Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Guaranteed waterproof quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

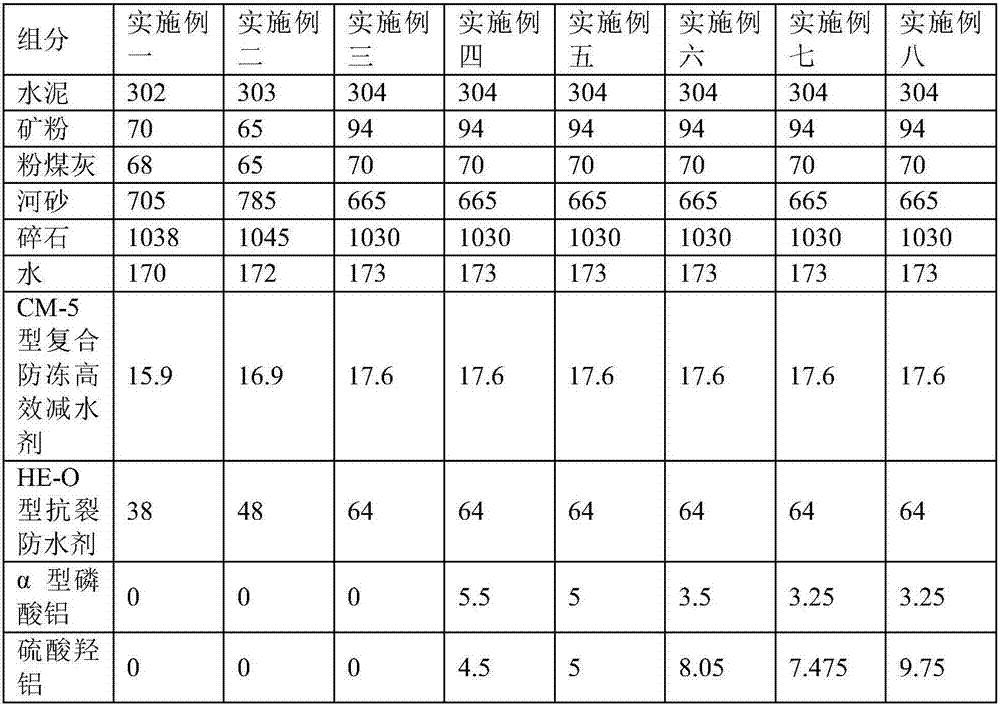

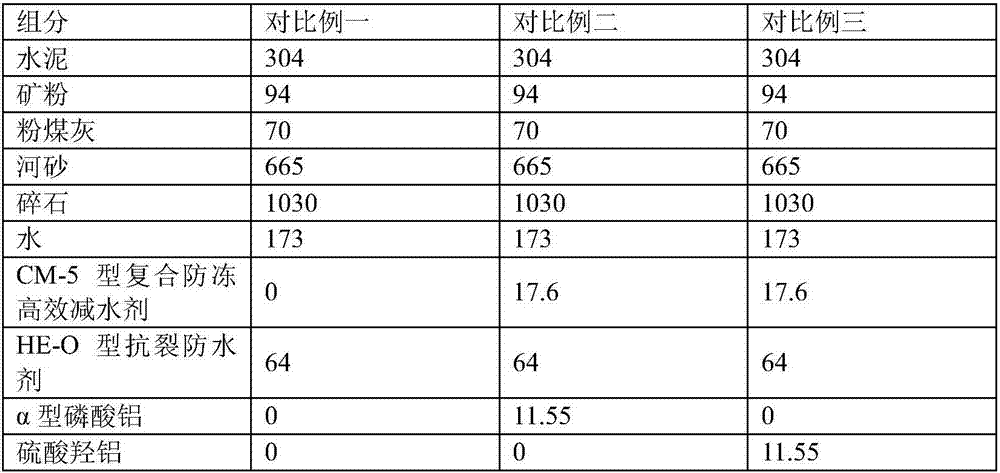

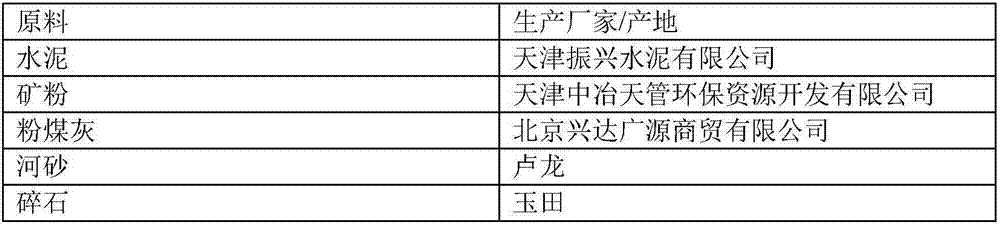

Concrete used for construction of super long concrete structure

The invention relates to concrete used for construction of a super long concrete structure. The concrete is characterized by being prepared from, by mass, 302-304 parts of cement, 65-94 parts of mineral powder, 65-70 parts of fly ash, 665-705 parts of river sand, 1030-1045 parts of broken stone, 15.9-17.6 parts of CM-5 type compound antifreeze high-efficiency water reducing agent, 38-64 parts of HE-O type anti-crack water proofing agent and 170-173 parts of water. Post-pouring joints are avoided from being left in the building construction process of the super long concrete structure, the construction progress is accelerated, the construction period is shortened, no structural cracks exist, the overall stability of the structure is improved, and the waterproof quality of a project can be ensured.

Owner:天津合嘉宏建混凝土有限公司

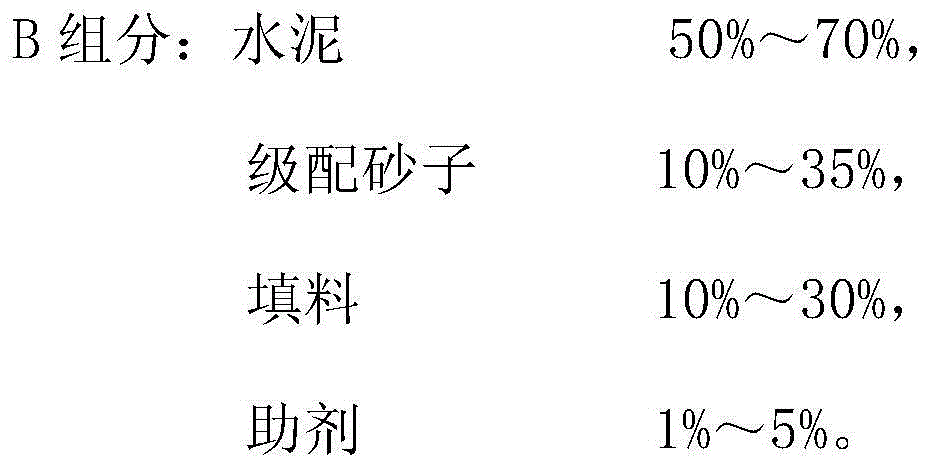

Wet base surface treating agent

Wet base surface treating agent comprises a component A and a component B, wherein the component A comprises the following raw materials in percentage by weight as follows: 50%-80% of emulsified asphalt, 10%-40% of modified emulsion and 1%-5% of an auxiliary; and the component B comprises the following raw materials in percentage by weight as follows: 50%-70% of cement, 10%-35% of graded sand, 10%-30% of filler and 1%-5% of an auxiliary. The wet base surface treating agent has the advantages of rapid drying, low cost, good waterproof performance, high sealing capacity and the like; experiments prove that the surface drying time of the wet base surface treating agent ranges from 13 min to 15 min; the wet basesurface primer is mainly applied to a building basement, a road or bridge surface and a wet tunnel base surface for basic layer processing, and can improve the adaptability of self-adhesive roll materials, SBS (styrene butadiene styrene) modified asphalt roll materials and high polymer roll materials to construction of the wet base surface.

Owner:XIANYANG DONGFANG YUHONG BUILDING MATERIAL CO LTD

Water proof comprehensive treatment construction method for construction roof

InactiveCN101392601AImprove waterproof performanceSimple processBuilding repairsSlurryFilm-coated tablet

The invention provides a construction method for waterproof comprehensive treatment on building roofing, which relates to the technical field of constructional engineering, in particular to the technical field of roofing waterproof system. The construction method comprises the following steps: cleaning leaking and penetrating parts; densifying the leaking and penetrating parts by a chemical slurry injecting method; densifying the clearance on the other surface of a structural layer by the chemical slurry injecting method after leak stoppage materials are completely solidified; brushing concave parts of the structural layer to be level by structural mortar; and brushing polyurethane film coating or spreading SBS coiled materials after the structural layer is dried. The construction method combines the self structural waterproof action and the waterproof action outside the structure for treatment, thereby achieving better waterproof effect. In addition, the construction method has the advantages of having simple working procedures, convenient construction and material fetching, bringing convenience to application, greatly reducing the probability of reworking and later maintenance, and reducing unnecessary loss and time waste.

