Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Good for completeness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressing-low-temperature continuous phase-change castor oil extraction method

InactiveCN103173275AAbundant resourcesReduce manufacturing costFatty-oils/fats productionCastor SeedSulfur hexafluoride

Owner:曹庸

Continuous phase-changed extraction method for orange peel oil

ActiveCN103146486AAbundant resourcesImprove qualityEssential-oils/perfumesFatty-oils/fats productionProduct gasPhase change

The invention provides a continuous phase-changed extraction method for orange peel oil. The method comprises the following steps of: placing dry crushed orange peel raw materials into an extraction kettle; compressing an extraction agent into a liquid under the condition that the pressure and the temperature are always lower than the critical pressure and the critical temperature of the extraction agent; enabling the extraction agent to flow through the extraction kettle at the flow speed of 100-150L / h under the conditions that the extraction temperature ranges from 35 DEG C to 55 DEG C, and the extraction pressure ranges from 0.5Mpa to 2Mpa, and continuously extracting for 50-120min; after the orange peel oil is extracted, enabling the extraction agent to flow into a liberation kettle for liberating at the temperature of 65-75 DEG C and the pressure of 0.1-0.4Mpa; heating and carrying out pressure-reduced phase change on the extraction agent to enable the extraction agent to become a gas, then, immediately condensing the gas to enable the gas to become a liquid, and enabling the liquid to flow through the extraction kettle for extracting the materials again; and circulating many times in such a way. The continuous phase-changed extraction method has the advantages of high supercritical extraction efficiency, no solvent residues in products and high aroma component retention rate; in addition, the extraction pressure and the liberation pressure are lower than the supercritical pressure and temperature; and meanwhile, the continuous phase-changed extraction method has the characteristics of large extraction volume, high mass handling capacity and low production cost of a conventional solvent.

Owner:GREENCREAM BIOTECH +2

Continuous-phase-change tea oil extraction method

InactiveCN103173279AReduce consumptionReduce energy consumptionFatty-oils/fats productionGas phaseProduct gas

The invention provides a continuous-phase-change tea oil extraction method. According to the invention, a dried and crushed tea seed raw material is placed into an extraction kettle of a continuous-phase-change extraction device; under a condition with a pressure constantly lower than an extracting agent critical pressure and a temperature constantly lower than an extracting agent critical temperature, the extracting agent is compressed into a liquid by using a high-pressure pump; the extracting agent flows through the extraction kettle with a certain flow rate, such that tea oil is extracted; the material is delivered into a resolution kettle; heating and pressure reducing are carried out, such that the extracting agent is changed into a gas phase; instant compression is carried out, the extracting agent is changed into liquid, and flows through the extraction kettle, such that the material is extracted again. The steps are repeated several times. The method provided by the invention has the advantaged of high efficiency, no solvent residue in product, and high aroma component retention rate of supercritical extraction and subcritical extraction methods. Extraction pressure and resolution pressure of the method are lower than those of supercritical extraction. The method also has the advantages of large extraction volume, large-amount batch production, low production cost, and the like of conventional solvent extraction methods. Also, the continuous-phase-change extraction method has the advantages that the extraction time is short, instant continuous extraction process can be realized, solvent demand is low, and the solvent can be recovered.

Owner:曹庸

Continuous phase change-based method for extracting tea polyphenol

InactiveCN104289007AExtraction DynamicsEfficient extractionOrganic chemistrySolid solvent extractionBiotechnologyPhenolic content in tea

The invention discloses a continuous phase change-based method for extracting tea polyphenol. The method comprises the steps of drying tea (including root, stems, leaves, flowers, fruits and the like) under 40-80 DEG C, wherein the content of moisture is controlled to 3-20 percent, crushing to powder of 20-80 meshes to obtain a tea powder material, feeding the tea powder material in an extraction kettle, compressing an extraction agent to a liquid extraction agent under the condition that the pressure and the temperature are lower than the critical pressure and the critical temperature of the extraction agent all the time, then continuously extracting the tea powder material in the extraction kettle for 50-120 minutes under the conditions that the extraction temperature is 50-70 DEG C and the extraction pressure is 0.3-2Mpa, and the liquid extraction agent can flow through the extraction kettle with the flow rate of 80-160L / h so as to obtain tea polyphenol, and enabling the extracted tea polyphenol to flow through a resolving kettle for resolving at 60-75 DEG C resolving temperature and 0.08-0.5Mpa resolving pressure. The method for preparing thw tea polyphenol has the high extraction rate of the tea polypheonl, and is safe, environmentally-friendly, low in cost and suitable for large-scale industrial production; the yield of the tea polyphenol prepared according to the method accounts for 10-35 percent of the yield of dry matters.

Owner:SOUTH CHINA AGRI UNIV

Continuous-phase-change soy sauce residue oil extraction method

ActiveCN103173280ALower retention rateHigh retention rateFatty-oils/fats productionSulfur hexafluorideGas phase

The invention provides a continuous-phase-change sauce residue oil extraction method. According to the invention, a dried and crushed sauce residue raw material is placed into an extraction kettle; under a condition with a pressure constantly lower than an extracting agent critical pressure and a temperature constantly lower than an extracting agent critical temperature, the extracting agent is compressed into a liquid; the extracting agent flows through the extraction kettle with a certain flow rate, such that castor oil is extracted; the material is delivered into a resolution kettle; heating and pressure reducing are carried out, such that the extracting agent is changed into a gas phase; instant compression is carried out, the extracting agent is changed into liquid, and flows through the extraction kettle, such that the material is extracted again. The steps are repeated several times. The extracting agent is one of ethanol, propane, butane, high-purity isobutane, R134a, dimethyl ether, liquefied petroleum gas, and sulfur hexafluoride. The method provided by the invention has the advantaged of high efficiency, no solvent residue in product, and high aroma component retention rate of a supercritical extraction method. Extraction pressure and resolution pressure of the method are lower than those of supercritical extraction. The method also has the advantages of large extraction volume, large-amount batch production, low production cost, and the like of a conventional solvent extraction method.

Owner:广东惠尔泰生物科技有限公司

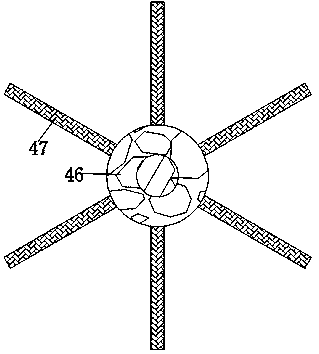

Dual-fuel nozzle for plasma catalysis gaseous fuel

InactiveCN103900106AAchieve co-firingImprove economyContinuous combustion chamberEngineeringProduct gas

The invention provides a dual-fuel nozzle for plasma catalysis gaseous fuel. The dual-fuel nozzle for the plasma catalysis gaseous fuel mainly comprises a low-temperature plasma discharging assembly, a gas circuit assembly, an oil circuit assembly and a nozzle fixing device. Cracked gas fuel enters an annular discharging gap of the low-temperature plasma discharging assembly in the radial direction and has a reforming reaction under the low-temperature plasma catalytic action to be converted into reformed gas with the higher heat value, a gas plasma micelle remaining after the catalytic reaction can be contained inside the reformed gas, the inflammability of the reformed gas is improved, finally the reformed gas flows out in a rotating mode through a gas flow guiding plate to form a recirculating zone, and the stability of burning is improved. According to the dual-fuel nozzle for the plasma catalysis gaseous fuel, the oil circuit assembly stretches into an external electrode of the low-temperature plasma discharging assembly, space can be saved, the oil supply states of oil and gas circuits can be controlled, the oil and gas circuits can be closed independently or simultaneously, the requirements for starting power and variable working condition power are met, the gas circuit assembly can also be utilized for spraying water, and NOx emission is reduced.

