Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "High parts strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

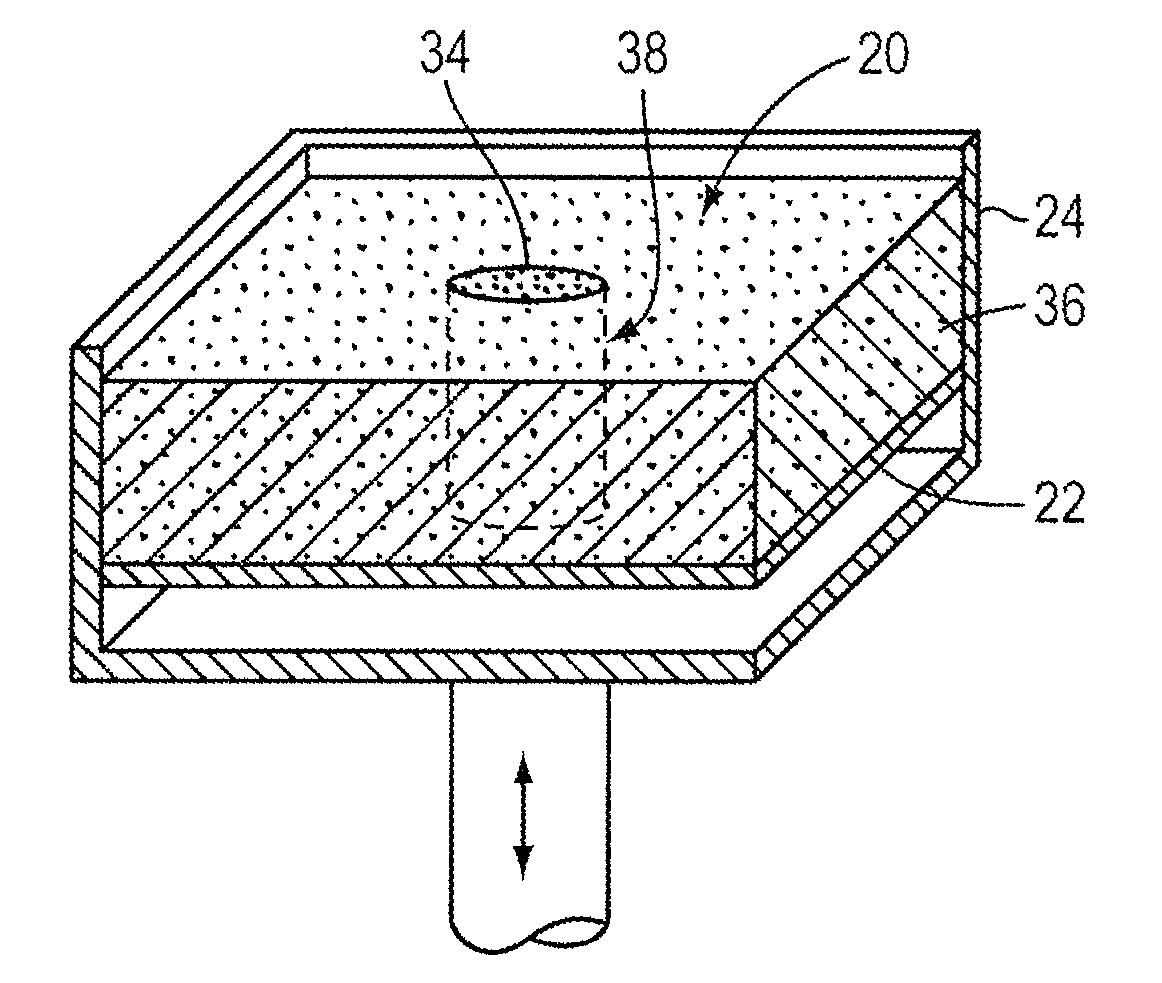

Three-Dimensional Printing Material System With Improved Color, Article Performance, and Ease of Use

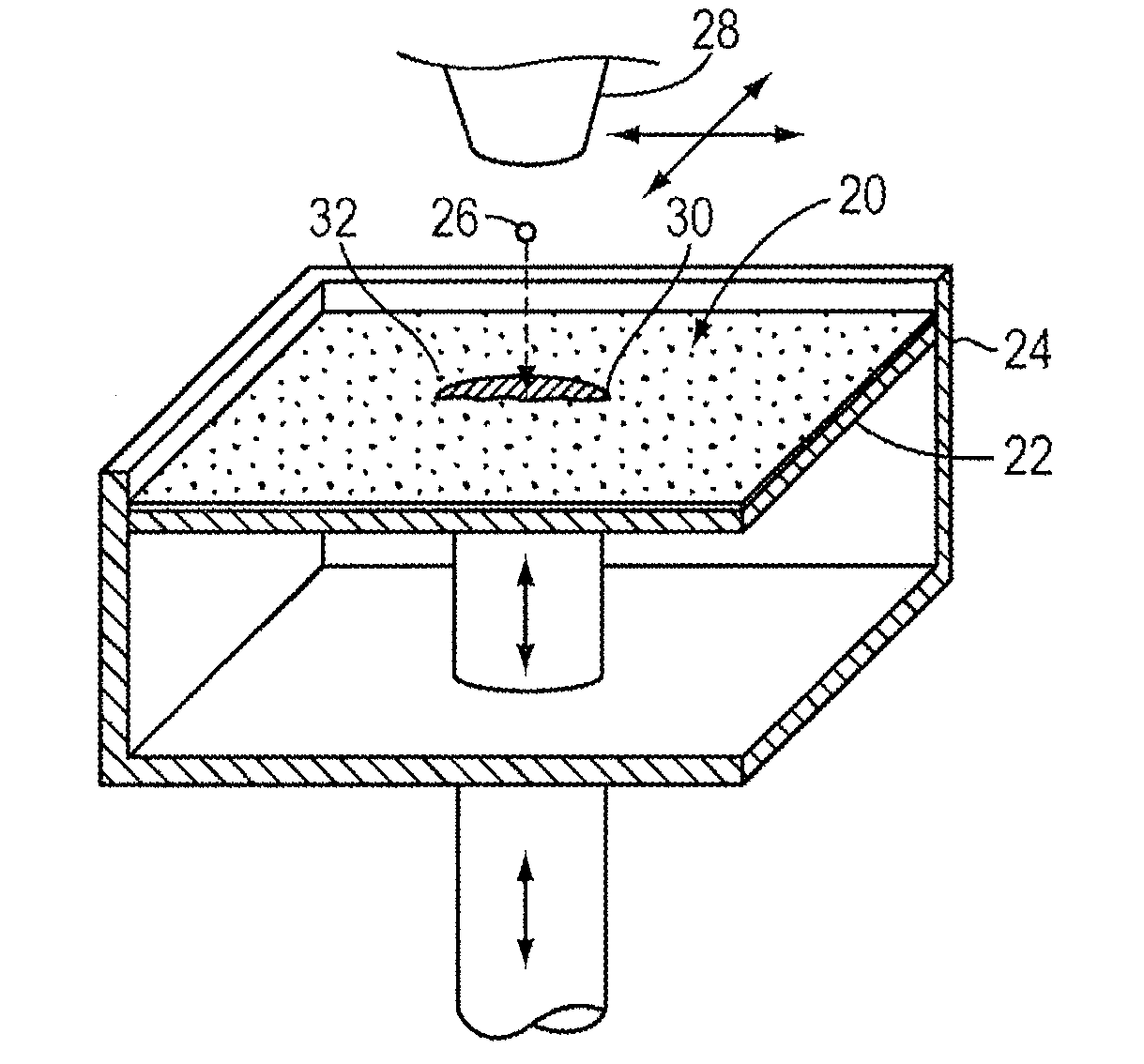

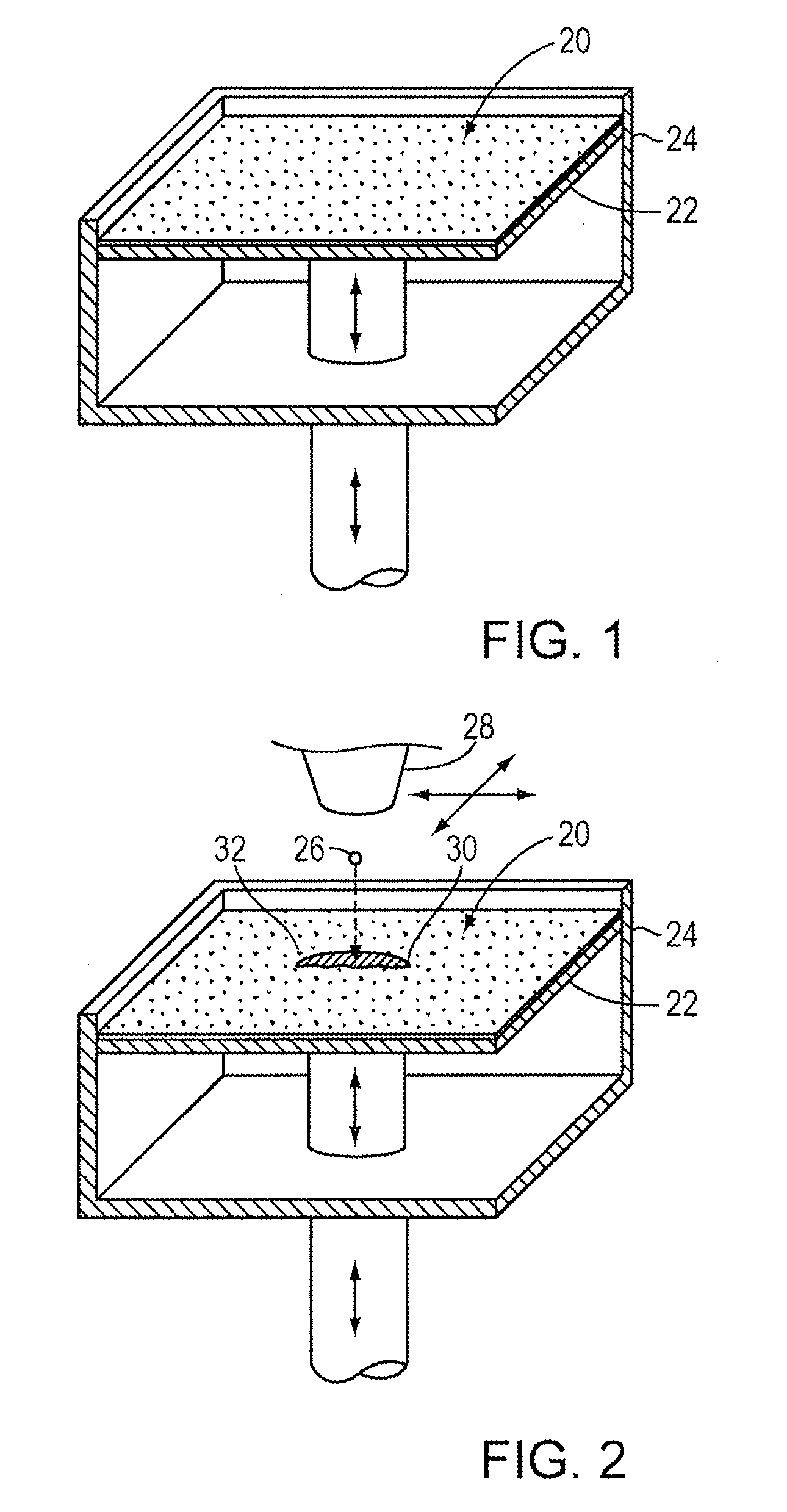

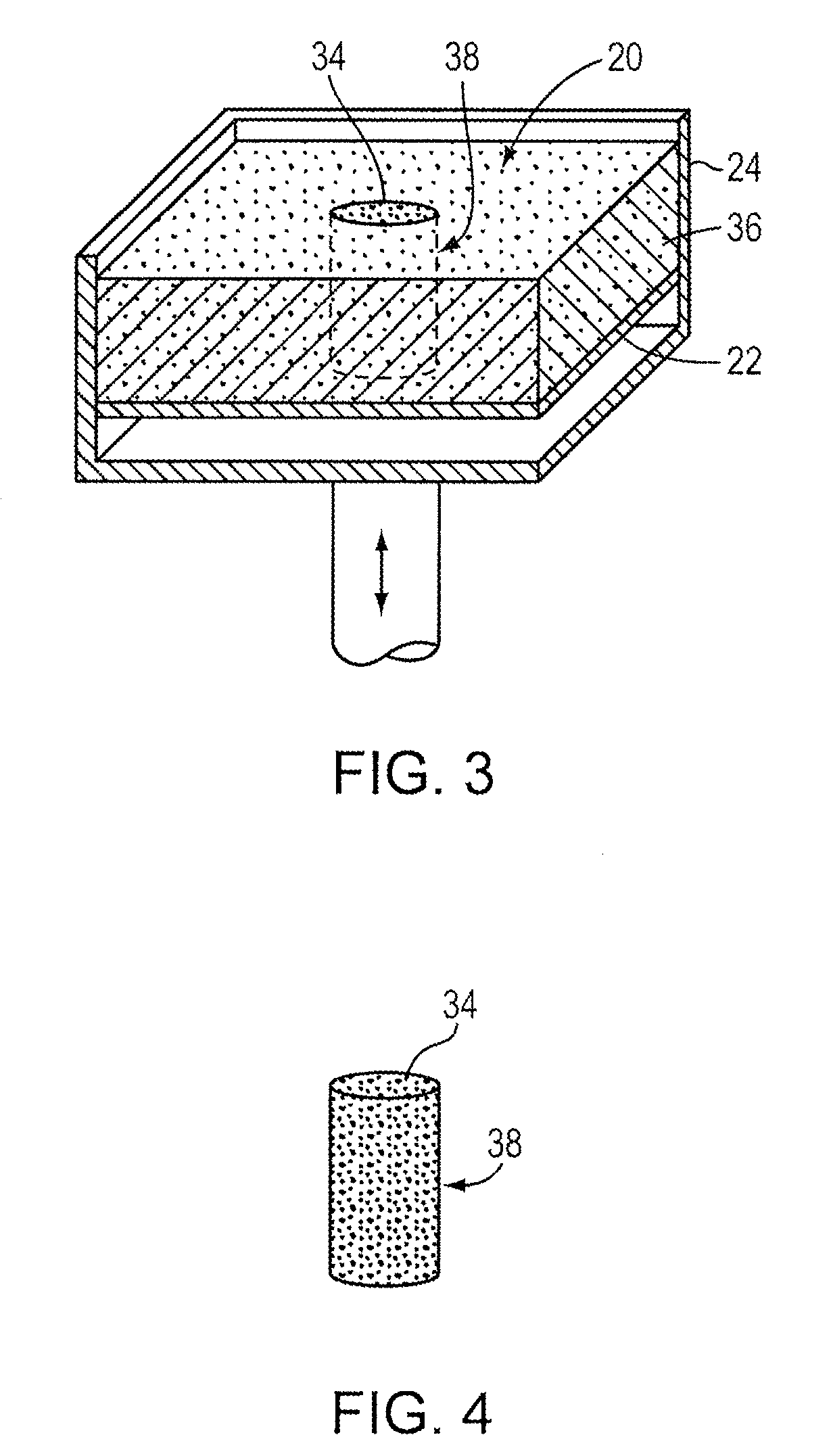

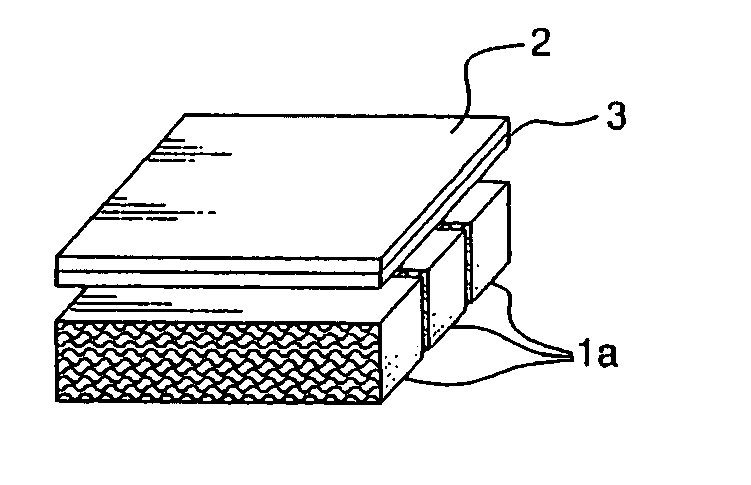

ActiveUS20080187711A1Strong and durable prototypeHigh green part strengthAdditive manufacturing apparatusOther chemical processesParticulatesWhitening Agents

A materials system and methods are provided to enable the formation of articles by three dimensional printing. The materials system includes particulate mixtures having a whitening agent and a solid particulate additive comprising an acid, the latter adapted for modifying a cure rate of an infiltrant. The materials system also includes aqueous fluids including optical brightening agents.

Owner:3D SYST INC

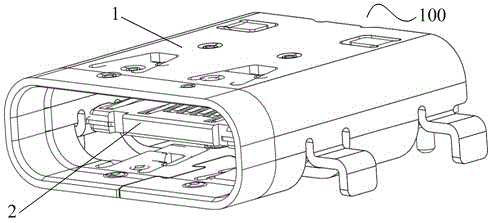

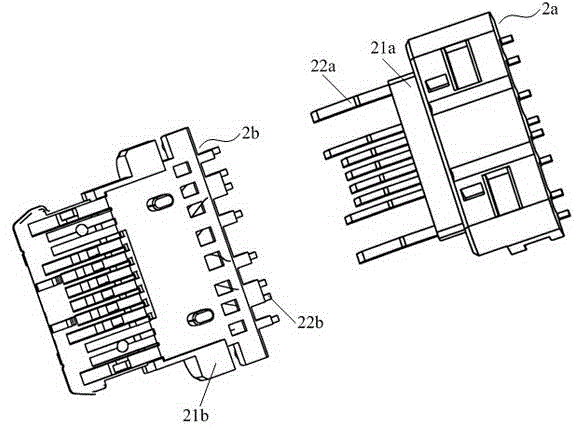

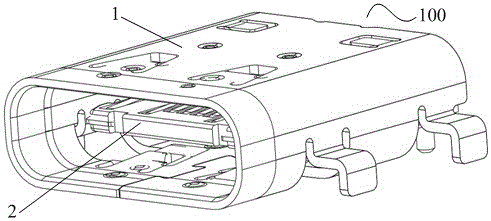

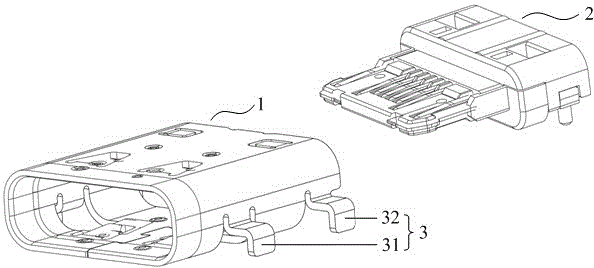

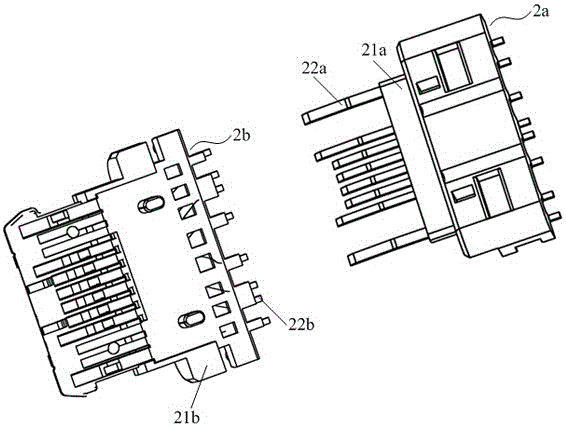

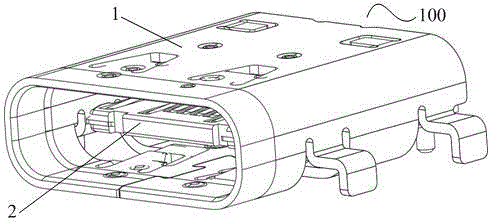

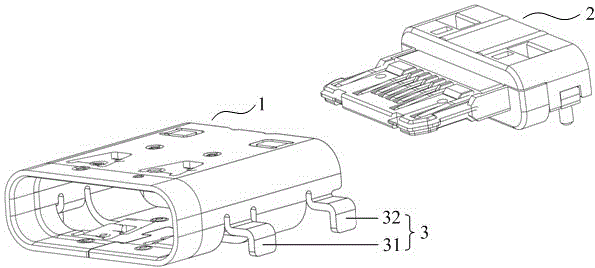

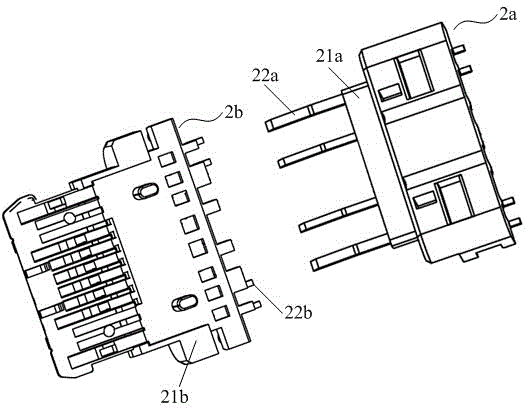

Type-C socket connector

ActiveCN104810657AReduce the number of assembliesReduce Tolerance RollupCoupling protective earth/shielding arrangementsEngineeringElectrical and Electronics engineering

The invention discloses a Type-C socket connector. The Type-C socket connector comprises a shell and an inserting component; the inserting component comprises an upper inserting component and a lower inserting component; the upper inserting component comprises an upper insulating body and an upper row of electric conductive terminals integrally formed with the upper insulating body; the lower inserting component comprises a lower insulating body, and a metallic shield sheet and a lower row of electric conductive terminals integrally formed with the lower insulating body; each insulating body is provided with twelve grooves respectively; each row of the electric conductive terminals is provided with eight terminals respectively; the metallic shield sheet is integrally formed with any two terminals in the lower row of the electric conductive terminals; the metallic shield sheet is downwards protruded to form a plate-shaped grounding part; the position of the terminals integrally formed with the metallic shield sheet corresponds to the position of the grounding part; and the grounding part and the metallic shield sheet are located in the different planes. The Type-C socket connector is used for reducing the assembly number of the parts, reducing the tolerance accumulation, satisfying the USB2.0 application, and greatly decreasing the number of the terminals, and is good for the stability of the product.