Owner:JIANGSU XINGSHA CONSTR ENG GRP

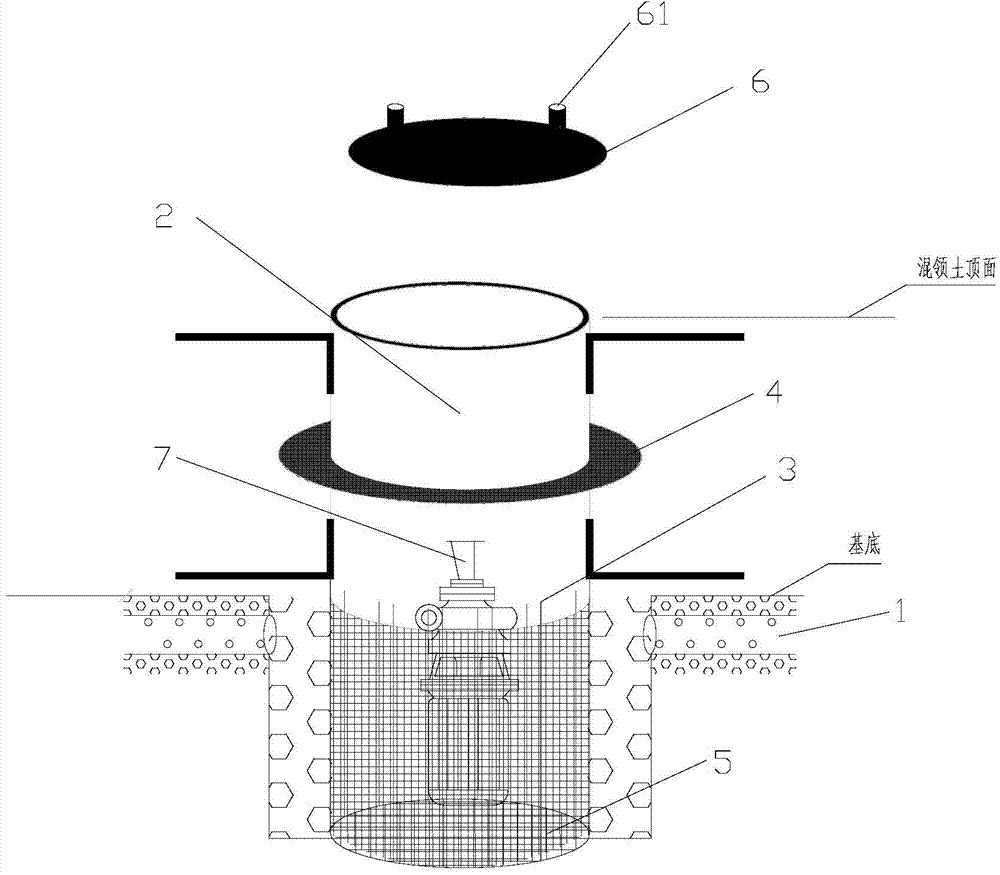

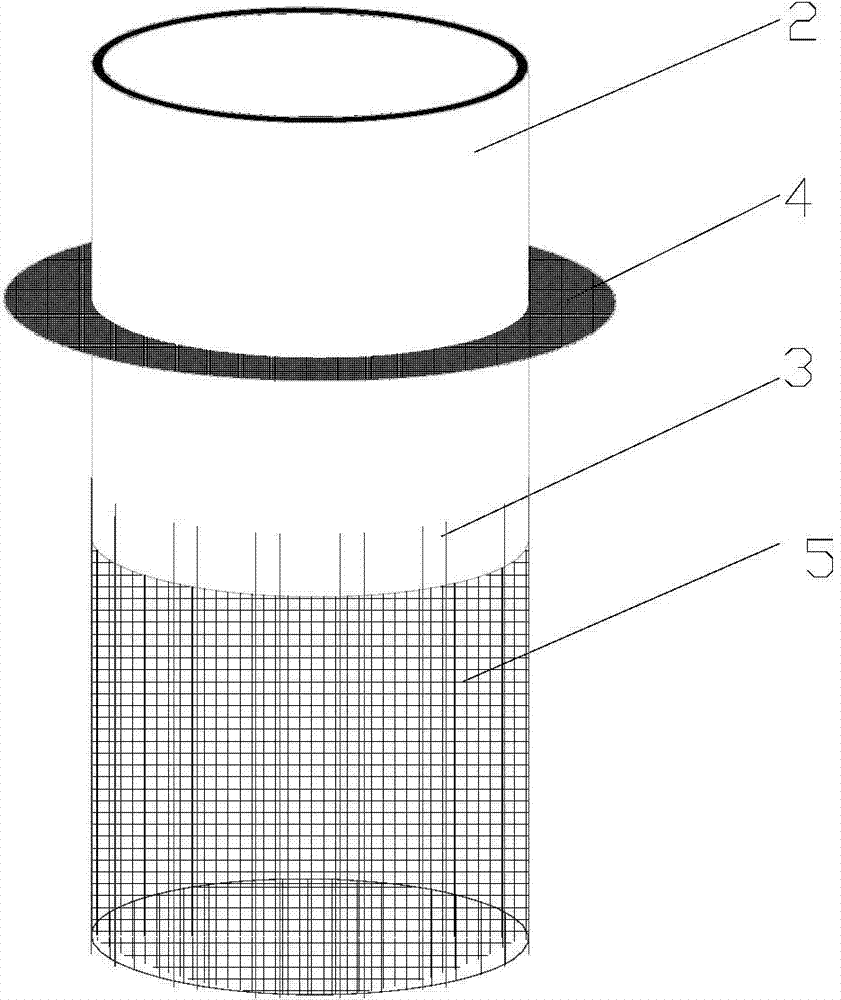

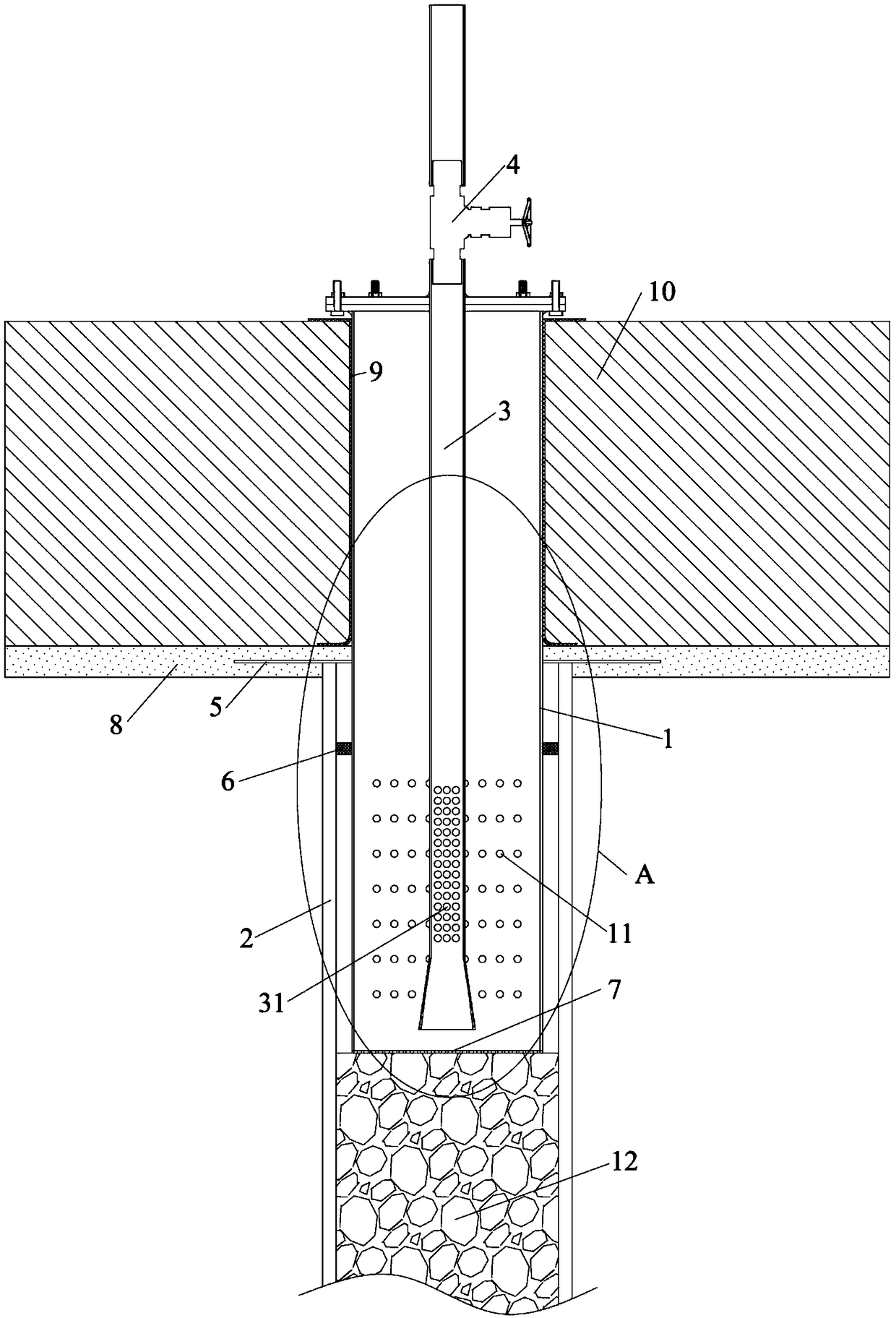

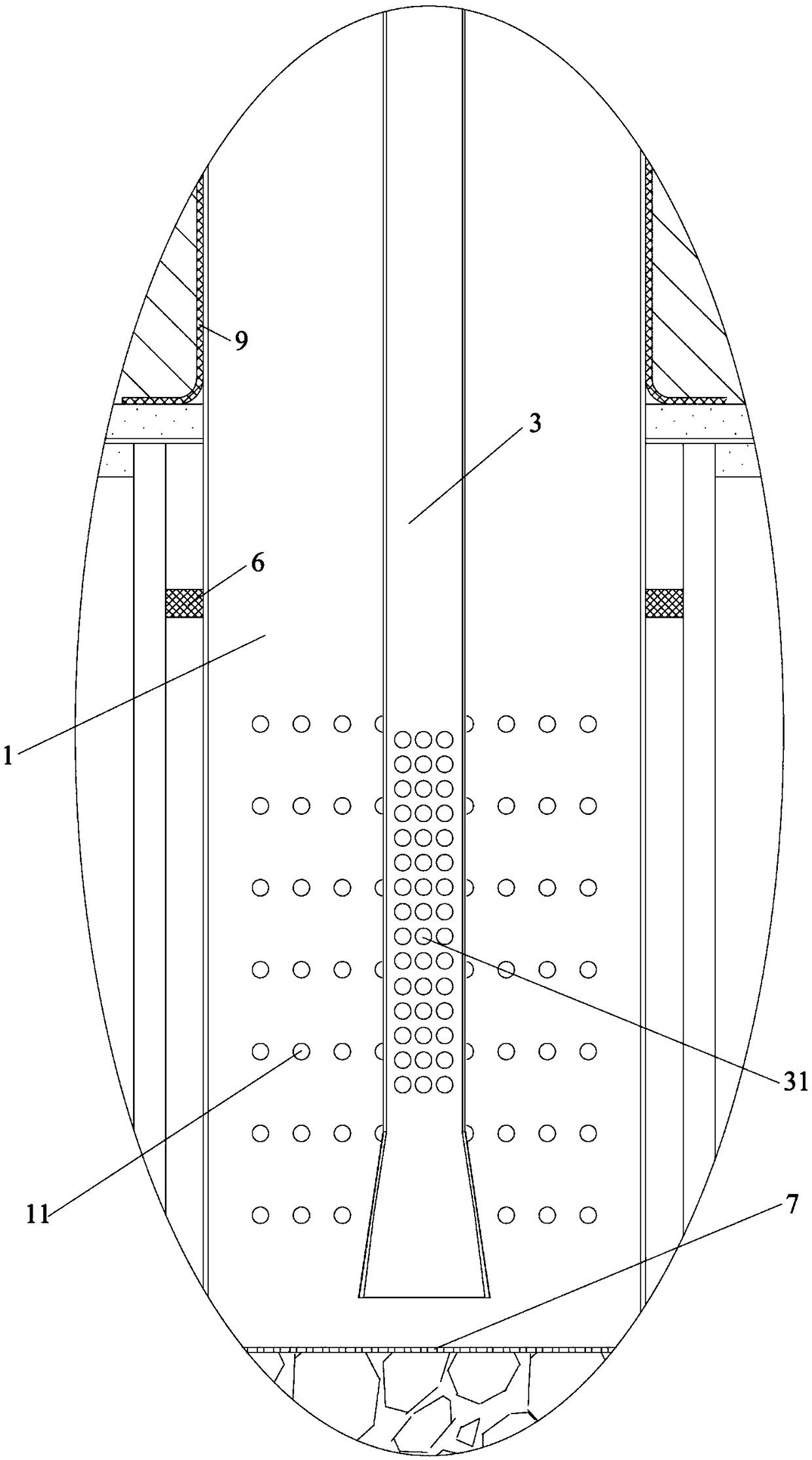

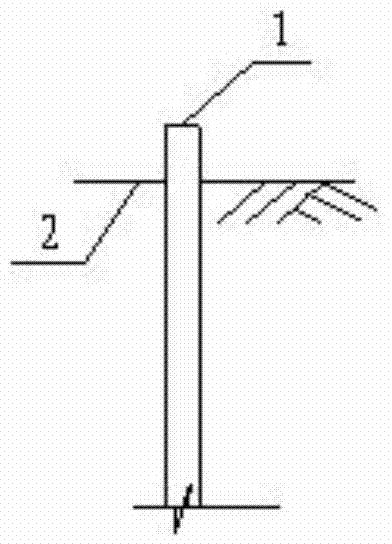

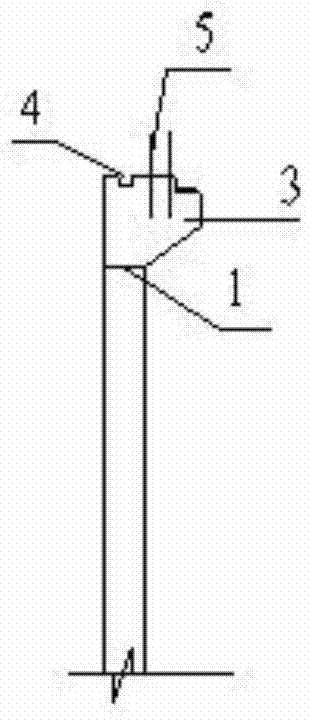

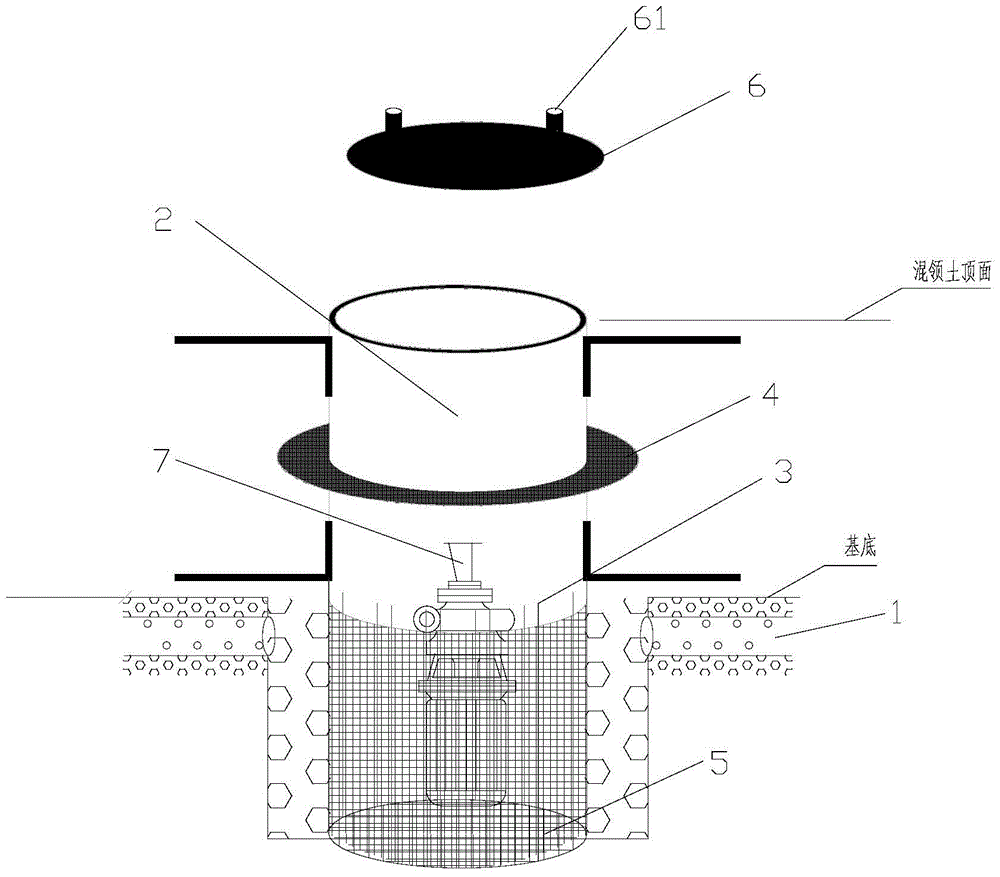

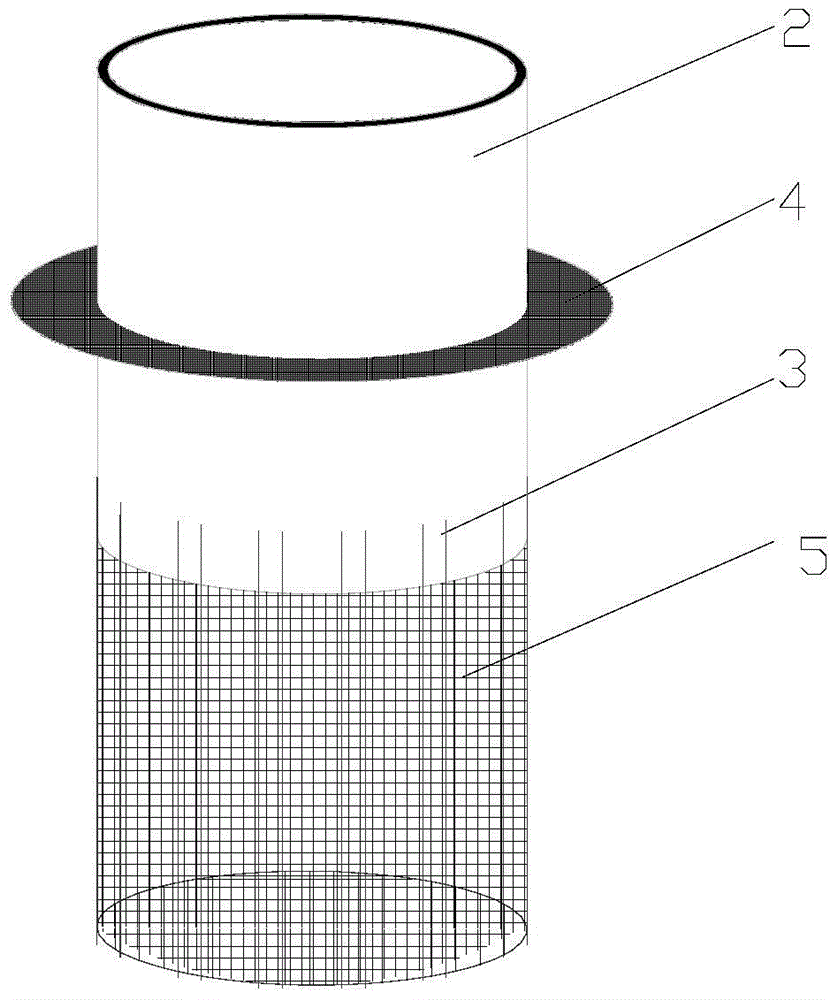

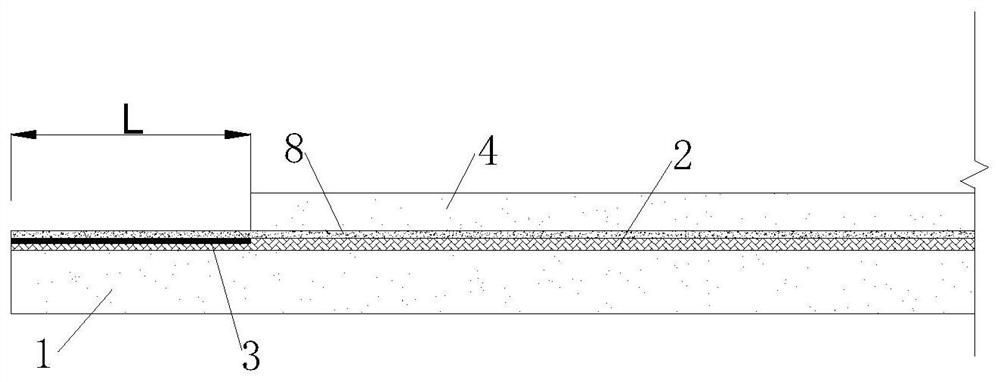

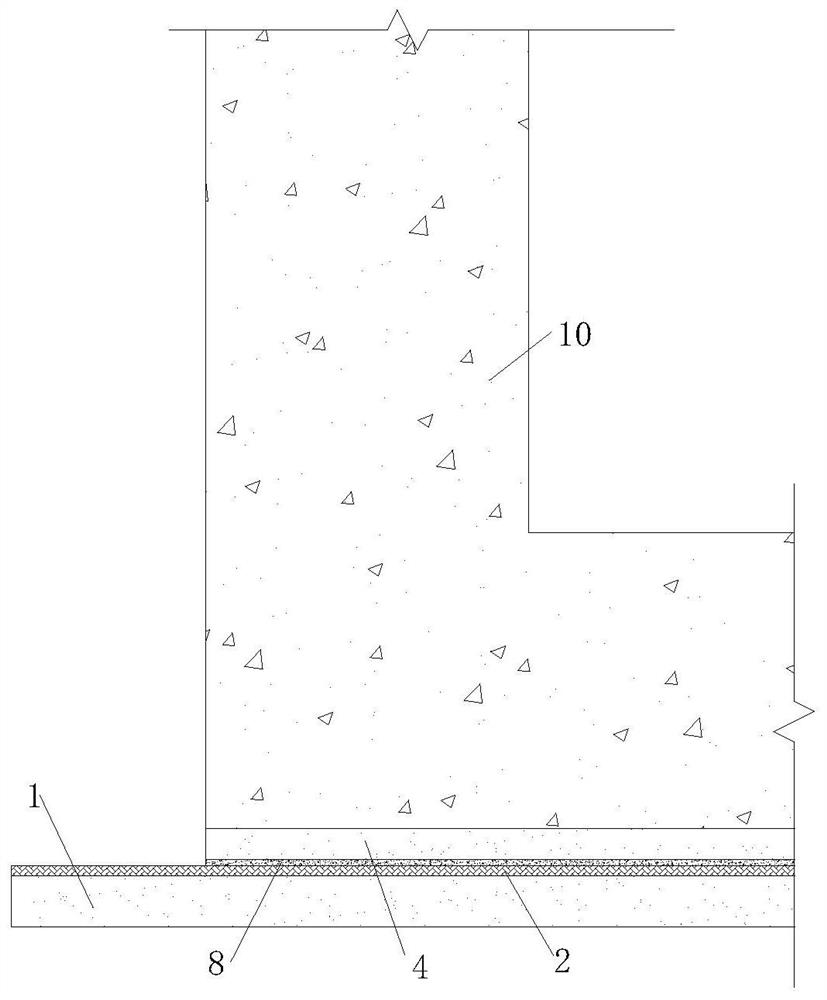

Water supply and drainage device for deep foundation pit and construction method based on water supply and drainage device

ActiveCN104846836AEffective isolationExtend your lifeFoundation engineeringEngineeringDrainage tubes

The invention discloses a water supply and drainage device for a deep foundation pit and a construction method based on the water supply and drainage device. The water supply and drainage device comprises a water collecting sleeve and a water suction pump, wherein the water suction pump is placed in the water collecting sleeve; the water collecting sleeve comprises a steel sleeve and a reinforcing bar grid; the reinforcing bar grid is arranged at the lower end of the steel sleeve and is integrally connected with the steel sleeve in a welded manner; the steel sleeve at the upper end of the water collecting sleeve is positioned in structural concrete; the reinforcing bar grid on the lower portion of the water collecting sleeve is positioned in a base below a structural bottom plate; and a plurality of drainage tubes are arranged on the periphery of the base. Compared with the prior art, the water supply and drainage device for the deep foundation pit and the construction method based on the water supply and drainage device have the advantages that a structural reserved hole is omitted, the structural waterproofing and the construction quality are greatly improved, the construction period is shortened, and the cost is reduced.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

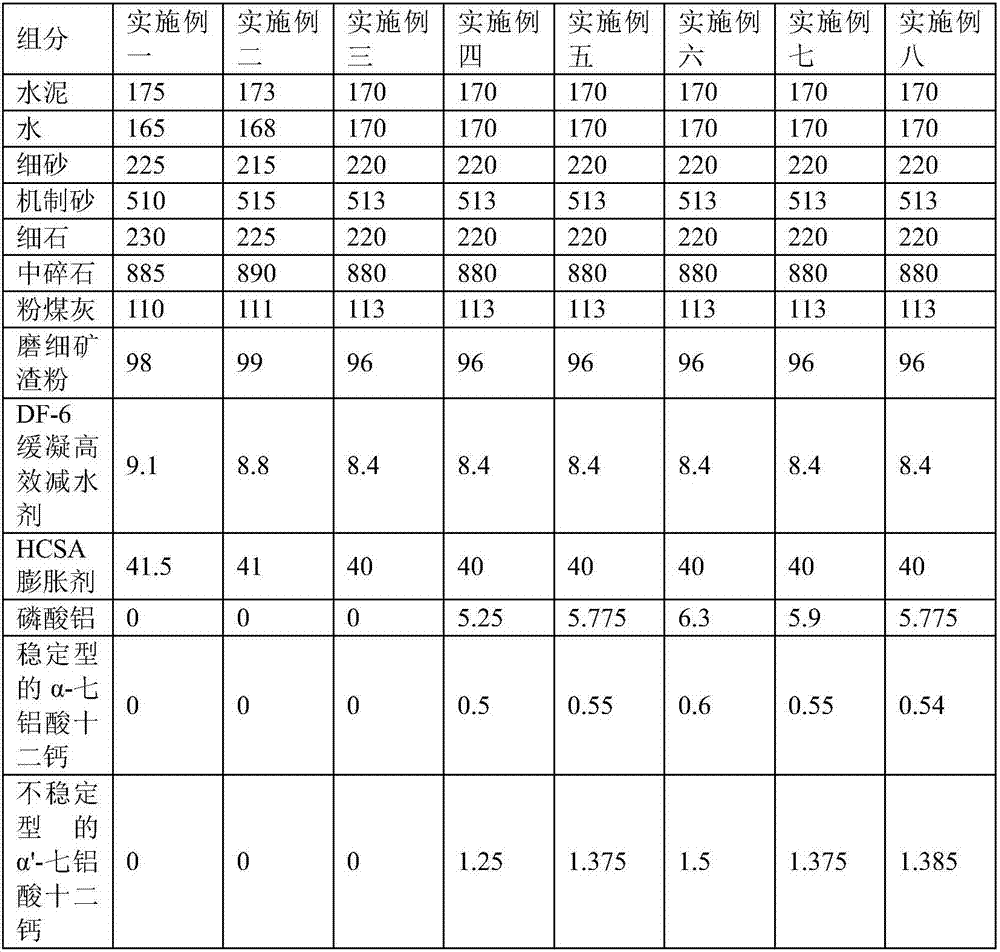

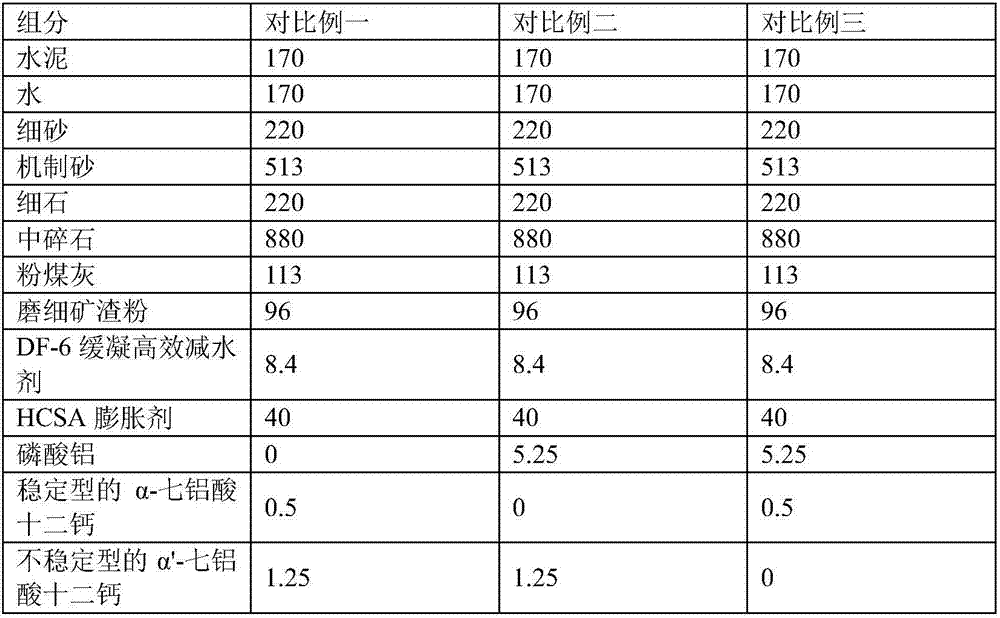

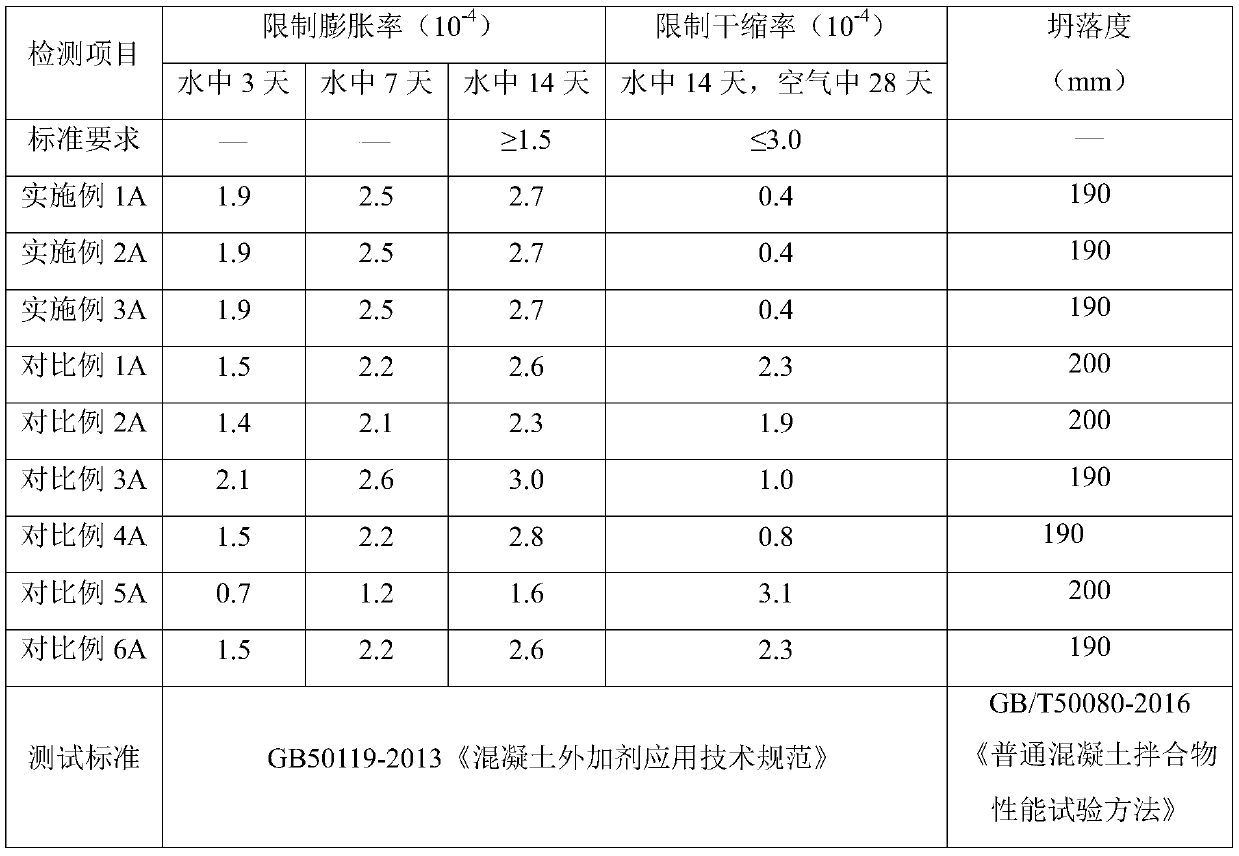

Expansive concrete for construction of super long concrete structure

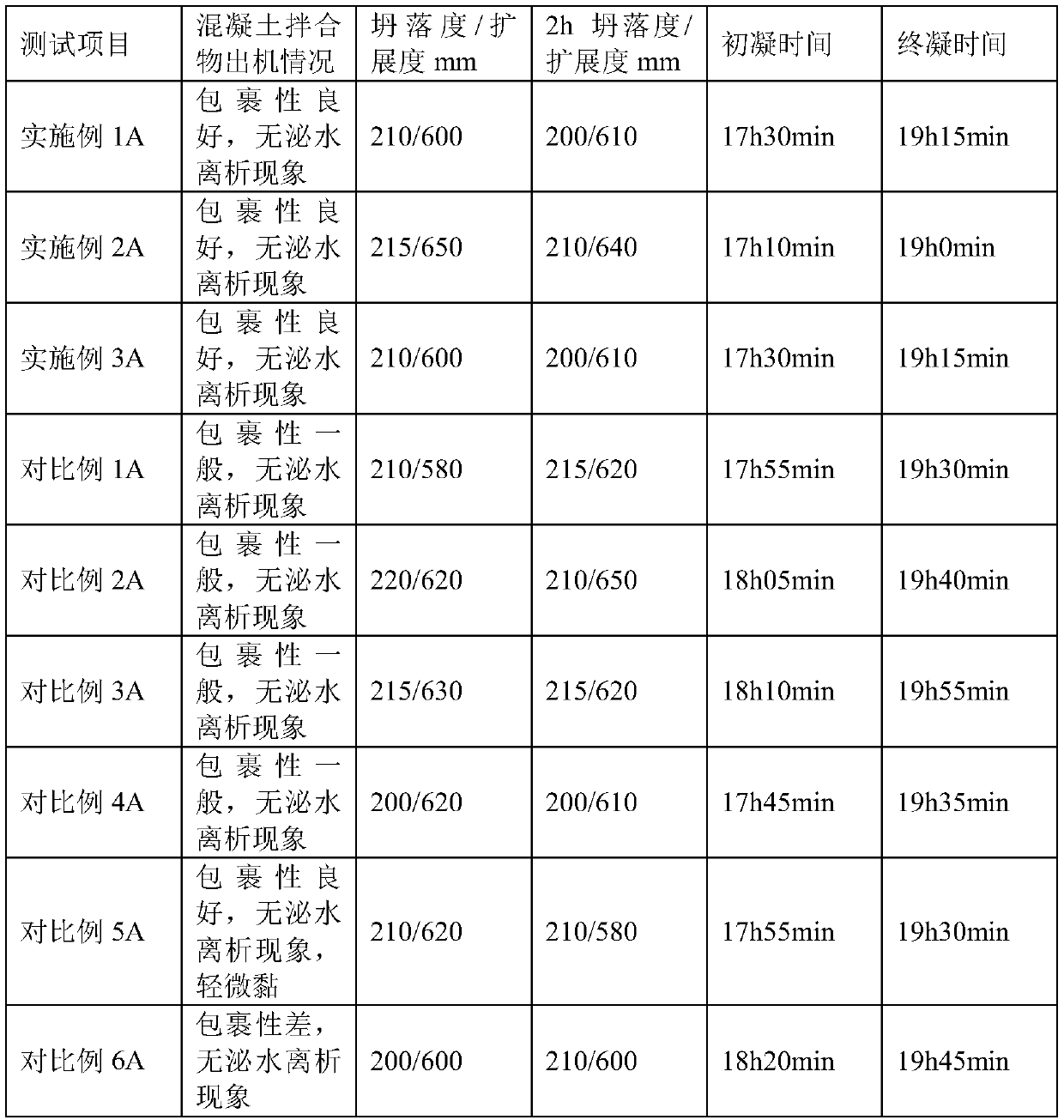

The invention relates to an expansive concrete for the construction of a super long concrete structure. The expansive concrete comprises, by mass, 170-175 parts of cement, 165-170 parts of water, 215-225 parts of fine sands, 510-515 parts of machine-made sand, 220-230 parts of fine stones, 880-890 parts of medium stones, 110-113 parts of fly ash, 96-99 parts of ground slag powder, 8.4-9.1 parts of a DF-6 set retarding superplasticizer and 40-41 parts of an HCSA expanding agent. The expansive concrete has the advantages of avoiding of reservation of late poured bands in the construction process of the super long concrete structure, acceleration of the construction schedule, shortening of the construction period, and realization of the improvement the overall stability of the structure and guaranteeing of the waterproof quality of the engineering due to no structural cracks.

