Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Guaranteed observation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

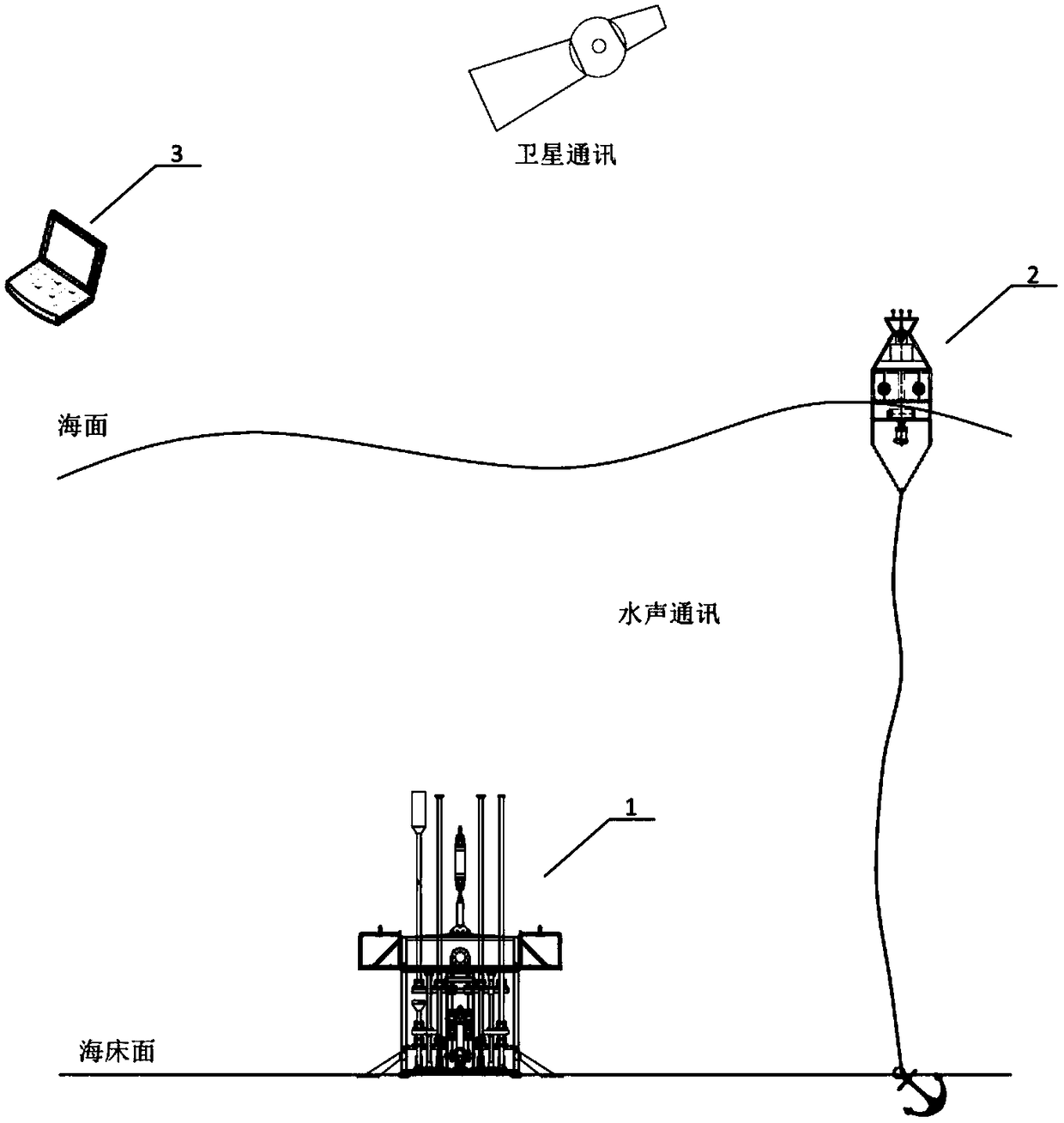

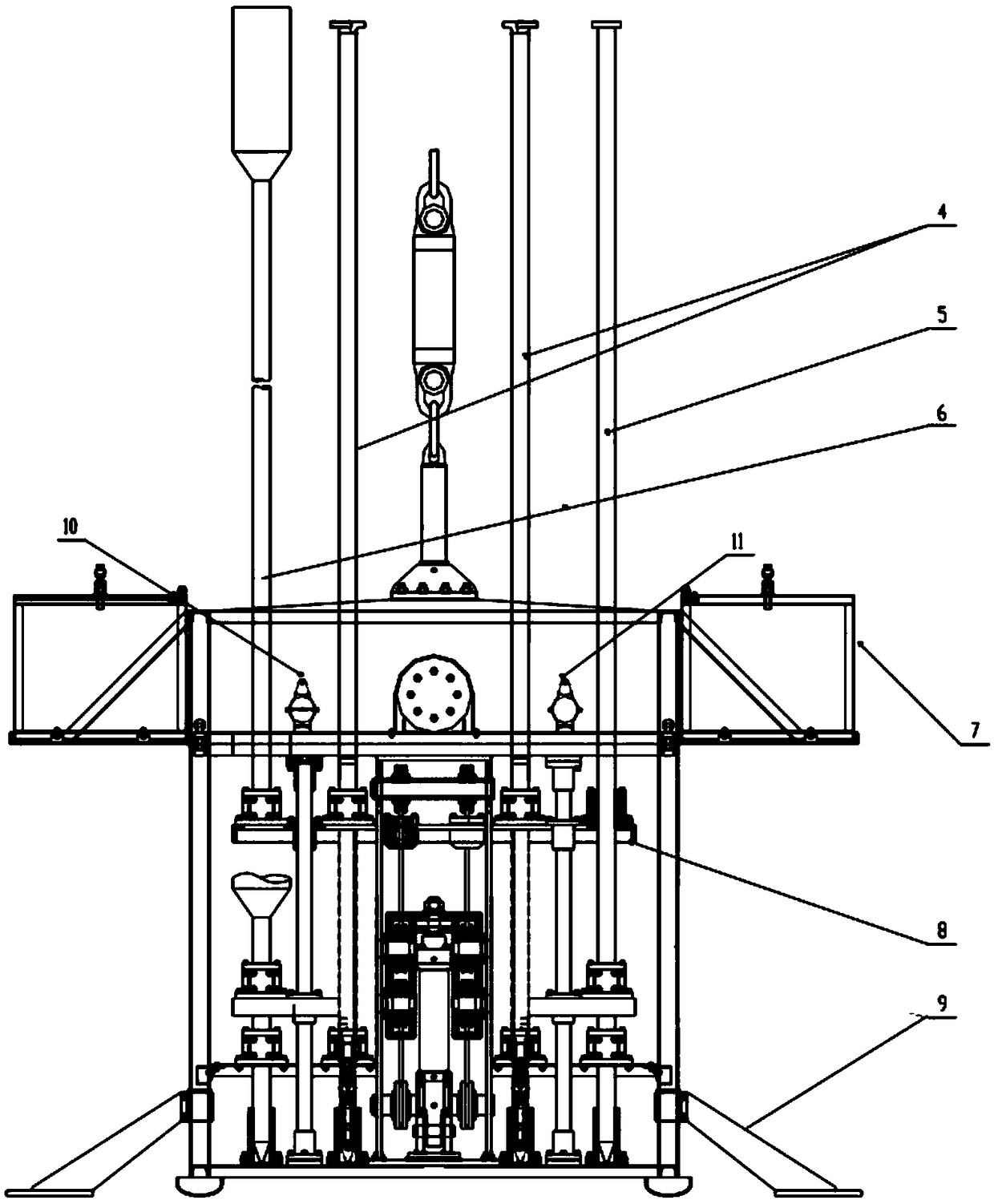

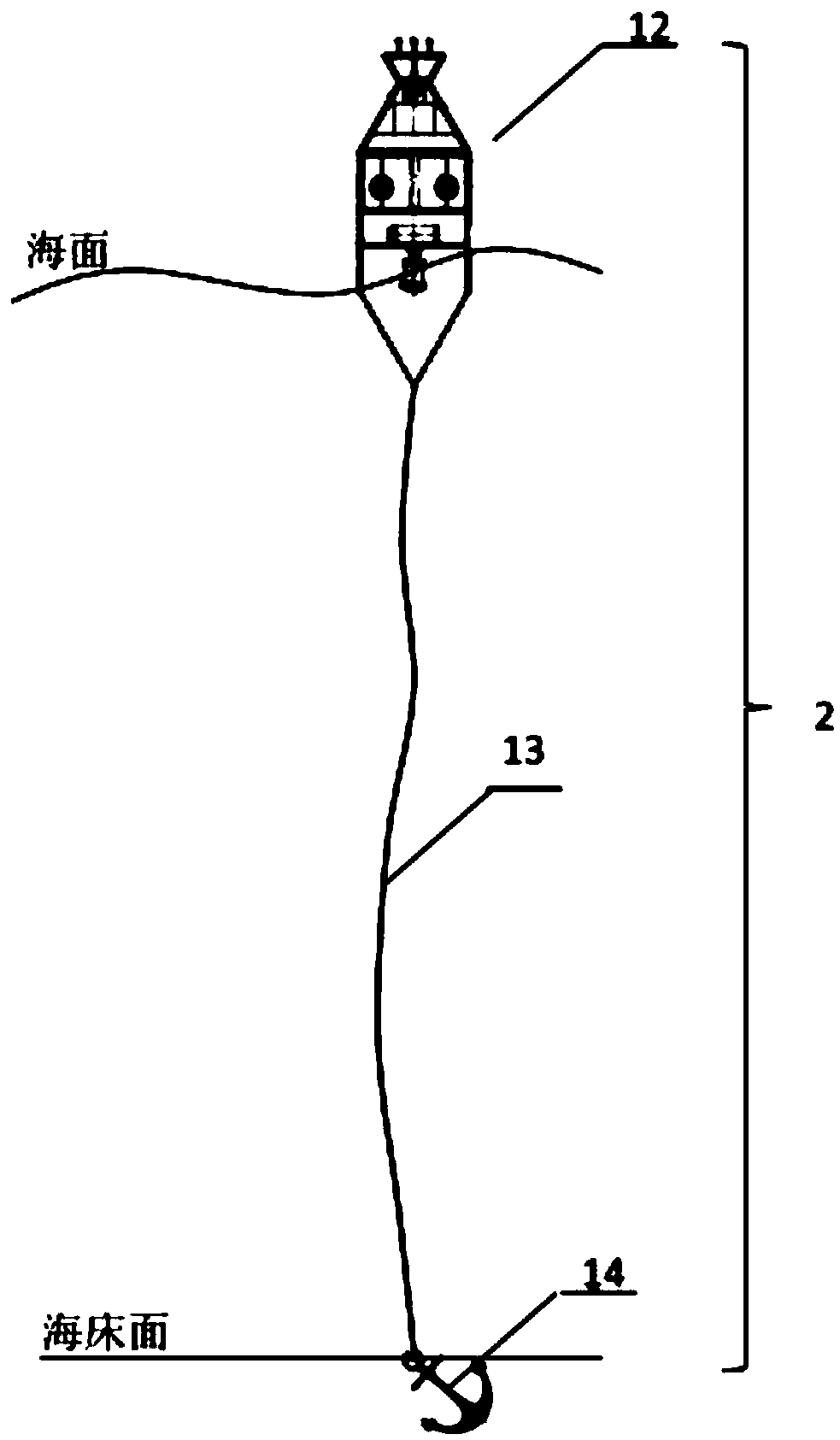

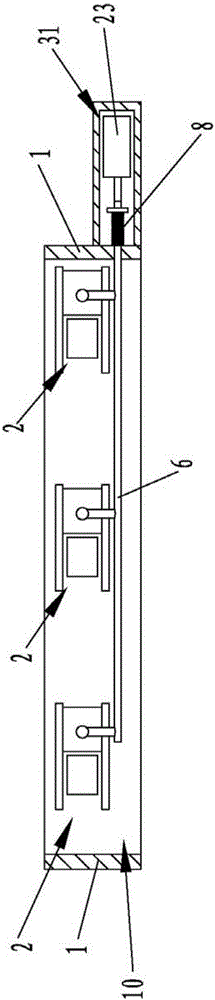

In-situ long-term real-time observation system and method for deep-sea engineering geological environment

ActiveCN108955764ALong-term observationReal-time observationMeasurement devicesElectrical batteryBuoy

The invention relates to an in-situ long-term real-time observation system and method for the deep-sea engineering geological environment. The in-situ long-term real-time observation system comprisesobservation instruments, a mat-supported carrying platform, an observation data relay and transmission buoy system, a remote observation data management server, a client and a matched release and recovery method. The observation instruments and the carrying platform are laid and recycled through a hydraulic penetration mechanism, an acoustic releaser and an underwater robot. The observation instruments and the mat-supported carrying platform are integrated with seawater batteries, and relay and transmission buoys are integrated with solar batteries, thereby realizing self power supply of a submarine observation platform and a sea surface data relay system. The remote observation data management server and the client can query and download the observation data and change parameter settings.The in-situ long-term real-time observation system overcomes the defects that a submarine observation network is long in construction time and great in capital investment and that the common mat-supported observation station cannot be powered by itself or perform real-time data transmission, realizes in-situ, long-term and real-time observation for the deep-sea engineering geological environmentand can be applied to projects such as long-term monitoring for the deep-sea hydrate mining environment and the like.

Owner:OCEAN UNIV OF CHINA

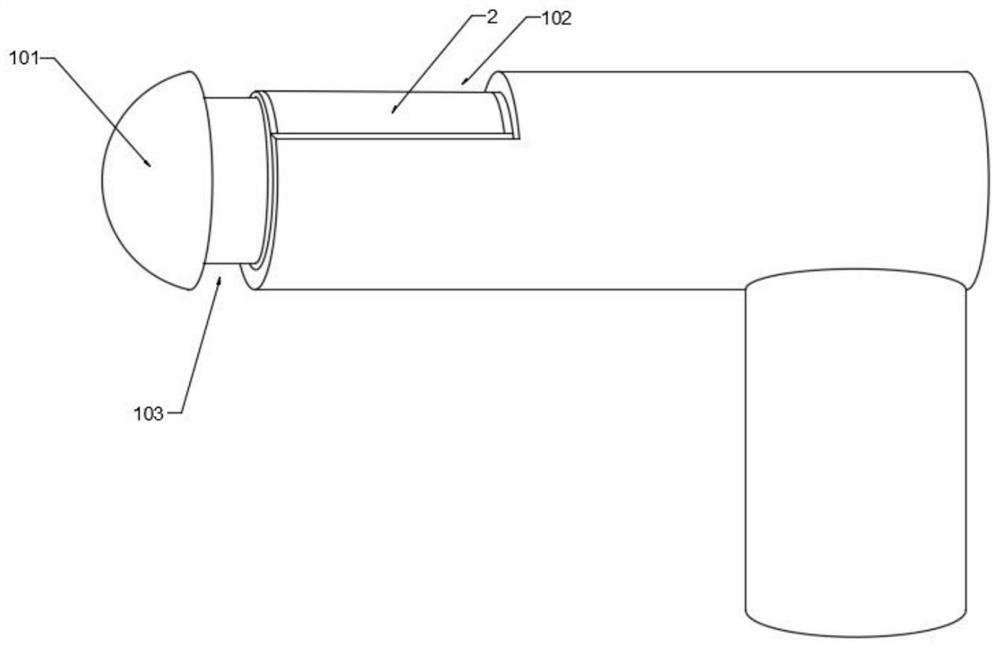

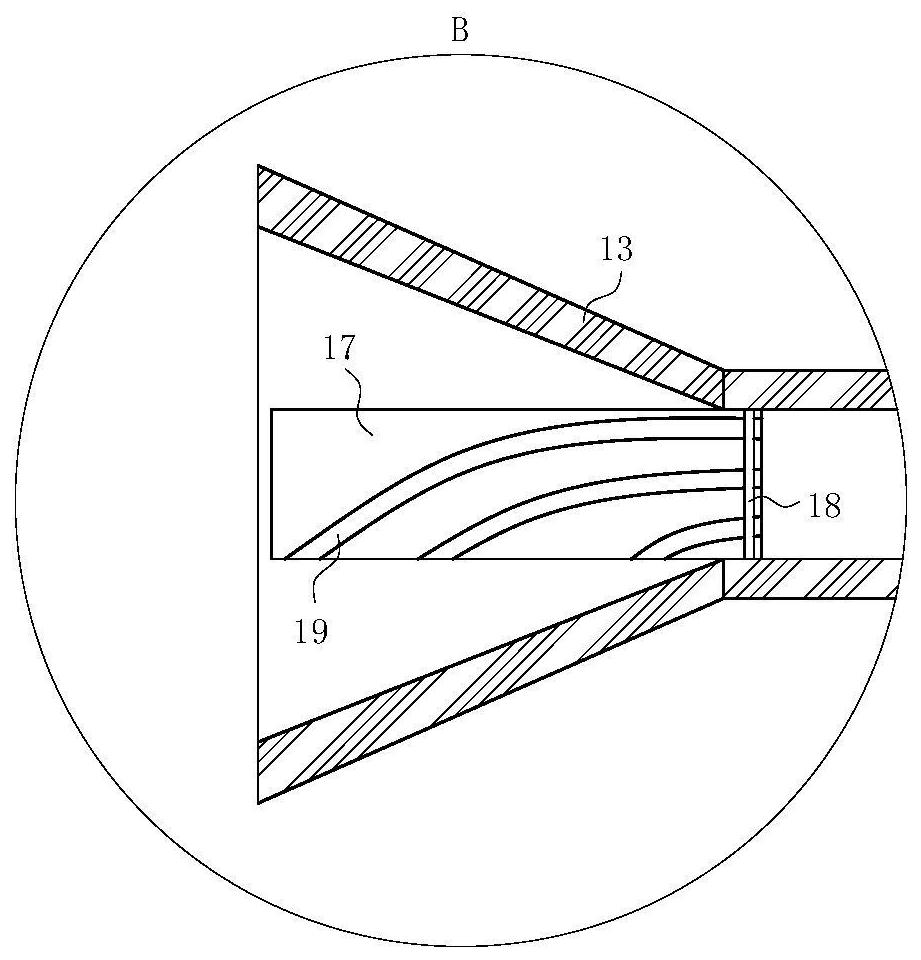

Self-cleaning observation window device

ActiveCN103913072AGuaranteed observation effectWill not affect the line of sightFurnace componentsCleaning using toolsEngineeringElectrical and Electronics engineering

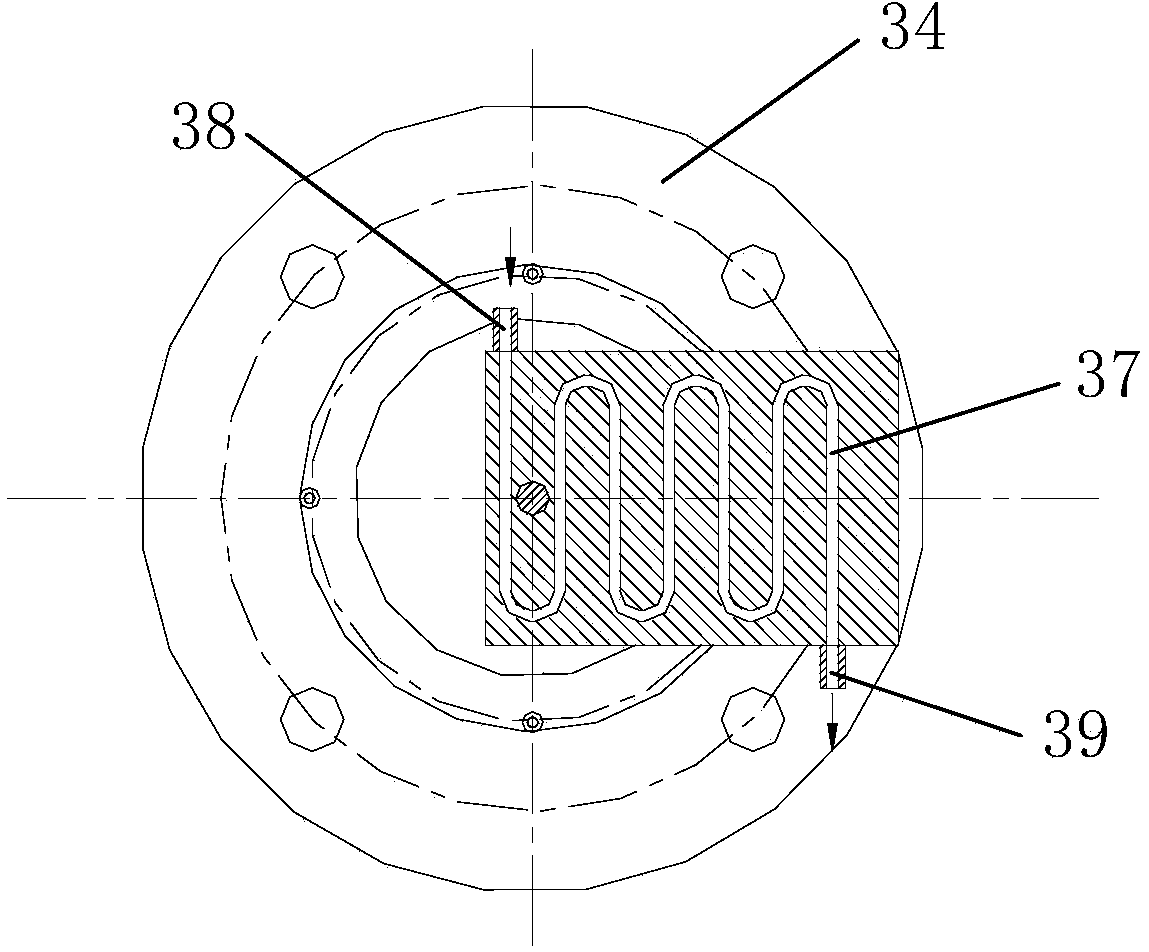

The invention relates to a self-cleaning observation window device comprising a housing with two end openings, observation window glass, a rotary drive mechanism, and a cleaning brush mechanism. One end opening of the housing is fixed to an article to be observed. The observation window glass is mounted at the other end opening of the housing. The fixed end of the rotary drive mechanism is fixed outside the housing; the moving end of the rotary drive mechanism is fixedly connected with the observation window glass; the rotary drive mechanism drives the observation window glass to rotary around a center shaft in the housing. The cleaning brush mechanism is fixed inside the housing and contacts with the inner surface of the observation window glass. The self-cleaning observation window device has the advantages that the rotary drive mechanism drives the observation window glass to rotate just after the housing is mounted on an opening of the article to be observed, the observation window glass is cleaned by the cleaning brush mechanism meanwhile, cleanliness of the observation window glass is ensured, no influence is generated upon interior temperature and vacuum degree of the article to be observed, and the self-cleaning observation window device is more widely applicable.