Owner:ALL BEST ELECTRONICS TECH CO LTD

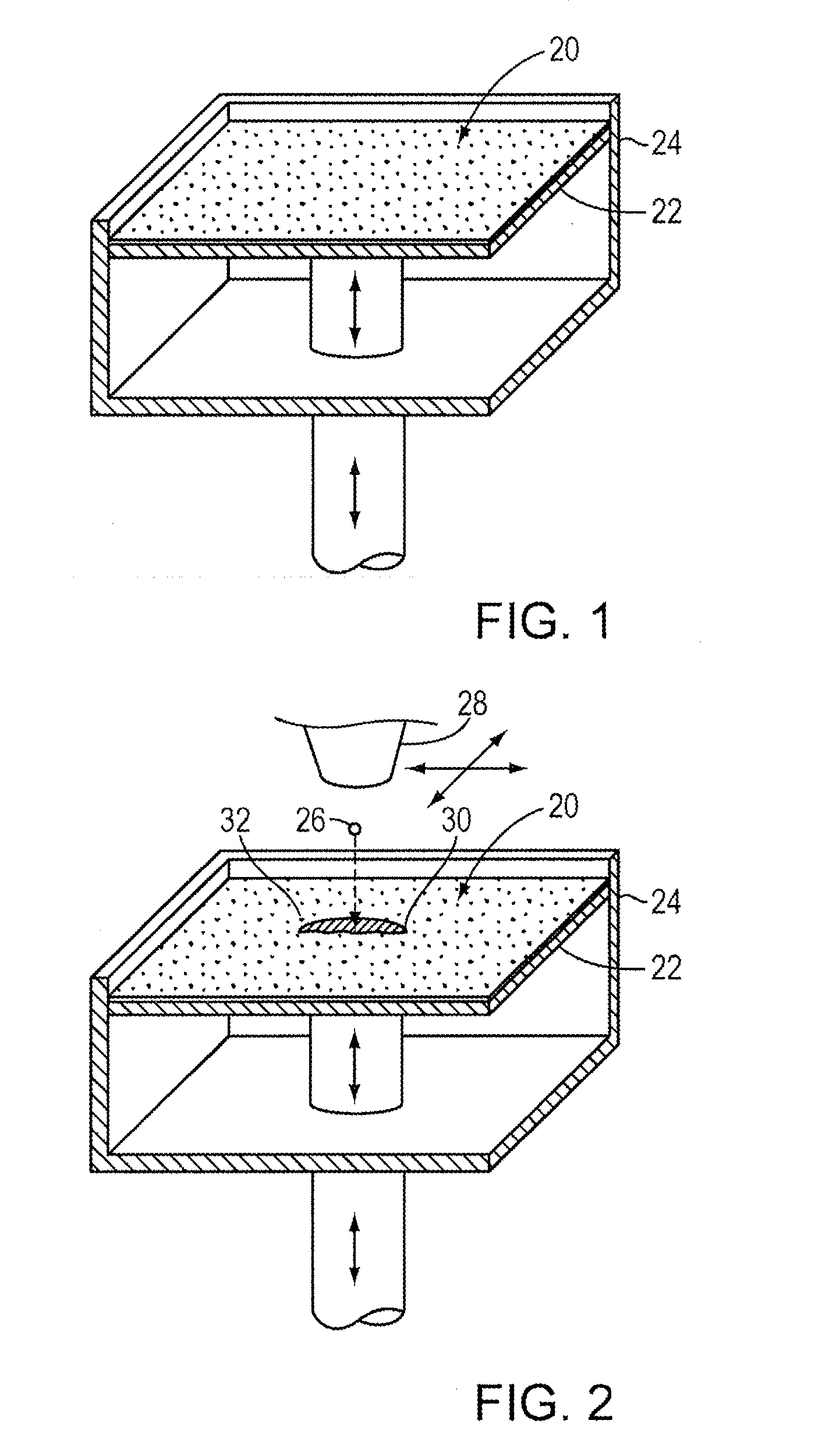

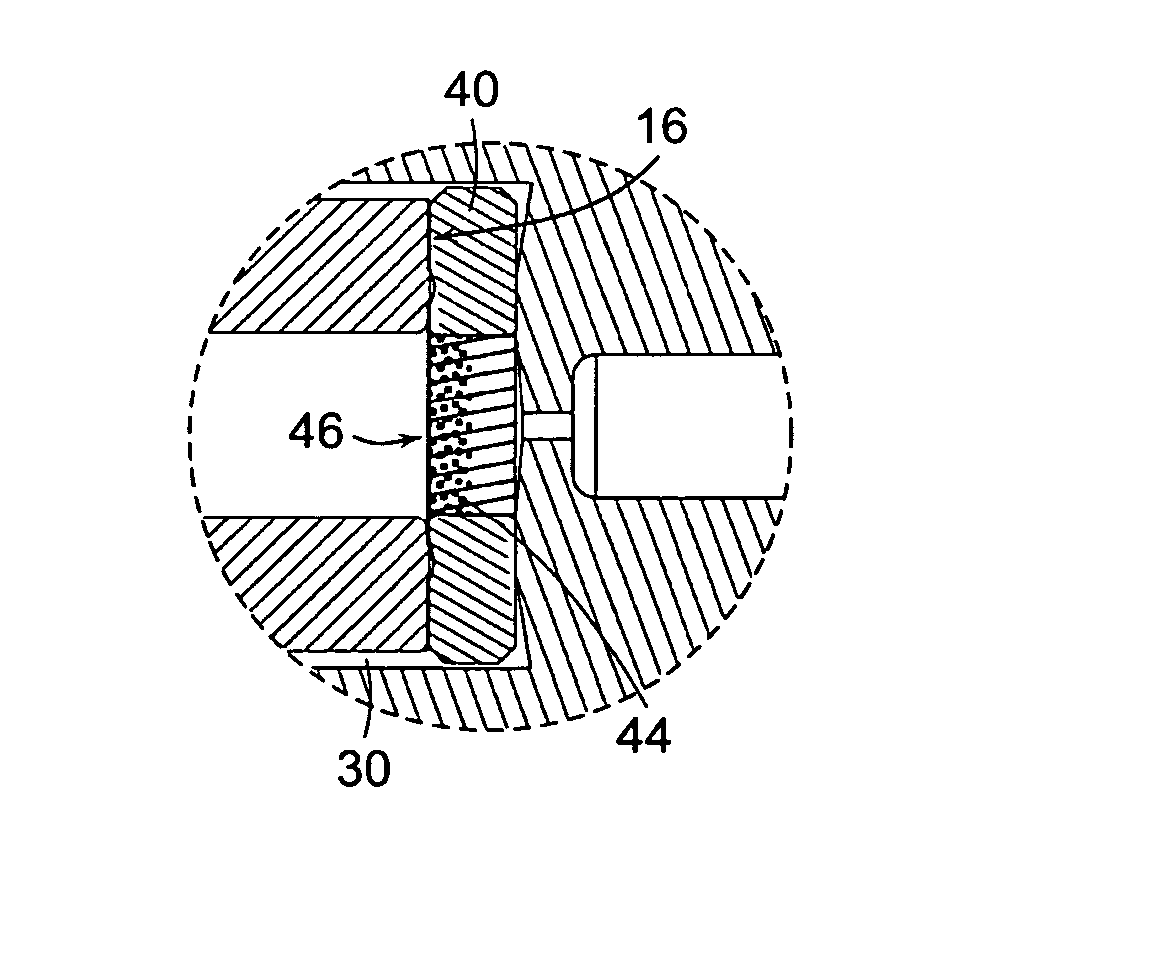

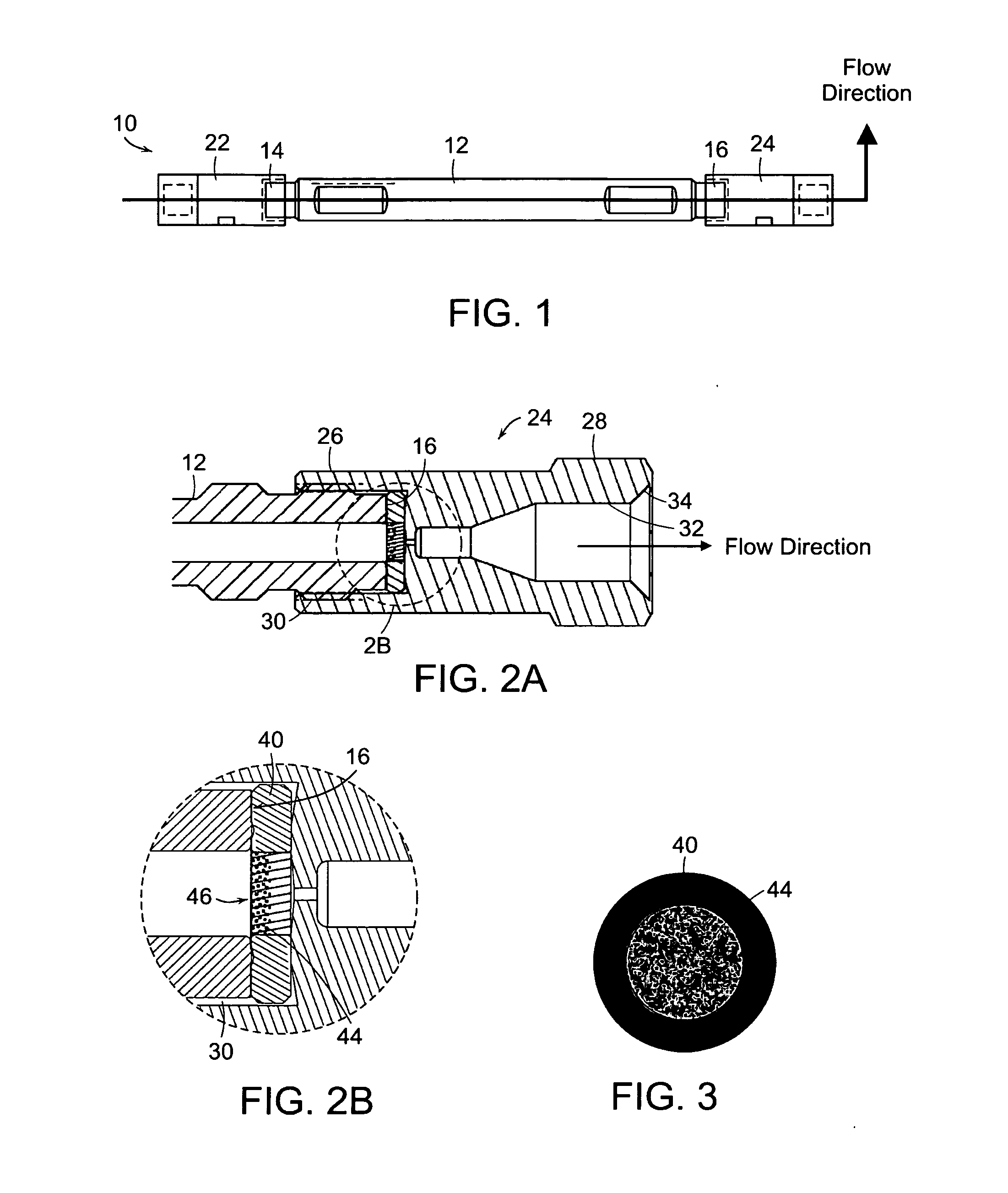

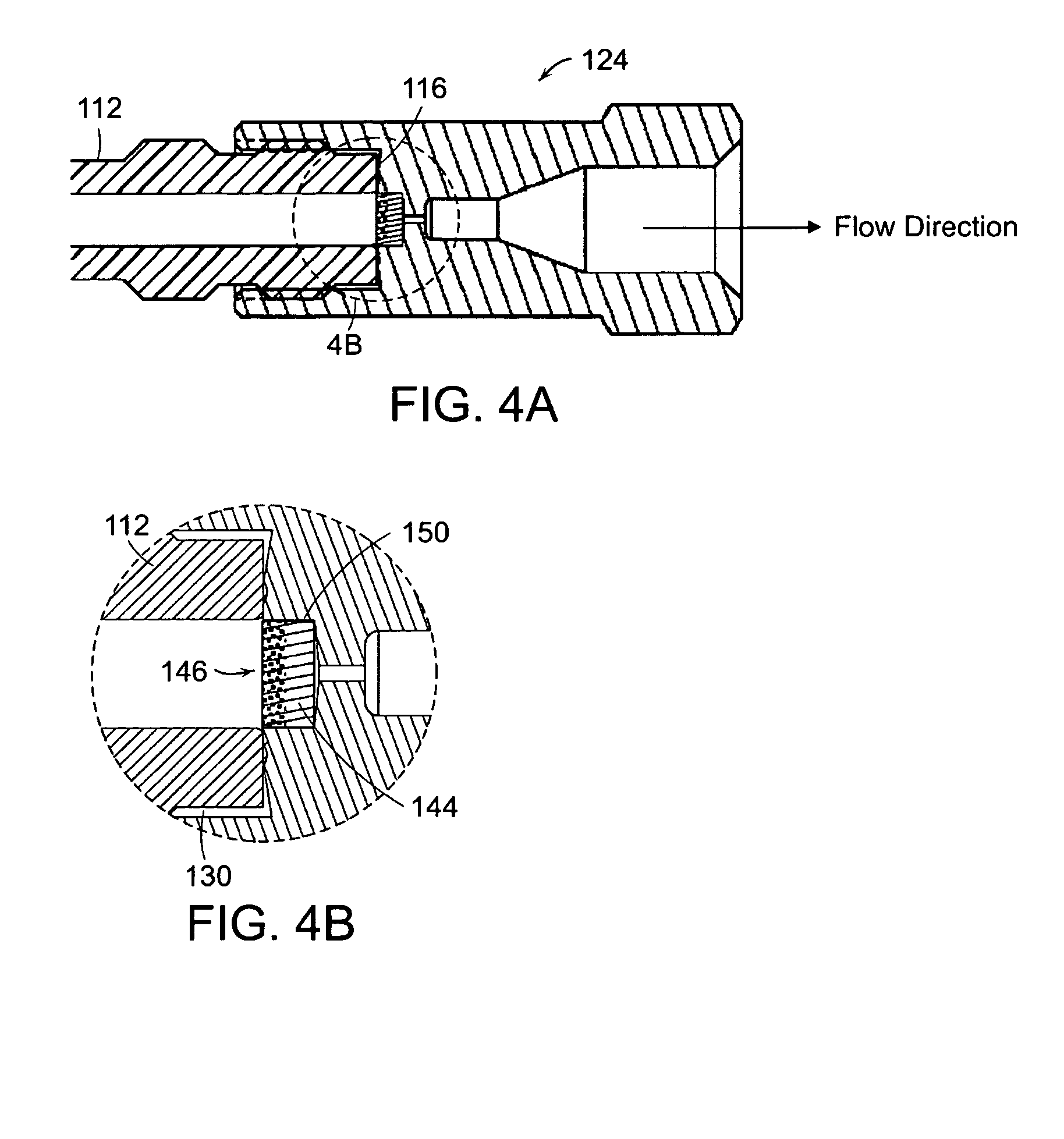

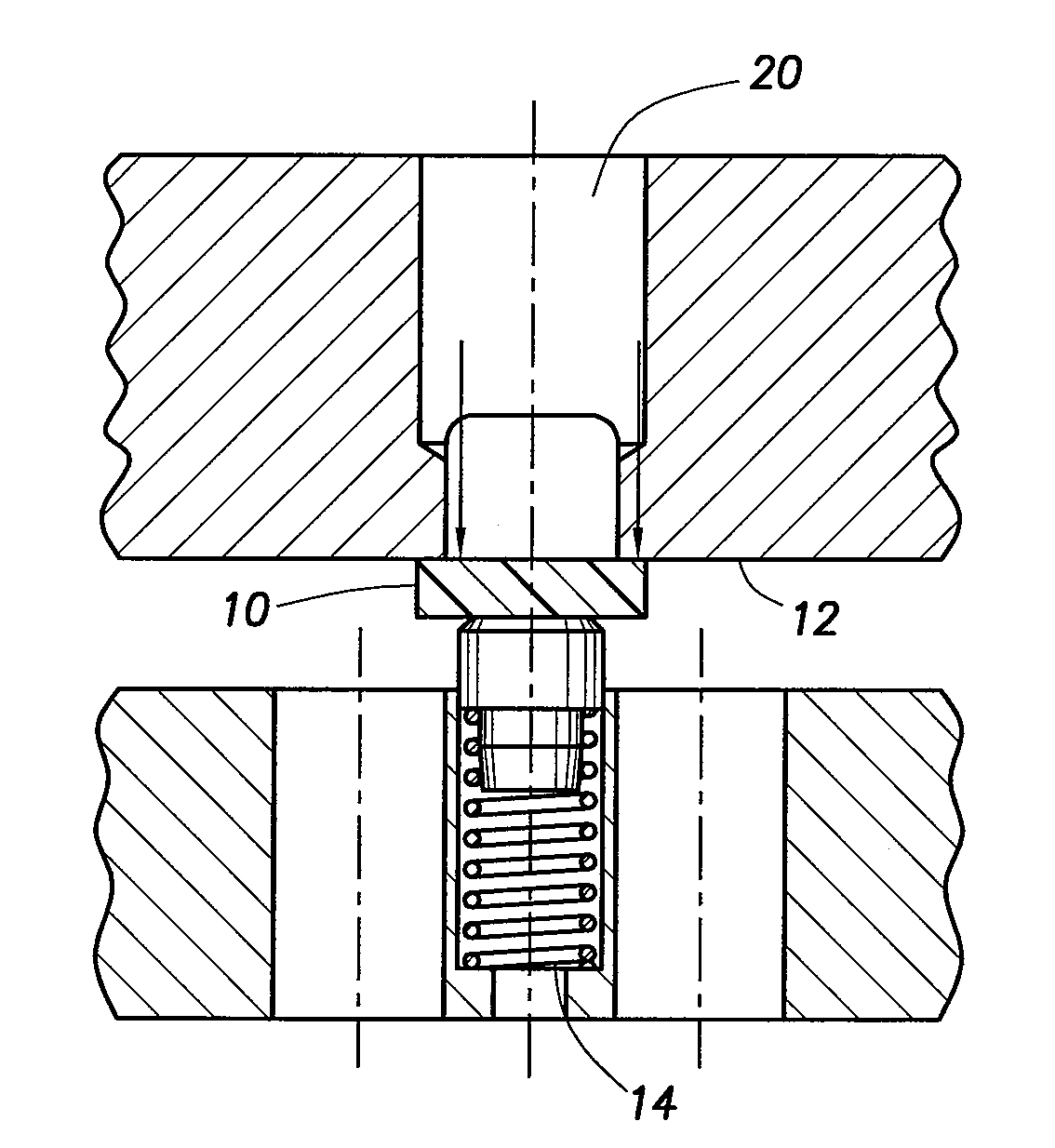

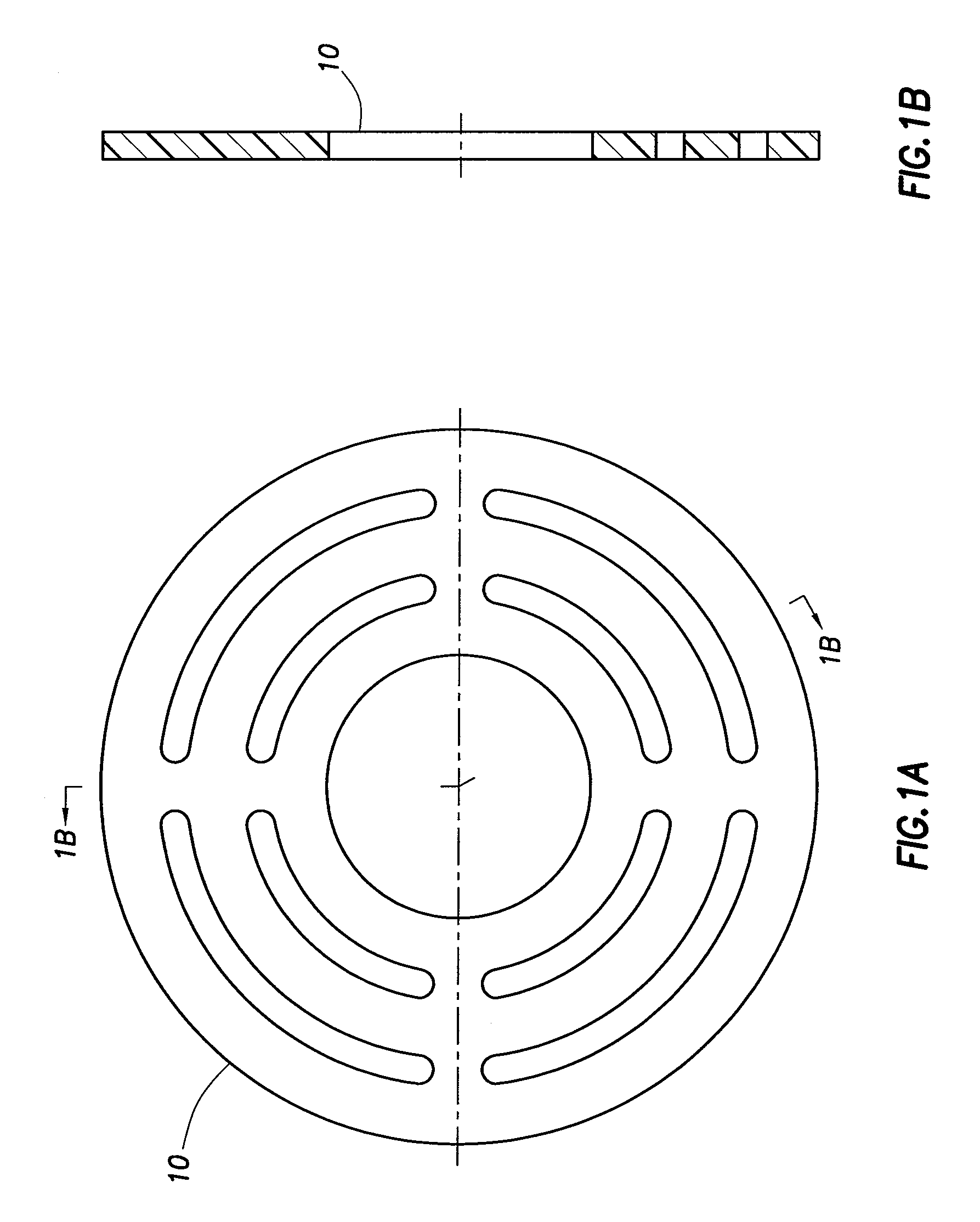

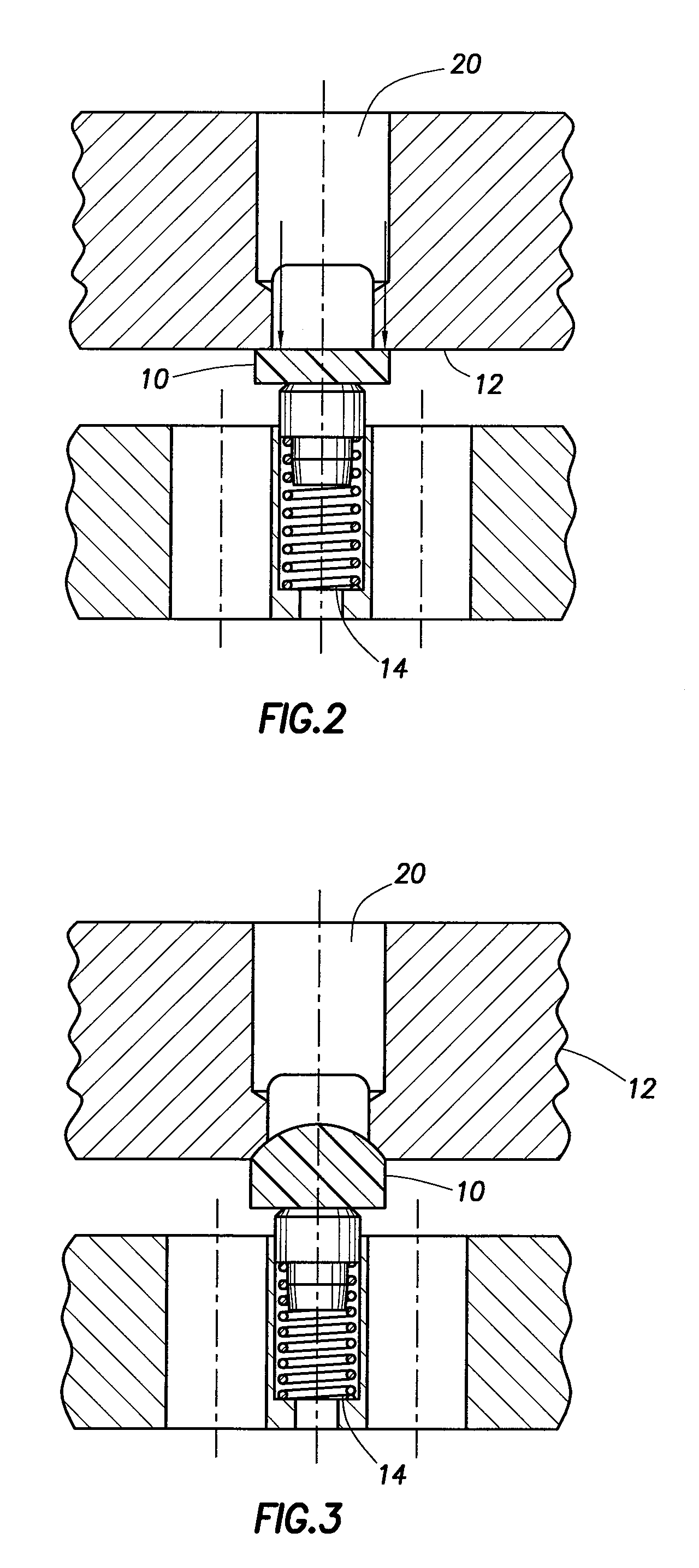

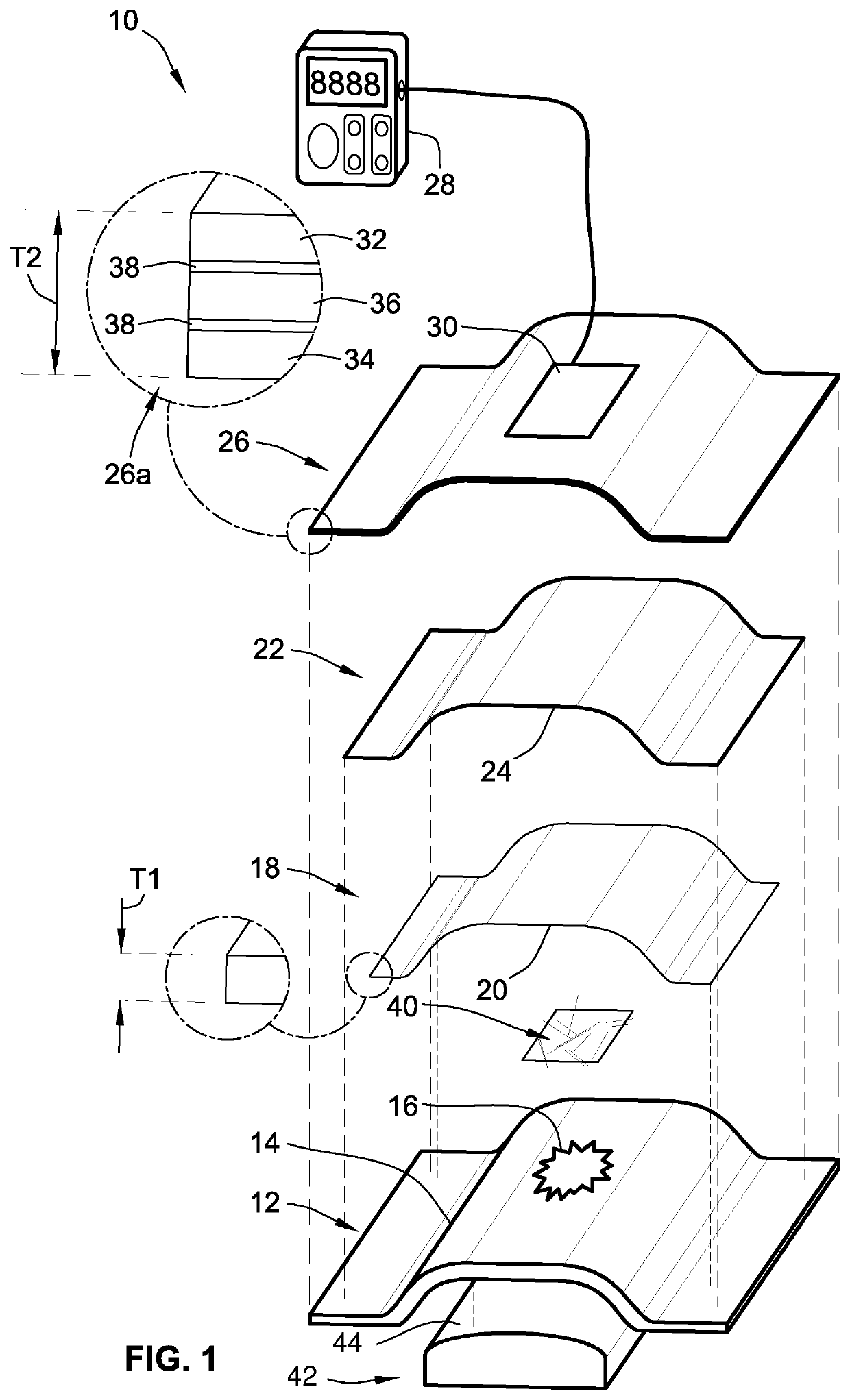

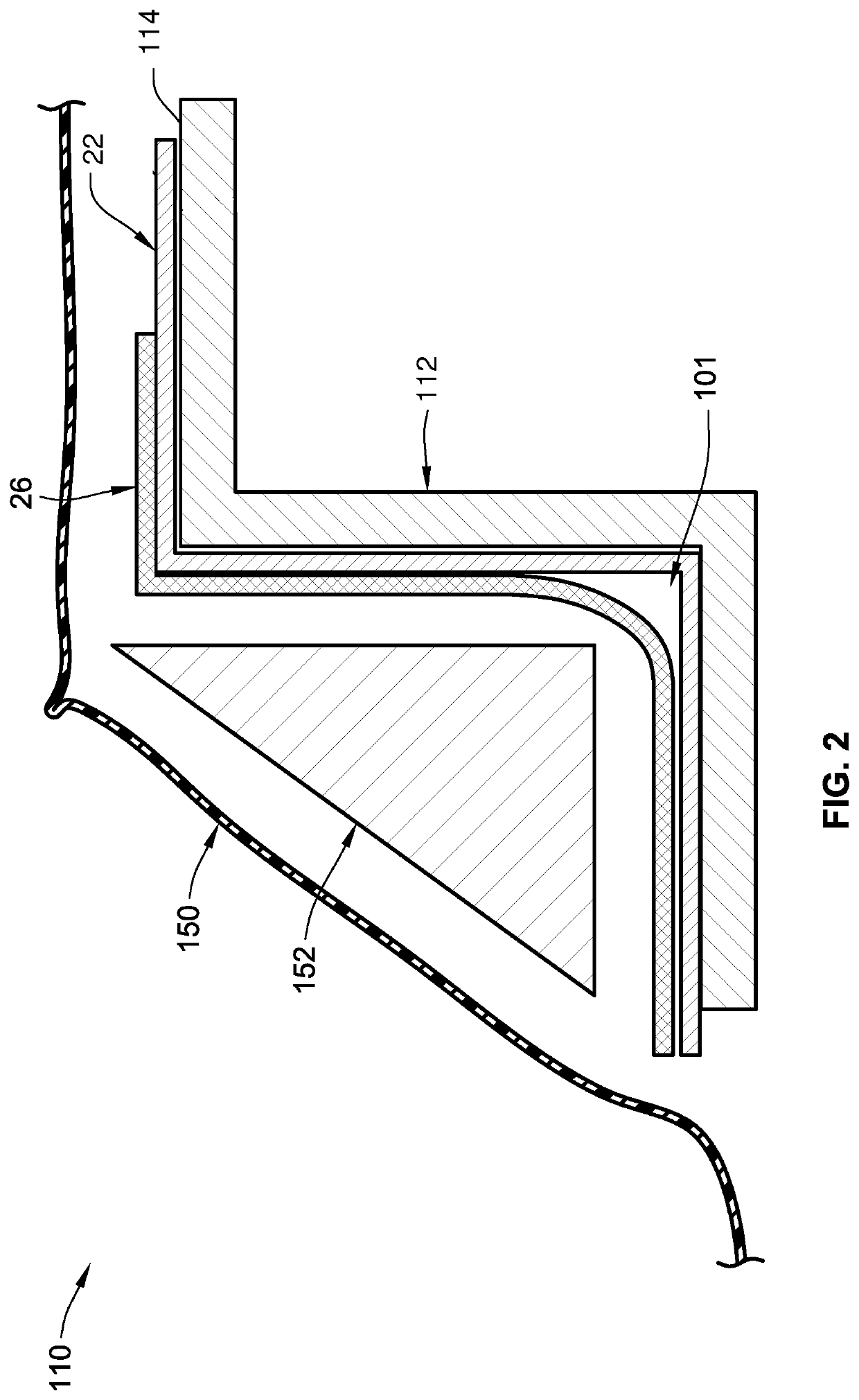

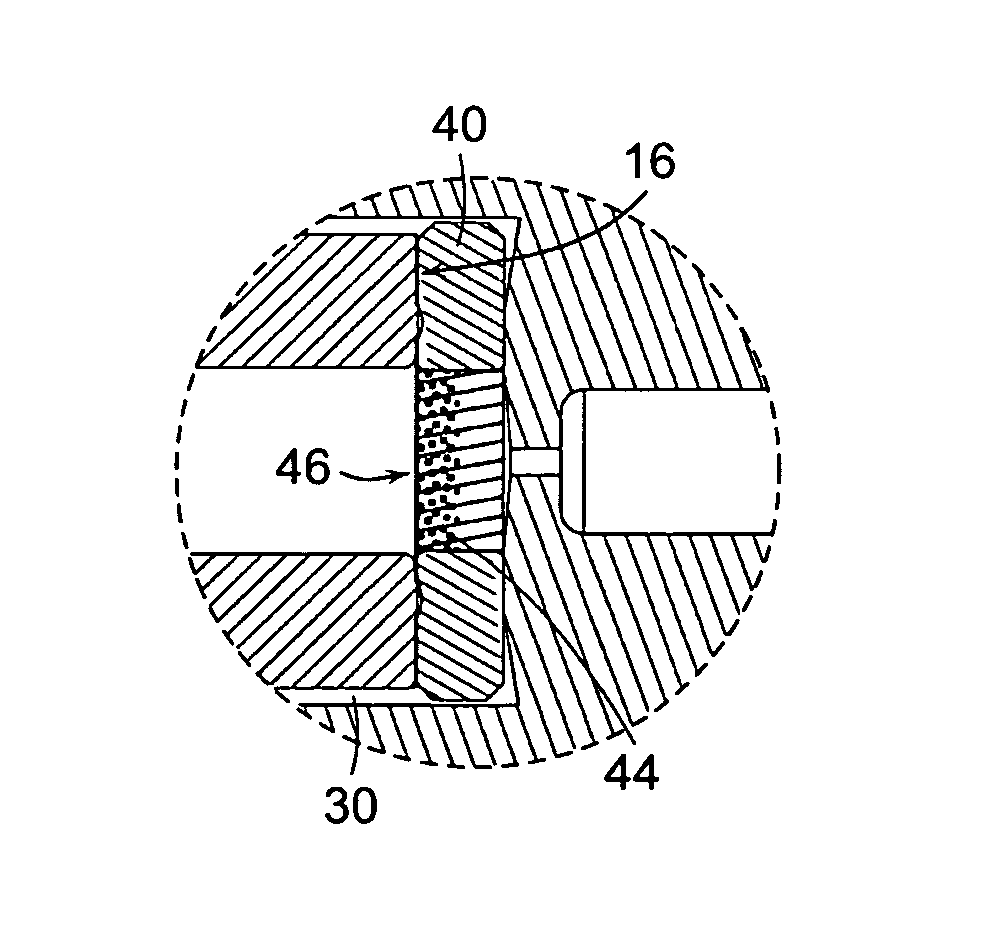

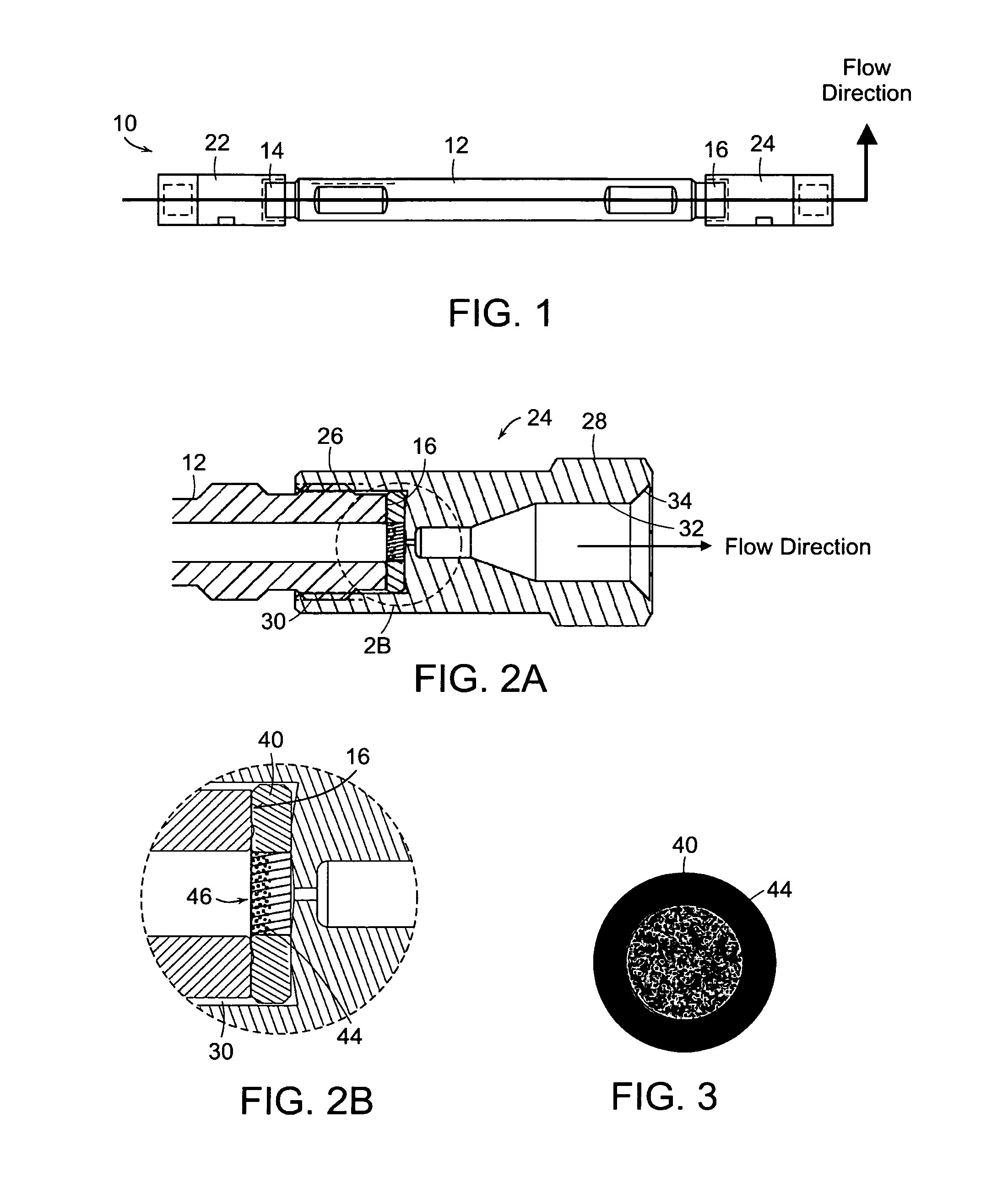

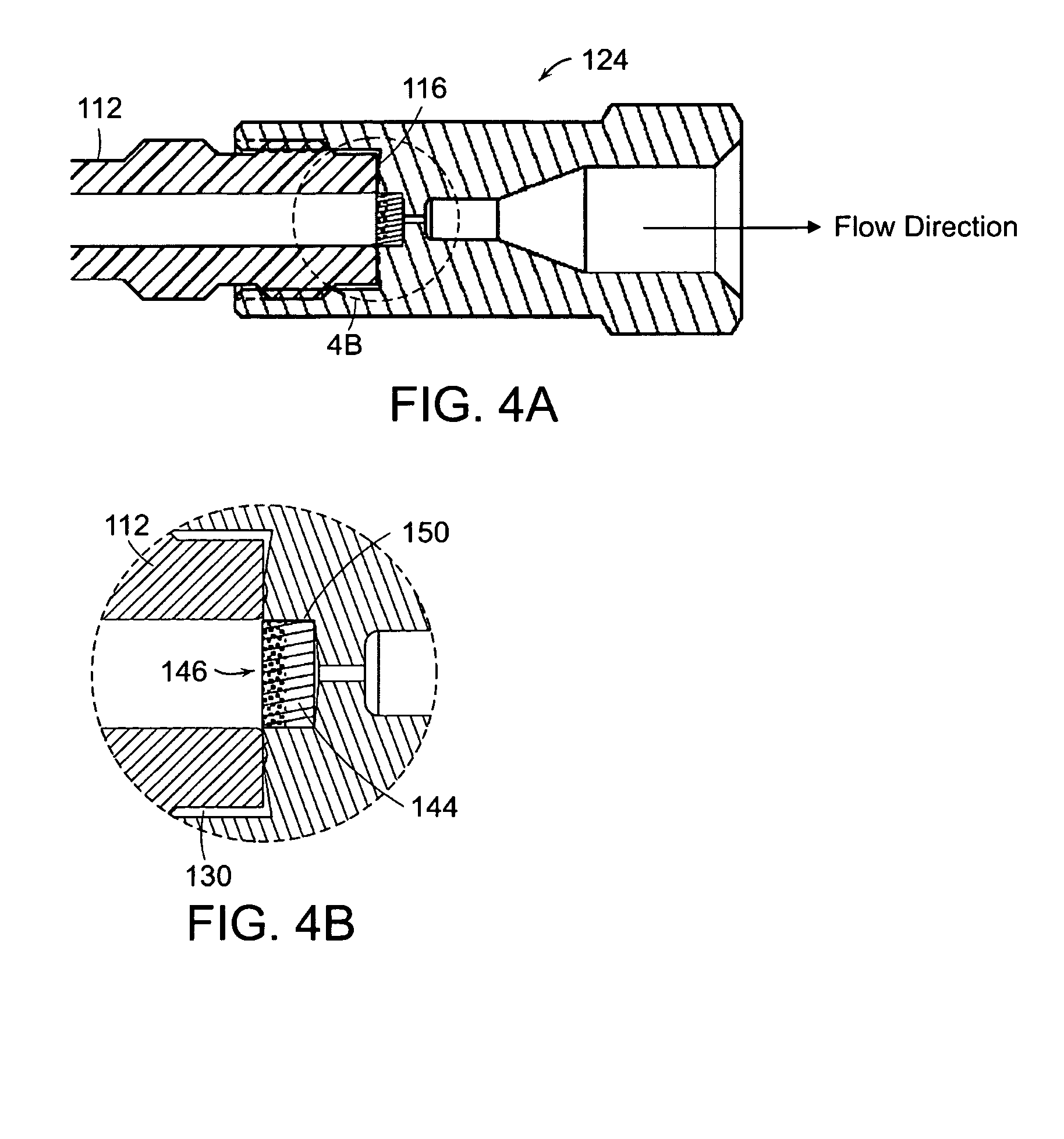

Frit for High Pressure Liquid Chromatography

ActiveUS20070295663A1Enhanced part strengthHigh parts strengthIon-exchange process apparatusComponent separationChromatographic columnChemistry

A frit (44) includes a porous support structure having a plurality of void spaces, where a plurality of secondary particles (46) are filled in the void spaces, the secondary particles (46) being dimensioned with respect to the void spaces such that the frit (44) retains packing materials with diameters of less than about 2.5 microns. Preferably one or more frits (44) are received in a high pressure liquid chromatography (HPLC) chromatographic column, where the column includes fittings and filter assemblies for receiving frits (44) at its inlet and outlet. The frit (44) can be constructed from a porous support structure with void spaces or pores that are filled with secondary particles (46) smaller those used to manufacture the support. The particles (46) contained in the void spaces are large enough to be retained by the support, but small enough to create a finer network of interconnected channels within the support's void spaces that are capable of retaining sub-2.5 micrometer particles.