Owner:HARBIN ENG UNIV

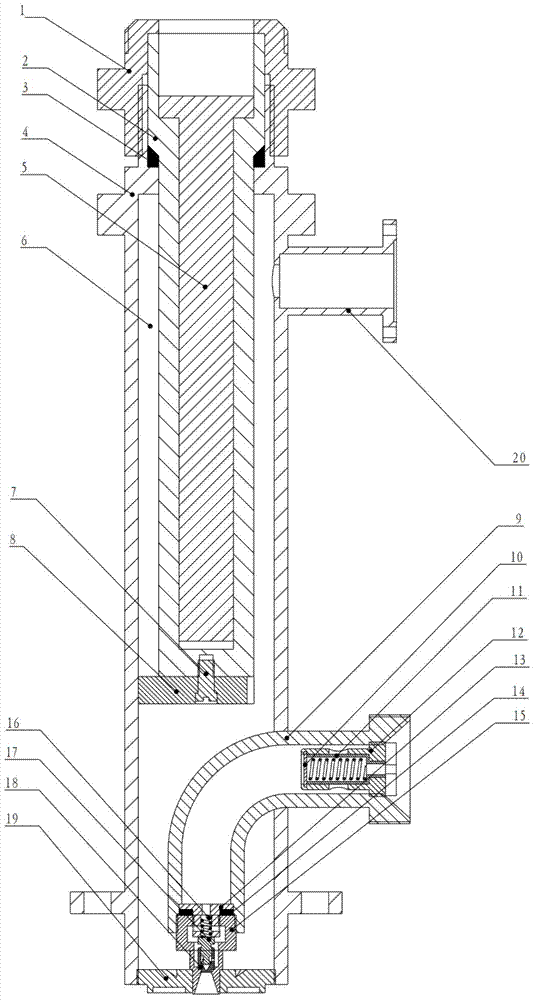

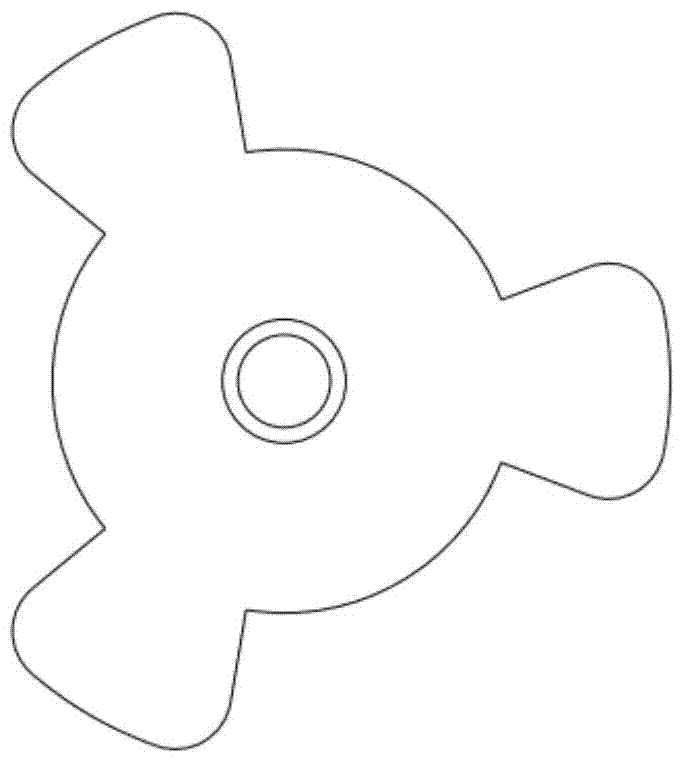

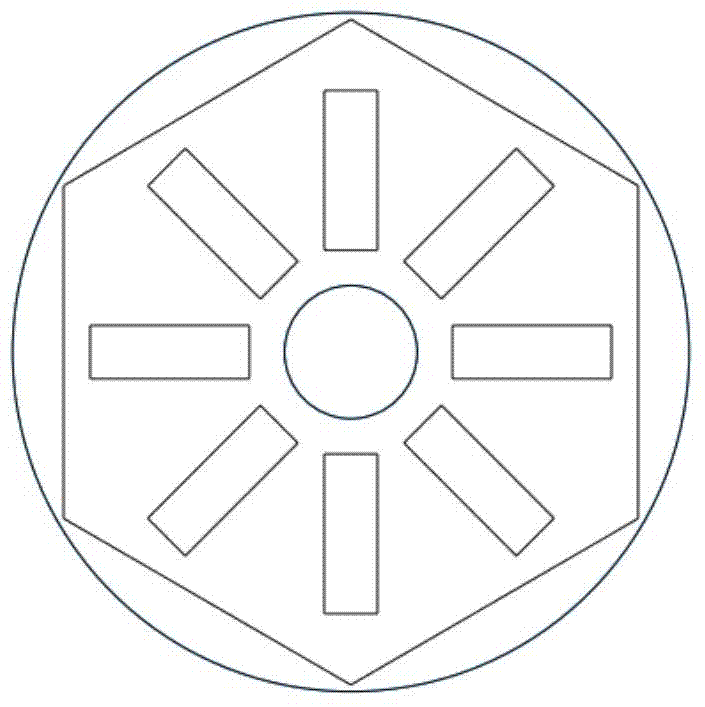

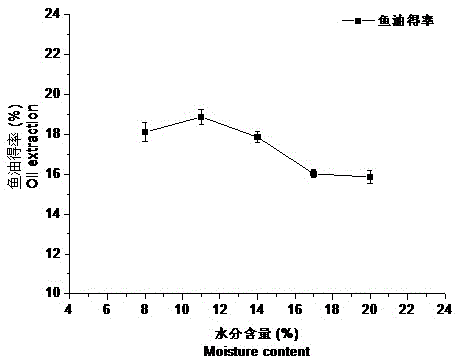

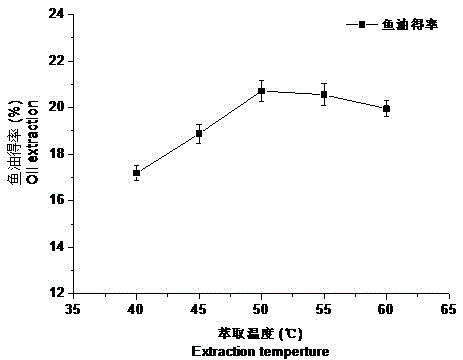

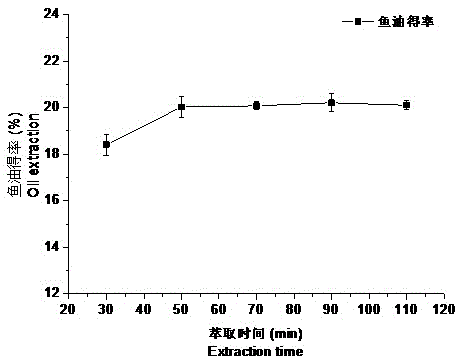

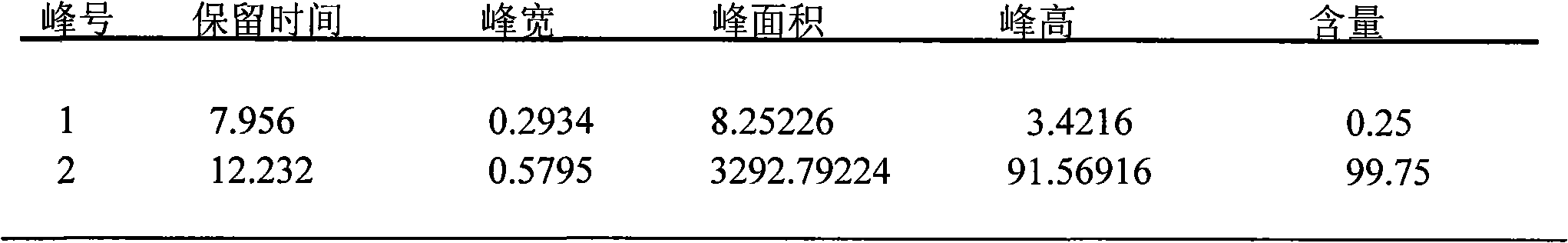

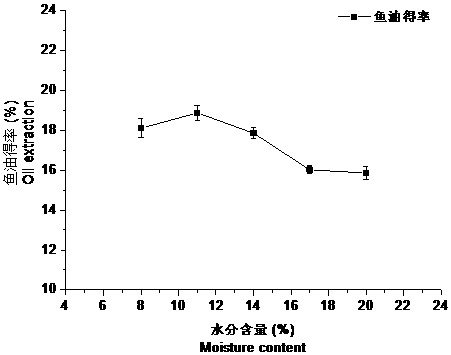

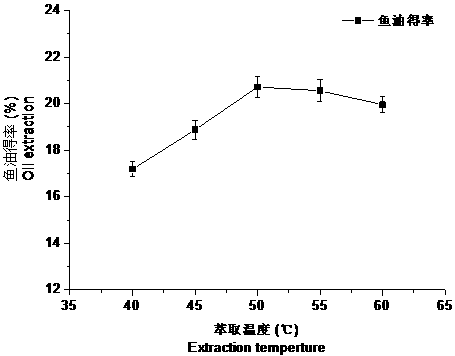

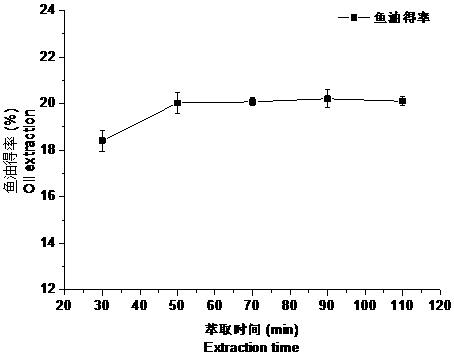

Method of extracting decapterus maruadsi oil through low-temperature continuous phase transition

ActiveCN105670781AHigh yieldReduce churnFatty-oils/fats productionPhysical chemistryDecapterus maruadsi

The invention discloses a method of extracting decapterus maruadsi oil through low-temperature continuous phase transition and decapterus maruadsi oil.The method includes: placing decapterus maruadsi powdery raw materials in an extraction kettle; under conditions of extraction temperature of 40-60 DEG C and extraction pressure 0.3-1.0 Mpa, compressing an extraction agent into liquid, enabling the liquid to flow through the extraction kettle at a flow rate of 100-150 L / h for continuous extraction of 30-110 min, and after decapterus maruadsi oil is extracted, enabling the liquid to enter an analysis kettle with analysis temperature of 50-80 DEG C and analysis pressure of 0.1-0.4 Mpa; performing phase transition on the extraction agent to form gas, immediately compressing the gas into liquid, enabling the liquid to flow through the extraction kettle, extracting materials again, enabling the materials to carry oil to enter an analysis tank through a solvent of an extraction tank, and obtaining a decapterus maruadsi oil product after analysis.Compared with conventional extraction methods, the method is accurate and stable in process, the decapterus maruadsi oil is high in quality, extraction rate is increased remarkably, and efficient extraction of ocean low-value decapterus maruadsi oil is realized, so that cost can be saved, product yield can be increased, and economic benefit of production enterprises can be improved.

Owner:SOUTH CHINA AGRI UNIV

High purity scutellarin salt bulk drug and preparation method thereof

ActiveCN101683332ALow costPromote environmental protectionOrganic active ingredientsOrganic chemistryChemistryScutellarin

The invention relates to a new bulk drug in pharmaceuticals industry, and preparation process thereof. The bulk drug of the invention wherein has a weight percentage of more than 98% scutellarin salt.The preparation method is composed of following steps: first, using breviscapinun saled in market as raw materials, adding 5 to 10 times of water by weight, being heated to 60 to 80 DEG, adding 10 to20 weight percentage of aqueous slkali until the pH value is 5 to 8; second, centrifugating the solution obtained in the step one and discarding the deposition, then the obtained solution going through macroporous resin column, washing and removing, discarding the deep brown part of the first eluant, and then collecting the yellow eluant part; third, the collected eluant is disposed in vacuum concentrator, concentrating until concentration of the scutellarin salt solution is 100 to 200 mg / ml; fourth, adding organic solvent to the concentrated solution obtained in the step three and stirring,depositing, standing and filtering; fifth, washing by using the same organic solvent of the step four for 3 to 6 times, drain, and drying at a temperature of 60 to 80 DEG, then the bulk drug is obtained.