Owner:BAOSTEEL ENG & TECH GRP

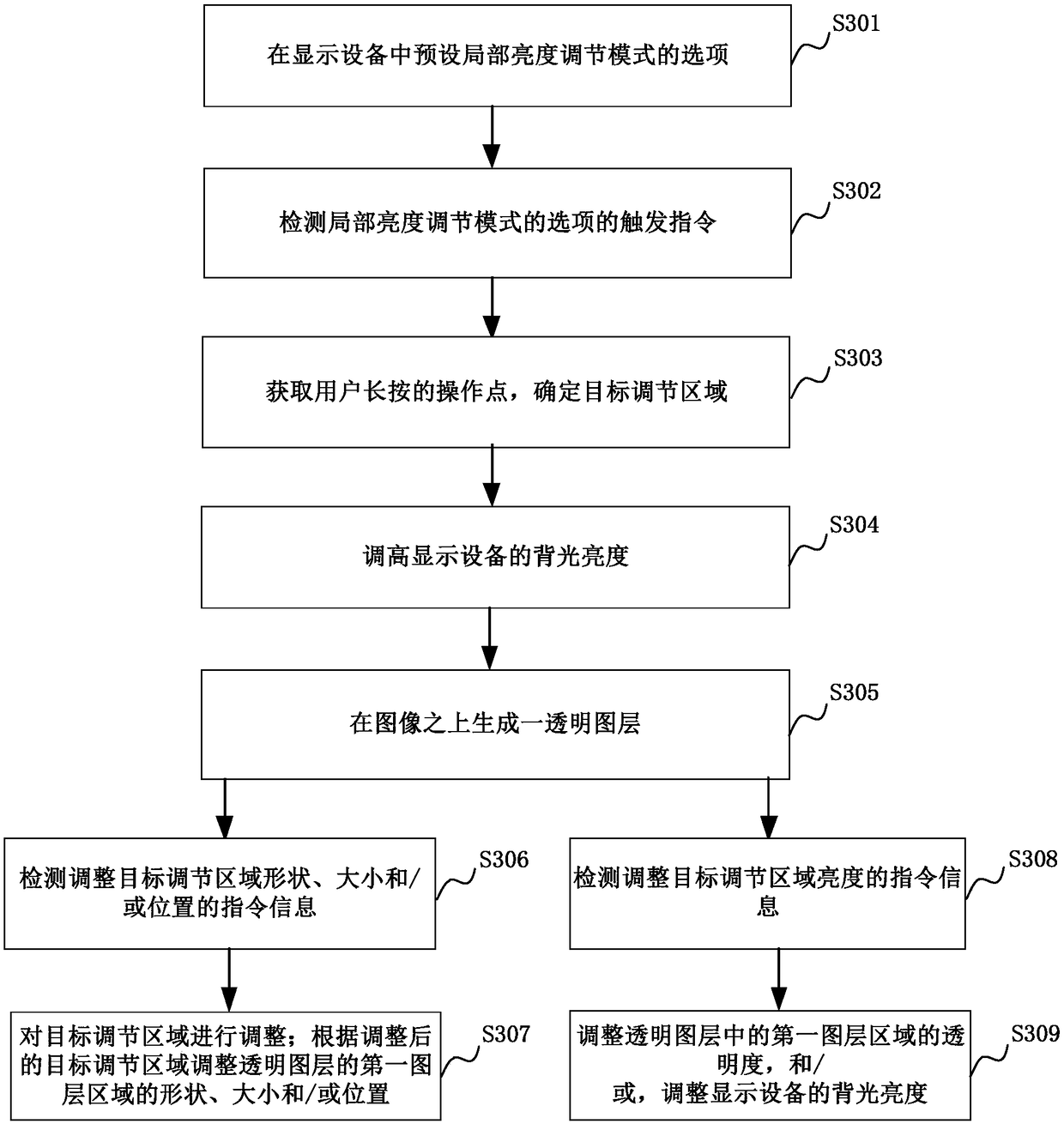

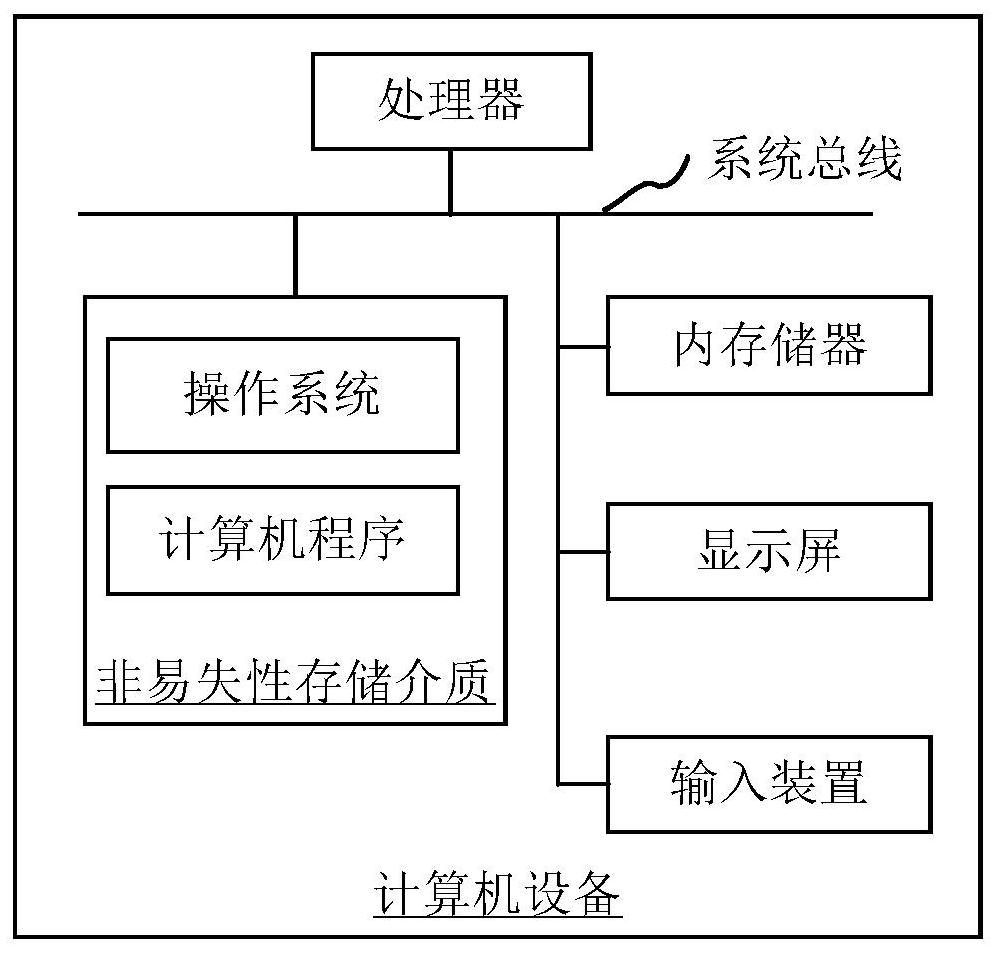

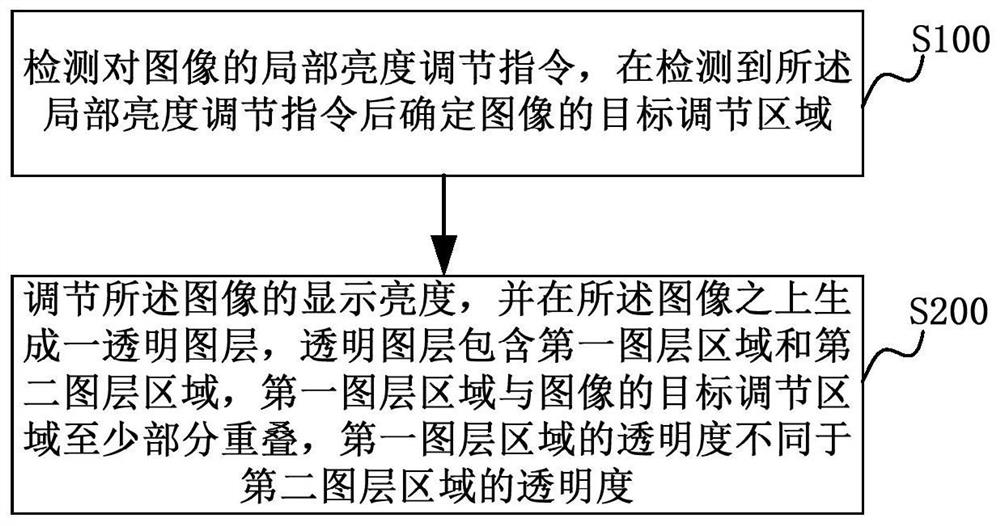

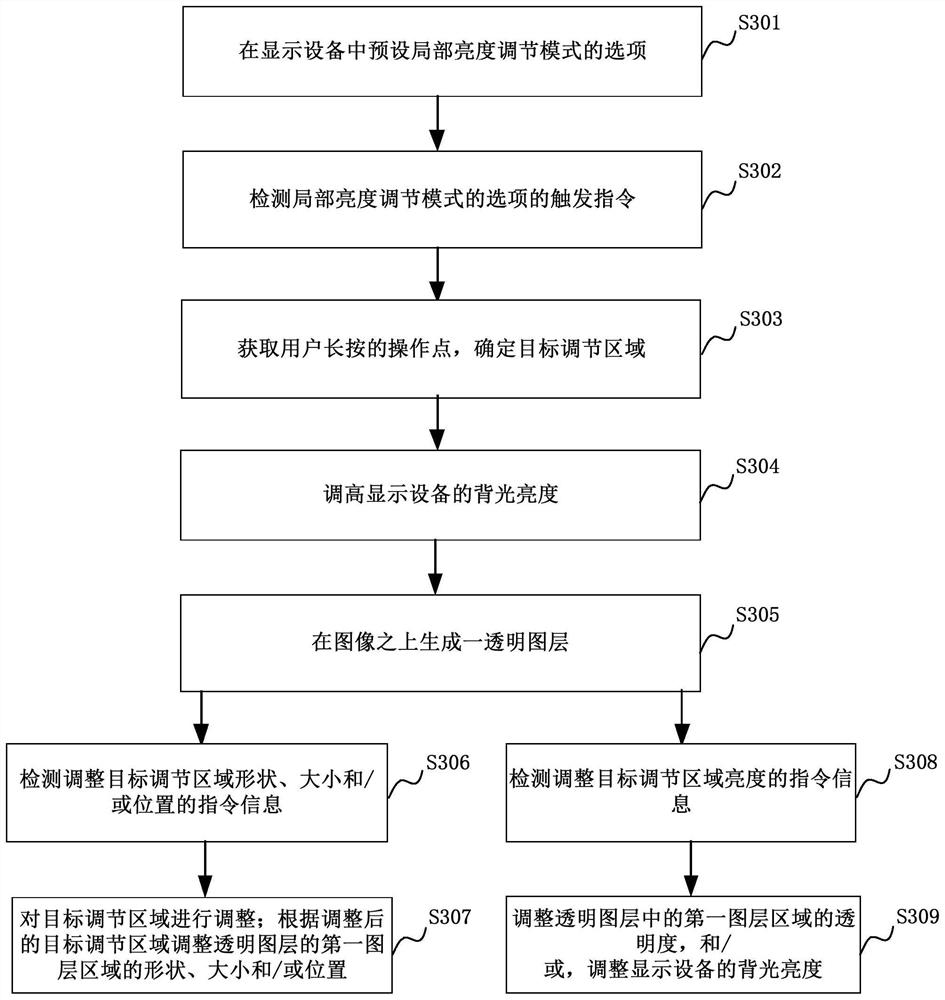

Image display adjusting method and device, computer equipment and storage medium

ActiveCN108646969AGuarantee the effect of observationRealize local brightness adjustment functionInput/output processes for data processingComputer equipmentComputer graphics (images)

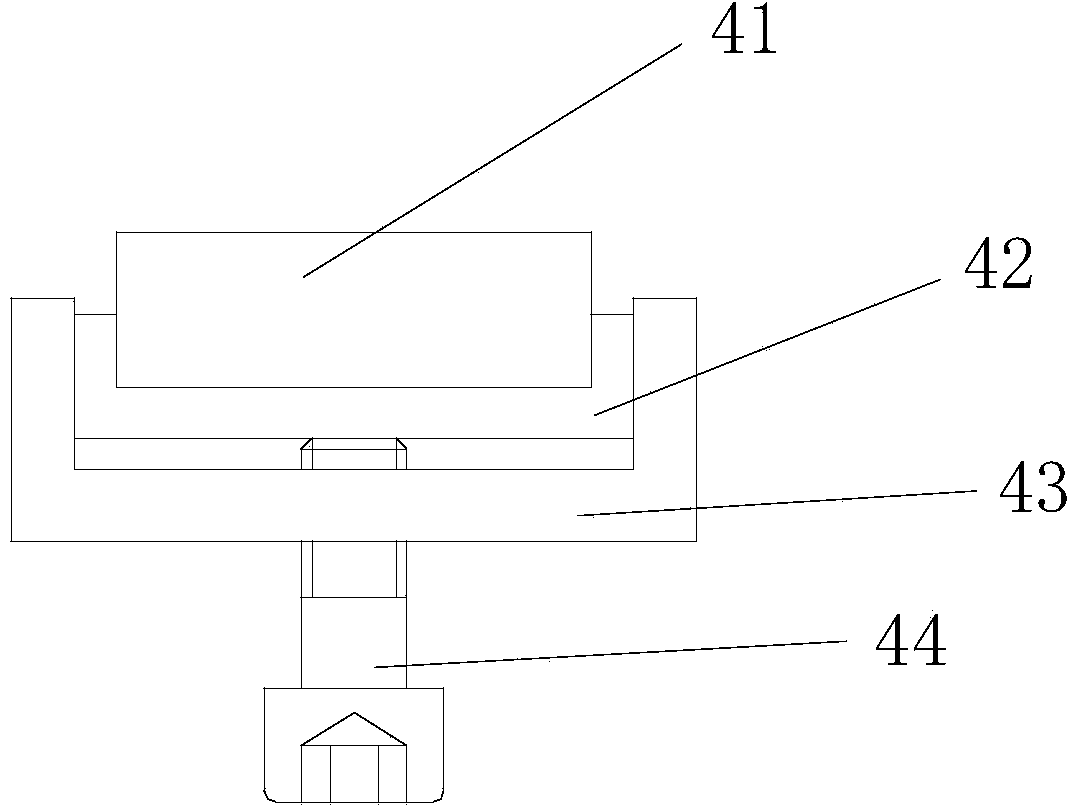

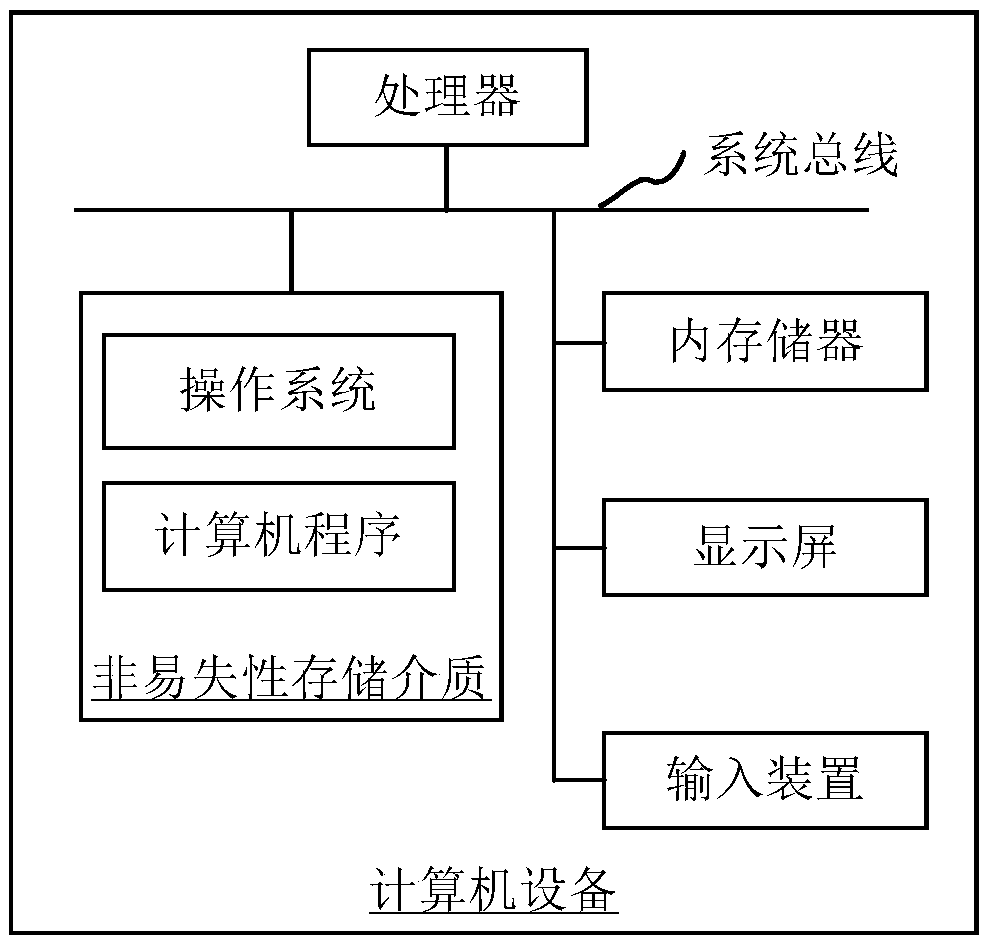

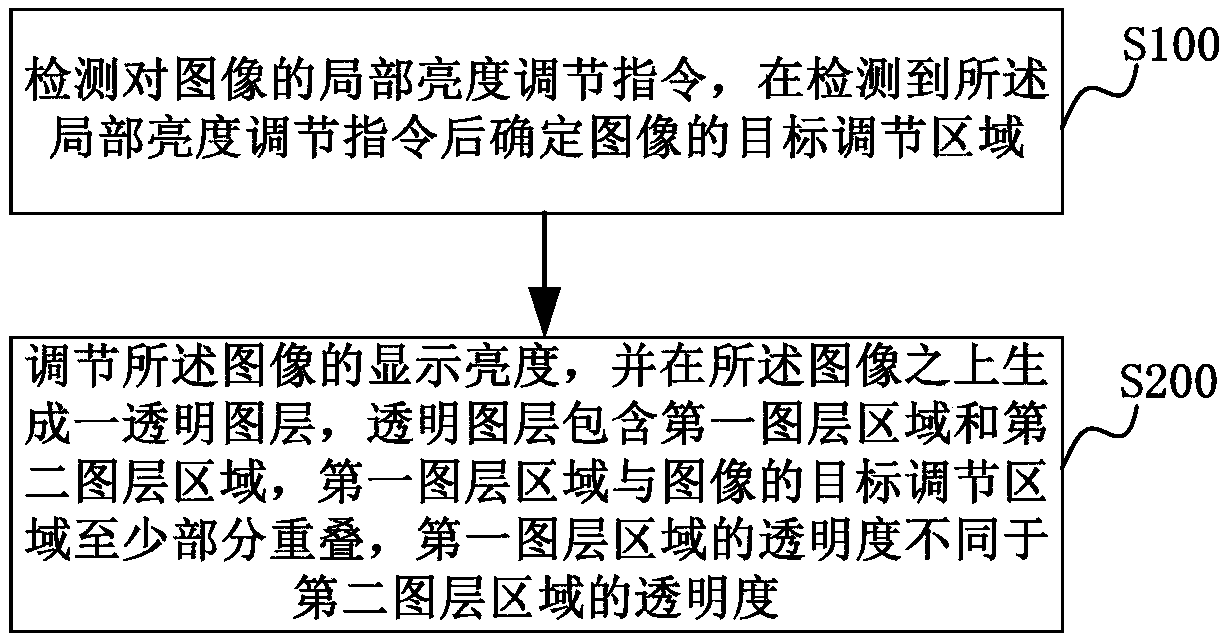

The invention relates to an image display adjusting method and device, computer equipment and a storage medium, which are applied in the field of image processing. The method comprises the following steps: detecting a local brightness adjusting command of an image, and determining a target adjusting area of the image after the local brightness adjusting command is detected; and adjusting the display brightness of the image, and generating a transparent layer on the image, wherein the transparent layer includes a first layer area and a second layer area, the first layer area and the target adjusting area of the image are at least partially overlapped, and the transparency of the first layer area is different from that of the second layer area. Through adoption of the image display adjustingmethod and device in the embodiment of the invention, the problem of difficulty in ensuring the image observing quality in an existing adjustment manner is solved, and the effect of adjusting the local display brightness of the image can be realized.

Owner:广州视创显示科技有限公司

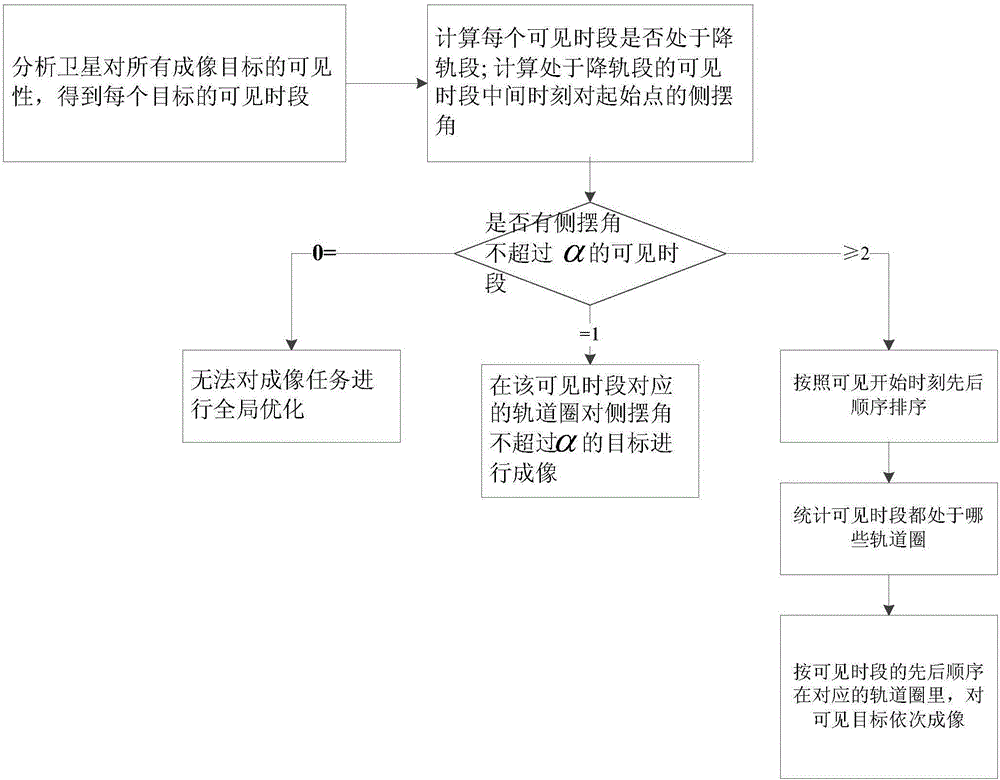

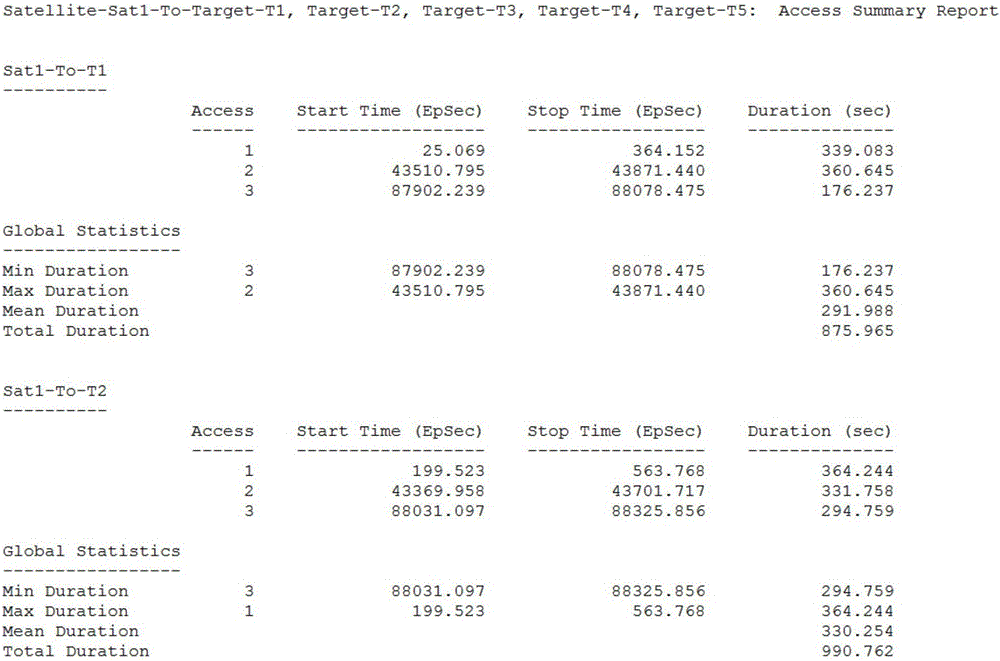

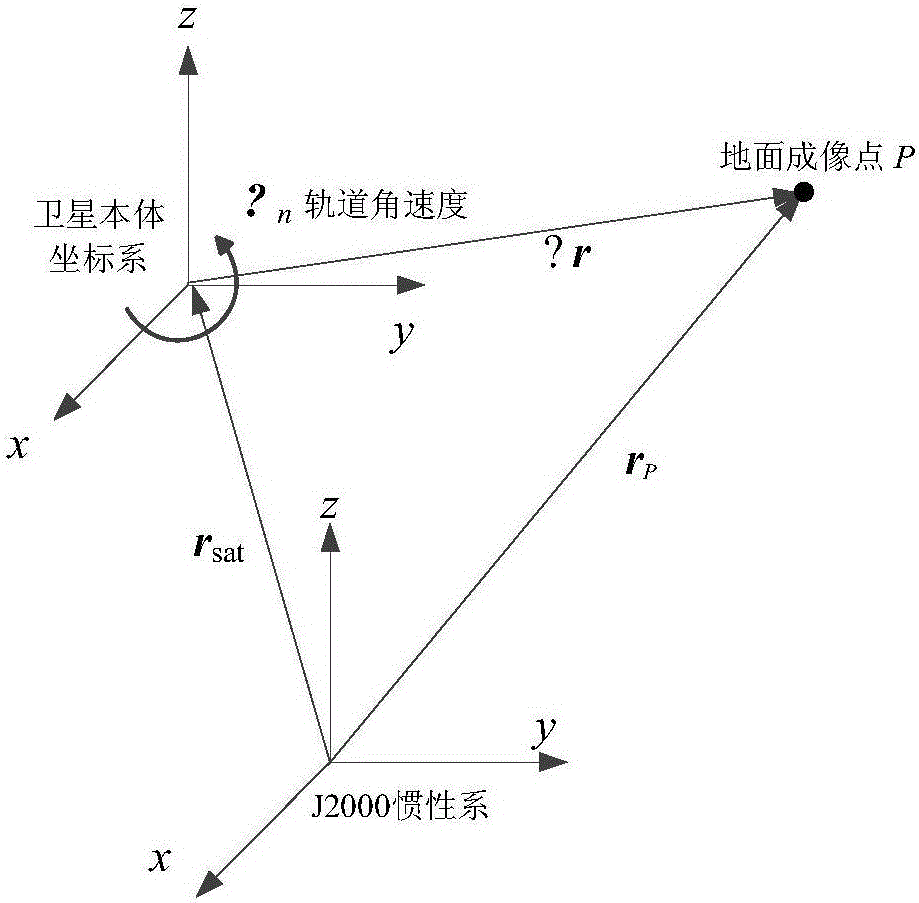

Method for global optimization and distribution of agile satellite imaging tasks

ActiveCN106353771AAchieving Global Optimal AllocationAchieve optimal distributionSatellite radio beaconingVisibilityImaging quality

The invention discloses a method for global optimization and distribution of agile satellite imaging tasks and belongs to the field of agile satellite imaging task planning. The method includes analyzing visibility of a satellite for all imaging targets, selecting visible time periods in an inbound pass segment and in which a lateral swing angle that the satellite points to each target start point at an intermediate moment does not exceed a specific range, and sequentially the imaging visible targets in corresponding orbit laps according to the sequence of the visible time periods. The method takes multiple factors such as satellite energies, imaging efficiency and imaging quality from the perspective of satellite application and puts forward the optimization principle that the target imaging time periods are in the inbound pass segment and the lateral swing angle at the intermediate moment of each visible time period is smaller than the specific range, and multiple imaging tasks are distributed to the proper orbit laps to enable the imaging task planning to be more reasonable and meet the satellite application requirements, so that observation results are optimized, imaging quality is guaranteed and energy consumption is reduced.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