Owner:WATERS TECH CORP

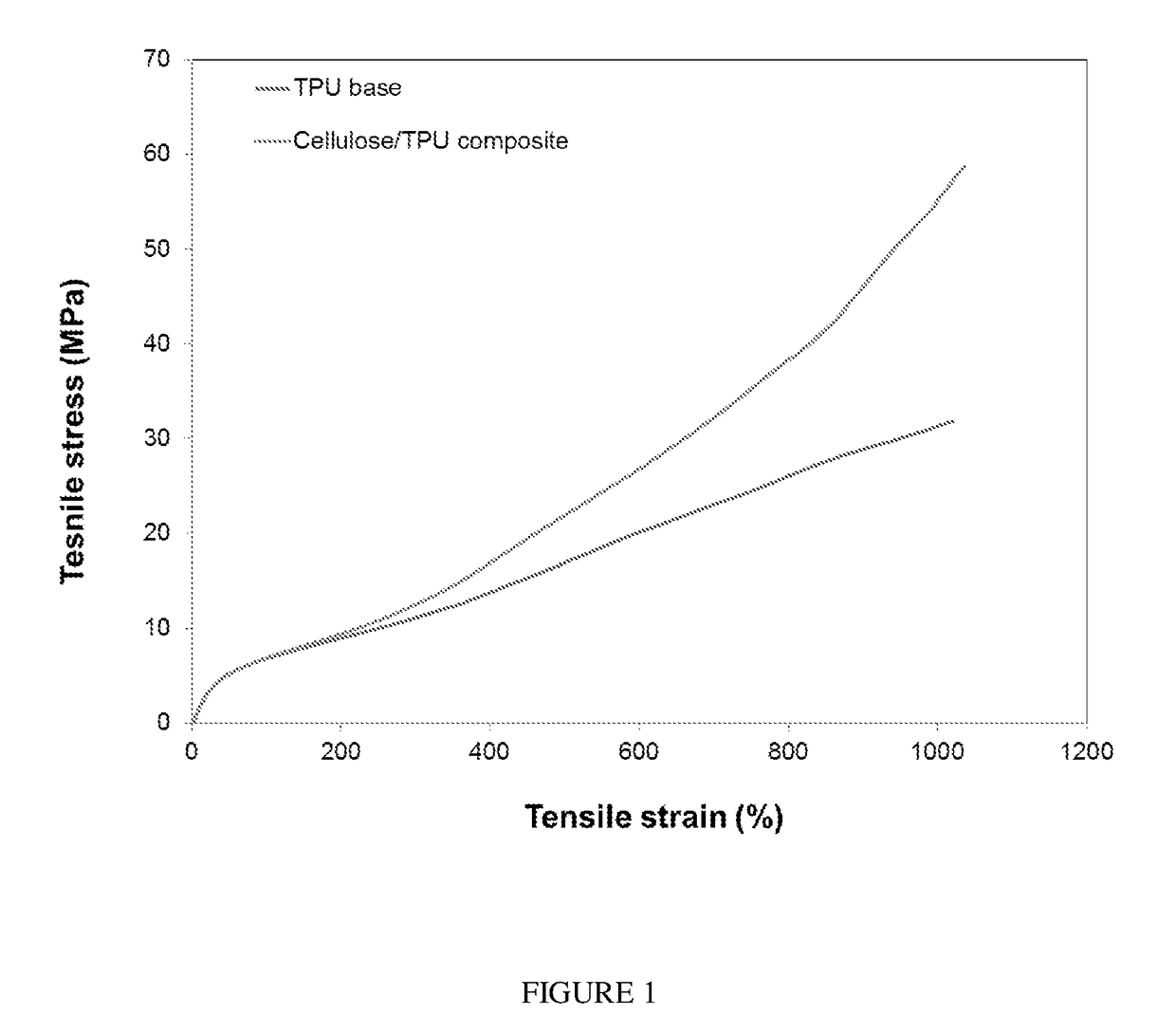

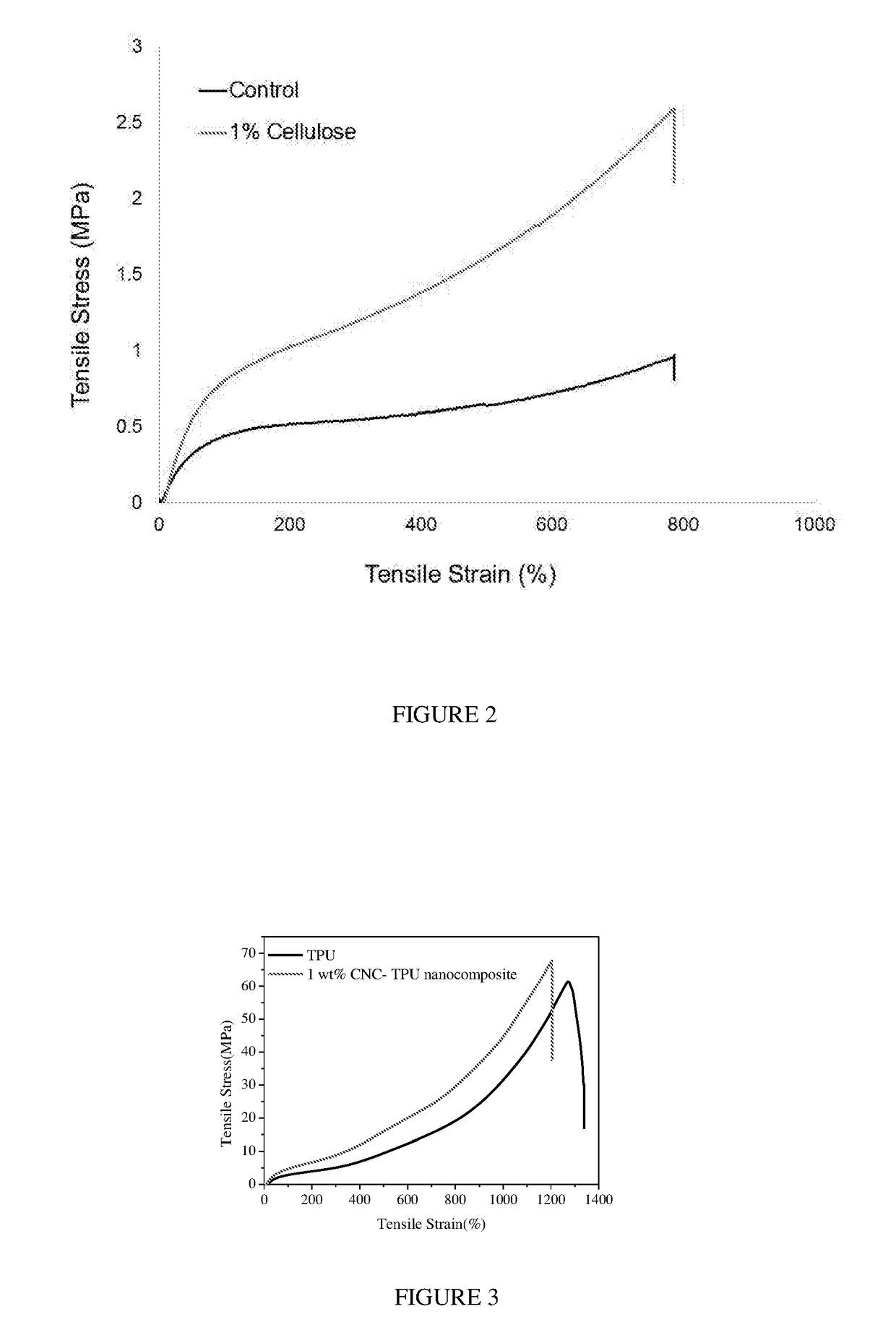

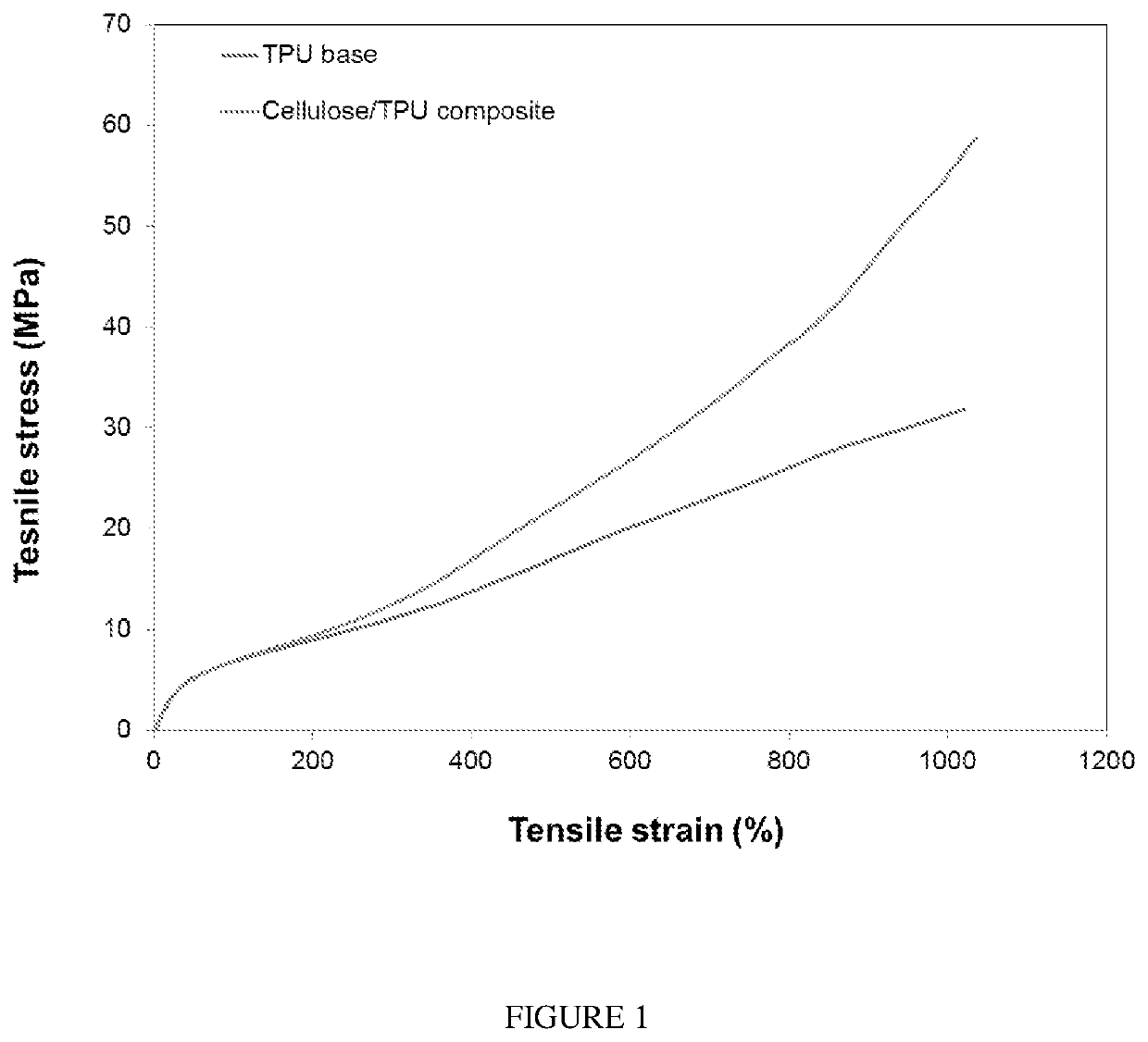

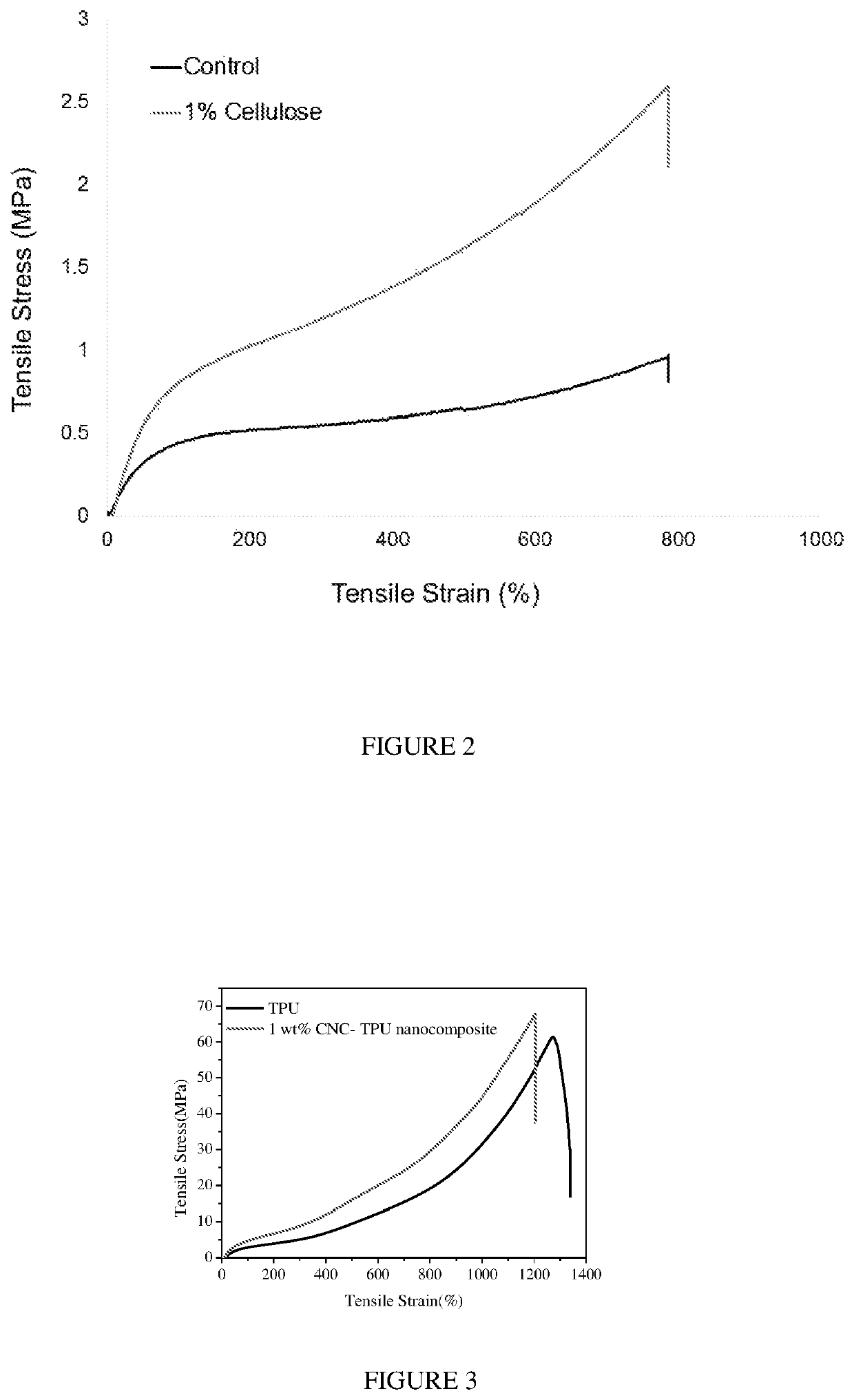

Nanocomposite elastomers

ActiveUS20170333602A1Reduce in quantityIncreasing the thicknessMaterial nanotechnologyHemicellulose adhesivesElastomerArid

A composite material comprising an elastomer and nanocellulose. The nanocellulose may comprise a nanocellulose material derived from plants having C4 leaf anatomy, or a nanocellulose material derived from a plant material having a lesser amount of lignin than hemi-cellulose, or a nanocellulose having a hemicellulose content of from 25% to 55% by weight of the nanocellulose material, or a nanocellulose comprising nanofibrils having a diameter of up to 5 nm, or a nanocellulose comprising nanocellulose material of plant origin comprising nanocellulose particles or fibres having an aspect ratio of at least 250, or the composite material having a stiffness of not greater than 2.5 times the stiffness of the elastomer without the nanocellulose material being present, or the nanocellulose particles or fibres being derived from a plant material having a hemicellulose content of 30% or higher (w / w). The nanocellulose may be derived from arid Spinifex.

Owner:THE UNIV OF QUEENSLAND

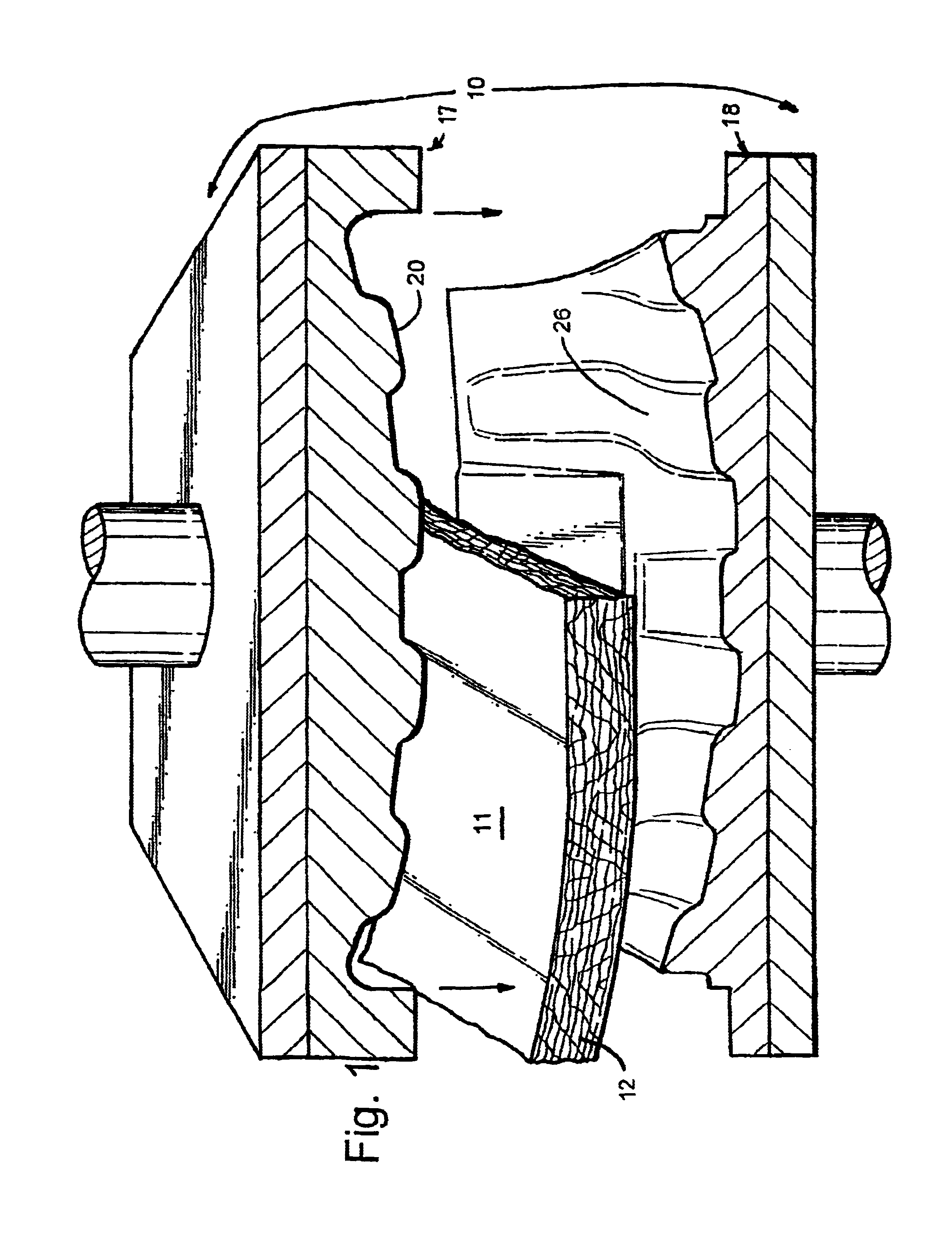

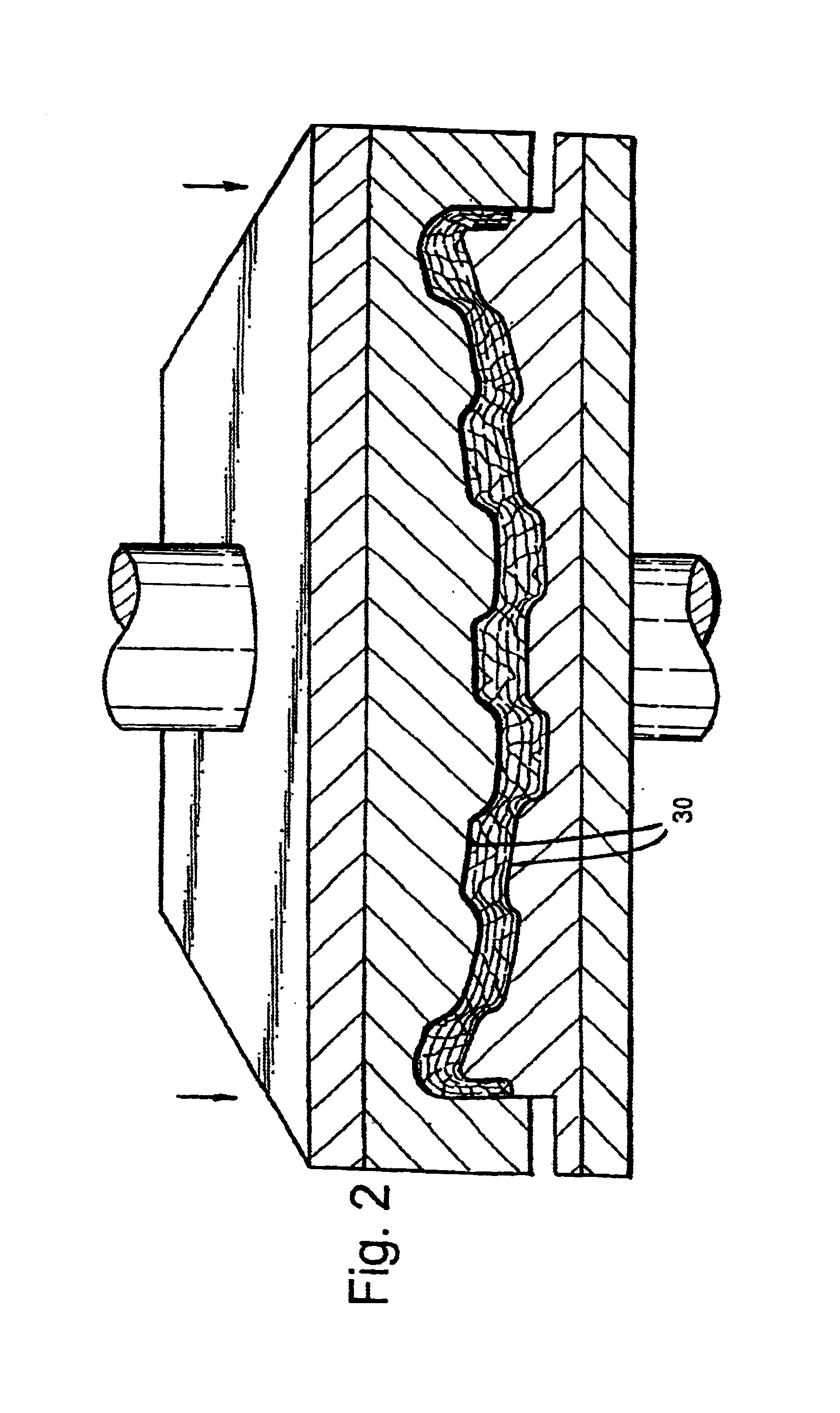

Elastomeric Sealing Element for Gas Compressor Valve

InactiveUS20090014678A1Gas tight sealReduce impact damageEngine sealsPositive displacement pump componentsAxial compressorElastomer

This invention relates to the use of elastomers with the sealing element of reciprocating gas compressor valves to increase the reliability of the gas tight seal within the reciprocating gas compressor valve and to increase the useful life of reciprocating gas compressor valve. The elastomeric material is either used as a coating layer on the sealing element of the reciprocating gas compressor valve, or as the entire sealing element. The elastomeric material acts as a cushion to reduce the wear on the sealing element, provides a superior gas tight seal, and is more tolerant of entrained dirt or liquids in the gas stream thereby increasing the operable life of the reciprocating gas compressor valve. Reducing the mean time between reciprocating gas compressor valve failures results in longer reciprocating gas compressor run times for the user, increased revenue generation for the user and safer operation of said equipment.

Owner:DELAWARE CAPITAL FORMATION

Three-dimensional printing material system with improved color, article performance, and ease of use

ActiveUS8167999B2Improve mechanical propertiesGood colorAdditive manufacturing apparatusCeramic shaping apparatusParticulatesWhitening Agents

A materials system and methods are provided to enable the formation of articles by three dimensional printing. The materials system includes particulate mixtures having a whitening agent and a solid particulate additive comprising an acid, the latter adapted for modifying a cure rate of an infiltrant. The materials system also includes aqueous fluids including optical brightening agents.

Owner:3D SYST INC

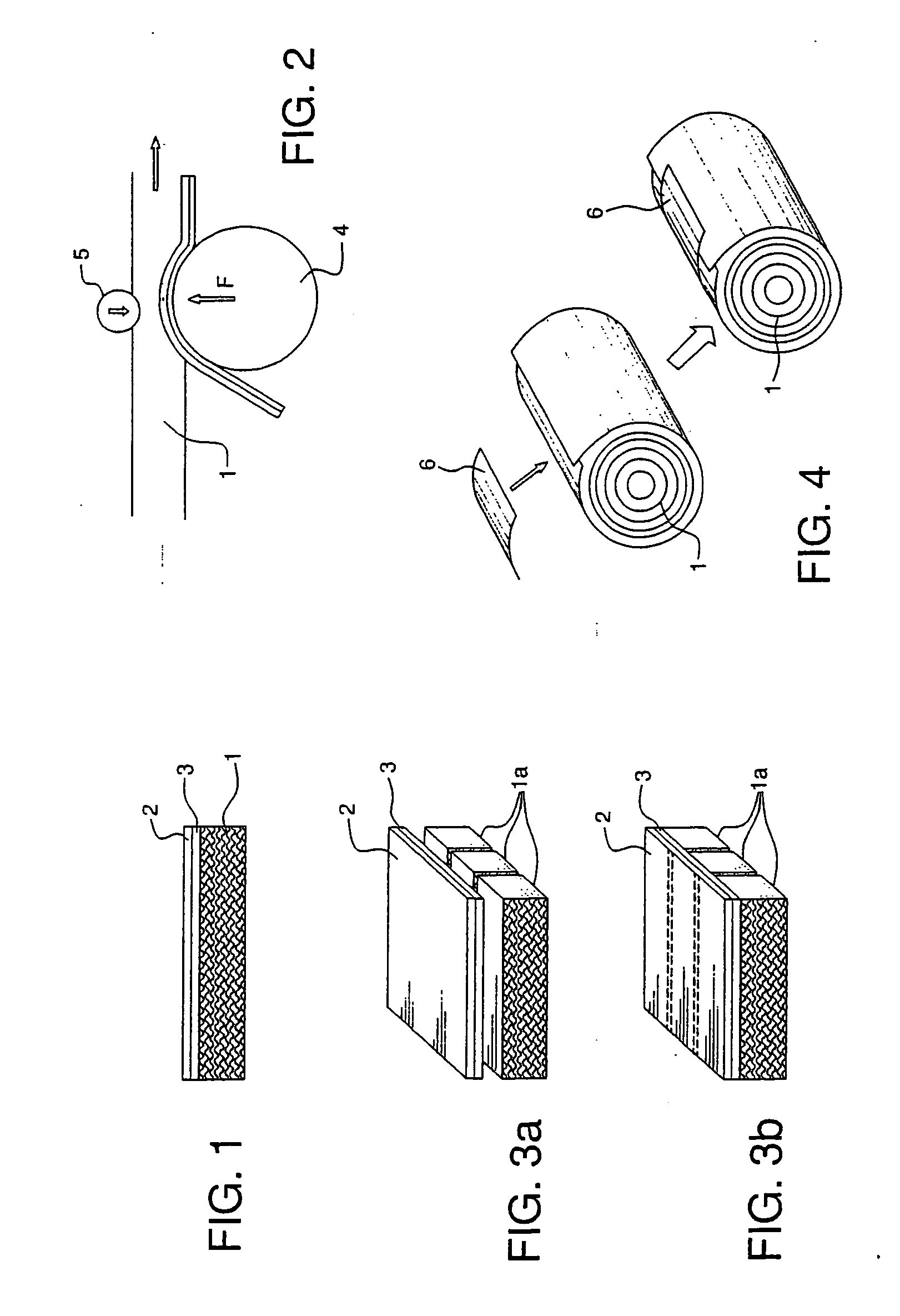

Mineral wool covered with complexes formed of organic polymer laminates

InactiveUS20050249910A1Improvement of facility of cutSuitable thermal stabilitySynthetic resin layered productsConstructions elementsPolyesterVapor barrier

A mineral wool insulation having a facing formed by a polyester lamina and polyethylene to form a vapor barrier attached to the insulation according to various preferred embodiments including, one, wherein the polyethylene adheres to the polyester and to the mineral wool, and another, wherein the insulation, and not the vapor barrier, is pre-cut lengthwise, and a further embodiment wherein, the polyethylene adheres to the insulation and the polyester.