Owner:天津合嘉宏建混凝土有限公司

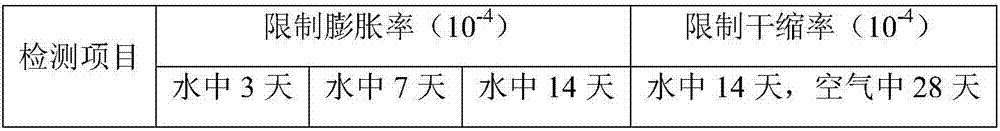

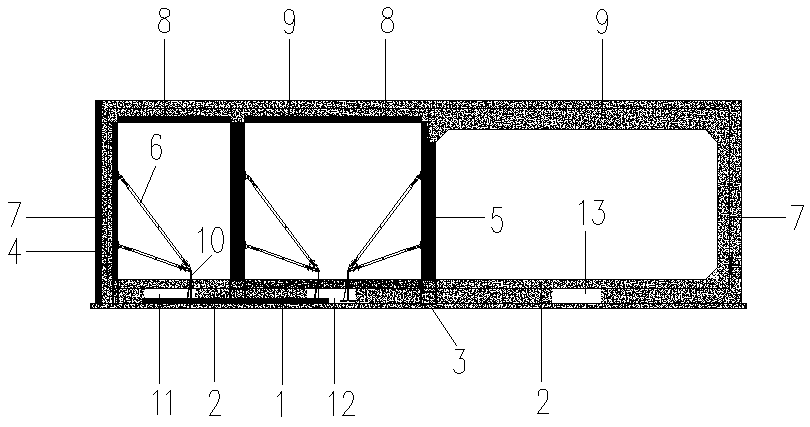

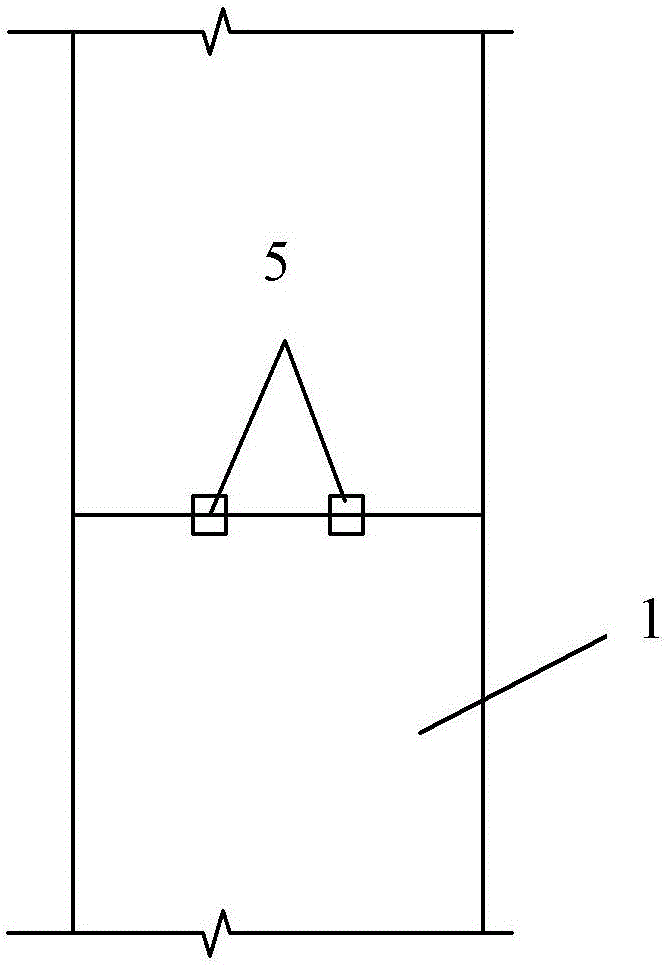

Multi-structure combined assembly pipe gallery with superposed member and construction method thereof

PendingCN110409492AEnsure safetyGuaranteed durabilityArtificial islandsUnderwater structuresEngineeringSolid core

The invention belongs to the field of underground comprehensive pipe gallery engineering, and in particular relates to a multi-structure combined assembly pipe gallery with a superposed member and a construction method thereof. The assembled pipe gallery comprises solid core prefabricated inner walls arranged on cast-in-place floors, the solid core prefabricated inner walls are arranged at the twosides of the middles of the cast-in-place floors, the sides of the solid prefabricated inner walls are provided with diagonal braces, a prefabricated reinforced truss superposed roof is installed between the tops of the solid prefabricated inner walls at the two sides, the upper side of the prefabricated reinforced truss superposed roof is a cast-in-place roof; the cast-in-place pipe gallery comprises cast-in-place outer walls arranged at one sides of the cast-in-place floors, cast-in-place structure roofs are arranged between the cast-in-place outer walls and the solid prefabricated outer walls; a semi-assembled pipe gallery comprises cast-in-place outer walls arranged at the other sides of the cast-in-place floors, double-sided prefabricated sandwich outer wall plates are arranged outside the cast-in-place outer walls; the double-sided prefabricated sandwich outer wall plates are provided with diagonal braces, and prefabricated reinforced truss superposed roofs are installed between the double-sided prefabricated sandwich outer wall plates and the solid prefabricated inner walls.

Owner:CONSTR & INSTALLATION ENG THE THIRD ENG GROUP OF CHINA RAILWAY +1

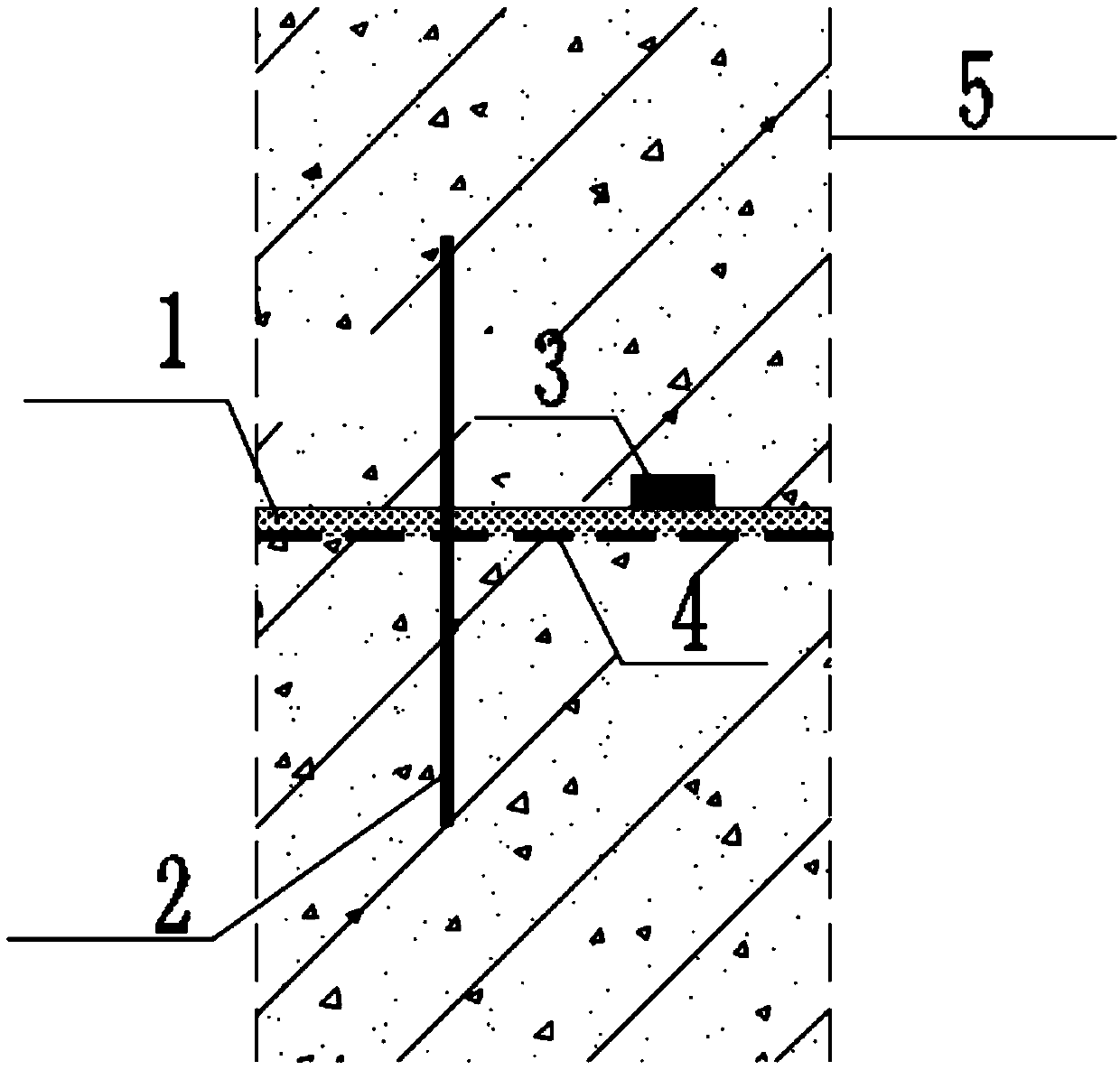

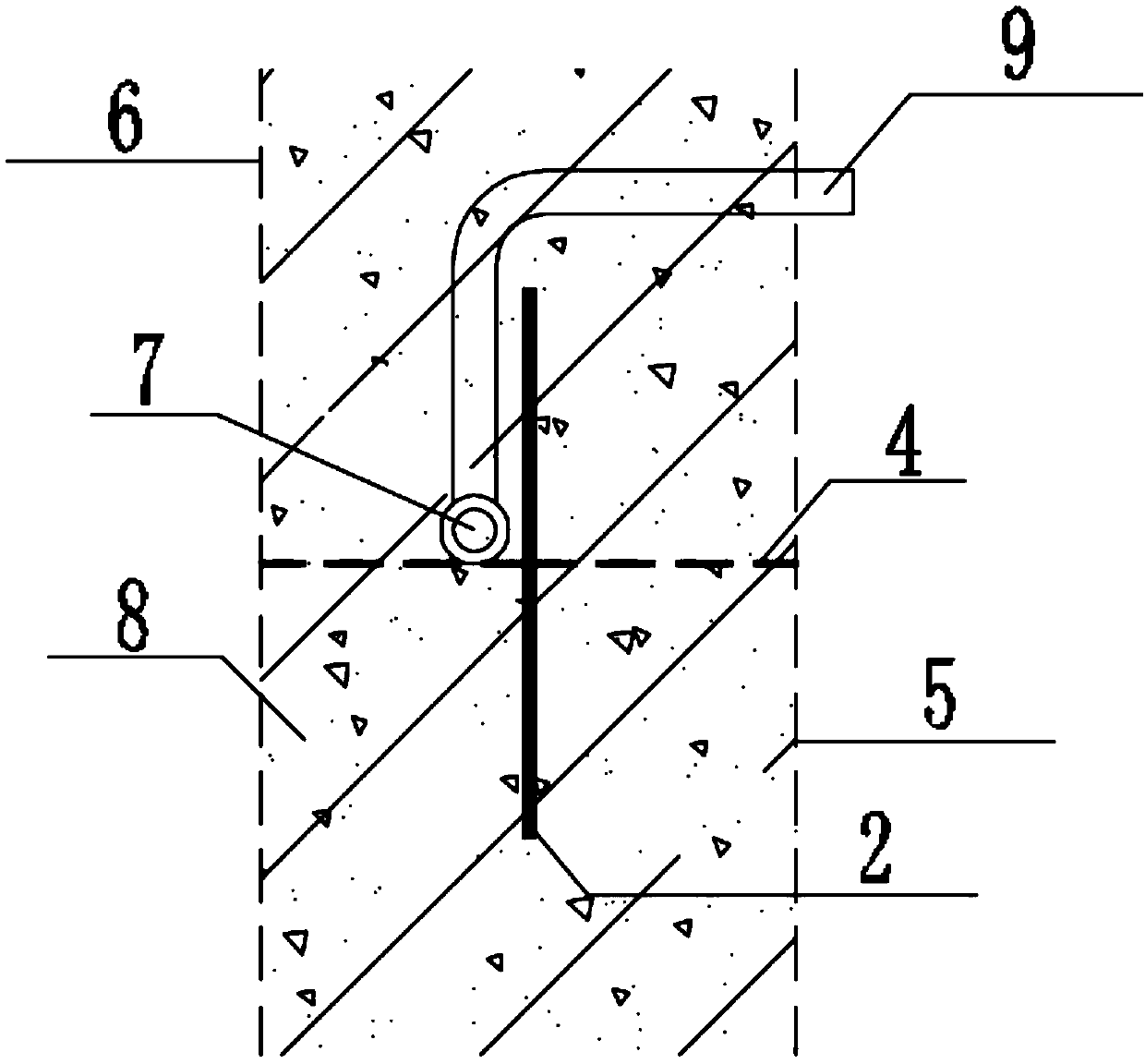

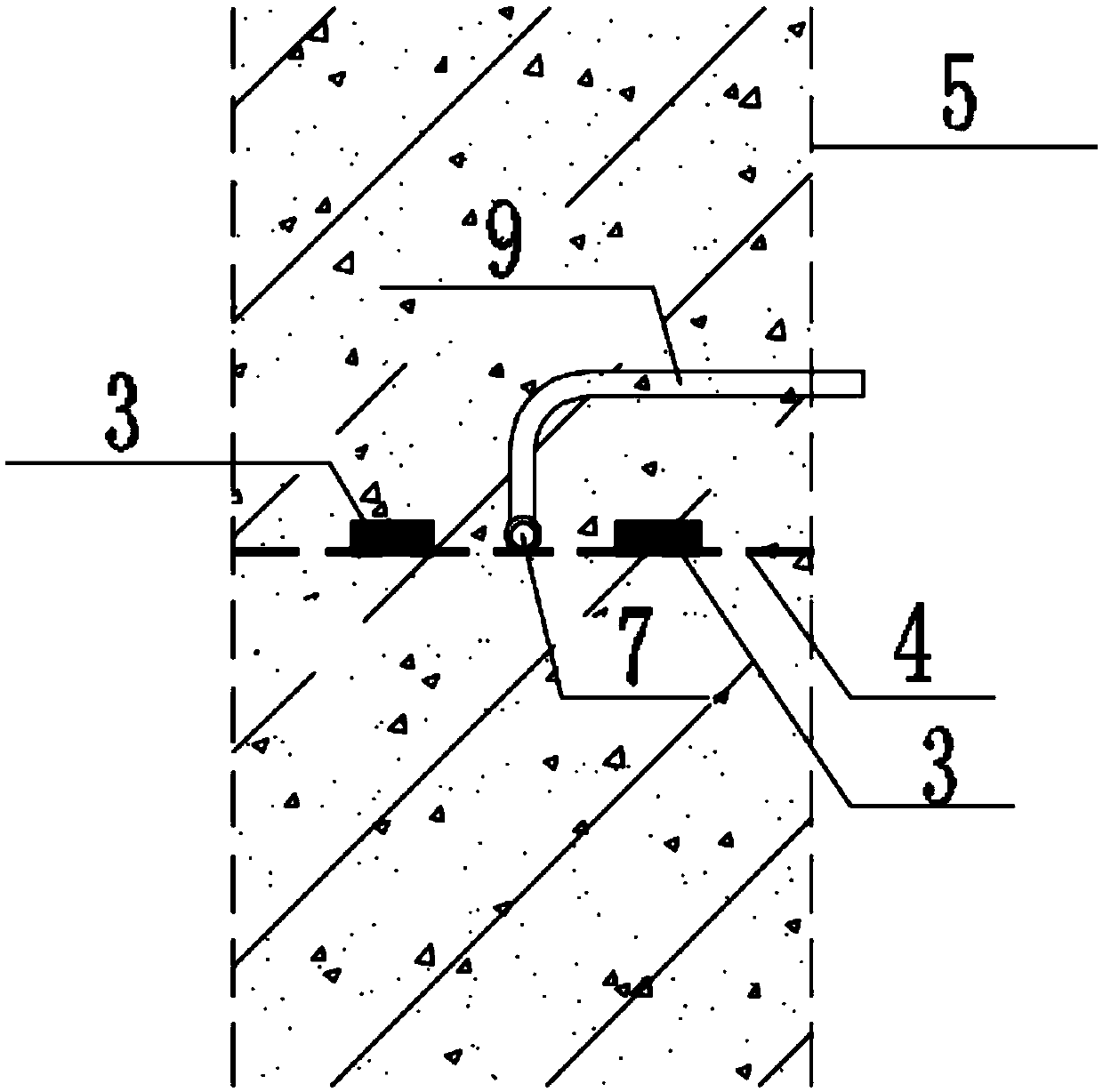

Waterproof method for precast concrete external wall hanging plate

InactiveCN107905388AImprove waterproof performanceGuaranteed waterproof qualityBuilding constructionsDraining tubeWater vapor

The invention discloses a waterproof method for a precast concrete external wall hanging plate. The waterproof method comprises the steps that a transverse drainage trough is formed in an upper opening of the precast concrete external wall hanging plate, and a vertical water releasing trough is formed in the vertical spliced seam of the precast concrete external wall hanging plate; a drainage pipeis arranged at a bottom concrete base, and rainwater invading the interior of the precast concrete external wall hanging plate is exhausted through the transverse drainage trough, the vertical waterreleasing trough and the drainage pipe; and a transverse vapour exhausting trough is formed in an lower opening of the precast concrete external wall hanging plate, a vapour exhausting pipe is arranged in a cast-in-place top pressing part at the top of the precast concrete external wall hanging plate, and water vapour remaining in a concrete external wall hanging plate system is exhausted throughthe transverse vapour exhausting trough, the vertical water releasing trough and the vapour exhausting pipe. By means of the waterproof method for the precast concrete external wall hanging plate, therainwater and the water vapor which invade the precast concrete external wall hanging plate can be exhausted downwards smoothly and permeated upwards smoothly, the purpose that the rainwater and thewater vapor which are permeated into the external wall hanging plate are exhausted is achieved, the waterproof effect of precast concrete external wall hanging plate is improved, and the method is especially suitable for the precast concrete exterior wall hanging plate in rainy and typhoon areas of the south of the Yangtze River in our country

Owner:GUANGSHA CONSTR GROUP

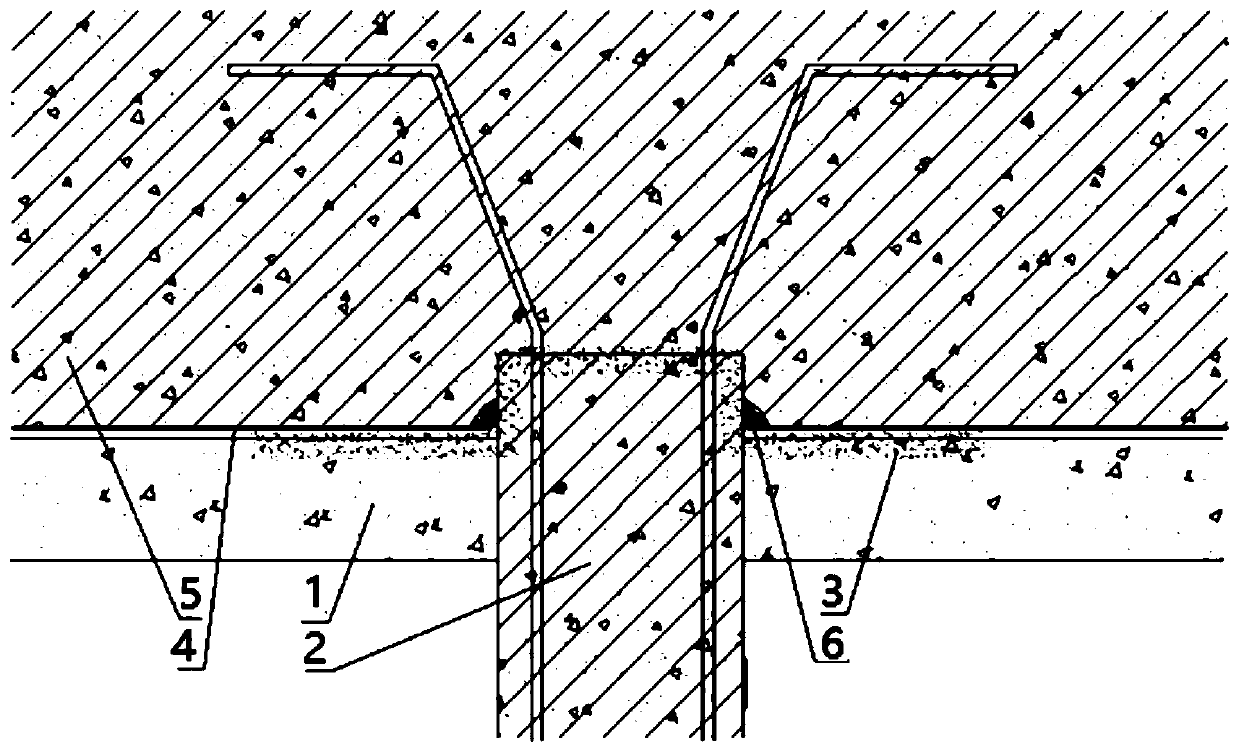

Waterproof method for construction joints of underground excavation section of open-cut station

InactiveCN109555162ASimple structureSimplify construction stepsArtificial islandsUnderwater structuresArchitectural engineeringCrystalline materials

The invention discloses a waterproof method for construction joints of an underground excavation section of an open-cut station. The waterproof method comprises the steps that the concrete construction joints of section pouring are divided into longitudinal construction joints and circumferential construction joints, and the two types of construction joints both adopt a rubber water-stop belt method and pre-embedded grouting pipes method to strengthen the waterproof treatment; when first-level fortification is required, the circumferential construction joints all adopt medium-embedded steel-edge rubber water-stop belts, and the joint surfaces are coated with cement-based permeable crystalline materials for waterproof treatment; the horizontal and longitudinal construction joints all adoptthe steel-edge rubber water-stop belts and water-swelling water-stop glue for waterproof treatment; construction joints at connecting openings with an auxiliary structure adopt double-channel water-swelling water-stop glue and the pre-embedded grouting pipes for waterproof treatment; when second-level fortification is required, the circumferential construction joints adopt the steel edge rubber water-stop belts for waterproof treatment; the horizontal and longitudinal construction joints all adopt the steel-edge rubber water-stop belts and the water-swelling water-stop glue for waterproof treatment; and station floor construction joints adopt the water-swelling water-stop glue or bentonite expansion water-stop strips for waterproof treatment.