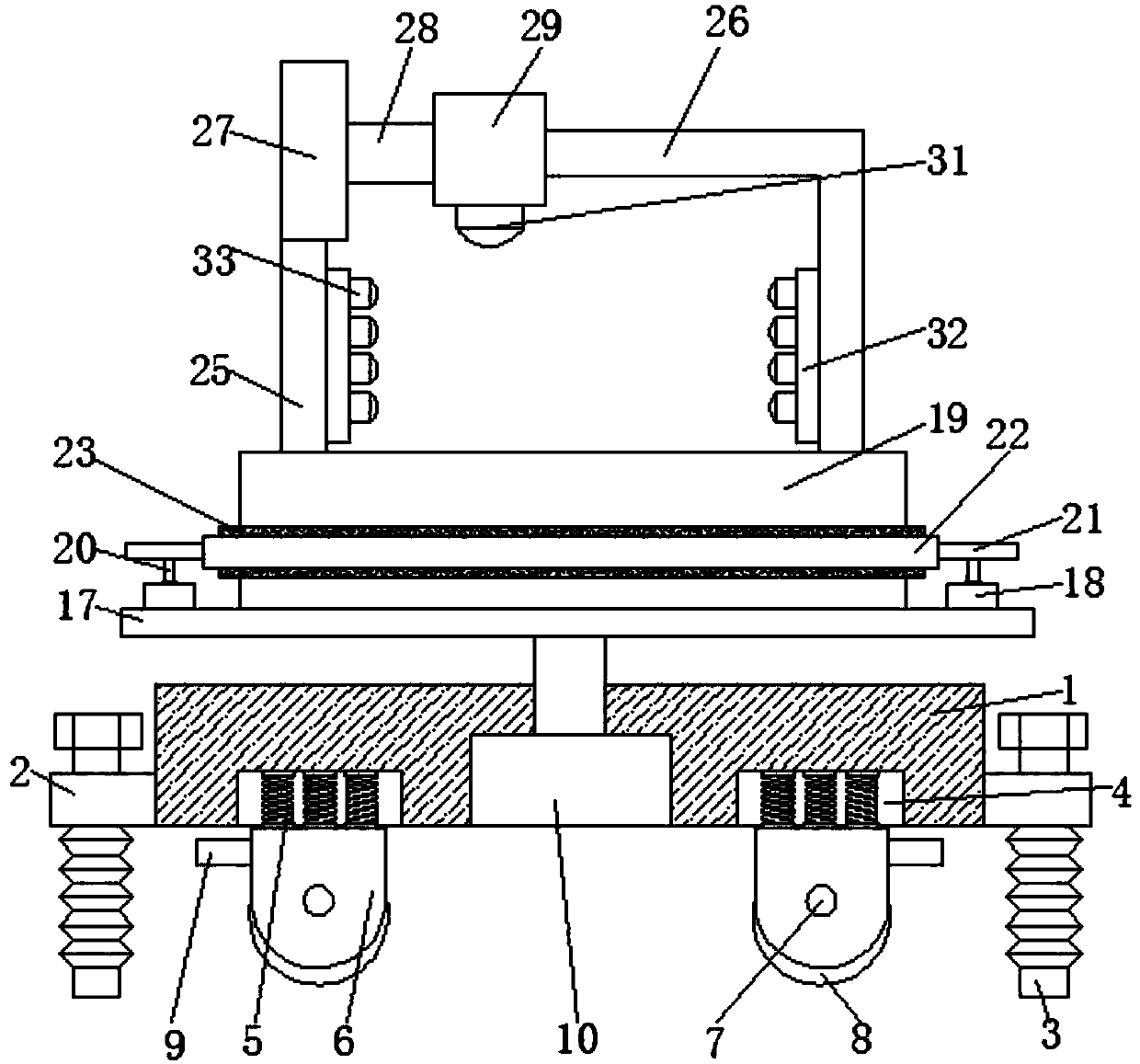

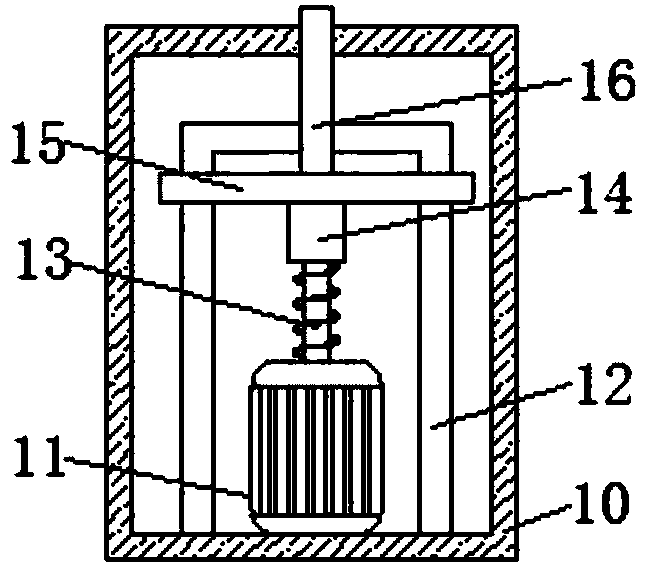

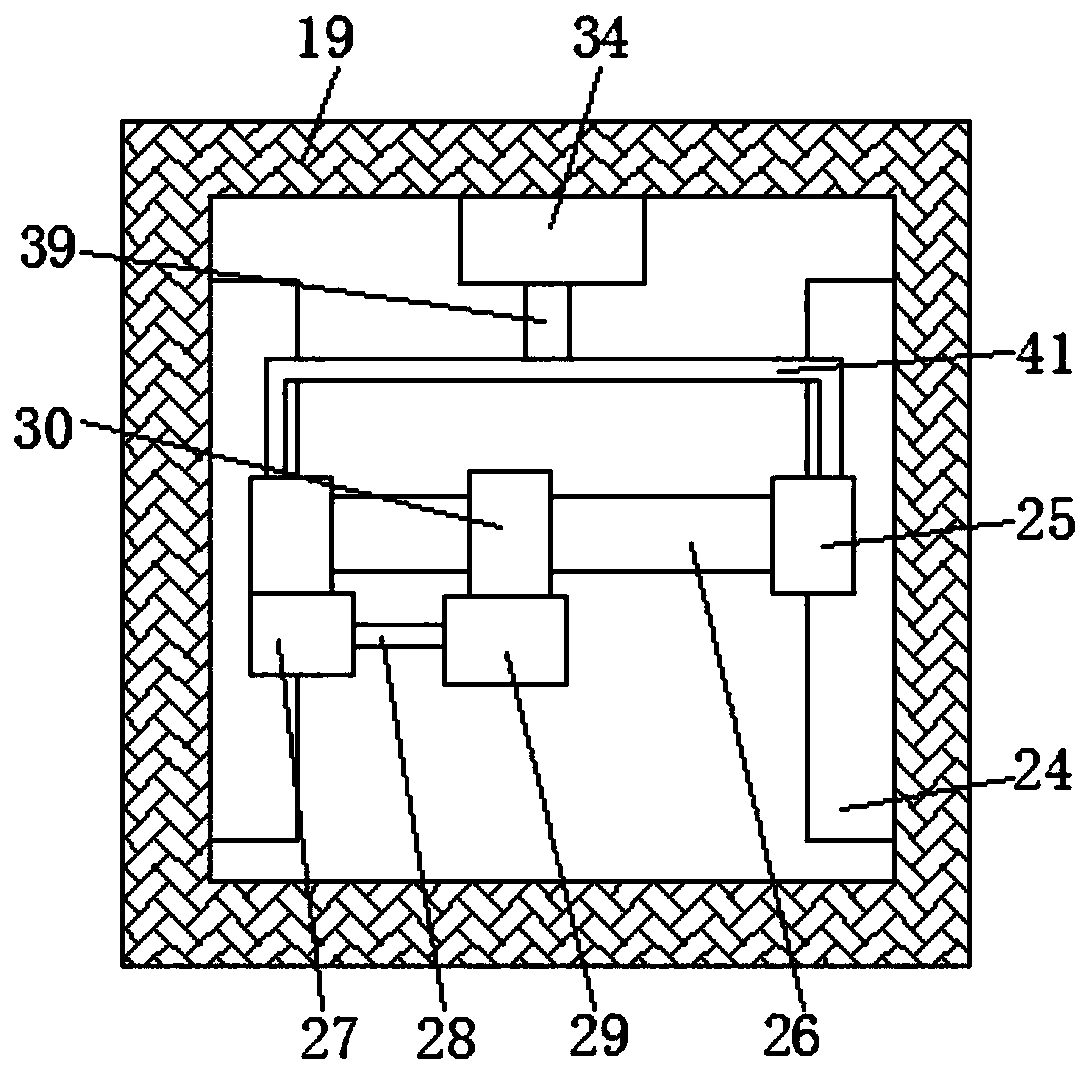

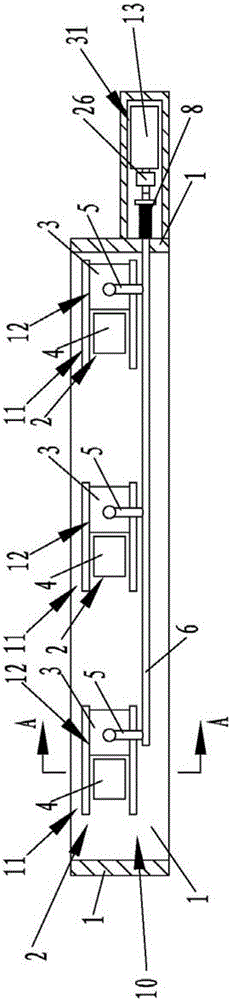

Multifunctional integrated laser engraving machine

InactiveCN107685194AEasy to observeStrengthen controlLighting elementsLaser beam welding apparatusEngineeringMultiple function

The invention discloses a multifunctional integrated laser engraving machine. The laser engraving machine comprises a base, two symmetrical fixing plates are fixedly connected with the left side and the right side of the base respectively, an installation bolt is fixedly connected with the top of each fixing plate, two installation grooves are formed in the bottom of the base in a bilaterally symmetric mode, a limiting spring is fixedly connected with the inner surface on the top of each installation groove, and a U-shaped plate is fixedly connected with the end, away from the inner surface onthe top of the corresponding installation groove, of each limiting spring. In the multifunctional integrated laser engraving machine, the effect of controlling the height of the bottom plate is achieved by arranging a stepping motor, a first threaded rod, a first limiting plate and a first telescoping rod, the effect that a worker conveniently selects an appropriate engraving work height according to work needs is further achieved, and then the effect that it is convenient for the worker to observe the engraving process is achieved. Therefore, the aim that the control of the worker over the laser engraving quality is easily improved is achieved through convenient observation, and the engraving process quality is improved.

Owner:SUZHOU MIKE LASER TECH SERVICE CO LTD

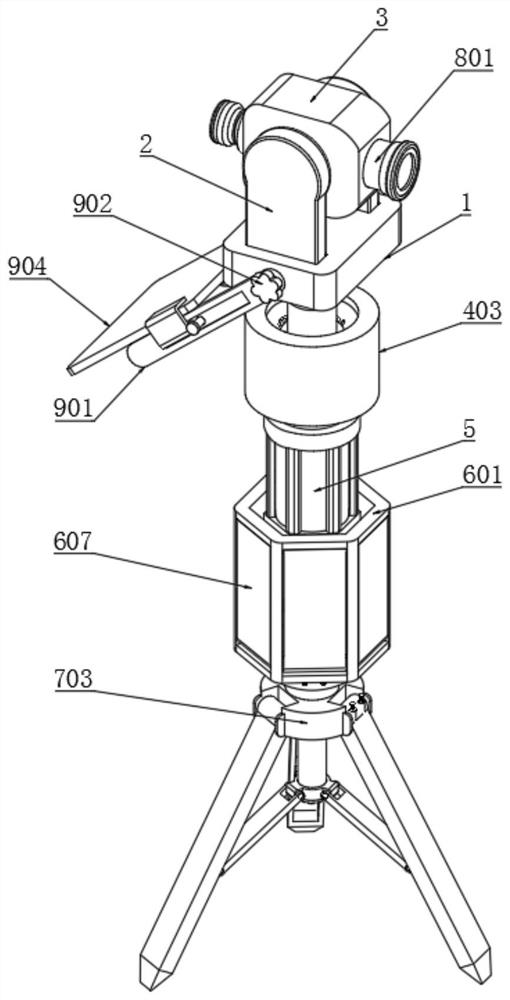

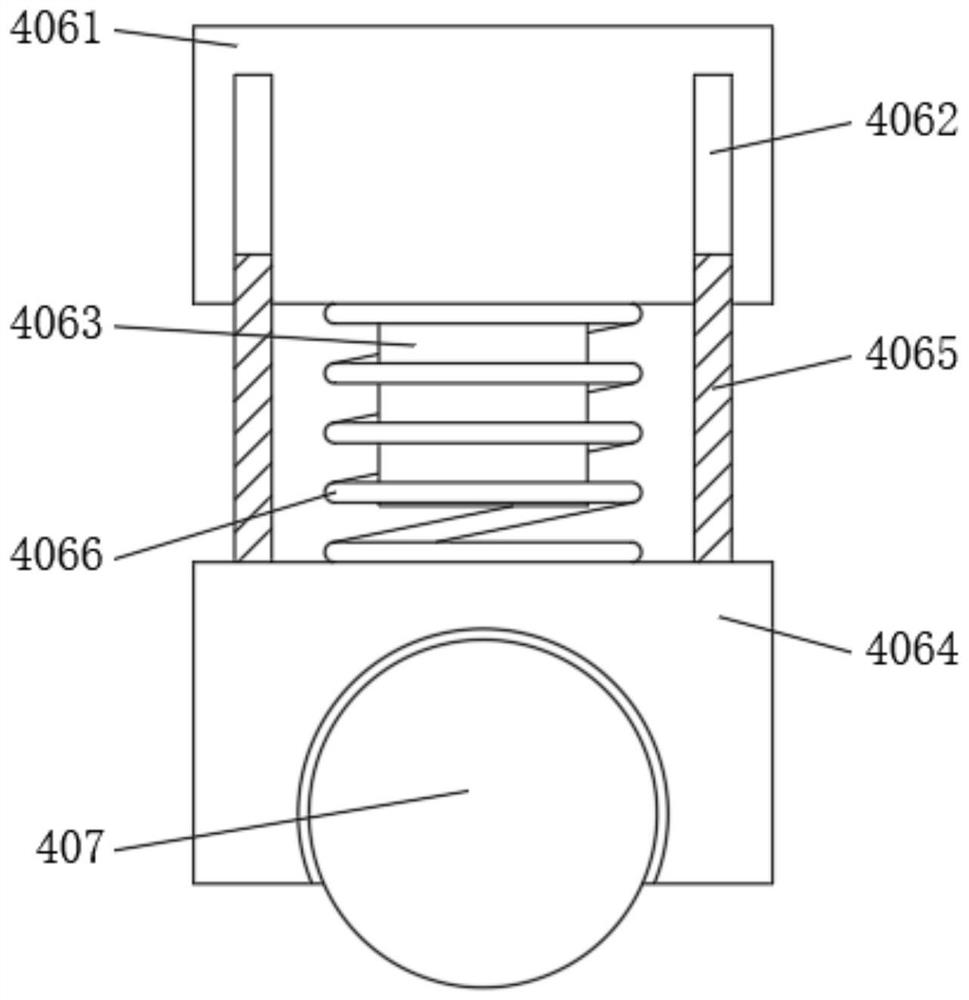

High-stability engineering surveying and mapping device

InactiveCN112880646AImprove the inflation effectEasy accessSurveying instrumentsGas passingStructural engineering

The invention discloses a high-stability engineering surveying and mapping device. The device comprises a connecting seat; fixing plates are symmetrically and fixedly connected to the top end of the connecting seat; a surveying and mapping instrument is rotatably connected between the two fixing plates; a buffering anti-deviation mechanism is rotatably connected to the bottom end of the connecting seat; a vertical cylinder is fixedly connected to the bottom end of the buffering anti-deviation mechanism; and a water surface floating mechanism is arranged at the outer side of the vertical cylinder. The device is scientific and reasonable in structure and safe and convenient to use; the water surface floating mechanism is arranged; and through cooperation of a pressing plate and a connecting rod, a rubber block is pushed to move in an air cylinder, air exhausting and pushing are conducted, meanwhile, a fixing rod is rotated, the fixing rod drives a lower limiting block and an upper limiting block to move, the positions of the lower limiting block and the upper limiting block are adjusted, so that the lower limiting block, the upper limiting block, a buffer spring and a sealing block are matched with one another; when an air bag strip is inflated, an air pipe is opened through air exhausting and closed through air pushing, and so that air conveniently enters the air cylinder through the air pipe.

Owner:韦宗海

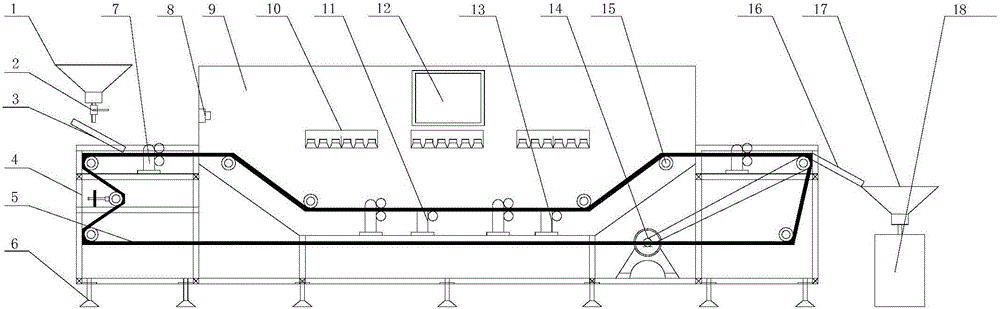

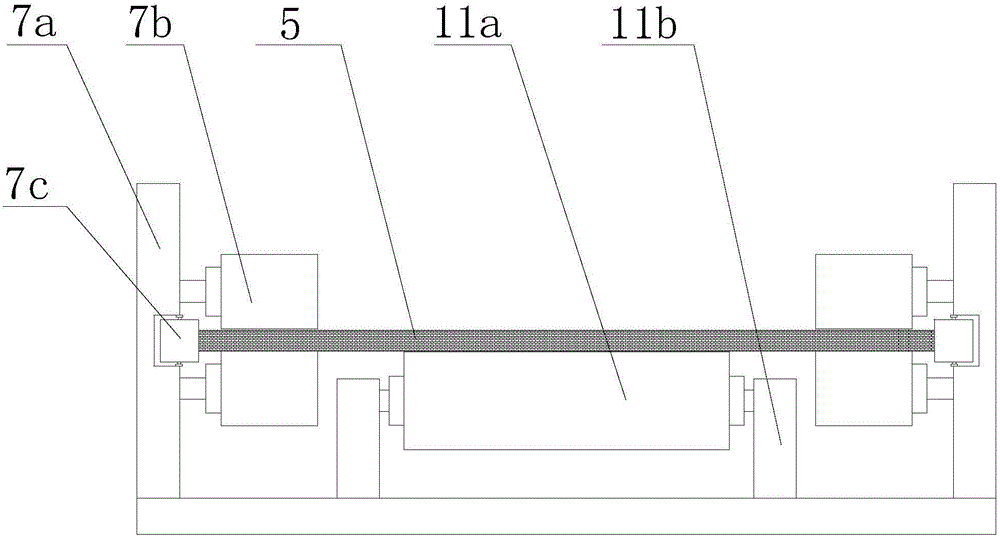

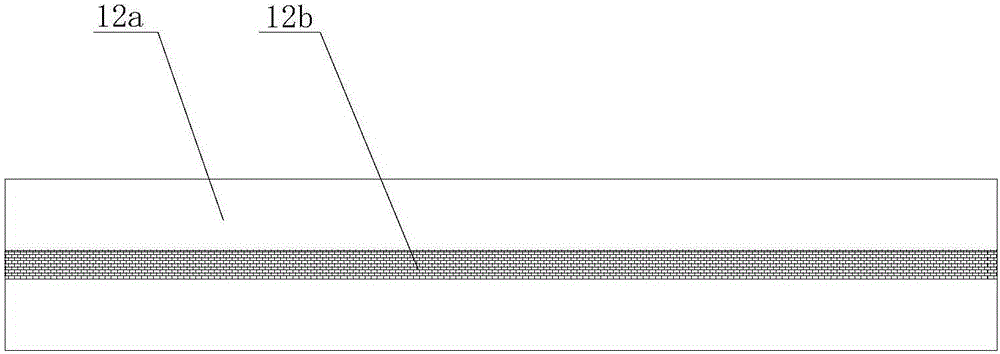

Medicinal material scattering preventing device in traditional Chinese medicinal material microwave drying process

InactiveCN105836466AAvoid failureGuaranteed uptimeConveyorsCharge manipulationMedicinal herbsStructural engineering

The invention relates to a medicinal material scattering preventing device in the traditional Chinese medicinal material microwave drying process. The medicinal material scattering preventing device comprises a rack, a metal box, a conveying belt and roller sets. The metal box is arranged in the middle portion of the rack. The conveying belt is arranged on the rack and penetrates the metal box. The multiple roller sets are arranged in the operation direction of the conveying belt. The medicinal material scattering preventing device further comprises a microwave generator and anti-deflection set racks. The microwave generator is arranged in the metal box. The anti-deflection set racks are arranged on the two sides of the conveying belt. A lug plate frame of the anti-deflection set rack on each side is provided with two anti-deflection wheels, wherein the two anti-deflection wheels are arranged above and below the conveying belt and used for clamping the conveying belt. The lug plate frame on each side is further provided with anti-clamping wheels, wherein the anti-clamping wheels are arranged between the corresponding two anti-deflection wheels, and the axis of each anti-clamping wheel is perpendicular to the axis of the corresponding anti-deflection wheel. An anti-deflection device of a belt conveyor is suitable for being used in a microwave dryer and has the advantages of being stable in running, low in fault rate and long in service life.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE +1

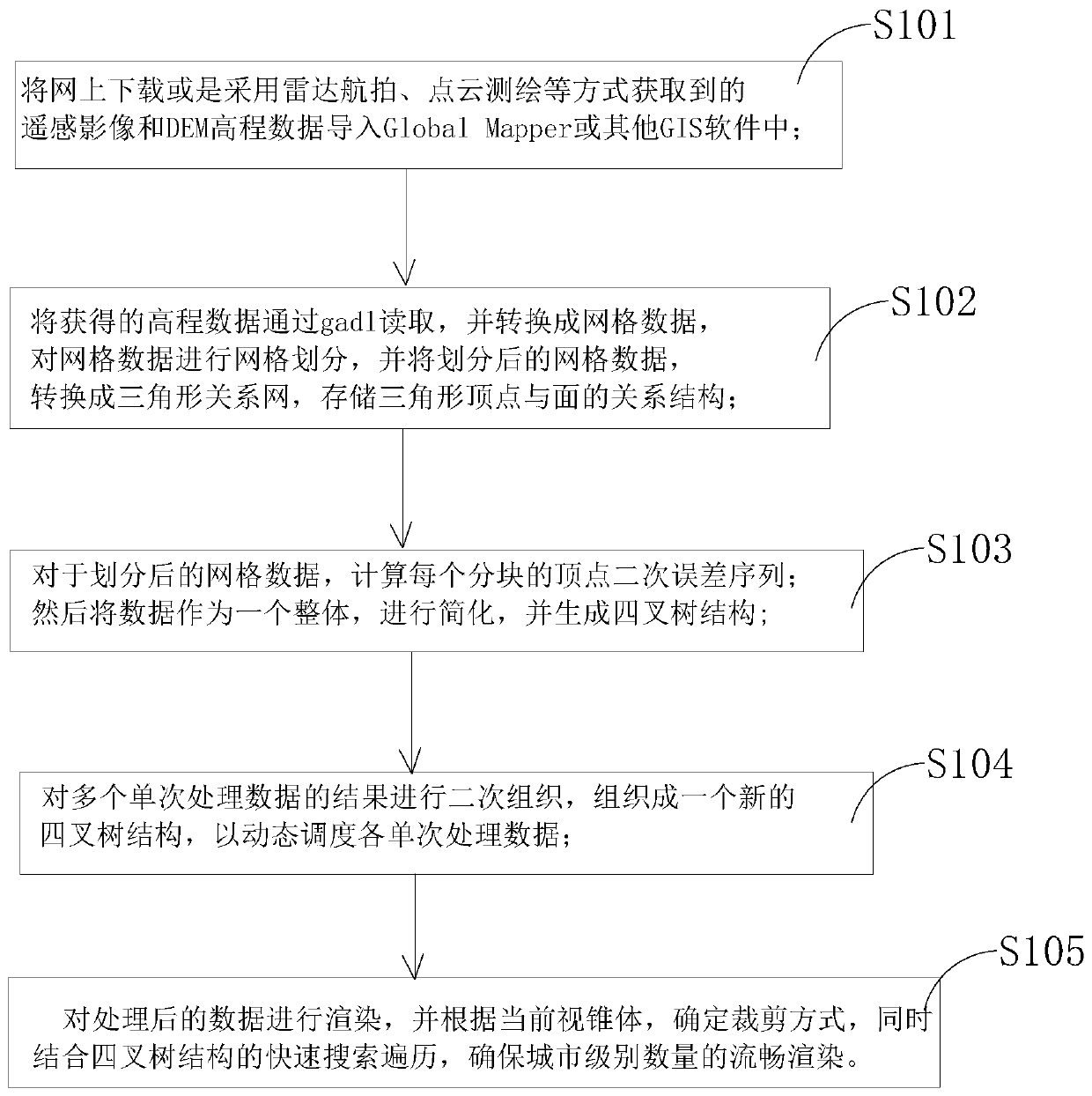

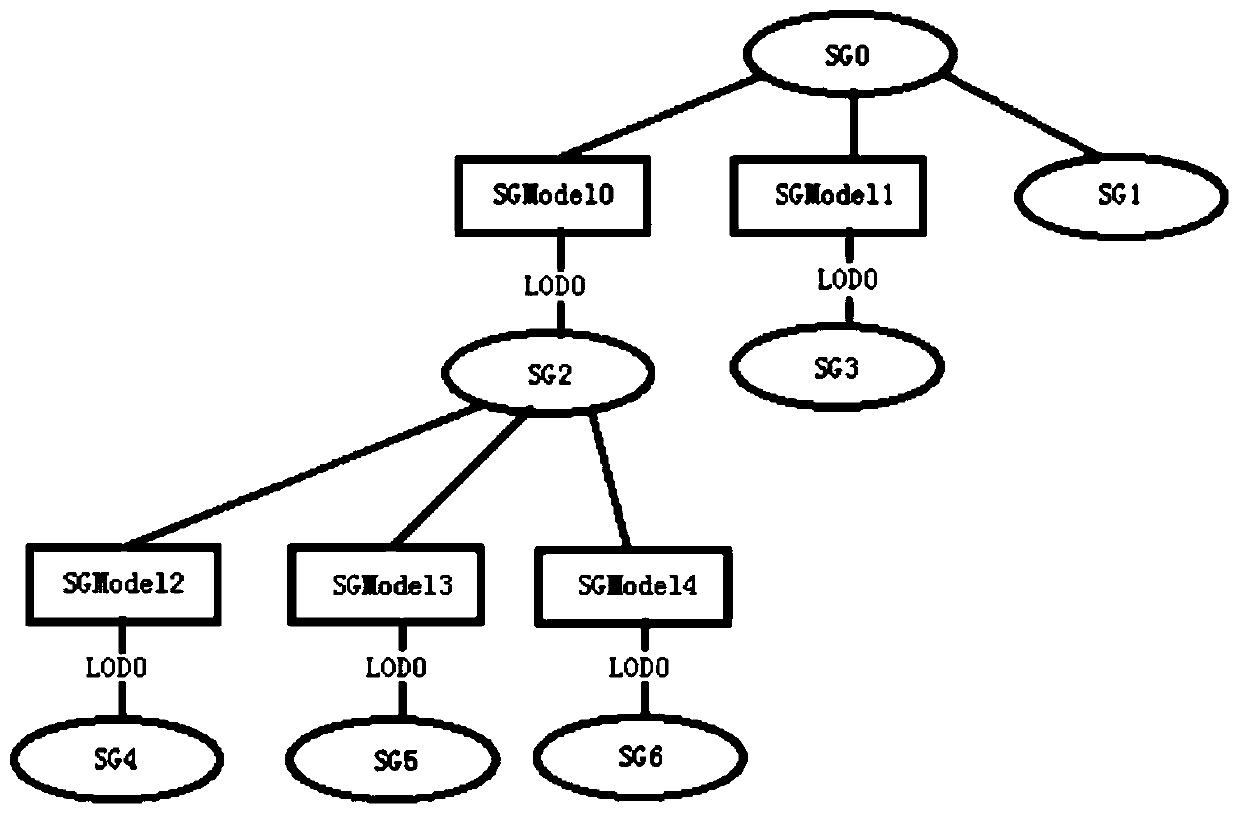

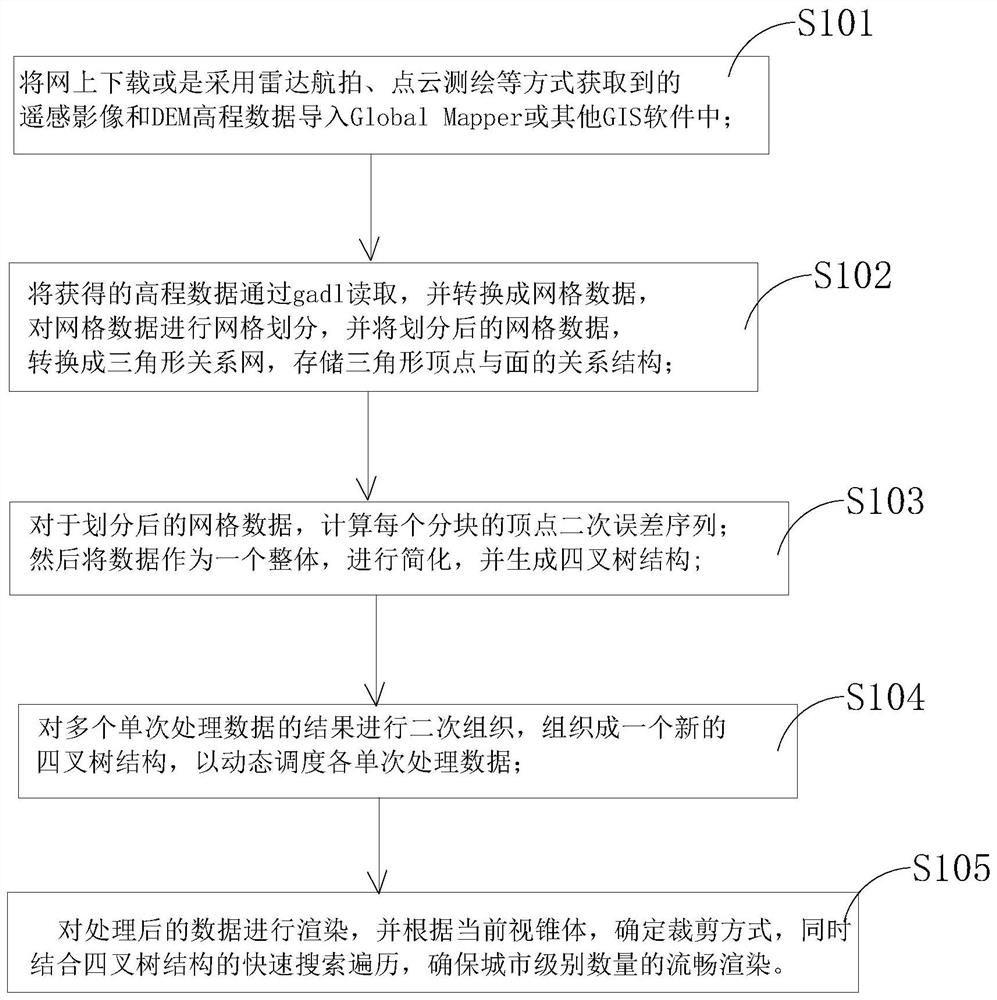

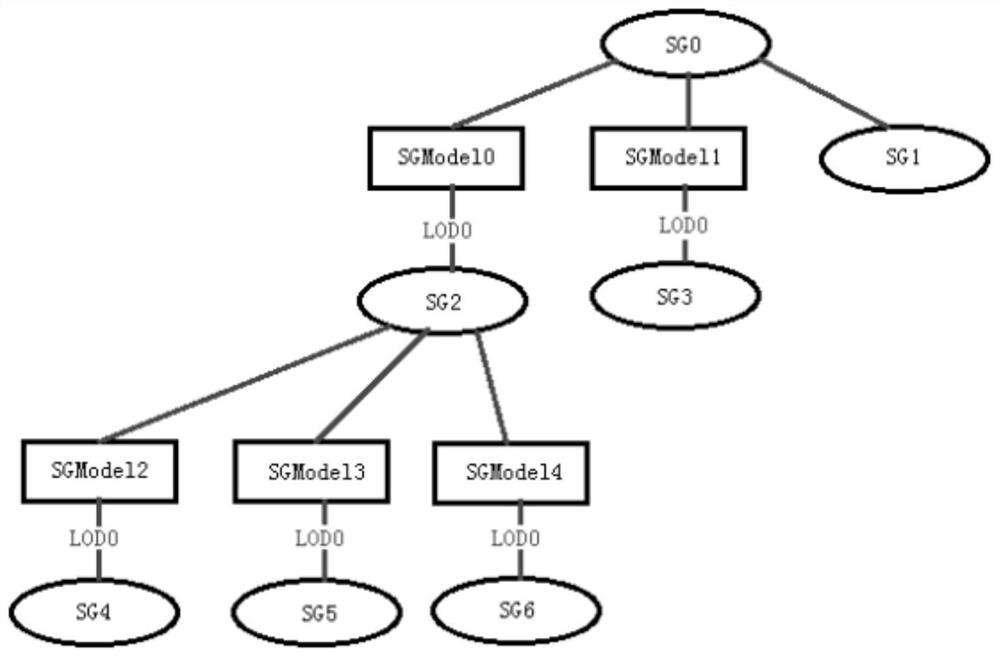

Terrain LOD generation method

The invention discloses a terrain LOD generation method. The terrain LOD generation method comprises the steps of: importing remote sensing images and DEM elevation data which are downloaded online oracquired by means of radar aerial photography, point cloud surveying and mapping and the like into Global Mapper or other GIS software; reading the obtained elevation data through gadl, converting the elevation data into grid data, performing grid division on the grid data, converting the divided grid data into a triangular relationship network, storing a relationship structure of triangular vertexes and surfaces, and calculating a vertex secondary error sequence of each block for the divided grid data; then simplifying the data by taking the data as a whole, and generating a quadtree structure; performing secondary organization on results of a plurality of single-time processing data to form a new quadtree structure so as to dynamically schedule each single-time processing data; and rendering the processed data, determining a cutting mode according to a current view frustum, and ensuring smooth rendering of the city-level number in combination with quick search traversal of the quadtree structure.

