ROV deep-sea cable laying operating system for manned submersible

A manned submersible and operating system technology is applied in the field of ROV deep-sea cable laying operation system, which can solve the problems of reducing cable laying efficiency, consuming a large amount of energy, unable to meet the needs of concealed operation, etc., so as to improve laying accuracy and reduce energy consumption. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described below.

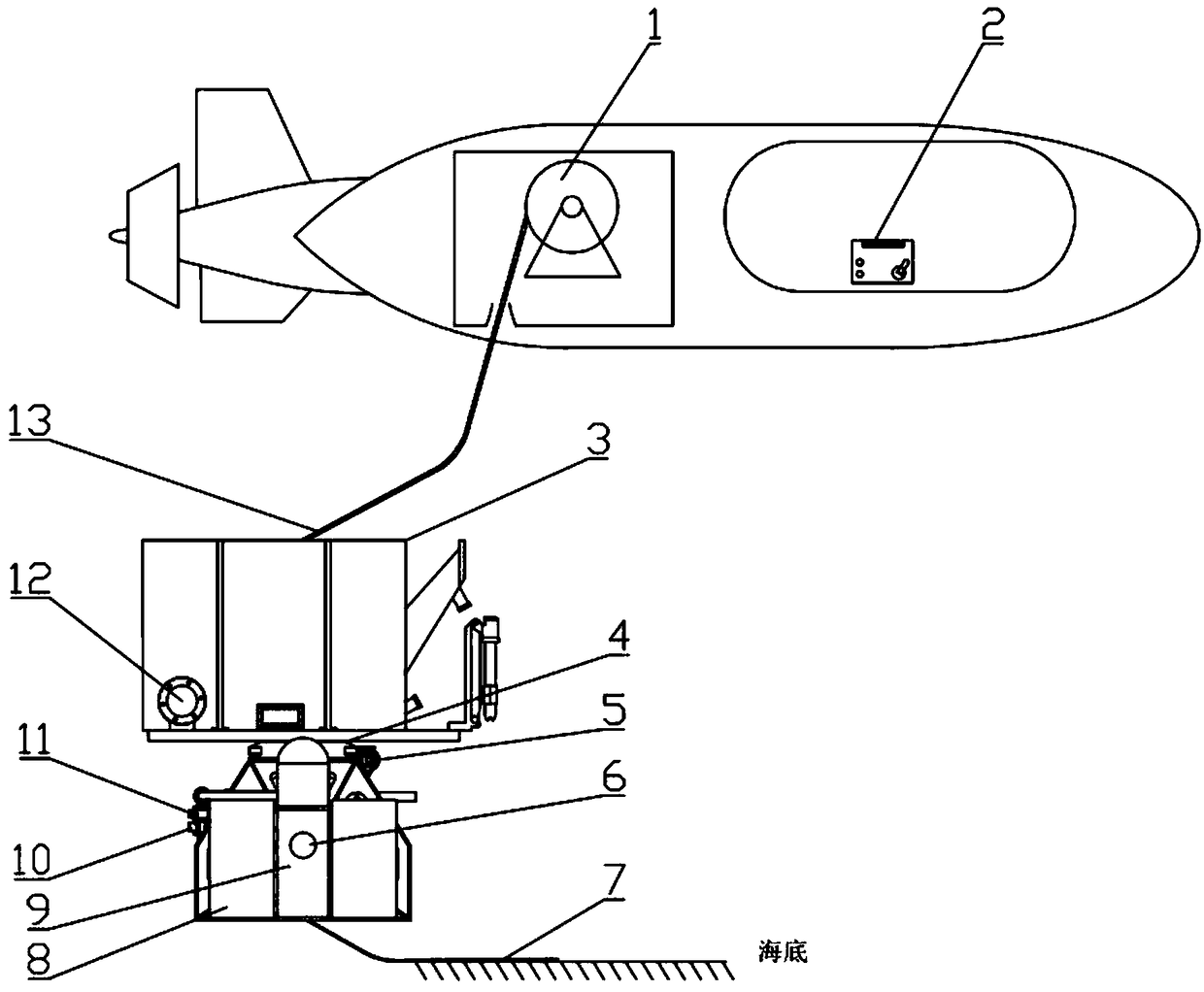

[0020] Such as figure 1 , figure 2 and image 3 As shown, the ROV deep-sea cable laying operation system for manned submersibles includes a retractable winch 1 and an ROV cable laying control box 2 arranged on the manned submersible, one end of the umbilical cable 13 and the reel of the retractable winch 1 Winding and electrically connected with the ROV cable laying control box 2, the other end of the umbilical cable 13 is connected with the remote control unmanned submersible 3 with the cable laying winch 4 and the hydraulic source 12, so that the remote control unmanned submersible 3, the cable laying winch 4 and the Real-time transmission and manipulation of signals between manned submersibles.

