Polishing device with high safety for industrial design

An industrial design and safety technology, applied in grinding/polishing safety devices, grinding drive devices, grinding automatic control devices, etc., can solve the problems of fine dust overflow, manual intervention, high work intensity, etc. The effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

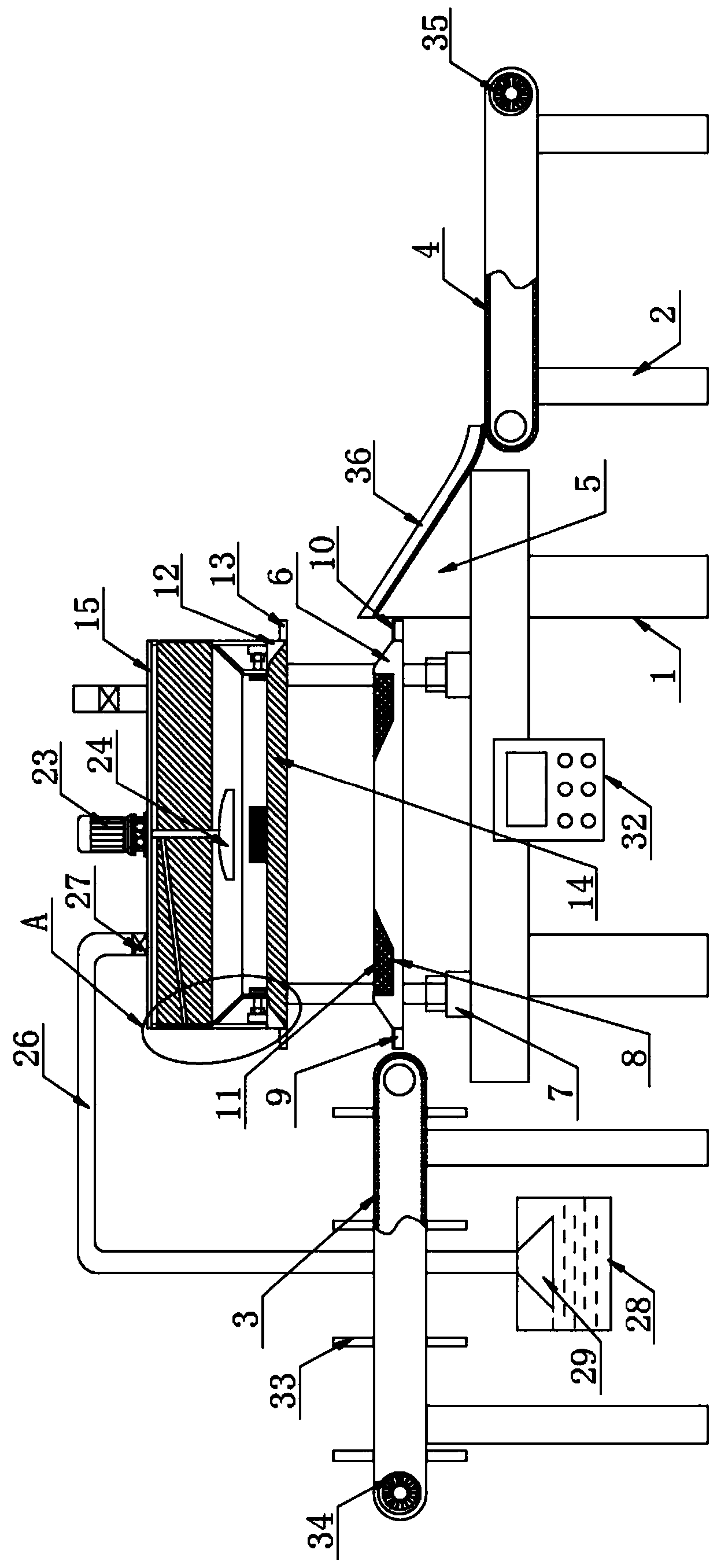

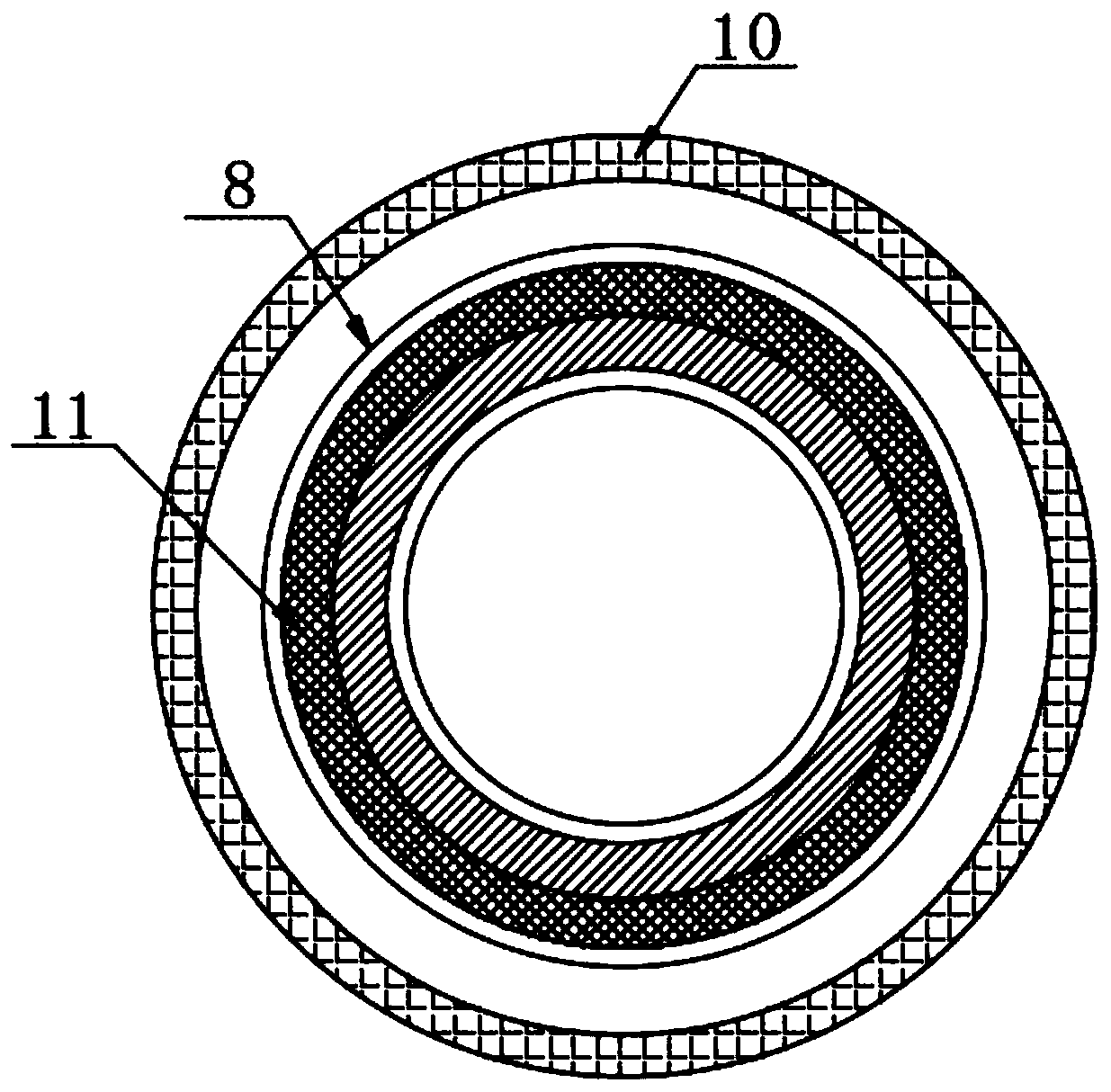

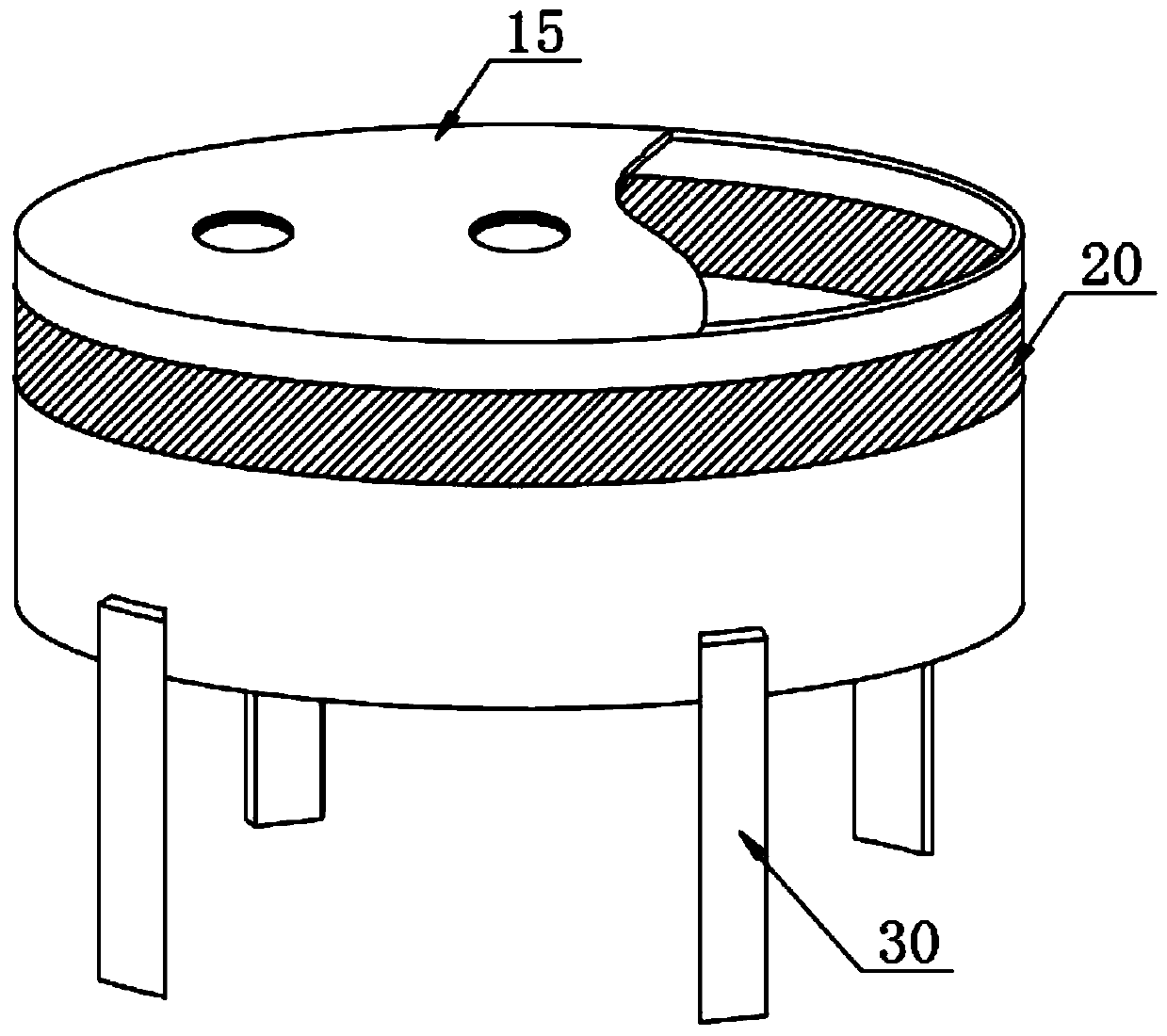

[0028] The present invention provides such Figure 1-8The shown a kind of grinding device with high safety for industrial design includes a frame 1, and brackets 2 are arranged on both sides of the frame 1, and the top of the bracket 2 on one side is provided with a first conveyor belt 3 and The top of the bracket 2 on the other side is provided with a