Owner:BEIJING MUNICIPAL CONSTR

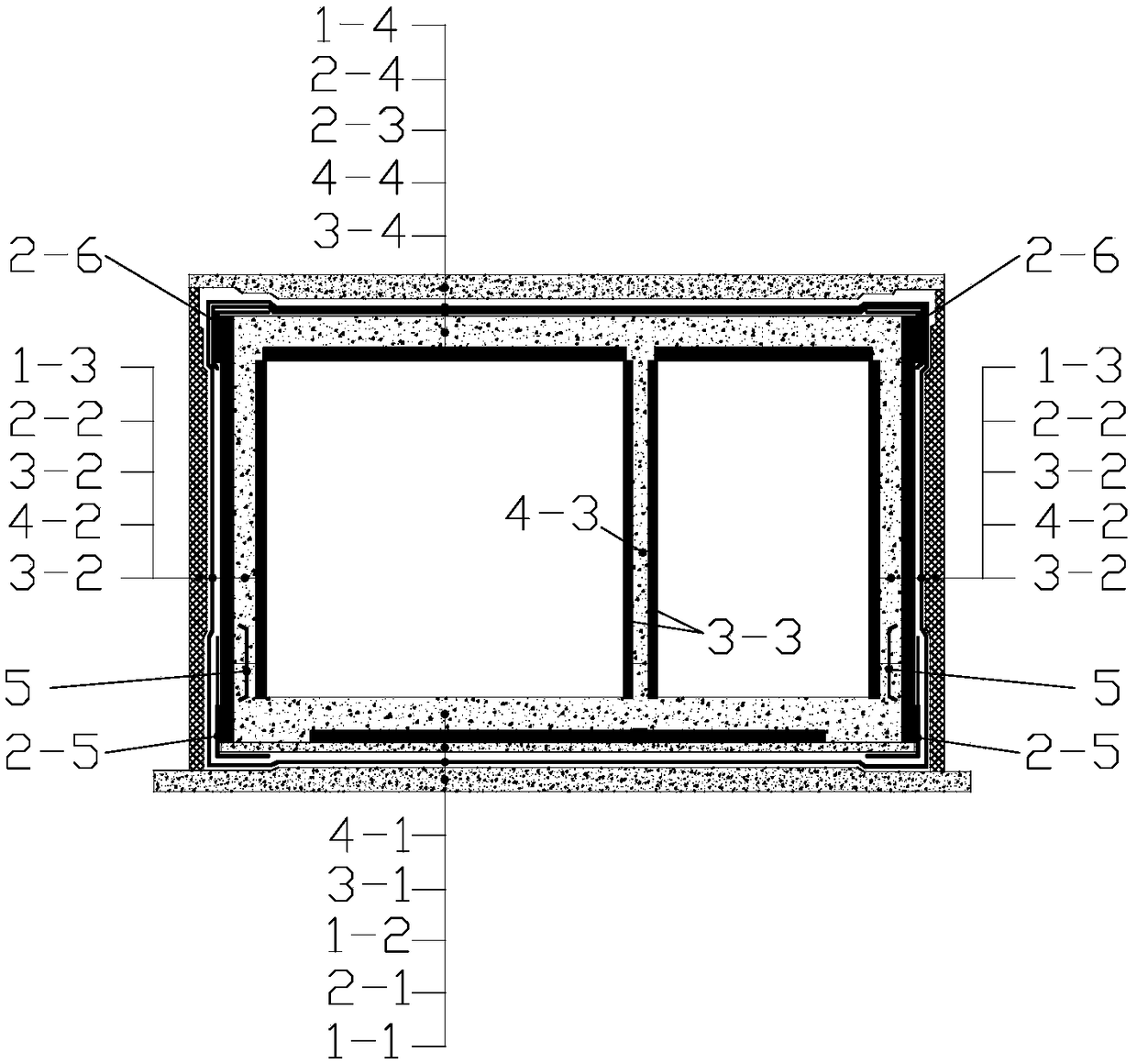

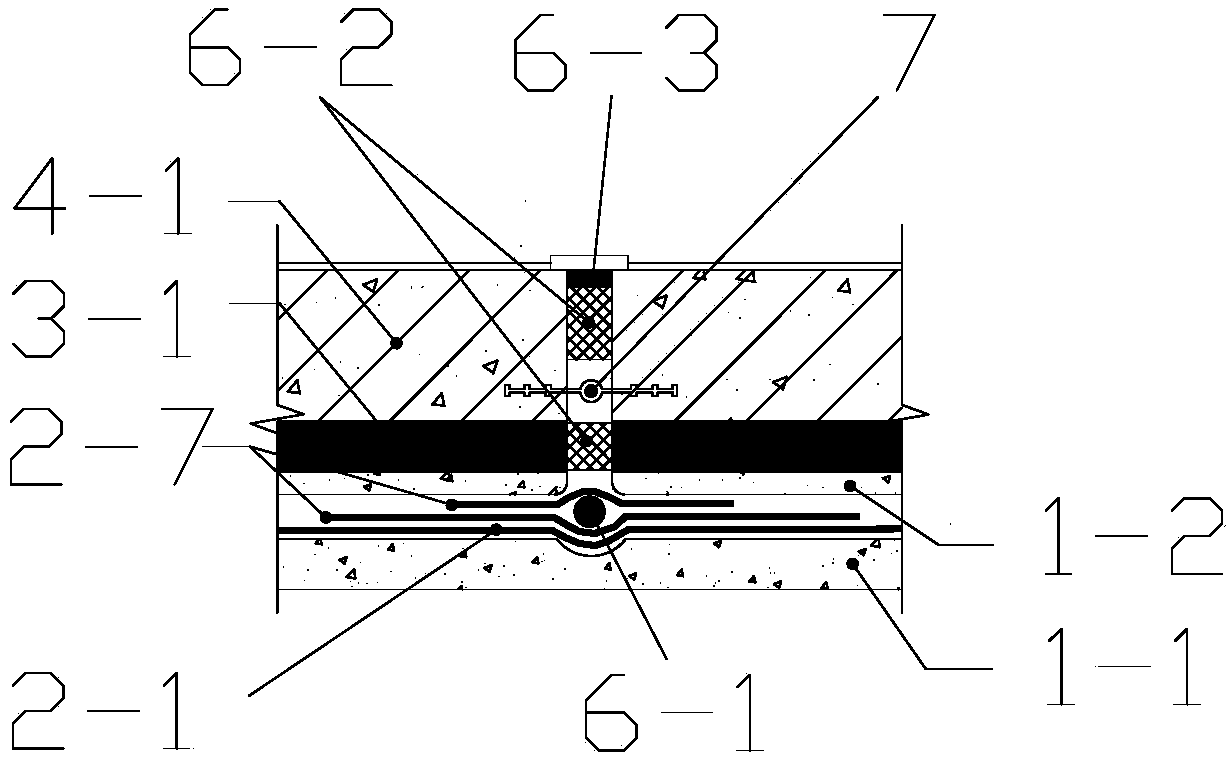

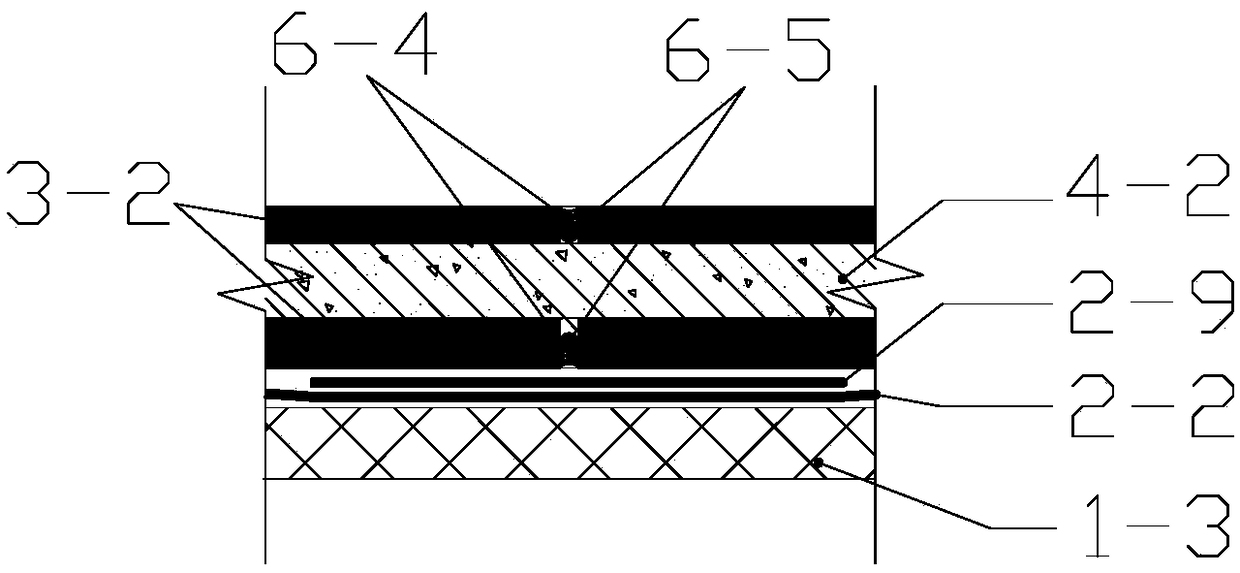

Full prefabricated superposed pipe gallery integrated waterproof structure and construction method

InactiveCN109056796AImprove waterproof qualityGuaranteed waterproof qualityArtificial islandsProtective foundationAgricultural engineeringEngineering

The invention discloses a full prefabricated superposed pipe gallery integrated waterproof structure and a construction method. A waterproof system is composed of a structural self-waterproof system and an auxiliary waterproof system. The structural self-waterproof system is composed of a prefabricated component part and a superposed concrete part, and the auxiliary waterproof system is composed of a structural external waterproof system and a deformation joint part waterproof system, wherein the prefabricated component part comprises a prefabricated bottom plate, a prefabricated wall plate and a prefabricated top plate; the superposed concrete part comprises a prefabricated bottom plate superposed concrete, a prefabricated wall plate superposed concrete and a prefabricated top plate superposed concrete; and the deformation joint part waterproof system is composed of the deformation joint part waterproof structurers of the prefabricated component bottom plate, the side wall and the topplate. The waterproof system supplements and improves the waterproof design and construction technology of China in the field, and the whole waterproof system is clear in system, simple in structure,convenient to construct, fast and efficient, easy to guarantee in quality and capable of being widely applied.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Basement bottom plate pre-laying anti-sticking TPO waterproof coiled material construction method

InactiveCN111173045AGood high and low temperature resistanceStrong chemical resistanceProtective foundationGasketsBasementStructural engineering

The invention discloses a basement bottom plate pre-laying anti-sticking TPO waterproof coiled material construction method, and relates to the technical field of underground building waterproofing. The method comprises the following steps of 1, base layer treatment, specifically, treating a base layer internal corner and a base layer external corner into an arc shape or a slope angle; 2, pile head treatment, specifically, cleaning a pile head, and coating the pile head and the periphery of the pile head with waterproof coating layers; 3, line snapping, specifically, paying off on the base layer and snapping out a planning line for paving the TPO waterproof coiled material; 4, pre-laying a coiled material, specifically, pre-laying the TPO waterproof coiled material on the base layer according to the planning line; and 5, welding joints of the coiled material, specifically, welding the joints of the TPO waterproof coiled material by using hot air welding equipment. The method is wide inapplication range, good in waterproof performance and free of waterproof blind areas.

Owner:SHANGHAI ORIENTAL YUHONG WATERPROOF TECH +1

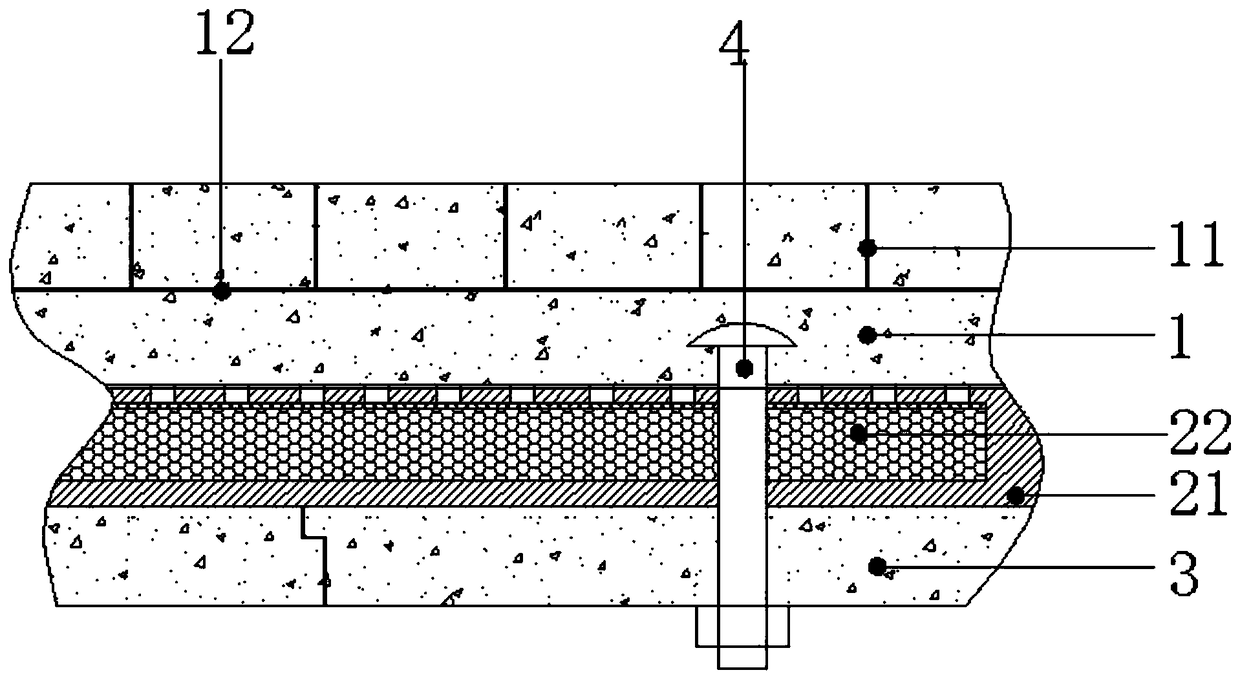

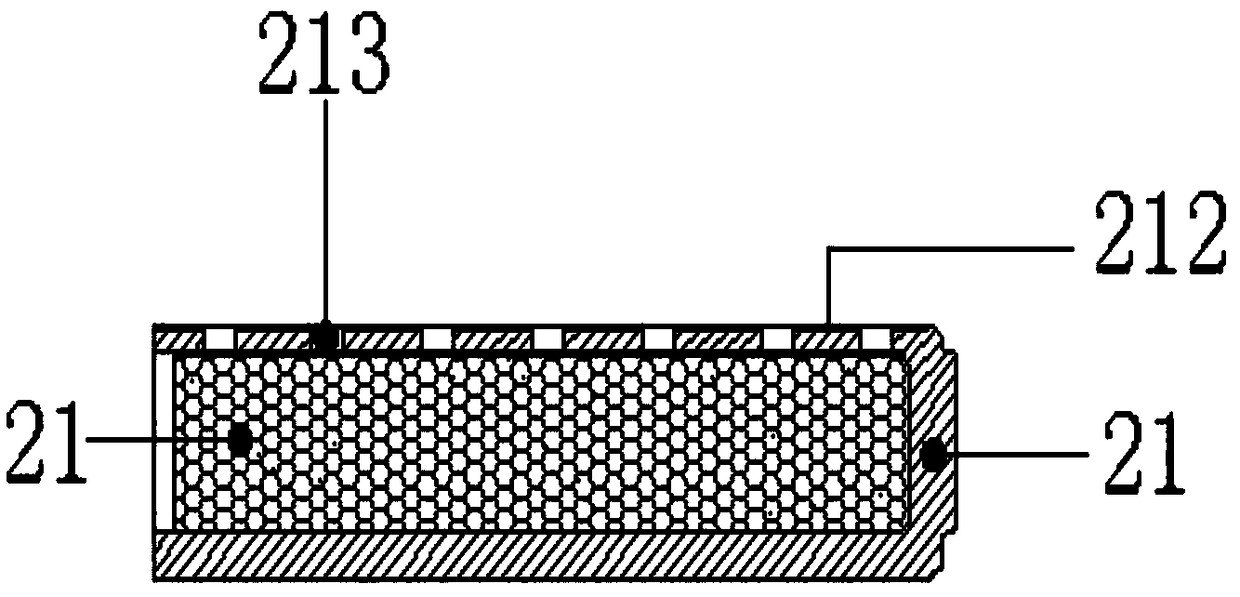

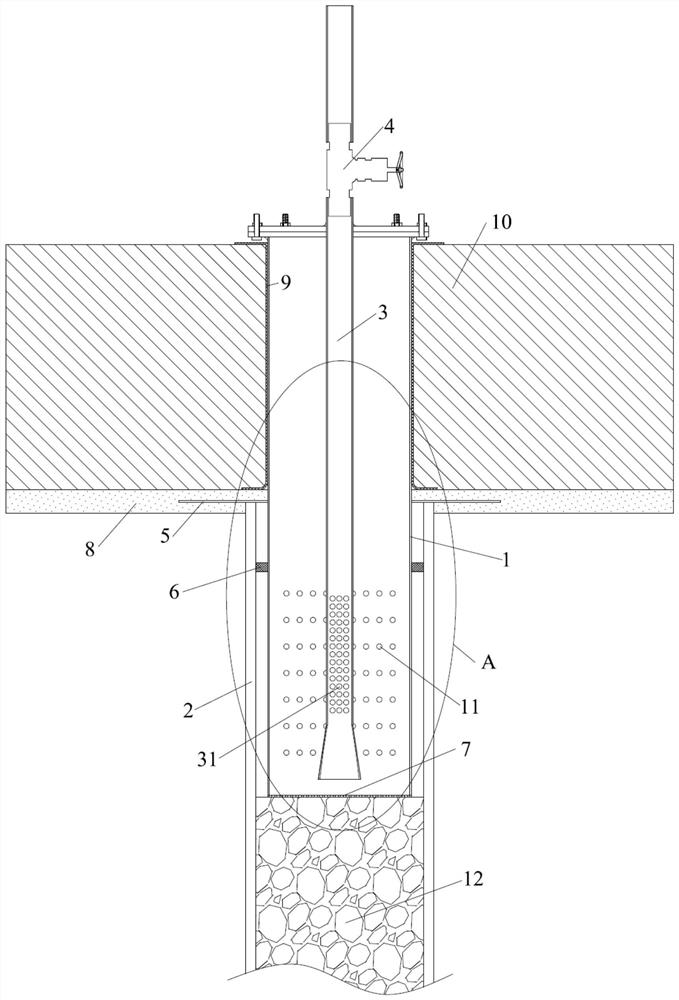

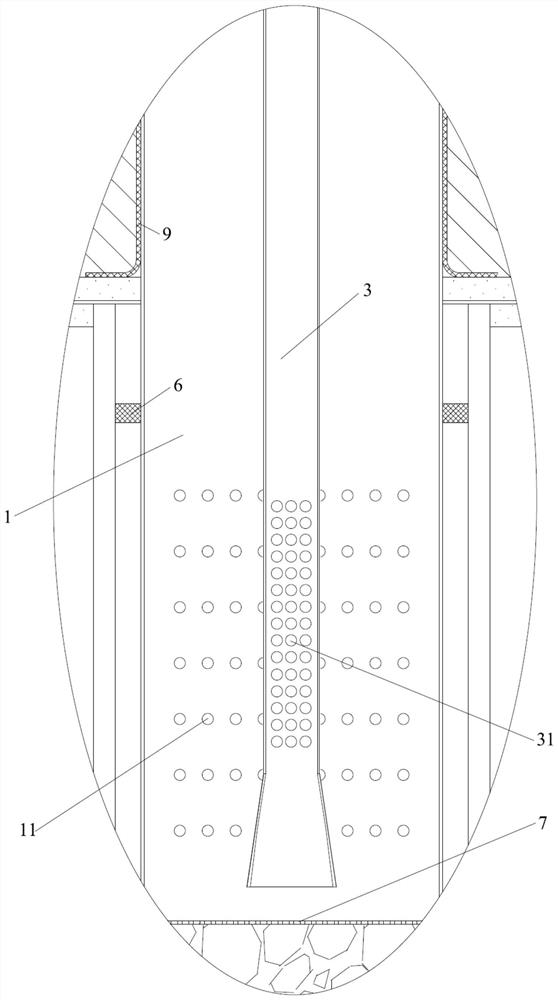

Well sealing device

The invention relates to the technical field of engineering construction and discloses a well sealing device. The well sealing device comprises a sleeve, a slurry injection pipe and a switch assembly.The first end of the sleeve stretches into a well pipe. The sleeve and the well pipe are sealed and fixedly connected. The slurry injection pipe is arranged in the sleeve. The first end of the slurryinjection pipe is exposed to the second end of the sleeve. The slurry injection pipe and the sleeve are sealed and fixedly connected. The switch assembly is arranged on the first end of the slurry injection pipe. According to the invention, the sleeve and the well pipe are sealed and fixedly connected, and the slurry injection pipe and the sleeve are sealed and fixedly connected, so slurry is injected into a pit bottom precipitation well from the slurry injection pipe; after the slurry injection, the switch assembly is closed, so confined water in the pit bottom precipitation well will not flow into a foundation pit and flow under the base plate from the pit bottom precipitation well to damage the base plate; and waterproof quality of the base plate can be ensured.

Owner:BEIJING TIANRUN CONSTR

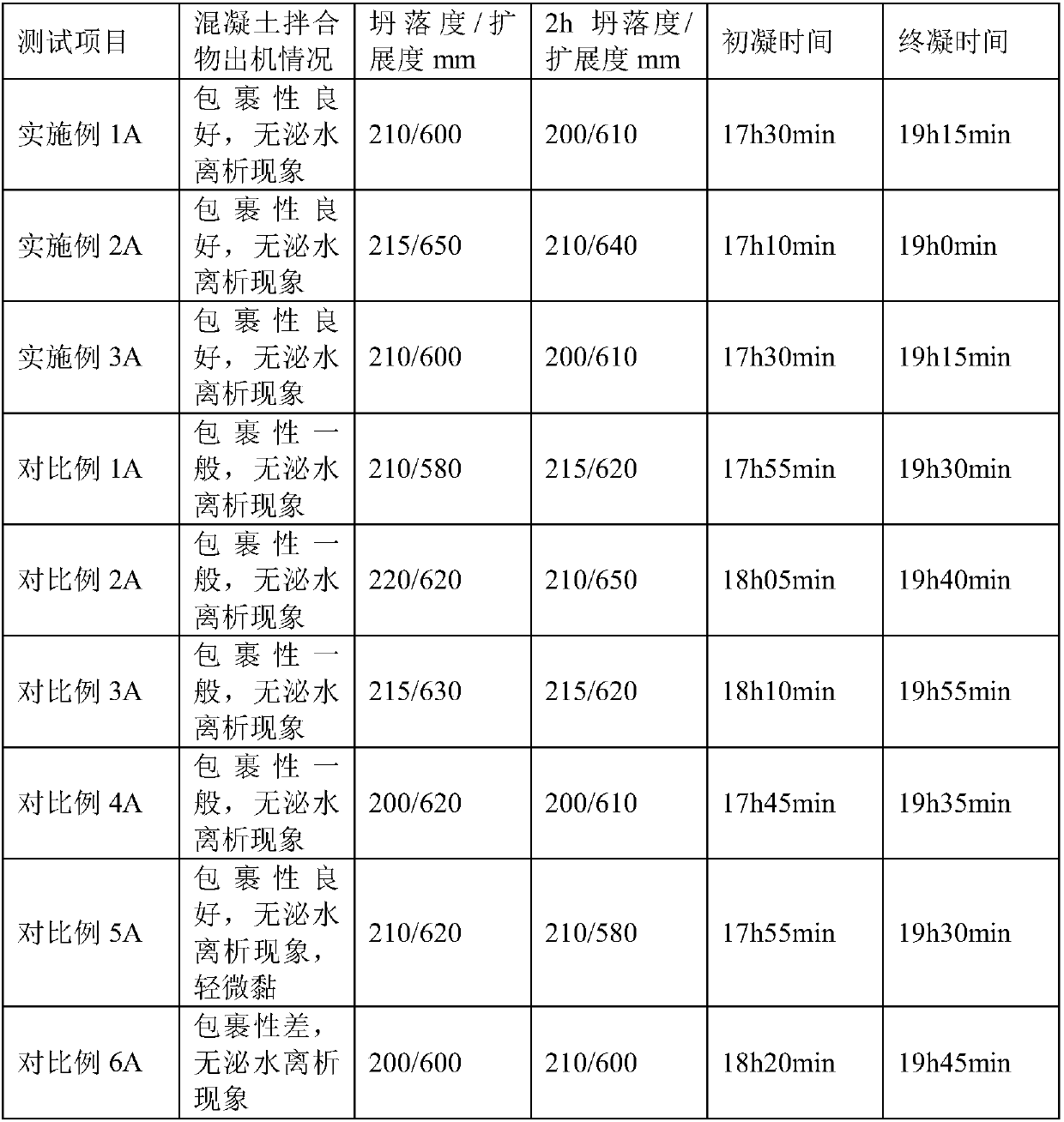

Mass concrete mixture and construction method of pouring wall body by mass concrete mixture

ActiveCN107673713AImprove stabilityGuaranteed waterproof qualityBuilding material handlingSlagSuperplasticizer

The invention relates to a mass concrete mixture and a construction method of pouring a wall body by the mass concrete mixture. The technical scheme adopted by the invention is that the mass concretemixture is prepared from the following raw materials in parts by weight: 165 parts of water, 214 parts of portland blast furnace slag cement, 743 parts of sand, 1070 parts of gravel, 103 parts of flyash, 95 parts of mineral powder, 4.94 parts of admixture and 0.9 part of polypropylene fibers, wherein the admixture is prepared from a JH-GHL polycarboxylate superplasticizer, an H-III type concrete mortar water-proofing agent, a UEA-H type concrete expanding agent, basic aluminum acetate and delta-aluminum oxide of which the weight ratio is 4 to 3 to 2 to 0.2 to 0.3. The construction method comprises the steps of pre-construction preparation, weighing of the raw materials, stirring of the raw materials, pouring, vibrating, primary leveling, maintenance, secondary leveling and measurement of the temperature. In the construction process of a mass concrete structure, indwelling of a post pouring belt can be avoided, the construction progress is speeded up and the construction period is shortened; in addition, without structural cracks, the overall stability of the structure is improved and the waterproof quality of a project can be ensured.

Owner:BCEG ROAD & BRIDGE CONSTR

Tunnel top waterproof structure and implementation method thereof

ActiveCN109339829APrevent infiltrationRealize partial waterproof effectUnderground chambersTunnel liningWater leakageStructural engineering

The invention discloses a tunnel top waterproof structure and an implementation method thereof, and belongs to the technical field of building waterproof. The tunnel top waterproof structure comprisesa concrete layer, a waterproof material layer, a structural supporting layer and bolts for fastening the layers. The waterproof material layer and the structural supporting layer adopt a splicing prefabricated type, the splicing gap of the waterproof material layer and the contact surface between the layers and the bolts are subjected to waterproof treatment, and thus the problem of water permeating from the contact gap is solved; and the waterproof material adopts layered and integrated types, multiple waterproof is achieved, and a main material of the waterproof material is a flexible material, so that the problem of water leakage caused by cracking or deformation of the concrete layer is effectively solved.