Owner:CERTAINTEED CORP

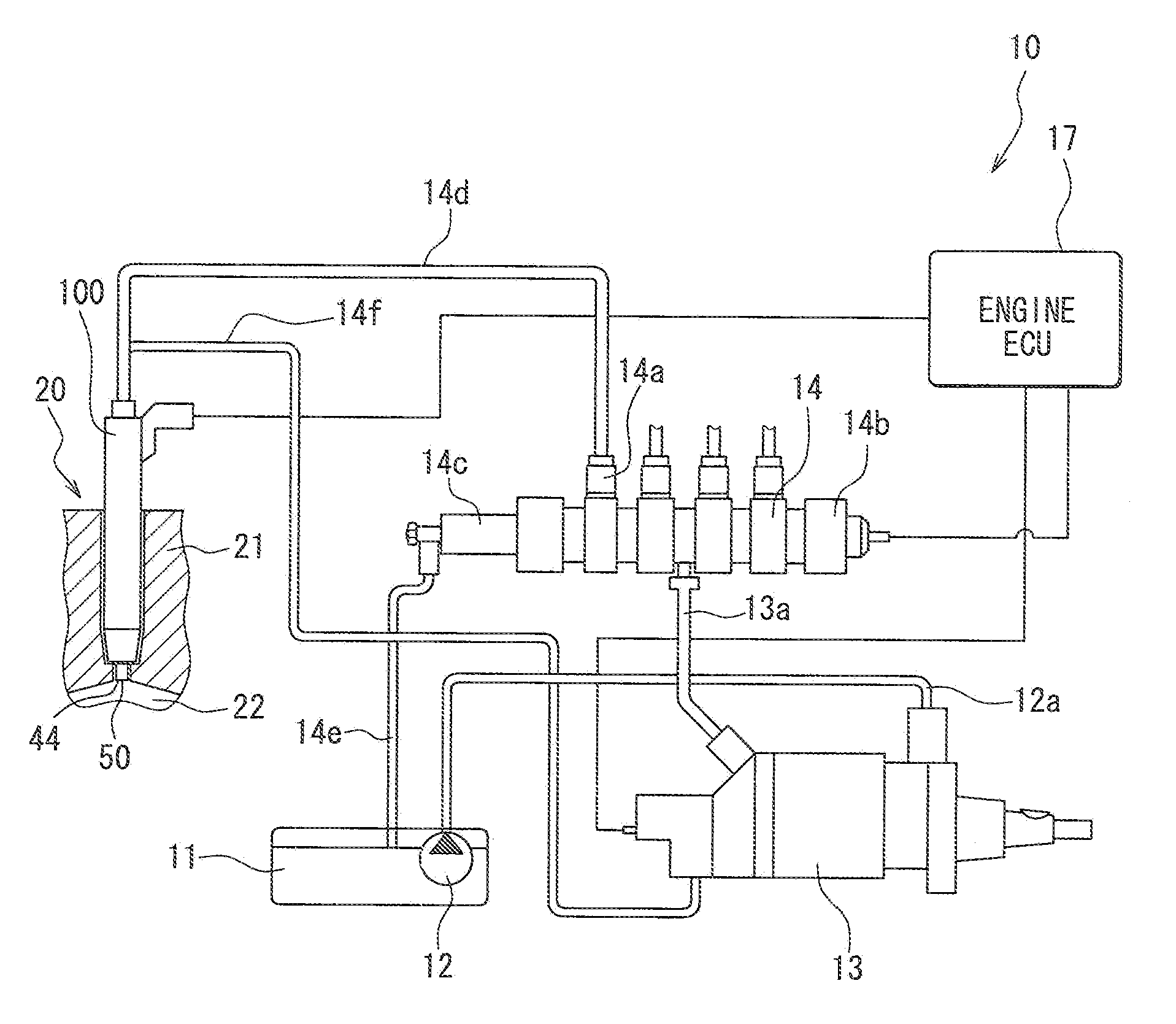

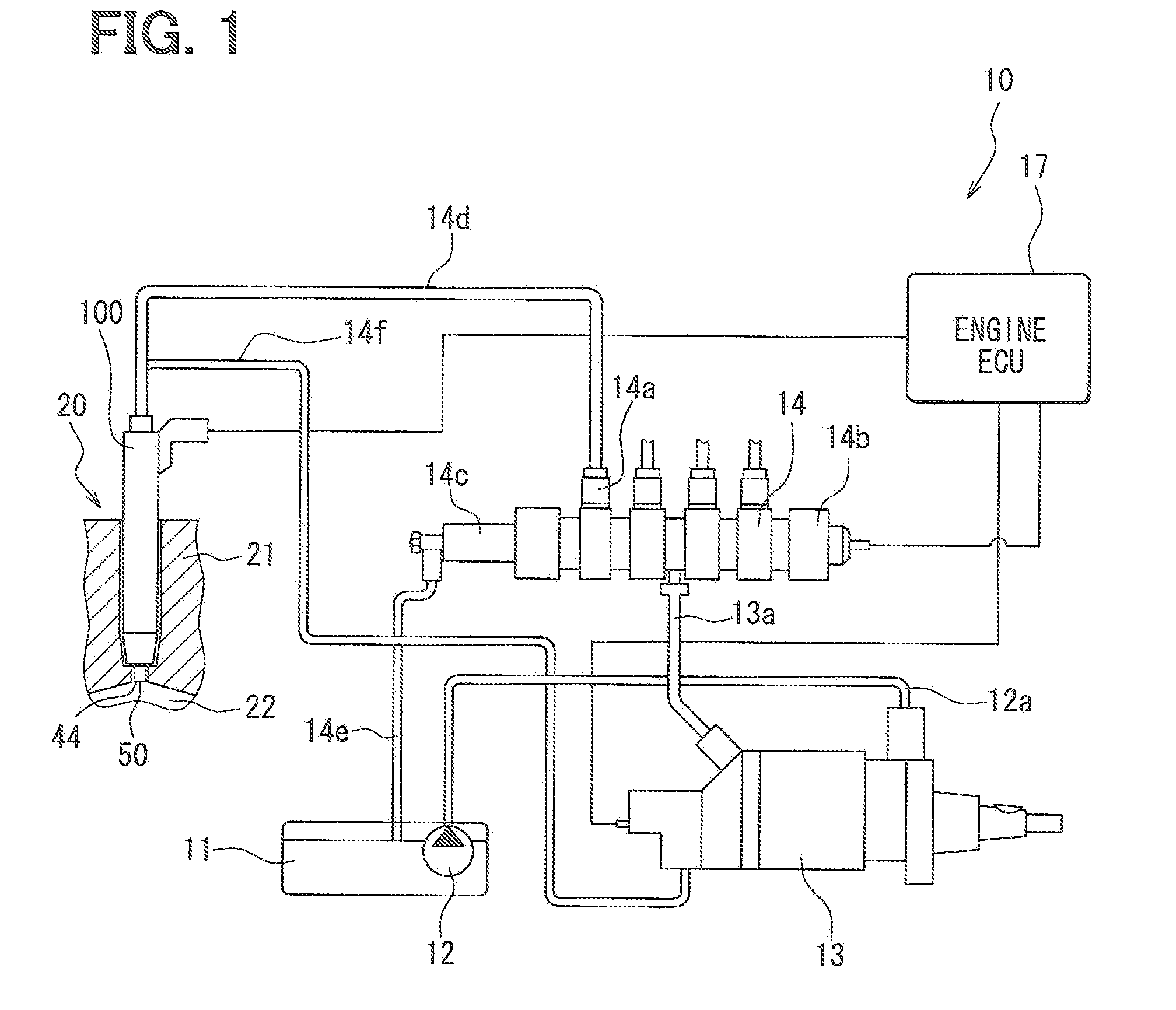

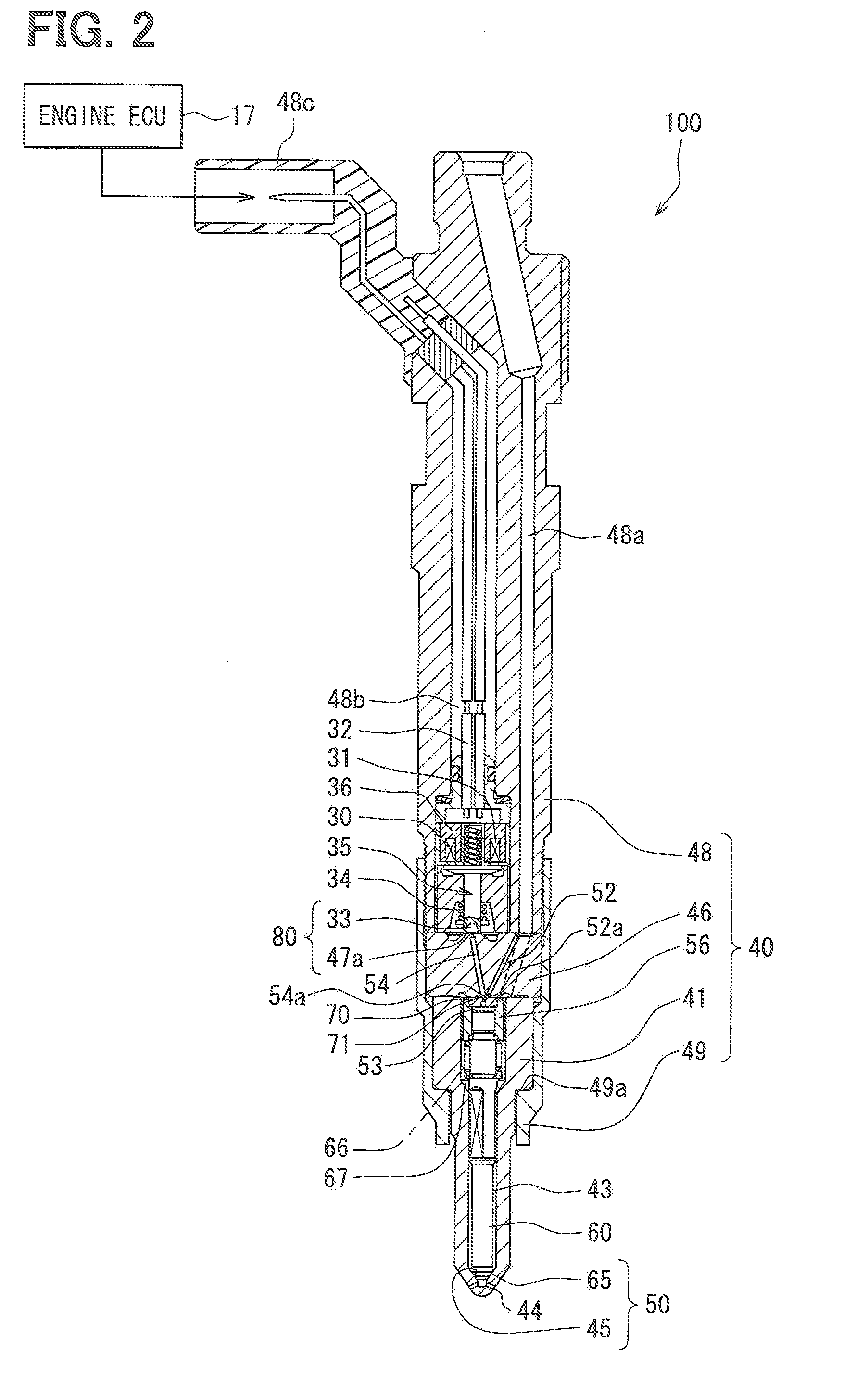

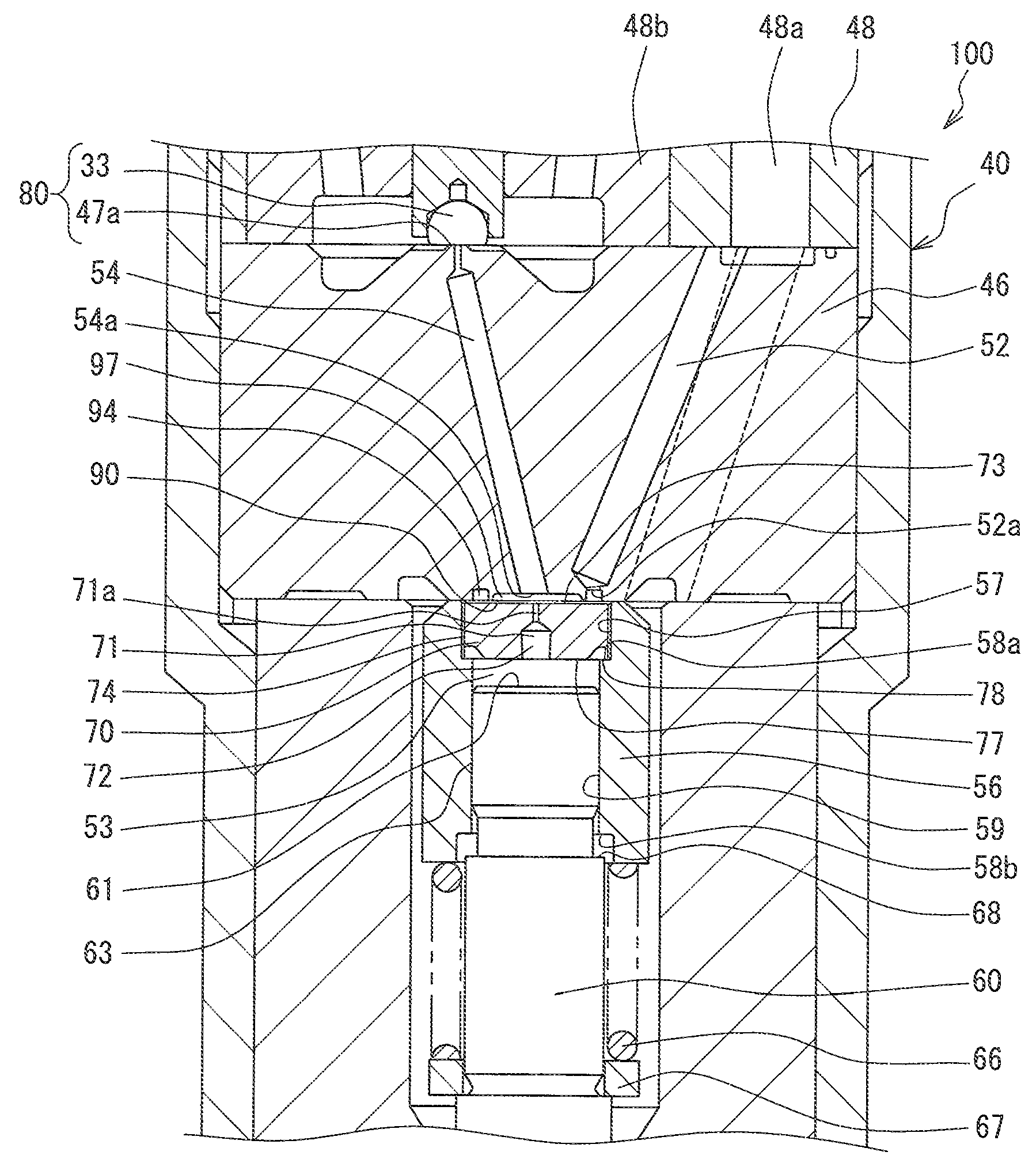

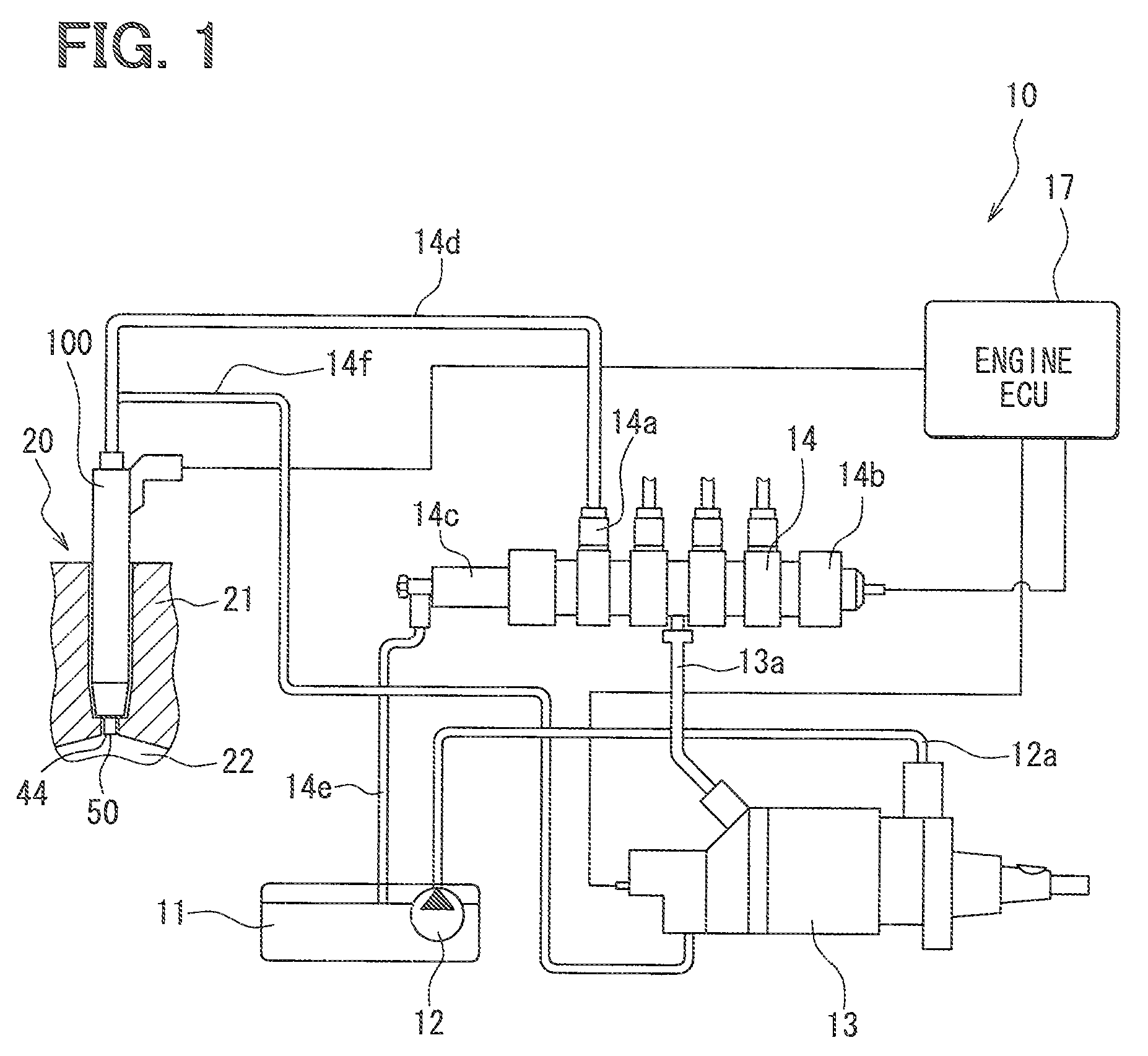

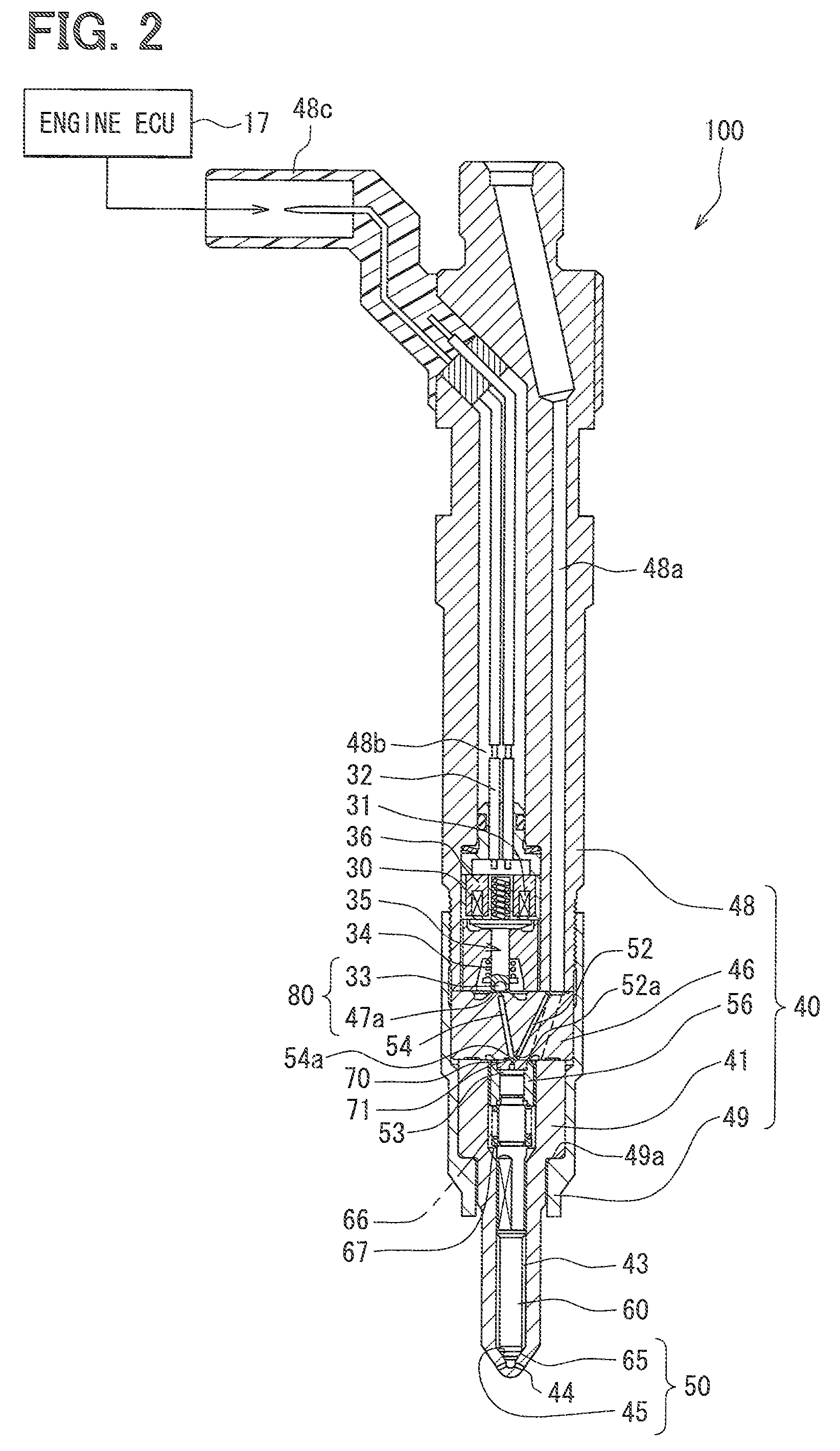

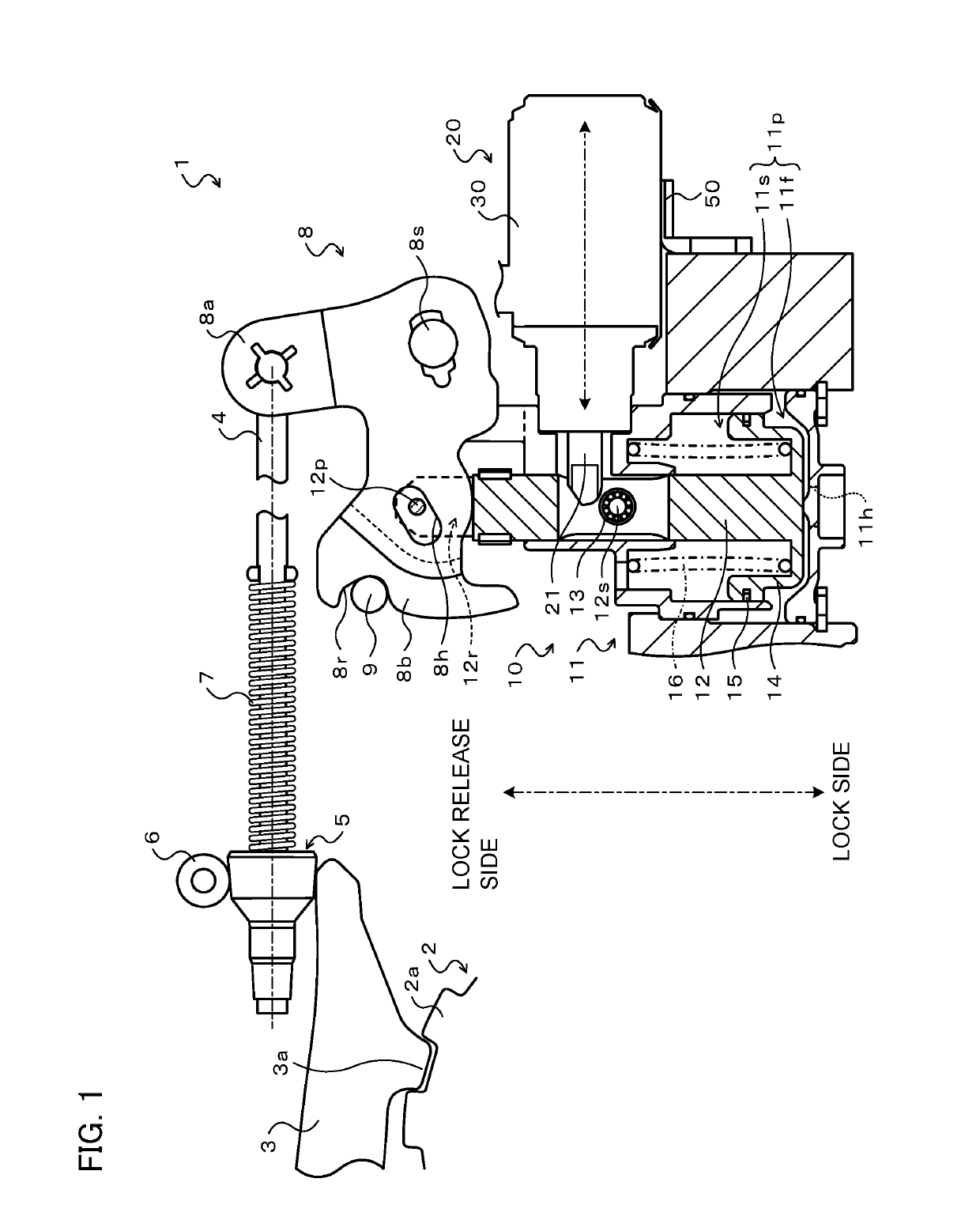

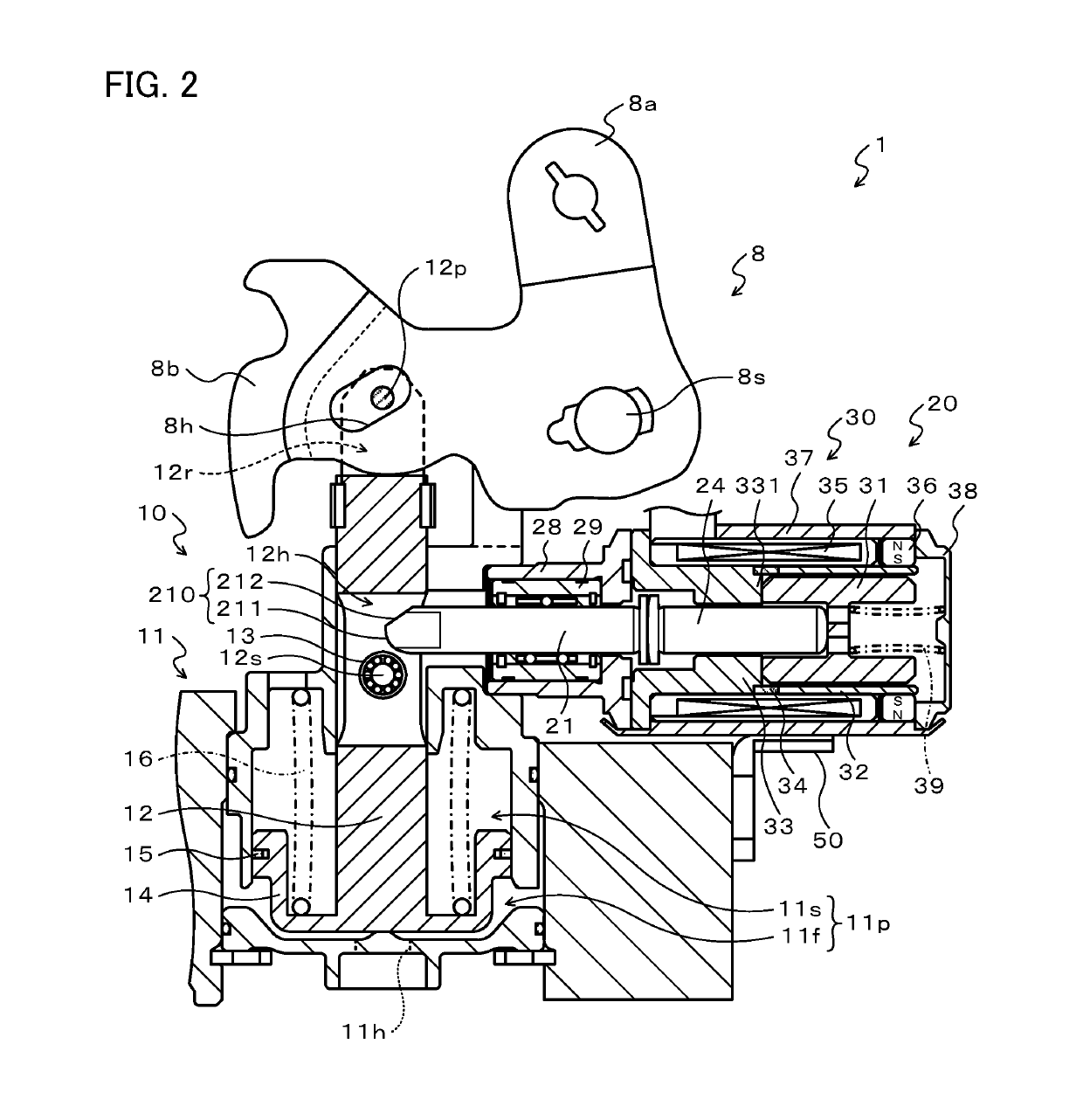

Fuel injection device

ActiveUS20110233309A1Accurately shutIncrease surface pressureMachines/enginesFuel injecting pumpsEngineeringPressure controlled ventilation

In a fuel injection device, a pressing surface of a pressing member presses an opening wall surface to interrupt communication between an inflow port and a pressure control chamber when communication between an outflow port and a return channel is made by a pressure control valve, and the pressing surface of the pressing member is displaced and separated from the opening wall surface to open the inflow port of the opening wall surface to the pressure control chamber when the communication between the outflow port and the return channel is interrupted by the pressure control valve. One of the pressing surface of the pressing member and the opening wall surface of the control body is provided with an inflow depressed portion and an outflow depressed portion partitioned from each other, and a depressed dimension of the inflow depressed portion is larger than a depressed dimension of the outflow depressed portion.

Owner:DENSO CORP

Wood strand molded parts having three-dimensionally curved or bent channels, and method for making same

InactiveUS6916523B2Increased strengthIncrease strength of partMechanical working/deformationWood working apparatusEngineering

Owner:GFP STRANDWOOD

Systems and processes for repairing fiber-reinforced polymer structures

InactiveUS20190351624A1Good mechanical integrityImprove thermal conductivityNon-macromolecular adhesive additivesSynthetic resin layered productsPolyresinBiomedical engineering

Presented are repair systems for fixing filler-reinforced polymer structures, methods for making / using such repair systems, and techniques for repairing surface damage / defects of multidimensional fiber-reinforced polymer (FRP) panels. A repair system for fixing a contoured surface of an FRP structure includes a flexible contact sheet that is fabricated from a thermally stable polymer, and has a textured contact surface that seats on the FRP structure and overlays the damaged area. A rigid cover sheet, which may be fabricated from a metal material, a polymeric material, and / or resin-impregnated fiber, has a complementary surface that conforms to the contoured surface of the FRP structure and covers the flexible contact sheet. The repair system also includes a heating element that lays against the rigid cover sheet and applies heat to the contoured surface with a substantially uniform profile that is sufficient to soften / melt portions of the FRP structure neighboring the damaged area.

Owner:GM GLOBAL TECH OPERATIONS LLC

High-strength cold rolled steel sheet having excellent deep drawability and bake hardenability and method for manufacturing the same

InactiveUS20130213529A1Excellent bake hardenabilityGood deep drawabilityHeat treatment process controlSheet steelChemical composition

A high-strength cold rolled steel sheet having excellent deep drawability and bake hardenability, with a tensile strength ≧440 MPa, an average r-value ≧1.20 and a bake hardening value ≧40 MPa, is obtained by subjecting a steel raw material having a chemical composition including C: 0.010-0.06 mass %, Si: more than 0C:\Users\ejensen\Desktop\!TEMP\.5 mass % but not more than 1.5 mass %, Mn: 1.0-3.0 mass %, Nb: 0.010-0.090 mass %, Ti: 0.015-0.15 mass % and satisfying(Nb / 93) / (C / 12)<0.20 to hot rolling, cold rolling and then to annealing including steps of heating to a temperature of 800-900° C. while a temperature region of 700-800° C. is an average heating rate <3° C. / s, and soaking and thereafter cooling at a rate ≧5° C. / s from the soaking temperature to a cooling stop temperature ≦500° C. to thereby form a microstructure including ferrite phase with an area ratio ≧70% and martensite phase with an area ratio ≧3%.