Owner:KUNMING LONGJIN PHARMA

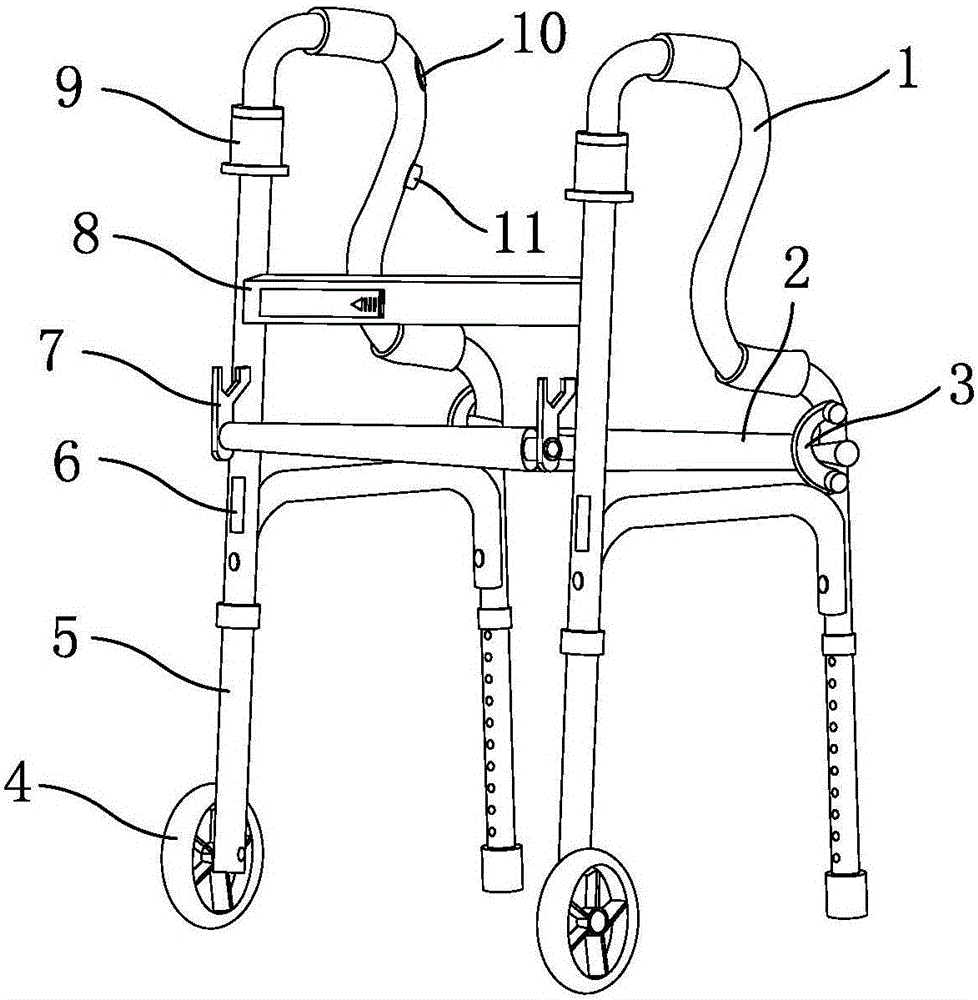

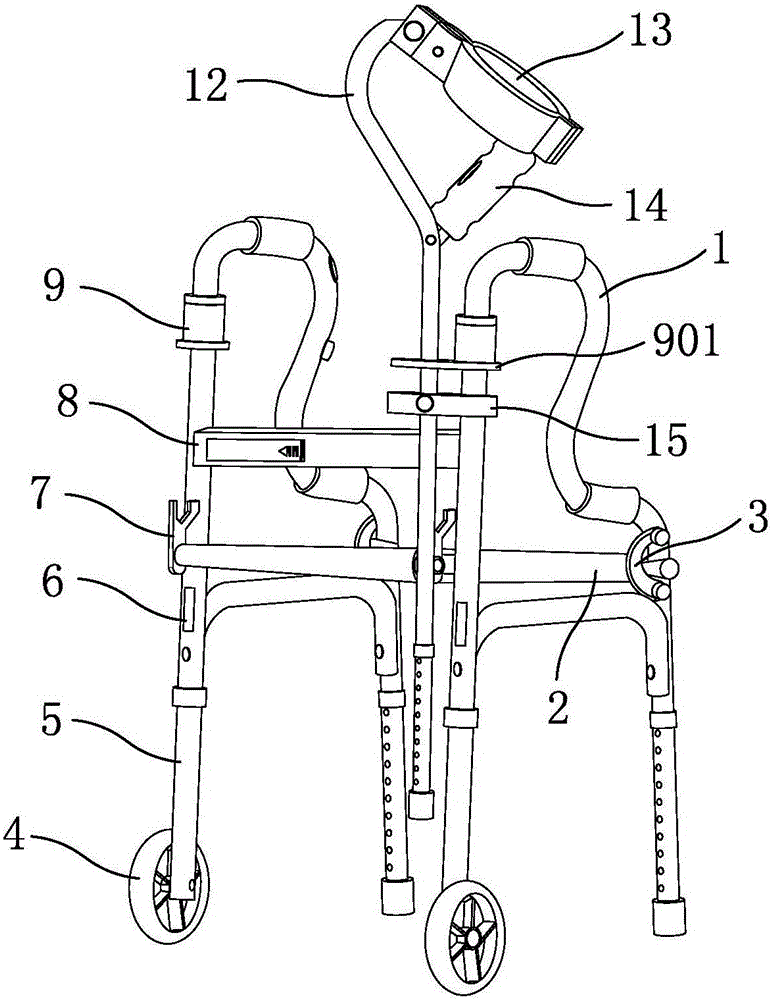

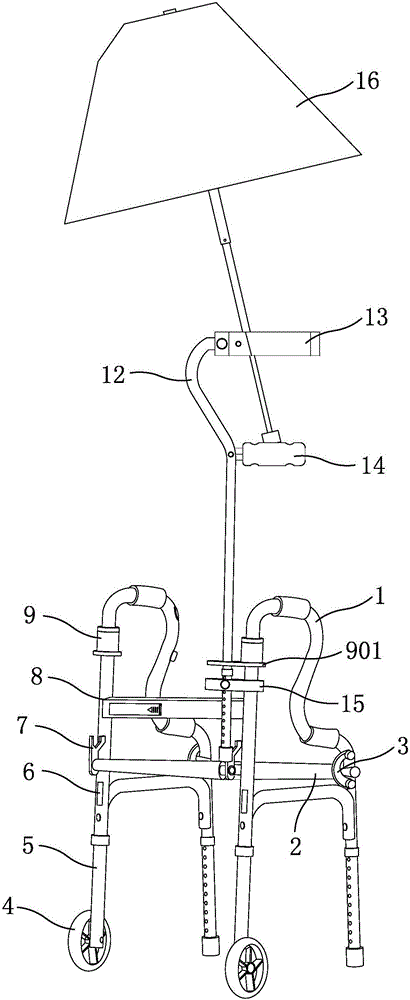

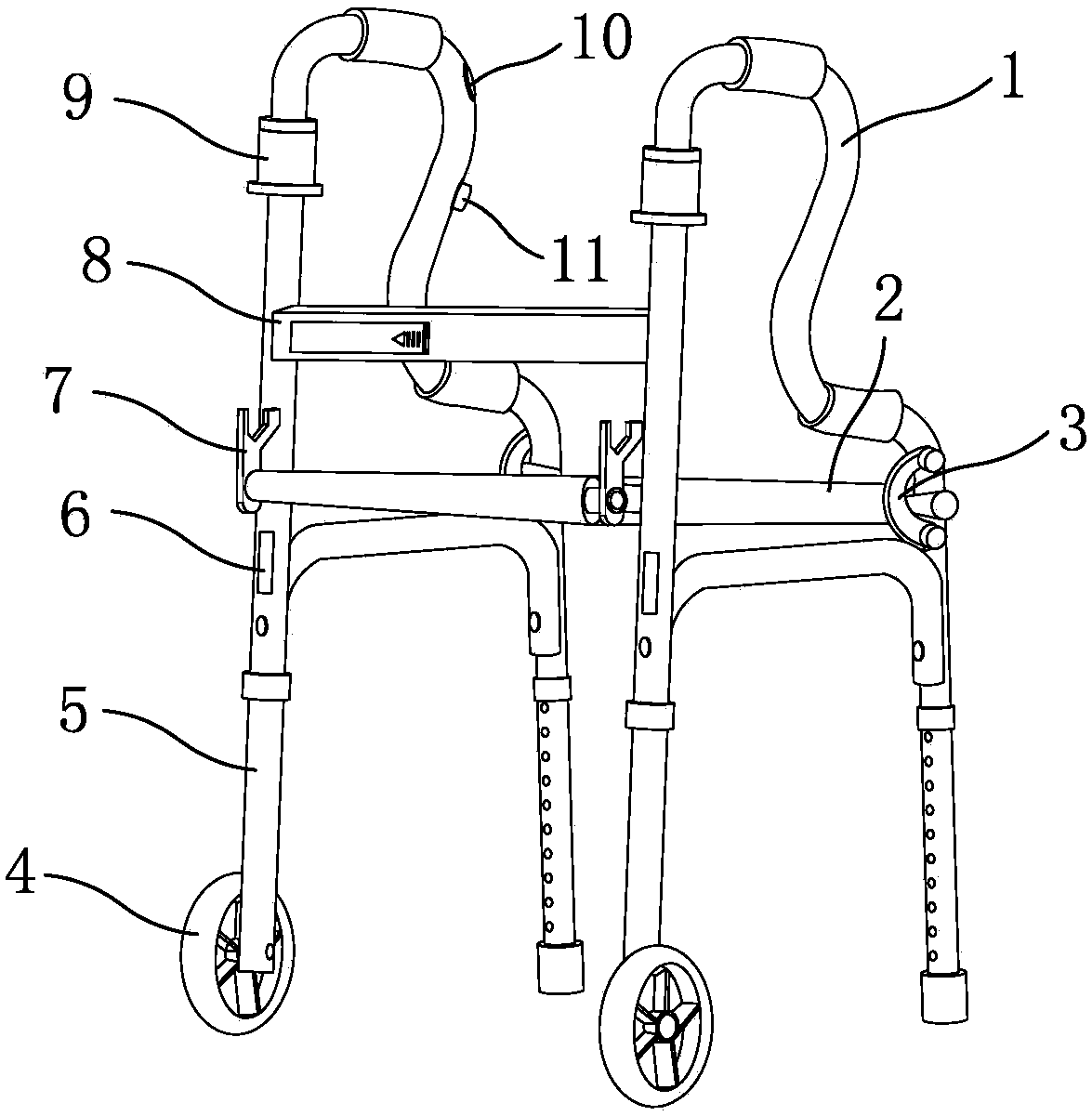

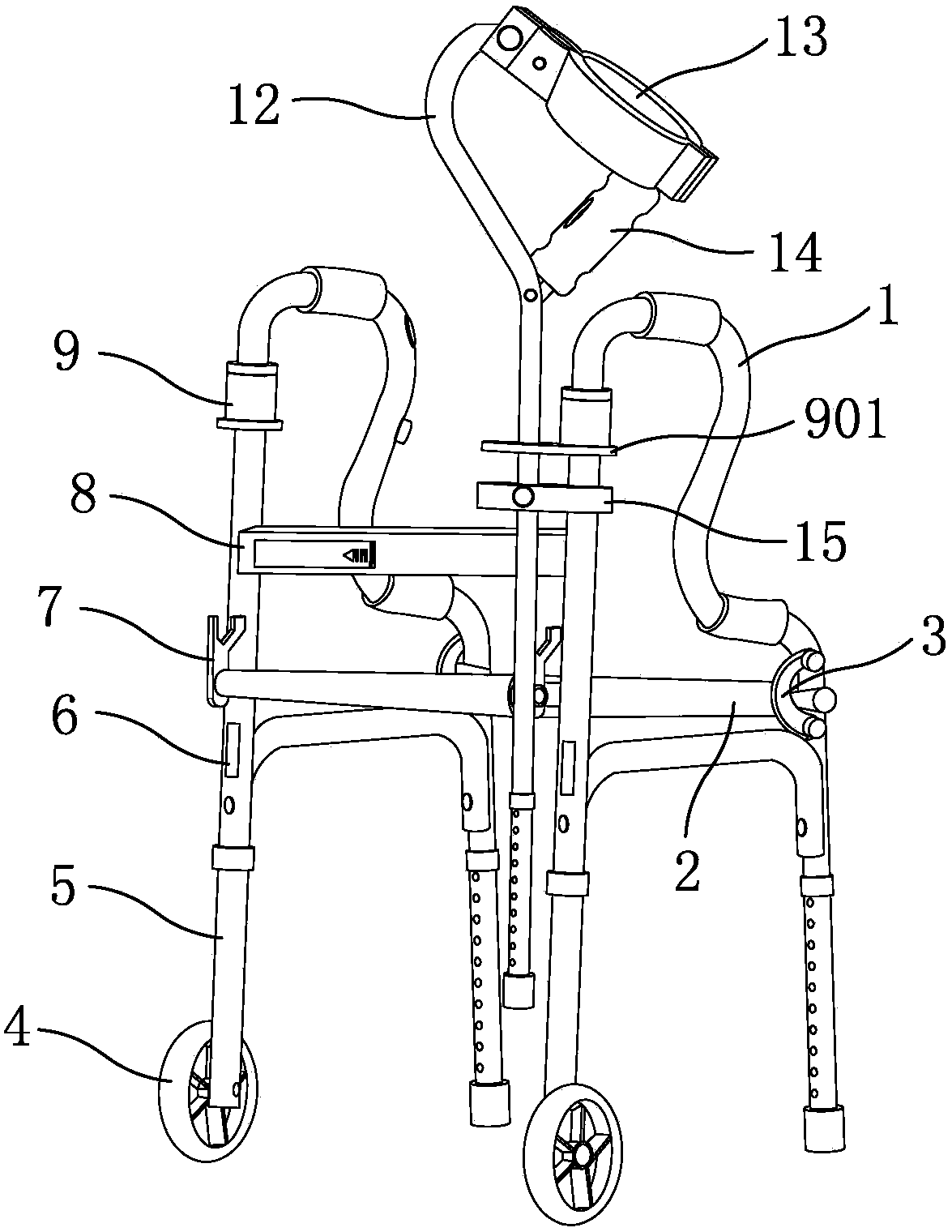

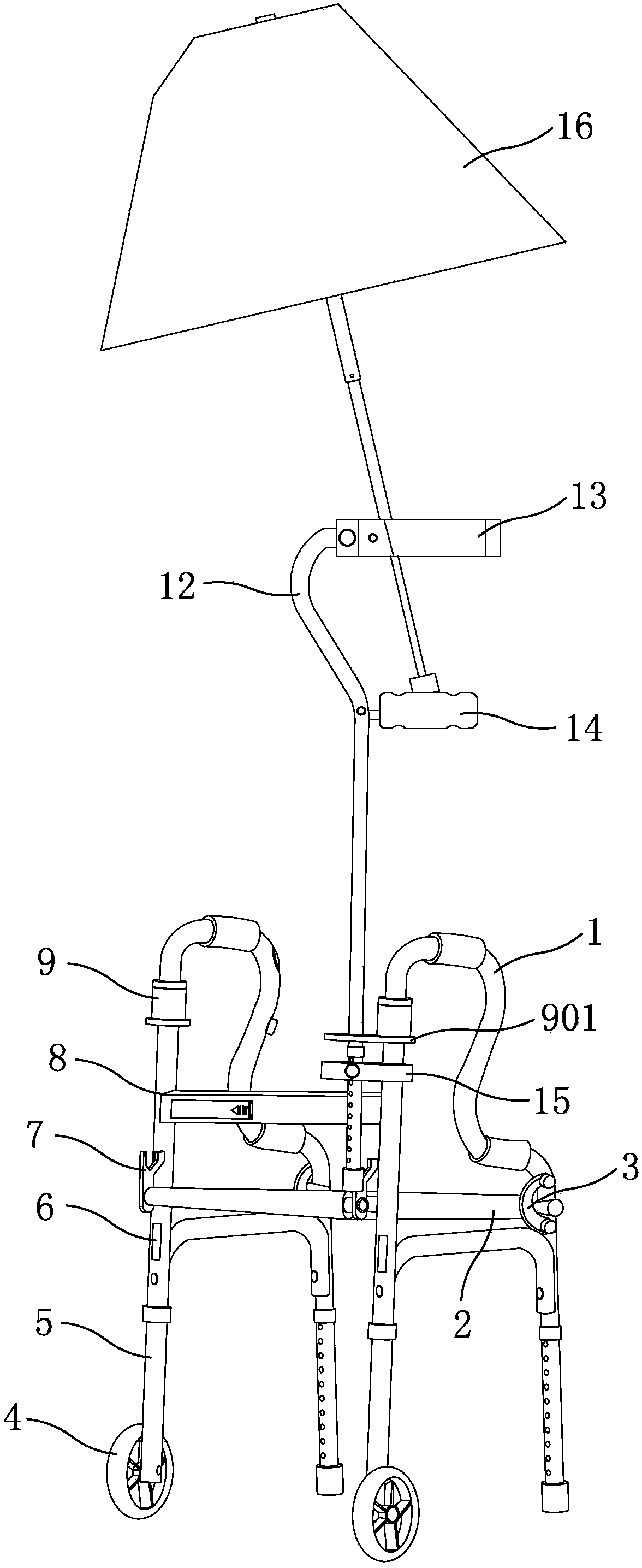

Multifunctional walking aid

ActiveCN106214432AReasonable structural designImprove stabilityWalking sticksWalking aidsEngineeringLED lamp

The invention relates to a multifunctional walking aid, and aims art solving the technical problems that an existing similar product is single in function and poor in structural design. A rest of the walking aid is formed by connecting two supports symmetrically arranged on the two sides through a cross beam, and the support on each side is provided with a U-shaped reinforcement tube; the cross beam arranged between the supports of the rest is internally provided with a GPS, a gravity sensor, an alerter, a timer, a rechargeable battery and a control circuit board, the cross beam is provided with a charging port and a battery cover, an LED lamp is arranged on the portion, where the U-shaped reinforcement tube is located, of each support, the armrest part of the support on one side is provided with a lamp button and an alarm button, and the lamp button, the alarm button, the LED lamp, the GPS, the gravity sensor, the alerter, the timer and the rechargeable battery are connected with the control circuit board through circuits; a canvas frame fixed to latch hooks and shelves form a seat surface through canvas, an axle of a walking wheel on the front side of each support is provide with a lock knob moving up and down, an arm sleeve and a holding rod are arranged on one side of a walking stick of the rest, and an umbrella handle of an umbrella is fixed to the arm sleeve.