Owner:CHINA MCC17 GRP

Construction method for basement construction bottom plate

ActiveCN104120740AGuaranteed durationQuality assuranceArtificial islandsUnderwater structuresBasementReinforced concrete

A construction method for a basement construction bottom plate includes the following steps that (1) a shear wall and a shear column are normally poured and punned to below the construction bottom plate by 550 mm; (2) inside and outside backfill soil is filled to be below the poured shear wall and the poured shear column by 400 mm and is punned; (3) concrete is poured and punned to construct a bracket, a groove is reserved and an insertion bar is connected normally according to design sizes; (4) an outer wall of the shear wall, the superstructure of the shear column and a coiled material waterproof part of the outer wall are constructed, a coiled material waterproof part is added to a second construction joint, and after a waterproof protection layer of the outer wall is completed, backfill soil is backfilled to the outer wall; (5) after the backfill soil becomes dense and solid within three months under normal circumstances, an under layer of the bottom plate, the coiled material waterproof parts and a protection layer are constructed; (6) bottom plate reinforced concrete is normally constructed; (7) the concrete is maintained, a joint of the construction bottom plate is examined, and if separation occurs, the joint is repaired in a factice caulking mode. The construction technology is simple, the construction period and quality are guaranteed, reworking is avoided, the manufacturing cost is lowered, energy is saved, and the environment is protected.

Owner:GUANGXI METALLURGICAL CONSTR

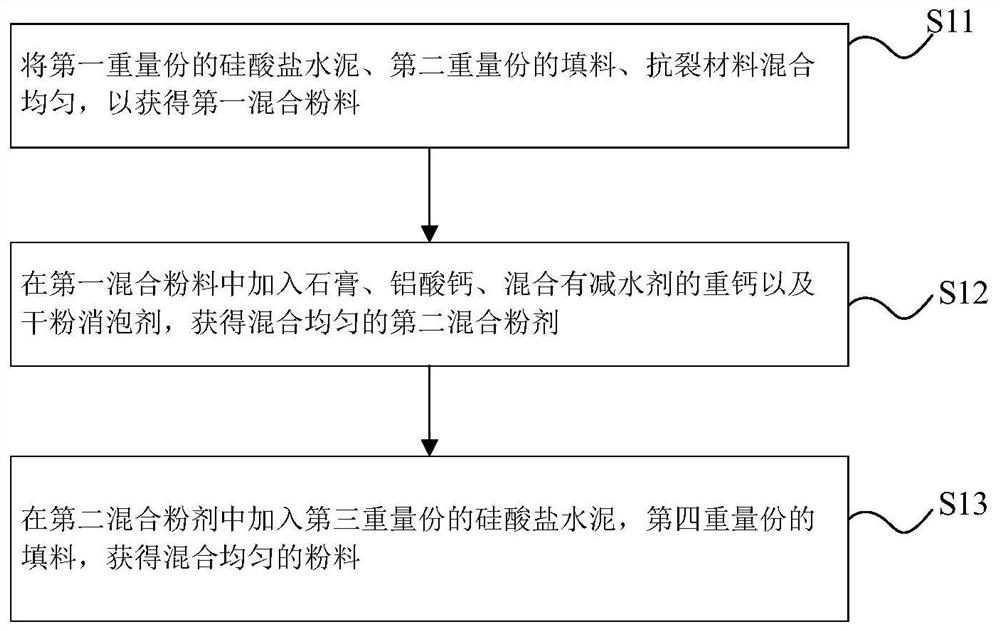

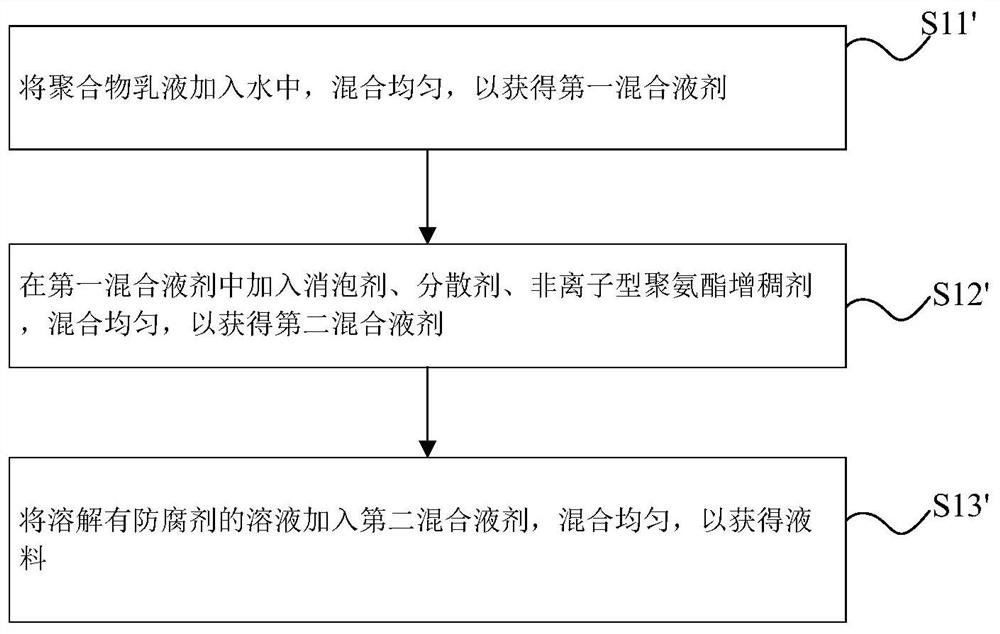

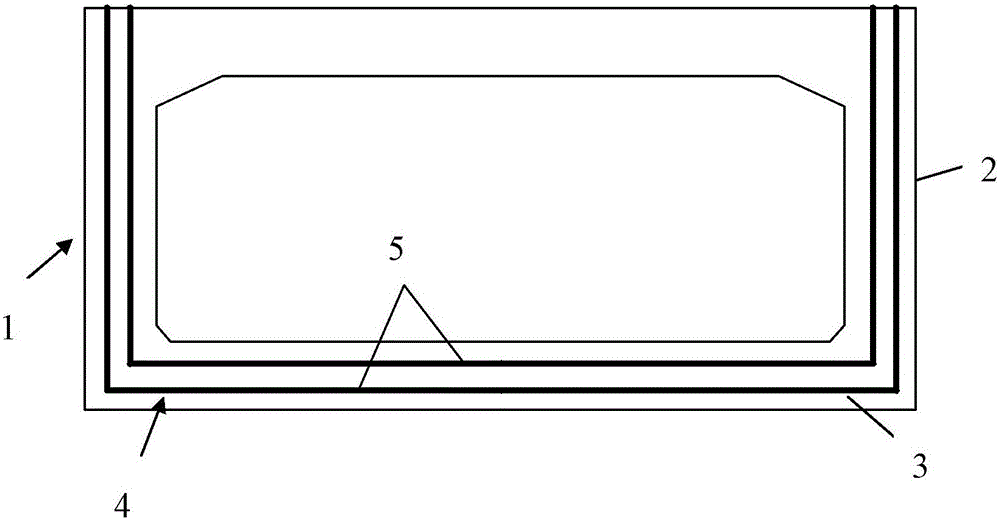

Polymer cement waterproof coating and preparation method thereof

ActiveCN113388276AGuaranteed waterproof qualityWell mixedCement coatingsPortland cementWater reducer

The embodiment of the invention provides a polymer cement waterproof coating and a preparation method thereof. The embodiment of the invention provides a polymer cement waterproof coating. The polymer cement waterproof coating is composed of a liquid material and a powder material; the powder material comprises the components in 100 parts by weight: 40-50 parts of Portland cement, 1-3 parts of calcium aluminate, 1-2 parts of gypsum, 5-10 parts of quartz sand, 10-15 parts of quartz powder, 17.6-42 parts of heavy calcium carbonate, 0.2-0.5 part of a water reducing agent, 0.2-0.3 part of a dry powder defoaming agent and 0-1.7 parts of an anti-cracking material; the liquid material comprises a polymer emulsion, an additive and water. According to the polymer cement waterproof coating provided by the embodiment, the thickness of a coating film formed through single-time coating construction is increased, the coating construction cost of the coating is reduced, and the construction efficiency is improved.

Owner:南通科顺建筑新材料有限公司

Construction method for tunnel bridge construction joint sealing system

InactiveCN106087761AGood waterproof effectGuaranteed waterproof effectArtificial islandsProtective foundationStructural engineeringCrystallization

The invention relates to a construction method for a tunnel bridge construction joint sealing system. The construction method comprises the steps that two U-shaped grooves are formed in the side wall of a frame bridge and the front end face and the rear end face of a bottom plate; a water-swelling sealing strip is installed in each U-shaped groove; the side wall and the front end face and the rear end face of the bottom plate with the water-swelling sealing strips installed are painted with a concrete adhesion agent; concrete is poured into an approach bridge formwork, and it is needed to be noted that strengthening ramming is conducted on joints in the ramming process. The construction method for the tunnel bridge construction joint sealing system has the advantages that the adhesion agent is transparent liquid, and thus the quality and the attractiveness of engineering are hardly influenced. Compared with cement which is permeable, the adhesion agent is waterproof, capable of being crystallized, and better in waterproof effect; the water-swelling sealing strip can swell with water in a narrow space and can fully prevent underground water from seeping into concrete. A multiple water blocking system can be formed, and the waterproof effect can be effectively ensured. The waterproof quality of engineering can be ensured while the cost is reduced.

Owner:CHINA RAILWAY SIXTH GRP TIANJIN RAILWAY CONSTR +1

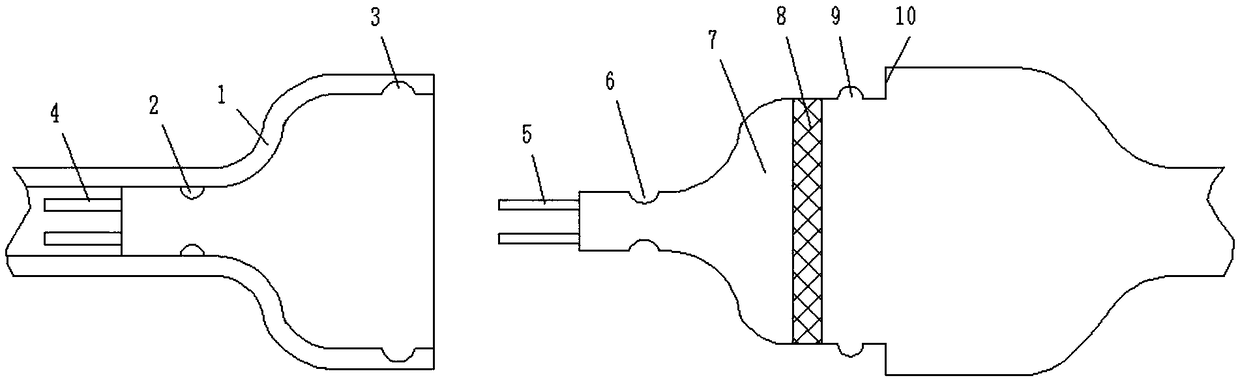

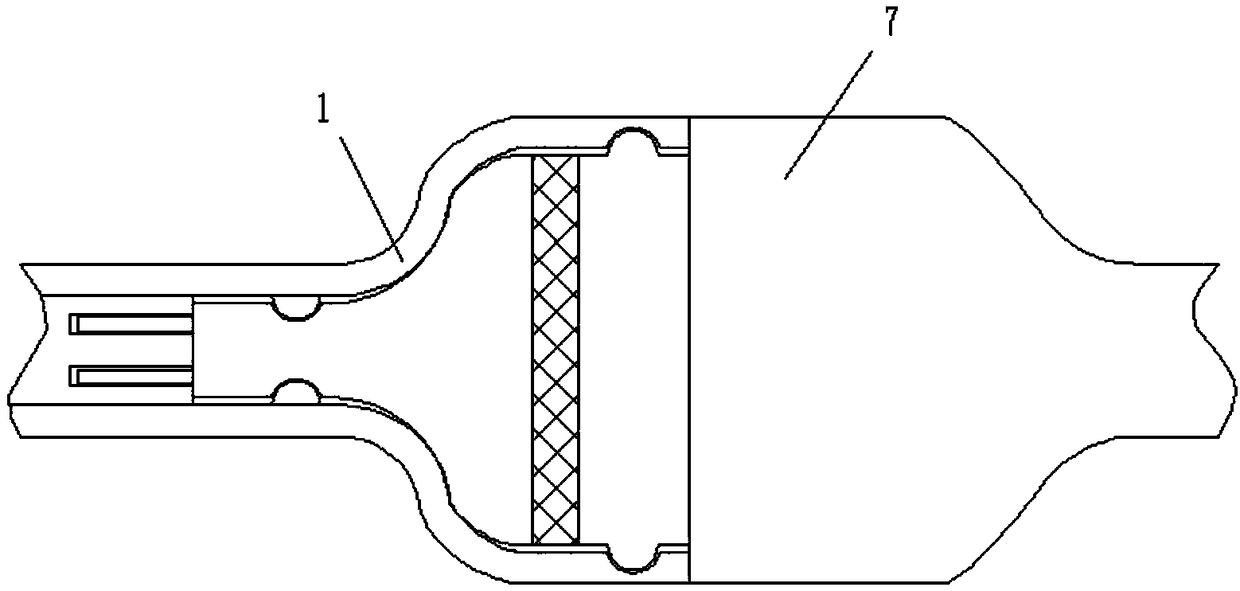

Waterproof connecting line joint

InactiveCN108183352AImprove sealingImprove fastnessCoupling contact membersCouplings bases/casesMating connectionRubber material

The invention discloses a waterproof connecting line joint, and the joint comprises a socket and a plug, which are connected closely and cooperatively, thereby improving the fastening performance andsealing performance. Moreover, the butt joint and disassembly of the socket and the plug are very convenient, and the socket and the plug are made of rubber materials, and the rubber materials are good in sealing performance. The front end of the socket consists of two hollow tubes with different diameters, wherein the inner wall of a big end is provided with a socket groove, and the interior of asmall end is provided with a socket convex block. The front end of the plug is provided with two solid tubes with different diameters, wherein the exterior of the small end is provided with a circular plug groove, and a big end is provided with a plug convex block. The plug is provided with a circular drying agent groove, and a drying agent is placed in the drying agent groove, and absorbs the moisture entering from a gap, thereby improving the waterproof performance of the interior of the joint. The drying agent can be replaced regularly, thereby guaranteeing the waterproof quality. A plug box has the same excircle diameter as the big end of the socket, and the sealing performance is improved after the cooperative connection. The joint is not liable to be scraped by a foreign object.