Owner:中国电力企业联合会电力建设技术经济咨询中心 +1

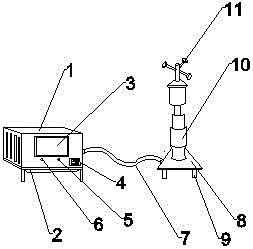

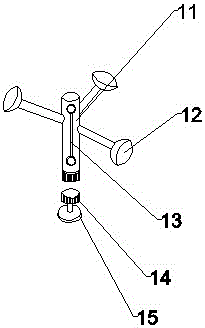

Anemobiagraph for building

InactiveCN106680534AEasy to analyzeGuaranteed observation effectNon-electrical signal transmission systemsFluid speed measurementVisual observationMeasurement device

The present invention discloses an anemobiagraph for a building. The anemobiagraph for the building comprises a working platform, an observation device is installed at the upper portion of the working platform, the outer surface of the observation device is provided with a LCD display screen, the lower portion of the LCD display screen is provided with an indicator light, the right side of the indicator light is provided with an annunciator, the right side of the annunciator is provided with an operating switch, the right side of the observation device is provided with an optical fiber, the right side of the optical fiber is provided with a pedestal and a support arm, the lower portion of the pedestal is provided with a support arm, the upper portion of the pedestal is provided with a supporting column, and the upper portion of the supporting column is provided with a measurement device. The anemobiagraph for a building is provided with the observation device and coordinates with the LCD display screen to allow users to perform visual observation and analysis of the measured data so as to ensure the integration and unity of the observation and the measurability of the anemobiagraph, and is provided with the indicator light and coordinates with the annunciator to allow the observation device to prompt users when it is detected that the periphery around the users has heavy wind so as to ensure safety of the users and devices.

Owner:CHENGDU JIAMEIJIA SCI & TECH

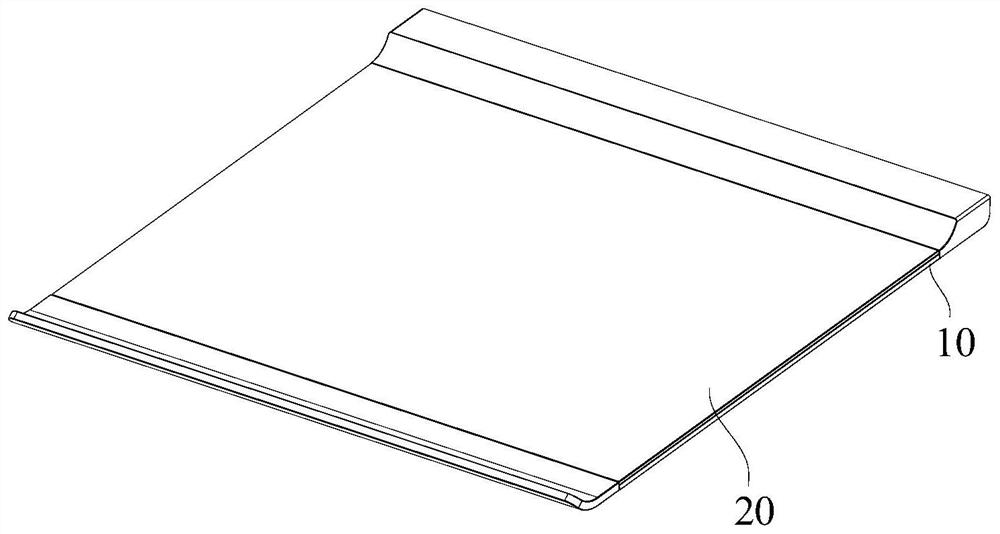

Processing technology of ultra-white glass white printing oven outer door glass

InactiveCN110833337AGuaranteed observation effectImprove product gradeRoasters/grillsCoatingsPrinting pressMechanical engineering

The invention relates to a processing technology of ultra-white glass white printing oven outer door glass in the technical field of glass product manufacturing. The ultra-white glass with a transmittance of more than 95% is selected and cut according to the design size of the oven outer door glass by using a full-automatic glass cutting machine to obtain an oven outer door glass substrate; the edges of the oven outer door glass substrate are edged by using a glass edger; after washing and drying with a washing machine, three layers of ultra-white ink are printed on a decorative area of the oven outer door glass substrate in three times through a screen printer; each layer of ultra-white ink is heated and cured after printing, and then placed in a horizontal continuous tempering furnace toheat and temper, so that the ultra-white ink is sintered with the oven outer door glass substrate into a whole; and after the oven outer door glass is naturally cooled, the oven outer door glass is rinsed with pure water, dried, and then packed and stored. According to the invention, the ultra-white ink can be sintered with the oven outer door glass substrate into a whole at a high temperature; therefore, the ultra-white ink is not easy to fall off, the durability is good, and the texture is better, so that the product is more beautiful and high-grade.

Owner:焦作飞鸿安全玻璃有限公司

Transformer substation control box demisting system

PendingCN110913517ATimely exclusionAvoid affecting secondary equipmentTransparent/reflecting heating arrangementsTemperature measurement of flowing materialsDewPower substation

The embodiment of the invention discloses a transformer substation control box demisting system. The system is arranged on a collection control box. An observation window is arranged on the collectioncontrol box; the system includes a demisting detection device which is used for detecting whether mist exists on the observation window or not, and a mist removing device which is used for removing the mist on the observation window. The mist removing device comprises a mist removing assembly used for removing mist and a dew removing assembly used for removing dew. The demisting detection deviceis connected with the mist removing device; the mist removing device operates according to the data provided by the demisting detection device; whether the observation window fogs or not and the fogging condition can be intelligently judged, fog is removed when fog occurs, condensation is removed when condensation occurs, the observation window is kept clear, the observation effect of the observation window is guaranteed, meanwhile, condensation is removed in time, and it is avoided that secondary equipment in the box is affected due to the fact that the condensation is gathered in the box.

Owner:GUANGDONG POWER GRID CO LTD +1

Pediatric gastrointestinal examination device for pediatricians

InactiveCN109480753AGuaranteed therapeutic effectPrevent leakageGastroscopesOesophagoscopesPediatric SurgeonDisplay device

The invention discloses a pediatric gastrointestinal examination device for pediatricians, and relates to the technical field of medical instruments. The device comprises a display device. The lower surface of the display device is provided with a gastroscope tube, and the tail portion of the gastroscope tube is provided with a peep structure. The upper surface and the lower surface of the inner wall of the gastroscope tube are respectively fixedly connected with a drainage tube. A plurality of connecting holes are formed in the sides of the two drainage tubes away from each other, and seepageholes are formed in the upper surface and the lower surface of the gastroscope tube at the positions corresponding to the plurality of connecting holes. The device is provided with a negative pressure drainage ball. When the inside is in the negative pressure state, gastric juice and saliva can be sucked into the drainage tube and collected into the negative pressure drainage ball through a catheter. Therefore, the device can prevent children from coughing and nausea during the process of gastrointestinal examination, and the negative pressure drainage technology is applied to ensure diagnosis and treatment of patients effectively.

Owner:张延蕊

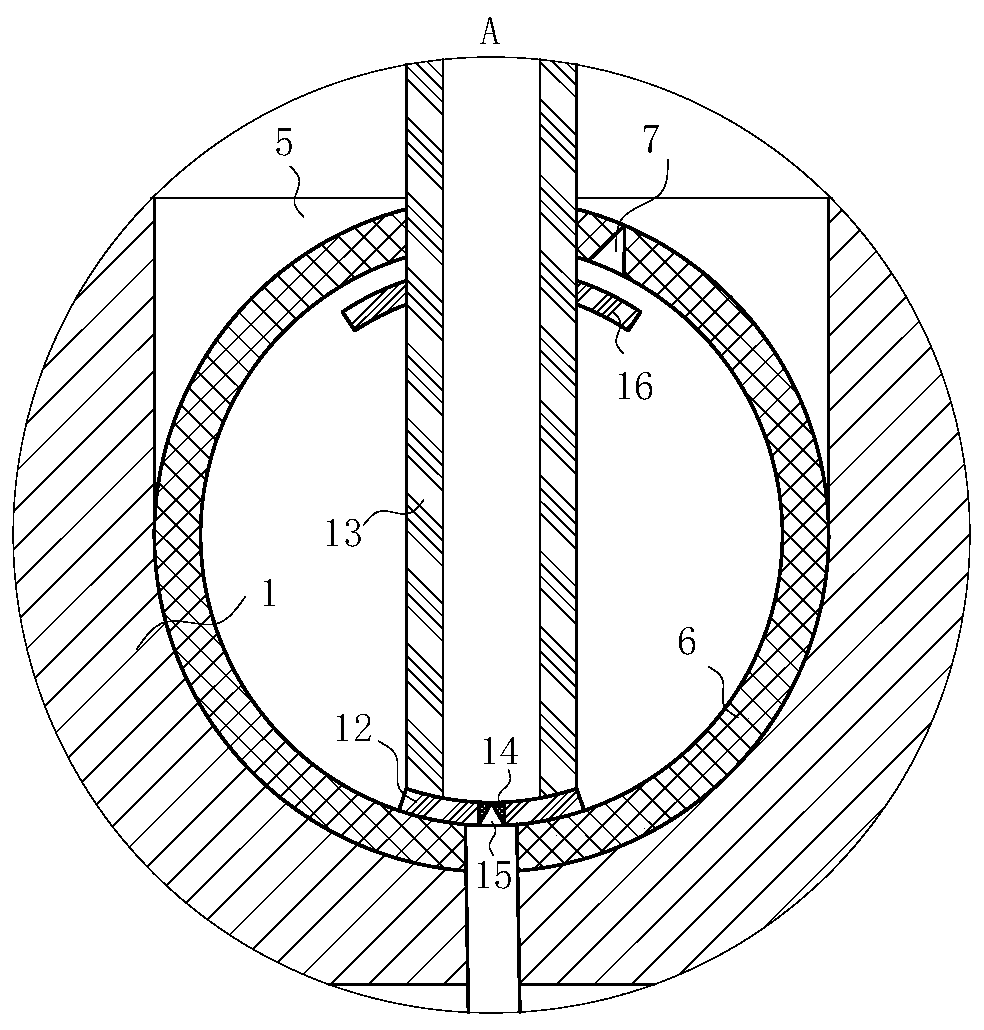

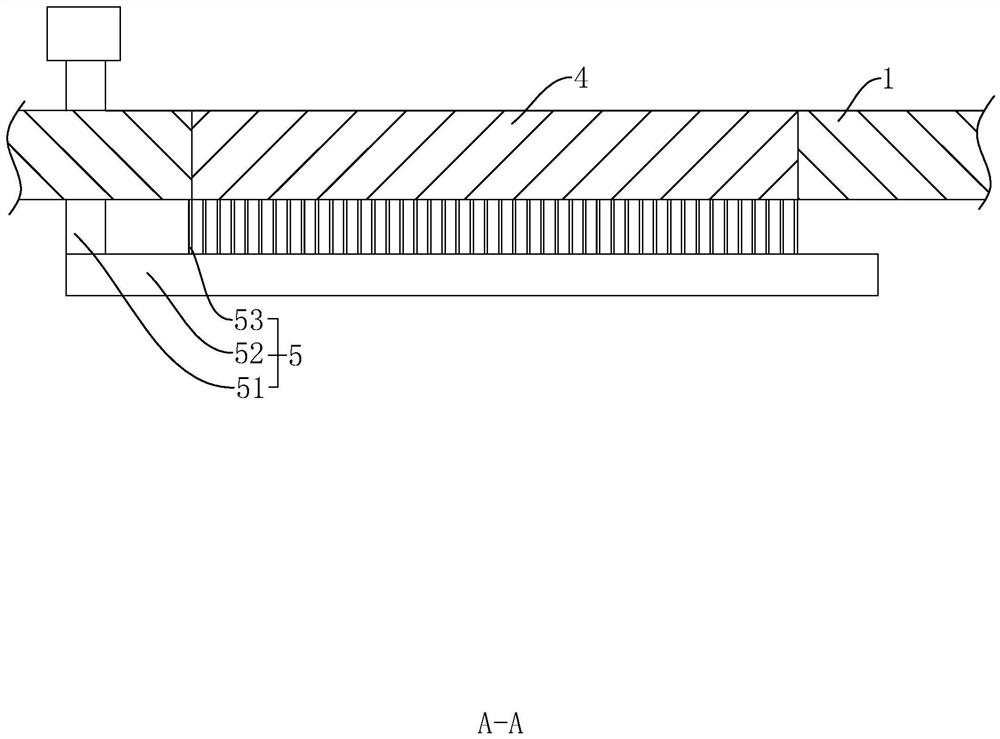

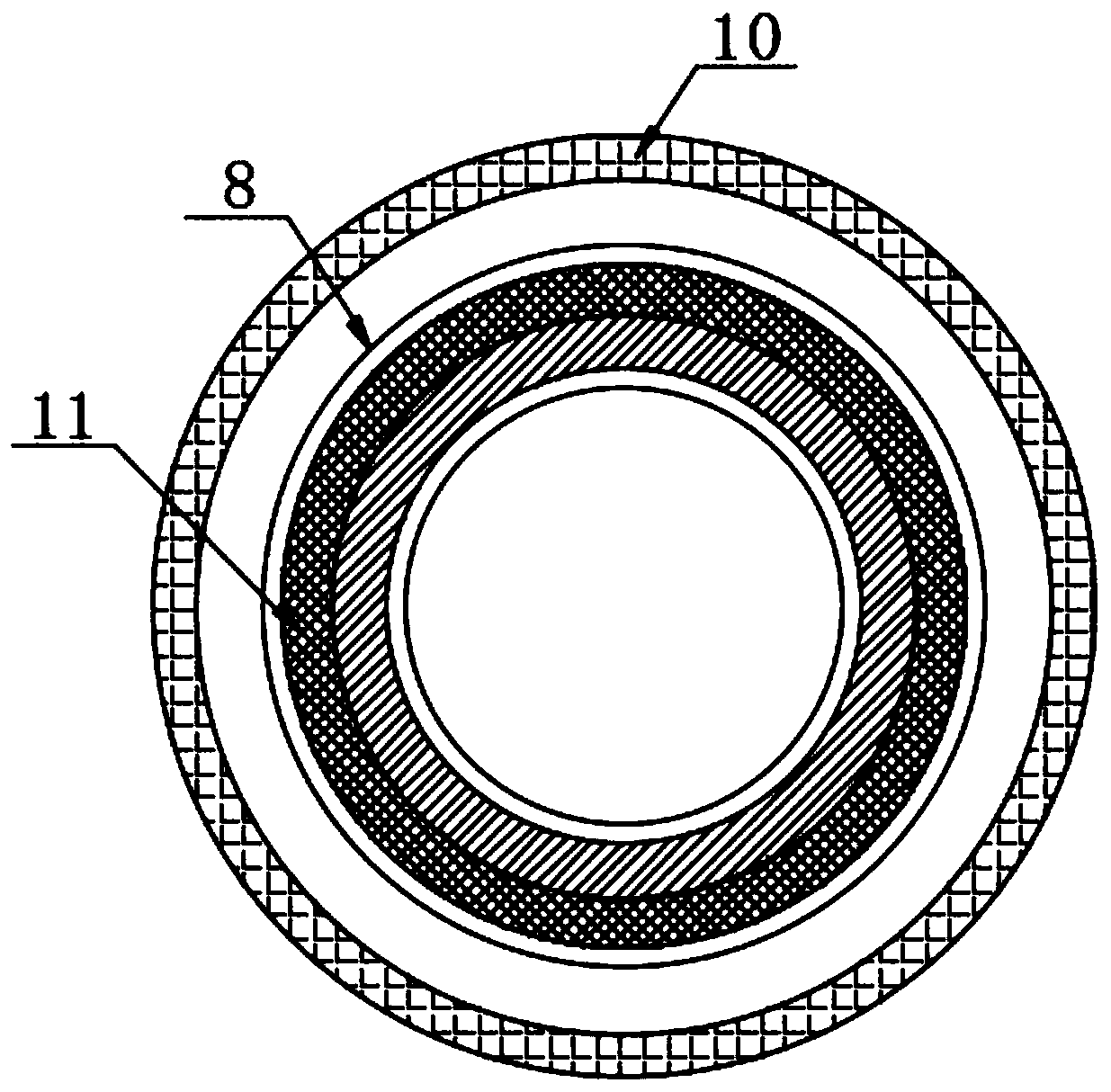

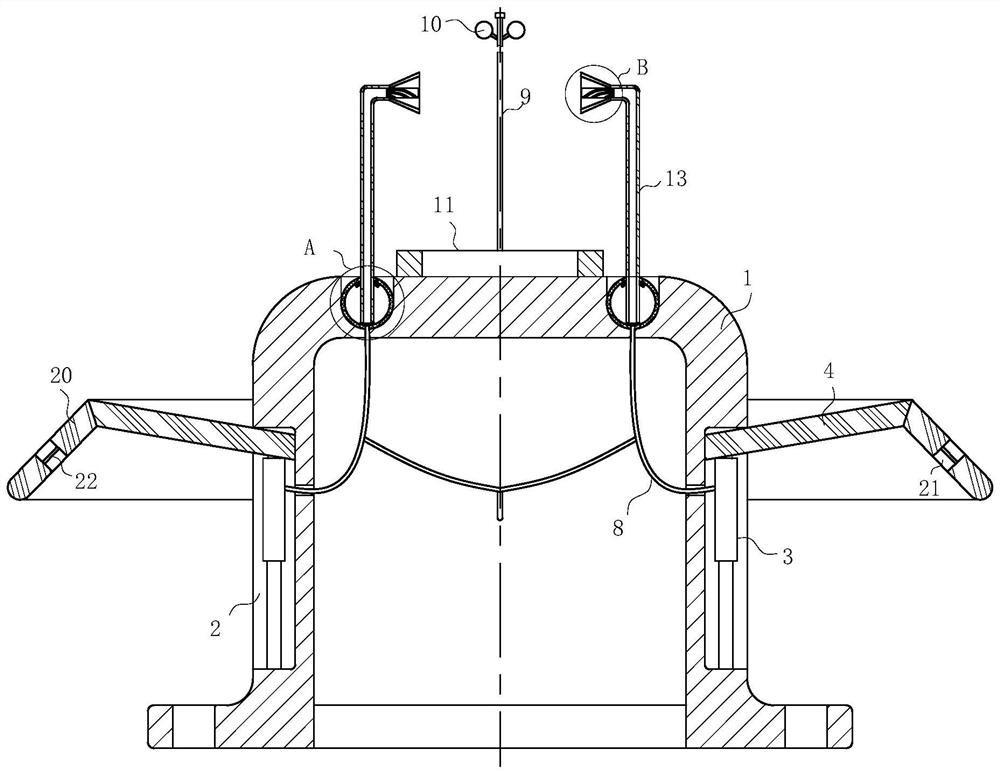

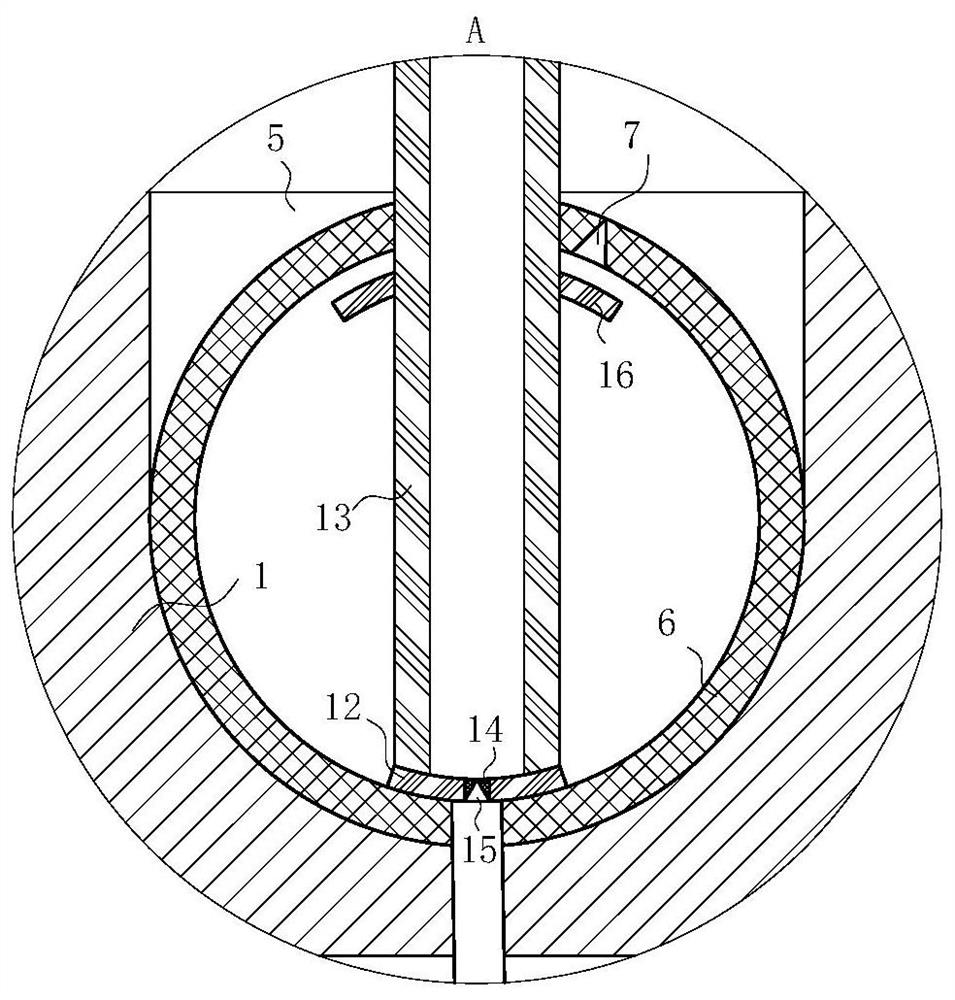

Vacuum reaction chamber and vacuum processing equipment

ActiveCN103695860AExtend your lifeGuaranteed observation effectElectrolysis componentsVacuum evaporation coatingHigh frequencyReaction chamber

The invention discloses vacuum reaction chamber and vacuum processing equipment. The vacuum chamber comprises a plurality of wallboards, wherein an observation device is arranged on at least one wall boards of the plurality of wallboards; the observation device comprises an observation window arranged on the wallboard and a shielding plate for shielding the observation window; the shielding plate can be moved between a first position for shielding the observation window and a second position not shielding the observation window. The vacuum processing equipment comprises the vacuum reaction chamber. In the vacuum reaction chamber and the vacuum processing equipment, the shielding plate can protect the observation window and further effectively shield the wallboard around the observation window. The vacuum reaction chamber and the vacuum processing equipment can effectively protect the observation window, prolongs the service life of the observation window, and effectively ensures the observation effect; meantime, the shielding plate can protect the wallboard around the observation window, namely the etched place with highest etching possibility on the wallboard, so as to prolong the entire service life of the wallboard and reduce the cost for high-frequency maintenance and labor loss.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