second conveyor belt 4, and one end of the top of the frame 1 is provided with an inclined platform 5, and the bottom end of the inclined platform 5 is smoothly connected with the end of the second conveyor belt 4 at the corresponding position. One side of the inclined platform 5 is provided with a stage 6, and a plurality of first electric push rods 7 are evenly distributed on the bottom edge of the stage 6, and the ends of the first electric push rods 7 are fixedly connected with the stage 6 , the top edge of the stage 6 is provided with a groove 8, the inside of the groove 8 is equipped with a waste box 11, and the bottom end...

Embodiment 2

[0037] The difference from Embodiment 1 is that both sides of the top road of the bracket 2 where the second conveyor belt 4 is located are fixed with limiting guide bars 40, and there are multiple sets of spacing between the two limiting guide bars 40. A baffle 41, the center of both ends of the baffle 41 is provided with a rotating rod, the rotating rod is movably connected to the limit guide bar 40 on the corresponding side through a bearing, and the distance between two adjacent baffles is greater than that of the baffle The width of the plate 41, the inside of the limit guide bar 40 is provided with a first buffer pad 42, the two sides of the baffle plate 41 are provided with a second buffer pad 43, the first buffer pad 42 and the second buffer pad 43 They are all made of silica gel material, which is beneficial to use the inertial force of the sliding workpiece to hit the baffle 41 when the polished workpiece slides along the inclined platform 5 to the top of the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com