Owner:杭州富阳宏伟金属制品有限公司

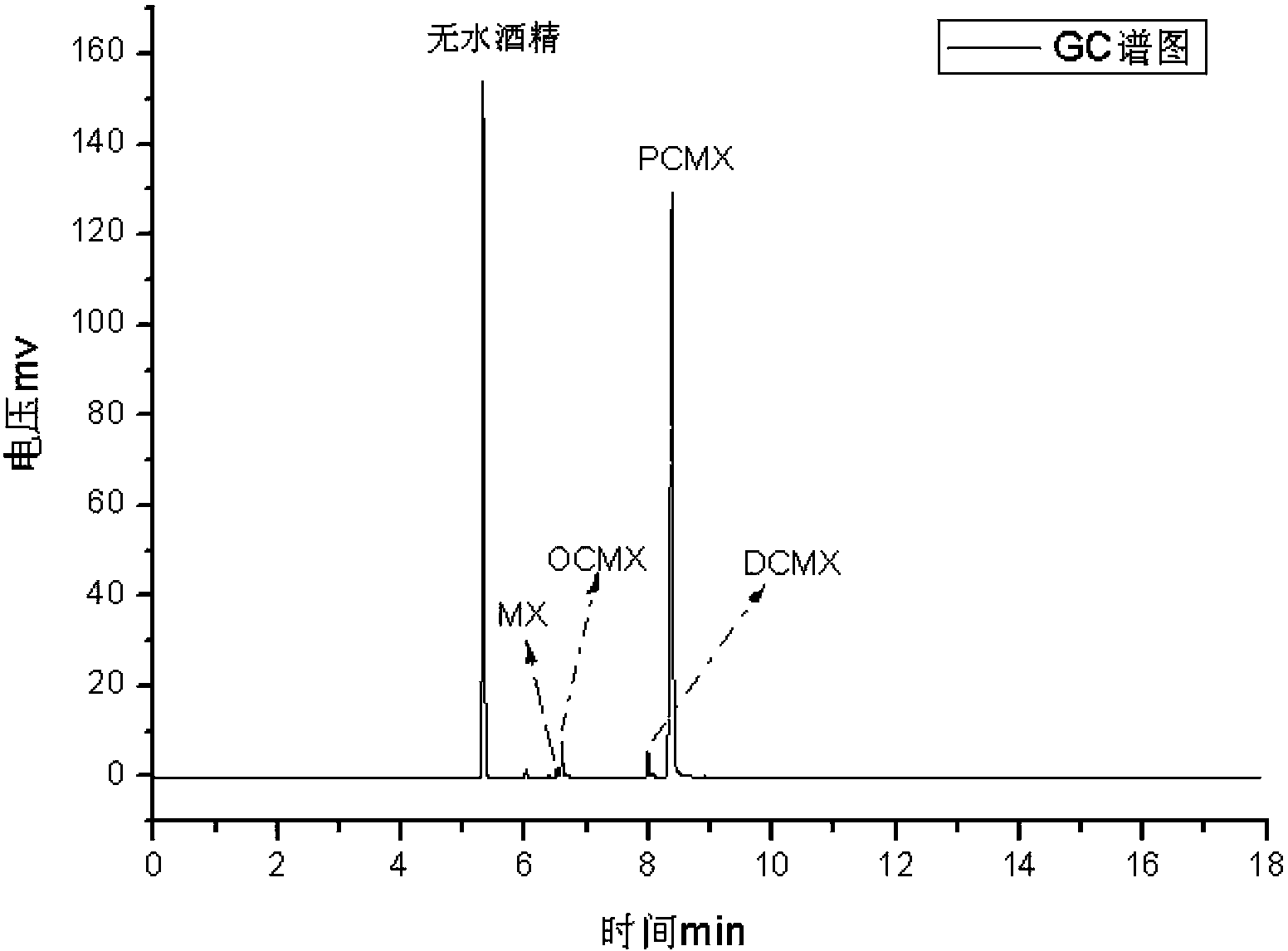

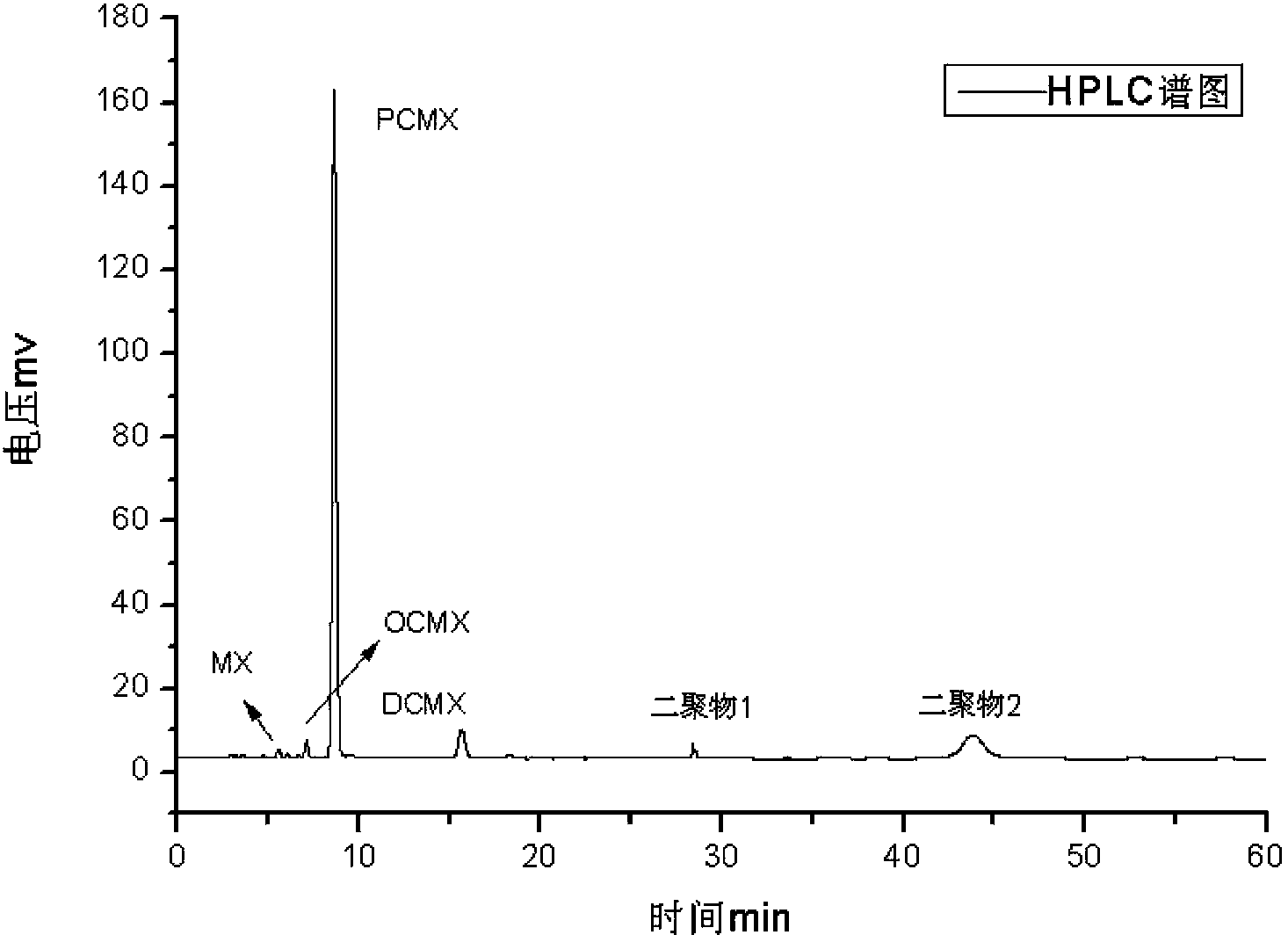

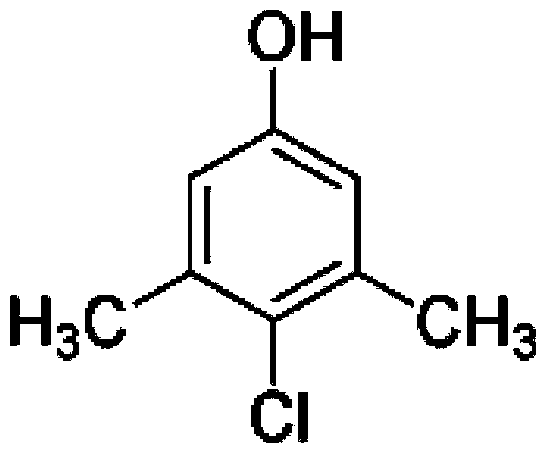

Preparing method for 4-chlorine-3,5-xylenol

ActiveCN103351282BGood choiceImprove conversion rateOrganic chemistryOrganic compound preparationOrganic solventEthyl Chloride

The invention provides a preparing method for 4-chlorine-3,5-xylenol. Cupric salt taken as catalyst reacts with 3,5-xylenol, oxygen and hydrochloric acid in inorganic and organic solvent, so as to obtain the 4-chlorine-3,5-xylenol. In order to further optimize the reaction process, the reaction is terminated when the conversion rate of the raw material, namely the 3,5-xylenol, reaches 50-90%, so that the generation of bipolymer is avoided, the selectivity of a target product is excellent, the total conversion rate is higher, the report method for preparing 4-chlorine-3,5-xylenol through oxidization and chlorination is completely optimized, as a result, the preparation of 4-chlorine-3,5-xylenol through oxidization and chlorination is completely suitable for large-scale industrial production.

Owner:湖南瑞冠生物化工科技有限公司

Method for extracting fructus perillae oil through continuous phase transition

ActiveCN103834467AAbundant resourcesReduce manufacturing costFatty-oils/fats productionSolventContinuous phase transition

The invention provides a method for extracting fructus perillae oil through continuous phase transition, which comprises the steps of putting the dried ground fructus perillae raw material into an extraction kettle; compressing an extraction agent into liquid under the conditions that the extraction temperature is 35-55 DEG C and the extraction pressure is 0.5-2MPa; enabling the liquid to flow through the extraction kettle at a flow speed of 100-150L / h, and continuously extracting for 50-120 minutes; after extracting the fructus perillae oil, enabling the fructus perillae oil to flow into a resolving kettle, wherein the resolving temperature is 65-75 DEG C, and the resolving pressure is 0.1-0.4MPa; heating and reducing pressure of the extraction agent so that the extraction agent phase is changed into gas; performing intermediate compression to change the gas into liquid which flows through the extraction kettle again, and performing secondary extraction on the material; circulating for multiple times. The method provided by the invention has the advantages of efficient supercritical extraction, no solvent residue in product and high retention rate of aroma components; moreover, the extraction pressure and the resolving pressure are lower than the supercritical values, and the method also has the characteristics of large extraction volume of conventional solvent, large batch treatment capacity, low production cost and the like.

Owner:GREENCREAM BIOTECH +2

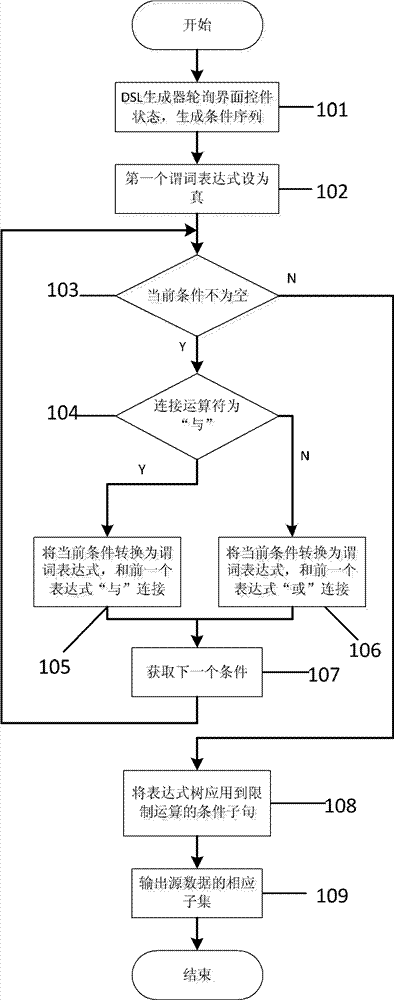

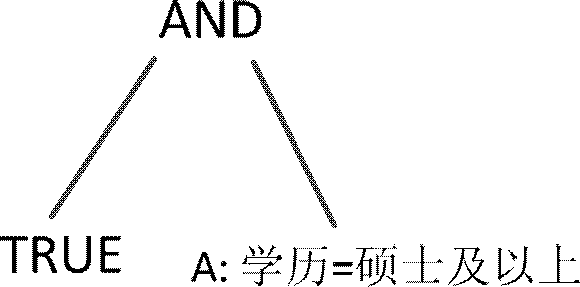

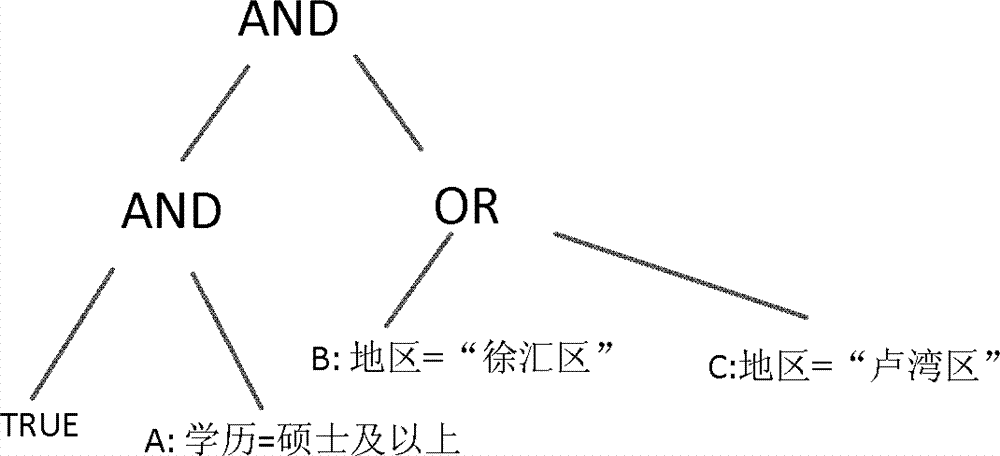

Processing method of sample data in television program assessment surveying process

InactiveCN102955823AGood for completenessImprove good performanceSpecial data processing applicationsDigital subscriber lineMultiple criteria

The invention relates to a processing method of sample data in the television program assessment surveying process. The processing method is characterized in that sample selection conditions are described by adopting languages in a DSL (Digital Subscriber Line) field, condition sequences are converted into composite predicate expression trees through a resolver, expression trees and raw data are loaded into an actuator for limiting operation, and finally corresponding relational data subsets are output. Compared with the prior art, the processing method can be used for realizing the function of selecting samples according to arbitrary multiple conditions and has the advantages of relatively good completeness, expansibility, portability and the like.

Owner:方方

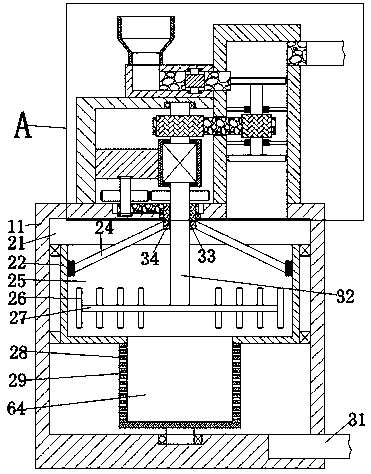

Screening device for rice processing

InactiveCN113842975AHigh size separation efficiencyAvoid subsequent processingGrain huskingGrain polishingAgricultural engineeringRice grain

The invention relates to the technical field of rice processing, in particular to a screening device for rice processing. The screening device comprises a storage hopper, wherein sieved small-particle materials are mounted on the lower side of the storage hopper, sieved large-particle materials are mounted on one side of the sieved small-particle materials, a support frame is arranged on the lower side of the sieved large-particle materials, a filter residue collecting box is arranged on the lower side of the sieved small-particle material, an exhaust fan is installed at the upper end of the other side of the sieved small-particle material, a cloth cylinder filter bag is installed at the outer end of the exhaust fan, a hulling component is installed at the lower end of the interior of the storage hopper, a feeding net is installed at the joint of the storage hopper and the sieved small-particle material, and a screen is mounted at the upper end of the interior of the sieved small-particle material. The screening device is of a closed structure, dust floating in the screening process is avoided, circulating dust filtration is achieved, the dust filtration efficiency is high, rice before screening is hulled, the hulling structure is elastic mixing and stirring blades, and the integrity of the rice is guaranteed.