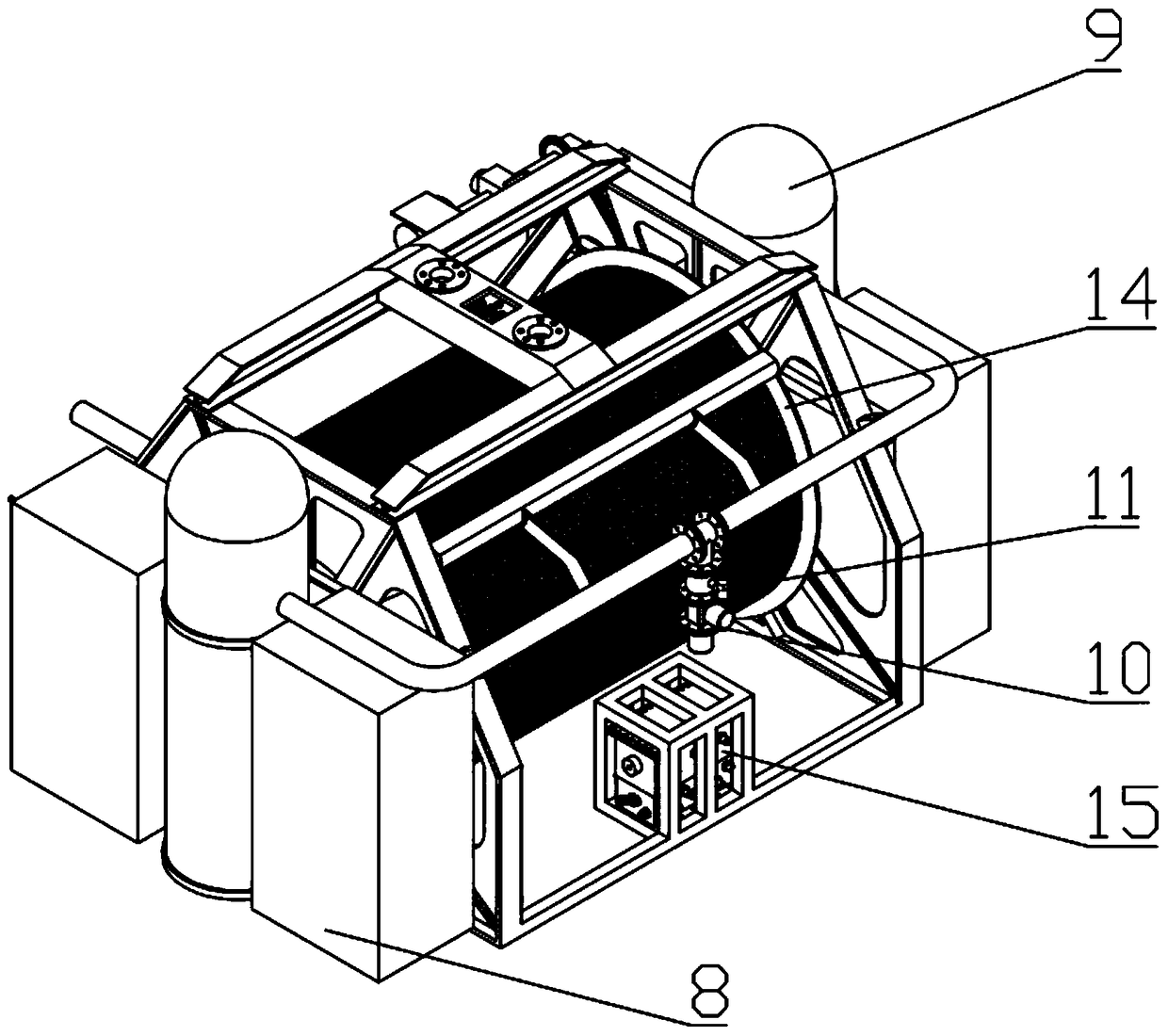

[0021] Such as figure 1 , figure 2 and Figure 4 Shown, the concrete structure of laying cable winch 4 is as follows:

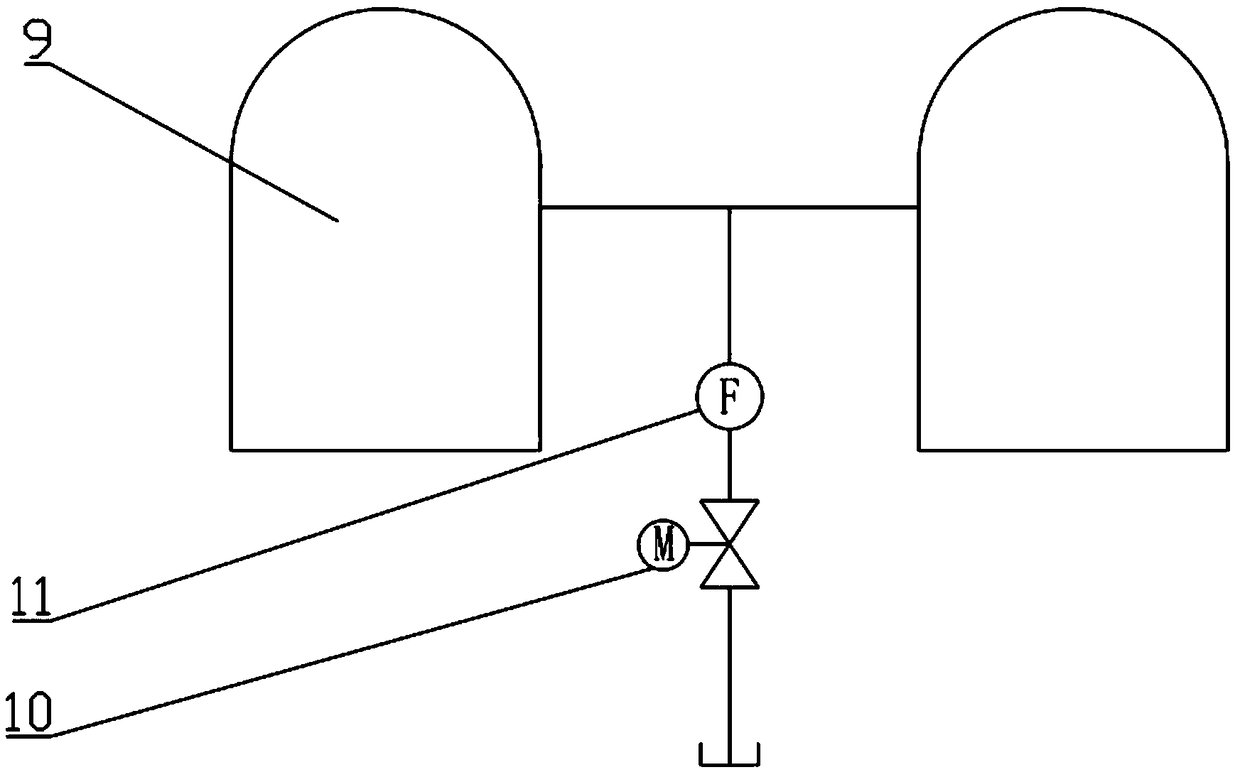

[0022] It includes a reel 14 and a control valve box 15 for retracting an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com