Owner:颍上贝斯特电子科技有限公司

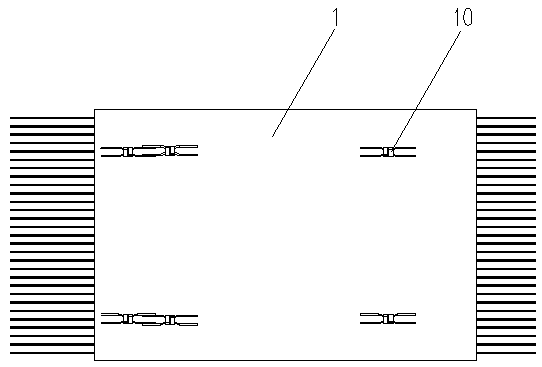

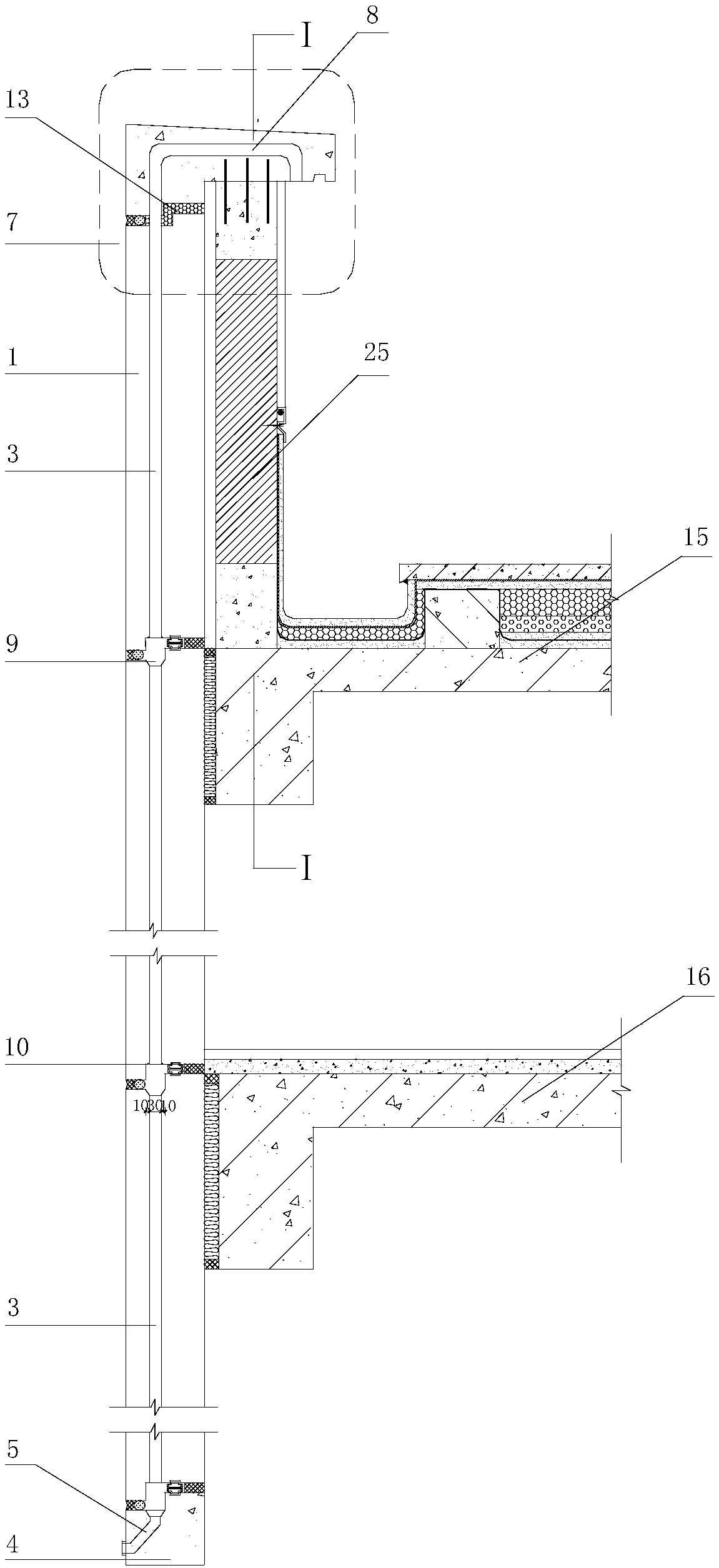

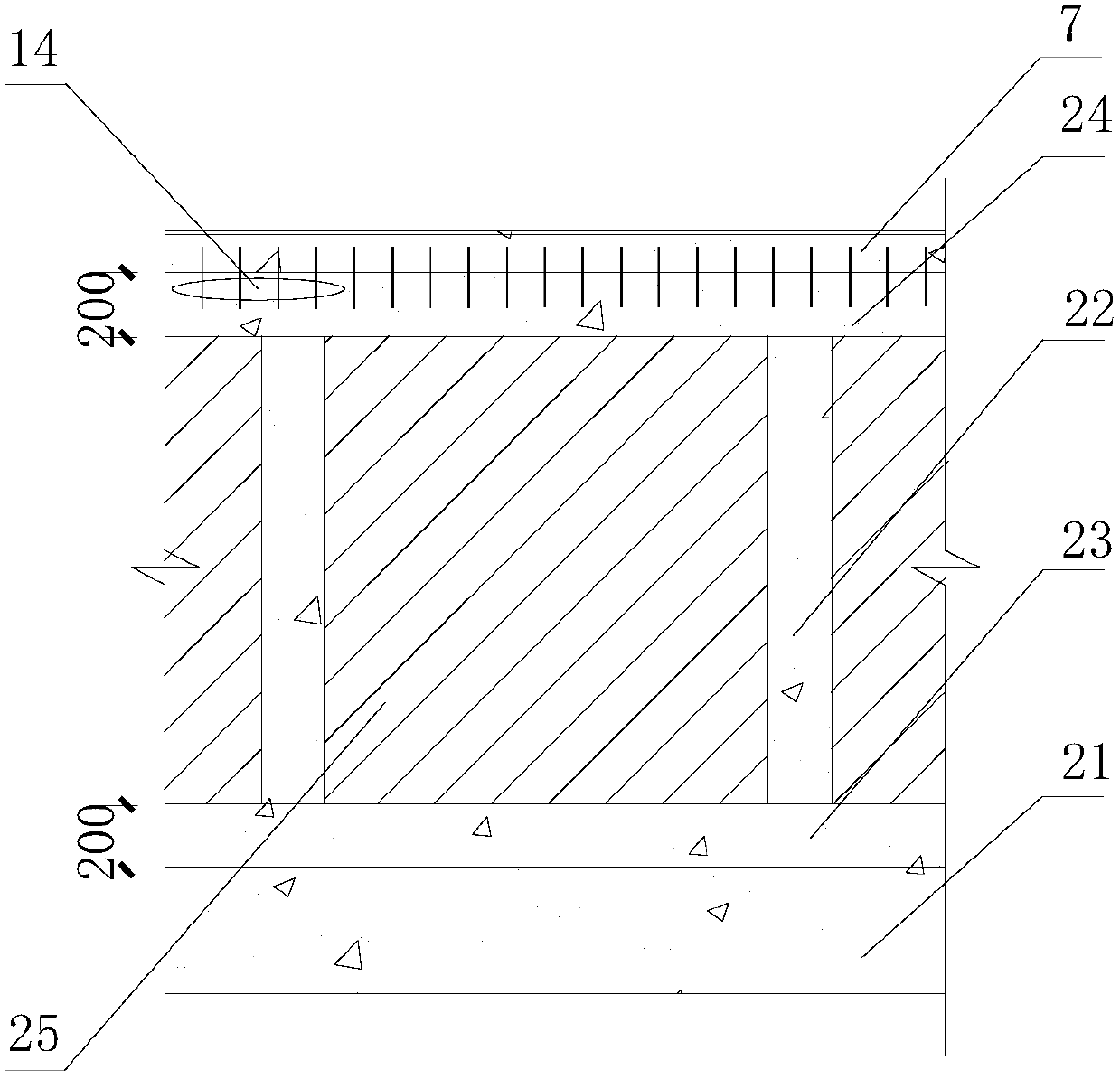

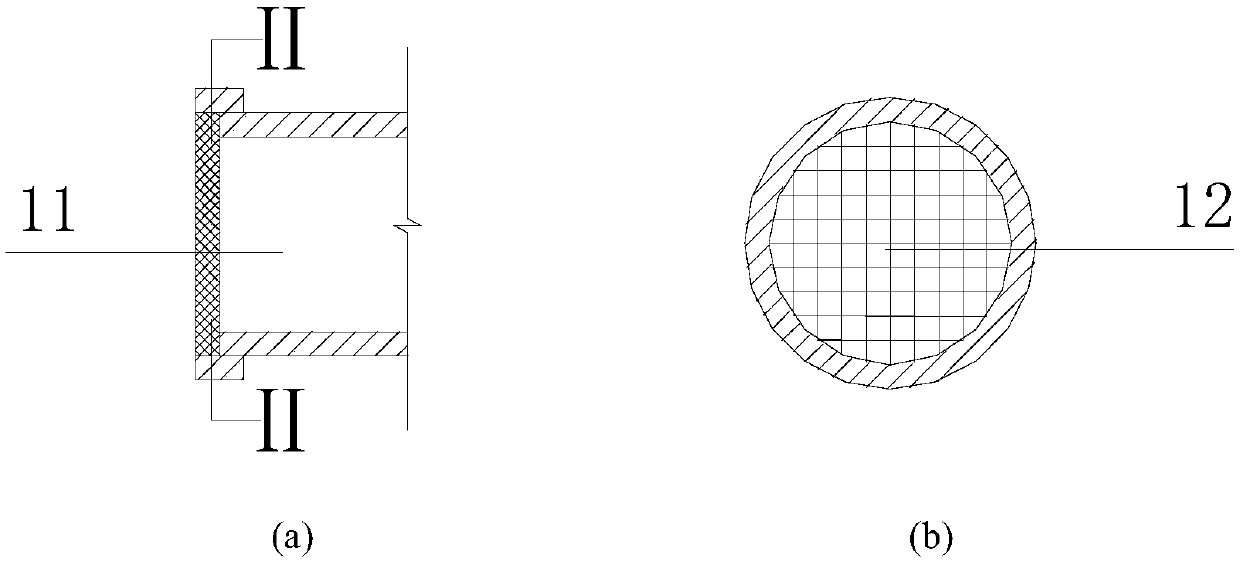

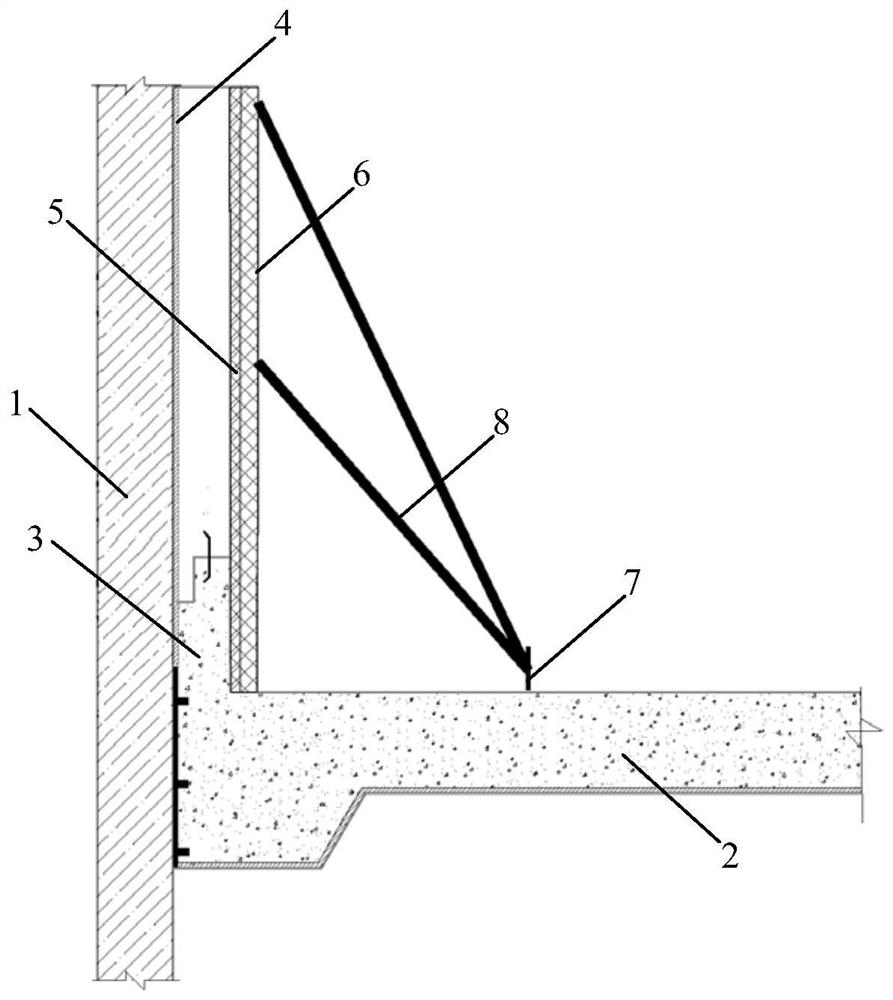

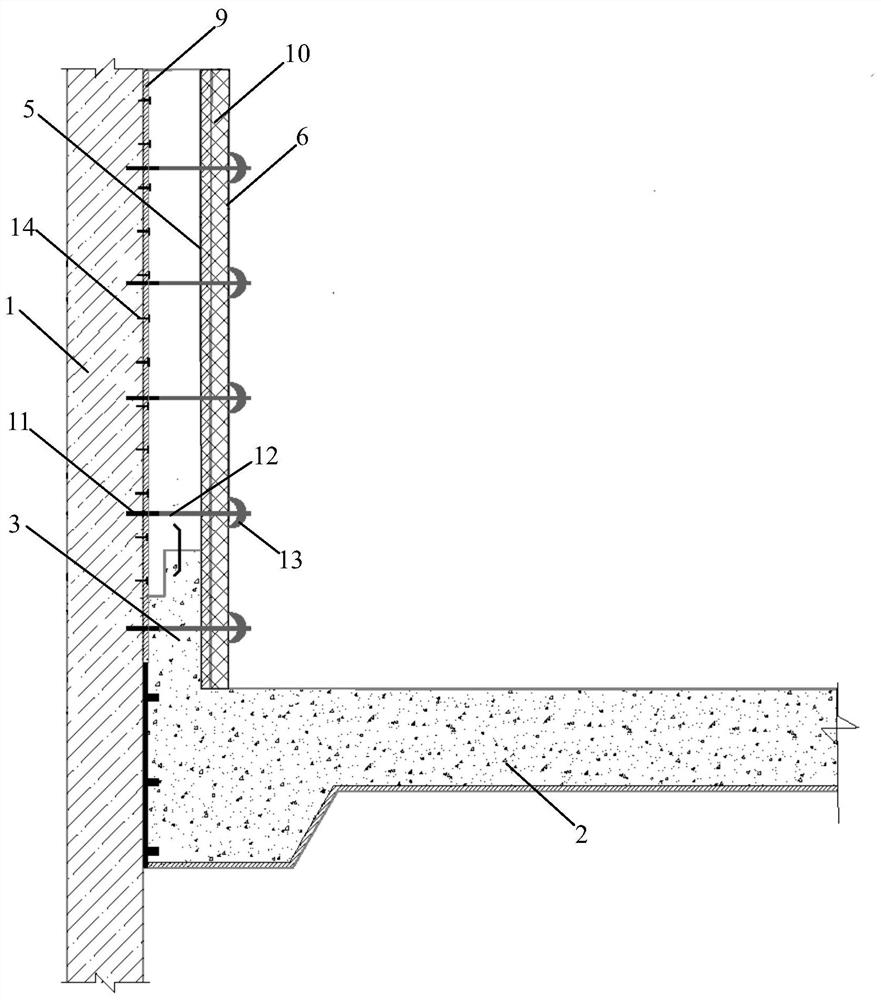

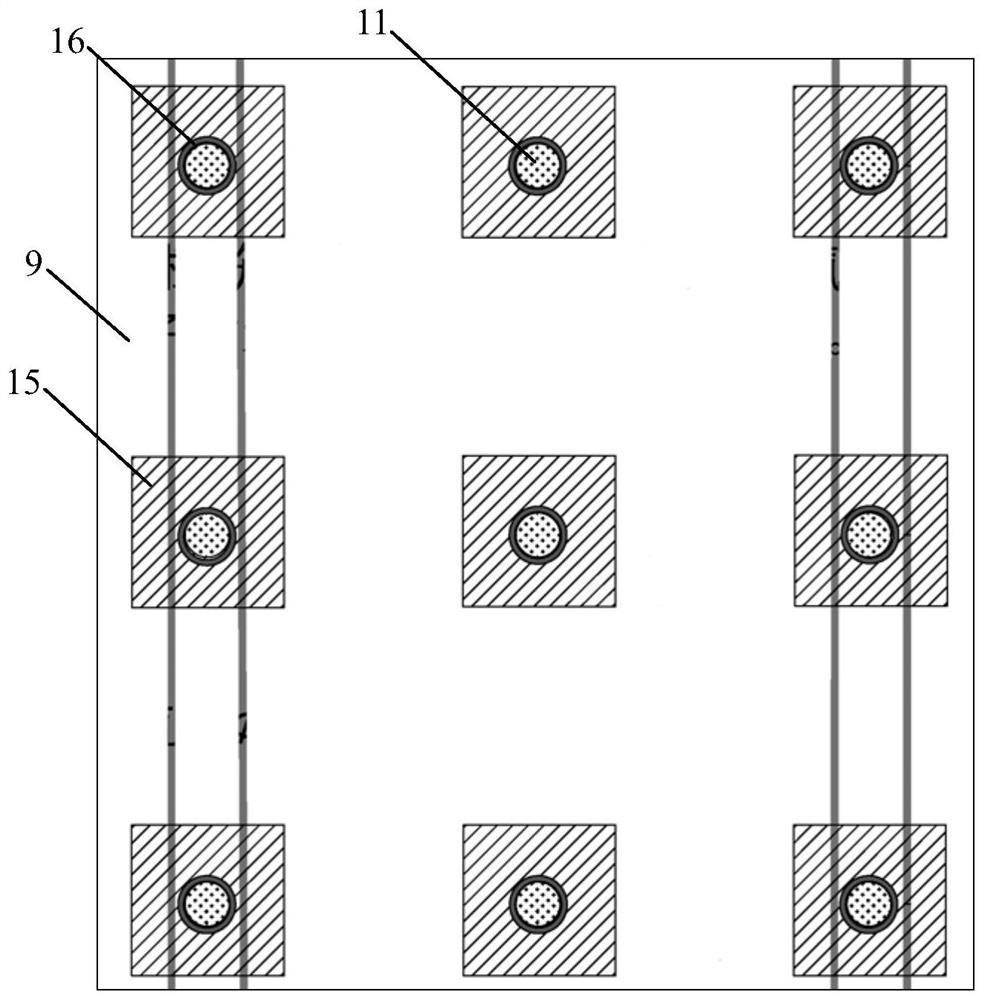

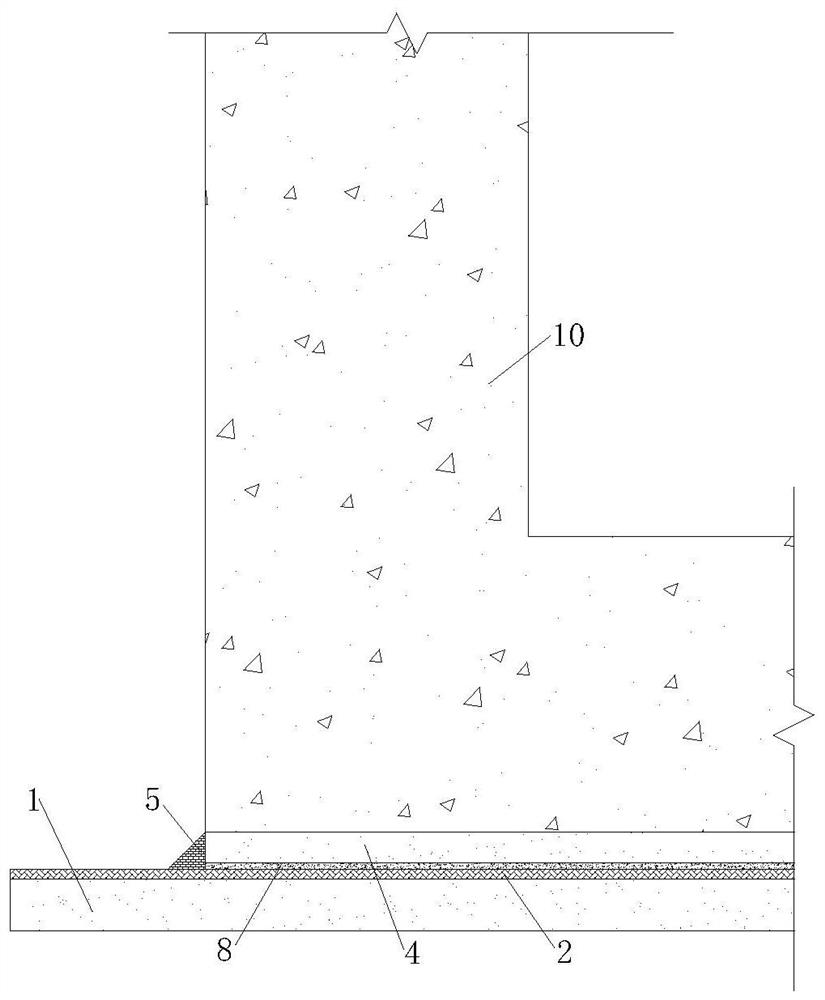

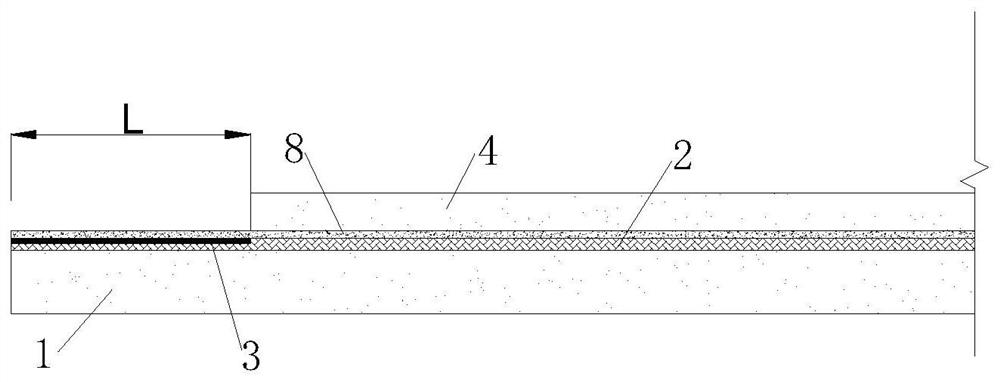

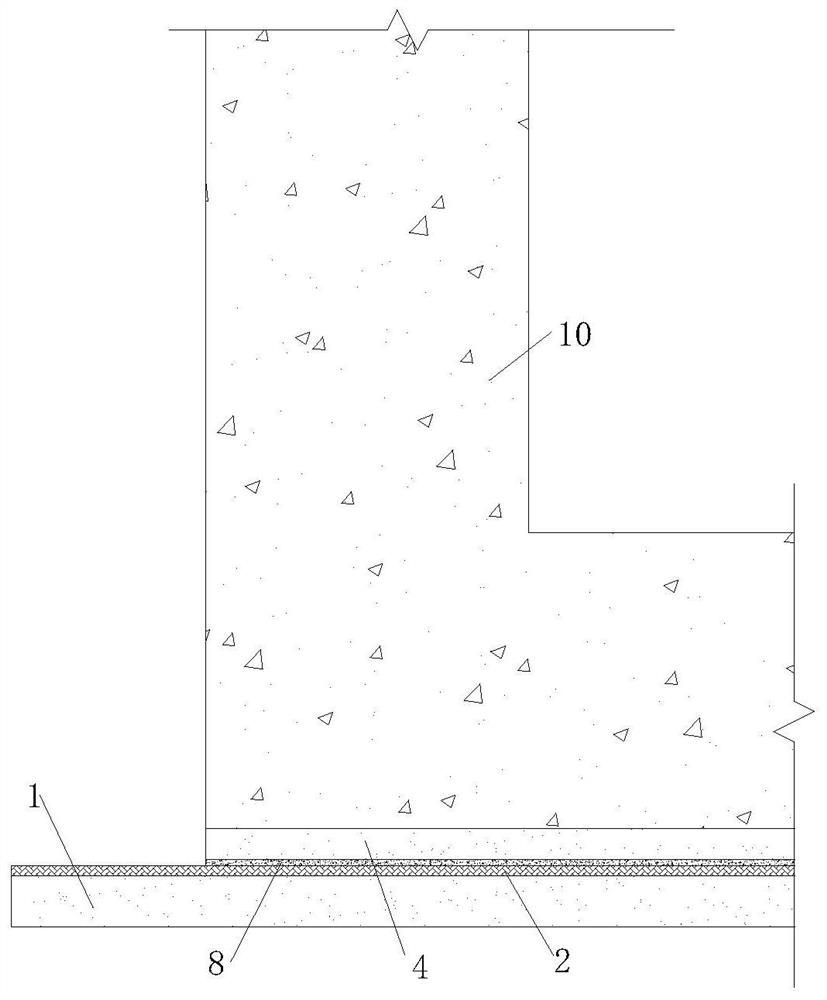

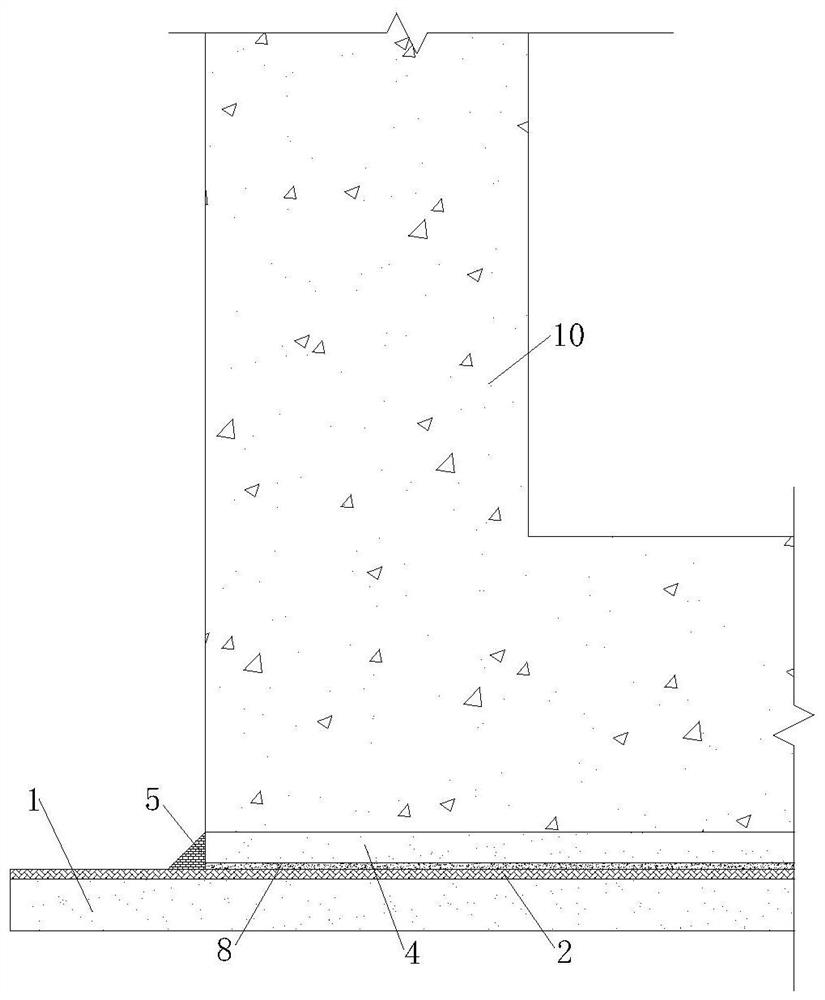

Two-in-one lining wall waterproof and structure integrated construction structure

InactiveCN112281886AGuaranteed waterproof qualityConvenient on-site constructionExcavationsGasketsSlurry wallScrew thread

The invention provides a two-in-one lining wall waterproof and structure integrated construction structure. A polymer self-adhesive film composite waterproof coiled material is laid on the right sidesurface of an underground diaphragm wall and is positioned above a vertical convex part, a lining wall pouring formwork is arranged on the right side of the polymer self-adhesive film composite waterproof coiled material, is vertically arranged in a front-back direction and is spaced from the polymer self-adhesive film composite waterproof coiled material in the left-right direction, the lower part of the left side surface is attached to the right side surface of the vertical convex part, embedded steel bars and opposite-pull screws are arranged in the left-right direction and are arranged ina straight line, the left ends of the embedded steel bars penetrate through the polymer self-adhesive film composite waterproof coiled material and are inserted into the right side surface of the underground diaphragm wall, the left ends of the opposite-pull screws penetrate through the lining wall pouring formwork and are connected with the right ends of the embedded steel bars, and opposite-pullnuts are arranged at the right ends sleeve and in threaded meshing with the right ends of the opposite-pull screws and abut against the right side surface of the lining wall pouring formwork. The two-in-one lining wall waterproof and structure integrated construction structure can facilitate field construction and guarantee the waterproof quality of the lining wall, and is ingenious in design.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