Owner:安徽慈弘农业发展有限公司

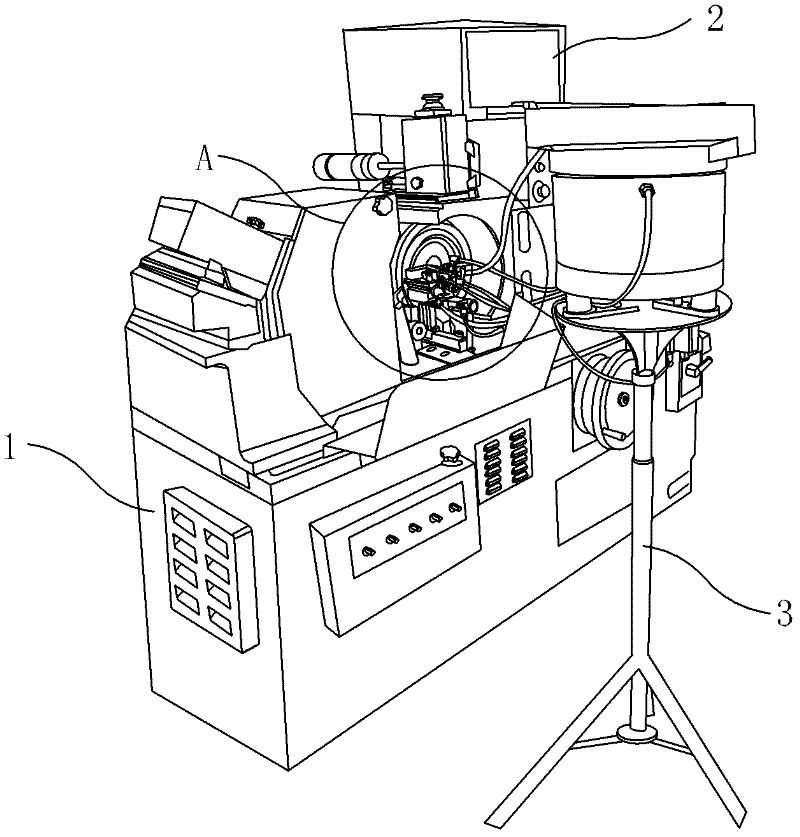

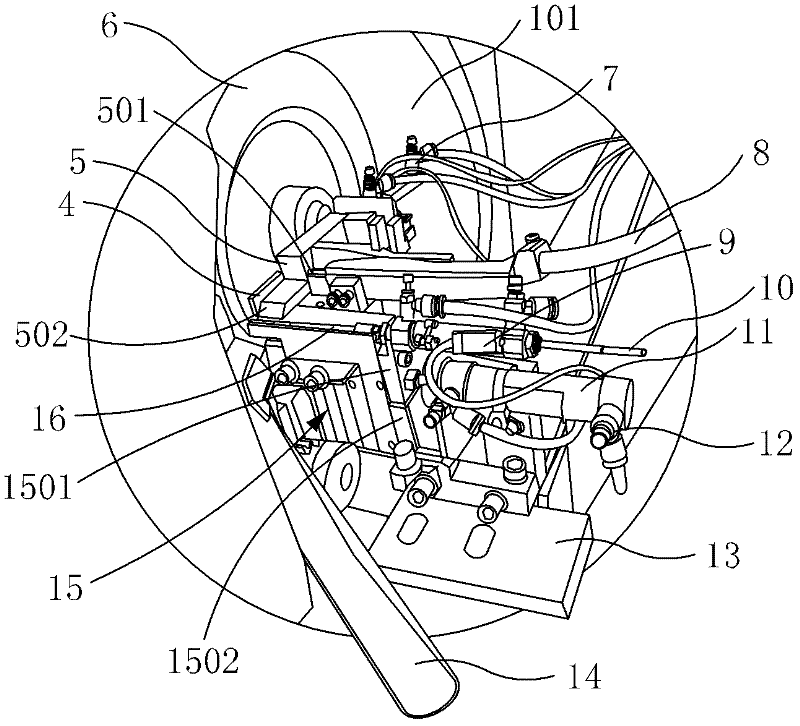

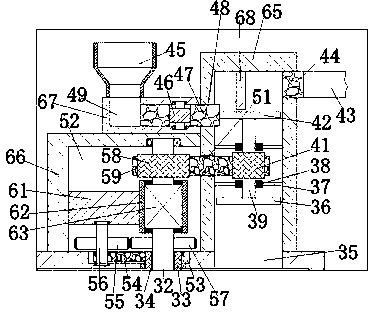

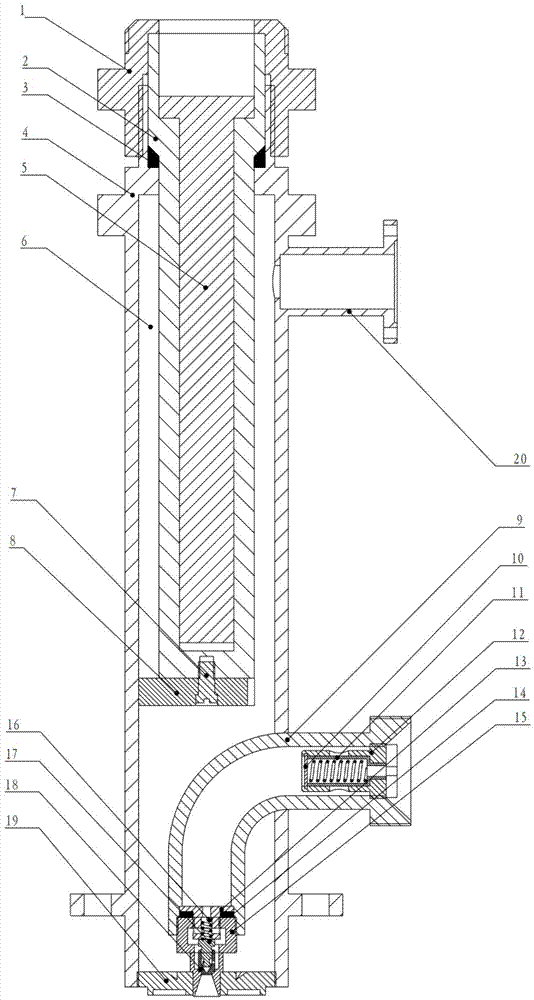

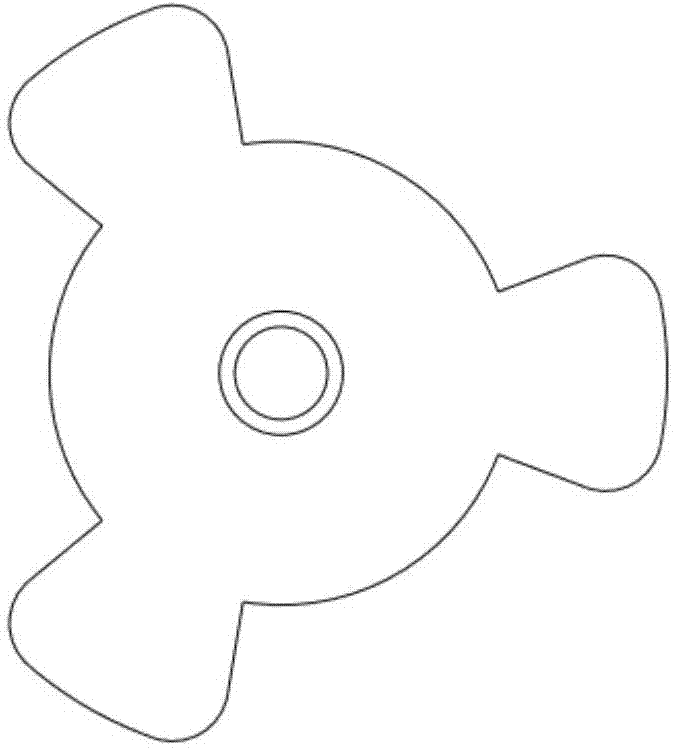

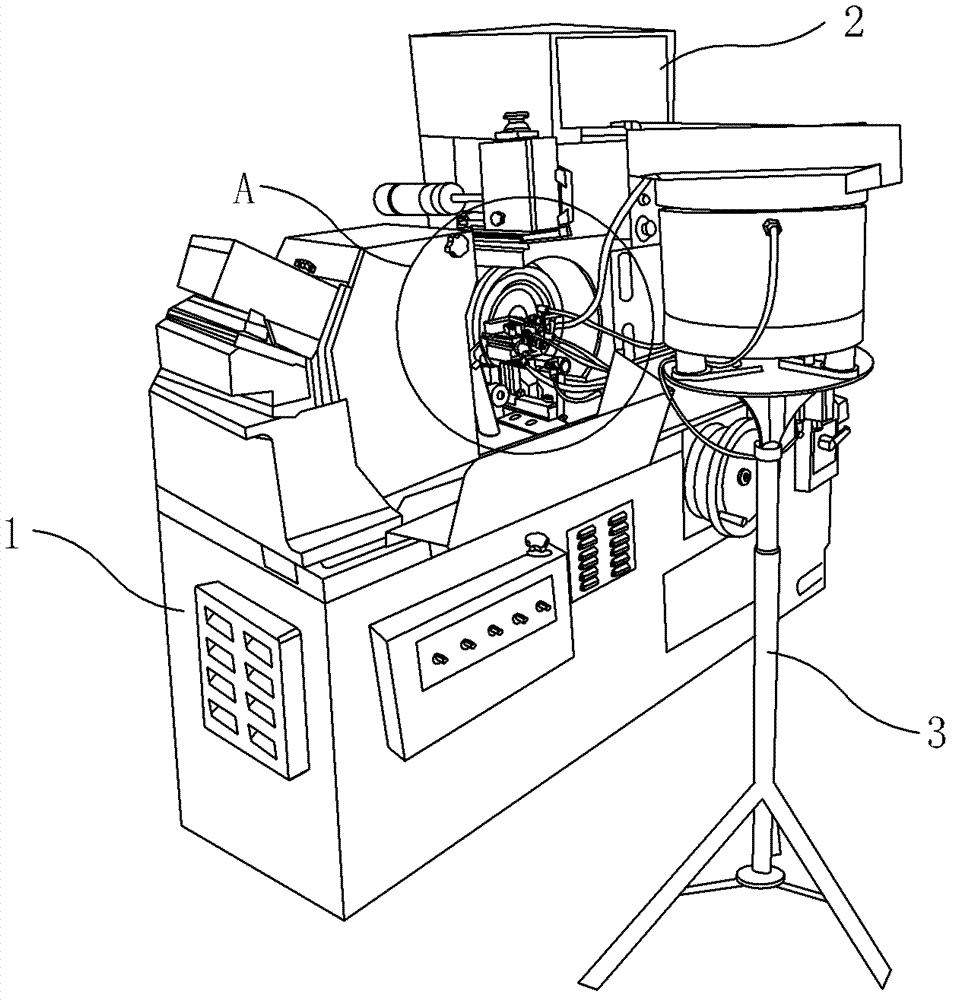

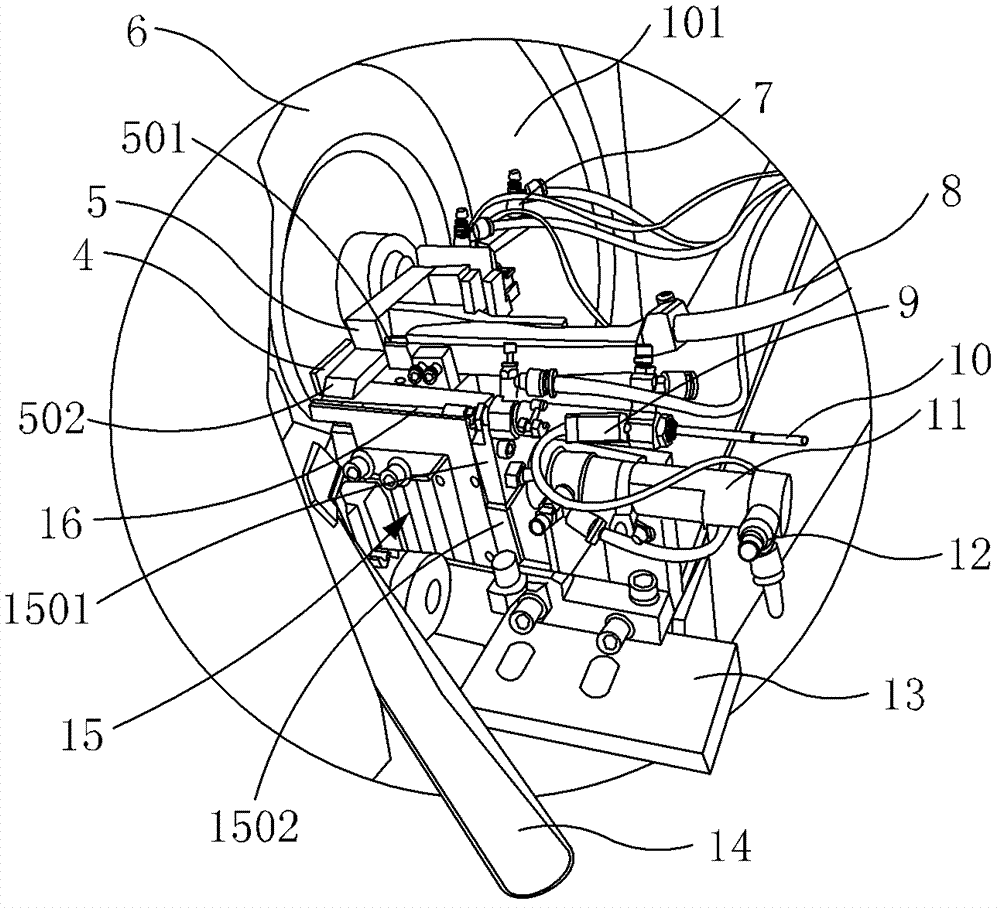

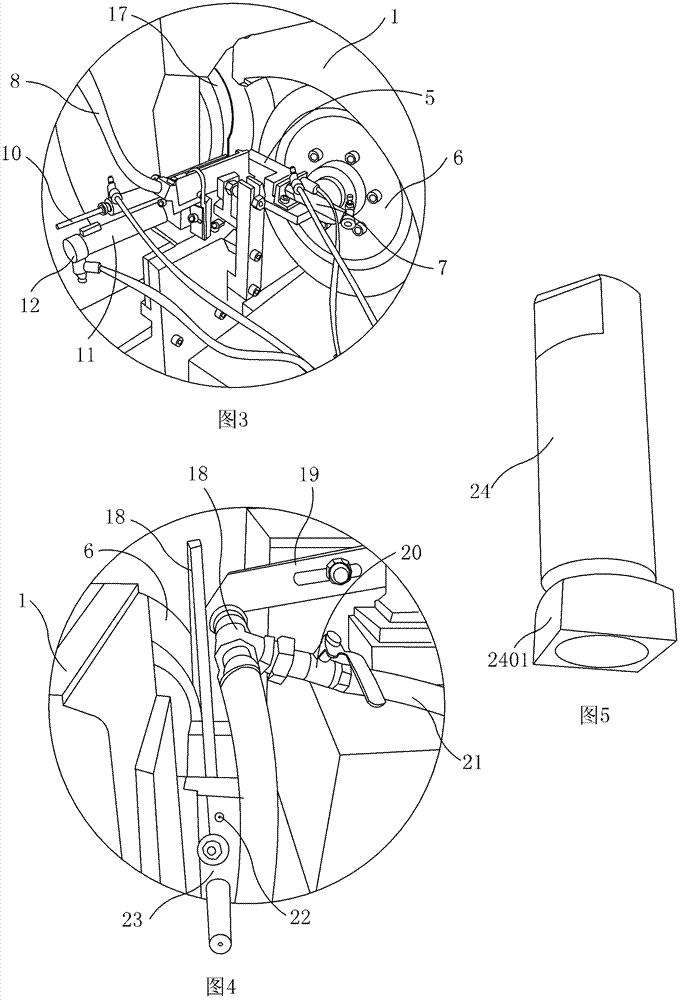

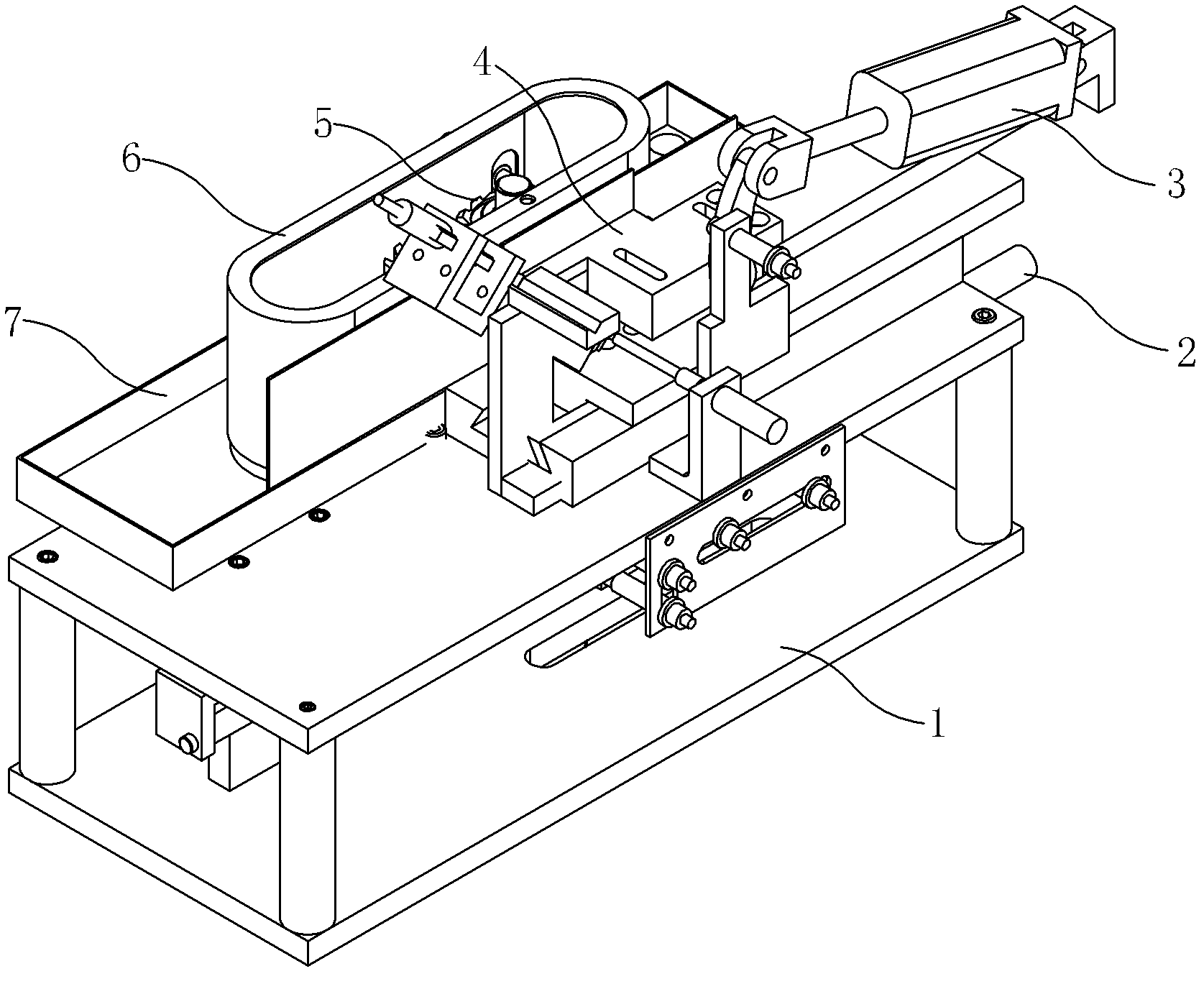

Automatic feeder machine for grinding machine and processing method thereof

ActiveCN102366909AReasonable designEasy to useRevolution surface grinding machinesBlade plateDrive shaft