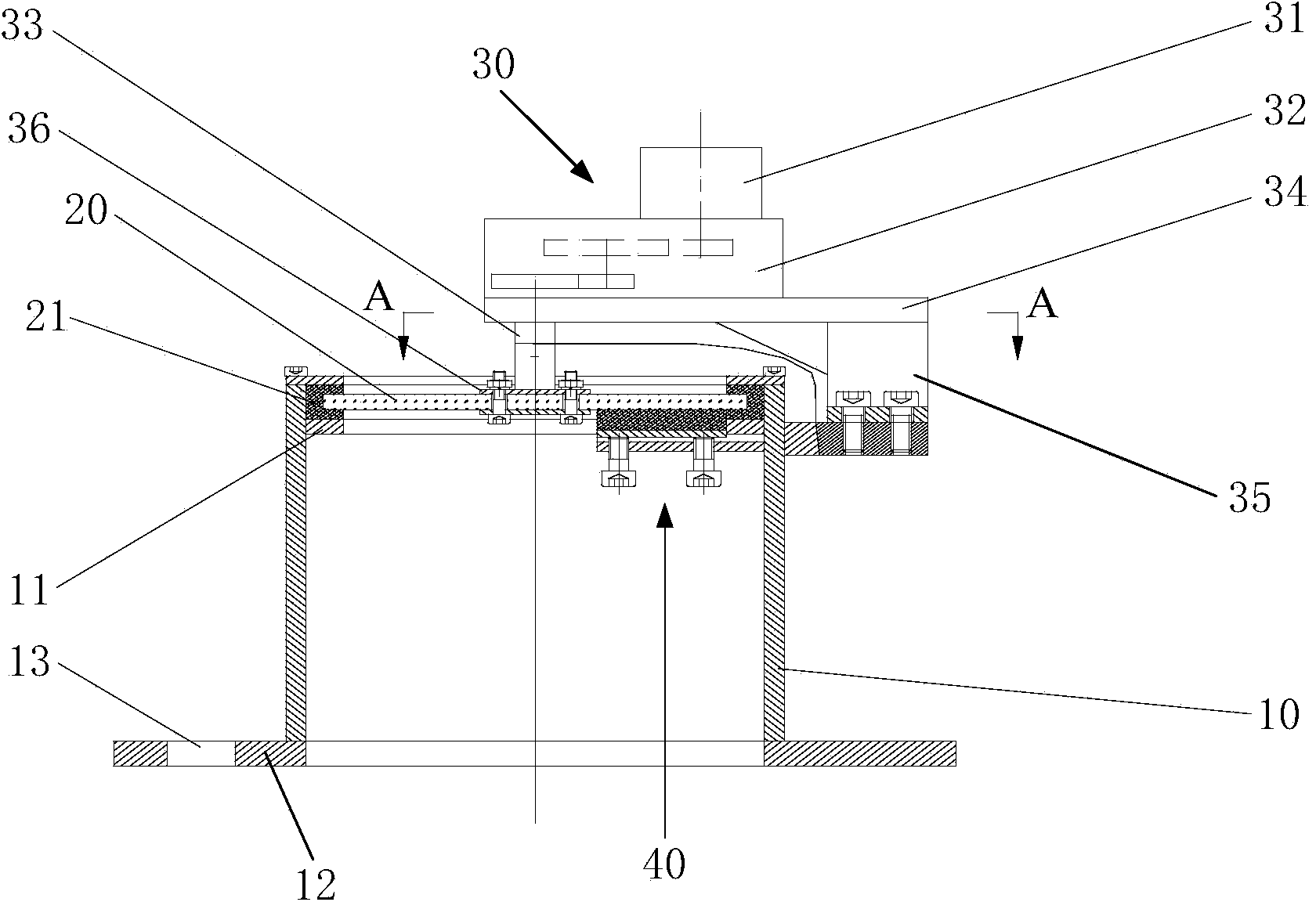

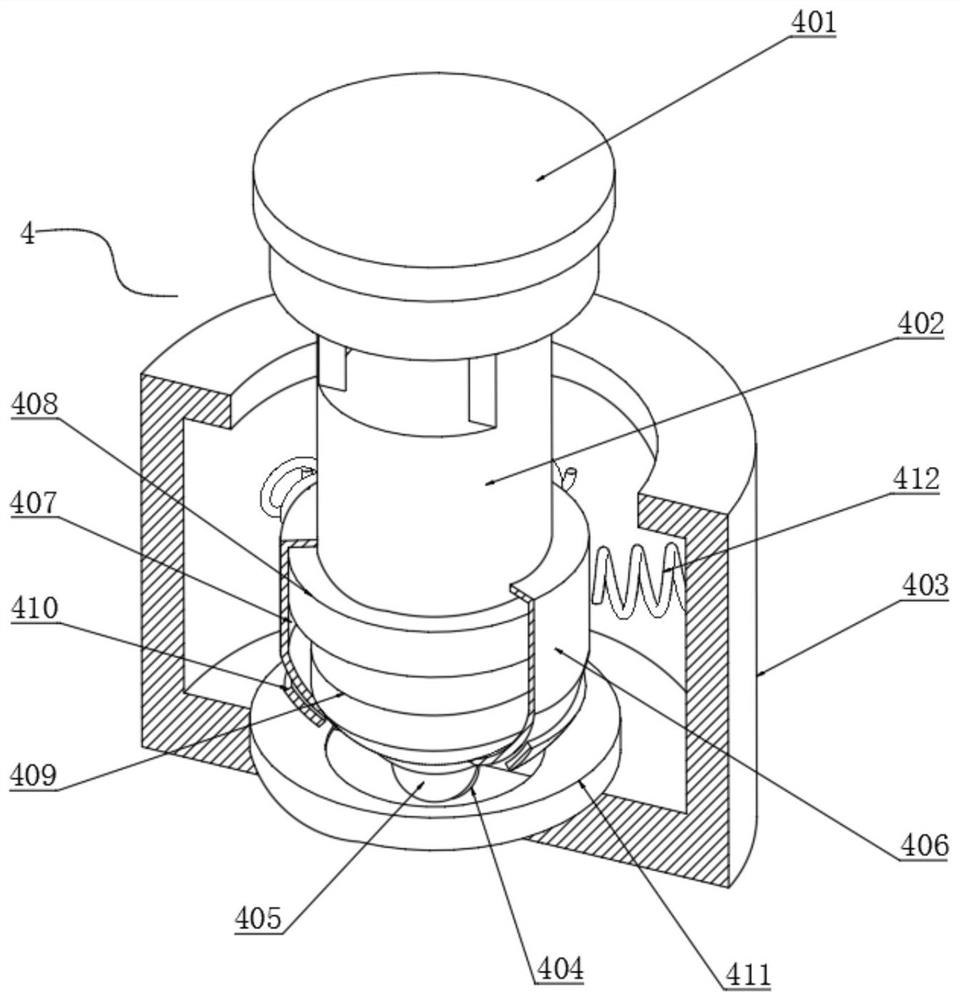

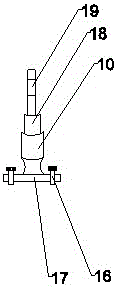

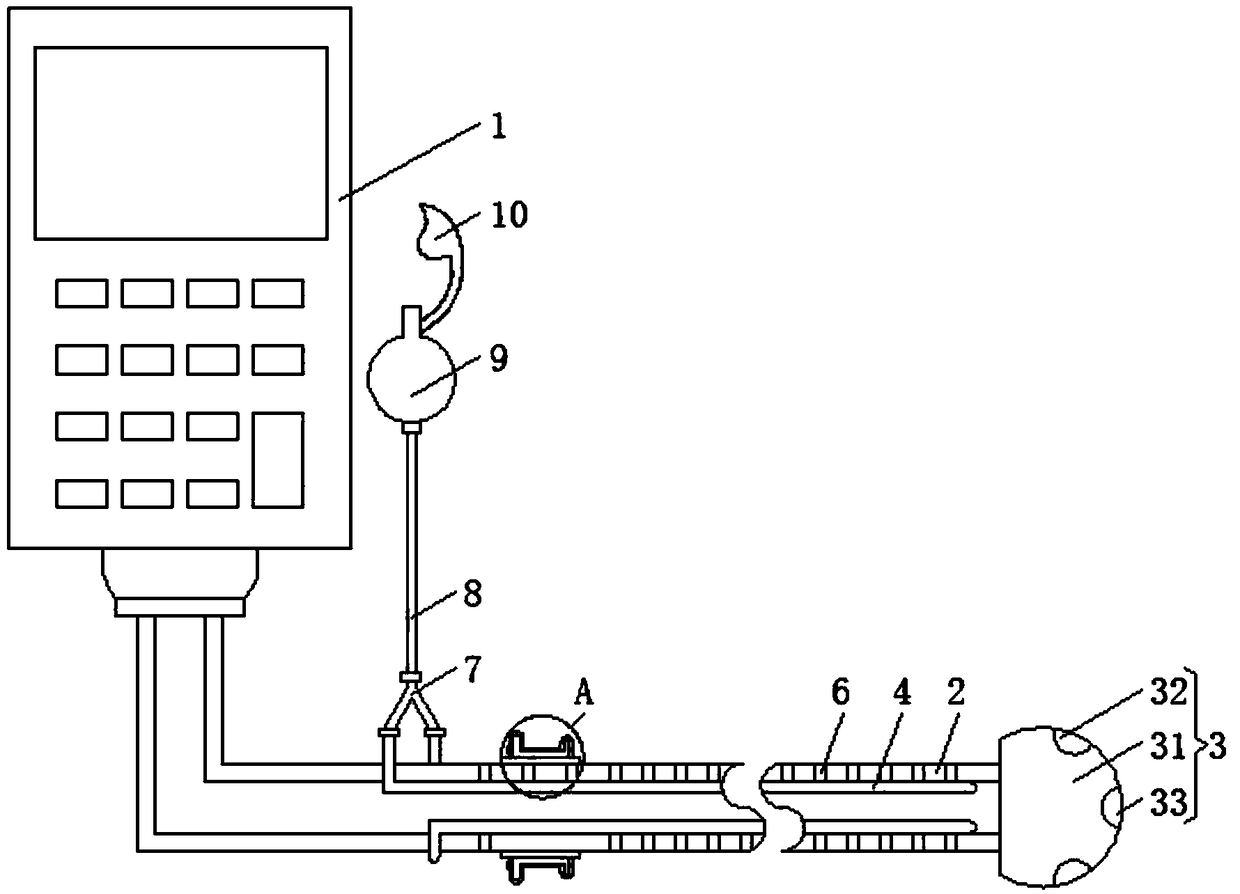

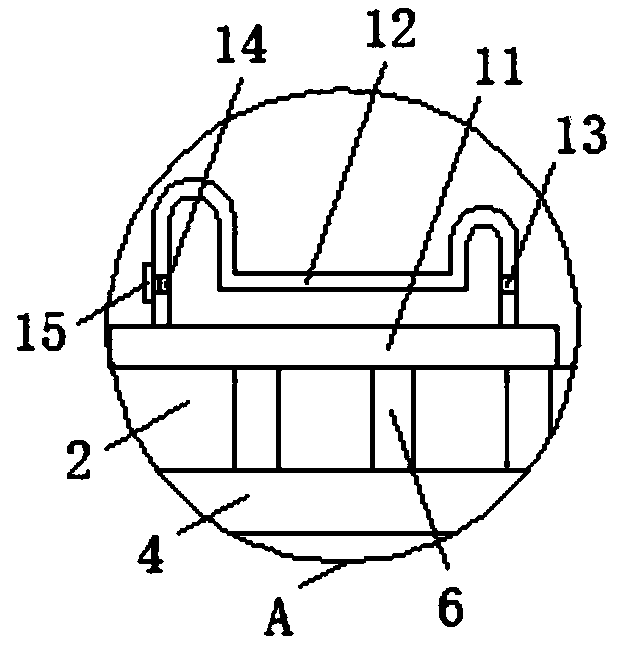

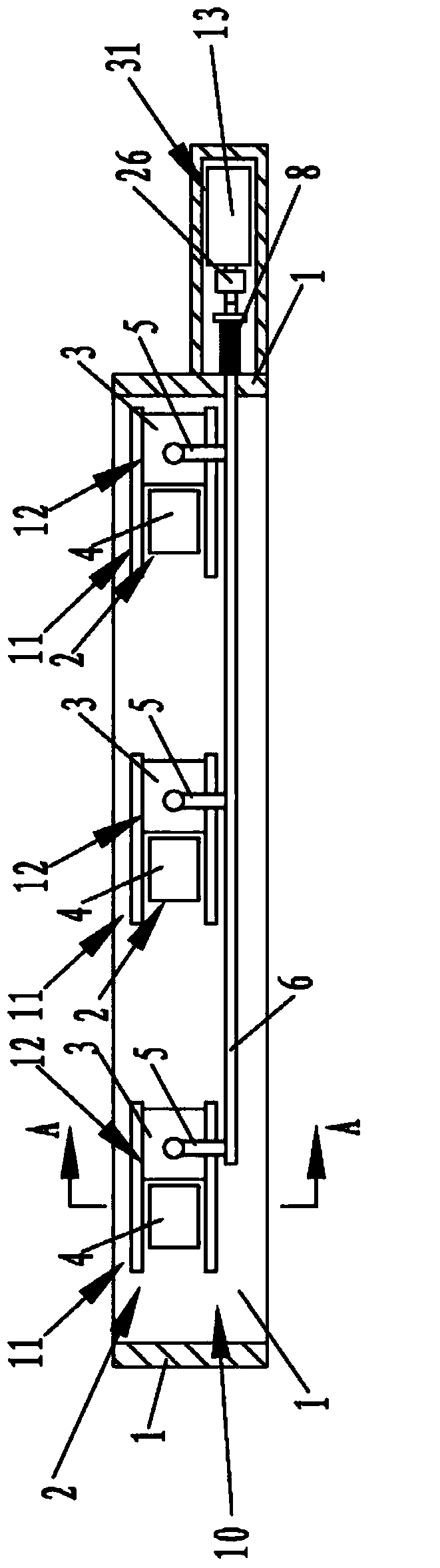

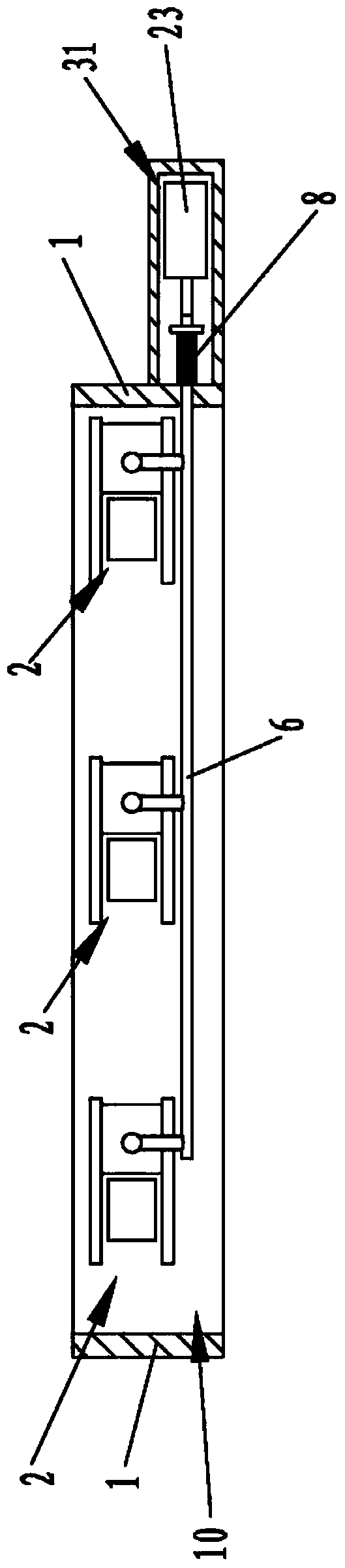

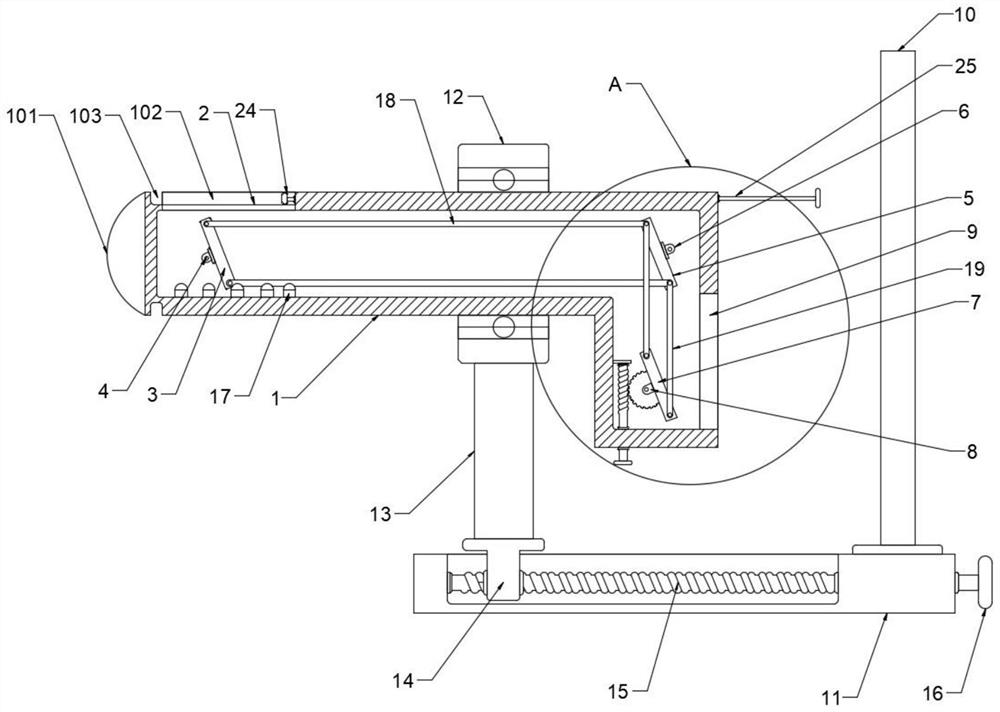

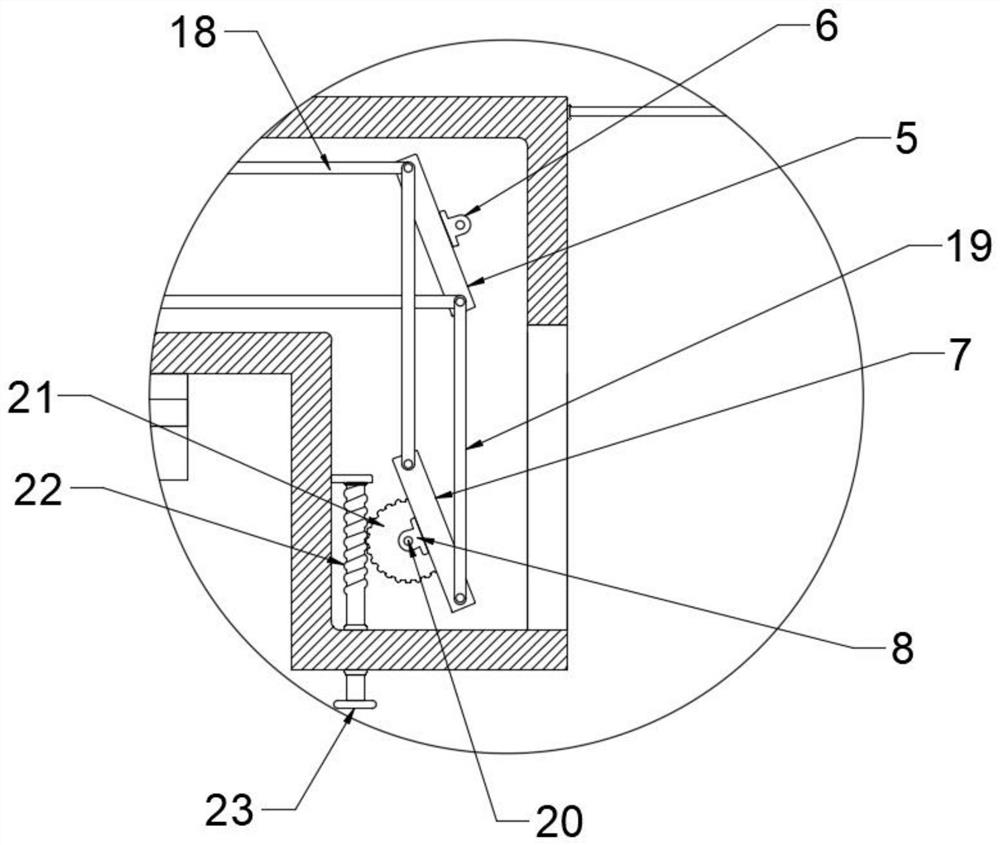

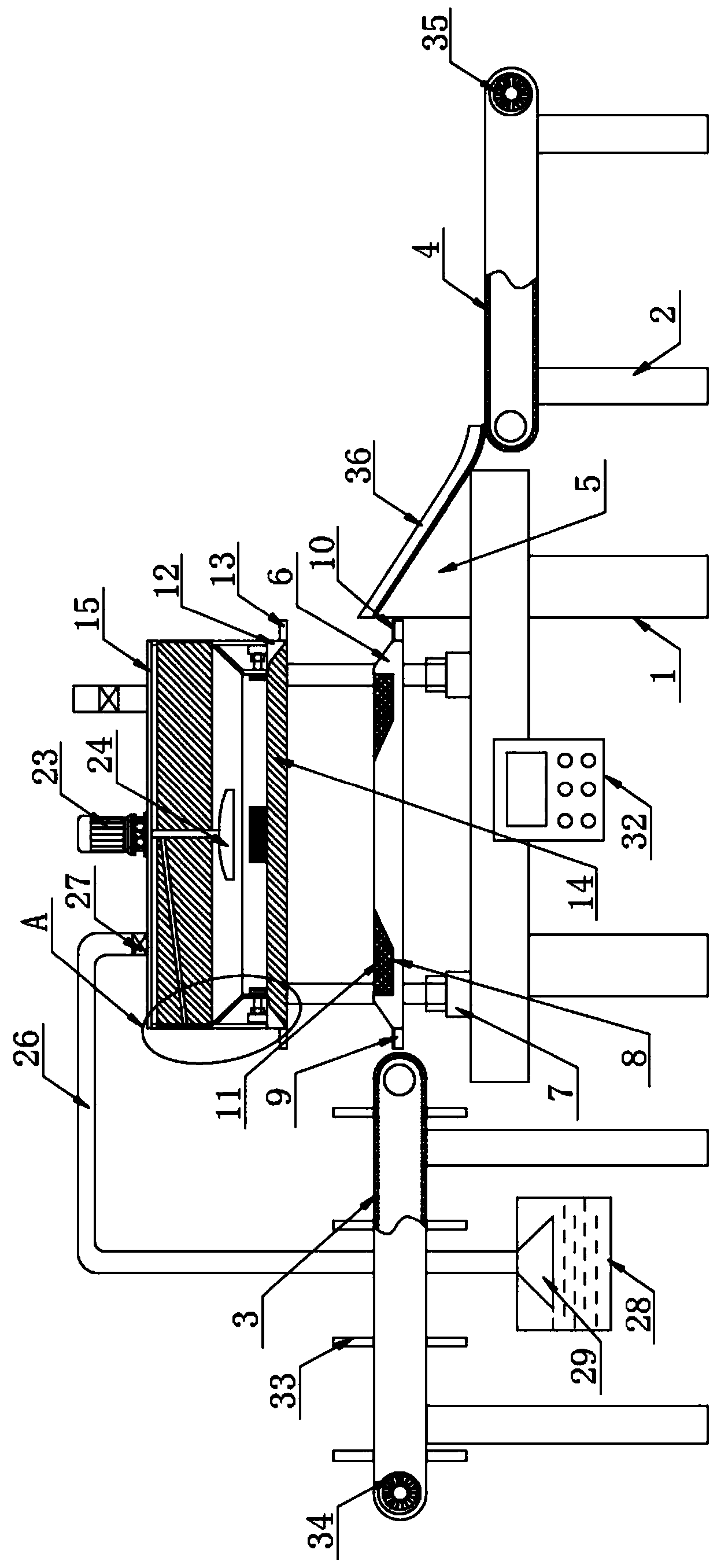

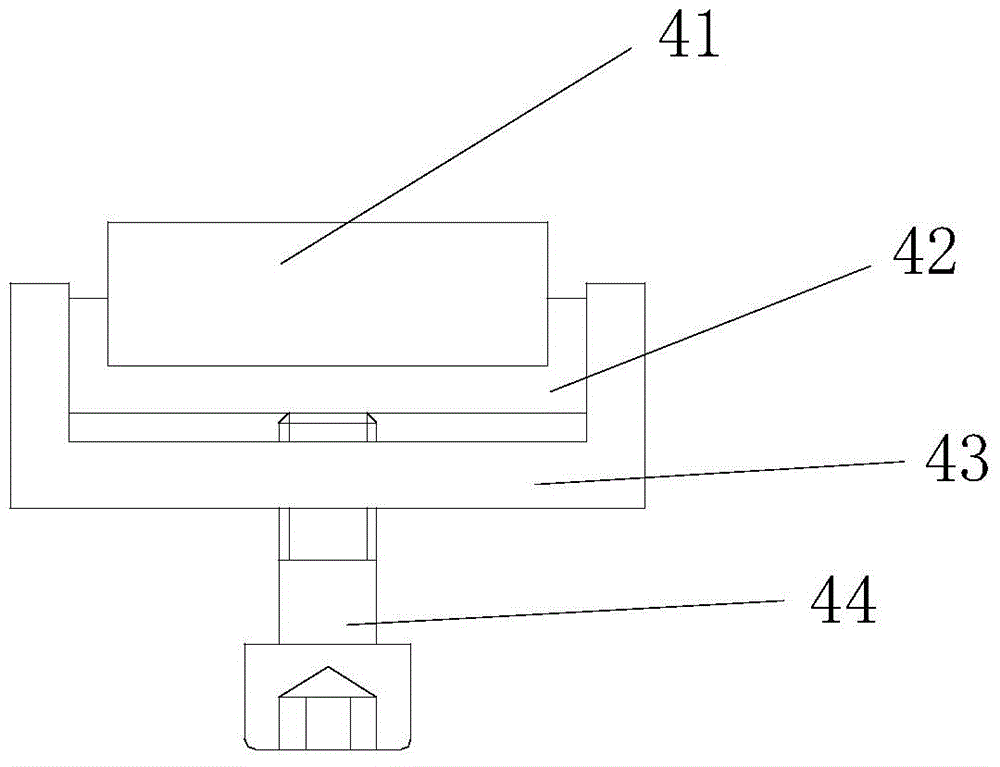

Observation instrument location operation device used for sea floor environment detection prediction

ActiveCN110515137AGuaranteed observation effectImprove comprehensivenessSurveying instrumentsGeological measurementsOcean bottomEngineering

The invention belongs to the technical field of sea floor detection auxiliary devices and in particular relates to an observation instrument location operation device used for seal floor environment detection prediction. The observation instrument location operation device comprises a locating seat, multiple containing grooves are formed in the outer surface of the locating seat, and a compressingcylinder is arranged in the containing grooves; an annular object receiving disc sheathes the outer side of the locating seat, and the annular object receiving disc is fixedly connected with the topof the compressing cylinder; an annular ring is formed in the top of the locating seat, and an annular air sac is arranged inside the annular ring. The observation instrument location operation deviceprovided by the invention has the advantages that the annular object receiving disc and the annular air sac are arranged, the upper surface of the annular object receiving disc can bear sediments inwater, and when a certain amount of sediments are accumulated, the compressing cylinder is extruded, so that gas in the annular air sac is sprayed out by virtue of a first gas jetting hole, disturbance effect on seawater at an observation instrument is realized, sediments deposited on the observation instrument mounted on a mounting seat are dispersed by the gas, the sediments fall off from the observation instrument, and observation effect of the observation instrument is guaranteed.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