Owner:JFE STEEL CORP

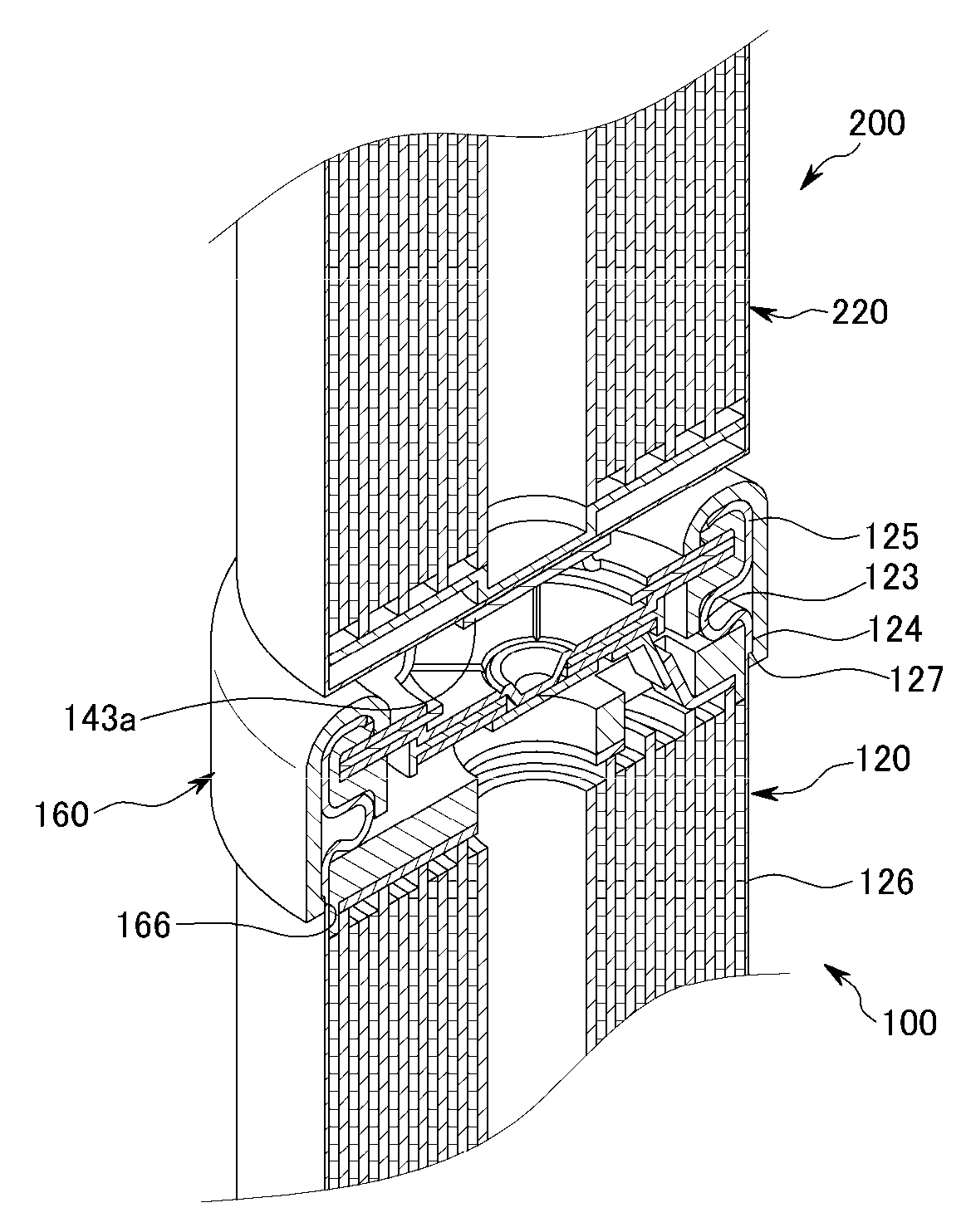

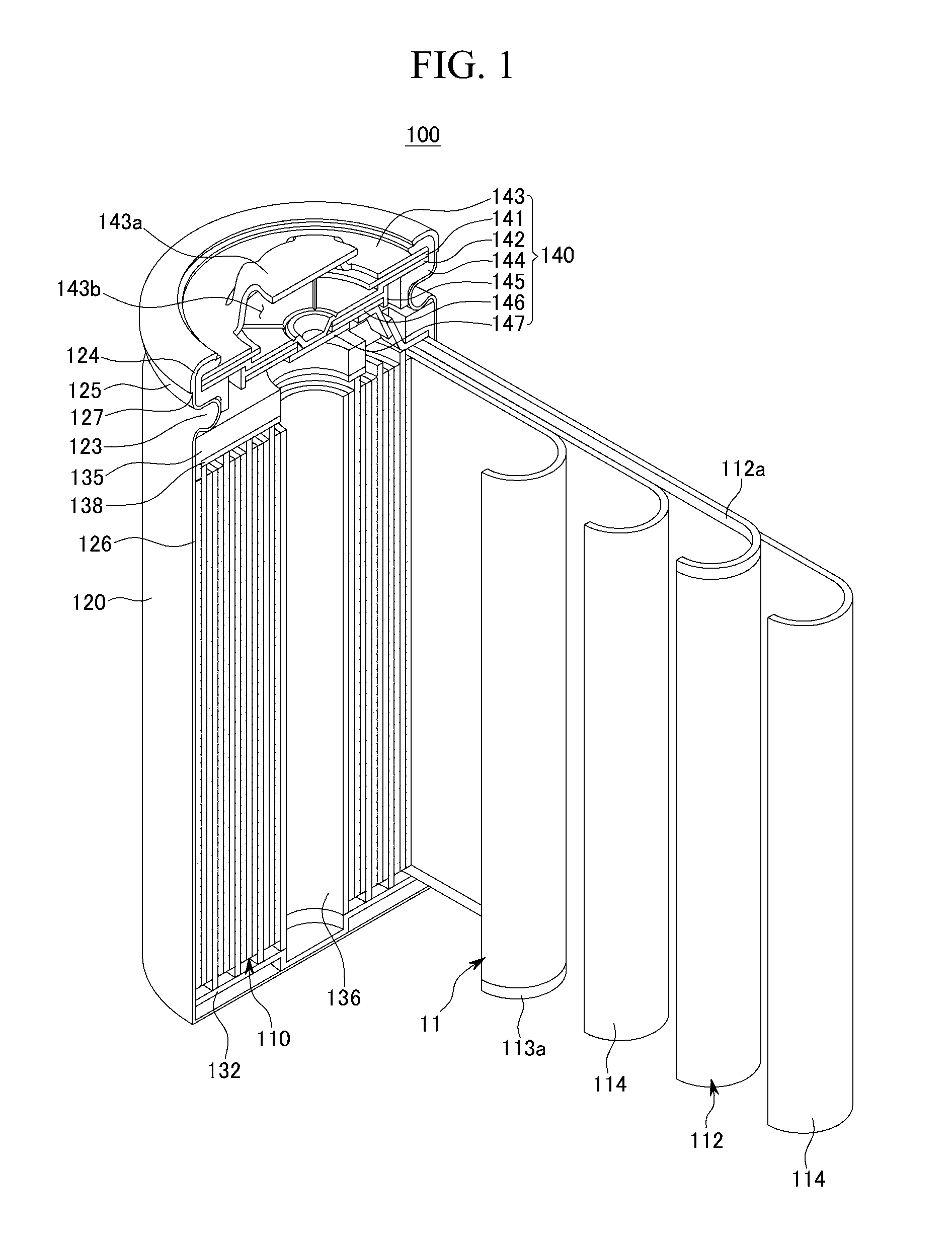

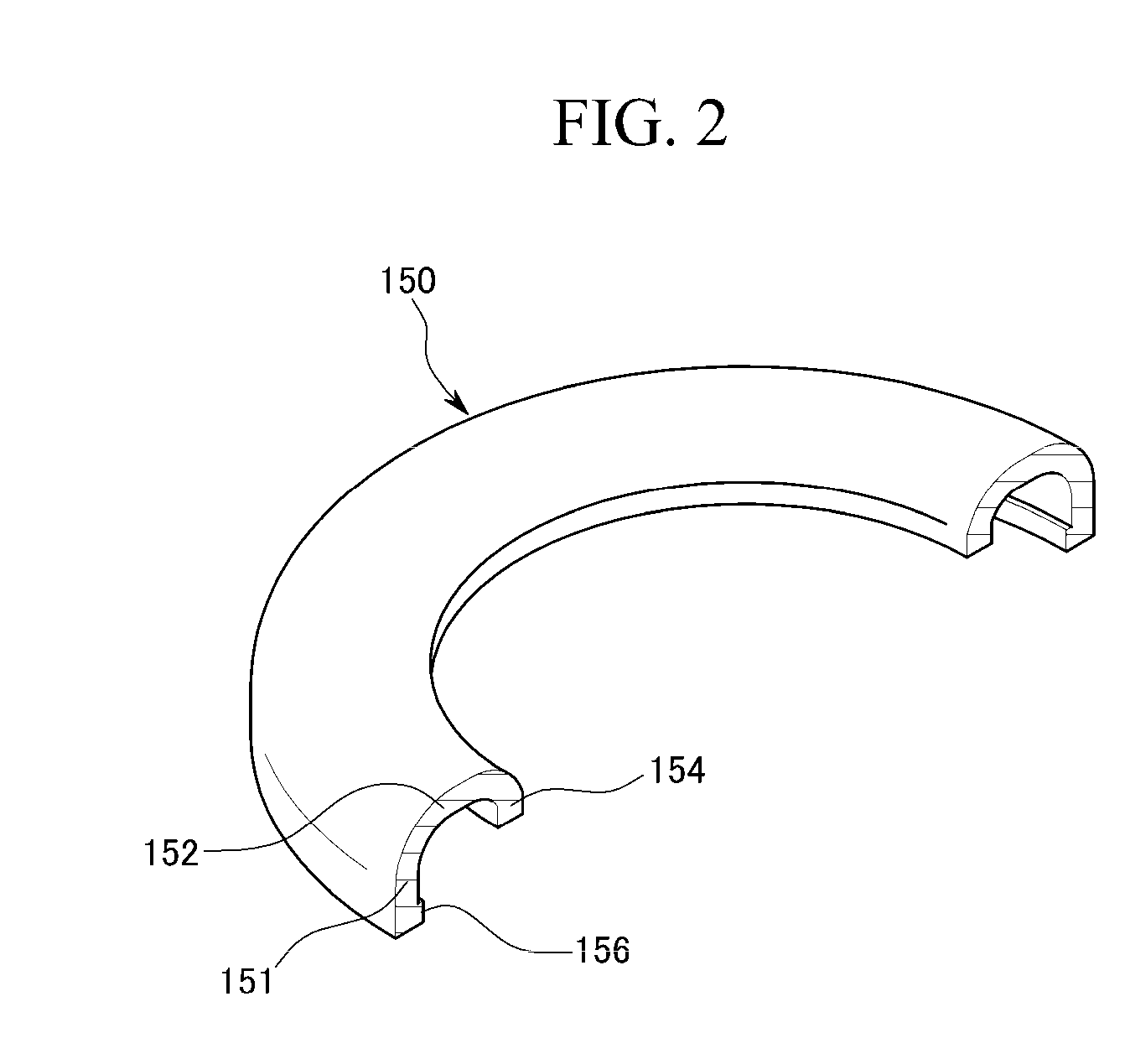

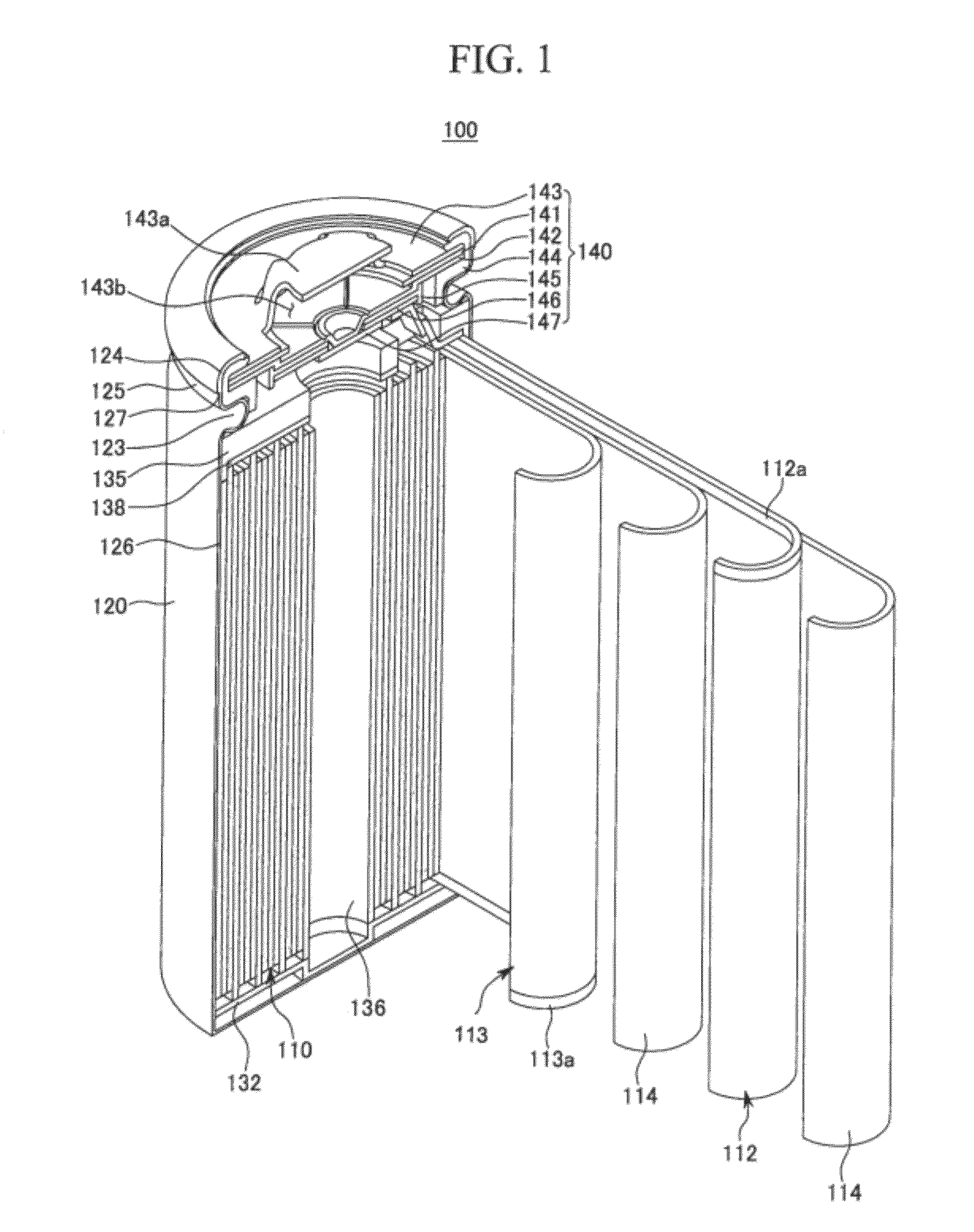

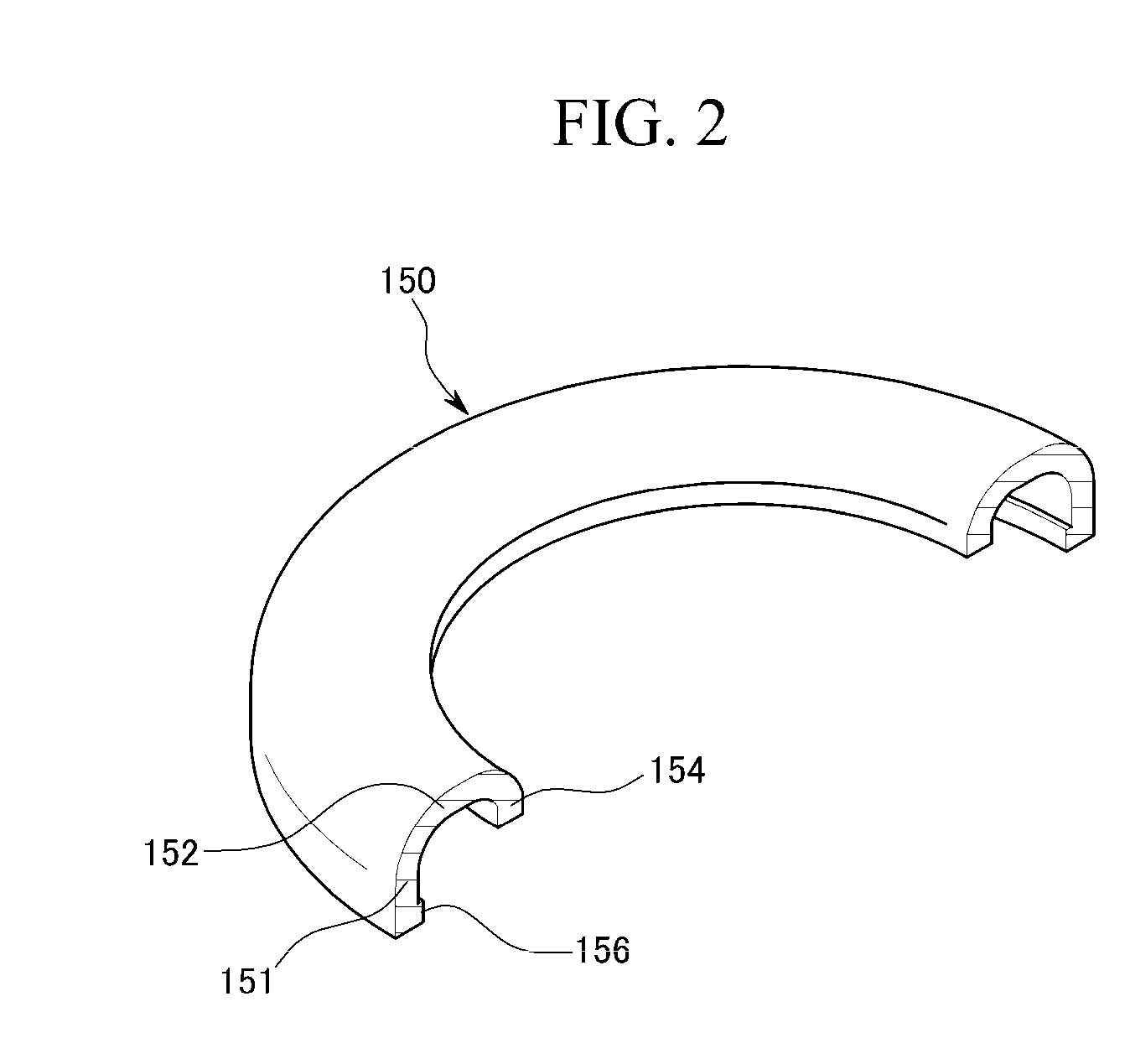

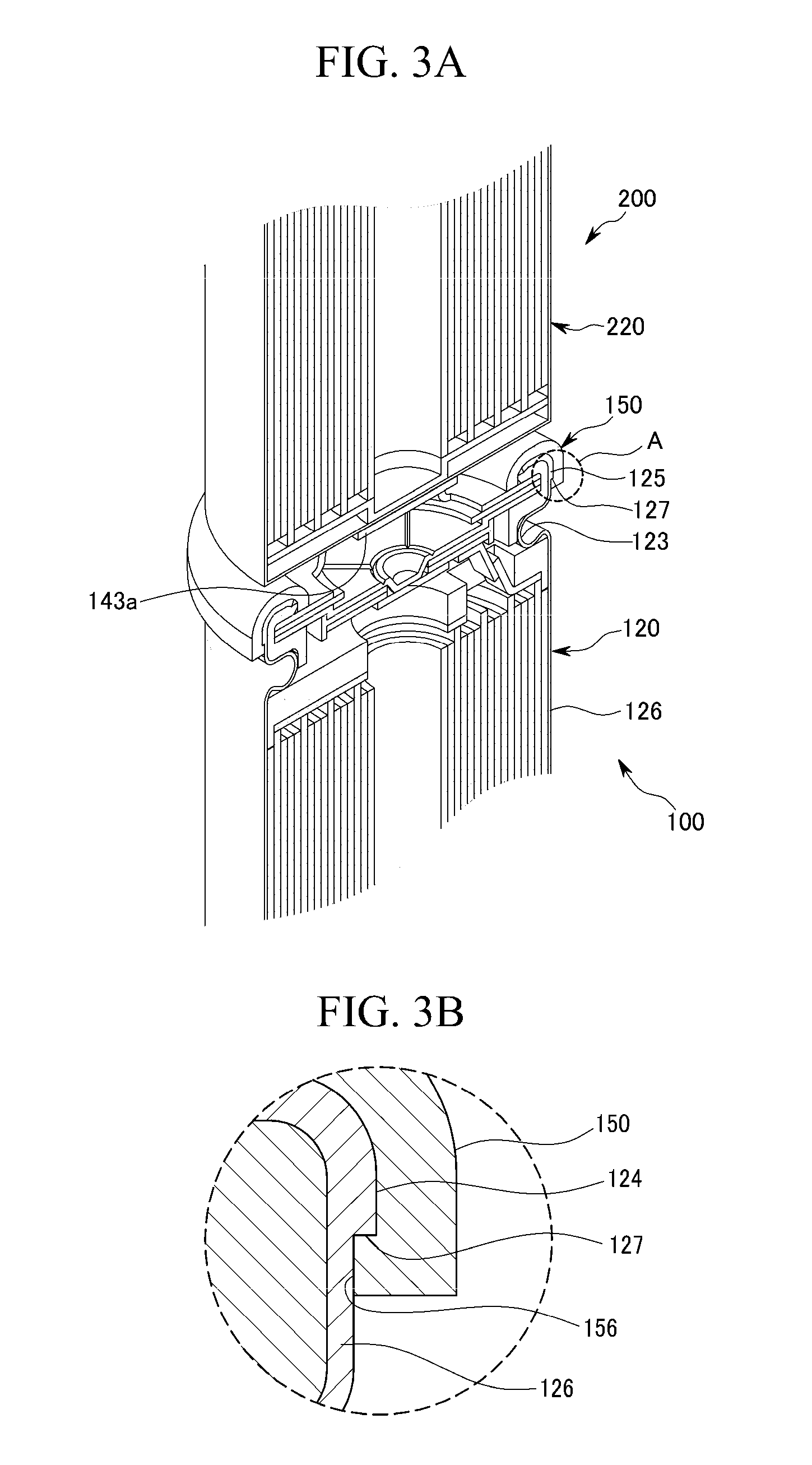

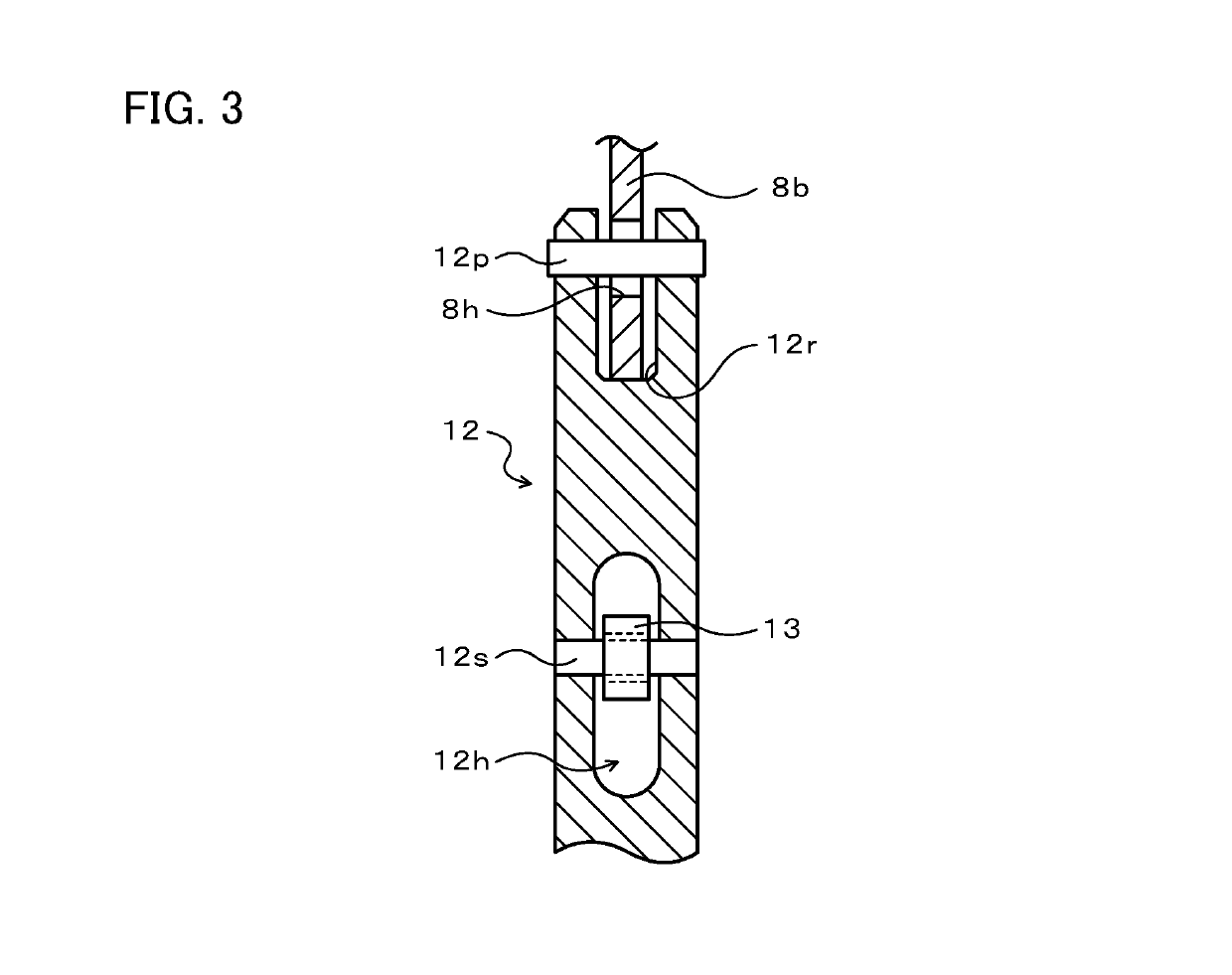

Rechargeable battery and battery module

ActiveUS20090092894A1High parts strengthHigh strengthPrimary cell to battery groupingFinal product manufactureRechargeable cellEngineering

A rechargeable battery having electrical stability includes an electrode assembly, a case, a cap assembly, and a spacer. The electrode assembly includes an anode, a cathode, and a separator interposed between the anode and the cathode. The case has an opening in which the electrode assembly is inserted and has a first thickness portion having a first thickness and a second thickness portion having a second thickness smaller than the first thickness. The cap assembly is coupled to the opening of the case and electrically connected to the electrode assembly. The spacer is fixed to an end of the case, and includes a supporting protrusion that engages with a portion of the case where the first thickness portion and the second thickness portion are connected to each other.

Owner:SAMSUNG SDI CO LTD

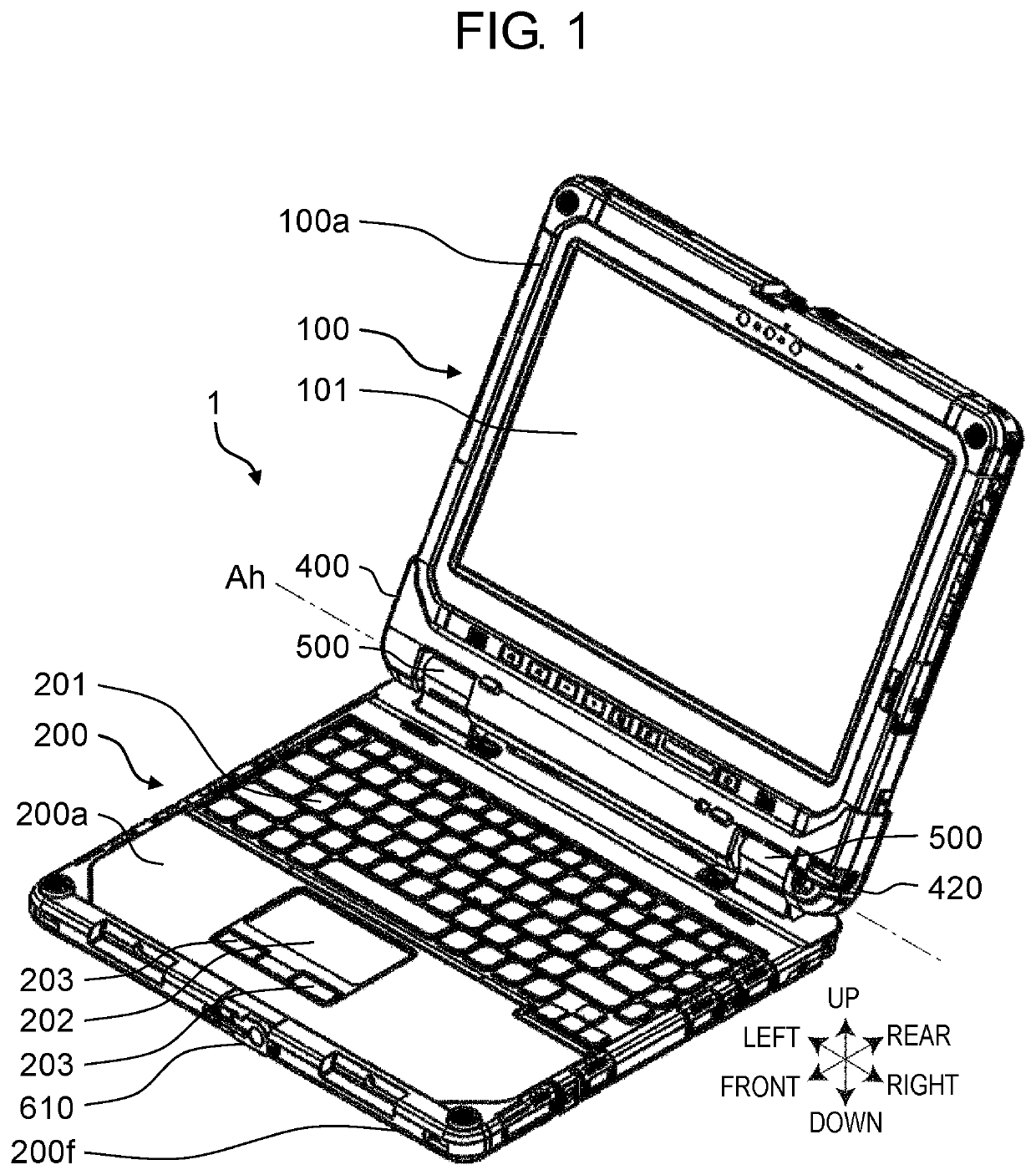

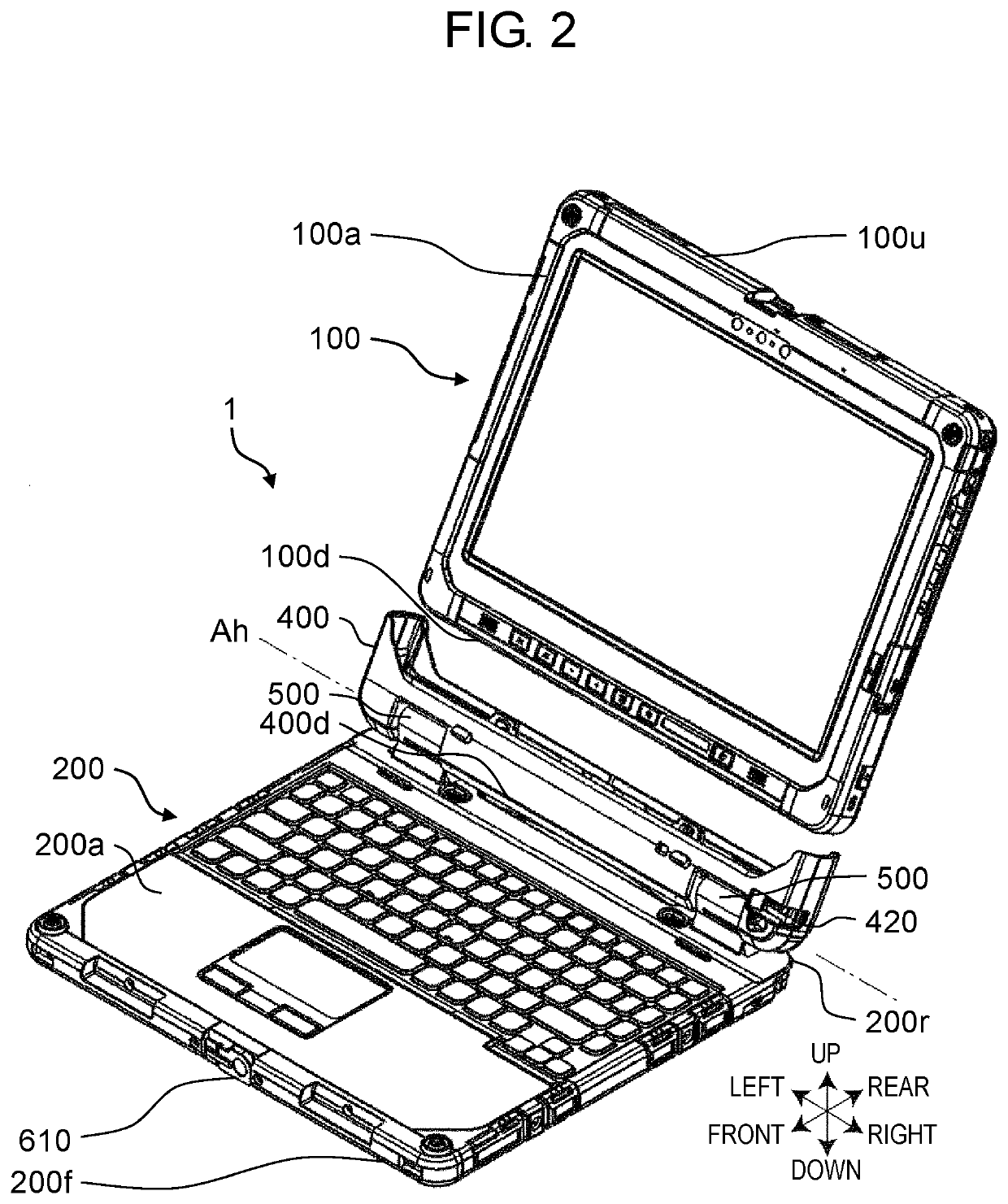

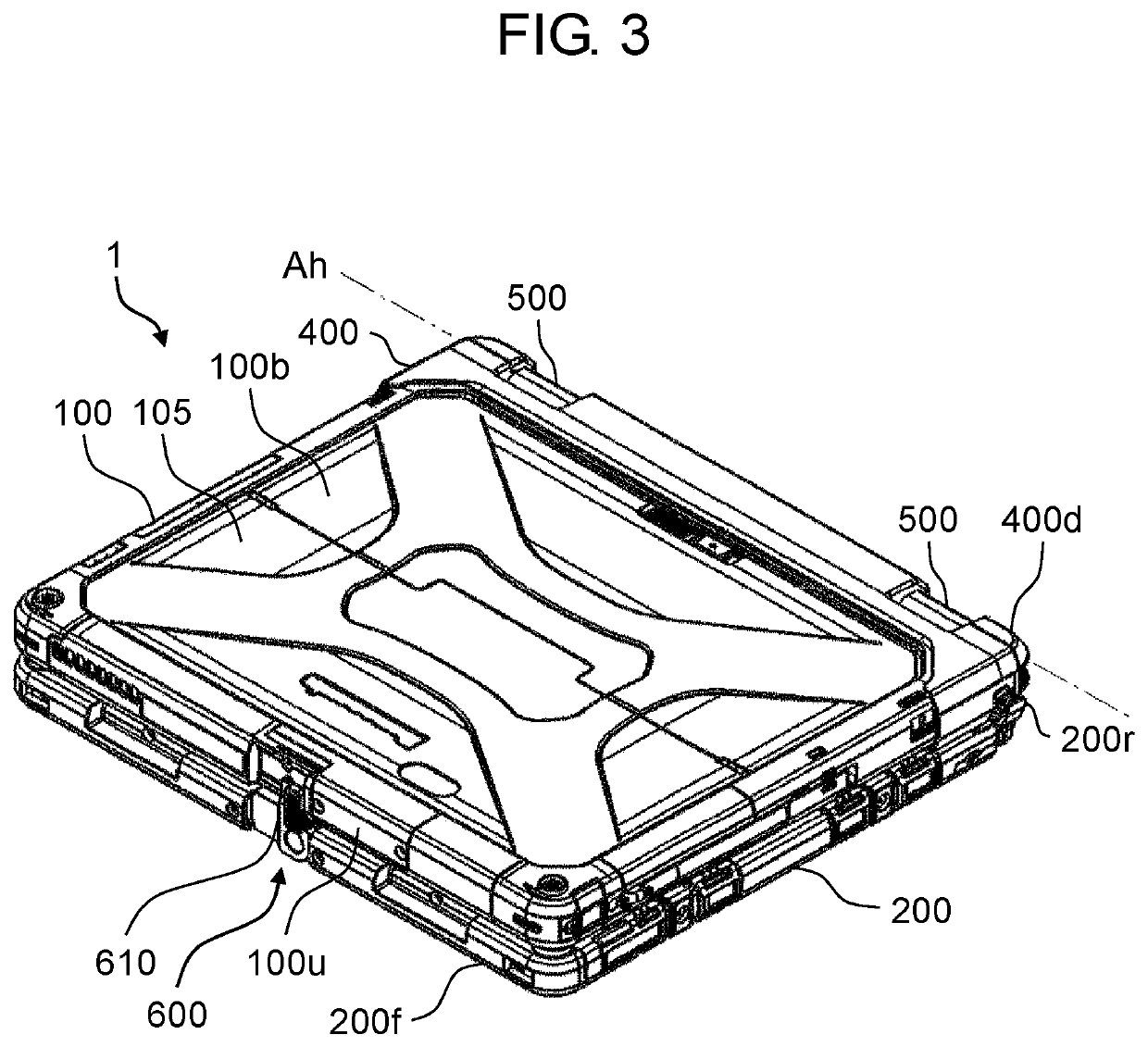

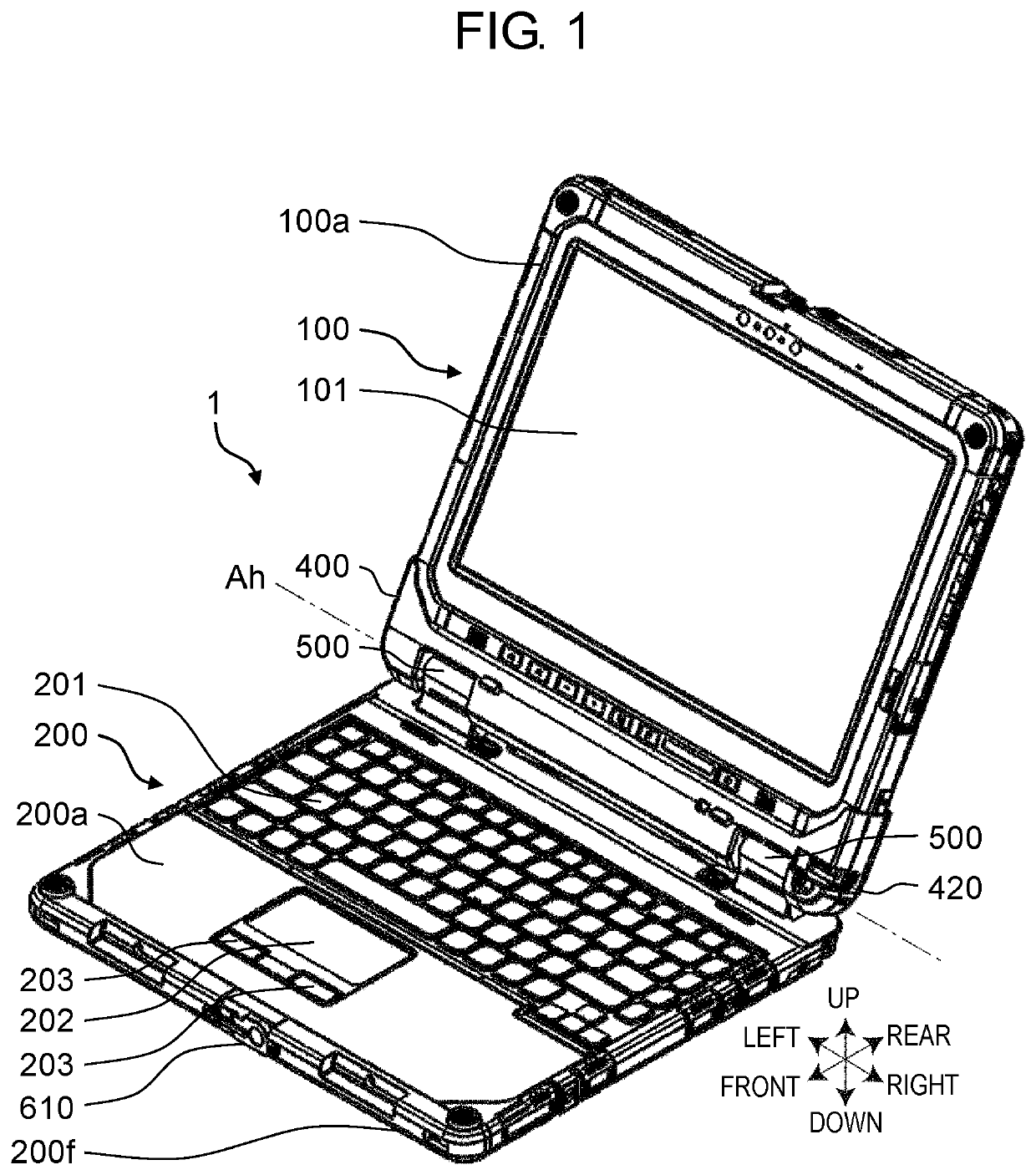

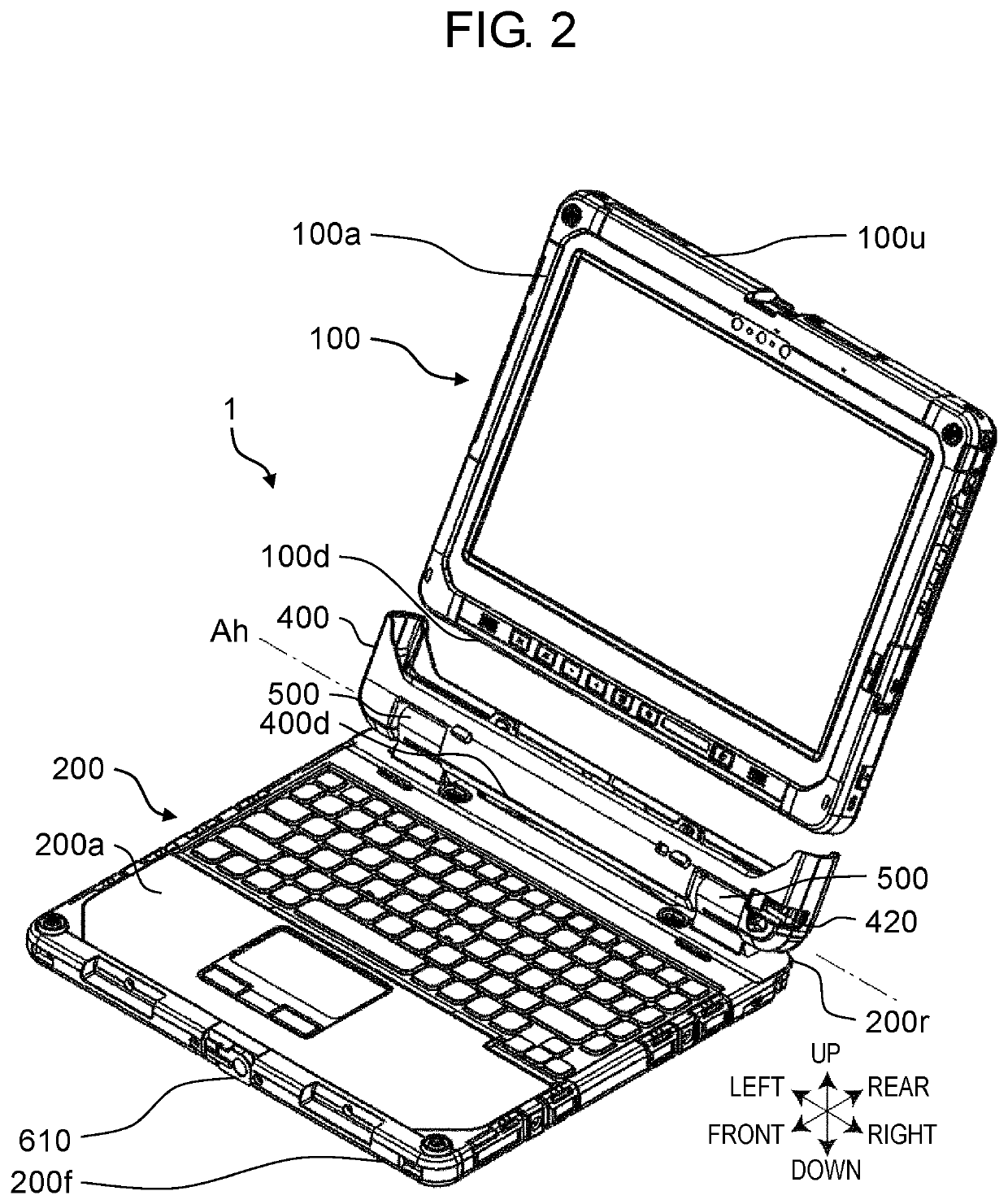

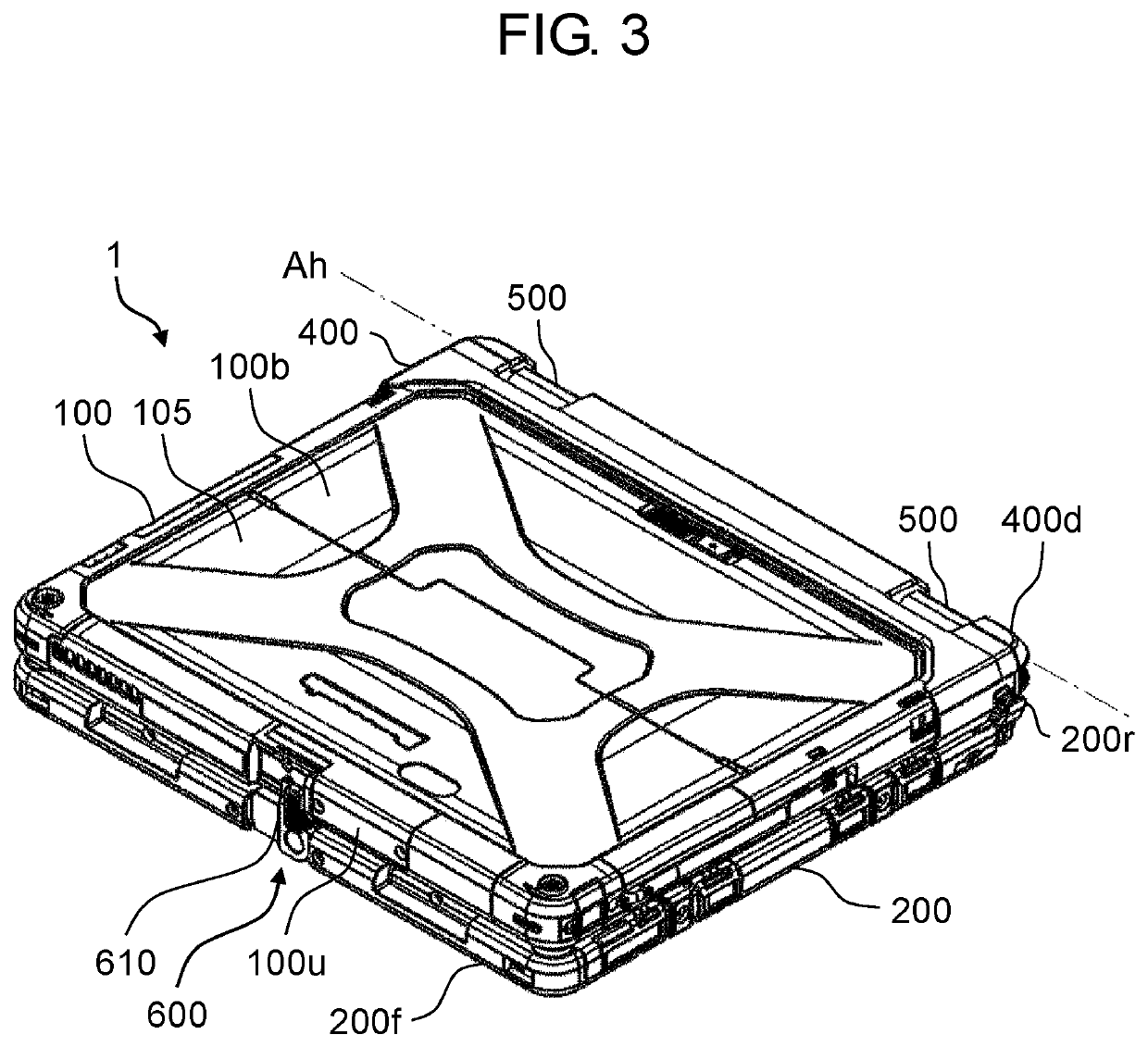

Electronic device

ActiveUS20190361492A1Simple structureReduce the number of partsBuilding locksCasings/cabinets/drawers detailsLocking mechanismEngineering