The invention relates to an automatic feeder machine for a grinding machine and a processing method thereof, designed for solving the technical problem that structural design of a like product is not good enough. The automatic feeder machine for the grinding machine is arranged on a lathe, the lathe is provided with a power distribution box, a feeder machine, a cutting board frame, a pipe adjusting frame, a ball valve and a cooling liquid pipe; key points are as follows: a base of the automatic feeder for the grinding machine is arranged at the front part of the lathe by virtue of a fixing base plate, the base is provided with a sliding block and a feeding pipe, the sliding block is opposite to the feeding pipe, the sliding block is provided with a third cylinder, the feeding pipe is connected with the feeder machine; a base corresponding to a cutting board table is provided with a second cylinder, the second cylinder is provided with a second magnetic switch and a feeding ejector rod; a cutting board table at the rear part of the lathe is correspondingly provided with a fourth cylinder, the fourth cylinder is provided with a discharging magnetic switch and a discharging ejector rod; and the lower base of the base of the lathe is provided with a discharge chute, an upper base is provided with a first cylinder, and the first cylinder is provided with a first magnetic switch. The automatic feeder machine provided by the invention is applicable to processing of a transmission shaft of a juice extractor and structural improvement of similar lathes and products.

Owner:NINGBO LONGTENG METAL MFG

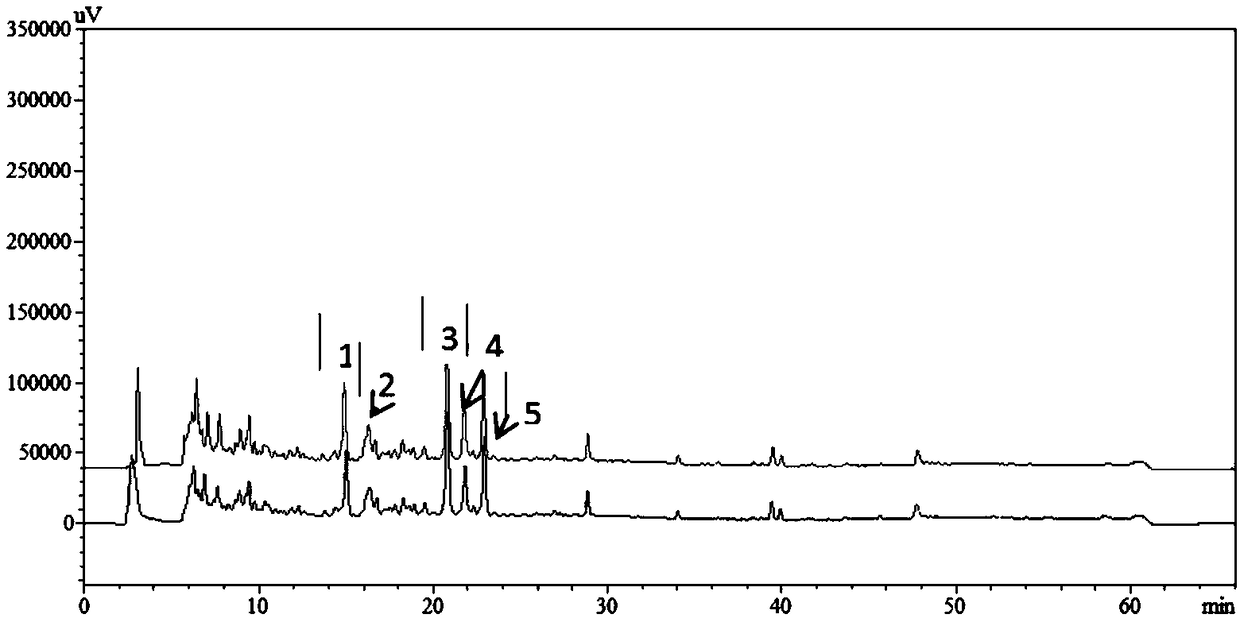

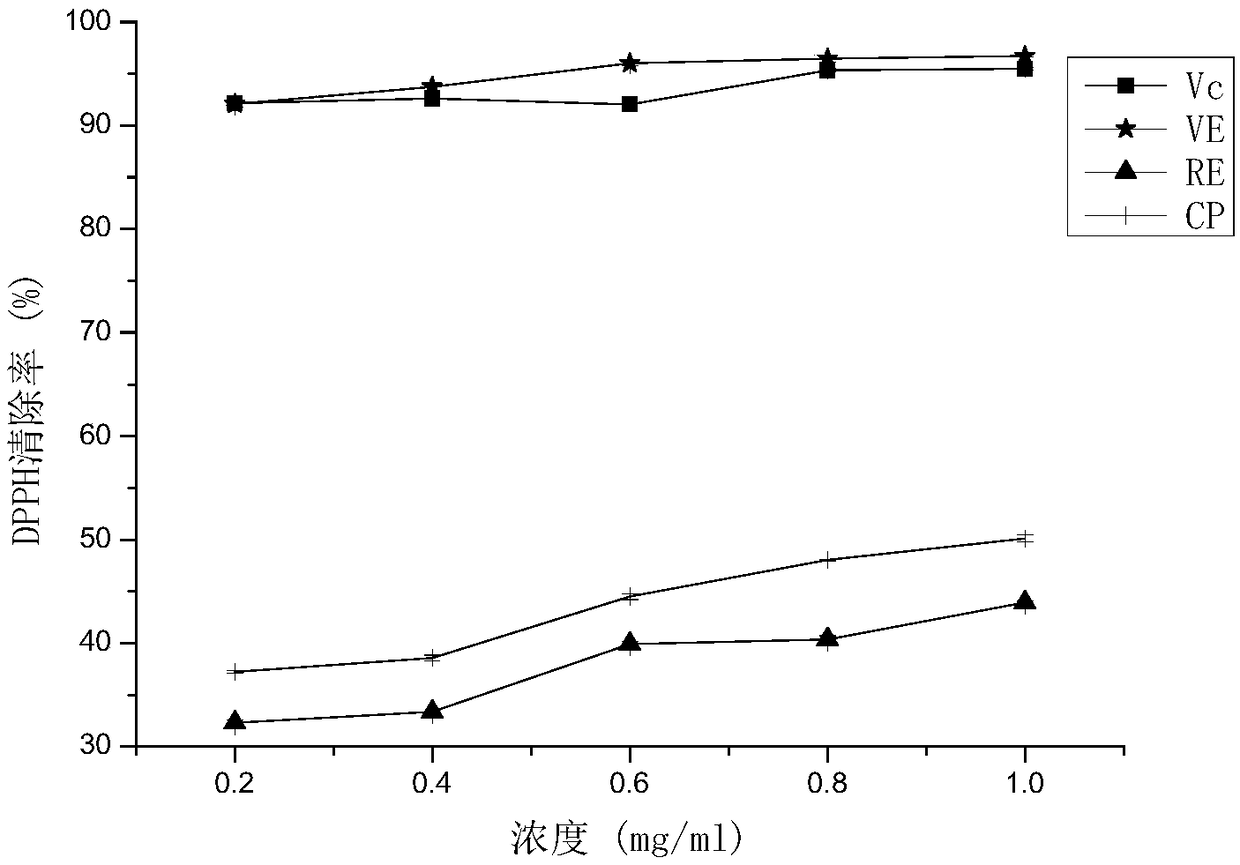

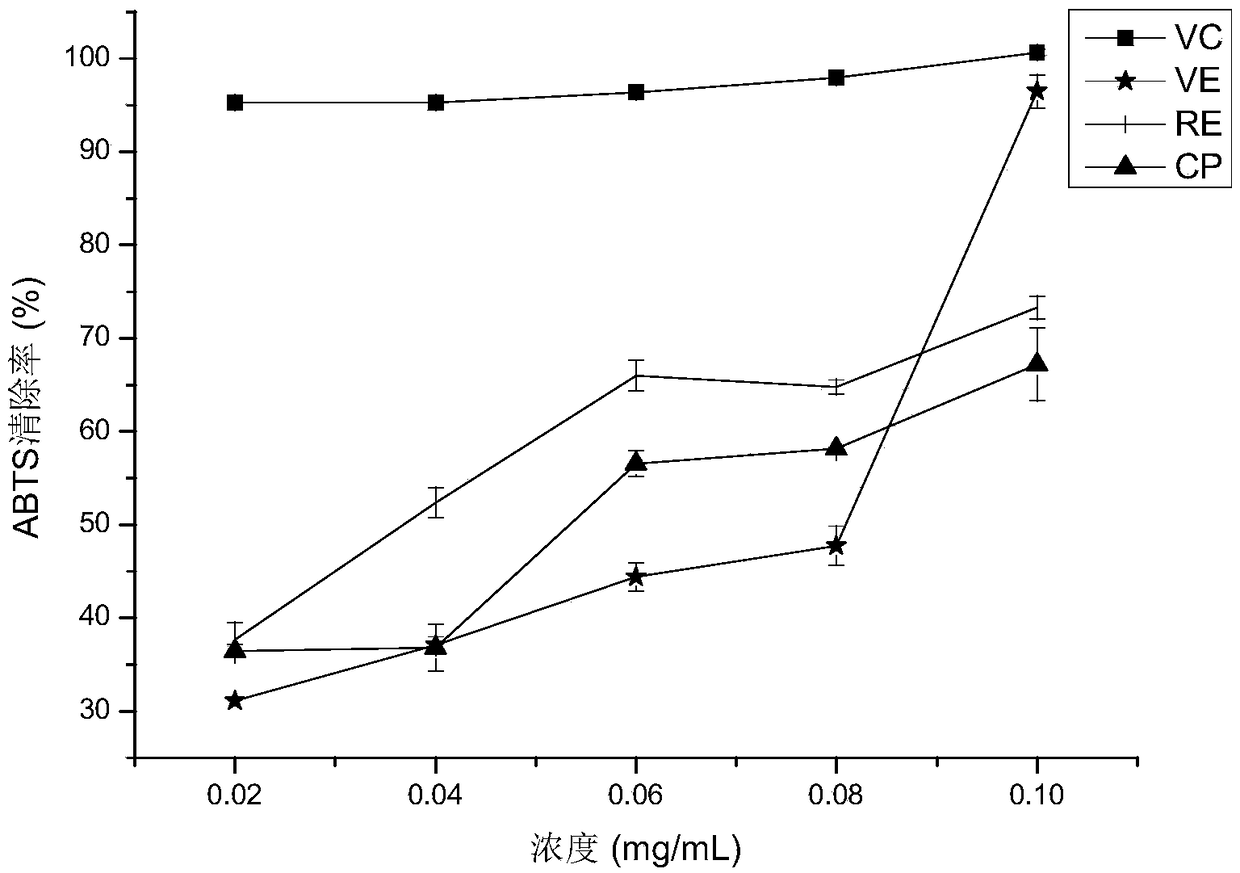

Method for greenly and efficiently extracting bergamot flavone and bergamot flavone

ActiveCN108854140AHigh extraction rateHigh yieldSolid solvent extractionEconomic benefitsPhase change

The invention discloses a method for greenly and efficiently extracting bergamot flavone and the bergamot flavone. The method is characterized in that the bergamot flavone is extracted by adopting thecombination of a continuous phase change technology and an ethanol reflux technology, and extraction technological conditions are optimized by taking the extraction rate of flavone as an index and adopting a response surface method on the basis of a single factor; main component analysis and comparison of extraction technological characteristics and in-vitro oxidation resistance are carried out on the bergamot flavone prepared under optimal conditions of the continuous phase change technology and a traditional ethanol reflux technology, so that the bergamot flavone is greenly and efficientlyextracted. A result shows that the extraction rate and the oxidation resistance of the bergamot flavone extracted through the technology are both remarkably higher than those of bergamot flavone obtained through the traditional ethanol reflux method (p is greater than 0.05), and main components of the obtained bergamot flavone are not affected (p is smaller than 0.05); the method provided by the invention is simple and fast in extraction technological process, strong in operability and low in cost, is environment-friendly and pollution-free, is good in completeness and repeatability and high in economic benefit, and is capable of realizing large-scale industrial production.

Owner:广东展翠食品股份有限公司 +1

Method for extracting oil from diatom through low-temperature continuous phase transition

InactiveCN106190527AReduce consumptionReduce energy consumptionFatty-oils/fats productionOil and greaseSolvent

The invention belongs to the field of oil extraction, and provides a method for extracting oil from diatom by a low-temperature continuous phase transition technique and by using ethanol as an extraction agent. The method comprises the specific steps of loading diatom dry powder or diatom ooze to an extraction kettle, under the condition that the pressure is lower than the critical pressure of the extraction agent and the temperature is lower than the critical temperature of the extraction agent, enabling the extraction agent namely the ethanol which is compressed into liquid to pass through the extraction kettle at a certain flow rate in a countercurrent manner for extraction, after extraction is completed, enabling the extraction agent namely the ethanol to enter a separation kettle, performing heating and performing decompressing so that the ethanol is turned into gas, and an extract is released. The ethanol gas is compressed into liquid, then the liquid enters the extraction kettle for extraction, and circulation is performed. The method disclosed by the invention has the advantages of being low in extraction and separation pressure and extraction and separation temperature, large in treating capacity, low in cost, and high in extraction rate, and products are free from solvent residues.