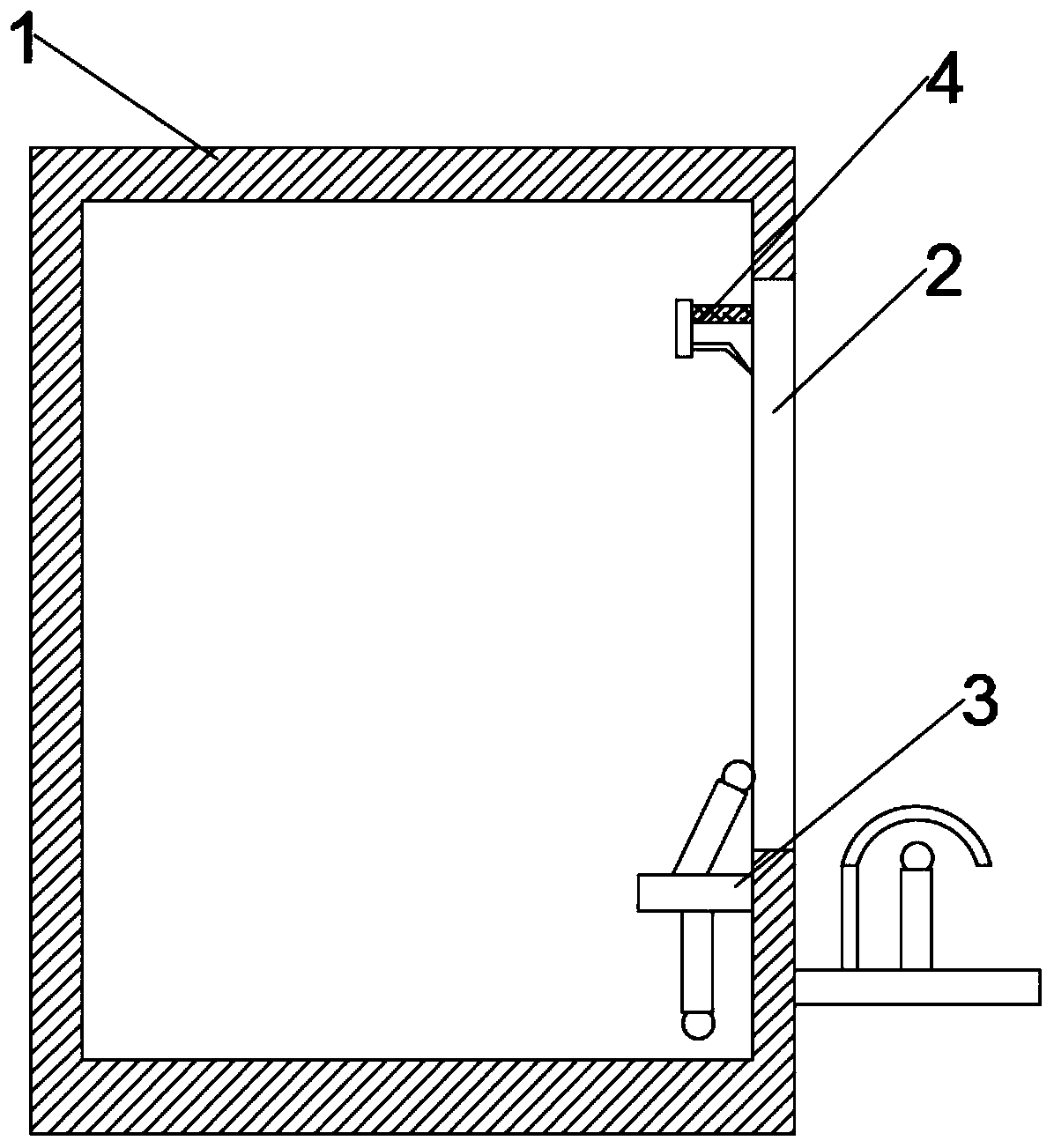

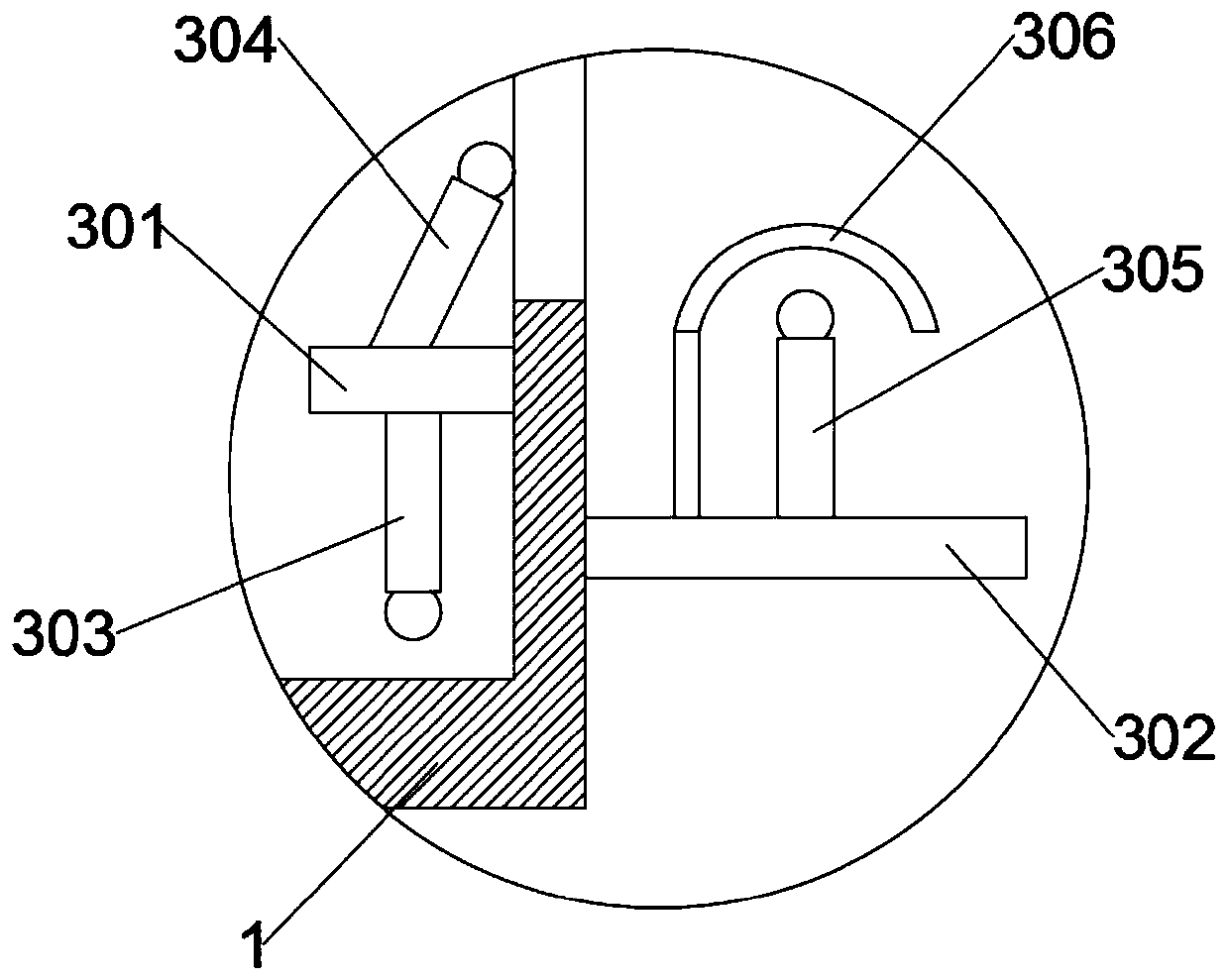

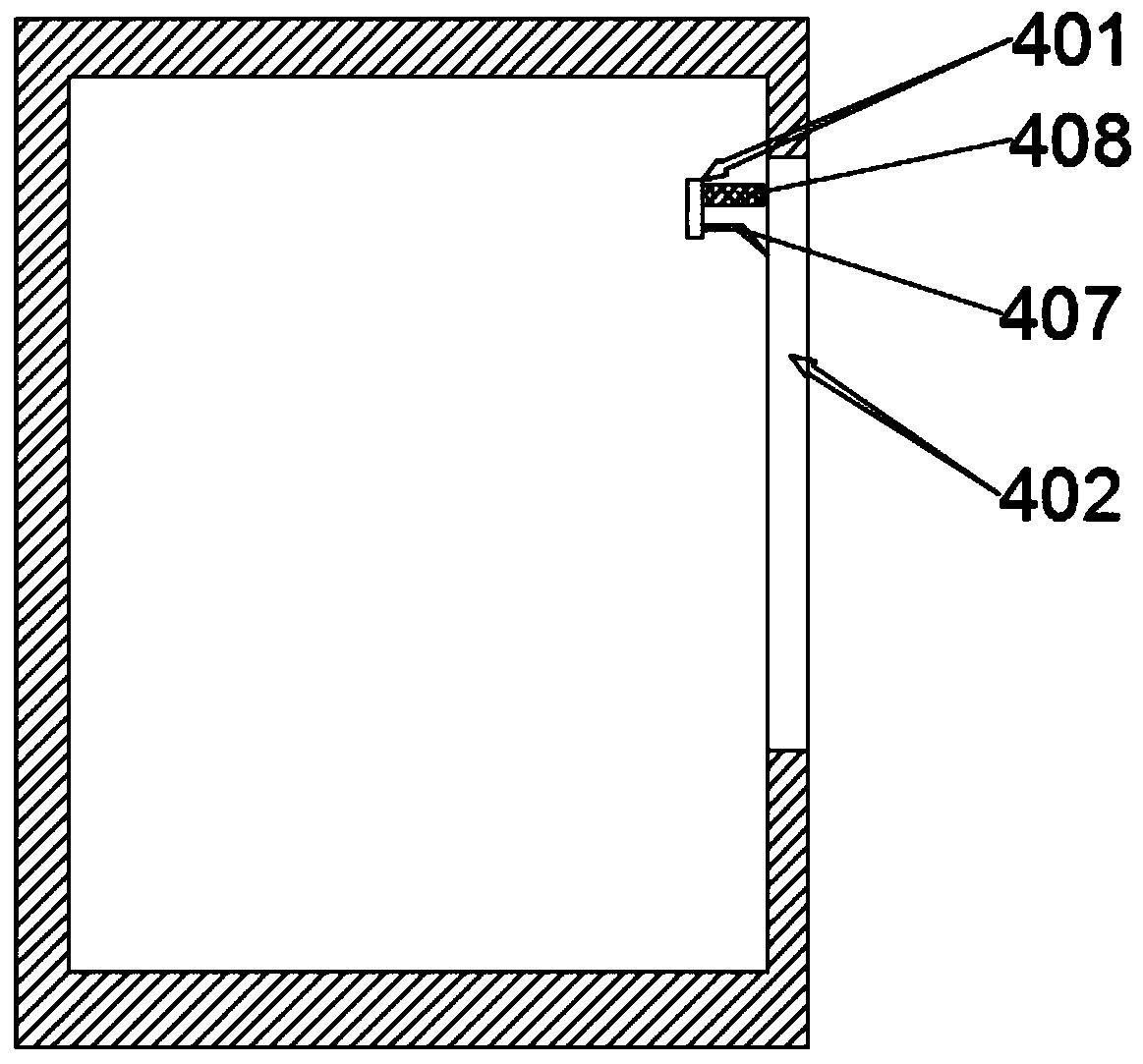

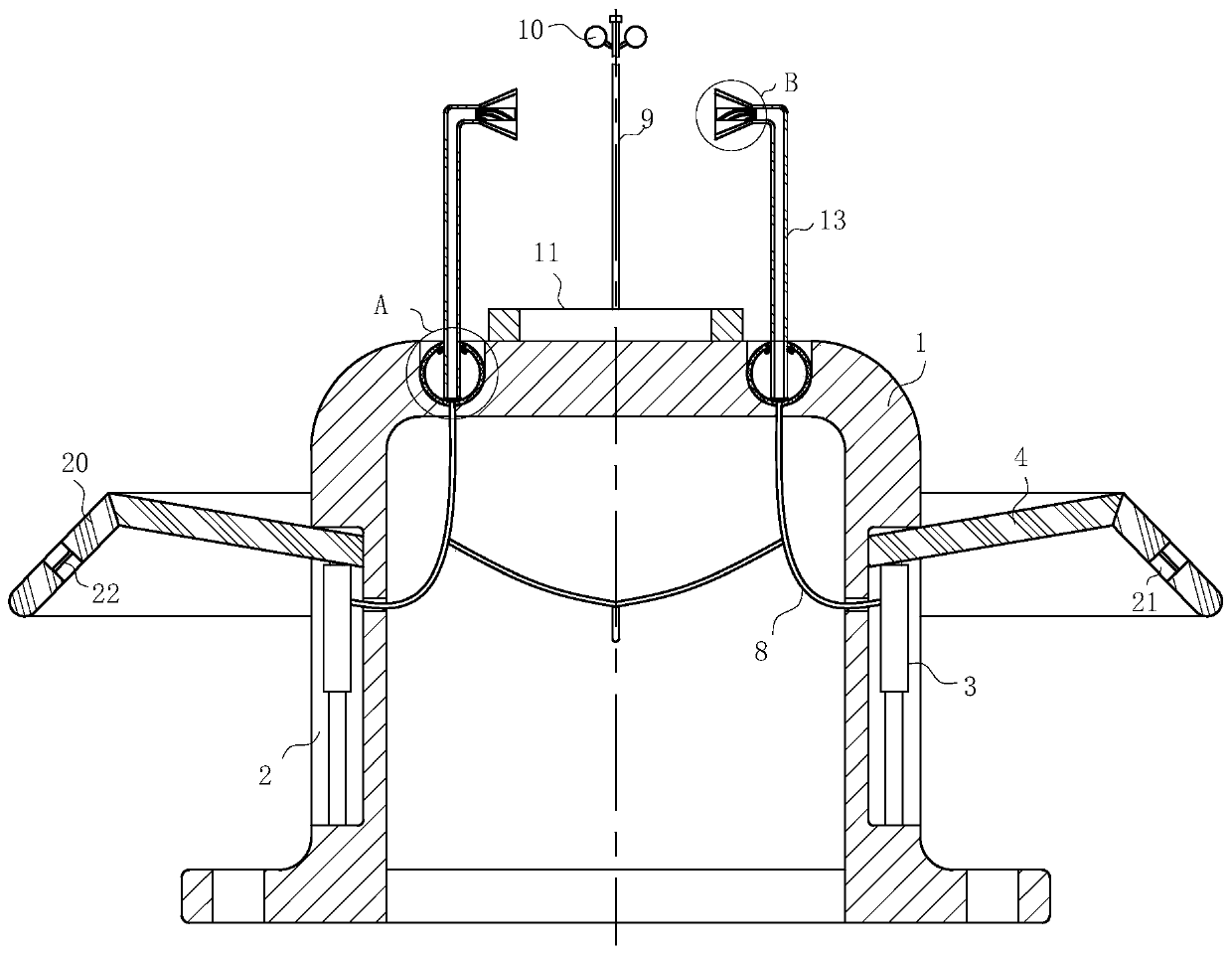

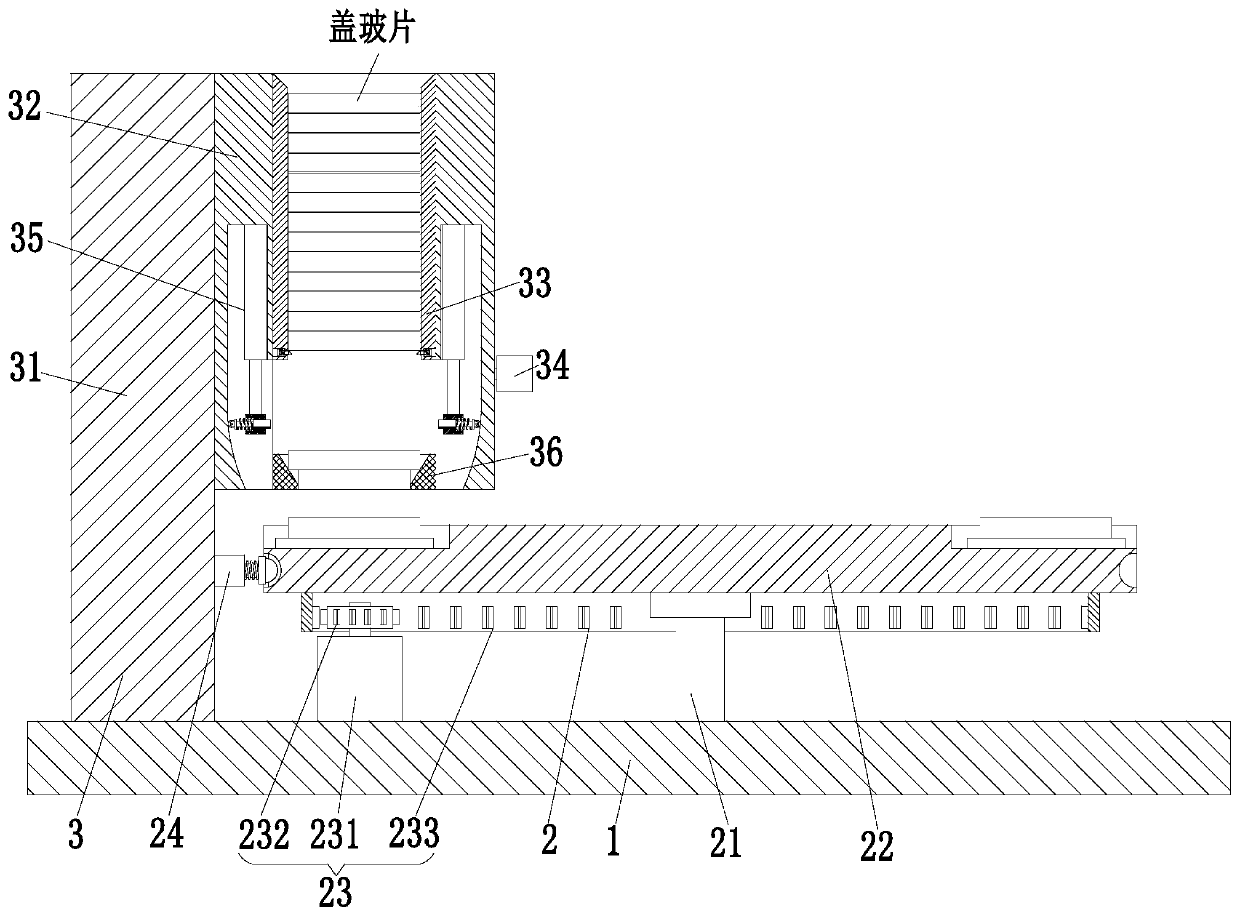

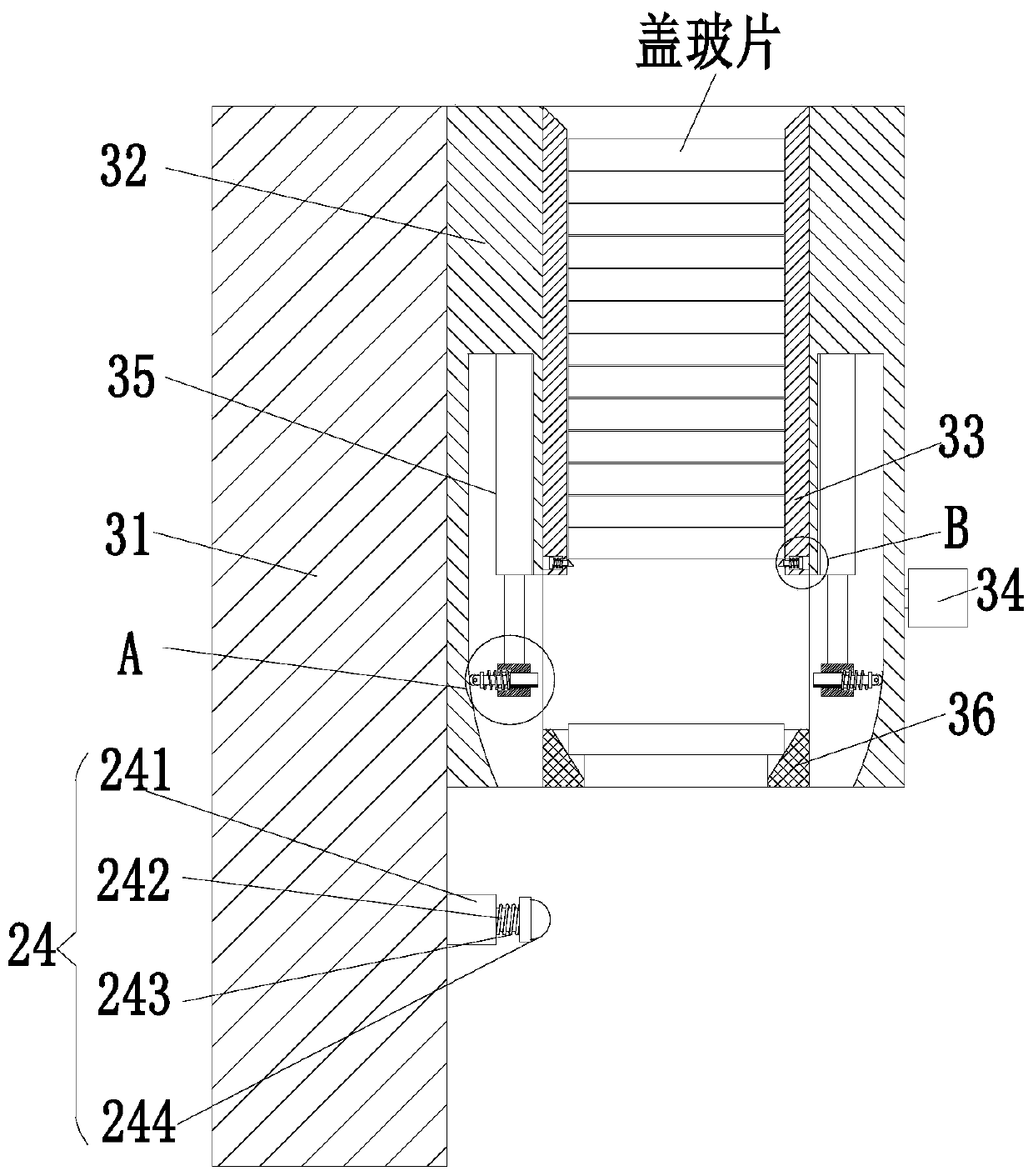

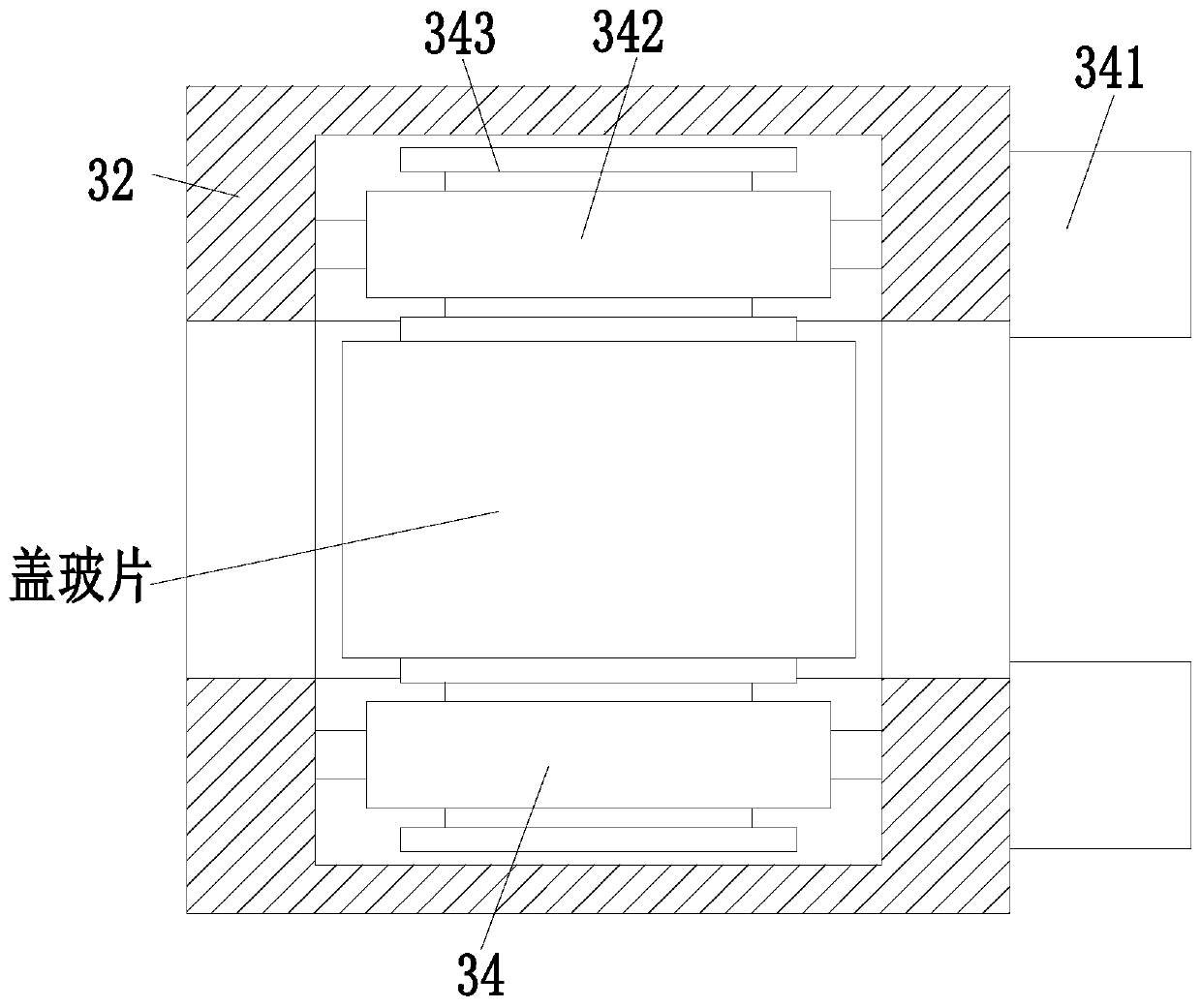

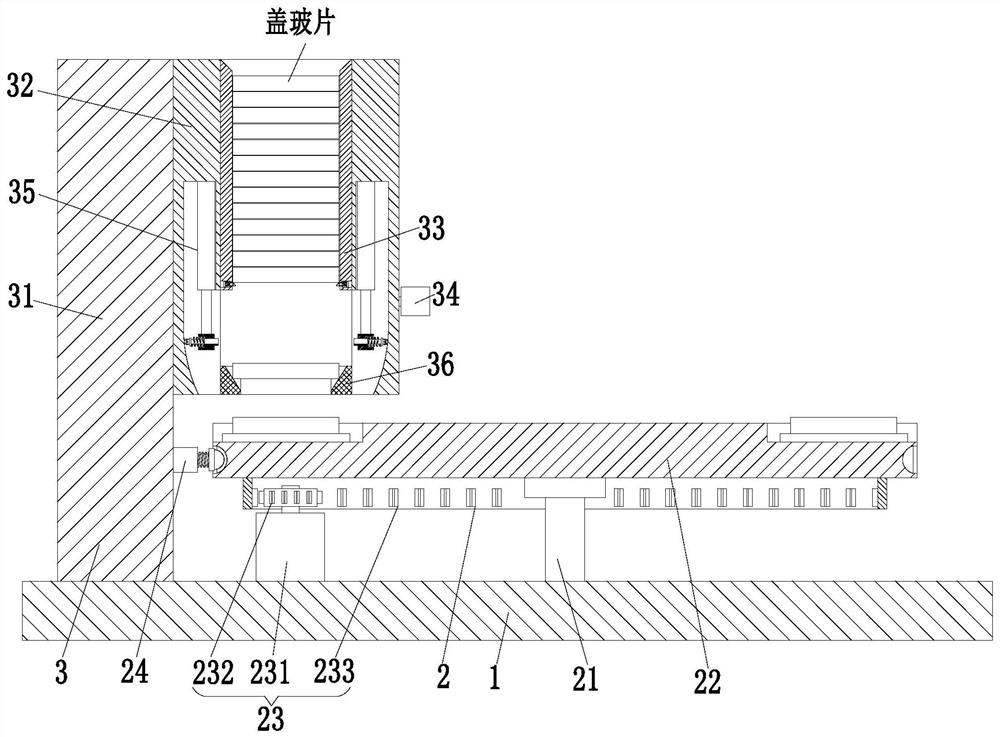

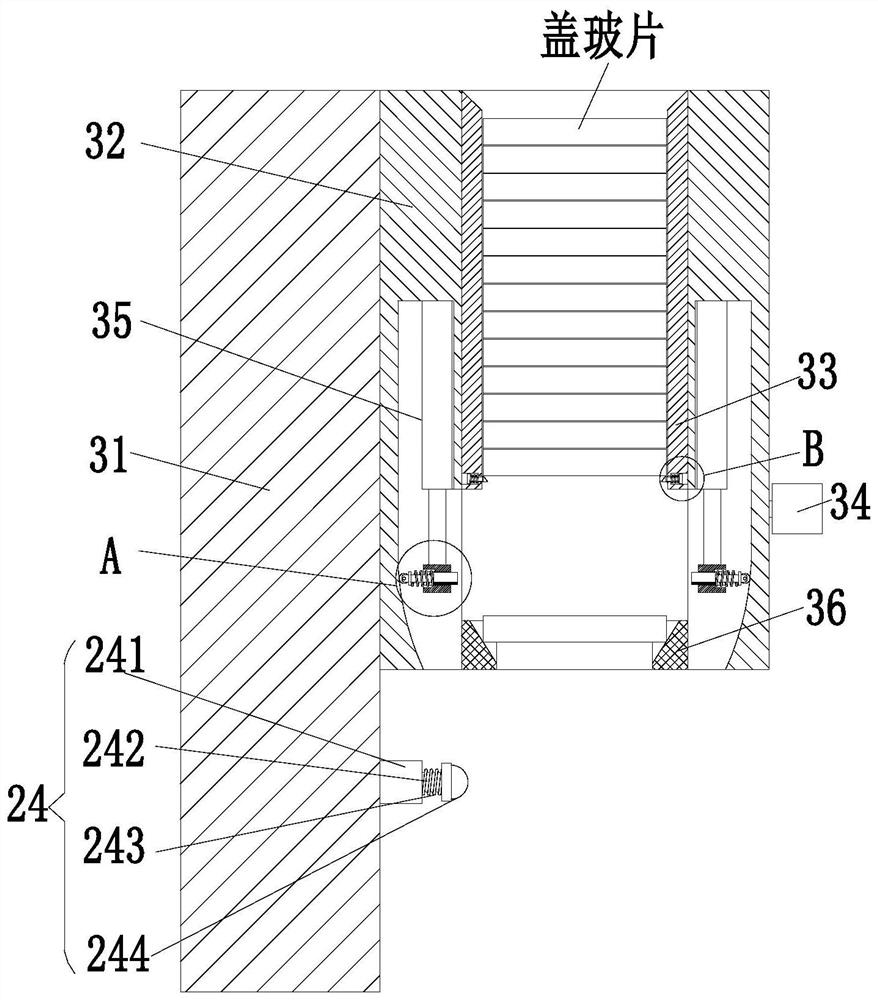

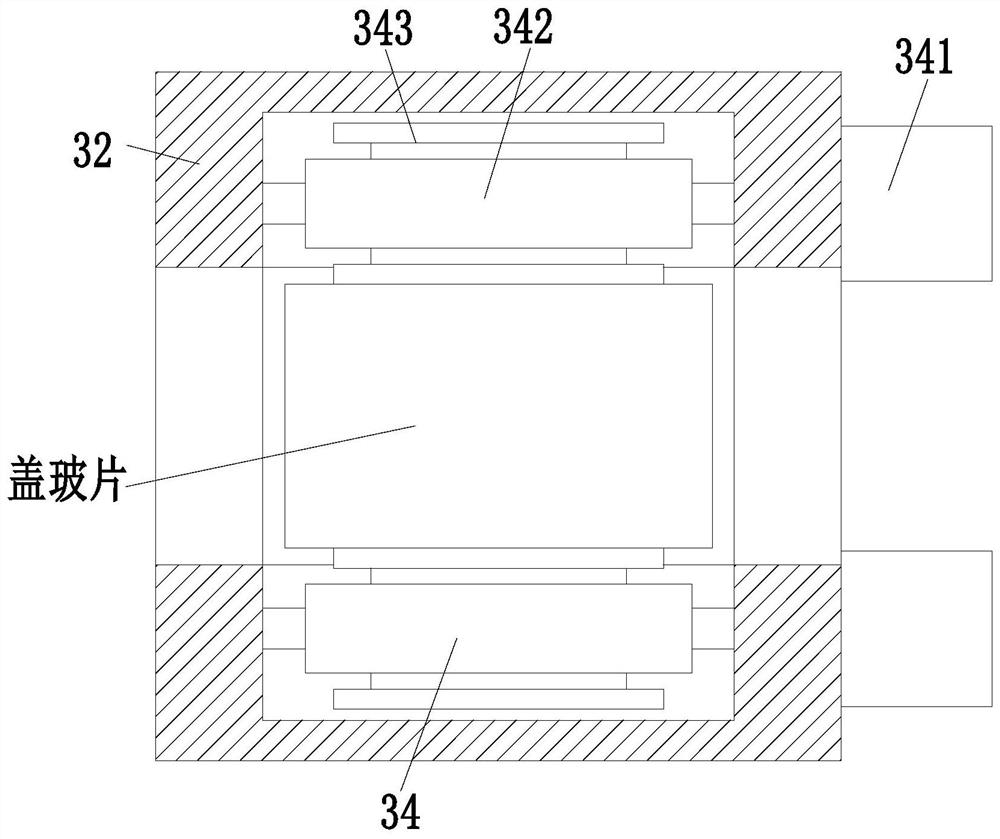

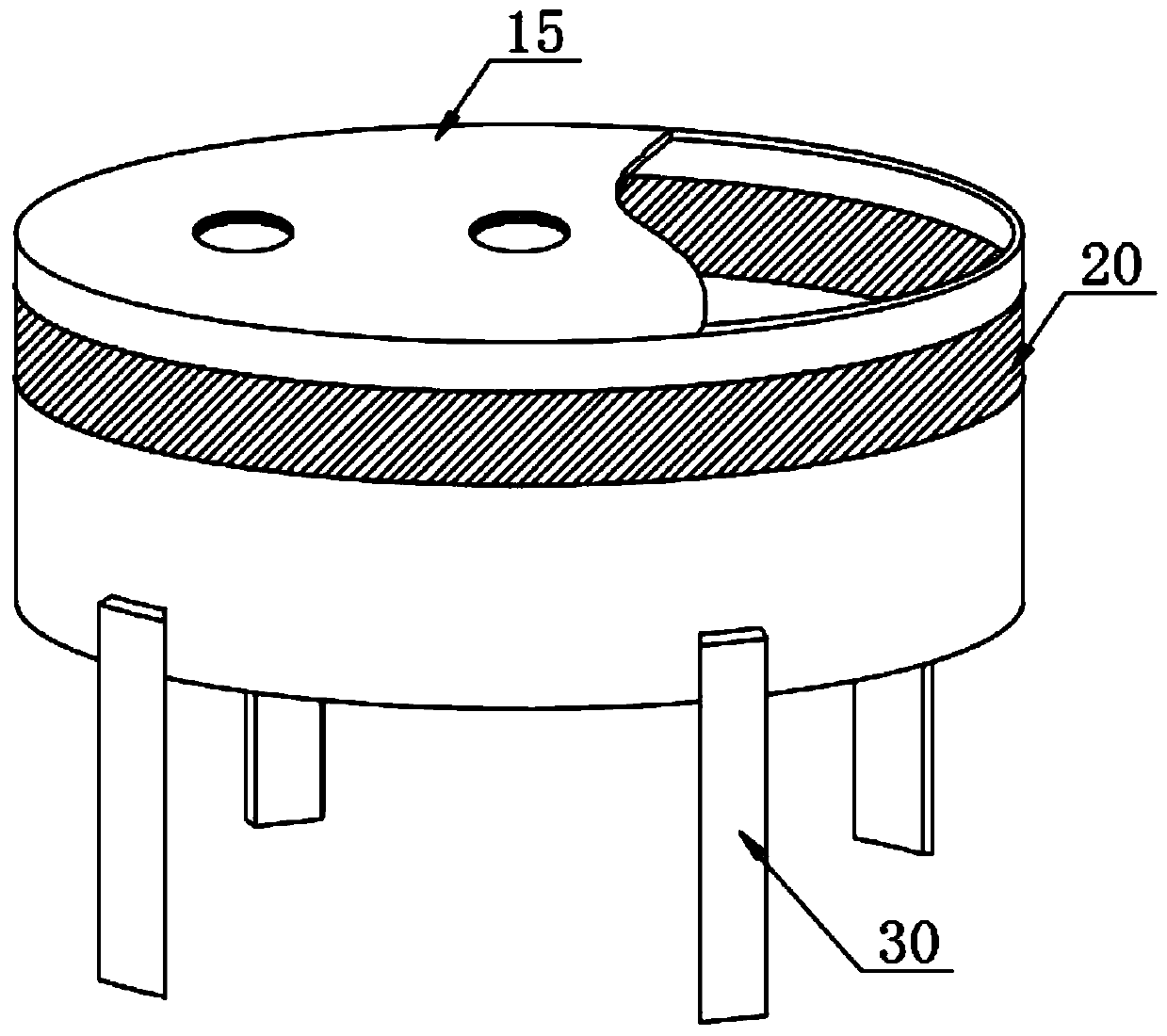

Chip mounting device for processing plant tissue slices serving as medical detection accessories

ActiveCN111231481AInhibition biasGuaranteed observation effectLamination ancillary operationsPreparing sample for investigationBiotechnologyPlant tissue

The invention relates to a chip mounting device for processing plant tissue slices serving as medical detection accessories, which comprises a bottom plate, a positioning device and a chip mounting device, the positioning device is installed in the middle of the upper end of the bottom plate, the chip mounting device is arranged on the left side of the positioning device, and the lower end of thechip mounting device is installed on the bottom plate. The device can solve the problems that when existing device conducts flaking processing on plant tissue slices, the processing effect is poor and the efficiency is low; the glass slide cannot be accurately positioned; therefore, the prepared plant slices are easy to deviate, and the observation effect is influenced; in addition, when existingequipment carries out flaking processing on plant tissue slices, cover glass and glass slides cannot be attached one by one, and therefore the problems that the processing efficiency is low, the production cost is high, the cover glass cannot be effectively protected, and the slice breaking phenomenon is likely to happen in the attaching process are solved.

Owner:新昌县勤勉生物医药科技有限公司

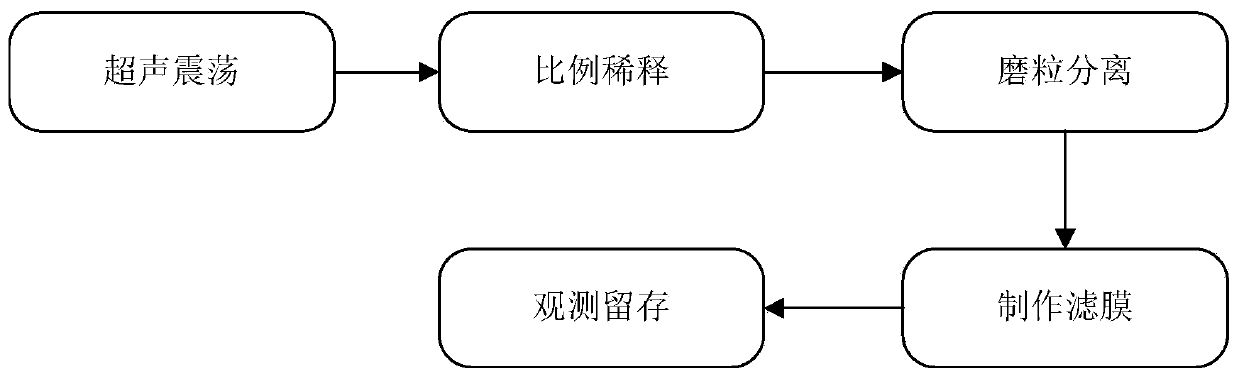

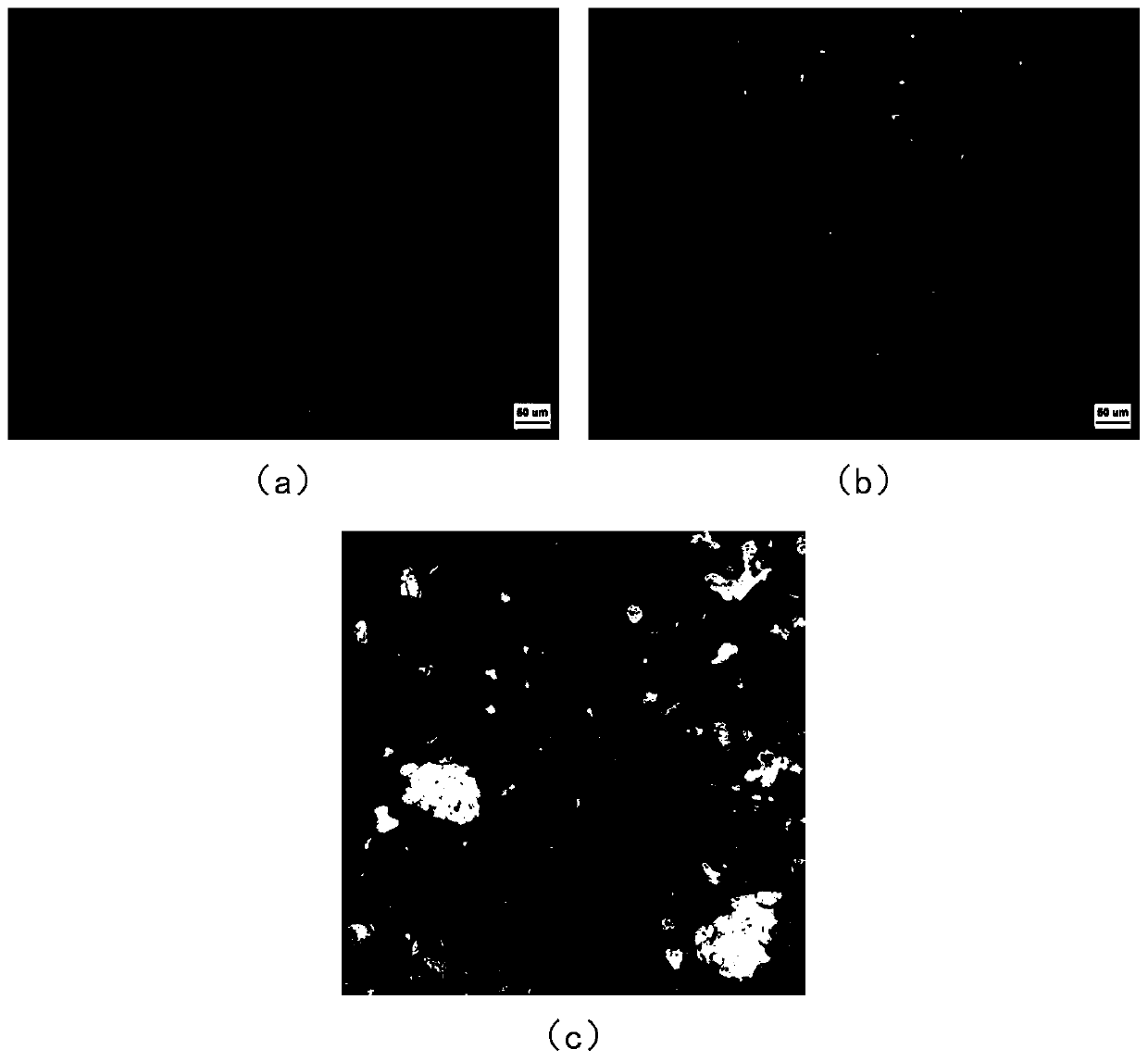

Offline abrasive particle extraction method

InactiveCN110987730AReduce stackingConvenient researchPreparing sample for investigationParticle and sedimentation analysisFiltration membraneKerosene

The invention provides an offline abrasive particle extraction method which comprises the following steps: Step 1, firstly, manually shaking up an offline oil liquid for 30 seconds, putting the offline oil liquid into an ultrasonic machine, and oscillating for 30 minutes to uniformly mix the oil liquid and abrasive particles and avoid agglomeration and deposition of the abrasive particles; Step 2,diluting the oil sample, namely diluting the collected oil sample with kerosene at a ratio of 3: 1 so as to ensure that the used oil sample can smoothly pass through a filter membrane, separating theoil liquid from the abrasive particles by using a syringe filter, and cleaning a syringe by using kerosene; Step 3, taking the filter membrane out of the syringe filter, preparing a glass slide on the glass slide, dripping two drops of clear solution on the glass slide, and putting the filter membrane on the clear solution to ensure that one surface with the abrasive particles is positioned above; and putting the mixture on a constant-temperature table for drying; and Step 4, observing under a microscope. The technical problem that in the prior art, abrasive particles are connected with one another, and consequently analysis of the abrasive particles is inaccurate is solved.

Owner:XIAN TECHNOLOGICAL UNIV

A patch device for medical detection accessories plant tissue slice processing

ActiveCN111231481BInhibition biasGuaranteed observation effectLamination ancillary operationsPreparing sample for investigationBiotechnologyPlant tissue

The invention relates to a chip mounting device for processing plant tissue slices serving as medical detection accessories, which comprises a bottom plate, a positioning device and a chip mounting device, the positioning device is installed in the middle of the upper end of the bottom plate, the chip mounting device is arranged on the left side of the positioning device, and the lower end of thechip mounting device is installed on the bottom plate. The device can solve the problems that when existing device conducts flaking processing on plant tissue slices, the processing effect is poor and the efficiency is low; the glass slide cannot be accurately positioned; therefore, the prepared plant slices are easy to deviate, and the observation effect is influenced; in addition, when existingequipment carries out flaking processing on plant tissue slices, cover glass and glass slides cannot be attached one by one, and therefore the problems that the processing efficiency is low, the production cost is high, the cover glass cannot be effectively protected, and the slice breaking phenomenon is likely to happen in the attaching process are solved.

