Inverted type person-bearable facing brick roof concealed buried exhaust pipeline invisible structure and construction method thereof

An exhaust duct and construction method technology, applied in the direction of roof, roof covering, roof ventilation, etc., can solve problems such as inability to repair or high maintenance cost, quality cannot be guaranteed, waterproof layer damage and failure, etc., and achieve comprehensive cost. Low cost, low comprehensive construction cost, no effect of rework and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The following are multiple project examples and drawings of the Phoenix Business Service Center project, the swimming pool of Wuhan Business School for the 7th Military World Games, the new student dormitory building of Wuhan Business School, and the Chedu Chuntaili (Phase I) project. The present invention will be further described.

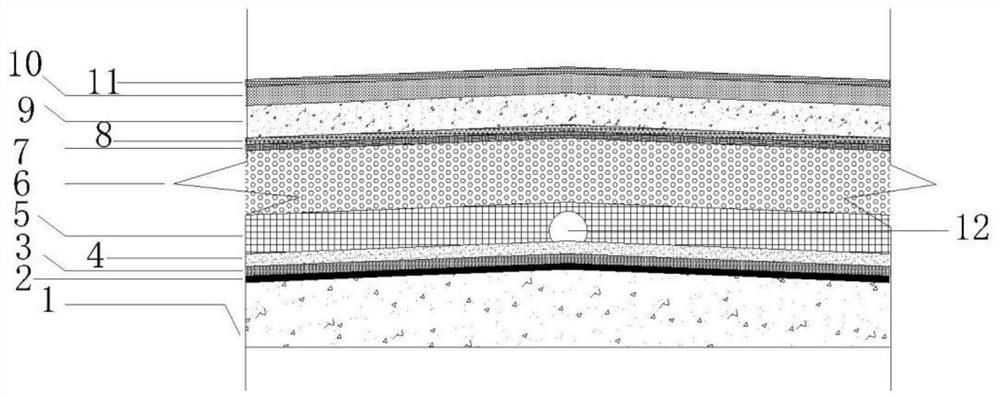

[0067] Such as Figure 1-8 As shown, the invisible structure of the inverted master facing brick roof with hidden exhaust pipes provided in this embodiment, the hierarchical structure of the master roof from the bottom layer to the top layer of the roof is as follows: reinforced concrete roof 1, spraying non-curing rubber asphalt waterproof coating 2 , self-adhesive 1.5mm thick tireless high polymer modified asphalt waterproofing membrane 3, use 20 thick 1:3 cement mortar leveling layer 4, measure and set out the positioning, and bury the already cut elliptical PVC air collecting duct 12 According to the layout diagram, several elliptical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com