Waterproof method for construction joints of underground excavation section of open-cut station

A technology for construction joints and stations, which is applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems affecting the safety of the catenary of the arch due to current flow, the increased impact on the safety of operation and traffic, and the safety of train operation. High practical value, good waterproof effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

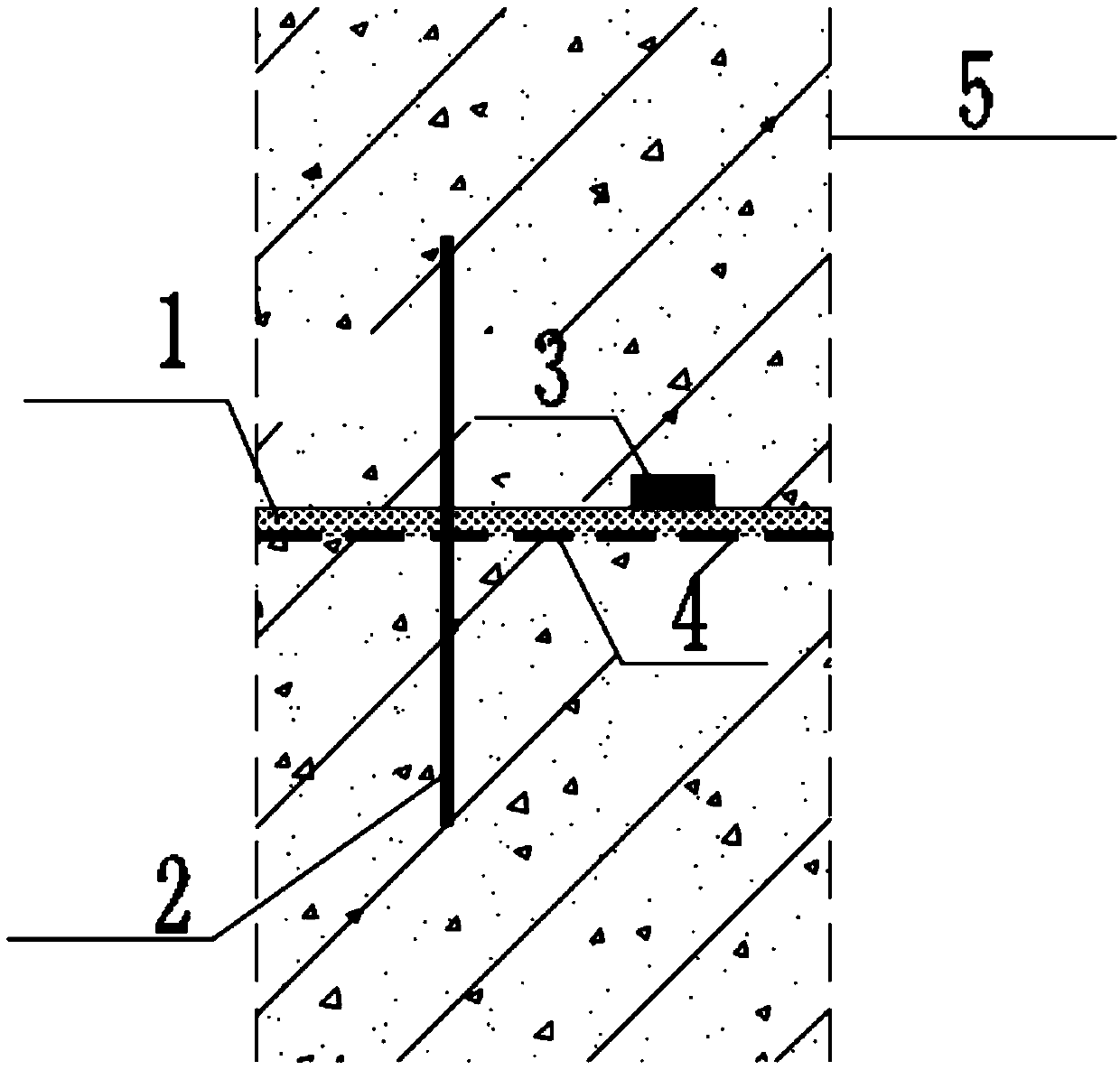

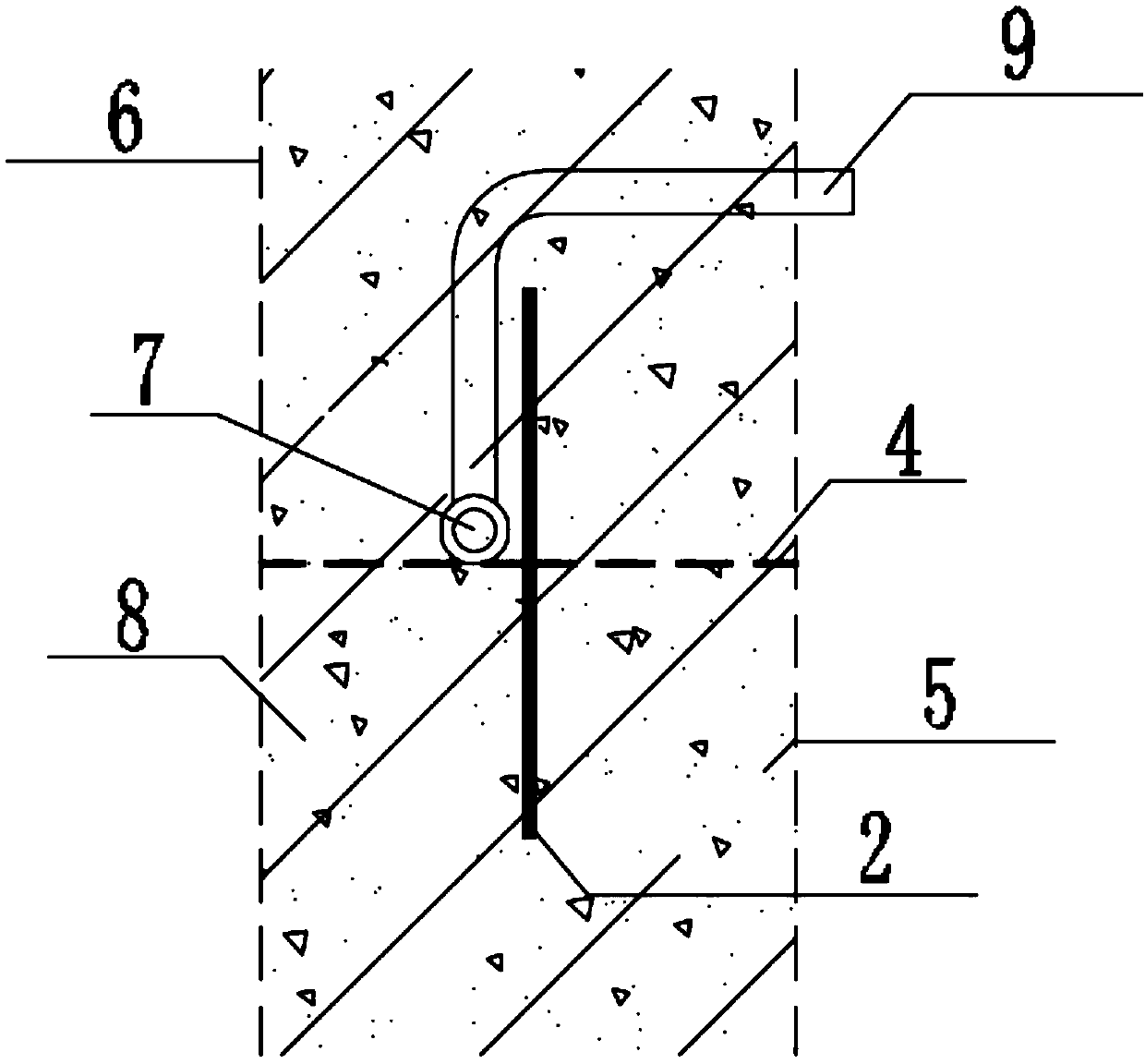

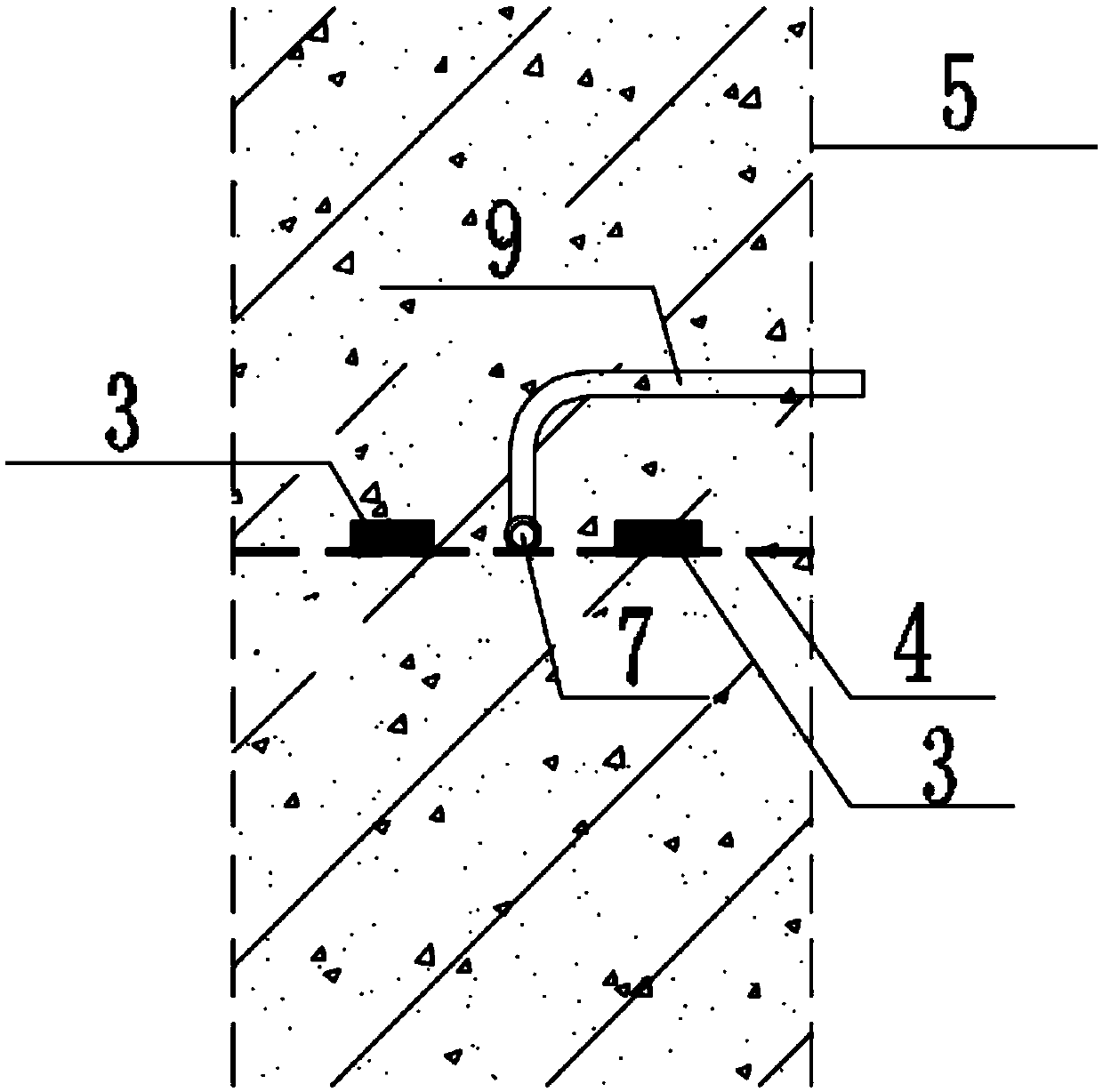

[0028] see Figure 1-Figure 5 , a method for waterproofing construction joints in the underground excavation section of an open-excavation station, comprising cement-based permeable crystalline material 1, rubber waterstop 2, water-stop glue 3, construction joint 4, pre-embedded grouting pipe 7 and grouting conduit 9, wherein , Concrete construction joints poured in sections 4 are divided into two types: longitudinal construction joints and circumferential construction joints. The longitudinal construction joints should not be left at the place where the shear force and bending moment are maximum or at the junction of the bottom plate and the side wall, but should be left above the bottom plate The surface of the wall is not less than 30mm; in order to avoid water leakage caused by shrinkage cracks between the two con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com