Carbon fiber prepreg actuating device for carbon fiber automatic filament paving machine

A carbon fiber prepreg and automatic wire laying technology is applied in the field of carbon fiber prepreg actuating devices to achieve the effects of reduced response time, short response time and short stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings.

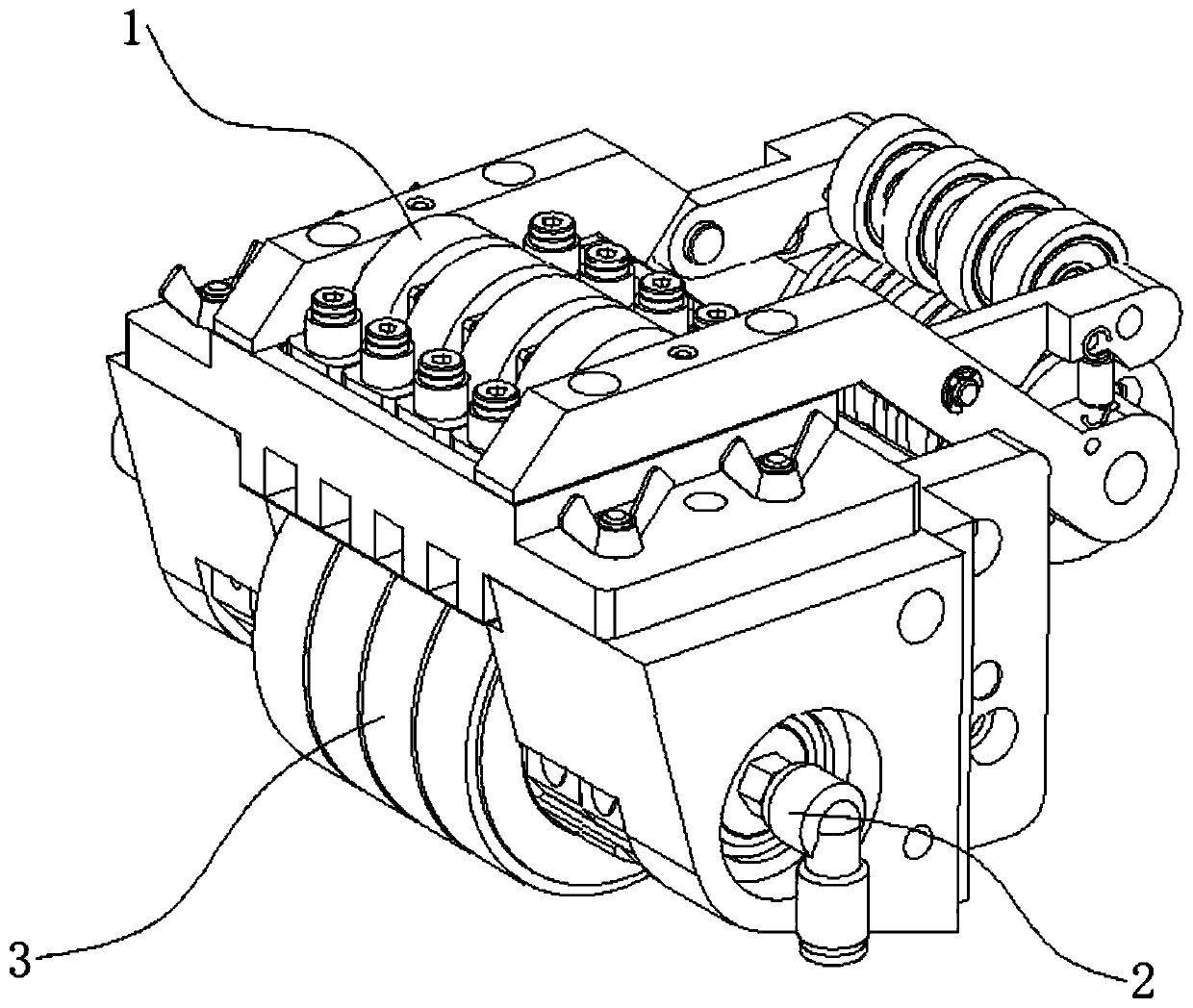

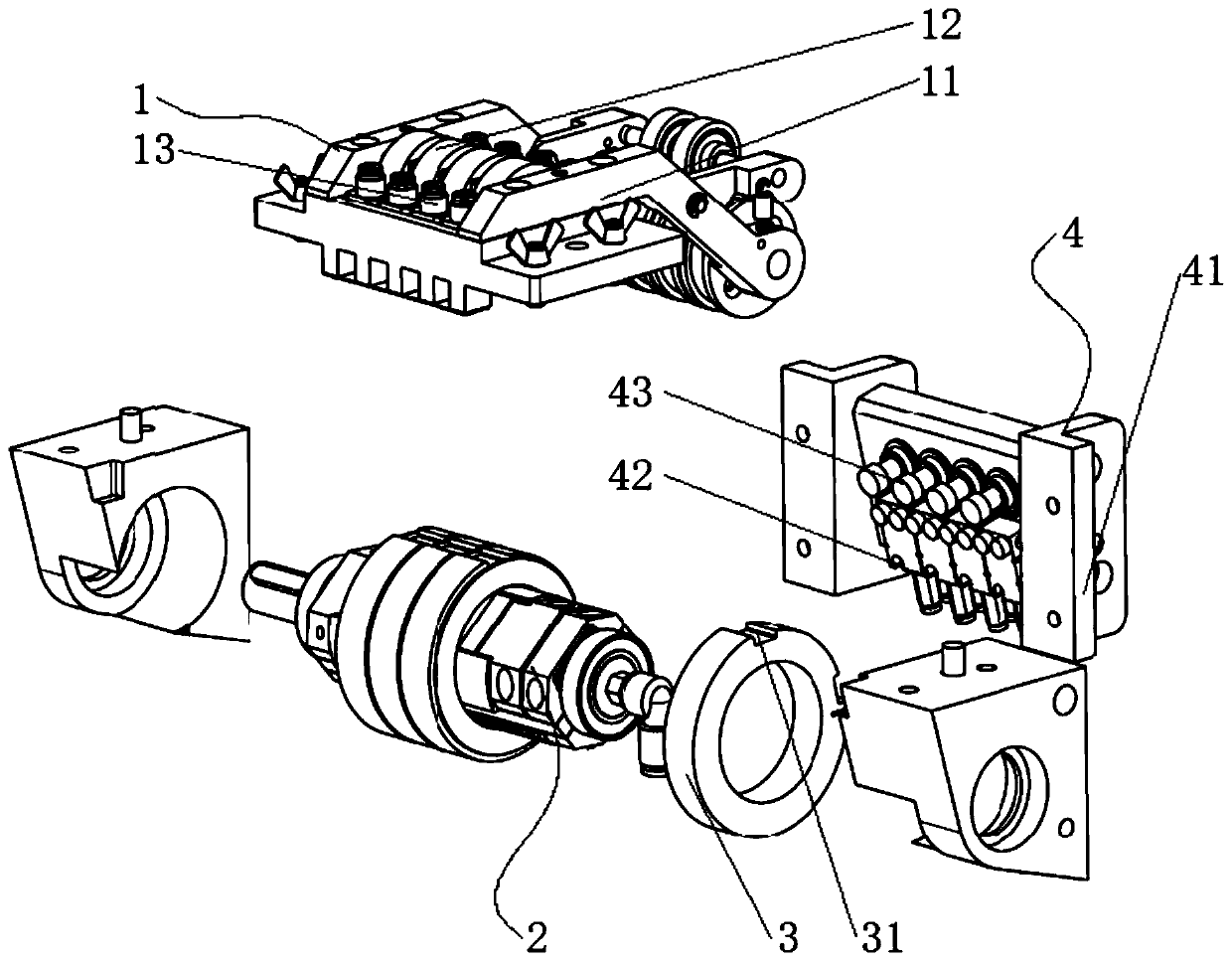

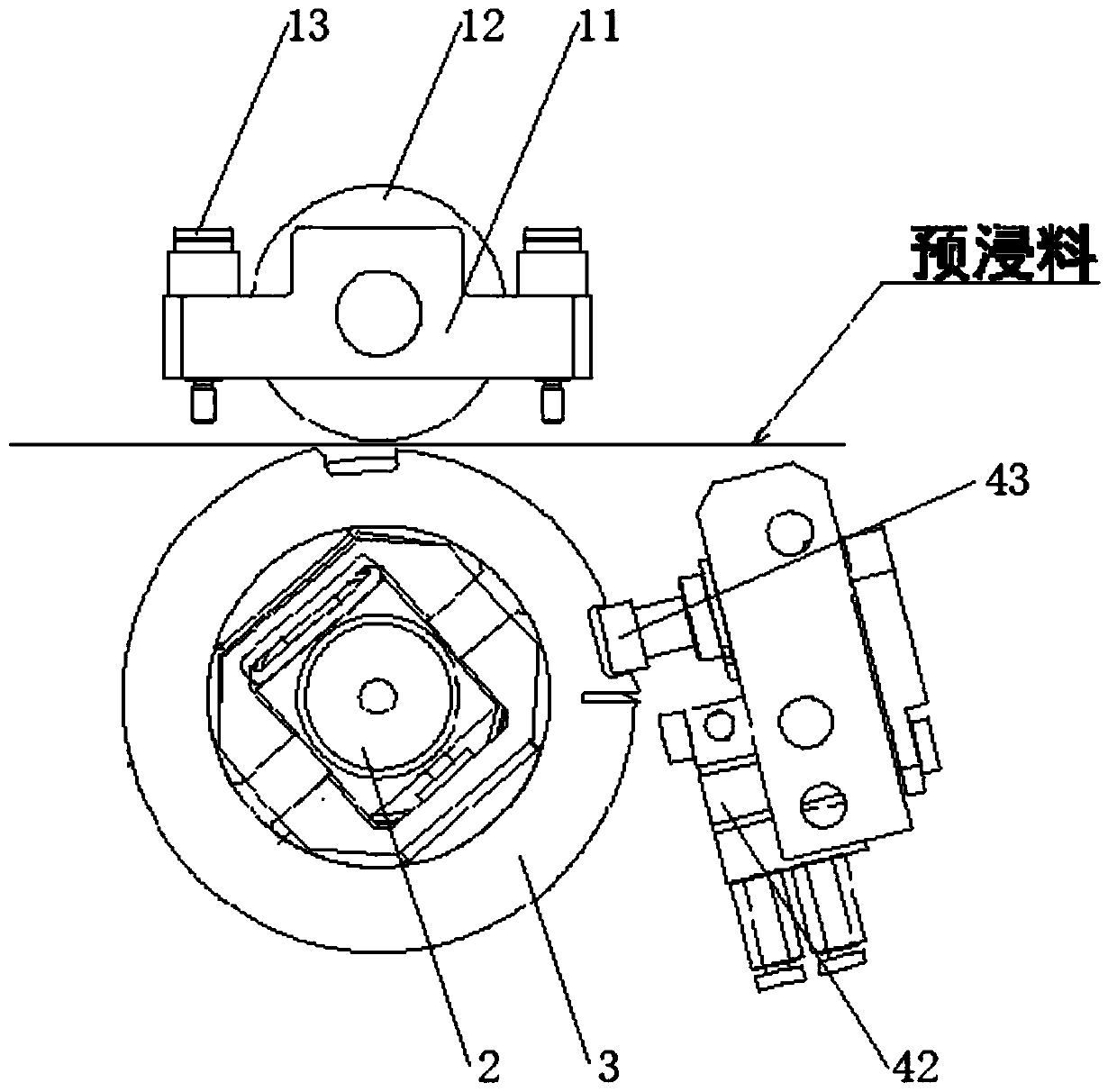

[0024] combine Figure 1-Figure 6 As shown, a carbon fiber prepreg actuating device for an automatic carbon fiber laying machine disclosed in this embodiment includes a chopping block wheel assembly 1; the chopping block wheel assembly 1 includes a set of chopping block wheel frames 11, the 11 is arranged on the automatic wire laying machine, several groups of anvil wheel 12 are arranged side by side on the anvil wheel frame 11, an air expansion shaft 2 is arranged below the anvil plate wheel assembly 1, and the two ends of the air expansion shaft 2 are arranged through the bearing seat On the automatic laying machine, several sets of cams 3 are arranged on the air expansion shaft 2, the carbon fiber prepreg yarn path passes between the cam 3 and the anvil wheel 12, and two sets of positioning grooves are processed on the cam 3 31. A set of carbon fiber prepreg cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com