Method for controlling concrete planeness of large-area steel bar truss template

A steel truss and control method technology, applied in the direction of construction, building structure, building material processing, etc., can solve the problem of low pass rate of flatness and achieve the effect of improving laying accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Embodiment: An example of concrete construction of a two-story structure on a certain floor in Xinzhan Development Zone, Hefei City.

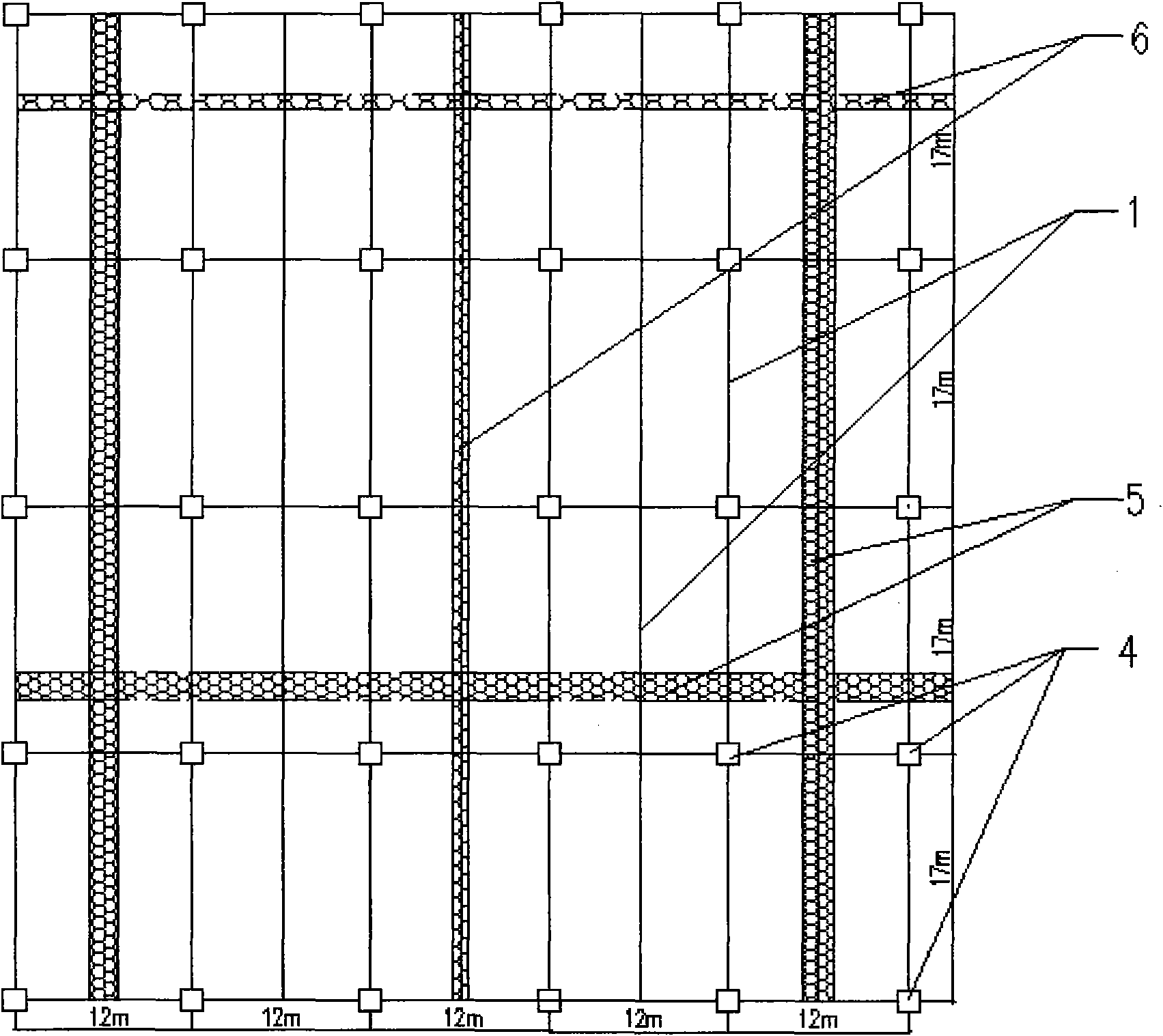

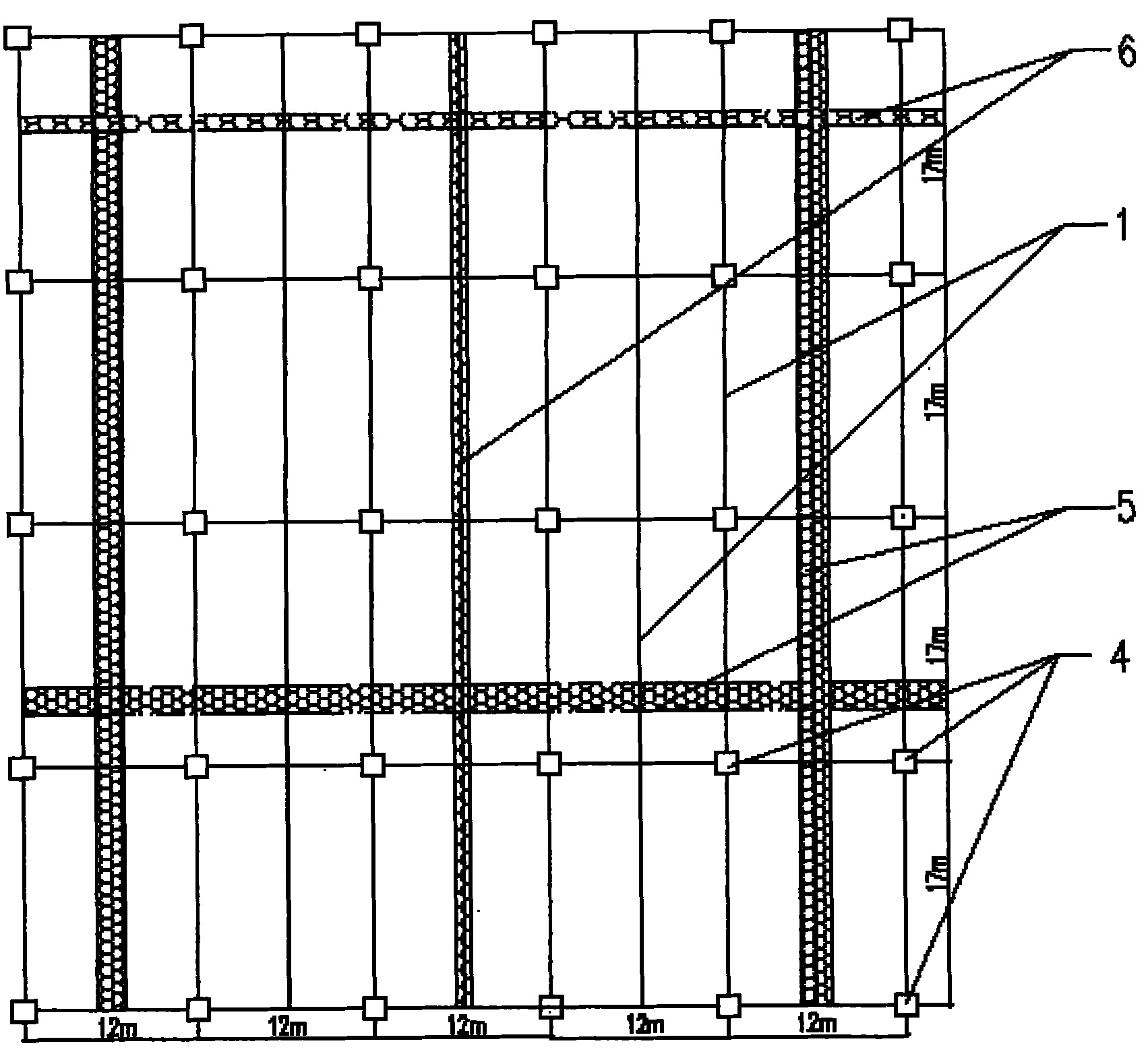

[0013] The paving area of this project is 43248M 2 , large area, roof column spacing 17000*12000mm, steel beam width 6000mm.