An electronic device includes a first unit, a second unit, and a lock mechanism. The lock mechanism includes: an engagement projection provided on a third side surface of the first unit; a latch provided on a fourth side surface of the second unit, the latch being rotatable around a rotation axis provided perpendicular to the fourth side surface between a first rotational position where the latch does not engage with the engagement projection and a second rotational position where the latch is engageable with the engagement projection, and an urging member that urges the latch to be positioned at the second rotational position. The latch has an inclined part. When the latch is located at the second rotational position and the first unit is changed to a closed state from a state where the first unit is not closed, the inclined part abuts on the engagement projection during the change.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

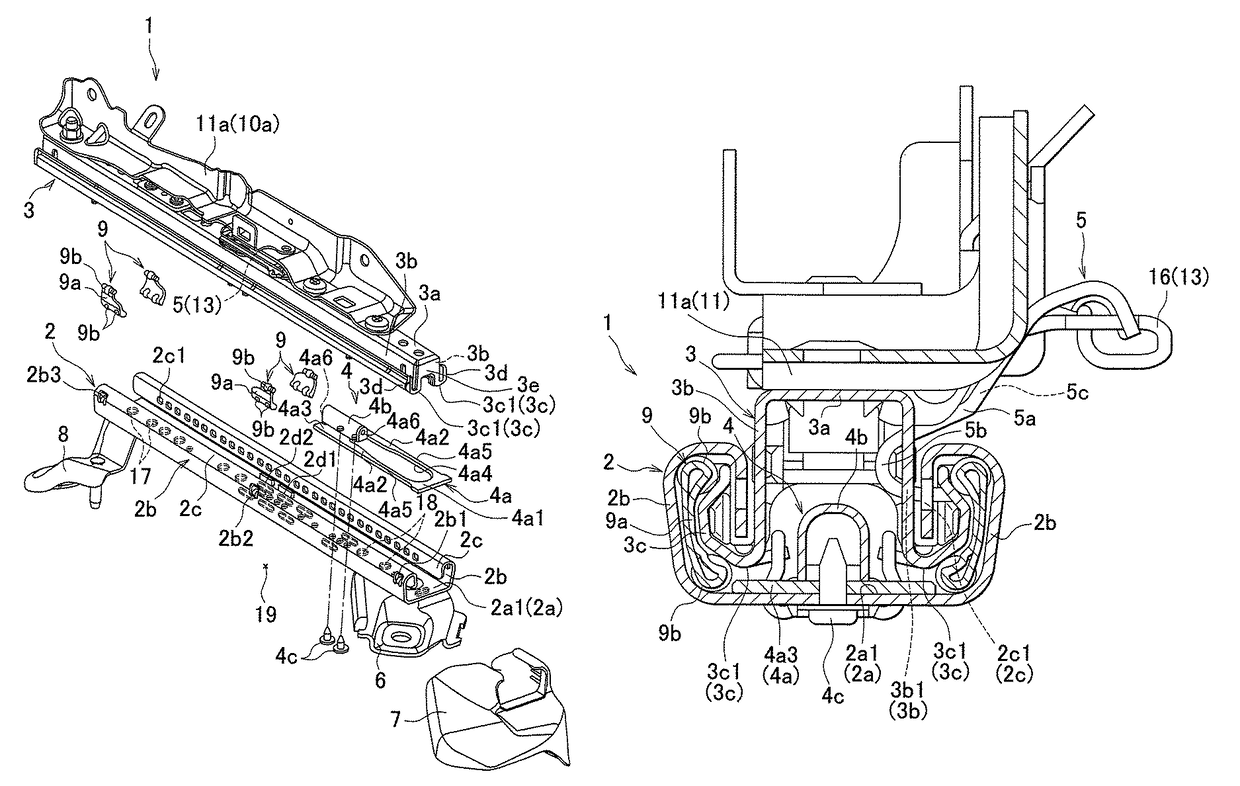

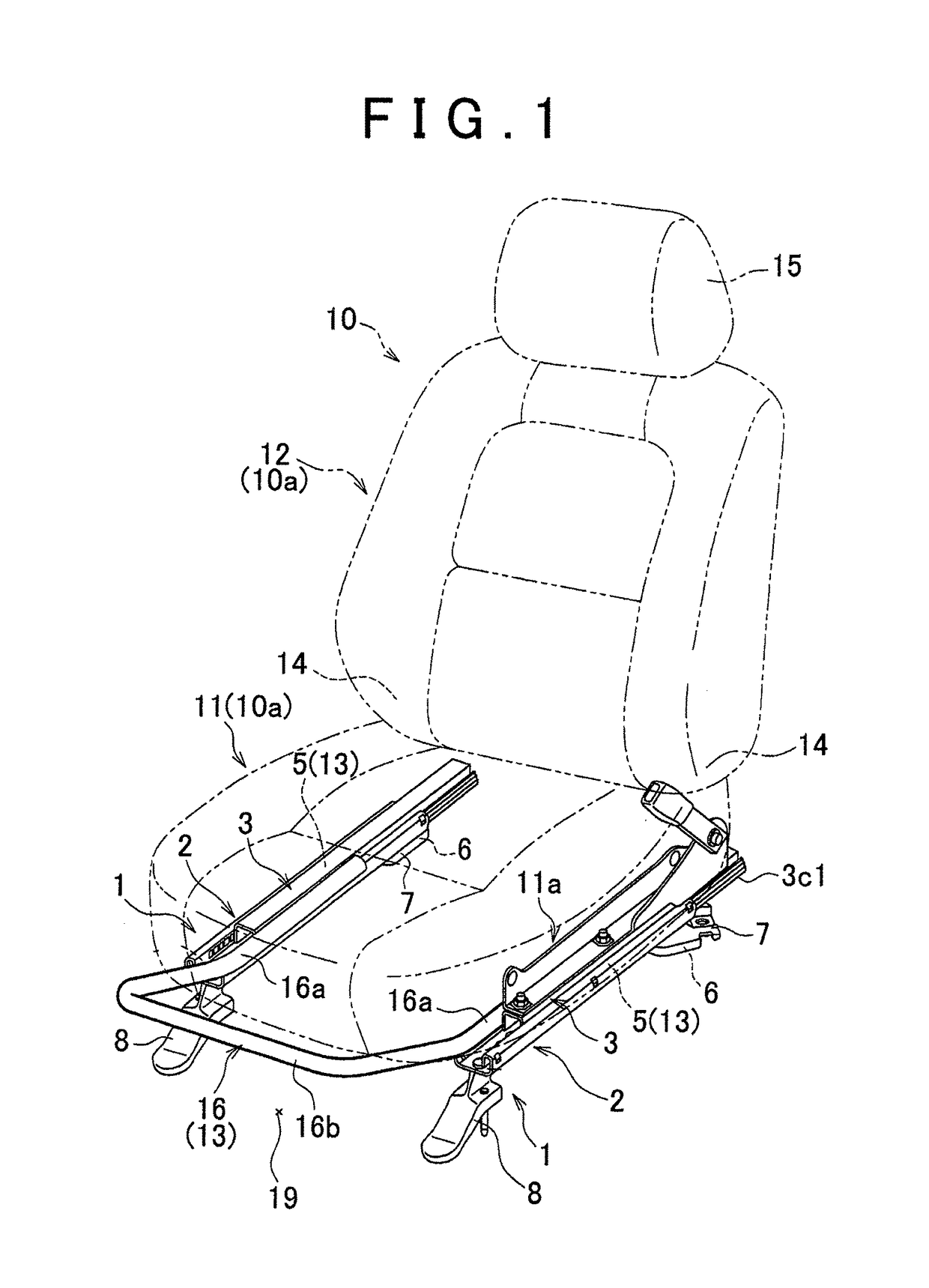

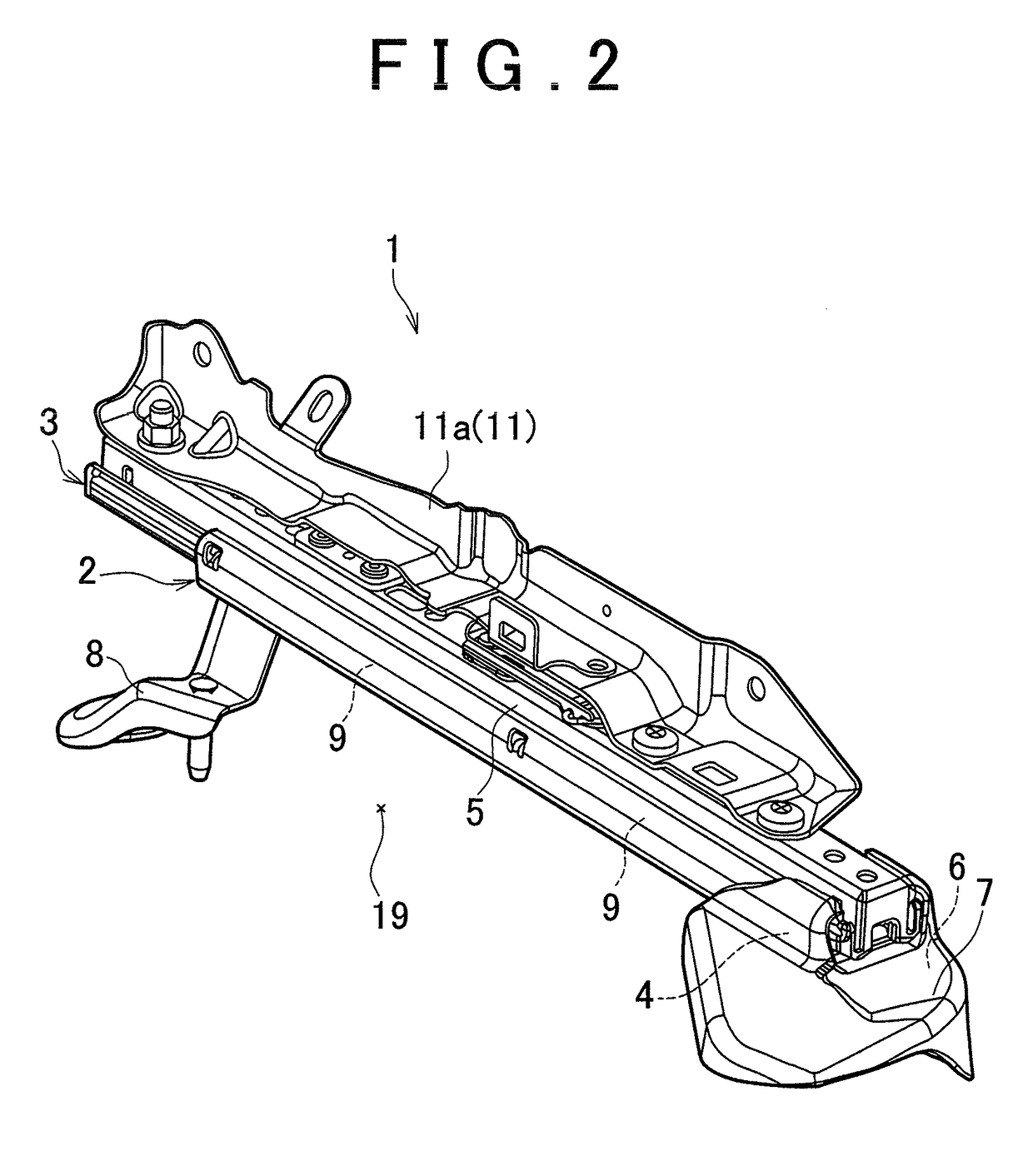

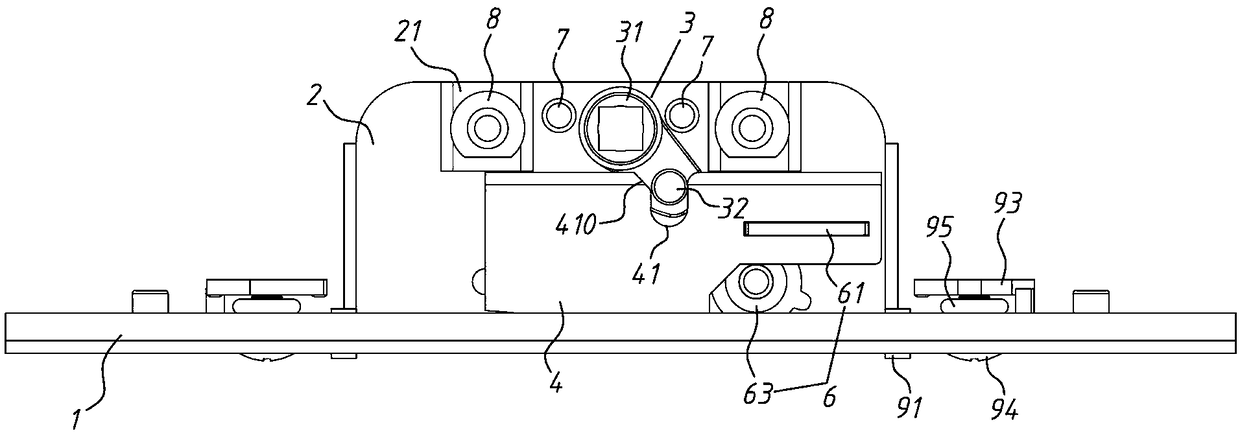

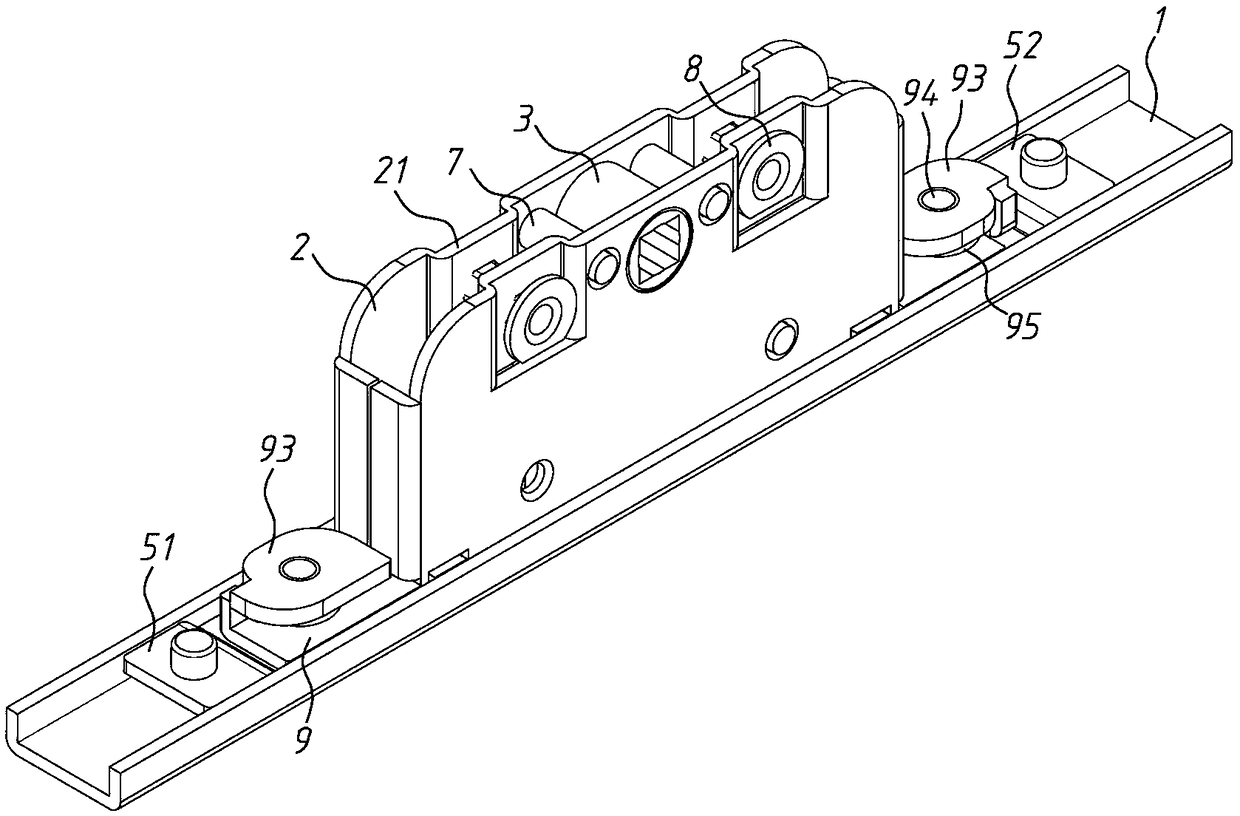

Vehicle seat slide mechanism

ActiveUS9802511B2Reduces tilting motionReduce distanceStands/trestlesKitchen equipmentLocking mechanismEngineering

A vehicle seat slide mechanism via which a seat assembly is slidably mounted on a vehicle floor is provided with: a lower rail that is mounted on the vehicle floor; an upper rail which is slidably attached on the lower rail and on which the seat assembly is attached; a lock mechanism that locks the upper rail on the lower rail in a releasable manner; and a gap reduction member that is provided between a first face formed at the lower rail and facing in a substantially vertical direction and a second face formed at the upper rail and facing to the first face.

Owner:TOYOTA BOSHOKU KK

Electronic device

ActiveUS11237591B2Simple structureReduce the number of partsBuilding locksCasings/cabinets/drawers detailsRotational axisSoftware engineering

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

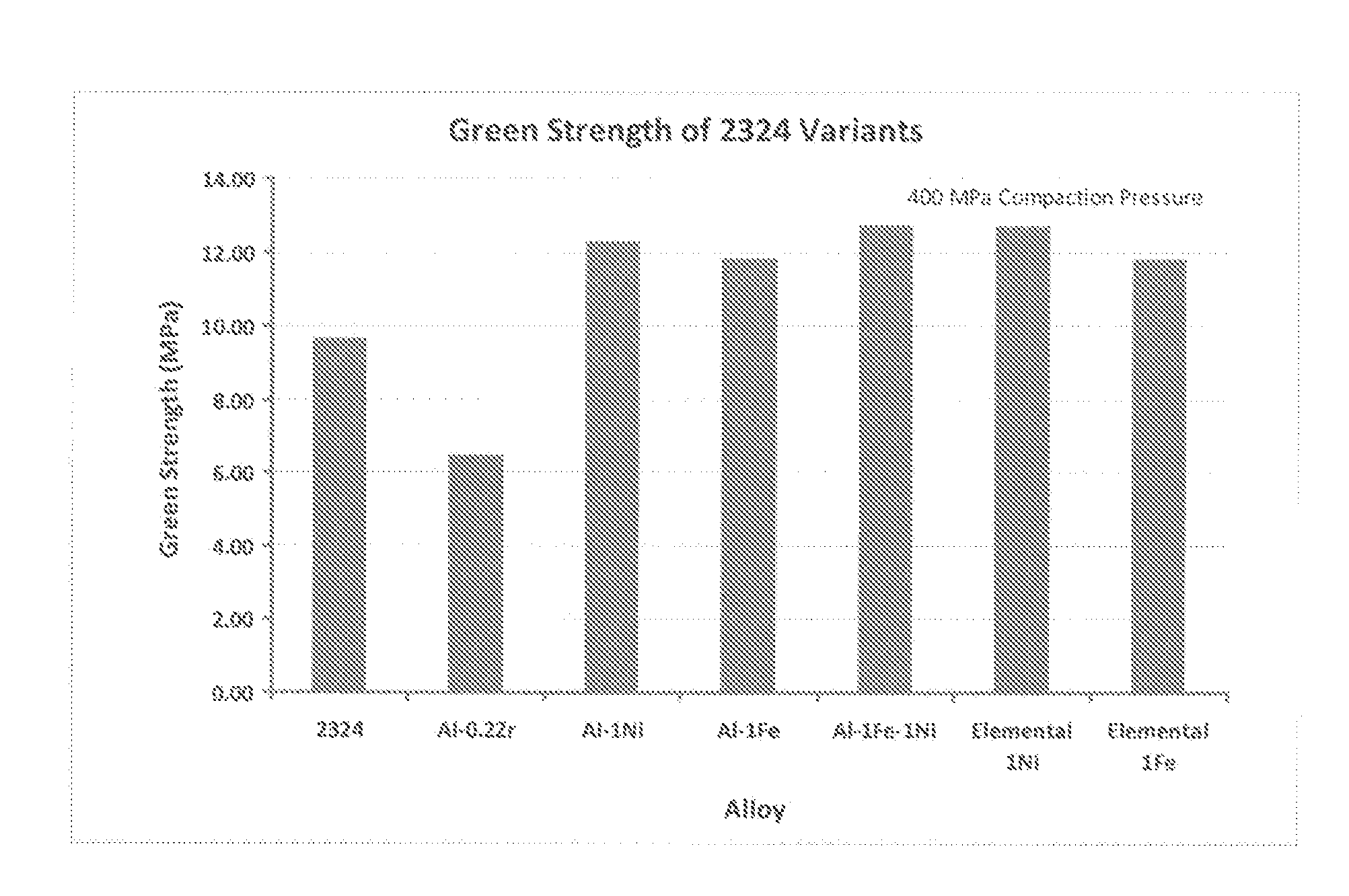

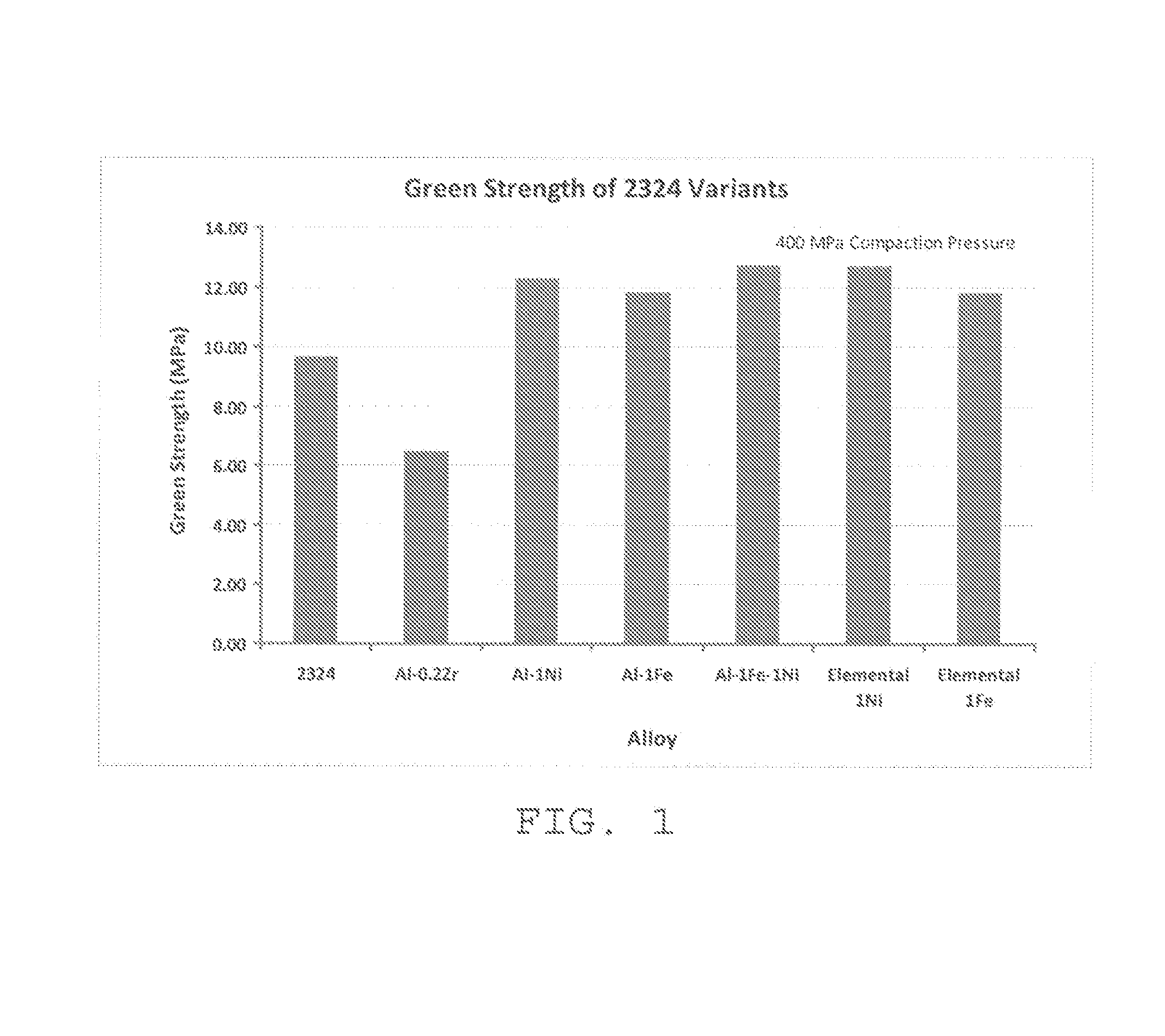

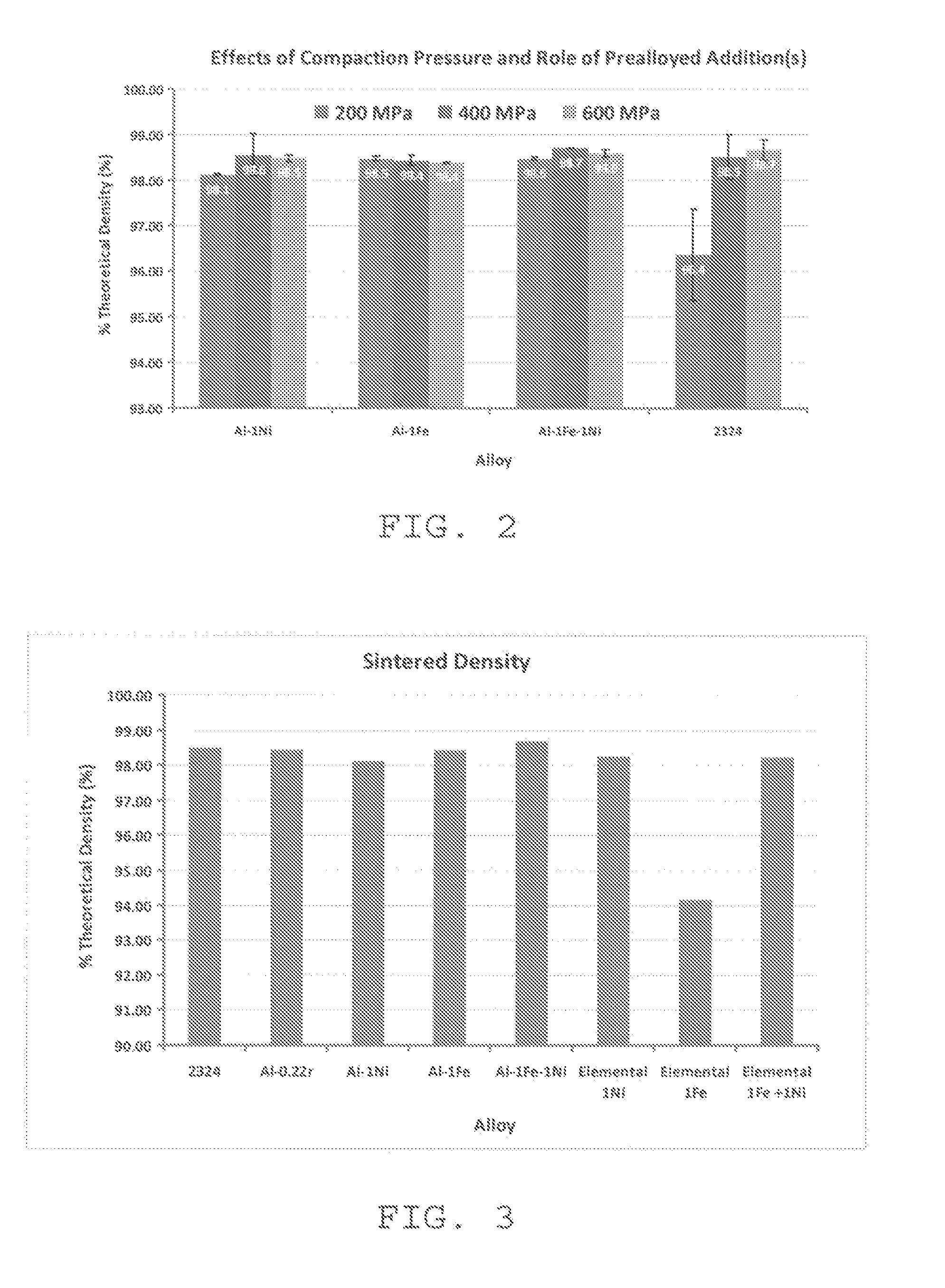

Aluminum alloy powder metal with transition elements

ActiveUS20130309123A1Promote formationImprove strength propertiesMetal boridesGrain treatmentsMetalAluminium alloy

A transition element-doped aluminum powder metal and a method of making this powder metal are disclosed. The method of making includes forming an aluminum-transition element melt in which a transition element content of the aluminum-transition element melt is less than 6 percent by weight. The aluminum-transition element melt then powderized to form a transition element-doped aluminum powder metal. The powderization may occur by, for example, air atomization.

Owner:SKN SINTER METALS LLC (US)