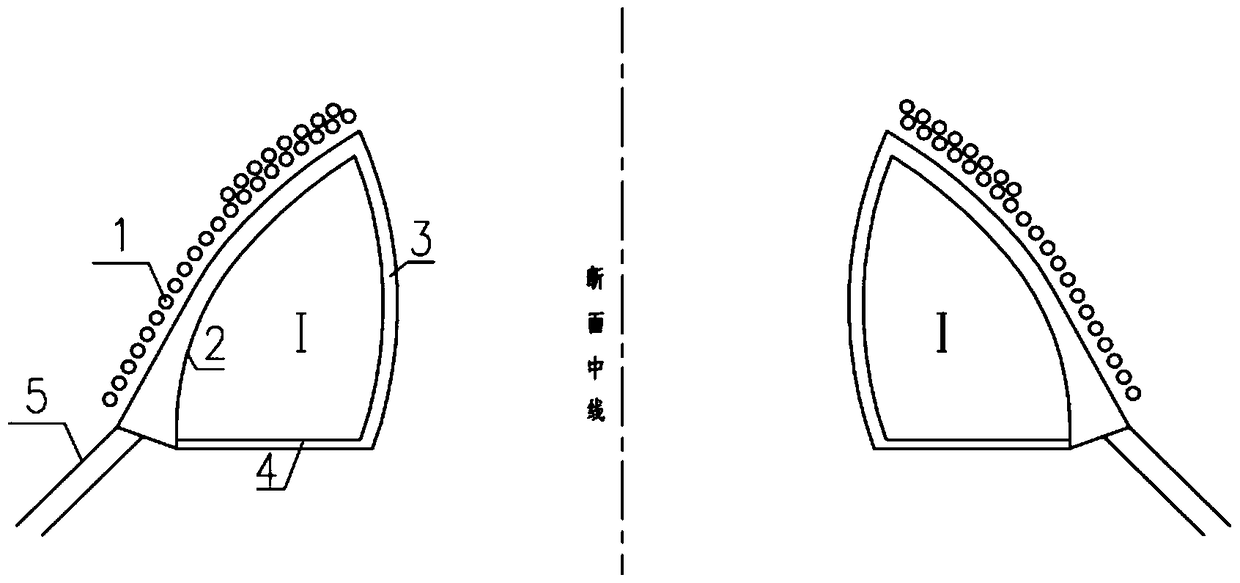

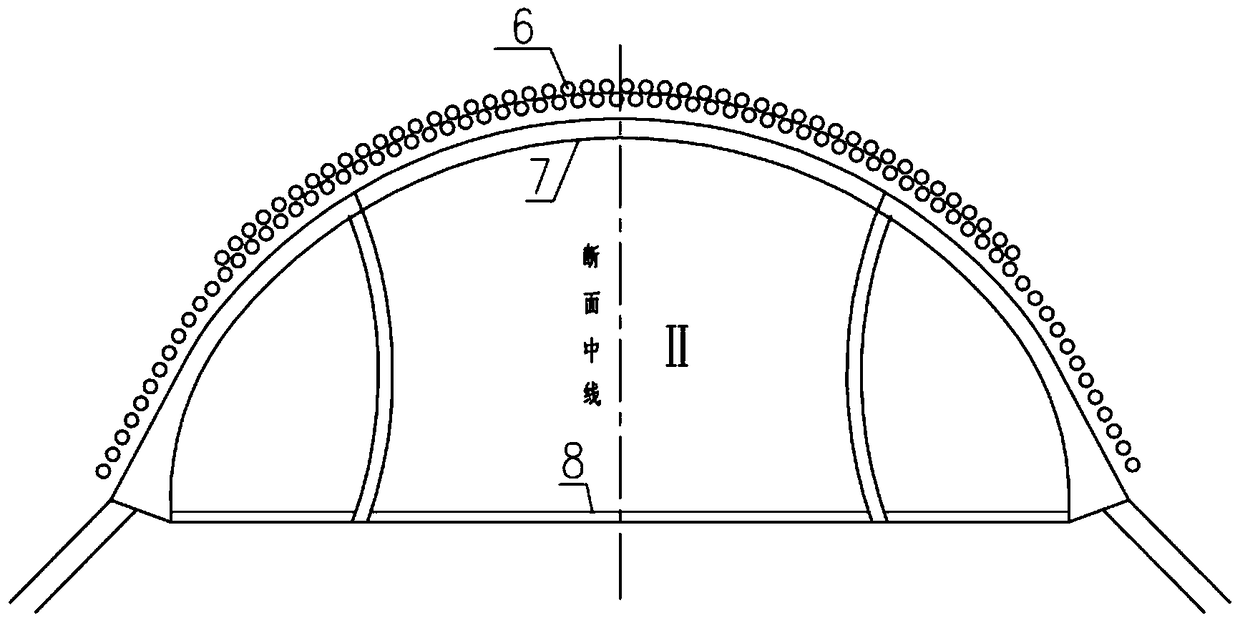

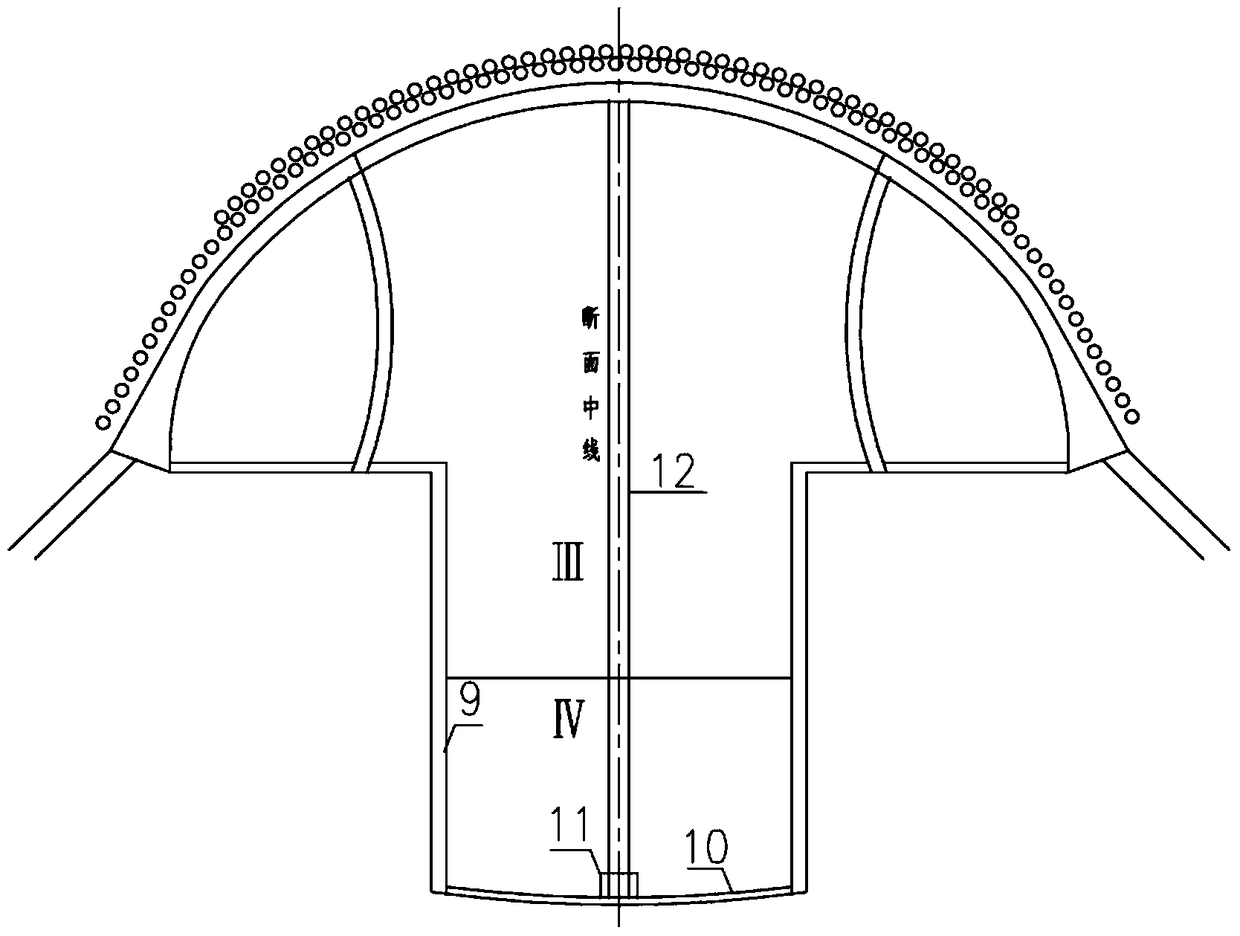

A Construction Method for the Replacement of Trough Supports in Single-Arch Super-Large-span Subway Stations in Composite Strata

The invention belongs to the technical field of design and construction of tunnels, underground engineering and urban rail transportation and particularly relates to a construction method for a composite stratum single-arch super long-span subway station through groove broaching and support substitution. The construction method is characterized in that an excavated section adopts three-layer three-part layered construction, specifically, side pilot tunnels on the two sides are constructed on the upper layer of the station at first, then a middle pilot tunnel is constructed, and the side pilot tunnels and the middle pilot tunnel are all manually excavated and constructed by adopting a bench method and are staggered at a distance of 15-20 m; two-layer construction is conducted on the lower portion of the station, middle groove broaching is conducted at first in a two-layer construction mode, a middle temporary support is established after middle groove construction is completed, then symmetrical edge groove broaching construction is also conducted in a two-layer mode, and temporary vertical support substitution and groove broaching are conducted so as to ensure the effect that an arch structure and arch foot surrounding rocks are stable; and secondary lining is sequentially conducted finally. The construction method for the composite stratum single-arch super long-span subway station through groove broaching and support substitution is suitable for construction of composite stratum single-arch super long-span station tunnels and underground structures, the structural stability is good, and the construction efficiency is improved.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

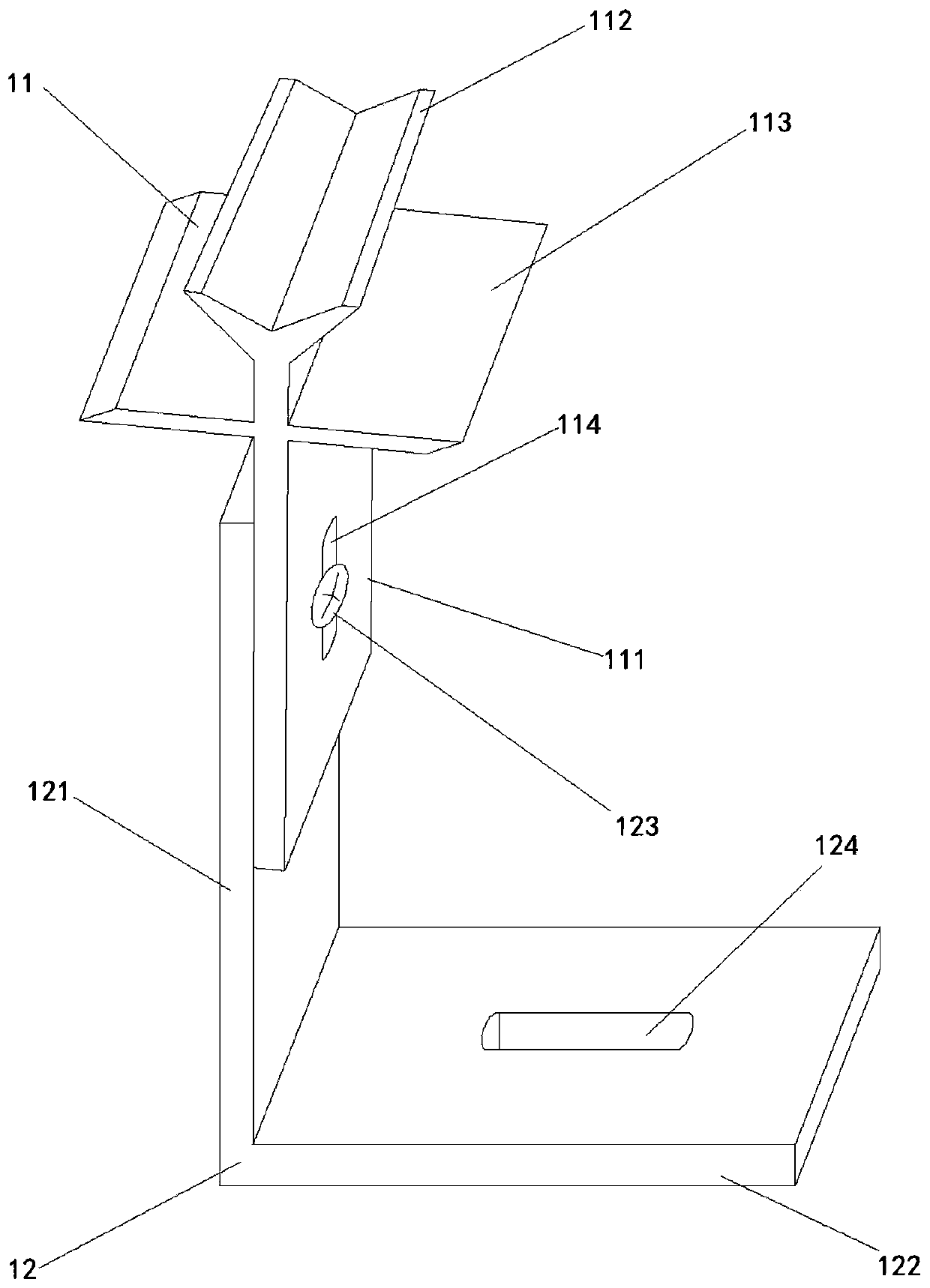

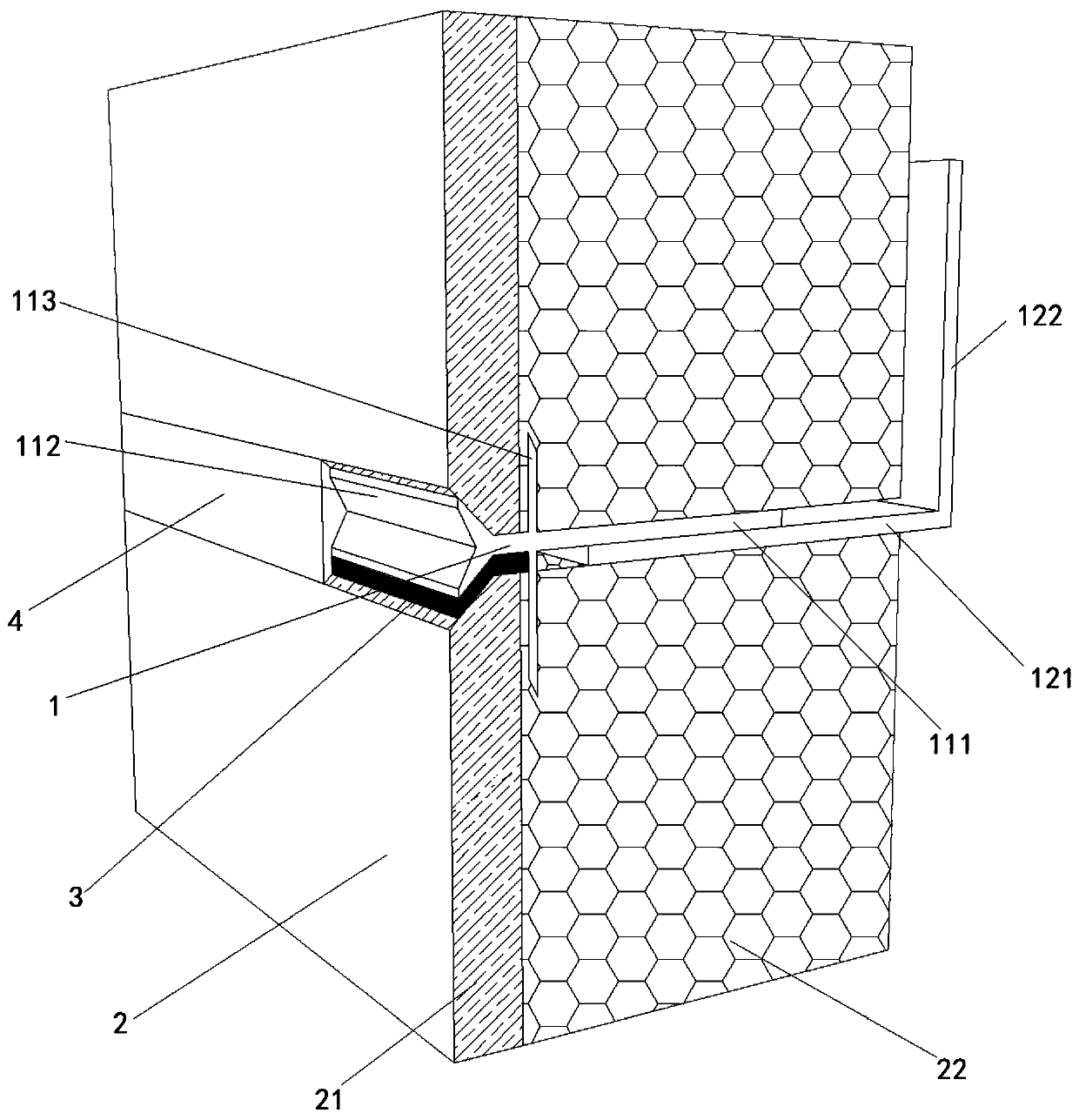

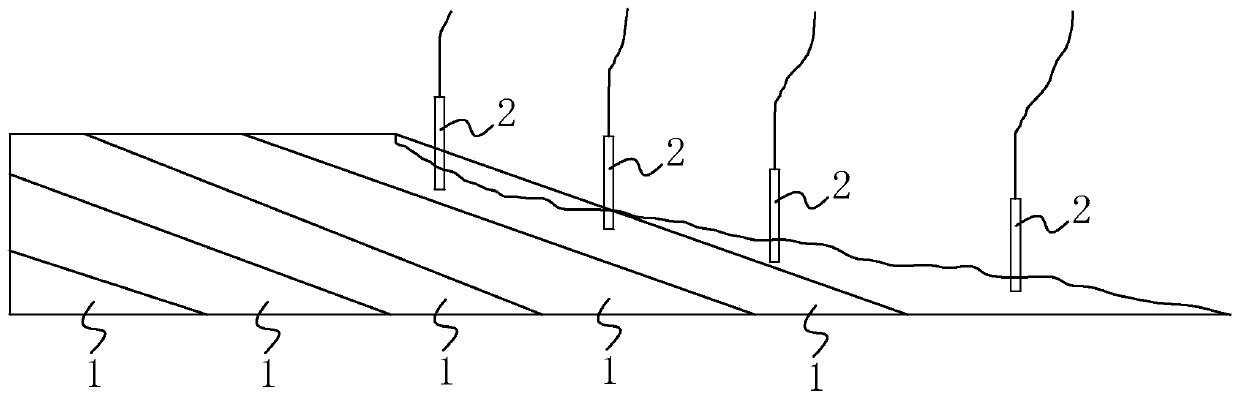

Auxiliary device for laying waterproof roll material for foundation slab and application method thereof

PendingCN110629802ASimple and convenient supportSimple and convenient fixationProtective foundationMechanical engineeringBuilding construction

Owner:MCC TIANGONG GROUP

Water supply and drainage device for deep foundation pit and construction method based on the water supply and drainage device

ActiveCN104846836BEffective isolationExtend your lifeFoundation engineeringEngineeringDrainage tubes

The invention discloses a water supply and drainage device for a deep foundation pit and a construction method based on the water supply and drainage device. The water supply and drainage device comprises a water collecting sleeve and a water suction pump, wherein the water suction pump is placed in the water collecting sleeve; the water collecting sleeve comprises a steel sleeve and a reinforcing bar grid; the reinforcing bar grid is arranged at the lower end of the steel sleeve and is integrally connected with the steel sleeve in a welded manner; the steel sleeve at the upper end of the water collecting sleeve is positioned in structural concrete; the reinforcing bar grid on the lower portion of the water collecting sleeve is positioned in a base below a structural bottom plate; and a plurality of drainage tubes are arranged on the periphery of the base. Compared with the prior art, the water supply and drainage device for the deep foundation pit and the construction method based on the water supply and drainage device have the advantages that a structural reserved hole is omitted, the structural waterproofing and the construction quality are greatly improved, the construction period is shortened, and the cost is reduced.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

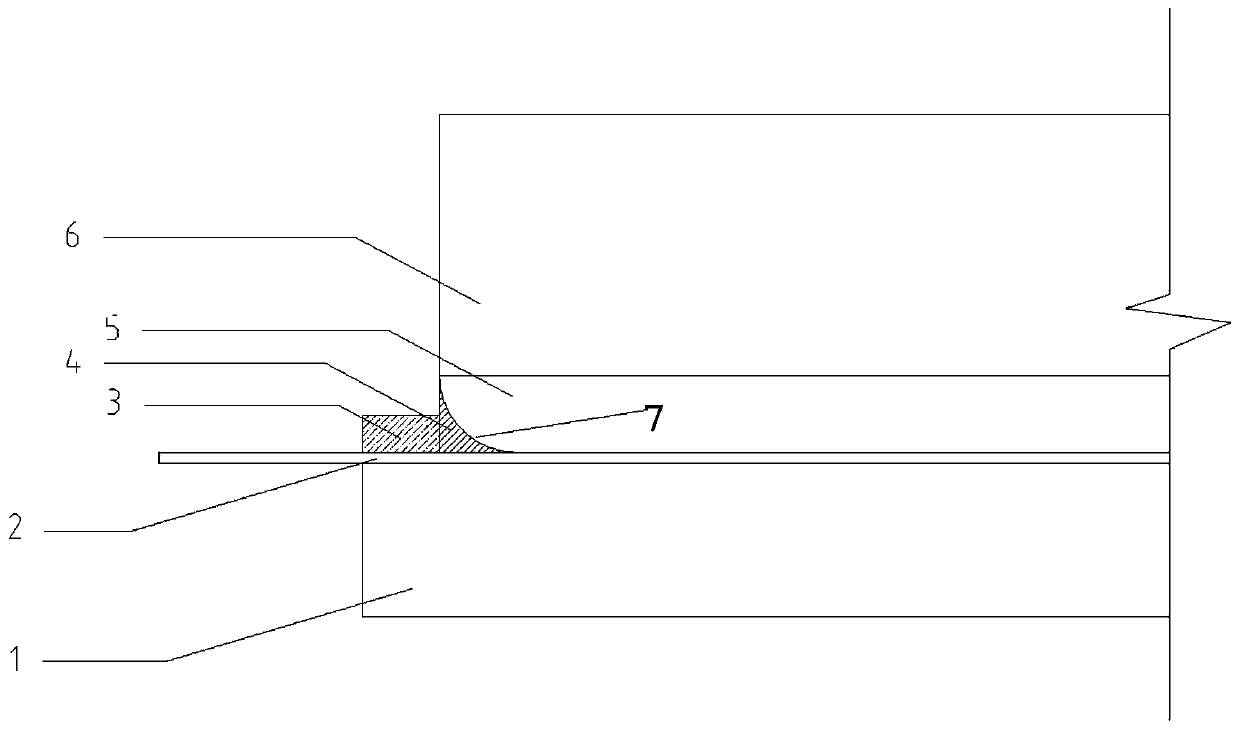

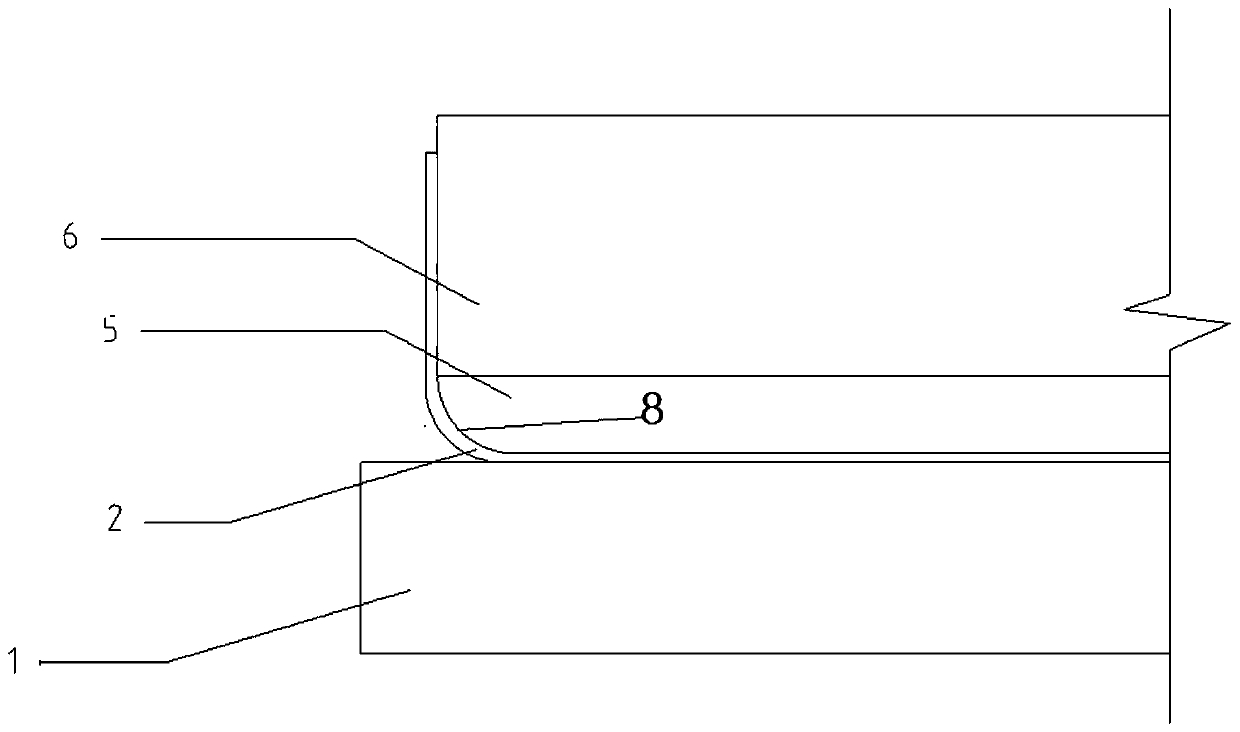

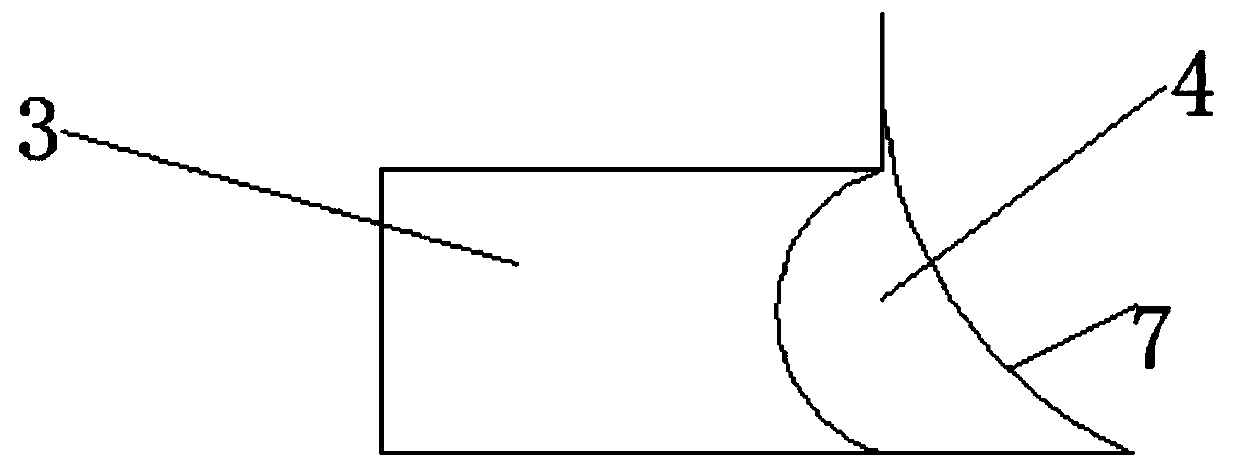

Waterproof construction method for external corner of bottom plate of urban underground comprehensive pipe gallery

ActiveCN113338335AGuaranteed waterproof qualitySimple construction methodArtificial islandsClimate change adaptationArchitectural engineeringLap joint