Owner:新昌县勤勉生物医药科技有限公司

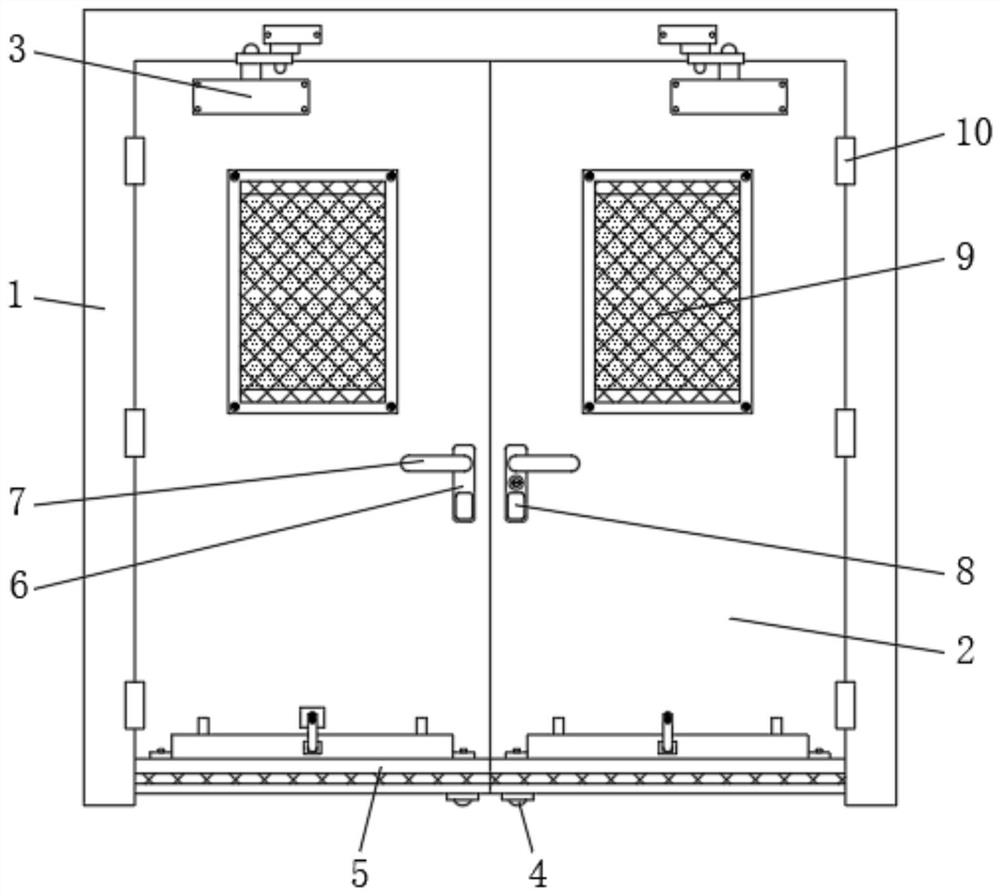

Improved fire-fighting fireproof door convenient to open and close

InactiveCN111810035AGuaranteed smoothnessEasy to switchFireproof doorsFixed grillesDisplay boardFire - disasters

The invention discloses an improved fire-fighting fireproof door convenient to open and close. The improved fire-fighting fireproof door comprises a door frame, wherein a movable door is arranged on the door frame, and a door closer is connected between the movable door and the door frame. According to the improved fire-fighting fireproof door convenient to open and close, a guide structure can form certain supporting and guiding, the opening and closing smoothness of the movable door is guaranteed, and then the movable door can be opened and closed conveniently; an elastic piece is adopted, so that balls can be in contact with the ground all the time even in an uneven ground environment, and the guiding effect is guaranteed; a blocking structure can quickly descend to seal a gap below themovable door, then the sealing performance is improved, and the smoke isolation effect is enhanced; a display board in an indicating structure can reflect light rays, so that a handle can be quicklyfound under the condition of power failure when a fire disaster occurs, and personnel evacuation is facilitated; and a protective structure is used in cooperation with transparent glass, so that the observation effect is guaranteed, meanwhile, the protection effect can be improved, and the practicability is enhanced.

Owner:绍兴嘉盾消防器材有限公司

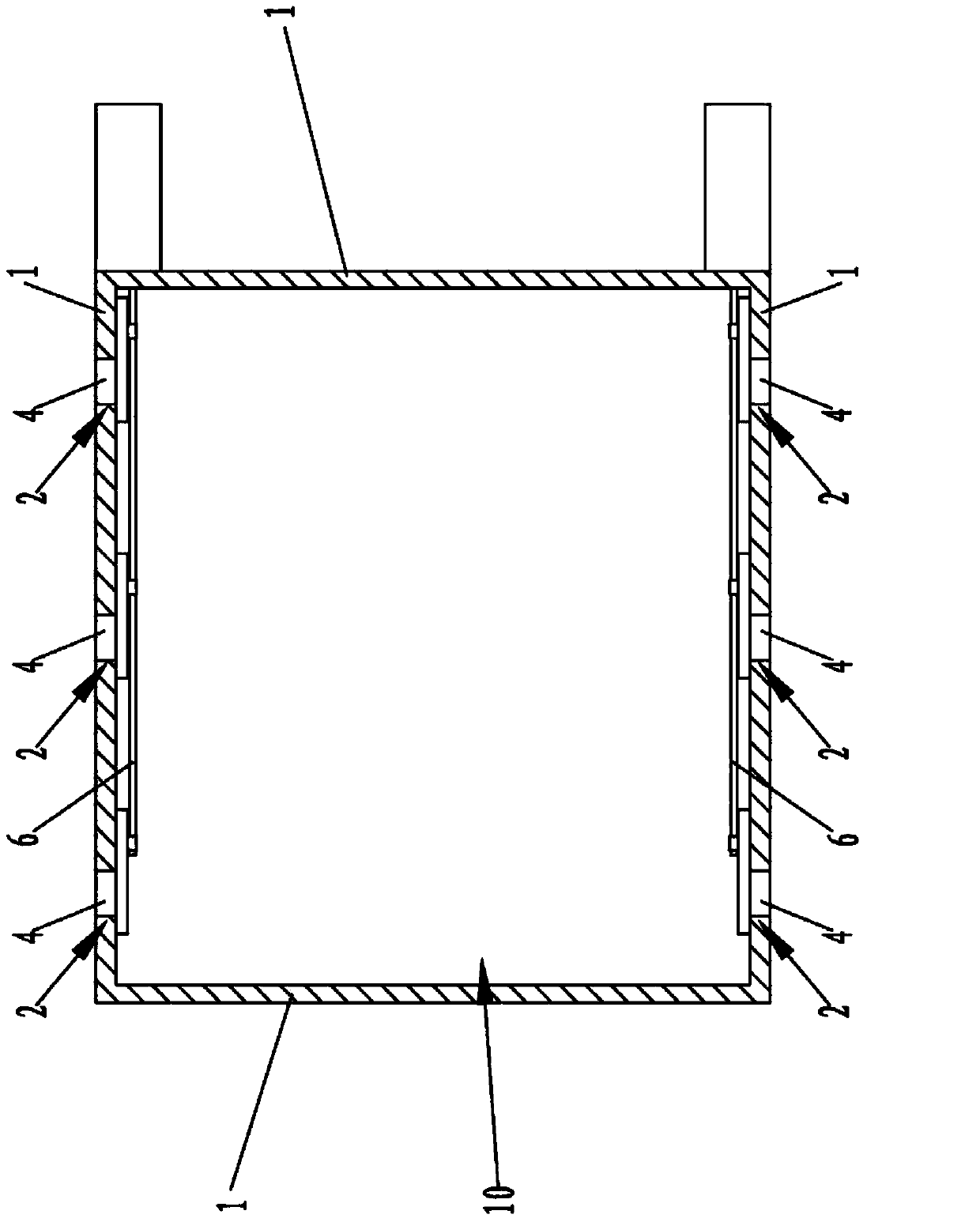

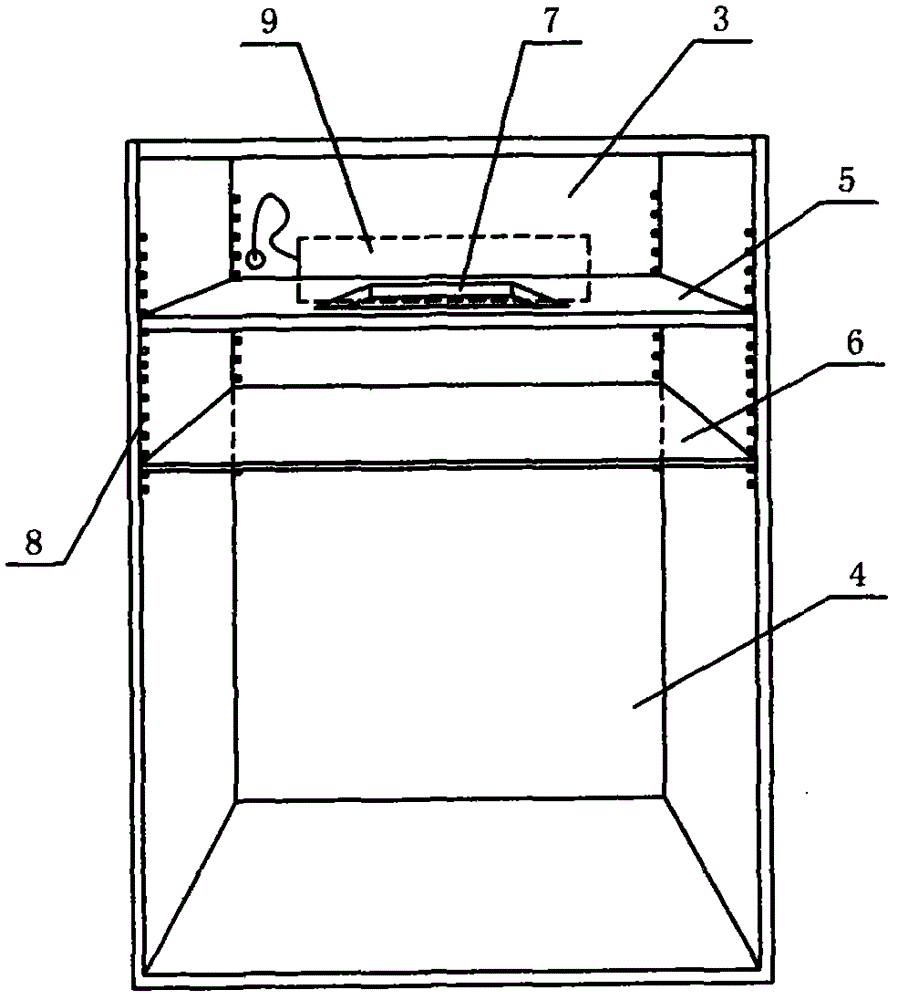

A light box for observing lighting effects

InactiveCN104931237BImprove applicabilityImprove and ensure applicabilityTesting optical propertiesOptoelectronicsIrradiation

The invention discloses a light box for observing lighting effects, which comprises a light box cavity, a light source support plate, a translucent diffusion plate, a blocking door and an adjustment device. The front and top surfaces of the light box cavity are open, and the adjustment device is arranged on the left and right sides of the inner cavity of the light box cavity. The middle part of the light source support plate is provided with a light source opening for irradiation, and the light source support plate and the diffusion plate are respectively connected to the adjustment device. On the upper side, the shielding door is installed at the position close to the upper side of the front opening of the light box cavity. Its structural design facilitates the replacement and installation of the lamps to be tested, and does not impose any restrictions on the size of the lamps to be tested, avoiding the influence of the light source on the observation process of the lower light source observation area after it is transmitted. At the same time, by adjusting the light source support plate and diffusion plate It can also meet the adjustment needs of different light source irradiation intensity, and realize the observation of light box lighting effects of different types of lamps.

Owner:广东省标准化研究院

A method for generating terrain lod

The invention discloses a terrain LOD generation method. The terrain LOD generation method comprises the steps of: importing remote sensing images and DEM elevation data which are downloaded online oracquired by means of radar aerial photography, point cloud surveying and mapping and the like into Global Mapper or other GIS software; reading the obtained elevation data through gadl, converting the elevation data into grid data, performing grid division on the grid data, converting the divided grid data into a triangular relationship network, storing a relationship structure of triangular vertexes and surfaces, and calculating a vertex secondary error sequence of each block for the divided grid data; then simplifying the data by taking the data as a whole, and generating a quadtree structure; performing secondary organization on results of a plurality of single-time processing data to form a new quadtree structure so as to dynamically schedule each single-time processing data; and rendering the processed data, determining a cutting mode according to a current view frustum, and ensuring smooth rendering of the city-level number in combination with quick search traversal of the quadtree structure.