Owner:东莞市民益生物科技有限公司

Deep sewage treatment device

InactiveCN108483730ASimple structureEasy to operateTreatment involving filtrationMultistage water/sewage treatmentBiochemical engineeringSewage

The invention discloses a deep sewage treatment device which comprises a first device main body and a stirring device, wherein the stirring device is arranged on the first device main body; the stirring device comprises a first cavity formed inside the first device main body; a first rotating block is rotationally arranged inside the first cavity; a second cavity opened upwards is formed inside the first rotating block; a second rotating block is fixedly connected with the lower end surface of the first rotating block; the lower end of the second rotating block is rotationally connected with the lower inner wall of the first cavity in a matching manner through a rotating shaft; a third cavity communicated with the second cavity is formed inside the second rotating block; a second device main body is fixedly connected with the right end of the upper end surface of the device main body. The deep sewage treatment device has the beneficial effects that the stirring uniformity of alums in sewage can be improved, a purifier can be added according to flowing water sizes, the device is simple to operate and worthy of recommendation, and purifier addition can be completed without artificialinterference.

Owner:PUJIANG ZHIYIN TECH CO LTD

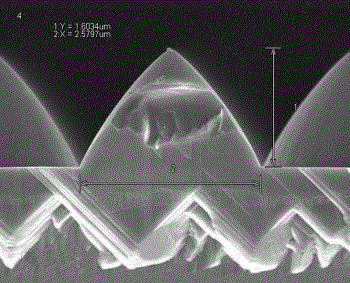

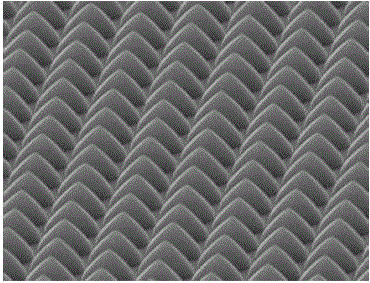

Photoetching method of graphical sapphire substrate

PendingCN106601601AImprove Exposure AccuracyHigh Exposure Precision LevelSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusImage resolutionLiquid state

The invention discloses a photoetching method of a graphical sapphire substrate. The method comprises the following steps: depositing a film on the graphical sapphire substrate, and performing particle removing and low-temperature drying processing on the film; under the condition that a rotation accelerated speed is not changed, adding a liquid-state photoresist and an adhesion agent in the middle of a substrate film surface drop by drop, uniformly covering the surface of a wafer with the liquid photoresist, and performing baking so as to form a photoresist membrane; projecting a graphic file on a mask on the substrate photoresist membrane, setting an exposure condition, and performing exposure processing; and under the condition that the rotation accelerated speed is not changed, spraying a developing solvent on the surface of the substrate photoresist membrane to perform development processing, and after the development is completed, performing development examination. According to the invention, the method has the following advantages: the exposure precision grade is high, the technical repeatability is good, the line dislocation density is low, the inner quantum density is high, the resolution is high, the finished product qualified rate and the yield are high, the graphical dimension of an obtained finished product is accurate, the integrity is good, the performance is stable, and the application prospect is wide.

Owner:福建中晶科技有限公司

Method for extracting hesperidin and pectin in young citrus fruits through continuous phase transition

InactiveCN109096353AEfficient continuous extraction processIncrease productivitySugar derivativesSugar derivatives preparationContinuous phase transitionCitrus fruit

The invention provides a method for extracting hesperidin and pectin in young citrus fruits through continuous phase transition. Dried and smashed young citrus fruit raw materials are subjected to continuous phase transition extraction with ethanol or methanol, wherein extraction conditions are as follows: the extracting agent velocity is 30-150 L / h, extractive temperature is 30-90 DEG C, the extraction pressure is 0.2-1.8 Mpa, extraction time is 2-24 h, separating temperature is 40-95 DEG C, the separating pressure is 0.1-1.5 Mpa; then, the young citrus fruit raw materials for hesperidin extraction is subjected to continuous phase transition extraction with tertiary water with pH 2-7, wherein extraction conditions are as follows: the extracting agent velocity is 30-120 L / h, extractive temperature is 50-95 DEG C, the extraction pressure is 0.1-1.6 Mpa, extraction time is 1-10 h, separating temperature is 55-90 DEG C, the separating pressure is 0.1-1.2 Mpa. The method is high in extraction rate, strong in continuous operability, simple and convenient to carry out, safe, friendly to the environment, low in cost and suitable for large-scale industrial production.

Owner:曹庸

A dual-fuel nozzle for plasma-catalyzed gaseous fuel

InactiveCN103900106BAchieve co-firingImprove economyContinuous combustion chamberProduct gasEngineering

The invention provides a dual-fuel nozzle for plasma catalysis gaseous fuel. The dual-fuel nozzle for the plasma catalysis gaseous fuel mainly comprises a low-temperature plasma discharging assembly, a gas circuit assembly, an oil circuit assembly and a nozzle fixing device. Cracked gas fuel enters an annular discharging gap of the low-temperature plasma discharging assembly in the radial direction and has a reforming reaction under the low-temperature plasma catalytic action to be converted into reformed gas with the higher heat value, a gas plasma micelle remaining after the catalytic reaction can be contained inside the reformed gas, the inflammability of the reformed gas is improved, finally the reformed gas flows out in a rotating mode through a gas flow guiding plate to form a recirculating zone, and the stability of burning is improved. According to the dual-fuel nozzle for the plasma catalysis gaseous fuel, the oil circuit assembly stretches into an external electrode of the low-temperature plasma discharging assembly, space can be saved, the oil supply states of oil and gas circuits can be controlled, the oil and gas circuits can be closed independently or simultaneously, the requirements for starting power and variable working condition power are met, the gas circuit assembly can also be utilized for spraying water, and NOx emission is reduced.

Owner:HARBIN ENG UNIV

Method for removing ricin in castor pulp by continuous phase-change extraction

ActiveCN103766598AAddressing a big problem with emergency gapsImprove utilization efficiencyAnimal feeding stuffFatty-oils/fats productionGas phaseRicin

The invention provides a method for removing ricin in castor pulp by continuous phase-change extraction, which comprises the following steps: putting a castor pulp raw material into an extraction kettle, and carrying out continuous extraction at 45-95 DEG C under the extraction pressure of 0.15-0.95 Mpa for 100-250 minutes at the flow rate of 130-210 L / hour; and after extracting the castor pulp, enabling the liquid to flow into a resolution kettle, and resolving at 70-95 DEG C under the pressure of -0.15 to -0.05 Mpa. The extractant is heated under reduced pressure into a gas phase and instantly cooled into a liquid, flows through the extraction kettle, and is subjected to toxin removal; and the cycle is repeated many times. The extractant is 30-100% methanol, ethanol and butanol. The method has the advantages of high toxin removal efficiency, almost no solvent residue and short time, and has the characteristics of high conventional solvent extraction capacity, high batch treatment capacity, low production cost and the like.

Owner:曹庸

A method for continuous phase change extraction of perilla seed oil

ActiveCN103834467BAbundant resourcesReduce manufacturing costFatty-oils/fats productionPerilla oilProduct gas

The invention provides a method for extracting fructus perillae oil through continuous phase transition, which comprises the steps of putting the dried ground fructus perillae raw material into an extraction kettle; compressing an extraction agent into liquid under the conditions that the extraction temperature is 35-55 DEG C and the extraction pressure is 0.5-2MPa; enabling the liquid to flow through the extraction kettle at a flow speed of 100-150L / h, and continuously extracting for 50-120 minutes; after extracting the fructus perillae oil, enabling the fructus perillae oil to flow into a resolving kettle, wherein the resolving temperature is 65-75 DEG C, and the resolving pressure is 0.1-0.4MPa; heating and reducing pressure of the extraction agent so that the extraction agent phase is changed into gas; performing intermediate compression to change the gas into liquid which flows through the extraction kettle again, and performing secondary extraction on the material; circulating for multiple times. The method provided by the invention has the advantages of efficient supercritical extraction, no solvent residue in product and high retention rate of aroma components; moreover, the extraction pressure and the resolving pressure are lower than the supercritical values, and the method also has the characteristics of large extraction volume of conventional solvent, large batch treatment capacity, low production cost and the like.

Owner:GREENCREAM BIOTECH +2

A method for continuous phase change extraction of pomelo fruit essential oil and naringin

ActiveCN109055011BEfficient extractionEstablish a continuous extraction processSugar derivativesEssential-oils/perfumesNaringinProcess engineering

The invention provides a method for continuously extracting pomelo fruit essential oil and naringin through continuous phase transition. The method comprises the following steps: extracting a pomelo fruit raw material after drying and smashing in conditions that an extracting temperature is 30-90 DEG C, a pressure is 0.3-1.8 Mpa, an extraction agent flow rate is 40-180 L / h, extraction time is 30-240 minutes, a separate temperature is 40-90 DEG C, and a separate pressure is 0.1-0.8 Mpa, to obtain the pomelo fruit essential oil through the continuous phase transition, and extracting the naringinin the conditions that the extracting temperature is 30-95 DEG C, the pressure is 0.1-1.5 Mpa, the extraction agent flow rate is 20-150 L / h, the extraction time is 2-18 hours, the separate temperature is 40-90 DEG C, and the separate pressure is 0.1-1 Mpa. The method is capable of extracting by using a continuous phase transition technology, high in extraction purity, safe, environmentally friendly, low in cost, and suitable for large-scale industrialized production.

Owner:SOUTH CHINA AGRI UNIV

Continuous phase-changed extraction method for orange peel oil

ActiveCN103146486BAbundant resourcesImprove qualityEssential-oils/perfumesFatty-oils/fats productionProduct gasPhase change

The invention provides a continuous phase-changed extraction method for orange peel oil. The method comprises the following steps of: placing dry crushed orange peel raw materials into an extraction kettle; compressing an extraction agent into a liquid under the condition that the pressure and the temperature are always lower than the critical pressure and the critical temperature of the extraction agent; enabling the extraction agent to flow through the extraction kettle at the flow speed of 100-150L / h under the conditions that the extraction temperature ranges from 35 DEG C to 55 DEG C, and the extraction pressure ranges from 0.5MPa to 2MPa, and continuously extracting for 50-120min; after the orange peel oil is extracted, enabling the extraction agent to flow into a liberation kettle for liberating at the temperature of 65-75 DEG C and the pressure of 0.1-0.4MPa; heating and carrying out pressure-reduced phase change on the extraction agent to enable the extraction agent to become a gas, then, immediately condensing the gas to enable the gas to become a liquid, and enabling the liquid to flow through the extraction kettle for extracting the materials again; and circulating many times in such a way. The continuous phase-changed extraction method has the advantages of high supercritical extraction efficiency, no solvent residues in products and high aroma component retention rate; in addition, the extraction pressure and the liberation pressure are lower than the supercritical pressure and temperature; and meanwhile, the continuous phase-changed extraction method has the characteristics of large extraction volume, high mass handling capacity and low production cost of a conventional solvent.

Owner:GREENCREAM BIOTECH +2

Automatic feeder machine for grinding machine and processing method thereof

ActiveCN102366909BReasonable designEasy to useRevolution surface grinding machinesBlade plateDrive shaft

The invention relates to an automatic feeder machine for a grinding machine and a processing method thereof, designed for solving the technical problem that structural design of a like product is not good enough. The automatic feeder machine for the grinding machine is arranged on a lathe, the lathe is provided with a power distribution box, a feeder machine, a cutting board frame, a pipe adjusting frame, a ball valve and a cooling liquid pipe; key points are as follows: a base of the automatic feeder for the grinding machine is arranged at the front part of the lathe by virtue of a fixing base plate, the base is provided with a sliding block and a feeding pipe, the sliding block is opposite to the feeding pipe, the sliding block is provided with a third cylinder, the feeding pipe is connected with the feeder machine; a base corresponding to a cutting board table is provided with a second cylinder, the second cylinder is provided with a second magnetic switch and a feeding ejector rod; a cutting board table at the rear part of the lathe is correspondingly provided with a fourth cylinder, the fourth cylinder is provided with a discharging magnetic switch and a discharging ejector rod; and the lower base of the base of the lathe is provided with a discharge chute, an upper base is provided with a first cylinder, and the first cylinder is provided with a first magnetic switch. The automatic feeder machine provided by the invention is applicable to processing of a transmission shaft of a juice extractor and structural improvement of similar lathes and products.

Owner:NINGBO LONGTENG METAL MFG

A method for continuous phase change extraction to remove ricin in castor meal

ActiveCN103766598BAddressing a big problem with emergency gapsImprove utilization efficiencyAnimal feeding stuffFatty-oils/fats productionGas phaseSolvent

Owner:曹庸

multifunctional walker

ActiveCN106214432BReasonable structural designImprove stabilityWalking sticksWalking aidsEngineeringLED lamp

Owner:杭州富阳宏伟金属制品有限公司

A method for continuous phase change extraction to remove allergens in castor meal

ActiveCN103766600BAddressing a big problem with emergency gapsImprove utilization efficiencyAnimal feeding stuffGas phaseSolvent

The invention provides a method for removing toxin allergen in castor pulp by continuous phase-change extraction, which comprises the following steps: putting a castor pulp raw material into an extraction kettle, and carrying out continuous extraction at 50-100 DEG C under the extraction pressure of 0.1-1.0 Mpa for 60-240 minutes at the flow rate of 130-180 L / hour; and after extracting the castor pulp, enabling the liquid to flow into a resolution kettle, and resolving at 60-100 DEG C under the pressure of -0.10 to -0.09 Mpa. The extractant is heated under reduced pressure into a gas phase and instantly cooled into a liquid, flows through the extraction kettle, and is subjected to toxin removal; and the cycle is repeated many times. The extractant is 55-100% methanol, ethanol or butanol. The method has the advantages of high toxin removal efficiency, almost no solvent residue and short time, and has the characteristics of high conventional solvent extraction capacity, high batch treatment capacity, low production cost and the like.

