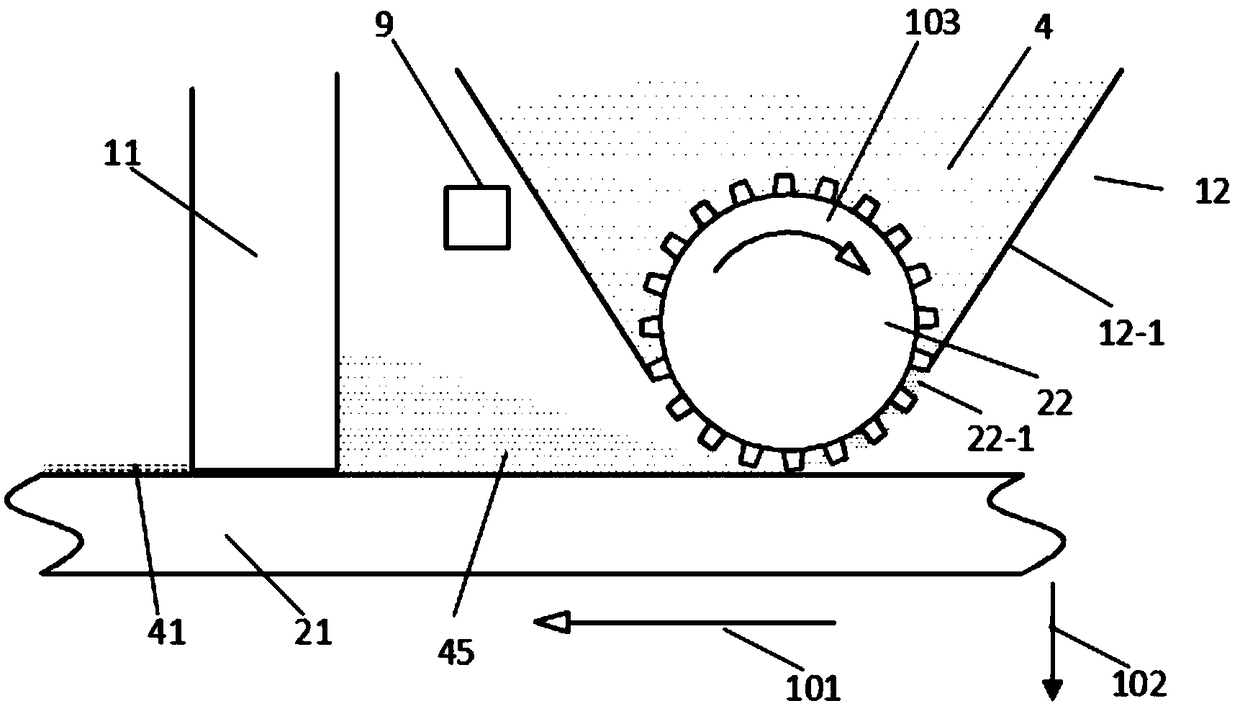

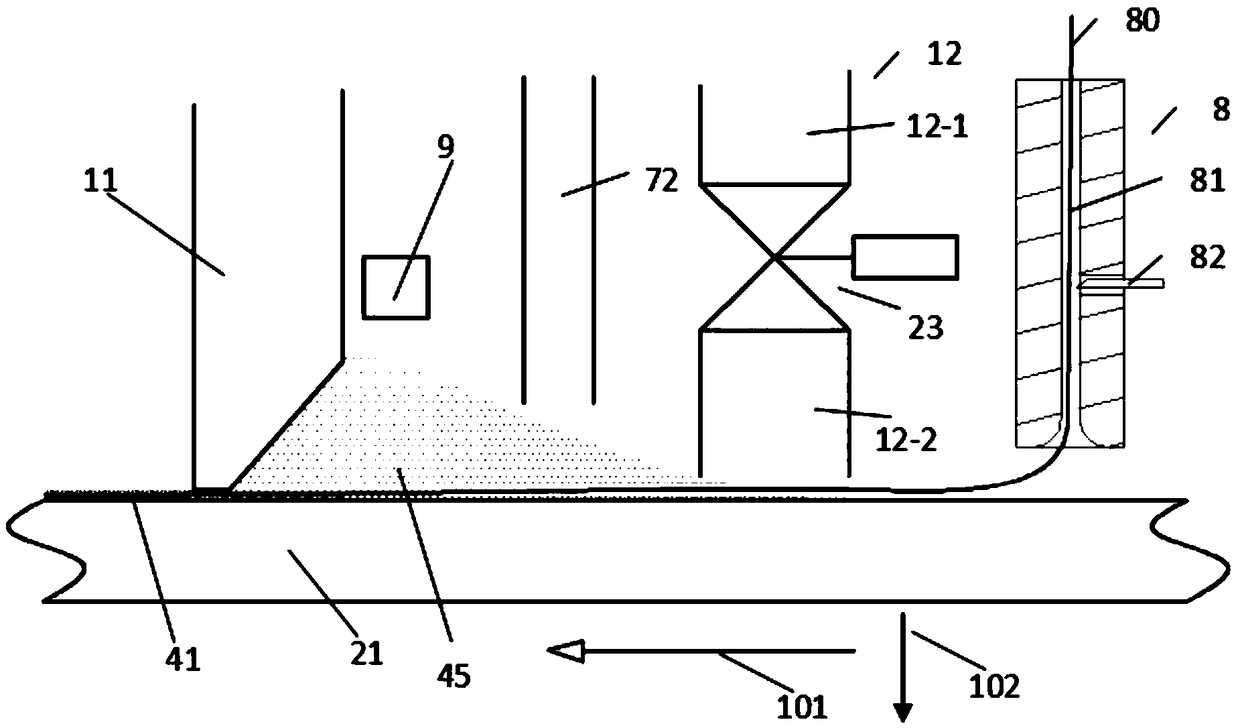

[0069] The present invention provides a material laying device, which is applied in the material laying procedure of the 3D printing process, including: a material bed 21, and a ring-shaped material laying area is arranged on the material bed 21, such as a circular material laying area, or It may be a rectangular ring-shaped material-laying area; the material-laying device, the material-laying device and the material bed 21 can move relative to the first direction, so that the material-laying device can carry out repeated material-laying along the ring-shaped material-laying area; the driving device is used for Drive the relative movement in the second direction between the laying device and the material bed 21. During the laying process, the distance between the laying device and the material bed 21 is enlarged, and the spiral printing material layer 41 laid in a stacked manner on the material bed . Wherein, the first direction refers to the direction of moving along the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com