The invention discloses a waterproof construction method for an external corner of a bottom plate of an urban underground comprehensive pipe gallery. The waterproof construction method comprises the steps that S1, a bottom plate waterproof structure is smeared; S2, a silicone oil paper layer is laid; S3, a mortar isolation layer is smeared; S4, a bottom plate protection layer is poured, and main body construction is conducted; S5, a part of the mortar isolation layer is removed, and the chamfers are flattened; S6, an outer waterproof layer and a waterproof reinforcing layer are smeared; and S7, a waterproof protection layer on the outer side of the bottom plate is poured, and a side wall protection layer is pasted. According to the waterproof construction method, the silicone oil paper layer and the mortar isolation layer are laid between the bottom plate waterproof structure and the bottom plate protection layer, by means of the combined structure of the silicone oil paper layer and the mortar isolation layer, after bottom waterproof construction of the underground comprehensive pipe gallery base layer is completed, in the construction process of a main body structure, the bottom plate waterproof layer at the lap joint part of the bottom plate external corner is protected and is not damaged in the main body construction process, and the waterproof quality of the bottom plate external corner is ensured.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

A waterproof construction method for the outer corner of the bottom plate of an urban underground comprehensive pipe gallery

ActiveCN113338335BGuaranteed waterproof qualitySimple construction methodArtificial islandsClimate change adaptationArchitectural engineeringLap joint

The invention discloses a waterproof construction method for the outer corner of the bottom plate of an urban underground comprehensive pipe gallery. The method comprises the following steps: first, applying a waterproof structure to the bottom plate; step two, laying a silicone oil paper layer; step three, applying a mortar isolation layer; And carry out the main construction; step 5, remove part of the mortar isolation layer and smooth the chamfer; step 6, apply the outer waterproof layer and waterproof reinforcement layer; step 7, pour the outer waterproof protective layer of the bottom plate and paste the side wall protective layer. In the present invention, a silicone oil paper layer and a mortar isolation layer are laid between the bottom plate waterproof structure and the bottom plate protective layer, and the combined structure of the silicone oil paper layer and the mortar isolation layer is used to complete the bottom waterproof construction of the base of the underground comprehensive pipe gallery. Then, in the construction process of the main structure, the base plate waterproof layer at the lap joint of the base plate's outer corner is protected from damage during the main body construction process, which ensures the waterproof quality of the base plate's outer corner.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

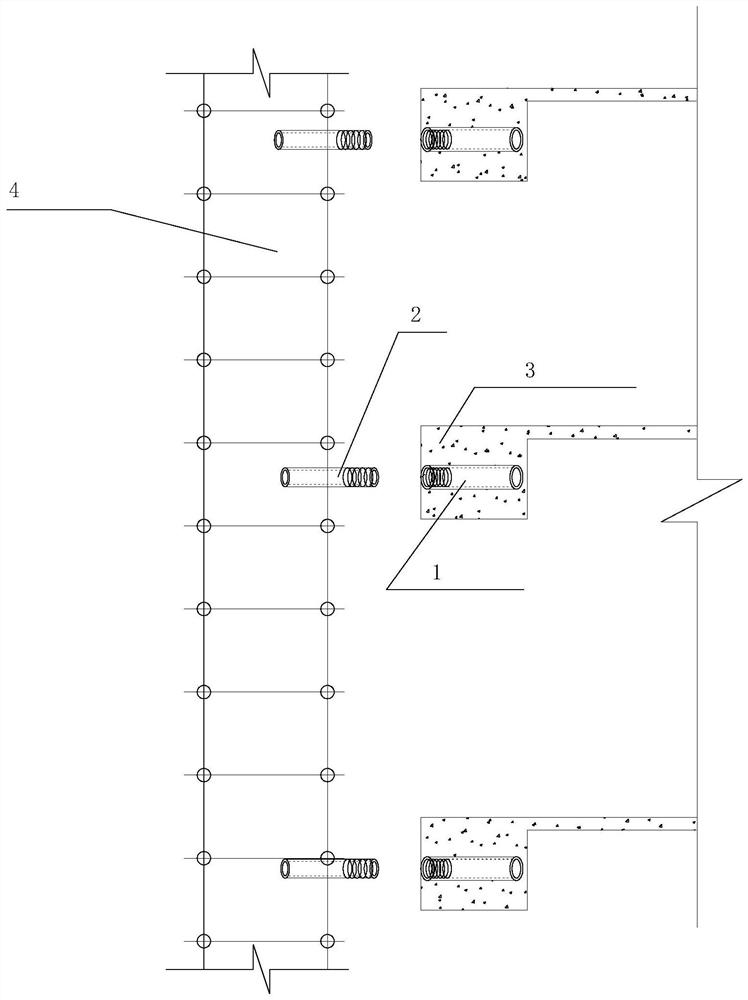

Combined anchoring piece and installation method for fixing heat preservation and decoration integrated plate with combined anchoring piece

PendingCN111305497AEasy to adjustReduce the risk of injuryCovering/liningsFlooringHeat conservationMechanical engineering

Owner:秦恒建设科技有限公司

A large-volume concrete mixture and its construction method for pouring walls

ActiveCN107673713BImprove stabilityGuaranteed waterproof qualityBuilding material handlingSlagSuperplasticizer

The invention relates to a mass concrete mixture and a construction method of pouring a wall body by the mass concrete mixture. The technical scheme adopted by the invention is that the mass concretemixture is prepared from the following raw materials in parts by weight: 165 parts of water, 214 parts of portland blast furnace slag cement, 743 parts of sand, 1070 parts of gravel, 103 parts of flyash, 95 parts of mineral powder, 4.94 parts of admixture and 0.9 part of polypropylene fibers, wherein the admixture is prepared from a JH-GHL polycarboxylate superplasticizer, an H-III type concrete mortar water-proofing agent, a UEA-H type concrete expanding agent, basic aluminum acetate and delta-aluminum oxide of which the weight ratio is 4 to 3 to 2 to 0.2 to 0.3. The construction method comprises the steps of pre-construction preparation, weighing of the raw materials, stirring of the raw materials, pouring, vibrating, primary leveling, maintenance, secondary leveling and measurement of the temperature. In the construction process of a mass concrete structure, indwelling of a post pouring belt can be avoided, the construction progress is speeded up and the construction period is shortened; in addition, without structural cracks, the overall stability of the structure is improved and the waterproof quality of a project can be ensured.

Owner:BCEG ROAD & BRIDGE CONSTR

A sealing device

The invention relates to the technical field of engineering construction, and discloses a well sealing device, which includes a casing, a grouting pipe and a switch assembly; the first end of the casing is inserted into the well pipe, and the casing and the well The pipe is sealed and fixedly connected; the grouting pipe is arranged in the casing, the first end of the grouting pipe is exposed to the second end of the casing, and the grouting pipe is sealed and fixedly connected to the casing ; The switch assembly is arranged on the first end of the grouting pipe. Due to the sealed and fixed connection between the casing and the well pipe, and the sealed and fixed connection between the grouting pipe and the casing, grouting is injected from the grouting pipe into the bottom dewatering well, and the switch assembly is closed after grouting, so the pressurized water in the bottom dewatering well will not flow In the foundation pit, the water will not flow from the bottom of the pit to the bottom of the bottom plate and damage the bottom plate, which can ensure the waterproof quality of the bottom plate.

Owner:BEIJING TIANRUN CONSTR

Scaffold wall connecting piece

PendingCN111677263AImprove construction safetyReduce security risksScaffold accessoriesScrew threadIndustrial engineering

An embodiment of the invention discloses a scaffold wall connecting piece. The scaffold wall connecting piece comprises a pre-embedded connecting piece and a wall connecting rod, the pre-embedded connecting piece is pre-embedded in an outer wall, the pre-embedded connecting piece is in threaded connection with one end of the wall connecting rod, the other end of the wall connecting rod is connected with an outer vertical rod of a scaffold through a fastener, and an end face of the pre-embedded connecting piece is flush with a side face of the outer wall. According to the scaffold wall connecting piece in the embodiment of the invention, the defect that the wall connecting rod penetrates through the wall is overcome; the processes of hole reserving, reserved hole plugging and the like of atraditional wall connecting rod in a wall body are omitted, and the construction progress is accelerated; the overall quality of an outer wall masonry is improved, and the waterproof quality of the outer wall is guaranteed; and the construction safety is improved, and potential safety hazards are reduced.

Owner:MCC5 GROUP CORP SHANGHAI

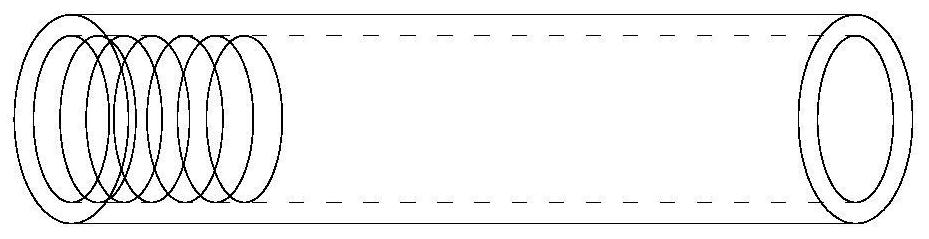

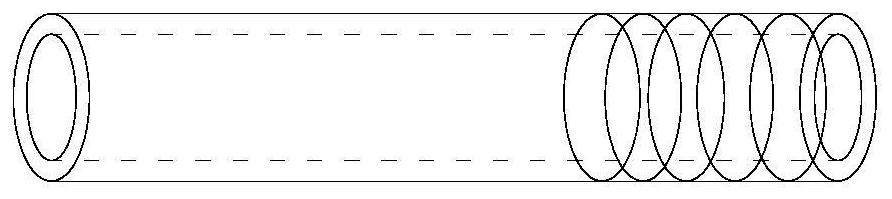

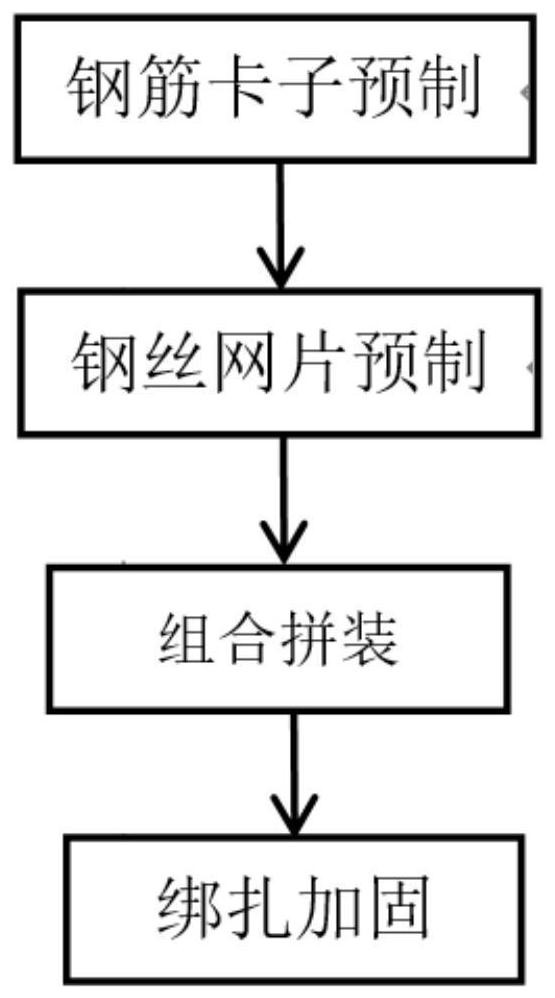

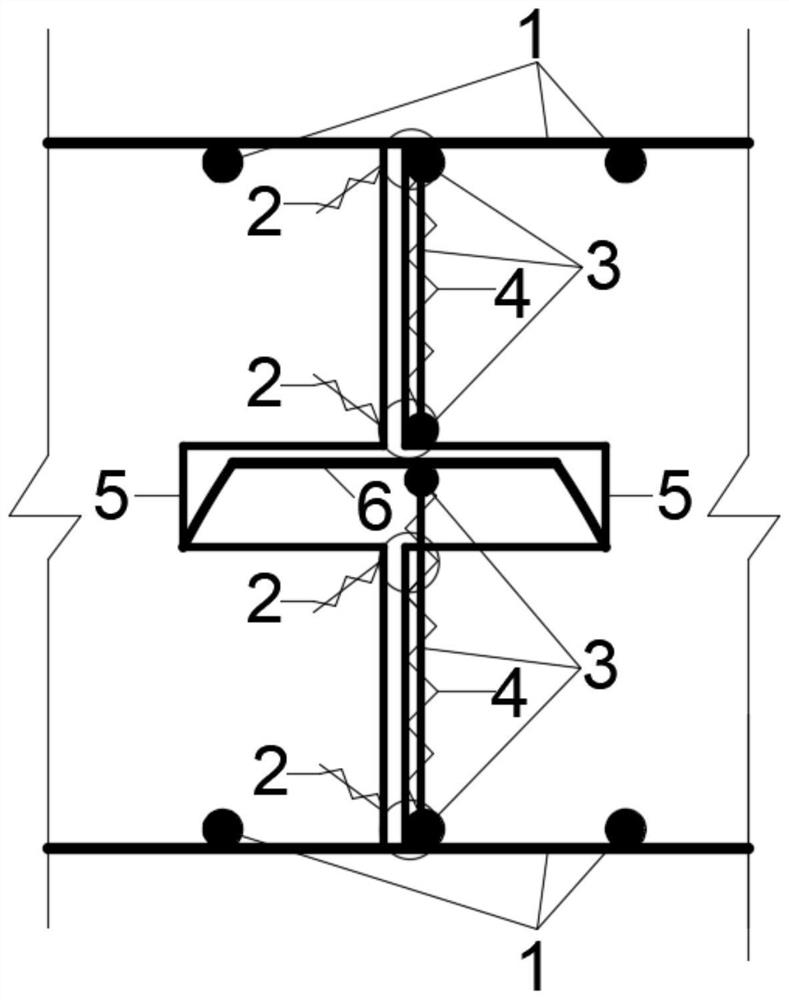

Non-destructive reinforcing combination device for water stop steel plate and manufacturing method of non-destructive reinforcing combination device

PendingCN114855882AEasy to handleGuaranteed waterproof qualityArtificial islandsClimate change adaptationWater stopRebar

The invention provides a waterstop steel plate lossless reinforcing combination device and a manufacturing method, the waterstop steel plate lossless reinforcing combination device comprises prefabricated steel bar clamps, a waterstop steel plate and a prefabricated steel wire mesh assembly, the waterstop steel plate is sleeved with the steel bar clamps, the multiple sets of steel bar clamps are arranged at intervals in the length direction of the waterstop steel plate, and the tops and the bottoms of the steel bar clamps are connected with structural steel bars through binding wires; the prefabricated steel wire mesh assembly comprises a steel wire mesh framework and a steel wire mesh, the steel wire mesh is connected with the steel wire mesh framework through binding wires, and the prefabricated steel wire mesh assembly is connected to the steel bar clamps through binding wires. Prefabricated steel wire mesh assemblies are arranged above and below the water stop steel plate. The device is simple in structure, convenient to operate, high in binding efficiency, good in water stop effect, capable of guaranteeing the waterproof quality of the water stop steel plate, capable of being recycled and reused, capable of saving cost and high in practicability, and the water stop steel plate does not need to be welded and reinforced.

Owner:CHINA FIRST METALLURGICAL GROUP

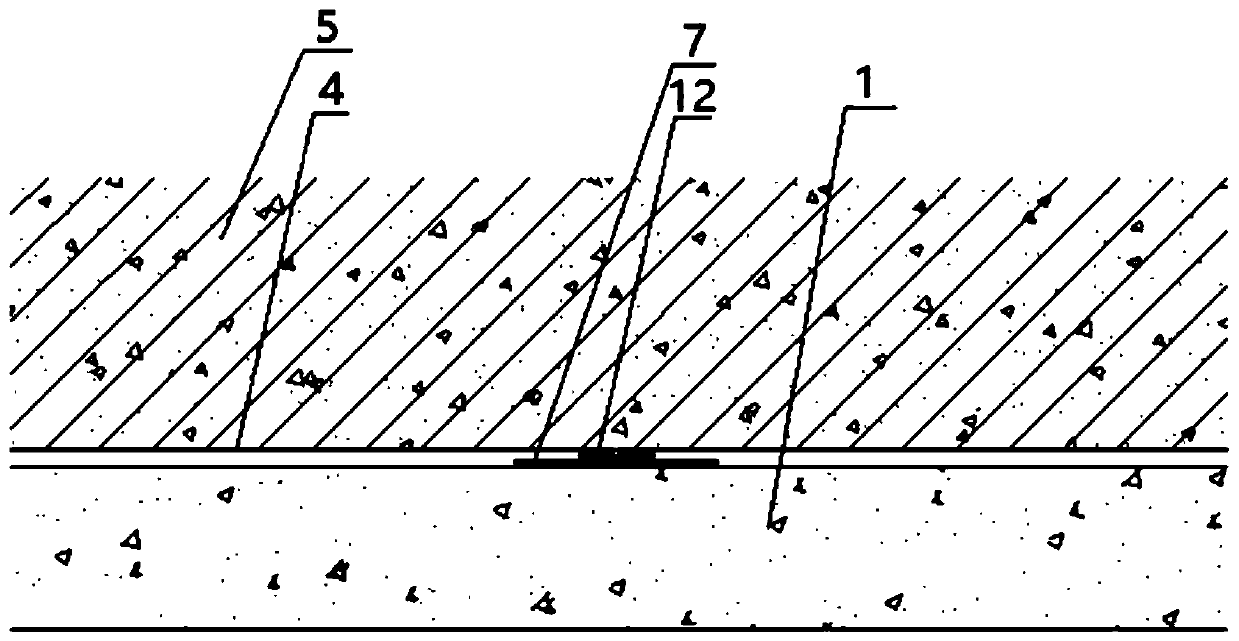

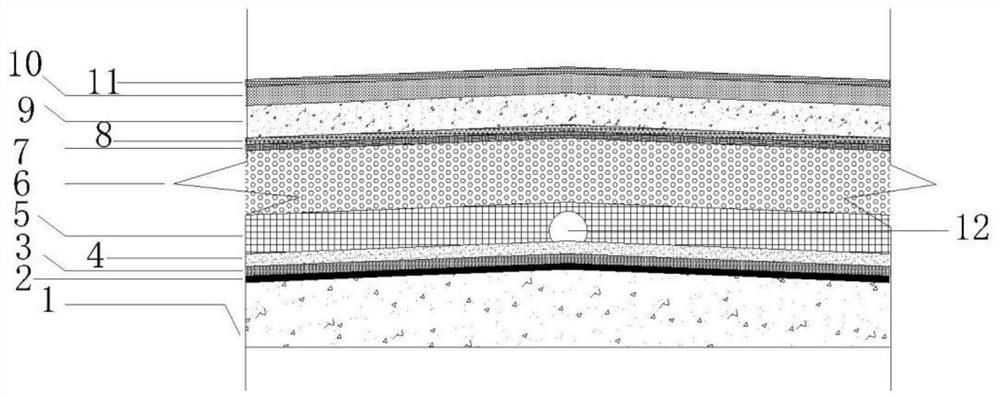

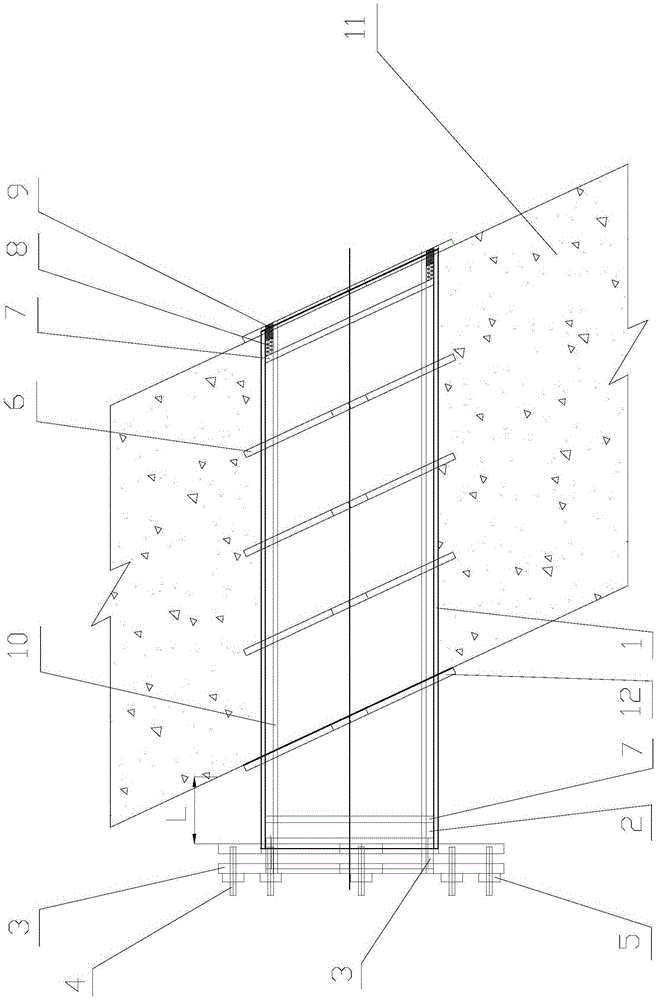

Inverted type person-bearable facing brick roof concealed buried exhaust pipeline invisible structure and construction method thereof

ActiveCN113006388AScientific and reasonable design settingsRigorous processLighting and heating apparatusBuild-up roofsRubberized asphaltRebar

The invention discloses an inverted type person-bearable facing brick roof concealed buried exhaust pipeline invisible structure and a construction method thereof. The inverted type person-bearable facing brick roof concealed buried exhaust pipeline invisible structure comprises a steel bar structure concrete roof, a sprayed non-cured rubber asphalt waterproof coating, a self-adhesive 1.5mm-thick tire-free high polymer modified asphalt waterproof coiled material, a 20-thick 1:3 cement mortar leveling layer, a point-adhesive 60-thick extruded polystyrene foam plastic plate for heat insulation, the thinnest 30-thick LC5.0 light aggregate concrete, a full-laid non-woven fiber cloth layer, a steel bar mesh, a 50-thick C20 fine aggregate concrete leveling layer, a roller-coated waterproof polymer layer and 8-10-thick facing anti-skid floor tiles which are sequentially arranged from the bottom layer to the top layer of the roof, and further comprises an oval PVC gas collecting flow guide pipe and an exhaust vertical pipe, wherein the oval PVC gas collecting flow guide pipe is horizontally arranged between the cement mortar leveling layer and the non-woven fiber cloth. According to the inverted type person-bearable facing brick roof concealed buried exhaust pipeline invisible structure and the construction method thereof, exhaust is smooth and free of blockage, water stains seeping from a construction layer above a part of heat preservation layer and condensate water in the heat preservation layer can be quickly guided and discharged in time, the comprehensive construction cost is low, and the service life of the roof is prolonged.

Owner:WUHAN CONSTR ENG

Flexible waterproof casing

The invention discloses a flexible waterproof sleeve which comprises a flange sleeve, a steel pipe, a flange gland and water stop rings. The flange sleeve horizontally penetrates an oblique concrete base body, the inclining direction of a flange at the inner opening port of the flange sleeve is consistent to an inclination angle of the concrete base body, the flange tightly adheres to an oblique plane of the inner side of the concrete base body, and a non-interfered distance is reserved between the flange at the outer opening end of the flange sleeve and an oblique plane of the outer side of the concrete base body. The steel pipe and the flange sleeve are coaxially arranged, and the flange gland press a rubber seal ring on the flange at the outer opening end of the flange sleeve between the flange sleeve and the steel pipe through a screw and a nut. A flexible joint filling material is filled between the flange sleeve at the inner opening end and the steel pipe, and a sealant is caulked into joints to achieve sealing. The water stop rings are evenly arranged on the flange sleeve at intervals. The flexible waterproof sleeve is especially suitable for installation of vibrating flexible waterproof sleeves with funnel-type side walls, a special usage mode of the flexible waterproof sleeve is changed into a common usage mode, the operability is good, and the flexible waterproof sleeve has general popularization significance.

Owner:CHINA 19TH METALLURGICAL FANGCHENGGANG DEVICE STRUCTURES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com