Owner:曹庸

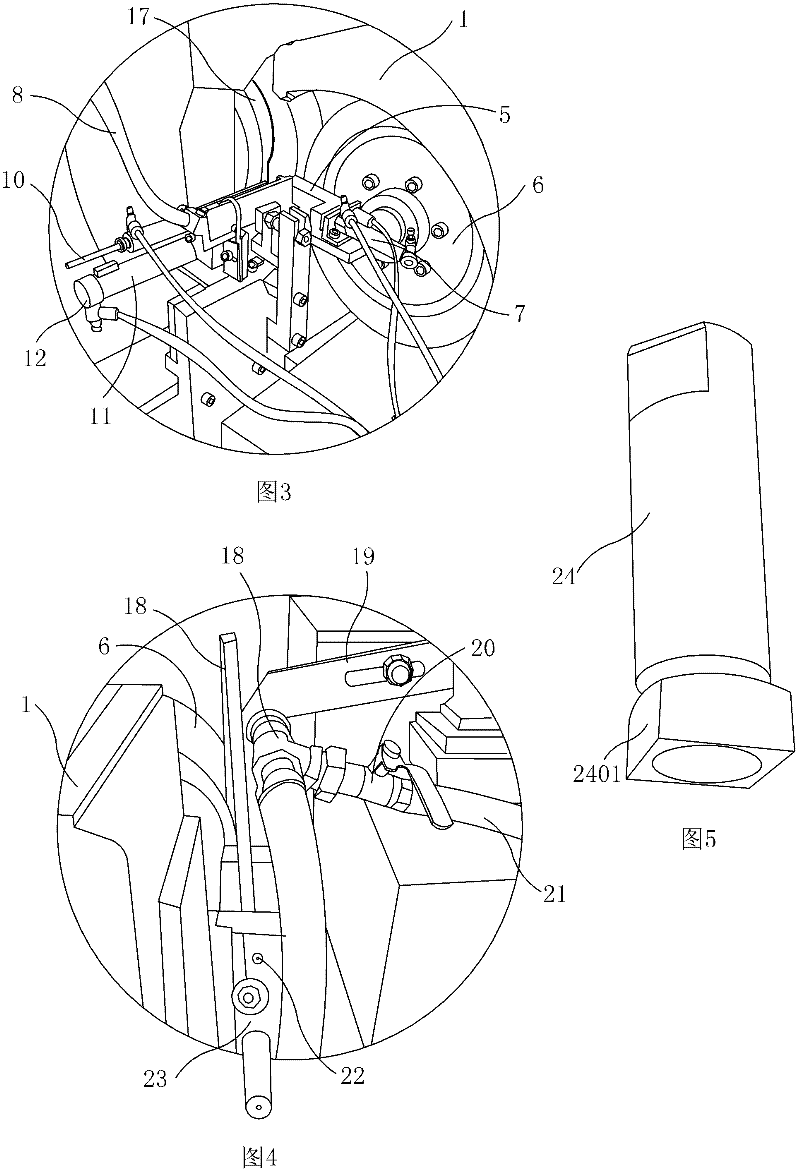

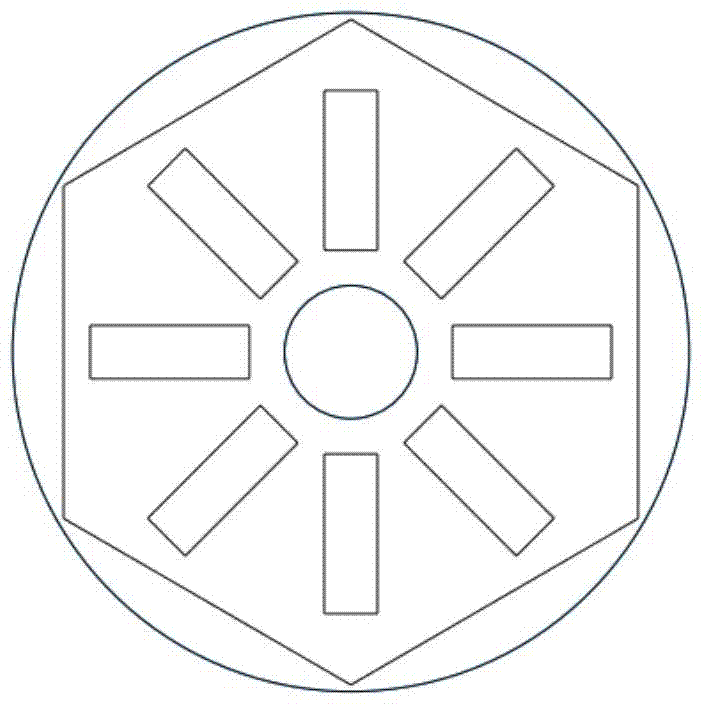

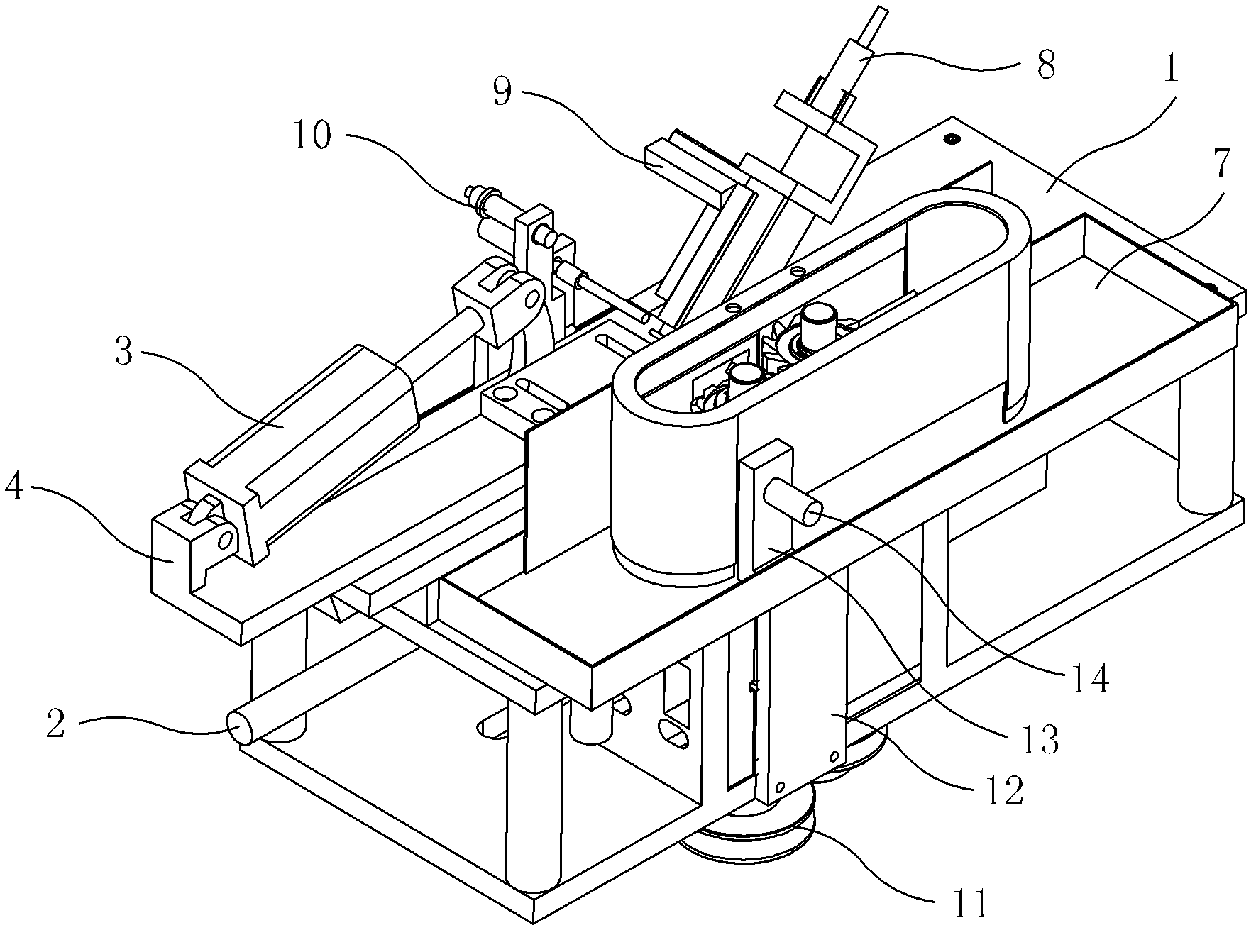

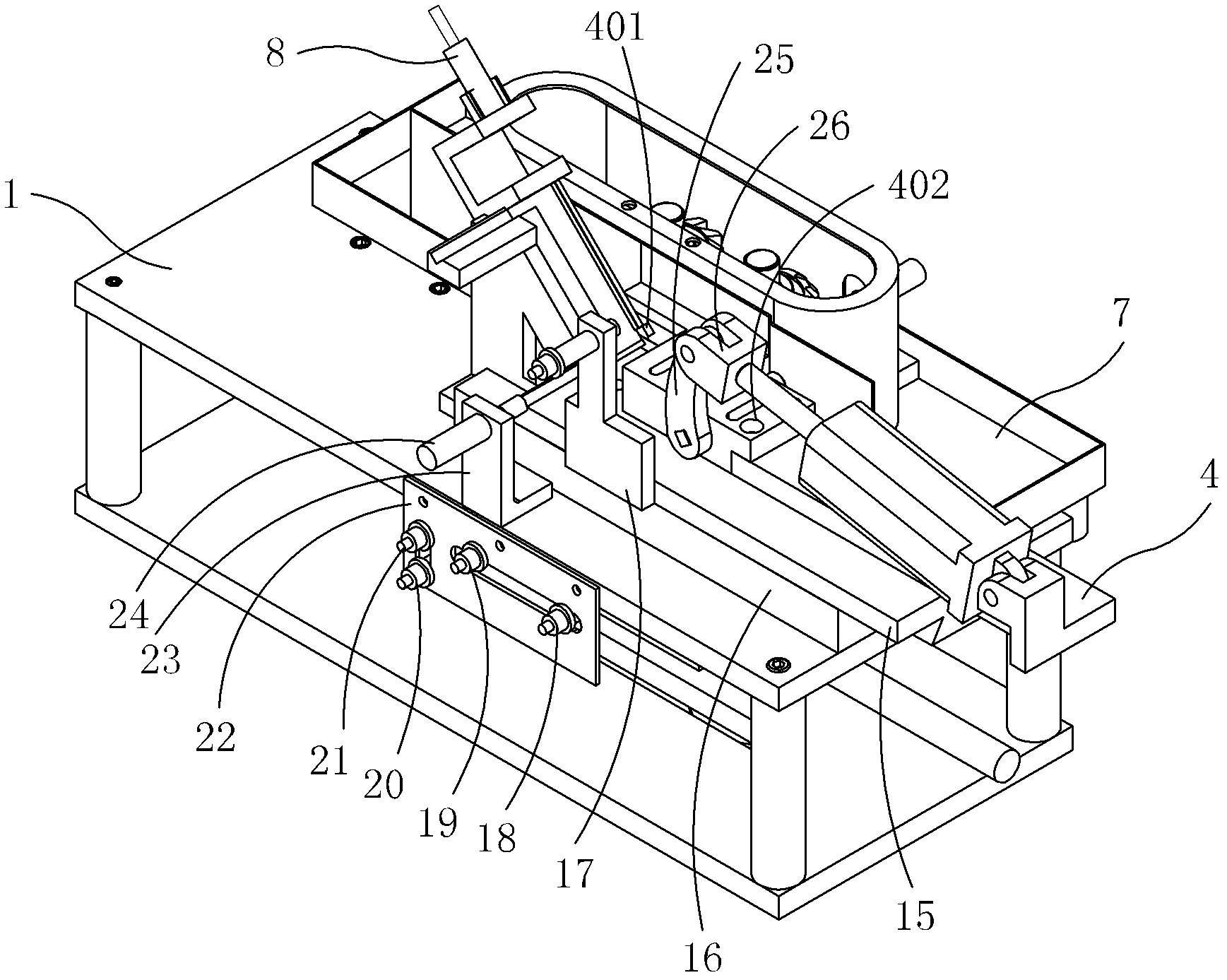

Milling edge-aligning beveller and processing method thereof

ActiveCN102430786BReasonable designEasy to useMilling equipment detailsMetal working apparatusMilling cutterDrive shaft

The invention relates to a milling edge-aligning beveller and a processing method thereof, which are designed for solving the technical problem of poor structural design in like products. A worktable of the milling edge-aligning beveller is provided with a feeding mechanism, a clamping mechanism, a shifting mechanism, a transmission mechanism, a discharging mechanism and a waterproof mechanism; the processing end of the transmission mechanism is provided with the waterproof mechanism; the shifting mechanism is connected with the clamping mechanism; the key points are as follows: a clamping cylinder base of the clamping mechanism is arranged on the table plane of the worktable; a clamping cylinder is arranged on the clamping cylinder base; the worktable is provided with a bearing seat of the transmission mechanism; a main shaft is arranged on the bearing seat; a tri-face edge milling cutter blade and a pulley disc are arranged at the two ends of the main shaft respectively; and at least one tri-face edge milling cutter blade is arranged on the transmission mechanism. According to the milling edge-aligning beveller provided by the invention, the transmission shaft is fed into the clamping mechanism through the feeding mechanism before processing; through the clamping of the clamping mechanism, the shifting is realized by the shifting mechanism, the processing is finished by the transmission mechanism, and products are discharged through the discharging mechanism. The milling edge-aligning beveller is suitable for processing transmission shafts of juicers and improving structures of like products.

Owner:NINGBO LONGTENG METAL MFG

A kind of low-temperature continuous phase change method for extracting the oil of the blue round trevally and the blue round trevally oil

The invention discloses a method of extracting decapterus maruadsi oil through low-temperature continuous phase transition and decapterus maruadsi oil.The method includes: placing decapterus maruadsi powdery raw materials in an extraction kettle; under conditions of extraction temperature of 40-60 DEG C and extraction pressure 0.3-1.0 Mpa, compressing an extraction agent into liquid, enabling the liquid to flow through the extraction kettle at a flow rate of 100-150 L / h for continuous extraction of 30-110 min, and after decapterus maruadsi oil is extracted, enabling the liquid to enter an analysis kettle with analysis temperature of 50-80 DEG C and analysis pressure of 0.1-0.4 Mpa; performing phase transition on the extraction agent to form gas, immediately compressing the gas into liquid, enabling the liquid to flow through the extraction kettle, extracting materials again, enabling the materials to carry oil to enter an analysis tank through a solvent of an extraction tank, and obtaining a decapterus maruadsi oil product after analysis.Compared with conventional extraction methods, the method is accurate and stable in process, the decapterus maruadsi oil is high in quality, extraction rate is increased remarkably, and efficient extraction of ocean low-value decapterus maruadsi oil is realized, so that cost can be saved, product yield can be increased, and economic benefit of production enterprises can be improved.

Owner:SOUTH CHINA AGRI UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com