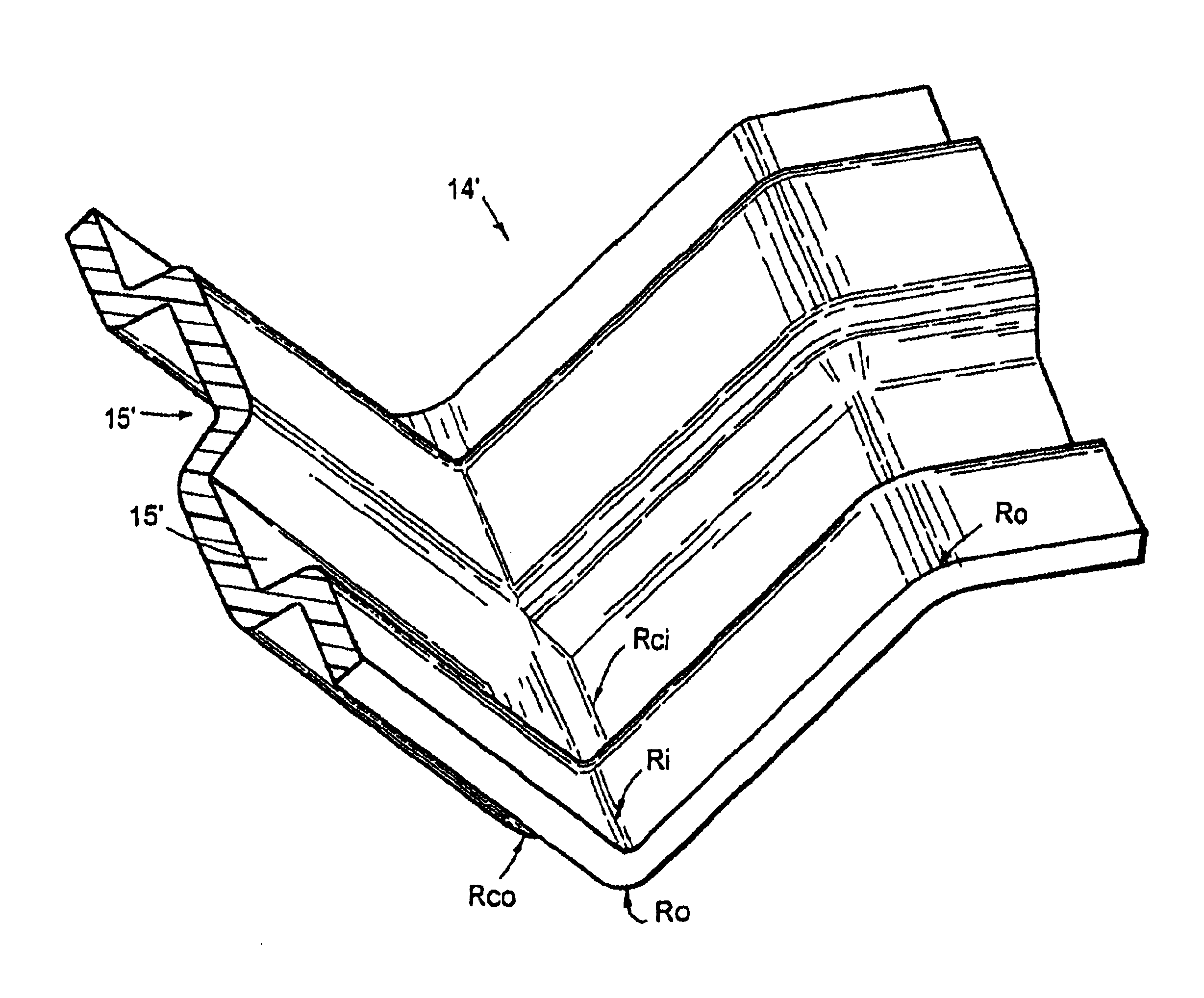

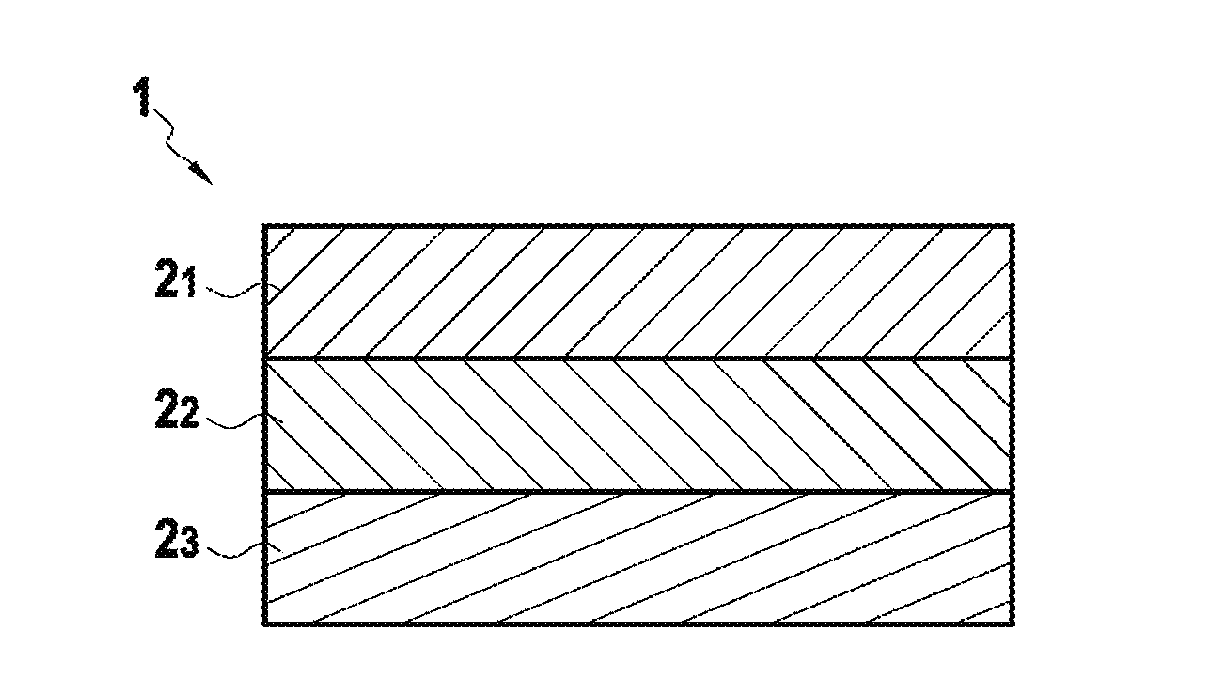

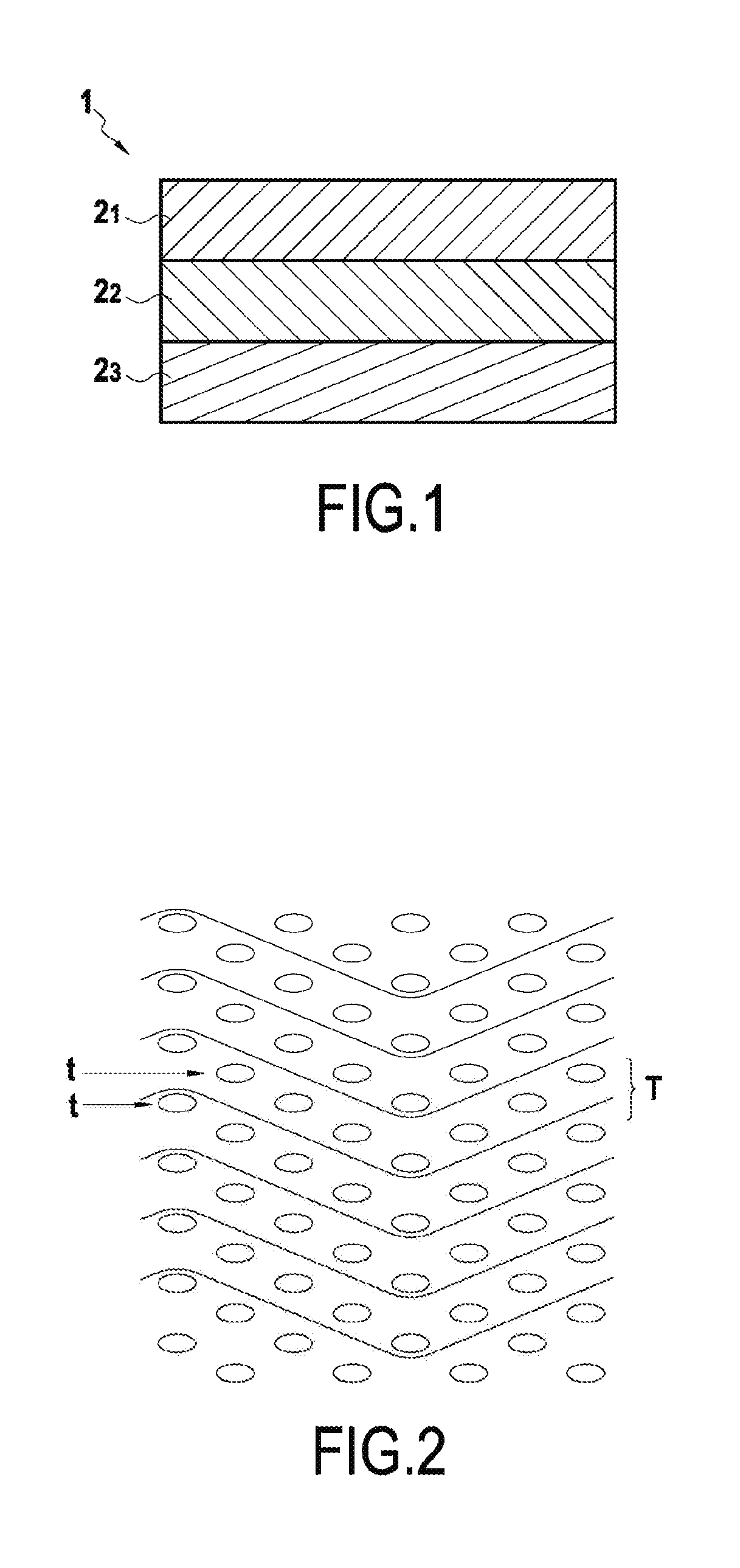

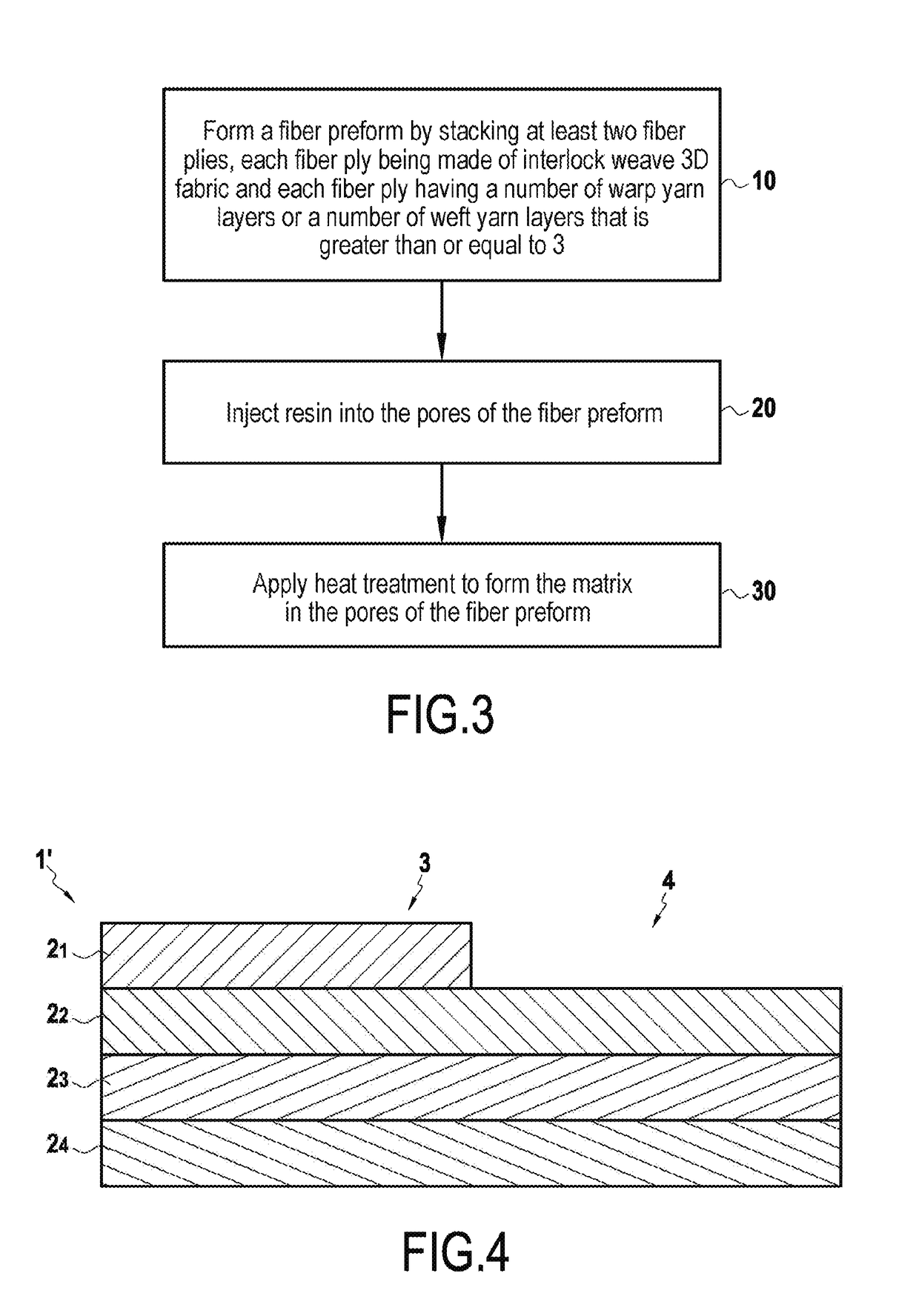

A composite material part

ActiveUS20180257996A1Improve mechanical propertiesLower energy requirementsAircraft power plant componentsCeramic layered productsMaterials scienceWeft yarn

A composite material part includes a fiber preform forming fiber reinforcement including a stack of at least two fiber plies, each of the fiber plies being made of an interlock weave three-dimensional fabric and each of the fiber plies having a number of warp yarn layers or a number of weft yarn layers that is greater than or equal to three; and a matrix present in the pores of the fiber preform.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

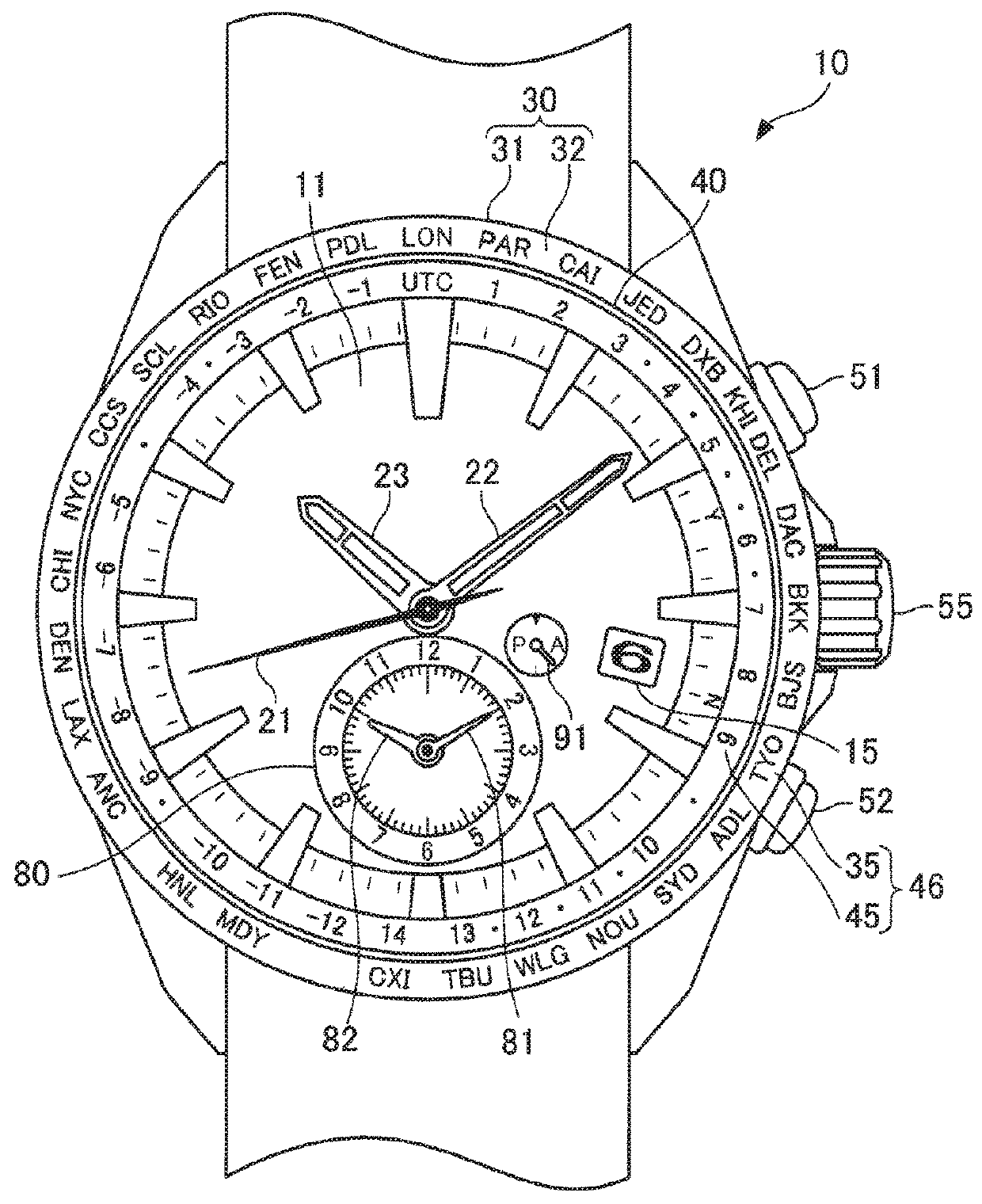

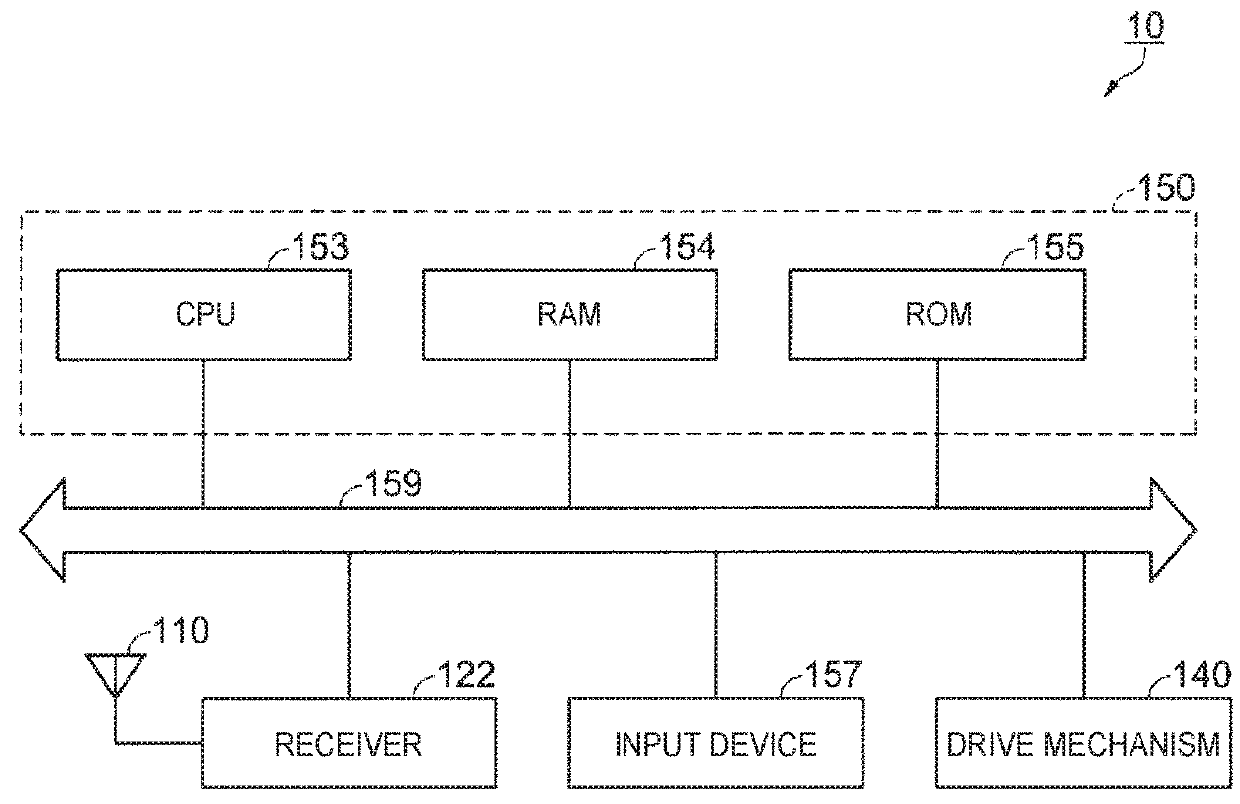

Electronic timepiece

InactiveUS20180275617A1Suppression of deformationSuppress shieldingElectronic time-piece structural detailsElectric windingElectrical batterySolar battery

The electronic timepiece has an optically transparent dial; a solar battery disposed relative to the dial in the direction in which the external light is emitted, and having a photovoltaic solar cell; an antenna disposed relative to the dial in the direction in which the external light is emitted, and receiving radio signals; and an outside case configured to house the dial, the solar battery, and the antenna. A through-hole is disposed in the solar battery; the antenna has an overlap with the through-hole when seen in plan view from a direction perpendicular to the dial; the solar battery has a flange protruding to the outside case side in plan view; and the flange is disposed so that in plan view the through-hole is located on the inside side of the outside case from the flange.

Owner:SEIKO EPSON CORP

A type‑c socket connector

ActiveCN104810657BReduce the number of assembliesReduce Tolerance RollupCoupling protective earth/shielding arrangementsEngineeringElectrical and Electronics engineering

The invention discloses a Type-C socket connector. The Type-C socket connector comprises a shell and an inserting component; the inserting component comprises an upper inserting component and a lower inserting component; the upper inserting component comprises an upper insulating body and an upper row of electric conductive terminals integrally formed with the upper insulating body; the lower inserting component comprises a lower insulating body, and a metallic shield sheet and a lower row of electric conductive terminals integrally formed with the lower insulating body; each insulating body is provided with twelve grooves respectively; each row of the electric conductive terminals is provided with eight terminals respectively; the metallic shield sheet is integrally formed with any two terminals in the lower row of the electric conductive terminals; the metallic shield sheet is downwards protruded to form a plate-shaped grounding part; the position of the terminals integrally formed with the metallic shield sheet corresponds to the position of the grounding part; and the grounding part and the metallic shield sheet are located in the different planes. The Type-C socket connector is used for reducing the assembly number of the parts, reducing the tolerance accumulation, satisfying the USB2.0 application, and greatly decreasing the number of the terminals, and is good for the stability of the product.

Owner:ALL BEST ELECTRONICS TECH CO LTD

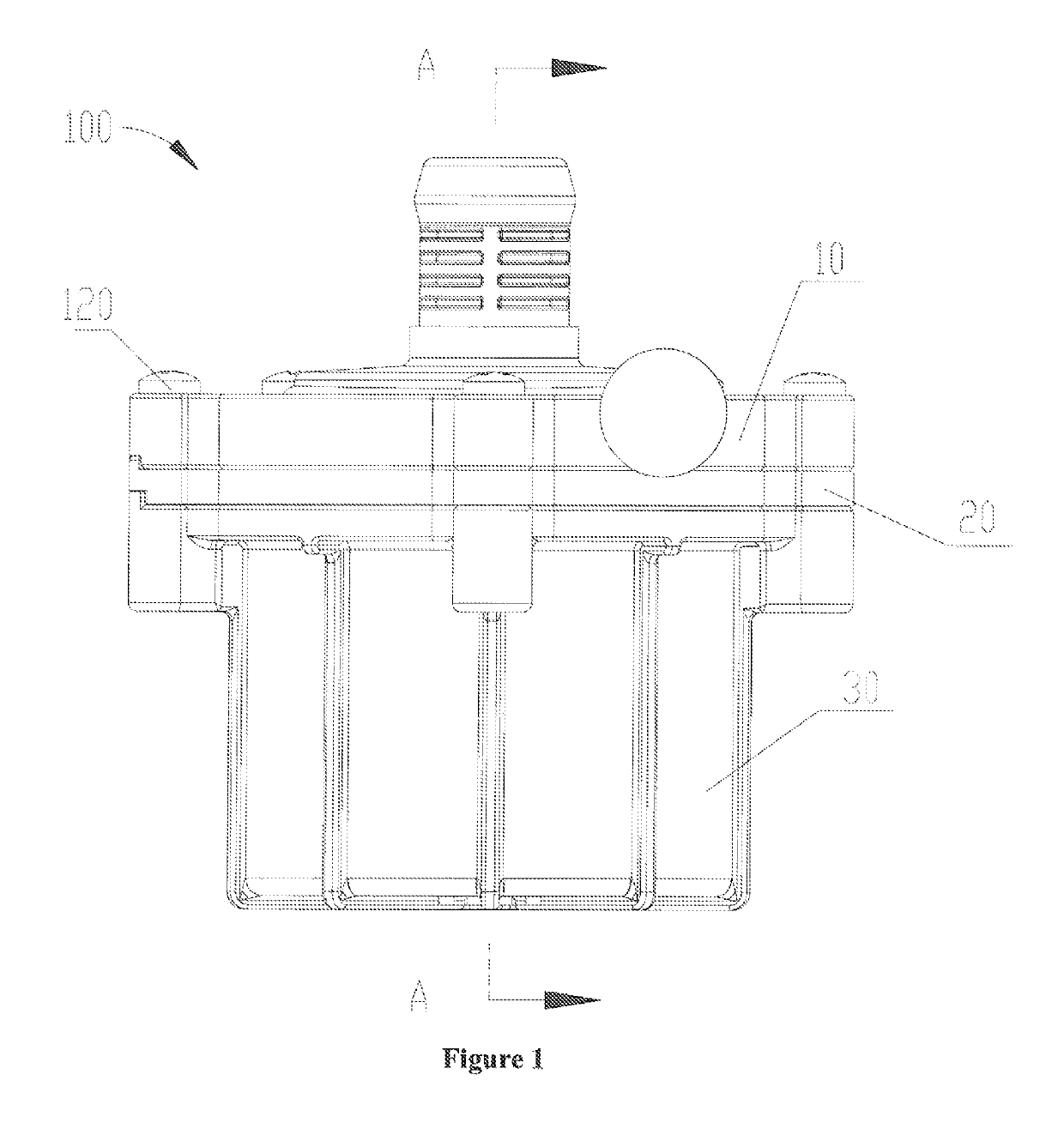

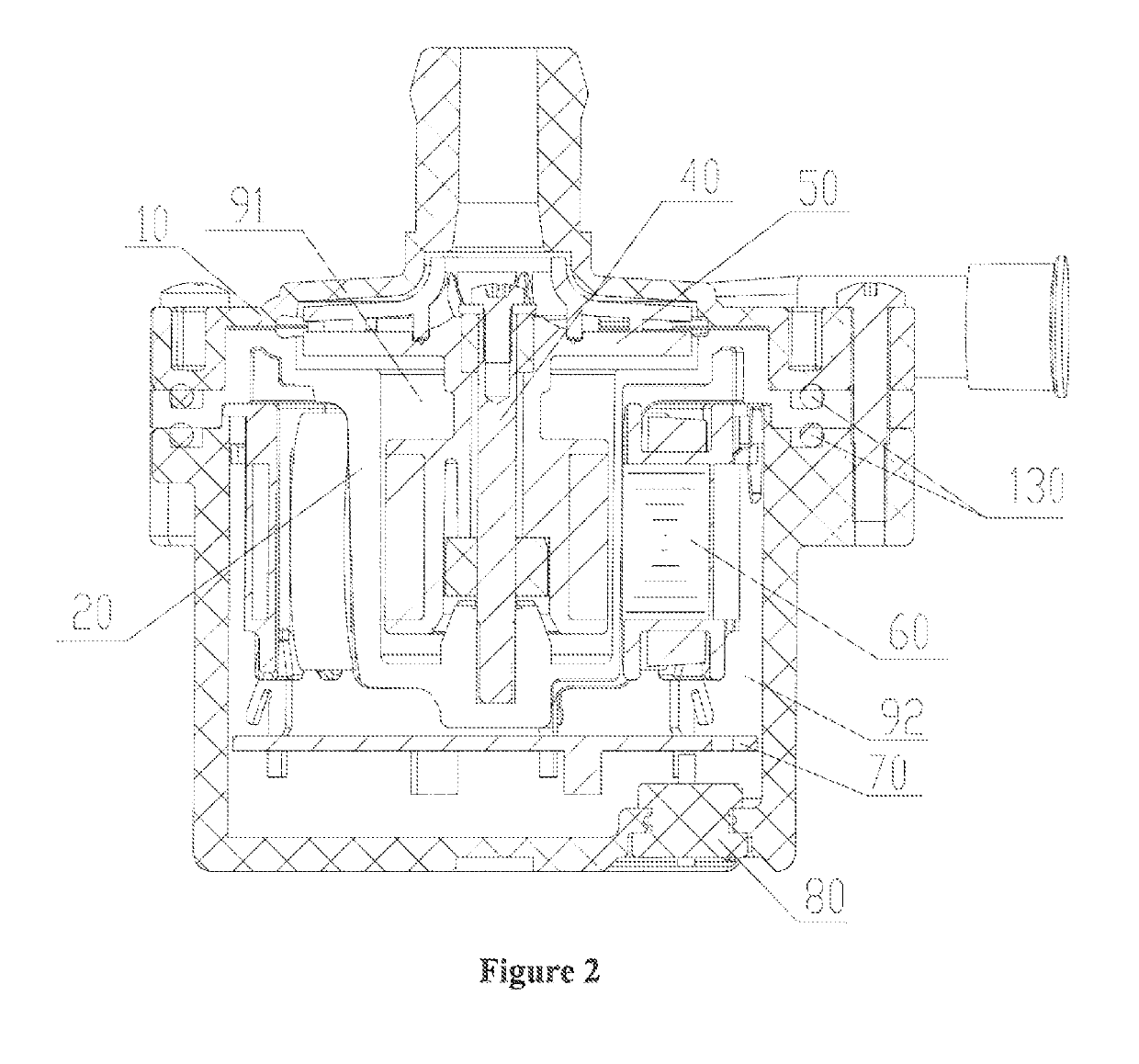

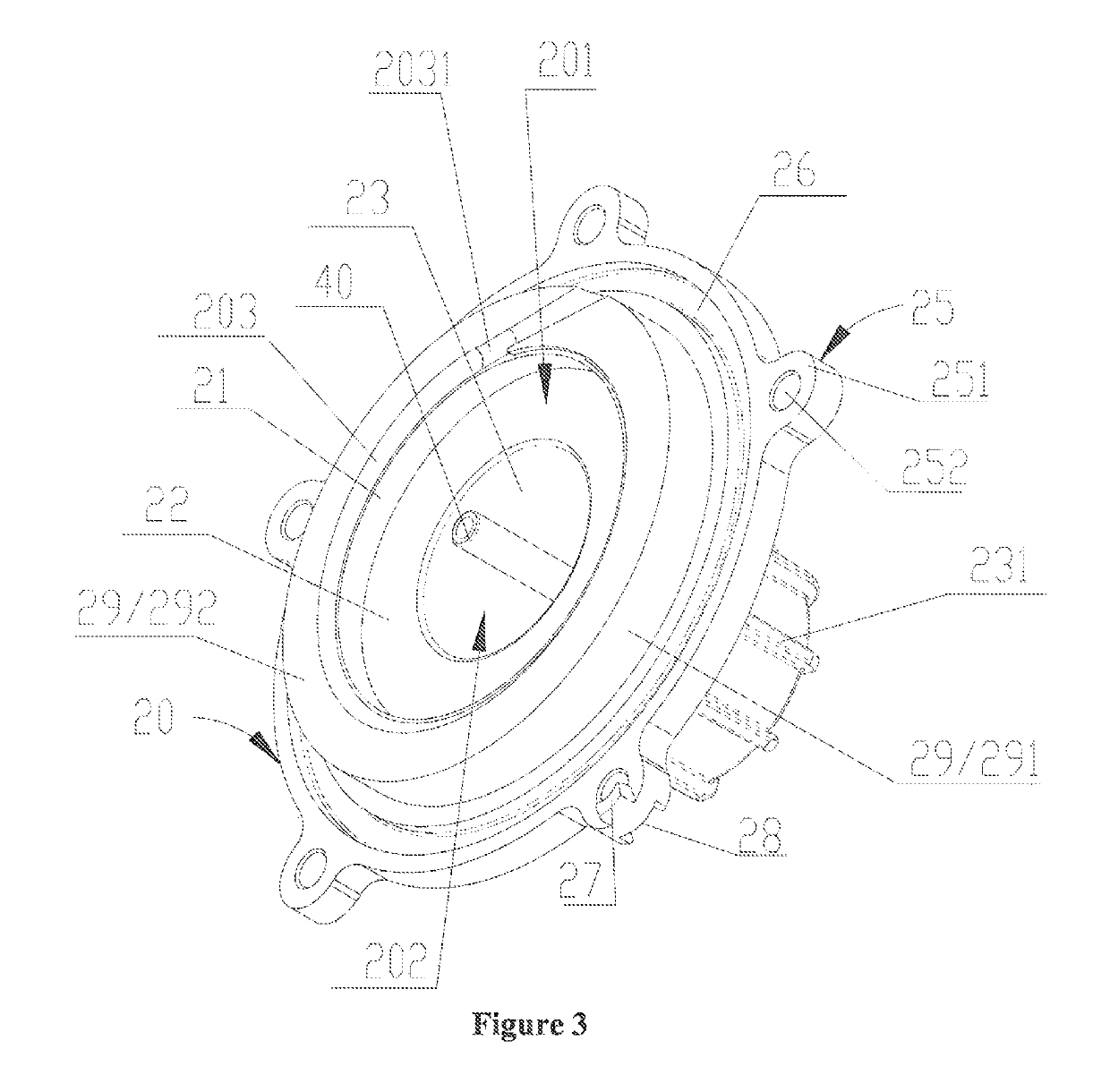

Electric pump

ActiveUS10326328B2High parts strengthHigh strengthEngine cooling apparatusSupports/enclosures/casingsImpellerEngineering

An electric pump is provided according to the application, which includes a housing, a shaft, an impeller, a rotor assembly, a stator assembly and an inner chamber. The shaft, the impeller and a rotor are arranged in the inner chamber. The housing includes a first housing, a partition and a second housing, and the partition divides the inner chamber into a wet chamber and at least one dry chamber. The partition includes a first side wall, a first bottom, a second side wall and a second bottom. The second side wall isolates the rotor assembly and the stator assembly. An outer peripheral surface of the second side wall is provided with reinforcing ribs, and the reinforcing ribs improve the strength of the second side wall.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

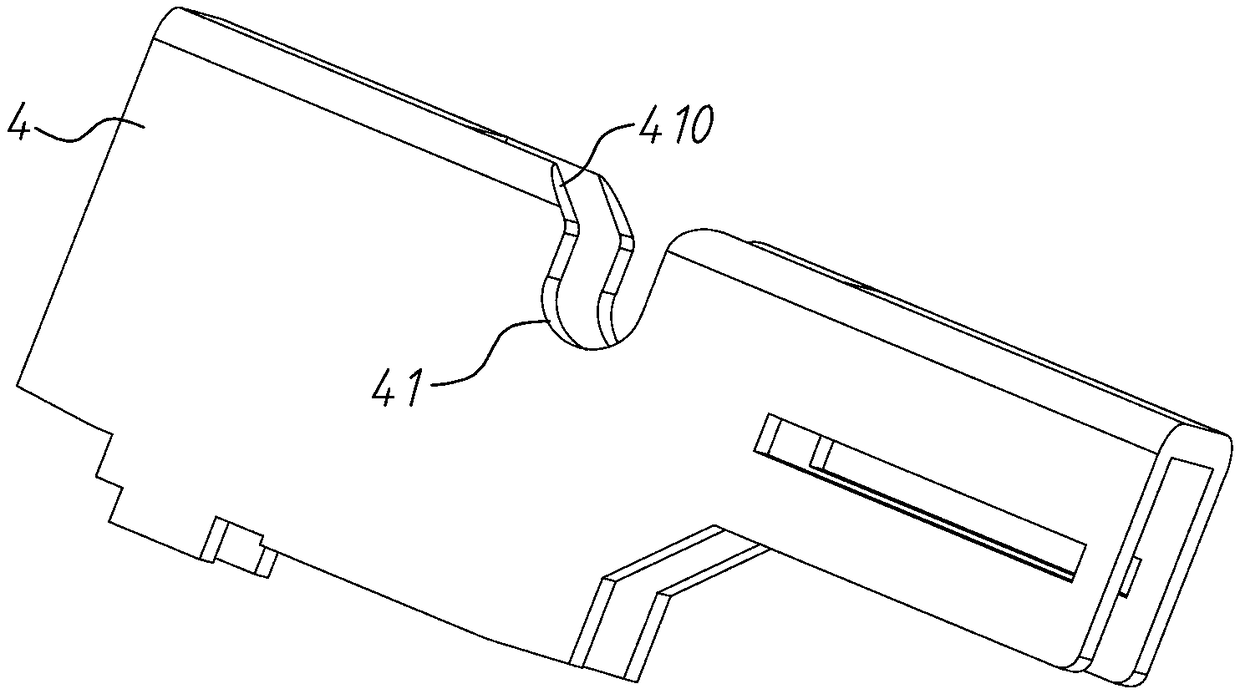

Two-way lock box structure and door/window using structure

PendingCN109025491AHigh parts strengthStrong stabilityBuilding locksEngineeringMechanical engineering

The invention provides a two-way lock box structure and a door / window using the structure. The technical key point of the two-way lock box structure is as follows: the two-way lock box structure comprises a bottom plate, two parallel panels mounted on the bottom plate, a rotating handle articulated with the panels, a driving part, a first driving bar linked with the driving part and capable of sliding along the bottom plate and a second driving bar capable of reversely driving with the driving part through a gear-rack component and sliding along the bottom plate, wherein the rotating handle comprises a shifting rod; the driving part is provided with a shifting groove driven to move horizontally by the shifting rod; a notch part capable of reversely stopping is formed in the top end of theshifting groove; the rotating handle also comprises a limiting part used for limiting upward swing of the shifting rod; when the shifting rod enters the notch part of the shifting groove, the shiftingrod is in an upward swing position; if the driving bars are reversely pushed, the shifting rod is continuously jacked upwards by the notch part; in addition, the limiting part is used for limiting the upward swing of the shifting rod, and the shifting rod is locked and cannot be pushed, so that the lock box structure has a function of preventing prying; the driving part can be punched and moldedby stainless steel; compared with the existing zinc alloy die-casting parts, the strength of the driving part is higher.

Owner:东莞市斯坦福五金有限公司

Frit for high pressure liquid chromatography

ActiveUS8999156B2High parts strengthIon-exchange process apparatusComponent separationFritFilling materials

A frit (44) includes a porous support structure having a plurality of void spaces, where a plurality of secondary particles (46) are filled in the void spaces, the secondary particles (46) being dimensioned with respect to the void spaces such that the frit (44) retains packing materials with diameters of less than about 2.5 microns. Preferably one or more frits (44) are received in a high pressure liquid chromatography (HPLC) chromatographic column, where the column includes fittings and filter assemblies for receiving frits (44) at its inlet and outlet. The frit (44) can be constructed from a porous support structure with void spaces or pores that are filled with secondary particles (46) smaller those used to manufacture the support. The particles (46) contained in the void spaces are large enough to be retained by the support, but small enough to create a finer network of interconnected channels within the support's void spaces that are capable of retaining sub-2.5 micrometer particles.