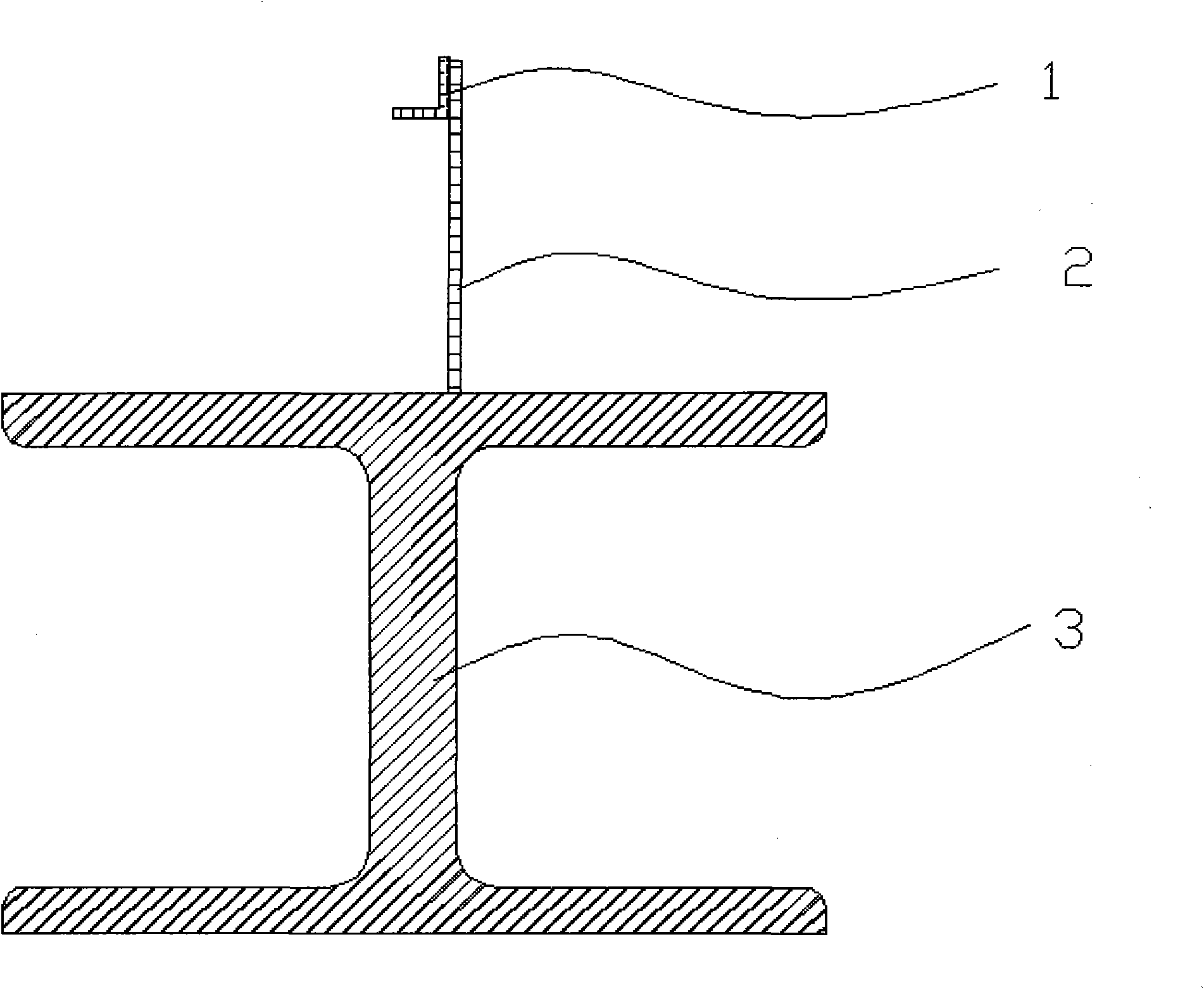

[0014] (1) Install the steel bar truss support formwork on the steel beam; take the roof column 4 as the benchmark, and control the elevation based on the thickness of the structural concrete that needs to be laid 150mm, and follow the direction of the truss mold on the steel beam, every Set a vertical short angle steel 2 on a straight line of 2000mm and bring an elevation control steel wire, the vertical short angle steel 2 is welded on the steel beam 3, and then set the direction along the straight line of the vertical short angle steel 2, 25*25*3 angle steel guide rail 1 and vertical short angle steel 2 are installed by spot welding, one side of angle steel guide rail 1 is placed vertically upwards and wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com