Owner:中国电力企业联合会电力建设技术经济咨询中心 +1

Vacuum reaction chamber and vacuum processing equipment

ActiveCN103695860BExtend your lifeGuaranteed observation effectElectrolysis componentsVacuum evaporation coatingPulp and paper industryVacuum chamber

The invention discloses vacuum reaction chamber and vacuum processing equipment. The vacuum chamber comprises a plurality of wallboards, wherein an observation device is arranged on at least one wall boards of the plurality of wallboards; the observation device comprises an observation window arranged on the wallboard and a shielding plate for shielding the observation window; the shielding plate can be moved between a first position for shielding the observation window and a second position not shielding the observation window. The vacuum processing equipment comprises the vacuum reaction chamber. In the vacuum reaction chamber and the vacuum processing equipment, the shielding plate can protect the observation window and further effectively shield the wallboard around the observation window. The vacuum reaction chamber and the vacuum processing equipment can effectively protect the observation window, prolongs the service life of the observation window, and effectively ensures the observation effect; meantime, the shielding plate can protect the wallboard around the observation window, namely the etched place with highest etching possibility on the wallboard, so as to prolong the entire service life of the wallboard and reduce the cost for high-frequency maintenance and labor loss.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

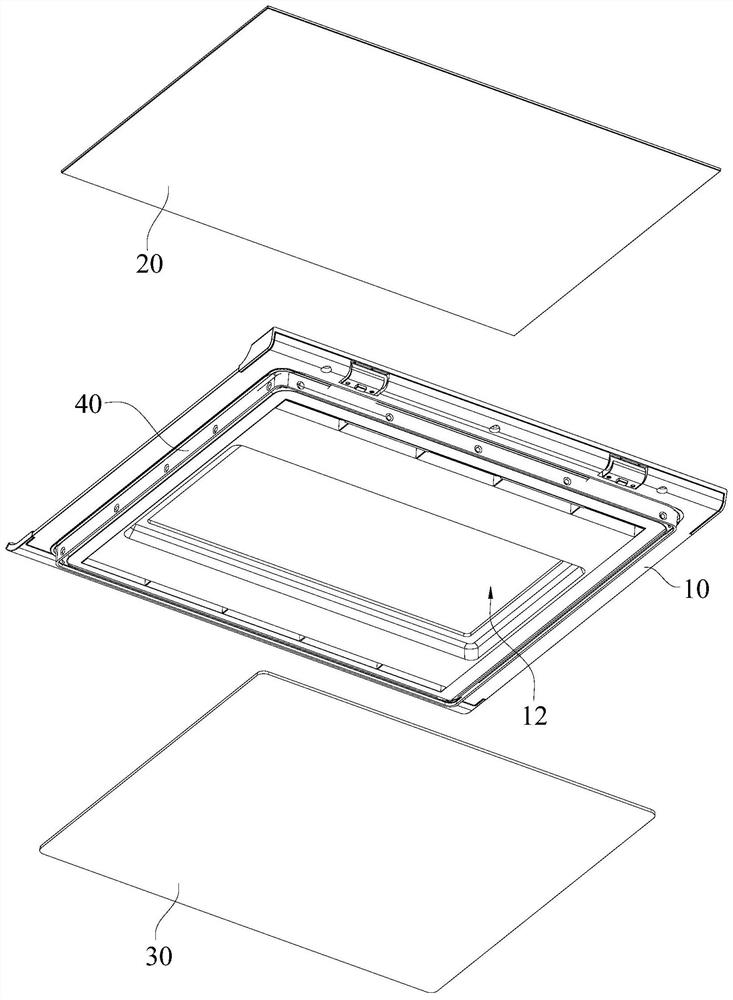

Dishwasher and its sealed door assembly

ActiveCN111904359BAchieve airtight protectionPrevent foggingTableware washing/rinsing machine detailsWater vaporEngineering

The present application belongs to the technical field of dishwashers, and in particular relates to a dishwasher and its airtight door assembly. The airtight door assembly includes a door panel, a first transparent panel and a second transparent panel. The bottom of the concave cavity is provided with an observation window, and the edge of the observation window is formed with ribs arranged around the observation window along the height direction of the door panel, and the first transparent plate is covered on the upper end surface of the door panel , and cover the concave cavity, a first sealing layer is provided between the first transparent plate and the rib, the second transparent plate is sealed and connected with the bottom of the door panel, and covers the observation window. In this way, the complete sealing protection of the observation window is realized, which can effectively prevent high-temperature water vapor from infiltrating into the observation window from the gap formed by the assembly of the door panel, the first transparent plate and the second transparent plate, thereby preventing the observation window from being exposed to high-temperature water vapor. Atomization occurs under the action of osmosis, effectively ensuring the observation effect of the observation window.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

A dust isolation device for interior decoration construction

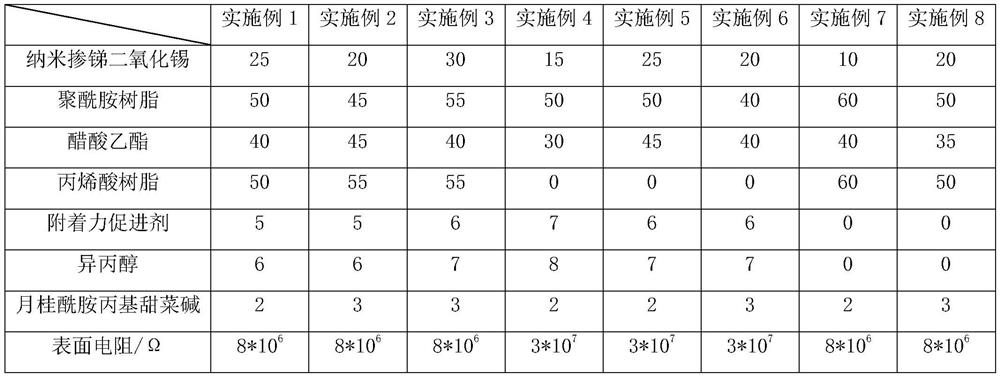

ActiveCN108970257BHigh light projectionGood chemical stabilityDispersed particle filtrationPolyamide coatingsPolyamideEnvironmental engineering

The invention discloses a dust isolating device for indoor decoration construction, which belongs to the technical field of decoration, and the dust isolating device comprises a dust-proof box, wherein a vacuum cleaner is connected to the side wall of the dust-proof box through a pipeline, an air pressure balance opening is arranged on the top wall of the dust-proof box, a filter cloth is arrangedinside the air pressure balance opening, a plurality of operation openings are arranged on the side wall of the dust-proof box, an operation glove inside the dust-proof box is arranged on each of theoperation openings, a visible glass is arranged above the operation glove inside the dust-proof box, a cleaning device for cleaning the inside wall of the visible glass is arranged on the side wall of the dust-proof box, a transparent dust-proof paint is coated on the inside wall of the visible glass, the dust-proof paint is prepared from the following raw materials in parts by weight: 10 to 30 parts of nanometer antimony-doped tin dioxide; 40 to 60 parts of polyamide resin; and 30 to 45 parts of ethyl acetate. The dust-proof paint has the following beneficial effects: The dust-proof paint has a good antistatic performance, so as to avoid dust adsorption on a visible glass, thereby ensuring the observation effect of the visible glass on the inside of the dust-proof box.

Owner:永嘉县城东市政建设有限公司

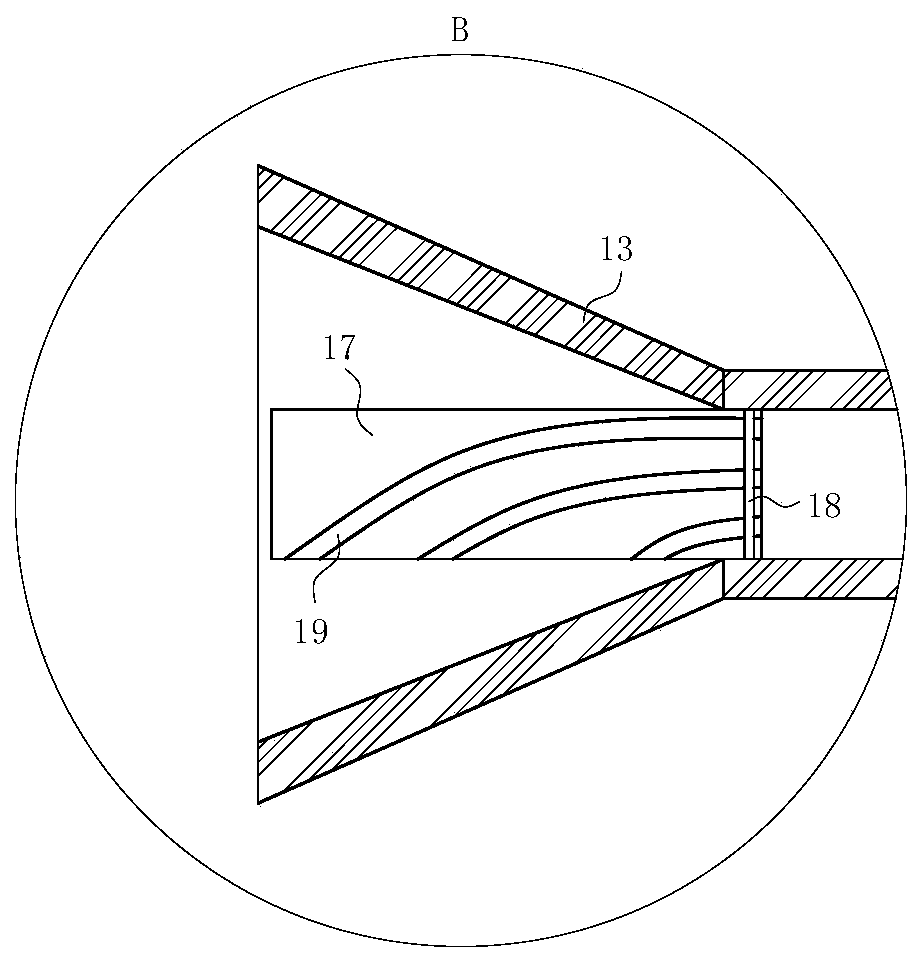

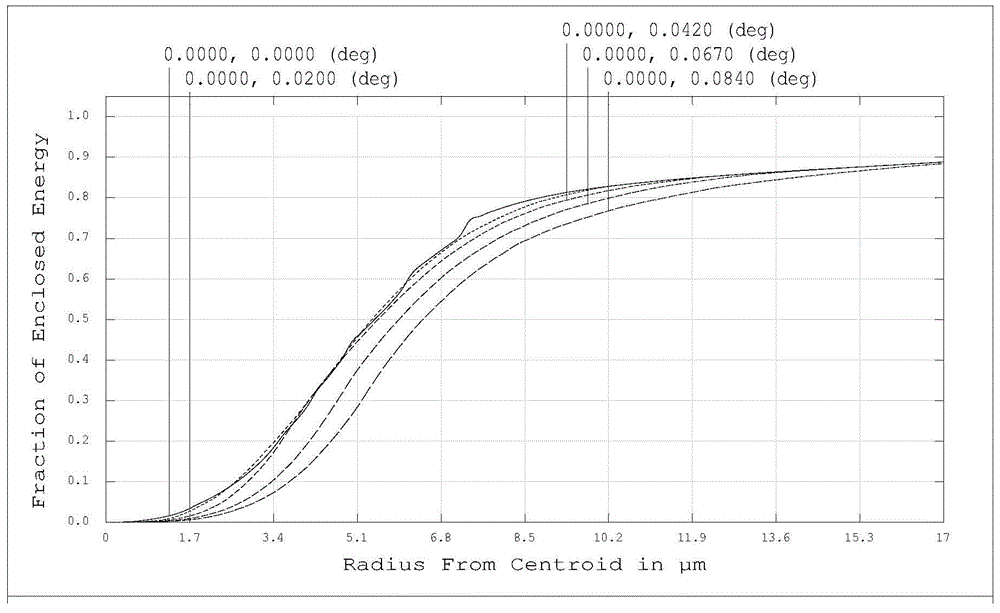

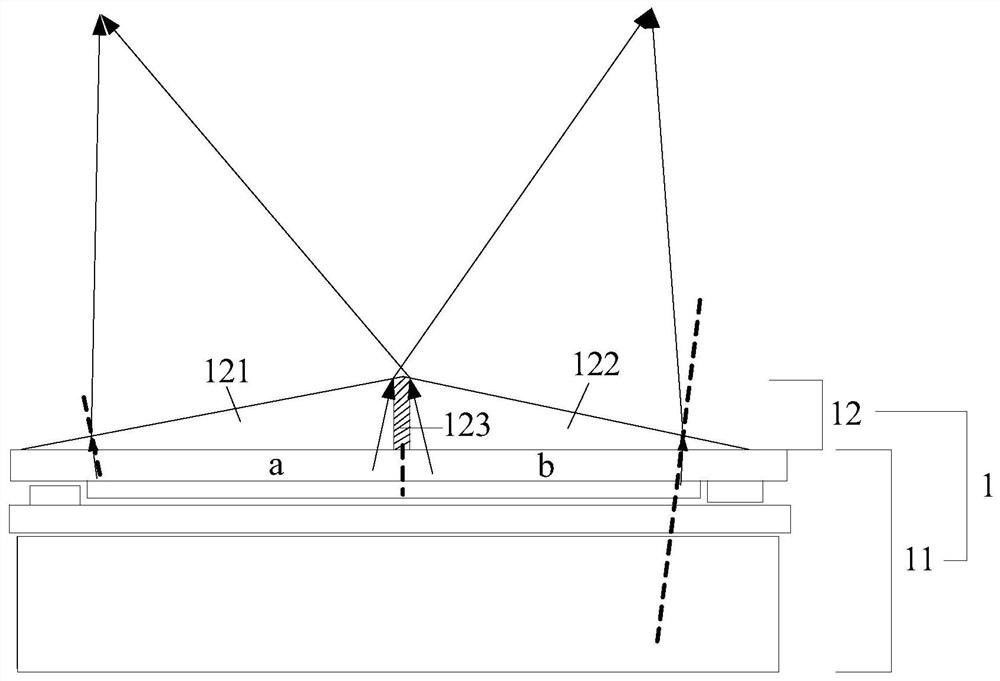

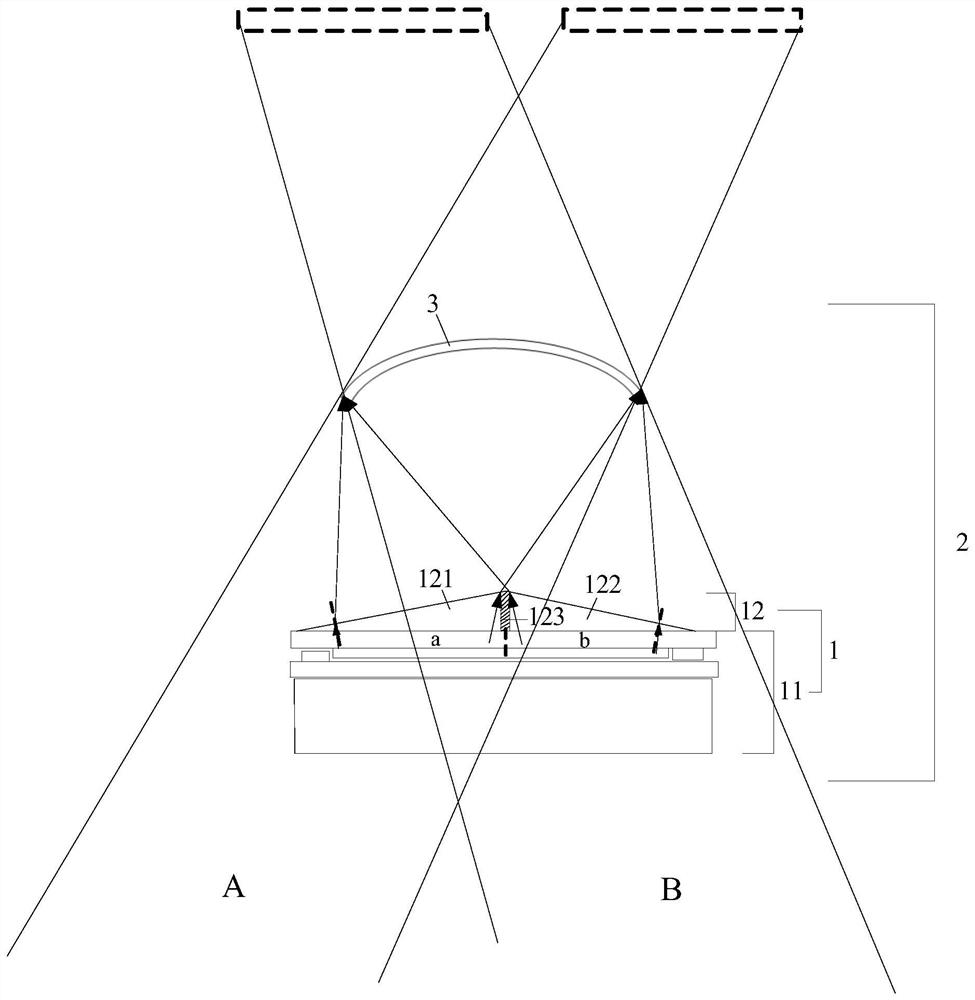

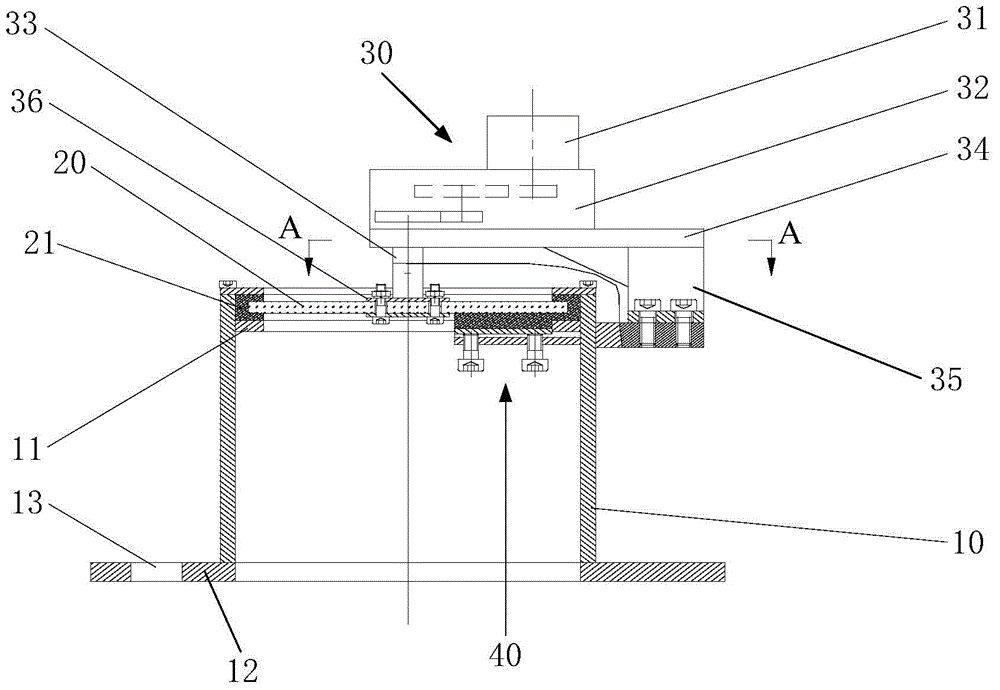

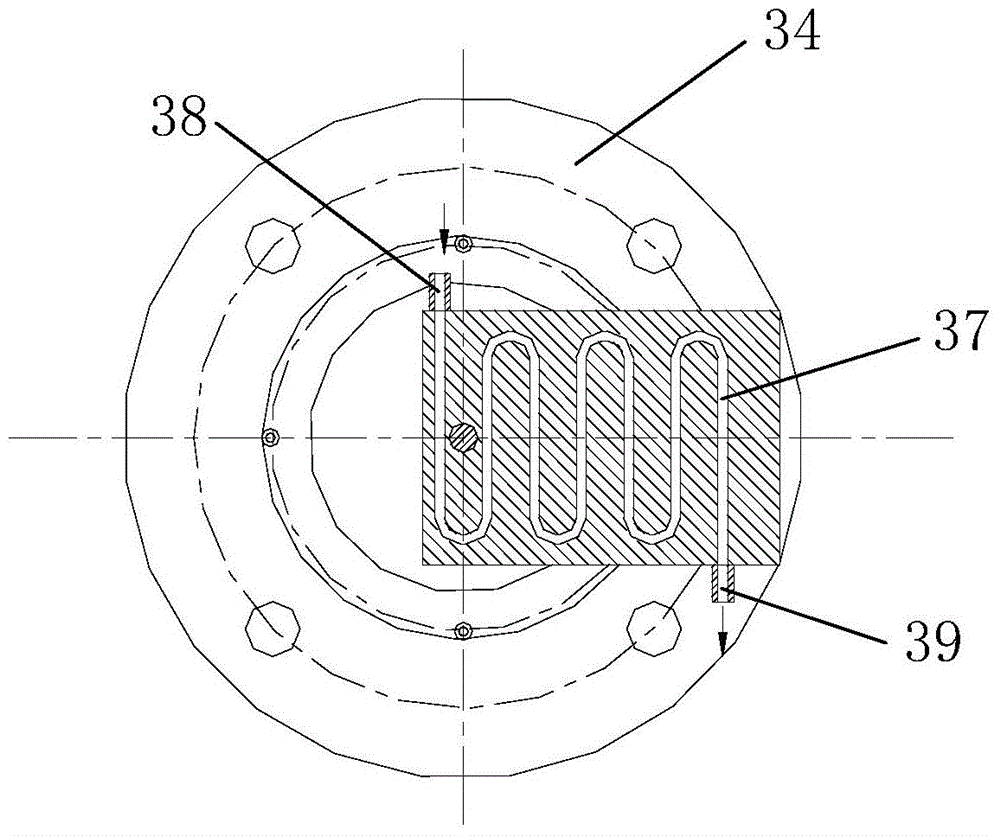

An all-time miniaturized star-tracking optical system

ActiveCN103439792BIncrease the detection areaReduce stray light levelsNavigation by astronomical meansOptical elementsFixed starsFiber

The invention provides a miniaturized fixed star tracking optical system capable of achieving whole-day observation. The whole-day miniaturized fixed star tracking optical system comprises an imaging unit, a band-pass fiber, a main reflector, an auxiliary reflector and a scan reflector and a through hole is formed in the center of the main reflector, wherein the imaging unit, the band-pass fiber, the main reflector, the auxiliary reflector and the scan reflector are sequentially arranged along an optical axis of an imaging optical path; incident light sequentially passes through the scan reflector, the main reflector and the auxiliary reflector, is reflected for three times, and then is emitted to the imaging unit through the central through hole of the main reflector and the band-pass filter; a part of an optical path of the incident light coincides with a part of an imaging optical path in the scanning field from 30 degrees to 50 degrees so that the requirement for miniaturization of the system can be satisfied; the main reflector and the auxiliary reflector are respectively provided with a light shield and the edge of the scan reflector perpendicularly extends so that a light shielding board can be formed. Field scanning is conducted through the scan reflector, a zone between the 30-degree airspace and the 80-degree airspace of the zenith can be observed all day, and an instant field of the system is smaller than 30'.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Visual mirror for vaginal examination

InactiveCN112890753ASimple structureEasy to operateEndoscopesVaginoscopesTissue fluidVaginal examination

The invention relates to a vaginal examination mirror, and particularly relates to a visual mirror for vaginal examination. The visual mirror for vaginal examination comprises an insertion tube inserted into the vagina, a reflector assembly installed in the insertion tube and an observation mirror arranged on the outer side of the insertion tube. By arranging the insertion tube, the reflector assembly comprising a first reflector, a second reflector and a third reflector, the observation mirror and an irradiation lamp bead; the vagina is visually observed, the structure is simple, and operation is convenient; by arranging a first transparent cover and a second transparent cover, tissue fluid in the vagina is prevented from entering the insertion tube; meanwhile, by arranging a scraper and a push rod, the tissue fluid is prevented from shielding the first transparent cover, and the observation effect is guaranteed; and by arranging a first linkage rod, a second linkage rod, a worm gear and a worm, the angles of the first reflector, the second reflector and the third reflector are conveniently and synchronously adjusted, the observation range is adjusted, and the observation effect is improved.

Owner:孙秀

Polishing device with high safety for industrial design

InactiveCN109702597AReduce frictional resistanceStable suctionGrinding drivesGrinding feed controlDesign technologyEngineering

The invention discloses a polishing device with high safety for the industrial design, and particularly relates to the technical field of the industrial design. The polishing device comprises a rack;brackets are arranged on the two sides of the rack correspondingly, a first conveyor belt is arranged at the top of the bracket on one side, and a second conveyor belt is arranged at the top of the bracket on the other side; a sloping bench is arranged at one end of the top of the rack, and the bottom end of the sloping bench is smoothly connected with the end of the second conveyor belt on the corresponding position; and an object table is arranged on one side of the sloping bench, and a plurality of first electric push rods are evenly distributed at the bottom edge of the object table. Workpieces in the polishing process are fed and discharged through the first conveyor belt and the second conveyor belt, and ascending position change of the object table is detected through a film pressure sensor to guarantee orderly automatic proceeding of positioning and polishing work to reduce manual intervention; and meanwhile, dust generated in the polishing process is sucked into a water tank by a fan to prevent the dust from escaping into air and then polluting the environment.

Owner:SHANDONG UNIV OF SCI & TECH

Display device and display device

ActiveCN108154803BReduce overlapReduce overlapping areasIdentification meansDisplay deviceEngineering

The invention provides a display device and display equipment. The display device comprises a display panel and an adjusting device; the display panel comprises a first display zone and a second display zone; the first display zone and the second display zone can display different images; the adjusting device is arranged on a light outlet face of the display panel, and used for adjusting the transmission direction of the emitting light in the first and second display zones, so that the transmission direction of the emitting light in the first display zone is far from the transmission directionof the emitting light in the second display zone. Through the equipment based on the adjusting device, the transmission direction of the emitting light in the first display zone is far from the transmission direction of the emitting light in the second display zone, thereby effectively reducing the overlapping degree of the emitting lights of two display zones on the display panel, reducing the overlapping zone of two observing zones, and guaranteeing the observing effect of two observing zones.

Owner:BOE TECH GRP CO LTD

A self-cleaning observation window device

ActiveCN103913072BGuaranteed observation effectWill not affect the line of sightFurnace componentsCleaning using toolsEngineeringElectrical and Electronics engineering

The invention relates to a self-cleaning observation window device, which includes a housing with openings at both ends, observation window glass, a rotational driving mechanism and a cleaning brush mechanism, wherein an opening at one end of the housing is fixed to an object to be observed, and the observation window The glass is installed at the opening at the other end of the housing; the fixed end of the rotational driving mechanism is fixed on the outside of the housing, and its movable end is fixedly connected to the observation window glass and drives the observation window glass in place. The inside of the housing rotates along a central axis; the cleaning brush mechanism is fixed inside the housing and in contact with the inner surface of the observation window glass. In the present invention, the housing only needs to be installed on the opening of the object to be observed, and the rotation drive mechanism is used to drive the observation window glass to rotate. At the same time, the cleaning brush mechanism cleans the observation window glass to ensure that the observation window glass is clean and the observation window glass is kept clean. The temperature and vacuum degree inside the object have no effect, and the applicability is wider.

Owner:BAOSTEEL ENG & TECH GRP

An observation instrument positioning operation device for detection and prediction of seabed environment

ActiveCN110515137BGuaranteed observation effectImprove comprehensivenessSurveying instrumentsGeological measurementsGas cylinderGas passing

The invention belongs to the technical field of seabed detection auxiliary devices, and specifically relates to a positioning operation device for observation instruments for seabed environment detection and prediction; Cylinder; the outer side of the positioning seat is sleeved with an annular object tray, and the annular object tray is fixedly connected to the top of the compression cylinder; the top of the positioning seat is provided with an annular ring, and an annular air bag is arranged inside the annular ring; The object tray and the annular air bag, the upper surface of the annular object tray can carry the sediment in the water, when the sediment reaches a certain amount, the compression cylinder is squeezed, so that the gas in the annular air bag is ejected through the first jet hole, and the observation instrument The seawater at the place has a disturbance effect, so that the sediment deposited on the observation instrument installed on the mounting base is washed away by the gas, and the sediment falls from the observation instrument, ensuring the observation effect of the observation instrument.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Image display adjustment method, device, computer equipment and storage medium

ActiveCN108646969BRealize local brightness adjustment functionGuaranteed observation effectInput/output processes for data processingImaging processingMedicine

The invention relates to an image display adjustment method, device, computer equipment and storage medium, and is applied in the field of image processing. The method includes: detecting a local brightness adjustment instruction for an image, determining a target adjustment area of the image after detecting the local brightness adjustment instruction; adjusting the display brightness of the image, and generating a transparent image on the image layer; the transparent layer includes a first layer area and a second layer area, the first layer area at least partially overlaps with the target adjustment area of the image, and the transparency of the first layer area is different from that of the second layer area The transparency of the second layer area. The embodiment of the present invention solves the problem that it is difficult to ensure the image observation quality in the existing adjustment method, and can realize the effect of adjusting the local display brightness of the image.

Owner:广州视创显示科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com