Construction method for precast type vibration damping track board

A construction method and track slab technology, which are applied in the directions of track, track laying, track maintenance, etc., can solve the problems of complicated construction procedures, construction precision track corrugation, slow construction progress, etc. Structural integrity and durability, the effect of increased automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

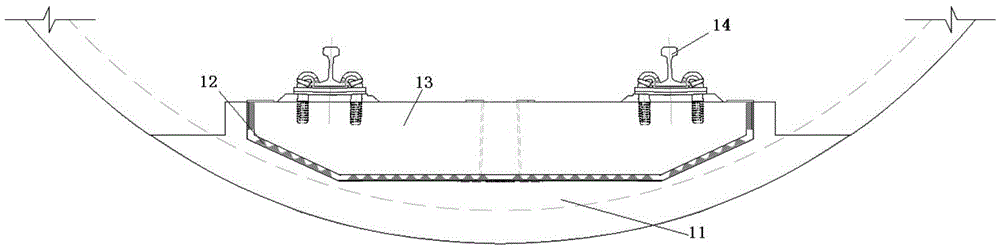

[0040] see figure 1 , shows the track structure with damping pads, this track structure includes concrete layer 11, vibration isolation layer 12, prefabricated slab 13 and steel rail 14, generally speaking, its construction method is to carry out construction step by step from bottom to top, both The concrete layer 11 is poured first, then the vibration isolation layer 12 and the prefabricated slab 13 are installed in sequence, and finally the rail is fixed. This method is traditional in operation, but in specific applications, defects such as poor compactness and easy movement of the prefabricated slab often occur.

[0041] And the applicant of the present invention gradually worked out a kind of prefabricated damping track construction method through long-term creative work, and it mainly comprises the following steps:

[0042] Step 1: track slab prefabrication;

[0043] Carry out civil structure bottom slab and boundary measurement, complete the binding of steel bars in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com