Owner:WATERS TECH CORP

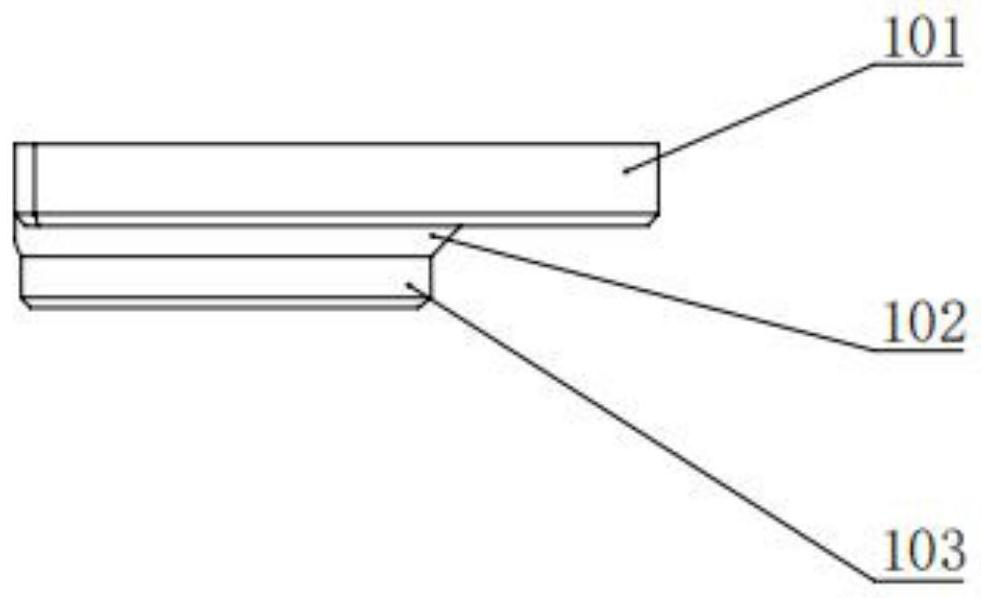

Type-C socket connector

InactiveCN104868287AHigh parts strengthReduce the risk of failureCoupling contact membersInformation transmissionUltimate tensile strength

The invention discloses a Type-C socket connector. The Type-C socket connector comprises a shell and plug-in assemblies, wherein the plug-in assemblies comprise an upper plug-in assembly and a lower plug-in assembly, the upper plug-in assembly comprises an upper insulating body and an upper row of conducting terminals which are integrally formed with the upper insulating body, and the lower plug-in assembly comprises a lower insulating body, metal shielding sheets and a lower row of conducting terminals which are integrally formed with the lower insulating body; notches for playing a clamping hook effect when being matched with a butting plug connector are formed in two sides of each metal shielding sheet; twelve grooves are formed in each insulating body, and at least four terminals are arranged on each row of conducting terminals; the metal shielding sheets are integrally formed with any two terminals in the lower row of conducting terminals, and the metal shielding sheets are raised downwards to form platy grounding parts. By adopting the Type-C socket connector, the assembling amount of components is reduced, the tolerance accumulation is reduced, the component strength of the lower plug-in assembly is effectively enhanced, and the amount of the conducting terminals is greatly reduced under the condition of guaranteeing electric quantity and stable information transmission.

Owner:ALL BEST ELECTRONICS TECH CO LTD

Rechargeable battery and battery module

ActiveUS8142921B2High parts strengthHigh strengthPrimary cell to battery groupingFinal product manufactureRechargeable cellEngineering

Owner:SAMSUNG SDI CO LTD

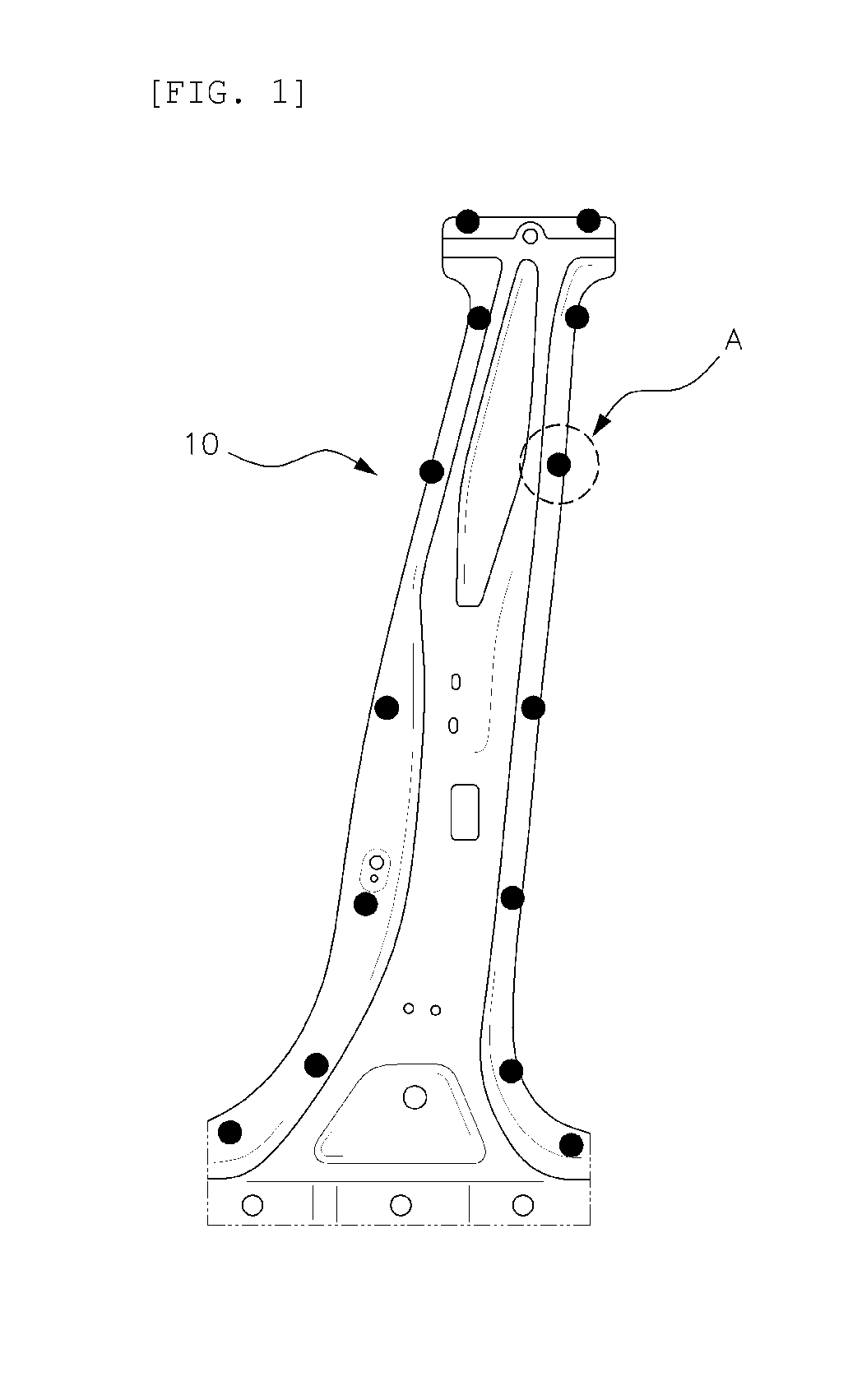

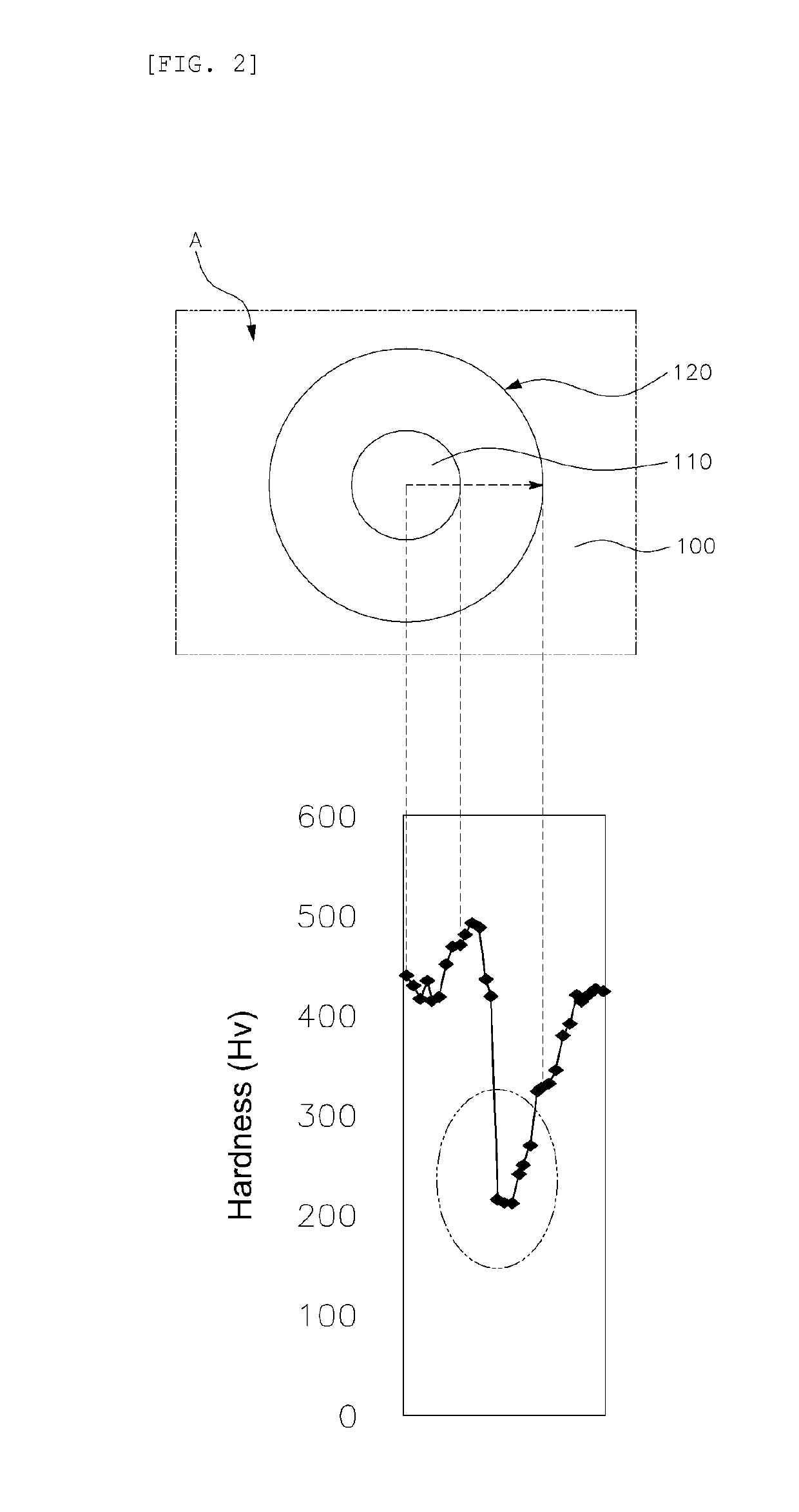

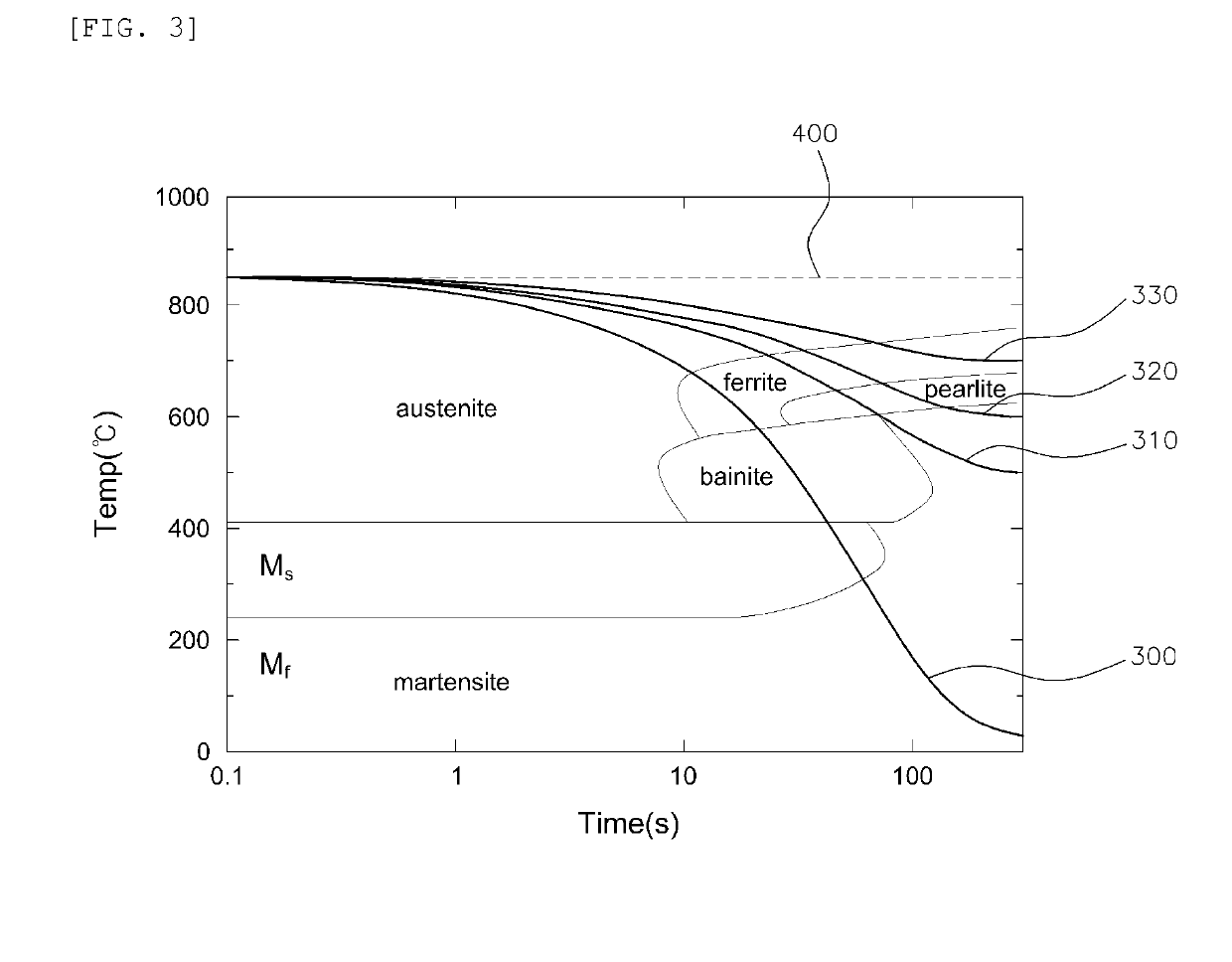

High frequency heat treatment method of ultra-high strength parts

InactiveUS10240219B2High parts strengthUltra-high strength partsIncreasing energy efficiencyQuenching devicesHot stampingPresent method

Disclosed is a high frequency heat treatment method of hot-stamping-treated ultra-high strength parts, which comprises: a first step of heating the parts until the temperature of a heat treatment zone thereof becomes the AC3 transformation point or higher; a second step of maintaining the temperature until phase transformation of the heat treatment zone to austenite is completed; and a third step of cooling the heat treatment zone to transform the structure thereof to ferrite-pearlite. The present method improves the energy absorbing efficiency by increasing the parts' elongation ratio by locally forming a softening structure which absorbs energy.

Owner:HYUNDAI MOTOR CO LTD

Fuel injection device

ActiveUS9038930B2Accurately shutIncrease surface pressureMachines/enginesFuel injecting pumpsPressure controlled ventilationPressure control

In a fuel injection device, a pressing surface of a pressing member presses an opening wall surface to interrupt communication between an inflow port and a pressure control chamber when communication between an outflow port and a return channel is made by a pressure control valve, and the pressing surface of the pressing member is displaced and separated from the opening wall surface to open the inflow port of the opening wall surface to the pressure control chamber when the communication between the outflow port and the return channel is interrupted by the pressure control valve. One of the pressing surface of the pressing member and the opening wall surface of the control body is provided with an inflow depressed portion and an outflow depressed portion partitioned from each other, and a depressed dimension of the inflow depressed portion is larger than a depressed dimension of the outflow depressed portion.

Owner:DENSO CORP

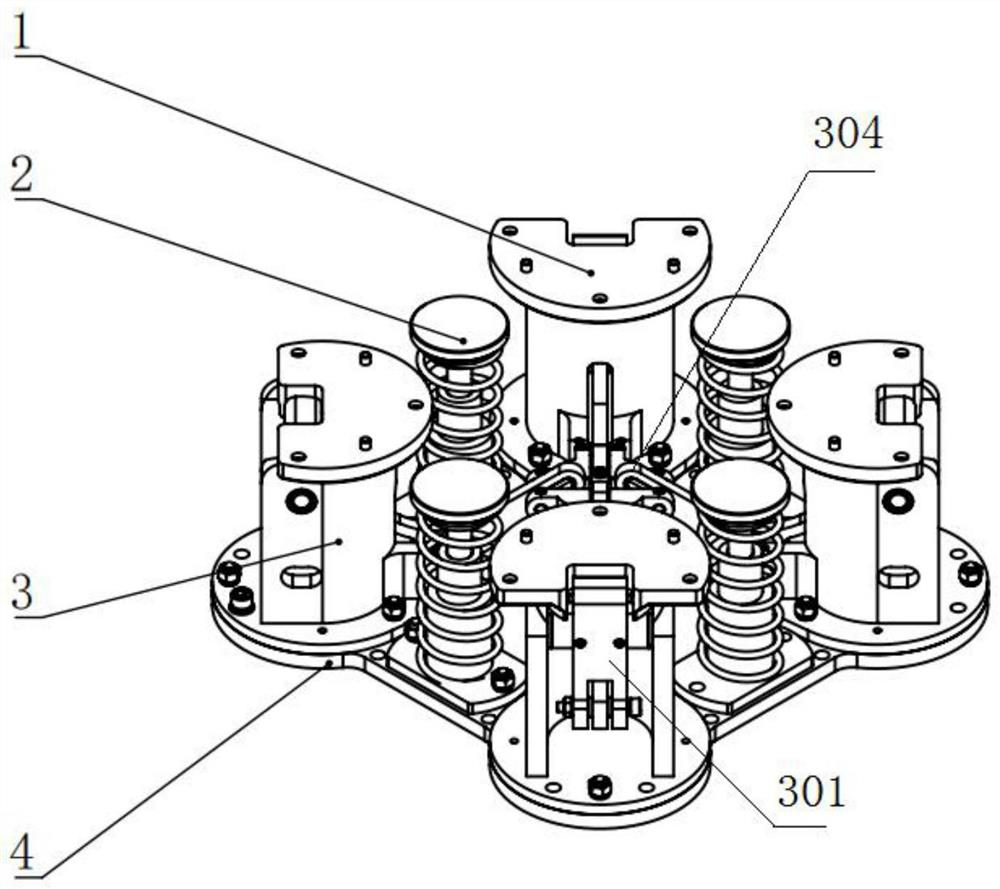

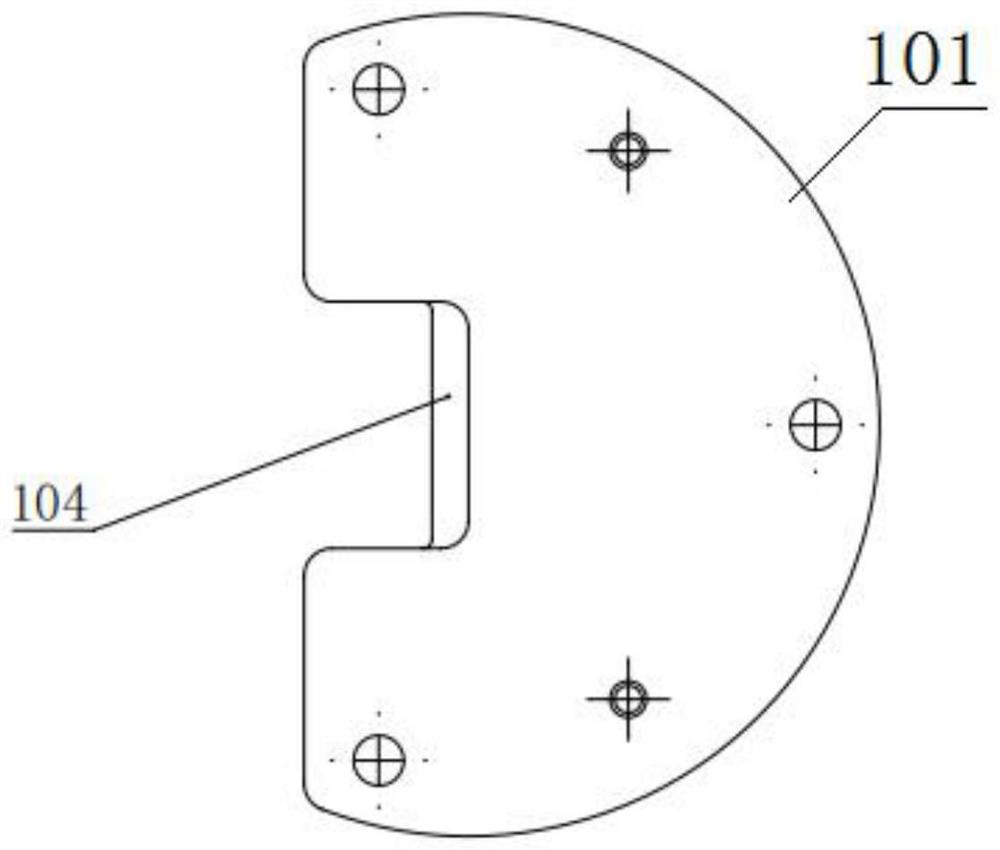

Non-initiating explosive device satellite and rocket separation unlocking device

PendingCN114353603AThe overall structure is simple and reliableLess prone to failureSelf-propelled projectilesAttitude controlStructural engineering

The invention provides a non-initiating explosive device satellite and rocket separation unlocking device. The device comprises a bottom plate, a thrust mechanism, an unlocking control mechanism, multiple sets of locking mechanisms and multiple satellite connecting plates. The bottom plate is fixedly connected with the rocket; the locking mechanism and the thrust mechanism are fixed to the end face, away from the rocket, of the bottom plate. The satellite connecting plates are arranged on the faces, away from the bottom plate, of the locking mechanisms, and each satellite connecting plate is connected with one locking mechanism in a locking mode. The end face, away from the locking mechanism, of the satellite connecting plate is fixed to the bottom of the satellite, and when the rocket is separated from the satellite, the satellite connecting plate moves along with the satellite. The unlocking control mechanism is fixed on the bottom plate and is connected with the locking mechanism; the end face, away from the bottom plate, of the thrust mechanism abuts against the bottom of the satellite. The thrust mechanism is used for providing thrust for separation of the satellite and the rocket. The structure is simple and reliable, the number of parts is small, the overall rigidity is high, vibration generated when the rocket flies is not amplified, and satellite separation attitude control is good.

Owner:北京中科宇航技术有限公司

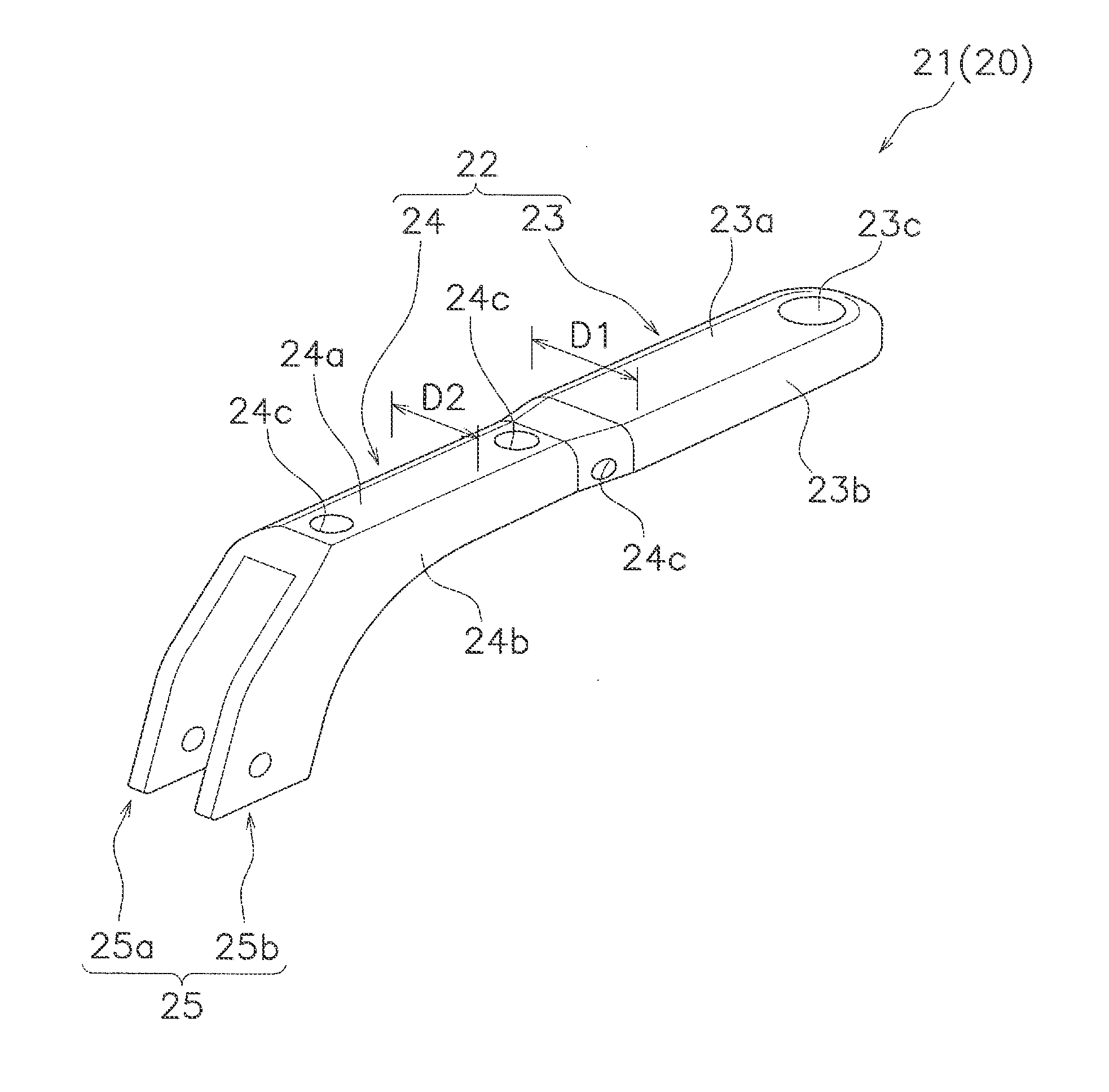

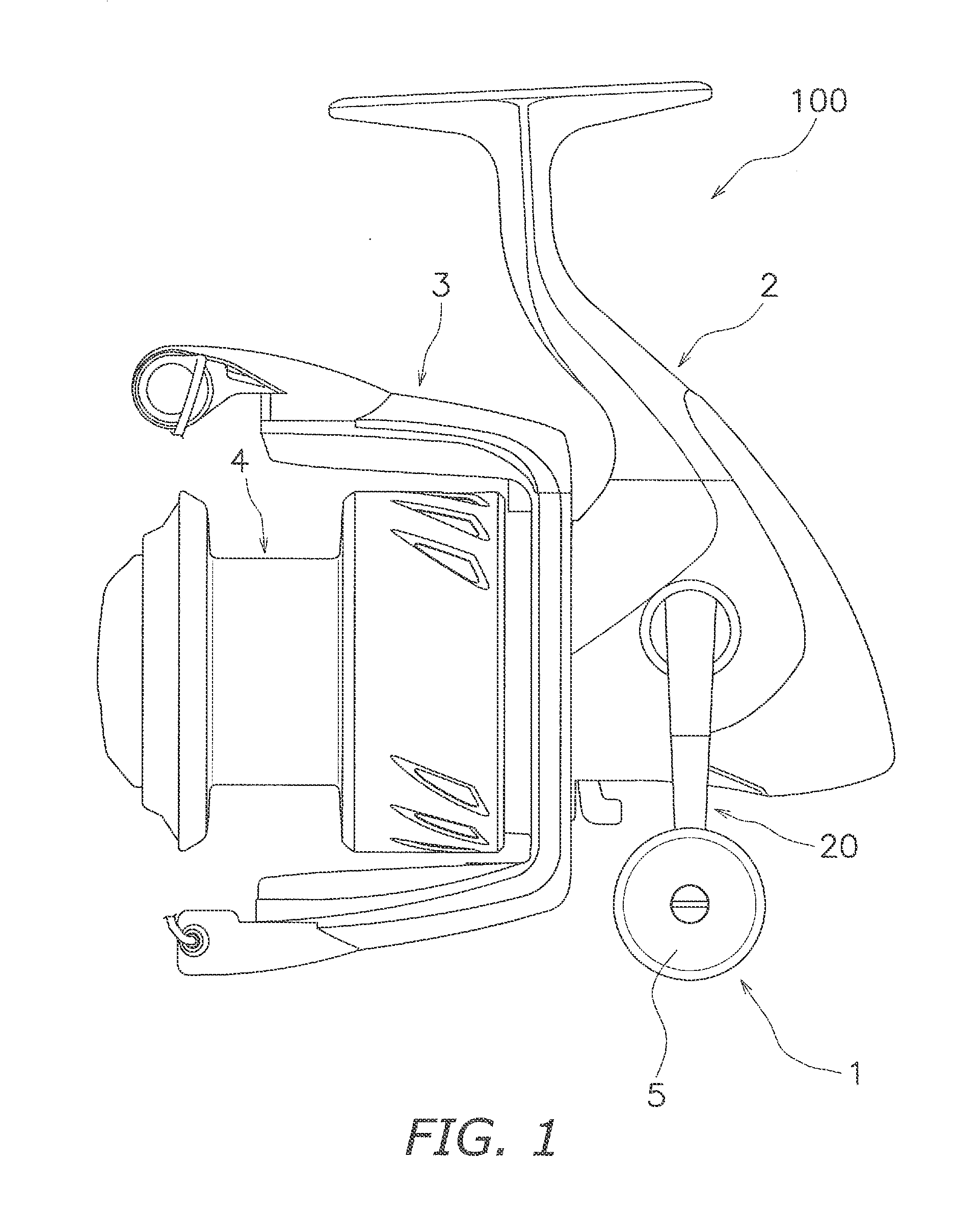

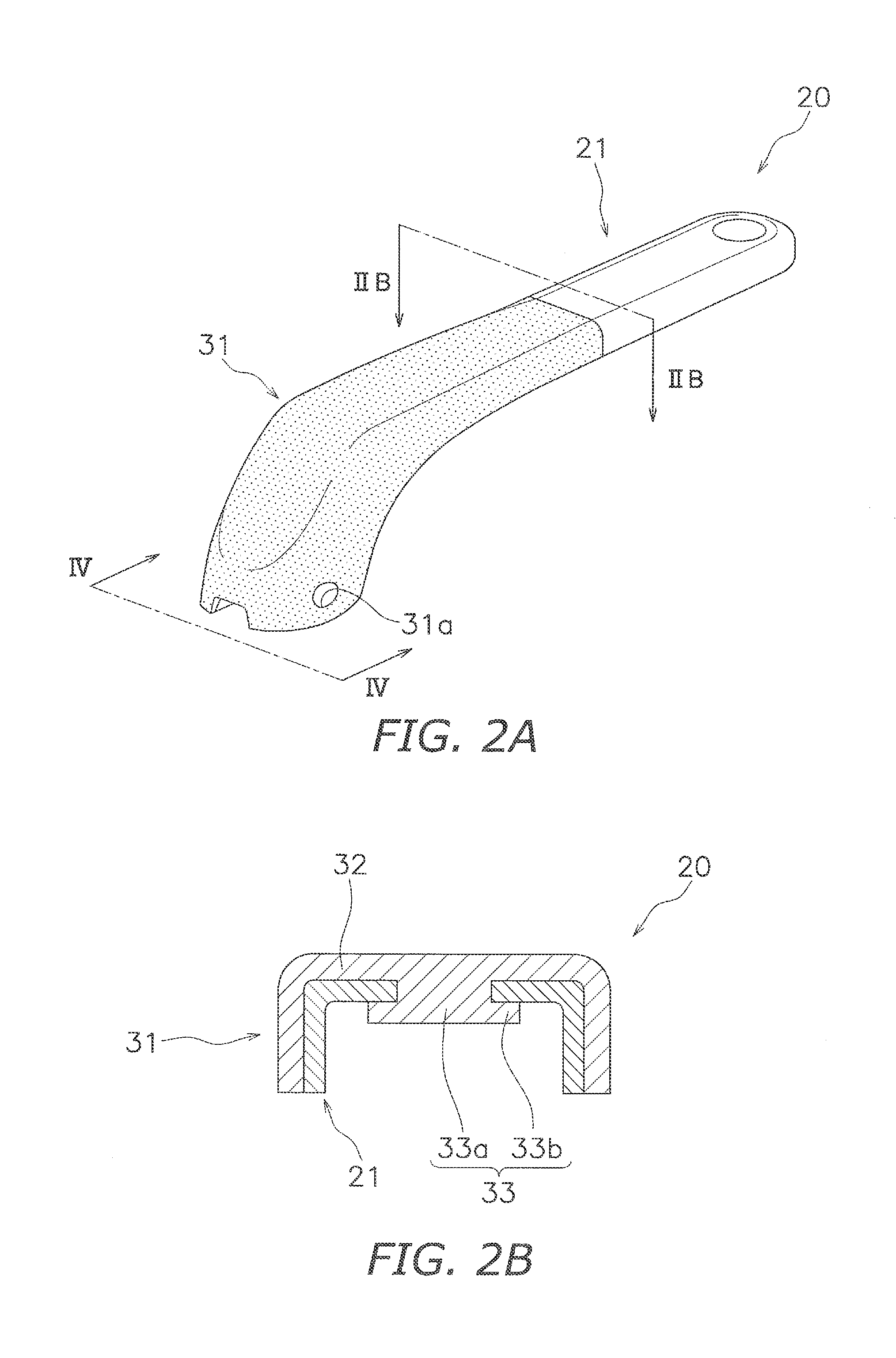

Handle assembly

ActiveUS20160088823A1Improve aestheticsHigh parts strengthControlling membersReelsEngineeringMechanical engineering

A present handle assembly is mounted to a handle shaft of a fishing reel. The handle assembly includes a handle arm and a handle knob. The handle arm is mounted to the handle shaft. The handle knob is mounted to the handle arm. The handle arm herein includes an arm body made of metal and a resin portion. The metallic arm body has a mount part and an arm part. The mount part is mounted to the handle shaft. The arm part is integrally formed with the mount part. The resin portion covers the mount part and at least a part of the arm part.

Owner:SHIMANO COMPONENTS MALAYSIA

Nanocomposite elastomers

ActiveUS10716877B2High parts strengthReduce intensityHemicellulose adhesivesMaterial nanotechnologyElastomerFiber

A composite material comprising an elastomer and nanocellulose. The nanocellulose may comprise a nanocellulose material derived from plants having C4 leaf anatomy, or a nanocellulose material derived from a plant material having a lesser amount of lignin than hemicellulose, or a nanocellulose having a hemicellulose content of from 25% to 55% by weight of the nanocellulose material, or a nanocellulose comprising nanofibrils having a diameter of up to 5 nm, or a nanocellulose comprising nanocellulose material of plant origin comprising nanocellulose particles or fibres having an aspect ratio of at least 250, or the composite material having a stiffness of not greater than 2.5 times the stiffness of the elastomer without the nanocellulose material being present, or the nanocellulose particles or fibres being derived from a plant material having a hemicellulose content of 30% or higher (w / w). The nanocellulose may be derived from arid Spinifex.

Owner:THE UNIV OF QUEENSLAND

Magnetic lock device and parking device

ActiveUS10385969B2Improve strength (hardness)Improve magnetic efficiencyBraking element arrangementsGearing controlDrive shaftEngineering

A magnetic lock device includes a lock shaft having an abutting portion capable of abutting against a roller of a piston rod of a hydraulic pressure actuator, a transfer shaft configured separately from the lock shaft, the transfer shaft abutting against an end surface of the lock shaft, and a magnetic portion locking (restricting movement to the right side in the drawing) the lock shaft, the transfer shaft, and a plunger by attracting the plunger toward an attracting portion using a magnetic force. The lock shaft is surface-hardened to have a higher hardness and the transfer shaft is made of non-magnetic material.

Owner:AISIN AW CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com